Page 1

FR - 2 / 3-8 / 45-50

EN - 2 / 9-14 / 45-50

DE - 2 / 15-20 / 45-50

ES - 2 / 21-26 / 45-50

RU - 2 / 27-32 / 45-50

NL - 2 / 33-38 / 45-50

IT - 2 / 39-44 / 45-50

FLEX 250 CEL

73502-V7-25/10/2016

Page 2

2

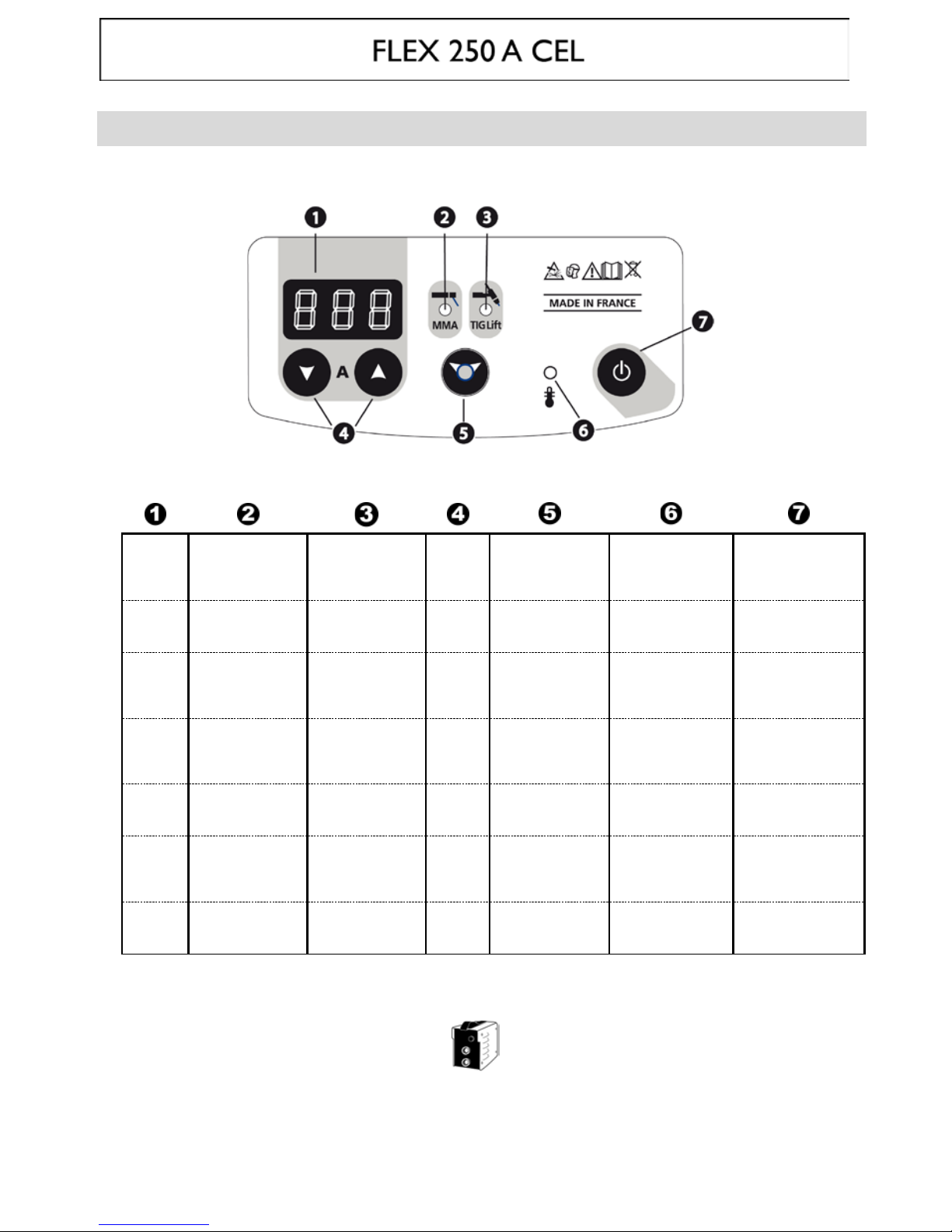

FACE AVANT/FRONTAL SIDE/FRONTSEITE UND ANSCHLÜSSE/CARA DELANTERA/ПЕРЕДНЯЯ ПАНЕЛЬ /

VOORZIJDE

FR

Afficheur Voyant mode

« soudage à

l’électrode » (MMA)

Voyant mode

« soudage à

l’électrode réfrac

taire»

(TIG)

Sélecteur

valeur +

ou -

Bouton sélection/

validation

Voyant de protection

thermique

Bouton de mise e n

marche / veille

EN

Display Mode indicator

« electrode welding »

(MMA)

Mode indicator « non

consumable electrode

welding» (TIG)

Select

button «

+

or – »

Selection / v alidation

button

Thermal protection

indicator

On/stand by button

DE

Anzeige

Schweißmodusanzeige

MMA

Schweißmodusanzeige

«WIG

Kontaktzündung»

(TIG)

Wahl

Drucktaster

+ oder -

Button-Auswahl /

Validierung

Gelbe

Übertemperaturanzeige

EIN/ AUS- Taste

ES

Indicador Indicador modo

« soldadura con

electrodo recubierto»

(MMA)

Indicador modo

« soldadura con

electrodo refractario»

(TIG)

Selector

valor + o -

Botón selección /

validación

Indicador luminoso

amarillo de protección

térmica

Puesta en marcha /

stand by

RU

Индикатор Лампочка режима

MMA

Лампочка режима

TIG

Клавиши

выбора +

или –

Клавиша выбора/

подтверждения

Желтый индикатор

температурной

защиты

Кнопка включение /

вахтенный режим

NL

Display Lampje voor

« booglassen met

beklede elektrode »

(MMA)

Lampje voor

« booglassen met

niet-afsmeltende

elektrode » (TIG)

Selectie

waarde +

of -

Knop selectie/

bevestiging

Lampje voor

thermische beveiliging

Aan/uit knop

IT

Schermo Spia modo "saldatura

all'elettrodo" (MMA)

Spia modo "saldatura

all'elettrodo

refrattari o " (TIG)

Selettore

valore + o

-

Tasto

selezione/conferma

Spia di protezione

termica

Tasto di avviamento /

standby

FLEX 250 CEL

17kg

Page 3

3

DESCRIPTION

Merci de votre choix ! Afin de tirer le maximum de satisfaction de votre poste, veuillez lire avec attenti on ce qui suit :

Ces postes de soudure Inverter, portables, ventilés, sont conçus pour le soudage à l’électrode enrobée (MMA) et à

électrode réfractaire (TIG Lift) en courant continu (DC). En MMA, ils soudent tout type d’électrode : rutile, inox,

fonte, basique et cellulosique. En Tig, ils soudent la plu part des métaux sauf l’alum inum et ses alliages. Ils sont

protégés pour le fonctionnemen t sur groupes électrogènes.

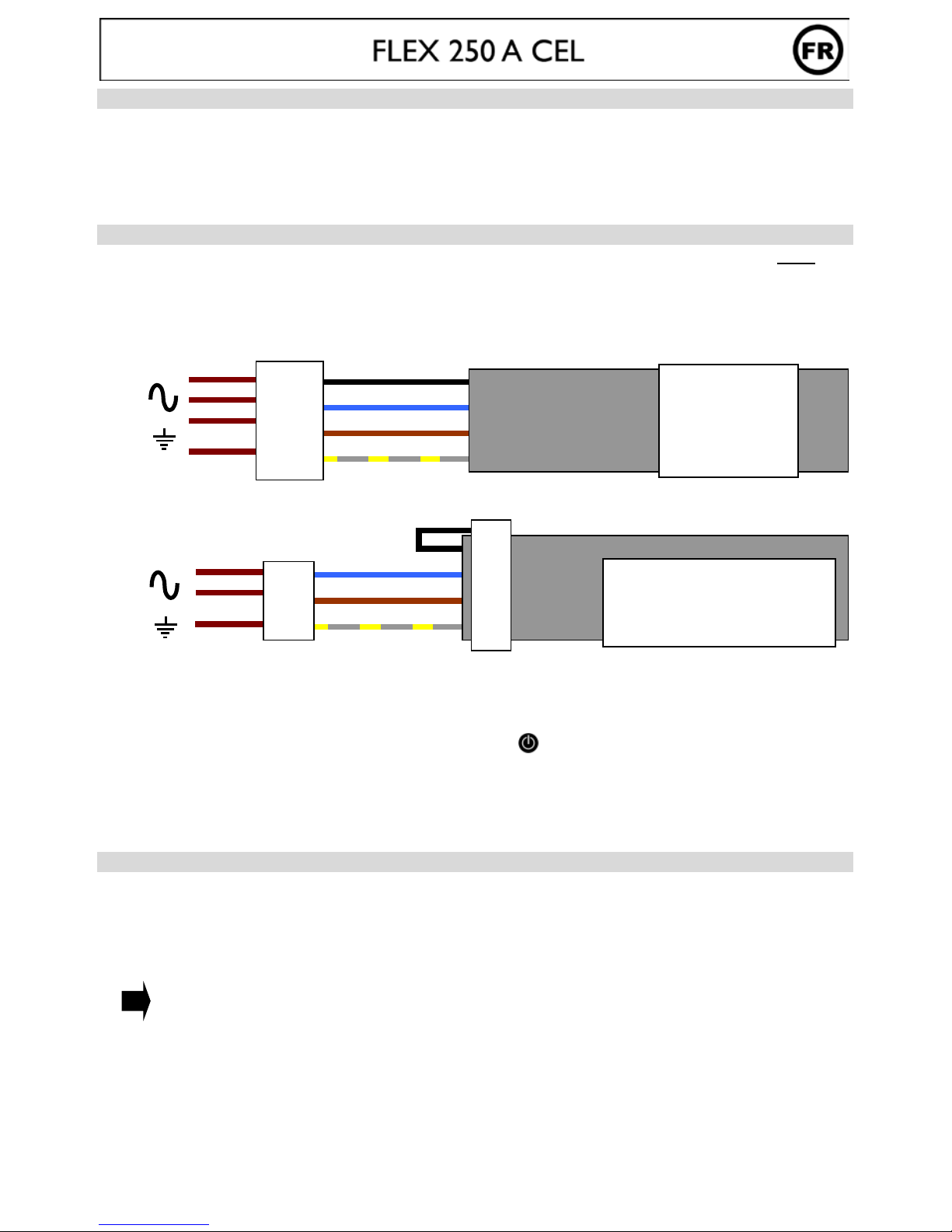

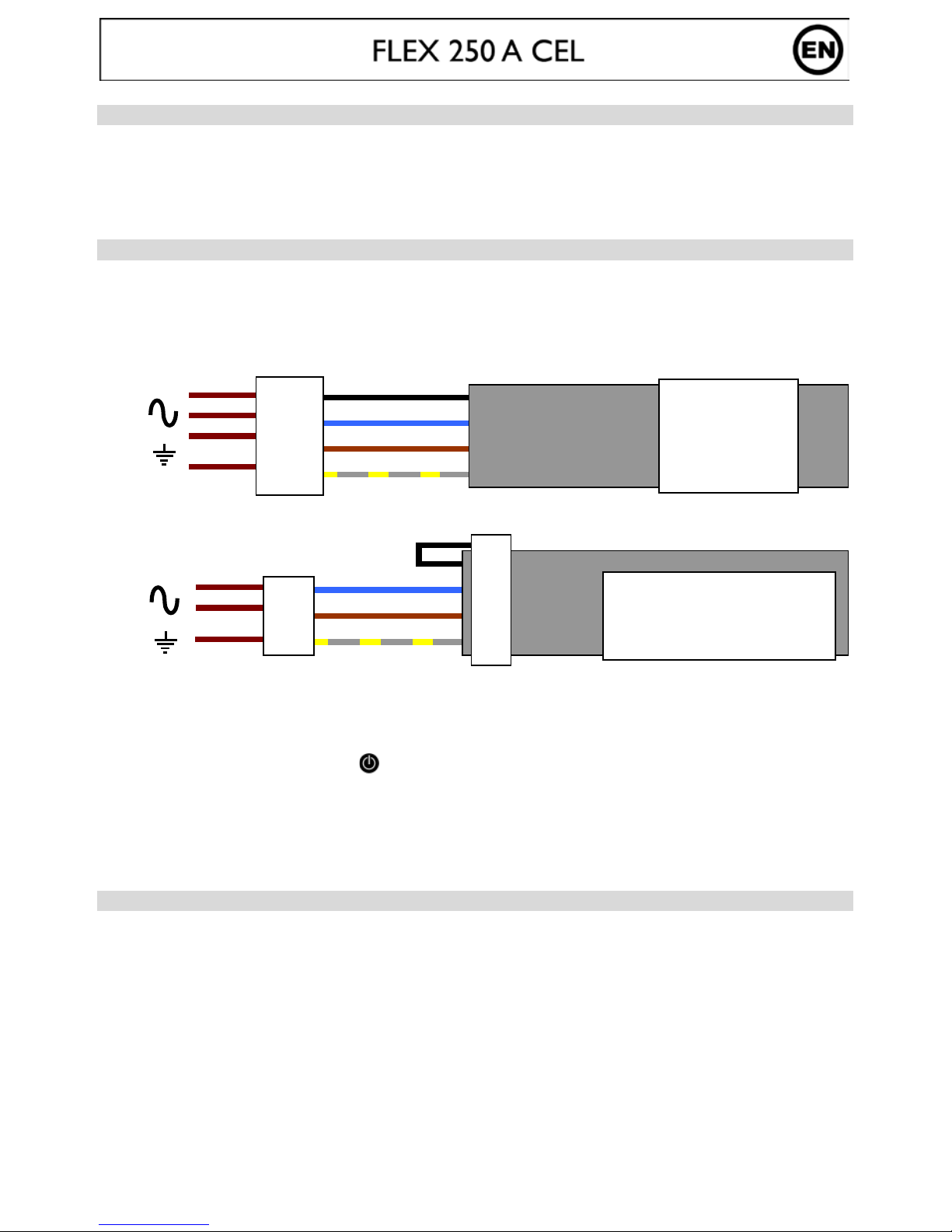

ALIMENTATION-MISE EN MARCHE

• Le FLEX 250 A CEL équipé d’un système « Flexible Voltage » s’alimente sur une ins tall at io n é lec triq ue AVEC terre

comprise entre 110V et 480V monophasée ou triphasée (50 - 60 Hz). Le courant effectif absorbé (I1eff) est

indiqué sur l'appareil pour les conditions d'utilisation maximales. Vérifier que l'alimentation et ses protections

(fusible et/ ou disjoncteur) sont com patibles avec le c ourant nécessaire en utilisation. Ce poste est livré sans prise.

