SERVICE INFORMATION

PHYACTION 190 / 190i

Copyright© Uniphy BV 1996-97

Phyaction® is a registered trademark of Uniphy BV

Art. Code 93001212.6

Phyaction is manufactured in The Netherlands by Uniphy BV

P.O.Box 558 , NL-5600 AN Eindhoven, the Netherlands

Tel. +31 499 491800 Fax. +31 499 474734

Table of contents

CHAPTER 1 GENERAL INFORMATION......................................................................... 1

1.1 Introduction ................................................................................................................................ 1

1.2 Safety aspects ............................................................................................................................ 1

1.3 Installation .................................................................................................................................. 2

1.4 Description of the controls ....................................................................................................... 2

1.5 Technical specifications............................................................................................................ 4

CHAPTER 2 THEORY OF OPERATION.......................................................................... 5

2.1 Introduction ................................................................................................................................ 5

2.2 General block diagram .............................................................................................................. 5

2.3 Ultrasound unit........................................................................................................................... 6

CHAPTER 3 PERFORMANCE CHECK............................................................................ 9

3.1 Safety inspection ....................................................................................................................... 9

3.2 IEC 601-1 safety tests ............................................................................................................... 10

3.3 Performance check of the ultrasound treatment heads ....................................................... 10

CHAPTER 4 TROUBLE SHOOTING ................................................................................. 12

4.1 Introduction ............................................................................................................................... 12

4.2 Description of the automatic selftest...................................................................................... 12

4.3 Description of the service software ........................................................................................ 15

4.4 Error messages ......................................................................................................................... 16

CHAPTER 5 EXCHANGING BOARDS AND MODULES .................................. 17

5.1 Introduction ............................................................................................................................... 17

5.2 Exchanging the software or the main board (PCB 192X) ..................................................... 17

5.3 Exchanging the ultrasound module........................................................................................ 17

5.4 Exchanging the LCD ................................................................................................................. 18

5.5 Exchanging the keyboard PCB (194X).................................................................................... 18

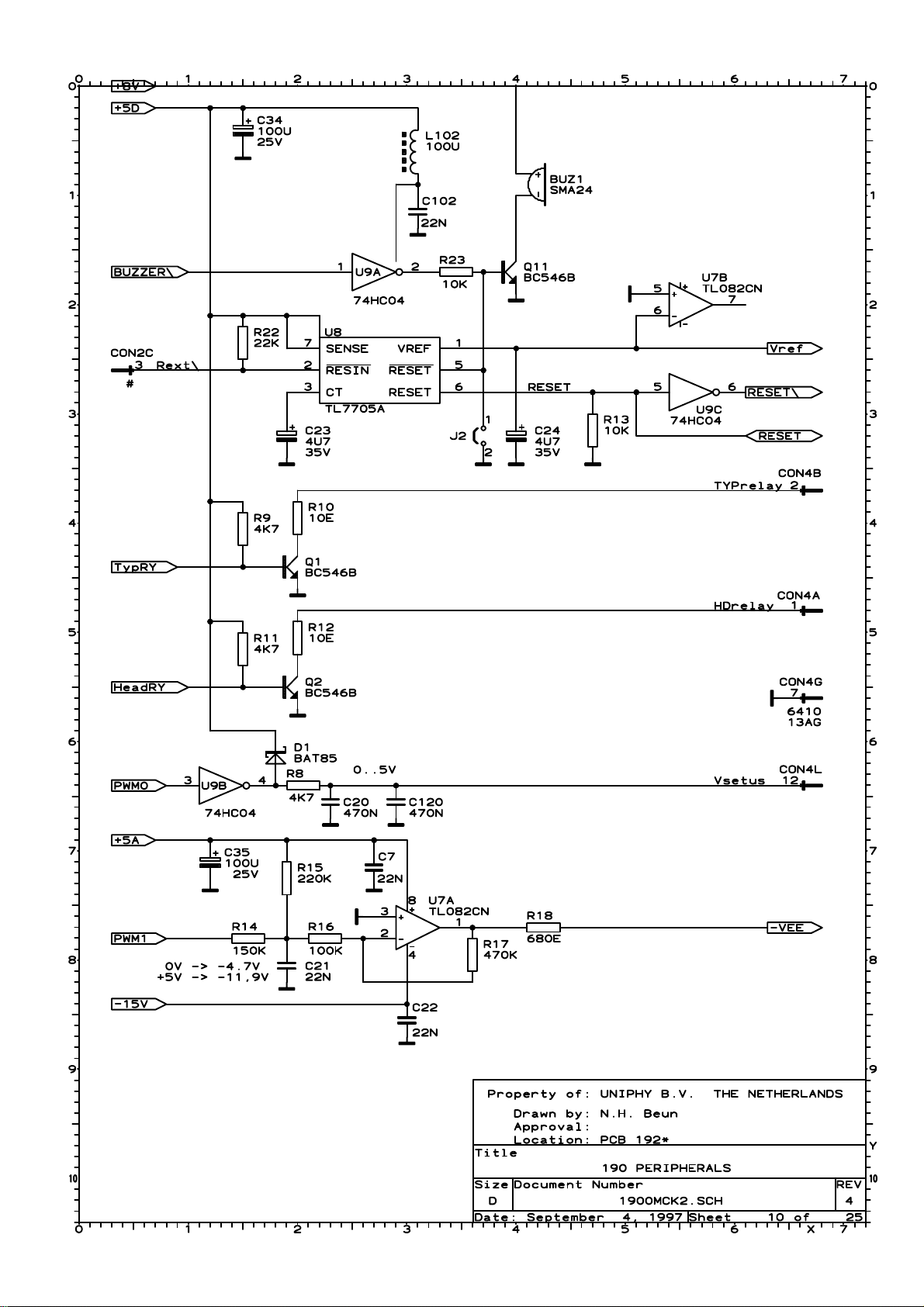

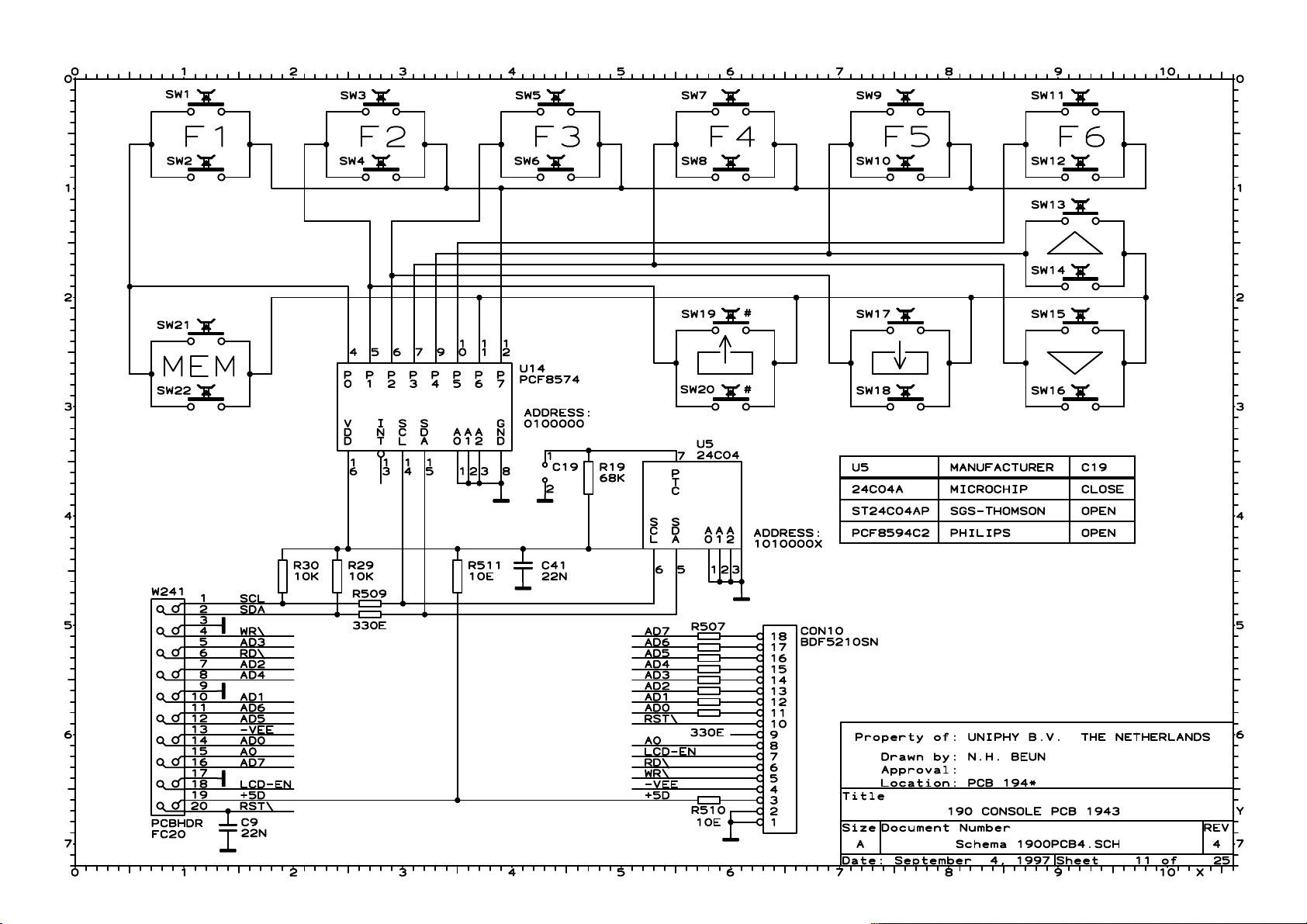

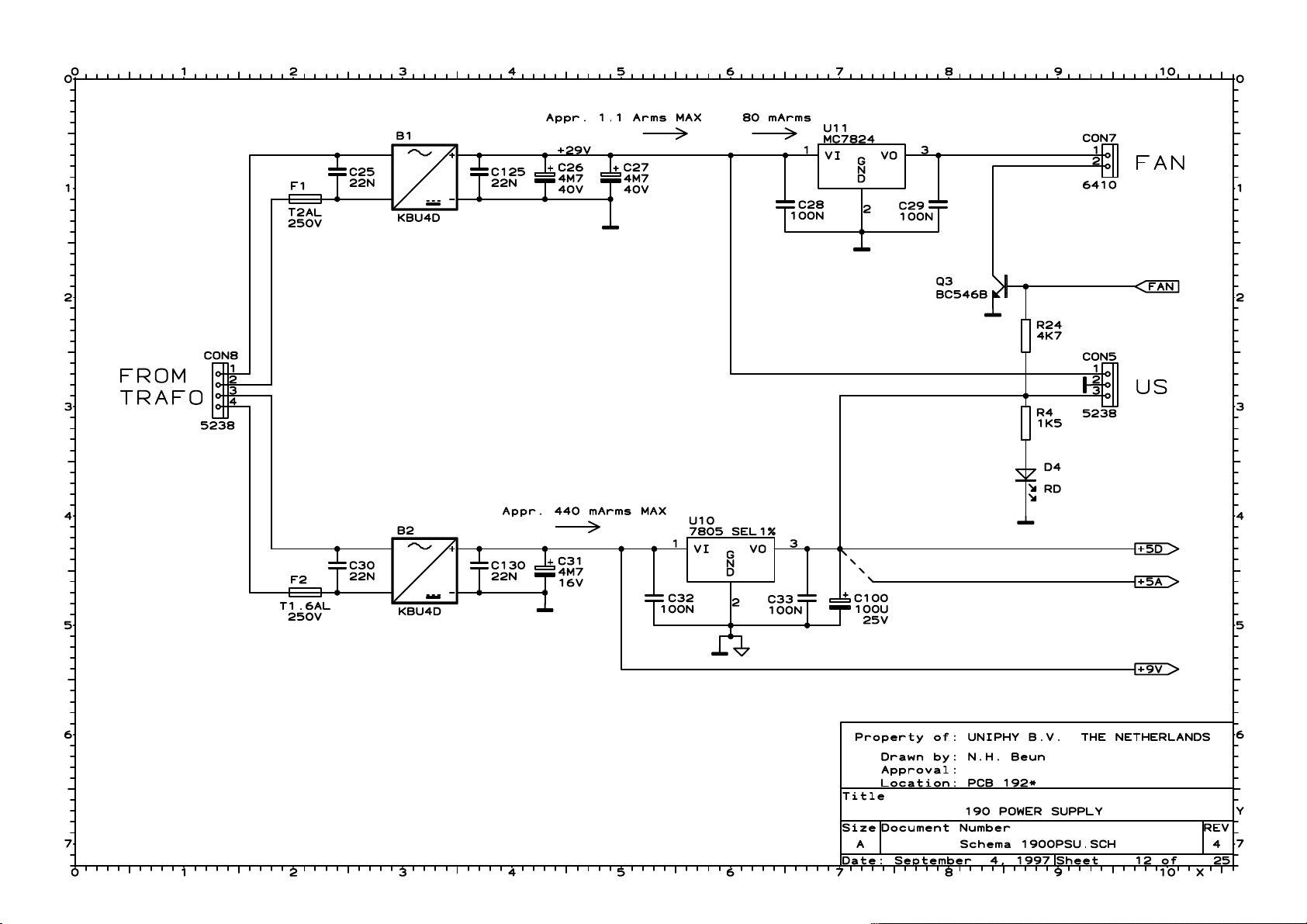

APPENDIX 1 CIRCUIT DIAGRAMS

APPENDIX 2 TUNING THE ULTRASOUND TREATMENT HEADS

APPENDIX 3 ERROR LIST

Table of contents - Service information Phyaction 190 / 190i

CHAPTER 1 GENERAL INFORMATION

1.1 Introduction

The Phyaction 190 is an appliance for ultrasound therapy and it can be used for combination therapy with an

external electrotherapy appliance.

