Page 1

DOC023.53.90007

sc1000 controller

USER MANUAL

April 2008, Edition 1

© Hach Company, 2008. All rights reserved. Printed in the U.S.A. as/cw

Page 2

Page 3

Table of Contents

Section 1 Specifications.................................................................................................................... 5

Section 2 General Information......................................................................................................... 9

2.1 Safety information........................................................................................................................ 9

2.1.1 Use of hazard information................................................................................................... 9

2.1.2 Precautionary labels ......................................................................................................... 10

2.2 General product information ...................................................................................................... 10

2.3 Controller storage ...................................................................................................................... 10

Section 3 Installation........................................................................................................................ 11

3.1 Mechanical installation............................................................................................................... 11

3.1.1 Controller dimensions ....................................................................................................... 12

3.2 Mounting the controller .............................................................................................................. 13

3.2.1 Wall mounting ................................................................................................................... 13

3.2.2 Vertical or horizontal pipe mounting.................................................................................. 14

3.2.3 Panel Mounting ................................................................................................................. 14

3.2.4 Sun-shield.........................................................................................................................14

3.3 Wiring safety information ........................................................................................................... 14

3.3.1 Electrostatic discharge (ESD) considerations................................................................... 15

3.4 Electrical installation .................................................................................................................. 16

3.4.1 Installation in hard-wired applications ............................................................................... 16

3.4.2 Installation using a power cord ......................................................................................... 17

3.4.3 Wiring for AC power at the controller ................................................................................ 20

3.4.4 Wiring for 24 VDC power at the controller ........................................................................ 24

3.5 DIN rail expansion modules....................................................................................................... 26

3.6 Expansion cards ........................................................................................................................ 27

3.6.1 Relay card connections.....................................................................................................28

3.6.2 Input card connections...................................................................................................... 31

3.6.3 Output card connections................................................................................................... 33

3.6.4 Modbus card connections ................................................................................................. 34

3.6.5 Profibus DP card connections........................................................................................... 35

3.6.6 Remove/Replace an expansion card................................................................................ 37

3.7 Install an sc1000 network (sc1000 bus connection) .................................................................. 37

3.7.1 sc1000 network connections............................................................................................. 38

3.8 Connect probes to the sc1000 controller ................................................................................... 43

3.8.1 Connect the probe data cable........................................................................................... 43

3.8.2 Add probe connections ..................................................................................................... 44

3.8.3 Connect AC powered sc probes ....................................................................................... 44

3.9 Service port connection (LAN connection)................................................................................. 44

3.10 GSM modem connection ......................................................................................................... 45

3.10.1 Safety precautions .......................................................................................................... 45

3.10.2 SIM card requirements.................................................................................................... 46

3.10.3 Insert the SIM card into the display module.................................................................... 47

3.10.4 Connect the external GSM antenna to the display module............................................. 48

3.11 Storage card (SD card)............................................................................................................ 49

3.11.1 Insert the storage card into the display module .............................................................. 49

3.11.2 Prepare the storage card ................................................................................................ 50

Section 4 System Start Up.............................................................................................................. 51

Section 5 Standard Operations...................................................................................................... 53

5.1 The display module.................................................................................................................... 53

5.1.1 Attach the display module to the probe module................................................................ 53

5.1.2 Tips for the use of the touch screen.................................................................................. 54

5.1.3 The display modes............................................................................................................ 54

1

Page 4

Table of Contents

5.2 The measured value display ......................................................................................................55

5.2.1 Daily and weekly trend lines..............................................................................................56

5.2.2 Configure the measured value display ..............................................................................56

5.3 The Graph display ......................................................................................................................56

5.4 The Main menu display ..............................................................................................................58

5.5 The alphanumeric keypad ..........................................................................................................59

5.6 Calibrate the touch screen .........................................................................................................59

5.7 Specify the displayed language..................................................................................................59

5.8 Set the time and date .................................................................................................................60

5.9 Set up system security (passcode protection)............................................................................60

5.9.1 Set the passcode...............................................................................................................60

5.10 Add and remove favorites ........................................................................................................61

5.11 Add new components...............................................................................................................61

5.12 Configure the network modules (Profibus/Modbus cards) .......................................................62

5.12.1 Configure the Profibus/Modbus card...............................................................................62

5.12.2 Error and status register..................................................................................................64

5.12.3 Profibus/Modbus configuration example .........................................................................66

5.13 Remote control.........................................................................................................................67

5.13.1 Prepare the LAN connection ...........................................................................................67

5.13.2 Set up the LAN connection..............................................................................................67

5.13.3 Set up the dial-up connection..........................................................................................68

5.13.4 Access the sc1000 controller through a web browser.....................................................70

5.14 Log data ...................................................................................................................................71

5.14.1 Save log files to the storage card ....................................................................................71

5.14.2 Save log files through browser access............................................................................71

5.14.3 Remove log files through browser access.......................................................................72

5.15 Formula editor for output and relay card ..................................................................................73

5.15.1 Add a formula..................................................................................................................73

5.15.2 Add a formula with measurement values from other probes...........................................74

5.15.3 Formula operations..........................................................................................................74

Section 6 Advanced Operations ....................................................................................................77

6.1 Sensor status menu ...................................................................................................................77

6.2 Sensor setup menu ....................................................................................................................77

6.3 System setup menu....................................................................................................................78

6.3.1 Output setup menu............................................................................................................78

6.3.2 Current inputs menu..........................................................................................................83

6.3.3 Relay menu .......................................................................................................................87

6.3.3.1 General relay settings (available in all relay working modes)...................................87

6.3.3.2 Function set to ALARM working mode .....................................................................88

6.3.3.3 Function set to FEEDER CONTROL working mode ................................................90

6.3.3.4 Function set to 2 POINT CONTROL working mode.................................................93

6.3.3.5 Function set to WARNING working mode ................................................................97

6.3.3.6 Function set to PWM CONTROL/LINEAR working mode ........................................99

6.3.3.7 Function set to PWM CONTROL/PID CONTROL working mode...........................102

6.3.3.8 Function set to FREQ. Control / Linear working mode...........................................103

6.3.3.9 Function set to FREQ. Control/PID CONTROL mode............................................105

6.3.3.10 Function set to TIMER working mode ..................................................................106

6.3.3.11 Function set to SYSTEM ERROR working mode.................................................108

6.3.4 Network Modules (Profibus, Modbus) .............................................................................109

6.3.4.1 Profibus ..................................................................................................................109

6.3.4.2 Modbus...................................................................................................................111

6.3.5 GSM module....................................................................................................................113

6.3.6 Device management........................................................................................................115

2

Page 5

Table of Contents

6.3.7 Display settings............................................................................................................... 115

6.3.8 Browser access............................................................................................................... 116

6.3.9 Storage card ................................................................................................................... 116

6.3.10 Security setup ............................................................................................................... 117

6.4 Test/Maint Menu...................................................................................................................... 117

6.4.1 Bus status ....................................................................................................................... 118

Section 7 Maintenance .................................................................................................................. 119

7.1 General maintenance............................................................................................................... 119

7.2 Fuse replacement.................................................................................................................... 119

Section 8 Troubleshooting ........................................................................................................... 121

8.1 General problems and GSM module errors............................................................................. 121

8.2 GSM Module errors.................................................................................................................. 122

8.3 Error and warning messages...................................................................................................122

8.3.1 Message type.................................................................................................................. 122

8.3.2 Message format .............................................................................................................. 123

8.3.3 Error and warning ID numbers........................................................................................ 123

8.4 SMS service............................................................................................................................. 124

8.4.1 Configure SMS destination ............................................................................................. 124

8.4.2 SMS format..................................................................................................................... 124

8.5 Test the expansion cards in the Maintenance menu ............................................................... 126

8.5.1 Test the output card ........................................................................................................ 126

8.5.2 Test the input card .......................................................................................................... 127

8.5.3 Test the relay card .......................................................................................................... 128

Section 9 Replacement Parts and Accessories....................................................................... 129

9.1 Expansion cards ...................................................................................................................... 129

9.2 External DIN rail modules ........................................................................................................ 129

9.3 Internal network components................................................................................................... 129

9.4 Accessories.............................................................................................................................. 129

9.5 Replacement parts................................................................................................................... 130

9.6 Exploded view drawings .......................................................................................................... 132

Section 10 Contact Information................................................................................................... 137

Section 11 Certification ................................................................................................................. 139

Appendix A DIN Rail Expansion Modules................................................................................. 141

3

Page 6

Table of Contents

4

Page 7

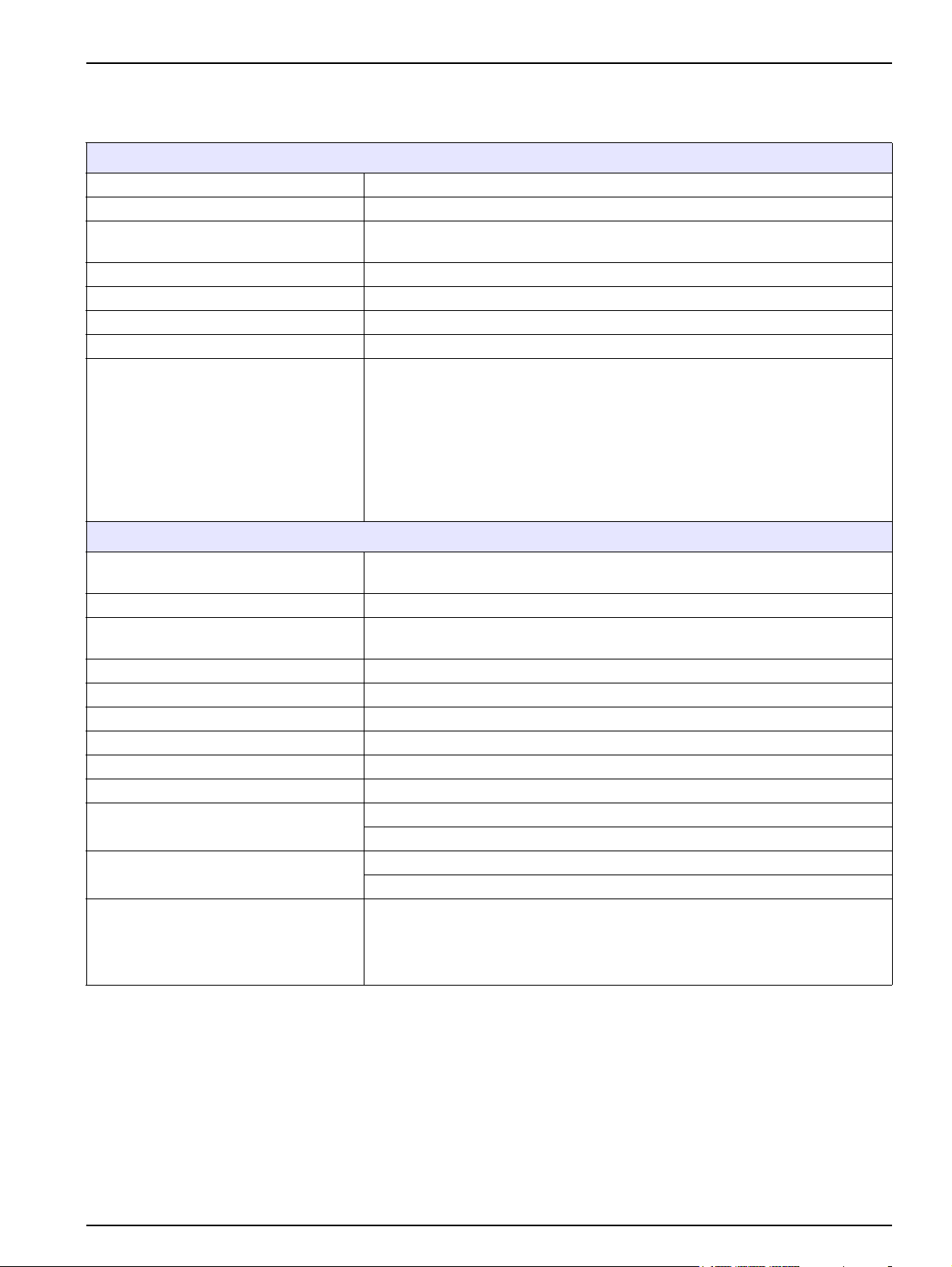

Section 1 Specifications

Specifications are subject to change without notice.

Display Module

Component description Display module for menu-based operation

Enclosure Plastic housing, enclosure rating IP65

Screen display

Operating temperature –20 to 55 °C (–4 to 131 °F); 95 % relative humidity, non-condensing

Storage temperature –20 to 70 °C (–4 to 158 °F); 95 % relative humidity, non-condensing

Weight Approximately 1.2 kg

Dimensions 200 × 230 × 50 mm (7.9 × 9 × 2 inches)

Optional expansions

Probe Module

QVGA, 320 x 240 pixels, viewing area: 111,4 mm x 83,5 mm, 256 colors, touch

screen

GSM modem

The sc1000 display module with integrated GSM/GPRS modem transmits data

SMS messages and GPRS services in GSM nets.

The sc1000 is offered with different GSM frequency bands:

MC55 EGSM900 GSM1800 GSM1900

MC56 GSM1800 GSM1900 GSM850

MC55/56 features GPRS multislot class 10 and supports the GPRS coding

schemes CS-1, CS-2, CS-3 and CS-4.

Component description

Enclosure Metal housing with corrosion-resistant surface finish, IP65 rating

Power requirements

Probe inputs (optional)

Measuring range Dependent on probe.

