Page 1

PEL-3000H

Page 2

Page 3

PEL-3000 Series Parallel Assembly Guide

1

PEL-3000H Parallel to 9KW contains the parts below

(i.e., PEL-3955H with outline Rack)

Model Name

Part Number

Quantity

Description

PEL-3111H

01EL311H00GT

1

1KW LOAD Master

PEL-3211H

01EL321H00GT

4

2KW LOAD Booster

Connection & Structure Accessory

Model Name

Part Number

Quantity

Description

PEL-005

11EL-00500101

1

Bus Bar Connector

PEL-006

11EL-00600101

1

Bus Bar Connector

(Included PEL-005)

PEL-007

11EL-00700101

1

Bus Bar Connector

(Included PEL-005)

PEL-008

11EL-00800101

1

Bus Bar Connector

(Included PEL-005)

PEL-009

11EL-00900101

1

Bus Bar Connector

(Included PEL-005)

GRA-413-E

01RA4130000GT

4

PEL-3111 3U Frame

(Optional)

GRA-414-E

01RA414E000GT

1

PEL-3111 3U Frame

(Optional)

Refer to the PEL-3000H Series Rack Parts details_EN.doc for the other models.

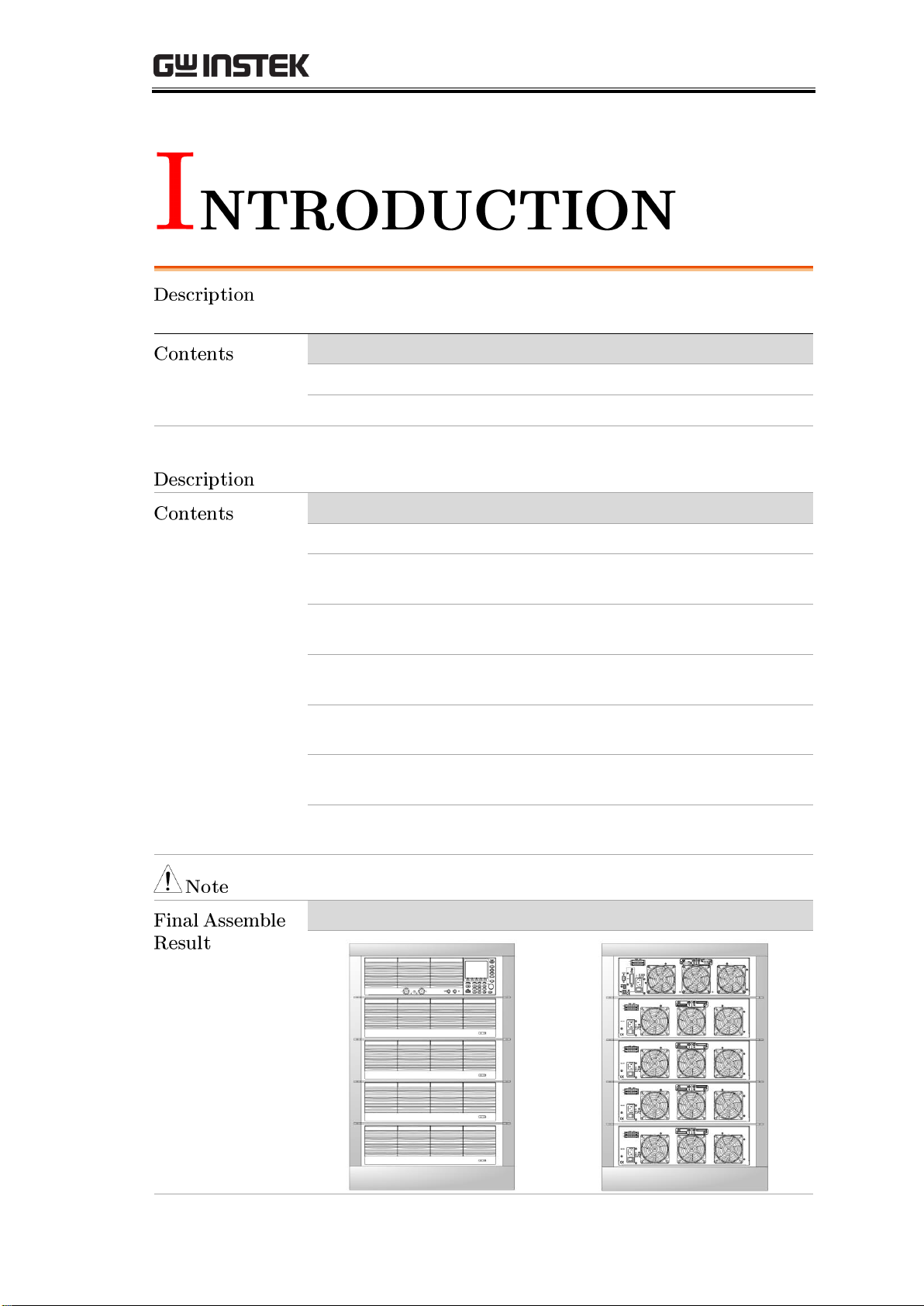

Front View

Rear View

Page 4

PEL-3000 Series Parallel Assembly Guide

2

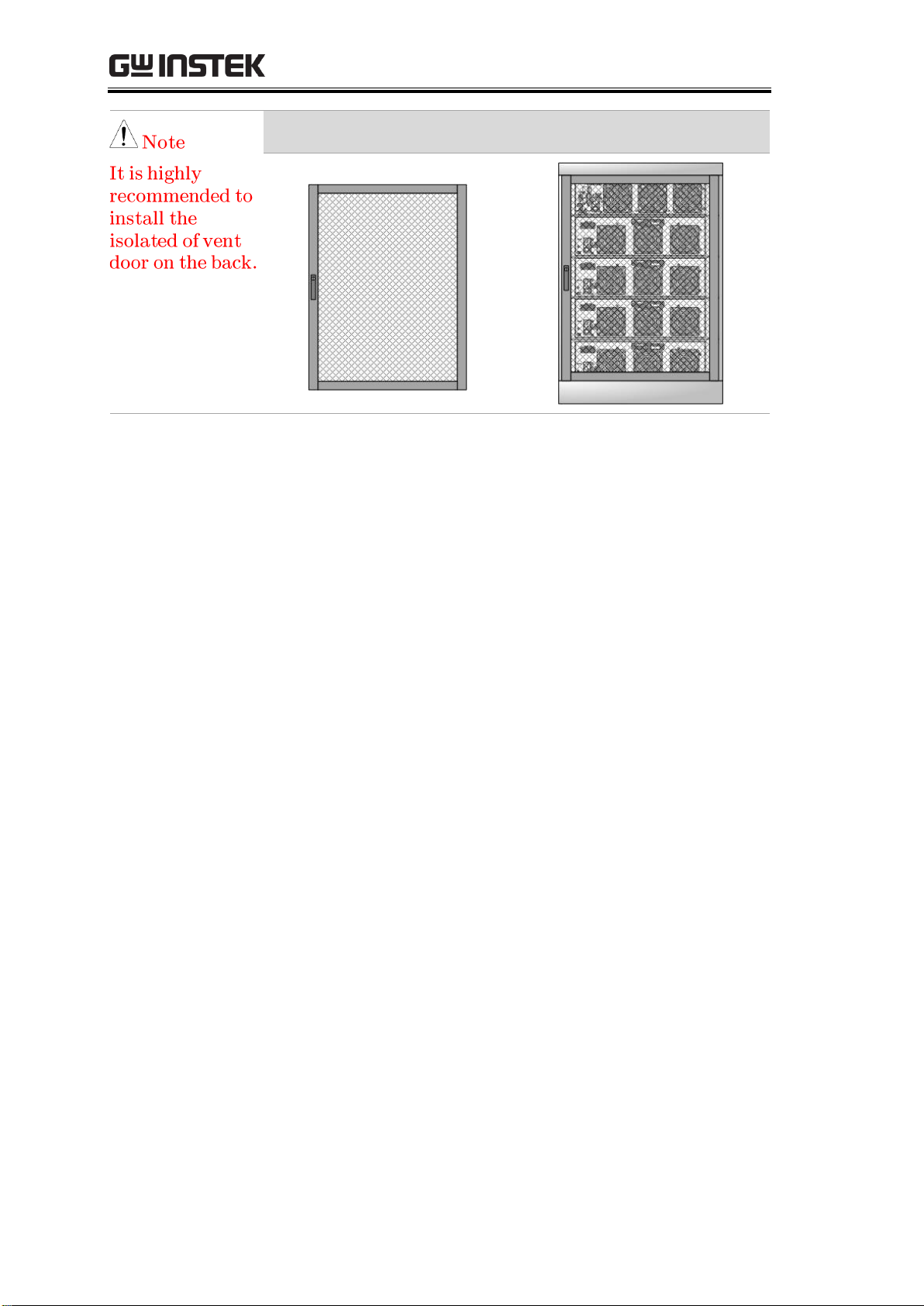

Isolated ventilation door

Rear View with

Isolated ventilation door

Page 5

PEL-3000 Series Parallel Assembly Guide

3

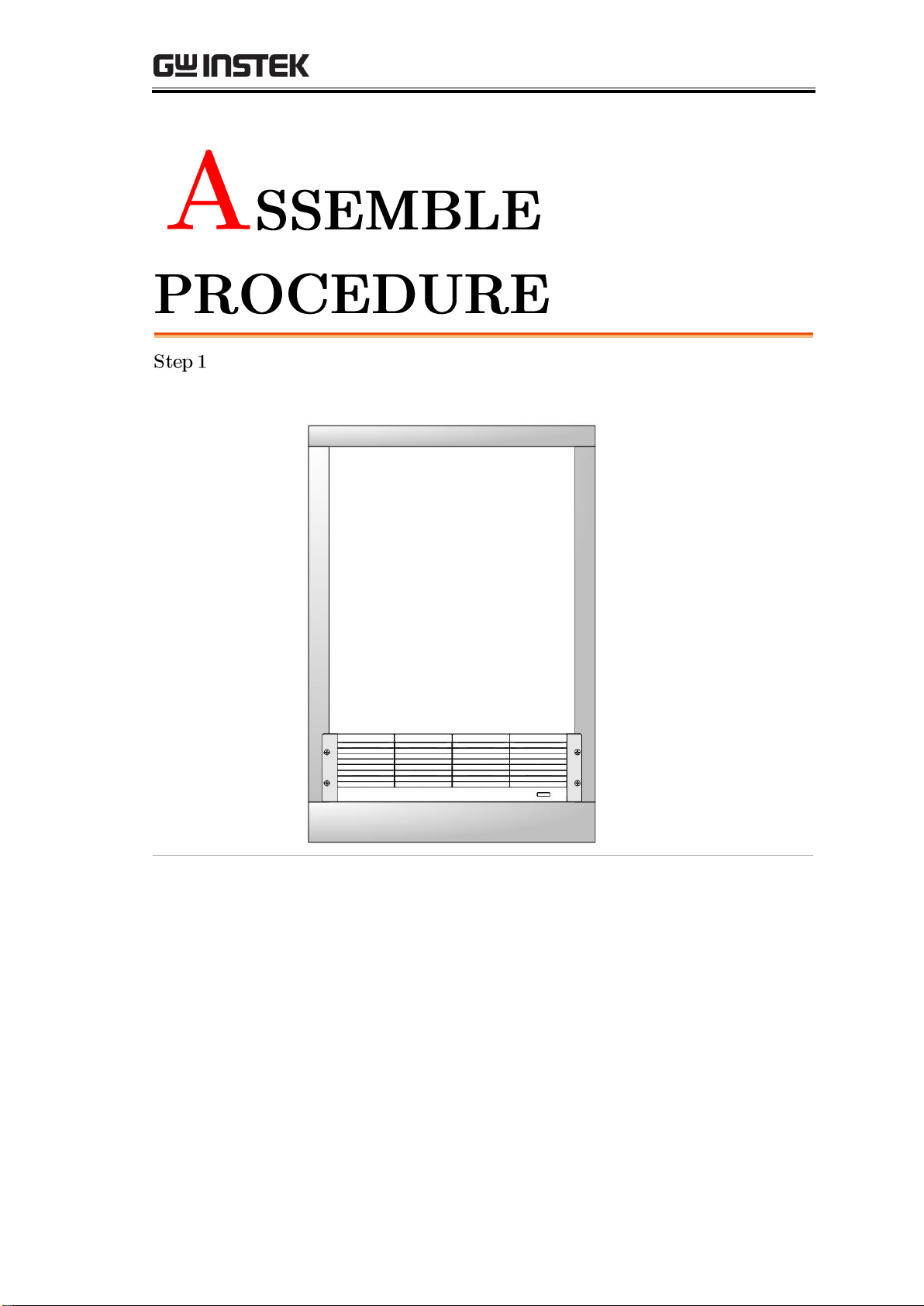

Put the 1st PEL-3211H on the bottom of the rack followed by fastening

the 4 screws for side bracket in the front but not tightening them

completely.

Page 6

PEL-3000 Series Parallel Assembly Guide

4

Screw the L-shape brackets in the interior side of rack. An approx. 1mm

distance between the bottom of brackets and the top of PEL-3211H is

required.

Put the 2nd PEL-3211H onto the L-shape brackets within the rack and,

again, fasten the 4 screws for side bracket in the front but not tighten

them fully followed by screwing another group of L-shape brackets

within the interior of rack.

2nd unit installation completion

L-shape

bracket

The L-shape brackets screwed

on the interior side of rack

Approx. 1mm between

bracket and the top of unit

Page 7

PEL-3000 Series Parallel Assembly Guide

5

Repeat the previous steps in order to install the rest of PEL-3211Hs and

further install the bracket (GRA-414-3) of PEL-3111H on the upper side

followed by installing the PEL-3111H onto the top of the bracket.