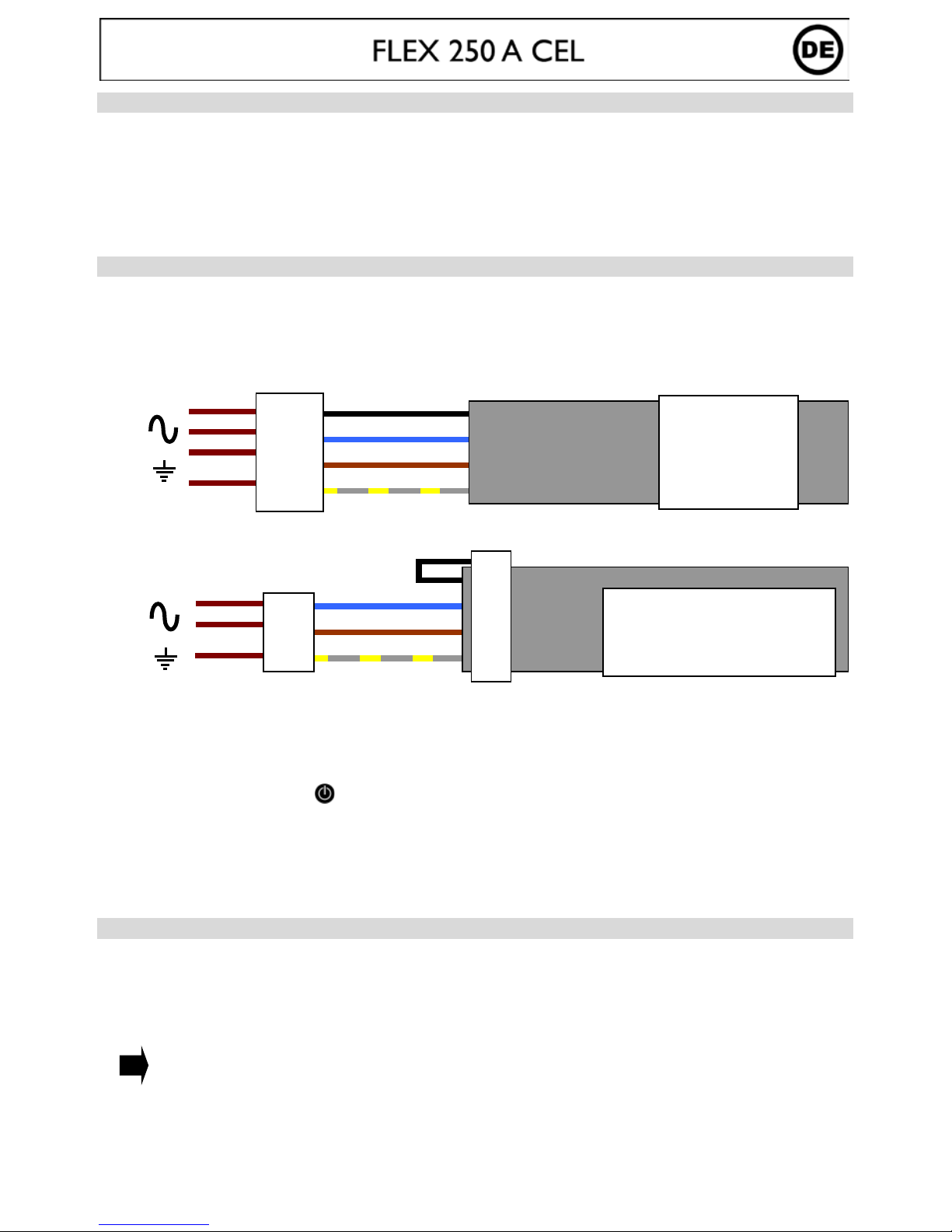

Schéma de connexion

3

+

Connection à une prise triphasée

2

+

Connection à une prise monophasée

*ATTENTION ! Dans le cas d’une connection à une prise monophasé, le fil inutilisé doit être isolé afin

qu’il n’entre jamais en contact avec les autres fils.

• La mise en marche s’effectue par une pression sur la touche ( )

• Ces appareils sont de Classe A. Ils sont conçus pour un emploi dans un environnement industriel ou

professionnel. Dans un environnement différent, il peut être difficile d’assurer la compatibilité électromagnétique,

à cause de perturbations conduites aussi bien que rayonnées.

• Ne pas utiliser dans un environnement comportant des poussières métalliques conductrices.

SOUDAGE A L' ÉLECTRODE ENROBEE (M OD E M MA)

• Brancher les câbles porte électrode et pince de masse dans les connecteurs. Respecter les polarités indiquées sur

l'emballage des électrodes.

• Respecter les règles classiques du soudage.

• Votre apparei l est muni de 3 fonctionnalités spécifiques aux Inverters :

Le H

OT START (mode réglable, cf ci-dessous) procure une surintensité en début de soudage.

L’A

RC FORCE (mode réglable, cf ci-dessous) délivre une surintensité qui évite le collage lorsque l’électrode

rentre dans le bain.

L'A

NTI-STICKING vous permet de décoller facilement votre électrode sans la faire roug ir en cas de collage.

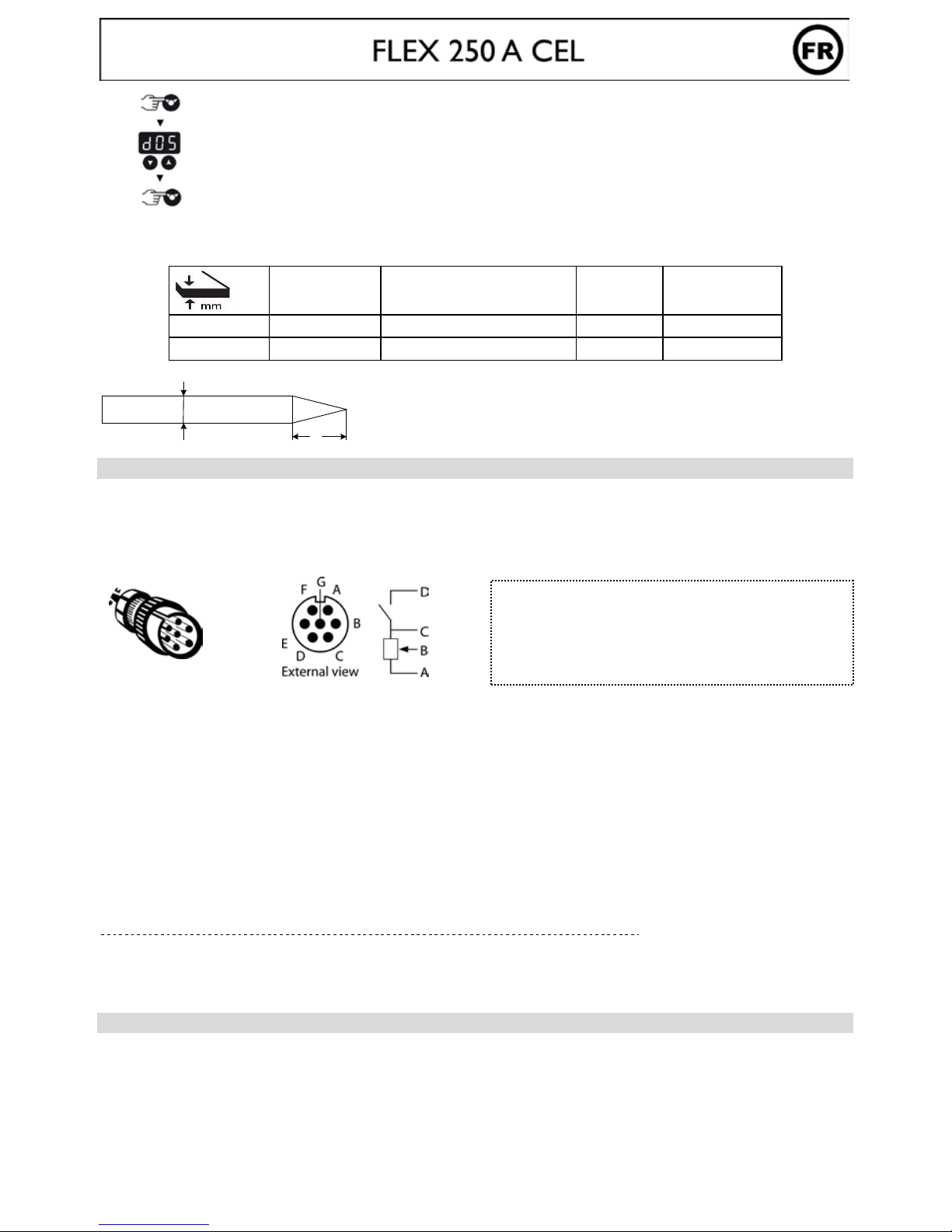

Activation du mode MMA et réglage de l’intensité :

- Sélectionner la position MMA avec le sélecteur (presser 3 secondes)

- Régler l’int ensité souhaitée (afficheur ) grâce aux touches.

1- phase 1

2- phase 2

3- phase 3

4- terre

1- phase 1

2- phase 2 ou neutre

3- Terre

*

Page 4

4

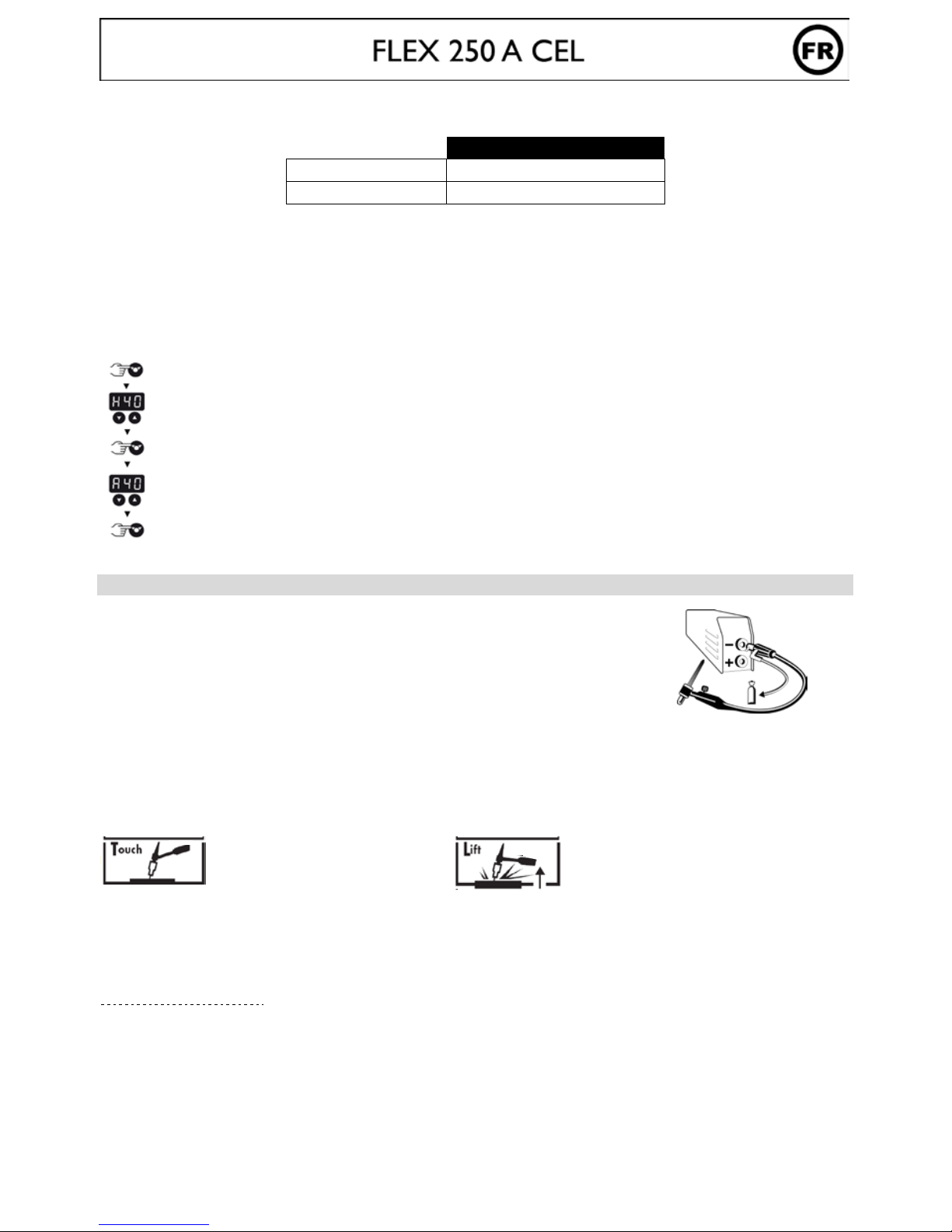

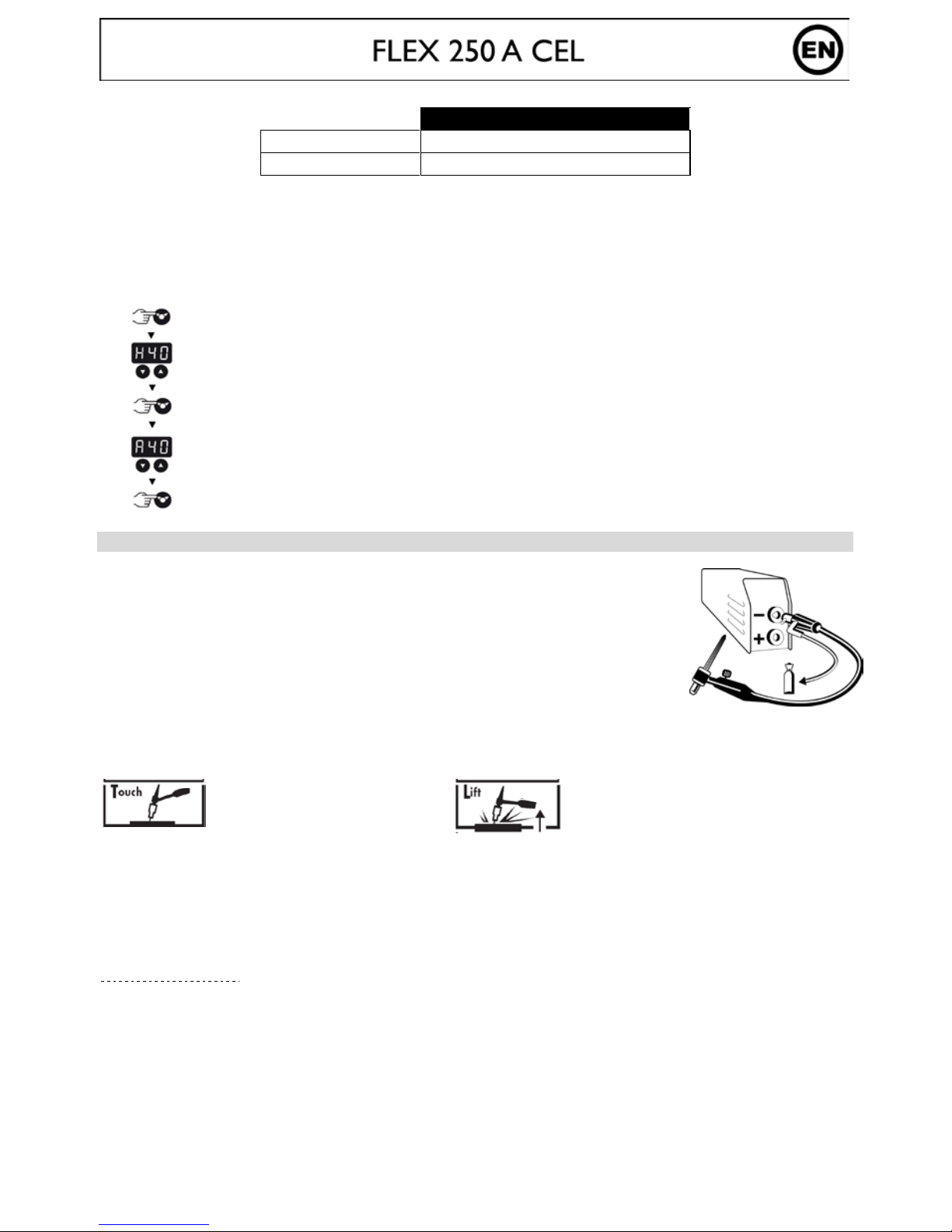

Hot Start et Arc Force réglables :

FLEX 250 A CEL

Hot Start 0 90%

Arc Force 0 90% ou type d’électrode

L’arc force est réglable de 0 à 90% puis passe sur des modes d’électrodes, « rut », « bas » et « cel ». Ces derniers

modes sont des réglages optimaux pour les différents types d’électrodes.

