Page 1

DOC022.53.80017

HQd Portable Meter

10/2017, Edition 6

User Manual

Page 2

Page 3

Table of Contents

Specifications.................................................................................................................................................................................. 5

General information..................................................................................................................................................................... 5

Safety information.............................................................................................................................................................................. 5

Use of hazard information.................................................................................................................................................................. 6

Precautionary labels.......................................................................................................................................................................... 6

Product overview............................................................................................................................................................................... 6

Product components.......................................................................................................................................................................... 6

Installation......................................................................................................................................................................................... 7

Install the batteries............................................................................................................................................................................. 7

Connect to AC power......................................................................................................................................................................... 8

User interface and navigation............................................................................................................................................... 9

User interface..................................................................................................................................................................................... 9

Display description............................................................................................................................................................................. 9

Navigation........................................................................................................................................................................................ 11

Startup............................................................................................................................................................................................... 11

Turn the meter on and off................................................................................................................................................................ 11

Change the language....................................................................................................................................................................... 11

Change the date and time................................................................................................................................................................ 11

Connect a probe.............................................................................................................................................................................. 12

Standard operation.................................................................................................................................................................... 12

About calibration.............................................................................................................................................................................. 12

About sample measurements.......................................................................................................................................................... 13

About check standards.................................................................................................................................................................... 13

Use a sample ID.............................................................................................................................................................................. 13

Use an operator ID........................................................................................................................................................................... 13

Data management....................................................................................................................................................................... 13

About stored data............................................................................................................................................................................. 13

View stored data.............................................................................................................................................................................. 14

View stored probe data............................................................................................................................................................. 14

1

Page 4

Print stored data............................................................................................................................................................................... 14

Change the report options........................................................................................................................................................ 15

Send data to a USB storage device................................................................................................................................................. 15

Open data files on a PC................................................................................................................................................................... 16

Data file description......................................................................................................................................................................... 16

Remove column headers................................................................................................................................................................. 18

Send data directly to a computer..................................................................................................................................................... 18

Advanced operation.................................................................................................................................................................. 18

Security options............................................................................................................................................................................... 18

Turn Security Options on.......................................................................................................................................................... 18

Full access options menu......................................................................................................................................................... 19

Restricted operator access options menu................................................................................................................................ 19

Set the display options..................................................................................................................................................................... 20

Set the sound options...................................................................................................................................................................... 20

Set the probe calibration reminder............................................................................................................................................ 21

Change the temperature units......................................................................................................................................................... 21

Set the measurement mode............................................................................................................................................................. 21

Set auto measurement intervals............................................................................................................................................... 21

Start interval measurements..................................................................................................................................................... 21

Prevent data log overflow in interval mode............................................................................................................................... 22

View instrument information............................................................................................................................................................. 22

Update the meter software............................................................................................................................................................... 22

Download software updates..................................................................................................................................................... 23

Transfer method settings................................................................................................................................................................. 23

Bi-directional Communication between the meter and a PC........................................................................................................... 23

About meter control.................................................................................................................................................................. 23

About meter configuration......................................................................................................................................................... 24

Maintenance................................................................................................................................................................................... 24

Clean the meter............................................................................................................................................................................... 24

Replace the batteries....................................................................................................................................................................... 24

Troubleshooting.......................................................................................................................................................................... 25

Table of Contents

2

Page 5

Replacement parts and accessories............................................................................................................................... 26

Examples of printed reports.................................................................................................................................................28

Table of Contents

3

Page 6

Table of Contents

4

Page 7

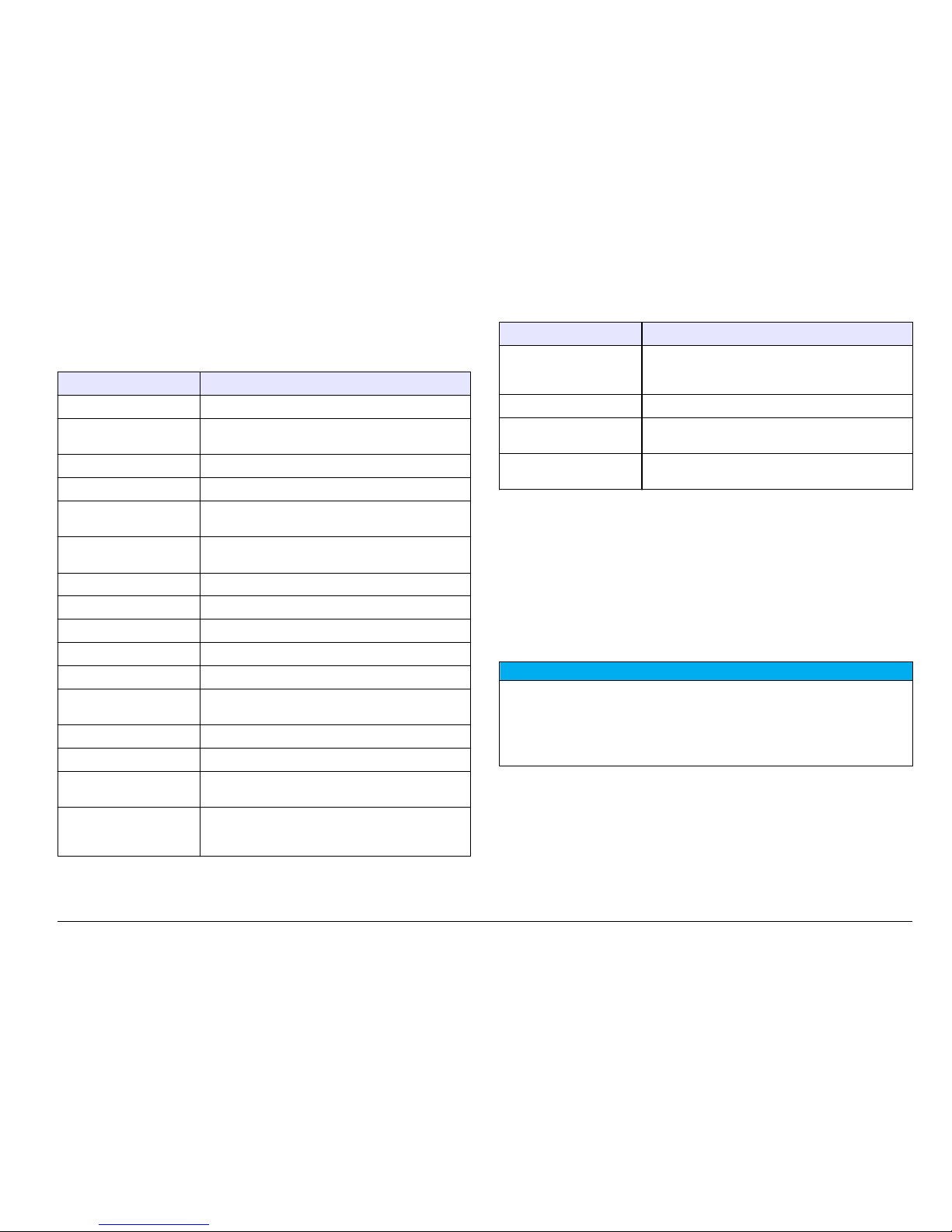

Specifications

Specifications are subject to change without notice.

Specification Details

Dimensions 19.7 x 9.5 cm (7.75 x 3.75 in.)

Weight 335 g (0.75 lb) without batteries; 430 g (0.95 lb) with

four AA alkaline batteries

Meter enclosure IP67, waterproof to 1 meter for 30 minutes

Battery enclosure Water resistant to 0.6 m (2 ft) for 15 seconds

Power requirements

(internal)

AA Alkaline or rechargeable Nickel Metal Hydride

(NiMH) batteries (4); battery life: up to 200 hours

Power requirements

(external)

Class II, external power adapter: 100–240 VAC,

50/60 Hz input; 4.5 to 7.5 VDC (7 VA) output

Meter protection class Class I

Storage temperature –20 to +60 °C (–4 to +140 °F)

Operating temperature 0 to +60 °C (32 to 140 °F)

Operating humidity 90% (non-condensing)

5-pin input connector M12 connector for IntelliCAL™ probes

8-pin input connector The 8-pin connector enables USB and external AC

power connectivity

USB/DC adapter Peripheral and host

Data memory (internal) 500 results

Data storage Automatic in Press to Read mode and Interval

Mode. Manual in Continuous Read Mode.

