Multi-Range DC Power Supply

PFR-100 Series

USER MANUAL

ISO-9001 CERTIFIED MANUFACTURER

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

TABLE OF CONTENTS

Table of Contents

SAFETY INSTRUCTIONS ................................................... 5

GETTING STARTED ........................................................... 9

PFR-100 Series Overview ...................... 10

Appearance .......................................... 13

Theory of Operation ............................. 20

OPERATION .................................................................... 32

Set Up .................................................. 33

Basic Operation ................................... 44

Test Scripts .......................................... 58

CONFIGURATION ........................................................... 66

Configuration Overview ....................... 67

ANALOG CONTROL ........................................................ 83

Analog Remote Control Overview ......... 84

Remote Monitoring ............................ 102

COMMUNICATION INTERFACE ..................................... 107

Interface Configuration ...................... 108

FAQ ............................................................................... 139

APPENDIX ................................................................

PFR-100 Factory Default Settings ....... 141

Error Messages & Messages .............. 143

LED ASCII Table Character Set ........... 144

PFR-100 Specifications....................... 145

PFR-100 Dimensions .......................... 151

Declaration of Conformity .................. 152

..... 141

3

PFR-100 Series User Manual

INDEX ............................................................................ 153

4

SAFETY INSTRUCTIONS

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the PFR-100 or to other

properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to insure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the

instrument.

5

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

Safety Guidelines

General

Guideline

CAUTION

Do not place any heavy object on the PFR-100.

Avoid severe impact or rough handling that

leads to damaging the PFR-100.

Do not discharge static electricity to the PFR-

100.

Use only mating connectors, not bare wires, for

the terminals.

Do not disassemble the PFR-100 unless you are

qualified.

Power Supply

WARNING

AC Input Voltage: 100Vac-240Vac

Frequency: 47Hz to 63Hz

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

Cleaning the PFR100

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals containing harsh material

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: 20%~ 80% (no condensation)

Altitude: < 2000m

Temperature: 0°C to 40°C

PFR-100 Series User Manual

6

SAFETY INSTRUCTIONS

(Pollution Degree) EN61010-1:2010 specifies the pollution degrees

and their requirements as follows. The PFR-100 falls under degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

Storage

environment

Location: Indoor

Temperature: -20°C to 70°C

Relative Humidity: 20 to 85%(no condensation)

Disposal

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

7

PFR-100 Series User Manual

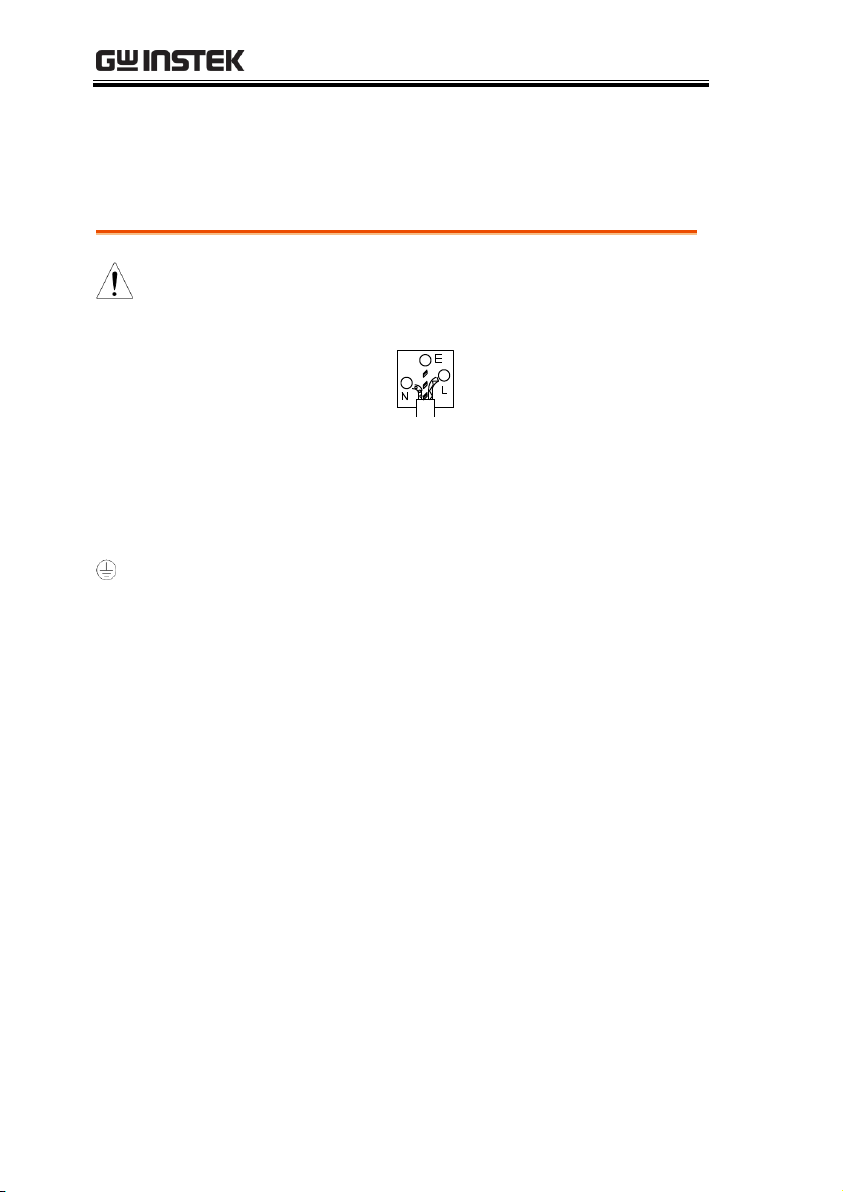

Green/ Yellow:

Earth

Blue:

Neutral

Brown:

Live (Phase)

Power cord for

the United Kingdom

When using the power supply in the United Kingdom, make sure

the power cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code:

As the colours of the wires in main leads may not correspond with

the coloured marking identified in your plug/appliance, proceed

as follows:

The wire which is coloured Green & Yellow must be connected to

the Earth terminal marked with either the letter E, the earth symbol

or coloured Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal

which is marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the

terminal marked with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment

or contact the supplier.

This cable/appliance should be protected by a suitably rated and

approved HBC mains fuse: refer to the rating information on the

equipment and/or user instructions for details. As a guide, a cable

of 0.75mm2 should be protected by a 3A or 5A fuse. Larger

conductors would normally require 13A types, depending on the

connection method used.

Any exposed wiring from a cable, plug or connection that is

engaged in a live socket is extremely hazardous. If a cable or plug is

deemed hazardous, turn off the mains power and remove the cable,

any fuses and fuse assemblies. All hazardous wiring must be

immediately destroyed and replaced in accordance to the above

standard.

8

GETTING STARTED

PFR-100 Series Overview ......................................... 10

Series lineup ................................................................................... 10

Main Features................................................................................. 10

Accessories ..................................................................................... 11

Appearance .............................................................. 13

Front Panel ..................................................................................... 13

Display Area ................................................................................... 16

Rear Panel ....................................................................................... 18

Theory of Operation ................................................ 20

Operating Area Description ........................................................ 20

CC and CV Mode .......................................................................... 22

Slew Rate ........................................................................................ 23

Bleeder Control ............................................................................. 24

Sink Current Table ........................................................................ 25

Alarms ............................................................................................. 26

Considerations ............................................................................... 27

Grounding ...................................................................................... 30

This chapter describes the power supply in a

nutshell, including its main features and front /

rear panel introduction. After going through the

overview, please read the theory of operation to

become familiar with the operating modes,

protection modes and other safety considerations.

