Page 1

Programmable Power Supply

PSH series

USER MANUAL

GW INSTEK PART NO. XXXX-XXXXXX

This manual contains proprietary information, which is protected

by copyrights. All rights are reserved. No part of this manual may

be photocopied, reproduced or translated to another language

without prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves

the rights to change specification, equipment, and maintenance

procedures at any time without notice.

ISO-9001 CERTIFIED MANUFACTURER

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng City, Taipei County 236, Taiwan.

Page 2

Table of Contents

Table of Contents

PSH User Manual

Buzzer sound Setting ................................51

Remote Operation.........................................52

Safety Instructions ........................................ 5

Safety Symbols ......................................... 6

Safety Guidelines....................................... 6

Power cord for the United Kingdom .............. 9

PSH Overview .............................................. 11

Main Features ..........................................12

PSH Series Lineup.....................................13

Package Contents .....................................14

Front Panel ..............................................16

Rear Panel ...............................................18

Display....................................................19

Setup ........................................................... 21

AC Power Cable Assembly..........................22

Remote Sensing and Local Sensing .............24

Load / Remote Sensing Wire Selection.........25

Load Configuration....................................26

Load Wire Assembly..................................30

Remote Sensing Wire Assembly ..................32

Functionality Check...................................34

Rack Mounting (Optional) ..........................40

Interface Selection....................................53

Command Syntax .....................................57

Command Set ..........................................58

Calibration ....................................................61

Calibration Preparation ..............................62

Entering calibration mode ..........................63

Output Voltage calibration..........................64

Output Current calibration .........................66

OVP Calibration ........................................68

FAQ...............................................................69

Appendix.......................................................71

Specifications...........................................71

Declaration of Conformity ..........................75

Index ............................................................76

Panel Operation ........................................... 43

Menu Key Overview ..................................44

Constant Voltage/ Constant Current Crossover

Characteristic...........................................45

Output Voltage Setting ..............................46

Output Current Setting ..............................47

OVP (Output Voltage Protection) Setting ......48

OCP (Output Current Protection) Setting ......49

Display Contrast Setting ............................50

3

4

Page 3

Safety Instructions

PSH User Manual

Safety Symbols

Safety

Guidelines

Power cord

Safety Instructions

This chapter contains important safety

instructions that must be followed when

operating PSH and when keeping it in storage.

Read the following before any operation to

insure safety and to keep the best condition for

PSH.

Safety Symbols .........................................6

Safety Guidelines....................................... 6

Power Supply ............................................ 7

Fuse ........................................................7

Cleaning PSH ............................................7

Operation Environment............................... 8

Storage Environment ................................. 8

Power cord for the United Kingdom .............. 9

Safety Symbols

These safety symbols may appear in this manual or on PSH.

Warning: Identifies conditions or practices that

WARNING

could result in injury or loss of life.

Caution: Identifies conditions or practices that

CAUTION

could result in damage to PSH or to other

properties.

DANGER High Voltage

Attention Refer to Manual

Protective Conductor Terminal

Earth (ground) Terminal

Safety Guidelines

General

Guideline

CAUTION

• Do not place any heavy object on PSH.

• Avoid severe impacts or rough handling that

leads to damaging PSH.

• Do not discharge static electricity to PSH.

• Do not block or obstruct cooling fan vent

opening.

• Do not perform measurements at power source

and building installation site (Note below).

• Do not disassemble PSH unless you are

qualified as service personnel.

(Note) EN 61010-1:2001 specifies the measurement

categories and their requirements as follows. PSH falls

under category II.

Measurement category IV is for measurement performed

5

6

Page 4

Safety Instructions

PSH User Manual

Power Supply

WARNING

Fuse

WARNING

Cleaning PSH

at the source of low-voltage installation.

Measurement category III is for measurement performed

in the building installation.

Measurement category II is for measurement performed

on the circuits directly connected to the low voltage

installation.

• Input voltage: 90 ~ 250 V AC, 50/60 Hz

• The power supply voltage should not fluctuate

more than 10%.

• Connect the protective grounding conductor of

the power cord to earth ground, to avoid

electrical shock.

PSH-1036A

6.3A/250V x2

PSH-2018A

PSH-3610A

PSH-6006A

PSH-1070A

PSH-2035A

PSH-3620A

6.3A/250V x2

0.5A/250V x1

15A/250V x1

PSH-6012A

PSH-10100A

PSH-2050A

PSH-3630A

6.3A/250V x3

0.5A/250V x1

20A/250V x1

PSH-6018A

• Make sure the correct type of fuse is installed

before powering up.

• Replace the fuse with the specified type and

rating only, for continued fire protection.

• Disconnect the power cord before fuse

replacement.

• Make sure the cause of the fuse blowout is

fixed before fuse replacement.

• Disconnect the power cord before cleaning.

Operation

Environment

WARNING

Storage

Environment

xylene, and acetone.

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: < 85%

Altitude: < 2000m

Temperature: 0°C to 40°C

Input Breaker Capacity: Over 20A (PSH-10100A,

2050A, 3630A, 6018A)

This is a Class A product which may cause radio

interference in a domestic environment. In such

case, take adequate measures.

(Note) EN 61010-1:2001 specifies the pollution degrees

and their requirements as follows. PSH falls under degree

2.

Pollution refers to “addition of foreign matter, solid,

liquid, or gaseous (ionized gases), that may produce a

reduction of dielectric strength or surface resistivity”.

Pollution degree 1: No pollution or only dry,

non-conductive pollution occurs. The pollution has no

influence.

Pollution degree 2: Normally only non-conductive

pollution occurs. Occasionally, however, a temporary

conductivity caused by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry,

non-conductive pollution occurs which becomes

conductive due to condensation which is expected. In

such conditions, equipment is normally protected against

exposure to direct sunlight, precipitation, and full wind

pressure, but neither temperature nor humidity is

controlled.

Location: Indoor

Relative Humidity: < 70%

Temperature: −10°C to 70°C

• Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid

into PSH.

• Do not use chemicals or cleaners containing

harsh materials such as benzene, toluene,

7

8

Page 5

Safety Instructions

Power cord for the United Kingdom

When using PSH in the United Kingdom, make sure the power

cord meets the following safety instructions.

NOTE: This lead / appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code:

Green/ Yellow: Earth

Blue: Neutral

Brown: Live (Phase)

As the colours of the wires in main leads may not correspond with the colours

marking identified in your plug/appliance, proceed as follows:

The wire which is coloured Green & Yellow must be connected to the Earth

terminal marked with the letter E or by the earth symbol

or Green & Yellow.

The wire which is coloured Blue must be connected to the terminal which is

marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the terminal marked

with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment or contact

the supplier.

This cable/appliance should be protected by a suitably rated and approved

HBC mains fuse: refer to the rating information on the equipment and/or user

instructions for details. As a guide, cable of 0.75mm2 should be protected by a

3A or 5A fuse. Larger conductors would normally require 13A types,

depending on the connection method used.

Any moulded mains connector that requires removal /replacement must be

destroyed by removal of any fuse & fuse carrier and disposed of immediately,

as a plug with bared wires is hazardous if a engaged in live socket. Any

re-wiring must be carried out in accordance with the information detailed on

this label.

or coloured Green

9

Page 6

PSH Overview

PSH User Manual

Main features

Series lineup

Package

contents

Panel

descriptions

PSH Overview

PSH Series are modular-type programmable

switching power supplies designed for broad

range of applications. The series consists of 12

models, output ranging from 360W to 1000W.

Switching technology and built-in PFC control

give PSH higher power efficiency, power density,

and power factor compared with other linear

power supplies. Protection mechanisms keep the

output voltage, current, and temperature within

limit. Remote control interface equipped with

SCPI command set and Lab-View Driver

facilitates ATE software development.

This chapter describes PSH series features and

appearances in a nutshell.

Main Features ......................................... 12

360W..................................................... 13

720W..................................................... 13

1000/ 1080W.......................................... 13

Main unit ................................................ 14

AC input cable kit .................................... 14

Output connection kit............................... 15

Manual................................................... 15

Front Panel ............................................. 16

Rear Panel .............................................. 18

Main Features

Performance

Operation

Protection

Interface

Optional items

• 12 models with wide output range: 6~100A,

10~60V, and 360~1000W.

• High power factor with PFC control

• High efficiency power conversion

• Compact size, light weight

• Constant voltage operation

• Constant current operation

• Output On/Off control

• Built-in buzzer

• Self test and calibration

• LCD display

• Over voltage protection (OVP)

• Over current protection (OCP)

• Over temperature protection (OTP)