Conseils :

Hot Start faible pour les tôles fines.

Hot Start élev é pour les métaux difficiles à souder (pièces sa les ou oxydées).

Pour régler le Hot Start et Arc Force, suivre les étapes page suivante.

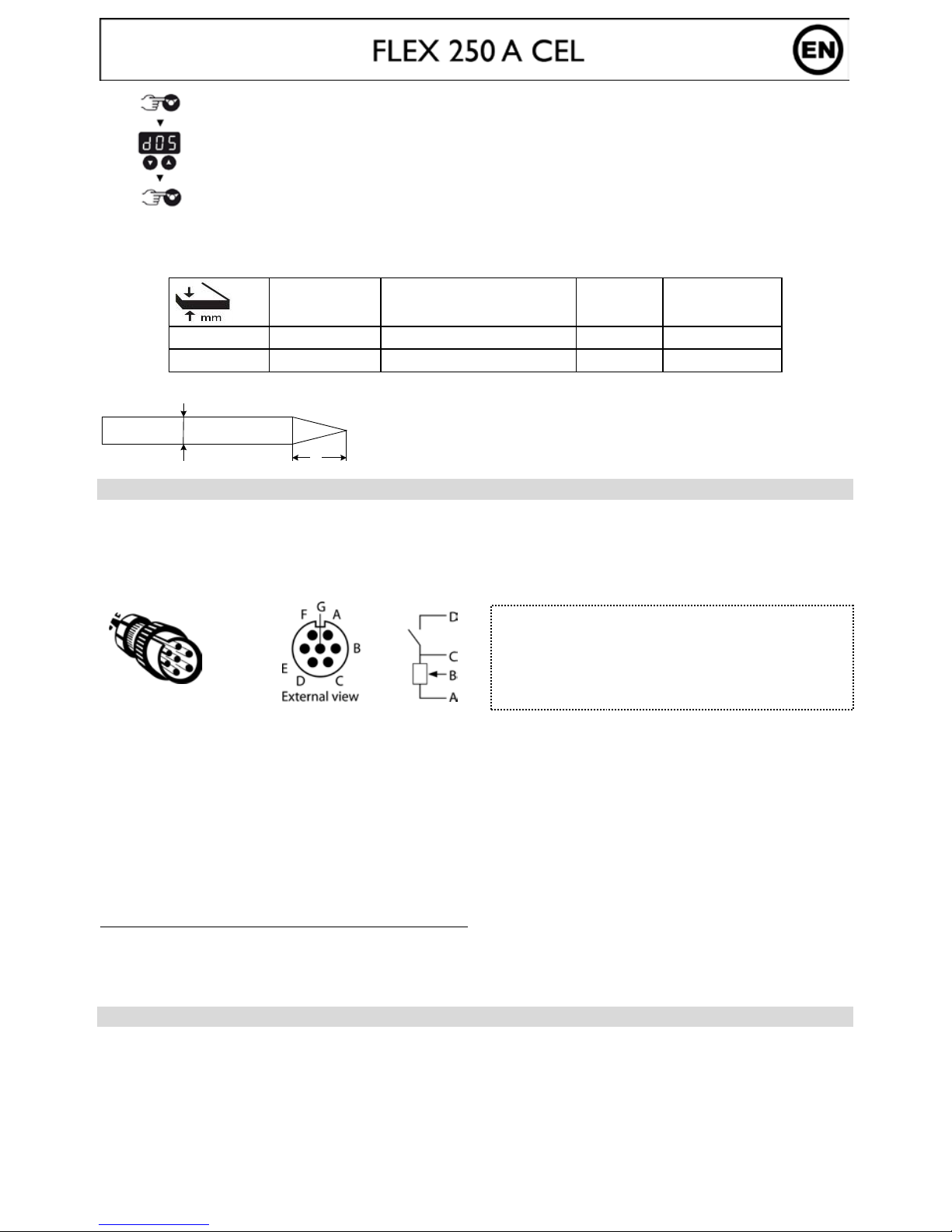

Presser le sélecteur

Régler le pourcentage d’Hot Start souhaité (afficheur ) grâce aux touches

Valider la valeur souhaitée en pressant sur le sélecteur

Régler le pourcentage d’Arc Force ou le type d’électrodes souhaité (afficheur ) grâce aux

touches .

Valider la valeur souhaitée en pressant sur le sélecteur

SOUDAGE TIG LIFT (MODE TIG)

Le soudage TIG DC req uie r t une pr o te ctio n g aze us e (A rgo n) .

Pour souder en TIG, suivre les étapes suivantes :

1. Connecter la pince de masse sur la polarité positive (+).

2. Brancher une torche « à valve » sur la polarité négative (-).

3. Raccorder le tuyau de gaz au manodétendeur de la bouteille de gaz.

Il sera parf ois nécessaire de le couper avant l’écrou si ce dernier n’est pas adapté au manodétendeur

4. Sélectionner la position TIG avec le sélecteur . (presser 3 secondes)

5. Régler l’intensité souhaitée (afficheur ) grâce aux touches , selon l’épaisseur à souder (30A/mm).

6. Régler le débit de gaz sur le manodétendeur de la bouteille de gaz, puis ouvrir la valve de la torche

7. Pour amorcer :

a- toucher l’électrode sur la

pièce à souder

b- relever l’électrode 2 à 5 mm

de la pièce à souder

8. En fin de soudure : Lever 2 fois l'arc (haut-bas-haut-bas) pour déclencher l'évanouissement automatique (cf

paragrap he ci-dessous). Ce mouvement doit être effectué en moins de 4 secondes, sur une hauteur de 5 à 10

mm. Puis fermer la valve de la torche pour arrêter le gaz après refroidissement de l'électrode.

Évanouissement automatique de l'arc à durée réglable

Activation de la fonction :

Cela correspond en fin de soudure au temps nécessaire pour la baisse progressive du courant de soudage jusqu’à

l’arrêt de l’arc. Cette fonction permet d’éviter les fissures et les cratères de fin de soudure.

Par défaut cette fonction n'est pas activée (OFF). Pour l'activer, procéder comme suit:

Page 5

5

1- Presser sur le sélecteur

2- Régler le temps d'évanouissement souhaité de 1 à 10 sec (afficheur ) grâce aux

touches

3- Valider la valeur souhaitée en pressant sur le sélecteur .

Combinaisons conseillées / affutage électrode

Courant (A)

∅

Electrode (mm)

= ∅ fil (métal d’apport)

∅

Buse

(mm)

Débit

(Argon l/mn)

0,5-5 10-130 1,6 9,8 6-7

4-10 130-250 2,4 11 7-8

Pour un fonctionnement optimal vous devez utiliser une électrode affûtée de la manière s uivante :

d

l

COMMANDE A DISTANCE

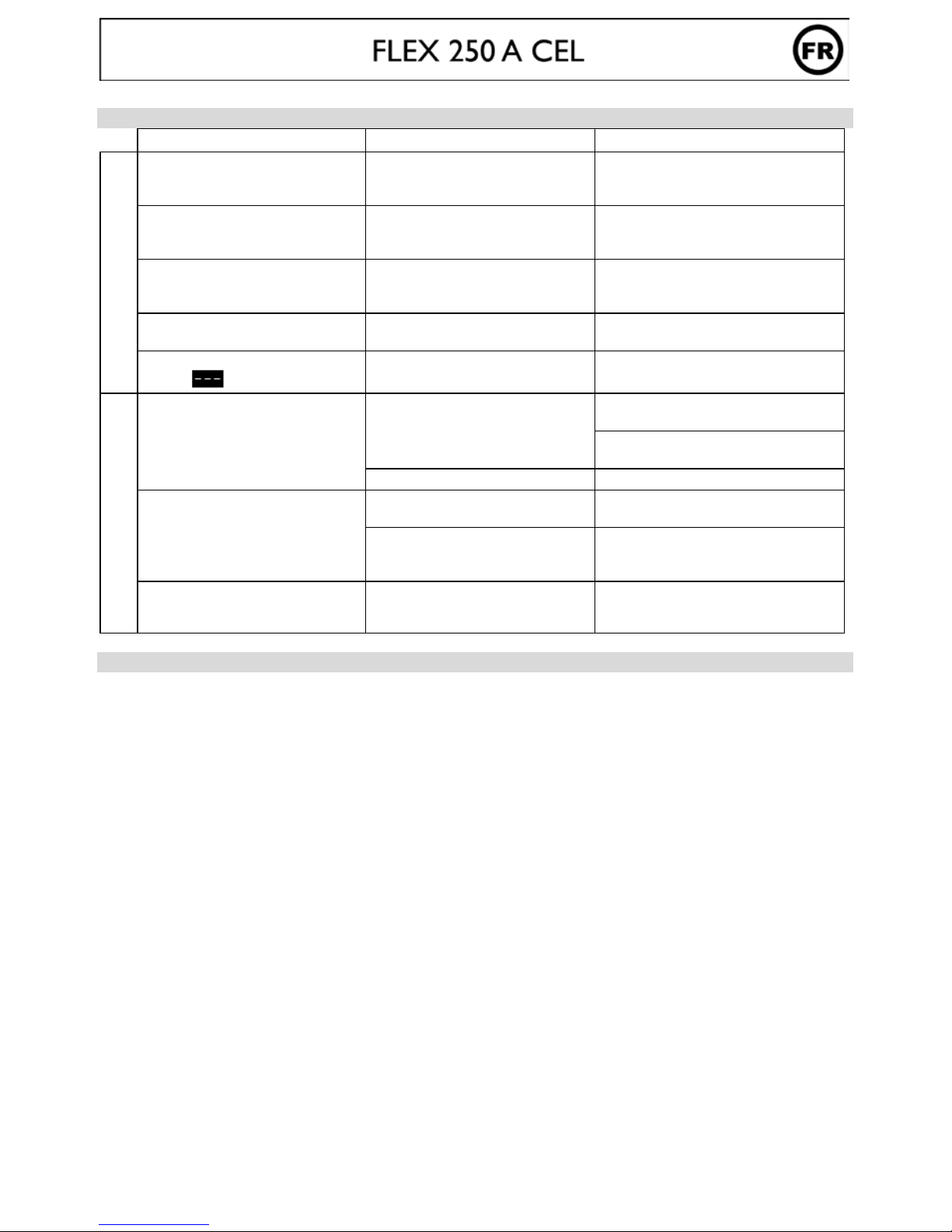

La commande à distance fonctionne en mode TIG et en MMA.

Connectique

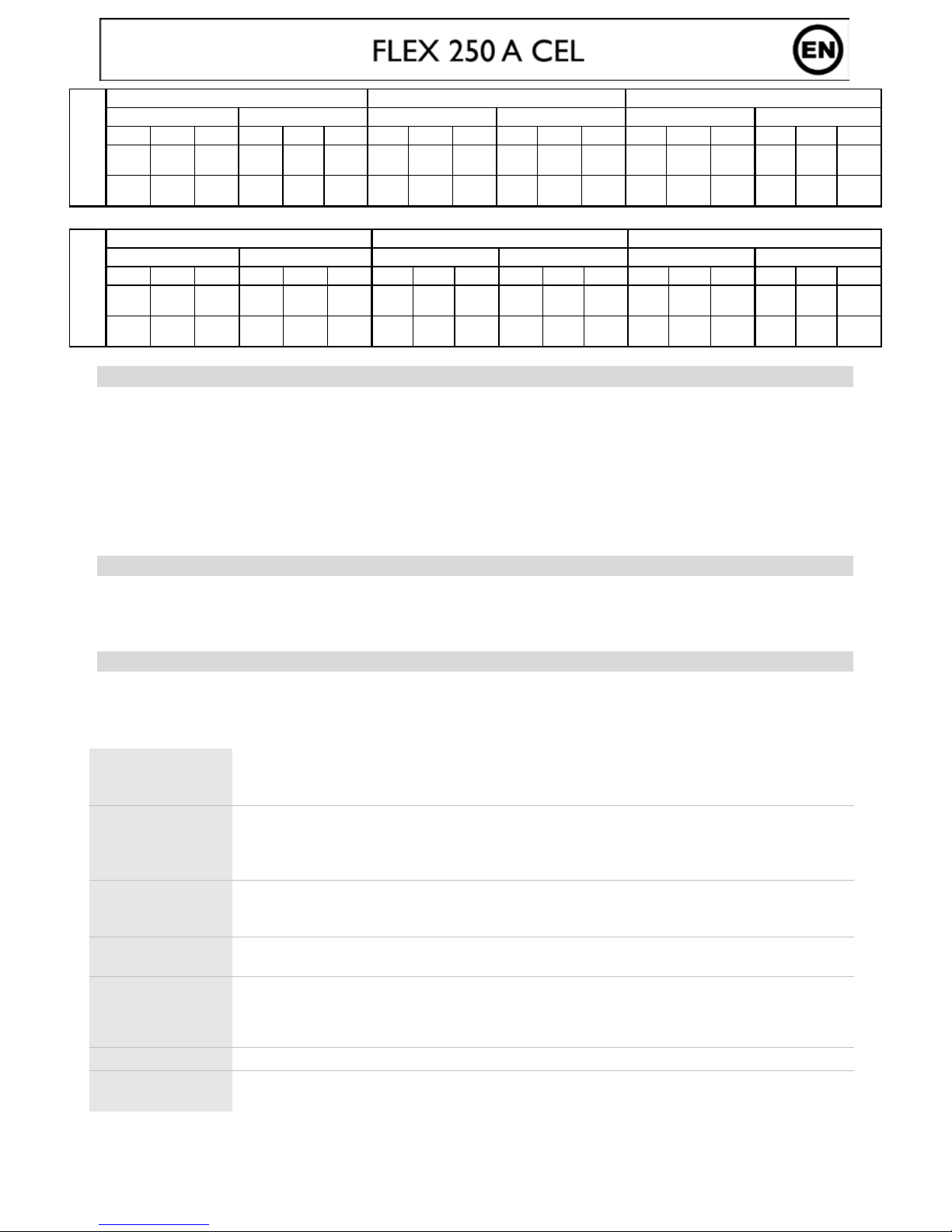

Le FLEX 250A CEL est équipé d’une prise femelle pour commande à distance. La prise mâle spécifique 7 points

(option ref. 045699) permet d’ y raccorder votre commande à distance manuelle (R C) ou à pédale (PEd).

Pour le câblage suivre le schéma ci-dessous.

Branchement

1- Allumer le poste

2- Brancher la pédale ou la télécommande sur la face avant de l’appareil.