GETTING STARTED

9

PFR-100 Series User Manual

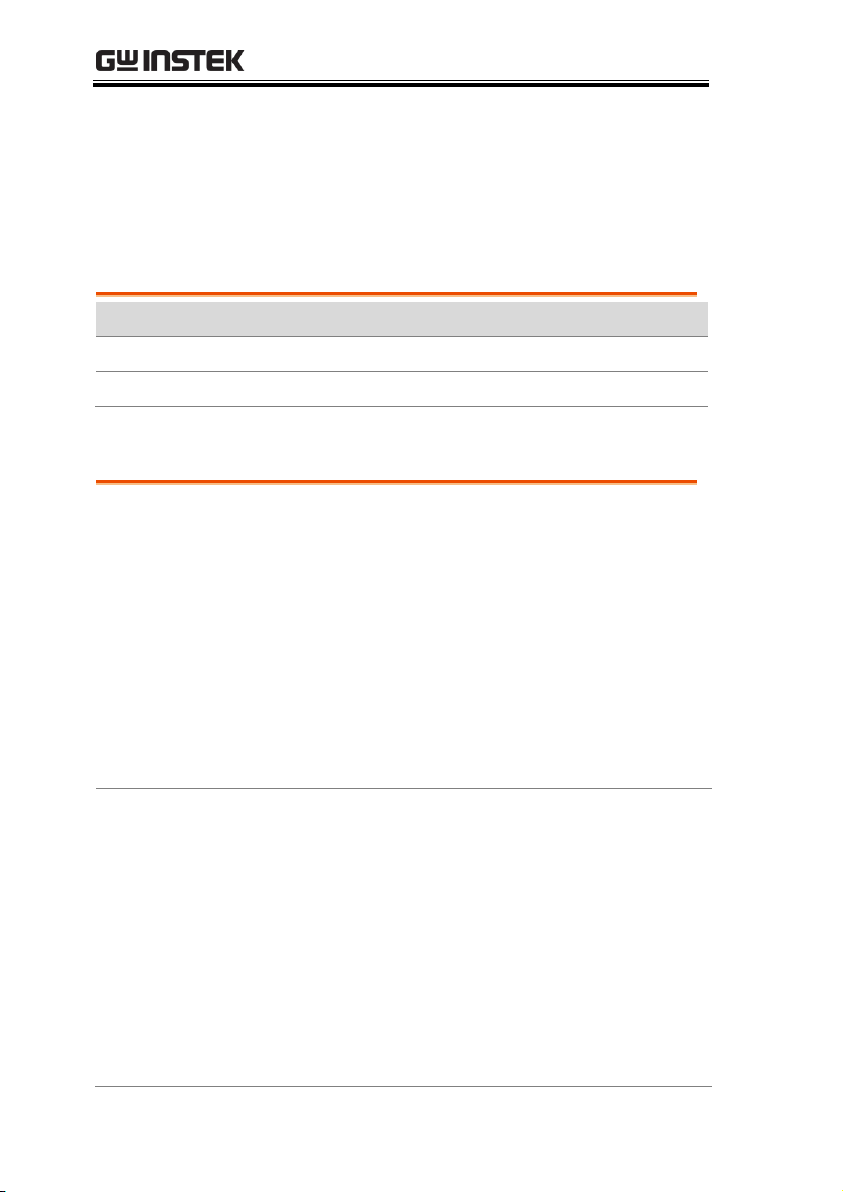

Model name

Operation Voltage

Operation Current

Rated Power

PFR-100L

0-50V

0-10A

100W

PFR-100M

0-250V

0-2A

100W

Performance

Variable voltage and current combinations with

5 times of coverage ratio of its range within the

rated power.

Constant voltage/constant current with

automatic crossover.

Active Power Factor correction.

Universal Input Voltage 85 - 265Vac, continuous

operation.

Natural convection cooling.

Features

Preset memory function.

Output ON/OFF delay function.

CV, CC priority start function. (prevents

overshoot with output ON)

Adjustable voltage and current slew rates.

Bleeder circuit ON/OFF setting. (to prevent

over-discharging of batteries)

OVP, OCP, AC FAIL, OPP and OTP protection.

Supports test scripts.

PFR-100 Series Overview

Series lineup

The PFR-100 series consists of 2 models, covering a number of

different current, voltage and power capacities:

Main Features

10

GETTING STARTED

Web server monitoring and control. (The

function is activated when connecting to LAN

Interface)

Analog monitor output.

Remote sensing to compensate for voltage drop

in load leads.

Built-in front panel and rear panel output

terminal.

Interface

Built-in USB and RS-232/485 interface.

External analog control function.

Optional LAN and GPIB interface.

Standard

Accessories

Part number

Description

Qty.

CD-ROM

User manual, Programming manual

1

Power Cord

1

GTL-134

Test leads for rear panel, 1.2m, 10A,

16AWG

1

PFR-001

Binding Posts Terminal Accessory Kit

(Output terminal cover × 1, Socket ×

1, Protection Cover × 2, Short Bar × 1)

1

GTL-104A

Test leads for PFR-100L (Binding

Posts Terminal), 1m, 10A

1

PFR-002

European Type Jack Terminal

Accessory Kit (Output terminal cover

× 1, Socket × 1, Protection Cover × 2,

Short Wire × 1)

1

GTL-105A

Test leads for PFR-100M, 1m, 3A

1

GTL-204A

Test leads for PFR-100L (European

Type Jack Terminal), 1m, 10A

1

Accessories

Before using the PFR-100 power supply unit, check the package

contents to make sure all the standard accessories are included.

11

PFR-100 Series User Manual

Optional

Accessories

Part number

Description

GRA-431-J-100

Rack mount adapter (JIS) with AC 100V

GRA-431-J-200

Rack mount adapter (JIS) with AC 200V

GRA-431-E-100

Rack mount adapter (EIA) with AC 100V

GRA-431-E-200

Rack mount adapter (EIA) with AC 200V

GTL-258

GPIB Cable, 2000mm

PSU-232

RS-232 Cable with DB9 Connector Kit. It

includes RS-232 cable with DB9 connector,

RS-485 used master cable (gray plug), slave

cable (black plug) and end plug terminal.

PSU-485

RS-485 Cable with DB9 Connector Kit. It

includes RS-485 cable with DB9 connector,

RS-485 used master cable (gray plug), slave

cable (black plug) and end plug terminal.

GTL-246

USB Cable (USB 2.0 Type A- Type B Cable,

4P)