• RS-232 (standard) / GPIB (optional) interface

• IEEE 488.2/SCPI compatible command set

• LabView driver

• GPIB remote control interface

• 19 inch standard rack mounting

Display

descriptions

11

Default display ........................................ 19

Menu mode display .................................. 20

12

Page 7

PSH Overview

PSH User Manual

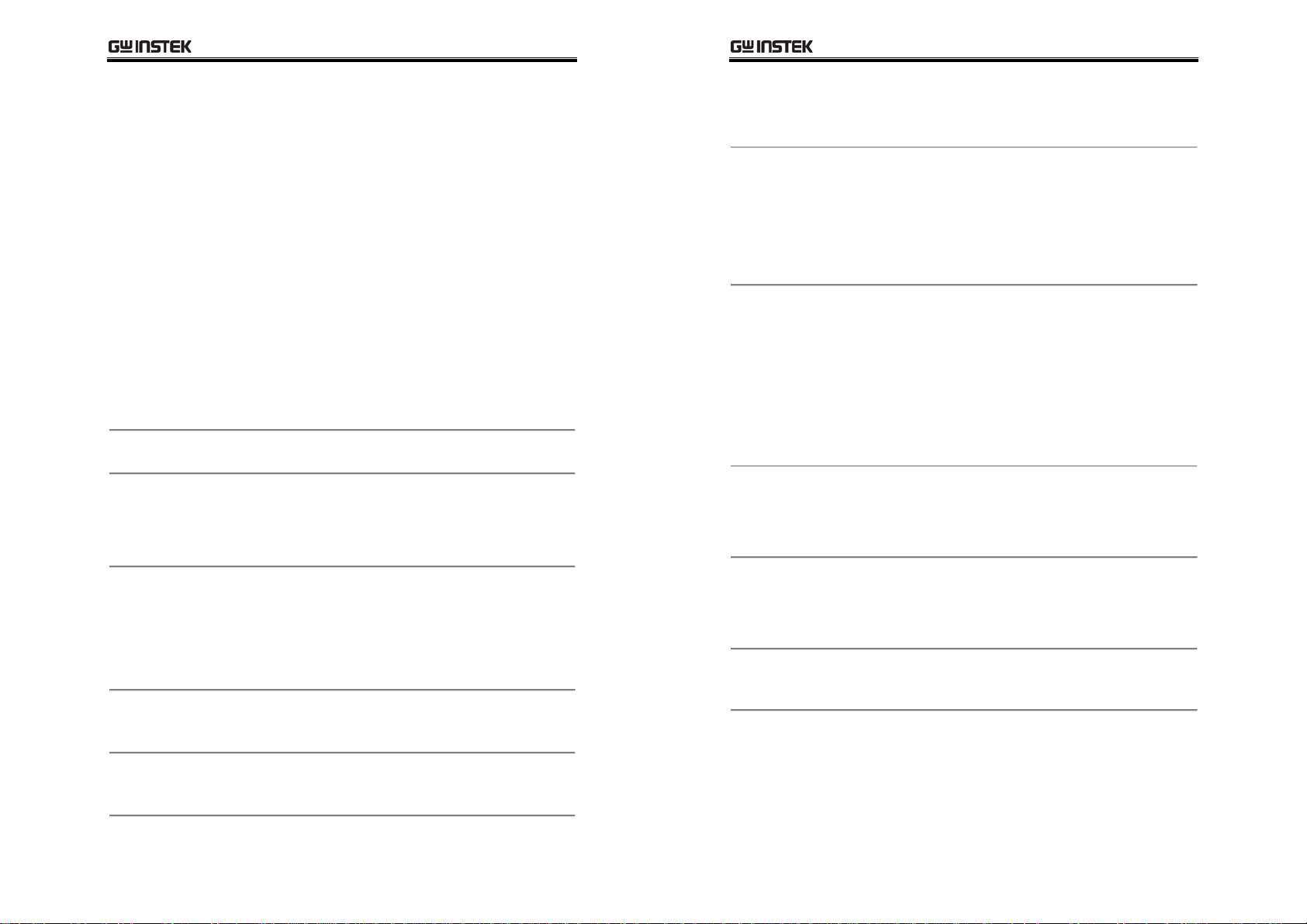

PSH Series Lineup

PSH series consist of the following 12 models with various output

voltage and current ratings. For the detailed specifications, see

page71.

360W

(Mainframe

only)

720W

(Mainframe +

one slave

module)

PSH-1036A

10V, 36A

PSH-2018A

20V, 18A

PSH-3610A

36V, 10A

PSH-6006A

60V, 6A

PSH-1070A

10V, 70A

PSH-2035A

20V, 35A

PSH-3620A

36V, 20A

PSH-6012A

60V, 12A

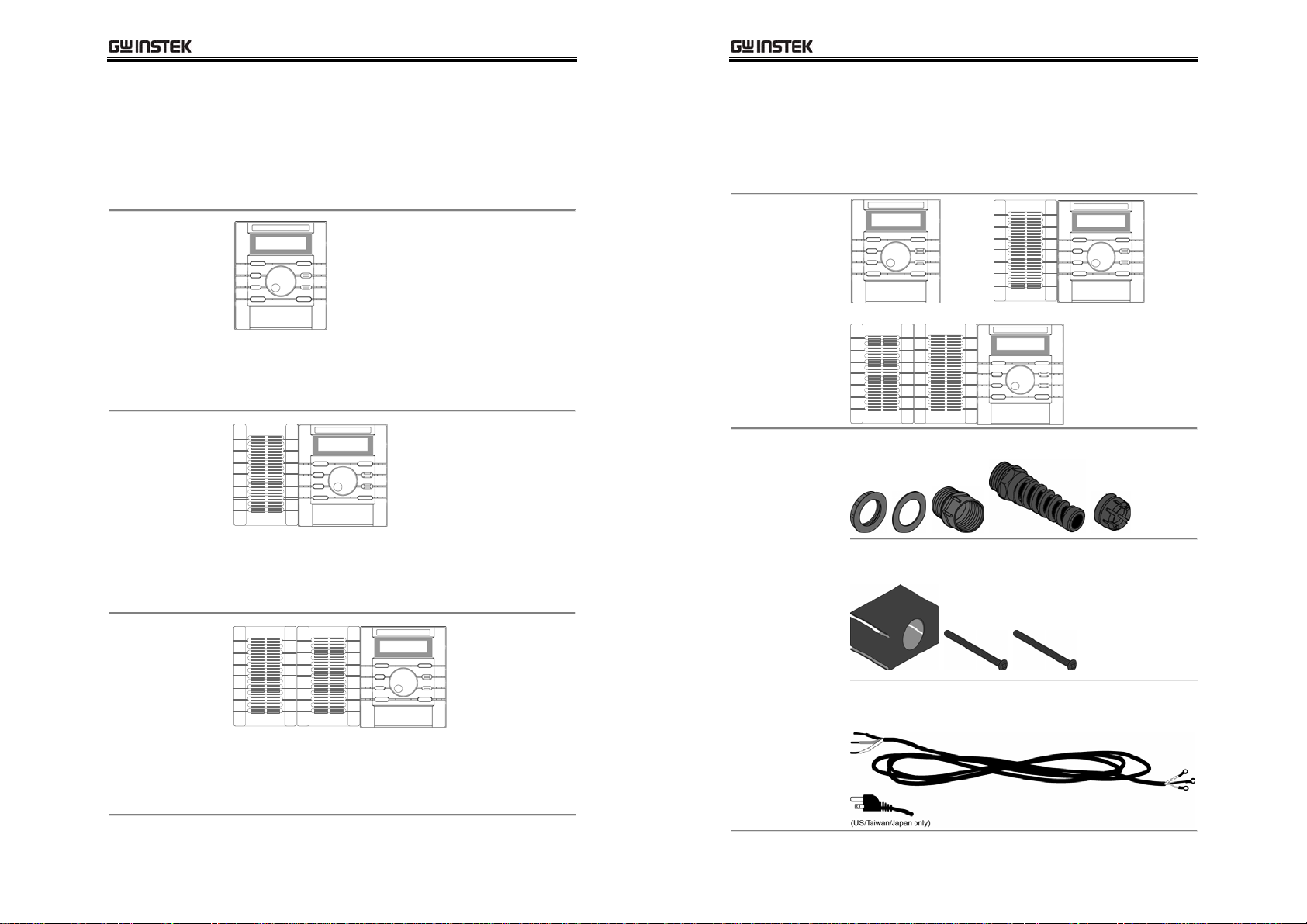

Package Contents

Check the contents before using PSH series. Contact your local

dealer in case there is a missing item.

Main unit

AC input cable

kit

• Cable gland

• Terminal cover

1000/ 1080W

(Mainframe +

two slave

modules)

PSH-10100A

10V, 100A

PSH-2050A

20V, 50A

PSH-3630A

• AC power input cord

36V, 30A

PSH-6018A

60V, 18A

13

14

Page 8

PSH Overview

PSH User Manual

Package Contents (cont.)

Output

connection kit

Manual

• Terminal cover

• Output cable screw

• User manual (this document)