Operating temperature –20 to 55 °C (–4 to 131 °F); 95 % relative humidity, non-condensing

Storage temperature –20 to 70 °C (–4 to 158 °F); 95 % relative humidity, non-condensing

Weight Approximately 5 kg, depending on configuration

Optional expansions Analog Outputs, Analog/Digital Inputs, Relays, Digital fieldbusses

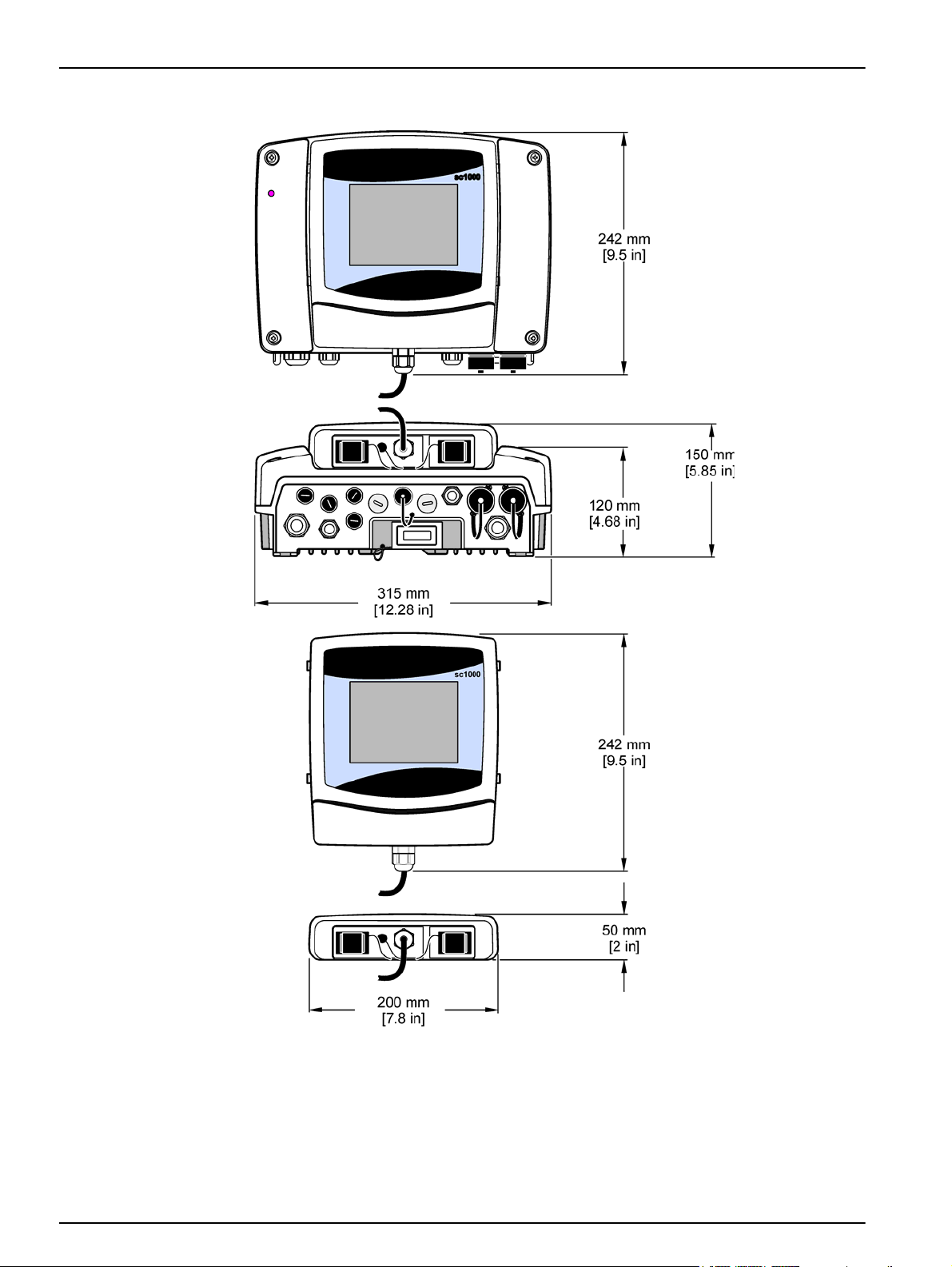

Dimensions

Fuse ratings

sc1000 network cable

1

Probe module for the connection of sc probes, optional expansions and power

supply

100–240 V ± 10 VAC, 50 / 60 Hz, max. 2000 VA, Category II or 24 VDC

(18–30 VDC), max. 75 W

4, 6, or 8 probes. All parameters can be configured and combined as required.

Without display module: 315 × 242 × 120 mm (12.4 × 10.1 × 4.8 inches)

With display module: 315 × 242 × 150 mm (12.4 × 10.1 × 6 inches)

100–240 VAC: F1, F2: M 3,5 A (medium slow-blow); F3, F4: T 8 A; 100–240 V

24 VDC: 1 fuse, T 6,3 A; 24 VDC

Double-shielded control cable with 2 cores, 24 AWG, stranded, CU wire

Characteristics impedance at 1 KHz > 100 W, wire color: red and green.

Outer sheath of the cable is UV and water resistant

External diameter of cable is 3.5–5 mm

5

Page 8

Specifications

Plug-in Expansion Cards

Component description Plug-in expansion cards for installation in the probe module

Operating temperature –20 to 55 °C (–4 to 131 °F); 95% relative humidity, non-condensing

Storage temperature –20 to 70 °C (–4 to 158 °F); 95% relative humidity, non-condensing

Analog output card

Analog/digital input card 4 x analog/digital inputs (0–20 mA or 4–20 mA) Terminals max. 1.5 mm

Internal relay card

Fieldbus interface card Modbus RS485 (YAB021), Modbus RS232 (YAB047) or Profibus DP (YAB020)

DIN Rail Switch Cabinet Expansion Modules

Function

Enclosure rating IP20

Power supply 24 VDC (max. 30 V) from base module

Operating temperature 4 to 40 °C (39 to 104 °F); 95% relative humidity, non-condensing

Storage temperature –20 to 70 °C (–4 to 158 °F); 95% relative humidity, non-condensing

Base module (LZX915)

Relay module (LZX920)

Output module (LZX919)

Input module (LZX921)

4 x analog current outputs (0–20 mA or 4–20 mA, max. 500 Ohm)

Terminals max. 1.5 mm2 (AWG15)

2

4 x change over contacts (SPDT)

Maximum switching voltage: 250 VAC, 125 VDC

Nominal Switching Current: 250 VAC, 5 A; 125 VAC, 5 A; 30 VDC, 5 A

Terminals max. 1.5 mm2 (AWG15)

For installation in the switch cabinet. Any expansions required can be combined

when a base module is available.

Supply of expansion modules with 24 VDC and connection to the sc1000

network

Setting terminating resistor (with DIP switch) for the sc1000 network

Provision of connection for a display module (LXV402) for the configuration of

the system

Base module can supply a maximum of 2000 mA to the extension modules.

Dimensions: 23 x 100 x 115 mm (1 x 4 x 4.5 in.)

4 x normally closed into change over contacts (SPDT)

Maximum switching voltage: 250 VAC, 125 VDC

Maximum switching current: 250 VAC, 5 A; 125 VAC, 5 A; 30 VDC, 5 A

Maximum switching power: 150 W

Can be programmed for limit, status-monitoring or for various control functions,

communication status indication by LED.

Terminals max. 2.5 mm2 (AWG 11)

Current consumption: <100 mA

Dimensions: 45 x 100 x 115 mm (2 x 4 x 4.5 in.)

2 analog current outputs (0–20 mA or 4–20 mA, max. 500 Ohm)

Terminals max. 2.5 mm2 (AWG 11)

Current consumption: <150 mA

Dimensions: 23 x 100 x 115 mm (1 x 4 x 4.5 in.)

Analog/Digital inputs (can be programmed as 0–20 mA or 4–20 mA), INPUT or

digital INPUT

Internal resistance: 180 Ohm

Terminals max. 2.5 mm2 (AWG 11)

Current consumption: <100 mA

Dimensions: 23 x 100 x 115 mm (1 x 4 x 4.5 in.)

6

Page 9

Specifications

Certifications

sc1000 with system components

- cTUVus to UL 61010-1 & CAN/CSA 22.2 No. 61010-1

North America

Europe

Warranty

Warranty 1 year

1

When installing additional probes, observe the maximum total power of the system. Only two 1720E Turbidity instruments can

be used simultaneously on an sc1000 probe module.

Important Note: All modules and cards are developed according to DIN EN 61326 “Surge

protection”.

sc1000 with GSM Module

- FCC ID No. QIPMC56

- Industry Canada ID No. 267W-MC56

sc1000 with system components:

- CE Conforms to LV-Directive 2006/95/EC, EMC-Directive 2004/108/EC

- TUV-GS to EN61010-1

sc1000 with GSM Module:

- CETECOM ICT GmbH Registration No. M352023P-EO

7

Page 10

Specifications

8

Page 11

Section 2 General Information

The information in this manual has been carefully checked and is believed to be

accurate. However, the manufacturer assumes no responsibility for any inaccuracies that

may be contained in this manual. In no event will the manufacturer be liable for direct,

indirect, special, incidental or consequential damages resulting from any defect or

omission in this manual, even if advised of the possibility of such damages. In the interest

of continued product development, the manufacturer reserves the right to make

improvements in this manual and the products it describes at any time, without notice or

obligation.

Revised editions are found on the manufacturer’s web site.

2.1 Safety information

Please read this entire manual before unpacking, setting up or operating this equipment.

Pay attention to all danger, warning and caution statements. Failure to do so could result

in serious injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this manual.

DANGER

The manufacturer products designed for outdoor use are provided with a high level

of ingress protection against liquids and dust. If these products are connected to a

mains electricity socket by means of a cable and plug rather than by fixed wiring,

the level of ingress protection of the plug and socket connection against liquids

and dust is considerably lower. It is the responsibility of the operator to protect the

plug and socket connection in such a manner that the connection has an adequate

level of ingress protection against liquids and dust and complies with the local

safety regulations.

When the instrument is used outdoors, it should be connected only to a suitable

socket with at least IP44 rating (protection against water sprayed from all

directions).

2.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Notice: Indicates a situation that is not related to personal injury.

Important Note: Indicates a situation which, if not avoided, may cause damage to the

instrument. Information that requires special emphasis.

Note: Information that supplements points in the main text.

9

Page 12

General Information

2.1.2 Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for Protective Earth (ground).

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

2.2 General product information

The sc1000 is a multi-parameter controller designed to function with any of the digital

probe family. A stand-alone sc1000 controller must have one display module and one

probe module. The probe module can be configured to accept up to 8 digital probes.

More probes can be connected by creating an sc1000 network. An sc1000 network must

have one display module and two or more probe modules. Only one display module is

allowed per network. Each probe module can be configured to accept up to 8 probes

each.

Each probe module can also be configured with relays, analog outputs, analog or digital

inputs, and digital fieldbus cards.

Note: An sc1000 network accepts a maximum of 32 devices (including internal expansion cards,

external modules and probes).

2.3 Controller storage

When storing the sc1000 controller, make sure that all important data is saved. Remove

power and disconnect all connections from the system. Remove the probe module from

its mounting. Store the probe module and display module in a protective film or dry cloth

in a dry place.

All configurations are stored in the I/O cards. After approximately two weeks the date and

time information is lost. The user has to enter the date and time information the next time

the controller is started.

10

Page 13

Section 3 Installation

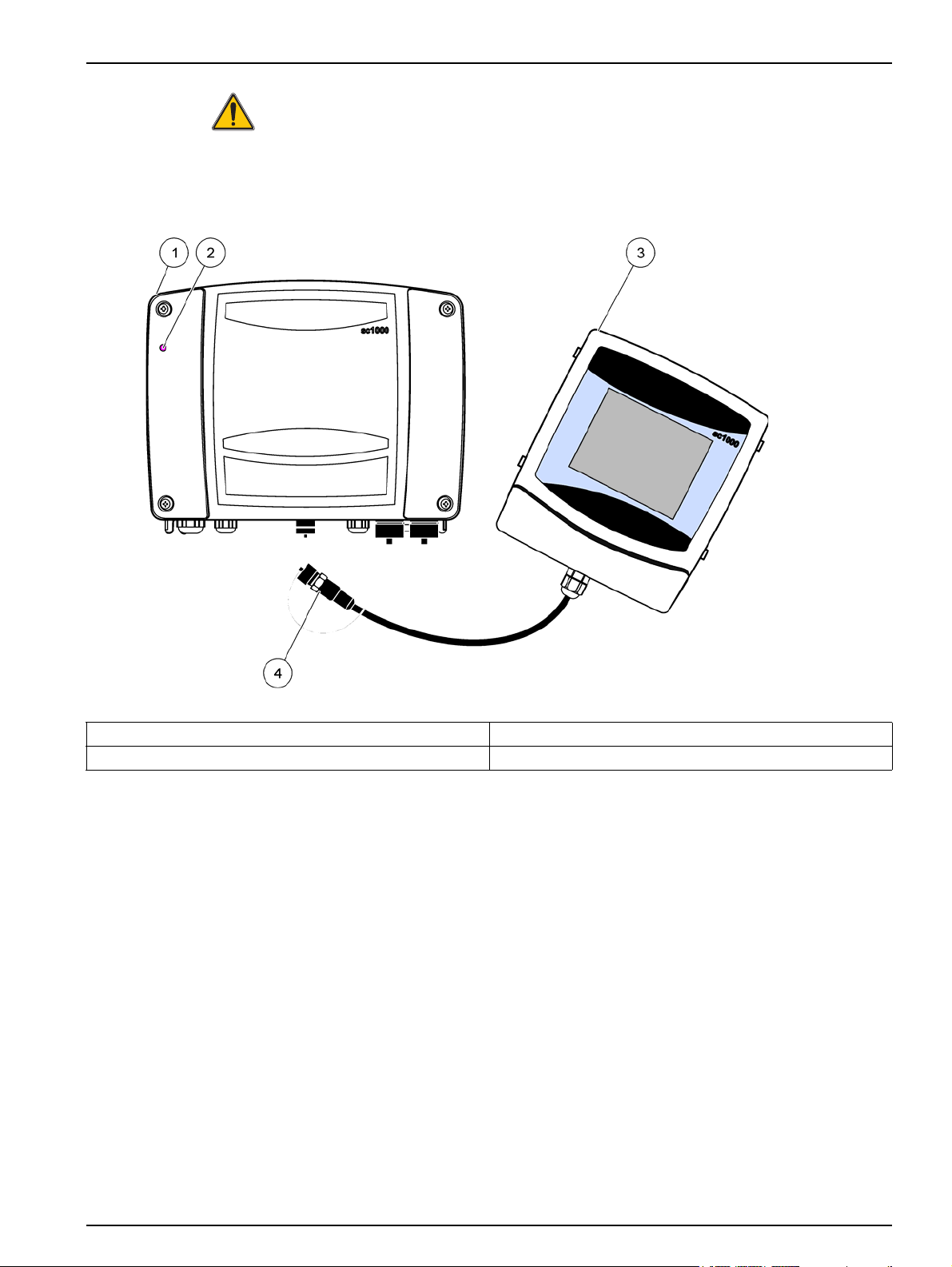

DANGER

Electrocution hazard. Only qualified personnel should conduct the tasks described

in this section of the manual.

