EN

P 11-15 / 31-40

www.gys.fr

73502 - V7 - 19/02/2014

I

Montage 3P & 162

D

escriPtion

SMARTMIG

2

I

Montage

DescriPtion

SMARTMIG

3

II

sMartMig 162-3P-182-183

SMARTMIG

III

sMartMig 142-162-182-183

IV

III

IV

IV

V

V

4

VI

SMARTMIG

5

SMARTMIG

DESCRIPTION

EN

Thank you for choosing this machine. To get the best from your machine, please read the following carefully :

The SMARTMIG is a traditional machine for welding semi-automatic MIG/MAG (DC current), and MMA (SMARTMIG 3P

Only). These machines can weld all types of wire : Steel, Stainless Steel, Aluminium, ux (no gas). The SMARTMIG 3P

is capable of welding electrodes up to 3.2mm.

Adjustment and Setting of these machines is easy with their SMART feature.

ELECTRICITY SUPPLY

This machine is supplied with a 16A plug (type CEE7/7). The absorbed current (I1eff) is indicated on the device at

maximum usage.

The Smartmig 162/3P/182 must be connected to a 230V 1PH with EARTH protected by a 16A circuit breaker (a 13A

circuit breaker for the Smartmig 142).

The Smartmig 183 must be connected to a 400V 3ph with EARTH protected by a 10A circuit breaker.

