Dual Measurement Multimeter

GDM-9060/9061

USER MANUAL

REV. C

ISO-9001 CERTIFIED MANUFACTURER

This manual contains proprietary information, which is protected by

copyrights. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

right to change specifications, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan (R.O.C.).

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS .................................................... 5

Safety Symbols .................................................................... 5

Safety Guidelines ................................................................. 6

GETTING STARTED .......................................................... 10

Characteristics ..................................................................... 11

Front Panel Overview .......................................................... 13

Rear Panel Overview ............................................................ 18

Status Bar ............................................................................ 21

Set Up.................................................................................. 24

BASIC MEASUREMENT .................................................... 26

Basic Measurement Overview ............................................. 27

AC/DC Voltage Measurement .............................................. 30

AC/DC Current Measurement ............................................. 37

2W/4W Resistance Measurement ........................................ 41

Continuity Test .................................................................... 44

Diode Measurement ............................................................ 47

Frequency/Period Measurement .......................................... 48

Capacitance Measurement .................................................. 53

Temperature Measurement ................................................. 56

DUAL MEASUREMENT .................................................... 66

Dual Measurement .............................................................. 67

ADVANCED MEASUREMENT ........................................... 77

Advanced Measurement Overview ...................................... 78

Relative Value Measurement ............................................... 79

Hold Measurement ............................................................. 81

Trigger Setting ..................................................................... 84

Filter Setting ........................................................................ 90

Math Measurement ............................................................. 93

DIGITAL I/O ................................................................... 117

Digital I/O Overview ........................................................... 118

3

GDM-906X Series User Manual

Application: Compare Mode ............................................... 120

Application: 4094 / User Mode ........................................... 127

Application: External Trigger ............................................... 135

SYSTEM & FIRMWARE ................................................... 137

View System Info ................................................................ 138

Firmware Update ................................................................ 139

MENU SETTING ............................................................. 141

Configure System ............................................................... 142

Configure Display ............................................................... 160

SCREENSHOT & LOG .................................................... 179

Capture ............................................................................... 180

Save Reading ...................................................................... 183

DISPLAY SETTING .......................................................... 187

Digit .................................................................................... 188

Display ................................................................................ 190

REMOTE CONTROL ....................................................... 209

Configure Interface ............................................................. 210

Web Control Interface ......................................................... 243

Command Syntax ................................................................ 248

Command Set ..................................................................... 251

Status system ..................................................................... 337

APPENDIX ...................................................................... 341

Fuse Replacement ............................................................... 342

Battery Replacement ........................................................... 346

Factory Default Parameters ................................................ 348

Specifications ..................................................................... 352

GDM-9061 Section ............................................................. 353

GDM-9060 Section ............................................................. 364

Declaration of Conformity .................................................. 376

INDEX ............................................................................ 377

4

SAFETY INSTRUCTIONS

WARNING

Warning: Identifies conditions or practices that could

result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that could

result in damage to the GDM-9060/9061 or to other

property.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection facility

or contact the supplier from which this instrument was

purchased.

SAFETY INSTRUCTIONS

This chapter contains important safety instructions that

you must follow when operating the GDM-9060/9061

and when keeping it in storage. Read the following

before any operation to insure your safety and to keep

the GDM-9060/9061 in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the GDM-9060/9061.

5

GDM-906X Series User Manual

General Guideline

CAUTION

Make sure that the voltage input level does not exceed

DC1000V/AC750V.

Make sure the current input level does not exceed 10A.

Do not place any heavy object on the instrument.

Avoid severe impact or rough handling that can lead to

damaging the instrument.

Do not discharge static electricity to the instrument.

Use only mating connectors, not bare wires, for the

terminals.

Do not block or obstruct the cooling fan vent opening.

Do not perform measurement at the source of a

low-voltage installation or at building installations

(Note below).

Do not disassemble the instrument unless you are

qualified as service personnel.

Make sure that the Sense LO terminal to Input LO is

limited to 2Vpk, the Sense HI to Sense LO terminals

are limited to 200Vpk and the Input LO to earth is

limited to 500Vpk.

(Note) EN 61010-1:2010 specifies the measurement categories and

their requirements as follows. The GDM-9060/9061 falls under

category II 300V.

Measurement category IV is for measurement performed at the source

of low-voltage installation.

Measurement category III is for measurement performed in the

building installation.

Measurement category II is for measurement performed on the circuits

directly connected to the low voltage installation.

Power Supply

WARNING

AC Input voltage: 100/120/220/240 V AC ±10%,

50Hz / 60Hz / 400Hz ±10%

The power supply voltage should not fluctuate more

than 10%.

Connect the protective grounding conductor of the

AC power cord to an earth ground, to avoid electrical

shock.

Safety Guidelines

6

SAFETY INSTRUCTIONS

WARNING

(GDM-9061 only)

Due to the fact that the Front/Rear Input Switch on

the front panel is not proposed as an active

multiplexer, do Not change the input switch when

signals are present on either rear or front set of

terminals. Intrument damage and risk of electric shock

may occur if switching the input switch when high

voltage or current is present.

Fuse

WARNING

Fuse type: T0.25A 100/120 VAC

T0.125A 220/240 VAC

Make sure the correct type of fuse is installed before

power up.

To avoid risk of fire, replace the fuse only with the

specified type and rating.

Disconnect the power cord before fuse replacement.

Make sure the cause of a fuse blowout is fixed before

fuse replacement.

Cleaning the

Instrument

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid into the

GDM-9060/9061.

Do not use chemicals or cleaners containing harsh

material such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free, almost

non-conductive pollution (Note below)

Temperature: Full accuracy for 0°C to 55°C.

Humidity:

< 30°C: < 80%RH (non-condensing)

30°C~40°C: <70%RH (non-condensing)

>40°C: <50%RH (non-condensing)

Altitude: <2000m

7

GDM-906X Series User Manual

(Note) EN 61010-1:2010 specifies the pollution degrees and their

requirements as follows. The GDM-9060/9061 falls under degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive pollution

occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution occurs.

Occasionally, however, a temporary conductivity caused by

condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-conductive

pollution occurs which becomes conductive due to condensation which

is expected. In such conditions, equipment is normally protected

against exposure to direct sunlight, precipitation, and full wind pressure,

but neither temperature nor humidity is controlled.

Storage

Environment

Location: Indoor

Temperature: −40°C to 70°C

Humidity: <90%RH(non-condensing)

Disposal

Do not dispose this instrument as unsorted municipal

waste. Please use a separate collection facility or contact

the supplier from which this instrument was purchased.

Please make sure discarded electrical waste is properly

recycled to reduce environmental impact.

8

SAFETY INSTRUCTIONS

Green/ Yellow:

Earth

Blue:

Neutral

Brown:

Live (Phase)

Power cord for the United Kingdom

When using the GDM-9060/9061 in the United Kingdom, make sure the

power cord meets the following safety instructions.

NOTE: This lead / appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code:

As the colours of the wires in main leads may not correspond with the

coloured marking identified in your plug/appliance, proceed as follows:

The wire which is coloured Green & Yellow must be connected to the Earth

terminal marked with either the letter E, the earth symbol or coloured

Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal which is

marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the terminal marked

with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment or contact

the supplier.

This cable/appliance should be protected by a suitably rated and approved

HBC mains fuse: refer to the rating information on the equipment and/or

user instructions for details. As a guide, a cable of 0.75mm2 should be

protected by a 3A or 5A fuse. Larger conductors would normally require 13A

types, depending on the connection method used.

Any exposed wiring from a cable, plug or connection that is engaged in a live

socket is extremely hazardous. If a cable or plug is deemed hazardous, turn

off the mains power and remove the cable, any fuses and fuse assemblies. All

hazardous wiring must be immediately destroyed and replaced in accordance

to the above standard.

9

GDM-906X Series User Manual

GETTING STARTED

This chapter describes the GDM-9060/9061 in a nutshell,

including an Overview of its main features and front /

rear panel introduction. After going through the

Overview, follow the Power-up sequence to properly

setup the GDM-9060/9061.

Please note the information in this manual was correct at

the time of printing. However as GW Instek continues to

improve its products, changes can occur at any time

without notice. Please see the GW Instek website for the

latest information and content.

Characteristics .................................................................... 11

Accessories ............................................................................... 12

Front Panel Overview .......................................................... 13

Measurement Keys (basic) ........................................................ 15

Measurement Keys (advanced) ................................................. 17

Rear Panel Overview ........................................................... 18

Status Bar ........................................................................... 21

Set Up ................................................................................. 24

Horizontal/Tilt/Vertical Applications ........................................ 24

Power Up .................................................................................. 25

10

GETTING STARTED

Performance

The highest DCV accuracy:

GDM-9061: 35ppm

GDM-9060: 75ppm

The highest current:

GDM-9061: 10A

GDM-9060: 3A

The highest voltage: 1000V

The highest ACV frequency response: 300 kHz

The fastest sampling rate:

1k Readings/sec (GDM-9060)

10k Readings/sec (GDM-9061)

Internal memory:

10k read memory (GDM-9060)

100k read memory (GDM-9061)

Data Logging to USB

Features

6

2

1

digits

Multi functions: ACV, DCV, ACI, DCI, 2W/4W R, Hz,

Temp, Continuity, Diode, Period, Capacitance test,

REL, dBm, Hold, MX+B, 1/X, REF%, dB, Compare

and Statistics.

Manual or Auto ranging

AC true RMS

Built-in DC Ratio function

Standard SCPI command set in emulation compatible

with Agilent 34401A

Up to 3 temerature measurements: RTD, Thermistor

and Thermocouples (Cold-Junction Compensation)

Graph Display: BarMeter, TrendChart, Histogram

Interface

USB device/RS232/GPIB(optional)/LAN for remote

control

9-pin Digital I/O port

USB device port supports USBCDC and USBTMC

USB Host

Software

Excel Addins

DMM-VIEWER2

Characteristics

The GDM-9060/9061 is a portable, dual-display digital

multimeter suitable for a wide range of applications, such

as production testing, research, and field verification.