Factory Installed

Options

Part number

Description

PFR-GL

LAN + GPIB interface

12

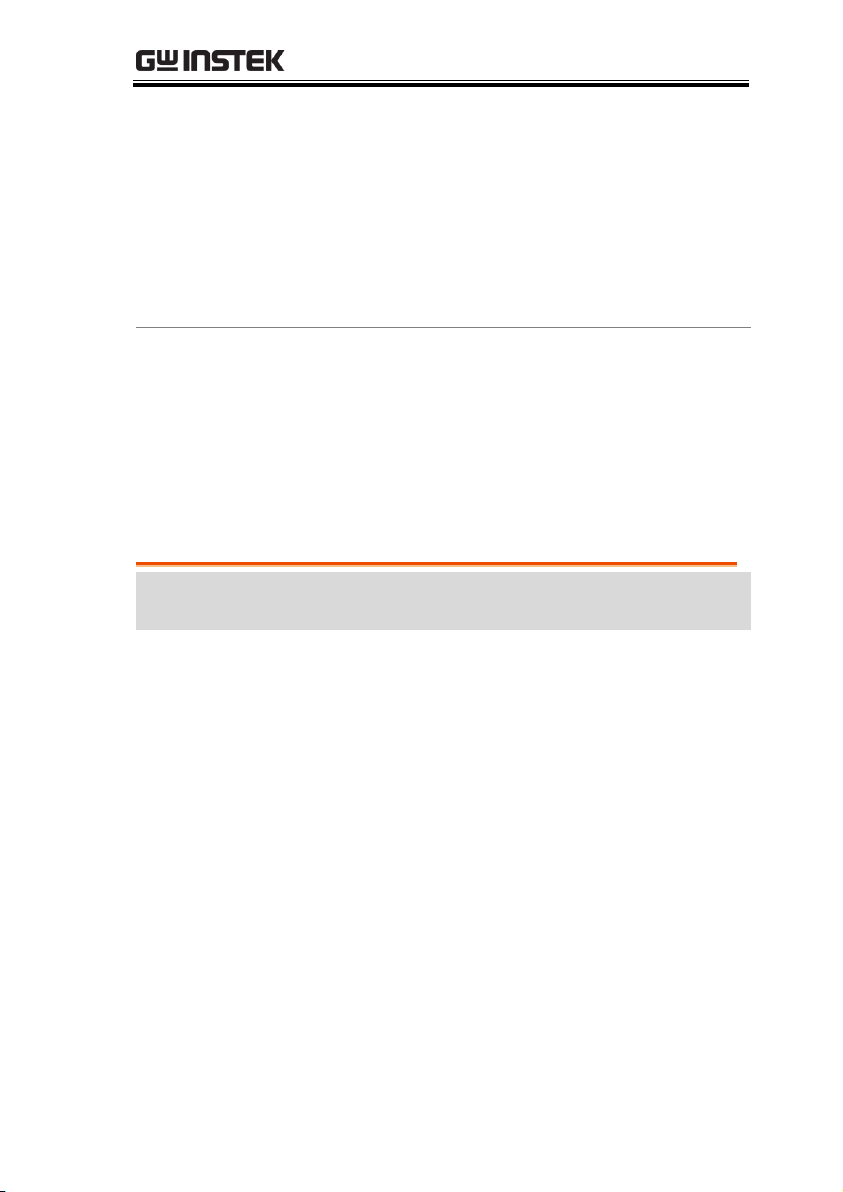

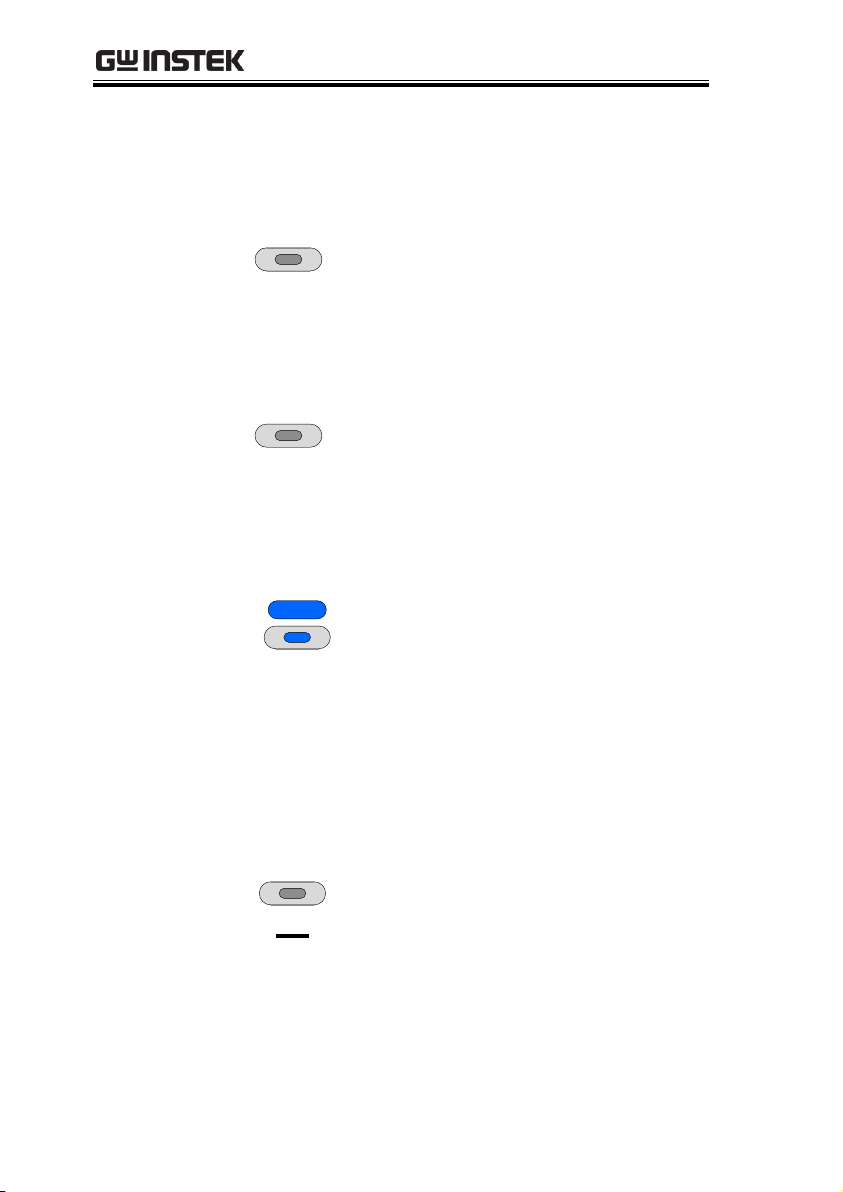

Appearance

A

W

V

W

RUNM3M2M1LANERR

ISR

C C

DLY

ALM

RMT

C V

VSR

Function Set

Output

PROTLock/Local

Shift

Voltage

Current

PFR-100L

0-50V / 0-10A 100W MAX

Multi-Range DC Power Supply

M 1

Test

M 2 M 3

ALM_CLRUnlock

PWR_DSPL

: Long Push

GND

MAX. 50V / 10A / 100W

2

Display Area

1

5

9

8

11

12

3

4

6

7

10

Display Area

The display area shows setting values, output

values and parameter settings. The function LEDs

below show the current status and mode of the

power supply. See page 16 for details.

1.

Voltage Knob

Voltage

Used to set the voltage value or select

a parameter number in the Function

settings.

2.

Current Knob

Current

Used to set the current value or

change the value of a Function

parameter.

3.

Function

Button

Function

M1

Used to configure the various

functions.

Front Panel

GETTING STARTED

13

PFR-100 Series User Manual

M1 Button

(+Shift) Used to recall the M1 setup.

(+Shift and hold) Used to save the

current setup to M1.

4.

Test Button

TEST

M2

Used to run customized scripts for

testing.

M2 Button

(+Shift) Used to recall the M2 setup.

(+Shift and hold) Used to save the

current setup to M2.

5.

Set Button

SET

M3

Used to set and confirm the output

voltage and output current.

M3 Button

(+Shift) Used to recall the M3 setup.

(+Shift and hold) Used to save the

current setup to M3.

6.

Shift Button

Shift

PWR_DSPL

Used to enable the functions that are

written in blue characters below

certain buttons.

PWR_DSPL

(Long push) Displays the output

power on the voltage meter or current

meter. Press the Voltage knob for

V/W, Press the Current knob for

A/W.

7.

Lock/Local

Button

Lock/Local

Unlock

Used to lock all front panel buttons

other than the Output Button or it

switches to local mode.

Unlock

Button

(Long push) Used to unlock the front

panel buttons.

14

GETTING STARTED

8.

PROT Button

PROT

ALM_CLR

Used to set and display OVP, OCP

and UVL.

ALM_CLR

Button

(Long push) Used to release

protection functions that have been

activated.

9.

Output

Button

Output

Used to turn the output on or off.

10.

Power Switch

Used to turn the power on/off.

11.

USB A Port

USB A port for data transfer, loading

test scripts etc.

12

Output

terminal

GND

MAX. 250V / 2A / 100W

DC output terminal for PFR100M is European Type Jack

Terminal.

The max. output is

250V/2A/100W

GND

MAX. 50V / 10A / 100W

DC output terminal for PFR100L is Binding Posts

Terminal or European Type

Jack Terminal.

The max. output is

50V/10A/100W

15

PFR-100 Series User Manual

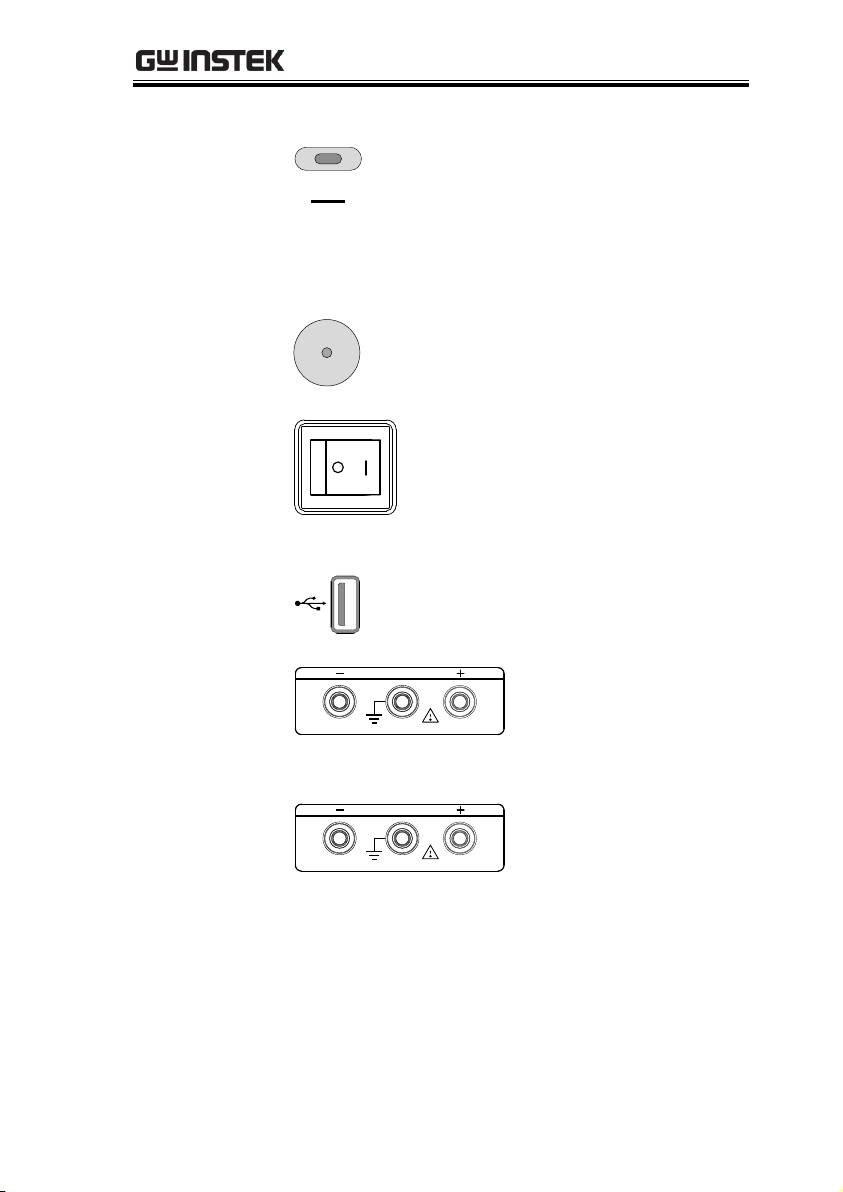

A

W

V

W

RUNM3M2M1LANERR

ISR

C C

DLY

ALM

RMT

C V

VSR

13

14

15

16

17

18

19

20 21 22 23 24

25

26

27

28

29

13.