In this chapter the important features from the users manual for service personnel are listed. In the next chapter

the theory of operation will be explained. In chapter 3 is described how service personnel can check the

operation of the Phyaction 190 and what maintenance operations should be carried out. The next chapter

contains information which could be very useful for trouble shooting such as a description of the automatic self

test and a list of the error numbers. The operations that have to be carried out if you want to exchange a printed

circuit board or another module are described in chapter 5.

1.2 Safety aspects

1.2.1 Electrical safety

The equipment can only be used in areas with provisions in accordance with current statutory requirements.

Pay particular attention to the use of protective earth, otherwise the patient leakage current can rise above the

permitted limit for type BF equipment.

1.2.2 Explosion safety

The equipment is not suitable for use in areas where flammable gasses or vapours are present. Therefore,

remove the mains plug from the socket before the area in which the equipment is located is disinfected, since

some disinfection solutions evaporate and subsequently form an explosive mixture.

1.2.3 Operational safety

- Using the equipment in the vicinity of short wave or microwave equipment can influence the correct

operation of the unit. Using this equipment when high frequency surgical equipment is connected to the

patient at the same time can result in burning under the electrodes when using it for combination therapy.

- Patients who have electrical implants (i.e. pacemaker) may only be treated following medical advice.

- The equipment is not suitable for use in damp areas.

- The equipment may not be disinfected or sterilized.

- Whenever the equipment is switched on (using the main switch) the microprocessor checks the entire

system for correct operation.

- The ultrasound heads, including the cable and the connectors should be checked regularly. In particular

attention should be paid to damage to the ultrasound heads through which liquids can enter the ultrasound

heads.

- The ultrasound heads should be handled carefully, because the properties of the ultrasound heads can alter

due to rough handling.

1.2.4 Use of the appliance

The equipment and accessories should only be used by authorized personnel and in accordance with all

instructions included in these operating instructions.

The Phyaction 190 is only to be used for providing ultrasound therapy. When connected to an electrotherapy

appliance the Phyaction 190 can be used to provide combination therapy.

1.2.5 Radio interference suppression and electromagnetic compatibility

This equipment meets the guidelines for ISM equipment relating to electromagnetic compatibility and is radio

interference suppressed according to EN55011. Also see section 1.2.3 Operational safety of this chapter,

concerning the use of the equipment in the vicinity of short wave and microwave equipment.

1. GENERAL INFORMATION Service information Phyaction 190 / 190i - Page 1

1.3 Installation

1.3.1 Incoming inspection

Check that the equipment and ultrasound head(s) have not been damaged during transportation and that the

accessories are intact and complete (see chapter 14 ACCESSORIES of the INSTRUCTIONS FOR USE). In

the event of damage and/or defect you should inform your supplier.

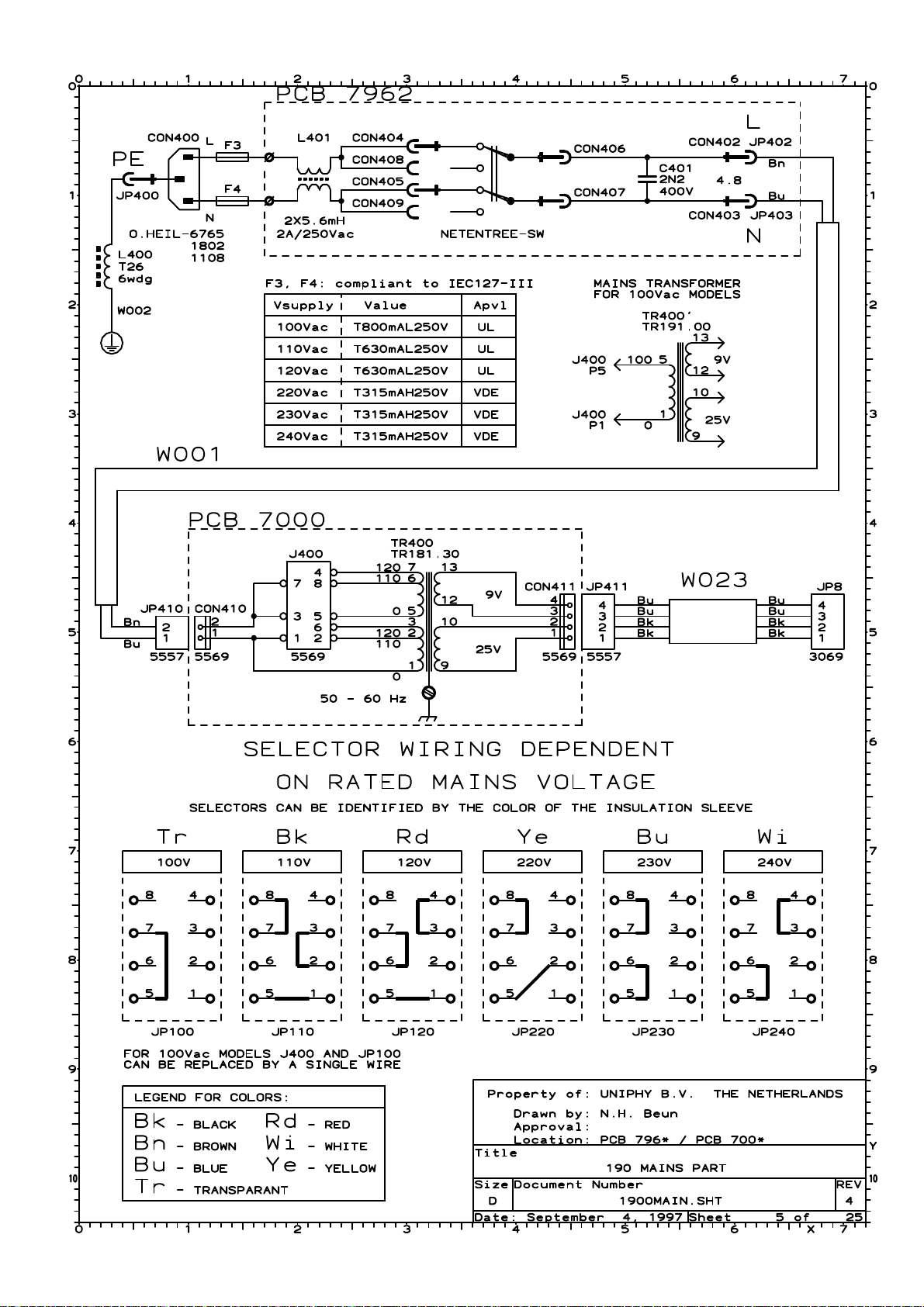

1.3.2 Mains voltage

Your equipment is suitable for a nominal voltage of 110, 220, 230 or 240 Volt AC, 50-60 Hz. Indicated on the

rear of the equipment will be the voltage for which it has been wired. You can not alter this yourself. Carefully

check this data before you place the mains plug in the socket. The mains input is on the back of the appliance

at the bottom.

1.3.3 Functional test

During production the equipment is tested for electrical safety. Whenever the equipment is switched on, the

processor performs an extensive test to ensure that the equipment is operating correctly. In addition you must

check whether the display and the indicator lamps are operating correctly. The green lamp indicates that the

appliance is connected to the mains supply and that the appliance is switched on. The red lamp illuminates

when the safety system has detected a fault which prevents the appliance being used. If the appliance is not

operating correctly, then you must not use the equipment and you must contact your supplier.

If you can not read or if it is difficult to read the display, then press the right hand blue button and the black ¿

button in order to darken the text or the black À button if you want to make the text lighter.

1.3.4 Location and transportation

The equipment must be set up horizontally and stable. You should ensure that the vents in the housing are not

blocked so that circulation of air is not hindered. Objects must not be placed on the equipment and you must

ensure that no liquid enters the equipment.

1.3.5 Fitting the head holder

As standard, a head holder is supplied with each treatment head. Before you use the Phyaction 190 for the first

time, we advise you to fix the head holder(s) to the appliance. The ultrasound treatment head can be connected

to the appliance easily and in a user-friendly manner into the head holder. At the same time this protects the

treatment head against damage by, for example, falling.

For a description of fixing the head holder to the appliance please refer to the drawing which you will find in the

packing for the head holder.

1.3.6 Checking the ultrasound heads

You can check which head belongs to which appliance by pressing the yellow button for 3 seconds. In the

middle of the screen which then appears, you will see the treatment head symbol with a statement of the ERA

on which treatment head(s) the appliance has been tuned. After this symbol there are 20 figures. If these

figures correspond exactly with the figures on the treatment head label then this treatment head belongs to that

appliance. If they do not correspond, you are using a treatment head which does not belong to that appliance. If

the middle screen is completely empty then the appliance has not been tuned to any treatment head and we

advise you to inform your supplier.

1.4 Description of the controls

On the last page of this operating instruction you will find an illustration of the equipment and the accessories.

1.4.1 Display

The display

1

consists of separate picture elements which are controlled by a processor so that you can see text

and figures. When you are performing a treatment, the display shows all of the information you require:

- The top left section provides information about the parameters which have been set.

- The right section provides information about the output power and the degree of contact of the treatment

head. This section also gives information about the treatment time.

- The bottom line of the display shows the functions of the blue buttons.

1. GENERAL INFORMATION Service information Phyaction 190 / 190i - Page 2

Lay-out of the therapy screen

1.4.2 Signal lamps

On the front, to the right of the display, there are two coloured lamps:

- The green lamp

switched on.

- The red lamp

2

indicates that the appliance is connected to the mains supply and that the appliance is

3

illuminates when the safety system has detected a fault which prevents the appliance being

used. A message appears on the display. See chapter 4 TROUBLE SHOOTING. The red lamp also

illuminates during the self test which is performed after switching on the appliance.

The yellow lamps

4

, beside the output connectors of the ultrasound head, illuminate for 2 seconds as soon as

the relevant ultrasound head has been selected. A yellow lamp also illuminates beside an output connector as

soon as ultrasound power is emitted.

1.4.3 Rotary knob

On the right-hand side at the front there is a large rotary knob

5

with which the intensity peak in Watt/cm2 can be

adjusted. When you rotate this knob fully anti-clockwise you will feel a click and it is in the zero position.

1.4.4 Push buttons

- Using the blue buttons

- The black buttons ¿ or À

already selected.

- The yellow button

6

a parameter can be selected. This display clearly shows the function of the buttons.

7

are used to increase or decrease the value of a parameter which you have

8

is used to return to the therapy screen. When the yellow button is depressed for 3

seconds, a screen appears in which the software version number, the release date of the software and the

treatment head parameters can be read.

- Using the green button

9

you can access the special memory function. 20 different treatments can be saved,

retrieved or changed.

1.4.5 Output connectors and sockets on the front

- The safety socket

metallic treatment surface of the ultrasound head forms the other electrode.

- The ultrasound head(s) are connected to the two connectors

10

on the far left is used for connecting the electrode cable during combination therapy. The

11

on the right. It makes no difference which

head(s) you connect to which connector. Two treatment heads can be connected at the same time provided

they do not have the same format.

1.4.6 Controls on the bottom at the rear of the appliance

The following controls can be found on the rear of the appliance:

- The mains input with mains switch

- The fuse holder

13

is located between the mains input and the mains switch. The rating of the fuse to be used

is stated on the rear of the appliance.

- The connector for connecting to the potential equalization busbar

12

.

14

.

1.4.7 Label on the rear of the appliance

The label containing the appliance data

15

is located on the rear of the appliance.

1.4.8 Ultrasound treatment heads

You have the choice of two ultrasound treatment heads

or 4 cm

2

. The treatment heads can be easily located in the multi-functional head holder17. With each treatment

16

with an ERA (Effective Radiating Area) of either 1 cm2

head both 1 MHz and 3 MHz ultrasound can be applied. Both treatment heads can be connected to the

appliance at the same time. Using the blue button you can select which you want to use.

The display indicates which format of treatment head has been selected at that moment. As soon as the

Phyaction 190 is switched on using the mains switch or from the stand-by position, or as soon as a treatment

1. GENERAL INFORMATION Service information Phyaction 190 / 190i - Page 3

head has been selected, the yellow lamp beside the selected head illuminates for 2 seconds on the appliance.