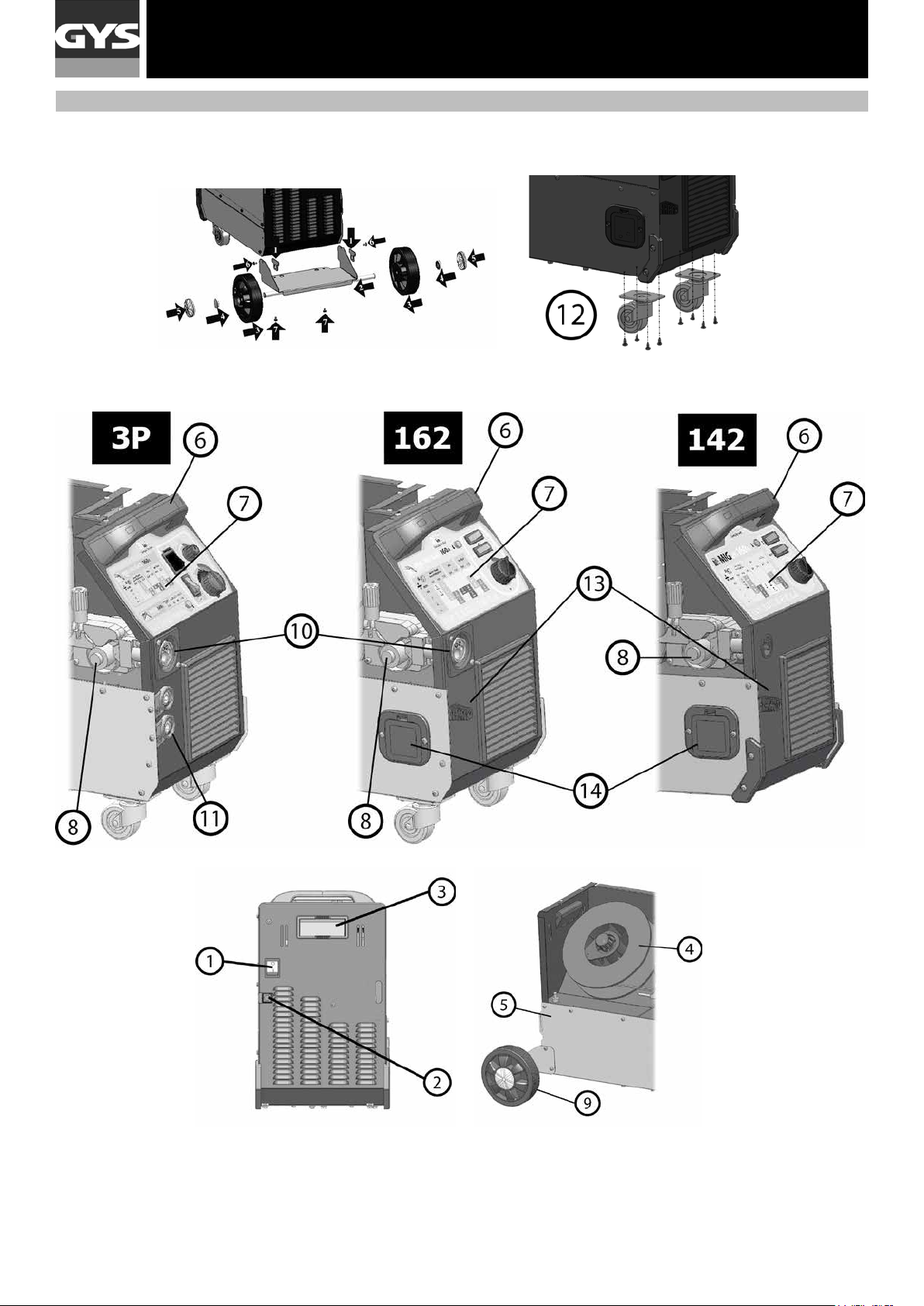

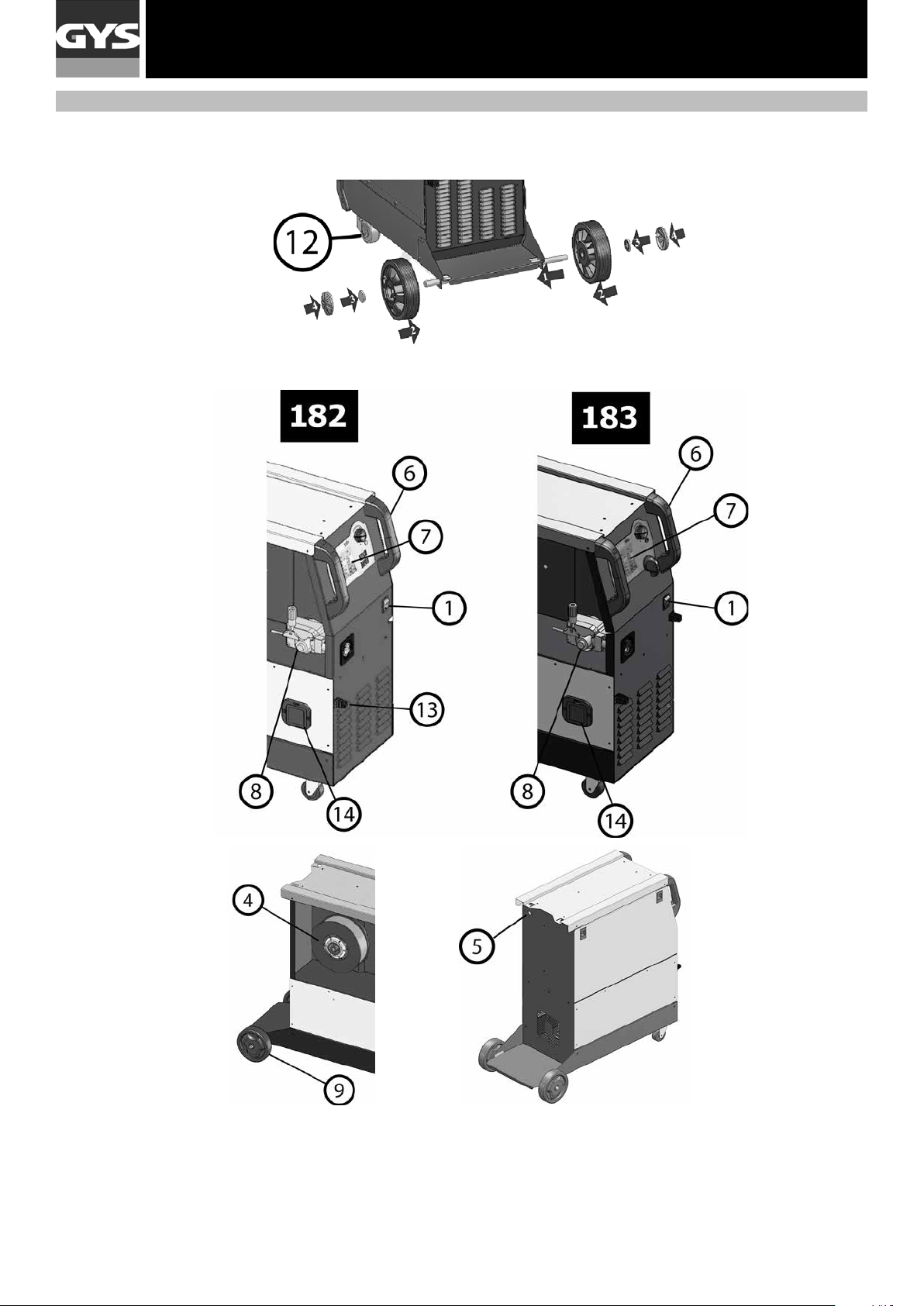

DEVICE PRESENTATION (FIG-I)

1- Power Switch Off/On

2- Power Cable

3- Rear handle

4- Wire Reel Support

5- Quick Gas Connector

6- Front Handle

7- Control panel and table for SMART feature

8- Drive Reel

9- Rear Wheels (162, 3P & 182 only)

10- EURO torch connector (162, 3P & 182 only)

11- 200A Rapid Connector (3P only)

12- Front Wheels (162, 3P & 182 only)

13- Fixed Power Cable (142, 162, & 182 only)

14- Case protected against polarity reversal (142, 162 &

182 only)

15- Fastening chain for bottles. Warning: fasten the

bottles correctly.

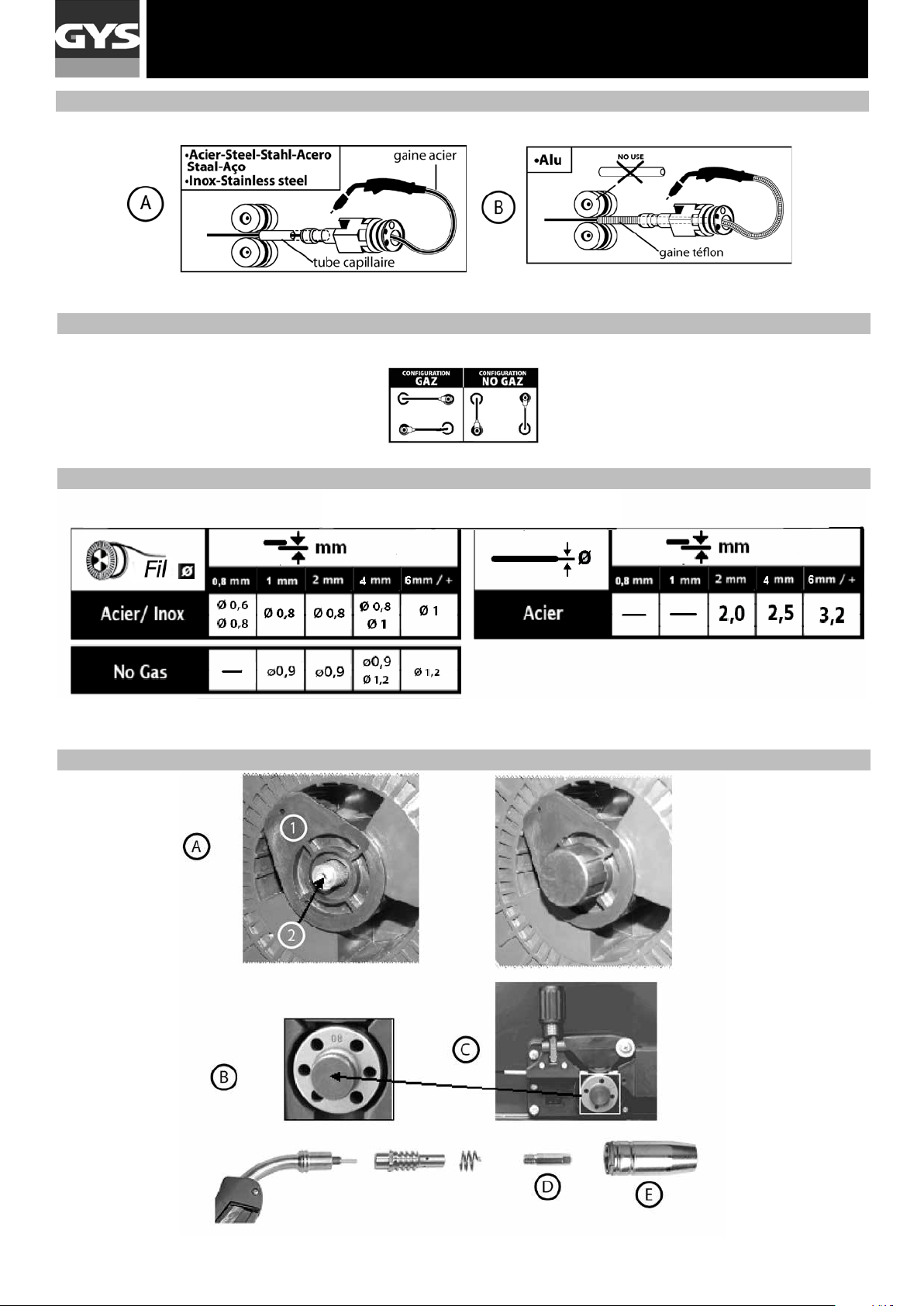

SEMI-AUTOMATIC WELDING FOR STEEL / STAINLESS STEEL (MAG MODE) (FIG-II)