VSR LED

Lights up when CV Slew Rate Priority is

enabled.

14.

CV LED

Lights in green during constant voltage mode.

15.

RMT LED

Lights in green during remote control.

16.

ALM LED

Lights in red when a protection function has

been activated.

17.

DLY LED

The Output On/Off Delay indicator LED.

18.

CC LED

Lights in green during constant current mode.

19.

ISR LED

Lights up when CC Slew Rate Priority is

enabled.

20.

ERR LED

Lights in red when an error has occurred.

21.

LAN LED

Lights up when the LAN remote connection is

established.

22.

M1 LED

Lights in green when the memory value are

being recalled or saved.

Display Area

16

GETTING STARTED

23.

M2 LED

Lights in green when the memory value are

being recalled or saved.

24.

M3 LED

Lights in green when the memory value are

being recalled or saved.

25.

V or W LED

Display Voltage or Watt unit.

26.

RUN LED

Lights up when a Test Script has been

activated.

27.

A or W LED

Display Current or Watt unit.

28.

Voltage Meter

Displays the voltage or the parameter number

of a Function parameter.

29.

Current Meter

Displays the current or the value of a Function

parameter.

17

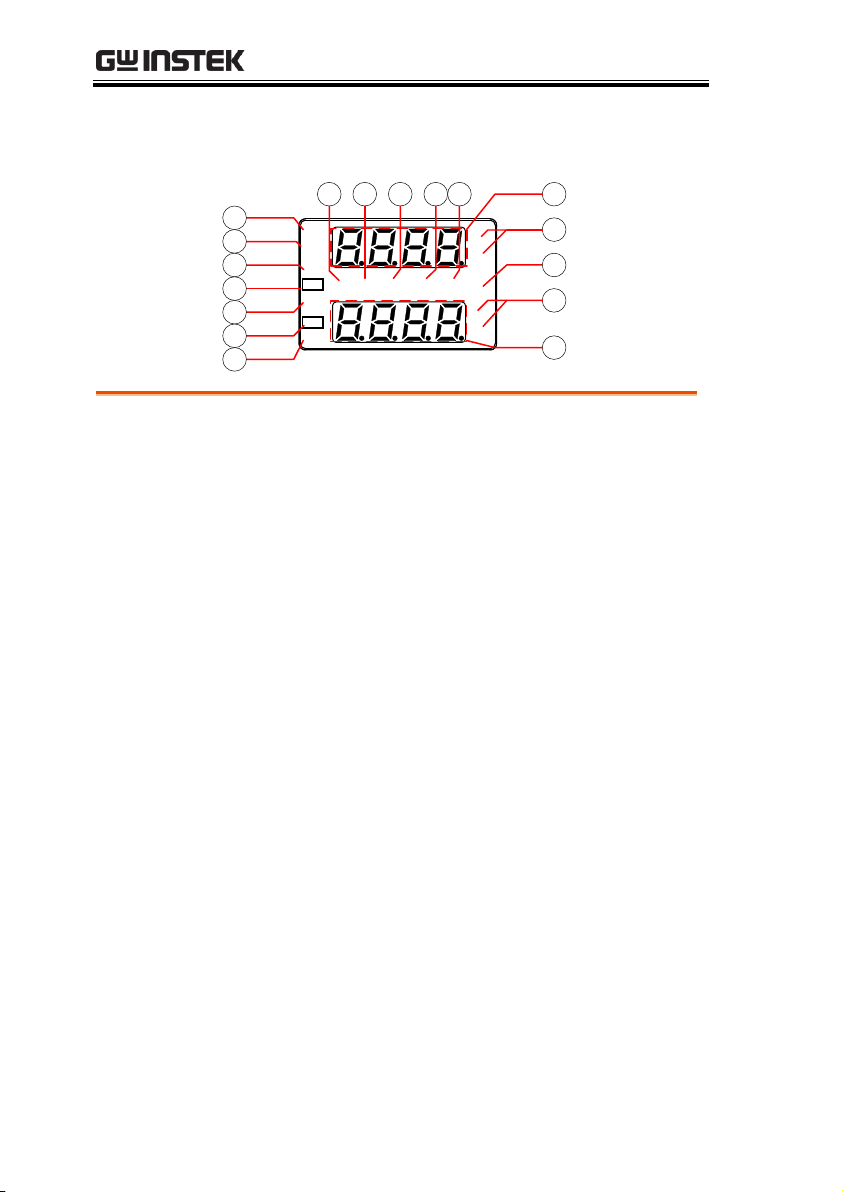

Rear Panel

V

S

N.C.

RS232

/ RS485

IN

OUT

100 240V

47 63Hz

150VA MAX.

AC

J1

S

N.C.

V

LAN

GPIB

protection cover

Analog control

1

2

3

4

5

6

7

8

9

1.

USB

USB port for controlling the PFR-100 remotely.

2.

LAN

Ethernet port for controlling the PFR-100

remotely (Factory Installed Options).

3.

Remote-OUT

RJ-45 connector that is used to daisy chain power

supplies with the Remote-IN port to form a

communication bus.

4.

Remote-IN

Two different types of cables can be used for

RS232 or RS485-based remote control.

PSU-232: RS232 cable with DB9 connector kit.

PSU-485: RS485 cable with DB9 connector kit.

5.

GPIB

GPIB connector for units equipped with IEEE

programming option. (Factory Installed Options)

PFR-100 Series User Manual

18

GETTING STARTED

6.

J1

External analog remote control connector.

7.

Ground

Screw

Connectors for grounding the output.

8.

Output

Terminals

It uses a 10 pin connector and a plug for the

output and sense terminal connections.

9

Line Voltage

Input

AC inlet.

19

Background

The PFR-100 power supplies are regulated DC

power supplies with a high voltage and current

output. These operate in CC or CV mode

within a wide operating range limited only by

the voltage or current output.

The operating area of each power supply is

determined by the rated output power as well

as the voltage and current rating.

