Page 1

Digital Storage Oscilloscope

GDS-2000A Series

OPTIONS USER MANUAL

ISO-9001 CERTIFIED MANUFACTURER

Page 2

July 2013

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan

Page 3

TABLE OF CONTENTS

Table of Contents

GETTING STARTED ........................................................... 4

GDS-2000A Options Overview ............... 5

Module Installation ................................ 6

Software Installation .............................. 7

Uninstalling Optional Software .............. 8

QUICK REFERENCE ........................................................... 9

Options Menu Tree .............................. 10

FUNCTION GENERATOR ................................................ 19

Function Generator Operation ............. 20

LOGIC ANALYZER ........................................................... 26

Logic Analyzer Operation ..................... 28

Bus Key Configuration .......................... 44

Trigger Settings .................................... 69

INDEX............................................................................. 80

3

Page 4

GDS-2000A Series Options Manual

GDS-2000A Options Overview ........................................... 5

Hardware Options ................................................................. 5

Module Installation ........................................................... 6

Software Installation ......................................................... 7

Uninstalling Optional Software .......................................... 8

GETTING STARTED

This chapter gives a brief overview of optional

modules and software available for the GDS2000A, how to install or uninstall any options

already installed on the scope.

4

Page 5

GETTING STARTED

Option Number

Description

DS2-LAN

Ethernet & SVGA output

DS2-GPIB

GPIB Interface

DS2-FGN

DDS Function Generator

DS2-8LA

8-Channel Logic Analyzer Card (GLA-08)with 8-Channel

Logic Analyzer Probe (GTL-08LA)

DS2-16LA

16-Channel Logic Analyzer Card (GLA-16)with

16-Channel Logic Analyzer Probe (GTL-16LA)

GDS-2000A Options Overview

The GDS-2000A has a number of options that can be installed to

increase the functionality of the base models. Some of the options

are hardware only, and some of the options require both hardware

modules and software to be installed. Below is a list of options

available for the GDS-2000A.

GW Instek will continue to develop modules and optional software.

Please see the GW Instek website or see your local distributor for

further updates.

Hardware Options

5

Page 6

GDS-2000A Series Options Manual

Background

The GDS-2000A has a number of optional modules

that can be installed into the module slots on the

rear panel. These modules must be installed before

power up.

Note

The modules are not hot-swappable. Please ensure the

power is off before connecting or disconnecting any of

the modules from the rear panel.

Steps

1. Make sure the power is turned off before

installing any of the optional modules.

2. Slide the tabs holding the module cover to the

unlock position and then remove

3. Install the optional module. Be sure to make

sure that the groves on the module line-up to

the slots in the module bay.

4. Slide the tabs back into the lock position.

5. Install the corresponding optional software, if

any. See the next section for installation

instructions.

Module Installation

6

Page 7

GETTING STARTED

Background

The GDS-2000A has optional software packages to

expand the functionality of the standard GDS2000A. Optional software may also require

optional hardware modules to also be installed. An

activation key is required to activate any optional

software. A different activation key is required for

each optional software package.

For the latest files and information regarding the

optional software packages, see the GW Instek

website: www.gwinstek.com or contact your

nearest distributor.

Steps

1. Install any hardware modules if needed. See

page 6 for installation details.

Panel Operation

2. Insert the USB serial key for the

desired option into the front panel

USB A port.

Demo

3. Press the Utility key then the File

Utilities soft-key.

Utility

4. Navigate to the desired file in the

USB file path.

When the desired installation file

has been found, press the Select

key to start the installation.

VARIABLE

Select

Software Installation

7

Page 8

GDS-2000A Series Options Manual

5. The installation will complete in a few seconds.

When finished a pop-up message will appear

asking you to restart the GDS-2000A.

6. Restart the GDS-2000A.

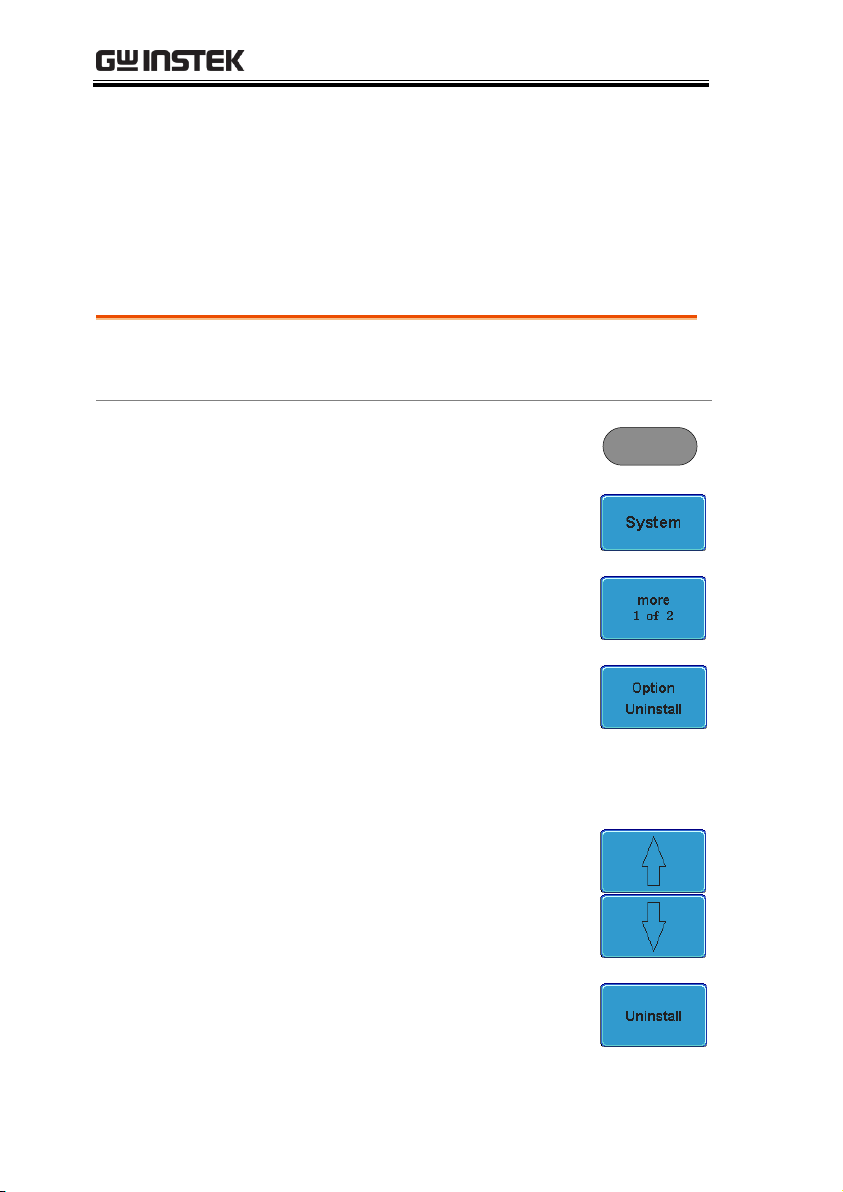

Background

Optional software packages such as the Search

function can be uninstalled from the system menu.

Panel Operation

1. Press the Utility key.

Utility

2. Press System from the bottom

menu.

3. Press more 1 of 2 from the side

menu.

4. Press Option Uninstall on the side

menu.

5. Select the optional software packages that you

wish to uninstall from the side menu.

6. Use the Up and Down arrows on

the side menu to select an option to

uninstall.

7. Press Uninstall to uninstall the

option.

Uninstalling Optional Software

8

Page 9

QUICK REFERENCE

Options Menu Tree ......................................................... 10

Option Key ........................................................................... 10

Function Generator ............................................................. 10

Logic Analyzer ...................................................................... 11

Search - Logic ....................................................................... 11

Search - Bus .......................................................................... 12

Trigger - Bus ......................................................................... 13

Trigger - Logic ...................................................................... 14

Bus ......................................................................................... 14

Bus - UART .......................................................................... 15

Bus – I2C ............................................................................... 16

Bus – SPI ............................................................................... 17

Bus – Parallel ........................................................................ 18

QUICK REFERENCE

This chapter describes the menu tree for the

option software.