3- L’afficheur clignote en affichant « No » (Rien),

4- Sélectionner votre type de commande à l’aide des touches :

No (Rien) « RC » (Remote Control/commande à distance) PEd (Pédale)

5- Après 2 secondes d’inactivité, l’afficheur se fige sur la valeur puis réaffiche l’intensité de soudage

Nb : En cas d’erreur, débrancher votre commande à distance, le poste vous indique que plus rien

n’est connecté : « No ». Puis rebrancher votre commande et refaites la sélection.

Remarque : Ce choix sera réafiché à chaque mise en route.

Fonctionnement

Commande à Distance.manuelle (opt ion ref. 045675) / Pédale (option ref. 045682)

La commande à distance manuelle permet de faire varier le courant de l’intensité mini (DC : 10A / MMA : 10) à

l’intensité définie par l’utilisateur (afficheur).

Dans cette configuration, tous les modes et fonctionnalités du poste sont acc essibles et paramétrables.

PROTECTION THERMIQUE ET FACTEURS DE MARCHE

• Protection thermique : le voyant s ’allume et la durée de refroidissement est de 1 à 5 mn en fonction de la

température ambiante.

• Laisser l’appareil branché après soudage pour permettre le refroidissement

• Le po ste dé crit a une caractéristique de sortie de type "courant consta nt". So n facteur de marche selon la norme

EN60974-1 est indiqué dans le tableau suivant :

L = 2,5 x d.

L

D : Contact du switch

C : Masse

B : Curseur

A : + 5V

Nb : la valeur du potentiomètre doit être de 10 KΩ

Ref.045699

Page 6

6

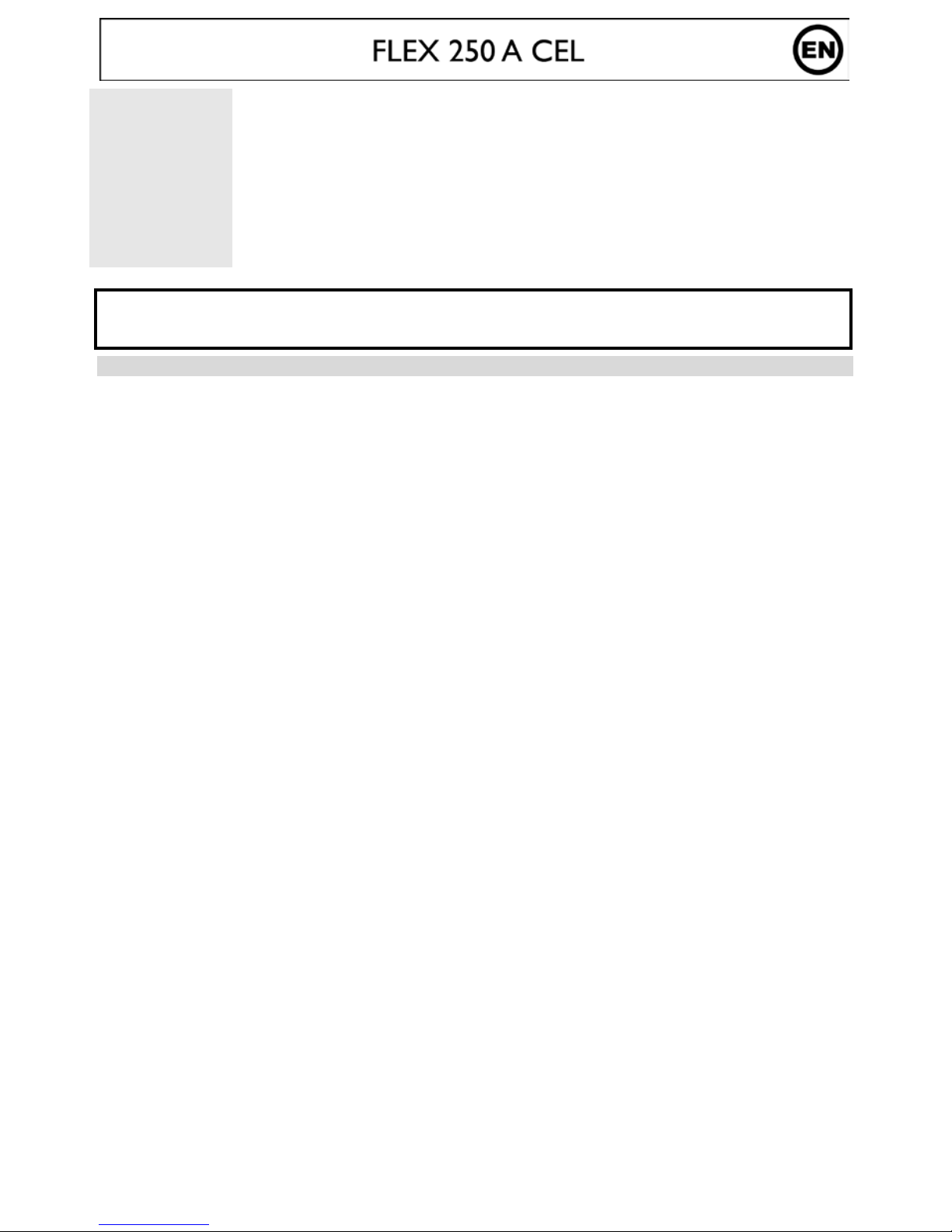

MMA

U1 = 110V U1 = 230V U1 = 400V

1~ 3~ 1~ 3~ 1~ 3~

30% 60% 100% 35% 60% 100% 41% 60% 100% 53% 60% 100% 40% 60% 100% 32% 60% 100%

140A 115A 90A 140A 125A 100A 200A 180A 150A 200A 190A 170A 250A 220A 190A 250A 200A 170A

25,6V 24,5V 23,6V 25,6V 25V 24V 28V 27,2V 26V 28V 27,6V 6,8V 30V 28,8V 27,6V 30V 28V 26,8V

TIG

U1 = 110V U1 = 230V U1 = 400V

1~ 3~ 1~ 3~ 1~ 3~

60% 60% 100% 100% 60% 100% 80% 60% 100% 100% 60% 100% 65% 60% 100% 43% 60% 100%

140A 140A 110A 140A 140A 140A 200A 200A 180A 200A 200A 200A 250A 250A 220A 250A 225A 180A

15,6V 15,6V 14,4V 15,6V 15,6V 15,6V 18V 18V 17,2V 18V 18V 18V 20V 20V 18,8V 20V 19V 17,2V

ENTRETIEN

• L'entretien ne doit être effectu é que par une personne qualifiée.

• Couper l'alime ntation en dé br a nchant la pr i se et atte ndr e l ’ arr êt du ve n tilateur avant de t ravailler s ur l'app are i l.

A l’intéri eur , les tensions et int ensités sont élevées et dangereuses.

• Deux à trois fois par an, enlever le capot et dépoussiérer à la soufflette. En p rofiter pour faire véri fier la tenue

des connexions électriques avec un outil isolé par un personnel qualifié.

• Contrôler régu lièrement l'état du c ordon d'al imentation. S i le câble d'aliment ation est e ndommagé, il doit êtr e

remplacé par le fabricant, son service après vente ou une personne de qualification similaire, afin d'éviter un

danger

CONSEILS

• Respecter les polarités (+/-) et intensités de soudage indiquées sur les boîtes d'électrodes

• Enlever l’électrode du porte-électrode lorsque le poste n'est pas utilisé.

• Laisser les ouïes de l'appareil libres pour l’entrée et la sortie d’air.

SÉCURITÉ

Le sou da ge à l'a rc p eut êtr e da ng er eux e t ca us er d es bl ess ur es gr av es v oir e m o rtel les . Prot ég ez v ou s

et protégez les autres.

Respecter les instructions de sécurité suivantes

:

Rayonnements

de l’arc

Protégez-vous à l’aide d’un masque muni de filtres conformes EN 169 ou EN 379.

Pluie, vapeur

d’eau, humidité

Utilisez votre poste dans une atmosphère propre (degré de pollution ≤ 3), à plat et à plus

d’un mètre de la pièce à souder. Ne pas utiliser sous la pluie ou la neige.

Choc électrique

Veiller à bien respecter les règles d’alimentation des postes citées au préala ble. Ne pas

toucher les pièces sous tension. Vérifier que le réseau d'alimentation est adapté au poste.

Chutes Ne pas faire transiter le poste au-dessus de personnes ou d’objets.

Brûlures

Porter des vêtem ents de travail en tis su ignifugé (coton, bleu ou jeans).

Travailler avec des gants de protection et un tablier ignifugé.

Protéger les autres en installant des paravents ininflammables, ou les prévenir de ne pas

regarder l'arc et garder des distances suffisantes.

Risques de feu

Supprimer tous les produits inflammables de l'espace de trav ail. Ne pas travailler en présence

de gaz inflammable.

Fumées

Ne pas inhaler les gaz et fumées de soudage. Utiliser dans un environnement correctement

ventilé, avec ex traction artifi c ielle si soudage en intérieur.

Précautions

supplémentaires

Toute opération de soudage :

- dans des lieux comportant des risques accrus de choc électriqu e,

- dans des lieux fermés,

- en présence de matériau inflammable ou comportant des risques d'explosion, doit toujours

être soumise à l'approbation préalable d'un "responsable expert", et effec tuée en présence

de personnes formées pour inter venir en cas d'urgence.

Les moyens tech niques de protections décrits dans la Spécification Technique CEI/IEC 62081

doivent être appliqués.

Le soudage en pos ition surélevée est interdit, sauf en cas d'u tilisation de plat es-formes de

sécurité.

Page 7

7

Les porteurs de stimulateurs cardiaques doivent consulter un médecin avant d'utiliser ces appareils.

Nous déconseillons toutefois l’utilisation de ces appareils par ces personnes.

Ne pas utiliser le poste pour dégeler des canalisations.

En soudage TIG, manipuler la bouteille de gaz avec précaution, des risques existent si la bouteille ou

la soupape de la bouteille sont endommagées.

RECOMMANDATION POUR RÉDUIRE LES ÉMISSIONS ÉLECTRO-MAGNÉTIQUES

Généralité

L’utilisateur e st res ponsab le de l’insta llatio n et de l’ut ilisa tion de l’app areil sui vant le s instruc tio ns du fabr icant. Si de s

perturbations électromagnétiques sont détectées, il est de la responsabilité de l’utilisateur de résoudre la situation

suivant les recommandations données dans la notice ou avec l’assistance technique du fabricant.

Evaluation de la zone de soudage

Avant d’insta ller l’appareil, l’utilis ateur devra é valuer les pro blèmes éle ctro-magné tiques potentie ls qui po urraient se

présenter dans la zone où est prévue l’installation, en particulier il devra tenir compte des indications suivantes :

a. Autres câblages, câblages de contrôle, câbles téléphoniques et de communication : au dessus, au

dessous et à côt é de l’appareil. ;

b. récepteurs et transmetteurs radio et télévision ;

c. ordinateurs et autres équipements de contrôle ;

d. équipements critiques pour la sécurité tels que les comma ndes de sécurité des équipements industriels ;

la santé des personnes qui se trouvent à proximité de la machine, par exemple des personnes qui portent un

simulateur cardiaque, un appareil auditif, etc… ;

e. équipements servant à calibrer et mesurer ;

f. l’immunité des autres appareils installés dans le local d’utilisation de l’appareil. L’utilisateur devra

s’assurer que les appareils du local sont compatibles entre eux. Ceci pourra de mander de prendre des

précaution s supplémentaires ;

g. le temps de la journée au cours de laquelle l’appareil devra fonction ner ;

h. la surface de la zone à prendre en considération autour de l’appareil dépendra de la structure des

édifices et des autres activités qui se déroulent sur le lieu. La zone considérée peut s’étendre au-delà des

limites des entreprises.

Recommandation sur les méthodes de réduction des émissions électro-magnétiques

a. Alimentation principale : Le poste de soudage devra être relié au réseau d’alimentation

conformément aux recommandations du fabricant. En cas d’interférences, il peut s’avérer utile de

prendre des précautions supplémentaires en filtrant la tension d’alimentation. Il peut s’avérer utile de

blinder le câble d’alimentation dans les installations fixes du poste de soudage, sous goulottes

métalliques ou dispositifs équivalents. Le blindage devrait être électriquement continu sur toute la

longueur du câble. Il devrait être relié au poste de soudage avec un bon contact électrique entre la

goulotte métallique et le boîtier du poste.

b. Câbles de soudage : Les câbles doivent être les plus courts possibles. Les regrouper et, si possible, les

laisser au sol.

c. Protecti on et blindage : La protection et le blindage sélectif d’autres câbles et matériels dans la zone

environnante peut limiter les pr oblèmes de perturbati on.

d. Mise à la terre de la pièce à souder : La mise à la terre de la pièce à souder peut limiter les

problèmes de perturbation. Elle peut être fait directement ou via un condensateur approprié. Ce choix est

fait en fonction des réglementations nationales.

Page 8

8

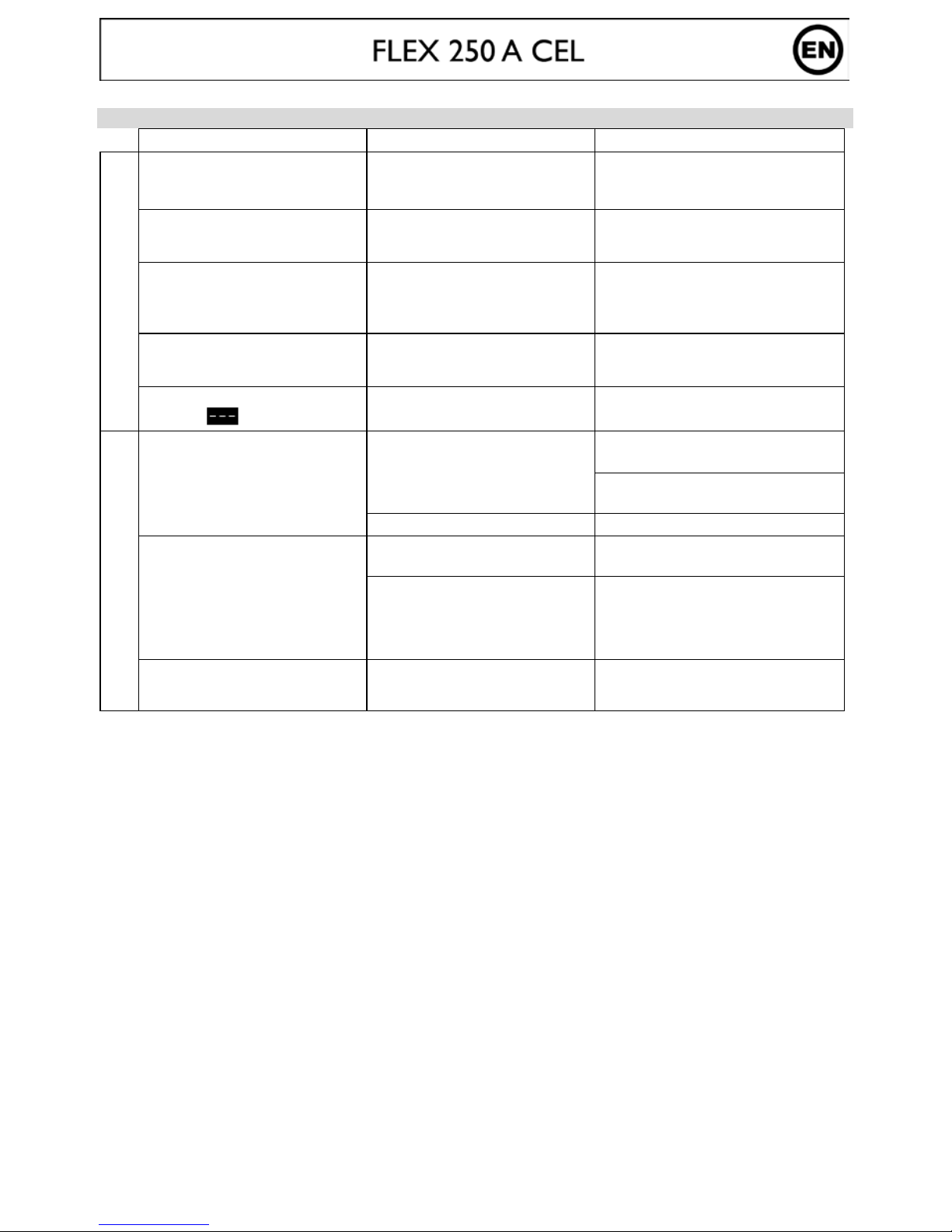

ANOMALIES, CAUSES, REMÈDES

Anomalies

Causes

Remèdes

MMA-TIG

L’appareil ne délivre pas d e courant

et le voyant jaune de protection

thermique est allumé .