11

GDM-906X Series User Manual

Standard

Accessories

Part number

Description

CD-ROM

UM, Software, Driver

82DM-90610M01

Safety Instruction Sheet

GTL-217

Test leads

GTL-246

USB Cable, USB 2.0, A-B type, 1200mm

Optional

Accessories

Part number

Description

11DM-90610101

GDM-9060/9061 GPIB Card

GTL-234

RS-232 Cable , 2000mm

GTL-205A

Temperature Probe Adapter with Thermal

Coupling (K-type)

GTL-308

4W+Shield Test leads, 1.5M

GDM-TL1

Test leads with sharp probe and SMT

grabber with miniature grabber accessory

Accessories

12

GETTING STARTED

1

2

3

4

5 8 7 0 A B

6 9 C D

Item

Description

1

ESC (Escape) Key

2

Print screen / Data log Key

3

USB Host Port

4

Power Switch

5

Main Display

6

Function keys (F1 through F6, functions vary per modes)

7

Knob key

8

Arrow Keys

9

Measurement Keys

0

Range Selection Keys

A

HI and LO Sense Terminals

B

HI and LO Input Terminals

C

AC/DC Current Input Terminals (10 A terminal available on

GDM-9061 only)

D

Front/Rear Input Switch (GDM-9061 only)

Front Panel Overview

13

GDM-906X Series User Manual

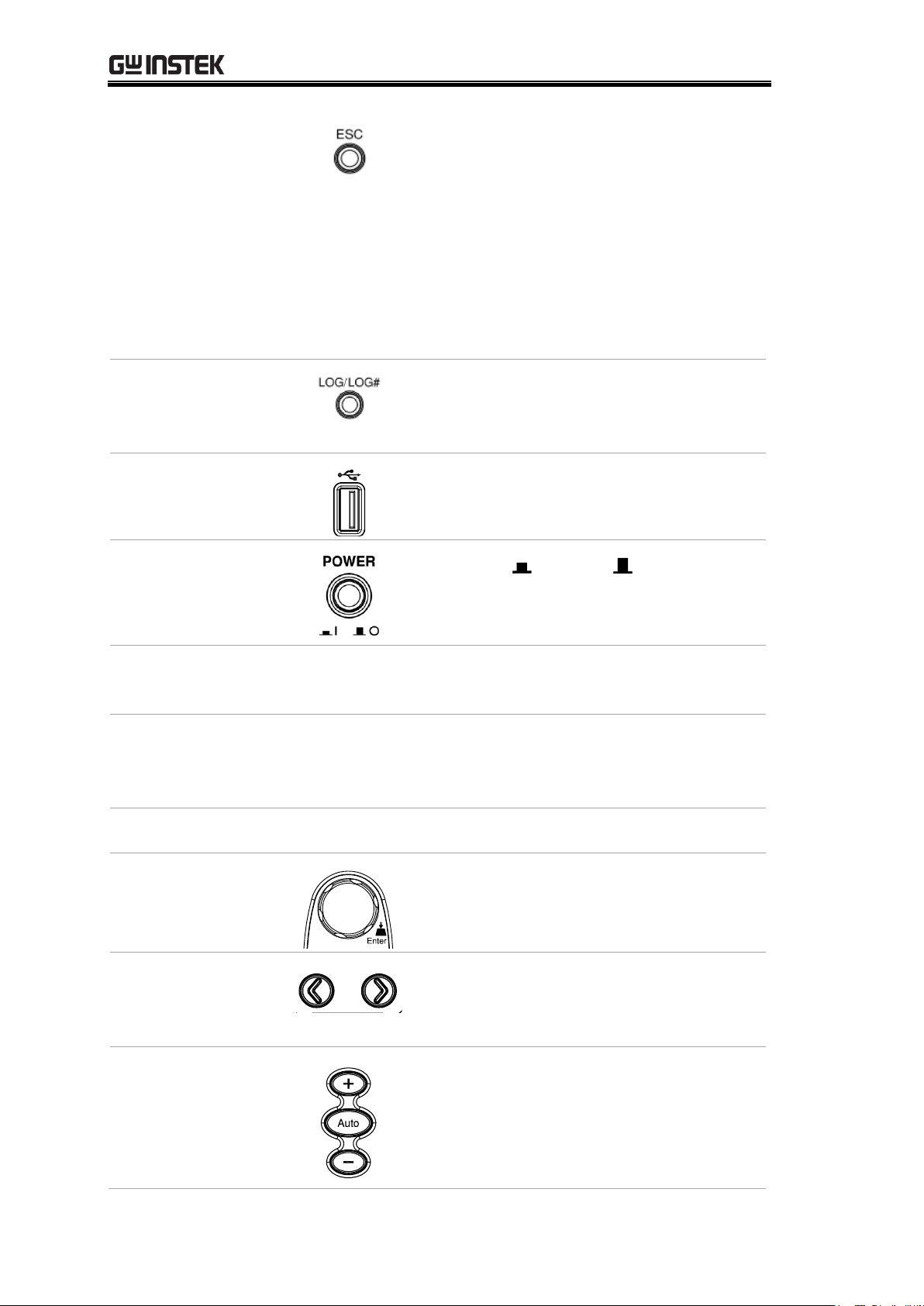

ESC (Escape) Key

Single press to escape from current page.

Presses and holds the ESC key for 2

seconds to toggle between full display

and simple display, which conceals the

status bar, math display as well as

additional info for lightweight use.

Refer to page 21, page 167 and page 175

for more details of status bar, math

display and additional info, respectively.

Screenshot / Data

Log Saving Key

Captures the current screenshot or saves

the data log for reading. For details, refer

to page 179.

USB Host Port

Connects with USB flash drive for data

storage.

Power Switch

Turns On or Off the main

power. For the power up sequence, see

page 25.

Main Display

The 4.3”TFT LCD shows measurement results and

parameters. For display configurations, see page 160.

Measurement

Keys

There are 4 rows in total of both basic and advanced

measurement keys deployed on the front panel. For the

details, refer to page 15 and page 17.

Function Keys

The 6 keys have varied functions per different settings.

Knob Key

Scrolls the knob to select parameters in

various setting pages. Press the key until

click to confirm setting.

Arrow Keys

Presses the left or right arrow keys to

move parameter cursor rightward or

leftward per requirement.

Range Selection

Keys

Presses the Auto key to activate

auto-range mode, whilst clicking “+” or

“–“ key can increase or decrease range

parameter, respectively.

14

GETTING STARTED

DC/AC 3A

Terminal

DC/AC current input

DC: 100μA~3A

AC: 100μA~3A

For details see page 37.

For the fuse replacement procedure, see

page 343.

Sense LO

Terminal

Accepts LO sense line in 4W resistance

measurement. For details, see page 41.

Sense HI

Terminal

Accepts HI sense line in 4W resistance

measurement. For details, see page 41.

Input LO

Terminal

Accepts ground (COM) line in all

measurements except the sense line in

4W Resistance (page 41).

The maximum withstand voltage

between this terminal and earth is

500Vpk.

Input HI

Terminal

Used as an input port for all

measurements except for DC/AC

Current measurements.

DC/AC 10A

Terminal

(GDM-9061 only)

Accepts DC/AC Current input.

For DCI or ACI details, see page 37.

Background

The upper 2 rows of measurement keys are used for

basic GDM-9060/9061 measurements such as voltage,

current, resistance, continuity, diode, frequency, period,

capacitance and temperature. Each key has a primary

and secondary function individually. The secondary

function is accessed in conjunction with the Shift key.

Measurement Keys (basic)

15

GDM-906X Series User Manual

Shift

The Shift key is used to select the

secondary functions assigned to each

front panel key. When pressed, the

Shift indicator appears in the display.

Local

For the Local key, it helps release

from the remote control and

returns the instrument to local

panel operation (page 210).

ACV

Measures AC Voltage (page 30).

Shift → ACV (ACI)

Measures AC Current (page 37).

DCV

Measures DC Voltage (page 30).

Shift → DCV (DCI)

Measures DC Current (page 37).

Ω2W (Resistance)

Measures 2-wire Resistance (page

41).

Shift → Ω2W (Ω4W

Resistance)

Measures 4-wire Resistance (page

41 ).

(Continuity)

Tests Continuity (page 44).

Shift →

(Diode )

Tests Diode (page 47).

FREQ (Frequency)

Measures Frequency (page 48).

Shift + FREQ

(Capacitance )

Measures Capacitance (page 53).

TEMP

(Temperature)

Measures Temperature (page 56).

16

GETTING STARTED

Background

The lower 2 rows of measurement keys are used for

more advanced functions. Each key has a primary and

secondary function. The secondary function is accessed

in conjunction with the Shift key.

REL

Measures the Relative value (page

79).

Shift → REL

(REL#)

Manually sets the reference value for

the Relative value measurement

(page 79).

Hold

Activates the Hold function (page

81).

Shift → Hold

(Hold#)

Manually sets the parameters for the

Hold measurement (page 81).

TRIG (Trigger)

Activates the Trigger function (page

84).

Shift → TRIG

(TRIG#)

Manually sets the parameters for the

Trigger function (page 84).

Menu

Enters the setting pages in various

Menus (page 142).

Shift → Menu

(Filter)

Manually sets the parameters for the

Filter function (page 90).

DISP

Display settings (page 187).

Shift → DISP

(Math)

The Math functions including dB,

dBm, Compare, MX+B, 1/X and

Percent manually (page 93).

Measurement Keys (advanced)

17

GDM-906X Series User Manual

1

240

2 5 9 0 A

4 3 6 7 8 B

Item

Description

1

HI and LO Sense Terminals (GDM-9061 only)

2

HI and LO Input Terminals (GDM-9061 only)

3

3 A Current Terminal (GDM-9061 only)

4

3 A Current Terminal Fuse

5

DIGITAL I/O Connector

6

RS-232 Interface Connector

7

USB Interface Connector (B Type)

8

Ethernet (LAN) Connector

9

Fan Vents

0

AC Mains Input (Power Cord Socket)

A

AC Mains Line Voltage Selector and Fuse Socket

B

GPIB Connector (optional)

Rear Panel Overview

18

GETTING STARTED

Power Cord Socket

Accepts the power cord. AC

100/120/220/240V ±10%,

50Hz / 60Hz /400Hz ±10%.

For power on sequence, see page

25.

Fuse Socket

Holds the main fuse:

100/120 VAC: T0.25A

220/240 VAC: T0.125A

For fuse replacement details, see

page 342.

RS-232C port

Accepts an RS-232C cable for

remote control; DB-9 male

connector.

For remote control details, see

page 214.

USB device port

Accepts a USB device cable for

remote control; Type B, female

connector.

For remote control details, see

page 211.

LAN port

Accepts a LAN for remote

control;

For remote control details, see

page 227.

Digital I/O port

Accepts a digital I/O cable for the

Hi/Lo limit tests; DB-9 pin,

female connector.

For digital I/O details, see page

117.

Optional GPIB port

Accepts an optional GPIB card.

For GPIB details, see page 223.

19

GDM-906X Series User Manual

Fan Vents

For heat ventilation when machine

is under operation.

Sense LO Terminal

(GDM-9061 only)

Accepts LO sense line in 4W

resistance measurement. For

details, see page 41.

Sense HI Terminal

(GDM-9061 only)

Accepts HI sense line in 4W

resistance measurement. For

details, see page 41.

Input LO Terminal

(GDM-9061 only)

Accepts ground (COM) line in all

measurements except the sense

line in 4W Resistance (page 41).

The maximum withstand voltage

between this terminal and earth is

500Vpk.

Input HI

Terminal

(GDM-9061 only)

Used as an input port for all

measurements except for DC/AC

Current measurements.

DC/AC 3A Terminal

(GDM-9061 only)

DC/AC current input

DC: 100μA~3A

AC: 100μA~3A

For details see page 37.

DC/AC 3.15A Input

Current Fuse

Holds the current fuse: T3.15A,

500V , 5*20mm

For fuse replacement details, see

page 343.

20

GETTING STARTED

Background

Identify each icon within the top status bar.

Status Bar

Display

1 2 3 4 5 6 7 8 9 0

A

Item

Description

1

Local/Remote control icon

2

RS-232/USB-CDC/USB-TMC/LAN/GPIB interface icon

3

Error icon for commands from remote control

4

Rear panel switch icon

5

Shift key identification icon

6

The first and second function menu switch icon

7

Digital I/O mode icon (User/4094)

8

USB flash drive connection icon

9

Beep/Key Sound setting icon

0

Internet connection status icon

A

Time display

Status Bar

21

GDM-906X Series User Manual

Local Control

It indicates the unit is under local

control mode.