9

Page 10

GDS-2000A Series Options Manual

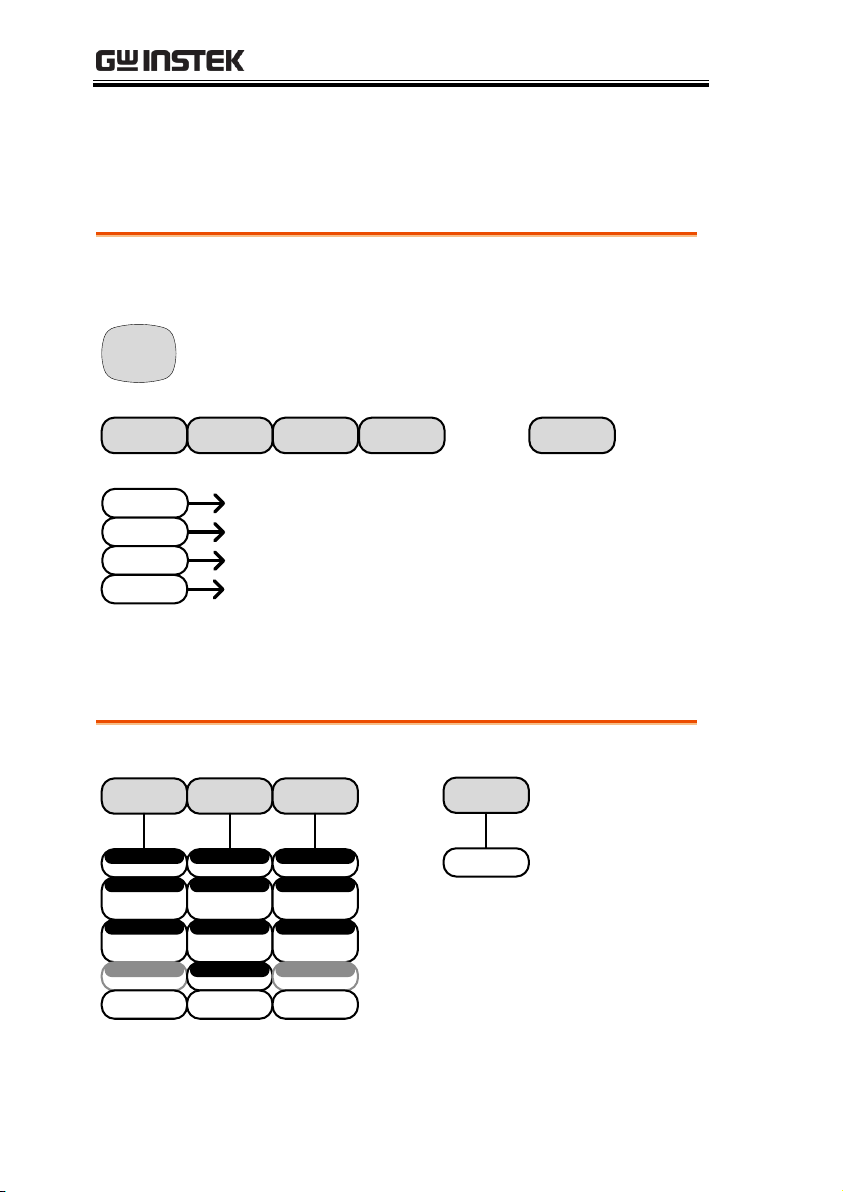

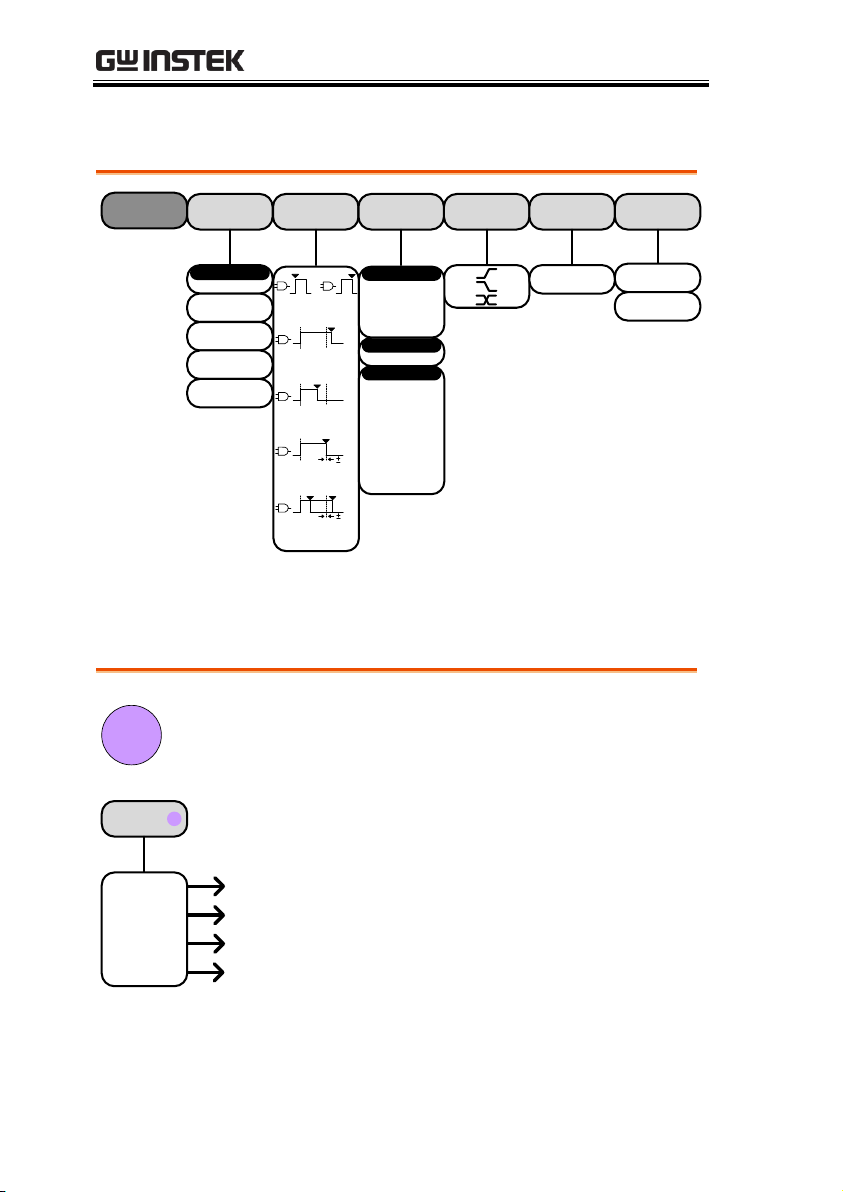

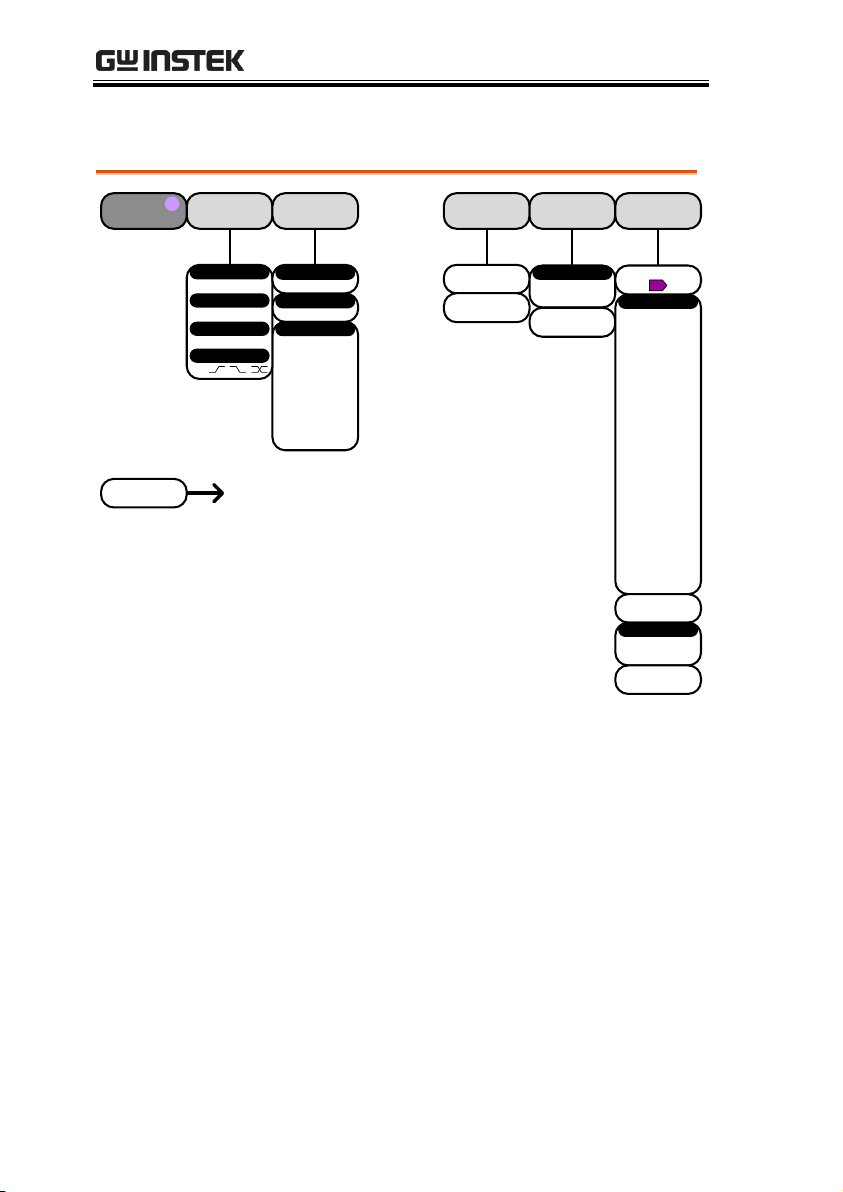

Accesses the functions in the Option menu.

Function

Gen 1

Function

Gen 2

I/O

Logic

Analyzer

Option

Logic

Analyzer

Function

Gen 1

Goes to the Logic Analyzer menu

Goes to the Function Generator menu

for the GEN 1 output

Function

Gen 2

Goes to the Function Generator

menu for the GEN 2 output

I/O

Goes to the options I/O menu

DVM

*Note: Any option that is not installed will be grayed-out.

Setup the Function Generator output.

Sine Square Triangle

0.1Hz ~ 5MHz

Frequency

30mVpp ~ 3Vpp

(into 50Ω)

Amplitude

±1.000V

(into 50Ω)

Offset

Dutycycle

Default

1kHz

0.1Hz ~ 5MHz

Frequency

30mVpp ~ 3Vpp

(into 50Ω)

Amplitude

±1.000V

(into 50Ω)

Offset

5% ~ 95%

Dutycycle

Default

1kHz

0.1Hz ~ 500kHz

Frequency

30mVpp ~ 3Vpp

(into 50Ω)

Amplitude

±1.000V

(into 50Ω)

Offset

Dutycycle

Default

1kHz

-20dB

ON

OFF

Options Menu Tree

Option Key

Function Generator

10

Page 11

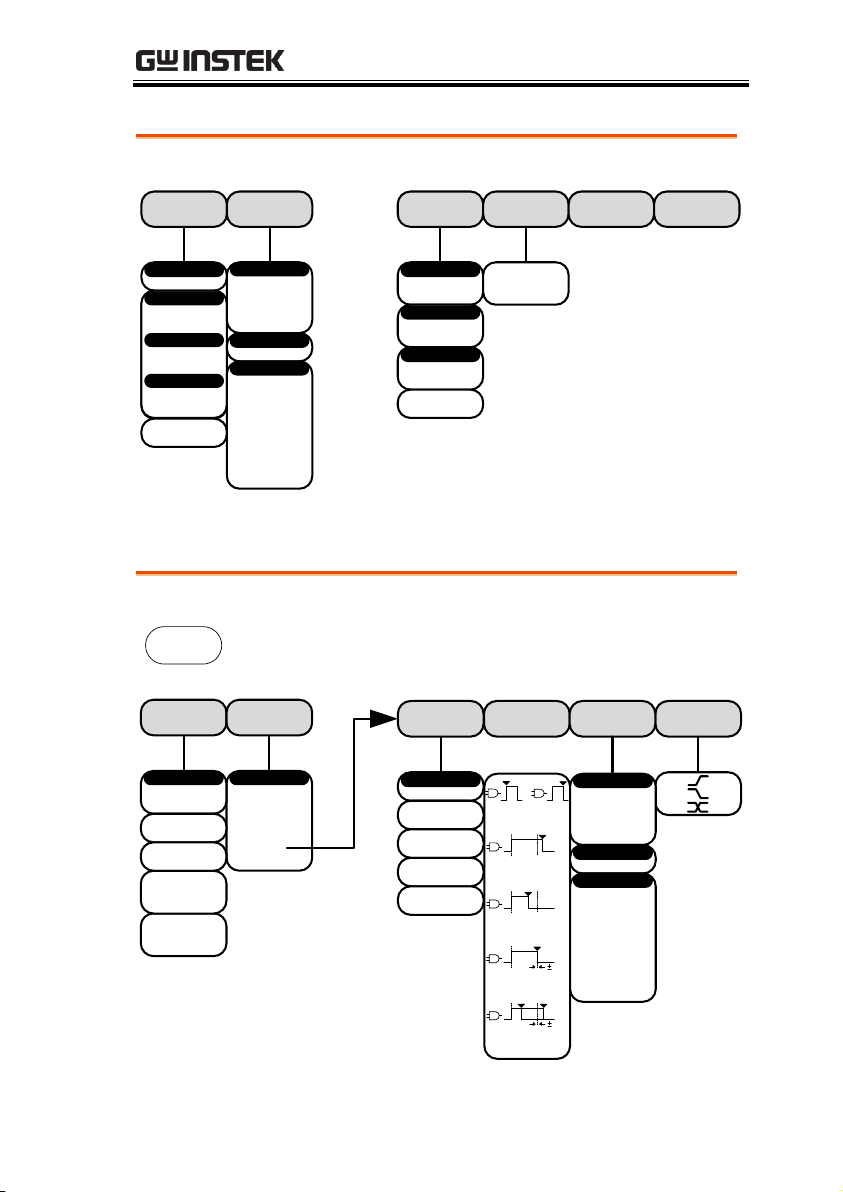

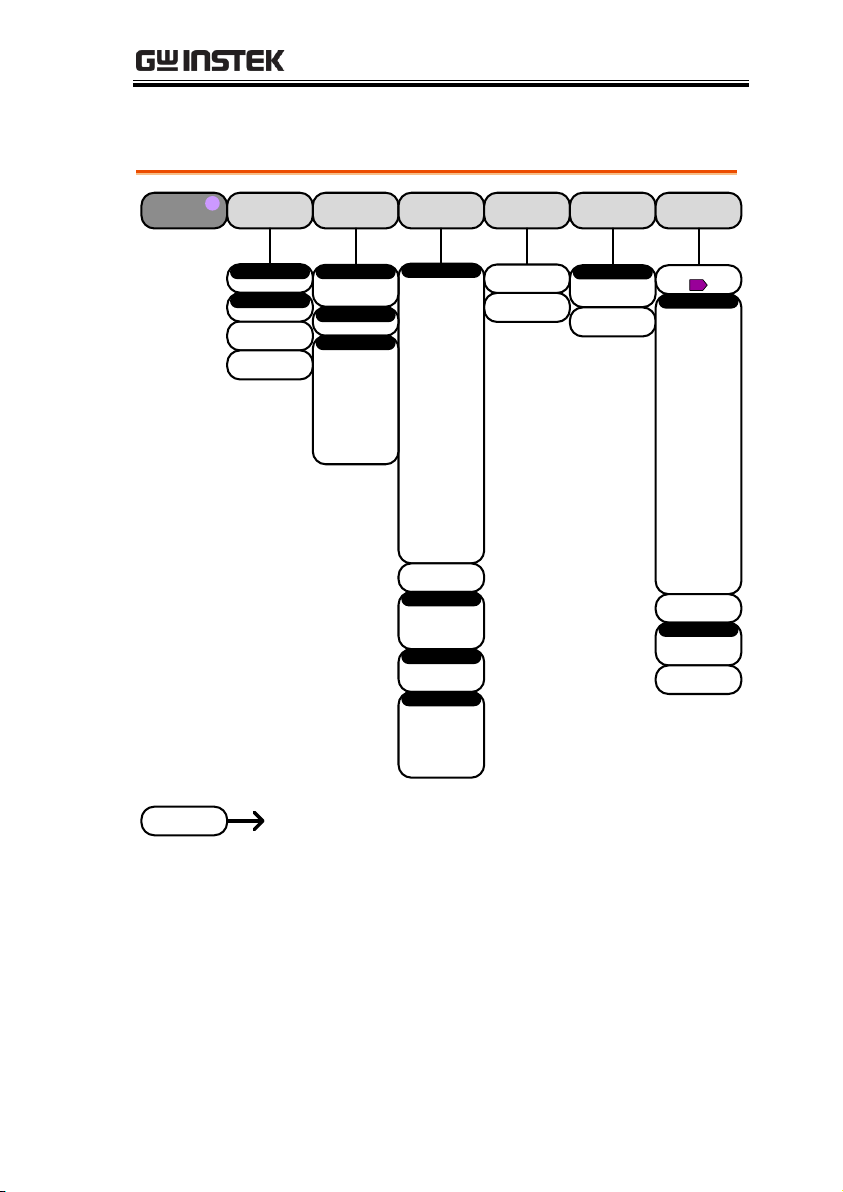

Logic Analyzer

Setup the Logic Analyzer inputs.

D15 – D0

On/Off

Thresholds

Analog

Waveform

Height

Sample Rate Go Back

D0 ~ D15

Select

On

Off

Set1~Set20

Filename.set

Display

On

Off

Turn On

Turn Off

Turn On

Turn Off

Display

D7~D0

D15~D8

Edit

Labels

D0~D3

D4~D7

D8~D11

D12~D15

Select

XX~XXV

Threshold

User

TTL

5.0V CMOS

3.3V CMOS

2.5V CMOS

ECL

PECL

0V

Choose Preset

Wave_A1

Wave_A2

Select

On

Off

Display

0.1~1.0 X

0.0~8.0 Div

Vertical

Edit

Labels

S

M

L

Set the Search function for logic events.

Edge

Pulse Width

Runt

Rise/Fall Time

Logic

Bus

Search

Clock EdgeWhen Threshold

Search

On

Off

Search

Save All

Marks

Clear All

Marks

Copy Trigger

Settings To

Search

Copy Search

Settings To

Trigger

Search Type

Define Inputs

Search

D0~D15

Select

Clock

High ( H )

Low ( L )

Don’t Care

( X )

5%

5%

Goes Goes

True False

Is True <

XXns

Is True =

XXns

Is True ≠

XXns

Is True >

XXns

D0~D3

D4~D7

D8~D11

D12~D15

Select

XX~XXV

Threshold

User

TTL

5.0V CMOS

3.3V CMOS

2.5V CMOS

ECL

PECL

0V

Choose Preset

Search - Logic

QUICK REFERENCE

11

Page 12

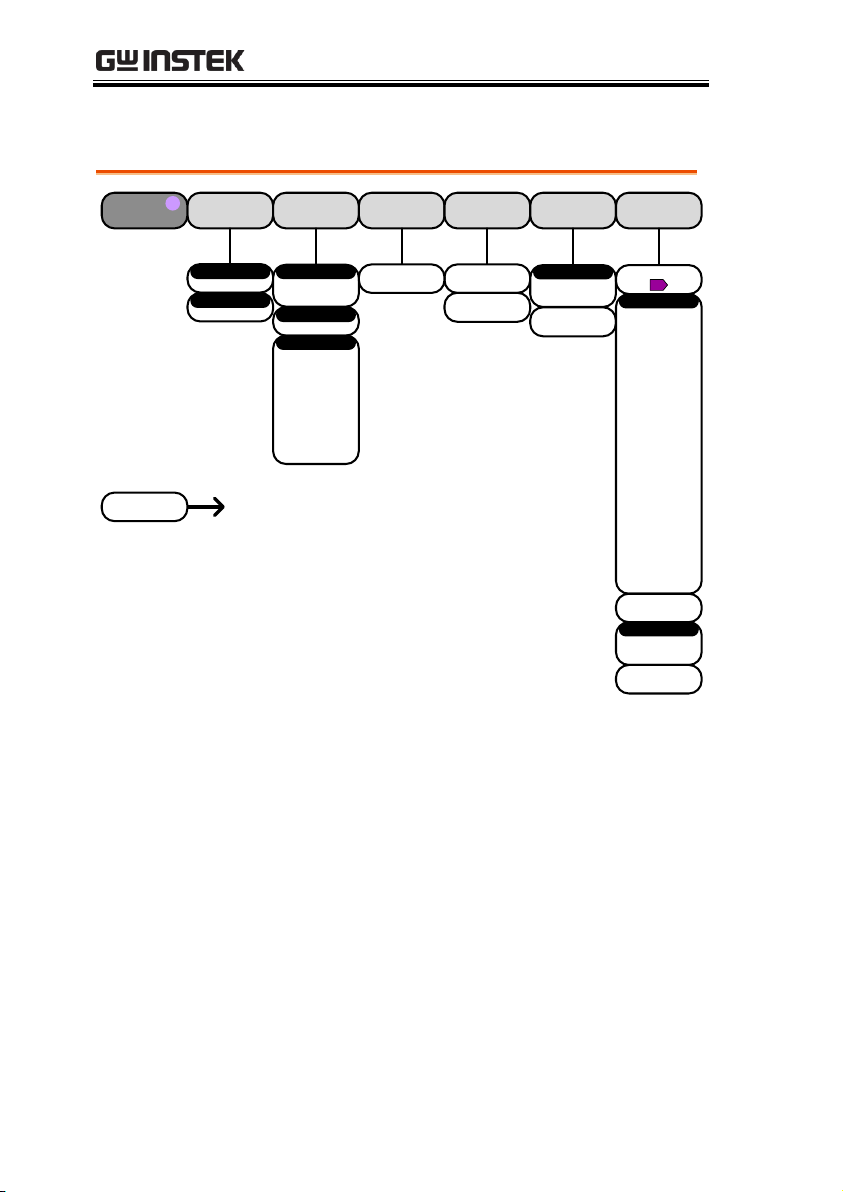

Search - Bus

Set the Search function for bus events.

Note: The source bus is determined from the bus trigger settings.