These machines can weld Steel and Stainless Steel wires of 0.6/0.8 or 1.0mm (except SMARTMIG 142) (Fig II - A)

The machine is delivered equipped to function with Ø 0.8mm Steel/Stainless steel wire, and the contact tip, roller throat

and the sleeve of the torch supplied are suitable for this application.

Should you wish to use 0.6mm wire, you will need to change the contact tip. The wire reel is reversable (0.6 / 0.8mm)

and will need to be inserted into the machine so that the gure 0.6 is visible. For welding with Ø 1.0mm wire, you will

need to use a specic roller and contact tip.

For welding with Steel or Stainless Steel it is necessary to use

For use with Steel/Stainless Steel, the gas requirement is Argon + CO2. (Ar+CO2).. The proportion of CO2 required will

vary depending on the use. For specic gas requirements, please contact your gas distributor. The gas ow in steel is

between 12 and 18 Litres/minute depending on the environment and experience of the welder.

SEMI-AUTOMATIC WELDING FOR ALUMINIUM (MIG MODE) (FIG-II)

The SMARTMIG 162 ,3P, 182 & 183 are delivered equipped for welding with Aluminium wire Ø 0.8 or 1.0mm (g II-B)

The SMARTMIG 142 is delivered equipped for welding Aluminium of Ø 0.8mm (Occasional and non-intensive). In this

case the wire used should be stiff to facilitate wire feeding.

For use with aluminium, the gas requirement is pure argon (Ar). For the specic gas requirements please contact your

distributor. The gas ow in Aluminium is between 20 and 30 Litres/minute depending on the environment, and the

experience of the welder.

Below are the differences between welding with Steel and Aluminium :

- Specic rollers are needed for welding with Aluminium.

- Adjust the pressure of the drive rolls to prevent the wire being crushed.

- Only use a capilliary tube for welding with Steel or Stainless Steel.

- Use a special Aluminium Torch with a teon sheath to reduce friction. DO NOT

cut the sheath close to the joint, it is used to guide the wire from the the rollers.

- Contact Tube : Use a special aluminium contact tube specic to the diameter of wire being used.

GASLESS WIRE WELDING (FIG. III)

These machines are capable of "Gasless" wire welding (cored wire) provided that the polarity is reversed.

To do this, turn the machine off, open up the machine (14) and make the electrical connections described in Figure C

of the page below. The Machines are originally congured for Gas welding.

11

SMARTMIG

PROCESS OF REELS AND TORCHES ASSEMBLY (FIG-V)

Remove the Nozzle (g V-E) from the torch by turning clockwise and then remove the contact tip, leaving the support

and the spring on the torch (g V-D).

• Open the door of the machine

FIG V-A : Position the reel on to the support.

• In case of 100mm (3P, 142, 162) wire reel use, do not install the adapter (1).

• Adjust the reel break (2) to avoid reel movement tangling the wire when welding stops. Be careful not to tighten

too much - the reel must rotate without straining the motor.

• Tighten the plastic screw (3).

FIG V-B : Installing the drive roller.

• Choose the correct diameter reel for the type of wire. The visible diameter indicated on the roller when tted in

place is the diameter currently in use (ie. 0.8mm is visible for use with 0.8mm wire).

FIG V-C : To select the adjustment of the drive rollers, proceed as follows :

• Loosen the drive roller knob as far as possible.

• Insert the wire until it exits the other side by about 2cm, tighten the knob again slightly.

• Start the motor by pressing the trigger of the torch.

• Tighten the knob (g V-C) whilst pressing the trigger until the wire starts to move.

Nb : When welding with Aluminium, use the minimum possible pressure to avoid crushing the wire

• Pull the wire out of the end of the torch by approximately 5cm, then attach the contact tip suitable for the wire used

and then the nozzle (g V-E).

EN

The SMARTMIG 142, 162, 3P machines can accommodate coils of 100 or 200mm diameter.

The SMARTMIG 182 machines can accommodate coils of 200 or 300mm diameter. To place a 200mm wire reel, rst

install the adapter (ref. 042889) on the support.

The SMARTMIG 3P can also weld with rutile electrodes of 2.0/ 2.5/ 3.2 mm diameter.

Below are the different combinations possible :

Smartmig 142 162 3P 182 183 gaz

steel/

stainless

steel

Alu* - 0,8/1,0 Pure Argon

No Gas 0,9 0,9/1,2 Electrodes - - 2/2,5/3,2 - - -

* We recommend a teon sheath (ref. 041578) and special Aluminium contact tip (Ø 0.8 ref. 041059 - Ø 1.0 ref.

041066)

To help you select the diameter of wire suitable for the job you want to perform, refer to the table on page 4 (FIG IV).

GAS COUPLING

- Connect a pressure regulator to the gas bottle. Connect the welding machine using the pipes supplied, and place

the two clamps to avoid leakages.

- Set the gas ow by adjusting the dial located on the pressure regulator.

NB : to help facilitate the adjustment of the gas ow, operate the drive rollers by pressing the trigger of the torch

(ensure that the drive roller is completely loose so the wire is not fed through).

This procedure does not apply to "Gasless" welding mode.

