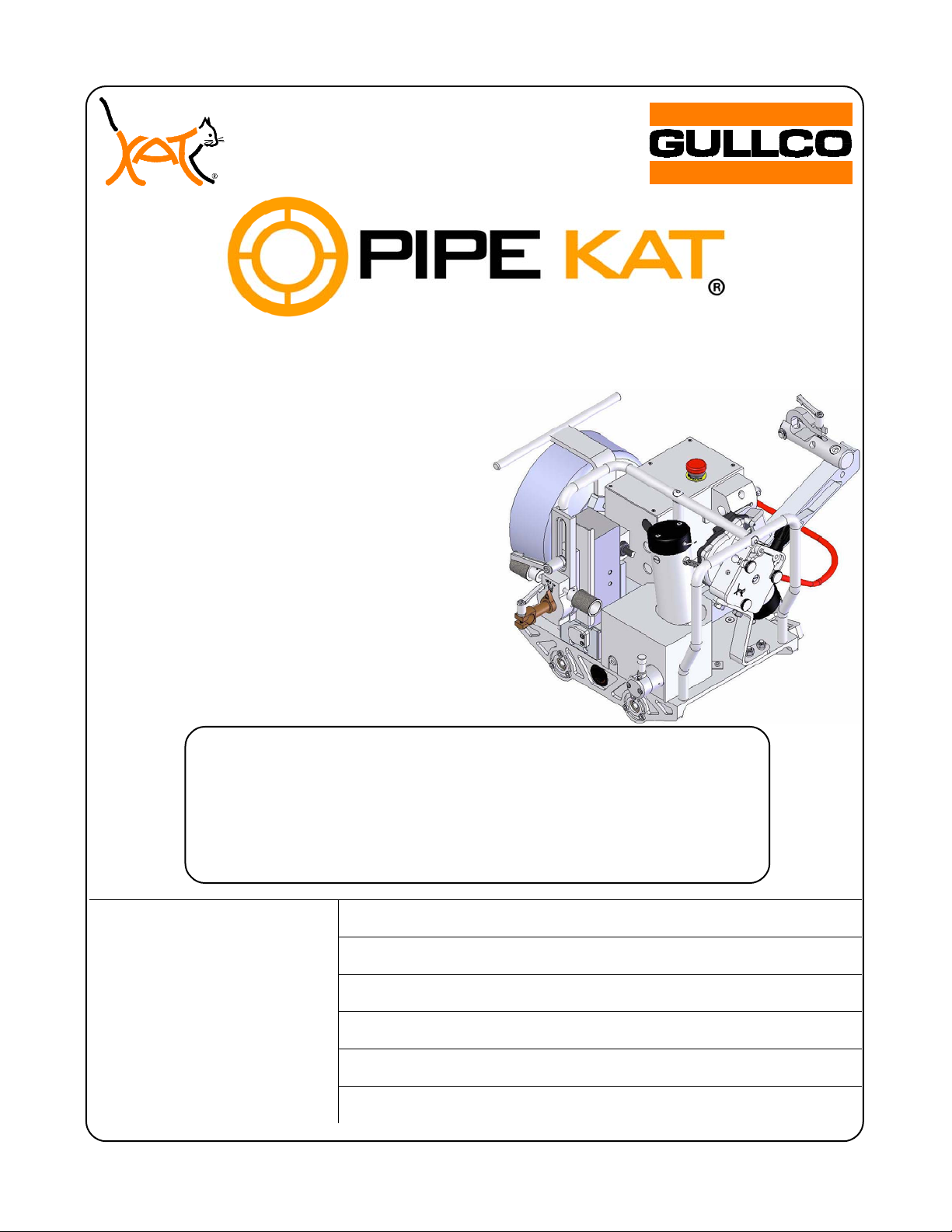

Gullco PK-500-LG-x User Manual

WELDING SYSTEM

LINEAR

OSCILLATOR

MODELS:

PK-500-LG-*

PK-500-LH-*

PK-500-LW-*

(*INDICATES VOLTAGE REFERENCE)

OPERATING

INSTRUCTIONS

Distributed by:

Phone: 905-953-4140 Fax: 905-953-4138 e-mail: sales@gullco.com

Phone: 440-439-8333 Fax: 440-439-3634 e-mail: ussales@gullco.com

Phone: +44 1257-253579 Fax: +44 1257-254629 e-mail:uksales@gullco.com

Phone: 61 (0) 7 3348-5515 Fax: 61 (0) 7 3348-5510 e-mail: ausales@gullco.com

Phone: 91-20-65260382 Fax: 91-20-26836656 e-mail: India.lo@gullco.com

GULLCO INTERNATIONAL LIMITED – CANADA

GULLCO INTERNATIONAL INC. – U.S.A.