Edge

Pulse Width

Runt

Rise/Fall Time

Logic

Bus

Search

Search On

Search

On

Off

Search

Save All

Marks

Clear All

Marks

Copy Trigger

Settings To

Search

Copy Search

Settings To

Trigger

Search Type

Source Bus

Search

UART*

I2C*

SPI*

Parallel*

Tx Start Bit

Rx Start Bit

Tx End of Packet

Rx End of Packet

Tx Data

Rx Data

Tx Parity Error

Rx Parity Error

Search On Search On

SS Active

MOSI

MISO

MOSI & MISO

Search On

Binary

Hex

Data

Start

Repeat Start

Stop

Missing Ack

Address

Data

Address/Data

*The source bus is determined from the bus trigger settings.

GDS-2000A Series Options Manual

12

Page 13

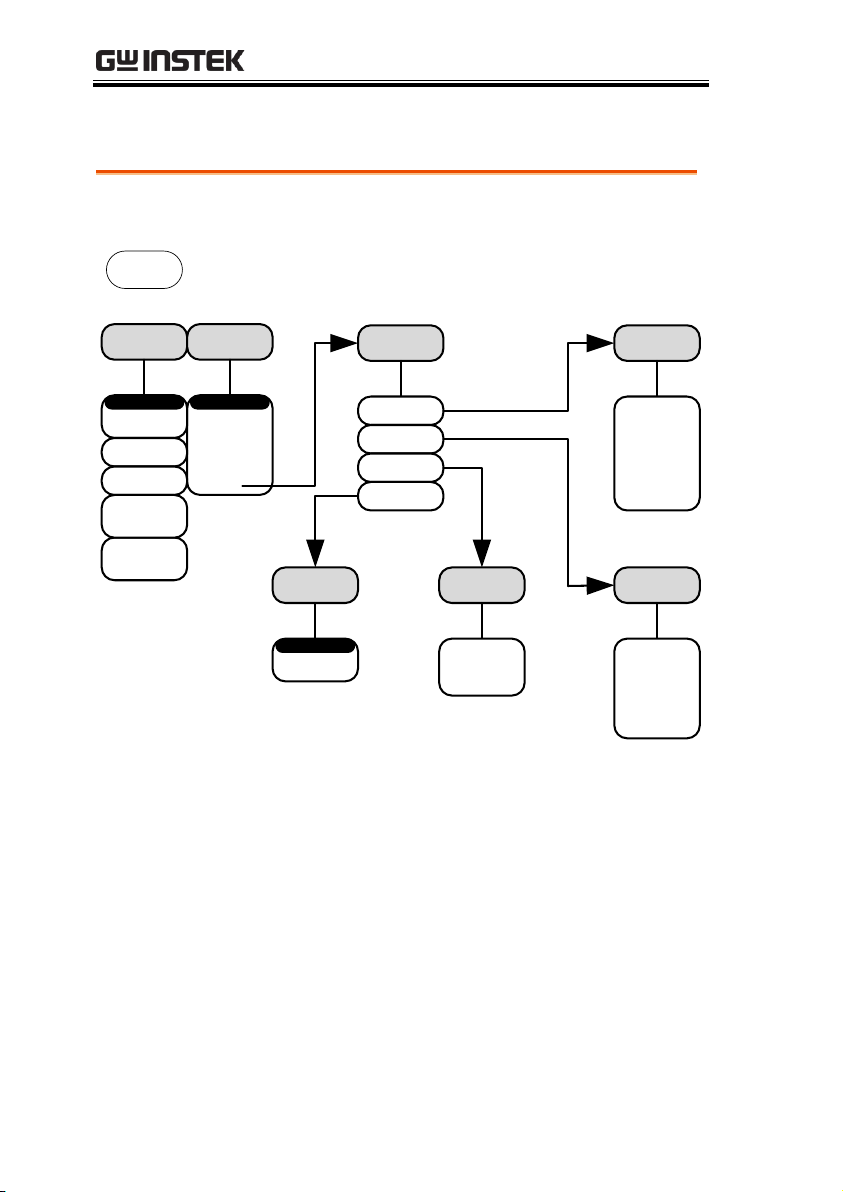

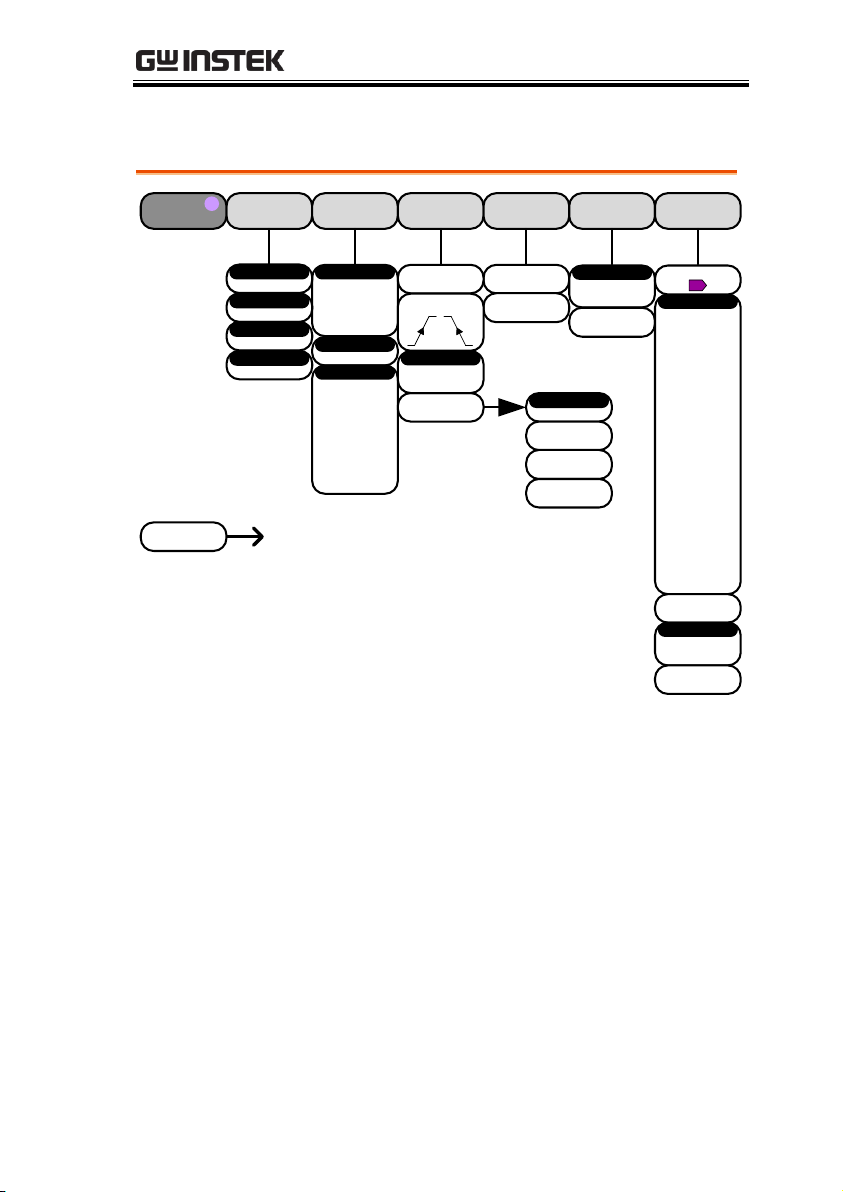

Trigger - Bus

Type

Bus

Source Bus

UART*

I2C*

SPI*

Parallel*

B

B

B

B

Search On

Tx Start Bit

Rx Start Bit

Tx End of Packet

Rx End of Packet

Tx Data

Rx Data

Tx Parity Error

Rx Parity Error

Trigger On

Start

Repeat Start

Stop

Missing Ack

Address

Data

Address/Data

Trigger On

SS Active

MOSI

MISO

MOSI & MISO

Trigger On

Binary

Hex

Data

*The source bus is set in the bus menu.

QUICK REFERENCE

13

Page 14

Trigger - Logic

Clock EdgeWhen Threshold

Define Inputs

D0~D15

Select

Clock

High ( H )

Low ( L )

Don’t Care

( X )

5%

5%

Goes Goes

True False

Is True <

XXns

Is True =

XXns

Is True ≠

XXns

Is True >

XXns

D0~D3

D4~D7

D8~D11

D12~D15

Select

XX~XXV

Threshold

User

TTL

5.0V CMOS

3.3V CMOS

2.5V CMOS

ECL

PECL

0V

Choose Preset

Type

Logic

Mode Holdof

Auto

Normal

10.0ns ~ 10.0s

Set to

Minimum

*The source bus is determined from the bus menu.

Bus

UART

I2C

SPI

Parallel

B

BUS

B

Goes to the UART bus menu

Goes to the I2C bus menu

Goes to the SPI bus menu

Goes to the Parallel bus menu

GDS-2000A Series Options Manual

Bus

14

Page 15

Define Inputs Threshold Configure

Bus Display

Event Table

Hex

Binary

Polarity Normal

(High = 0)

50, 75, 110,

134, 150, 300,

600, 1200,

1800, 2000,

2400, 3600,

4800, 7200,

9600, 14400,

15200, 19200,

28800, 19200,

28800, 31250,

38400, 56000,

57600, 76800,

115200,

128000,

230400,

460800,

921600,

1382400,

1843200,

2764800

Baud Rate

Edit Labels

Bus

UART

B

D0~D15

Tx Input

D0~D15

Rx Input

Polarity Inverted

(High = 1)

XX~XXV

Threshold

User

TTL

5.0V CMOS

3.3V CMOS

2.5V CMOS

ECL

PECL

0V

Choose Preset

Tx

Rx

Select

Data bits

8

Odd

Even

None

Parity

On

Off

Packets

00(NULL)

0A(LF)

0D(CR)

20(SP)

FF

End of Packet

On

Off

Event Table

Save

Event Table

ACK

AD0

ADDR

ANALOG

BIT

CAS

CLK

CLOCK

CLR

COUNT

DATA

DTACK

ENABLE

HALT

INT

IN

IRQ

LATCH

LOAD

NMI

User Preset

Edit Character

On

Off

Label Display

Label For

B

Go Back

Goes to the Keypad menuEdit Character

Bus - UART

QUICK REFERENCE

15

Page 16

Bus – I2C

Define Inputs Threshold

Include R/W

in address

Bus Display

Event Table

Hex

Binary

Edit Labels

Bus

I2C

B

D0~D15

SCLK

D0~D15

SDA

XX~XXV

Threshold

User

TTL

5.0V CMOS

3.3V CMOS

2.5V CMOS

ECL

PECL

0V

Choose Preset

SCLK

SDA

Select

On

Off

Event Table

Save

Event Table

ACK

AD0

ADDR

ANALOG

BIT

CAS

CLK

CLOCK

CLR

COUNT

DATA

DTACK

ENABLE

HALT

INT

IN

IRQ

LATCH

LOAD

NMI

User Preset

Edit Character

On

Off

Label Display

Label For

B

Go Back

Goes to the Keypad menuEdit Character

Yes

No

GDS-2000A Series Options Manual

16

Page 17

Bus – SPI

SCLK

SS

MOSI

MISO

Define Inputs Threshold Configure

Bus Display

Event Table

Hex

Binary

Edit Labels

Bus

SPI

B

D0~D15

SCLK Input

D0~D15

SS Input

XX~XXV

Threshold

User

TTL

5.0V CMOS

3.3V CMOS

2.5V CMOS

ECL

PECL

0V

Choose Preset

Select

On

Off

Event Table

Save

Event Table

ACK

AD0

ADDR

ANALOG

BIT

CAS

CLK

CLOCK

CLR

COUNT

DATA

DTACK

ENABLE

HALT

INT

IN

IRQ

LATCH

LOAD

NMI

User Preset

Edit Character

On

Off

Label Display

Label For

B

Go Back

Goes to the Keypad menuEdit Character

Yes

No

D0~D15

MOSI Input

D0~D15

MISO Input

more 1 of 2

SCLK

Active High

Active Low

SS

4~32 bits

Word Size

Bit Order

MS First

Bit Order

LS First

more 2 of 2

QUICK REFERENCE

17

Page 18

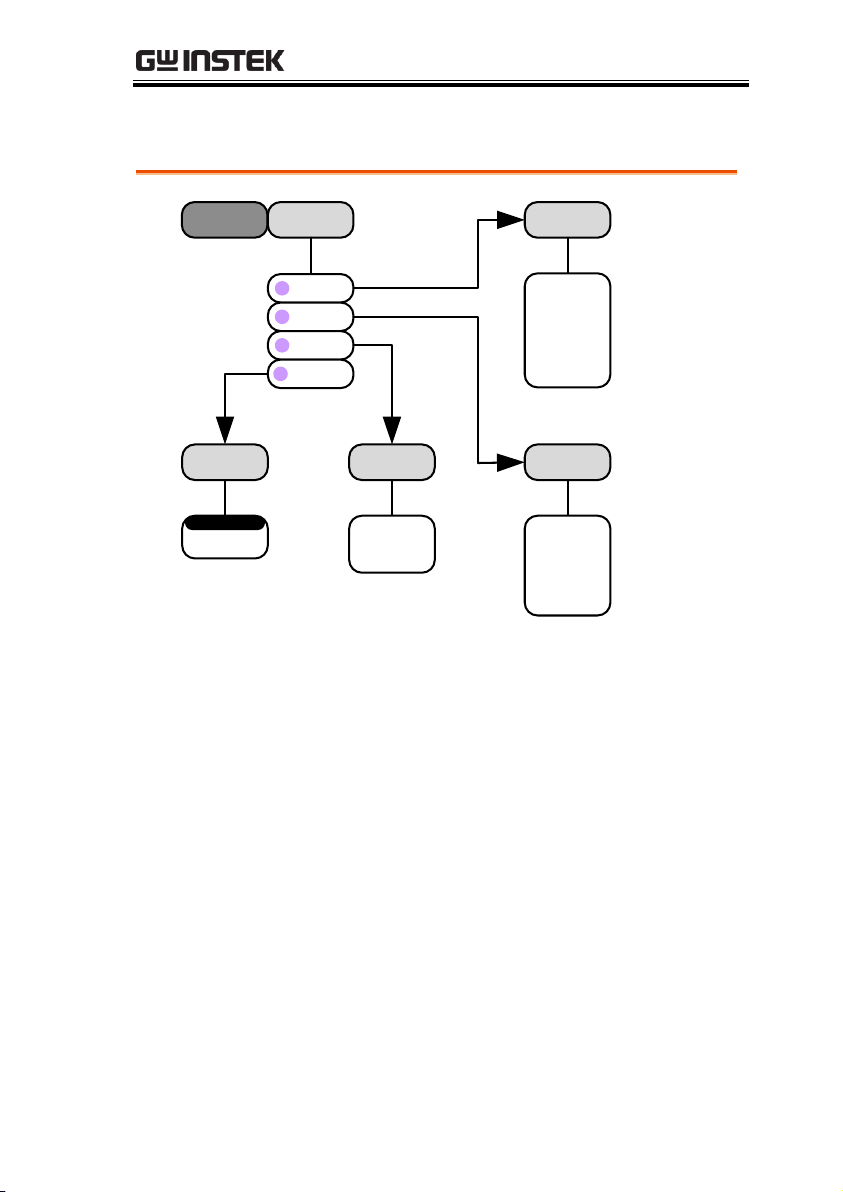

Bus – Parallel

Define Inputs Threshold

Bus Display

Event Table

Hex

Binary

Edit Labels

Bus

Parallel

B

XX~XXV

Threshold

User

TTL

5.0V CMOS

3.3V CMOS

2.5V CMOS

ECL

PECL

0V

Choose Preset

On

Off

Event Table

Save

Event Table

ACK

AD0

ADDR

ANALOG

BIT

CAS

CLK

CLOCK

CLR

COUNT

DATA

DTACK

ENABLE

HALT

INT

IN

IRQ

LATCH

LOAD

NMI

User Preset

Edit Character

On

Off

Label Display

Label For

B

Go Back

Goes to the Keypad menuEdit Character

Bit D0~D15

D0~D15

1~16

Off

Select Ch

Select Signal

Number of Bits

Clock Edge

D0~D15

Select

GDS-2000A Series Options Manual

18

Page 19

FUNCTION GENERATOR

Function Generator Operation ......................................... 20

Overview ............................................................................... 20

Function Generator Specifications ........................... 20

Using the Function Generator Option ............................. 21

Function Generator Calibration ......................................... 24

FUNCTION GENERATOR

19

Page 20

GDS-2000A Series Options Manual

Background

The DDS Function Generator module allows the

GDS-2000A to create basic sine, square and

triangle waveforms.