• Programming manual

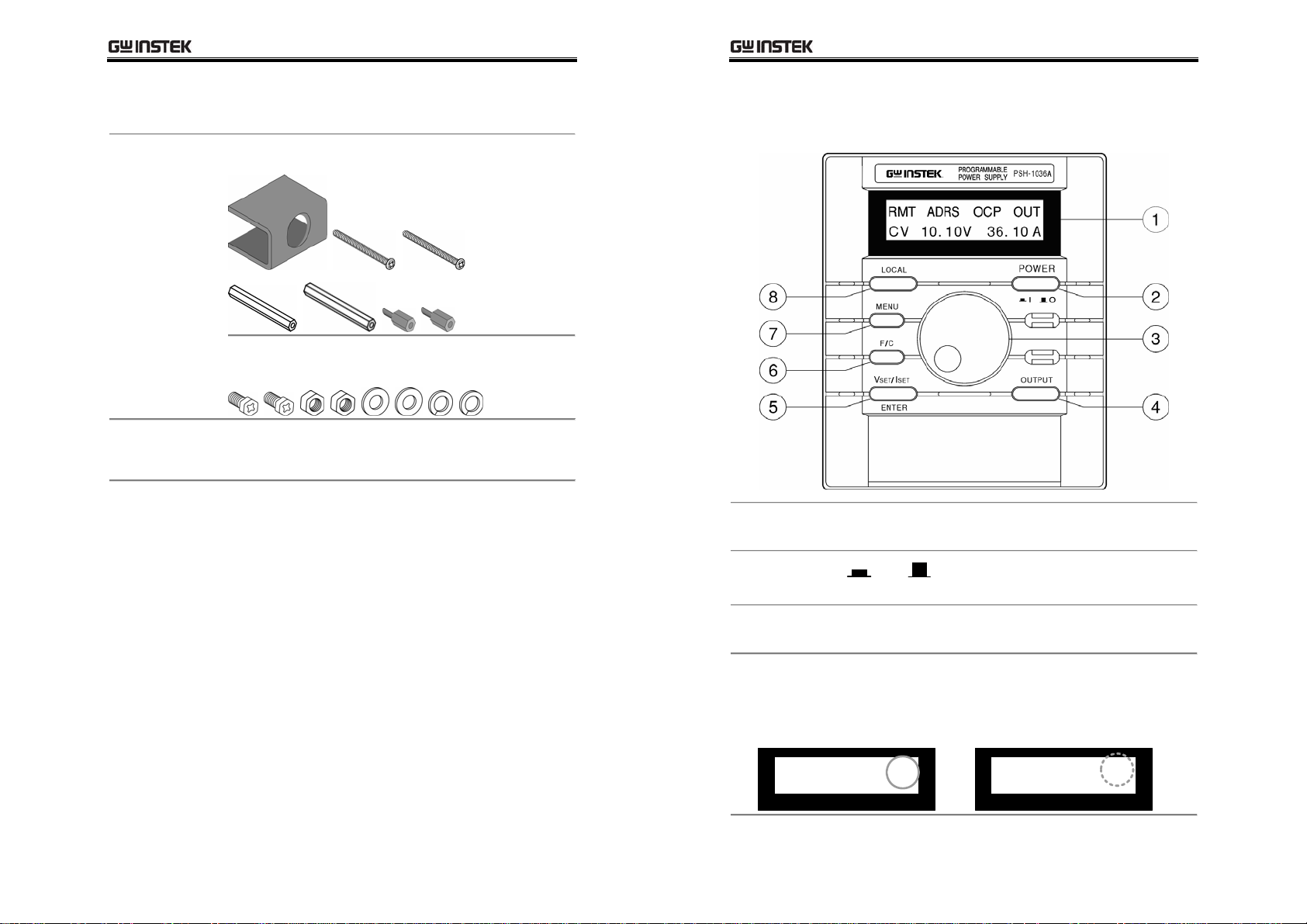

Front Panel

1 LCD Display

2 Power

Switch

3 Wheel knob

4 Output

Switch

Shows the output and the configuration status.

See page19 for details.

Sets parameters. Turn right: increase, turn left:

decrease.

Turns the output On or Off. When On, the “OUT”

sign appears on the display.

On Off

Out On

OCP OUT

CV 2.58V 2.01A

15

16

Out Off

OCP

SET 2.58V 2.01A

Page 9

PSH Overview

5 Vset/ Iset/

Enter key

PSH User Manual

Rear Panel

Switches between voltage setting mode and

current setting mode, or confirm the entered

value in the menu mode (see page44).

Vset (edit Voltage)

OCP

.58V 2.01A

SET 2

6 F/C (Fine/

Coarse) key

Switches the editing location and resolution:

before (coarse) or after (fine) the decimal point.

Fine (after decimal)

SET 2.58

7 Menu key

OCP

V 2.01A

Enters into the menu mode. For details, see

page44.

Default mode

OCP OUT

CV 2.58V 2.01A

8 Local key

Switches from remote control mode to local

operation mode (page56), OR releases OVP/OCP

error messages and go back to normal operation

(page37), OR enters the calibration mode when

pressed for more than 5 seconds (page61).

Error message example

OCP Error! Press

“Local” to reset

Iset (edit Current)

SET 2.58V 2

OCP

Coarse (before decimal)

SET 2

OCP

.58V 2.01A

Menu mode (OVP setting)

Set OVP

* 21.10V

Calibration mode

Calibration

Voltage

.01A

1 Ground

Terminal

2 Output

Terminal

3 Sense Terminal

Connect the output line shield (page25) and

the remote sensing line shield (page32).

Connect DUT (Device Under Test). For details,

see page24.

Connect the feedback line to compensate for

cable loss. For details, see page24 (theory),

4 RS232/ GPIB

Terminal

page32 (cable connection).

Connect the remote control line. For remote

control details, see page52. GPIB requires an

optional module. For installation details, see

the service manual.

Note: Only one interface module (RS232 or

GPIB) can be installed at a time.

5 AC input

Terminal

Connect the AC power input cable. For

details, see page22.

17

18

Page 10

PSH Overview

PSH User Manual

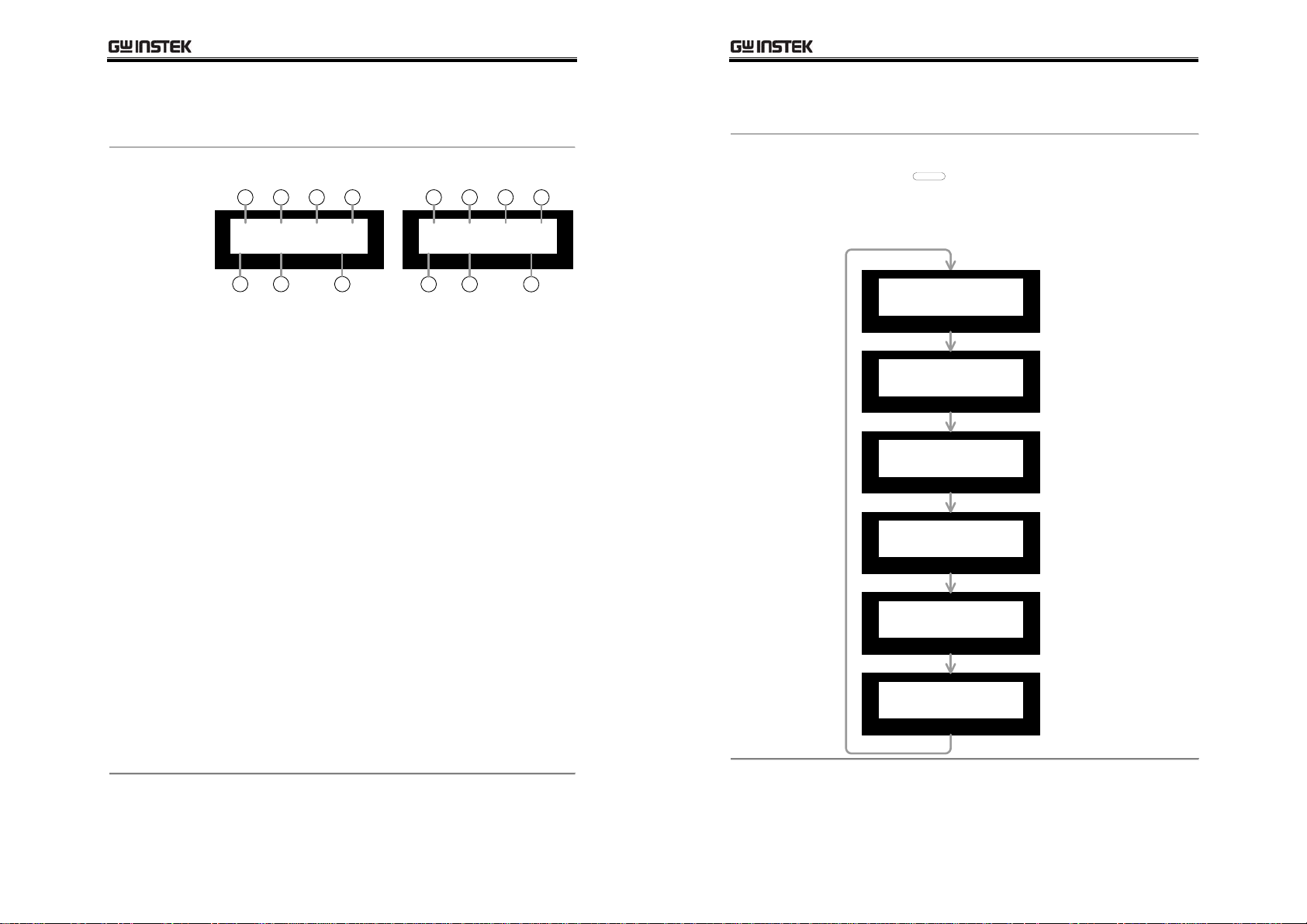

Display

Default

display

Display mode

A B C D

RMT ADRS OCP OUT

CV 10.10V 36.10A

E F G

Editing mode

A B C D

SET 10.10V 36.10A

E F G

OCP

A RMT: remote control mode

(Nothing): panel operation mode

Not available in editing mode

B ADRS: RS-232 or GPIB address (available

in remote control)

Not available in editing mode

C OCP: Output Current Protection On

(Nothing): Output Current Protection Off

D OUT: Output On

(Nothing): Output Off

Not available in editing mode

E CV/CC: Current and Voltage display

mode (Constant Voltage/ Constant

Current)

SET: Current and Voltage editing mode

F Output Voltage readback value (display

mode)

Output Voltage setting value (editing

mode)

G Output Current readback value (display

mode)

Output Current setting value (editing

mode)

Display (cont.)

Menu mode

display

The following displays appear when pressing the

Menu key

press the Menu key repeatedly. When inactive for

more than 5 seconds, the display goes back to the

default mode.

MENU

. To move to the next configuration,

OCP OUT

CV 2.58V 2.01A

Set OVP

21.10V

Set OCP

ON (OFF)

Set Contrast

70%

Set Buzzer

ON (OFF)

Interface RS232

Baud Rate 9600

(Default display)

Output Voltage

Protection setting.

For details, see

page48.

Output Current

Protection setting.

For details, see

page49.

Display contrast

setting. For details,

see page50.

Buzzer setting. For

details, see page51.

Remote control

interface setting. For

details, see page52.

19

20

Page 11

Setup

PSH User Manual

AC power cable

assembly

Load

configuration

Wire assembly

Setup

This chapter describes load configurations and

setup procedures. Follow these instructions to

properly install PSH series.