La protection thermique du poste

s’est enclench ée .

Attendre la fin de la période de

refroidissement, environ 2 min. Le

voyant s’éteint.

L’afficheur est allu mé mai s

l’appareil ne délivre pas de courant.

Le câble de pince de masse ou

porte électrode n’est pas connecté

au poste.

Vérifier les branchements.

Le poste est alimenté, vous

ressentez des picotements en

posant la main sur la carrosser ie .

La mise à la terre est défectueus e.

Contrôler la prise et la terre de vo tre

installation.

Le poste soude mal Erreur de polarité

Vérifier la polarité co nseillée sur la

boîte d'électrode.

Lors de la mise en rou te, l’affic heur

indique

La tension d’alimentation est

supérieure à la limite (440V +1 5% )

Vérifier votre installation électrique ou

votre groupe électrogène

TIG

Arc instable

Défaut prove nant de l'électrode en

tungstène

Utiliser u ne électrode en tungstène de

taille appropriée

Utiliser une électrode en tungstène

correctement préparée

Débit de gaz trop important Réduire le débit de gaz

L'électrod e en tungst ène s'oxyd e et

se ternit en fin de soudage

Zone de soudage.

Protéger la z one de soud age cont re les

courants d'air.

Problème de gaz, ou coupure

prématurée du gaz

Contrôler et s erre r tou s le s rac cord s d e

gaz. Attendre que l'électrode

refroidisse avant de couper le gaz.

L'électrod e fond Erreur de polarité

Vérifier qu e la pin ce de masse es t bi en

reliée au +

CONDITIONS DE GARANTIE FRANCE

• La garan tie c o u vr e to ut défaut ou vic e de fabricat io n p endant 2 ans, à compter de la date d’achat (pièces et main

d’œuvre).

• La garantie ne couvre pas les erreurs de tension, incidents dus à un mauvais usage, chute, démontage ou toute

autre avarie due au transport.

• La garantie ne couvre pas l’usure normale des pièces (Ex. : câbles, pinces, etc.).

En cas de panne, retournez l’appareil à votre distributeur (port dû refusé), en y joignant :

- Le justificatif d’achat daté (facture, tickets de caisse…)

- Une note explicative de la panne.

Après la garantie, notre SAV assure les réparations après acceptation d’un devis.

Page 9

9

DESCRIPTION

Thank you for choosing our product! In order to take the most of your welder, please read the following

instructions carefully:

The FLEX 250 A CEL is a portable inverter welding machine, for e lectrode welding (MMA) and TIG Lift in DC. The

machine wel ds rutiles, basic, stainless steel, c ast iron and celulosic e lectrodes. In TIG, it welds mo st metals exc ept

aluminium and alloys. It is protected for use on generators.

POWER SUPPLY – START UP

• The FLEX 250 A CEL is a Flexible Voltage machine can be plugged into a mains s upply between 110V and 480V in

single or three phase (50 - 60 Hz). The absorb ed effec tive c urren t (I1eff ) is sho wn on the machi ne for m aximum

useage conditions. Check that the power supply and i ts protection (fuse amd/or circuit-breaker) are compatible

with the necessary current required for use.

Connection diagram

3

+

Connection to a 3 phase power supply

2

+

Connection to a single phase power supply

*WARNING ! Connection to a single phase plug, the unused wire must be isolated so that it

never comes into contact with the other wires.

• Turn on the machine by pressing ( )

• This machine is a A-class device. It is designed to be used in an industrial or professional environment. In

a different environment, it can be difficult to ensure electromagnetic compatibility, due to conducted

disturbances as well as radiation.

• The FLEX 250 A CEL features primary regulation, it is recommended to use the cables supplied with the

unit.

ELECTRODE WELDING (MMA MODE)

• Leave the machine connected to the supply after welding in order to let it cool down.

• Thermal protection : when the thermal protection is activated, the cooling time is about 2 to 5 min

depending on external temperature.

• Your machine is equipped with 3 functions :

Hot Start gives an adjustable* overcurrent at the beginning of welding.

Arc Force delivers an overcurrent which avoids sticking when the electrode enters the

welding pool.

Anti-Sticking allows easy removal of the electrode in case of sticking.

Selection of MMA Mode and intensity setting :

- Select the MMA position with the selector.

- Adjust the desired current (display ) using the key .

1- phase 1

2- phase 2

3- phase 3

4- Earth

1- phase 1

2- phase 2 ou neutre

3- Earth

Page 10

10

Hot Start & Arc Force adjustments:

FLEX 250 A CEL

Hot Start 0 90%

Arc Force 0 90%, or type of electrode

Adjust the Arc Force from 0 to 90%, then switch to electrode mode « rut », « bas » or « cel ». These modes

are optimum settings for each different types of electrode.

Advice :

low Hot Start : for thin metal sheets

high Hot Start for metals that are difficult to weld (dirty or oxidized pieces)

To adjust the Hot Start and Arc Force, go through the following steps.

Press button

Set the required Hot Start percentage (display ) using button

Validate the required figure by pressing the button

Set the required Arc Force percentage (display ) using key .

Validate the required figure by pressing the selector button.

TIG LIFT

DC TIG welding requires protective gas (argon).

Follow the steps below :

1. Connect the earth clamp to the positive socket (+).

2. Connect a torch to the negative socket (-).

3. Connect the gas pipe from the torch to the gas cylinder

4. Select TIG mode using the selection button .

5. Adjust the desired current (display ) using the key .

Advice : Take 30A/mm as a default setting and adjust according to the welding workpiece.

6. Set the gas flow on the flowmeter of the gas cylinder, and then open the valve of the torch

7. To st art :

a- Touch the workpiece with

the electrode

b-

Raise the electrode from

2 to 5 mm from the

workpiece

8. At end of welding :

Raise the torch 2 times in quick succession(raise-lower-raise-lower) to trigger the automatic downslope

(see section below). This movement must be performed in less than 4 sec, at a height of 5 to 10 mm.

Then close the valve of the torch to stop the gas after the electrode has cooled.

Automatic Arc slope with adjustable time

Function activation :

This corresponds to the time required at the end of welding for the gradual decline in the welding current

until the arc stops. This function helps to avoid cracks and craters at end of welding.

Page 11

11

1- Press button for 3 seconds

2. Set the automatic arc slope from 1 to 10 sec (display) using key.

3. Validate the required figue by pressing button .

Recommended combinations / Electrode grinding

Current (A)

Ø Electrode (mm)

= Ø wire (filler metal)

Ø Nozzle

(mm)

Flow rate

(Argon L/mn)

0,5-5 10-130 1.6 9.8 6-7

4-8

130-200

2.4

11

7-8

To optimise the weld, use an electrode ground as below :

d

l

REMOTE CONTROL

The remote control operates in TIG and MMA mode.

Connector technology

The FLEX 250A CEL is equipped with a female socket for remote control. The specific 7 poi nt male plug (product

ref.045699) enables connection to a manual remote control (RC) or foot pedal (PEd).

For the cabling layout, see the diagram below.

Connecting

1- Power up the machine

2- Plug the pedal/remote control to the connecting socket on the machine.

3- The screen will flash and display « No » (Nothing),

4- Select the type of control using keys :

« No » (Nothing) / « RC » (Remote Control) / « PEd » (Pedal)

5- After 2 seconds the display will freeze on the chosen selection, then displays the welding current.

NB: In case of error, unplug the remote control, (« No » will be displayed) and re-start the connection process.

Remark: Remote type choice will be required each time the machine is powered up.

Functions

Manual remote control (ref.045675) / Pedal (ref.045682):

The remote control enables the variation of current from mi nimum inte nsity ( DC: 10A / M MA: 10A ) to an i ntensity

defined by the user.

In this configuration, all modes and functions of the machine are accessible and can be set.

THERMAL PROTECTION & DUTY CYCLE

• Thermal protection : when thermal protection is activated, cooling time is about 2 to 5 min depending on

external temperature.

• Leave the machine connected to the supply after welding in order to let it cool down.

• The welding unit describes an output characteristic of "constant current" type. The duty cycles following

the norm EN60974-1 (at 40°C on a 10mn cycle) are indicated in the table here below :

L = 2.5 x d.

L

D: Switch contact

C: Earth

B: Cursor

A: + 5V

Nb: The Potenti om eter value must be 10 KΩ

Ref.045699

Page 12

12

MMA

U1 = 110V U1 = 230V U1 = 400V

1~ 3~ 1~ 3~ 1~ 3~

30% 60% 100% 35% 60% 100% 41% 60% 100% 53% 60% 100% 40% 60% 100% 32% 60% 100%

140A 115A 90A 140A 125A 100A 200A 180A 150A 200A 190A 170A 250A 220A 190A 250A 200A 170A

25,6V 24,5V 23,6V 25,6V 25V 24V 28V 27,2V 26V 28V 27,6V 6,8V 30V 28,8V 27,6V 30V 28V 26,8V

TIG

U1 = 110V U1 = 230V U1 = 400V

1~ 3~ 1~ 3~ 1~ 3~

60% 60% 100% 100% 60% 100% 80% 60% 100% 100% 60% 100% 65% 60% 100% 43% 60% 100%

140A 140A 110A 140A 140A 140A 200A 200A 180A 200A 200A 200A 250A 250A 220A 250A 225A 180A

15,6V 15,6V 14,4V 15,6V 15,6V 15,6V 18V 18V 17,2V 18V 18V 18V 20V 20V 18,8V 20V 19V 17,2V

MAINTENANCE

• Maintenance should only be carried out by a qualified person.

• Ensure the machine is unplugged, and that the ventilator inside has stopped before carrying out

maintenance work. (DANGER High Voltage and Currents).

• JBDC recommends removing the steel cover 2 or 3 times a year to remove any excess dust. Take this

opportunity to have the electrical connections checked by a qualified person with an insulated tool.

• Regularly check the condition of the power supply cord. If damaged, it will need to be replaced by the

manufacturer, its after sales service or a qualified person.

• Ensure the ventilation holes of the device are not blocked to allow adequate air circulation.

ADVICE

• Follow welding polarities and currents indicated on the electrode packaging

• Remove the electrode from the electrode holder when not in use.

• Ensure the ventilation holes of the device are not blocked to allow adequate air circulation.

SAFETY

Arc welding can be dangerous and can cause serious and even fatal injuries.

Protect yourse lf and others .

Ensure the following safety precautions are taken:

Arc radiation

Protect yourself with a helmet fitted with filters in compliance with EN169 or EN

379

Rain, steam,

humidity

Use your welding unit in a clean/dry environment (pollution factor ≤ 3), on a flat

surface, and more than one meter from the welding work-piece. Do not use in rain

or snow.

Electric shock

This device must only be used with an earthed power supply. Do not touch the

parts under high voltage. Check that the power supply is suitable for this unit.

Falls

Do not underestimate the weight of the apparatus. Do not move the unit over people or

objects . Do not drop it. Do not set it down heavily.

Burns

Wear protective or fire-proof clothing (overalls, jeans).

Use welder gloves and a fire-proof apron.

Protect the others by installing non flammable protection wall, or prevent the others

from looking at the arc and have them keep a sufficient distance

Fire risks

Avoid all flammable products in the working area. Do not work near flammable gas.

Fumes

Do not inhale welding gases and fumes. Use the device in a well ventilated

environment, with artificial extraction if welding indoors

Page 13

13

Additional

Precautions

Any welding operation undertaken in.....

- rooms where there is an increased risk of electric shocks,

- Poorly ventilated rooms,

- In the presence of flammable or explosiv e m aterial,

......should always be approved by a "responsible expert" , and made in presence of

people trained to intervene in case of emergency.

Technical protection as described in the Technical Specification CEI/IEC 62081

must be implem ented.

Welding in raised positions is forbidden, except in case of safety platforms use.

People wearing Pacemakers are advised to see their doctor before using this device.

Do not use the welding unit to unfreeze pipes.

Handle gas bottles with care - there is increased danger if the bottle or its valve are damaged.

RECOMMENDATION TO REDUCE ELECTRO-MAGNETIC EMISSIONS

General

The user is re sponsible for instal ling and using the w elding equipment acc ording to manuf acturer’s instruc tions. If

electromagnetic disturbances are detected, then it shall be the responsibility of the user of the welding equipmen t to

resolve the situation with the technical assistance of the manufacturer.

Evaluation of the welding area

Before installing welding equipment the user shall make an assessment of potential electromagnetic problems in the

surrounding area

a. Other wiring, power cables, telephones and communication cable s; above, below and adjacent to the

welding machine

b. Radio and television transmitters and receivers

c. Computer and other control equipm ent

d. Equipment critical for safety purposes such as safety checks of industrial equipment

e. The health of people in the vincity, for example people wearing pace m ake r s a nd h e aring aids

f. Equipment used for calibration or measurements

g. The af fects on other equip ment in the room. The user must ensure that other equipmen t used in the

same vicinity is compatible. This may require additional protection measures;

h. The time of day when welding or other activities are carried out

i. The size of the area to be considered will depend on the structure of the building and any other

processes in the area. The surrounding area may extend beyond the boundaries of the buildings.

Recommendation to reduce electro-magnetic emission

a. Mains power supply: the equipment must be plugged to the power mains as specified in the

Manufacturer’s instructions. If interference occurs, additional measures such as filtering of the mains

supply may be required. It may be us eful to s hie ld the supply cable for perma nent ins tall atio ns may h ave

to be shielded in metal co nduits or s imilar.T he shielding s hould be contino us for the entire lengh o f the

cable. It should als o be connec t to the we lding mach ine wi th secure electrical contact between the metal

conduit and the casing.

b. Welding cables: The welding cables should be kept as short as pos sible and sho uld be positio ned clo se

together, running at or close to floor level.

c. Protection and reinforcement: Selective screening and sh ielding of other cables and equipment in the

surrounding area may alleviate problems of interference. Shielding of the entire welding area may be

considered for special applications

d. Connect the earth directly to the workpiece to be welded: Where necessary, the connection of

the workpiece t o earth should be made by a direct connection to the w orkpiece, but in some countries

where direct connection is not permitted, the bonding should be achieved by suitable capacitance,

selected according to national regulations.