GULLCO INTERNATIONAL [U.K.] LIMITED - EUROPE

GULLCO INTERNATIONAL PTY LIMITED - AUSTRALIA

GULLCO INTERNATIONAL INDIA PRIVATE LIMITED

GULLCO INTERNATIONAL SHANGHAI – LIMITED

Phone: +8621-50460341 Fax: +8621-50463554 e-mail: c.zhang@gullco.com

Website: www.gullco.com

Revised: June 3, 2013 GD-070

i

TABLE OF CONTENTS

SAFETY INSTRUCTIONS ............................................................................................................................ 2

SAFETY PRECAUTIONS ............................................................................................................................. 3

PIPE KAT

SYSTEM COMPONENTS ......................................................................................................... 4

®

GENERAL DESCRIPTION ........................................................................................................................... 5

PIPE BAND ................................................................................................................................................... 6

PIPE BAND SIZING .................................................................................................................................. 6

MOUNTING PIPE BAND (TRACK) ON THE PIPE ................................................................................... 7

MOUNTING THE CARRIAGE ON THE PIPE BAND (TRACK) ............................................................... 8

CARRIAGE UMBILICAL .............................................................................................................................. 9

REMOTE PENDANT .................................................................................................................................. 11

PIPE KAT

CARRIAGE .............................................................................................................................. 13

®

MAIN CONTROL BOX OPERATION ......................................................................................................... 16

FRONT PANEL ....................................................................................................................................... 16

LEFT SIDE PANEL ............................................................................................................... .................. 17

RIGHT SIDE PANEL ............................................................................................................................... 18

CARRIAGE OSCILLATOR CONTROL ...................................................................................................... 19

OSCILLATOR CONTROL PROGRAMMING .......................................................................................... 20

GENERAL PROGRAMMING MODE ...................................................................................................... 22

ADVANCED PROGRAMMING MODE ................................................................................................... 25

PIPE KAT

OSCILLATOR CONTROL ERROR CODES ........................................................................ 27

®

OSCILLATOR CONTROL FACTORY DEFAULTS ................................................................................. 29

CARRIAGE CONTROL .............................................................................................................................. 30

CARRIAGE CONTROL PROGRAMMING .............................................................................................. 34

GENERAL PROGRAMMING MODE ...................................................................................................... 35

ADVANCED PROGRAMMING MODE ................................................................................................... 36

PIPE KAT

CARRIAGE CONTROL ERROR CODES ............................................................................ 39

®

CARRIAGE CONTROL FACTORY DEFAULTS ......................................................................................... 41

WELDING POWER SOURCE INTERFACE CONNECTION ..................................................................... 43

AUTOMATIC CYCLE OPERATION ........................................................................................................... 45

AUTOMATIC CYCLE SEQUENCE OF EVENTS....................................................................................... 46

GENERAL SPECIFICATIONS ................................................................................................................... 48

OPTIONAL EQUIPMENT ........................................................................................................................... 49

1

SAFETY INSTRUCTIONS

Although the PIPE KAT® is manufactured for safe and dependable operation, it is impossible to

anticipate those combinations of circumstances which could result in an accident. An operator

of the PIPE KAT

set-up and maintenance.

Read and understand the operation manual before operating or performing service of this

equipment. Become familiar with the machines operation, applications and limitations. Keep

the operation manual in a clean and readily available location.

This equipment is normally used to automate / semi-automate welding processes. These

processes usually have any combination of the following; bright and hot arcs, flying sparks,

fumes, ultraviolet and infrared radiated energy, hot work-pieces, compressed gases, etc. The

onus is on the operator of this equipment to know, understand and follow all the safety

precautions associated with the process being used.

is cautioned to always practice "Safety First" during each phase of operation,

®

A careless operator invites trouble, and failure to follow safety practices may cause serious

injury or even death. Important safety precautions are given in the following:

Electrical Shock Prevention

Do not use this equipment in damp or wet locations.

Do not expose this equipment to rain.

Never carry this equipment by the cables or pull the cables to disconnect

from the receptacle.

Keep all cables from heat, oil and sharp edges.

Inspect all cables periodically and replace if damaged.