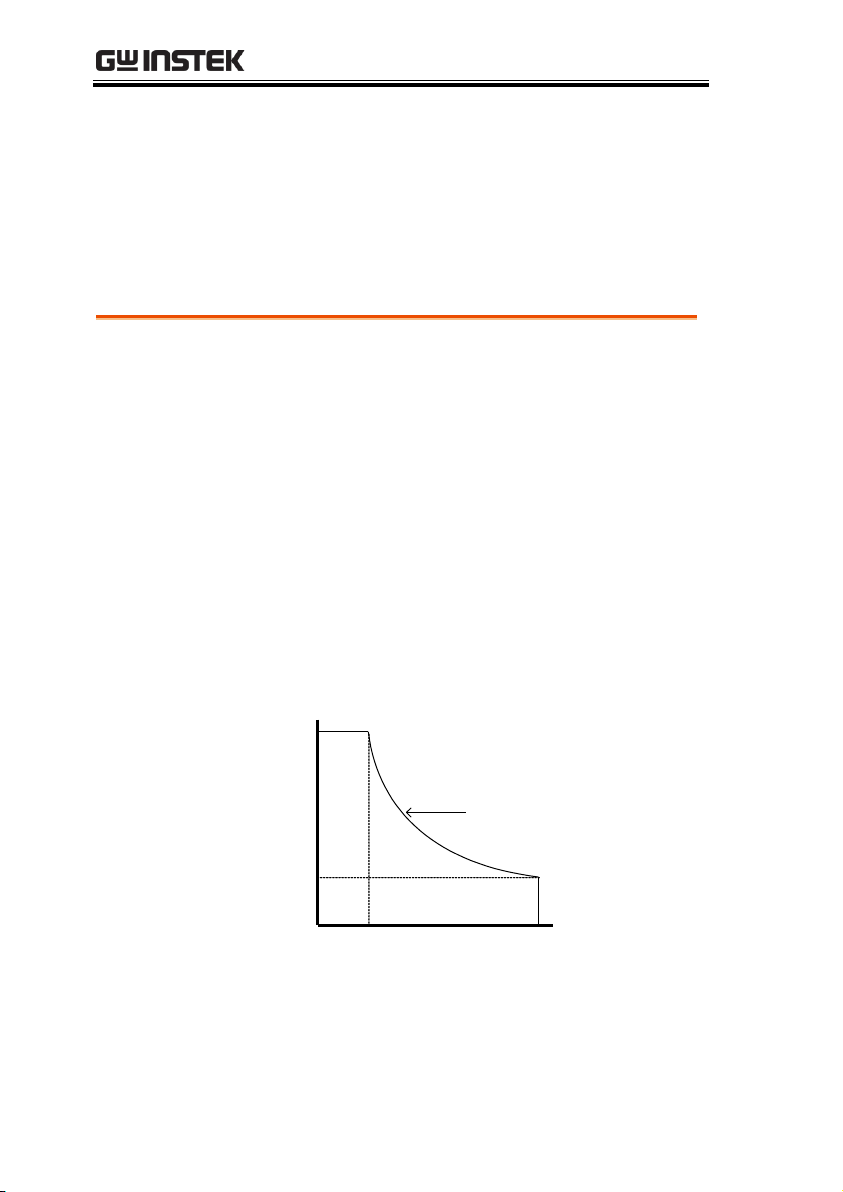

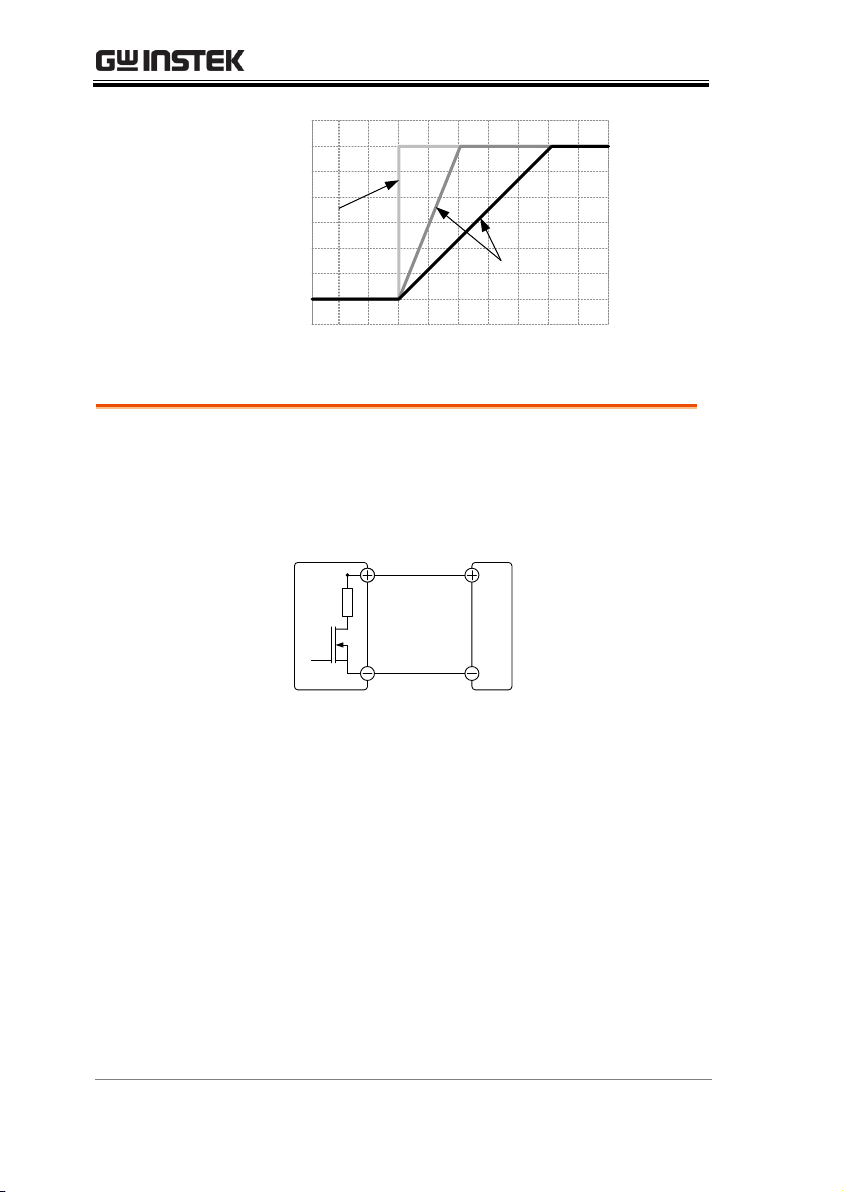

For example the operating area and rated

power output for the PFR-100L is shown

below.

50

100W rated power

10

2 10

PFR-100L Operating Area

Current (A)

Voltage (V)

When the power supply is configured so that

the total output (current x voltage output) is

less than the rated power output, the power

supply functions as a typical constant current,

PFR-100 Series User Manual

Theory of Operation

The theory of operation chapter describes the basic principles of

operation, protection modes and important considerations that

must be taken into account before use.

Operating Area Description

20

GETTING STARTED

constant voltage power supply.

If however, the power supply is configured

such that the total output (current x voltage

output) exceeds the rated power output, the

effective output is actually limited to the power

limit of the unit. In this case the output current

and voltage then depend purely on the load

value.

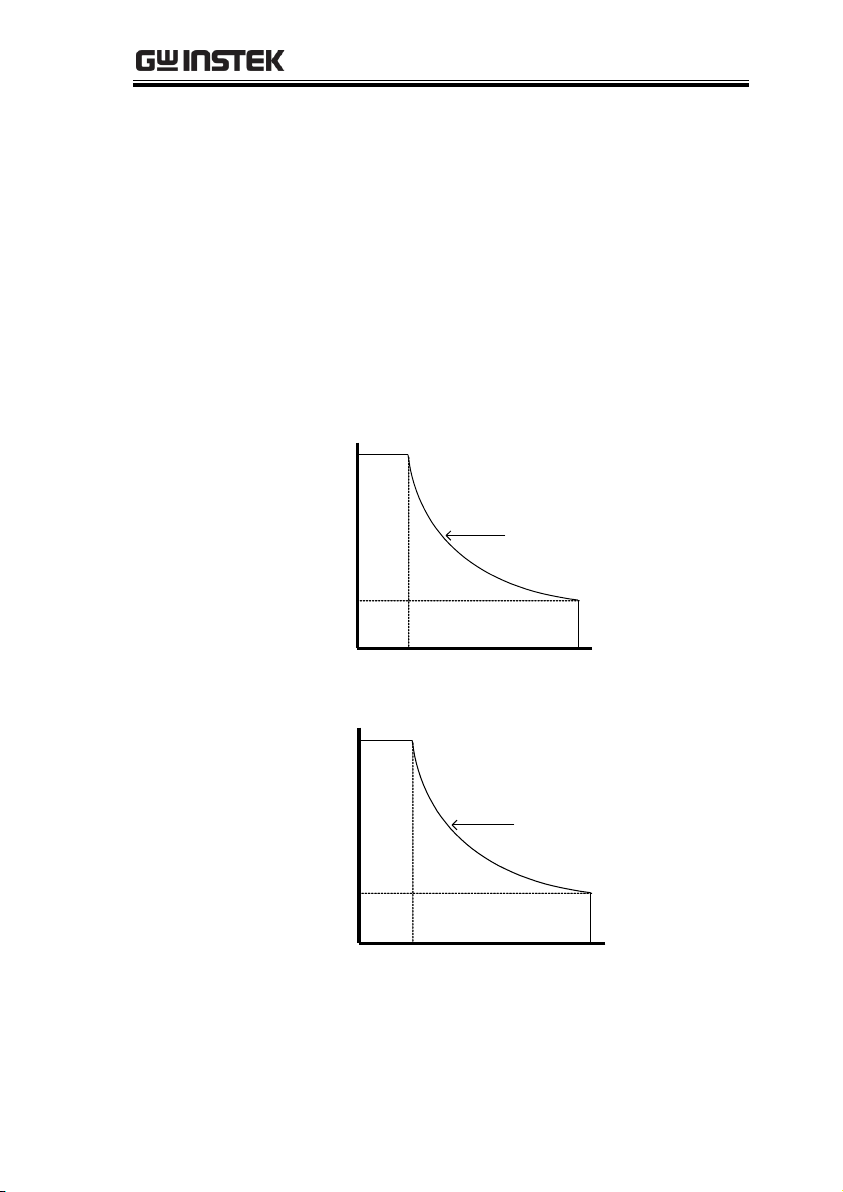

Below is a comparison of the operating areas of

each power supply.

50

100W rated power

10

2 10

PFR-100L Operating Area

Current (A)

Voltage (V)

250

100W rated power

50

0.4 2

PFR-100M Operating Area

Current (A)

Voltage (V)

21

CC and CV Mode

CC and CV mode

Description

When the power supply is operating in

constant current mode (CC) a constant current

will be supplied to the load. When in constant

current mode the voltage output can vary,

whilst the current remains constant. When the

load resistance increases to the point where the

set current limit (I

SET

) can no longer be

sustained the power supply switches to CV

mode. The point where the power supply

switches modes is the crossover point.

When the power supply is operating in CV

mode, a constant voltage will be supplied to

the load, whilst the current will vary as the

load varies. At the point that the load

resistance is too low to maintain a constant

voltage, the power supply will switch to CC

mode and maintain the set current limit.

The conditions that determine whether the

power supply operates in CC or CV (V

SET

), the

load resistance (RL) and the critical resistance

(RC). The critical resistance is determined by

V

SET/ISET

. The power supply will operate in CV

mode when the load resistance is greater than

the critical resistance. This means that the

voltage output will be equal to the V

SET

voltage

but the current will be less than I

SET

. If the load

resistance is reduced to the point that the

current output reaches the I

SET

level, the power

supply switches to CC mode.