Remote Control

It indicates the unit is under remote

control. Refer to page 209 for details.

RS-232

It indicates RS-232 interface is activated.

Refer to page 214 for details.

USB - CDC

It indicates USB - CDC interface is

activated. Refer to page 214 for details.

USB - TMC

It indicates USB - TMC interface is

activated. Refer to page 214 for details.

LAN

It indicates LAN interface is activated.

Refer to page 227 for details.

GPIB

It indicates GPIB interface is activated.

Refer to page 223 for details.

ERROR

It indicates error occurs in commands.

To erase the error icon, it is required to

read or sweep the error by remote

control commands or reboot action.

Refer to page 323 for details.

Rear Panel

It indicates rear panel control. When the

icon appears, only rear panel is available;

otherwise, use front panel for

measurement. Refer to page 18 for details.

Shift

It indicates the shift key is being pressed

ready for in conjunction with other keys

for additional functions. Refer to page

15 for details.

First function

menu

It indicates the active bottom menu

corresponding to function keys is the

first menu. Click the Knob key (Enter)

to switch to the second function menu.

22

GETTING STARTED

Second function

menu

It indicates the active bottom menu

corresponding to functional keys is the

second menu. Click the Knob key (Enter)

to switch to the first function menu.

Digital I/O –

4094 mode

It indicates Digital I/O – 4094 mode is

enabled. Refer to page 127 for details.

Digital I/O –

User mode

It indicates Digital I/O – User mode is

enabled. Refer to page 127 for details.

Flash Drive –

Capture

It indicates the Capture mode is ready

for the connected flash drive. Refer to

the page 179 for details of Capture.

Flash Drive –

Save Reading

It indicates the Save Reading mode is

ready for the connected flash drive. Refer

to page 183 for details of Save Reading.

Flash Drive –

Failure

It indicates something error occurs and

thus flash drive fails to connect to unit.

Sound – Beep

It indicates sound of beep is enabled.

Refer to page 142 for details.

Sound - Key

It indicates sound of key is enabled.

Refer to page 143 for details.

Sound – All

It indicates sounds of beep and key are

both enabled.

Sound – Off

It indicates sounds of beep and key are

both disabled.

Internet On

It indicates internet connection is

established. Refer to page 227 for details.

Internet Off

It indicates internet connection is Not

well established.

Time Display

It indicates the time display. For detailed

setting, refer to page 145.

23

GDM-906X Series User Manual

Pull out the handle sideways and rotate it clockwise for the applications below.

Horizontal

Tilt

Place the unit horizontally.

Rotate the handle for tilt stand.

Vertical

Place the handle vertically for hand carry.

Set Up

Horizontal/Tilt/Vertical Applications

24

Power Up

Steps

1. Ensure the correct line voltage is

clearly shown on the fuse socket

(240V in the right figure for

example). If not, see page 342 to

set the proper line voltage and fuse.

2. Connect the power

cord to the AC

Voltage input.

Note

Make sure the ground connector on the power cord is

connected to a safety ground. This will affect the

measurement accuracy.

3. Push the power button

until click to turn on the

main power switch on

the front panel.

4. The screen firstly shows the logo brand of

GWINSTEK followed by the message “Load the

default parameter” indicating default parameter is loaded

in the initial startup.

GETTING STARTED

25

GDM-906X Series User Manual

BASIC MEASUREMENT

Basic Measurement Overview ............................................ 27

Refresh Rate .............................................................................. 27

Automatic (Internal)/Single Triggering ..................................... 29

AC/DC Voltage Measurement ............................................. 30

Select Voltage Range ................................................................. 31

General Voltage Setting ............................................................. 32

Voltage Conversion Table .......................................................... 35

Crest Factor Table ...................................................................... 36

AC/DC Current Measurement ............................................ 37

Select Current Range ................................................................. 39

General Current Setting ............................................................ 40

2W/4W Resistance Measurement ....................................... 41

Select Resistance Range ............................................................ 42

General Resistance Setting ....................................................... 43

Continuity Test .................................................................... 44

Set Continuity Threshold ........................................................... 45

Diode Measurement ........................................................... 47

Frequency/Period Measurement ......................................... 48

Frequency/Period In-Depth Setting ........................................... 51

Capacitance Measurement ................................................. 53

Cable Open Function ................................................................. 54

Select Capacitance Range .......................................................... 55

Temperature Measurement ................................................. 56

General Temperature Setting .................................................... 57

Thermocouple Sensor Type ....................................................... 58

Reference Junction Temperature (SIM Temperature) ................ 58

Thermocouple Setting ............................................................... 59

RTD 2W/4W Setting .................................................................. 60

Set User Type of RTD 2W/4W .................................................... 61

Thermistor 2W/4W Setting ....................................................... 63

Set User Type of Thermistor 2W/4W ......................................... 64

26

BASIC MEASUREMENT

Background

Basic measurement refers to the several types of measurements

assigned to the upper 2 row keys on the front panel.

Measurement

type

ACV

AC Voltage

DCV

DC Voltage

ACI

AC Current

DCI

DC Current

Ω 2W/ Ω 4W

2-wire and 4-wire Resistance

Continuity/Diode

FREQ

Frequency/Capacitance

TEMP

Temperature

Advanced

measurement

Advanced measurement (page 75) mainly refers to the

operation using the result obtained from one or more of the

basic measurements.

Background

Refresh rate defines how frequently the GDM-9060/9061

captures and updates measurement data. A faster refresh rate

yields a lower accuracy and resolution. A slower refresh rate

yields a higher accuracy and resolution. Consider these

tradeoffs when selecting the refresh rate.

Measurement Type

Refresh Rate Available

DCV/DCI/ 2W/4W

5/s

20/s

60/s

100/s

400/s

1k/s*1

1.2k/s*2

2.4k/s*2

4.8k/s*2

7.2k/s*2

10k/s*2

ACV/ACI

1/s

5/s

20/s

Continuity / Diode

60/s

100/s

400/s

Frequency & Period

1s

100ms

10ms

Capacitance

2/s

Temperature

5/s

20/s

60/s

Note

*1

is applicable to GDM-9060, whilst *2 is specifically for GDM-9061.

Basic Measurement Overview

Refresh Rate

27

GDM-906X Series User Manual

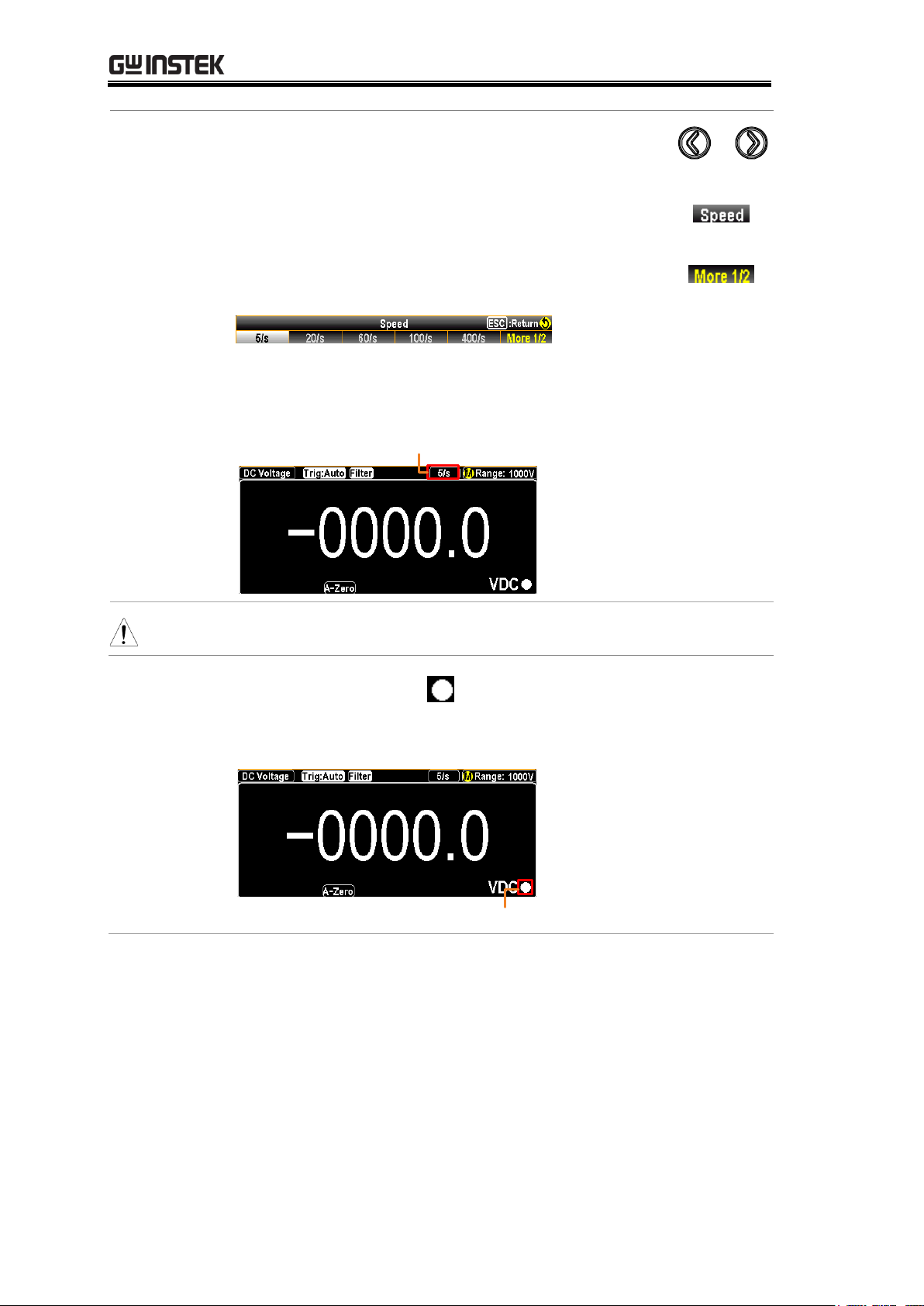

Selection

Procedure

Press the left or right arrow keys to change the

refresh rate.

You can also press the F2 (Speed) key to select a

desired rate for measurement. Press corresponding

function key in accord with the desired option on

screen display. Also, the F6 (More ½) key shows

when available options are more than single page.

The refresh rate will be shown at the upper right

corner of the display. See the example below.

Active Refresh Rate

Note

The refresh rate cannot be set for capacitance measurement.

Reading

indicator

The reading indicator , which is located in the lower-right

corner of display, flashes according to the defined refresh rate

setting.

Reading Indicator

28

BASIC MEASUREMENT

Overview

By default, the GDM-9060/9061 automatically triggers

according to the refresh rate. See the previous page for refresh

rate setting details. The TRIG key, on the other hand, is used to

manually trigger once per click.

Single Trigger

Simply press the TRIG key to Single trigger

measurement. Pressing once stands for trigger for

single time. See the figure below for example.

Indicator Single Trigger Mode

Automatic

(Internal)

Trigger

Press and hold the TRIG key for 2 seconds to

return to the Automatic (Internal) Trigger.