Inspect the security of all cables periodically and repair if loose.

Disconnect the power cord when not in use.

Disconnect the power cord positively to prevent electrical shock before

repair and service of the equipment.

Bodily Injury Prevention

Do not wear loose clothing, jewelry and loose, long hair which may get

caught into automatic systems or moving parts.

Ensure that the Pipe Band/track is well secured when installed.

Keep lifting handles dry, clean and free from oil and grease.

Keep hands away from the underside of the PIPE KAT

carriage when

®

there is the slightest possibility of it moving.

Always wear protective gloves when handling the track, to prevent injury

from sharp edges.

2

SAFETY PRECAUTIONS

The following cautionary/warning label is attached to each “PIPE KAT”® main control box

The above label pictorially represents the following:

“Warning:Read the manual before turning the unit on and before performing service.

Also, positively disconnect the unit from all power supplies before

servicing!”

IMPORTANT

READ THIS BEFORE OPERATING THE PIPE KAT® CARRIAGE

WARNING! Always turn the main power off before connecting/disconnecting any cables

to/from the PIPE KAT

result in control damage.

Do not cycle the power on and off in quick succession to the PIPE KAT

have diverse affects.

Ensure that an adequate and well-maintained weld return path is provided with good electrical

contact. Failure to do so may result in the welding current passing through the carriage and

damaging the wiring and electrical components.

carriage and main control box. Failure to comply may

®

system, as this may

®

ALL THE SAFE PRACTICES AND PRECAUTIONS MAY NOT BE GIVEN IN WRITING.

SOME ARE BASED ON COMMON SENSE, BUT OTHERS MAY REQUIRE TECHNICAL

BACKGROUND TO EXPLAIN.