3.1 Mechanical installation

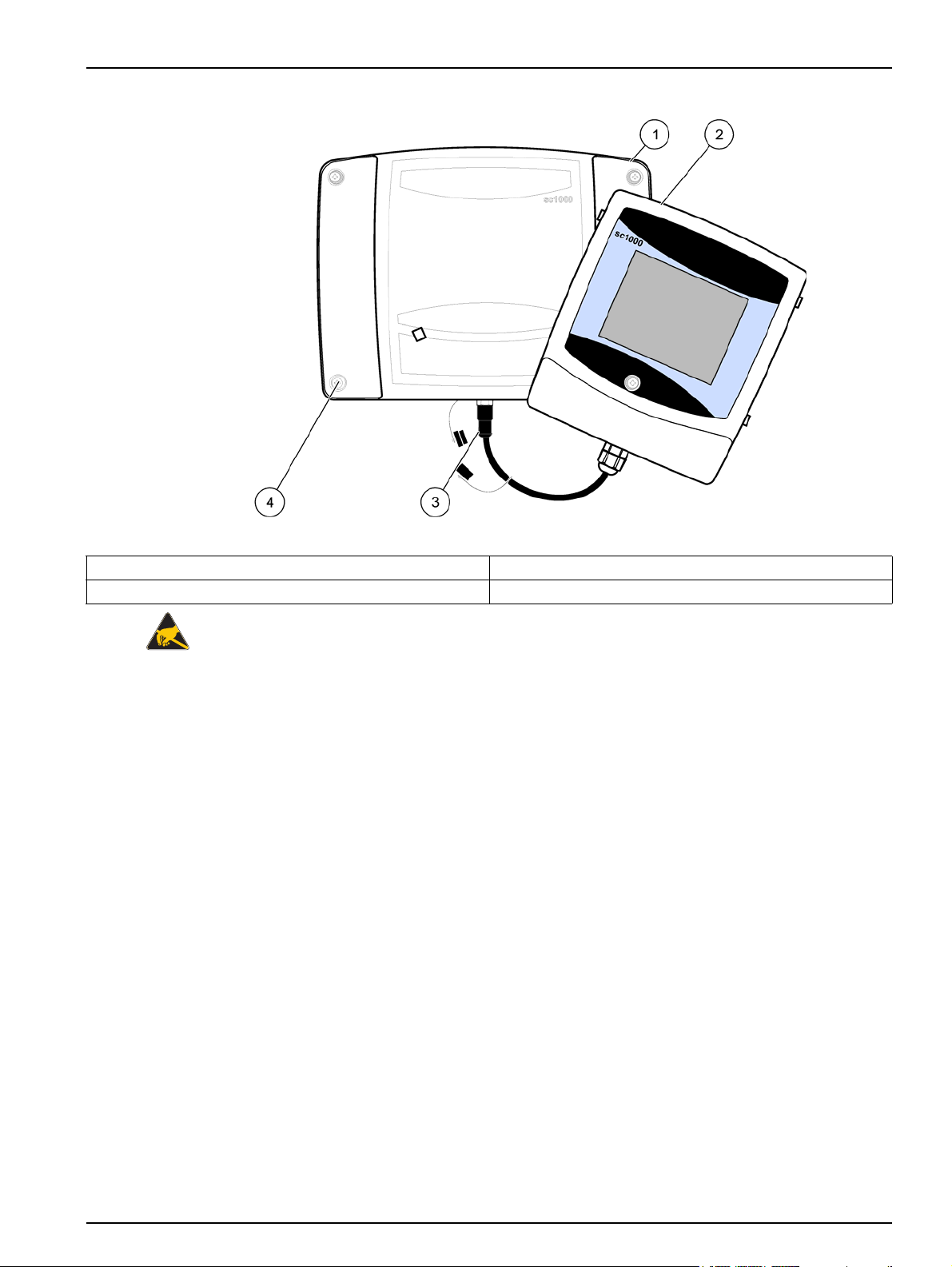

Figure 1 Probe module with display module

1 Probe module 3 Display module

2 LED indicator 4 Connector, display module to probe module

11

Page 14

Installation

3.1.1 Controller dimensions

12

Figure 2 sc1000 controller dimensions

Page 15

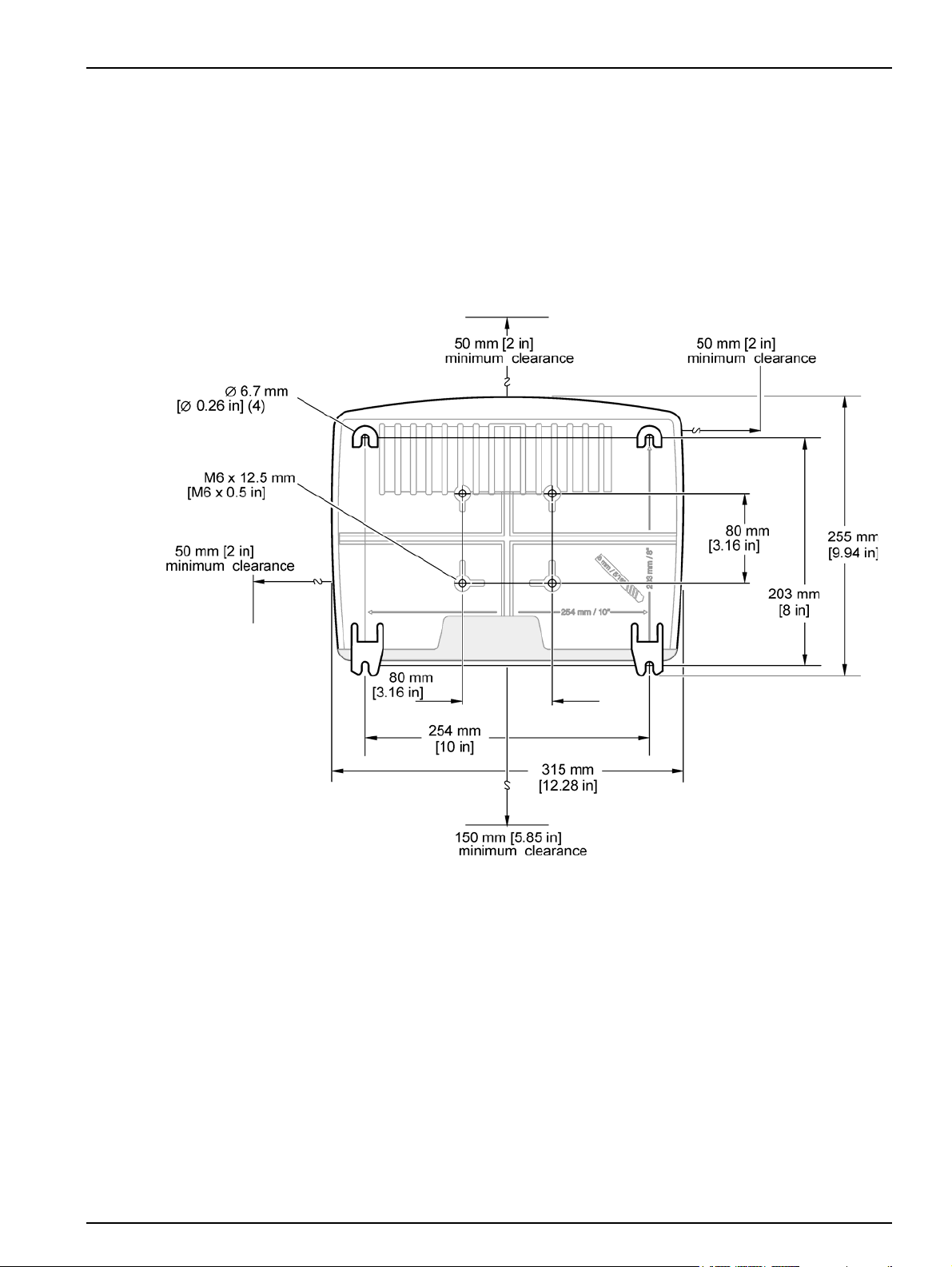

3.2 Mounting the controller

3.2.1 Wall mounting

Leave a minimum of 5 cm (2 in.) of space at the top and sides for cooling purposes and

display module installation. Leave a minimum of 15 cm (6 in.) of space underneath for the

cable connections. Refer to Figure 3 for proper wall mounting dimensions.

1. Install four bolts into the wall.

2. Hang the sc1000 controller over the bolts and attach the supplied washers and

hand-tighten the two bottom bolts.

Installation

Figure 3 sc1000 controller mounting features

13

Page 16

Installation

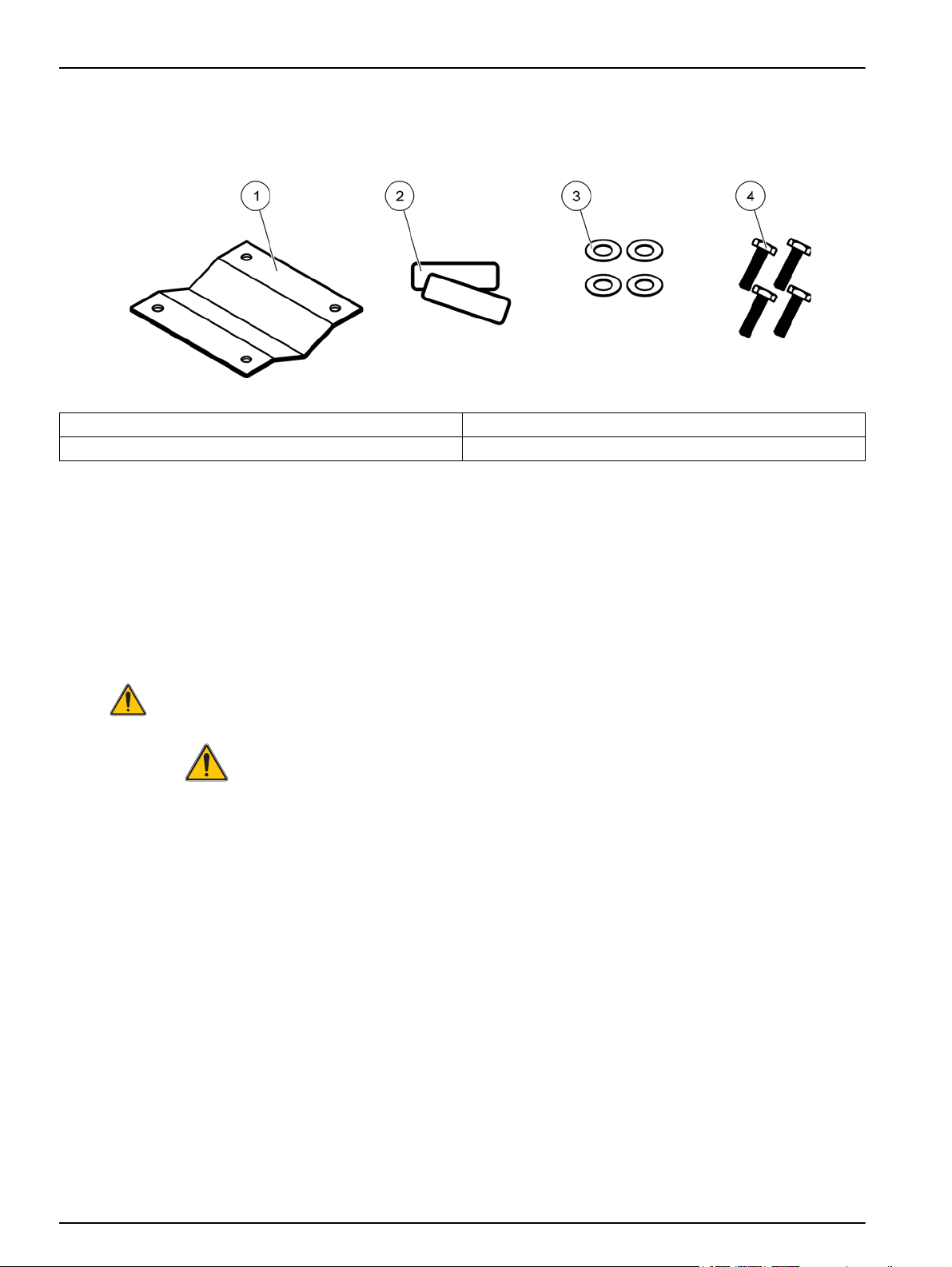

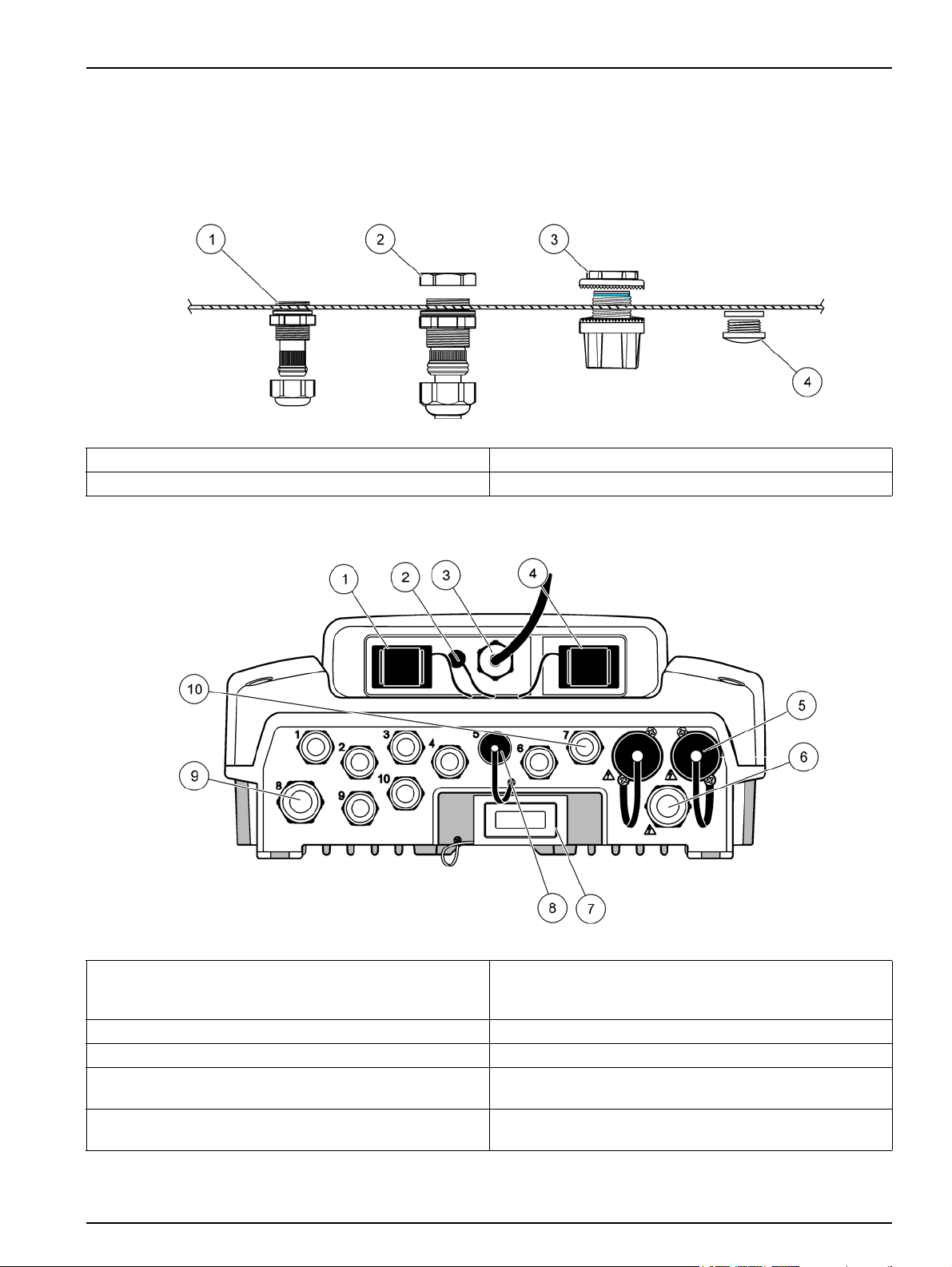

3.2.2 Vertical or horizontal pipe mounting

Refer to Figure 4 for mounting descriptions. For more information on pipe mounting refer

to the instructions supplied with the mounting kit.

Figure 4 Pipe mounting hardware

1 Bracket, pipe mount (LZY001) 3 Flat washer (4x) (LZX948)

2 Rubber pads (8x) (LZX948) 4 Hexagon head screw (4x) M5 x 30 mm (LZX948)

3.2.3 Panel Mounting

Refer to the instruction sheet supplied with the mounting hardware for installation

instructions.

