GYS Smartmig 142, Smartmig 162, Smartmig 3p, Smartmig 182, Smartmig 183 User guide

EN

P 11-15 / 31-40

www.gys.fr

73502 - V7 - 19/02/2014

I

Montage 3P & 162

D

escriPtion

SMARTMIG

2

I

Montage

DescriPtion

SMARTMIG

3

II

sMartMig 162-3P-182-183

SMARTMIG

III

sMartMig 142-162-182-183

IV

III

IV

IV

V

V

4

VI

SMARTMIG

5

SMARTMIG

DESCRIPTION

EN

Thank you for choosing this machine. To get the best from your machine, please read the following carefully :

The SMARTMIG is a traditional machine for welding semi-automatic MIG/MAG (DC current), and MMA (SMARTMIG 3P

Only). These machines can weld all types of wire : Steel, Stainless Steel, Aluminium, ux (no gas). The SMARTMIG 3P

is capable of welding electrodes up to 3.2mm.

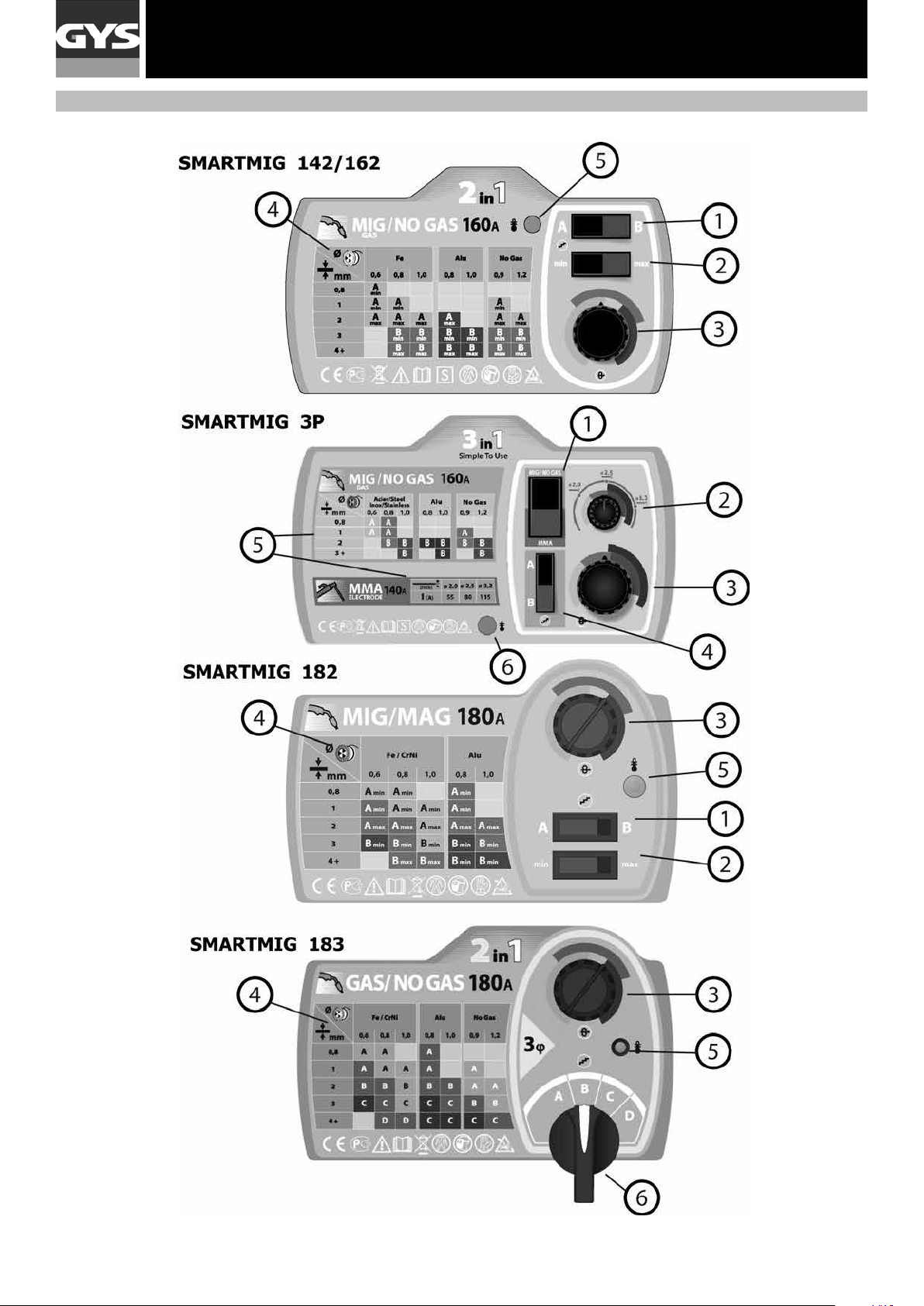

Adjustment and Setting of these machines is easy with their SMART feature.

ELECTRICITY SUPPLY

This machine is supplied with a 16A plug (type CEE7/7). The absorbed current (I1eff) is indicated on the device at

maximum usage.

The Smartmig 162/3P/182 must be connected to a 230V 1PH with EARTH protected by a 16A circuit breaker (a 13A

circuit breaker for the Smartmig 142).

The Smartmig 183 must be connected to a 400V 3ph with EARTH protected by a 10A circuit breaker.