Indicator Auto (Internal)

Trigger Mode

(Press & hold

for 2 seconds)

Note

Single triggering is not supported for capacitance

measurements.

Automatic (Internal)/Single Triggering

29

GDM-906X Series User Manual

Voltage type

AC

0 ~ 750V

DC

0 ~ 1000V

Activate ACV/

DCV

Press the ACV key or DCV key to

measure AC or DC voltage,

respectively.

or

ACV/DCV mode

display appears

The mode will switch to ACV, DCV mode immediately.

See the figure below for example.

DC or AC Voltage

Indicates DC or AC Voltage mode

5/s

Indicates the active refresh rate

Indicates Automatic range selection

Range: 100mV

Indicates the available range of Voltage

+000.1066 mVDC

Indicates the exact measured value

Connect the test

lead and measure

Connect the test lead between the

Input HI and Input LO terminals.

The display updates the reading.

AC/DC Voltage Measurement

30

BASIC MEASUREMENT

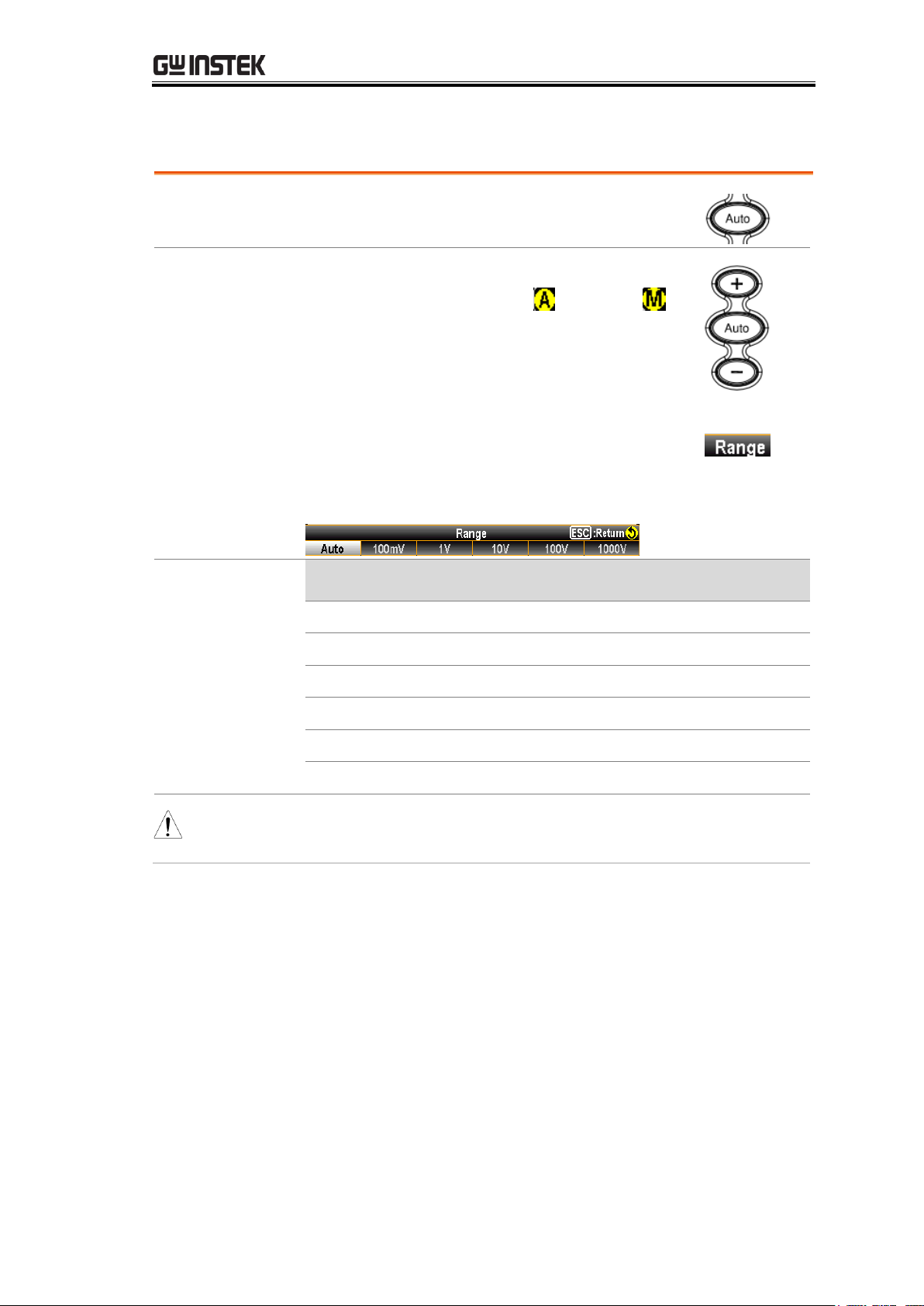

Auto range

To turn the automatic range selection

On/Off, press the Auto key.

Manual range

Press the “+” or the “-” key to select the

range. The Auto indicator turns to

indicating Manual range selection.

If the appropriate range is unknown,

select the highest range.

You can also press the F1 (Range) key to

select a range for the measurement.

Press the F1 ~ F6 key to select a desired

range for the voltage measurement.

Selection list

Range

Resolution

Full scale

100mV

0.1μV

119.9999mV

1V

1 μV

1.199999 V

10V

10 μV

11.99999 V

100V

100 μV

119.9999 V

750V (AC)

1mV

787.500 V

1000V (DC)

1mV

1050.000 V

Note

For more detailed parameters, see the specifications on

page 353.

Select Voltage Range

31

GDM-906X Series User Manual

General Voltage Setting

F2 (Speed) key

to select refresh

rate

DCV:

Press the F1 ~ F5 key to select the desired rate

Press the F6 (More 1/2) key for next page with

more options as the figure shown below.

ACV:

Press the F1 ~ F3 key to select the desired rate

F3 (Auto Zero)

key to enable

Auto Zero (DCV

mode only)

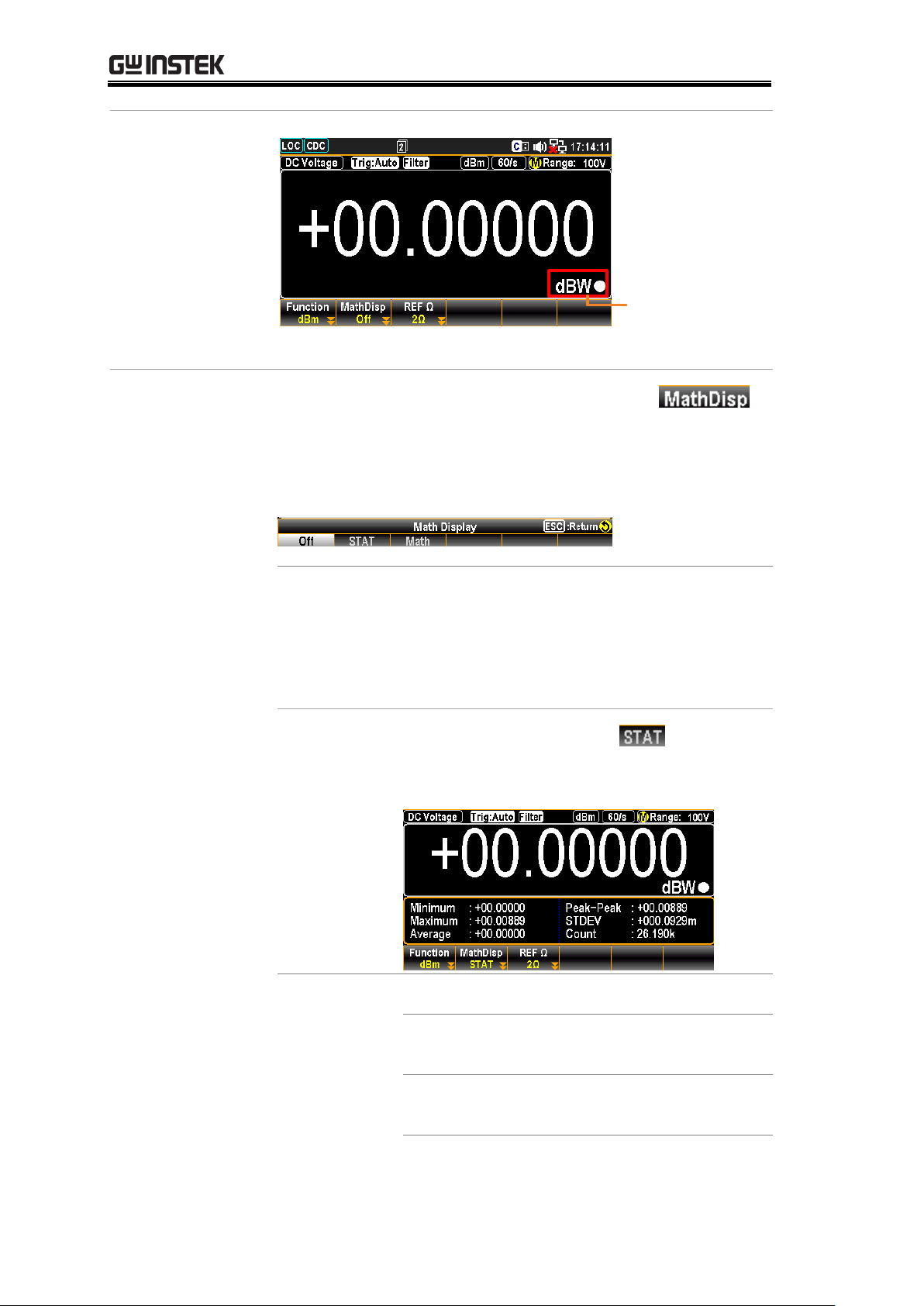

Background

Autozero provides the most

accurate measurements, but requires

additional time to perform the zero

measurement. With autozero

enabled (On), the GDM-9060/9061

internally measures the offset

following each measurement. It then

subtracts that measurement from

the preceding reading. This prevents

offset voltages present on the

GDM-9060/9061’s input circuitry

from affecting measurement

accuracy. With autozero disabled

(Off), the GDM-9060/9061

measures the offset once and

subtracts the offset from all

subsequent measurements.

Display

When turning On the Auto Zero, the display

shows an icon indicating the Auto

Zero mode is currently being activated.

32

BASIC MEASUREMENT

F4 (Input R) key

to select input

resistance

Background

Specify the input impedance to the

test leads (Input R). This specifies

the measurement terminal input

impedance, which is either Auto or

10 MΩ.

The Auto mode selects high

impedance (Hi-Z) for the 100

mV, 1 V and 10 V ranges, and 10

MΩ for the 100 V and 1000 V

ranges. In most situations, 10 MΩ

is high enough to not load most

circuits, but low enough to make

readings stable for high impedance

circuits. It also leads to readings with

less noise than the (Hi-Z) option,

which is included for situations

where the 10 MΩ load is

significant.

Vs = ideal voltage of DUT

Rs = input impedance of DUT

Ri = input impedance of

GDM-9060/9061 (either 10M or

10G available (Hi-Z))

Deviation (%) = Rs/(Rs+Ri) * 100

Display

When “Auto” is selected, the display shows

an icon indicating the Auto mode is

currently being activated.