Note

The function generator option can only be used

with firmware version 1.13 or later. However it is

highly recommended that firmware version V1.16

or later be installed to access the full functionality

of the module. The instructions on the following

pages are based on V1.16 or later.

Please see the GW Instek website for the latest

firmware and the firmware installation procedure.

Waveforms

Sine, Square, Triangle

Frequency range

0.1Hz ~ 5MHz for sine

0.1Hz ~ 5MHz for square

0.1Hz ~ 500KHz for triangle

Frequency Stability

±50ppm

Frequency Accuracy

±50ppm (± 0.25Hz)

Aging

±5ppm/Year

Amplitude Range

60mVpp ~ 6Vpp (into 1MΩ)

30mVpp ~ 3Vpp (into 50Ω)

Amplitude Accuracy

±10%

Attenuator

-20dB

Impedance

50Ω

DC Offset

±2V (into 1MΩ)

±1V (into 50Ω)

Duty Control Range

5%(min) ~ 95%(max)

(Square wave only)

Rise or Fall Time

≤ 15ns (Square wave only)

Function Generator Operation

Overview

Function Generator Specifications

20

Page 21

FUNCTION GENERATOR

Background

This section will describe how to use the function

generator modules. To use the function generator

option, the DS2-FGN function generator module

must be installed. Please see page 6 for installation

details.

Note

The GDS-2000A can have two function generator

modules installed at the same time. Operating the

CDS-2000A using one or two function generator

modules is the same.

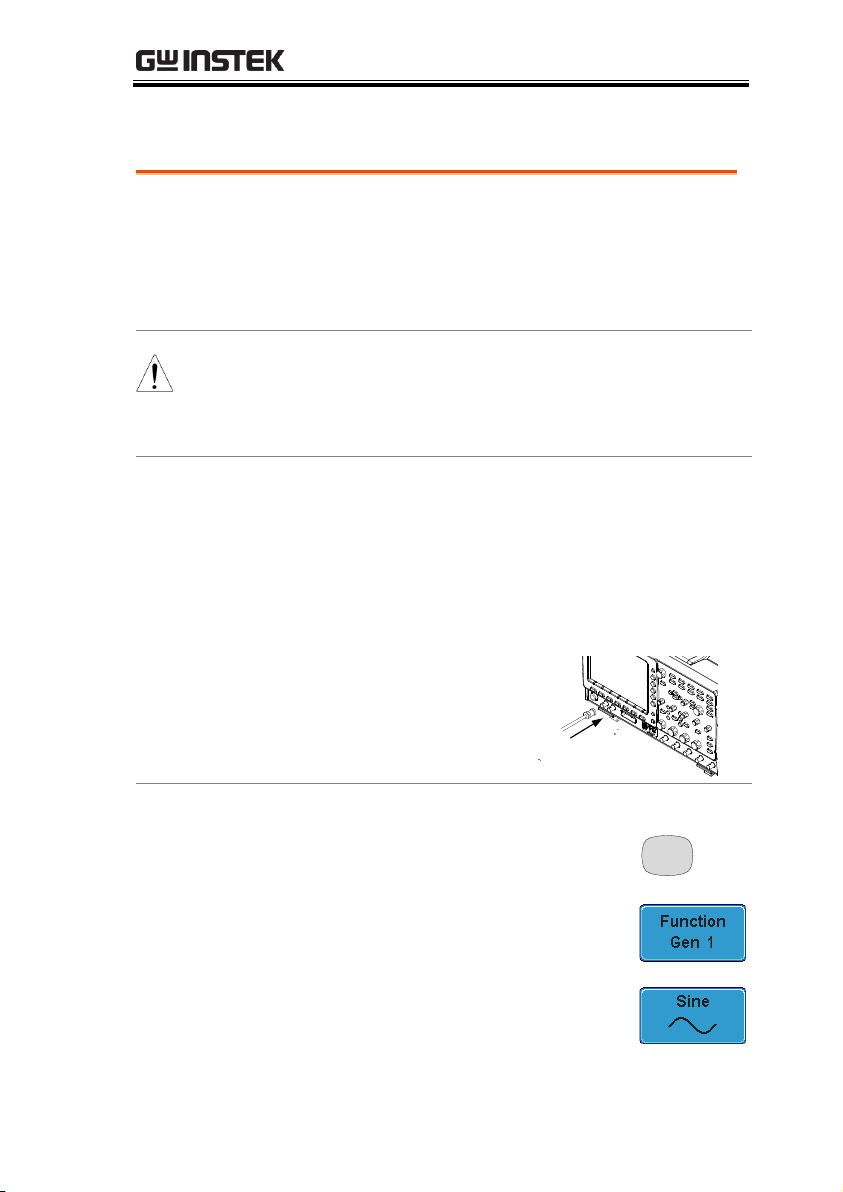

Connection

1. The function generator signal is output from

the GEN 1 or GEN 2 outputs on the front panel.

If the function generator module is installed in

slot one, then the signal is output from GEN 1,

and if the function generator is installed in slot

two, then the signal is output from GEN 2.

2. Connect a BNC cable

to the appropriate

output (GEN 1 or

GEN 2).

Panel Operation

1. Press the Option key.

Option

2. Press Function Gen 1 or Function

Gen 2 from the bottom menu.

3. Select Sine, Square or Triangle from

the bottom menu.

Using the Function Generator Option

21

Page 22

GDS-2000A Series Options Manual

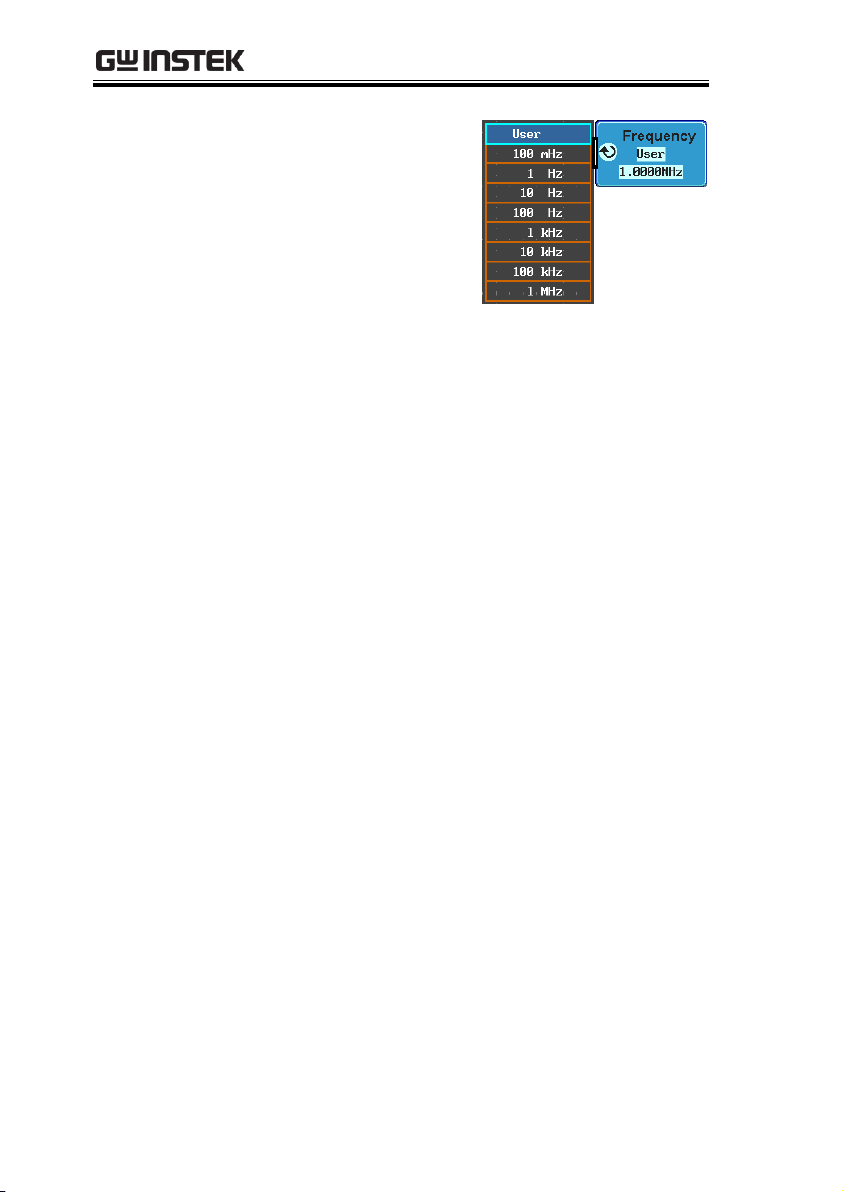

4. Press Frequency from

the side menu.

Use the Variable

knob to highlight

either User or a preset

frequency base unit.

The frequency can now be adjusted using fine

adjustment or coarse adjustment:

Range

100mHz ~ 5MHz (500kHz for

triangle)

COARSE ADJUSTMENT:

Press the Frequency soft-key again to reduce the

frequency menu.

Use the Variable knob to adjust the frequency

at the selected base unit.

The adjusted frequency will automatically be

saved to the User variable.

FINE ADJUSTMENT:

Press the Select key. The frequency can now be

adjusted one digit at a time.

Use the Left and Right soft-keys to select a

digit.

Use the Variable knob to adjust the digit.

Pressing the Default soft-key will return the

frequency back to the default base unit. (not

available for the User variable)

Press Go Back when you have finished

editing the frequency.

The adjusted frequency will automatically be

saved to the User variable.

22

Page 23

FUNCTION GENERATOR

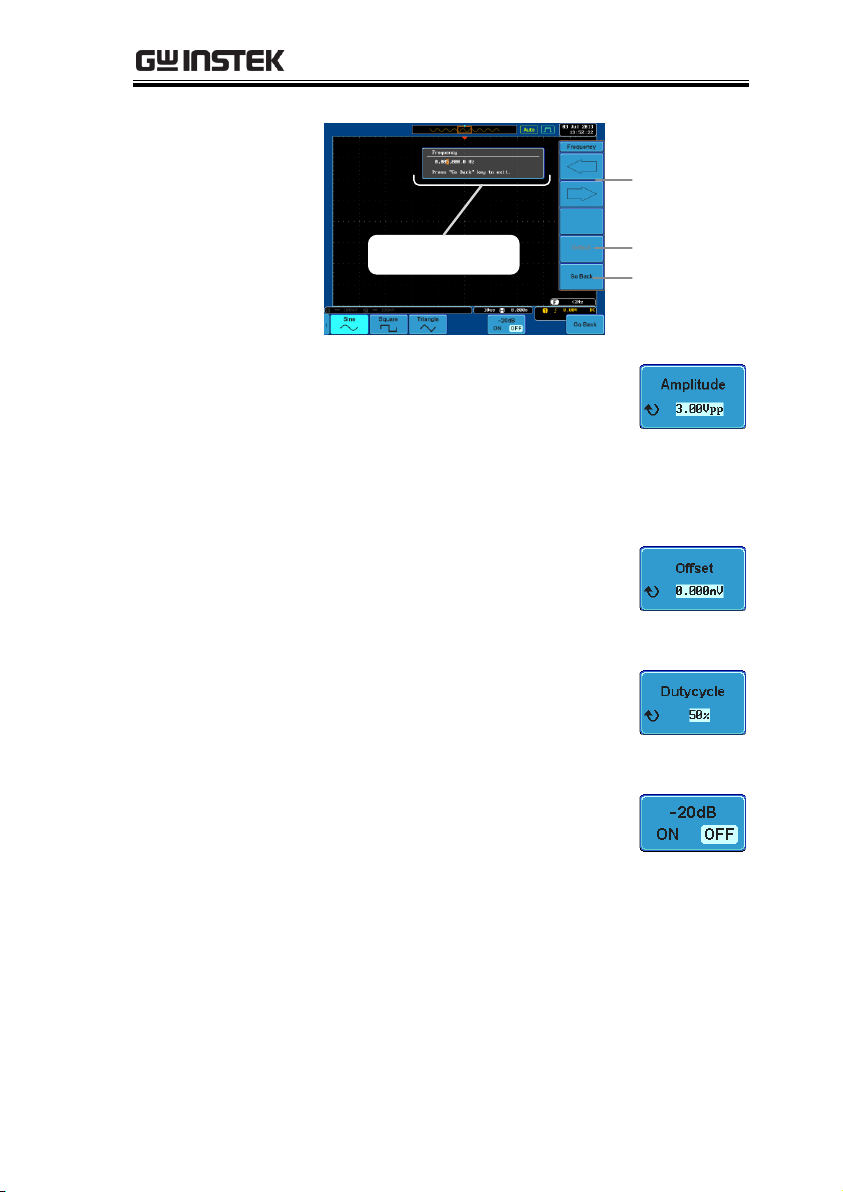

Fine adjustment

mode

Left and

Right soft-

keys

Default

Go Back

5. Press the Amplitude key to set the

amplitude.

Range

300mVpp ~ 3Vpp (into 50Ω load)*.

*range depends on attenuation

settings.

6. Press the Offset key to set the DC

offset.

Range

±1.000V (into 50Ω load).

7. Press DutyCycle (Square wave

only) to set the duty cycle.

Range

5% to 95%.

8. Press -20dB to attenuate the output

by 20dB.

Range

ON, OFF

9. The signal will be output immediately from the

GEN 1 or GEN 2 outputs.