Data export USB connection to PC or USB storage device

(limited to the storage device capacity). Transfer

entire data log or as readings are taken.

Specification Details

Connections Integrated USB type A (for USB flash memory

device, printer, keyboard) and Integrated USB type

B (for PC)

Temperature correction Off, automatic and manual (parameter dependent)

Measurement display lock Continuous measurement, Interval or Press to Read

mode. Averaging function for LDO probes.

Keyboard External PC keyboard connector via USB/DC

adapter

General information

In no event will the manufacturer be liable for direct, indirect, special,

incidental or consequential damages resulting from any defect or

omission in this manual. The manufacturer reserves the right to make

changes in this manual and the products it describes at any time, without

notice or obligation. Revised editions are found on the manufacturer’s

website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or

misuse of this product including, without limitation, direct, incidental and

consequential damages, and disclaims such damages to the full extent permitted

under applicable law. The user is solely responsible to identify critical application

risks and install appropriate mechanisms to protect processes during a possible

equipment malfunction.

Please read this entire manual before unpacking, setting up or operating

this equipment. Pay attention to all danger and caution statements.

Failure to do so could result in serious injury to the operator or damage

to the equipment.

Make sure that the protection provided by this equipment is not impaired.

Do not use or install this equipment in any manner other than that

specified in this manual.

English

5

Page 8

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

C A U T I O N

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

N O T I C E

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol on the

instrument is referenced in the manual with a precautionary statement.

This symbol, if noted on the instrument, references the instruction

manual for operation and/or safety information.

This symbol indicates that the marked item can be hot and should not

be touched without care.

Electrical equipment marked with this symbol may not be disposed of

in European domestic or public disposal systems. Return old or endof-life equipment to the manufacturer for disposal at no charge to the

user.

Product overview

The HQd series portable meters are used with digital IntelliCAL™ probes

to measure various parameters in water. The meter automatically

recognizes the type of probe that is connected to the meter.

Measurement data can be stored and transferred to a printer, PC or USB

storage device.

The HQd series meters are available in 4 models:

• HQ11d—pH/mV/ORP

• HQ14d—conductivity, salinity, total dissolved solids (TDS), resistivity

• HQ30d—all IntelliCAL probes, 1 probe connector

• HQ40d—all IntelliCAL probes, 2 probe connectors

Features common to all models:

• Automatic probe and parameter recognition

• Instrument guided calibration procedures

• Calibration data stored in the probe

• Probe specific method settings for regulatory compliance and Good

Laboratory Practice (GLP)

• Security Options

• Real-time data logging via USB connection

• USB connectivity to PC/printer/USB storage device/keyboard

• Bi-directional communication with PC-based systems via a virtual

serial port connection

• Sample ID and Operator ID for data traceability

• Adjustable automatic shut-off

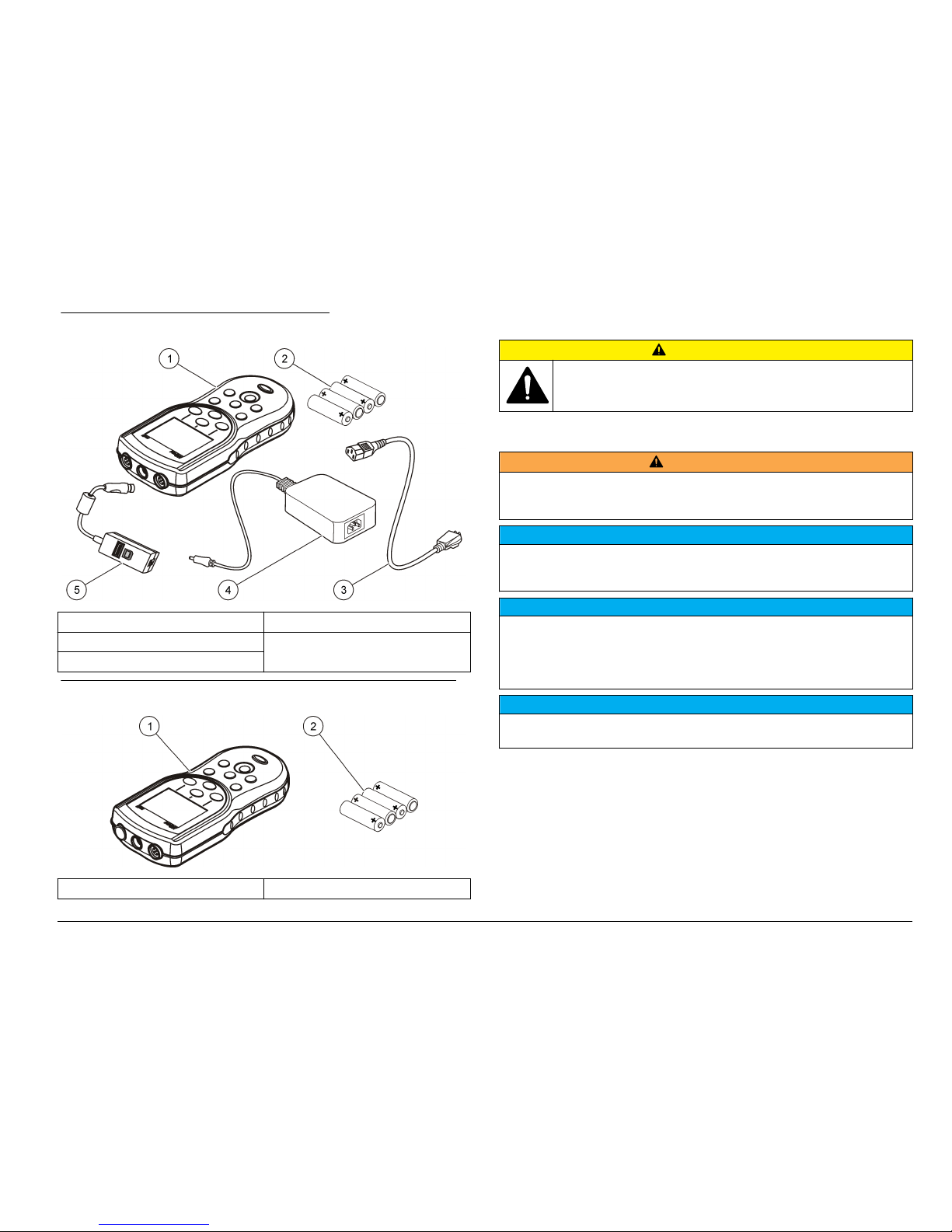

Product components

Refer to Figure 1 and Figure 2 to make sure that all components have

been received. If any items are missing or damaged, contact the

manufacturer or a sales representative immediately.

6

English

Page 9

Figure 1 Meter components (HQ40d model)

1 Meter 4 AC-DC power supply

2 AA batteries (pk/4) 5 USB/DC adapter

3 AC power cord

Figure 2 Meter components (HQ11d, HQ14d and HQ30d models)

1 Meter 2 AA batteries (pk/4)

Installation

C A U T I O N

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

Install the batteries

W A R N I N G

Explosion hazard. Incorrect battery installation can cause the release of explosive

gases. Be sure that the batteries are of the same approved chemical type and

are inserted in the correct orientation. Do not mix new and used batteries.

N O T I C E

The battery compartment is not waterproof. If the battery compartment becomes

wet, remove and dry the batteries and dry the interior of the compartment. Check

the battery contacts for corrosion and clean them if necessary.

N O T I C E

When using nickel metal hydride (NiMH) batteries, the battery icon will not

indicate a full charge after freshly charged batteries have been inserted (NiMH

batteries are 1.2 V versus 1.5 V for alkaline batteries). Even though the icon does

not indicate complete charge, 2300 mAH NiMH batteries will achieve 90% of

instrument operation lifetime (before recharge) versus new alkaline batteries.

N O T I C E

To avoid potential damage to the meter from battery leakage, remove the meter

batteries prior to extended periods of non-use.