33

F5 (DCV Ratio)

key to enable

DCV Ratio

Background

The GDM-9060/9061 is able to

calculate DCV ration by measuring

input voltage from the Input

terminals and the reference voltage

from the Sense terminals. Before

activating the DCV Ration, it is

required to wire test leads as the

following illustration.

The equation of DCV ratio is like

the following mathematical

calculation:

See the above equation from which

DC Reference Voltage indicates the

measured voltage from the Sense

terminals.

Display

DCV Ratio

Reading

Input Voltage

Reading

Reference

Voltage Reading

From the screenshot above for example, the

INP: +00.86308V (input voltage) is divided

by the REF: +00.85414V (reference voltage),

and the result turns out the DCV ratio:

+1.010457 shown in giant reading clearly.

GDM-906X Series User Manual

34

BASIC MEASUREMENT

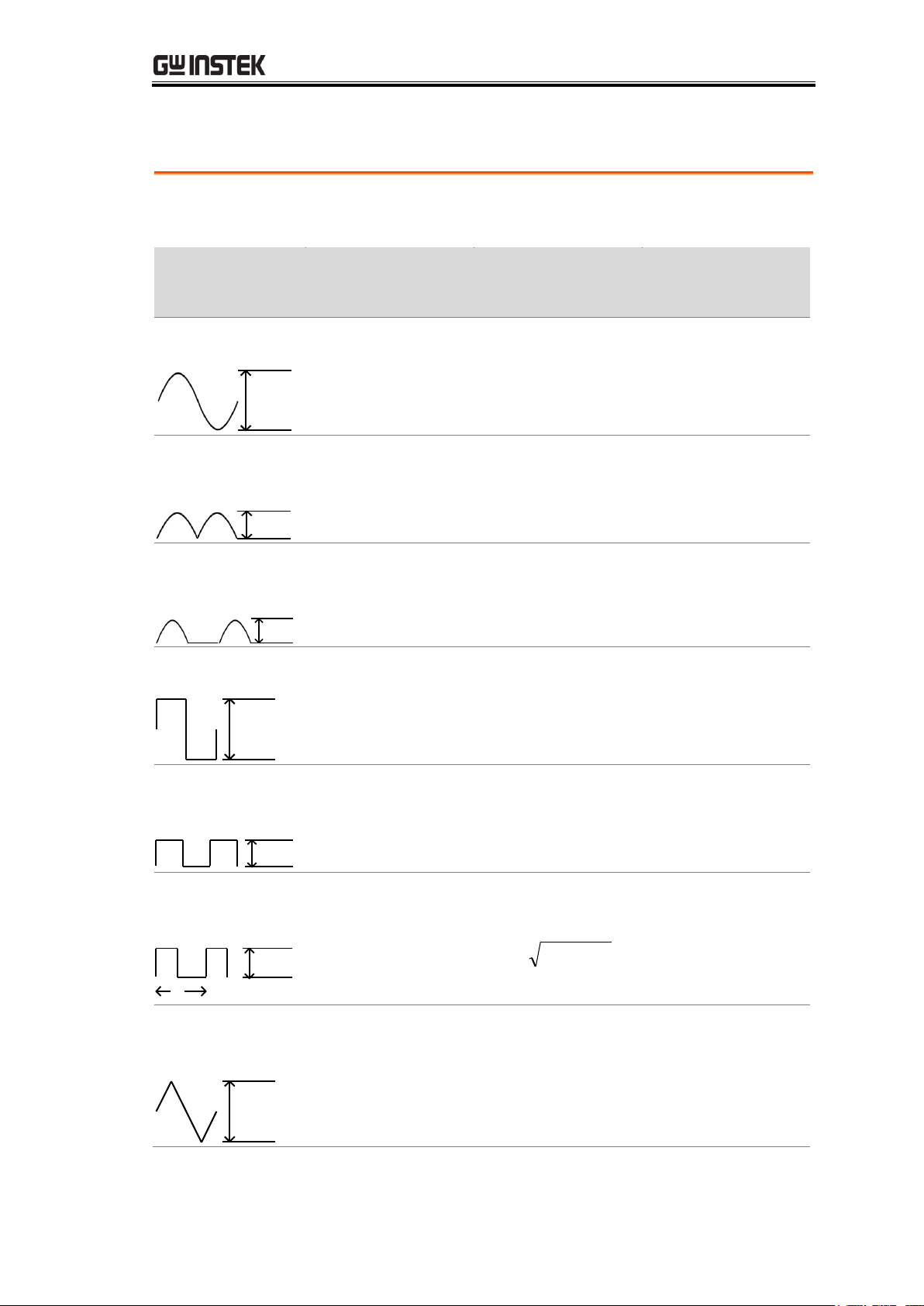

Background

This table shows the relationship between AC and DC

reading in various waveforms.

Waveform

Peak to Peak

AC

(True RMS)

DC

Sine

PK-PK

2.828

1.000

0.000

Rectified Sine

(full wave)

PK-PK

1.414

0.435

0.900

Rectified Sine

(half wave)

PK-PK

2.000

0.771

0.636

Square

PK-PK

2.000

1.000

0.000

Rectified

Square

PK-PK

1.414

0.707

0.707

Rectangular

Pulse

PK-PK

X

Y

2.000

2K

K=

)2

( DD

D=X/Y

2D

D=X/Y

Triangle

Sawtooth

PK-PK

3.464

1.000

0.000

Voltage Conversion Table

35

GDM-906X Series User Manual

Background

Crest factor is the ratio of the peak signal amplitude to the

RMS value of the signal. It determines the accuracy of AC

measurement. If the crest factor is less than 3.0, voltage

measurement will not result in error due to dynamic range

limitations at full scale. If the crest factor is more than 3.0,

it usually indicates an abnormal waveform as seen from the

below table.

Waveform

Shape

Crest factor

Square wave

1.0

Sine wave

1.414

Triangle

sawtooth

1.732

Mixed

frequencies

1.414 ~ 2.0

SCR output

100% ~ 10%

1.414 ~ 3.0

White noise

3.0 ~ 4.0

AC Coupled

pulse train

>3.0

Spike

>9.0

Crest Factor Table

36

BASIC MEASUREMENT

Background

The GDM-9061, with front/rear input terminals, has two

input terminals for current measurement: the 3A terminal

for current less than 3A and a 10A terminal for

measurements up to 10A, which can measure between 3

~ 10A for both AC and DC current. On the other hand,

for the GDM-9060, which has no rear input terminals,

nor 10A terminal, it offers merely a 3A terminal for

current measurement less than 3A.

Current type

GDM-9060

AC/DC 3A

GDM-9061

AC/DC 3A/10A

Activate ACI/ DCI

Measure

Press the Shift → ACV or Shift →

DCV key to measure AC or DC

current, respectively.

+

or

ACI/DCI mode

display appears

The measurement will switch to ACI, DCI mode

immediately. See the figure below for example.

AC or DC Current

Indicates DC or AC Current mode

5/s

Indicates the active refresh rate

Indicates Automatic range selection

Range: 100mA

Indicates the available range of Current

000.03 mAAC

Indicates the exact measured value

AC/DC Current Measurement

37

GDM-906X Series User Manual

Connect the test

lead and measure

Connect the test lead between the

3A terminal and the Input LO

terminal or DC/AC 10A terminal

and the Input LO terminal,

depending on the input current.

The display updates the reading.

For current ≤ 3A use the 3.15A

terminal.

For current up to 12A use the 10A

terminal.

38

BASIC MEASUREMENT

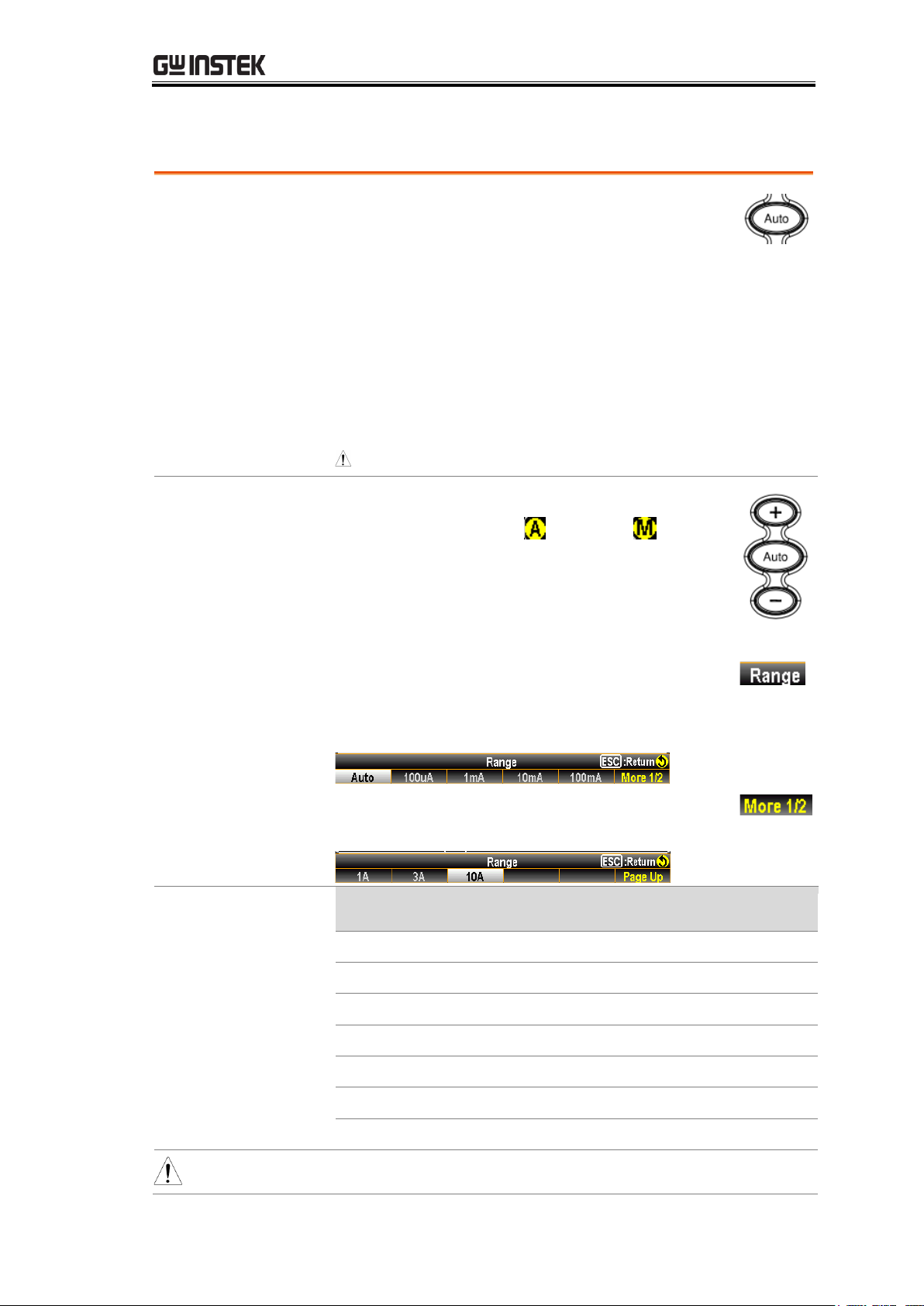

Auto range

To turn the automatic range selection On/Off,

press the AUTO key. The most appropriate

range for the currently used input jack will be

automatically selected. The GDM-9060/9061 is

able to do this by remembering the last manually

selected range and using that information to

determine the smallest current range that the

auto-range function will switch to. When the

current input is switched to another terminal, the

range must be manually set.