Furthermore, each treatment head has a colour indication at two positions: the 4 cm

and the 1 cm

2

is yellow.

2

treatment head is green

When the surface of the treatment head makes insufficient contact with the patient this is shown on the screen.

The ultrasound power is then automatically turned down so that overheating of the treatment head and

subsequent wear is reduced. The treatment time also stops when there is insufficient contact and this starts

again as soon as contact is re-established. In this way the set time is actually utilized.

The appliance should always be tuned to the associated treatment heads. For every new appliance the heads

are already tuned to the appliance. However, when a new (another) treatment head is purchased, the appliance

should be tuned to the new head. When you press the yellow button for 3 seconds, a screen appears in which

you can check whether you are using the correct treatment heads with the appliance. In Appendix 2 TUNING

THE ULTRASOUND TREATMENT HEADS, the tuning process is described.

1.4.9 Head holder

For each Phyaction 190 a head holder for each treatment head is supplied as standard. You can fit this to the

appliance easily yourself.

For a description of fixing the head holder to the appliance please refer to the drawing which is enclosed in the

packing for the head holder.

1.5 Technical specifications

1.5.1 Specifications Phyaction 190

Duty-cycle: continuous 1:1

pulsating 1:2, 1:4, 1:8, 1:16

Treatment clock: adjustable 0-30 minutes, linked to contact control

Intensity: 0 - 1.5 W/cm

0 - 2 W/cm

0 - 3 W/cm

Read-out: intensity in W/cm

2

at 3.3 MHz continuous

2

at 0.8 MHz continuous

2

at 0.8 and 3.3 MHz pulsating

2

effective output power in W

Pulse repetition frequency: 100 Hz

Memory: 20 memory places available

Combination therapy: possibility to connect an electrotherapy appliance

1.5.2 Specifications treatment heads

ERA: 1 cm

2

(model 91) and 4 cm2 (model 92)

Frequencies: 0.8 MHz and 3.3 MHz

BNR: < 5 at 0.8 MHz

< 4 at 3.3 MHz

The treatment heads are watertight according to IEC 601-2-5.

1.5.3 Technical information

Dimensions: 38 x 22 x 15 cm

Weight: 5 kg

Insulation class: I, type BF

Voltage: 110, 220, 230 or 240 Volt, 50-60 Hz

Input current: maximum 300 mA

at 220 V and 600 mA

eff

at 110 V

eff

1.5.4 Replaceable parts

Fuses in the mains entrance.

1. GENERAL INFORMATION Service information Phyaction 190 / 190i - Page 4

CHAPTER 2 THEORY OF OPERATION

2.1 Introduction

In this chapter the electronics of the Phyaction 190 will be explained. A description on the level of functional

block diagrams will be used. The electronics will be described in more depth when safety aspects are

concerned.

The Phyaction 190 is a device for ultrasound therapy. The user -the physical therapist- can set a number of

parameters. The parameters are converted in electric signals for the ultrasound unit by a microcontroller. Also

the microcontroller continuously checks whether the ultrasound unit produces the proper amount of ultrasound

energy.

2.2 General block diagram

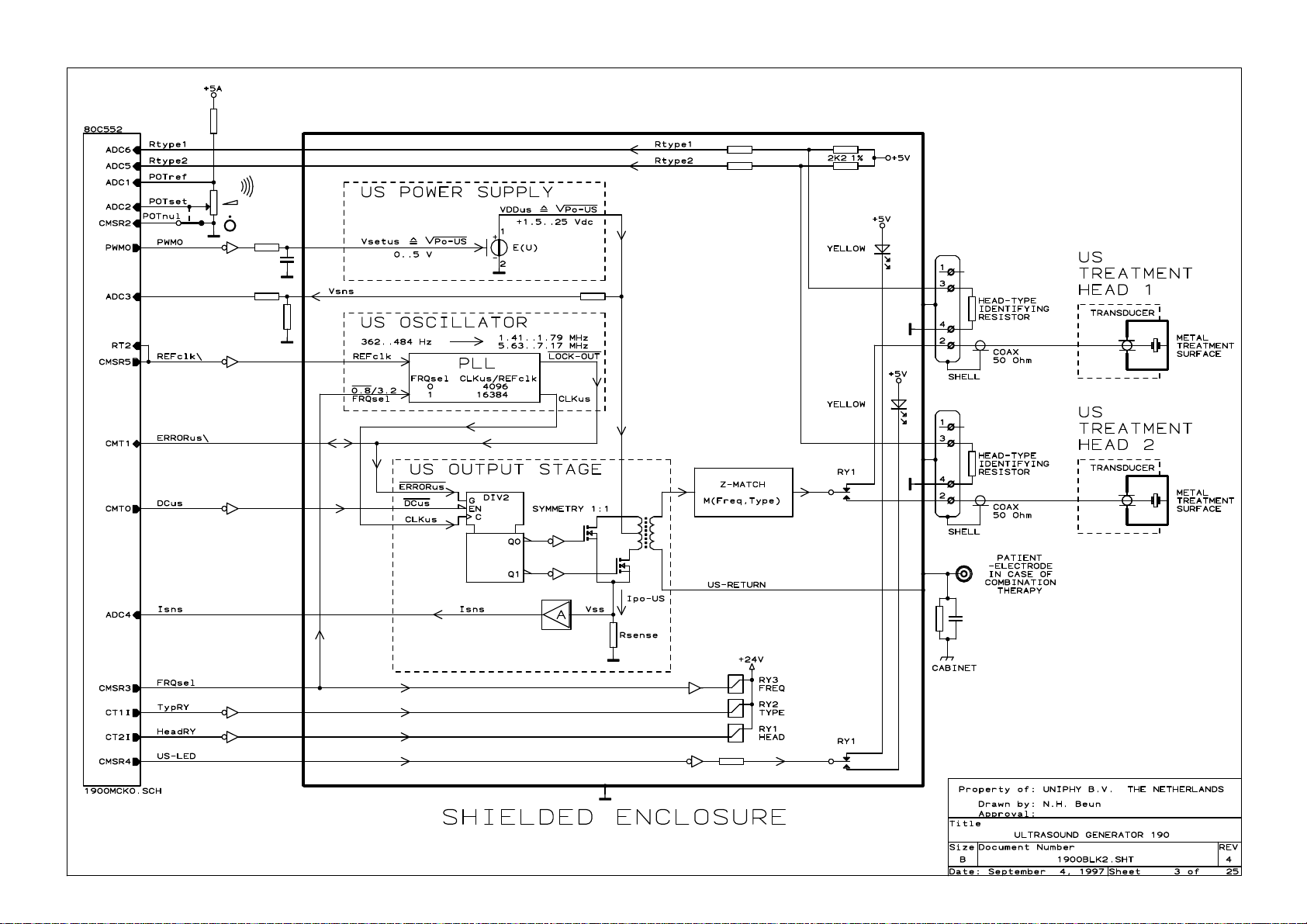

The block diagram of the Phyaction 190 is shown in figure 2.1. The microcontroller core, shown in the middle of

the diagram, controls the complete apparatus. The user can set most of the parameters with the keyboard,

which is shown at the left of the microcontroller. The intensity of the ultrasound can be set with the intensity

knob, drawn to the right of the microcontroller. The actual parameters and the amount of ultrasound energy

actually being administered to the patient is shown on the graphical display.

Figure 2.1, Functional block diagram of the Phyaction 190

The ultrasound unit, drawn under the microcontroller, generates the electrical signal the US-head converts into

ultrasonic vibrations. The 4 mm banana safety socket, drawn close to the ultrasound unit, allows the user to

apply combination therapy when an electrotherapy device is connected to this bus.