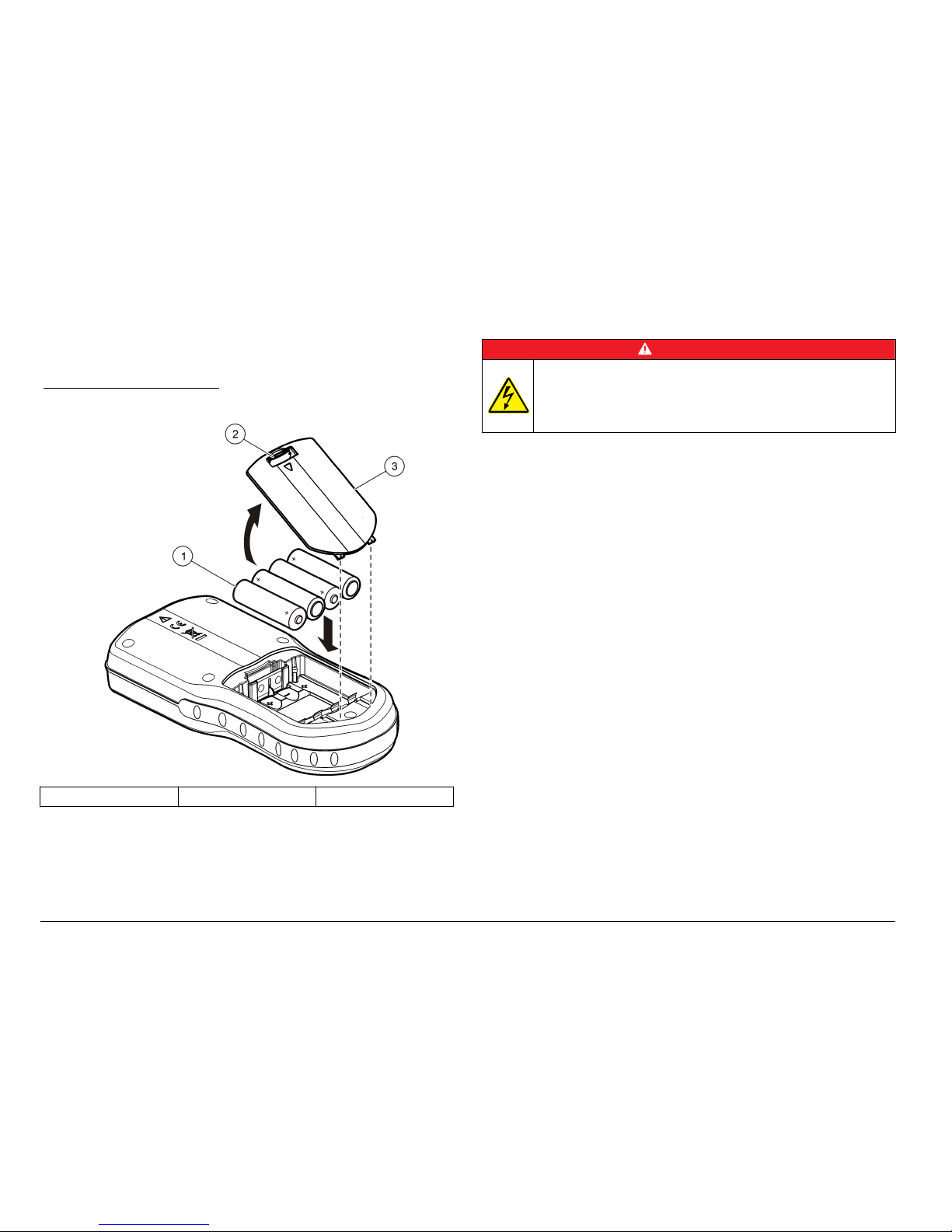

The meter can be powered with AA alkaline or rechargeable NiMH

batteries. To conserve battery life, the meter will power off after

5 minutes of inactivity. This time can be changed in the Display Options

menu.

For battery installation refer to Figure 3.

English

7

Page 10

1. Pull the release tab on the battery cover and the remove the cover.

2. Install 4 AA alkaline or 4 AA nickel metal hydride (NiMH) batteries.

Make sure that the batteries are installed in the correct polarity.

3. Replace the battery cover.

Figure 3 Battery installation

1 Batteries 2 Release tab 3 Battery cover

Connect to AC power

D A N G E R

Electrocution Hazard. AC power outlets in wet or potentially wet

locations MUST ALWAYS be provided with a Ground Fault Circuit

Interrupting (GFCI/GFI) circuit breaker. The AC-DC power adapter for

this product is not sealed and must not be used on wet benches or in

wet locations without GFCI protection.

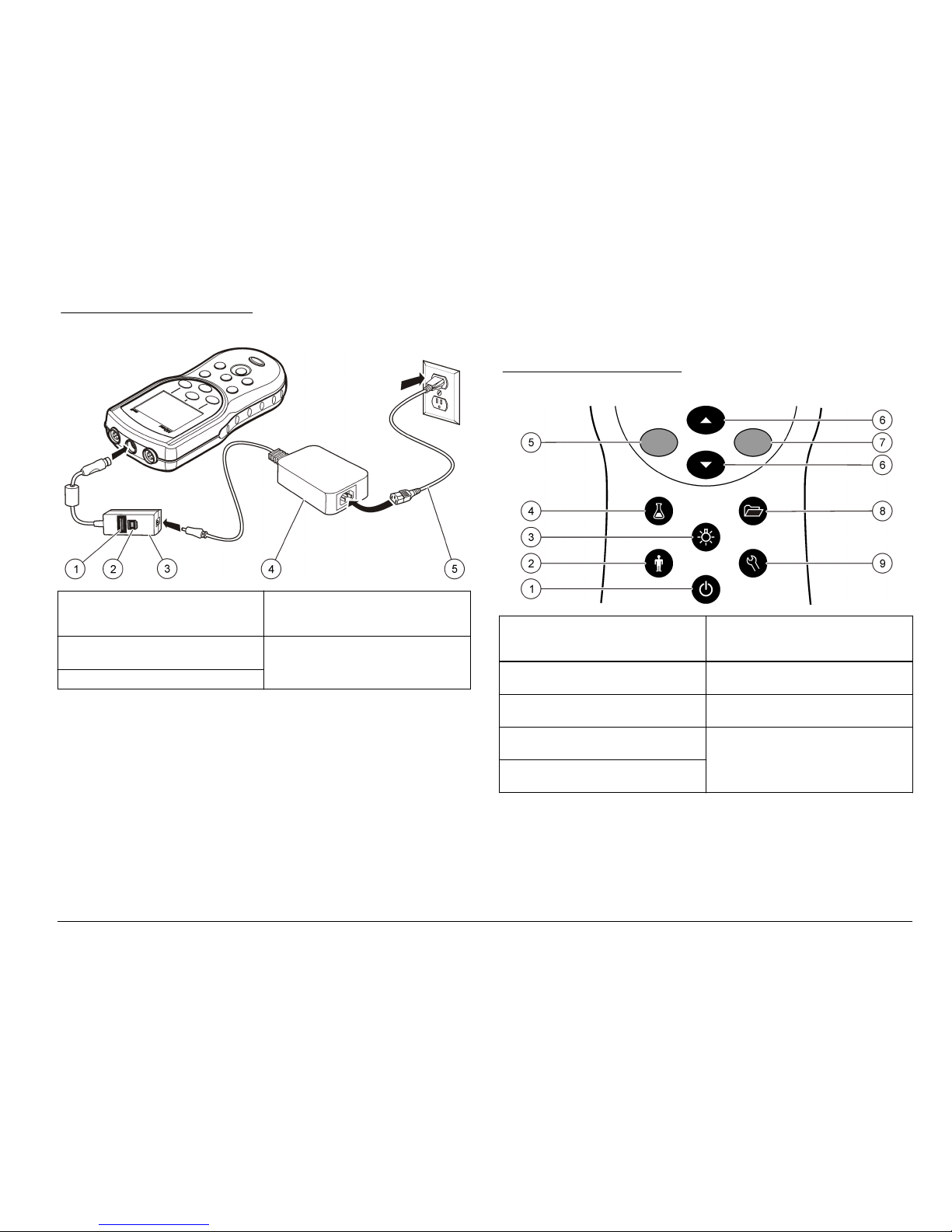

The meter can be powered by AC power with an AC power adapter kit.

The kit includes an AC-DC power supply, USB/DC adapter and AC

power cord.