23

Page 24

GDS-2000A Series Options Manual

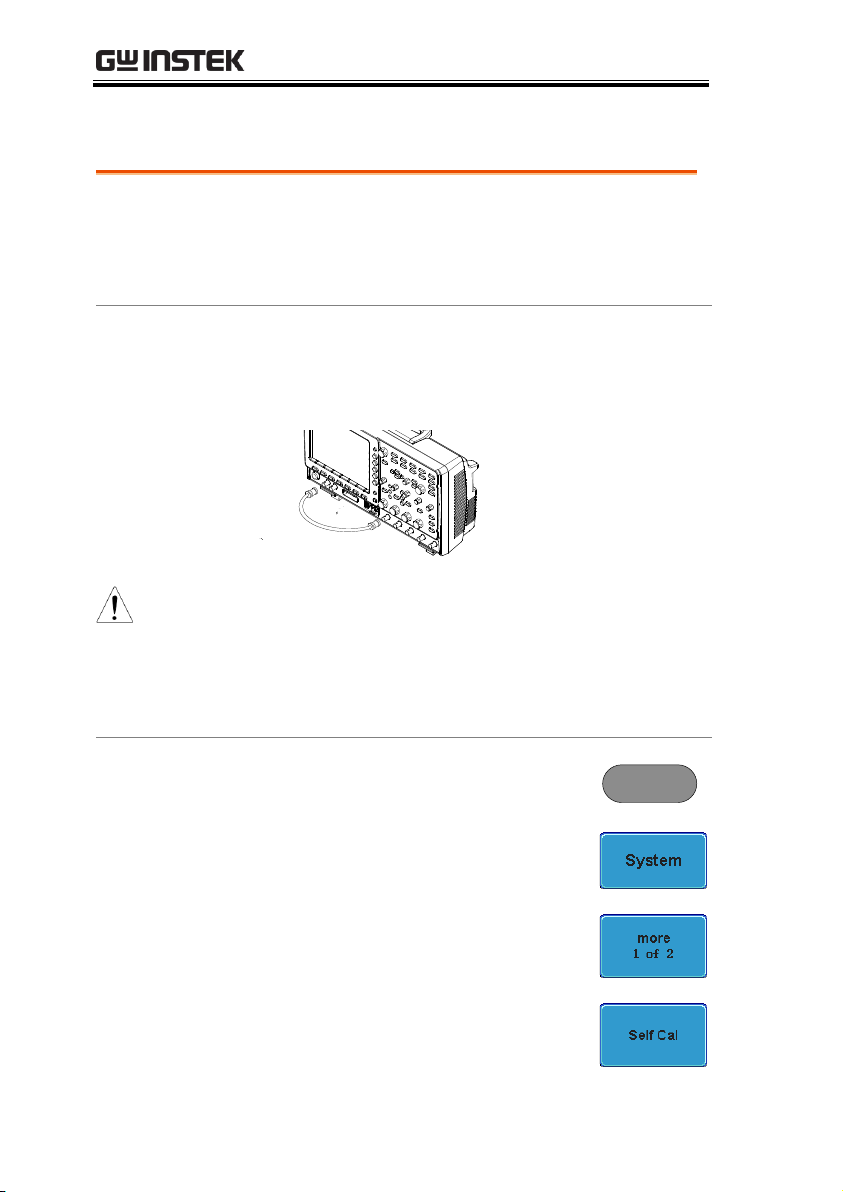

Background

The function generator module can also be

calibrated from the System menu. The calibration

function is only available for firmware version

V1.16 or later.

Connection

Connect the GEN 1 or GEN 2 output (depending

on which module slot the function generator is

installed in) to CH1 using a BNC cable.

CH1

GEN 1

or

GEN 2

Note

If two function generator modules are installed,

the system will automatically choose to calibrate

the function generator in module slot 1. If you

wish to calibrate the second function generator,

first select it from the Option menu (Option key >

Function Gen 2).

Panel Operation

1. Press the Utility key.

Utility

2. Press System from the bottom

menu.

3. Press More 1 of 2 from the side

menu.

4. Press Self CAL from the side menu.

Function Generator Calibration

24

Page 25

FUNCTION GENERATOR

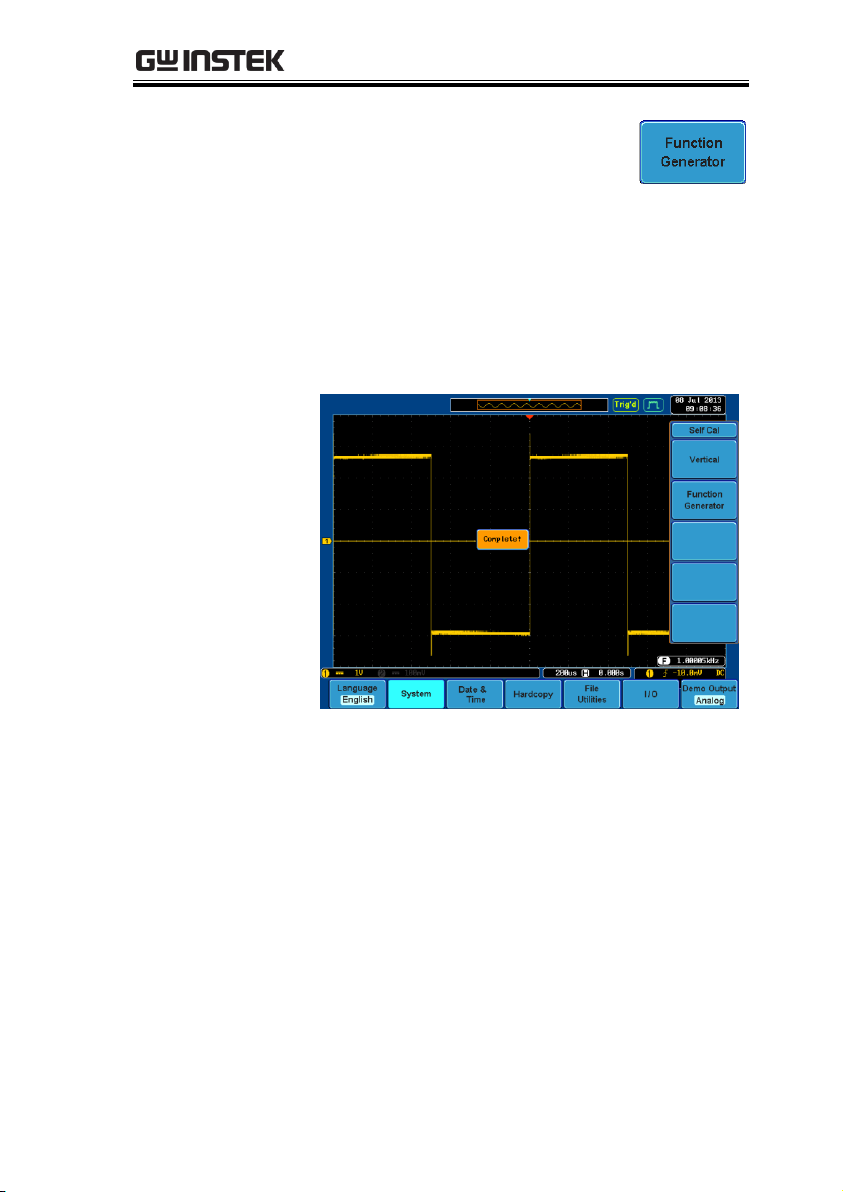

5. Press Function Generator from the

side menu.

Wait a few moments for the calibration to

finish. “Complete” will be displayed on the

screen when the calibration has completed.

If the calibration fails, please check the

connection and perform the calibration

procedure again.

25

Page 26

GDS-2000A Series Options Manual

Logic Analyzer Operation ................................................ 28

Overview ............................................................................... 28

Using the Logic Analyzer Probes ....................................... 29

Digital Display Overview .................................................... 30

Activating Digital Channels ................................................ 31

Activate Digital Channels as a Group ...................... 31

Activate Individual Channels .................................... 32

Moving the Digital Channels or Creating Digital

Channel Groups .......................................................... 33

Digital Channel Vertical Scale ............................................ 38

Digital Channel Threshold Levels ..................................... 38

Analog Waveform ................................................................ 40

Adding Labels to Digital Channels .................................... 41

Bus Key Configuration ..................................................... 44

Bus Display ........................................................................... 44

Parallel Bus ............................................................................ 46

Input Configuration ................................................... 46

Threshold Configuration ........................................... 47

Bus Encoding .............................................................. 48

Parallel Bus Event Table ............................................ 49

Adding a Label to the Parallel Bus ........................... 50

Serial Bus ............................................................................... 53

Serial Bus Overview ................................................... 53

UART Serial Bus Configuration ............................... 54

I2C Serial Bus Interface .............................................. 56

SPI Serial Bus Interface ............................................. 57

Bus Encoding .............................................................. 59

Threshold Configuration .................................................... 59

Serial Bus Event Tables ............................................. 61

Event Tables Format .................................................. 64

Adding a Label to the Serial Bus............................... 65

Using Cursors with the Serial Bus ............................ 67

LOGIC ANALYZER

26

Page 27

LOGIC ANALYZER

Trigger Settings ............................................................... 69

Serial Bus Trigger Settings .................................................. 69

UART BUS Trigger Settings ..................................... 69

I2C Bus Trigger Settings ............................................. 70

SPI Bus Trigger Settings ............................................ 73

Parallel Bus Trigger .............................................................. 74

Common Bus Trigger Settings ........................................... 75

Bus Trigger Mode ....................................................... 75

Logic Trigger ........................................................................ 76

Logic Trigger Mode .................................................... 79

Logic Trigger Holdoff ................................................ 79

27

Page 28

GDS-2000A Series Options Manual

Background

The Logic Analyzer inputs can only be used when

a Logic Analyzer option is installed (GW Instek

part no. DS2-8LA or DS2-16LA). Both the 8-chanel

and 16-channel models have a sample rate of

500MSa/s with bandwidth of 200MHz.

The logic analyzer inputs can be used to measure

discrete inputs or can be used to measure values

on a parallel or serial bus.

Supported Logic

Thresholds

TTL, CMOS,

ECL, PELC,

User- defined

The GDS-2000A supports common

logic thresholds and supports

user-defined thresholds of ± 10V if

the in-built threshold levels are

unsuitable.

Digital Trigger

Types

Edge, Pulse

Width, Rise and

Fall, Bus, Logic

As standard, the digital channels

support basic edge, pulse width,

rise and fall as well as bus and

logic triggers.

Logic Analyzer Operation

Overview

28

Page 29

LOGIC ANALYZER

Background

This section will describe how to connect the

digital channels to the device under test. To use the

digital channels the optional logic analyzer module

must be installed. Please see page 6 to install the

logic analyzer module.

Connection

1. Turn the DUT off to protect it from being short

circuited when the probes are attached.

2. Insert the Logic

Analyzer probe into

the Logic Analyzer

input.

3. Connect the ground lead from the logic

analyzer probe to the circuit ground on the

DUT.

GND

4. Connect another probe lead to a point of

interest on the circuit. Make note of which

probe lead is connected to which point.

5. Repeat step 3 with any remaining probes.

Signal 2

Signal 3

GND

Signal 1

….

Using the Logic Analyzer Probes

29

Page 30

GDS-2000A Series Options Manual

Analog

waveform

indicator

Digital

channel

indicators

Digital waveforms

Analog waveform

Digital

channel

group

Analog Waveform

Indicator

Used to show the position of the analog waveform

outputs.

Active analog

waveform

Activated analog

waveform

Digital Channel

Indicators

Used to show the position and grouping of the

digital channels.

Active digital channel

Activated digital

channel

Digital Channel

Group

When digital channels are grouped together,

they are shown as being pinned together.

When grouped, digital channels can moved

as a single group.

Digital Display Overview

30

Page 31

LOGIC ANALYZER

Background

The digital channels can be turned on or off in

groups of eight, D0~D7 and D8~D15.

Panel Operation

6. Press the Option key.

Option

7. Press Logic Analyzer from the

bottom menu.

8. Press D15 – D0 On/Off key.

9. Select which group of digital

inputs you want turned on or off

from the side menu.

Group1

D0~D7

Group2

D8~D15

10. The digital channels will appear on the

graticule.

Note

When all the digital channels are turned on, they

will appear as a single group.

Activating Digital Channels

The digital channels can be initially turned on in groups of 8 or

individually.

Activate Digital Channels as a Group

31

Page 32

GDS-2000A Series Options Manual

Background

Each digital channel or group can be turned on or

off individually.

Panel Operation

1. Press the Select soft-key.

2. Use the variable knob to highlight

a channel or a group.

VARIABLE

3. A 'tick' next to a particular channel or group

indicates that that channel or group is currently

on.

Channel 0~2 is off

Channel 3~15 is on

4. Press the Display soft-key or the

Select key to toggle the selected

channel or group on or off.

or

Select

Activate Individual Channels

32

Page 33

LOGIC ANALYZER

5. Press the Select soft-key again to

reduce the menu.

Note

Channels can also be selected just by turning the

variable knob when the mode is set to LA move mode.

In this mode the selected channel or group will be

shown on the Select soft-key. However this method

will only show those channels/groups that have

already been turned on. See page 33 for details.

Note

The digital channels must first be activated. See

page 31.

Background

The logic analyzer has two basic modes of

operation for selecting or moving digital channels.

LA Select mode: This mode is used to select digital

channels that have already been activated.

LA Move mode: This mode is used to move the

vertical position of the digital channels and to

group digital channels into groups.

The Select key is used to toggle between both

modes when in the D15~D0 On/Off menu.

Panel Operation

1. Press the D15~D0 On/Off key. The

scope will initially be in 'LA Select

mode'.

Moving the Digital Channels or Creating Digital Channel Groups

33

Page 34

GDS-2000A Series Options Manual

2. Use the variable knob to choose a

channel or group. The selected

channel/group will be shown on

the Select key. Only channels that

have been activated can be selected

this way.

VARIABLE

Below, channel 4 is selected.

Channel 4 is selected

Note: If the Variable knob cannot select a channel,

press the Select key to toggle the scope into 'LA

Select mode'.

3. Press the Select key. The mode

toggles from 'LA Select mode' to

'LA Move mode'.

A message will indicate which

mode is currently active.

Select

34

Page 35

LOGIC ANALYZER

The Move mode is used to move the digital

channel position on the graticule as well as to

group the channels. If you turned on all the

digital channels, you will notice that they are

already grouped as a single group.

You can tell when it is in move mode as the

selected channel/group flashes and the labels

for the other channels/groups become grayed

out.

Channel 4 is in the

'Move' mode and

the labels for the

other channels are

grayed out

4. Use the variable knob to position

the selected channel/group:

VARIABLE

If you position the channel indicator over the

next/previous channel, it will split the group

into 2.

Split the group above the selected channel:

Split the group below the selected channel:

35

Page 36

GDS-2000A Series Options Manual

If you continue to move the channel indicator

past the next/previous channel, it will move the

indicator anywhere within that group.

5. If you move the indicator outside of the group,

it will remove the selected channel from the

group.

36

Page 37

LOGIC ANALYZER

6. Press the Select key again. This will

return you to the LA Select mode.

You can tell when it is in the Select

mode as no channel will be grayed

out.

Select

37

Page 38

GDS-2000A Series Options Manual

Background

The digital channels have 3 preset scales, S, M, L.

Panel Operation

1. From the D15~D0 On/Off menu,

press Height to toggle the vertical

scale of the digital channels.

Height

S, M, L

Note

If more than 8 digital channels are active, the large (L)

option will be disabled.

Note

Threshold levels can be set to four groups of

digital channels: D0~D3, D4~7, D8~D11 and

D12~D15. Each group can have a different

threshold level.

The GDS-2000A has 4 preset threshold levels and a

user-defined threshold. A user-defined threshold

level can be set for each group. Any signal over the

threshold level corresponds to a high (1), any

signal under the threshold level is a low (0).

Panel Operation

1. From the D15~D0 On/Off menu,

press the Thresholds soft-key.

2. Press Select from the side menu

and choose a group of channels.

Digital Channel Vertical Scale

Digital Channel Threshold Levels

38

Page 39

LOGIC ANALYZER

3. Press Choose Preset to select a pre-

set logic threshold.

Logic Type

Threshold

TTL

1.4V

5.0V CMOS

2.5V

3.3V CMOS

1.65V

2.5V CMOS

1.25V

ECL

-1.3V

PECL

3.7V

0V

0V

4. Press Threshold to set a user

defined threshold for the currently

selected group.