3.2.4 Sun-shield

The optional sun-shield is highly recommended for all outdoor installations. Refer to the

instruction sheet supplied with the sun-shield for installation instructions.

3.3 Wiring safety information

DANGER

Electrocution hazard. Always disconnect power to the instrument when making

electrical connections.

When making any wiring connections to the sc1000 Controller, the following warnings

and notes must be adhered to, as well as any warnings and notes found throughout the

individual installation sections. For more safety information refer to Safety information on

page 9.

Remove the display module before performing any wiring tasks (Figure 5).

14

Page 17

Installation

Figure 5 Remove display module and probe module cover

1 Probe module cover 3 Connector, display module

2 Display module 4 Screw (4x)

3.3.1 Electrostatic discharge (ESD) considerations

Important Note: To minimize hazards and ESD risks, maintenance procedures not

requiring power to the analyzer should be performed with power removed.

Delicate internal electronic components can be damaged by static electricity, resulting in

degraded instrument performance or eventual failure. The manufacturer recommends

taking the following steps to prevent ESD damage to your instrument:

• Before touching any instrument electronic components (such as printed circuit cards

and the components on them) discharge static electricity from your body. This can be

accomplished by touching an earth-grounded metal surface such as the chassis of an

instrument, or a metal conduit or pipe.

• To reduce static build-up, avoid excessive movement. Transport static-sensitive

components in anti-static containers or packaging.

• To discharge static electricity from your body and keep it discharged, wear a wrist

strap connected by a wire to earth ground.

• Handle all static-sensitive components in a static-safe area. If possible, use anti-static

floor pads and work bench pads.

15

Page 18

Installation

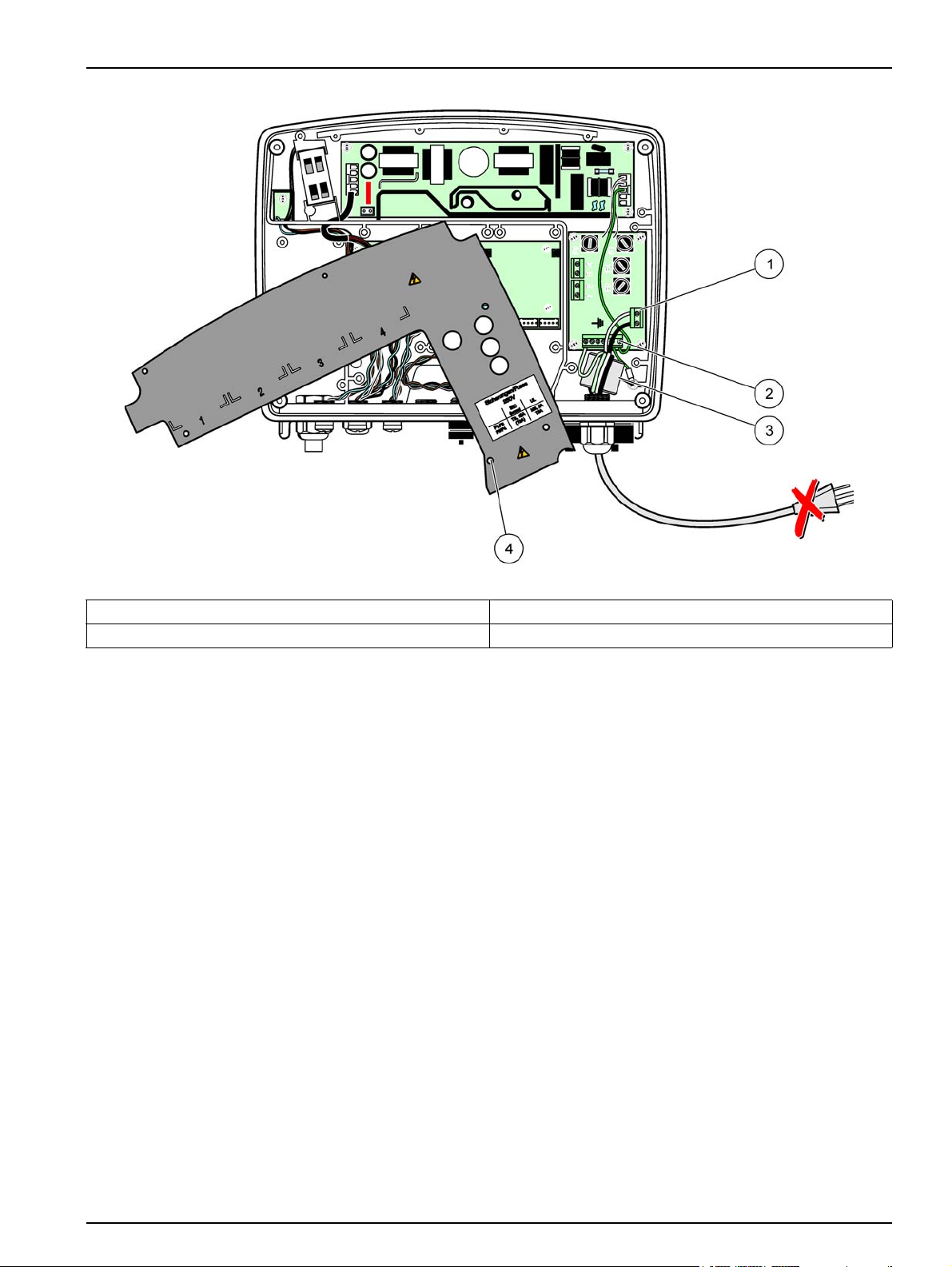

3.4 Electrical installation

DANGER

Electrocution hazard. Only qualified personnel should conduct the installation

tasks described in this section of the manual.

DANGER

Electrocution hazard. Always install a ground fault interrupt circuit (GFIC)/ residual

current circuit breaker (rccb) with a maximum trigger current of 30 mA. If installed

outside, provide overvoltage protection.

If installed outdoors, provide overvoltage protection between the power and the sc1000

controller. Make sure the data and power cables do not cause tripping and do not contain

any sharp bends. Refer to Figure 7 for housing breakout information.

High-voltage wiring for the controller is conducted behind the high voltage barrier in the

controller enclosure. The barrier must remain in place unless a qualified installation

technician is installing wiring for power, alarms, or relays. See Figure 9 for barrier

removal information.

The instrument can be wired for line power by hard-wiring in conduit or by wiring to a

power cord if allowed by local electrical code. A local disconnect designed to meet local

electrical code is required and must be identified for all types of installation.

Do not connect the electrical power supply to the AC power until the sc1000 controller

has been fully wired, fused, and the high voltage barrier and probe module cover have

been replaced.

3.4.1 Installation in hard-wired applications

In hard-wired electrical applications, the power and safety ground service drops for the

instrument must be 18 to 12 AWG. A sealing-type strain relief must be used to maintain

the IP65 environmental rating. See Figure 6 for strain relief and conduit opening sealing

plug assembly. See Figure 13 for wiring information.

Note: There is no on/off switch to disconnect the probe module from AC Power.

16

Page 19

3.4.2 Installation using a power cord

A sealing-type strain relief to maintain the IP65 environmental rating and a power cord

less than 3 meters (10 feet) in length with three 18-gauge conductors (including a safety

ground wire) can be used, see Section 9 on page 129. See Figure 6 for strain relief and

conduit opening sealing plug assembly. See Figure 14 on wiring information.

Figure 6 Using the optional strain relief and conduit plug

1 Strain relief, small 3 Conduit

2 Strain relief, large 4 Plug, sealing

Installation

Figure 7 Housing breakouts

1 Storage card slot 6 AC power connection (PS1), strain relief M20 x 1.4 mm

(4-8 mm cable diameter), conduit, different version of

power cord (optional)

2 GSM antenna connection (optional) 7 Network interface

3 Cable assembly for connection to probe module 8 Cable assembly for connection to display module

4 Service port 9 Relay connection—2.19 mm for conduit or strain relief

M20x1.5 with union mount (9–13.5 mm cable diameter)

5 Power outlet for 100–240 VAC powered sc probes 10 Configured as either sc probe connectors or

strain-reliefs, M16 x 1.5 (5–6 mm cable diameter)