1. Turn the meter off.

2. Plug the AC power cord into the AC-DC power supply (Figure 4).

3. Connect the AC-DC power supply to the USB/DC adapter.

4. Connect the USB/DC adapter to the meter.

5. Plug the AC power cord into an AC receptacle.

6. Turn the meter on.

8 English

Page 11

Figure 4 AC power connection

1 USB storage device/printer/Qwerty

keyboard connection (USB

peripheral)

4 AC-DC power supply

2 Personal computer connection

(USB host)

5 AC power cord

3 USB/DC adapter

User interface and navigation

User interface

Figure 5 Keypad description

1 ON/OFF: turn on or turn off the

meter

6 UP and DOWN key: scroll through

menus, enter numbers and letters

or change the reading screen view

2 OPERATOR ID: associate data with

an individual

7 GREEN/RIGHT key: reads, selects,

confirms or stores data

3 BACKLIGHT: illuminate the display

screen

8 DATA LOG: recall or transfer stored

data

4 SAMPLE ID: associate data with a

sample location

9 METER OPTIONS: change

settings, run check standards, view

meter information

5 BLUE/LEFT key: calibrates, cancels

or exits the current menu

Display description

Measurement screen

The meter display shows the concentration, units, temperature,

calibration status, operator ID, sample ID, date and time (Figure 6).

English

9

Page 12

Figure 6 Single screen display

1 Calibration status indicator 9 Time

2 Main measurement value and unit 10 Date

3 IntelliCAL probe type and port

indicator

11 Read (OK, Select)

4 Battery status 12 Display size icon

5 Power source 13 Calibrate (Cancel, Exit)

6 Sample temperature (ºC or ºF) 14 Sample and operator identification

7 Secondary measurement unit 15 Stability or display lock indicator

8 Tertiary units (for some probes)

Big-screen mode

The font size of the sample reading can be increased or decreased with

the key (Figure 7).

Note:

When two probes are connected, push and hold the key to select the

big-screen mode. The big-screen mode can also be selected in the Display Options

menu (Refer to Set the display options on page 20).

Figure 7 Single-screen display—big-screen mode

1 Calibration status indicator 5 Main measurement unit

2 IntelliCAL probe type and port

indicator

6 Display size icon

3 Power source or battery status 7 Sample temperature (ºC or ºF)

4 Main measurement value 8 Stability or display lock indicator

Dual-screen mode (HQ40d model only)

When two probes are connected to the HQ40d meter, the display can

show the reading from both probes simultaneously or show just one

probe (Figure 8).

Note: For probe calibration, change the screen mode to the single screen mode.

To change the screen mode to single or dual screen, use the

and

keys. In dual screen mode, the key will select the probe on the

left and the key will select the probe on the right.

10

English

Page 13

Figure 8 Dual-screen display

1 Probe that is connected to port on

left

3 Measurement information for probe

on left

2 Probe that is connected to port on

right

4 Measurement information for probe

on right

Navigation

The meter contains menus to change various options. Use the

and

keys to highlight different options. Push the GREEN/RIGHT key to

select an option. There are two ways to change options:

1. Select an option from a list: Use the and keys to select an

option. If check boxes are shown, more than one option can be

selected. Push the BLUE/LEFT key under Select.

Note: To deselect check boxes, push the BLUE/LEFT key under Deselect.

2. Enter an option value using the arrow keys:

Push the and keys to enter or change a value.

3. Push the GREEN/RIGHT key to advance to the next space.

4. Push the GREEN/RIGHT key under OK to accept the value.

Startup

Turn the meter on and off

Push the key to turn on or turn off the meter. If the meter does not

turn on, make sure that the batteries are properly installed or that the AC

power supply is properly connected to an electrical outlet.

Change the language

The display language is selected when the meter is powered on for the

first time. The language can also be changed from the Meter Options

menu.

Access to the language menu can be restricted with the Security

Options. Refer to Security options on page 18.

1. Push the key and select Language.

2. Select a language from the list.

Note: While turning the meter on, the language can also be changed when the

power key is pushed and held.

Change the date and time

The date and time can be changed from the Date & Time menu.

English 11

Page 14

1. Push the key and select Date & Time.

2. Update the time and date information:

Option Description

Format Select one of the formats below for the date and time. Use the

and keys to select from the format options.

dd-mm-yyyy 24h

dd-mm-yyyy 12h

mm/dd/yyyy 24h

mm/dd/yyyy 12h

dd-mmm-yyyy 24h

dd-mmm-yyyy 12h

yyyy-mm-dd 24h

yyyy-mm-dd 12h

Date Use the and keys to enter the current date.

Time Use the and keys to enter the current time.

The current date and time will be shown on the display.

Connect a probe after the date and time setup, so that the meter is ready

to take a measurement.

Connect a probe

1. Make sure that the display shows the current time and date.

Note: The time stamp for a probe is set when the probe is first connected to

the meter. This time stamp makes it possible to record the probe history and

record the time when measurements are made.

2. Plug the probe into the meter (Figure 9).

3. Push and turn the locking nut to tighten.

Figure 9 Probe connection

1 Probe connection port

(HQ40d only)

2 USB/DC adapter port 3 Probe connection port

Standard operation

About calibration

Each probe uses a different type of calibration solution. Make sure to

calibrate the probes frequently to maintain the highest level of accuracy.

Note: For step-by-step instructions, refer to the documents that are included with

each probe.

The calibration icon

can indicate that:

• the calibration timer has expired

• the LDO sensor cap should be replaced

12

English

Page 15

• the calibration is out of range

• the calibration results are outside acceptance criteria settings

About sample measurements

Each probe has specific preparation steps and procedures for taking

sample measurements. For step-by-step instructions, refer to the

documents that are included with the probe.

About check standards

Run Check Standards verifies equipment accuracy by measuring a

solution of a known value. The meter will indicate if the Check Standard

passed or failed. If the Check Standard fails, the calibration icon is

shown until the probe is calibrated.

The meter can be set to automatically show a reminder for check

standard measurement at a specified interval with a specified

acceptance criteria. The reminder, value of the check standard, and

acceptance criteria can be changed. For step-by-step instructions, refer

to the documents that are included with the probe.

Use a sample ID

The sample ID tag is used to associate measurements with a particular

sample location. If assigned, stored data will include the sample ID.

1. Push the key.

2. Select, create or delete a sample ID:

Option Description

Current ID Select an ID from a list. The current ID will be

associated with sample data until a different ID is

selected.

Create a New SampleIDEnter a name for a new sample ID.

Delete Sample ID Delete an existing sample ID.

Use an operator ID

The operator ID tag associates measurements with an individual

operator. All stored data will include the operator ID.

1. Push the key.

2. Select, create or delete an operator ID:

Option Description

Current ID Select an ID from a list. The current ID will be

associated with sample data until a different ID is

selected.

Create a New

Operator ID

Enter a name for a new operator ID (maximum

10 names can be entered).

Delete Operator ID Delete an existing operator ID.

Data management

About stored data

The following types of data are stored in the data log:

• Sample measurements: stored automatically each time a sample is

measured in the Press to Read or Interval Mode. When the

continuous measurement mode is used, data is stored only when

Store is selected.

• Calibrations: stored only when Store is selected at the end of a

calibration. Calibration data is also stored in the IntelliCAL (R) probe.

• Check standard measurements: stored automatically each time a

check standard is measured (in the Press to Read or Interval Mode).

When the data log becomes full (500 data points), the oldest data point

is deleted when a new data point is added. The entire data log can be

deleted to remove data that has already been sent to a printer or PC

(

key > Delete Data Log). To prevent deletion of the data log by a

user, use the Security Options menu.

English

13

Page 16

View stored data

The data log contains sample, calibration and check standard data. The

most recent data point in the data log is tagged as Data Point 001.

1. Push the key.

2. Select View Data Log to view the stored data. The most recent data

point is shown. The top of the screen shows whether the data is from

a sample reading, a calibration or a check standard. Push the

key to view the next most recent data point.

Option Description

Reading Log Reading Log—shows sample measurements including

the time, date, operator and sample ID. Select Details to

view the associated calibration data.

Calibration Log Calibration Log—shows calibration data. Select Details

to view additional information about the calibration.

Check Standard

Log

Check Standard Log—shows check standard

measurements. Select Details to view the calibration

data that was associated with the measurement.