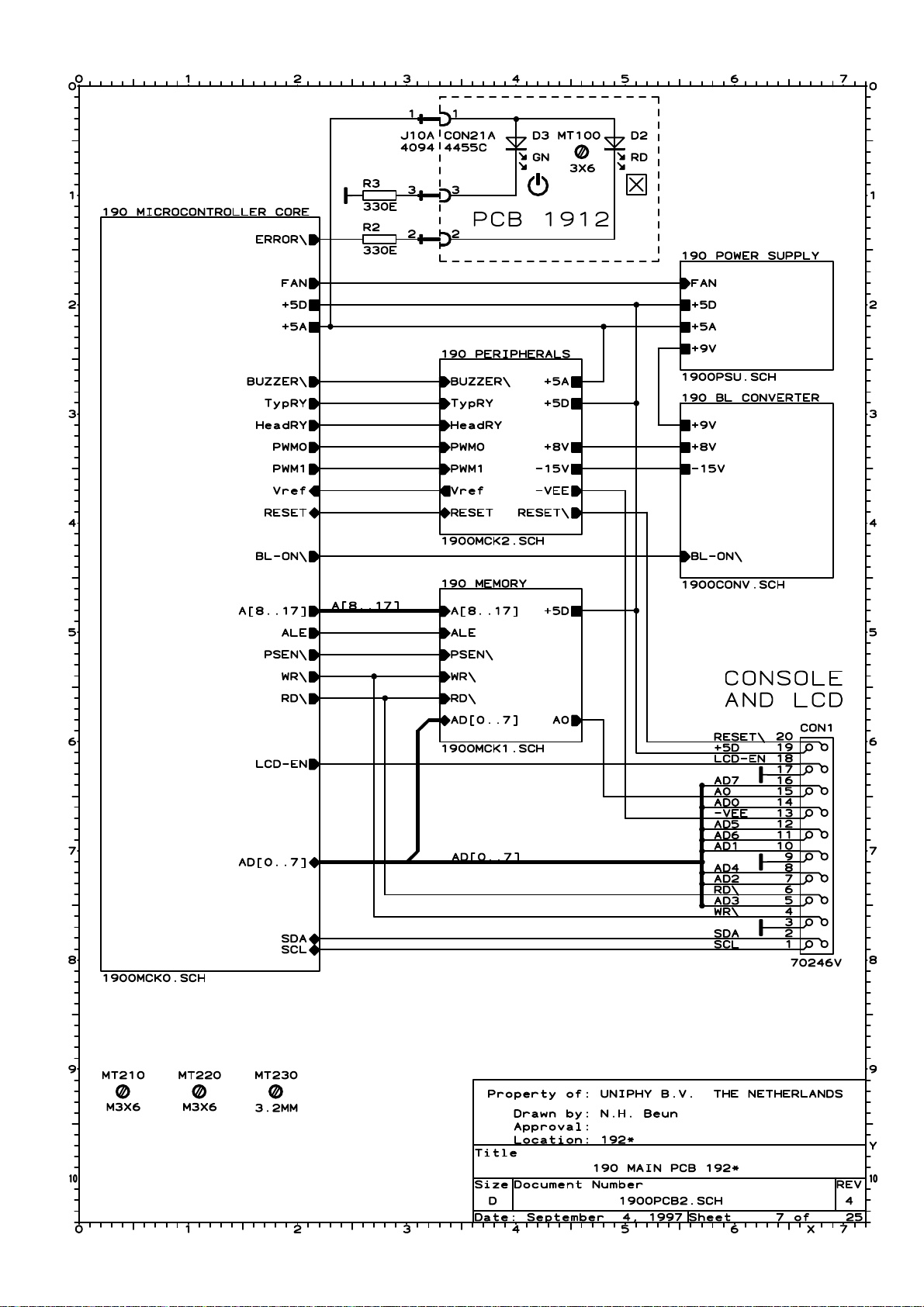

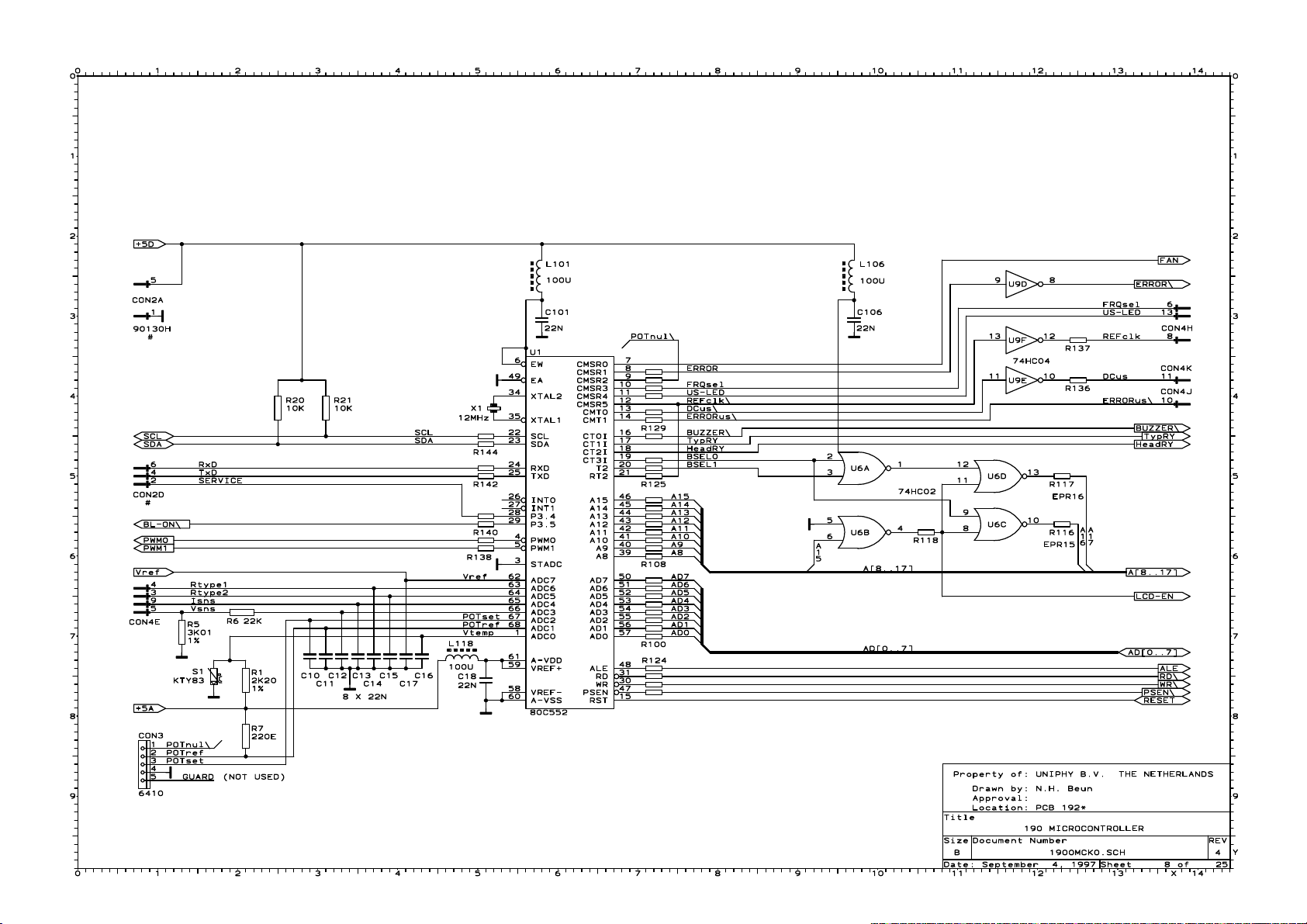

2.2.1 The microcontroller core

The microcontroller used in the Phyaction 190 is an 80C552. The 80C552 is an MCS-51 type controller (8051)

with a number of extra features on the chip:

- 256 byte RAM memory (instead of 128 byte in 8051)

- 3 timer / counters (2 in 8051)

- eight channel 10-bit AD converter (N.A. in 8051)

2. THEORY OF OPERATION Service information Phyaction 190 / 190i - Page 5

- 5 eight-bit wide I/O ports (4 in 8051)

- 2 eight-bit pulse width modulators (PWM) (N.A. in 8051)

2

- I

C bus for serial data transfer (N.A. in 8051)

- UART for serial data transfer (e.g. RS232)

- watchdog timer (N.A. in 8051)

Next to the microcontroller the following parts are present in the core:

- 8 kByte (expandable to 32 kByte) RAM data memory

- 1 Mbit EPROM program and constant data memory

- 256 byte I

2

C E2PROM non-volatile data memory

- 2 HCMOS IC's for decoding and buffering purposes

2.2.2 Keyboard

The keyboard is a matrix of 10 push buttons connected to the microcontroller via an I

2

C I/O expander. The

microcontroller software defines the function of each key. The user can use the keyboard to set and change a

number of parameters (such as the active treatment head, treatment frequency, duty-cycle, treatment time etc.)

2.2.3 Graphical user interface

A 240 x 64 dots LCD display with CFT backlight is used as graphical user interface. On it the user can see the

current function of the function keys, the parameters, the remaining treatment time, the selected intensity and

the resulting effective energy being radiated by the treatment head. Further the contact ration between

treatment head and patient is shown on the display.

2.2.4 Safety socket

The 4 mm banana safety socket is directly connected to the tin can of the ultrasound unit. This Tin can is the

'ground' of the circuitry, which is also connected to the metal front of the treatment heads. This socket can be

used for combination therapy with external electrotherapy appliances.

2.2.5 Serial interface

No serial interface is available to the user. Only with an opened apparatus the serial interface can be used for

testing purposes. This interface is a 5V-level RS232 interface (a direct connection to the UART of the

microcontroller). The interface is for extended service features (used by manufacturer only).

2.2.6 Power supply

The power supply is a conventional one with a mains transformer suited for medical purposes. It is equipped

with the required primary and secondary fuses, two bridge rectifiers and two capacitors. The unstabilised +29 V

is used to feed the ultrasound unit. In the ultrasound unit the +29 V is further used to create a controlled

ultrasound supply and two stabilized supplies of +24 V and +15 V.

The unstabilised +9 V is used to create a microcontroller controlled switchable +8 V for the LCD contrast and its

backlight and to create a +5 V for the logic components. A reset signal for the microcontroller and LCD is

generated when the +5 V comes in or when it drops below a certain voltage.

2.3 Ultrasound unit

The functional block diagram of the ultrasound unit is shown in figure 2.2. Since the signals to generate

ultrasound are made using a square wave of about 1 MHz or 3 MHz, it is necessary to encapsulate the

complete ultrasound unit, including the ultrasound crystal, in a metal case (a Faraday cage). In figure 2.2 the

metal case is indicated by the dashed line. The electronics is put into a 'tin can'. It will be clear that the

ultrasound treatment head cannot be put in the tin can, so to maintain the shielding the crystal is put in an

aluminium cup, while the signal wire from the electronics to the crystal is a double braided coaxial cable (double

shielded).

The keyboard is used to set the various parameters, such as duty-cycle, treatment time and frequency (1 MHz

or 3 MHz). The microcontroller computes the operating frequency of the crystal, using a couple of treatment

head parameters fed to the apparatus at installation time. The same head parameters are also used to

calculate the administered amount of ultrasound energy and the rate of contact between treatment surface and

patient. Keeping track of the treatment time is also done by the microcontroller.

2. THEORY OF OPERATION Service information Phyaction 190 / 190i - Page 6

Figure 2.2, Functional block diagram of the ultrasound unit

Countdown of the treatment time is stopped when the microcontroller notes that there is no or not enough

contact between treatment head and patient. The intensity of the ultrasound can be adjusted by the user using

the intensity knob. Depending on the voltage Vpotus the microcontroller computes and sets the required voltage

Vus with the controlling voltage VSetUs in order to generate the desired amount of ultrasound.

2.3.1 PLL

The required ultrasound frequency Fus of 0.8 MHz or 3.3 MHz cannot be generated by the microcontroller

itself. For this reason a phase locked loop (PLL) is used to transform a low-frequent signal RefClock, that the

microcontroller can generate, up to the desired steering frequency of 2XFus. The modulator divides this double

frequency and mixes it with the desired duty-cycle.

The frequency generated by the microcontroller is always around 400 Hz. In order to obtain ultrasonic

frequencies of both 0.8 MHz and 3.3 MHz a programmable divider is used in the PLL. Whenever the PLL is out

of lock (e.g. when changing the frequency for contact control calculations) the Lock-error signal is used to stop

the modulator in order to prevent erroneous frequencies being produced by the treatment head.

2.3.2 Modulator

To obtain a symmetrical steering signal for the power stage the modulator switches its outputs with half the

input frequency. Also the modulator mixes the duty-cycle signal synchronously with the ultrasound frequency to

prevent spikes. An amplitude modulation with 100% modulation depth (the signal being switched on and off) is

the result of this mixing. With the Lock-error signal the modulator can be forced to shutdown. This action can be

taken by the PLL when it is out of lock or by the microcontroller. The Lock-error line can be used as an input as

well as an output by the microcontroller.

2.3.3 Voltage controller

A pulse controlled downward converter voltage controller is used to convert the unstabilized +29V to the

desired ultrasound voltage. The voltage controller is made in such a way that its output voltage is linear

proportional to its input voltage VSetUs. Thus the microcontroller can adjust the ultrasonic power by setting

VSetUs proportional to the square root of the desired output power. The microcontroller constantly monitors the

output voltage of the voltage controller. If the output voltage is too high (because of a hardware failure), the

microcontroller will shut down the ultrasound unit and give an error message.

2. THEORY OF OPERATION Service information Phyaction 190 / 190i - Page 7

2.3.4 Power stage

The power stage is a switched balance class-D end stage. The generated output power is controlled by Vus,

generated by the voltage controller. The above mentioned modulator controls whether the power stage is

active. Power MOSFETs are used as switching elements. The MOSFETs are driven by buffers that also take

care of a small delay in driving the MOSFETs, to prevent them of being active simultaneously. If either one of

the MOSFETs has become defective, both of them should be replaced. In that case the adjustment of the

delays in the FET-drivers should be carried out. This adjustment cannot be executed in the field, it has to be

carried out only by Uniphy personnel.

2.3.5 Impedance matching

The ultrasound crystal is mainly a capacitive load. Its impedance differs, among other things, with the size of the

crystal and its operating frequency. For this reason the microcontroller can match the impedance by switching

one or two inductors and when necessary capacitors in the output stage.

2.3.6 US head

The ultrasound treatment head is of course a very important part of the apparatus. It converts the electric signal

into ultrasound using a piezo crystal. This crystal, with a diameter depending on the desired head size, is glued

in an aluminium cup that minimizes electromagnetic radiation and enables the crystal to be used on to

operating frequencies.

The aluminium cup can also be used as a second electrode if combination therapy is desired. A separate

electrotherapy device needs to be connected to the safety socket for combination therapy.

A resistor is in the connector of the treatment head to enable the microcontroller to detect whether a head is

connected and to recognize the type of head that is connected.

2. THEORY OF OPERATION Service information Phyaction 190 / 190i - Page 8

CHAPTER 3 PERFORMANCE CHECK

3.1 Safety inspection

This inspection is for technical maintenance purposes only. It is recommended that this test is carried out once

a year. If the appliance is serviced, the full IEC 601-1 tests have to be carried out. A short description of these

tests is in section 3.2.

3.1.1 Visual inspection

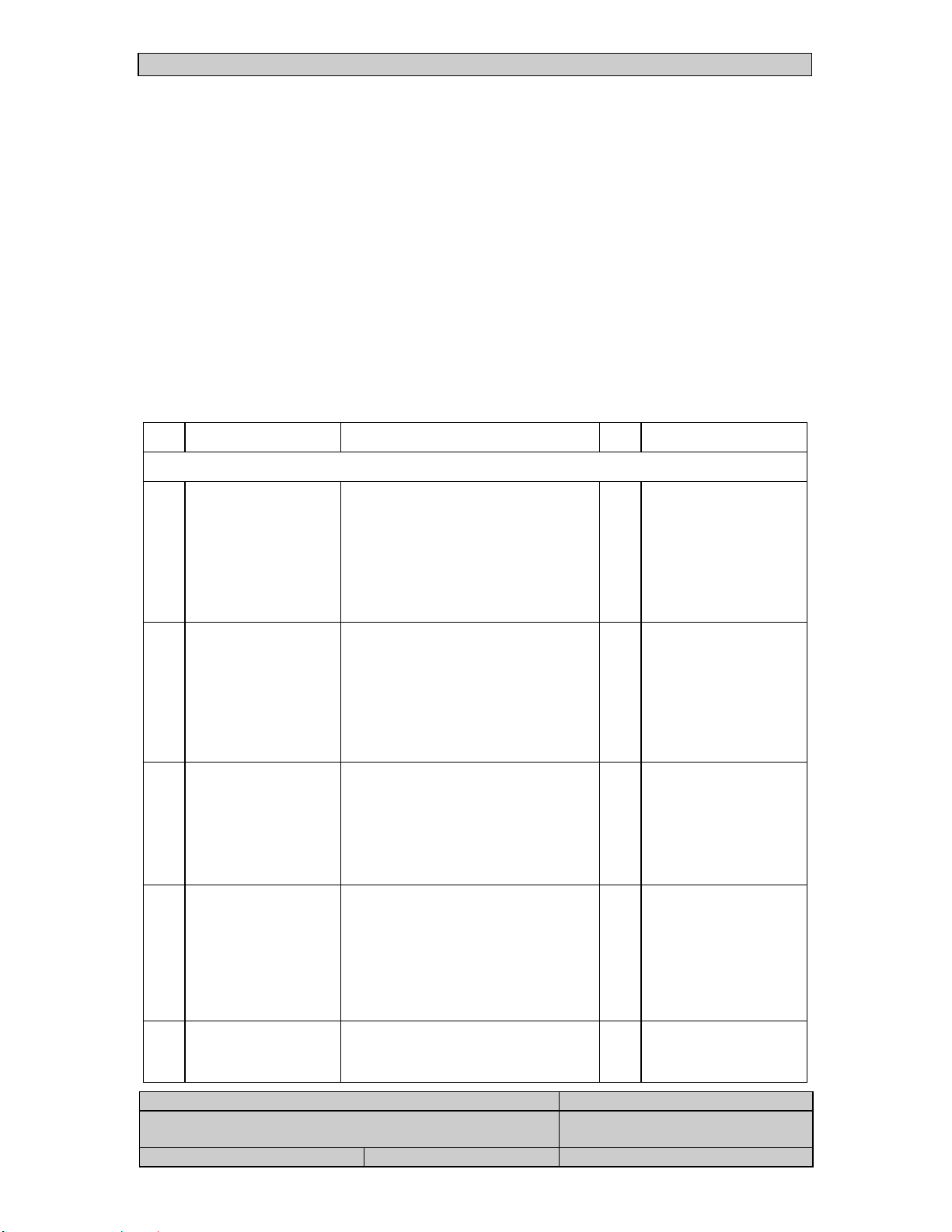

Passed, when all applicable items are answered with YES.