0,6/0,8 0,6/0,8/1,0 Argon +

CO2

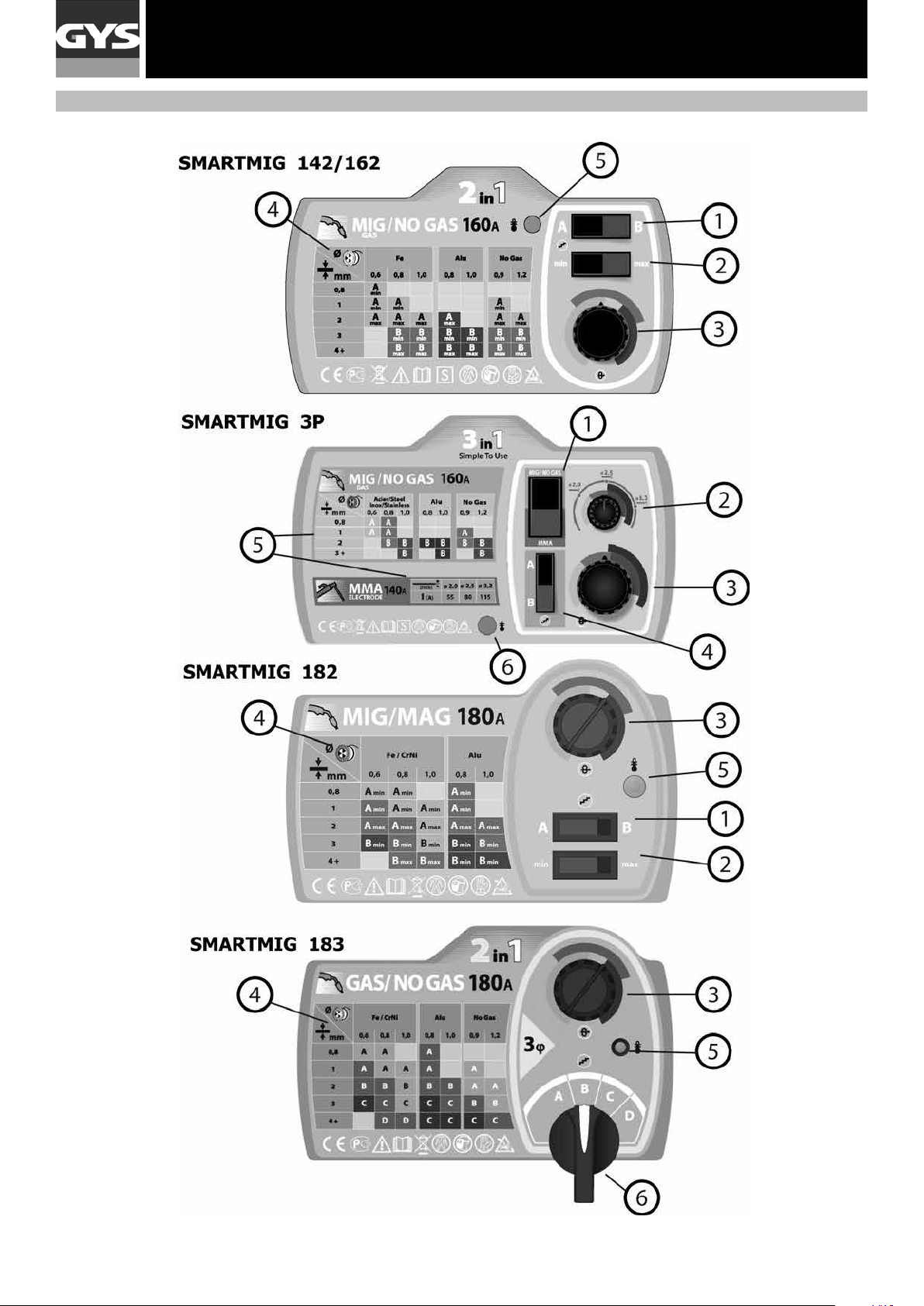

CONTROL PANEL (FIG. VI)

Smartmig 142/162/182/183 Smartmig 3P

1- Voltage selection button A / B 1- Mode select button MIG/MMA.

2- Voltage selection button min/max. 2- Power adjustment knob MMA or MIG.

3- Wire speed regulator. 3- Wire speed regulator.

4- « SMART » settings table MIG/MAG 4- Voltage selection button A / B

5- Thermal Protection light. 5- « SMART » settings table MIG/MAG & MMA.

6- positions switch 6- Thermal Protection light.

12

SMARTMIG

DIRECTIONS OF USE (FIG VI)

MIG/MAG MODE:

SMARTMIG feature allows you to adjust the voltage and the wire speed.

Use the SMART table to nd the correct settings based on the type of wire, and the thickness of the metal workpiece.

Then based on the recommendation indicated, simply select :

• The voltage (buttons A/ B & min/max for SMARTMIG 142 & 162 ; button A/B for SMARTMIG 3P)

• Wire speed - adjust the regulator (3) to the colour zone indicated.

Examples :

To weld 0.8mm thick steel, use 0.6 mm diameter steel wire (SMARTMIG 142 & 162) :

• Move button (1) to the « A » position

• Move button (2) to the « min » position

• Move the regulator (3) to the zone of lightest colour and adjust « by sound » if required

To perform the same operation with SMARTMIG 3P :

• Move button (4) to the « A » position

• Move the regulator (2) to « min » or « max »

• Move the regulator (3) to the zone of lightest colour, and adjust « by sound » if required.

MMA MODE (SMARTMIG 3P ONLY) :

Connect the electrode holder and earth clamp to the machine, respecting the polarity indicated on the electrode packaging. Then adjust the position.

Example :

For welding metal 4mm thick :

• Move button (1) to the « MMA » position.

• Adjust the regulator (2) to the zone corresponding with electrode diameter 2.5mm.

EN

ADVICE AND THERMAL PROTECTION

• Respect the normal rules of welding

• Leave the machine plugged in after welding to allow it to cool

• Thermal Protection : The LED will illuminate. Cooling will take between 10 and 15 minutes depending on the

ambient temperature.

DUTY CYCLE & WELDING ENVIRONMENT IN USE

• The welding unit describes an output characteristic of "constant current" type. The duty cycles following the standard EN60974-1 (at 40°C on a 10mn cycle) are indicated in the table here below :

x/60974

@40°C (T

cycle=10min)

X%-max 20%-90A 20%-115A 25%-110A 15%-115A 15%-140A 15%-140A

60% 60A 70A 70A 40A 80A 90A

Note: the running hot tests have been carried out at atmosphere temperature and duty cycle has been determined at 40°C by simulation.

These are A-class devices. They are designed to be used in an industrial or professional environment. In a different

environment, it can be difcult to ensure electromagnetic compatibility, due to conducted disturbances as well as

radiation. From 1st December 2010, the new standard EN 60974-10 will be applicable : Warning: these materials do

not comply with IEC 61000-3-12. If they are to be connected to a low-voltage mains supply, it is the responsibility of

the user to ensure they can be connected. If necessary consult the operator of your electrical distribution system.