View stored probe data

Make sure that a probe is connected to the meter. If two probes are

connected, select the appropriate probe when prompted.

1. To view the calibration data that is stored in a probe, push the

key and select View Probe Data. The current calibration and

calibration history for the probe can be viewed.

Option Description

View Current

Calibration

The current calibration information shows the calibration

details for the most recent calibration. If the probe has

not been calibrated by the user, the factory calibration

data is shown.

View Calibration

History

The calibration history shows a list of the times when the

probe was calibrated. Select a date and time to view a

summary of the calibration data.

Print stored data

The meter must connect to AC power to start the USB connection. Make

sure that the connection to AC power is made before the meter is

powered on.

All data can be sent to a printer. Compatible printers should support a

minimum of 72 columns of data, be capable of printing up to

500 continuous data-stream events in 1, 2 and 3 lines of text and fully

support code page 437 and code page 850.

1. Turn off the meter. Make sure that the meter is connected to AC

power. Refer to Connect to AC power on page 8.

2. Connect the printer to the meter with a USB cable type A. Refer to

Figure 10.

3. Turn on the meter.

4. Push the key.

5. Select Send Data Log. Wait for the display to show “Transfer

Complete” and wait for the printer to stop printing. Disconnect the

printer.

14 English

Page 17

Figure 10 Connection to the printer

1 Meter 7 USB cable

2 AC-DC power supply 8 USB/DC adapter

3 AC power cord 9 Port for probe connection

4 AC power outlet 10 Port for USB/DC adapter

5 Power supply for printer (optional) 11 Port for probe connection

6 Printer, FCC Part 15B, Class B

compliant

Change the report options

Printed reports for sample data can contain 1, 2 or 3 lines of information.

Refer to Examples of printed reports on page 28 for further

information.

1. Push the key. Select Report Options.

2. Select Report Type and select one of the options.

Option Description

Basic report One line of data.

Advanced report Two lines of data. The first line contains the same

information as in the basic report.

Total report Three lines of data. The first two lines contain the same

information as in the advanced report.

Send data to a USB storage device

N O T I C E

The transfer of a large number of data points will take some time. DO NOT

disconnect the USB storage device until the transfer is complete.

Data can be transferred to a USB storage device for storage or transfer

to a computer.

1. Turn off the meter. Make sure that the meter is connected to AC

power.

2. Plug the USB storage device into the meter before the meter is

powered on.

3. Turn on the meter.

4. Push the key.

5. Select Send Data Log. Wait for the display to show “Transfer

Complete” and for any lights on the USB storage device to stop

flashing. Then remove the USB device.

Note: If the data transfer is slow, reformat the USB storage device to use the

file allocation table (FAT) format for the next use.

English

15

Page 18

Open data files on a PC

Data that has been downloaded to a USB storage device can be

transferred to a computer. The data is sent in a text (.txt) file format.

1. Plug the USB storage device into the computer.

2. Find the data file. The file will have the following format: “Meter Serial

Number-Data File Type-Date Time”. Example: 9999NN000000SENDDATA-0603131624.TXT

3. Save the data file to a location on the computer.

4. Open a spreadsheet program such as Microsoft® Excel

®

spreadsheet software.

5. Open the data file from the spreadsheet program. Select the

delimited option with comma as the delimiter.

The data will be shown in the spreadsheet program.

Note: If an application is used that is not compatible with column headings, the

headings can be omitted. Refer to Remove column headers on page 18.

Data file description

Data that is saved to a USB storage device and then opened in a

spreadsheet application will have multiple columns of data. A description

for each of the columns is shown in Table 1.

Table 1 Spreadsheet column descriptions

Column header name Data description and example values

Type Type of data: RD = Reading; CL = Calibration; CK =

Check Standard; CH = Calibration History; IC =

Current Calibration

Parameter Type Parameter: LDO, pH, CD (conductivity), ORP,

ISE

Date Date of reading: stored in user-defined date format

Time Time of reading: stored in user-defined format

Operator ID Operator ID that was used when the data was

recorded. Shows “- - -” if no operator ID is used.

Table 1 Spreadsheet column descriptions (continued)

Column header name Data description and example values

Probe Model Model number of probe, for example pHC101,

CDC401, LDO101

Probe SN Probe serial number

If two probes are connected to the HQ40d meter, the

serial number shows “<“ or “>” to identify the port (left

or right) the probe was connected to during the

reading.

Method name User-defined name of the probe settings that were

used for the reading.

Sample ID Sample ID that was used when the data was

recorded. Shows "Sample ID" if the default sample ID

is used.

Primary Reading Value Measured value. Shows “—" if the value was out of

range.

Primary Reading Units Measurement units, for example pH or µS/cm

Supp Reading 1 First supplemental reading (example: temperature), if

applicable

Supp Units 1 Units for first supplemental reading, if applicable.

Supp Reading 2 Second supplemental reading (example: “mV” for pH),

if applicable

Supp Units 2 Units for second supplemental reading, if applicable

Supp Reading 3 Third supplemental reading, if applicable

Supp Units 3 Units for third supplemental reading, if applicable.

Reading Setting 1–4 Any settings that affect the reading, for example

“NaCl/Non-Linear”

Any settings that affect

the reading, for example

“NaCl/Non-Linear”

Reading Message 1–4 Any message that was shown

during the measurement, for example “Out of limits”.

16 English

Page 19

Table 1 Spreadsheet column descriptions (continued)

Column header name Data description and example values

Check Std Value Value of the check standard that was used to verify

accuracy, for example: 7.00 pH–25 ºC (pH, tempcompensated); 7.01 pH (pH, custom)

Check Std Units Check standard units, for example μS/cm.

Note: pH is not displayed here as it is included in the previous

column.

Check Std Graph Bar-graph showing the measurement in relation to the

acceptance limits. Example: “6.901 <—|—> 7.101”.

Check Std Status Status of the check standard reading. Example:

“Reading within limits”, “Reading outside limits”

Calibration Status

Status of the calibration that is in use. = current

calibration is valid; = calibration has expired.

Cal Date Date of calibration reading: stored in user-defined date

format

Cal Time Time of calibration reading: stored in user-defined

time format

Cal Operator ID The operator ID specified when the probe was

calibrated. Shows “- - -” if undefined.

Cal Slope Name Slope (pH or LDO) or cell constant (conductivity)

Cal Slope The slope value for the calibration

Cal Slope Aux Used by pH to give the percent of nominal slope

Cal Slope Units Units of the calibration slope. Example: “mV/pH” for

pH

Cal Offset Calibration offset value

Cal Offset Units Calibration offset units. Example: “mV” for pH.

Cal r² Calibration correlation coefficient without a unit (may

be blank)

Table 1 Spreadsheet column descriptions (continued)

Column header name Data description and example values

Cal Number of Std’s Number of standards used during calibration, for

example 5. May be blank depending on record type,

parameter type, and method settings.

Cal Std 1 Known value of the first calibration standard

Cal Std 1 Units Units of the first calibration standard

Cal Std 1 Primary Value Measured value of the first calibration standard

Cal Std 1 Primary Units Associated units for the calibration measurement

Cal Std 1 Supp Value Value of supplemental measurement, for example

temperature

Cal Std 2–7 Known value of additional calibration standards, if

used

Cal Std 2–7 Units Units of additional calibration standards, if used

Cal Std 2–7 Primary

Value

Measured values of additional calibration standards, if

used

Cal Std 2–7 Primary

Units

Associated units for additional calibration

measurements, if used

Cal Std 2–7 Supp Value Value of supplemental measurement, for example

temperature

Cal Std Supp Units Units applicable to all secondary calibration readings.

Example: “ºC” or “ºF” for temperature

Cal Message 1–4 Any messages about the calibration

Date/Time POSIX Date and time of reading stored in POSIX format

(number of seconds from January 1, 1970) Example:

1149234913

Cal Date/Time POSIX Date and time of calibration stored in POSIX format

(number of seconds from January 1, 1970). Example:

1111320348

Meter SN Meter serial number used to take the measurement

English 17

Page 20

Remove column headers

When transferred data is viewed in a spreadsheet program, the first row

of data contains headings to identify the type of data in each column. If

an application or post-processing method is used that is incompatible

with the headers, the column headers can be omitted.