PFR-100 Series User Manual

22

GETTING STARTED

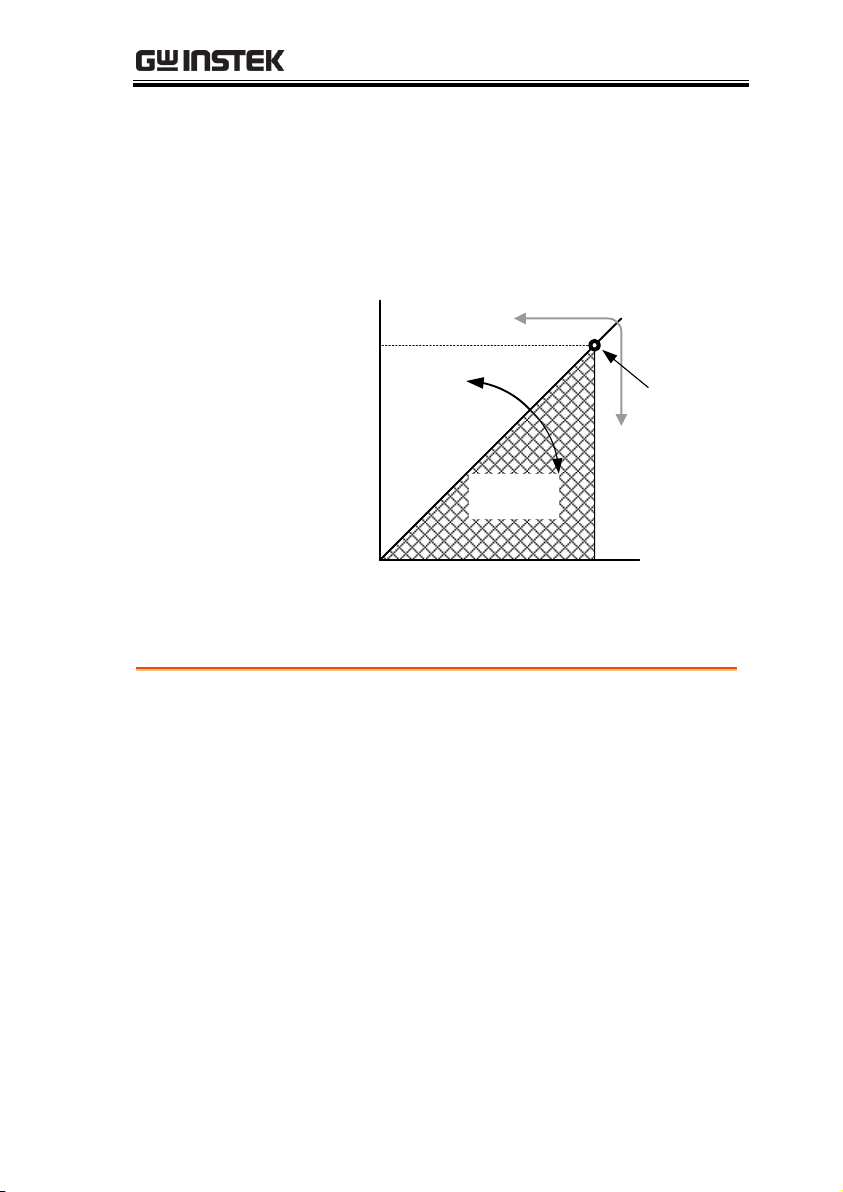

Conversely the power supply will operate in

CC mode when the load resistance is less than

the critical resistance. In CC mode the current

output is equal to I

SET

and the voltage output is

less than V

SET

.

RL=R

C

RL<R

C

VSET

ISET

CV

CC

V

I

RL>R

C

Crossover

point

Theory

The PFR-100 has selectable slew rates for CC

and CV mode. This gives the PFR-100 power

supply the ability to limit the current/voltage

draw of the power supply. Slew rate settings

are divided into High Speed Priority and Slew

Rate Priority. High speed priority mode will

use the fastest slew rate for the instrument.

Slew Rate Priority mode allows for user

adjustable slew rates for CC or CV mode. The

rising and falling slew rate can be set

independently.

Slew Rate

23

High Speed

Priority

mode

Slew rate =

Enabled

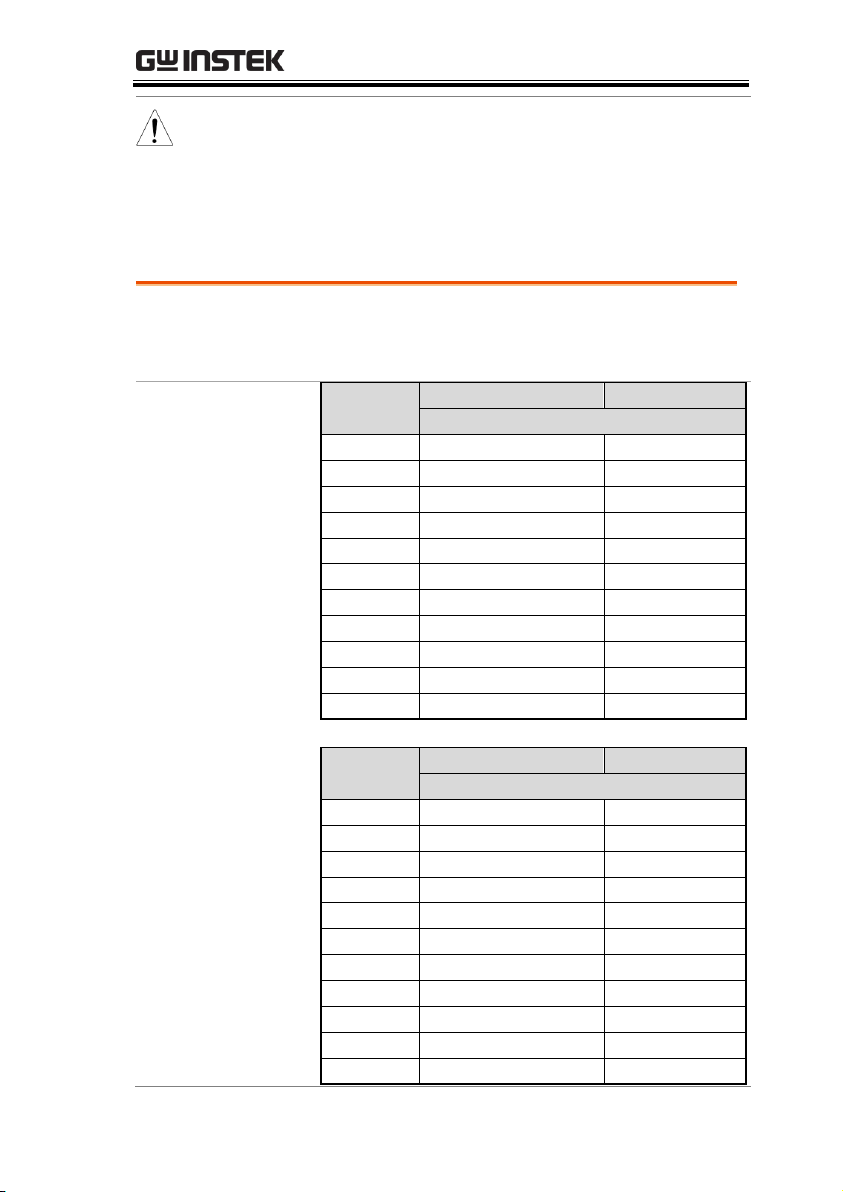

Bleeder Control

Background

The PFR-100 DC power supplies employ a

bleed resistor in parallel with the output

terminals.

PFR-100

Load

Bleed

resistor

Bleed resistors are designed to dissipate the

power from the power supply filter capacitors

when power is turned off and the load is

disconnected. Without a bleed resistor, power

may remain charged on the filter capacitors for

some time and be potentially hazardous.

In addition, bleed resistors also allow for

smoother voltage regulation of the power

supply as the bleed resistor acts as a minimum

voltage load.

The bleed resistance can be turned on or off

using the configuration settings.

PFR-100 Series User Manual

24

Note

By default the bleed resistance is on. For battery

charging applications, be sure to turn the bleed

resistance off as the bleed resistor can discharge

the connected battery when the unit is off.