Auto Range not allowed on 10A

Manual range

Press the “+” or the “-” key to select the range.

The AUTO indicator turns to

indicating Manual range selection.

If the appropriate range is unknown, select the

highest range.

You can also press F1 (Range) key to select a

range for the measurement.

Press the F1 ~ F5 key to select a desired range

for the measurement.

Press the F6 (More 1/2) key for next page with

more options as the figure shown below.

Selectable Current

Ranges

Range

Resolution

Full scale

INJACK

100µA

0.1nA

119.9999 µA

3A

1mA

1nA

1.199999 mA

3A

10mA

10nA

11.99999 mA

3A

100mA

100nA

119.9999mA

3A

1A

1μA

1.199999 A

3A

3A

1μA

3.150000 A

3A

10A

10μA

10.50000 A

10A

Note

For further details, see the specifications on page 353.

Select Current Range

39

GDM-906X Series User Manual

General Current Setting

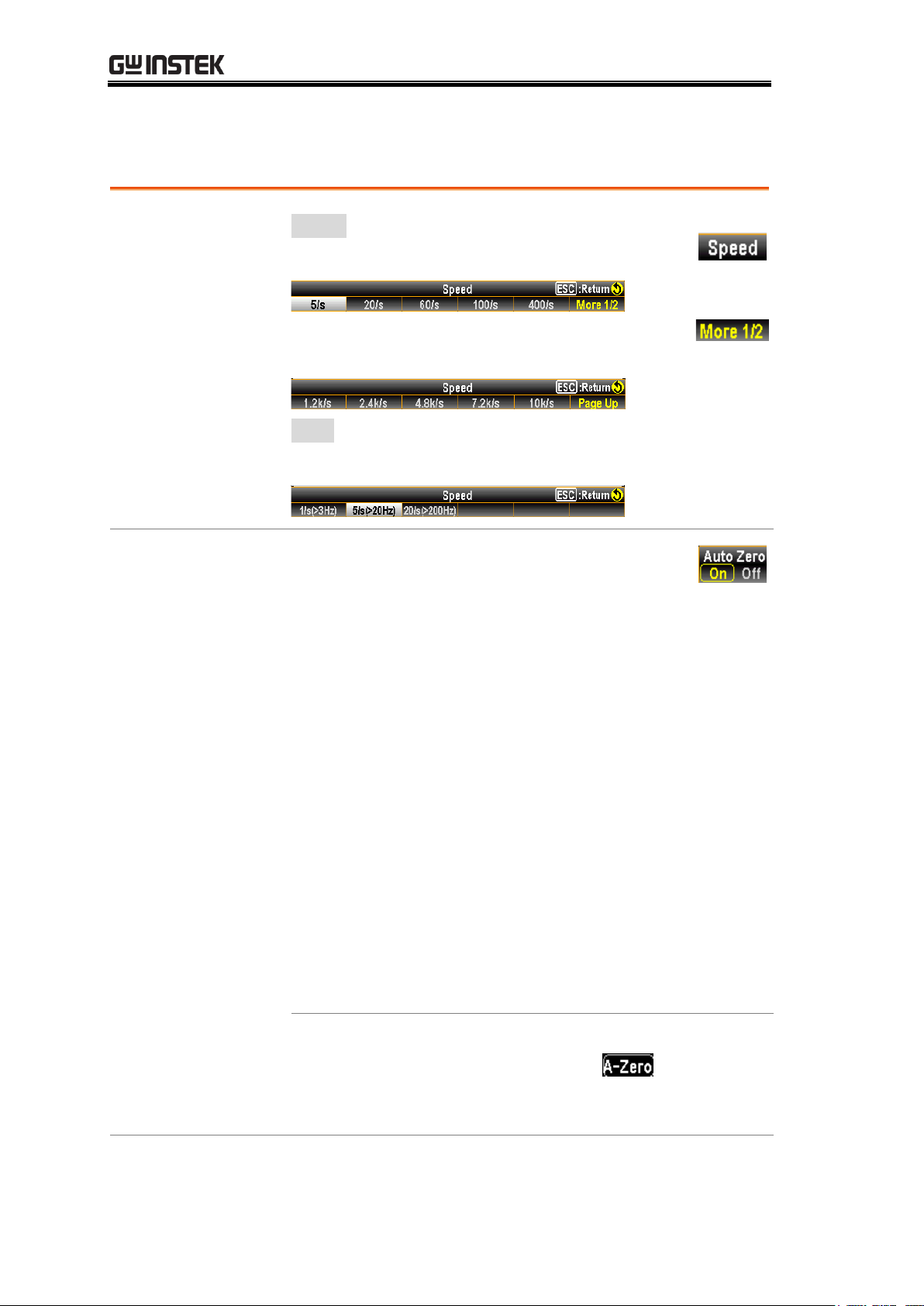

F2 (Speed) key to

select the rate

DCI:

Press the F1 ~ F5 key to select the desired rate

Press the F6 (More 1/2) key for next page with

more options as the figure shown below.

ACI:

Press the F1 ~ F3 key to select the desired rate

F3 (Auto Zero) key

to enable Auto Zero

(DCI mode only)

Background

Autozero provides the most

accurate measurements, but

requires additional time to

perform the zero measurement.

With autozero enabled (On), the

GDM-9060/9061 internally

measures the offset following

each measurement. It then

subtracts that measurement from

the preceding reading. This

prevents offset voltages present

on the GDM-9060/9061’s input

circuitry from affecting

measurement accuracy. With

autozero disabled (Off), the

GDM-9060/9061 measures the

offset once and subtracts the

offset from all subsequent

measurements.

Display

When turning On the Auto Zero, the

display shows an icon indicating

the Auto Zero mode is currently being

activated.

40

BASIC MEASUREMENT

Measurement

type

2-wire OHM

Uses the standard Input HI-LO terminals.

Recommended for measuring resistances

larger than 1kΩ.

4-wire OHM

Compensates the test lead effect using the

4W compensation terminals

(SENSE HI/LO terminals), in addition to

the standard Input HI-LO terminals.

Recommended for measuring sensitive

resistances smaller than 1kΩ.

Activate 2W or

4W Measurement

Press the Ω2W key to activate 2W

resistance measurement.

Press the Shift Ω2W key to

activate 4W resistance measurement.

+

2W/4W resistance

mode display

appears

The mode will switch to the selected resistance mode

immediately. Press the Shift Ω2W key on the front

panel as figure shown below.

2 or 4-Wire OHM

Indicates 2W or 4W Resistance mode

5/s

Indicates the active refresh rate

Indicates Automatic range selection

Range: 100 Ω

Indicates the available range of Resistance

000.0651 Ω

Indicates the exact measured value

2W/4W Resistance Measurement

41

GDM-906X Series User Manual

Connect the test

lead and measure

For 2W measurement, connect the test leads between the

Input HI terminal and the LO terminal.

For 4W measurement, connect the test leads between the

Input HI terminal and the LO terminal, as the way to 2W

measurement. Also, connect another sense leads between

the SENSE LO and HI terminals.

Auto range

To turn the automatic range selection On/Off,

press the Auto key.

Manual range

Press the “+” or the “-” key to select the range.

The Auto indicator turns to indicating

Manual range selection. If the appropriate range

is unknown, select the highest range.

You can also press the F1 (Range) key to select a

range for the measurement.

Press the F1 ~ F5 key to select a desired range

for the measurement.

Press the F6 (More 1/2) key for next page with

more options as the figure shown below.

Selectable

Resistance Ranges

Range

Resolution

Full scale

100Ω

0.1mΩ

119.9999Ω

1kΩ

1mΩ

1.199999kΩ

10kΩ

10mΩ

11.99999kΩ

Select Resistance Range

42

BASIC MEASUREMENT

100kΩ

100mΩ

119.9999kΩ

1MΩ

1Ω

1.199999MΩ

10MΩ

10Ω

11.99999MΩ

100MΩ

100Ω

119.9999MΩ

Note

For more details, see the specifications on page 353.

General Resistance Setting

F2 (Speed) key to

select the rate

Press the F1 ~ F5 key to select the desired rate

Press the F6 (More 1/2) key for next page with

more options as the figure shown below.

F3 (AutoZero) key

to enable Auto Zero

Background

Autozero provides the most

accurate measurements, but

requires additional time to

perform the zero measurement.

With autozero enabled (On), the

GDM-9060/9061 internally

measures the offset following

each measurement. It then

subtracts that measurement from

the preceding reading. This

prevents offset voltages present

on the GDM-9060/9061’s input

circuitry from affecting

measurement accuracy. With

autozero disabled (Off), the

GDM-9060/9061 measures the

offset once and subtracts the

offset from all subsequent

measurements.

Display

When turning On the Auto Zero, the

display shows an icon indicating

the Auto Zero mode is currently being

activated.