AC Power Cable Assembly......................... 22

AC power cable requirement ..................... 23

Remote Sensing and Local Sensing ............ 24

Load / Remote Sensing Wire Selection........ 25

Single Load + Local Sensing...................... 26

Single Load + Remote Sensing .................. 26

Multiple Loads + Local Sensing .................. 27

Multiple Loads + Remote Sensing .............. 27

Series Operation + Local Sensing............... 28

Series Operation + Remote Sensing ........... 29

Load Wire Assembly................................. 30

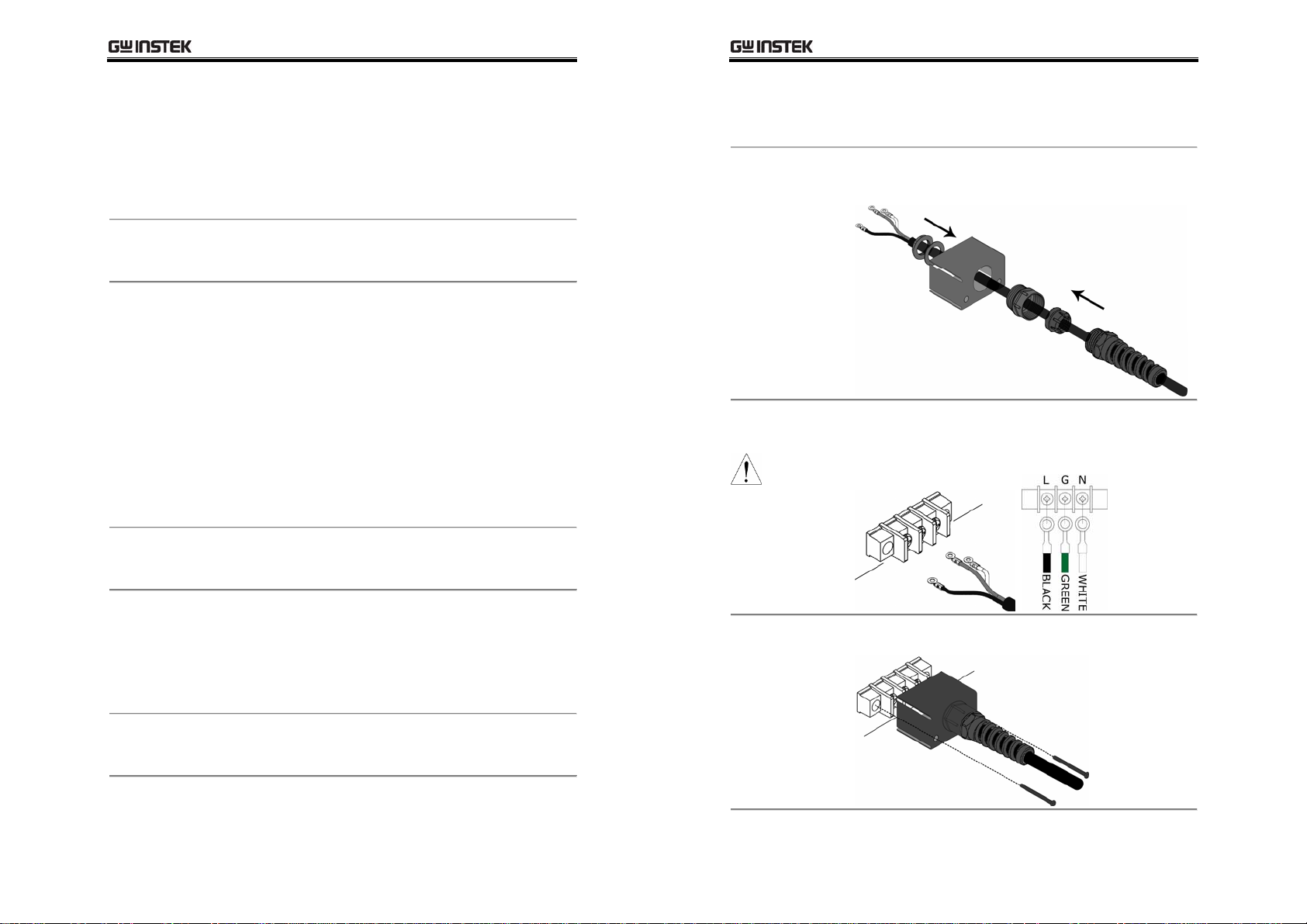

AC Power Cable Assembly

1 Cable gland +

Terminal Cover

2 Cable wire +

Terminal

CAUTION

Put the power cable through the cable gland and

the terminal cover, screw them together.

Screw the wire onto the AC input terminal. Note

the wire color: Neutral (white), GND (green), and

Line (black).

Remote Sensing Wire Assembly ................. 32

Functionality

Check

Preparation............................................. 34

Output Voltage & OVP Check ..................... 35

Output Current Check .............................. 37

3 Terminal

cover +

Terminal

Screw the terminal cover onto the terminal.

OCP Check.............................................. 38

Rack mounting

(optional)

21

Rack mounting kit contents....................... 40

Rack mounting assembly .......................... 41

22

Page 12

Setup

PSH User Manual

AC power cable requirement

Here is the AC power cable specification, in case of using cables

other than the attached one.

Cable length

Cable gland

Cable type

(recommended)

Model: H05 VV-F

≤ 3m

KSS or PG-2013

Model: SJT

Type: 3 x 14 AWG stranded copper

Rating: 60°C min, 300V

Diameter: 9.143~10.03 mm

Type: 3G 1.5mm

2

stranded copper

Rating: 300V/500V

Diameter: 8.5 ± 0.2 mm

Remote Sensing and Local Sensing

Remote sensing compensates the cable loss between PSH and load,

up to 0.5V. Use remote sensing whenever the load voltage has to

be accurate.

Local Sensing

(default)

VSET = VOUT

V

OUT > VLOAD

Remote

Sensing

VSET = VLOAD

VOUT > VSET

VSET

PSH Load

Output

Setting

|VSET–VOUT|

The sense terminal is internally connected to the

PSH output terminal. The delta between the

voltage setting level (V

level (V

voltage (V

OUT) is compensated. The load terminal

LOAD) might become lower than the

output due to cable loss.

VSET

PSH Load

Output

Setting

|VSET–VLOAD|

VOUT VLOAD

VOUT

Sense

SET) and the actual output

OUT VLOAD

V

VLOAD

Sense

The sense terminal is connected to the load input

terminal. The delta between the voltage setting

level (V

compensated. The output voltage (V

SET) and the actual load voltage (VLOAD) is

OUT) might

become higher than the setting due to the

compensation.

23

24

Page 13

Setup

PSH User Manual

Load / Remote Sensing Wire Selection

The following instructions apply to both load wire and remote

sensing wire, unless noted.

Wire size (FOR

LOAD ONLY)

Wire length

Wire shielding

Load wires must have enough current capacity

to minimize cable loss and load line impedance.

Voltage drop across a wire should not excess

0.5V. The following list is the wire current rating

at 450A/cm

Wire size

(AWG)

2

.

Max.

current (A)

Wire size

(AWG)

Max.

current (A)

20 2.5 6 61

18 4 4 97

16 6 2 155

14 10 1 192

12 16 1/0 247

10 21 2/0 303

8 36

To avoid excessive cable loss, shorten the

distance between PSH and load as much as

possible. Remote sensing compensates cable

loss up to 0.5V.

To minimize noise effect and load line

impedance, use shielded pair wiring. Twisted

wires are more effective, especially for remote

sensing.

Load Configuration

Select the appropriate configuration for the target application.

For local sensing and remote sensing explanation, see the

previous page.

For connection guideline, see page25 (wire selection), page30 (load

connection), page32 (remote sensing connection).

Single PSH + single load

Single Load +

Local Sensing

Single Load +

Remote

Sensing

—OUT

PSH

+OUT

—Sense

+Sense

Connect the output wire to the load and the sense

terminal to the PSH local output monitor.

PSH

+OUT

—Sense

+Sense

—IN

Load

+IN

—IN—OUT

Load

+IN

Connect both the output wire and the remote

sensing wire to the load.

Wire shield should be connected to the rear

panel ground connector.

25

26

Page 14

Setup

PSH User Manual

Single PSH + multiple Load

Condition

Multiple Loads

+ Local

Sensing

Multiple Loads

+ Remote

Sensing

• Output current for each load follows the load

requirement.

• When the sum of the load current surpasses the

rating, PSH automatically switches to CC

(Constant Current) mode.

—OUT

PSH

+OUT

—Sense

+Sense

All loads share one PSH output.

Distribution

—OUT

PSH

+OUT

—Sense

+Sense

Create a distribution point between PSH and the

loads. PSH compensates the cable loss up to the

distribution point.

To maximize compensation, make sure the

distribution point is closer to the load side.

Point

—IN

+IN

—IN

+IN

—IN

+IN

—IN

+IN

Load #1

Load #2

Load #1

Load #2

Multiple PSH + single load (series operation)

Condition

Series

Operation +

Local Sensing

• Up to four PSH series (with identical output

ratings) can be cascaded.

• Output voltage is the sum of the cascaded PSH.

• Output current is the same as a single PSH.

—IN—OUT

PSH #1

+OUT

+IN

Load

—Sense

+Sense

—OUT

PSH #2

+OUT

—Sense

+Sense

First PSH:

Negative output → Negative load input

Positive output → The next PSH negative output

Intermediate PSH:

Negative output → The previous PSH positive

output

Positive output → The next PSH negative output

Last PSH:

Negative output → The previous PSH positive

output

Positive output → Positive load input

27

28

Page 15

Setup

PSH User Manual

Series Operation (cont.)

Series

Operation +

Remote

Sensing

PSH #1

+OUT

—Sense

+Sense

—OUT

PSH #2

+OUT

—Sense

+Sense

First PSH:

Negative output → Negative load input

Positive output → The next PSH negative output

Negative sense → Negative load input

Positive sense → Positive output monitor

Intermediate PSH:

Negative output → The previous PSH positive

output

Positive output → The next PSH negative output

Negative sense → The previous PSH positive

output

Positive sense → Positive output monitor

—IN—OUT

+IN

Load

Load Wire Assembly

1. Wire

selection

2. Terminal

screw

replacement

3. Terminal

connection

Select the appropriate wire according to the

guideline on page25.