142 162

MIG/MAG MMA

3P

182 183

MAINTENANCE

- Maintenance should only be carried out by a qualied person.

- Switch the machine off, ensure it is unplugged, and that the ventilator inside has stopped before carrying out maintenance work. (DANGER High Voltage and Currents).

- GYS recommends removing the steel cover 2 or 3 times a year to remove any excess dust. Take this opportunity to

have the electrical connections checked by a qualied person with an insulated tool.

- Regularly check the condition of the power supply cord. If damaged, it will need to be replaced by the manufacturer,

its’ after sales service or a qualied person.

- Ensure the ventilation holes of the device are not blocked to allow adequate air circulation.

13

SMARTMIG

SECURITY

Arc welding can be dangerous and can cause serious and even fatal injuries.

Protect yourself and others. Ensure the following safety precautions are taken:

Arc radiation: Protect yourself with a helmet tted with lters in compliance with EN169 or EN 379.

Rain, steam, damp: Use your welding unit in a clean/dry environment (pollution factor ≤ 3), on a at surface, and

more than one meter from the welding work-piece. Do not use in rain or snow.

Choc électrique: This device must only be used with an earthed power supply. Do not touch the parts under high

voltage. Check that the power supply is suitable for this unit.

Falls: Do not place/carry the unit over people or objects.

Burns: Wear protective (re-proof) clothing (cotton, overalls or jeans).

Wear protective gloves and a re-proof apron.

Ensure other people keep a safe distance from the work area and do not look directly at the welding arc.

Protect others by installing re-proof protection walls.

Fire risks: Remove all ammable products from the work area. Do not work in presence of ammable gases.

Fumes: Do not inhale welding gases and fumes. Use the device in a well ventilated environment, with articial extrac-

tion if welding indoors.

EN

Additional Precautions: Any welding operation undertaken in.....

- rooms where there is an increased risk of electric shocks,

- Poorly ventilated rooms,

- In the presence of ammable or explosive material,

Use should always be approved by a "responsible expert", and made in presence of people trained to intervene in case

of emergency.

Technical protection as described in the Technical Specication CEI/IEC 62081 must be implemented. Welding in raised

positions should not be undertaken, except in case of safety platforms use.

People wearing Pacemakers are advised to see their doctor before using this device.

Do not use the welding unit to unfreeze pipes.

Handle gas bottles with care - there is increased danger if the bottle or its valve are damaged.

14

ANOMALIES, CAUSES, REMÈDES

symptoms possible causes remedies

The welding wire speed is not

constant.

SMARTMIG

Debris is blocking up the opening.

The wire skids in the rollers.

EN

Clean out the contact batch or change

it and replace the anti-adherence pro-

duct. Ref.041806

Control the roller pressure or replace

it.

Wire diameter non-compatible with

roller

Covering wire guide in the torch non-

compatible.

The wire-feeder motor doesn’t ope-

rate.

Bad wire feeding.

No welding current.

The wire jams (after the rollers).

Reel or roller brake too tight. Release the brake and rollers.

Electrical supply problem.

Covering wire guide dirty or damaged. Clean or replace.

Reel brake too tight Release the brake.

Bad connection to the main supply.

Bad earth connection.

Torch trigger inoperative. Check the torch trigger / replace torch.

Guide wire sheath crushed. Check the sheath and torch body.

Wire jammed in the torch Clean or replace.

No capillary tube. Check the presence of capillary tube.

Wire speed too fast Reduce the wire speed.

The gas ow rate is not sufcient.

Gas bottle empty. Replace it.

Gas quality unsatisfactory. Replace it.

Check that the power switch is in the

"On" position.

Check the mains connection and

look if the plug is fed by 400 V (3PH)

power socket.

Check the earth cable (connection and

clamp condition).

Adjust ow range 15 to 20 L / min.

Clean the working metal.

The welding bead is porous.

Very important ashing particules.

No gas ow at the end of the torch. Bad gas connection.

Air ow or wind inuence. Prevent drafts, protect welding area.

Gas nozzle dirty. Clean or replace the gas nozzle.

Poor quality wire.

Surface to weld in bad condition. (rust,

etc…)

Arc voltage too low or too high. See welding settings.

Bad earth connection.

Insufcient gas ow. Adjust the gas ow.

Use suitable WIRE for MIG-MAG wel-

ding.

Clean the metal before welding.

Adjust the earth cable for a better

connection.

Check the gas connection at the

welding machine. Check the owmeter

and the solenoid valves.