Is the user manual there?

Is the casing of the appliance undamaged?

Is the label well readable?

Are the controls, display, lights and connectors all right?

Are the mains input and the equipotentiality busbar all right?

yes no

Are ultrasound treatment heads, cables and connectors undamaged? (Pay special

attention to possible leaks in the treatment heads, such as cracks or loosened

seems.)

Are the labels on the ultrasound treatment heads readable?

3.1.2 Functional test

Passed, when all applicable items are answered with YES (or not applicable).

yes no

Is the automatic selftest executed successfully at power on?

Is the appliance adjusted to all treatment heads? 1 cm²

4 cm²

Does the ultrasound output correspond with the power displayed on the 1 cm²

LCD, for both frequencies at maximum intensity? 4 cm²

3.1.3 Test of the electrical safety according to VDE 0751

Parameter Measured value Limit Remarks

Protective earth resistance

Ω

< 0.2 Ω

Enclosure leakage current

Patient leakage current

µA < 1000 µA

µA < 5000 µA

Also register the measured values in the device records and compare them with the values measured in the

past to alert for a possible potentially dangerous tendency.

3. PERFORMANCE CHECK Service information Phyaction 190 / 190i - Page 9

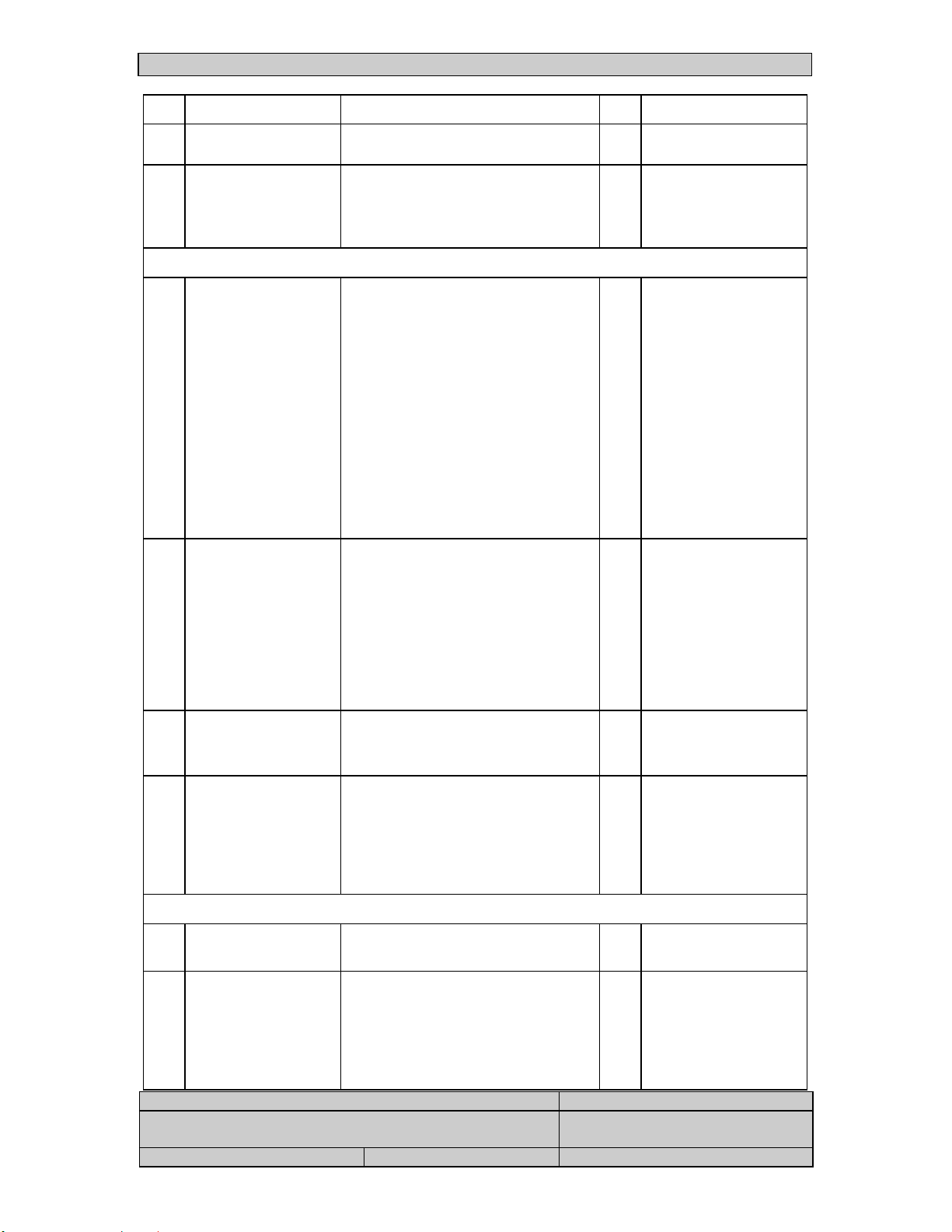

3.2 IEC 601-1 safety tests

For the full description of these tests we refer to the IEC 601-1 (1988) for Class I, Type BF equipment. Here is

just a short reminder list of the tests and the test limits.

Measurements limits

Insulation resistance mains

Insulation resistance applied part

Protective earth resistance

Enclosure leakage current normal

Enclosure leakage current open lead

Enclosure leakage current open earth

Enclosure leakage current reverse

Enclosure leakage current open lead

Enclosure leakage current open earth

Earth leakage current normal

Earth leakage current open lead

Earth leakage current reverse

Earth leakage current open lead

Patient leakage current normal

Patient leakage current open lead

Patient leakage current open earth

Patient leakage current reverse

Patient leakage current open lead

Patient leakage current open earth

Mains on applied part normal

Mains on applied part reverse

Dielectric strength A.P. + CASE to MAINS *

Dielectric strength MAINS + CASE to A.P. *

> 2.0 MΩ

> 2.0 MΩ

< 0.2 Ω

< 100 µA

< 500 µA

< 500 µA

< 100 µA

< 500 µA

< 500 µA

< 500 µA

< 1000 µA

< 500 µA

< 1000 µA

< 100 µA

< 500 µA

< 500 µA

< 100 µA

< 500 µA

< 500 µA

< 5000 µA

< 5000 µA

> 1500 V

> 1500 V

rms

rms

* These tests need only be executed if repairs have been made in the mains part or in the output circuits.

3.3 Performance check of the ultrasound treatment heads

In the software of the Phyaction 190 a special menu for service purposes only is included. Most of these

features can be used for trouble shooting. You can find the description of the other items of the service software

in chapter 4 TROUBLE SHOOTING, section 4.3 Description of the service software. In this section the software

that is made to check the contact detection of the ultrasound heads will be described.

You enter the service menu by holding down the fourth and sixth blue function key while switching on the

device. As soon as you hear the buzzer you should release the keys. If you did it right, you will see at the

bottom of the start-up screen that the Phyaction 190 is in service mode. You can now enter the service menu by

holding down the yellow key for about 3 seconds. For software version 3.01 and up you should press the fourth

and sixth blue function key again to get the full service menu. You should be aware that the full service menu is

for service personnel only, so never tell a physiotherapist or doctor how to enter this menu, because they might

do things that will harm the appliance or the treatment heads. To check the performance of the ultrasound

head, select menu item 3 Check Vusi dry/wet.

You can connect one or two treatment heads, the appliance will measure both at the same time if two heads

are connected. On the LCD you will see an instruction to make the heads dry. Make sure that no water or gel is

on the treatment surface of the heads. Then you press the green button (memory), as instructed. The

3. PERFORMANCE CHECK Service information Phyaction 190 / 190i - Page 10

microcontroller will measure a voltage (Vusi) which is related to the current that is flowing through the treatment

head: Vusi dry. After this measurement you will see an instruction on the LCD to put the treatment heads in

water. Put the treatment heads in a spacious bowl of water (room temperature) and make sure that the

ultrasound waves which are reflected by the bottom or the side of the bowl don't come back to the treatment

heads, because that might affect the integrity of the measurement. Then press the green button as instructed.

The microcontroller will then measure the same parameter as before: Vusi wet. In the following table are the

values for the different frequencies and treatment heads which should be met.

Head type frequency Vusi dry / Vusi wet

Small 1 MHz > 1.5

Small 3 MHz > 1.3

Large 1 MHz > 1.5

Large 3 MHz > 1.3

If the measured values don't meet the specifications, you can first try to remeasure it with the treatment head in

a different angle in the bowl of water. If that is giving similar results, then check the numbers on the treatment

head label with the numbers in the appliance (see section 1.3.6 Checking the ultrasound heads or Appendix 2

TUNING THE ULTRASOUND TREATMENT HEADS). If all of these things are checked and meet the

specifications, then the treatment head is probably defective and should be exchanged.

3. PERFORMANCE CHECK Service information Phyaction 190 / 190i - Page 11

CHAPTER 4 TROUBLE SHOOTING

4.1 Introduction

If a Phyaction 190 is defective, in most cases the unit will detect an error in the automatic self test. A full

description of this test will therefore help the service technician in finding the error. In the next paragraph you

will find this description. Some errors may only occur during normal operation, so you will also find the tests that

are carried out during normal operation in that section. To give the service technician some extra tools for

trouble shooting, Uniphy has developed a special service menu with features specially for service operations.

This service software is described in section 4.3. Finally in Appendix 3 you will find a list of all possible error

messages and possible causes.

4.2 Description of the automatic selftest

This paragraph describes the internal self test of the Phyaction 190, the (critical) error messages and the

possible cause of the errors.

The following categories of errors are identified:

- Errors during self test

- Errors during normal use

- Software errors

If simple errors occur that can be corrected by the user an error message appears on the bottom line of the

display. These messages show the kind of error and a possible solution. These errors are described in the user

manual. Errors that cannot be corrected by the user are displayed as shown in figure 4.1 (where the numbers

are randomly chosen).

Figure 4.1, Error message

The error codes presented after 'Code:' are described in paragraphs 4.2.3 and 4.2.4. In some cases the

hexadecimal number after 'Value' gives additional information about the error. The error address indicates the

address of the routine where the error occurred. The hexadecimal values after 'Stack:' represent the position of

the stack pointer and the contents of the stack, showing the value of the program counter when the error routine

was called.

If the error routine detects that the LCD display is not functioning properly, or if the display is not yet initialized,

the buzzer will be activated a number of times. The number of beeps indicate the type of error (see also

paragraphs 4.2.3 and 4.2.4)

4.2.4 Error shutdown procedure

If the processor detects an error that cannot be corrected by the user, the complete ultrasound unit is put in a

safe condition and the processor will enter an infinite loop in which normal operation is not possible. If an error

is encountered that the user can correct, it will depend on the kind of error whether the ultrasound unit is

switched off or continues working.

The following shutdown procedure takes place:

- The red ERROR-LED is switched on

- The Fan starts working

- The buzzer will sound for approximately half a second

- The duty-cycle is set to 0

- The ultrasound voltage is set to its minimum value

5. TROUBLE SHOOTING Service information Phyaction 190 / 190i - Page 12

- The ERROR-us line is activated, inhibiting the 1MHz or 3MHz to enter the power stage of the ultrasound unit

- If the LCD cannot be accessed a number of beeps will be generated

- If the RS-232 port can be used the error number is sent over the RS-232 channel

- The error information is sent to the LCD (when it can be accessed)

- A short description of the error is displayed (e.g. I²C error)

- All interrupts are disabled

- The processor enters an infinite loop

4.2.5 Description of the self test

Since the microcontroller performs the self test, it will start by testing itself and its program and data memory. If

this test shows no errors, the microcontroller will check its analog and digital I/O ports. Next the ultrasound unit

is tested. And finally a number of small tests is performed. The latter tests are done both during self test and

during normal operation.

If the unit does not complete its self test, when no errors are displayed and the buzzer does not sound the

following should be checked:

- All supplies, including mains (is the mains plug connected properly and are the fuses not blown?)

- Is the internal wiring properly connected?

- Is the microcontroller operating properly?