Replace the two screws on the output terminal

with the hex screw in the output connection kit.

Screw load wires to the terminal.

Last PSH:

Negative output → The previous PSH positive

output

Positive output → Positive load input

Negative sense → The previous PSH positive

output

Positive sense → Positive load input

29

30

Page 16

Setup

PSH User Manual

Load Wire Assembly (cont.)

4. Terminal

cover assembly

5. Wire shield

connection

(recommended)

Screw the output terminal cover to the rear

panel.

Connect the load wire shield to the rear panel

ground connector.

Remote Sensing Wire Assembly

Select the appropriate wire according to the guideline on page25.

Local sensing

The sense terminal is connected to the output

monitor terminal with bare wires.

Remote Sensing

1. Take off the wire jumpers.

2. Screw wires to the sense (S) side.

• Do not screw remote sensing wires to the

CAUTION

monitor (M) side.

• M+, M− are for output monitoring only. NEVER

screw load wires to the remote sensing

terminal.

31

32

Page 17

Setup

PSH User Manual

Remote Sensing Wire Assembly (cont.)

5. Wire shield

connection

CAUTION

To minimize noise effect, we recommend

covering the remote sensing wire with ground

shield and connect it to the ground terminal.

An open remote sense circuit leads to output

level overshoot. Make sure the line is securely

connected.

Functionality Check

Check the PSH basic functionalities before operation.

Preparation

Check items

Equipment

When there is a

problem…

• Output Voltage

• OVP functionality

• Output Current

• OCP functionality

Digital

• DC Voltage Accuracy: <±0.1%

Multimeter

• Recommended model:

GDM-8245, GDM-8246

Current Shunt • Current range: >100A

• Accuracy: <±0.1%

PSH – Current

• Voltage rating: >70V

Shunt cable

• Current rating: >100A

Multimeter –

• N/A

Current Shunt

cable

Run calibrations (page61). If this does not solve

the issue, refer to the service center.

33

34

Page 18

Setup

PSH User Manual

Output Voltage & OVP Check

Connection

PSH Series

Digital Multimeter

V

A

Checking step

1. Power On PSH and connect the Multimeter Voltage

measurement terminal.

2. Set Output Voltage and Output Current to the rating value.

• Vset/Iset/Enter key

VSET/ ISET

ENTER

PSH-2018A (20V, 18A)

switches the cursor between

Voltage and Current.

• F/C key

F/C

switches the cursor

between before and after the

decimal point.

— +

SET 20.00V 18.00A

4. Make sure the Multimeter shows no value (No output).

5. Press the Output key

OUTPUT

and turn On the output.

The display changes into CV

(Constant Voltage) mode and

shows the OUT sign on the top

right corner.

CV 20.00V 18.00A

OUT

6. Make sure the Multimeter reading and the PSH display show

approximately the same Voltage.

7. Increase the PSH output voltage beyond the OVP value.

8. Make sure the display shows an error message.

Press the Local key

back to the normal display.

LOCAL

to get

OVP Error! Press

“Local” to reset

9. Make sure the output is now turned Off in the display and the

Multimeter shows no value (No output).

• Wheel knob changes the value.

3. Press the Menu key once and set the OVP value to rating

voltage + 100mV.

Press the Vset/Iset/Enter

VSET/ ISET

ENTER

key

to confirm the OVP

Set OVP

20.10V

setting.

35

36

Page 19

Setup

PSH User Manual

Output Current Check

Connection

Digital Multimeter PSH Series

V

A

Checking step

1. Power On PSH and connect the Multimeter/ Current Shunt

terminal.

2. Set the Output Voltage and Current value to the rating.

• Vset/Iset/Enter key

VSET/ ISET

ENTER

switches

the cursor between Voltage and

Current.

• F/C key

F/C

switches the cursor

before and after the decimal point.

• Wheel knob changes the value.

3. Make sure the Multimeter/Current Shunt shows no output.

4. Press the Output key

OUTPUT

5. Make sure the Multimeter/Current Shunt reading and the

PSH display show approximately the same Current.

Current

Shunt

PSH-2018A (20V, 18A)

—

+

SET 20.00V 18.00A

and turn On the output.

OCP Check

Connection

Current

Shunt

PSH-2018A (20V, 18A)

—

SET 20.00V 18.00A

Set OCP

ON

VSET/ ISET

ENTER

to confirm the setting.

+

Digital Multimeter PSH Series

V

A

Checking step

1. Power On PSH and connect the Multimeter / Current Shunt

terminal.

2. Set the Output Voltage and Current value to the rating.

• Vset/Iset/Enter key

VSET/ ISET

ENTER

switches the cursor between

Voltage and Current.

• F/C key

F/C

switches the cursor

before and after the decimal point.

• Wheel knob changes the value.

3. Press the Menu key twice to view the OCP setting.

Turn the wheel knob

to change

OCP setting to ON.

Press the Vset/Iset/Enter key

37

38

Page 20

Setup

PSH User Manual

The OCP sign appears on the

upper side of the display.

4. Press the Output key

CV 20.00V 18.00A

OUTPUT

and turn On the output.

OCP

5. Make sure the display shows the error message.

Press the Local key

back to the normal display.

LOCAL

to get

OCP Error! Press

“Local” to reset

6. Make sure the output is now turned Off in the display and the

Multimeter / Current Shunt shows no value (No output).

Rack Mounting (Optional)

PSH can be mounted on standard 19 inch rack using GRA-403

rack mounting kit.

Rack mounting kit contents

Main bracket x 1

Front panel x 1

Large decoration board x 1

Small decoration board x 2

Medium decoration board x 2

Binding plate x 6

Handle x 2

Screw M4 * 0.7 L=10mm x 4

Screw M3 * 0.5 L = 8mm x 18

39

40

Page 21

Setup

PSH User Manual

Rack mounting assembly

1. Rack

mounting layout

Confirm the rack mount layout. Make sure there

is a space between each PSH. Below is the

example of rack mounting layout.

2. Decoration

board assembly

Once the layout is fixed, screw the decoration

boards to the front panel using M3 screws.

4. Main bracket

assembly

Fix the PSH to the main bracket using M3

screws.

Fix the front panel and the handle to the main

bracket using M4 screws.

3. Binding plate

assembly

41

Take off two M3 screws from PSH side panels,

front and rear. Hold the binding plate between

PSH and drive the same screws in.

42

Page 22

Panel Operation

PSH User Manual

Menu key

overview

CV/ CC

characteristic

Output Voltage

setting

Output Current

setting

OVP setting

OCP setting

Display contrast

setting

Buzzer sound

setting

Panel Operation

This chapter describes the manual operations

done at the front panel, together with the

constant voltage/ constant current crossover

characteristics.

Menu Key Overview ................................. 44

Constant Voltage/ Constant Current Crossover

Characteristic.......................................... 45

Output Voltage Setting ............................. 46

Output Current Setting ............................. 47

Note ...................................................... 47

Set the OVP value.................................... 48

Clear OVP error ....................................... 48

Turn the OCP On/Off ................................ 49

Clear OCP error ....................................... 49

Display Contrast Setting ........................... 50

Buzzer sound Setting ............................... 51

Buzzer condition...................................... 51

Menu Key Overview

Press the Menu key

Menu key repeatedly.

CV 2.58V 2.01A

Set OVP

* 21.10V

Set OCP

* ON (OFF)

Set Contrast

* 70%

Set Buzzer

* ON (OFF)

Interface RS232

Baud Rate 9600

MENU

OCP OUT

. To move to the next item, press the

Default display

Output Voltage Protection setting

To set the value, use the wheel

knob

To select the editing point (before or

after the decimal point), press the

F/C key

Output Current Protection setting

To enable or disable OCP, use the

wheel knob

“OCP” appears on the default

display.

Display contrast setting

To set the display contrast, use the

wheel knob

Turn right: increases contrast

Turn left: decreases contrast

Buzzer setting

To enable or disable buzzer sound,

use the wheel knob. The buzzer

sounds when trying to set a value

beyond the specification.

Remote control interface setting

RS232 (standard): To set the baud

rate, use the wheel knob

GPIB (optional): To set the GPIB

address, use the wheel knob

.

F/C

repeatedly.

. When enabled,

.

.

.

43

44

Page 23

Panel Operation

PSH User Manual

Constant Voltage/ Constant Current

Crossover Characteristic

PSH series automatically switch

between constant voltage mode

and constant current mode,

according to the load change.

When the load current is

smaller than the limit (I

SET),

PSH operates in Constant

Voltage mode, changing the

current level according to the

load but keeping the Voltage

level at the limit (V

SET).

When the load current is the

same as the limit (I

SET), PSH

operates in Constant Current

mode, changing the Voltage level

according to the load but

keeping the Current level at the

limit (I

SET).

Let’s take recharging a 12V battery as an example. PSH output

setting is 13.8V, 1A. An empty battery puts a heavy current load

on the power supply. PSH starts running at Constant Current

mode, supplying full 1A current but keeping the voltage lower

than 13.8V. As the battery becomes charged, the load also

becomes smaller. PSH then switches to Constant Voltage mode,

supplying less than 1A current but supplying full 13.8V.

V

VSET

Constant

Voltage

Constant

Current

ISET

VSET = Output Voltage setting

I

SET = Output Current setting

Output Voltage Setting

Operation

1. Press the Vset/ Iset key

repeatedly to move the underline

to the Voltage side.

2. Press the F/C key

underline before or after the

decimal point.

3. Use the wheel knob

I

Range

Step

0.00V ~ rating voltage

10mV (rating voltage < 36V)

20mV (rating voltage ≥ 36V)

VSET/ ISET

SET 2

F/C

to move the

SET 2

to change the output voltage.