Range

±10V

39

Page 40

GDS-2000A Series Options Manual

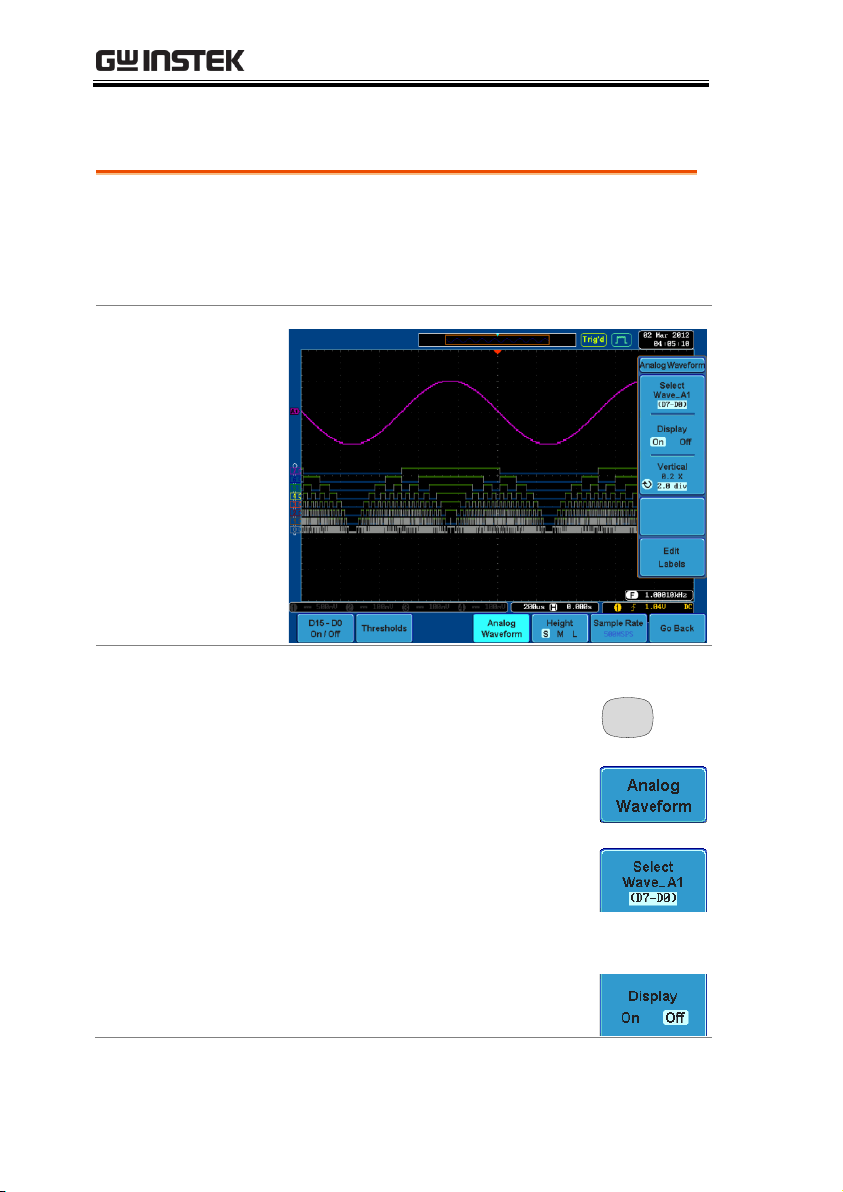

Background

The analog waveform function combines the

digital channel inputs into two 8-bit analog

waveforms. The analog waveforms are created

from the digital channel groups D0~7 and D8~15.

Example

Panel Operation

1. Press the Option key.

Option

2. Press the Analog Waveform key.

3. Press Select and select which

analog waveform you which to

display, Wave_A1 (D7~D0) or

Wave_A2 (D15~D8).

Display on Screen

4. Press Display to display the

selected waveforms on the screen.

Analog Waveform

40

Page 41

LOGIC ANALYZER

Set Vertical

Position

5. Press Vertical until div parameter is

highlighted. Use the Variable knob

to set the position.

Set Vertical Scale

6. Press Vertical until X scale

parameter is highlighted. Use the

Variable knob to set the scale.

Edit Labels

7. Press Edit Labels to edit the label

for the currently selected analog

waveform. See page 41 for details.

Note

Only one analog waveform can be displayed at a time.

Background

Digital labels can be added to each digital channel

or to one of the analog waveforms.

Panel Operation

1. To edit labels for the digital

channels, press the Edit Labels softkey from the D15~D0 On/Off

menu.

To edit labels for the analog

waveforms, press the Edit Labels

soft-key from the Analog Waveform

menu.

2. Press Label For and select a channel

or waveform.

Label For

D0~D15

A1, A2

Adding Labels to Digital Channels

41

Page 42

GDS-2000A Series Options Manual

3. To choose a preset label, Press User

Preset from the side menu and

choose a label.

Labels

ACK, AD0, ADDR, ANALOG,

BIT, CAS, CLK, CLOCK, CLR,

COUNT, DATA, DTACK,

ENABLE, HALT, INT, IN, IRQ,

LATCH, LOAD, NMI

Edit Label

4. Press Edit Character to edit the

current label.

5. The Edit Label window appears.

6. Use the Variable knob to highlight

a character.

VARIABLE

42

Page 43

LOGIC ANALYZER

Press Enter Character to select a

number or letter.

Press Back Space to delete a

character.

Press Editing Completed to create

the new label and return to the

previous menu.

Note: this key must be pressed to

create a label, even for a preset

label.

Press Cancel to cancel the editing

and return to the Edit Label

menu.

7. The label will appear next to corresponding

channel indicator.

Below, the label “LABEL_1” was created for

the D0 channel.

D0 is labeled as

LABEL_1

Remove Label

Press Label Display to toggle the

selected label on or off.

43

Page 44

GDS-2000A Series Options Manual

Bus indicator

Digital channel indicators

Trigger

configuration

Data Start bit Stop bit

Start Bit

The Start bit is shown as a open bracket (Serial bus

data only).

Stop Bit

The Stop bit is shown as an closed bracket (Serial

bus data only).

Data

Data packets can be shown in Hex or Binary. The

color of the packet is the same as the channel color.

Error Indicator

If there is an error in decoding the serial data, an

error indicator will be shown.

Bus Indicator

The Bus indicator shows the bus position. The

active bus is shown with a solid color. The Variable

knob can be used to horizontally position the Bus

indicator when it is active.

Active bus

(solid indicator)

Activated bus

(transparent indicator)

Bus Key Configuration

The Bus key is used to configure the Parallel and Serial bus inputs.

The Bus menu also features an event tables to track and save your

bus data.

Bus Display

44

Page 45

LOGIC ANALYZER

Trigger

Configuration

Shows the bus trigger (B) and the Trigger On

settings.

45

Page 46

GDS-2000A Series Options Manual

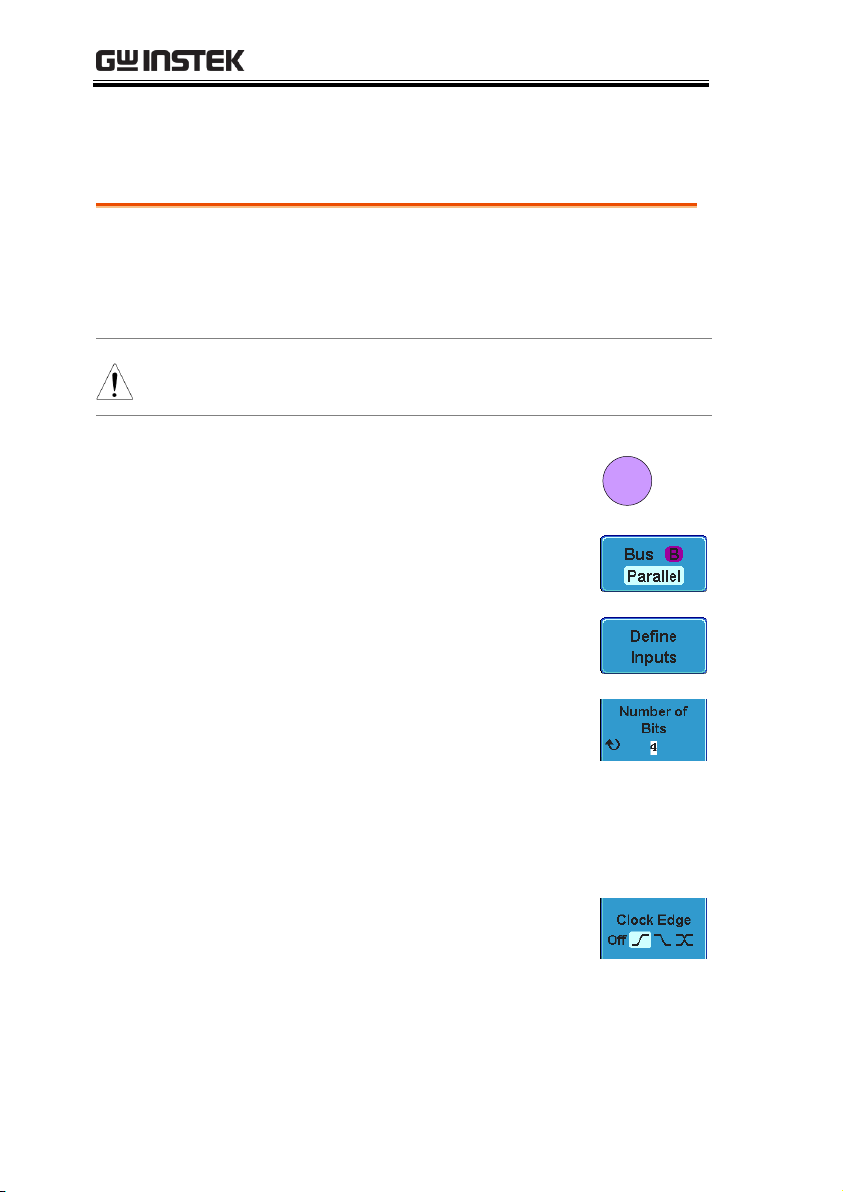

Background

The digital channels can be configured as a parallel

bus. The number of bits that define the bus as well

as which bit is used as the bus clock can also be

configured.

Note

The trigger should also be set to parallel bus.

Please see page 74 for details.

Panel Operation

1. Press the Bus key.

B

BUS

2. Press the Bus soft-key and select

Parallel from the side menu.

3. Press Define Inputs from the bottom

menu.

4. Press Number of Bits from the side

menu and select the number of bits

for the data bus.

By default the bus is assigned bits

D0, D1, D2 and so on up to the last

bit.

5. You may also assign a bit as a

clock. This bit will be one of the

bits in the bus. To add a clock bit,

press Clock Edge and select type of

clock edge. Selecting Off will

disable the clock bit.

Parallel Bus

Input Configuration

46

Page 47

LOGIC ANALYZER

6. If you wish to define which channels are

assigned to the bus, press Select Signal from the

side menu and select the bit that wish to assign.

Channel 1 is

currently

assigned to bit 1.

7. Next, press Select Ch and select

which channel is assigned to the

bit selected above.

8. Repeat steps 6 and 7 for any remaining bits and

for the clock, if enabled.

Background

The threshold levels for the parallel bus can be set

to either a user-defined threshold level or to preset threshold.

Operation

1. Press Thresholds from the bottom

menu.

2. Press Select from the side menu

and select a digital channel.

3. Press Choose Preset to select a pre-

set logic threshold for the selected

channel.

Logic Type

Threshold

TTL

1.4V

5.0V CMOS

2.5V

Threshold Configuration

47

Page 48

3.3V CMOS

1.65V

2.5V CMOS

1.25V

ECL

-1.3V

PECL

3.7V

0V

0V

4. Press Threshold to set a user

defined threshold for the selected

input.

Range

±10V

Note

Setting the threshold levels from the Bus menu will

also change the threshold levels set in the Logic

Analyzer menu (page 38).

Bus Encoding

Background

The bus that is displayed on the screen or in the

event tables can be set to either hex or binary

formats.

Operation

Press Bus Display from the Bus

menu and choose either Hex or

Binary from the side menu.

GDS-2000A Series Options Manual

48

Page 49

LOGIC ANALYZER

Event Table

The parallel bus event table lists when each data

event on the bus occurred. The data is displayed as

either hex or binary, depending on the bus display

settings.

Event tables can be saved to disk in a CSV format. The

files will be named “Event_TableXXXX.CSV”, where

XXXX is a number from 0000 to 9999. See page 64 for

details.

Operation

1. Press Event Table from the bottom

menu.

2. Press Event Table from the side

menu to turn the event table on or

off.

Event

On, Off

3. To save the event table, press Save

Event Table.

Use the variable knob to scroll through the

event table.

Parallel Bus Event Table

49

Page 50

GDS-2000A Series Options Manual

Example

Time of event

Event data

Background

A label can be added to the parallel bus.

Panel Operation

1. To add a label to the bus, press

Edit Labels from the Parallel Bus

menu.

2. To choose a preset label, Press User

Preset from the side menu and

choose a label.

Labels

ACK, AD0, ADDR, ANALOG,

BIT, CAS, CLK, CLOCK, CLR,

COUNT, DATA, DTACK,

ENABLE, HALT, INT, IN, IRQ,

LATCH, LOAD, NMI

Edit Label

3. Press Edit Character to edit the

current label.

Adding a Label to the Parallel Bus

50

Page 51

LOGIC ANALYZER

4. The Edit Label window appears.

5. Use the Variable knob to highlight

a character.

VARIABLE

Press Enter Character to select a

number or letter.

Press Back Space to delete a

character.

Press Editing Completed to create

the new label and return to the

previous menu.

Note: this key must be pressed to

save the label, even for the preset

labels.

51

Page 52

GDS-2000A Series Options Manual

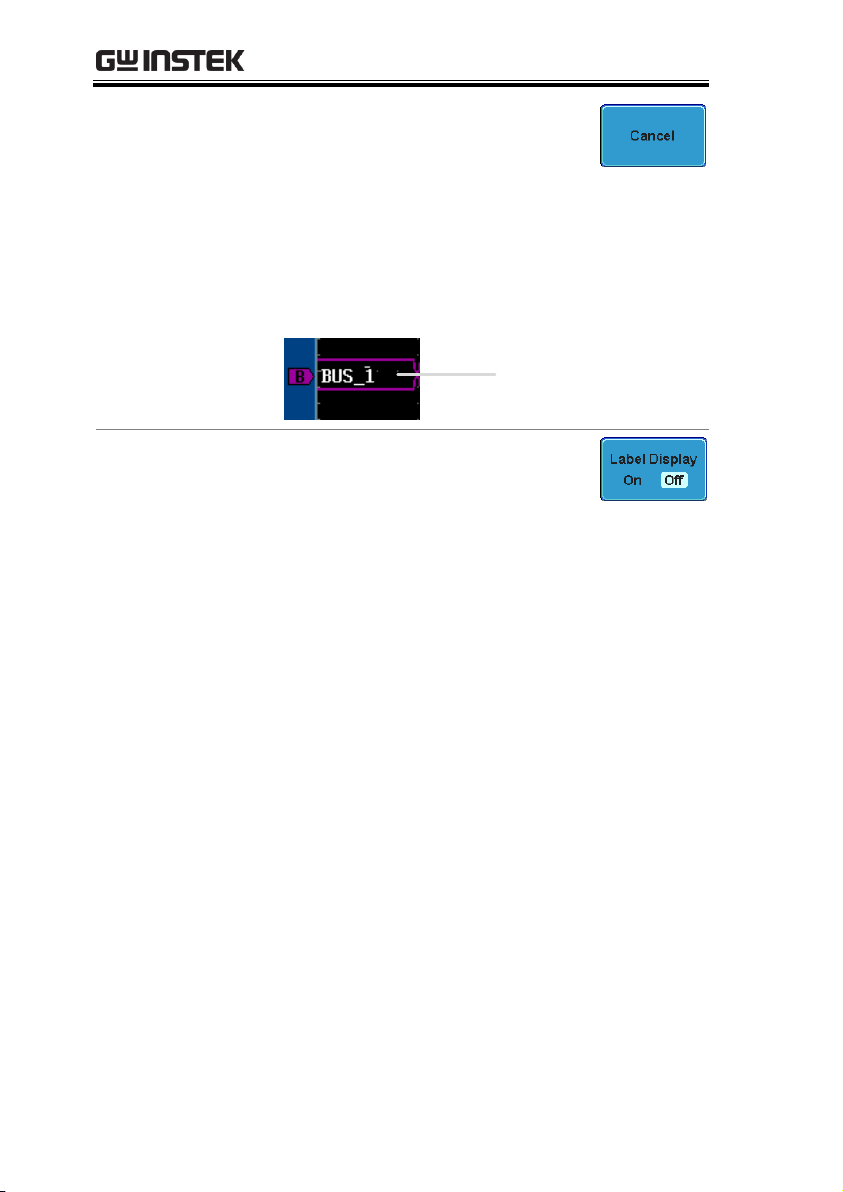

Press Cancel to cancel the editing

and return to the Edit Label

menu.