1. Push the key.

2. Select Column Headers.

3. Set the column headers to off.

Send data directly to a computer

Data can be transferred from any HQd series meter directly to a

computer when the HQ40d PC Application is installed. The data can be

sent in real time during data collection, or the entire data log can be

transferred.

To download the most current version of the software, refer to the

applicable product page on the manufacturer's website.

1. Install the HQ40d PC Application on the computer.

2. Turn off the meter. Make sure that the meter is connected to AC

power.

3. Connect the PC to the meter with a USB type B cable.

4. Turn on the meter.

5. Open the HQ40d PC Application on the computer. Click on the green

triangle in the menu bar to start a connection.

6. Collect the data in real time or transfer the data from the data log:

• Real time—when a data point is stored in the meter, the result is

sent simultaneously to the PC Application (refer to Set the

measurement mode on page 21).

• Data log—push the key and select Send Data Log. Wait for

the display to show “Transfer Complete.” The data is sent as a

comma separated values (.csv) file.

The data is shown in the HQ40d PC Application window.

Advanced operation

Security options

The Security Options menu is used to protect the meter setup and

method settings from unwanted changes. This menu is available in the

Full Access Options menu.

The Setup Measurement Mode, Date and Time, Temperature Units,

Language, Probe settings, Delete data log and Security Options screens

are disabled in the Operator Access Options menu. All menu options are

enabled in the Full Access Options menu.

Note: The Full Access Options menu is shown when the key is pushed when

Security Options is OFF, whether or not a password has been set.

When the meter is powered on for the first time and Security Options is

selected, the display prompts the user to set a password. Until the meter

is shut off, pushing the key will still display the Full Access Options

menu, even after Security Options is turned on and a password has

been set. After the meter is shut off and powered on again with Security

Options on, the Operator Access Options menu is displayed until a valid

password is entered.

Store the password in a safe and accessible place. If the specified

password is forgotten and Security Options is turned on, the operator is

locked out of the restricted menus. Contact technical support if the

password is lost.

Turn Security Options on

The Security Options and the Set Password options are used together to

prevent access to restricted menus.

18 English

Page 21

1. Push the key and select Security Options.

2. Change the settings as needed to allow or prevent menu access.

Option Description

Security

Options

When Security Options is on, and a password has been

specified, the password is required to enable the Full

Access Options menu. If the meter is turned off while

Security Options is on, the password is required to enable

the Full Access Options menu again when the meter is

turned on.

Set Password Set a password that must be entered to enable the Full

Access Options menu. The requirement for password entry

is controlled by setting Security Options on or off.

Full access options menu

The Full Access Options menu is displayed when Security Options is

OFF or when Security Options is ON and a valid password is entered

(Table 2). These options do not need to be changed if the factory default

settings are used.

Table 2 Full Access Options

Option Description

(Probe model) settings Settings such as measurement options, calibration

options, check standard options, units and resolution.

Refer to the probe documentation for more information.

Note: A probe must be connected to the meter.

Run check standard Measure standard solution (available for pH,

conductivity, ORP and ISE probes)

Measurement mode Press to Read

Interval: Duration and Interval

Continuous

Instrument information Probe information

Meter information

Table 2 Full Access Options (continued)

Option Description

Security options ON or OFF

Set password

Display options Contrast

Auto shutoff

Backlight

Mode

Sounds Key press

Stability alert

Calibration reminder

Date and time Format

Date

Time

Temperature units Set temperature units

Language Select language

Restricted operator access options menu

The Operator Access Options menu is shown at meter startup when

Security Options is ON (Table 3). When a valid password is entered, the

menu changes to Full Access Options.

English

19

Page 22

Table 3 Operator access options

Option Description

(Probe model) settings Only methods (if methods exist) can be selected. Refer

to the probe documentation.

Note: A probe must be connected to the meter.

Run check standard Measure standard solution (available for pH,

conductivity, ORP and ISE probes)

Note: A probe must be connected to use this option.

Instrument information Probe information

Meter information

Access password Enter password

Display options Contrast

Auto shutoff

Backlight

Mode

Sounds Key press

Stability alert

Calibration reminder

Set the display options

Use Display Options to change the display contrast, battery saving autoshutoff options, the backlight option or the detailed or big reading screen

mode.

1. Push the key and select Display Options.

2. Select which display option to change.

Option Description

Contrast Adjust the contrast of the display. The lightest setting is 0 and

the darkest setting is 9.

Option Description

Autoshutoff

To maximize battery life, set a time period after which the

meter will automatically power off if no key is pushed (1, 2, 5,

10, 30 min, 1 h, 2 h or never). Auto-shutoff is not active when

the meter is connected to AC power or in the Interval Reading

Mode.

Backlight The display backlight is turned off when the key is pushed.

Is it possible to set a time period after which the backlight will

automatically power off if no key is pushed.

Mode Select Detailed or Big screen size. Detailed will show more

information with smaller numbers and text. Big will show less

information with larger numbers and text.

Note: The screen size can also be selected from the measure

mode (refer to Display description on page 9).

Set the sound options

The meter can make an audible sound when a key is pushed, when

stability is reached or when the calibration reminder is due. The meter

also makes an audible sound when it begins transferring data to a USB

storage device and again when the data transfer is complete.

1. Push the key and select Sound.

2. Choose which events will produce an audible sound. Multiple items

can be selected.

Option Description

Key Press The meter will make an audible sound whenever a key is

pushed.

Stability Alert The meter will make an audible sound whenever

measurement stability is reached.

Cal reminder The meter will make an audible sound when calibration is

due.

Note: Refer to Set the probe calibration reminder

on page 21 to set the calibration reminder to on or off.

20 English

Page 23

Set the probe calibration reminder

Make sure that a probe is connected to the meter.

1. Push the key and select the probe settings.

2. Select Modify Current Settings.

3. Select Calibration Options.

4. Select Calibration Reminder.

Option Description

Calibration

reminder

Reminder repeat: Off, 2 h, 4 h, 8 h, 2 d, 5 d, 7d

Expires: Immediately, Reminder + 30 min, Reminder + 1 hr,

Reminder + 2 hr, Continue Reading

The meter can be set to make an audible sound when

calibration is due. Calibration expires after a specified time

set by the user.

Note: The meter cannot be used to read samples after

calibration has expired unless Continue Reading is

selected.

Change the temperature units

To select degrees Celsius or Fahrenheit:

1. Push the key and select Temperature Units.

2. Select the Celsius or Fahrenheit option.

Set the measurement mode

One of three modes can be used to specify when measurements are

taken and how the data is stored. When a data point is stored, the result

is sent simultaneously to any device (PC/printer/ USB storage device)

that is connected to the meter.

1. Push the key and select Measurement Mode.

2. Select Mode.

3. Select one of the measurement modes.

Option Description

Press to Read The sample is measured only when the GREEN/RIGHT key

under Read is pushed. Data is stored in the data log

automatically when the stability criteria are met.

Interval The sample is measured at regular intervals for a specified

duration (refer to Set auto measurement intervals

on page 21). Data is stored in the data log automatically.

Continuous The sample is measured continuously. Data is stored in the

data log only when the GREEN/RIGHT key under Store is

pushed.

Set auto measurement intervals

When the measurement mode is set to Interval, the time intervals and

duration must be specified. Measurements are stored at the user-defined

intervals whether or not stability criteria are met.

Note: Use of an external USB storage device or direct printer connection while in

Interval Measurement mode prevents data from being over-written in the data log.

Data points are over-written on a First In/First Out basis. Refer to Prevent data log

overflow in interval mode on page 22.

1. Push the key and select Measurement Mode.

2. Select Mode.

3. Select Interval as the Measurement Mode.

4. Select Duration and select the total time that measurements will be

taken for (15 min, 30 min, 1 h, 4 h, 8 h, 24 h, 48 h or no limit).

5. Select Interval and select how often measurements will be taken

(every 10 s, 30 s, 1 min, 5 min, 15 min or 30 min).

Start interval measurements

During interval measurements, the meter goes into a standby state

between readings to conserve power. The auto-shutoff option is

disabled. Measurements stop when the selected interval duration has

passed. The auto-shutoff option then becomes active.

English

21

Page 24

Interval measurements are suspended for calibrations, check standard

measurements or when the key is pushed. Interval measurements

resume when returning to the measurement screen.