Page 14

14

TROUBLESHOOTING

Anomalies

Causes

Remedies

MMA-TIG

The device does not deliver any

current and the yellow indicator

thermal default light

is on.

Thermal protection is active.

Wait for the end of the cooling

period, approx 2 minutes. The

indicator light turns off.

The display is on but the device

does not deliver any current.

The earth clam p or electrode

holder is not properly connected

to the unit.

Check the connections.

If, when the unit is on and you

put your hand on the welding

unit’s body, you feel tingling

sensation.

The welding unit is not correctly

connected to the earth.

Check the plug and the earth of

your electrical network.

The display is on but the device

does not deliver any current.

The cable of the earth clamp or

electrode hol der is not connected

to the welder.

Check the connections.

When starting up, the display

indicates .

The voltage is over the limit

440V +15%.

Have the electrical installation

checked.

TIG

Unstable arc.

Failure of the tungsten electrode.

Ensure the correct size of electrode

is being used.

Use a well prepared tungsten

electrode

Too important gas flow rate.

Reduce gas flow rate.

The

tungsten electrode oxidizes

and tarn

ishes at the end of the

weld.

Welding zone.

Protect welding zone against air

flow.

Fault coming from post-gas or

the gas has been stopped

prematurely.

Check and tighten all gas

connections . W ai t un til the elec trode

cools down before stopping the gas.

The electrode melts.

Polarity error.

Check that the earth c lamp is really

connected to +.

Page 15

15

BEZEICHNUNG

Wir freuen uns, dass Sie sich für ein Markengerät unserer Firma entschieden haben und danken Ihnen für das

entgegengebrachte Vertrauen. Bitte lesen Sie sorgfältig vor dem Erstgebrauch diese Betriebsanleitung .

Das FLEX 250A CEL ist ein tragbares, luftgekühltes Schweißinverter, konzipiert um Schweißarbeiten an

ummantelten- (MMA) und hitzebeständigen (WIG Lift) Elektroden bei Gleich strom (DC) durchführe n zu könne n. Im

MMA Modus k önnen alle gäng igen Rutil-, Edelstahl-, Guss-, basischen und zellulosehaltigen. Im WIG Modus ist es

möglich die meisten Metalle mit Ausnahme von Legierungen und Aluminium zu schweißen. Dieses Gerät ist

generatortauglich und gegen Überspannung geschützt.

ANSCHLUSS - INBETRIEBNAHME

• Das FLEX 250 A CEL ist ein mit « flexible Voltage » ausgestattetes Gerät, dass mit Netzspannungen zwischen

110V und 480V, einphasig oder dreiphasig (50-60 Hz), betrieben w erden ka nn. Die tats ächliche S tromaufna hme

(l1eff) ist auf dem Gerät als maximale Betriebsbedingung angegeben. Überprüfen Sie, dass die Netzspannung und

die Absicherung (Sicherung) kompatibel für die Anwendung des Gerätes ist.

Anschlussdiagramm

3

+

Dreiphasiger Anschluss

2

+

Einphasiger Anschluss

Dem Gerät liegt ein Adapter für den Anschluss an eine einphasige Versorgung bei. Dieser darf

AUSCHLIESSLICH zu diesem Zweck verwendet werden! Bitte beachten Sie die geänderten

Leistungsdaten bei einphasigem Anschluss.

• Zum Starten drücken Sie die ( )

• Dieses Gerät ist K lasse A und ist für den industriellen und/ oder professionellen Gebrauch geeignet. In einem

anderen Umfeld ist die elektromagnetische Verträglichkeit schwieriger zu gewährleisten. Verwenden Sie das Gerät

nicht in Räumen, in denen sich in der Luft metallische Staubpartikel befinden, die Elektrizität leiten können.

• Das FLEX 250A CEL v erfügt über Einste llmöglichkeite n in Bezug auf den Netzansc hluss. Es wird e mpfohlen die

mitgelieferten Kabel zu verwenden

SCHWEISSEN MIT UMHÜLLTEN ELEKTRODEN (MMA MODUS)

• Schließen Sie Elektroden- und Massekabel an die entsprechenden Anschlüsse an. Beachten Sie die auf der

Elektrodenpackung beschriebenen Polaritätsangaben

• Beachten Sie die allgemeinen Regeln zur Unfallprävention beim Schweißen

• Ihr Schweißgerät ist mit drei spezif ischen Funktionen zur Verbesserung der Schweißeigenschaften au sgerüstet:

Hot Start (einstellbar, s. nachfolgender Abschnitt): Erhöht den Schweißstrom beim Zünden der

Elektrode

Arc Force (einstellbar, s. nachfolgend er Abschnitt): Erhöht kurzz eitig den Sc hweißstrom. E in mögliches

Festbrennen (Sticking) der Elektrode am Werkstück während des Eintauchens ins

Schweißbad wird verhindert.

Anti Sticking: Verbessert den Einbrand und verhindert mögliches Festbrennen

Auswahl der Betriebsart und Stromstärke:

- Wählen Sie mit der Drucktaste den MMA Modus aus

1- phase 1

2- phase 2

3- phase 3

4- Erde

1- phase 1

2- phase 2 ou neutre

3- Erde

Page 16

16

- Wählen Sie mit der Drucktaste die gewünschte Stromstärke (Anzeige ) aus

Konfiguration Hot Start und Arc Force:

FLEX 250 A CEL

Hot Start

0 90%

Arc Force

0 90% oder Elektrod entyp

Justieren Sie den Arc-Force von 0 bis 90 %, dann schalten Sie auf E letroden Modus « rut », « bas » oder « cel ».

Diese Modi sind optimierte Einstellungen für die verschiedenen Elektrodentypen.

Hinweis:

Niedriger Hot Start für dünne Metallbleche;

hoher Hot Start für schwer zu schweißende Metalle mit verschmutzen oder oxidierten Stellen.

Um Hot Start und Arc Force einzustellen, gehen Sie wie folgt vor:

Drücken Sie 3 Sek. lang die Taste

Stellen Sie den gewünschten Prozentsatz (Anzeige) mithilfe der Taste ein

Bestätigen Sie die gewünschte Einstellung mit der Taste

Stellen Sie den gewünschten Prozentsatz (Anzeige) mit Taste ein

Bestätigen Sie die gewünschte Einstellung mit der Taste

WIG KONTAKTZÜNDUNG

Verwenden Sie b eim WIG DC- Schweißen Argon- Schutzgas.

Um im WIG Modus zu sc hweißen, gehen Sie bitte wie folgt vor:

1. Schließen Sie die Massek lemme an der (+) Schweiß buchse an

Schließen Sie einen Brenner mit Ventil an der (-) Buchse an

2. Verbinden Sie die Brennergasleitung über den Druckminderer direkt an der Gasflasche.

Trennen Sie Überwurfmutte r und Flansch vo n der Brennerg asleitung, wenn diese nicht auf d en Druckmindere r

passen und fixieren Sie die Ga sleitung direkt am Gasnippel des Manometers

3. Wählen Sie mithilfe des Drucktasters den WIG Modus an

4. Stellen Sie den gewünschten Schweißstrom (Anzeige ) mithilfe des Drucktasters ein

5. Gehen Sie danach wie folgt vor:

a- Werkstück mit der

electrode berührer und

Brennertaster

b-

Brenner 2 bis 5mm über

dem Werkstück anheben

6. Zum Schweiße nd e :

Heben Sie den Brenner zwei Mal (auf-ab-auf-ab), um die Funktion „Automatisches Stromabsenken“ (s.

nachfolgender Abschnitt) zu aktivieren. Führen Sie diese Bewegung innerhalb von 4 Sek. 5-10mm über dem

Werkstück aus und schließen Sie das Gasventil erst, wenn der Lichtbogen erloschen ist und die Elektrode sich

abgekühl t ha t.

Automatische Stromabsenkfunktion mit Zeiteinstellung

Start der Funktion:

Am Ende des Schweißprozesses wird der Strom in definierter Zeit stufenlos heruntergefahren.

Diese Funktion hilft, Sprünge und Krater am Ende der Schweißnaht zu vermeiden.

Diese Funktio n ist zunächst inaktiv (Zeit 0 Sek.). Um sie zu aktivieren, gehen Sie bitte wie

folgt vor:

Page 17

17

1- Drücken Sie 3 Sek. lang die Taste

2- Stellen Sie die gewünschte Absenkzeit zwischen 1 und 10 Sek.

(Anzeige ) mit der Taste ein

3- Betästigen Sie die Gewünschte Einstellung mit der Taste

Empfohlene Schweißeinstellungen/ Elektrode schleifen

Strom (A)

Ø Elektrode (mm)

= Ø Zusatzdraht

Ø Düse

(mm)

Gasströmung

(Argon l/min)

0,5-5 10-130 1,6 9,8 6-7

4-8 130-200 2,4 11 7-8

Um einen optim alen Schweißverlauf zu gewährleisten, nutzen Sie nur Elektroden, welche nach folgendem Vorbild

geschliffen wurden:

d

l

ANSCHLUSS FÜR FERNSTEUERUNG

Die Fernregelung funktioniert im WIG- und im E-Hand-Modus.

Das FLEX 250A CEL verfügt über einen Anschl uss für eine Fernregel ung. Der passende 7-polige Stecker (Zubehör

Art.-Nr. 045699) ermöglicht Ihnen den Anschluss einer Fernbedienung (RC) oder Fußfernregelung (PED).

Verkabelung siehe Zeichnung:

Anschluss:

1- Gerät ansc halten

2- Fussfernreglung oder Handfernbedienung an das Gerät anschliessen

3- Die digitale Anzeige zeigt « NO » an

4- Mit den Tasten wählen Sie den Typ der Fernsteuerung aus:

No « RC » (Handfernbedienung / Remote Control) PEd (Fussfe r ns te ue rung)

5- Nach 2 Sekunden blinkt die digi tale Anzeige nicht mehr. Die Stromstärke in A m pere wird angezeigt.

Im Falle eines Fehlers die Fernsteuerung trennen. Mit „No“ zeigt das Gerät an, dass nichts angeschlossen ist.

Bemerkung: Diese Anzeige erscheint bei jedem Neu st art

Fernsteuerungsbetrieb

Hand Fernbedienung (Zubehör Art.-Nr. 045675) / Fussfernregler (Zubehör Art.-Nr. 045682) :

Die Fernbedienung ermöglicht die Fernsteuerung des Schweißstroms ab der minimalen Stromstärke (DC: 10 A /

MMA: 10A) bis zu d er durc h den Anw ende r eing estell ten max imale n Stro mstä rke . In die ser Einste llung si nd alle Modi

und Funktionen des Gerätes verfügbar und können reguliert werden.

THERMISCHE ÜBERWACHUNG & EINSCHALTDAUER

• Thermischer Überlastschutz: Lassen Sie das Gerät sich- je nach Umge bungs tempe ratur- 1 bis 5 min abkü hlen, bis

die Kontrollanzeige erlischt

• Lassen Sie das Gerät auch nach Schweißende einige Zeit am Stromnetz angeschlossen, damit sich das abkühlen

kann

Die JBDC-Schweißgeräte entsprechen in ihrer Charakteristik einer Konstantstromquelle. Die Einschaltd aue r entspric h t

wie unten beschrieben der Norm EN60974-1 (bei 40°C und einem 10min Zyklus):

L = 2,5 x d.

L

D: Start/Stop Kontakt

C: Masse

B: Regelung

A: + 5V

NB: Der Wert des Poti muss 10 KΩ sein

Ref.045699

Page 18

18

MMA

U1 = 110V U1 = 230V U1 = 400V

1~ 3~ 1~ 3~ 1~ 3~

30% 60% 100% 35% 60% 100% 41% 60% 100% 53% 60% 100% 40% 60% 100% 32% 60% 100%

140A 115A 90A 140A 125A 100A 200A 180A 150A 200A 190A 170A 250A 220A 190A 250A 200A 170A

25,6V 24,5V 23,6V 25,6V 25V 24V 28V 27,2V 26V 28V 27,6V 6,8V 30V 28,8V 27,6V 30V 28V 26,8V

TIG

U1 = 110V

U1 = 230V

U1 = 400V

1~

3~

1~

3~

1~

3~

60%

60%

100%

100%

60%

100%

80%

60%

100%

100%

60%

100%

65%

60%

100%

43%

60%

100%

140A 140A 110A 140A 140A 140A 200A 200A 180A 200A 200A 200A 250A 250A 220A 250A 225A 180A

15,6V 15,6V 14,4V 15,6V 15,6V 15,6V 18V 18V 17,2V 18V 18V 18V 20V 20V 18,8V 20V 19V 17,2V

INSTANDHALTUNG

• Die Instandhaltungsarbeiten dürfen nur von qualifiziertem Fachpersonal durchgeführt werden

• Nehmen Sie regelmäßig (mindestens 2 bis 3 Mal im Jahr) das Gehäuse ab und reinigen Sie das Innere des

Gerätes mit Pressluft. Lassen Sie regelmäßig Prüfungen des Geräts auf seine elektrische Betriebssicherheit von

qualifizier te m Fachperson al d urchführe n

• Trennen Sie vor dem Öffnen des Gerätes die Stromversorgung zum Gerät und warten Sie, bis der Ventilator sich

nicht mehr dreht. Im Gerät sind die Spannungen sehr hoch und deshalb ge fä h rl ich

• Prüfen Sie regelmäßig den Zustand der Netzzuleitung. Wenn diese beschädigt ist, muss sie durch den Hersteller,

seinen Reparaturservice oder eine qualifizierte P erson ausgetauscht werd en, um Gefahren zu vermeid en

• Verdecken Sie nicht die Lüftungsschlitze

HINWEISE - EMPFEHLUNGEN

• Beachten Sie die Angaben auf der Elektrodenverpackung für Schweißstrom und Polari tät.

• Entfernen Sie nach dem Schweißprozess d ie Elektrode aus ih rem Halter.

• Führen Sie regelmäßig die Wartungsarbeiten durch.

UNFALLPRÄVENTION

Lichtbogenschweißen kann gefährlich sein und zu schweren - unter Umständen auch tödlichen Verletzungen führen. Schützen Sie daher sich selbst und andere . Beachten Sie unbedingt die f olge nden

Sicherheitshinweise:

Lichtbogenstrahlung

Gesichtshaut und Augen sind durch ausreichend dimensionierte EN 175 konforme

Schutzschirme mit Spezialschutzgläsern nach EN 169 / 379 vor der intensiven

Ultraviolettstrahlung zu schützen.

Auch in der Nähe des Lichtbogens befindliche Personen oder Helfer müssen auf

Gefahren hingewiesen und mit den nötigen Schutzmitteln ausgerüstet werden.

Umgebung

Benutzen Sie da s Gerät nur in sauberer und gegen Nässeeinwirkung geschützter

Umgebung.

Feuchtigkeit

Stromversorgung

Achten Sie auf den Stromanschluss der jeweiligen Geräte. Keine Spannungsführenden

Teile berühren.

Transport

Unterschätzen Sie nicht das Gewicht der Anlage. Bewegen Sie das Gerät nicht

über Personen oder Sachen hinweg, und lassen Sie es nicht herunterfallen oder

hart aufse tz e n.