3

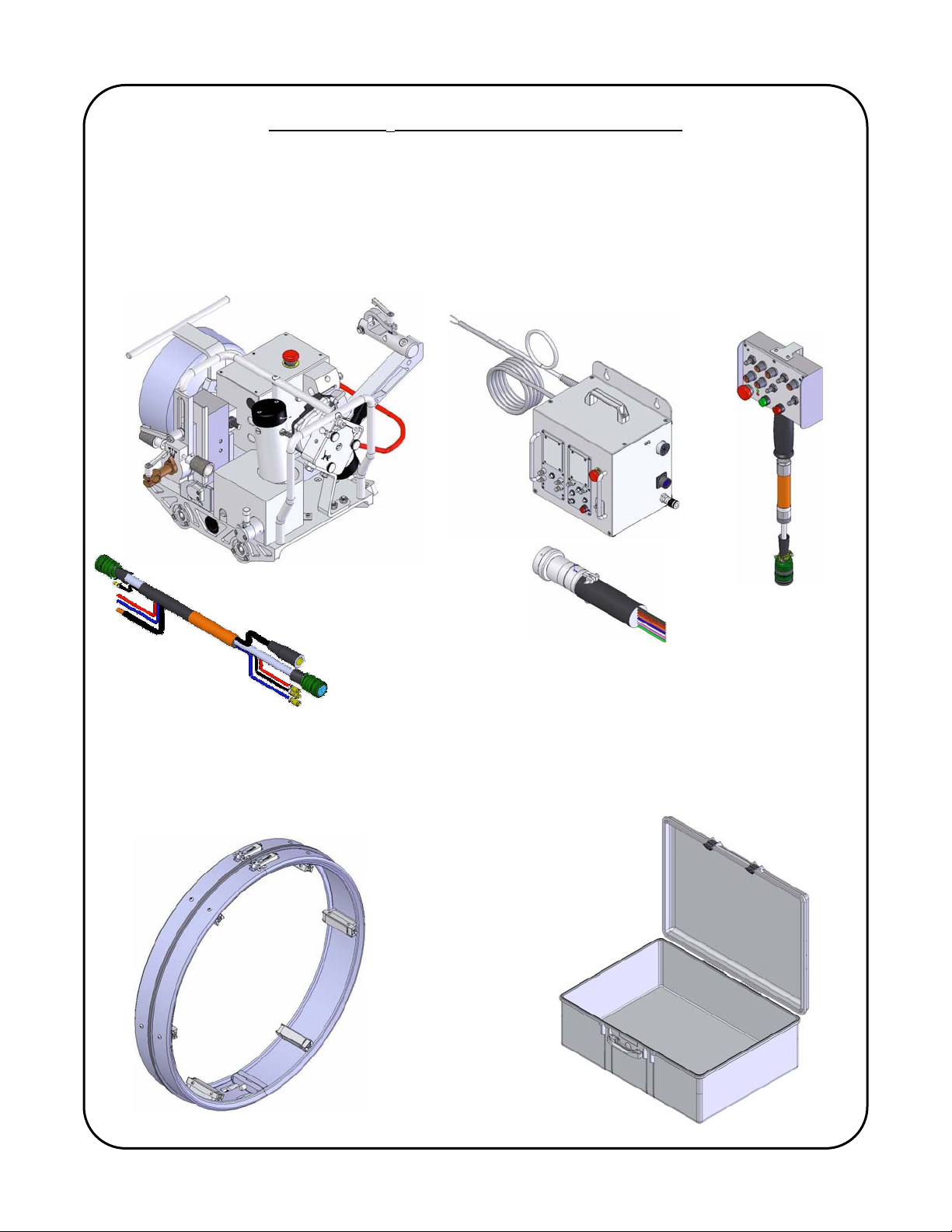

THE PIPE KAT® WELDING SYSTEM COMPONENTS

This manual covers the operation instructions of the following PIPE KAT® systems

PK-500-LG-*, PK-500-LH-*, PK-500-LW-* (* indicates input voltage: “A”=42 VAC; “B” =115

VAC; “C”= 230 VAC).

PIPE KAT

CARRIAGE PIPE KAT® MAIN CONTROL PIPE KAT®

®

WITH UMBILICAL WITH WELDING POWER SOURCE REMOTE

INTERFACE CABLE ASSEMBLY PENDANT

PIPE KAT

PIPE BAND STORAGE / TRANSPORTATION CASES

®

4

GENERAL DESCRIPTION

The PIPE KAT

is an advanced portable travel carriage designed for orbital welding. It is

®

an electrically powered track guided carriage that travels in forward and reverse directions at

precisely controlled speeds. It consists of 24 VDC permanent magnet gear motor which

engages the aluminum pipe band (track) through the self-aligning wheel system. Pipe bands are

designed and manufactured to customer specific applications (pipe diameter). The band is

typically constructed from extruded aluminum which insures a long life and durability in harsh

conditions.

The onboard wire feeder and wire spool holder is driven by a 24 VDC motor which feeds

wire to the welding torch at precisely controlled speeds. The wire spool holder accepts standard

8” / 10 lbs [20.3cm/4.54kgs] spools.

The Gullco Linear Oscillator is a compact, light weight, yet durable, reciprocating device

with a high torque, high resolution and low vibration stepper motor. It imparts a linear motion to

the weld gun. The low voltage Oscillator control provides a large, easy to read, multi-page

graphical display and offers programmable and electronic adjustment over the following

functions.

Oscillation width

Oscillation speed

Independent left and right dwells

Oscillation centre positioning (steering)

Multiple oscillation program storage

The precise control of these features enables accurate and repetitive weld oscillation.

The Gullco Carriage control provides control and adjustment over vertical slide, wire

feeder and carriage drive motor.

A motorized torch slide provides 2” or 50mm of tip-to-work distance adjustment, this serves as a

fine adjustment to control and maintain the proper torch to pipe height during setup and welding.

This motorized torch slide is connected to the linear oscillator by an adjustable radial Lead &

Lag mounting bracket

The versatile torch mounting bracketry provides a greater variation of torch mounting/positioning

flexibility.

INTENDED / FORESEEN USAGE

The Gullco PIPE KAT

is intended to automate and improve the quality of the welding

®

operation at precisely controlled speeds, along the Pipe Band as well as providing the interface

between the welding motion and the arc start and stop signals. The PIPE KAT

operates with

®

precise motion from start to finish regardless of the number of passes or the work pieces

involved, improving the quality, efficiency and repeatability of the process. Detrimental factors

such as poor or awkward accessibility, operator fatigue, or inconsistent workmanship are

eliminated. Required quality levels are consistently attained and productivity and profitability

increased.

5

PIPE BAND

The Pipe Band is constructed from extruded aluminum and uses adjustable stand-offs

that serve as spacers to maintain the correct distance from the band to the pipe. The Pipe Band

utilizes a quick adjustment latches that allows the operator to mount and remove the band

easily. It is important that the Pipe Band is properly maintained and not subjected to any abuse

as it serves an important role in the carriages drive system. The operator must play close

attention to the condition of mating edge of the band that the PIPE KAT

carriage wheels run

®

on. Care must be taken to ensure that the band is kept clean from dirt and debris that could

damage the band. Also premature wear or damage to the band could result from improper

mounting of the PIPE KAT

carriage.