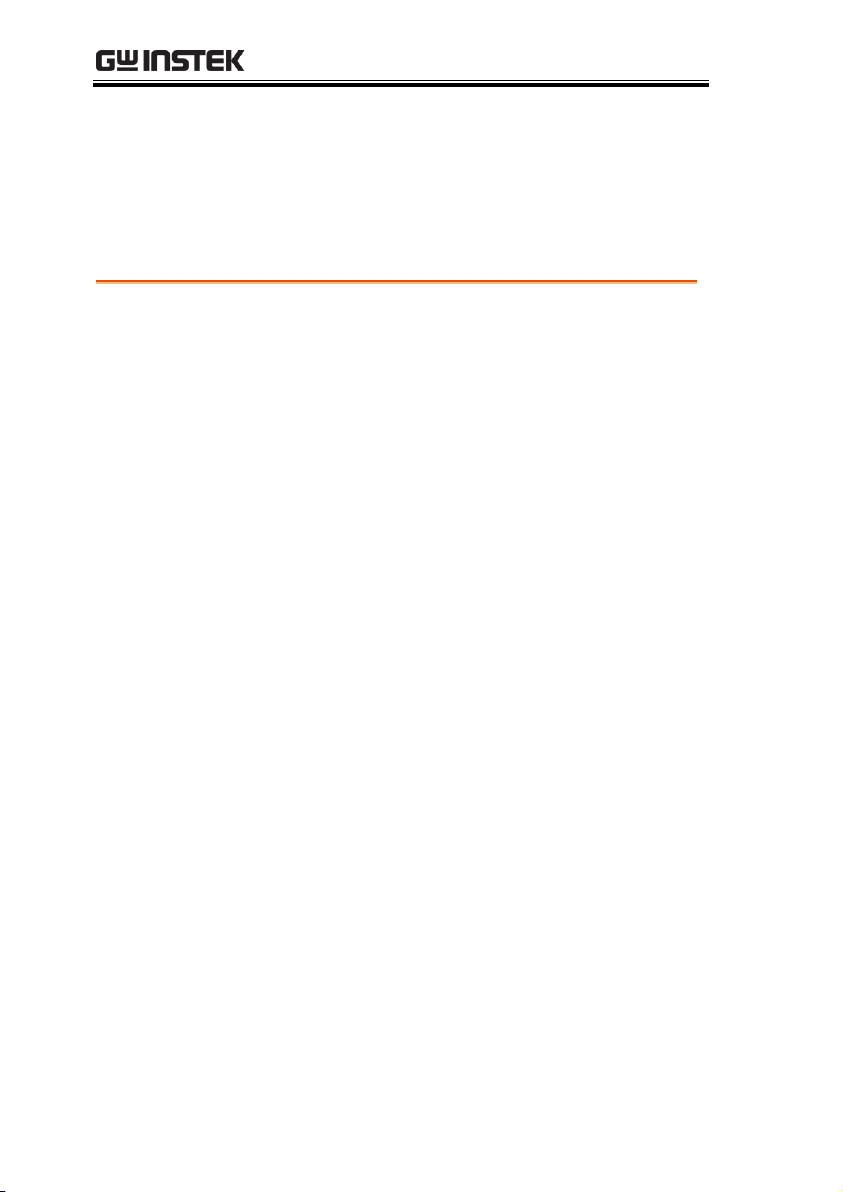

Sink Current Table

Background

Sink current (reference value) from an external

voltage source according to the bleeder circuit

setting.

PFR-100M

Vout

Bleeder ON

Bleeder OFF

Sink Current

(V)

(A)

(mA)

25

0.135

0.001

50

0.119

0.007

75

0.103

0.014

100

0.087

0.022

125

0.071

0.032

150

0.055

0.034

175

0.039

0.043

200

0.034

0.051

225

0.031

0.067

250

0.028

0.086

PFR-100L

Vout

Bleeder ON

Bleeder OFF

Sink Current

(V)

(A)

(mA)

5

0.746

0.006

10

0.658

0.009

15

0.570

0.013

20

0.482

0.017

25

0.375

0.026

30

0.310

0.038

35

0.257

0.038

40

0.236

0.048

45

0.218

0.074

50

0.200

0.200

GETTING STARTED

25

PFR-100 Series User Manual

OVP

Over voltage protection (OVP) prevents a high

voltage from damaging the load. This alarm

can be set by the user.

OCP

Over current protection prevents high current

from damaging the load. This alarm can be set

by the user.

OPP

Over power protection prevents abnormally

use from damaging the PFR-100.

When the output power is over 103W, the

alarm signal will be lit and start to counter.

After a little time, OPP will be triggered and

turn off output.

UVL

Under voltage limit. This function sets a

minimum voltage setting level for the output.

It can be set by the user.

OHP

Over temperature protection protect the

instrument from overheating

AC

AC Fail. This alarm function is activated when

a low AC input is detected.

SENSE ALARM1

This alarm function is activated when real

output voltage is larger than sense output

voltage.

Vo_real > Vo_sense + 1.5V for PFR-100L

Vo_real > Vo_sense + 2.5V for PFR-100M

Alarms

The PFR-100 power supplies have a number of protection features.

When one of the protection alarms is set, the ALM icon on the

display will be lit.

please see page 44.

For details on how to set the protection modes,

26

GETTING STARTED

SENSE ALARM2

This alarm function is activated when sense

output voltage is larger than real output

voltage.

Vo_sense > Vo_real + 1V

Shutdown

Force Shutdown is not activated as a result of

the PFR-100 series detecting an error. It is a

function that is used to turn the output off

through the application of a signal from the

rear-panel analog control connector when an

abnormal condition occurs.

Alarm output

Alarms are output via the analog control

connector. The alarm output is an isolated

open-collector photo coupler output.

Inrush current

When the power supply switch is first turned

on, an inrush current is generated. Ensure there

is enough power available for the power

supply when first turned on, especially if a

number of units are turned on at the same

time.

Caution

Cycling the power on and off quickly can cause the

inrush current limiting circuit to fail as well as

reduce the working life of the input fuse and power

switch.

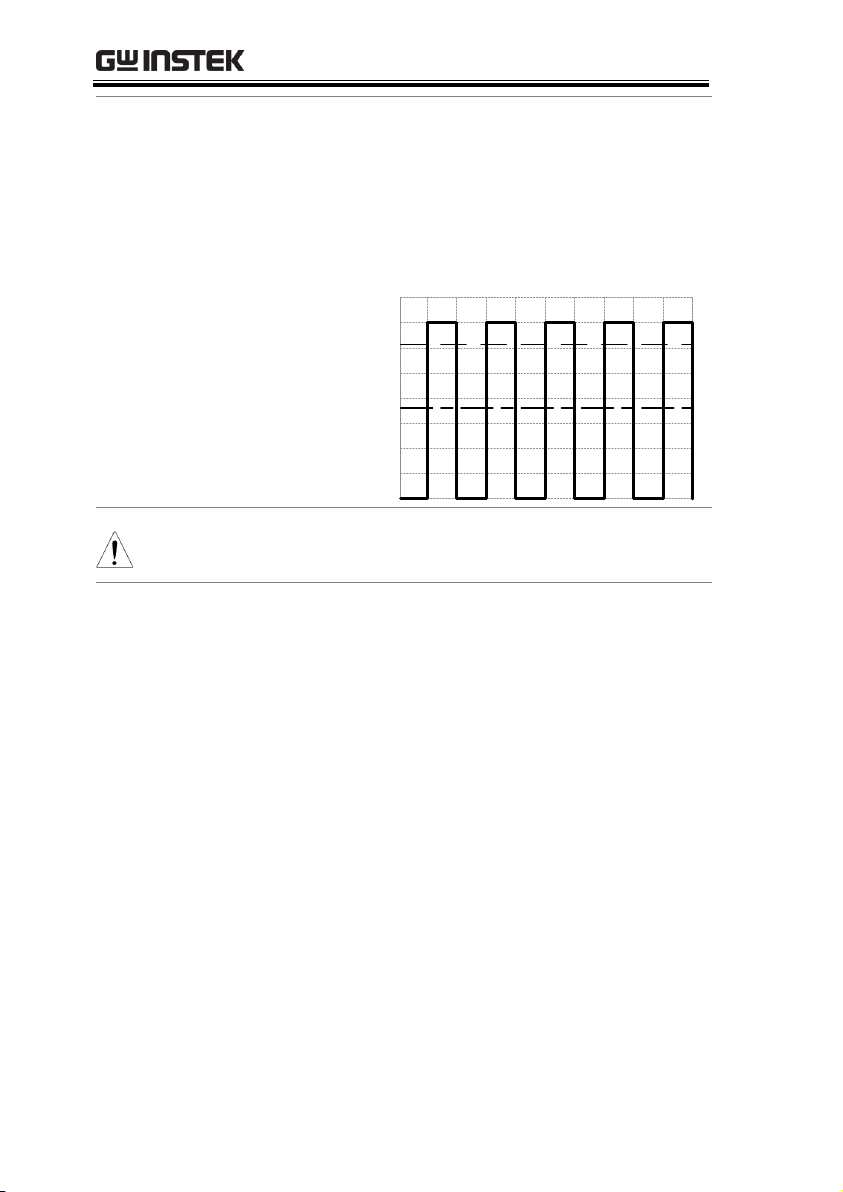

Pulsed or Peaked

loads

When the load has current peaks or is pulsed, it

is possible for the maximum current to exceed

the mean current value. The PFR-100 power

supply ammeter only indicates mean current

values, which means for pulsed current loads,

Considerations

The following situations should be taken into consideration when

using the power supply.