Verbrennungsgefahr

Schützen Sie sich durch geeignete trockene Schweißerkleidung (Schürze, Handschuhe,

Kopfbedeckung sowie feste Schuhe). Tragen Sie auch die Schutzbrille, wenn Sie

Schlacke abk lopfen. Sc hützen Sie a ndere dur ch nicht entz ündbare T rennwänd e. Nicht

in den Lichtbogen schauen und ausreichende Distanz halten.

Brandgefahr

Entfernen Sie alle ent flammbar en Prod ukte vom Schweiß platz un d arbeite n Sie nicht in

der Nähe von brennbaren Stoffen und Gasen

Schweißrauch

Die beim Schweißen entstehenden Gase u nd der Rauch sind gesundheitsschädlic h. De r

Arbeitsplatz sollte daher gut belüftet sein und der entstehende Rauch und die Ga se

müssen abgesaugt werden.

Page 19

19

Weitere Hinweise

Führen Sie Schweißarbeiten

-in Bereichen mit erhöhten elektrischen Risiken,

-in abgeschlo ss e ne n Rä um e n,

-in der Umgebung von entflammbaren oder explosiven Produkten

nur in Anwesenheit von qualifiziertem Rettungs- und/oder Fachpersonal durch. Treffen

Sie Vorsichtsmaßnahmen in Übereinstimmung mit "IEC 62081". Schweißarbeiten an

Gegenständen in erhöhter Position dürfen nur auf professionell aufgebauten Gerüsten

durchgeführt werden.

Halten Sie beim Arbeiten ausreichend Abstand zu Personen mit Herzschrittmacher! Personen mit

Herzschrittmacher dürfen mit dem Gerät nicht ohne ä rztliche Zustimmung arbeiten!

Das Gerät ist nicht geeignet für das Auftauen von Leitungen! Achten Sie beim Umgang mit Gasflaschen auf

sicheren Stand und Schutz des Flaschenventils! Beschädigte Flaschen stellen ein Sicherheitsrisiko dar!

HINWEISE ZUR REDUZIERUNG VON ELEKTROMAGNETISCHEN STÖRUNGEN

Allgemein

Es liegt in der Ver antwortung des Anwend ers dafür Sorge zu tragen, dass die Schweißausrüstung nach den Vorgaben

des Herstellers angeschlossen und verwendet wird. Liegen elektromagnetische Störungen vor, ist der Anwender

dafür verantwortlich dieses Problem mithilfe des technisc hen Supports des Herstellers zu beheben.

Prüfung des Schweißbereiches

Prüfen Sie vor Anschluss der Schweißausrüstung die Arbeits umgebung auf potentielle elektromagnetische Probleme.

a. Allgemeine Verkabelung, Steuerkabel, Fernmeldekabel und Datenleitungen über, unter und in direkter Nähe

des Schweißgerätes;

b. Radio/ TV Sende- und Empfangsgeräte;;

c. Computer und andere Kontrollgeräte;;

d. Empfindliche Anlagen für bspw. Sicherheitsüberprüfungen von industrieller Ausrüstung;

e. Gesundheitszustand (Herzschrittmache r, Hörgerät, usw.) der sich in der Umgebung des Gerätes befindlichen

Personen;

f. Geräte zum Kalibrieren und Messen;;

g. Unempfindlichkeit anderer externer Ausrüstung in der Nähe des Gerätes. Dies kann zusätzliche

Sicherheitsmaßnahmen erfodern.;

h. Tageszeit, zu der Schweiß- und andere Arbeiten durchgeführt w erden sollen;;

i. Berücksichtigung der Geräteumgebung, in Abhängigkeit der Gebäudestruktur und anderer Vorgänge am

Arbeitsplatz. Diese Umgebungsgrenze kann sich auch über die Grundstücksgrenzen erstrecken.

Hinweise zu den Methoden zur Reduzierung von elektromagnetischen Störungen

a. Hauptstromversorgung: Die Schweißausrüstung muss nach Herstellerangeben angeschlossen werden.

Treten Störungen auf, sind eventuell weitere Sicherheitsmaßnahmen, wie die Filterung der

Versorgungsspannung, notwe ndig.

b. Schweißkabel: Die Schweißkabel sollten so kurz wie möglich gehalten werden und gemeinsam auf bzw.

möglichst nahe am Bodenbereich verlaufen.

c. Schutz und Verstärkung: Selektiver Schutz und Abschirmung von anderen Kabeln und Geräten in der

Umgebung kann Störungsprobleme verringern. Das Maschinennetzkabel muss eventl. abgeschirmt werden. Die

Abschrirm ung muss der ge s amte n Kabellänge e nts pr e chen. Achten Sie darauf, dass das Schweißgerätegehäuse

extra geerdet ist.

d. Erdung des Werkstückes: Die Erdung des zu verschweißenden Werkstücks kann eventuelle

Störungsprobleme verringern. Sie sollte direkt bzw. über einen entsprechenden Kondensator erfolgen, je nach

landesspezifischen Vorgaben.

Page 20

20

FEHLERSUCHE

Fehler

Ursache

Lösungen

MMA-TIG

Das Gerät l iefert kein en

Schweißstrom und die gelbe

Übertemperaturanzeige leuchtet.

Der Übertemperaturschutz wurde

ausgelöst.

Warten Sie ca. 2 min bis der

Kühlvorgang abgeschlossen ist. Die

Anzeige erlischt danach.

Die Anzeige ist an, das Gerät liefert

jedoch keinen Schweißs trom.

Masseklem me ode r

Elektrodenhalter- Kabel sind nicht

korrekt mit dem Gerät verbunden .

Überprüfen Sie die Ans chlüsse.

Bei Berühru ng des Gerätes,

verspüren Sie ein leichtes Kribbeln.

Das Gerät ist nicht korrekt geerdet.

Überprüfen Sie den Netzansc hluss und

die Erdverbindung.

Die Maschine schweißt nicht

korrekt.

Polaritätsfehler.

Überprüfen Sie die vo m Hersteller

angegebene Polarität der Elektroden.

Beim Start zeigt das Display für

eine Sek .

Die Spannung liegt außerhalb des

Spannungstoleranzbereiches:

440V +15%

Überprüfen Sie die Netzspannung.

TIG

Unstabiler Lichtbogen.

Schlechte Wo lf ram-Elektrode.

Benutzen Sie eine Wolfram-Elektrode

von angemessener Länge.

Benutzen Sie eine sauber

angeschliffene Elektrode.

Zu hohe Gasströmung. Reduzieren Sie die Gasmenge.

Die Wolfram-

Elektrod e oxidiert un d

verfärbt sich am Ende des

Schweißvorgangs dunkel.

Schweißumgebung.

Schützen Sie die Schweißumgebung

vor Wind oder L uftzug.

Fehler wird durch Gasnachströmen

oder defektes Gasventil verursacht.

Überprüfen Sie die Gasanschlüs se.

Die Elektrode glüht.

Polaritätsfehler.

Überprüfen Sie ob die Masseklemme

an der (+) Buchse angeschlossen ist.

GARANTIE

Die Garantieleistung des Herstellers erfolgt ausschließlich bei Fabrikations- oder Materialfehlern, die binnen 24

Monate nach Kauf angezeigt werden (Nachweis Kaufbeleg). Nach Anerkenntnis des Garantieanspruchs durch den

Hersteller bzw. seines Beauftragt en erfolgen eine für den Käufer kostenlose Reparatur und ein kostenloser Ersatz

von Ersatzteilen. Der Garantiezeitraum bleibt aufgrund erfolgter Garanti eleistungen unverändert.

Ausschluss:

Die Garantieleistung erfolgt nic ht bei Defekten, die durch unsachgemäßen Gebra uch, Sturz oder harte Stöße sowie

durch nicht autorisierte Reparaturen oder durch Transportschäden, die in Folge des Einsendens zur Reparatur,

hervorgerufen worden sind. Keine Garantie wird für Verschleißteile (z.B . Kabel, Klemmen, Vorsatzscheiben etc.)

sowie bei Gebrauchsspuren übernommen.

Das betreffende Gerät bitte imm er m it Kaufb eleg un d kurz er Fe hle rbe schr eib ung a ussc hlie ßl ich über d en F achh ande l

einschicken. Die Reparatur erfolgt erst nach Erhalt einer schriftlichen Akzept anz (Unterschrift) des zuvor vorge legten

Kostenvoranschlags durch den Besteller. Im Fall einer G arantiele istung trägt JBDC aussc hließli ch die Kos ten für de n

Rückversand an den Fachhändler.

Page 21

21

DESCRIPCION

¡Gracias por su elección! Para sacar la mayor satisfacción de su aparato, lea atentamente lo siguiente:

Este aparato es de soldadura Inverter, portable y con ventilación, para la soldadura con electrodos recubiertos

(MMA) y con electrodos refractarios (TIG Lift) en corriente continua (DC). En modo MMA, permite soldar todo tipo de

electrodos: rutilo, inox, básico y hierro colado. En modo Tig, permite soldar la mayoría de los metales excepto

aluminio y sus aleaciones. Está protegido para el funcionamiento con grupos electrógenos.

ALIMENTACION-PUESTA EN MARCHA

• El FLEX 250 A CEL, dotado de un sistema « Flexible Voltage » se alimenta con una instalación eléctrica CON tierra

situada entre 110V y 480V monofásica o trifásica (50 - 60 Hz). La corriente efectiva absorbida (I1eff) para

condiciones de uso máximas está precisada sobre el equipo. Comprobar que la alimentación y sus protecciones

(fusible y/o disyuntor) sean compatibles con la corriente necesaria en uso.

Esquema de conexión

3

+

Conexión a un enchufe trifásico

2

+

Conexión a un enchufe monofásico

*¡Cuidado! En c aso de conexió n a una toma monofásica, el cable que no se usa se debe aislar para que

no entre nunca en contacto con los otros cables.

• La puesta en marcha se efectua apretando el botón ( )

• Estos aparatos son de Clase A. Son concebidos para un uso industrial o profesional. En un

entorno dist into, puede ser difícil asegurar la compatibilidad electromagnética, debido a las interf erencias

propagadas por conducción y por radiación. No utilizar en un entorno con polvo metálico conductor.

• El FLEX 250 CEL dispone de una regul aciόn de la corriente primaria, se aconseja utilizar los cables incluidos con

el aparato.

SOLDADURA CON ELECTRODO R EC UB IE RT O (M OD O MMA)

• Conectar lo s cab le s del portaelectrodo y de la pinza de m asa a lo s c one ctores. Respe tar las po lar idad es i nd icad as

sobre el embala je de los electrodos.

• Respetar las prácticas clásicas de la soldadura.

• Su aparato cuenta con 3 funcionalidades específicas de los Inverters :

El Hot Start procura una sobreintensidad al cebado (modo regulable, ver más abajo).

El Arc Force procura una sobreintensidad para evitar la pegadura cuando el electrodo entra en el baño.

(modo regulable, ver más abajo)

El Anti-Sticking le permite despegar facilmente su electrodo sin que se ponga roja en caso de

pegadura.

Puesta en marcha del modo MMA y regulación de la intensidad:

- Elegir la posición MMA con la tecla de selección

- Elegir la intensidad deseada (indicador ) mediante las teclas .

1- fase 1

2- fase 2

3- fase 3

4- tierra

1- fase 1

2- fase 2 o neutro

3- tierra

Page 22

22

Hot start & Arc force regulables:

FLEX 250 A CEL

Hot Start

0 90%

Arc Force

0 90% o tipo de electrodo

El arc force se puede regular de 0 a 90%, luego pasa por los modos de electrodos « rut », « bas » y « cel ».

Estos últimos modos son regulaciones optimas para los distintos tipos de electrodos.

Consejos :

Hot start bajo para chapas finas.

Hot start elevado para metale s difíc ile s d e soldar (partes sucias u oxidadas).

SOLDAD URA TIG LI FT (MODO TI G)

La soldadura TIG DC requiere una atmósfera gaseosa (Argon).

Para soldar con el TIG, seguir las etapas siguientes:

1. Conectar l a pi n za d e mas a so b re la po l ar idad positi v a (+).

2. Conectar u n a antorcha « con válvula » sobre la polaridad negativa (-).

3. Conectar el tubo de gas de la entorcha sobre la bombona de gas

4. Elegir la posición TIG con la tecla de selección .

5. Ajustar la intensidad deseada (indicador ) mediante las teclas .

Consejo : Elegir como base 30A / mm y ajustar según el metal a soldar.

6. Regular el caudal de gas con el manometro de la bombona de gas y abrir la válvula de la entorcha

7. Para cebar :

a. tocar con el electrodo el

metal a soldar

b. levantar el electrodo de 2

a 5mm del metal a soldar

8. Al final de la soldadura :

Levantar el arco 2 veces (arriba-abajo-arriba-abajo) para iniciar el desvanecimiento automático (ver

el paráfo de abajo). Este movimiento debe realizarse en menos de 4 seg., con una altura de 5 a

10mm. Después, cerrar la válvula de la entorcha para cortar el gas tras el enfriamiento del electrodo.

Desvanecimiento del arco automático con duración regulable

Activación de la función :

Al final de la soldadura, corresponde al tiempo necesario para una baja progresiva de la

corriente de soldadura hasta el paro del arco. Esta función permite evitar las grietas y

cráteres de finales de soldadura.

Por defecto, esta función no está activada (tiempo a 0 segundos). Para activarla, seguir

las etapas siguientes:

1- Pulsar 3 segundos la tecla de selección

2- Ajustar el tiempo de desvanecimiento deseado de 1 a 10 seg (indicador )

gracias a las teclas

4. Validar el valor deseado pulsando la tecla de selección .

Para regular el Hot Start & Arc Force, seguir las etapas siguientes:

Pulsar 3 segundos sobre la tecla de selección

Ajustar el porcentaje deseado (indicador ) mediante las teclas

Validar el valor deseado pulsando la tecla de selección

Ajustar el porcentaje deseado (indicador ) mediante las teclas .

Validar el valor deseado pulsando la tecla de selección

Page 23

23

Combinaciones aconsejadas / afiladura electrodos

Corriente

(A)

∅ Electrodo (mm)

= ∅ Hilo (metal de

aportación)

∅

Boquilla

(mm)

Caudal

(Argon l/mn)

0,5-5 10-130 1,6 9,8 6-7

4-8

130-200

2,4

11

7-8

Para un funcionamiento óptimo, se debe utilizar un electrodo afilado de este modo:

d

l

CONTROL A DISTANCIA

El control a distancia funciona en modo TIG y MMA.

Conectores

El FLEX 250A CEL tiene equipado un acoplamiento para un control a distancia. La clav ija específica de 7 puntos

(opción ref. 045699) permite conectar su control a distancia manual (RC) o a pedal (PEd).

Para el cablead o, seguir el esquema siguiente:

Conexión

1- Encender el aparato.

2- Conectar el pedal o el mando en la parte de delante del aparato.

3- El indicador digital muestra « No » (Nada ),

4- Seleccione el tipo de control a distancia con :

No (Nada) « RC » (Control remoto / mando a distancia) PEd (Pedal)

5- Tras dos segundos de inactividad, el indicador se detiene en el valor y vuelve a indicar la intensidad de soldado.