OCP

.58V 2.01A

OCP

.58V2.01A

Display

The display indicates CV (Constant Voltage) or CC

(Constant Current) on the left side.

Constant Voltage

OCP OUT

CV 2.58V 1.99A

45

Constant Current

OUT

CC 1.33V 2.00A

46

Page 24

Panel Operation

PSH User Manual

Output Current Setting

Operation

1. Press the Vset/ Iset key

repeatedly to move the underline

to the Current side.

2. Press the F/C key

underline before or after the

decimal point.

3. Use the wheel knob

Range

Step

Note

0.00A ~ rating current

10mA

When the output current exceeds the setting

value, PSH automatically switches from CV

(Constant Voltage) to CC (Constant Current)

mode.

VSET/ ISET

F/C

to move the

to change the output current.

SET 2.58V 2

OCP

OCP

SET 2.58V 2

.01A

.01A

OVP (Output Voltage Protection) Setting

Set the OVP value

1. Press the Menu key

repeatedly until the OVP menu

appears.

2. Press the F/C key

underline before or after the

decimal point.

3. Use the wheel knob

4. Press the Iset/Vset/Enter key

Clear OVP error

1. When the output voltage exceeds

OVP value, the output is shut off

and an OVP error message

appears on the display.

MENU

F/C

to move the

to change the value.

VSET/ ISET

ENTER

OCP OUT

CV 2.58V 2.01A

Set OVP

* 21.10V

Set OVP

.10V

* 21

to confirm the value.

OVP Error! Press

“Local” to reset

LOCAL

2. Press the Local key

to clear

the error message (the output is

still Off).

Range

Step

0.00V ~ rating voltage

10mV (rating voltage < 36V)

20mV (rating voltage ≥ 36V)

47

48

Page 25

Panel Operation

PSH User Manual

OCP (Output Current Protection) Setting

Turn the OCP On/Off

1. Press the Menu key

repeatedly until the OCP menu

appears.

2. Use the wheel knob

the status to ON (or OFF).

3. Press the Iset/Vset/Enter key

Clear OCP error

1. When the output current exceeds

the current setting, the output is

shut off and an OCP error message

appears on the display.

MENU

to change

CV 2.58V 2.01A

Set OCP

OFF

Set OCP

ON

VSET/ ISET

ENTER

to confirm the setting.

OCP Error! Press

“Local” to reset

OCP OUT

Display Contrast Setting

Operation

1. Press the Menu key

repeatedly until the Contrast

menu appears.

2. Use the wheel knob

increase, Counterclockwise: decrease.

Range

Step

5% ~ 95%

6%

MENU

CV 2.58V 2.01A

OCP OUT

Set Contrast

71%

to change the contrast. Clockwise:

2. Press the Local key

LOCAL

to clear

the error message (the output is

still Off).

Range

49

According to the output current

50

Page 26

Panel Operation

PSH User Manual

Buzzer sound Setting

Operation

1. Press the Menu key

repeatedly until the Buzzer menu

appears.

2. Use the wheel knob

the buzzer setting to ON (or OFF).

3. Press the Iset/Vset/Enter key to

confirm the value.

Buzzer

condition

When “Set Buzzer ON”, the buzzer sounds under

the following conditions.

* When pressing the panel keys

* When the value setting exceeds the limit

MENU

to change

OCP OUT

CV 2.58V 2.01A

Set Buzzer

OFF

Set Buzzer

ON

Remote Operation

This chapter describes the IEEE 488.2 based

remote control configuration, command syntax,

and command set overview. For further

descriptions and examples, refer to the

programming manual.

Interface

configuration

Command set

RS232 (Standard).................................... 53

GPIB (Optional) ....................................... 55

Interface functionality check ..................... 56

Command Syntax .................................... 57

General commands .................................. 58

Status commands .................................... 59

Miscellaneous commands.......................... 60

51

52

Page 27

Remote Operation

PSH User Manual

Interface Selection

RS232 (Standard)

Baud rate

setting

1. Press the Menu key

Interface menu appears.

CV 2.58V 2.01A

Interface RS232

Baud Rate 9600

2. Use the wheel knob to select the baud

rate.

3. Press the Iset/Vset/Enter key

confirm the setting.

OCP OUT

MENU

repeatedly until the

VSET/ ISET

ENTER

to

PC RS-232 pin

assignment

PSH – PC

connection

1 2 3 4 5

Pin 2: TxD

Pin 3: RxD

Pin 5: GND

6 7 8 9

Pin 1, 4, 6 ~ 9: No Connection

Null-modem connection, in which transmit (TxD)

and receive (RxD) lines are crosslinked, is

required.

PSH PC

RxD

Pin2

Pin3

Pin5

TxD

GND

TxD

RxD

GND

Pin2

Pin3

Pin5

4. Connect the RS232 cable between your PC

and PSH rear panel. PSH switches to remote

control mode as soon as the connection is

established.

RS-232

interface

protocol

PSH RS-232 pin

assignment

Baud rate: 9600, 4800, 2400, 1200 (selectable)

Parity: None (fixed)

Stop bit: 1 (fixed)

Data bit: 8 (fixed)

1 2 3 4 5

Pin 2: RxD

Pin 3: TxD

Pin 5: GND

6 7 8 9

53

Pin 1, 4, 6 ~ 9: No Connection

54

Page 28

Remote Operation

PSH User Manual

GPIB (Optional)

Refer to the service manual for GPIB module installation.

Note: The RS232 module has to be replaced with the GPIB

module: they cannot be used together.

Address setting

1. Press the Menu key

Interface menu appears.

OCP OUT

CV 2.58V 2.01A

Interface GPIB

Address 8

2. Use the wheel knob

GPIB address: 1 ~ 30

3. Press the Iset/Vset/Enter key

confirm the setting.

MENU

repeatedly until the

to select the address.

VSET/ ISET

ENTER

to

Interface functionality check

Remote mode

display

Functionality

check

In the remote control mode, the display shows

“RMT” on the top left corner. The panel operation

is disabled.

RMT OCP

CV 0.05V 1.05A

To enable panel operation, press the Local

LOCAL

key

. This also disconnects the remote

control.

Run this query command via the terminal.

*idn?

This should return the Manufacturer, Model

number, Serial number, and Firmware version in

the following format.

GW.Inc,PSH-2018A,12345678,FW1.00

4. Connect the GPIB cable between your PC and

PSH rear panel. PSH switches to remote

control mode as soon as the connection is

established.

GPIB

constraints

• Address range: 1 ~ 30

• Altogether less than 15 devices, less than 20m

total cable length, maximum 2m between each

device

• Unique address assigned for each device

• At least 2/3 of the GPIB devices turned On

• No loop or parallel structure

55

56

Page 29

Remote Operation

PSH User Manual

Command Syntax

The commands are fully compatible with IEEE488.2 (1992)

standard and partially compatible with SCPI (1994) standard.

Example

command

Command

Header

Parameter

example

Message

Terminator

:chan1:prot:curr <0/1> LF

4321

1: Command Header

2: Single space

3: Parameter

4: Message Terminator OR Message Separator

Several command header elements (nodes) can be

concatenated to form a complex command.

The above example can be separated into:

:chan1: (root node) + prot: + curr:

<0/1> 0 or 1.

<1~4> Integer between 1, 2, 3, or 4.

<0.01~5> Decimal number between 0.01 and 5.

Marks the end of a command line. Any of the

following is acceptable, in accordance with

IEEE488.2 standard.

LF^END Line feed code (hexadecimal 0A)

with END message

LF Line feed code

<dab>^END Last data byte with END message

Command Set

Commands are non-case sensitive.

For more detailed information, refer to the Programming Manual

which is downloadable from www.gwinstek.com.tw

General commands

:chan1:curr? Returns the output current (unit: A).

Range: 0.01~rating current

:chan1:curr

<0.01~rating>

:chan1:volt? Returns the output voltage (unit: V).

:chan1:volt

<0.01~rating>

:chan1:meas:cu

rr?

:chan1:meas:vo

lt?

:chan1:prot:cur

r?

:chan1:prot:cur

r <0/1>

:chan1:prot:volt? Returns the Over Voltage Protection value.

:chan1:prot:volt

<0.01~rating>

:chan1:prot:cle Clears the OCP & OVP protection message from

:outp:stat? Returns the output status.

:outp:stat

<0/1>

Sets the output current (unit: A).

Range: 0.01~rating current

Range: 0.01~rating voltage

Returns the output voltage (unit: V).

Range: 0.01~rating current

Returns the actual output load current (unit: A).

Returns the actual output load voltage (unit: V).

Returns the Over Current Protection status.

Range: 0 (Off), 1 (On)

Sets the Over Current Protection.

Range: 0 (Off), 1 (On)

Range: 0.01~rating (unit: V)

Sets the Over Voltage Protection value.

Range: 0.01~rating (unit: V)

the display.

Range: 0 (Output Off), 1 (Output On)

Sets the output status.

Range: 0 (Output Off), 1 (Output On)

.

Message

Separator

57

; (semicolon) Command separator.

58

Page 30

Remote Operation

PSH User Manual

Status commands

*cls Clears all event status registers (Output Queue,

Operation Event Status, Questionable Event

Status, Standard Event Status)

*ese? Returns the ESER (Event Status Enable

Register) contents.

Example: 130→means ESER=10000010

*ese <0~255> Sets the ESER contents.

Example: *ese 65→sets ESER to 01000001

*esr? Returns and clears the SESR (Standard Event

Status Register) contents.

Example: 198→means SESR=11000110

*sre? Returns the SRER (Service Request Enable

Register) contents.

Example: 3→means SRER=00000011

*sre <0~255> Sets the SRER contents.

Example: *SRE 7→SRER=00000111

*stb? Returns the SBR (Status Byte Register) contents.

Example: 81→means SBR=01010001

:stat:oper:cond? Returns the Operation register contents.