17

Page 20

Installation

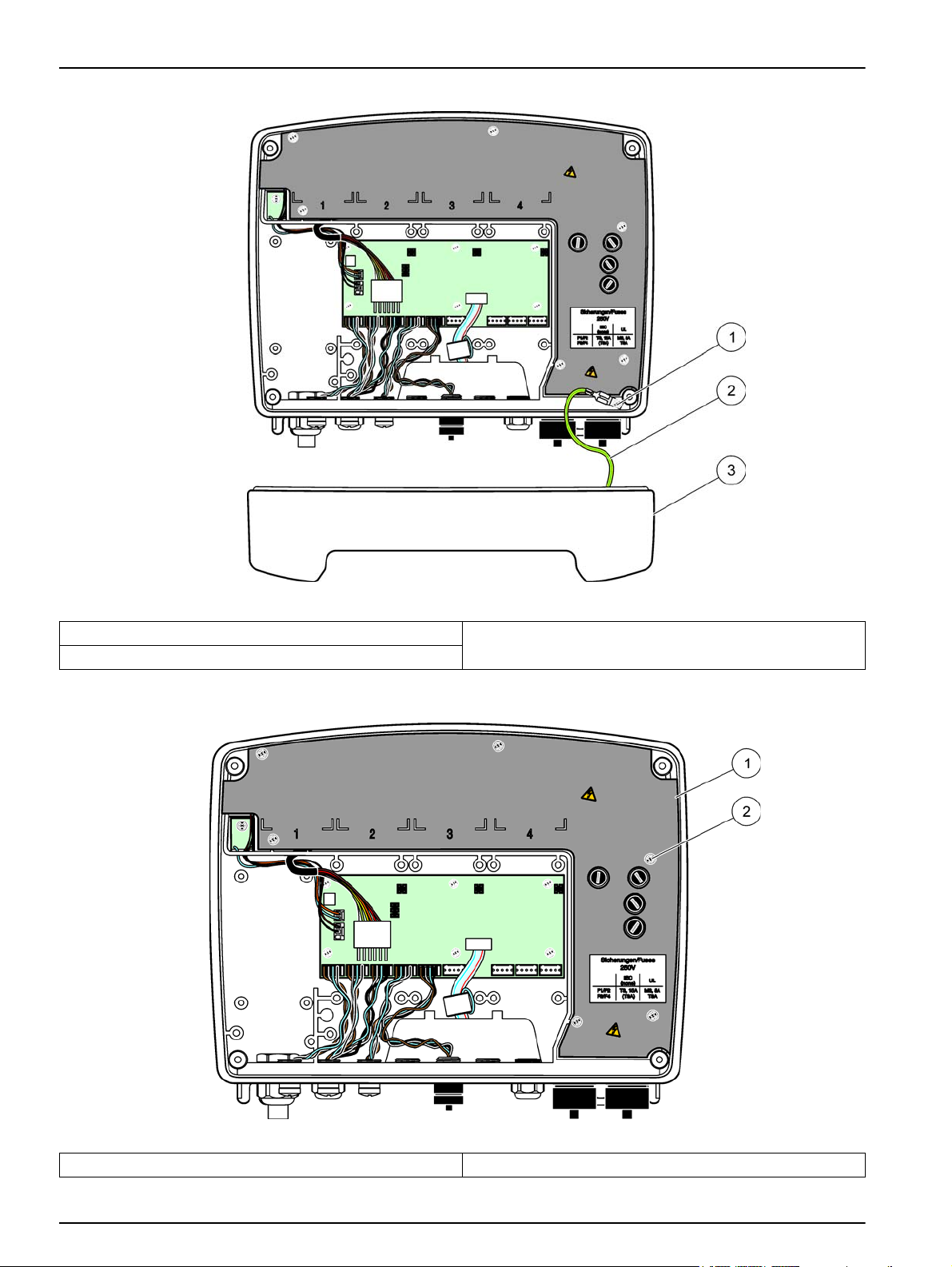

Figure 8 Removing the probe module cover

1 Ground screw 3 Probe module cover

2 Ground wire

Figure 9 Removing high voltage barrier

1 High voltage barrier 2 Screw (6x)

18

Page 21

Installation

Figure 10 Wiring for power

1 AC power connections 3 Ferrite will fit snugly in this area

2 Earth Ground Connections 4 Barrier should fit easily into position

19

Page 22

Installation

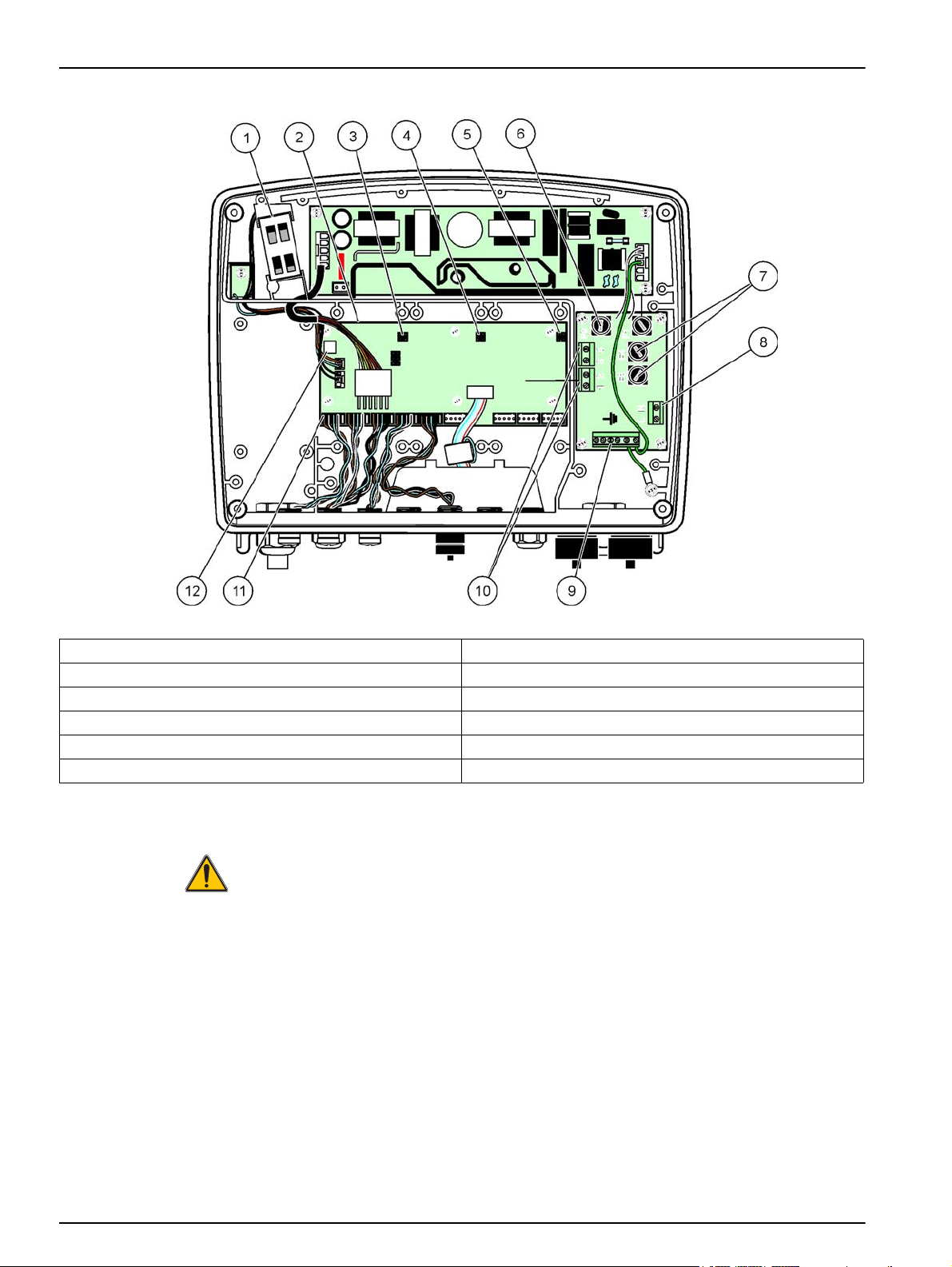

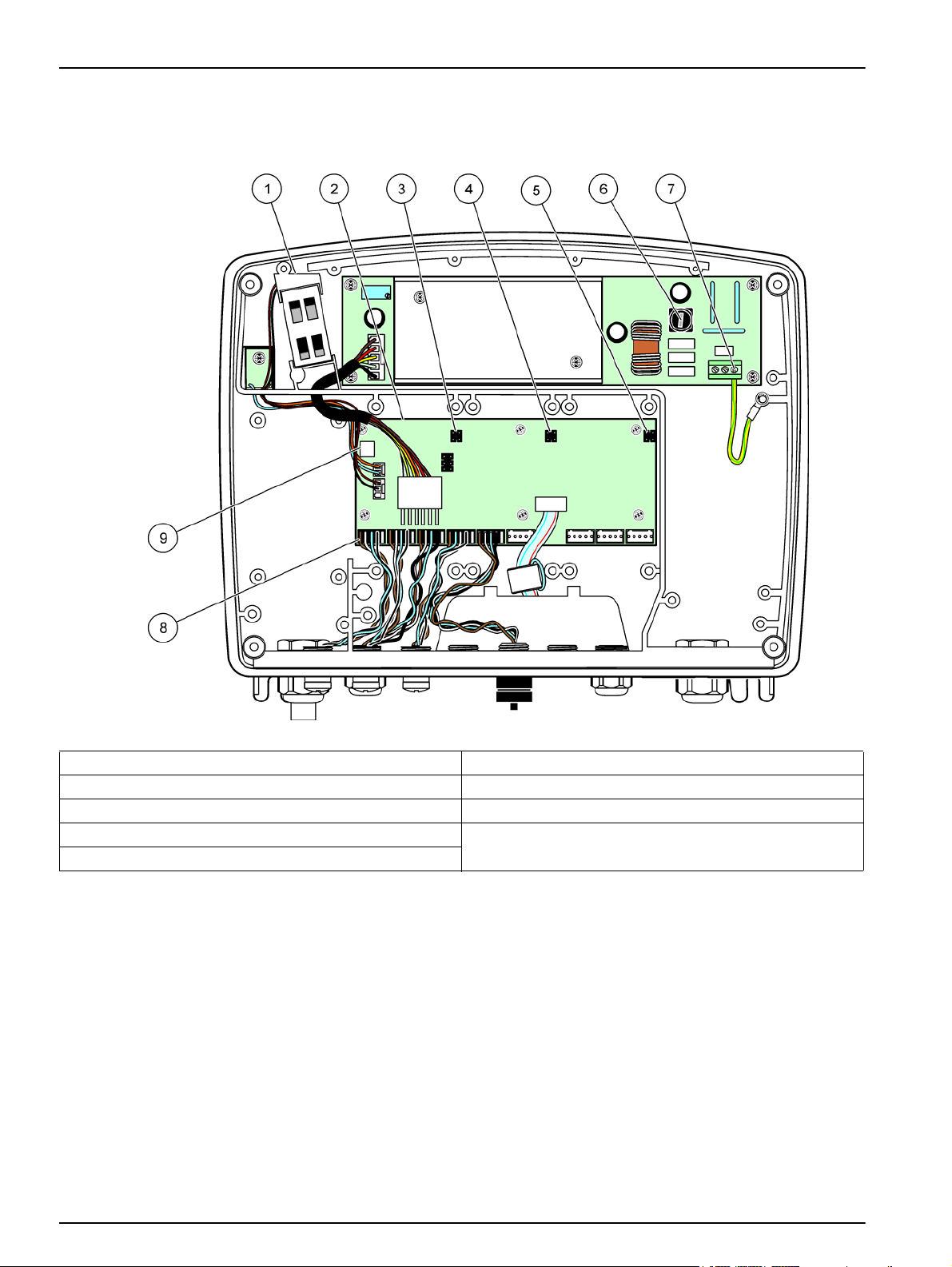

Figure 11 Inside the AC probe module

1 Fan 7 Fuse (2x), F3 and F4: T 8A; 100–240 V, slow-blow

2 Main circuit board 8 AC power connections

3 Connector for expansion slot 9 Earth ground connection

4 Connector for expansion slot 10 Power outlet connection

5 Connector for expansion slot 11 Probe connections

6 Fuse (2x), F1 and F2: M 3.5A, medium blow 12 Relay card connection

3.4.3 Wiring for AC power at the controller

DANGER

Electrocution hazard. Failure to connect to a good low impedance Protective Earth

ground can result in both a shock hazard and poor performance against

electro-magnetic interferences.

1. Obtain appropriate fittings with IP65 environmental rating.

2. Remove the display module from the probe module (Figure 5).

3. Remove the four screws securing the probe module front cover. Open the probe

module and disconnect the chassis ground connection from the ground stud to the

cover.

4. Remove the six screws from the high voltage barrier and remove the barrier.

20

5. Insert the wires through the PG1 opening and strain relief fitting or conduit hub.

Tighten the strain relief if used, to secure the cord.

Page 23

Installation

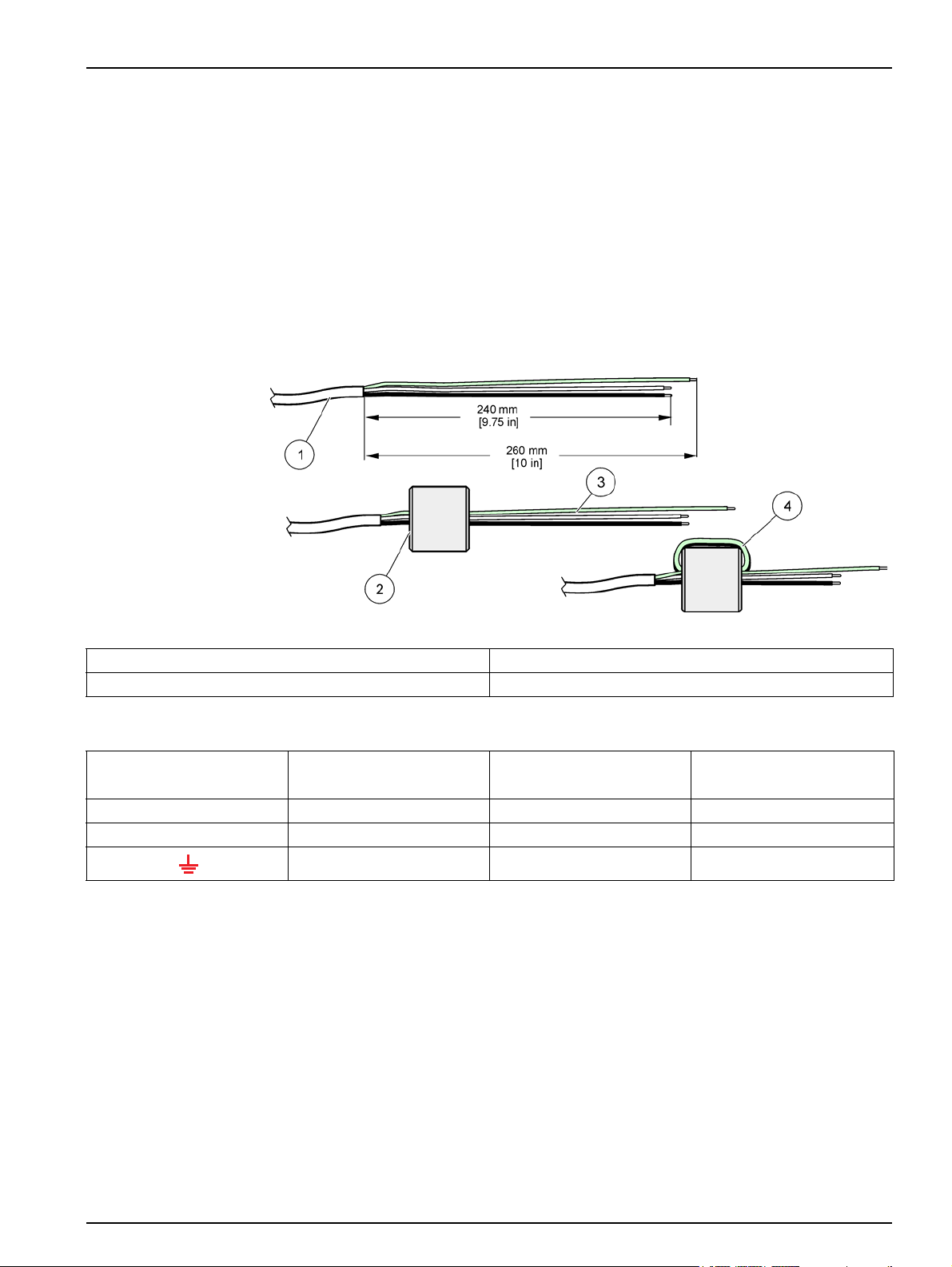

6. Strip the cable outer insulation 260 mm (10 in.) (Figure 12). Shorten all wires except

the earth wire 20 mm (0.78 in.), so the earth cable is 20 mm (0.78 in.) longer than the

other cables.

7. Feed the stripped power cable through the ferrite core twice (Figure 12) and wire into

the terminal as shown in Table 1 and Figure 10. Tug gently after each insertion to

make sure that the connection is secure.

8. Seal any unused openings in the controller box with conduit opening sealing plugs.

9. Install the high voltage barrier.

10. Connect the chassis ground connection to the ground stud of the probe module

cover.