43

GDM-906X Series User Manual

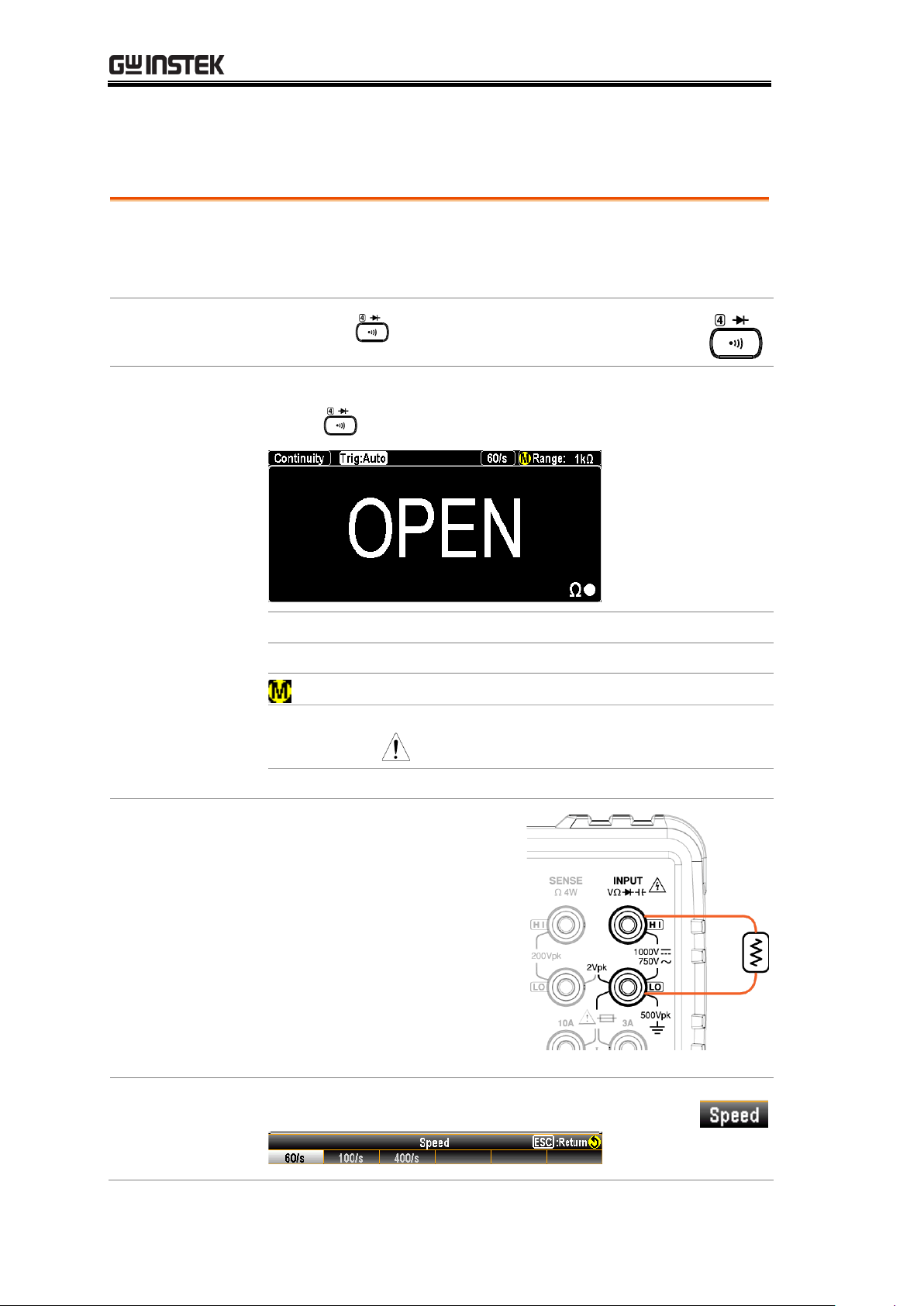

Background

The continuity test checks that the resistance in the DUT is

low enough to be considered continuous (of a conductive

nature).

Activate

continuity test

Press the key to activate continuity testing.

Continuity mode

display appears

The mode will switch to continuity testing immediately.

Press on the front panel as figure shown below.

Continuity

Indicates Continuity measurement

60/s

Indicates the active refresh rate

Indicates Manual range selection

1kΩ

Indicates the available range of Continuity

Note: the range selection is fixed in 1kΩ

OPEN Ω

Indicates the currently measured result

Connect the test

lead and measure

Connect the test lead between

the Input HI terminal and the

LO terminal. The display

updates the reading.

F2 (Speed) key to

select the rate.

Press the F1 ~ F3 key to select the desired rate

Continuity Test

44

BASIC MEASUREMENT

F3 (Auto Zero)

key to enable Auto

Zero

Background

Autozero provides the most

accurate measurements, but

requires additional time to

perform the zero measurement.

With autozero enabled (On), the

GDM-9060/9061 internally

measures the offset following each

measurement. It then subtracts

that measurement from the

preceding reading. This prevents

offset voltages present on the

GDM-9060/9061’s input circuitry

from affecting measurement

accuracy. With autozero disabled

(Off), the GDM-9060/9061

measures the offset once and

subtracts the offset from all

subsequent measurements.

Display

When turning On the Auto Zero, the display

shows an icon indicating the Auto

Zero mode is currently being activated.

F4 (BeepVol) key

to select the Vol

Press the F2 ~ F4 key to select the volume level

or press the F1 key to set Beep volume off

Background

The continuity threshold defines the maximum resistance

allowed in the DUT when testing the continuity.

Threshold Range

Threshold

1 to 1000Ω (Default Threshold:10Ω)

Resolution

1Ω

Set Continuity Threshold

45

GDM-906X Series User Manual

Procedure

Press the F5 key to enter the Threshold of

Continuity menu as the figure below shown.

Set the continuity threshold level.

1. Use the Left/Right arrow keys to move cursor

and scroll the Knob key or press Number

keys to enter the desired value.

2. Press the F6 (Enter) key or the Knob key until

click to confirm the threshold settings.

Display

46

BASIC MEASUREMENT

Background

The diode test checks the forward bias characteristics of a

diode by running a constant forward bias current of

approximately 1mA through the DUT.

Activate diode

test

Press the Shift+ key to activate

diode measurement.

+

Diode mode

display appears

The screen will switch to Diode mode immediately as the

figure shown below.

Diode

Indicates the Diode measurement

60/s

Indicates the active refresh rate

Indicates Manual range selection

5V Indicates the available range of Diode

Note: the range selection is fixed in 5V

0.449395 VDC

Indicates the exact measured value

Connect the test

lead and measure

Connect the test lead between

the Input HI terminal and the

LO terminal; Anode-V,

Cathode-COM. The display

updates the reading.

F2 (Speed) key to

select the rate.

Press the F1 ~ F3 key to select the desired rate

Diode Measurement

47

GDM-906X Series User Manual

F3 (Auto Zero)

key to enable Auto

Zero

Background

Autozero provides the most

accurate measurements, but

requires additional time to

perform the zero measurement.

With autozero enabled (On), the

GDM-9060/9061 internally

measures the offset following each

measurement. It then subtracts

that measurement from the

preceding reading. This prevents

offset voltages present on the

GDM-9060/9061’s input circuitry

from affecting measurement

accuracy. With autozero disabled

(Off), the GDM-9060/9061

measures the offset once and

subtracts the offset from all

subsequent measurements.

Display

When turning On the Auto Zero, the display

shows an icon indicating the Auto

Zero mode is currently being activated.

Description

The GDM-9060/9061 can be used to measure the frequency or

period of an input signal.

Range

Frequency

3Hz ~1MHz

Period

1.0μs ~333ms

Activate

frequency or

period test

To measure Frequency, press the FREQ key

followed by clicking the F3 (Measure) key to enter

the Measure menu. Click the F1 (Frequency) key

and the measured frequency will be displayed on

the primary screen with the period value displayed

on the sub section beneath.

Frequency/Period Measurement

48

BASIC MEASUREMENT

To measure Period, press the FREQ key followed

by clicking the F3 (Measure) key to enter the

Measure menu. Click the F2 (Period) key and the

measured period will be displayed on the primary

screen with the frequency value displayed on the

sub section beneath.

Display

Frequency Mode

Indicator Frequency Mode

Period Value in Sub Section

Frequency

Value

Period Mode

Indicator Period Mode

Frequency Value in Sub Section

Period

Value

Frequency

mode display

appears

The mode will switch to the Frequency or Period mode

immediately. Press on the front panel followed by

clicking F3 key to choose Frequency as shown below.

Frequency

Indicates Frequency measurement

100ms

Indicates the active refresh rate

Indicates Manual range selection

49

GDM-906X Series User Manual

100 mV

Indicates the available range of Voltage

59.96609 Hz

Indicates the exactly measured Frequency value

16.67609ms

Indicates the exactly measured Period value

Connection

Depending on different inputs, connect test lead to varied terminals.

In terms of voltage, connect test leads between the Input HI

terminal and the LO terminal. The display updates the reading.

In terms of current, connect test leads between the 3A terminal

and the LO terminal or DC/AC 10A terminal (GDM-9061 only)

and the LO terminal. The display updates the reading.

50

BASIC MEASUREMENT

Background

The input voltage/current range for frequency/period

measurements can be set to Auto range or to manual. By

default, the voltage/current range is set to Auto for both

the period and frequency.

Auto range

Press the Auto/Enter key. Auto will be

displayed on the upper right corner.

F2 (Gate Time) key

to select gate time

Background

It is the threshold to recalculate

frequency/period. Slower the gate time,

e.g., 1s, more accurate the reading value.

Press the F2 key to enter gate time menu. Click

the F1 – F3 key for the desired gate time. See

the figure below with available options.

F4 (InJack) key to

select voltage or

current

Background

In accordance with the target inputs,

choose the corresponding selection per

condition. E.g., select “3A” when the

input current is below 3A amplitude.

Press the F4 (InJack) key to determine whether

the voltage or current 3A or current 10A

(GDM-9061 only) to be measured. Press the F1 –

F3 key to select desired option. See the figure

shown below with options available.

F5 (Time Out) key

to select timeout

Background

It defines the exact value for timeout,

which means measurement will be

suspended after reaching the set timeout

value when none of input is detected.

Frequency/Period In-Depth Setting

51

GDM-906X Series User Manual

Press the F5 key to enter timeout menu. Click

the F1 – F2 key for the desired timeout setting.

See the figure below with available options.

Note: When selecting “Auto”, the timeout

setting will fully sync with the gate time value.

F1 (AC Range) key

to manually select

range setting

Press the “+” or the “-” key to promptly

select the range. The Auto indicator

turns to indicating Manual range

selection. If the appropriate range is

unknown, select the highest range.

You can also press the F1 (AC Range) key to

select a range for the measurement.

Depending on the InJack setting, the

available options vary. See examples below.

When InJack is Voltage:

Press the F1 ~ F6 key to select a desired

range for the measurement.

When InJack is 3A:

Press the F1 ~ F5 key to select a desired

range for the measurement.

Press the F6 (More 1/2) key for next page

with more options as figure shown below.

When InJack is 10A (GDM-9061 only):

Press the F1 ~ F2 key to select a desired

parameter for the measurement.

52

BASIC MEASUREMENT

Background

The capacitance measurement function checks the

capacitance of a component.

Activate

capacitance test

Press the Shift → to activate

capacitance measurement.

+

Capacitance

mode display

appears

The screen will switch to capacitance mode immediately.

Press + on the front panel as shown below.

Capacitance

Indicates the Capacitance measurement

2/s

Indicates the active refresh rate

Note: refresh rate of Capacitance is fixed in 2/s.

Indicates Automatic range selection

Range: 100nF

Indicates the available range of Capacitance

105.0 nF

Indicates the exact measured value

Connect the test

lead and measure

Connect the test lead between

the Input HI terminal and the

LO terminal; Positive-HI,

Negative-LO. The display

updates the reading.

Capacitance Measurement

53

GDM-906X Series User Manual

Background

Cable open function will be activated when capacitance

range is between 1nF and 10nF. It is required to proceed

to Cable Open function when capacitance is between 1nF

and 10nF in which test leads connected will result in

measuring capacity in small scale.

Display

Range 1nF

or 10nF

Cable

Open (F3)

Activate cable open

function

Connect test leads followed by pressing the F3

(Cable Open) key to proceed to Cable Open

function. The measured value will be rectified and

returned to zero as the figure shown below.

Connect the test

lead and measure

Follow the connection method of capacitance

measurement to measure and obtain

precise-prone value.

Note

Except for 1nF/10nF, all are Not applicable to Cable

Open function.

Cable Open Function

54

BASIC MEASUREMENT

Auto range

To turn the automatic range selection On/Off,

press the Auto key.

Manual range

Press the “+” or the “-” key to select the range.

The Auto indicator turns to indicating

Manual range selection. If the appropriate range

is unknown, select the highest range.

You can also press the F1 (Range) key to select a

range for the measurement.

Press the F1 ~ F5 key to select a desired range

for the measurement.

Press the F6 (More 1/2) key for next page with

more options as the figure shown below.