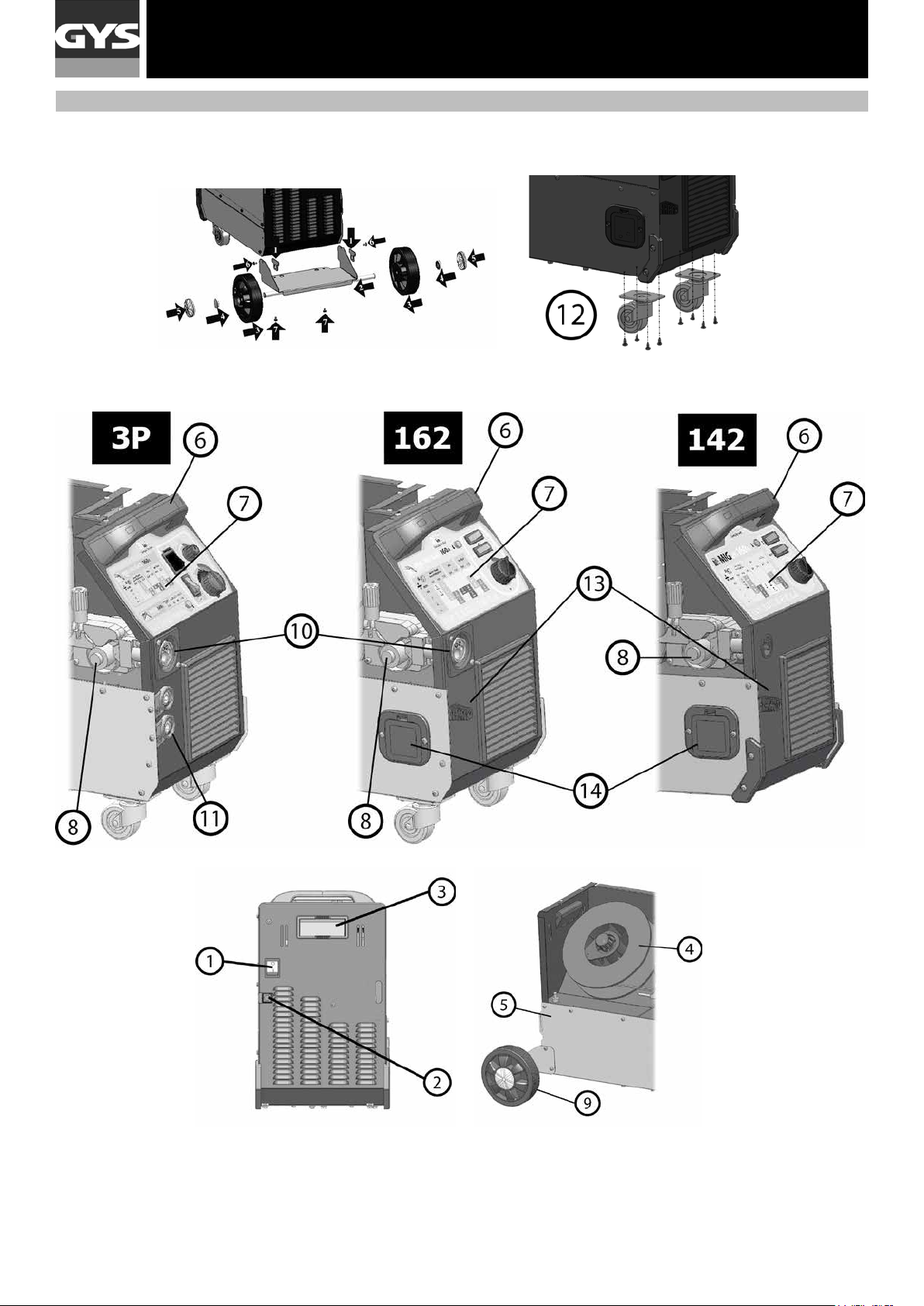

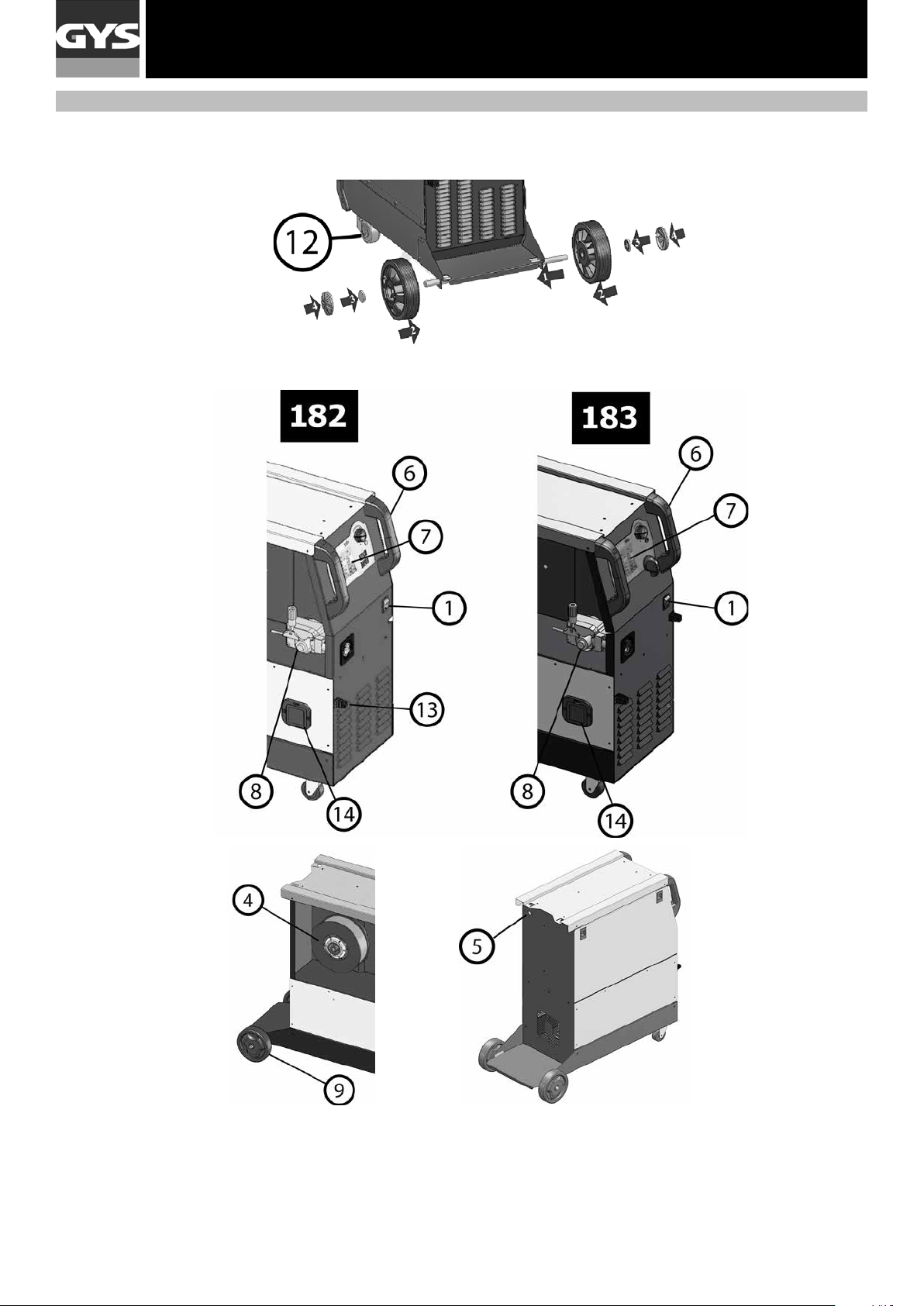

DEVICE PRESENTATION (FIG-I)

1- Power Switch Off/On

2- Power Cable

3- Rear handle

4- Wire Reel Support

5- Quick Gas Connector

6- Front Handle

7- Control panel and table for SMART feature

8- Drive Reel

9- Rear Wheels (162, 3P & 182 only)

10- EURO torch connector (162, 3P & 182 only)

11- 200A Rapid Connector (3P only)

12- Front Wheels (162, 3P & 182 only)

13- Fixed Power Cable (142, 162, & 182 only)

14- Case protected against polarity reversal (142, 162 &

182 only)

15- Fastening chain for bottles. Warning: fasten the

bottles correctly.