:stat:oper:enab? Returns the mask conditions of the event

register. Range: 0~32767

Example: 32767 means all 15bits are set to 1.

:stat:oper:enab

<0~32767>

:stat:oper:even? Returns the operation register contents.

:stat:pres Sets the operation register and questionable

:stat:ques:enab? Returns the mask conditions of the event

:stat:ques:enab

<0~32767>

:stat:oper:even? Returns the questionable register contents.

Returns the mask conditions of the event

register. Range: 0~32767

Example: 32767 sets all 15bits to 1.

Example: 32767 means all 15bits are set to 1.

enable register to zero.

register. Range: 0~32767

Example: 32767 means all 15bits are set to 1.

Returns the mask conditions of the event

register. Range: 0~32767

Example: 32767 sets all 15bits to 1.

Example: 32767 means all 15bits are set to 1.

Miscellaneous commands

*idn? Returns the power supply ID as Manufacturer,

Model No, Serial No, Firmware version.

Example: GW.Inc,PSH-2018A,12345678,FW1.00

*opc? “1” is placed in the output queue when all the

pending operations are completed.

*opc Sets the operation complete bit (bit0) in SERS

(Standard Event Status Register) when all the

pending operations are completed.

*rcl <1~99> Recalls the panel setup from internal memory.

Example: *RCL 1→recalls setup from memory1

*rst Recalls the default panel setup (reset the device).

*sav <1~99> Saves the panel setup to internal memory.

Example: *SAV 1→saves setup to memory1

*tst? Run the self-test for RAM and ROM and returns

0 (successful) or -300 (unsuccessful).

*wai Prevents execution of further commands until all

the pending operations are completed.

:syst:err? Returns the error number followed by the error

message from the queue.

Example: 0, “No error”

:syst:vers? Returns the SCPI version.

Example: 1994.0

59

60

Page 31

Calibration

PSH User Manual

Setup

Calibration

Calibration

Run calibration when the output exceeds the

specification, or when the functionality check

(page34) fails. To get the optimal result, make

sure PSH is powered for at least 30 minutes

before the calibration.

Calibration Preparation ............................. 62

Entering calibration mode ......................... 63

Output Voltage calibration......................... 64

Output Current calibration......................... 66

OVP Calibration ....................................... 68

Calibration Preparation

Calibration

condition

Calibration

items

Calibration

Equipment

• At least 30 minutes of warm-up time

• Temperature: 23 ± 5 °C

• Relative Humidity: ≤ 80%

• Minimum/ Maximum Output Voltage

• Minimum/ Maximum Output Current

• OVP functionality

Digital

• DC Voltage Accuracy: <±0.1%

Multimeter

• Recommended model:

Current Shunt • Current range: >100A

• Accuracy: <±0.1%

PSH – Current

• Voltage rating: >70V

Shunt cable

• Current rating: >100A

Multimeter –

• N/A

Current Shunt

cable

GDM-8245, GDM-8246

61

62

Page 32

Calibration

PSH User Manual

Entering calibration mode

1. Press the Local key for 5 seconds.

The password entry menu

appears.

2. Enter the model number as the

password.

Wheel knob

F/C key

changes the digit.

F/C

moves the cursor to

the next digit.

3. Press the Vset/Iset/Enter key

4. The calibration menu appears.

Wheel knob

Vset/Iset/Enter key

• Minimum/Maximum output

selects the item.

VSET/ ISET

ENTER

confirms the selection.

voltage calibration

• Minimum/Maximum output

current calibration

(PSH-2018A)

VSET/ ISET

ENTER

as confirmation.

Please enter the

Password: 0

Please enter the

Password: 2018

Calibration

Voltage

Calibration

Current

Output Voltage calibration

Connection

Digital Multimeter

V

Calibration step

A

1. Enter the Voltage calibration

menu. See page63 for details.

2. Press the Vset/Iset/Enter

VSET/ ISET

ENTER

key

and enter Minimum

Voltage calibration mode.

PSH Series

— +

Calibration

Voltage

Calibration

Voltmin 0.00V

• Over Voltage Protection calibration

• Save the calibration result and exit

the calibration menu

• Exit calibration menu without

saving the calibration result

Calibration

OVP

Calibration

Save

Calibration

Exit

3. Adjust the display value to the

Multimeter reading.

Wheel knob

F/C key

changes the value.

F/C

moves the cursor

before and after the decimal point.

4. Press the Vset/Iset/Enter

VSET/ ISET

ENTER

key

to confirm the setting.

The display enters Maximum

Voltage calibration mode.

Multimeter reading: 0.02V

Calibration

Voltmin 0.02

V

Calibration

Voltmax 20.00V

63

64

Page 33

Calibration

PSH User Manual

5. Adjust the display value to the

Multimeter reading.

Wheel knob

F/C key

changes the value.

F/C

moves the cursor

before and after the decimal point.

6. Press the Vset/Iset/Enter

VSET/ ISET

ENTER

key

to confirm the setting.

The display goes back to the

default calibration menu.

7. Save the result and exit the

calibration mode (Save), OR

Exit the calibration mode without

saving the result (Exit).

Multimeter reading:

20.03V

Calibration

Voltmax 20.03

Calibration

Voltage

Calibration

Save

Calibration

Exit

Output Current calibration

Connection

V

Digital Multimeter PSH Series

V

A

Calibration step

1. Enter the Current calibration

menu. See page63 for details.

2. Press the Vset/Iset/Enter

VSET/ ISET

ENTER

key

and enter Maximum

Current calibration mode.

Current

Shunt

—

+

Calibration

Current

Calibration

CurrMax 18.00A

65

3. Adjust the display value to the

Multimeter / Current Shunt

reading.

Wheel knob

F/C key

changes the value.

F/C

moves the cursor

before and after the decimal point.

4. Press the Vset/Iset/Enter

VSET/ ISET

ENTER

key

to confirm the setting.

The display enters Minimum

Current calibration mode.

66

Multimeter reading :18.02A

Calibration

CurrMax 18.02

A

Calibration

CurrMin 0.00A

Page 34

Calibration

PSH User Manual

5. Adjust the display value to the

Multimeter / Current Shunt

reading.

Wheel knob

F/C key

changes the value.

F/C

moves the cursor

before and after the decimal point.

6. Press the Vset/Iset/Enter

VSET/ ISET

ENTER

key

to confirm the setting.

The display goes back to the

default calibration menu.

7. Save the result and exit the

calibration mode (Save), OR

Exit the calibration mode without

saving the result (Exit).

Multimeter reading: 0.02A

Calibration

CurrMin 0.02

A

Calibration

Current

Calibration

Save

Calibration

Exit

OVP Calibration

Connection

No connection required

Calibration step

1. Enter the Voltage calibration

menu. See page63 for details.

2. Press the Vset/Iset/Enter

VSET/ ISET

ENTER

key

. PSH calibrates OVP

automatically.

3. The display goes back to the

default calibration menu.

4. Save the result and exit the

calibration mode (Save), OR

Exit the calibration mode without

saving the result (Exit).

Calibration

OVP

Calibration

OVP

Calibration

OVP

Calibration

Save

100%

67

Calibration

Exit

68

Page 35

FAQ

FAQ

The OVP value/ OCP status has not been changed.

After editing OVP value and OCP status, press

VSET/ ISET

the Vset/Iset/Enter key

Otherwise the setting does not change.

The front panel does not respond.

When in remote control mode, PSH does not

respond to panel operations. Terminate the

remote operation or press the Local key

on the front panel. The “RMT” message

disappears from the display and panel operation

is resumed.

The actual output is lower than the setting.

The cable loss might be causing the load voltage

lower than the setting. Upgrade the output cable

to a better capacity and/or use the remote sense

to compensate for the voltage drop. See page25

(theory) and page25 (cable assembly).

The actual output is much higher than the setting.

The remote sensing (page24) compensates for

the cable loss for up to 0.5V. If the output level

goes much higher, the remote sensing terminal

might be disconnected. Make sure the

connection is secure. See page32 for details.

The load wire does not fit into the terminal.

ENTER

to confirm.

LOCAL

Make sure you are NOT connecting the load wire

to the remote sensing terminal. Refer to page30

for connection details.

If there is still a problem, please contact your local dealer or

GWInstek at www.gwinstek.com.tw

/ marketing@goodwill.com.tw.

69

Page 36

Appendix

PSH User Manual

Appendix

Specifications

The specifications apply under the following conditions: PSH is

powered on for at least 30 minutes, within +20°C~+30°C.

Common specification

Recovery Time CV mode ≤ 2ms (50% step load change from

25%~75%)

Response Time

Temperature

Coefficient

Protection Over Voltage Protection, Over Current Protection, Over

Output On/Off Available

AC Power Input 100~230V, 50/ 60 Hz

Operation

Condition

Storage

Condition

Accessories User manual, Programming manual, Cable gland, AC

Voltage Up ≤ 150ms (10%~90% ≤ 95% rating

load)

Voltage Down ≤ 150ms (90%~10% ≥ 10% rating

load)

Voltage (mVrms) ≤ 10mVrms,100mVpp,20Hz~20MHz Ripple & Noise

Current (mArms) ≤ 0.2% + 40mA

Voltage

(25±5°C)

Heat Protection, Inrush Current Protection

Location Indoor

Altitude ≤ 2000m

Ambient

temperature

Relative

Humidity

Installation Category II (for details, see page6)

Pollution Degree 2 (for details, see page8)

−10°C~70°C, 70% RH (maximum)

power cord, AC input cover, O/P terminal cover

≤ 100ppm/ °C

Specification: 10°C~35°C (50°F~95°F)

Operation: 0°C~40°C (32°F~104°F)

85% RH (maximum), non condensing

PSH-1036A/ 2018A/ 3610A/ 6006A

Output PSH-1036A 10V, 36A

PSH-2018A 20V, 18A

PSH-3610A 36V, 10A

PSH-6006A 60V, 6A

Regulation

(C.V.) Line ≤ 0.05% + 5mV

Regulation

(C.C.)