15

SMARTMIG

PIECES DETACHEES / SPARE PARTS / ERSATZTEILE/ PIEZAS DE RECAMBIO/ ЗАПЧАСТИ

sMartMig 142 / 162

N° Désignation 142 162

1 Support bobine_ Reel stand_ Rollenhalter_ Soporte de bobina_ Подставка для катушки 71601

2 Electrovanne_ Solenoid valve_ Elektroventil_ Electro-válvula_ Электроклапан C51461 71540

3 Roue arrière_ Wheels_ Durchmesser Rad_ Rueda_ колесо - 71370

4 Moto-dévidoir _ Wire feeder _ Drahtvorschub _ Devanadera _ Подающее устройство 51026 51041

5 Boitier gaz/no gaz _ Gas/No gas change box _ Deckelklappe für Polaritätsumkehrung _

Caja de inversión de polaridad _ Коробка инверсии полярности

6 Roue avant / Front wheels / Vorderrad / Rueda de atrás / Переднее колесо - 71181

7 Voyant thermique _ Thermal light _ Wärmeschütz Kontrollicht _ Indicador térmico_

Индикатор температурной защиты

8 Inverseur (x2) _ Switch (x2) _ Schalter (x2) _ Botón (x2) _ Переключатель (x2) 52464

9 Bouton potentiomètre_ Potentiometer knob _ Potentiometer _ Potenciómetro botón_

Потенциометр

10 Raccord européen_ Euro connector_ _Conector Euro_ Разъем для горелки

европейского стандарта

11 Grille de ventilateur _ Fan grid _ Ventilatorgrill _ Rejilla de ventilador _ Решетка

вентилатора

12 Pince de masse _ Earth clamp _ Massekabel_ Cable de masa_ Кабель массы 71118

13 Pieds d'angles gauche _ Left Angle feet _ Winkel-Füsse links _ Pie izquierdo _ Ножки

слева

13 Pieds d'angles droite _ Right Angle feet _ Winkel-Füsse rechts _ Pie derecho _ Ножки

справа

14 Torche_ Torch_ Brenner_ Antorcha_ Горелка 71392 71394

15 Poignée avant _ Front handle _ Vorderer Griff _ Puño delantero _ Рукоятка 72072

16 Circuit _ Board _ Karte _ Carta _ Плата 53183 53258

17 Ventilateur _ Fan _ Ventilator_Ventilador_ вентилятор 51023

18 Pont de diodes_Rectier_ Gleichrichter_Puente de LED_ Диодный мост 52180 52178

19 Self de sortie _ Choke _ Drossel_ Self _ Дроссель 53179 53180

20 Transformateur _ Transformer _ Tranformator _ Transformador _ Транформатор 53176 53177

21 Poignée arrière _ Rear handle _ Hinterer Griff _ Puño _ Рукоятка 71515

22 Interrupteur I/O _ I/O switch _ Ein/Aus Schalter _ Conmutador I/O_ Interrupteur I/O _

Выключатель I/O

23 Cordon secteur _ Main cable _ Netzstromkabel _ Cable de alimentación _ Питающий

кабель

51384

51019

73009

- 51025

51010

56021x2 56021

x1

56022x2 56022x1

52460

C51109 C51110

31

SMARTMIG

sMartMig 3P

N° Désignation 3P

1 Support bobine _ Reel stand _ Rollenhalter_ Soporte de bobina_ Подставка для катушки 71601

2 Electrovanne_ Solenoid valve_ Elektroventil_ Electro-válvula_ Электроклапан 71540

3 Roue arrière _ Rear wheel _ Durchmesser Rad _ Rueda _ колесо 71370

4 Moto-dévidoir _ Wire feeder _ Drahtvorschub _ Devanadera _ Подающее устройство 51041

5 Sélecteur mode _ Mode switch _ Modus Schalter _ Botón de modo _ Выбор режима 52458

6 Bouton potentiomètre _ Potentiometer knob _ Potentiometer _ Potenciómetro botón _

Потенциометр

7 Bouton potentiomètre_ Potentiometer knob _ Potentiometer _ Potenciómetro botón _

Потенциометр

8 Inverseur _ Switch _ Schalter _ Botón _ Переключатель 52464

9 Voyant thermique _ Thermal light _ Wärmeschütz Kontrollicht_ Indicador térmico _

Индикатор температурной защиты

10 Raccord européen _ Euro connector_ _Conector Euro_ Разъем для горелки

европейского стандарта

11 Connecteur texas _ Dinze plug _ Texasbuchse _ Conectador _ Коннектор 51477

12 Grille support de ventilateur _ Fan grid _ Ventilatorgrill _ Rejilla de ventilador _ Решетка

вентилатора

13 Pieds d'angles (x4) _ Angle feet (x4) _ Füsse (x4) _ Pies (x4) _ Ножки (x4) 51385

14 Roue avant _ Front wheels _ Vorderrad _ Rueda de atrás _ Переднее колесо 71181

15 Poignée avant _ Front handle _ Vorderer Griff_ Puño_ Ручка 72072

16 Circuit potentiomètres _ Potentiometer board _ Potentiometer Karte _ Carta de potenció-

metros _ Плата потенциометра

17 Ventilateur _ Fan _ Ventilator _ Ventilador _ вентилятор 51023

18 Circuit contrôle moteur_ Motor control board _ Motorkontrolle Karte _ Carta de control del

motor _ Плата управления двигателя

19 Pont de diodes _ Rectier _ Gleichrichter_Puente de LED_ Диодный мост 52179

20 Circuit CEM _ EMC Board _ Elektromagnetische Verträglichkeit Karte _ Carta de protección

contra campos magnéticos_ Плата электромагнитной совместимости

21 Self de sortie _ Choke _ Drossel _ Self _ Дроссель 53181

22 Transformateur _ Transformer _ Tranformator _ Transformador _ Транформатор 53178

23 Poignée arrière _ Rear handle _ Hinterer Griff_ Puño_ Ручка 71515

24 Interrupteur M/A _ Main switch _ Ein/Aus – Schalter_ Interruptor On/Off_ Выключатель

вкл/выкл

25 Cordon secteur_ Mains cable _ Netzstromkabel_ Cable de alimentación _ Питающий

кабель

26 Torche amovible _ Removable torch _ Brenner _ Antorcha _ Горелка 71394

27 Pince de masse _ Earth clamp _ Masseklemme_ Pinza de masa_ Кабель массы 71116

28 Porte-électrodes _ Electrode holder _ Elektrodenhalter_ Porta electrodos _

Елктрододержатель

73099

73009

51019

51025

51010

53189

53184

53182

52460

C51111

71053

32

SMARTMIG

sMartMig 182 / 183

9

7

11

12

2

1

4

5

13

8

17

18

10

14

6

16

3

N° Désignation 182 183

Support bobine_ Reel stand_ Rollenhalter_ Soporte de bobina_ Подставка

1

для катушки

Electrovanne_ Solenoid valve_ Elektroventil_ Electro-válvula_

2

Электроклапан

3 Roue arrière_ Wheels_ Durchmesser Rad_ Rueda_ колесо 71370

Moto-dévidoir _ Wire feeder _ Drahtvorschub _ Devanadera _ Подающее

4

устройство

Boitier gaz/no gaz _ Gas/No gas change box _ Deckelklappe für Polari-

5

tätsumkehrung _ Caja de inversión de polaridad _ Коробка инверсии

полярности

6 Roue avant / Front wheels / Vorderrad / Rueda de atrás / Переднее колесо 71181

Voyant thermique _ Thermal light _ Wärmeschütz Kontrollicht _ Indicador

7

térmico_ Индикатор температурной защиты

Inverseur (x2) _ Switch (x2) _ Schalter (x2) _ Botón (x2) _ Переключатель

8

(x2)