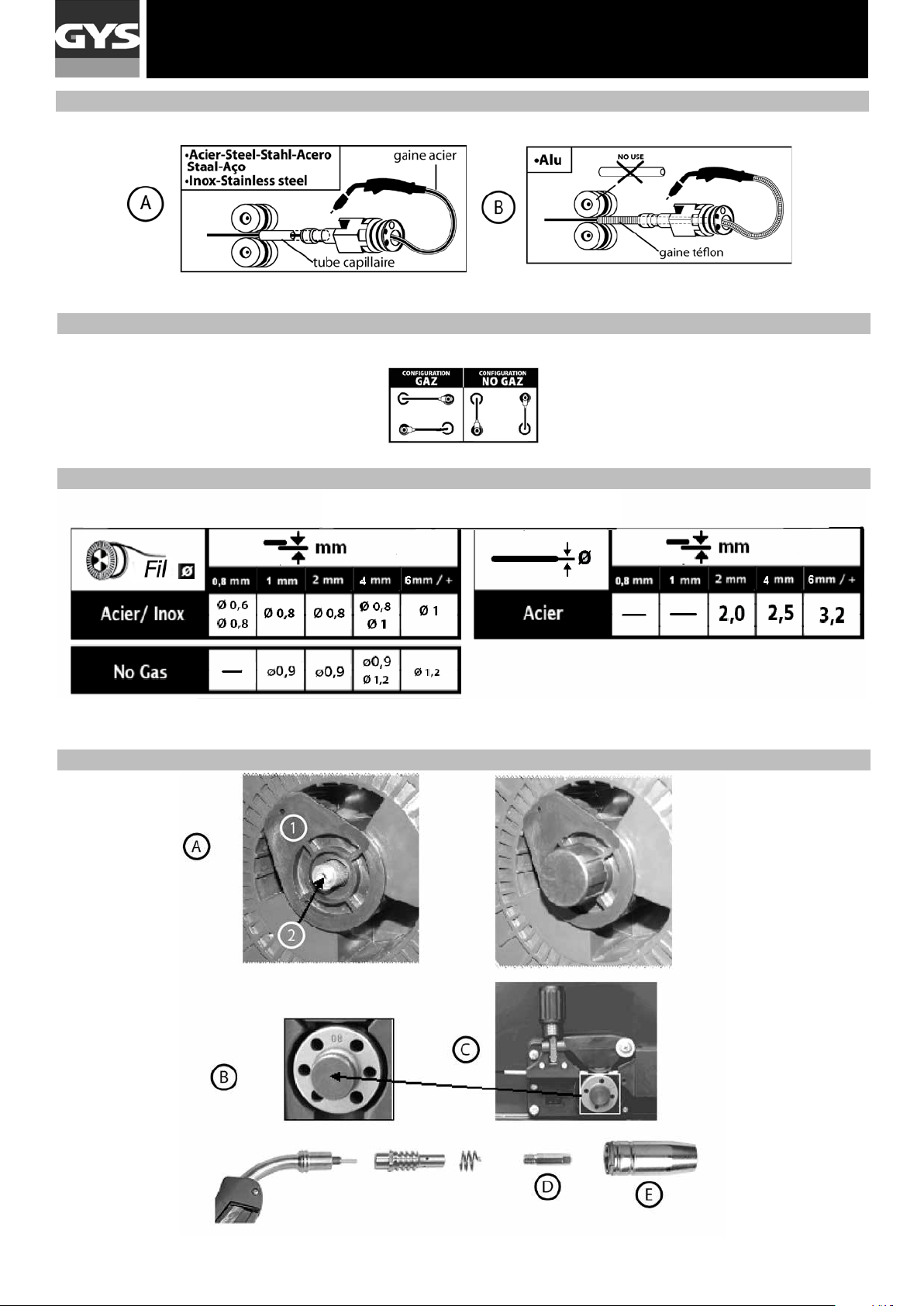

SEMI-AUTOMATIC WELDING FOR STEEL / STAINLESS STEEL (MAG MODE) (FIG-II)

These machines can weld Steel and Stainless Steel wires of 0.6/0.8 or 1.0mm (except SMARTMIG 142) (Fig II - A)

The machine is delivered equipped to function with Ø 0.8mm Steel/Stainless steel wire, and the contact tip, roller throat

and the sleeve of the torch supplied are suitable for this application.

Should you wish to use 0.6mm wire, you will need to change the contact tip. The wire reel is reversable (0.6 / 0.8mm)

and will need to be inserted into the machine so that the gure 0.6 is visible. For welding with Ø 1.0mm wire, you will

need to use a specic roller and contact tip.

For welding with Steel or Stainless Steel it is necessary to use

For use with Steel/Stainless Steel, the gas requirement is Argon + CO2. (Ar+CO2).. The proportion of CO2 required will

vary depending on the use. For specic gas requirements, please contact your gas distributor. The gas ow in steel is

between 12 and 18 Litres/minute depending on the environment and experience of the welder.

SEMI-AUTOMATIC WELDING FOR ALUMINIUM (MIG MODE) (FIG-II)

The SMARTMIG 162 ,3P, 182 & 183 are delivered equipped for welding with Aluminium wire Ø 0.8 or 1.0mm (g II-B)

The SMARTMIG 142 is delivered equipped for welding Aluminium of Ø 0.8mm (Occasional and non-intensive). In this

case the wire used should be stiff to facilitate wire feeding.

For use with aluminium, the gas requirement is pure argon (Ar). For the specic gas requirements please contact your

distributor. The gas ow in Aluminium is between 20 and 30 Litres/minute depending on the environment, and the

experience of the welder.

Below are the differences between welding with Steel and Aluminium :

- Specic rollers are needed for welding with Aluminium.

- Adjust the pressure of the drive rolls to prevent the wire being crushed.

- Only use a capilliary tube for welding with Steel or Stainless Steel.

- Use a special Aluminium Torch with a teon sheath to reduce friction. DO NOT

cut the sheath close to the joint, it is used to guide the wire from the the rollers.

- Contact Tube : Use a special aluminium contact tube specic to the diameter of wire being used.

GASLESS WIRE WELDING (FIG. III)

These machines are capable of "Gasless" wire welding (cored wire) provided that the polarity is reversed.

To do this, turn the machine off, open up the machine (14) and make the electrical connections described in Figure C

of the page below. The Machines are originally congured for Gas welding.

11

Loading...

Loading...