Ripple & Noise

Program

Accuracy

Program

Resolution

Readback

(Meter)

Accuracy Current ≤ 0.2% + 30mA

Readback

(Meter)

Resolution

Fuse 6.3A/ 250V AC x 2

Dimensions 108 x 141 x 388 mm

Weight Approx. 3.3kg

Load ≤ 0.1% + 5mV

Load ≤ 0.2% + 5mA

Line ≤ 0.2% + 5mA

Voltage (mVrms) ≤ 10mVrms, 100mVpp,

20Hz~20MHz

Current (mArms) ≤ 0.2%

Volt age ≤ 0.05% + 25mV (rating ≤ 36V)

≤ 0.05% + 50mV (rating > 36V)

OVP ≤ 0.1% + 50mV (rating ≤ 36V)

≤ 0.1% + 100mV (rating > 36V)

Current ≤ 0.2% + 30mA

Voltage & OVP 10mV (rating ≤ 36V)

20mV (rating > 36V)

Current 10mA

Volt age ≤ 0.05% + 25mV (rating ≤ 36V)

≤ 0.05% + 50mV (rating > 36V)

Volt age 10mV (rating ≤ 36V)

20mV (rating > 36V)

Current 10mA

71

72

Page 37

Appendix

PSH User Manual

PSH-1070A/ 2035A/ 3620A/ 6012A

Output PSH-1070A 10V, 70A

PSH-2035A 20V, 35A

PSH-3620A 36V, 20A

PSH-6012A 60V, 12A

Regulation

(C.V.) Line ≤ 0.05% + 5mV

Regulation

(C.C.)

Ripple & Noise

Program

Accuracy

Program

Resolution

Readback

(Meter)

Accuracy Current ≤ 0.2% + 60mA (rating ≤ 10V)

Readback

(Meter)

Resolution

Fuse 6.3A/ 250VAC x 2, 0.5A/ 250VAC x 1, 15A/ 250VAC x 1

Dimensions 188 x 141 x 388 mm

Weight Approx. 6.2kg

Load ≤ 0.1% + 5mV

Load ≤ 0.2% + 10mA

Line ≤ 0.2% + 10mA

Voltage (mVrms) ≤ 10mVrms, 100mVpp,

20Hz~20MHz

Current (mArms) ≤ 0.2% + 20mA

Voltage ≤ 0.05% + 25mV (rating ≤ 36V)

≤ 0.05% + 50mV (rating > 36V)

OVP ≤ 0.1% + 50mV (rating ≤ 36V)

≤ 0.1% + 100mV (rating > 36V)

Current ≤ 0.2% + 60mA (rating ≤ 10V)

≤ 0.2% + 30mA (rating ≤ 60V)

Voltage & OVP 10mV (rating ≤ 36V)

20mV (rating > 36V)

Current 20mA (rating ≤ 10V)

10mA (rating ≤ 60V)

Voltage ≤ 0.05% + 25mV (rating ≤ 36V)

≤ 0.05% + 50mV (rating > 36V)

≤ 0.2% + 30Ma (rating ≤ 60V)

Voltage 10mV (rating ≤ 36V)

20mV (rating > 36V)

Current 20mA (rating ≤ 10V)

10mA (rating ≤ 60V)

PSH-10100A/ 2050A/ 3630A/ 6018A

Output PSH-10100A 10V, 100A

PSH-2050A 20V, 50A

PSH-3630A 36V, 30A

PSH-6018A 60V, 18A

Regulation

(C.V.) Line ≤ 0.05% + 5mV

Regulation

(C.C.)

Ripple & Noise

Program

Accuracy

Program

Resolution

Readback

(Meter)

Accuracy Current ≤ 0.2% + 90mA (rating ≤ 10V)

Readback

(Meter)

Resolution

Fuse 6.3A/ 250VAC x 3, 0.5A/ 250VAC x 1, 20A/ 250VAC x 1

Dimensions 268 x 141 x 388 mm

Weight Approx. 9.3kg

Load ≤ 0.1% + 5mV

Load ≤ 0.2% + 15mA

Line ≤ 0.2% + 15mA

Voltage (mVrms) ≤ 10mVrms, 100mVpp,

20Hz~20MHz

Current (mArms) ≤ 0.2% + 40mA

Volt age ≤ 0.05% + 25mV (rating ≤ 36V)

≤ 0.05% + 50mV (rating > 36V)

OVP ≤ 0.1% + 50mV (rating ≤ 36V)

≤ 0.1% + 100mV (rating > 36V)

Current ≤ 0.2% + 90mA (rating ≤ 10V)

≤ 0.2% + 60mA (rating ≤ 20V)

≤ 0.2% + 30mA (rating ≤ 60V)

Voltage & OVP 10mV (rating ≤ 36V)

20mV (rating > 36V)

Current 30mA (rating ≤ 10V)

20mA (rating ≤ 20V)

10mA (rating ≤ 60V)

Volt age ≤ 0.05% + 25mV (rating ≤ 36V)

≤ 0.05% + 50mV (rating > 36V)

≤ 0.2% + 60mA (rating ≤ 20V)

≤ 0.2% + 30Ma (rating ≤ 60V)

Volt age 10mV (rating ≤ 36V)

20mV (rating > 36V)

Current 30mA (rating ≤ 10V)

20mA (rating ≤ 20V)

10mA (rating ≤ 60V)

73

74

Page 38

Appendix

PSH User Manual

Declaration of Conformity

We

GOOD WILL INSTRUMENT CO., LTD.

(1) No.7-1, Jhongsing Rd., Tucheng City, Taipei County, Taiwan

(2) No. 69, Lu San Road, Suzhou City (Xin Qu), Jiangsu Sheng, China

declare, that the below mentioned product

Type of Product: Power Supply

Model Number:

PSH-1036A/ 2018A/ 3610A/ 6006A

PSH-1070A/ 2035A/ 3620A/ 6012A

PSH-10100A/ 2050A/ 3630A/ 6018A

are herewith confirmed to comply with the requirements set out in the Council

Directive on the Approximation of the Law of Member States relating to

Electromagnetic Compatibility (89/336/EEC, 92/31/EEC, 93/68/EEC) and Low

Voltage Directive (73/23/EEC, 93/68/EEC).

For the evaluation regarding the Electromagnetic Compatibility and Low Voltage

Directive, the following standards were applied:

◎ EMC

EN 61326-1: Electrical equipment for measurement, control and laboratory use

–– EMC requirements (1997 + A1:1998 + A2:2001 + A3:2003)

Conducted Emission

Radiated Emission

EN 55011: Class A 1998 + A1:1999 +

A2:2002

Current Harmonics

EN 61000-3-2: 2000 + A2:2005

Voltage Fluctuations

EN 61000-3-3: 1995 + A1:2001

------------------------- Surge Immunity

------------------------- Conducted Susceptibility

------------------------- Power Frequency Magnetic Field

------------------------- Voltage Dip/ Interruption

◎ Safety

Low Voltage Equipment Directive 73/23/EEC

Safety Requirements

IEC/EN 61010-1: 2001

Electrostatic Discharge

EN 61000-4-2: 1995 + A1:1998 + A2:2001

Radiated Immunity

EN 61000-4-3: 2002 + A1:2002

Electrical Fast Transients

EN 61000-4-4: 2004

EN 61000-4-5: 1995 + A1:2001

EN 61000-4-6: 1996 + A1:2001

EN 61000-4-8: 1993 + A1:2001

EN 61000-4-11: 2004

Index

A

AC input

cable assembly................................... 22

cord requirement............................... 23

terminal............................................. 18

C

calibration

certificate........................................... 15

CC

characteristic..................................... 45

cleaning PSH ....................................... 5, 7

current

OCP setting ....................................... 49

output setting.................................... 47

CV

characteristic..................................... 45

D

display

contrast setting ................................. 50

default mode...................................... 19

fine/coarse.......................................... 17

menu mode ...................................20, 44

output On/Off .................................... 16

remote control mode.......................... 17

E

EN 55011 ............................................... 75

EN 61000 ............................................... 75

EN 61010 ........................................6, 8, 75

F

faq .......................................................... 69

feature list ............................................. 12

front panel.............................................. 16

faq ...................................................... 69

functionality check

OCP.................................................... 38

output current ................................... 37

output voltage.................................... 35

OVP.................................................... 35

setup .................................................. 34

fuse

rating ................................. 7, 72, 73, 74

safety instruction................................. 7

G

GPIB

interface setting................................. 55

I

IEEE remote control

general commands............................. 58

miscellaneous commands.................. 60

status commands...............................59

syntax ................................................ 57

O

OCP

check .................................................. 38

operation environment

safety instruction............................. 5, 8

output

cable assembly................................... 30

cable selection.................................... 25

current check ..................................... 37

current setting................................... 47

faq ...................................................... 69

load configuration.............................. 26

terminal ............................................. 18

75

76

Page 39

Index

voltage check ......................................35

voltage setting..............................43, 46

OVP

check...................................................35

P

package contents ....................................14

power supply

safety instruction ................................ 7

protection

OCP setting ........................................49

OVP setting ........................................48

PSH lineup .............................................13

R

rack mounting

assembly method................................41

parts list .............................................40

rear panel ...............................................18

remote control

display mode.......................................17

terminal..............................................18

remote sensing

cable assembly....................................32

cable selection ....................................25

configuration ..................................... 26

theory................................................. 24

S

safety

guidelines............................................. 6

symbol.................................................. 6

UK power cord..................................... 9

sound setting ......................................... 51

specification ........................................... 71

storage environment

safety instruction ............................ 5, 8

T

table of contents....................................... 3

V

verification

equipment.......................................... 64

output voltage.................................... 66

setup .................................................. 63

voltage

output setting .................................... 46

OVP setting ....................................... 48

77

Loading...

Loading...