11. Install the probe module cover and screw into place.

Figure 12 Proper wire preparation and ferrite core wiring

1 Power cable wire preparation 3 Power cable wires

2 Ferrite core 4 Power cables wrapped around ferrite core

Table 1 AC power wiring information

Terminal number Terminal description

L Hot (L1) Black Brown

N Neutral (N) White Blue

Protective Earth (PE) Green Green w/yellow tracer

Wire color code for North

America

Wire color code for Europe

21

Page 24

Installation

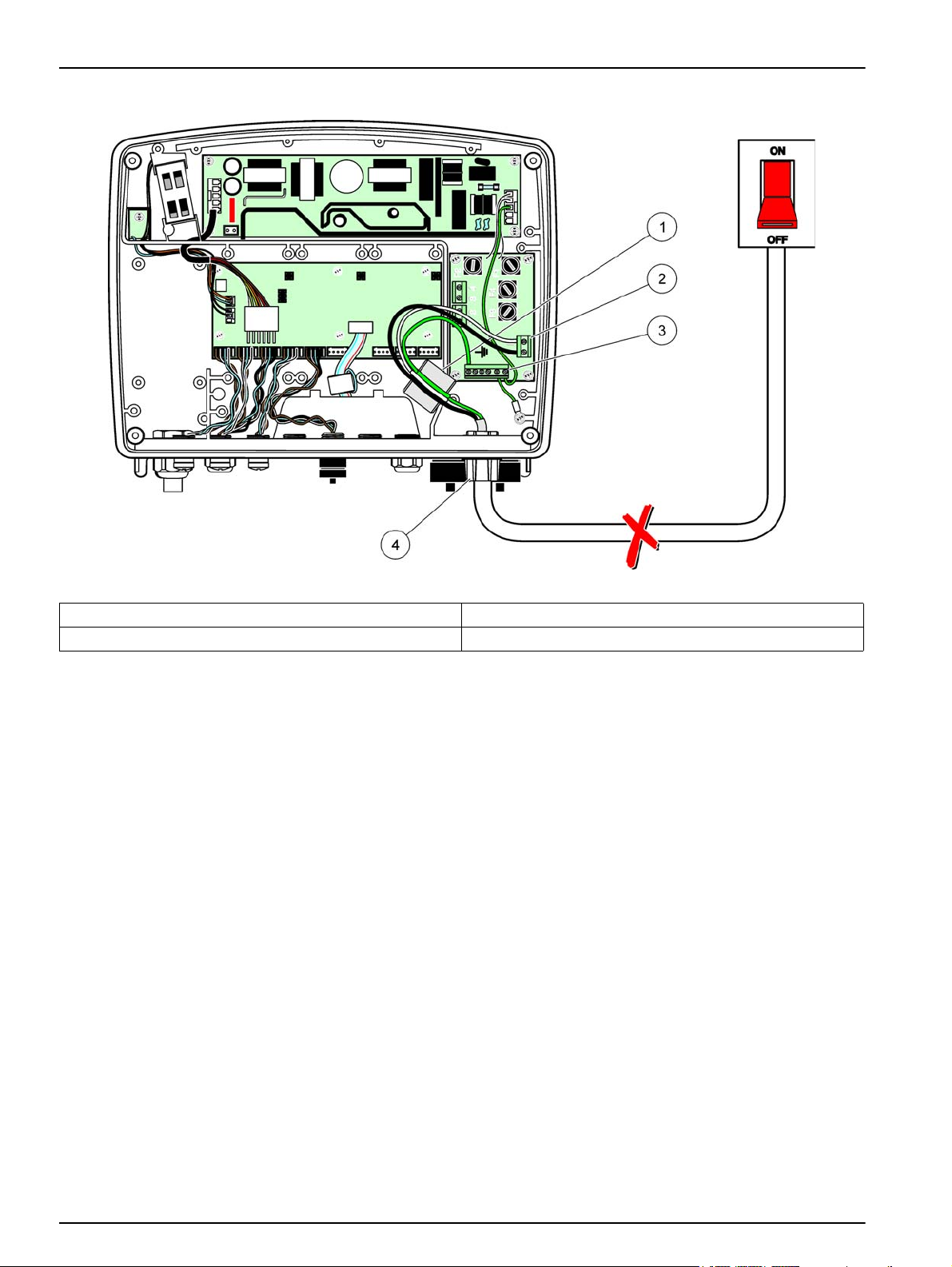

Figure 13 Hard-wired installation

1 Ferrite core (Electromagnetic interference device) 3 Earth ground connection

2 AC power connections (optional, LZX970) 4 Conduit hub, strain relief

22

Page 25

Installation

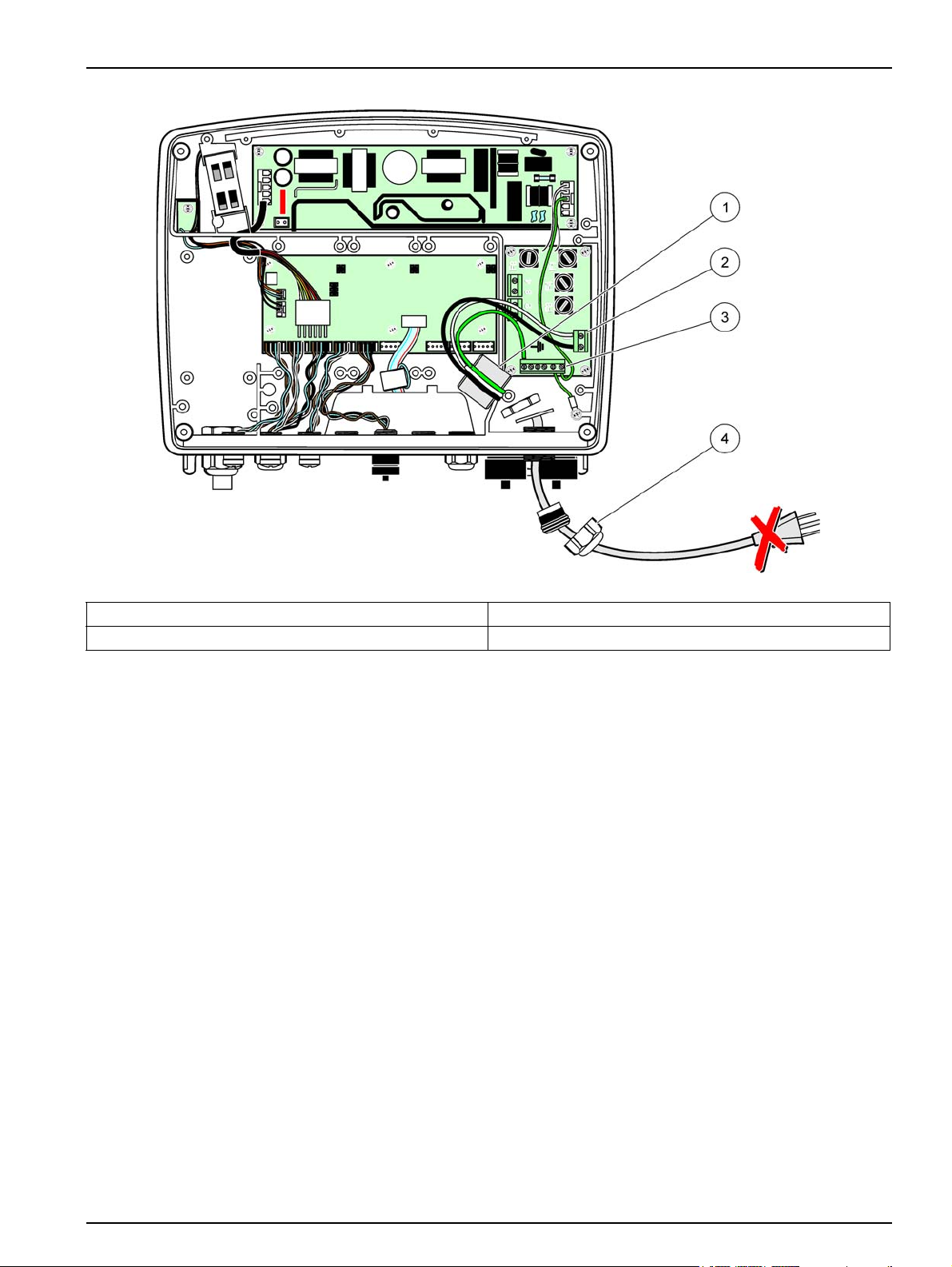

Figure 14 Installation with power cord

1 Ferrite core (Electromagnetic Interference Device) 3 Earth ground connection

2 AC power connections 4 Strain relief

23

Page 26

Installation

3.4.4 Wiring for 24 VDC power at the controller

Important Note: The AC power outlets cannot be used with the 24 VDC power supply.

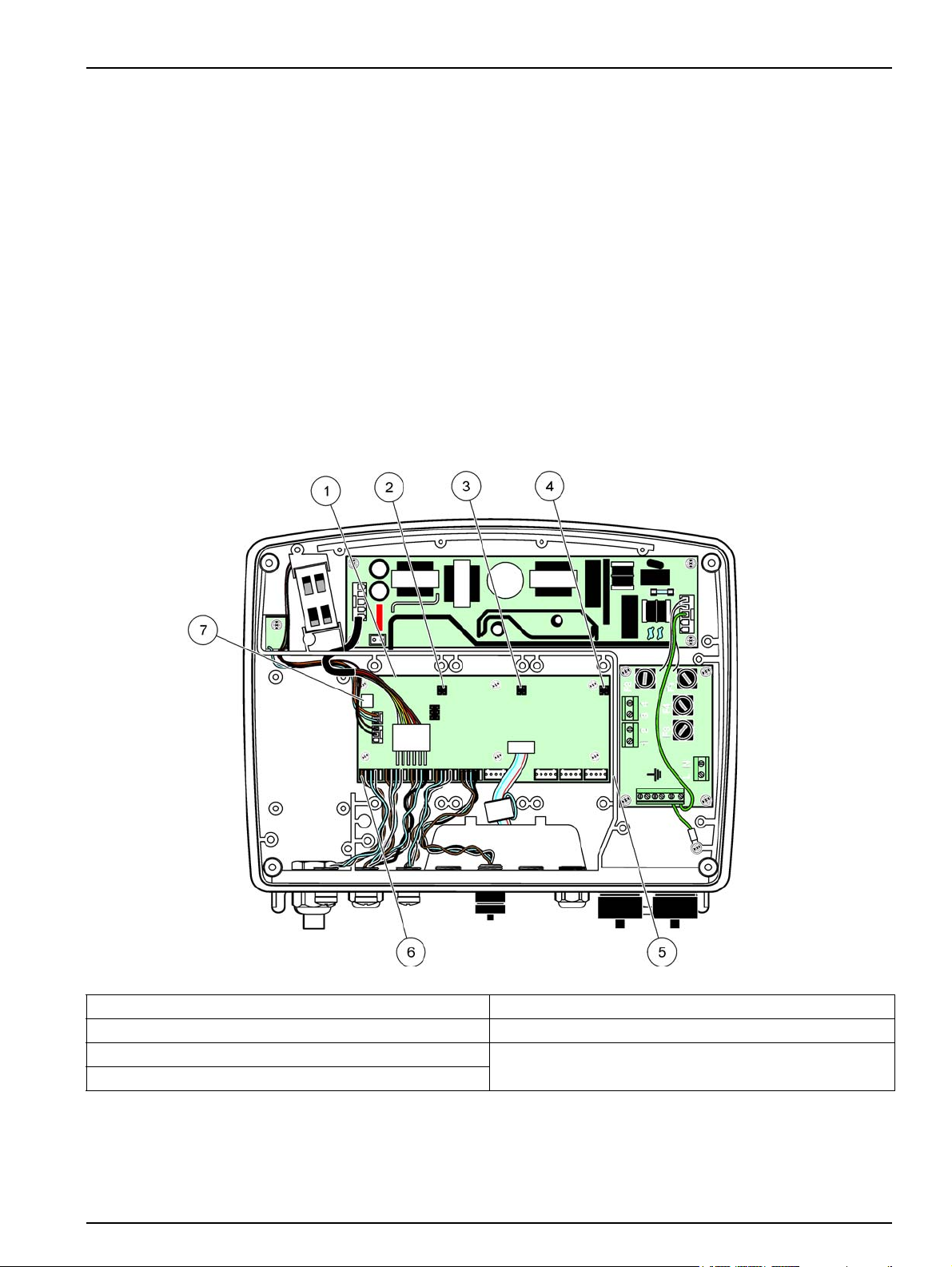

Figure 15 Inside the 24 VDC probe module

1 Fan 6 Fuse, T 6.3A, slow-blow

2 Main circuit board 7 24 VDC power connections

3 Connector for expansion slot 8 Probe connections

4 Connector for expansion slot 9 Relay card connection

5 Connector for expansion slot

24

Page 27

Installation

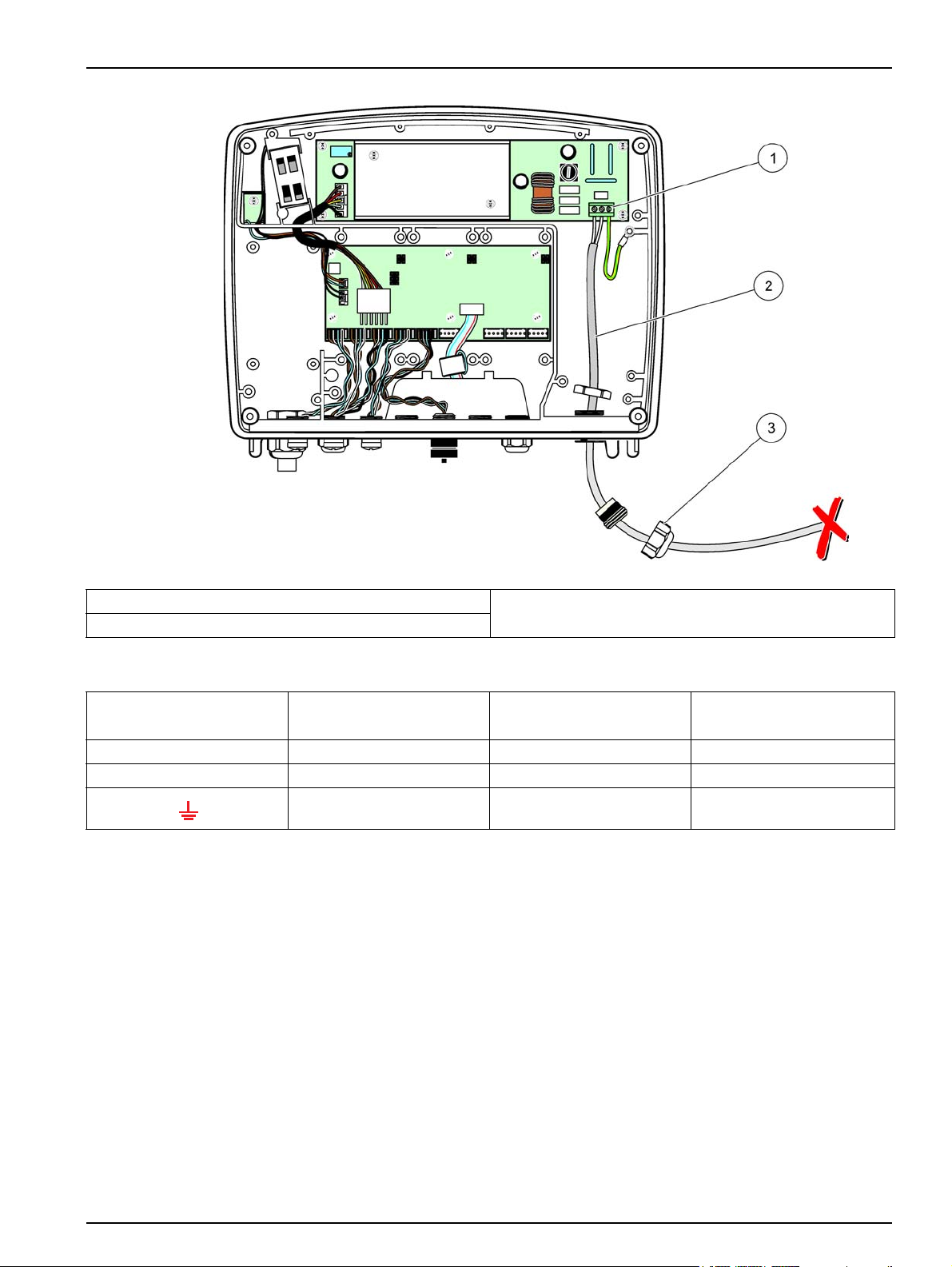

Figure 16 Wiring for 24 VDC power

1 24 VDC power terminal block 3 Strain relief

2 Cable

Table 2 DC power wiring information

Terminal number Terminal description

+ +24 VDC Red Brown

- 24 VDC Return Black Blue

Protective Earth (PE) Green Green w/yellow tracer

Wire color code for North

America

Wire color code for Europe

25

Page 28

Installation

3.5 DIN rail expansion modules

CAUTION

The expansion modules for control cabinet installation use the 24 VDC power

supply in the control cabinet. Make sure that the correct power supply is provided.

Install a residual current circuit breaker. The modules have an environmental rating

of IP20 and must always be mounted in an enclosure suitably rated for power and

environment.

The sc1000 controller can be expanded with DIN rail expansion modules.

The following DIN rail module options can be installed:

• Base module (for connecting power, sc1000 network and display module)–The base

module is required for the installation of expansion modules on the control cabinet.

• Relay card with 4 relays

• mA output card with 2 outputs

• mA input card with 2 inputs (analog or digital)–One base module can provide up to

2000 mA of power to the other modules connected to it on the DIN rail.

The total number of modules that can be connected together is limited by the power

supply from the base module. Up to 13 communication modules can be attached to each

base module. When more than 13 communication modules are needed, a second base

module must be connected through the sc1000 network.

Refer to Appendix A on page 141 for more information about the DIN rail expansion

modules.

26

Page 29

3.6 Expansion cards

The sc1000 controller can be expanded with internal plug-in expansion cards. Each

expansion component can be identified with its serial number on the sc1000 network and

programmed as required. The serial number is located on the card.

It may be necessary to remove an existing expansion card, if the expansion card is

blocking access to certain connectors. Refer to section 3.6.6 on page 37 for more

information.