6. The label will appear next to the bus indicator.

Below, the label “BUS_1” was created for the

parallel bus.

The parallel bus is

labeled as BUS_1

Remove Label

Press Label Display to toggle the label

on or off.

52

Page 53

LOGIC ANALYZER

UART

Universal Asynchronous Receiver Transmitter.

The UART bus is able to accommodate a wide

range of various common UART serial

communications.

The UART serial bus software is suitable for a

number of RS-232 protocol variants.

Inputs

Tx, Rx

Threshold

Tx, Rx

Configuration

Baud rate, Parity, Packets, End of

packets, Input polarity

Trigger On

Tx Start Bit, Rx Start Bit, Tx End of

Packet, Rx End of Packet, Tx Data,

Rx Data, Tx Parity Error, Rx Parity

Error

I2C

Inter Integrated Circuit is a two line serial data

interface with a serial data line (SDA) and serial

clock line (SCLK). The R/W bit can be configured.

Inputs

SCLK, SDA

Threshold

SCLK, SDA

Configuration

Addressing mode, Read/Write in

address

Trigger On

Start, Repeat Start, Stop, Missing

Ack, Address, Data, Address/Data

Serial Bus

The Serial Bus for Logic Analyzer software includes support for 3

common serial interfaces, SPI, UART and I2C. Each interface is fully

configurable to accommodate variations in the basic protocols.

Each input can be displayed as binary or hexadecimal. An event

table can also be created to aid in debugging.

Serial Bus Overview

53

Page 54

GDS-2000A Series Options Manual

SPI

The SPI (Serial Interface Peripheral) bus is fully

configurable to accommodate the wide variety of

SPI interfaces. This bus is only available on 4

channel models.

Inputs

SCLK, SS, MOSI, MISO

Threshold

SCLK, SS, MOSI, MISO

Configuration

SCLK edge, SS logic level, Word

size, Bit order

Trigger On

SS Active, MOSI, MISO,

MOSI&MISO

Background

Basic RS-232 protocol uses single-ended data

transmissions. The signal voltage levels can be

high (±15V)* and employ active low signaling.

High speed variants of RS-232, such as RS-422 and

RS-485 use differential signaling and commonly

employ low voltage differential signals with active

high signaling.

Universal Asynchronous Receiver / Transmitter

(UART) or RS-232 driver/receiver ICs commonly

used for embedded applications typically use

active high signaling with standard IC signal

levels.

*Note: the GDS-2000A does not support ±15V

signaling for the Logic Analyzer inputs)

UART Serial Bus Configuration

The UART bus menu is designed to decode RS-232 and other

common RS-232 variants such as RS-422, RS-485. The software

configuration is also flexible enough to decode the many

proprietary protocols based on RS-232.

54

Page 55

LOGIC ANALYZER

Operation

1. Connect each of the bus signals (Tx, Rx) to one

of the logic analyzer inputs. Connect the

ground potential of the bus to the logic

analyzer’s ground probe line.

GND

Rx

Tx

2. Press the Bus key.

B

BUS

3. Press Bus from the bottom menu

and choose the UART serial bus on

the side menu.

Define Inputs

4. Press Define Inputs from the bottom

menu.

5. From the side menu choose the Tx

Input and the Rx

Input source and the signal

polarity.

Tx

OFF, D15~D0

Rx

OFF, D15~D0

Polarity

Normal (High = 0), Inverted (High

= 1)

Configuration

The Configure key sets the baud rate, number of data

bits and parity.

55

Page 56

GDS-2000A Series Options Manual

1. Press Configure from the bottom

menu.

2. From the side menu select the Baud rate, Data

bits, Parity, Packets and End of Packet bits.

Baud Rate

50, 75, 110, 134, 150, 300, 600, 1200,

1800, 2000, 2400, 3600, 4800, 7200,

9600, 14400, 15200, 19200, 28800,

31250, 38400, 56000, 57600, 76800,

115200, 128000, 230400, 460800,

921600, 1382400, 1843200, 2764800

Data Bits

8 (fixed)

Parity

Odd, Even, None

Packets

On, Off

End of

Packet

(Hex)

00(NUL), OA(LF), OD(CR), 20(SP),

FF

Panel operation

1. Connect each of the bus signals (SCLK, SDA) to

one of the logic analyzer inputs. Connect the

ground potential of the bus to the logic

analyzer’s ground probe line.

I2C Serial Bus Interface

The I2C bus is a 2 wire interface with a serial data line (SDA) and

serial clock line (SCLK). The I2C protocol supports 7 or 10 bit

addressing and multiple masters. The decode software will trigger

on any of the following conditions: a start/stop condition, a restart,

a missing acknowledge message, Address, Data or Address&Data

frames. The I2C trigger can be configured for 7 or 10 bit addressing

with the option to ignore the R/W bit as well as triggering on a

data value or a specific address and direction (read or write or

both).

56

Page 57

LOGIC ANALYZER

GND

SCLK

SDA

2. Press the Bus key.

B

BUS

3. Press Bus from the bottom menu

and choose I2C from the side menu.

Define Inputs

4. Press Define Inputs from the bottom

menu.

5. From the side menu choose the

SCLK input and the SDA Input.

SCLK

D15~D0

SDA

D15~D0

Include R/W in

address

To configure whether you want the

R/W bit to be included in the

address, press Include R/W in

address and set to Yes or No in the

side menu.

R/W Bit

Yes, No

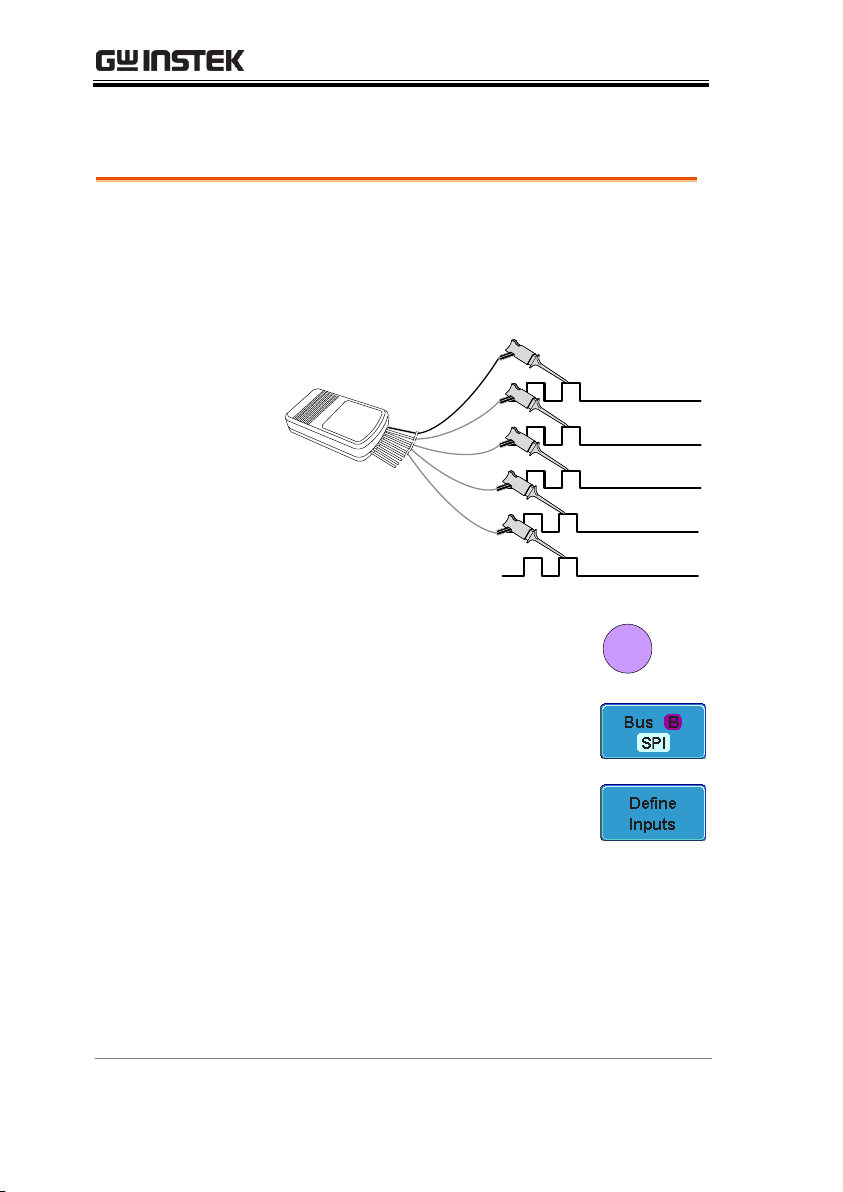

SPI Serial Bus Interface

The serial peripheral interface (SPI) is a full duplex 4 wire

synchronous serial interface. The 4 signals lines: Serial clock line

(SCLK), slave select (SS), Master output/slave input (MOSI, or

57

Page 58

GDS-2000A Series Options Manual

Panel operation

1. Connect each of the bus signals (SCLK, SS,

MOSI, MISO) to one of the logic analyzer

inputs. Connect the ground potential of the bus

to the logic analyzer’s ground probe line.

GND

SCLK

SS

MOSI

MISO

2. Press the Bus key.

B

BUS

3. Press Bus from the bottom menu

and choose the SPI serial bus.

Define Inputs

4. Press Define Inputs from the lower

menu.

5. From the side menu choose the

SCLK, SS, MOSI and MISO inputs.

SCLK

D15~D0

SS

D15~D0

MOSI

OFF, D15~D0

MISO

OFF, D15~D0

SIMO) and the Master input/slave output (MISO, or SOMI). The

word size is configurable from 4 to 32 bits. The SPI triggers on the

data pattern at the start of each framing period.

58

Page 59

Configuration

The Configure menu sets the data line logic level,

SCLK edge polarity, word size and bit order.

1. Press Configure from the bottom

menu.

2. From the side menu select SCLK edge, SS logic

level, word Size and Bit order.

SCLK

rising edge , falling edge

SS

Active High, Active Low

Word Size

4 ~ 32 bits

Bit Order

MS First, LS First

Bus Encoding

Background

The bus that is displayed on the screen or in the

event tables can be set to either hex or binary

formats.

Operation

Press Bus Display from the Bus

menu and choose either Hex or

Binary from the side menu.

Background

The threshold levels for the Serial buses can be set

to either a user-defined threshold level or to preset threshold.

Set the Threshold

1. Press Threshold from the bottom

menu.

LOGIC ANALYZER

Threshold Configuration

59

Page 60

GDS-2000A Series Options Manual

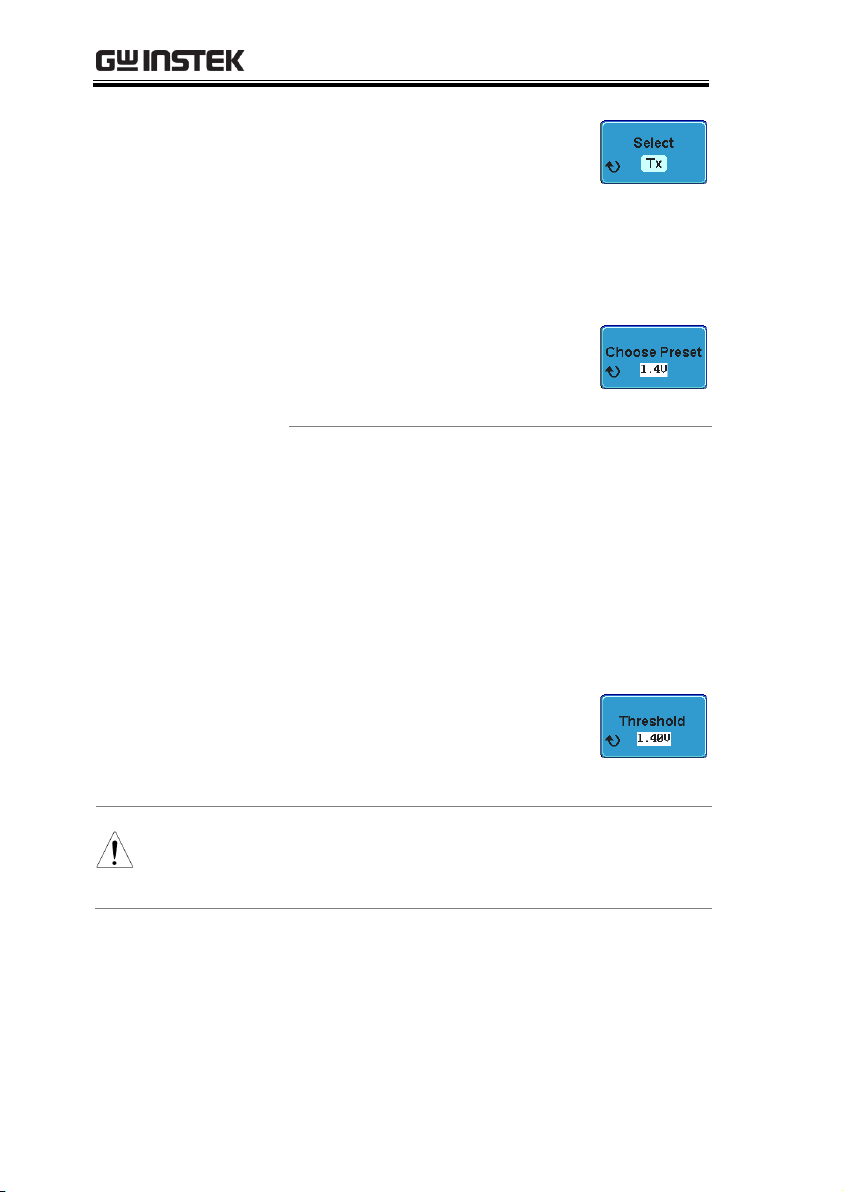

2. Press Select from the side menu

and choose a one of the serial bus

lines.

UART

Tx, Rx

I2C

SCLK, SDA

SPI

SCLK, SS, MOSI, MOSI

3. Press Choose Preset to select a pre-

set logic threshold.