Bouton potentiomètre_ Potentiometer knob _ Potentiometer _ Potenciómetro

9

botón_ Потенциометр

Pince de masse _ Earth clamp _ Massekabel_ Cable de masa_ Кабель

10

массы

11 Poignée avant _ Front handle _ Vorderer Griff _ Puño delantero _ Рукоятка 56047

12 Circuit _ Board _ Karte _ Carta _ Плата 97186C 97199C

13 Ventilateur _ Fan _ Ventilator_Ventilador_ вентилятор 51023 51001

14 Pont de diodes_Rectier_ Gleichrichter_Puente de LED_ Диодный мост 52188 52187

15 Self de sortie _ Choke _ Drossel_ Self _ Дроссель 96055 96074

Transformateur _ Transformer _ Tranformator _ Transformador _

16

Транформатор

Interrupteur I/O _ I/O switch _ Ein/Aus Schalter _ Conmutador I/O_ Inter-

17

rupteur I/O _ Выключатель I/O

Cordon secteur _ Main cable _ Netzstromkabel _ Cable de alimentación _

18

Питающий кабель

Commutateur 4 positions / 4 positions switch / 4 Positionen

19

Betriebsartenschalter / Conmutador 4 posiciones / 4-х позиционный

переключатель

Torche_ Torch_ Brenner_ Antorcha_ Горелка 71485

Contacteur / switch / Schalter / Botόn / переключатель - 51113

15

71603

71540

51108

51384

51019 52004

52466 -

73009

71910

96054 96073

52460 52461

21491 21475

- 51228

19

33

SCHÉMA ÉLECTRIQUE / CIRCUIT DIAGRAM / SCHALTPLAN / DIAGRAMA ELECTRICO /

ЭЛЕКТРИЧЕСКАЯ СХЕМА

sMartMig 142

sMartMig 162

SMARTMIG

sMartMig 3P

34

sMartMig 182

SMARTMIG

71540

sMartMig 183

35

SMARTMIG

FR

Gys atteste que les postes de soudure Smartmig 142-162-3P-182-183 sont fabriqués conformément aux exigences

des directives Basse tension 2006/95/CE du 12/12/2006, et aux directives CEM 2004/108/CE du 15/12/2004. Cette

conformité est établie par le respect des normes harmonisées EN60974-1 de 2005, EN 50445 de 2008, EN 60974-10

de 2007. Le marquage CE a été apposé en 2011.

EN

The equipment described on this manual is conform to the instructions of low voltage 2006/95/CE of 12/12/2006, and

the instructions of CEM 2004/108/CE of the 15/12/2004. This conformity respects the standards EN60974-1 of 2005,

EN 50445 de 2008, EN60974-10 of 2007. CE marking was added in 2011.

DE

GYS erklärt, dass die synergisch geregelten Schweißanlagen Smartmig 142-162-3P-182-183 richtlinienkonform mit

folgenden europäischen Bestimmungen hergestellt wurden: Niederspannungsrichtlinie 2006/95/CE –12.12.2006 und

EMV- Richtlinien 2004/108/CE – 15.12.2004 elektromagnetische Verträglichkeit- hergestellt wurden. Diese Geräte

stimmen mit den harmonisierten Normen EN60974-1 von 2005, EN 50445 von 2008, EN60974-10 von 2007 überein.

CE Kennzeichnung: 2011

ES

Gys certica que los aparatos de soldadura SMARTMIG 142, 162 , 3P, 182 y 183 son fabricados en conformidad con

las directivas baja tensión 2006/95/CE del 12/12/2006, y las directivas compatibilidad electromecánica 2004/108/CE

del 15/12/2004. Esta conformidad está establecida por el respeto a las normas EN60974-1 de 2005, EN 50445 de

2008, EN 60974-10 de 2007. El marcado CE fue jado en 2011.

DÉCLARATION DE CONFORMITÉ

DECLARATION OF CONFORMITY

KONFORMITÄTSERKLÄRUNH

DECLARACION DE CONFORMIDAD

RU

Gys заявляет, что сварочные аппараты SMARTMIG 142, 162, 3P, 182 и 183 произведены в соответствии с

директивами Евросоюза 2006/95/CE о низком напряжении от 12/12/2006, а также с директивами CEМ 2004/108/

CE от 15/12/2004. Данное соответствие установлено в соответствии с согласованными нормами EN60974-1 2005

г, EN 50445 2008 г, EN 60974-10 2007 г. Маркировка ЕС нанесенна в 2011 г.

ДЕКЛАРАЦИЯ О СООТВЕТСТВИИ

01/05/2012

Société GYS

134 BD des Loges

53941

Saint-Berthevin

France

Nicolas BOUYGUES

Président Directeur Général

36

SMARTMIG

CONDITIONS DE GARANTIE FRANCE

La garantie n’est valable que si le bon a été correctement rempli par le vendeur. La garantie couvre tout défaut ou

vice de fabrication pendant 1 an, à compter de la date d’achat (pièces et main d’œuvre). La garantie ne couvre pas

les erreurs de tension, incidents dus à un mauvais usage, chute, démontage ou toute autre avarie due au transport.

La garantie ne couvre pas l’usure normale des pièces (Ex. : câbles, pinces, etc.). En cas de panne, retournez l’appareil à la société GYS (port dû refusé), en y joignant : Le présent certicat de garantie validé par le vendeur Une note

explicative de la panne. Après la garantie, notre SAV assure les réparations après acceptation d’un devis.

HERSTELLERGARANTIE

Die Garantieleistung des Herstellers erfolgt ausschließlich bei Fabrikations- oder Materialfehlern, die binnen 12 Monate

nach Kauf angezeigt werden (Nachweis Kaufbeleg). Nach Anerkenntnis des Garantieanspruchs durch den Hersteller

bzw. seines Beauftragten erfolgen eine für den Käufer kostenlose Reparatur und ein kostenloser Ersatz von Ersatzteilen. Der Garantiezeitraum bleibt aufgrund erfolgter Garantieleistungen unverändert. Ausschluss: Die Garantieleistung

erfolgt nicht bei Defekten, die durch unsachgemäßen Gebrauch, Sturz oder harte Stöße sowie durch nicht autorisierte

Reparaturen oder durch Transportschäden, die infolge des Einsendens zur Reparatur, hervorgerufen worden sind.

Keine Garantie wird für Verschleißteile (z. B. Kabel, Klemmen, Vorsatzscheiben etc.) sowie bei Gebrauchsspuren übernommen. Das betreffende Gerät bitte immer mit Kaufbeleg und kurzer Fehlerbeschreibung ausschließlich über den

Fachhandel einschicken. Die Reparatur erfolgt erst nach Erhalt einer schriftlichen Akzeptanz (Unterschrift) des zuvor

vorgelegten Kostenvoranschlags durch den Besteller. Im Fall einer Garantieleistung trägt GYS ausschließlich die Kosten

für den Rückversand an den Fachhändler.