Nb : En caso de error, desconecte el control a distanci a, e l aparato le indic a que no hay nada : « No ». Tras ello,

volver a conectar el control a distancia y volver a realizar la selección.

Aviso : Esta opción se volvera a indicar en cada uso.

Funcionamiento

Comando a distancia manual (opción ref. 045675) / Pedal (opción ref. 045682)

El comm ando a distanc ia permite v ariar la co rriente de intens idad mínima (DC: 10ª / MMA : 10) a una i ntensidad

definida por el usuario.

En esta configuración, todos los modos y funcionalidades del aparato son accesibles y configurables.

PROTECCI ON TERMICA Y FAC T ORE S DE MARC HA

• Protección térmica: el indicador luminoso se enciende, la duración del enfriamiento es de 1 a 5 mn

dependiendo de la temperatura ambiente.

• Dejar el aparato conectado después de su us o para permitir su enfriamiento.

• El aparato descrito tiene una característica de salida de tipo « corriente constante ». Los factores de marcha

según la norma EN60974-1 están indicados en las tablas siguientes :

L = 2,5 x d.

L

D : Contacto del interruptor

C : Masa

B : Cursor

A : + 5V

Nb : El valor del potenciometro debe ser de 10 KΩ

Ref.045699

Page 24

24

MMA

U1 = 110V U1 = 230V U1 = 400V

1~ 3~ 1~ 3~ 1~ 3~

30% 60% 100% 35% 60% 100% 41% 60% 100% 53% 60% 100% 40% 60% 100% 32% 60% 100%

140A 115A 90A 140A 125A 100A 200A 180A 150A 200A 190A 170A 250A 220A 190A 250A 200A 170A

25,6V 24,5V 23,6V 25,6V 25V 24V 28V 27,2V 26V 28V 27,6V 6,8V 30V 28,8V 27,6V 30V 28V 26,8V

TIG

U1 = 110V

U1 = 230V

U1 = 400V

1~

3~

1~

3~

1~

3~

60%

60%

100%

100%

60%

100%

80%

60%

100%

100%

60%

100%

65%

60%

100%

43%

60%

100%

140A 140A 110A 140A 140A 140A 200A 200A 180A 200A 200A 200A 250A 250A 220A 250A 225A 180A

15,6V 15,6V 14,4V 15,6V 15,6V 15,6V 18V 18V 17,2V 18V 18V 18V 20V 20V 18,8V 20V 19V 17,2V

MANTENIMIENTO

• El mantenimiento deber ser realizado por una persona calificada.

• Cortar la alimentación desconectando el enchufe de la toma y esperar la parada del ventilador antes de

empezar las reparaciones sobre el aparato. Al interior, la tensión y la intensidad son elevadas y

peligrosas.

• A menudo (2 o 3 veces por año), sacar la tapa y desempolvar con una pistola de aire comprimido.

Aprovechar la ocasión para comprobar, por una persona calificada, el estado de las conexiones

eléctricas con una herramienta aislada.

• Controlar regularmente el estado del cable de alimentación. Si éste está dañado, tiene que ser

remplazado por el fabricante, su servicio postventa o por una persona con calificación similar, para

evitar cualquier peligro.

CONSEJOS

• Respetar las polaridades e intensidades de soldadura indicadas sobre los embalajes de electrodos

• Sacar el electrodo del portaelectrodo cuando el aparato no está en uso

• Dejar las aperturas del aparato libres para la aireación.

SEGURIDAD

La soldadura al arco puede ser peligrosa y causar heridas graves e incluso mortales. Es

imprescindible protegerse y proteger a los demás.

Respetar las instrucciones de seguridad siguientes :

Radiación del

arco

Protegerse mediante una máscara conforme a las normas EN 169 o EN 379.

Lluvia importante,

Vapor de agua,

Humeda

Utilizar su aparato en una atmósfera propia (grado de polución ≤ 3), de plano y a una

altura de no más de 1 metro de la parte a soldar. No utilizar bajo lluvia o nieve.

Choque eléctrico

Velar por respetar las instrucciones previas de conexiόn a la ali m e ntaciόn eléctrica. No

tocar las partes bajo tensión. Comprobar que la red de alimentación está adaptada al

aparato.

Caídas

El aparato no debe pasar por encima de personas u objetos.

Quemaduras

Llevar ropa de obra en tejido ig nifugado (algodón, mono de trabajo o vaqueros).

Trabajar con guantes de protección y un delantal de soldadura.

Proteger a los demás instalando biombos de protección ignífugos, o informándoles

de no mirar el arco y quedarse a distancia suficiente.

Riesgo de

incendio

Suprimir todos productos inflamables del área de trabajo. Las obras no pueden

realizarse en presencia de gas inflamable.

Humos

No inhalar los gases y humos de la soldadura. Utilizar en un medio ambiente

correctamente ventilado, con extractores adaptados si se suelda en el interior.

Page 25

25

Precauciones

suplementarias

Cualquiera operación de soldadura :

-en lugares en los cuales existen importantes riesgos de choques eléctricos,

-en lugares cerrados,

-en presencia de material inflamable o sujetos a riesgos de explosión

siempre tiene que ser sometida a la aprobación previ a de un “responsable

experimentado” y ejecutarse en presencia de personas formadas para intervenir en

caso de urgencia.

Es imprescindible aplicar las medidas técnicas de protecciones descritas en la

especificación técnica CEI/IEC 62081.

Está prohibido soldar en posición realzada, salvo si se utiliza una plataforma de seguridad.

Las personas con marcapasos ti e nen que visi t ar al médico ant es de utili z ar estos apar a t os.

No utilizar el apar at o para desh elar las cañerías

En modo TIG, manipular la bombona de gas con precauciones, existen riesgos si la bombona o

la válvul a de la bombon a e stán dañadas .

RECOMENDACIÓN PARA REDUCIR LAS EMI SIONES ELECTRO-MAGNETICAS

Generalidad

El usuario es re spons able de la ins talac ión y del uso del equipo según las instrucciones del fabricante. Si se detectan

perturbaciones electrom agnéticas, es responsabilidad del usuario resolver la situación según las recomendaciones

dadas en el manual de uso o con la asistencia técnica del fabricante.

Evaluación del área de soldadura

Antes de instalar su equipo, el usuario tendrá que evaluar los problemas electromagnéticos potenci ales que podr ían

intervenir en el área donde está prevista la instalación, en particular tendrá que tener en cuenta las indicaciones

siguientes:

a. Otros cableados, cableados de control, cableados telefónico s y de com unicació n: arriba, abajo y al l ado

del equipo ;

b. Receptores y transmisores radio y televisión ;

c. Ordenadores y otros equipos de control ;

d. Equipamientos críticos para la seguridad como mandos de seguridad de equipamientos industriales;

e. La salud de las personas que se encuentran a proximidad de la máquina, por ejemplo personas que

llevan un marcapasos, un audífono, etc… ;

f. Equipamientos para calibrar y medir ;

g. La inmunidad de otros equipos instalados en el lugar donde está el equipo. El usuario tendrá que

asegurarse que los demás equipos del lugar son compatibles entre ellos. Esto podrá requerir

precauciones suplementarias;

h. El tiempo del día durante el cual se tendrá que hacer funcionar el equipo;

i. La superficie del área que habrá que considerar en torno al equipo dependerá de la estructura de los

edificios y otr as actividades que se desarrollan en el lugar. El área considerada puede extenderse más

allá de los límites de las empresas.

Recomenda c i on es s ob re lo s mé todos de reducción de las emisiones electromagnéticas

a. Alimentación principal: El aparato de so ldadura tendrá q ue ser conectad o a la red de alime ntación

conforme a las recomendaciones del fabricante. En caso de interferencias, puede ser útil tomar

precauciones suplementarias filtrando la te nsió n d e al ime ntac ió n. Tambi én p uede ser útil blindar el cable

de alimen tac ión en las instalacio ne s fi j a s d e l ap ar at o de so ldadura, bajo bande jas metálicas o dispositivos

equivalentes. El blindaje tendrá que ser eléctricamente contenido en la longitud entera del cable. Tendrá

que ser directamente conectado al aparato de soldadura con un buen co ntac t o elé ctr ico e ntre la bande ja

metálica y la caja del aparato.

b. Cables de soldadura : Los cables deben ser lo más cortos posibiles. Agruparlos y, si es posible,

dejarlos en el suelo.

c. Protección y blindaje: La protección y el blindaje selectivo de otros cables y materiales en la zona

cercana puede limitar problemas de perturbación.

d. Soldado a ras del suelo: el soldado a ras del suelo puede limitar problemas de perturbación. Puede

realizarse directamente o via un condensador apropiado. Esta elección se hace según las

reglamentaciones nacionales.

Page 26

26

ANOMALIAS, CAUSAS, SOLUCIONES

Anomalias

Causas

Solución

MMA-TIG

El aparato no libera ninguna

corriente y el indicador luminoso

amarillo de defecto térmico está

encendido .

La protección térmica del

aparato se ha puesto en marcha.

Esperar el final del enfriamiento

(más o menos 2 mn). El indicador

luminoso se apaga

El indicador está encendido pero

el aparato no libera ninguna

corrriente.

El cable de la pinza de masa o

del portaelectrod o no está

conectado al aparato.

Comprobar las conexiones.

El aparato está enchufado. Al

poner la mano sobre la tapa, se

sienten picores.

La conexión con la tierra está

mal hecha.

Comprobar la toma de tierra de su

instalación

El aparato no suelda bien. Error de polaridad.

Comprobar la polaridad aconsejada

sobre el embala je del electrodo

Durante la puesta en marcha del

aparato, el indicador indica

.

La tensión de alimentación está

superior a 440 V (+15%)

Comprobar su red eléctrica o su

grupo electrógeno

TIG

Arco inestable.

Defecto del electrodo tungsteno.

Utilizar un electrodo tungsteno con

tamaño ade cuado

Utilizar un electrodo tungsteno

correctamente preparado

Caudal de gas demasiado alto. Disminuir el caudal de gas

El electrodo tungsteno se oxida y

se empaña al final de la

soldadura.

Area de la soldadura.

Proteger el area de soldadura contra

las corrientes de aire.

Problema de gas, o interupción

prematurada de gas.

Comprobar y apretar todos los

empalmes de gas. Esperar que el

electrodo se enfrie antes de cortar

el gas.

El electrodo se funde. Error de polaridad.

Comprobar que la pinza de masa

está bien conectada al +

Page 27

27

ОПИСАНИЕ

Благодарим вас за выбор аппарата нашей марки! Чтобы полностью использовать его возможности,

пожалуйста, изучите данную инструкцию :

FLEX 250 A CEL является малогабаритным сварочным инвертором со встроенным вентилятором для сварки

электродом с обмазкой (MMA) и тугоплавким электродом (TIG Lift) на постоянном токе (DC). При сварке МMA

аппарат позволяет варить любым видом электрода: с рутиловой обмазкой (электроды для сварки на

переменном токе), с основной обмазкой (электроды для сварки на постоянном токе), электродами для сварки

чугуна, электродами для сварки нержавеющей стали и др. В режиме Tig, он варит большую часть металлов за

исключением алюминия и его сплавов. Он может работать от электрогенератора .

ПИТАНИЕ – ЗАПУСК В РАБОТУ

• FLEX 250 A CEL оборудован системой « Flexible Voltage » и должен быть подключен к однофазной или

трехфазной электроустановке 110-480В С ЗАЗЕМЛЕНИЕМ (50 - 60Гц). Эффективный потребляемый ток

(I1eff) указан на аппарате для условий максимального использования. Убедитесь, что питание и защиты

(предохранитель и/или плавкий предохранитель) адаптированы для тока, необходимого для

использования аппарата.

Схема подключения

3

+

Подключение к трехфазной розетке

2

+

Подключение к однофазной розетке

*ВНИМАНИЕ! В случае подключения к однофазной розетке, неиспользуемый провод должен

быть изолирован таким образом чтобы он не касался других проводов.

• Запуск в работу осуществляется нажатием на кнопку ( )

• Этот аппарат относится к Классу A. Он создан для использования в промышленной и

профессиональной среде. В любой другой среде ему будет сложно обеспечить электромагнитную

совместимость из-за кондуктивных и индуктивных помех. Не использовать в среде содержащей

металлическую пыль-проводник.

• Так как регулировка FLEX 250A CEL на первичной цепи, советуем использовать кабели,

поставляющиеся в наборе с аппаратом

СВАРКА ЭЛЕКТРОДОМ С ОБМАЗКОЙ (РЕЖИМ МMA)

• Подключите кабель электорододержателя и зажима массы в коннекторы. Соблюдайте полярность

указанную на упаковке с электродами.

• Следуйте общепринятым правилам сварки.

• Ваш аппарат снабжен 3 функциями свойственными инвертору:

Hot Start (регулируемый режим, см ниже) выдает импульс высокого тока (по сравнению с током сварки) в

момент пожига дуги

Arc Force (режим регулируется, см ниже) выдает сверхток препятствующий привариванию электрода в

момент его погружения в жидкий металл

Anti-Sticking позволяет легко отделить электрод не вызывая его приваривания в случае замыкания

электрода на землю

Активирование режима MMA и регулировка интенсивности:

- Выбрать позицию MMA с помощью кнопки

1- фаза 1

2- фаза 2

3- фаза 3

4- земля

1- фаза 1

2- фаза 2 или ноль

3- земля

Page 28

28

- Отрегулировать желаемую интенсивность (индикатор ) с помощью кнопок .

Регулируемые Hot start и Arc force:

FLEX 250 A CEL

Hot Start 0 90%

Arc Force

0 90% или тип электрода

L’arc force регулируется от 0 до 90%, затем переходит на тип электрода, « rut », « bas » и « cel ». Данные

режимы являются оптимальными настройками для разного типа электродов.

Наш совет :

Слабый Hot start, для тонких листов металла – повышенный Hot start для трудно

свариваемых металлов (плохо очищенные или окисленные детали)

Для регулировки Hot Start иt Arc Force следуйте следующим этапам:

Нажать 3 секунды на кнопку

Укажите желаемое процентное соотношение (индикатор ) с помощью кнопок

Подтвердите выбранное значение нажатием кнопки

Укажите желаемое процентное соотношение (индикатор ) с помощью кнопок

Подтвердите выбранное значение нажатием кнопки

СВАРКА TIG LIFT (РЕЖИМ TIG) (АРГОНОДУГОВАЯ СВАРКА)

Сварка TIG DC (при постоянном токе) требует использования защитного газа (Aргон).

Для сварки в режиме TIG, следуйте следующим этапам:

1. Подключите зажим массы на положительную полярность (+).

2. Подсоедините горелку с вентилем к отрицательной полярности (-).

3. Подсоедините газовую трубку горелки к газовому баллону

4. Выберите позицию TIG с помощью кнопки .

5. Отрегулируйте желаемую силу тока (индикатор ) с помощью кнопок .

Отрегулируйте расход газа на редукторе газового баллона и отгоройте вентиль на горелке

7. Для пожига дуги:

a- коснитесь детали

электродом

b- поднимите электрод на 2-

5мм от свариваемой детали

Окончание сварки:

9. Поднять дугу 2 раза (вверх-вниз-вверх-вниз) чтобы спровоцировать автоматическое затухание (см

параграф ниже). Это действие должно занять минимум 4 секунды на высоте от 5 до 10мм. Затем