Assembly completion for 5 units

Page 8

PEL-3000 Series Parallel Assembly Guide

6

Assemble the L-type copper stick (PEL-005) onto the output terminal in

the rear side of each unit as the figure below shown.

L-type copper stick assembly

L-type copper sticks assembly completion

In accordance with the figure below, assemble the copper sticks for unit

conjunction followed by fastening the screws in the front of rack tightly.

Copper sticks assembly diagram

Diagram of rear side for copper

sticks assembly

Page 9

PEL-3000 Series Parallel Assembly Guide

7

Page 10

PEL-3000 Series Parallel Assembly Guide

8

Install the parallel cables in accord with the following figure.

The last cable connecting to the last unit cannot be clipped with core. When

only one PEL-3111H connects to a PEL-3211H (Booster) in parallel, the cable

in the Booster end cannot be clipped with core.

Page 11

PEL-3000 Series Parallel Assembly Guide

9

Refer to the figure below; connect the AC power cords for all units to the

power sockets in the rear side individually followed by powering on the

power switch that is underneath the power socket (─ indicates power ON).

Attentively check if the indicator in the front panel of all units lights up

with red color:

I. Master indicator lights up as the figure below:

II. Booster indicator lights up as the figure below (STBY indicator

lights up):

Page 12

PEL-3000 Series Parallel Assembly Guide

10

Power on the power switch in the Master front panel and the indicator

lights up in green as figure below shown:

Press

Main

> Configure[F5] > Next Manu[F4] in the front panel

followed by selecting “4” for Booster number within Configure page,

which indicates 4 Booster units in parallel. See the steps figures below:

Select Booster number corresponding to the actual Booster number in parallel.

Page 13

PEL-3000 Series Parallel Assembly Guide

11

Properly confirm if the indicator in the front panel of all PEL-3211H

(Booster) lights up with LINK in green, which means the software setting

connects to Booster appropriately. Refer to the figure below.

Page 14

PEL-3000 Series Parallel Assembly Guide

12

The current sink power of PEL-3111H and PEL-3211H is 1KW:2KW;

therefore, the ratio of current sink will always be the exactly 1:2.

E.g., PEL-3322H (3KW); when current sink is set 30A, Master (PEL-3111H)

will sink current by 10A, whilst Booster (PEL-3211H) will sink current by

20A.

E.g., PEL-3955H (9KW); when current sink is set 90A, Master

(PEL-3111H) will sink current by 10A, whilst the rest of the 4 Booster

(PEL-3211H) will sink current by 20A individually.

First dismantle all of the positive parallel copper sticks and parallel cables

in the rear output terminal of unit.

Check the 1st Booster current:

I. Connect the parallel cable to the J2 connector in the rear of

PEL-3111H in one end and the J1 connector in the rear of

PEL-3211H in the other end.

II. Power on both PEL-3111H and the 1st PEL-3211H, while keep

the rest units power-off. Set the unit PEL-3111H as the parallel

mode via the following procedure:

III. Select from the main interface

a. Configure > Next Menu > Parallel > Operation; select: Master

b. Configure > Next Menu > Parallel > Parallel; select: OFF

c. Configure > Next Menu > Parallel > Booster; select: 1

Page 15

PEL-3000 Series Parallel Assembly Guide

13

IV. Based on the connection method in the figure below, connect

current sink cable to the unit followed by setting current sink

value for unit. Measure the currents from both the current sink

cable of Master positive pole and the current sink cable of Booster

positive pole, via current probe, to validate the accuracy of

currents. The measured current value of Master is supposed to be

1/3 of the set value, whereas the measured current value of

Booster should be 2/3 of the set value.

Page 16

PEL-3000 Series Parallel Assembly Guide

14

The 2nd Booster current checkup:

I. Connect the parallel cable to the J2 connector in the rear of

PEL-3111H in one end and the J1 connector in the rear of

PEL-3211H in the other end.

II. Power on both PEL-3111H and the 2nd PEL-3211H, while keep

the rest units power-off. Set the unit PEL-3111H as the parallel

mode. The setting procedure is identical to the setting of the 1st

PEL-3211H validation.

III. Based on the connection method in the figure below, connect

current sink cable to the unit followed by setting current sink

value for unit. Measure the currents from both the current sink

cable of Master positive pole and the current sink cable of Booster

positive pole, via current probe, to validate the accuracy of

currents. The measured current value of Master is supposed to be

1/3 of the set value, whereas the measured current value of

Booster should be 2/3 of the set value.

Follow the previous steps to validate the 3rd and the 4th Booster

respectively.

The assembly procedure and system setting are completely finished.

Press

Main

to return back to the main screen and the current sink test

is properly ready to initiate.

Loading...

Loading...