Logic Type

Threshold

TTL

1.4V

5.0V CMOS

2.5V

3.3V CMOS

1.65V

2.5V CMOS

1.25V

ECL

-1.3V

PECL

3.7V

0V

0V

4. Press Threshold to set a user

defined threshold for the currently

selected group.

Range

± 10V

Note

Setting the threshold levels from the Bus menu will

also change the threshold levels set in the Logic

Analyzer menu (page 38).

60

Page 61

LOGIC ANALYZER

Background

The serial bus event tables list when each data

event on the bus occurred. The data is displayed as

either hex or binary, depending on the bus display

settings.

Event tables can be saved to disk in a CSV format.

The files will be named “Event_TableXXXX.CSV”,

where XXXX is a number from 0000 to 9999. See

page 64 for details.

Operation

1. Press Event Table from the bottom

menu.

2. Press Event Table from the side

menu to turn the event table on or

off.

Event

On, Off

Use the Variable knob to scroll through the

event table.

Data Detail

(I2C only)

3. To view the data at a particular

address in more detail, turn Data

Detail On. This is only available for

the I2C bus.

Detail

On, Off

Use the Variable knob to scroll through the

Data Detail event table.

Serial Bus Event Tables

61

Page 62

GDS-2000A Series Options Manual

Save Event Table

4. To save the event table, press Save

Event Table. The Event table will be

saved to the current file path in a

CSV format. See page 64 for

details.

Use the variable knob to scroll through the

event table.

Example:

UART Event table

Time of triggerTxRx

Errors

Select cursor

Example:

I2C Event table

Time of trigger

Repeat Start

Address

Data at address

Missing Ack

Select cursor

62

Page 63

LOGIC ANALYZER

Example:

I2C Data Detail

Time of trigger

Address

Data Detail

Select cursor

Note

Data Detail is only available with the 12C bus.

Example:

SPI Event table

Time of trigger

MOSI MISO

Select cursor

63

Page 64

GDS-2000A Series Options Manual

File Type

Each event table is saved as

Event_TableXXXX.CSV into the designated file

path. Each event table is numbered sequentially

from 0000 to 9999. For example the first event table

will be saved as Event_Table0000.CSV, the second

as Event_Table0001.CSV, and so on.

Event Table Data

Each event table saves a timestamp of each event

relative to the trigger as well as the data in each

frame/packet at the time of an event. The

frame/packet data is saved in HEX format.

The table below lists in order the data saved for

each event table.

UART

Time, Tx frame data, Rx frame data,

Errors.

I2C

Time, Repeat Start, Address, Data,

Missing Ack.

SPI

Time, MISO frame data, MOSI

frame data.

Event Tables Format

Each bus type (Parallel, UART, I2C, SPI) can have an event table

saved containing each bus event as a .CSV file. For serial buses, an

event is defined as the data on the bus when a Stop or End of

Packet (UART) is encountered. For parallel buses, an event

depends on the number of bits on the bus. The data associated with

each event and the time of each event is recorded.

64

Page 65

LOGIC ANALYZER

Example

Below shows the data associated with an SPI event

table in a spreadsheet.

Time MOSI MISO

-11.60us 0D87 0D87

-10.16us 06C0 06C0

-8.720us 8343 343

-7.282us 243 243

-5.840us 0C88 0C88

Background

A Label can be added to the serial buses. This label

will appear next to the bus indicator on the left

hand-side of the display.

Panel Operation

1. To add a label to the bus, press Edit

Labels from the Parallel Bus menu.

2. To choose a preset label, Press User

Preset from the side menu and

choose a label.

Labels

ACK, AD0, ADDR, ANALOG,

BIT, CAS, CLK, CLOCK, CLR,

COUNT, DATA, DTACK,

ENABLE, HALT, INT, IN, IRQ,

LATCH, LOAD, NMI

Edit Label

3. Press Edit Character to edit the

current label.

Adding a Label to the Serial Bus

65

Page 66

GDS-2000A Series Options Manual

4. The Edit Label window appears.

5. Use the Variable knob to highlight

a character.

VARIABLE

Press Enter Character to select a

number or letter.

Press Back Space to delete a

character.

Press Editing Completed to create

the new label and return to the

previous menu.

Note: this key must be pressed to

save the label, even for the preset

labels.

66

Page 67

LOGIC ANALYZER

Press Cancel to cancel the editing

and return to the Edit Label

menu.

6. The label will appear next to the bus indicator.

Below, the label “BUS_1” was created for the

bus.

The bus is labeled

as BUS_1

Remove Label

Press Label Display to toggle the label

on or off.

Background

The cursors can be used to read bus values at any

position.

Note

Ensure that one of the serial buses has been

selected and is activated.

Panel Operation

1. Press the Cursor key. Horizontal

cursors appear on the display.

Cursor

2. Press the H Cursor soft-key and

select which cursor(s) you wish to

position.

Range

Description

Left cursor ( ) movable, right

cursor position fixed

Right cursor ( ) movable, left

cursor position fixed

Using Cursors with the Serial Bus

67

Page 68

GDS-2000A Series Options Manual

Left and right cursor ( + )

movable together

3. The cursor position information appears on the

top left hand side of the screen.

Example: SPI cursors.

Cursor

Hor. position, Bus value(s)

Cursor

Hor. position, Bus value(s)

4. Use the Variable knob to move the

movable cursor(s) left or right.

VARIABLE

68

Page 69

LOGIC ANALYZER

Panel Operation

1. Set the Bus to UART in the bus

menu.

Page 54

2. Press the Trigger Menu key.

Menu

3. Press Type from the bottom menu.

4. Press Others from the side

menu and select Bus.

5. Press Trigger On and select the

triggering condition for the UART

bus.

Trigger On

Tx Start Bit, Rx Start Bit, Tx End of

Packet, Rx End of Packet, Tx Data,

Rx Data, Tx Parity Error, Rx Parity

Error

Trigger On – Tx

Data, Rx Data

If Tx Data or Rx Data was configured for the

Trigger On setting, then the number of bytes and

data can also be configured.

1. Press Data from the bottom menu.

Trigger Settings

Serial Bus Trigger Settings

UART BUS Trigger Settings

The UART bus trigger conditions can be set at any time after the

bus settings have been set to UART.

69

Page 70

GDS-2000A Series Options Manual

2. Press Number of Bytes from the side

menu and choose the number of

bytes for the data.

UART

1~10 Bytes

3. Press Data from the side menu to

edit the triggering data.

To edit the data, use the Variable

knob to highlight a binary or hex

digit and press Select. Use the

Variable knob to choose a value for

the digit and press Select to

confirm.

VARIABLE

Binary

0,1,X (don’t care)

Hex

0~F, X (don’t care)

ASCII

ASCII characters for

the equivalent Hex

characters 00 to FF

The Trigger on settings will be reflected on the

Trigger Configuration icon.

Panel Operation

1. Set the Bus to I

2

C in the bus menu.

Page 56

2. Press the Trigger Menu key.

Menu

3. Press Type from the bottom menu.

I2C Bus Trigger Settings

The I2C bus trigger conditions can be set at any time after the bus

settings has been set to 12C.

70

Page 71

LOGIC ANALYZER

4. Press Others from the side

menu and select Bus.

5. Press Trigger On and select the

triggering condition for the

selected bus.

Trigger On

Start, Repeat Start, Stop, Missing

Ack, Address, Data, Address/Data

Trigger On – Data

If Data or Address/Data was configured for

the Trigger On setting, then the number of

bytes, data and addressing mode (I2C) can be

configured.

6. Press Data from the bottom menu.

7. Press Number of Bytes from the side

menu and choose the number of

bytes for the data.

I2C

1~5 Bytes

8. Press Addressing Mode to toggle

between 7 and 10 bit addressing

modes.

9. Press Data from the side menu to

edit the triggering data.

To edit the data, use the Variable

knob to highlight a binary or hex

digit and press Select. Use the

Variable knob to choose a value for

the digit and press Select to

confirm.

VARIABLE

71

Page 72

GDS-2000A Series Options Manual

Binary

0,1,X (don’t care)

Hex

0~F, X (don’t care)

Trigger On Address

If Address or Address/Data was configured

for the Trigger On setting, then the triggering

address must be configured.

10. Press Address on the bottom menu.

11. Press Addressing Mode to toggle

between 7 and 10 bit addressing

modes.

12. To choose a preset address as the

default address, press Choose Preset

and select a preset address.

Address

Description

0000 000 0

General Call

0000 000 1

START Byte

0000 1XX X

Hs-mode

1010 XXX X

EEPROM

0000 001 X

CBUS

Press Apply Preset to set the default

address to the preset.

Note

Presets are not available for Trigger On

Address/Data.

13. Press Address from the side menu

to manually edit the triggering

address.

To edit the address, use the

72

Page 73

LOGIC ANALYZER

Variable knob to highlight a binary

or hex digit and press Select. Use

the Variable knob to choose a value

for the digit and press Select to

confirm.

VARIABLE

Binary

0,1, X (don’t care)

Hex

0~F, X (don’t care)

Direction

14. Press Direction on the bottom menu

and choose the direction from the

side menu.

Direction

Write, Read, Read or Write

Panel Operation

1. Set the Bus to SPI in the bus menu.

Page 57

2. Press the Trigger Menu key.

Menu

3. Press Type from the bottom menu.

4. Press Others from the side

menu and select Bus.

5. Press Trigger On and select the

triggering condition for the SPI

bus.

SPI

SS Active, MOSI, MISO,

MOSI&MISO

SPI Bus Trigger Settings

The SPI bus trigger conditions can be set at any time after the bus

setting has been set to SPI.

73

Page 74

GDS-2000A Series Options Manual

Trigger On – Data

If MOSI, MISO or MISO/MOSI was

configured for the Trigger On setting, then the

number of words and the data can be

configured.

6. Press Data from the bottom menu.

7. Press Number of Words from the

side menu and choose the number

of words for the data.

SPI

1~32 Words

8. Press MOSI or MISO from the side

menu to edit the triggering data.

To edit the data, use the Variable

knob to highlight a binary or hex

digit and press Select. Use the

Variable knob to choose a value for

the digit and press Select to

confirm.

VARIABLE

Binary

0,1,X (don’t care)

Hex

0~F, X (don’t care)

Background

The parallel bus can be set up to trigger on a

specified data pattern.

Panel Operation

1. Press the Trigger Menu key.

Menu

2. Press Type from the bottom menu.

Parallel Bus Trigger

74

Page 75

LOGIC ANALYZER

3. Select Others → Bus from

the side menu. The Bus

indicator appears at the

bottom of the display.

From left: Bus trigger, Data source

4. Press Data from the bottom menu.

5. Press Data from the side menu to

edit the triggering data.

To edit the data, use the Variable

knob to highlight a binary or hex

digit and press Select. Use the

Variable knob to choose a value for

the digit and press Select to

confirm.

VARIABLE

Binary

0,1,X (don’t care)

Hex

0~F, X (don’t care)

6. The bus will now trigger when the specified

data appears on the bus.

Trigger Mode

1. Like the other trigger configurations, the Bus

Trigger mode can be set to Auto (Untriggered

Roll) and Normal.

This applies to the serial and parallel buses.

Common Bus Trigger Settings

Bus Trigger Mode

75

Page 76

2. Press Mode from the bottom menu

to change the triggering mode.

3. Use the side panel to select Auto or

Normal triggering modes.

Range

Auto, Normal

Logic Trigger

Background

The digital channels can be set up to trigger on

specified logic levels and for a specified clock edge.

For example the digital channels can be set to

trigger on the rising edge of the clock signal when

bit 1 (D1) is high and all other channels are

ignored.

Panel Operation

1. Press the Trigger Menu key.

Menu

2. Press Type from the bottom menu.

3. Select Others → Logic from

the side menu. The Logic

indicator appears at the

bottom of the display.

From left: Bits D15~D0

4. Press Define inputs from the

bottom menu.

GDS-2000A Series Options Manual

76

Page 77

LOGIC ANALYZER

5. Press Select on

the side menu

and select a

channel.

6. Next, select a

logic level for

the selected

channel, or set

the selected

channel as the

clock signal.

Logic

Clock, High (H), Low (L), Don’t

Care (X)

7. If Clock was selected, press Clock

Edge from the bottom menu and

select a clock transition.

8. Repeat steps 5 to 7 for the remaining channels.

9. The chosen logic levels will be reflected in the

trigger indicator at the bottom of the screen.

The color of each channel, if active will also be

displayed. If a channel is not turned on, it will

be grayed-out.

Example

D15 ~ D0

D0 clock edge

D1 = High

D2 = don’t care

D3 = don’t care

D15 ~ D4 = turned off

10. The bus will now trigger when the specified

logic appears on the bus.

77

Page 78

GDS-2000A Series Options Manual

Trigger Threshold

Levels

The trigger threshold levels for the can assigned

from a selected number of preset logic levels or a

user-defined threshold level can be set.

Note

The threshold levels set with the logic bus menu

will replace the logic levels that are set in the Logic

Analyzer menu (page 38).

1. Press Thresholds from the bottom

menu.

2. Press Select from the side menu

and choose a group of channels.

Group

D0~D3, D4~D7, D8~D11,

D12~D15

3. Press Choose Preset to select a pre-

set logic threshold.

Logic Type

Threshold

TTL

1.4V

5.0V CMOS

2.5V

3.3V CMOS

1.65V

2.5V CMOS

1.25V

ECL

-1.3V

PECL

3.7V

0V

0V

4. Press Threshold to set a user

defined threshold.

Range

± 10V

78

Page 79

LOGIC ANALYZER

Background

Like the other trigger configurations, the Logic

Trigger can be set to Auto (Untriggered Roll) and

Normal.

1. Press Mode from the bottom menu

to change the triggering mode.

2. Use the side panel to select Auto or

Normal triggering modes.

Range

Auto, Normal

Background

The holdoff function defines the waiting period

before the GDS-2000A starts triggering again after

a trigger point. Please see the user manual for

further details.

1. To set the Holdoff time, press the

Holdoff menu button on the bottom

menu.

2. Use the side menu to set the

Holdoff time.

Range

10ns~10s

Pressing Set to Minimum sets the

Holdoff time to the minimum,

10ns.

Logic Trigger Mode

Logic Trigger Holdoff

79

Page 80

INDEX

INDEX

Digital channels

activation ....................................... 31

analog waveform .......................... 40

grouping ........................................ 33

labels ............................................... 41

position ........................................... 33

threshold ........................................ 38

vertical scale .................................. 38

Display

Bus ................................................... 44

logic analyzer ................................ 30

Event table format ..................... 64

Function generator

operation .................................. 21, 24

overview ........................................ 20

Install optional software ............. 7

Logic Analyzer

overview ........................................ 28

probes ............................................. 29

Logic bus

trigger settings

mode .......................................... 79

trigger settings .............................. 76

Module installation ..................... 6

Parallel bus

configuration ................................. 46

encoding ......................................... 48

event table ...................................... 49

labels ............................................... 50

threshold ........................................ 47

trigger settings .............................. 74

mode .......................................... 75

Serial bus

cursors ............................................ 67

encoding ......................................... 59

event tables .................................... 61

labels ............................................... 65

overview ........................................ 53

threshold ........................................ 59

trigger settings

holdoff ....................................... 79

I2C ............................................... 70

mode .......................................... 75

SPI .............................................. 73

UART ......................................... 69

Serial Bus .................................... 53

I2C .................................................... 56

SPI ................................................... 58

UART .............................................. 54

Uninstall optional software ........ 8

80

Loading...

Loading...