27

PFR-100 Series User Manual

the actual current can exceed the indicated

value. For pulsed loads, the current limit must

be increased, or a power supply with a greater

capacity must be chosen. As shown below, a

pulsed load may exceed the current limit and

the indicated current on the power supply

ammeter.

Current limit

level

Measured

Ammeter

current

Note

The LED message showed on the display will vary

depending on the F-17 setting.

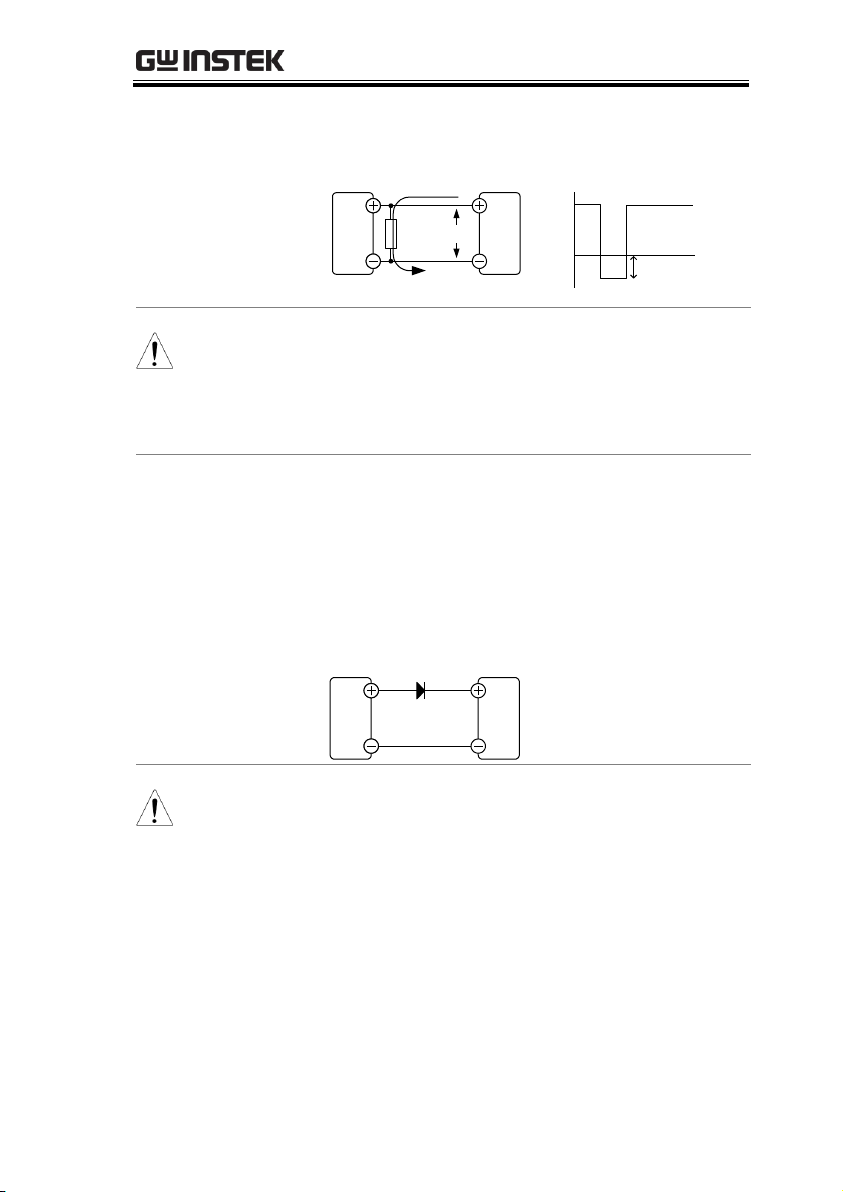

Reverse Current:

Regenerative load

When the power supply is connected to a

regenerative load such as a transformer or

inverter, reverse current will feed back to the

power supply. The PFR-100 power supply

cannot absorb reverse current. For loads that

create reverse current, connect a resistor in

parallel (dummy load) to the power supply to

bypass the reverse current. To calculate the

resistance for the dummy resistor, RD, first

determine the maximum reverse current, IR,

and determine what the output voltage, EO,

will be.

28

GETTING STARTED

RD(Ω) ≤ EO(V) ÷ IR(A)

PFR-100

Load

R

D

I

R

I

R

-

+

E

O

Output

Current

Note

The current output will decrease by the amount of

current absorbed by the resistor.

Ensure the resistor used can withstand the power

capacity of the power supply/load.

Reverse Current:

Accumulative

energy.

When the power supply is connected to a load

such as a battery, reverse current may flow

back to the power supply. To prevent damage

to the power supply, use a reverse-currentprotection diode in series between the power

supply and load.

PFR-100

Load

Diode

CAUTION

Ensure the reverse withstand voltage of the diode

is able to withstand 2 times the rated output

voltage of the power supply and the forward

current capacity can withstand 3 to 10 times the

rated output current of the power supply.

Ensure the diode is able to withstand the heat

generated in the following scenarios.

When the diode is used to limit reverse voltage,

remote sensing cannot be used.

29

PFR-100 Series User Manual

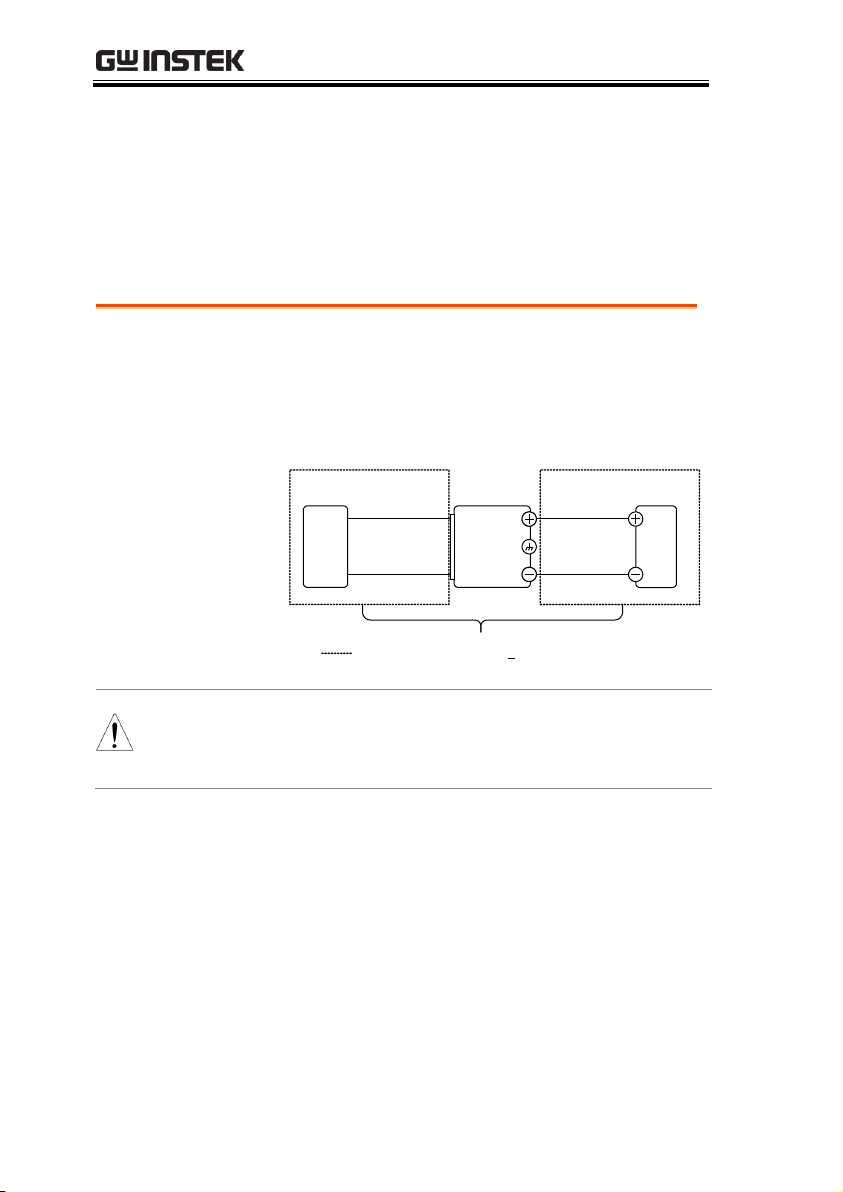

Floating

As the output terminals are floating, the load

and all load cables must have an insulation

capacity that is greater than the isolation

voltage of the power supply.

PFR-100

Load

Ext-V

Ext-R

Analog

connector

( ) Insulation capacity > isolation voltage

of power supply

WARNING

If the insulation capacity of the load and load

cables are not greater than the isolation voltage of

the power supply, electric shock may occur.

Grounding

The output terminals of the PFR-100 power supplies are isolated

with respect to the protective grounding terminal. The insulation

capacity of the load, the load cables and other connected devices

must be taken into consideration when connected to the protective

ground or when floating.

30

Loading...

Loading...