- Is the program EPROM with a proper program installed?

- Are data-, address- and control lines of the processor in order?

It will be clear that the user can check the mains and fuses. All other possible error causes have to be tested be

a service technician.

The next paragraphs discuss the internal tests performed in the automatic self test. The order in which the tests

are discussed is not necessarily the same as the order in which they are performed.

Microcontroller core test

The following tests will be performed to check proper functioning of the microcontroller and its required

hardware (program and data memory).

1) The ALU and a number of instructions are verified. When an error is met ERROR 00 is generated and 6

beeps will sound.

2) The internal memory (the registers of the microcontroller) is checked. If an error is met in the internal

memory ERROR 01 is generated and 6 beeps will sound. Value indicates in which register the error is

encountered.

3) The external RAM is checked. If an error is met in the external RAM or if the RAM is not present, ERROR 02

is generated and 6 beeps will sound.

4) The first 32 kByte of program memory is tested against a known checksum. If the calculated checksum

differs from the expected checksum ERROR 04 is generated and 6 beeps will sound.

After the internal core test, the microcontroller will test the peripherals:

1) The bank-switching hardware is tested. If bank 0 cannot be found, ERROR 03 will be generated and 6

beeps will sound.

2) Timer 0 and timer 1 are initialized and tested. If timer 0 works improperly either ERROR 07 or ERROR

09 with Value 00 will be generated (which error is actually generated depends on the place in the

program where the error is occured). If timer 1 does not function properly ERROR 09 with Value 01 will

be generated. Together with ERROR 07 or ERROR 09 six beeps will sound.

3) The Analog to Digital converter hardware is checked. This test is done in two steps with different error

codes if it fails.

a) Testing of the ADC sequence and interrupt handling. In case of an ERROR 08 is generated and 6

beeps will sound.

b) Verifying the converted values. The reference voltage Vref of the reset IC is an accurate reference

for checking the ADC. If the measured Vref is above 2.63V or below 2.39V ERROR 56 is

generated. This error is caused by not proper functioning of either the reset circuit or the ADC.

4) The serial (RS-232) interface is initialized and tested. ERROR 27 is generated if a time out occurs.

5) Timer 2 is initialized and tested. ERROR 09 with Value 02 is generated on a time out.

5. TROUBLE SHOOTING Service information Phyaction 190 / 190i - Page 13

6) The Liquid Crystal Display is initialized and tested. ERROR 21 is generated on a time out. Since this

error message most probably cannot be displayed, 1 longer beep and three short beeps are generated.

7) The I²C bus is initialized and tested. ERROR 11 is generated on a time out. Value will show the address

of the device that has caused a time out.

8) The second part of the program EPROM is checked (Checksum). If an invalid checksum is found

ERROR 05 is generated and 6 beeps will sound.

9) The keyboard is checked. If a key is pressed during self test ERROR 41 is generated. The key that is

pressed is shown in Value.

10) The I²C E²PROM (the non-volatile memory) is checked. If it contains an incorrect checksum ERROR 31

is generated with the (new) checksum as Value. If the E²PROM has an invalid signature, ERROR 32 is

generated.

11) A reference voltage of 2.5V is measured. If the measured value is above 2.63V (086h) or below 2.39V

(079h) ERROR 56 is generated. The measured 8-bit AD value of Vref is shown as Value. With this

reference voltage both the reset IC and the ADC are checked.

12) The Intensity potentiometer is checked. The reference voltage on the potentiometer must be between

3.75V (0BFh) and 4.40V (0E0h), otherwise ERROR 54 is generated. Further, the voltage of the

potentiometer must correlate with the zero-switch of the potentiometer. If the switch indicates that the

potentiometer is in its zero position, the measured voltage must not exceed 0.19V (00Ah), or else

ERROR 55 is generated.

Test of the ultrasound unit

Checking the treatment head types

During self test the microcontroller checks the voltages from the treatment head resistors. If an unknown head

is found, i.e. if a voltage is not between 0.88V (02Ch) and 1.48V (04Bh), between 2.20V (070h) and 2.80V

(08Eh) or above 4.90V (0F9h), ERROR 58 is generated. Value 10 indicates an invalid voltage on the left

output, while Value 01 indicates this for the right output. During normal operation an unknown head type does

not generate a critical failure. During start-up though, it could indicate a hardware error in the head detection

hardware.

Checking the ultrasound voltage

1) After power on of the unit the PWM is in its minimum position (

0

/

). Any voltage still present in the

255

ultrasound unit (e.g. caused by a rapid off and on switching) is discharged by switching the ultrasound unit

on for a short moment. Next Vsense is measured and should be below 3.0V. If Vsense is above this value,

ERROR 51 is generated.

2) The PWM is set to a value close to maximum (

235

/

). The ultrasound voltage should reach at least 23.5V

255

within appr. 40 msec, otherwise ERROR 52 is generated.

The two values that are just measured (at PWM 0 and PWM 235) are used to determine the behaviour of the

SMPS power supply.

3) The duty-cycle is set to zero and Isns is measured. The voltage representing Isns should be below 0.05V,

otherwise ERROR 59 will be generated.

4) The PWM is set to its minimum value (

0

/

) and the ultrasound unit is activated. Now the ultrasound voltage

255

should reach a value of less than 17.0V within appr. 1 second. Otherwise ERROR 53 will be generated.

5) During self test and also during normal use the PLL is checked on not going out of lock. If the PLL does go

out of lock, ERROR 60 is generated.

Other tests during normal use

The following tests are performed on a regular basis during normal use:

1) The internal temperature is checked. If it goes above appr. 45°C, the fan is switched on. Should the inner

temperature rise above appr. 65°C, a critical error: ERROR 70 is generated.

2) The reference voltage over the intensity potentiometer is tested constantly. If this voltage is outside its limits

(from 3.75V (0BFh) to 4.40V (0E0h) ), a critical error is generated (ERROR 54)

3) The PLL is tested during body contact measurement. If the PLL goes out of lock ERROR 60 is generated.

This error can be caused either by the PLL or by a malfunction in timer 2.

4) The ultrasound voltage is constantly checked. If this voltage is higher than 28.5V, ERROR 57 is generated.

5) Every time an I²C device is accessed, the I²C protocol is checked on a time out. If a device does not respond

within a certain time limit, ERROR 11 is generated, with Value the address of the not responding device.

6) Every time the LCD display is accessed it has to respond within a certain time. Otherwise ERROR 21 is

5. TROUBLE SHOOTING Service information Phyaction 190 / 190i - Page 14

generated.

7) Every time the software waits on a signal from timer 0, timer 0 is also checked. If a time out is given,

ERROR 07 is generated.

8) Once the microcontroller has entered its normal program loop, it should never leave this loop. If the

microcontroller leaves the normal program loop ERROR 90 is generated.

4.3 Description of the service software

In the software of the Phyaction 190 a special menu is included for service purposes only. Most of these

features can be used for trouble shooting. You enter the service menu by holding down the fourth and sixth blue

function key while switching on the device. As soon as you hear the buzzer you should release the keys. If you

did it right, you will see at the bottom of the start-up screen that the Phyaction 190 is in service mode. You can

now enter the service menu by holding down the yellow key for about 3 seconds. For software version 3.01 and

up you should press the fourth and sixth blue function key again to get the full service menu. You should be

aware that the full service menu is for service personnel only

, so never tell a physiotherapist or doctor how to

enter this menu, because they might do things that will harm the appliance or the treatment heads.

Figure 4.2, Full service menu

If you press the yellow button in the main service menu, you return to the normal therapy screen. To get the

appliance out of the service mode you have to turn off the device.

In the following sections all menu items of the service menu will be described.

4.3.1 Set head parameters

Item 1 of the service menu, Set head parameters, is described in Appendix 2 TUNING THE APPLIANCE TO

AN ULTRASOUND TREATMENT HEAD.

4.3.2 Show ADC / Potnul / Keyboard

With item 2 of the service menu, Show ADC / Potnul / Keyboard, you can read back the voltages at the Analog

to Digital Convertor inputs. Also the measured internal temperature is displayed. At the right of the screen you

will see a picture of the keyboard of the Phyaction 190. Pressing one of the keys should light up the

corresponding key on the picture. Pressing the up key will start the fan, pressing the down key will stop the fan.

To exit this screen and return to the main service menu, you hold the yellow key for 5 seconds.

4.3.3 Check Vusi dry/wet

Item 3 of the service menu, Check Vusi dry/wet, is described in section 3.3 Performance check of the

ultrasound treatment heads.

5. TROUBLE SHOOTING Service information Phyaction 190 / 190i - Page 15

4.3.4 E²PROM menu, FDA/EC/Standby toggle

If you choose item 4 of the service menu, E²PROM menu, FDA/EC/Standby toggle, you will get another menu,

2

the E

PROM MENU, see figure 4.3.

Figure 4.3, E²PROM menu

In this menu you have several choices to display and alter the contents of the I²C E²PROM.

1. Show E²PROM Contents

If you choose this item the contents of the memory is displayed on the LCD. It starts with the head parameters

with the measured Vusi, then the contrast is shown and the default setting (TÜV / FDA). On the last line of this

screen treatment memory use is shown. If one of the black keys ¿ or À is pressed, you can scroll through a

hexadecimal display of the memory contents.

2. FDA Settings

With the blue function key F2 you can set the appliance in the FDA (American) settings. An arrow head will

appear before the FDA settings line. In FDA mode the duty cycle will be displayed in a percentage instead of a

ratio (example 25% instead of 1:4) and you can toggle between intensity and peak power setting.

3. EU/TÜV Settings

With the blue function key F3 you can set the appliance in the European or TÜV settings. These settings are

also the default settings when an E²PROM is initialised. An arrow head will appear before the EU/TÜV settings

line.

4. Toggle DEMO mode

If the appliance is not generating ultrasound, it will show a screen saver after 5 minutes of non activity. After

approximately 5 minutes the screen saver disappears and the LCD backlight is switched off. To prevent the

appliance to go in screen saver mode (e.g. for demonstrations) you can press the blue function key F4. An

arrow head will appear before this line to indicate that the screen saver is disabled. Pressing F4 again will

enable the screen saver.

5. Clear Treatment memory

The treatment memory can be cleared one location at a time in the memory menu. However if you want to clear

the complete treatment memory (e.g. after filling it with test values) you can use this function.

4.3.5 Flip (mirror) screen

When servicing the appliance it is very easy to put it on its rear side. In this position you can unscrew the

bottom plate and open it towards you. In this position it is possible to turn on the appliance while it is opened, so

you can measure signals for trouble shooting purposes. If you still want to be able to see the information on the

LCD, it is very convenient to put a mirror behind the appliance. Flipping the screen with this menu item enables

you to read the information on the LCD, even though it is in a mirror.

4.4 Error messages

Every error is internally represented by a number. If an error is encountered, this number is shown on the LCD

display (if possible) and sent to the serial port (if possible). Should the microcontroller not be able to show the

number on the display, an acoustic signal is given. The list is in Appendix 3.

5. TROUBLE SHOOTING Service information Phyaction 190 / 190i - Page 16

CHAPTER 5 EXCHANGING BOARDS AND MODULES

5.1 Introduction

The most frequent service operations will be the exchanging of boards or modules, because it would be too

time consuming and costly to do component level service in the field. When exchanging boards or modules

there are a few things that should be noticed. These attention points will be described in this chapter.

If you want to exchange a module or a board you will have to open the appliance. It is probably easy to place

the appliance on its rear side, with the bottom side towards you. You can unscrew the 5 screws of the bottom

plate and tilt it towards you. If you want to test and make measurements you can leave the cables and

connectors where they are, but if you want to exchange a board or module it is better to disconnect the cables

and seperate the bottom plate from the rest of the appliance.

If you have exchanged a board or module, always test the appliance. This functional test starts with switching

the device on and checking the 4 LEDs, the fan and the LCD. If no error messages appear, check the memory

(can you store a setting and retrieve it). Finally check the contact detection of the ultrasound heads. After this

you should do a safety test (short description in section 3.2).

In general it should be said that you should take the necessary precautions to prevent electrostatic discharges

occur on the delicate electronic circuits of the unit. These precautions implicate that you should ground the unit,

use a grounded desk overlay, ground the tools such as solder irons and you should be connected to ground by

the usual wrist or ankle strap.

5.2 Exchanging the software or the main board (PCB 192X)

If you want to exchange the software or the main board of the appliance, you first open the appliance as

described in section 5.1 Introduction. You disconnect the cable from the transformer to the main board and the

cable of the fan. Then you remove the two screws from the main board, which are located at the back of the

appliance (between the ultrasound module and the back side). You disconnect the cable from the main board to

the keyboard and the cable of the backlight of the LCD. Now you can shift out the board and exchange the

EPROM. If you want you can disconnect the other 4 cables, but that is not really necessary. If you want to

exchange the main board you will have to disconnect the cables from console and from the LCD backlight, take

out the board and disconnect the remaining cables.

If you have exchanged the software or the main board, shift back the PCB on its place and connect all cables.