When an instrument is ordered, it comes pre-installed with the appropriate plug-in

expansion cards. The following options can be connected:

• Relay card with 4 relays

• Digital field-bus cards (Modbus (RS485), Modbus (RS232), Profibus DP)

• mA output card with 4 outputs

• mA input card with 4 inputs (analog or digital)

• sc-probe connectors

Installation

Figure 17 Expansion card main circuit board connections

1 Main circuit card 5 Mounting holes, input cards (4 each)

2 Connector for expansion slot #2 6 sc probe connections

3 Connector for expansion slot #3 7 Relay card connection

4 Connector for expansion slot #4

27

Page 30

Installation

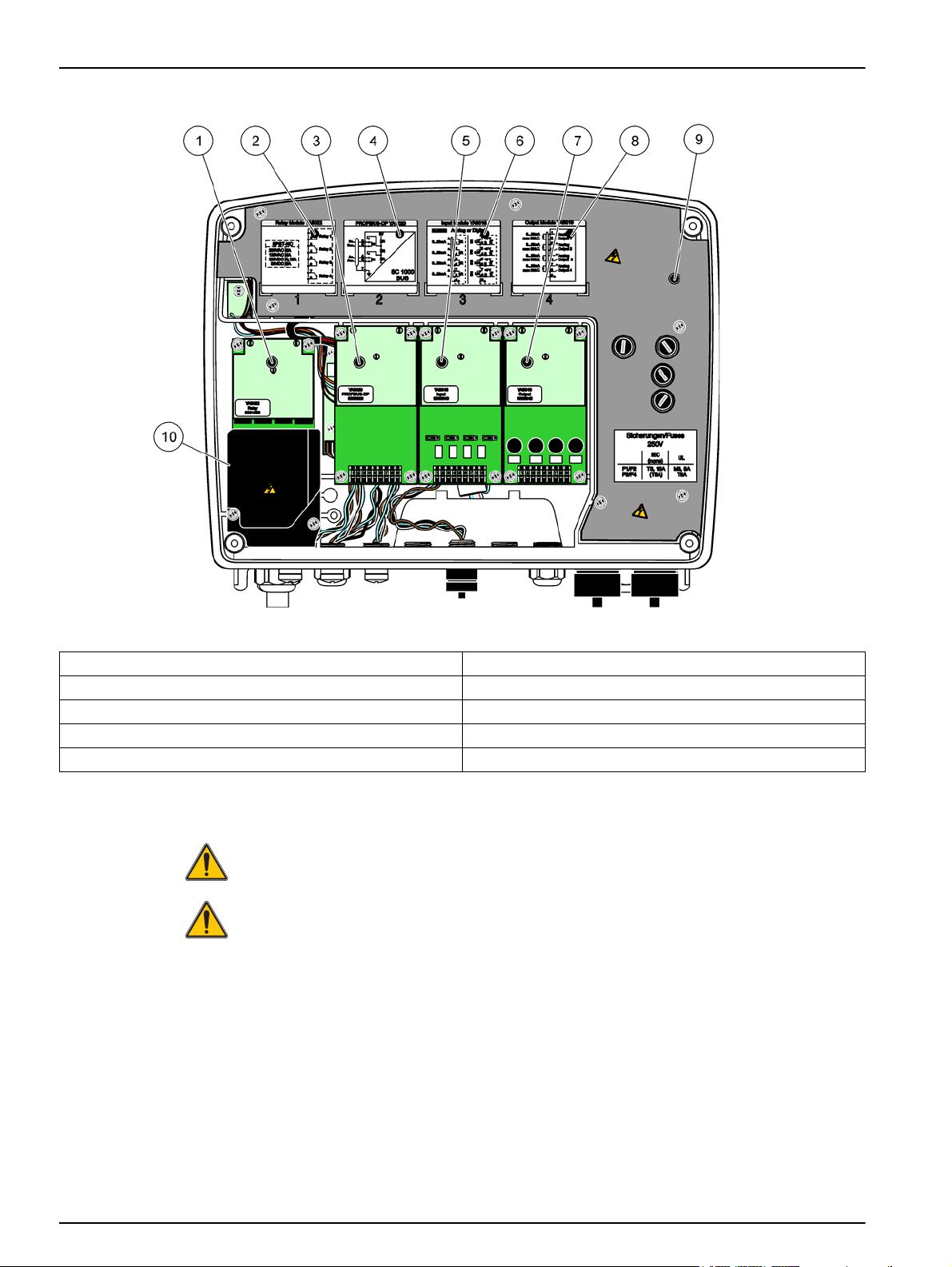

Figure 18 Expansion card ports

1 Relay card 6 mA output or input wiring information

2 Relay wiring information 7 mA output or input card

3 Field-bus or mA output or input card 8 mA output or input wiring information

4 Field-bus or mA output or input card wiring information 9 Main high voltage barrier

5 mA output or input card 10 Relay voltage barrier

3.6.1 Relay card connections

DANGER

Electrocution hazard. Relays must either be wired as low or high voltage.

DANGER

Fire hazard: Relay loads must be resistive. User must externally limit current to the

relays to 5 Amps by use of a fuse or breaker.

The relay connector accepts 18–12 AWG wire (as determined by load application). Wire

gauge less than 18 AWG is not recommended.

If the instrument is equipped with the relay card option, the instrument will include 4

relays, each with one change over contact. In this configuration, steps 3, 4 and 6 in To

make a relay card connection are not applicable.

The relays can switch maximum 250 VAC, 5A. Each relay can be configured for different

applications.

28

Page 31

Installation

To make a relay card connection

For instruments not equipped with a relay card, do the steps listed below to make relay

card connections.

1. Remove power from the instrument. Remove the probe module cover.

2. Remove the screws on the plastic relay cover. Remove the plastic cover.

3. Connect the relay card to the appropriate slot (Figure 18). Use a magnetic

screwdriver to secure the four phillips-head screws to the card. It is easier to connect

the cards with the module in its normal vertical mounted position, rather than laid

horizontally on a bench.

4. Install the card connector to the appropriate connection on the main circuit board

(Figure 17).

5. Feed the cable through the base of the module and properly prepare and insert each

wire (Figure 19) into the terminal according to Figure 20/Table 3 and Figure 21/Table

4. Tug gently after each insertion to make sure that the connection is secure.

6. Write the serial number from the rating plate on the supplied sticker and attach it to

the main high voltage barrier (Figure 18). This serial number is the same internal

address of the card on the network.

7. Install the relay and probe module cover.

After installation and connection of a plug-in expansion card, the card must be configured

to the system. For relay card setup instructions, refer to section 6.3.3 on page 87.

Figure 19 Proper wire preparation and insertion

1 Strip ¼-in (64 mm) of insulation. 2 Seat insulation against connector with no bare wire

exposed.

Figure 20 Relay card (YAB022, normally closed)

1 Terminal Block–Refer to Table 3 for terminal assignments.

29

Page 32

Installation

Table 3 Relay card (YAB022, normally closed) terminal assignments

Terminal Designation Relay 1–4

1

2

3

4

5

6

7

8

Relay 1 (normally closed contacts)

Relay 2 (normally closed contacts)

Relay 3 (normally closed contacts)

Relay 4 (normally closed contacts)

Maximum switching voltage:

250 VAC;

125 VDC

Maximum switching current:

250 VAC, 5A

125 VAC, 5A

30 VDC, 5A

Maximum switching power:

1500 VA

150 W

Figure 21 Relay card (YAB076, change over)

1 Conductor (Pull to remove from the board, when wiring

outside devices to terminal connectors)

2 Relay 1 5 Relay 12

3 Relay 7 6 Terminal Block – Refer to Table 4 for terminal

4 Relay 6

assignments

30

Page 33

Table 4 Relay card (YAB076, change over) terminal assignments

Terminal Designation Relay 1–4

1 Relay 1 (normally closed contacts)

2 Relay 1 (common)

3 Relay 1 (normally opened contacts)

4 Relay 2 (normally closed contacts)

5 Relay 2 (common)

6 Relay 2 (normally opened contacts)

7 Relay 3 (normally closed contacts)

8 Relay 3 (common)

9 Relay 3 (normally opened contacts)

10 Relay 4 (normally closed contacts)

11 Relay 4 (common)

12 Relay 4 (normally opened contacts)

Maximum switching voltage:

250 VAC;

125 VDC

Maximum switching current:

250 VAC, 5A

125 VAC, 5A

30 VDC, 5A

Maximum switching power:

1500 VA

3.6.2 Input card connections

With the input card, the sc1000 receives external analog signals (0–20 mA/4–20mA) and

digital signals. The signals can be scaled as required and given names, parameters, and

units.

Installation

150 W

To make an input card connection:

1. Remove power from the instrument. Remove the probe module cover.

2. Connect the input card to the appropriate slot (Figure 18). Use a magnetic

screwdriver to secure the four screws to the card.

3. Install the card connector to the appropriate connection on the main circuit board

(Figure 17)).

Note: The inputs can be switched between analog and digital using the jumper switches. Place the

jumper on both pins to switch to digital, place the jumper on one pin to switch to analog.

4. Feed the cable through the base of the module and properly prepare and insert each

wire into the terminal according to Figure 22 and Table 5. Tug gently after each

insertion to make sure that the connection is secure.

5. Write the serial number from the rating plate on the supplied sticker and attach it to

the main high voltage barrier (Figure 18).

6. Install the probe module cover.

After installation and connection of a plug-in expansion card, the card must be configured

to the system. For input card setup instructions, refer to section 6.3.2 on page 83.

31

Page 34

Installation

1 Jumper switches

Digital input=Jumper closed

Analog input=Jumper opened

Figure 22 Input card (YAB018) cable connections and jumper setting

2 Terminal block– Refer to Table 5 for terminal assignments.

Table 5 Input card (YAB018) terminal assignments

Terminal Designation

1 Input 1 +

2 Input 1 –

3 Input 2 +

4 Input 2 –

5 Input 3 +

6 Input 3 –

7 Input 4 +

8 Input 4 –

9 PE (Protective earth)

32

Page 35

3.6.3 Output card connections

If the instrument is equipped with the output card option, the mA output card supplies up

to 4 analog (0–20 mA/4–20 mA) signals into an impedance of max. 500 Ohm.

Note: The sc1000 mA output card cannot be used to provide power to a 2-wire (loop-powered)

transmitter.

To make an output card connection:

1. Remove power from the instrument. Remove the probe module cover.

2. Connect the output card to the appropriate slot (Figure 18). Use a magnetic

screwdriver to secure the four screws to the card.

3. Install the card connector to the appropriate connection on the main circuit board

(Figure 17).

4. Feed the cable through the base of the module and properly prepare and insert each

wire into the terminal according to Figure 23 and Table 6. Tug gently after each

insertion to make sure that the connection is secure.

5. Write the serial number from the rating plate on the supplied sticker and attach it to

the main high voltage barrier (Figure 18).

6. Install the probe module cover.

Installation

After installation and connection of a plug-in expansion card, the card must be configured

to the system. For output card setup instructions, refer to section 6.3.1 on page 78.

Figure 23 Output card (YAB019) cable connections

1 Terminal Block–Refer to Table 6 for terminal assignments.

Table 6 Output card (YAB019) terminal assignments

Terminal Designation

1 Output 1+

2 Output 1 –

3 Output 2 +

4 Output 2 –

5 Output 3 +

6 Output 3 –

7 Output 4 +

8 Output 4 –

9 Shield (Connected to protective earth)

33

Page 36

Installation

3.6.4 Modbus card connections

Modbus RS485 (YAB021) and Modbus RS232 (YAB047) are available. For more detailed

information refer to the bus system manual.

To make a Modbus card connection:

1. Remove power from the instrument. Remove the probe module cover.

2. Connect the Modbus card to the appropriate slot (Figure 18). Use a magnetic

screwdriver to secure the four screws to the card.

3. Install the card connector to the appropriate connection on the main circuit board

(Figure 17).

4. Feed the cable through the base of the module and properly prepare and insert each

wire into the terminal according to Figure 24/Table 7 and Figure 25/Table 8.

5. Write the serial number from the rating plate on the supplied sticker and attach it to the

main high voltage barrier (Figure 18).

6. Install the probe module cover.

After installation and connection of a plug-in expansion card, the card must be configured

to the system. For Modbus card setup instructions, refer to section 6.3.4.2 on page 111.

)

Figure 24 Modbus RS485 (YAB021) card connections

1 Card (Reverse side) 3 Jumper 1&2 unplugged for full duplex (4-wire)

2 Jumper 1&2 plugged for half duplex (2-wire) 4 Terminal block (Refer to Table 7 for terminal

assignments)

Table 7 Modbus RS485 card (YAB021) terminal assignments

Terminal Modbus RS485 designation with 4 wires Modbus RS485 designation with 2 wires

1 Not Used Not Used

2 Not Used Not Used

3 Output – –

4 Output + +

5 Input – –

6 Input + +

7 Shield (connected to Protective Earth) Shield (connected to Protective Earth)

34

Page 37

Figure 25 Modbus RS232 (YAB047) card connections

1 Terminal Block (Refer to Table 8 for terminal assignments)

Installation

Table 8 Modbus RS232 card (YAB047) terminal assignments

Terminal Modbus RS232 designation

1 Not Used

2 Ground

3 Not Used

4 TXD (Transmitting line Modbus Card)

5 Not Used

6 RXD (Receiving line Modbus Card)

7 Not Used

3.6.5 Profibus DP card connections

Refer to the documentation supplied with the Profibus DP card for more information.

Refer to the appropriate probe manual for operating instructions, instrument profiles,

and GSD files. Refer to the company web site for the latest GSD files and documentation.

To make a Profibus card connection:

1. Remove power from the instrument. Remove the probe module cover.

2. Connect the Profibus card to the appropriate slot (Figure 18). Use a magnetic

screwdriver to secure the four screws to the card.

3. Install the card connector to the appropriate connection on the main circuit board

(Figure 17).

4. Feed the cable through the base of the module and properly prepare and insert each

wire into the terminal according to Figure 26 and Table 9. Make sure that the shield is

connected to a threaded spacer on the board.

5. Write the serial number from the rating plate on the supplied sticker and attach it to

the main high voltage barrier (Figure 18).

6. Install the probe module cover.

35

Page 38

Installation

After installation and connection of a plug-in expansion card, the card must be configured

to the system. For Profibus card setup instructions refer to section 6.3.4.1 on page 109.

Figure 26 Profibus DP card (YAB020) connections

1 Network termination activated, last device on network 3 Terminal Block – Refer to Table 9 for terminal

2 Network termination deactivated, other devices on network

after this device.

assignments.

Table 9 Profibus DP card (YAB020) terminal assignments

Terminal Designation

1 Not used

2 Not used

3 B in (wire color red)

4 A in (wire color green)

5 B out (wire color red)

6 A out (wire color green)

7 PE (Protective Earth)

36

Page 39

3.6.6 Remove/Replace an expansion card

It may be necessary to remove an existing expansion card if probe connectors are

obstructed.

Important Note: The compact connectors are a very tight fit and the connections can

easily break off. Do not apply excessive force when fitting and removing the compact

connectors.

To remove/replace an expansion card:

1. Delete the card in the sc1000 controller. Refer to section 6.3.6 on page 115.

2. Remove power from the instrument. Remove the probe module cover.

3. Disconnect all cable connections to the card.

4. Remove the screws securing the card and remove the card.

5. Replace the card and configure the card.

3.7 Install an sc1000 network (sc1000 bus connection)

An sc1000 network connects up to 32 participants (Figure 27). Participants are defined as

anything attached to the network including probes and optional cards but not counting the

display module or probe modules. Only one display module is allowed for one sc1000

network.

Installation

Each probe module has an sc1000 network interface (Figure 28). Use the sc1000

network cable and the sc1000 network connector to set up a network. Suitable cable and

network connector is available from the manufacturer.

Figure 27 sc1000 network

1 Profibus/Modbus connection 4 Probe module

2 sc1000 controller (Display and probe module) 5 Probe

3 sc1000 bus connection

37

Page 40

Installation

Figure 28 Plugging the network connector to the network interface

1 Probe module 3 sc1000 network connector

2 sc1000 network interface 4 sc1000 network interface cover

3.7.1 sc1000 network connections

To attach a network connector:

1. Strip the insulation from the communication cable (Figure 29).

2. Feed the cable through the union nut, rubber seal, and connector housing

(Figure 31).

3. Connect the cable to the network connector circuit board as shown in Table 10.

Network Connector Assembly

4. Place the circuit board with the cable connected in the bottom part of the metal

frame.

5. Tighten the cable connector.

6. Place the top of the metal frame on the bottom and press together.

7. Feed the frame into the sc1000 connector. The frame will only fit in one position. If

necessary, rotate the frame.

8. Attach the circuit board and the frame to the front with the two self-tapping screws

provided.

38

Page 41

Installation

9. If necessary, set the terminating resistor.

Note: When using the connector with the last module on the network segment, one union nut

remains unused. Seal the union nut with the plug supplied. Refer to Figure 31.