Selectable

Capacitance Ranges

Range

Resolution

Full scale

1nF

1pF

1.199nF

10nF

10pF

11.99nF

100nF

100pF

119.9nF

1μF

1nF

1.199μF

10μF

10nF

11.99μF

100μF

100nF

119.9μF

Note

For further details, please see the specifications on page

363.

Note

The refresh rate settings and the EXT trigger cannot be

used in the capacitance mode.

Select Capacitance Range

55

GDM-906X Series User Manual

Background

The GDM-9060/9061 can measure temperature utilizing

several devices including Thermocouple, RTD

(Resistance Temperature Detector) as well as Thermistor.

To measure temperature, the GDM-9060/9061 accepts a

device input and calculates the temperature from the

voltage fluctuation.

Temperature

Range

Thermocouple

-200°C ~ +1820°C (vary by sensor types)

RTD

-200°C ~ +630°C

Thermistor

-80°C ~ +150°C

Activate

temperature

measurement

Press the TEMP key to activate

temperature measurement.

Temperature mode

display appears

Temperature

Indicates Temperature measurement

+ 0214.552 °C

Indicates the exact measured value

T Couple

Indicates the active Probe

Type R

Indicates the active Type

Connect the test

lead and measure

Connect the sensor lead

between the Input HI

terminal and the LO

terminal. The display

updates the reading.

Temperature Measurement

56

BASIC MEASUREMENT

F2 (Speed) key

to select the rate

Press the F1 ~ F3 key to select the desired rate

F3 (Auto Zero)

key to enable

Auto Zero

Background

Autozero provides the most

accurate measurements, but requires

additional time to perform the zero

measurement. With autozero

enabled (On), the GDM-9060/9061

internally measures the offset

following each measurement. It then

subtracts that measurement from

the preceding reading. This prevents

offset voltages present on the

GDM-9060/9061’s input circuitry

from affecting measurement

accuracy. With autozero disabled

(Off), the GDM-9060/9061

measures the offset once and

subtracts the offset from all

subsequent measurements.

Display

When turning On the Auto Zero, the display

shows an icon indicating the Auto

Zero mode is currently being activated.

F4 (Unit) key to

select unit of

temperature

Press the F4 (Unit) key to enter the Temperature

Unit menu followed by clicking the F1 – F3 key to

choose desired temperature unit. See the figure

shown below.

General Temperature Setting

57

GDM-906X Series User Manual

Background

The GDM-9060/9061 accepts thermocouple inputs and

calculates the temperature from the voltage difference of

two dissimilar metals. Thermocouple sensor type is one

of the main factors to be considered.

Parameter

Thermocouple

Sensor Type

Measurement

Range

Resolution

J

-210 to +1200˚C

0.002 °C

K

-200 to +1372˚C

0.002 °C

N

-200 to +1300˚C

0.003 °C

R

-50 to +1768˚C

0.01 °C

S

-50 to +1768˚C

0.01 °C

T

-200 to +400°C

0.002 °C

B

+250 to +1820˚C

0.01 °C

E

-200 to +1000°C

0.002 °C

Background

(Thermocouple

only)

When a thermocouple is connected to the

GDM-9060/9061, the temperature difference between

the thermocouple lead and the GDM-9060/9061 input

terminal should be taken into account and be cancelled

out; otherwise an erroneous temperature might be added.

The value of the reference junction temperature should

be determined by the user.

Type

Range

Resolution

SIM

(simulated)

-20°C ~ +80°C

0.01°C

The terminal temperature is manually defined by user.

Default value: Auto

Thermocouple Sensor Type

Reference Junction Temperature (SIM Temperature)

58

Procedure

1. Press the F1 (Probe) key to enter the Temperature

Probe menu followed by clicking the F1 (TCouple) key

to activate Thermocouple mode. See the figure

shown below.

2. Press the F5 (Type) key to enter the Sensor Type

menu as the figure shown below. Click the F1 – F5 key to

select a desired sensor type per situations.

3. Press the F6 (More 1/2) key to enter the next

page with more sensor types available for selection.

4. Further press the F6 (Simulated) key after

returning to the previous menu page. You can select either

the default fixed “23.00” or the “Auto” option for the so-called

“Reference Junction Temperature” as following.

When selecting “23.00” by F1 (23.00) key , the display

shows an icon indicating the simulated baseline is 23°C.

If choosing “Auto” by F2 (Auto) key , the subset menu

appears with additional option. Press the F3 (ADJ:+00.00) key

followed by inputting a desired parameter as the following

figure (+10 for example).

5. Press the F6 (Enter) key or the Knob key to

confirm the setting. The icon appears on display

indicating the simulated 34.5 °C, which derives from the input

terminal temperature plus the defined +10 degrees. That is, the

input terminal temperature is 34.5 – 10 = 24.5 °C.

BASIC MEASUREMENT

Thermocouple Setting

59

GDM-906X Series User Manual

Background

The GDM-9060/9061 supports 2 or 4 wire RTD. It is

important to specify the type of temperature sensor used.

Parameter

RTD type

Range

Resolution

All (based on PT100)

-200~630°C

0.001°C

Procedure

1. Press the F1 (Probe) key to enter the Temperature

Probe menu followed by clicking either the F2 (RTD 2W)

or F3 (RTD 4W) key to activate RTD

2W/4W mode. See the figure shown below.

2. Press the F5 (Type) key to enter the Sensor Type menu

as the figure shown below. Click the F1 – F5 key to select a

desired sensor type per your requirement.

3. The display shows the latest setting. See the example of the

figure below where RTD 2W: PT100 is currently activated by

user.

Probe: RTD 2W

Type: PT100

Temperature

Measurement

R0 Value

RTD 2W/4W Setting

60

BASIC MEASUREMENT

Background

The User Type allows any customized RTD sensor coefficients

to be used. The User Type is available for user to configure the

alpha, beta, delta and R0 coefficients individually, as defined by

the Callendar–Van Dusen equation.

Type

Coefficient

Alpha (α)

Beta (β)

Delta (δ)

PT100

0.00385

0.10863

1.49990

D100

0.00392

0.10630

1.49710

F100

0.00390

0.11000

1.49589

PT385

0.00385

0.11100

1.50700

PT3916

0.00392

0.11600

1.50594

Equation

-200°C to 0°C

range

-0°C to 630°C

range

Operate

Procedure

1. Press the F5 (Type) key to enter the Sensor Type

menu followed by pressing the F6 (User) key to

activate User Type.

Set User Type of RTD 2W/4W

61

GDM-906X Series User Manual

2. Press the F6 (User Type) key to enter the User

Type Setup menu where α, β, δ and R0 coefficients can be

set up respectively.

3. Click the F1 (α:0.003850) key to enter the RTD Alpha

Setup page as the figure shown below. Use the Left/Right arrow

keys to move cursor and scroll the Knob key or press

Number keys to enter the desired value.

α default: 0.00385

α range: 0 ~ 9.999999

4. Press the F6 (Enter) key or the Knob key to confirm

the input α value and repeat the previous steps 2 - 4 to set

up the β (Beta), δ (Delta) and R0 coefficients individually.

β default: 00.10863, δ default: 1.49990, R0 default: 100

β, δ range: 0 ~ 9.999999, R0 range: 80 ~ 120

RTD Beta Setup

RTD Delta Setup

RTD R0 Setup

5. After returning to the User Type Setup page, if necessary,

press the F6 (PT100 DEF) key to restore to the

default coefficients’ setting based on the PT100 sensor type.

62

BASIC MEASUREMENT

Background

The GDM-9060/9061 supports 2 or 4 wire Thermistor. It is

important to specify the type of temperature sensor used.

Parameter

Type

Range

Resolution

All

-80~150°C

0.001°C

Procedure

1. Press the F1 (Probe) key to enter the Temperature

Probe menu followed by clicking either the F4 (Therm2W)

or F5 (Therm4W) key to activate

Therm 2W/4W mode. See the figure shown below.

2. Press the F5 (Type) key to enter the Sensor Type

menu as the figure shown below. Click the F1 – F3 key to

select a desired sensor type per your requirement.

3. The display shows the latest setting. See the example of the

figure below where Thermistor 2W: 10kΩ is currently

activated by user.

Probe: Therm2W

Type: 10kΩ

Temperature

Measurement

Thermistor 2W/4W Setting

63

GDM-906X Series User Manual

Background

The User Type allows any customized Thermistor sensor

coefficients to be used. The User Type is available for user to

configure the A, B and C coefficients individually as defined by

the Steinhart–Hart equation.

Type

Coefficient

A B C

2.2k

0.0014733

0.0002372

1.07E-07

5k

0.0012880

0.0002356

9.56E-08

10k

0.0010295

0.0002391

1.57E-07

Equation

Operate

Procedure

1. Press the F5 (Type) key to enter the Sensor Type

menu followed by pressing the F4 (User) key to

activate User Type.

2. Press the F6 (User Type) key to enter the User

Type Setup menu where A, B, and C coefficients can be set up

respectively.

Click the F1 (A:1.2880E-03) key to enter the

THERM A Setup page as the figure shown below. Use the

Left/Right arrow keys to move cursor and scroll the Knob

key or press Number keys to enter the desired value.

A range: 0 ~ 9.9999 (default: 1.2880E-03)

Set User Type of Thermistor 2W/4W

64

BASIC MEASUREMENT

3. Press the F6 (Enter) key or the Knob key to

confirm the input α value and repeat the previous steps 2 - 4

to set up the B and C coefficients individually.

B range: 0 ~ 9.9999 (default :2.35600E-04)

C range: 0 ~ 9.9999 (default :9.55700E-08)

THERM B Setup

THERM C Setup

4. After returning to the User Type Setup page, if necessary,

press the F6 (5 kΩ DEF) key to restore to the

default coefficients’ setting based on the 5 kΩ sensor type.

65

GDM-906X Series User Manual

DUAL MEASUREMENT

Dual Measurement ............................................................. 67

Refresh Rate .............................................................................. 70

Connect the Test Leads ............................................................. 71

The error influence on V+I Dual Measurement ......................... 74

The error of current shunt ......................................................... 75

66

DUAL MEASUREMENT

Background

The dual measurement mode allows you to use the 2nd

display to show another item, thus viewing two different

measurement results at once.

When the multimeter is used in dual measurement mode,

both displays are updated from either a single

measurement or from two separate measurements. If the

primary and secondary measurement modes have the

same range, rate and rely on the same fundamental

measurement, then a single measurement is taken for

both displays; such as ACV and frequency/period

measurements. If the primary and secondary displays use

different measurement functions, ranges or rates, then

separate measurements will be taken for each display. For

example, ACV and DCV measurements.

Most of the basic measurement functions, except for

resistance/continuity/diode/capacitance can be used in

the dual measurement mode.

The following table shows the available measurement

combinations.

Primary Display

Secondary Display

ACV

DCV

ACI

DCI

FREQ

Temp

ACV

X ● ● ● ●

X

DCV

● X ● ● X

●

ACI

● ● X ● ●

X

DCI

● ● ● X X

●

FREQ

● X ● X X

X

Note

When two different measurements are taken, there is a

switching delay between the first measurement and the

second measurement.

Dual Measurement

67

GDM-906X Series User Manual

1st Measurement

item setting

Choose one of the basic

measurement functions from the

table above to set the measurement

mode for the primary display.