Also connect the transformer cable. Leave the appliance on its rear side and switch it on. If any error message

appears on the LCD, switch the appliance off and try to repair the cause of the error. After you have succeeded,

you remove the external mains cable and fix the main board with the two screws. Then check whether all

cables are connected (fan !!) and close the case. After you have screwed in the 5 screws on the bottom plate,

you should do a short functional test and a safety test (short description in section 3.2).

5.3 Exchanging the ultrasound module

To remove the ultrasound module, you first remove the bottom plate as described in section 5.1 Introduction.

Make sure there are no treatment heads connected to the device. The easiest way to place the appliance is

with the front side down. Put it on a soft underground to make sure you don't damage the front side. Disconnect

the internal cable from the safety socket and unscrew the safety socket. Remove the screw to the tab at

R82/C82, then unscrew the three other screws to release the ultrasound module. You can take the module out

of the appliance case, remove the screws from the D-subminiature connector at the back of the module and

disconnect the cable.

If you install a new module there are a few things that you have to pay attention to. You start with connecting

the cable to the module and fixing it with two screws. There are two O-rings between the front panel and the

LEMO chassis parts (the sockets for the ultrasound output) to prevent any liquid from entering the appliance at

that place. Make sure the O-rings are undamaged and are positioned in the chambers around the holes for the

connectors. If you place the module you should make sure the LEDs are positioned in the LED-lenses. Before

you fix the module with the screws you should lift the appliance to make sure the O-rings are still on their place.

6. EXCHANGING BOARDS AND MODULES Service information Phyaction 190 / 190i - Page 17

The three screws with the mounting material can now be placed. These screws are thread-forming screws. The

best way to screw them in is as follows. You put the screw in the hole and first turn it anti-clockwise with a

screwdriver. If you feel that the screw is falling into the thread, you screw it in (clockwise). In this way you

prevent that a second thread is formed. This second thread wouldn't be very strong and there is even a

possibility the screw won't hold at all. This would mean you would have to exchange the front panel, which is at

lot of work and a lot of money. Do not forget to fix the tab at R82/C82, ESD performance would be severely

impaired. Finally you can put in the safety socket, fix it and connect the cable.

After this you install the bottom plate and do a functional test and a safety test.

5.4 Exchanging the LCD

If you have to exchange the LCD, you first have to remove the main PCB as decribed in section 5.2 Exchanging

the software or the main board (PCB 192X). Then you remove the flexcable on the keyboard PCB. After that

you can unscrew the four screws in the corners of the LCD module. Now you can take the LCD module out of

the appliance.

If you put in a new LCD module, make sure the LCD glass and the inside of the glass that is glued in the front

panel are clean. You can put in the new module and fix it with the four screws. These screws are threadforming screws. The best way to screw them in is as follows. You put the screw in the hole and first turn it anticlockwise with a screwdriver. If you feel the screw is falling into the thread, you screw it in (clockwise). In this

way you prevent that a second thread is formed. This second thread wouldn't be very strong and there is even

a possibility the screw won't hold at all. This would mean you would have to exchange the front panel, which is

at lot of work and a lot of money. Finally connect the cable on the keyboard panel and re-install the main board.

After this you install the bottom plate and do a functional test and a safety test.

5.5 Exchanging the keyboard PCB (194X)

If you want to exchange the keyboard PCB you will have to remove the bottom plate as described in section 5.1

Introduction. Remove the flexcable from the LCD and the cable that is coming from the main board. Now you

can remove the five screws and exchange the board.

Between the keyboard PCB and the key knobs is a silicon foil, to prevent any water to reach the electronic

circuits or the mains transformer. If there are any holes in the foil, you should exchange that as well.

You can fix the new keyboard PCB with the five screws. These screws are thread-forming screws. The best

way to screw them in is as follows. You put the screw in the hole and first turn it anti-clockwise with a

screwdriver. If you feel that the screw is falling into the thread, you screw it in (clockwise). In this way you

prevent that a second thread is formed. This second thread wouldn't be very strong and there is even a

possibility that the screw won't hold at all. This would mean you would have to exchange the front panel, which

is at lot of work and a lot of money. Finally you connect the two cables and install the bottom plate and do a

functional test and a safety test.

If you switch on the appliance with a new keyboard it may take some time before you get information on the

screen. This is because the E²PROM memory on the keyboard has to be initialised. This is also the reason why

you will get an error message (Error 32, E²PROM completely blank). Wait for the error message and switch the

appliance off and on again. Because the memory is on this PCB, you have to realise the patient memory

and all

data of the treatment heads are erased. This means you have to reinstall the treatment heads (see Appendix

2).

6. EXCHANGING BOARDS AND MODULES Service information Phyaction 190 / 190i - Page 18

Phyaction 190

Ultrasound treatment head installation procedure

Valid from SW-version 3.01

In order to tune a treatment head to the Phyaction 190, it is necessary to take the following steps:

1) Turn off the Phyaction 190

2) Connect the treatment head you wish to tune

to the Phyaction 190

3) Press the blue function keys number 4 and 6

(the right most blue key and the blue key

third from the right) and keep them pressed

4) Turn on the Phyaction 190, while function

keys 4 and 6 are pressed.

When you hear the buzzer sound, release

both function keys. When you have done this

correctly, you will see the screens from figure

1, followed by figure 2 (of course the version

numbers can differ). When you release the

keys too late, you will get an error message

(error 41).

5) In the normal user screen (see figure 3) the

word 'Service' will appear in the top right

corner.

6) Keep the yellow key pressed, until the

'Service Menu' appears (see figure 4).

7) Now press function key 1 (Set head

parameters). Figure 5 appears on the

screen. If it does not appear, check if a

treatment head is connected.

8) If necessary, select the desired head with

function key 1. Then enter the correct head

parameters, using the up and down keys and

the left and right keys (function keys 3 and

4). The head parameters are on the label of

the treatment head.

9) When the parameters are entered correctly

you can press the Ok button (function key 5).

The screen as shown in figure 6 will appear.

When the Phyaction 190 detects an invalid

set of parameters, the Ok key will not be

accepted.

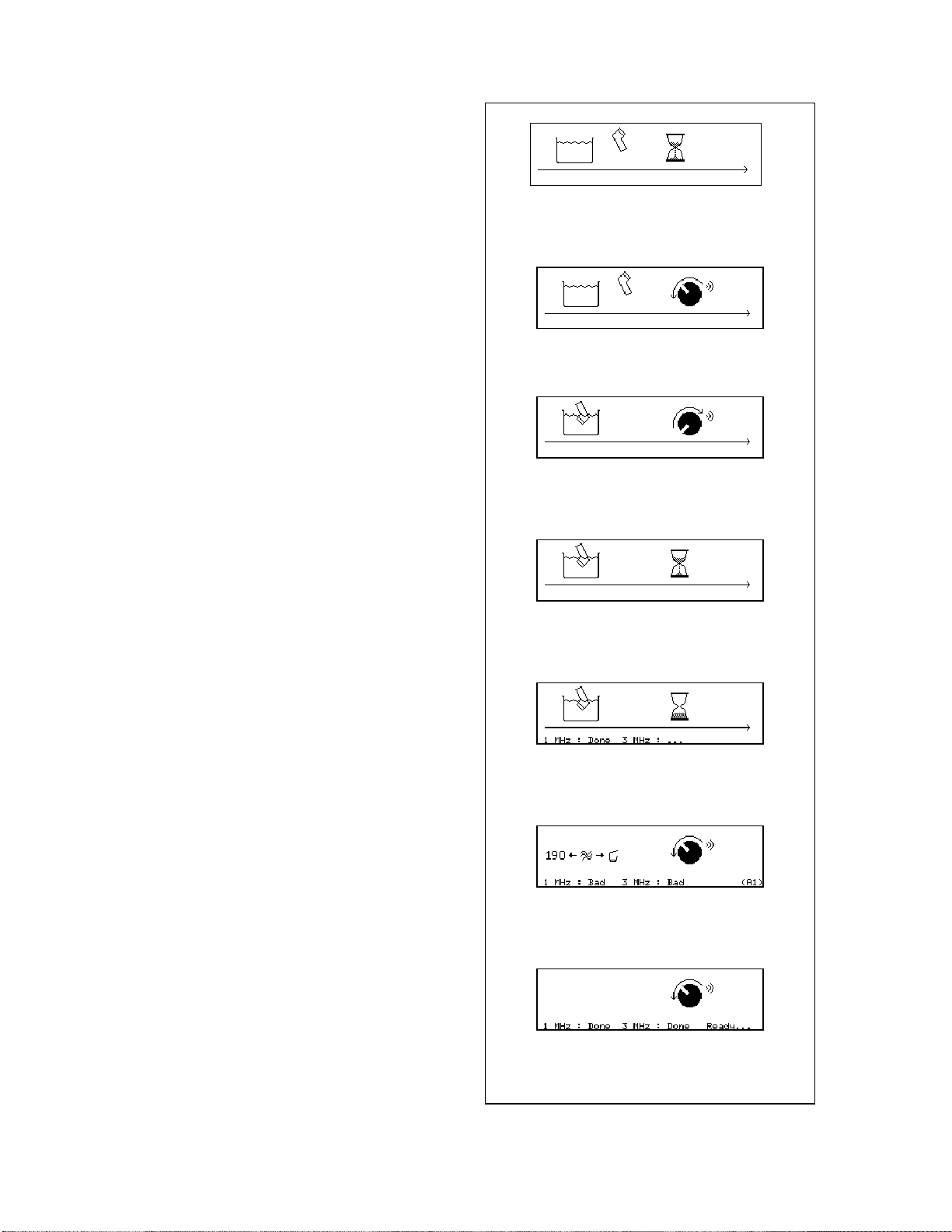

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

10) Ensure the treatment head to be dry and

clean, then turn up the intensity knob. The

Phyaction 190 will now tune the treatment

head. The Phyaction 190 will show figure 7

during tuning.

11) When you see the screen as in figure 8, turn

back the intensity knob to its zero position.

12) Put the selected treatment head in a large

bowl amply filled with water (about 18°C).

Keep the treatment head in such a way that

the generated ultrasound cannot reflect onto

the treatment head.

13) Now turn up the intensity knob (see figure 9).

The Phyaction will now tune the treatment

head. The Phyaction 190 will show figure 10

and 11 during tuning. The Phyaction will

show if the tuning has succeeded. It shows

the frequency at which it is tuning the head,

followed by the message 'Done' or 'Bad'.

14) If one or two of the results are 'Bad', the

tuning has not succeeded. A code

representing the reason why the tuning has

not succeeded, occurs in the lower right

corner (see figure 12). Turn back the

intensity knob to its zero position. Now wait

until the service menu appears again.

Repeat the steps from step 7 (including

checking of the head parameters).

When the result is still bad, contact your

supplier.

15) When the treatment head is tuned on both

frequencies (see figure 13), turn back the

intensity knob to its zero position. Now wait

until the service menu appears again.

16) Now you have tuned the treatment head to

the Phyaction 190.

17) If you want to tune another treatment head,

continue with step 7 and choose the other

treatment head

18) Turn off the Phyaction 190 (but remember,

not before the service menu has appeared)

19) Turn on the Phyaction 190 and check the

contact control of the head(s) you have just

tuned (see the Instructions for use).

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Figure 13

Short list of error numbers

Microcontroller core:

00 err_CPU An internal CPU error is found (ALU/instructions)

01 err_IntRAM Internal RAM error

02 err_RAM External RAM error

03 err_Bankswitch Bankswitching error

04 err_ROM0 Checksum error in the first part of the program ROM

05 err_ROM1 Checksum error in the second part of the program ROM

Peripherals:

06 err_CPUsfr Special function register start-up error

07 err_CPUtimer0 Timer 0 error

08 err_ADC AD converter time out

09 err_CPUtimers Timer error (timer 0, 1 or 2)

I²C bus:

10 err_I2C General I²C error

11 err_I2C_TimeOut Time out of the I²C bus

12 err_I2C_ReadErr I²C Error during read

14 err_I2C_WriteErr I²C Error during write

User interface:

20 err_LCD General LCD error

21 err_LCD_TimeOut LCD time out error

27 err_Ser_TimeOut Serial port time out

E²PROM errors:

30 err_E2PROM General E²PROM error

31 err_E2PROM_Checksum Checksum error in the E²PROM

32 err_E2PROM_Blank E²PROM completely blank

Keyboard:

40 err_Keyboard General keyboard error

41 err_KeyPressed Key pressed during power up

Internal voltages:

50 err_Voltage General error voltage inputs

51 err_Vsense0 Vus too high at start-up

52 err_Vsense1 Vus too low during reference test

53 err_Vsense2 Vus too high after discharge

54 err_VPotRef PotRef value incorrect

55 err_VPotNul PotNul active while Pot_US > 10

56 err_VRef Vref value incorrect

57 err_Vddus Vddus too high

58 err_Errorhead Error head or unknown head found at start-up

59 err_VIsns Isns too high during no ultrasound

Phase locked loop:

60 err_PLL_Lock PLL out of lock

Internal temperature:

70 err_VTemp Internal temperature too high

Auteur: W. Thijssen Paraaf:

File: C:\WINDOWS\Temporary Internet

Files\OLK1242\EL190001.DOC

Versie: 1.1 Datum: Pagina: 1 /

Uniphy B.V.