10. If this connector is the end of the network, insert the rubber seal in the connector.

11. Tighten the union nut by two turns.

12. Insert the sealing plug in the unused union nut and rubber seal.

13. Tighten the union nut.

14. Set a terminating resistor at the last network connector to the ON position (see

Figure 32 and Table 11).

15. Plug the connector into the probe module.

Figure 29 Removing the insulation from the communication cable

1 Cable, 2-conductor 3 Circuit card/bottom shell, cable, and cable clamp

subassembly

2 Connector, (network connector printed circuit board) 4 Network cable installed in connector

Table 10 Communication connector terminal assignments

Connection Cable Signal Length

1A Incoming or last device A

1B Incoming or last device B

2A To further devices A

2B To further devices B

Note: If the network connector is terminated, 2A and 2B are set to off.

25 mm (1 in.)

35 mm (1.4 in.)

39

Page 42

Installation

Figure 30 Network connector components

1 Housing, network connector 7 Insert, plastic label (network connector housing)

2 Network connector printed circuit board with shell bottom 8 Not used

3 Shell, top 9 Plug, rubber, cord grip

4 Screws, self-tapping (2x) 10 Seal, cord grip (2x)

5 Clamp, network cable(s) 11 Cord grip (2x)

6 Screw, pan head

40

Page 43

Installation

Figure 31 Connecting the network connector to the sc1000 network terminating resistor

1 Shell, bottom 6 Housing, network connector

2 Network connector printed circuit board with shell bottom 7 Seal, cord grip

3 Clamp, network cable(s) 8 Cord grip

4 Screw, pan head 9 Plug, rubber, cord grip

5 Cables, network

1

Route cables as shown and make sure that clamp is fastened securely.

2

Use this plug if the cord grip is not used, refer to inset in Figure 31.

1

10 Screws, self-tapping (2x)

2

41

Page 44

Installation

Figure 32 Setting a terminating resistor (DIP switch in the connector)

1 Housing, network connector 3 Dip switch (note position assignments as shown)

2 Cap, rubber 4 Insert, plastic label

Table 11 Communication connector terminating resistor (communication termination)

Switch setting Terminating resistors Connection 2

On Enabled Disabled

Off Disabled Enabled

Note: The DIP switch can also be operated when the connector is fitted. The OFF and ON switch

positions are also printed on the connector housing. Use the switch for commissioning and

troubleshooting segment by segment. Shut down the segments one by one and check for function

and errors.

42

Page 45

3.8 Connect probes to the sc1000 controller

All sc series probes can be used on the sc1000 controller.

Important Note: Plan the route for the probe cable and lay the data and power cables so

that they do not cause a trip hazard and the cables do not have any sharp bends.

For details on the installation and operation of the probe, refer to the appropriate probe

manual.

3.8.1 Connect the probe data cable

1. Unscrew the protective cover on the controller socket (Figure 33). Retain the

protective cover. When you remove the probe, re-fit the protective cover.

2. Align the connector plug with the socket, pay attention to the orientation of the

connector lugs.

3. Hand-tighten the union nut.

Note: Keep the middle connection of the probe module free. Use the free port to connect the display

module to each probe module in a network.

Installation

Figure 33 Removing the protective cover

1 sc probe connection 2 Protective cover

43

Page 46

Installation

3.8.2 Add probe connections

When all probe connectors on the sc1000 controller are already in use for probes, more

probe connectors can be added (max. 8 probe connectors). It may be necessary to

remove an existing expansion card if accessibility to probe connectors is obstructed (refer

to section 3.6.6 on page 37).

Note: If a probe module has the maximum number of probes, more probes may be added to the

system by purchasing additional probe modules.

To add probe connections:

1. Remove power from the instrument. Open the probe module cover.

2. Remove the fitting or plug from a spare probe socket hole.

3. Screw a new probe connector into the housing and connect the probe connector to a

probe connection on the main circuit board. Any available probe connector can be

used.

4. Assemble the housing.

3.8.3 Connect AC powered sc probes

Note: AC power outlets can only be connected when a 100 V–240 V power supply is fitted in the

sc1000 controller.

Most sc-probes draw power directly from the sc probe connection. However, certain sc

probes may require supplemental 100–240 VAC power (e.g., to run pumps or heating

elements). These AC powered sc-probes have two cables that connect to an sc1000

probe module: a standard sc-probe connector and a special connector for drawing

AC power from the probe module.

To connect AC powered probes to a probe module:

1. Unscrew the cover on the AC power outlet.

2. Connect the power connector from the analysis instrument to one of the

AC power outlets.

3. Connect the sc-probe connector to any available sc-probe socket.

3.9 Service port connection (LAN connection)

The service port of the sc1000 controller is a 10 MB/s Ethernet interface at the display

module (Figure 7). To use the service port, connect an Ethernet cross-over cable from a

computer to the service port. The Ethernet connection can be used to run all sc1000

controller functions or calibrate the probes through any web browser.

Configure the network adapter inside the computer to communicate with the sc1000

controller.

Important Note: It is recommended to use an external Ethernet USB network adapter as

an interface to the sc1000 controller. The use of a second network adapter makes sure

that the sc1000 controller connection does not have any impact to the default local area

network (LAN) connection (for example the regular office network).

44

To setup and prepare a LAN connection, refer to section 5.13.1 on page 67 and

section 5.13.2 on page 67.

Page 47

3.10 GSM modem connection

The display module can optionally contain a built-in tri-band modem (Figure 7). The GSM

modem connection allows fully remote operation of the sc1000 controller, including

transfer of data and software updates. The GSM modem requires a SIM card, an external

GSM antenna and must meet the requirements in Table 12:

Europe USA/Canada

Installation

Table 12 GSM modem requirements

• GSM 900 or EGSM 900

(EGSM 900 = GSM 900 with expanded

frequency range)

• GSM 1800

• GSM 1900

The main modem features are:

• Maintain the sc1000 controller and sc1000 network

• Set up logging

• Download logged data

• Send out errors and warnings as a short message (SMS)

For GSM modem connection information, refer to section 5.13.3 on page 68.

3.10.1 Safety precautions

The following safety precautions must be observed during all phases of the installation,

operation, maintenance or repair of any cellular terminal or mobile phone incorporating

MC55/56. The manufacturer assumes no liability for customer failure to comply with

these precautions.

CAUTION

The GSM modem connection cannot be used in hazardous locations.

• GSM 850

• GSM 1800

• GSM 1900

The manufacturer and its suppliers reject any express or indirect guarantee for the use

with High Risk Activities.

In addition to the following safety considerations, obey all the regulations specific to the

country in which the equipment is installed.

Important Note: Cellular terminals or mobile phones operate using radio signals and

networks. These connections are not guaranteed at all times under all conditions. The

cellular terminal or mobile phone must be switched on and in a service area with adequate

signal strength.

Safety precautions for GSM modem installation

• This unit is to be installed by a trained technician employing proper installation

practices for a Radio Frequency Transmitter, including proper grounding of any

external antennas.

• Do not operate the device in hospitals and/or near medical instruments such as

cardiac pacemakers or hearing aids.

• Do not operate the device near highly combustible areas such as gas stations, fuel

depots, chemical plants and blasting works.

• Do not operate the equipment in the proximity of combustible gases, steams or dust.

45

Page 48

Installation

• Do not expose the equipment to strong vibrations or impacts.

• The GSM/GPRS modem can cause disturbances when in the proximity of television

sets, radios or PCs.

• Do not open the GSM/GPRS modem. Any change of the equipment is inadmissible

and leads to the loss of the operating permission.

• This unit is to be installed by a trained technician employing proper installation

practices for a Radio Frequency Transmitter, including proper grounding of any

external antennas.

• Using the GSM services (SMS messages, data communication, GPRS etc.) is likely to

incur additional costs from a service provider. The user is exclusively responsible for

any damages and costs incurred.

• Do not use or install this equipment in any manner other than that specified in this

manual. Inappropriate use will void the warranty.

Safety precautions for SIM card installation

• The SIM card can be taken out. Keep the SIM card out of the reach of children.

Harmful if swallowed.

• Remove all power before replacing SIM card.

Safety precautions for antenna installation

• Only use antennas, which are recommended or supplied by the manufacturer.

• The antenna must be mounted at least 20 cm away from any person.

• Do not let antenna rise up outside of protected buildings and secure antennas against

lightning!

• Remove all power before replacing an antenna.

3.10.2 SIM card requirements

The SIM card must be enabled by a provider and registered in the sc1000 controller.

The SIM card requirements are:

• GSM network supports “GSM Phase 2” (minimum)

• Includes the services “SMS (short messaging service)” and “Data Services”.

• Complies with the standards “ISO 7816-3 IC” and “GSM 11.11”.

Note: Contact the local Hach/HachLange support to discuss the SIM card and provider

requirements.

46

Page 49

3.10.3 Insert the SIM card into the display module

Important Note: The touch screen is scratch sensitive. Never place the touch screen on a

hard and scratching surface.

To insert the SIM card into the display module:

1. Disconnect the display module from the probe module.

2. Place the display module on a soft and flat base.

3. Remove the SIM card cover from the back side of the display module (Figure 34).

4. Press the button to eject the card holder for the SIM card.

5. Put the SIM card into the SIM card holder, and put the SIM card holder into the SIM

card slot.

6. Attach the cover with the two cover bolts.

7. Connect the display module to the probe module.

Installation

Figure 34 Insert the SIM card

1 Display module 3 SIM card

2 SIM card holder 4 SIM card cover

47

Page 50

Installation

3.10.4 Connect the external GSM antenna to the display module

Important Note: To guarantee proper functionality, only use the antenna that is supplied

by the manufacturer.

The standard antenna is directly attached to the GSM antenna connection at the display

module. In case of low radio signal strength, connect a roof antenna or an external

outdoor antenna.

If the distance between the position of the antenna and the display module is too long,

use one 10m extension cable (LZX955) to extend the connection.

To connect an external GSM antenna:

1. Mount all necessary components.

2. Connect an extension cable between the display module and the external GSM

antenna if necessary.

3. Remove the standard antenna.

4. Attach the antenna cable to the GSM antenna connection at the display module

(Figure 7). Use the supplied adapter to connect the antenna connector and the GSM

antenna connection (Figure 35).

Figure 35 Connect the external GSM antenna

1 Sun roof (optional) 3 External GSM antenna (LZX990)

2 Display module 4 GSM antenna connection at the display module

48

Page 51

3.11 Storage card (SD card)

Note: The manufacturer recommends to use SanDisk® SD card with a capacity of 1 Gigabyte.

Important Note: If the sc1000 controller or the storage card is damaged and does not

save and backup data correctly, the manufacturer cannot be held liable for any data loss.

The display module contains a built-in storage card slot. The storage card is used to store

and transfer log files from all devices, update sc1000 controller software or restore

settings without network access.

3.11.1 Insert the storage card into the display module

To insert the storage card into the display module (Figure 36):

1. Remove the storage card cover at the display module.

2. Insert the storage card into the storage card slot.

3. Close the storage card cover.

Installation

Figure 36 Insert the storage card to the display module

1 Storage card slot 3 Storage card

2 Storage card cover at the display module

49

Page 52

Installation

3.11.2 Prepare the storage card

A plain/new storage card has to be prepared first with the ERASE ALL command of the

sc1000 software.

To prepare the storage card:

1. Select SYSTEM SETUP, STORAGE CARD, ERASE ALL.

2. Confirm the message.

3. The sc1000 software removes all files from the storage card and creates the storage

card folder structure (Table 13).

4. The storage card is ready for use.

Folder name Content

dev_setting Configurations and settings

sc1000 Log files, Backup files

update Files for software update

Table 13 Storage card, folder structure

50

Page 53

Section 4 System Start Up

Important Note: During initial commissioning, make sure all plug-in expansion cards,

expansion modules, and all probes are correctly connected and wired in the system.

1. Supply power to the controller. When the LED light turns green, the display module

and the attached devices are communicating.

2. Follow the touch screen calibration prompts. After the touch screen calibration is

complete the operating system starts and the display automatically prompts for the

user language, time and date.

Note: Touch screen calibration is required for each user. Calibrating the system to a stylus will

prevent the need for multiple operator calibrations. The initial touch screen calibration is stored

in the display module. To change the touch screen calibration, switch the display module on and

off. Press the screen during start-up to display the touch screen calibration mode.

3. Select the appropriate language and time and date settings.

4. Switch the display module off and on.

5. Confirm the attached probes and devices.

6. Press

7. The controller automatically scans for connected probes. The scan may take several

For more information on using the display module, refer to section 5.1 on page 53.

OK.

minutes to complete.

51

Page 54

System Start Up

52

Page 55

Section 5 Standard Operations

5.1 The display module

The sc1000 display module is a color graphical user interface that uses touch screen

technology. The touch screen is a 5.5” (14 cm) LCD monitor. The touch screen display

must be calibrated prior to configuring or viewing data (refer to section 5.6 on page 59). In

normal operation the touch screen displays the measured values for the probes selected.

One display module controls a single probe module or a number of probe modules

connected by a sc1000 network. The display module is portable and can be disconnected

and moved within the network.

Prior to configuring the system it is important to program the display language (refer to

section 5.7 on page 59) and the Date and Time information (refer to section 5.8 on

page 60).

Figure 37 Display module overview

1 Display module 5 Service port

2 Display screen 6 Cable connection to the probe module

3 Access to SIM card (only for optional GSM modem) 7 Slot for storage card

4 Antenna connection (only for optional GSM modem) 8 Connector

5.1.1 Attach the display module to the probe module

Attach the display module to the probe module (refer to Figure 38). Connect the cable

connector from the display module to the middle socket on the probe module (refer to

Figure 37.

53

Page 56

Standard Operations

Figure 38 Attach the display module to the probe module

5.1.2 Tips for the use of the touch screen

The entire screen of the display module is touch-activated. To make a selection, press

the screen with a fingernail, fingertip, pencil eraser or a stylus. Do not press the screen

with a sharp object, such as the tip of a ball point pen.

• Do not place anything on top of the screen, to prevent damage or scratching on the

screen.

• Press buttons, words or icons to select them.

• Use scroll bars to move up and down long lists very quickly. Press and hold the scroll

bar, then move up or down to move through the list.

• Highlight an item from a list by pressing it once. When the item has been successfully

selected, it will be displayed as reversed text (light text on a dark background).

5.1.3 The display modes

The display module offers different display modes and a pop-up toolbar:

• Measured value display: Default display when a probe is connected and the sc1000

controller is in measurement mode. The sc1000 controller automatically identifies the

connected probes and displays associated measurements.

• Graph display: Option in the measured value display. Displays measured values as

graphs. The Graph display is accessed through the pop-up toolbar.

54

• Main menu display: Software interface for setting up parameters and settings of a

device, probe and display module. The Main menu is accessed through the pop-up

toolbar.

• Pop-up toolbar: The pop-up toolbar provides access to the sc1000 controller and

probe settings and is normally hidden from view. To view the toolbar, touch the

bottom-left of the screen. The toolbar contains the buttons described in Figure 39.

Page 57

Figure 39 Measured value display with pop-up toolbar

1 Measured value display—Displays up to 4 measured

values

GRAPH button—Displays 1, 2 or 4 measured values as