1. From the Main Measurement screen, select Start to begin interval

measurements. The screen will show “Recording” and the remaining

time of the duration. The sample number automatically advances

when each reading is taken.

2. To stop interval measurements, select Stop.

3. To repeat the interval measurement after it has been stopped or

completed, select Start.

Prevent data log overflow in interval mode

When measurements are taken at specified intervals (Table 4), each

result is automatically stored. The meter can store up to 500 data

records. When 500 records have been stored, data is replaced on a firstin, first-out basis. To prevent loss of data, connect the meter to a

PC/printer/USB storage device.

Note: Stop interval measurements before changes are made to a method or to

meter settings.

Table 4 Recommended interval/duration pairs

Interval Duration

10 seconds 1 hour

30 seconds 4 hours

1 minute 8 hours

5 minutes 24 hours

Note: When 2 probes are connected to the meter, use the next lowest

recommended duration time. For example, for a 30-second interval, set the

duration to 1 hour to prevent data log overload with 2 probes.

View instrument information

The instrument information menu shows specific information such as the

serial number for the meter or IntelliCAL (R) probe(s).

1. Push the key and select Instrument Information.

2. Select (Probe model) Information or Meter Information.

Option Description

Probe

information

The Probe Information screen shows the probe model

number, serial number, software version and date of first

use. For LDO and LBOD probes, the lot code for the

sensor cap and the remaining time before sensor cap

replacement is shown.

Note: A probe must be connected to the meter.

Meter

information

The Meter Information screen shows the meter model

number, serial number, software version and memory

information. The amount of memory used and the number

of available user method settings, operator IDs and sample

IDs is shown.

Update the meter software

A USB storage device that contains software update files is used to

update the meter software.

Note: The meter must be turned off and then on again before the software update

will begin. The software update initiates upon meter startup after the USB device is

correctly inserted.

N O T I C E

Do not remove the USB device until the “Update complete” message is shown.

The meter can become damaged if the USB device is removed before the update

process is complete.

1. Save stored data from the data log to a USB storage device or to a

PC. Refer to Send data to a USB storage device on page 15 and

Send data directly to a computer on page 18.

2. Turn off the meter.

3. Connect the USB/DC adapter, AC-DC power supply and cord (

Figure 4 on page 9).

22

English

Page 25

4. Insert the USB storage device that contains the software update files

into the USB/DC adapter.

5. Turn on the meter.

The update process starts. The display will show “Updating meter to

<firmware version>”. After an interval, the display changes to

“Updating files, please wait...” In addition, the display will show a

rotating flask and emit a periodic audio signal during the update

process.

Note: A large capacity USB storage device increases the time required for

completion of the update process, even if most of the device memory is empty.

6. Wait for the meter to finish the software update. When the update

process is complete, the message “Update complete. Remove USB

device” is shown. The meter will turn off after the USB device has

been removed.

7. Repeat steps 1 through 6 to update the software in other HQd

meters as necessary.

Download software updates

To download the most current version of the software, refer to the

applicable product page on the manufacturer's website.

1. Transfer the update files to a USB storage device.

2. Follow the instructions in Update the meter software on page 22 to

update the software in the meter.

Transfer method settings

Probe settings that have been changed by the user for measurements,

calibrations or check standards (Meter Options > (Probe Model) Settings

> Modify Current Settings) can be copied to a USB storage device. The

USB device can then be used to transfer the method settings to other

HQd meters that accept the same probes.

N O T I C E

Make sure the USB storage device does not contain HQd meter software update

files to prevent unintentional updates.

1. Turn off the meter.

2. Connect the meter to AC power (Figure 4 on page 9).

3. Plug the USB storage device into the USB/DC adapter before the

meter is powered on.

4. Turn on the meter.

5. Push the key and select Transfer Methods. If the USB device

already contains a method settings file, an option to export or import

methods is shown. Select Export Methods.

6. In the Select Methods to Export screen, select one or more methods

to copy to the USB device. A check mark is shown next to each

selected method.

7. Select OK. The settings are copied to the USB storage device. When

complete, the Transfer Summary screen is shown.

8. Connect the AC power and USB device to a meter that will receive

the method settings. Turn the meter on.

9. Push the key and select Transfer Methods. If the USB device

already contains a method settings file, an option to export or import

methods is shown. Select Import Methods.

10. In the Select Methods to Import screen, select one or more methods

to transfer to the meter. A check mark is shown next to each selected

method.

11. Select OK. The user method settings are transferred from the USB

storage device to the meter. When complete, the Transfer Summary

screen is shown. Select details to view additional information about

the transfer.

12. Disconnect the USB storage device from the meter.

Bi-directional Communication between the meter and

a PC

For measurement automation the meter can be used to implement a

command set for meter remote control or automated data transfer. The

command set can be used to perform minimal configuration and to

control the meter. To set up the meter for communication and control,

refer to About meter configuration on page 24. For additional

information and the command set contact Technical Support.

About meter control

The virtual serial connection can be used to control meter functions from

a PC. For example, the functions include starting a measurement cycle,

English

23

Page 26

turning off the meter and sending the entire measurement (including

calibrations) to the PC or other information management system.

About meter configuration

To use the meter communication and control from the PC, an INF file

must be installed.

1. The meter software must be version 2.0.0.710 or higher.

To download the most current version of the software, refer to the

applicable product page on the manufacturer's website.

2. Open the Zip file.

3. Copy the INF file from the software upgrade package to a convenient

location on the PC.

Note: The INF file must be installed to use the meter manual control from a

PC.

4. Turn on the meter.

5. Push the key and select Instrument Information.

6. Select USB Device Type and then select Virtual Serial to use the

virtual serial port on the meter.

7. Push OK. The meter will automatically restart to complete the setting

change.

8. Connect the meter with the USB cable to the PC and turn on the

meter.

Windows XP starts the "Found New Hardware Wizard".

9. Select "No, not at this time" to the query "Can Windows connect to

Windows Update to search for software?"

10. Click Next. The next wizard screen will prompt.

11. Select "Install from a list or specific location (Advanced)" to the query

"What do you want the wizard to do?"

12. Click Next. The next wizard screen will prompt.

13. Select the option "Search for the best driver in these locations."

14. Uncheck the "Search removable media (floppy, CD-ROM)" option

and select the "Include this location in the search:" and click the

"Browse" button.

15. Select the INF folder or location and click OK.

16. Click Next. The new software will be installed.

17. Click Finish to complete the Found New Hardware Wizard for: HQd

Meter - Virtual Serial Port.

18. To make sure that the installation succeeded, go to Computer

Management>Device Manager>Ports. The new installed port is listed

as HQd Meter - Virtual Serial Port (COM#).

19. The meter is now ready for communication with PC-based systems

using the Virtual Serial port. A program interface must be developed

by the user for the command set used to control the meter functions

from the PC. Contact Technical Support for more information and

command set documentation.

Maintenance

C A U T I O N

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

Clean the meter

The meter is designed to be maintenance-free and does not require

regular cleaning for normal operation. Exterior surfaces of the meter may

be cleaned as necessary.

1. Wipe the surface of the meter with a damp cloth.

2. Use a cotton-tipped applicator to clean or dry the connectors.

Replace the batteries

W A R N I N G

Explosion hazard. Incorrect battery installation can cause the release of explosive

gases. Be sure that the batteries are of the same approved chemical type and

are inserted in the correct orientation. Do not mix new and used batteries.

For battery replacement, refer to Figure 11. Make sure that the cover is

tightly closed to maintain the IP67 enclosure rating.

24

English

Page 27

1. Pull the release tab on the battery cover and the remove the cover.

2. Remove the batteries.

3. Install 4 AA alkaline or 4 AA nickel metal hydride (NiMH) batteries.

Make sure that the batteries are installed in the correct polarity.

4. Replace the battery cover.

Figure 11 Battery replacement

1 Batteries 2 Release tab 3 Battery cover

Troubleshooting

Refer to the following table for common problem messages or

symptoms, possible causes and corrective actions.

Error/Warning Description Solution

Connect a Probe Probe disconnected

or connected

improperly

Tighten the locking nut on the

probe connector.

Disconnect the probe and then

connect the probe again

Software not

updated to most

current version

To download the most current

version of the software, refer to

the applicable product page on

the manufacturer's website.