Software:

90 err_End_Of_Main Unexpected end of program

Acoustic error messages

If an error is found, four different types of acoustic signals can be given:

- 2 sec. beep : Non-critical error during normal use, to be corrected by the user.

1

/2 sec. beep : Critical error, not of the CPU, that can be displayed.

-

1

/2 sec. + 3 short beeps : Time out of the LCD (Error 21), an error that normally cannot be

-

displayed

- 6 short beeps : Critical CPU error (00 to 09). The microcontroller tries to show this

error on the LCD display.

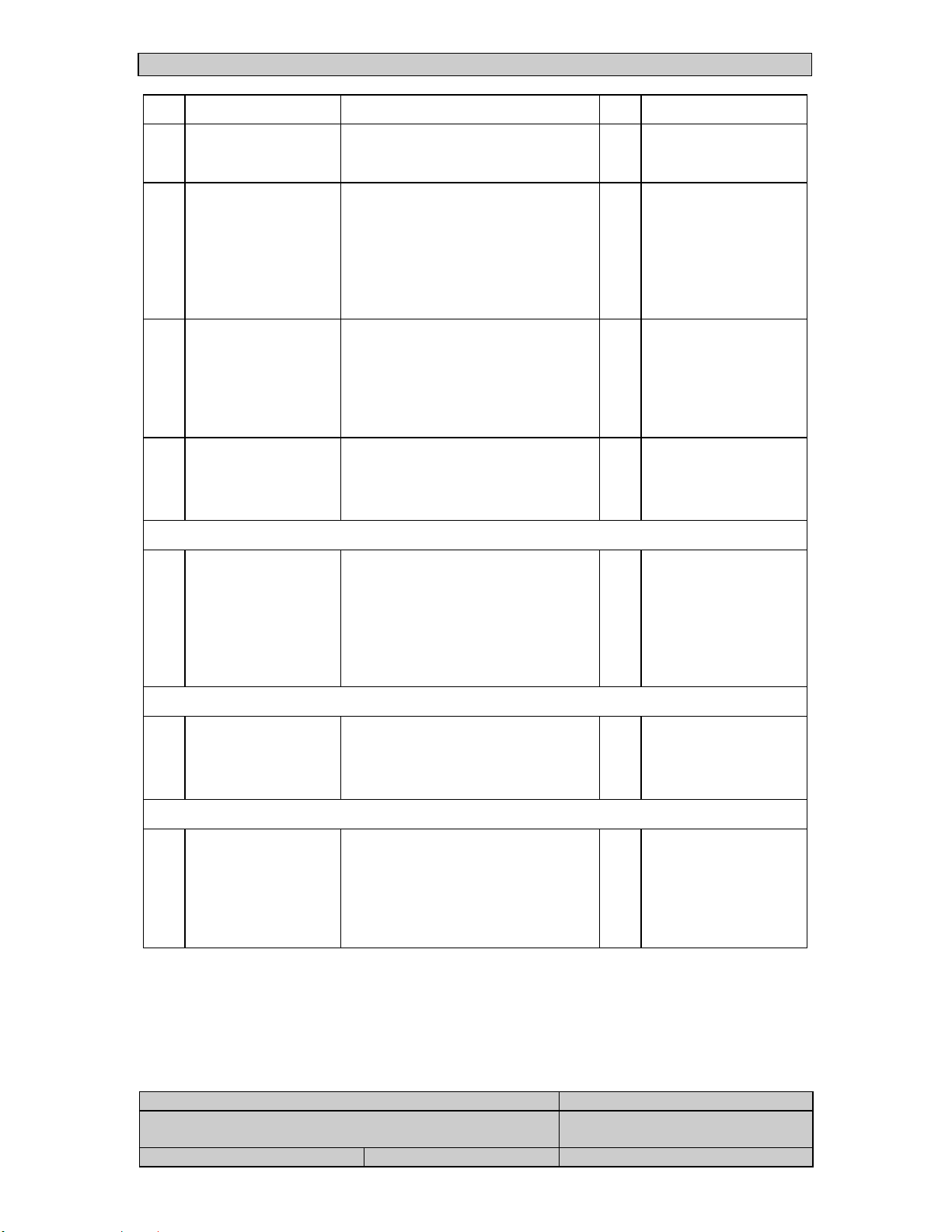

List of errors with possible causes

Nr. Name Description Val Comment

1. Microcontroller core

00 err_CPU An error is found in the ALU or the

instructions of the microcontroller.

Check the microcontroller and the

software.

01 err_IntRAM An error is found in the internal

RAM of the microcontroller.

Probably the microcontroller needs

to be replaced. Otherwise check the

software.

02 err_RAM An error is found in the external

RAM.

Check the RAM and the

data/address lines.

03 err_Bankswitch Bankswitching of the program ROM

is not functioning properly.

Check the bankswitching hardware

and the appropriate processor lines.

00

If value differs from

xx

00, an incorrect

internal register bank

is addressed.

Six short beeps will

sound.

xx Value indicates at

which memory

location the error is

found.

Six short beeps will

sound.

xx Value indicates in

which 256 byte block

the error is found.

Six short beeps will

sound.

01 Value shows the bank

number

(At present always

01).

Six short beeps will

sound.

04 err_ROM0 Incorrect checksum in the first 32

xx Value contains the

kByte of the EPROM. Check the

EPROM contents and the

Auteur: W. Thijssen Paraaf:

File: C:\WINDOWS\Temporary Internet

Uniphy B.V.

Files\OLK1242\EL190001.DOC

Versie: 1.1 Datum: Pagina: 2 /

LSB of the 16 bit

checksum

Nr. Name Description Val Comment

data/address lines.

05 err_ROM1 Incorrect checksum in the second

32 kByte of the EPROM.

Check the EPROM contents and the

data/address lines.

2. Peripherals

Six short beeps will

sound.

80

Six short beeps will

sound.

06 err_CPUsfr The reset values of the Special

function registers (sfr) differ from

the expected values.

Check the microcontroller and the

software.

07 err_CPUtimer0 Timing of timer 0 is incorrect.

Check the microcontroller and the

software.

08 err_ADC No interrupt from the AD converter.

Check the microcontroller and the

software.

00

sfr: PCON

01

sfr: IEN1

02

sfr: IP0

03

sfr: IP1

04

sfr: ADCON

05

sfr: TCON

06

sfr: TMOD

07

sfr: TM2CON

08

sfr: CTCON

09

sfr: TM2IR

0A

sfr: S0CON

Six short beeps will

sound.

xx Value gives an

estimate of the

number of times timer

0 has caused an

interrupt since a 10

msec flag was set.

Six short beeps will

sound.

00

Six short beeps will

sound.

09 err_CPUtimers Improper functioning of Timer 0, 1,

or 2.

Check the microcontroller and the

software.

3. I²C bus

10 err_I2C General I²C error for internal use.

(Mask for detecting an I²C error).

11 err_I2C_TimeOut Time out of an I²C device. Check

the addressed device.

Check the complete I²C bus and the

microcontroller if Value=40 (the

first device accessed).

Auteur: W. Thijssen Paraaf:

File: C:\WINDOWS\Temporary Internet

Files\OLK1242\EL190001.DOC

Versie: 1.1 Datum: Pagina: 3 /

00

01

02

Only for internal use.

Uniphy B.V.

timer 0

timer 1

timer 2

Six short beeps will

sound.

The user sees this

message if an I²C

error occurs. Value

contains the address

of the device that

caused the time out.

Nr. Name Description Val Comment

40

I/O expander (write)

41

I/O expander (read)

A0

E²PROM (write)

A1

E²PROM (read)

12 err_I2C_ReadErr Only for testing purposes.

13 err_I2C_WriteErr Only for testing purposes.

4. User interface

20 err_LCD General LCD error for internal use.

(Mask for detecting an LCD error).

21 err_LCD_TimeOut LCD communication error. Check

the LCD, the connections (data /

address lines) to the LCD, the

selection logic and the

microcontroller.

27 err_Ser_TimeOut RS-232 communication error.

Check the microcontroller and the

software.

5. E²PROM errors

30 err_E2PROM General E²PROM error for internal

use. (Mask for detecting an LCD

error).

31 err_E2PROM_Check

sum

32 err_E2PROM_Blank A signature that should be stored in

Incorrect E²PROM checksum.

Probably the unit is switched off

during a write to the E²PROM. The

checksum will be corrected

automatically. If this error occurs

regularly check the E²PROM.

the E²PROM is not found and the

software erases the E²PROM. This

error always occurs in a totally new

unit. If this error occurs in an

existing unit, the E²PROM should be

checked. If considered appropriate,

check the software.

Only for internal use.

xx Value contains the

status of the LCD.

One longer beep and

three short beeps will

sound.

Only for internal use.

xx Value shows the

checksum as stored in

the E²PROM.

This error will always

00

show if a new keyboard PCB is installed

or the E²PROM is

replaced. In those

cases the E²PROM

will be empty so no

signature will be

found. Otherwise this

error may never

occur.

6. Keyboard

40 err_Keyboard General keyboard error for internal

use. (Mask for detecting a keyboard

error).

41 err_KeyPressed A key action is detected during

power up.

Auteur: W. Thijssen Paraaf:

File: C:\WINDOWS\Temporary Internet

Files\OLK1242\EL190001.DOC

Versie: 1.1 Datum: Pagina: 4 /

For internal use only.

xx

Uniphy B.V.

Value contains the

number of the detec-

Nr. Name Description Val Comment

If no key is pressed during power

up, check the keyboard and the

keyboard PCB.

7. Internal voltages

ted key. This function

also discourages the

user if trying to enter

the service menu.

50 err_Voltage General voltage error for internal

use. (Mask for detecting an internal

voltage error).

51 err_Vsense0 Vus is too high ( > 3.0V ) at power

up.

Check the SMPS in the ultrasound

unit.

Check the PWM of the

microcontroller.

52 err_Vsense1 Vus is too low ( < 23.5V ) at the

reference value.

Check the SMPS in the ultrasound

unit.

Check the connections between

main PCB and ultrasound unit.

Check the power supplies. Check

the PWM.

53 err_Vsense2 Vus too high after discharge. ( >

17.0V ).

Check the SMPS in the ultrasound

unit.

Check the PWM.

For internal use only.

xx Value represents the

measured voltage:

Hexadecimal

representation of the

measured voltage *

10

(so at 3.5V:

decimal 35 -> 23h).

xx Value represents the

measured voltage:

Hexadecimal

representation of the

measured voltage *

10

(so at 22.5V:

decimal 225 -> E1h).

xx Value represents the

measured voltage:

Hexadecimal

representation of the

measured voltage *

10

(so at 22.5V:

decimal 225 -> E1h).

54 err_VPotRef The value of VPotRef is outside its

limits ( < 3.75V = BFh or >

4.40V = E0h).

Check the wiring of the intensity

potentiometer.

55 err_VPotNul The intensity potentiometer switch

indicates that the potentiometer

should be at zero, but the measured

voltage is too high

( > 0.19V = 0Ah).

Check the wiring of the

potentiometer.

Check the processor lines.

56 err_VRef The reference voltage is outside its

limits ( < 2.39V = 79h or

> 2.63V = 86h).

Auteur: W. Thijssen Paraaf:

File: C:\WINDOWS\Temporary Internet

Files\OLK1242\EL190001.DOC

Versie: 1.1 Datum: Pagina: 5 /

xx Value is the (8-bit)

xx Value is the (8-bit)

xx Value is the (8-bit)

Uniphy B.V.

measured voltage of

PotRef.

measured voltage of

the intensity

potentiometer.

measured voltage of

Vref.

Nr. Name Description Val Comment

Check the reset circuit.

Check the ADC of the micro-

controller.

57 err_Vddus The ultrasound voltage is too high

( > 28.5V ).

Check the SMPS in the ultrasound

unit.

58 err_Errorhead During self test an unknown head is

detected.

Check for an unknown head being

connected.

Check the head type detection

hardware.

59 err_VIsns Isns is too high if no ultrasound is

produced ( V > 0.05V ).

Check the power stage in the

ultrasound unit.

8. Phase locked loop

60 err_PLL_Lock The PLL in the ultrasound unit is out

of lock.

Check RefClock and check the PLL

circuit in the ultrasound unit.

Check timer 2 of the

microcontroller.

xx Value represents the

measured voltage:

Hexadecimal

representation of the

measured voltage

(so at 29.3V:

decimal 29 -> 1Dh).

01

Unknown head type

in the right output.

10

Unknown head type

in the left output.

xx Value is the (8-bit)

measured voltage of

Vusi. (so 0.05V ->