37

SMARTMIG

ICONES/SYMBOLS/ZEICHNENERLÄRUNG/SIMBOLOS GRAFICOS/CИMBOЛЬL

A Ampères - Amps - Ampere - Amperios - Ампер

V Volt - Volt - Volt - Voltios - Вольт

Hz Hertz - Hertz - Hertz - Hertz - Герц

IP21 Protégé contre l’accès aux parties dangereuses avec un doigt, et contre les chutes verticales de

gouttes d'eau - Protected against rain and against ngers access to dangerous parts - Geschützt

gegen Berührung mit gefährlichen Teilen und gegen senkrechten Wassertropfenfall - protegido

contra el acceso a las partes peligrosas con los dedos, y contra las caídas verticales de gotas de

agua. - Аппарат защищен от доступа рук в опасные зоны и от вертикального падения капель

воды Сварка на постоянном токе

Courant de soudage continu - Welding direct current - Gleichschweißstrom - La corriente de soldadura es continua - Сварка на постоянном токе

Uo Tension assignée à vide - Rated no-load voltage - Leerlaufspannung - Tensión asignada de vacío -

Напряжение холостого хода

U1 Tension assignée d’alimentation - rated supply voltage - Netzspannung - Tensión de la red -

Напряжение сети

I1max Courant d’alimentation assigné maximal (valeur efcace) - Rated maximum supply current (effective

value) - Maximaler Versorgungsstrom (Effektivwert) - Corriente máxima de alimentación de la red Максимальный сетевой ток (эффективная мощность)

I1eff Courant d’alimentation effectif maximal - Maximum effective supply current - Maximaler tatsächli-

cher Versorgungsstrom - Corriente de alimentación efectiva máxima - Максимальный эффективный

сетевой ток

EN60 974-1 L’appareil respecte la norme EN60974-1 - The device complies with EN60974-1 standard relative

to welding units - Das Gerät entspricht der Norm EN60974-1 für Schweißgeräte - El aparato está

conforme a la norma EN60974-1 referente a los aparatos de soldadura - Аппарат соответствует

европейской норме EN60974-1

I1max Courant d’alimentation assigné maximal (valeur efcace). - Rated maximum supply current (effective

value). - Maximaler Versorgungsstrom (Effektivwert). - Corriente máxima de alimentación de la red. Максимальный сетевой ток (эффективная мощность)

I1eff Courant d’alimentation effectif maximal. - Maximum effective supply current. - Maximaler tatsä-

chlicher Versorgungsstrom. - Corriente de alimentación efectiva máxima. - Максимальный

эффективный сетевой ток.

Transformateur-redresseur monophasé Single-phase converter-rectier - Einphasiger Trafo/Frequenzumwandler - Transformador-recticador monofásico - однофазный инвертор, с трансформацией и

выпрямлением.

Transformateur-redresseur triphasé Tri-phase converter-rectier - Einphasiger Trafo/Frequenzumwandler - Transformador-recticador trifásico - однофазный инвертор, с трансформацией и

выпрямлением. - Trasformatore-raddrizzatore tri-fase

X(40°C) Facteur de marche selon la norme EN 60974-1 (10 minutes – 40°C) - Duty cycle according to the

standar EN 60974-1 (10 minutes – 40°C) - Einschaltdauer gemäß EN 60974-1 (10 Minuten – 40°C)

- Factor de marcha según la norma EN 60974-1 (10 minutos – 40°C). - ПВ% по норме EN 60974-1

(10 минут – 40°С)

I2 : courant de soudage conventionnnel correspondant - I2 : corresponding conventional welding current - I2 : entsprechender Schweißstrom - I2 : Corrientes correspondientes - I2 : Токи,

соответствующие Х*

U2 : Tensions conventionnelles en charges correspondantes - U2 : conventional voltages in corresponding load - U2 : entsprechende Arbeitsspannung - U2 : Tensiones convencionales en carga - U2 :

соответствующие сварочные напряжения*

38

SMARTMIG

Convient au soudage dans un environnement avec risque accru de choc électrique. La source de

courant elle-même ne doit toutefois pas être placée dans de tels locaux. - Adapted for welding

in environment with increased risks of electrical shock. However, the welding source must not be

placed in such places. - Geeignet für Schweißarbeiten im Bereich mit erhöhten elektrischen Risiken.

Trotzdem sollte die Schweißquelle nicht unbedingt in solchen Bereichen betrieben werden. - Adaptado a la soldadura en un entorno que comprende riesgos de choque eléctrico. La fuente de corriente ella misma no debe estar situada dentro de tal locales. - Адаптирован для сварки в среде с

повышенным риском электрошока. Однако сам источник питания не должен быть расположен

в таких местах.

Appareil conforme aux directives européennes. - The device complies with European Directive.

- Gerät entspricht europäischen Richtlinien. - El aparato está conforme a las normas europeas. Устройство соответствует европейским нормам.

Conforme aux normes GOST (Russie). - Conform to standards GOST / PCT (Russia). - in Übereinstimmung mit der Norm GOST/PCT. - Conforme a la normas GOST (PCT) (Rusia). - Продукт

соответствует стандарту России (РСТ).

L’arc électrique produit des rayons dangereux pour les yeux et la peau (protégez-vous !). - The electric arc produces dangerous rays for eyes and skin (protect yourself !). - Der elektrische Lichtbogen

verursacht Strahlungen auf Augen und Haut (Schützen Sie sich !). - El arco produce rayos peligrosos

para los ojos y la piel (¡ Protéjase !). - Электрическая дуга производит опасные лучи для глаз и

кожи (защитите себя!). - Внимание! Сварка может вызвать пожар или взрыв.

Attention, souder peut déclencher un feu ou une explosion. - Caution, welding can produce re or

explosion. - Achtung! Schweißen kann Feuer oder Explosion verursachen. - Cuidado, soldar puede

iniciar un fuego o una explosión. - Внимание! Сварка может вызвать пожар или взрыв.

Attention ! Lire le manuel d’instruction avant utilisation. - Caution ! Read the user manual. - Achtung!

Lesen Sie die Betriebsanleitung. - Cuidado, leer las instrucciones de utilización. - Внимание !

Читайте инструкцию по использованию.

Produit faisant l'objet d'une collecte sélective- Ne pas jeter dans une poubelle domestique. - Separate

collection required, Do not throw in a domestic dustbin. - Für die Entsorgung Ihres Gerätes gelten

besondere Bestimmungen (Sondermüll). Es darf nicht mit dem Hausmüll entsorgt werden. - Este

aparato es objeto de una recolección selectiva. No debe ser tirado en un cubo doméstico. - Продукт

требует специальной утилизации. Не выбрасывать с бытовыми отходами.

ACCESSOIRES / ACCESSORIES / ZUBEHÖR

39

SMARTMIG

40

Loading...

Loading...