Problem with probe Connect a different IntelliCAL

probe to verify if problem is with

probe or meter

Probe Not Supported Probe disconnected

or connected

improperly

Tighten the locking nut on the

probe connector.

Disconnect the probe and then

connect the probe again.

Software not

updated to most

current version

To download the most current

version of the software, refer to

the applicable product page on

the manufacturer's website.

Problem with probe Connect a different IntelliCAL

probe to the meter to verify if

problem is with the meter or the

probe.

HQd meter does not

support IntelliCAL

probe

Contact Technical Support.

Bootloader

X.X.XX.XX error

Software not

updated to most

current version.

To download the most current

version of the software, refer to

the applicable product page on

the manufacturer's website.

English 25

Page 28

Error/Warning Description Solution

0 days remaining

message (For LDO

and LBOD only)

LDO or LBOD

sensor cap used for

365 days

Replace the LDO or LBOD

sensor cap and iButton®.

There are 0 days

remaining in the life

of the LDO sensor

cap.

Replace the LDO sensor cap.

Calibration will be allowed.

However, the calibration icon

and question mark will appear on

the measurement screen even if

the calibration has passed.

Meter set to

incorrect date and

time

1. Disconnect the probe from

the meter.

2. Remove the meter batteries.

3. Install the meter batteries

properly. Follow the polarity

makings.

4. Set correct date and time in

the meter.

5. Connect the probe and verify

that message has been

removed.

Software not

updated to most

current version

To download the most current

version of the software, refer to

the applicable product page on

the manufacturer's website.

Meter not configured Software error(s) If the meter starts up correctly,

back up the Data Log and

Method files.

To download the most current

version of the software, refer to

the applicable product page on

the manufacturer's website.

Error/Warning Description Solution

Meter will not power

on or powers on

intermittently

Batteries are not

installed correctly

Examine battery orientation to

make sure the batteries follow

the polarity markings. Test again.

Clean the battery terminals, then

install new batteries.

Connect AC power adapter and

test again.

Software not

updated to most

current version

To download the most current

version of the software, refer to

the applicable product page on

the manufacturer's website.

Damaged meter Contact Technical Support.

Unable to access

Full Access Options

screen

Correct password

has not been

entered

Contact Technical Support.

Unable to access

Full or Operator

Access Options

screen

Software not

updated to most

current version

To download the most current

version of the software, refer to

the applicable product page on

the manufacturer's website.

Replacement parts and accessories

Note: Product and Article numbers may vary for some selling regions. Contact the

appropriate distributor or refer to the company website for contact information.

Replacement parts

Description Item no.

AC Power/USB Adapter Kit, 115 VAC 5826300

AC Power/USB Adapter Kit, 230 VAC 5834100

Batteries, Alkaline AA 1938004

Battery cover 9245500

Battery Contact, dual fixed 5188400

26 English

Page 29

Replacement parts (continued)

Description Item no.

Battery Contact, dual spring 5188800

Cable, USB 6 ft (1.8 m), Type A male, Type B male 5924000

Field Kit (includes Protective Glove Kit for meter and five

120-mL sample cups)

5825800

Field Case for 2 probes with up to 5 m cables (10 m total).

Includes empty case, insert for meter and probe storage,

4 containers for sample collection.

8505500

Field Case for 3 probes with up to 5 m cables (15 m total).

Includes empty case, insert for meter and probe storage,

4 containers for sample collection.

8505501

Field Case for 2 probes with greater than 5 m cables (30 m

total). Includes empty case, insert for meter with protective

glove.

8505600

Keyboard (QWERTY), USB type LZV582

Printer, USB Thermal Printer Kit, DPU-S445, 100 - 240 V

AC

US:

LQV161.53.10000

EU:

LQV161.99.10000

Printer Paper for DPU-S445, thermal, 5/pk 5836000

Probe Clips, color coded (5 colors, 2 clips of each color),

10/pk

5818400

Probe Depth Marker (rugged cables) 5828610

Probe Holder, standard (fits on protective glove) 5829400

Protective Glove Kit for meter 5828700

Universal Probe Stand for standard IntelliCAL Probes 8508850

English 27

Page 30

Examples of printed reports

Printed reports contain a report header and all stored data for samples, check standards and calibrations.

Report header

The first line of a report shows the report header (Figure 12).

Figure 12 Report header

1 Meter serial number

1

3 Date and time, 24 h (YYMMDDhhmm)

2 Report label 4 File type extension

Data reports

Sample data can be printed in a basic, advanced or total report format.

• Total report—refer to Figure 13.

• Advanced report—refer to Figure 14.

• Basic report—refer to Figure 15.

1

The probe serial number is shown on calibration history and current calibration reports.

28 English

Page 31

Figure 13 Basic report for sample data—1 line

1 Data type (RD=reading) 6 Units

2 Parameter (pH, LDO, etc.) 7 Sample ID: user-defined; shows “SAMPLE ID” if undefined

3 Time (hh:mm:ss in 24 h or user-defined format) 8 Sample ID counter

4 Date (DD-MM-YY or user-defined format) 9 Operator ID: user-defined; shows “- - -” if undefined

5 Measured value

Figure 14 Advanced report for sample data—2 lines

1 Probe model 4 Additional units: shows all additional units associated with the reading.

2 Error message (if applicable) 5 Probe settings: shows the highest-priority setting associated with the reading

3 Probe serial number (a “<“ or “>” on the HQ40d meter indicates the probe

position)

English 29

Page 32

Figure 15 Total report for sample data—3 lines

1 Method name for probe settings 4 Calibration slope/ratio/constant

2 Time of calibration, prefaced by “CAL” and displayed as hh:mm in 24 h (or user-

defined) format

5 Offset—contents vary depending on type of parameter and user settings. May

be blank.

3 Date of calibration (DD-MM-YY or user-defined format) 6 Operator ID: user-defined; shows “- - -” if undefined

Check standard reports

Check standard data is printed with 1 line of information (Figure 16)

Figure 16 Check standard report

1 Report type (ST = check standard) 5 Measured value

2 Report type (ST = check standard) 6 Units

3 Time (hh:mm:ss in 24 h or user-defined format) 7 Check standard status: Pass/Fail based on the acceptance criteria

4 Date (DD-MM-YY or user-defined format) 8 Operator ID: user-defined; shows “- - -” if undefined

Calibration reports

Calibration data is printed when the data log is sent to the printer or when probe data is sent to the printer. Calibration data is printed with 2 lines of

information (Figure 17).

30

English

Page 33

Figure 17 Calibration report

1 Report type (CL = calibration, IC = current calibration) 7 Probe serial number (a “<“ or “>” on the HQ440d meter indicates the probe

position)

2 Parameter (pH, LDO, etc.) 8 Calibration slope/ratio/constant

3 Method name for probe settings 9 Offset—contents vary depending on type of parameter and user settings. May

be blank.

4 Time of calibration, prefaced by “CAL” and displayed as hh:mm in 24 h (or user-

defined) format

10 r²: contents vary depending on type of parameter being read, configuration of

specific method and number of calibration standards used. May be blank.

5 Probe model 11 Operator ID: user-defined; shows “- - -” if undefined

6 Date of calibration (DD-MM-YY or user-defined format)

The calibration history can be printed from the probe data menu. Refer to Figure 18.

English 31

Page 34

Figure 18 Calibration history report

1 Report type (CH=calibration history) 5 Date of calibration (DD-MM-YY or user-defined format)

2 Parameter (pH, LDO, etc.) 6 Probe serial number (a “<“ or “>” on the HQ40d meter indicates the probe

position).

3 Time of calibration, prefaced by “CAL” and displayed as hh:mm in 24 h (or user-

defined) format

7 Calibration slope/ratio/constant

4 Probe model 8 Offset—contents vary depending on type of parameter and user settings. May

be blank.

32 English

Page 35

Page 36

HACH COMPANY World Headquarters

P.O. Box 389, Loveland, CO 80539-0389 U.S.A.

Tel. (970) 669-3050

(800) 227-4224 (U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf, Germany

Tel. +49 (0) 2 11 52 88-320

Fax +49 (0) 2 11 52 88-210

info-de@hach.com

www.de.hach.com

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

©

Hach Company/Hach Lange GmbH, 2010, 2013, 2017. All rights reserved.

*DOC022.53.80017*

Loading...

Loading...