®

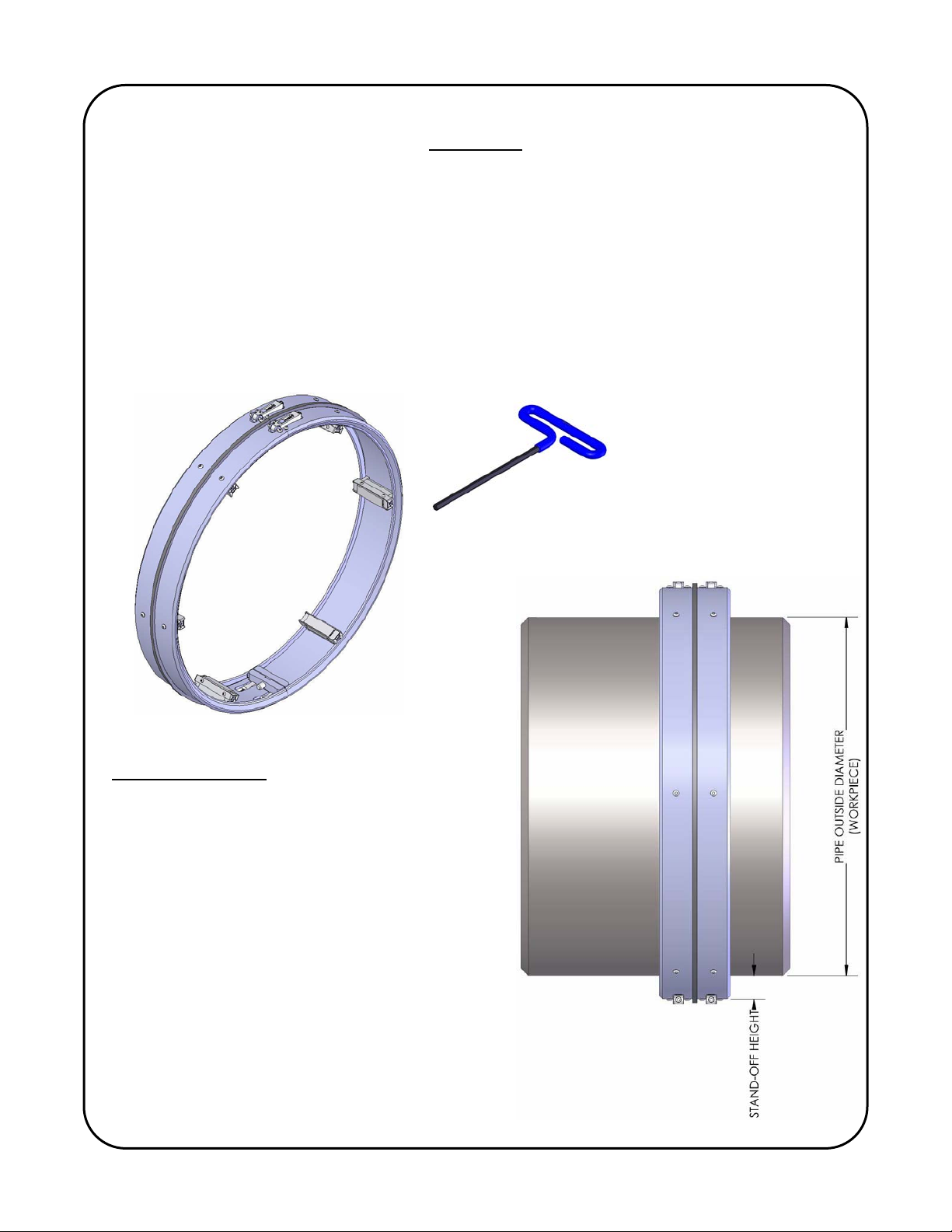

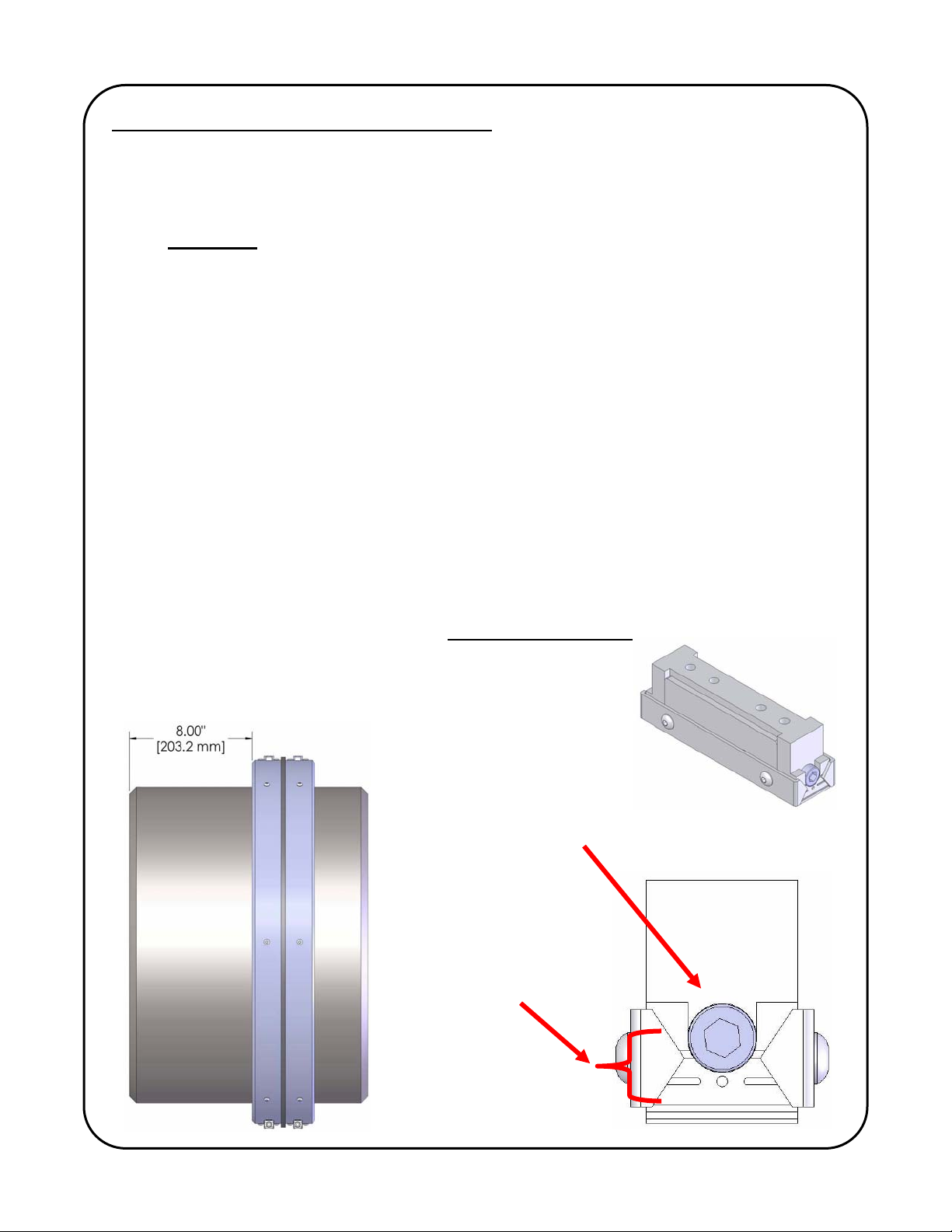

PIPE BAND SIZING

All Pipe Bands are manufactured to customer

specified pipe diameters & stand-off lengths.

The standard (minimum) stand-off height is 1.75”

[44.5mm]. Spacers can be used to increase the

height off the stand-offs.

The minimum spacer height can be used in

conjunction with standard stand-offs is 0.50”

[12.7mm]

6

MOUNTING PIPE BAND (TRACK) ON THE PIPE

1. Loosen latch screws on both top swing latches and bottom fixed latches. Do not remove

these screws.

2. Swing open the top pair of latches.

3. Separate or split the two bottom halves (fixed latches) of track away from each other.

Important ! The bottom halves must be a minimum of 3/16” [5mm] apart from each

other. This minimum distance will allow the track to safely open without causing

interference between the two track halves.

4. Place track on pipe by sliding over the end, or by opening the track to fit over the pipe

outside diameter.

5. Close latch over catch and tighten adjustment screw enough to allow the track to move,

but still remain on the pipe.

6. Align track to weld joint. The optimal distance is approximately 8.00” [203.2 mm]

between the inside edge of track and the center of the weld joint. NEVER use a hammer

or other such object to hit the Pipe Band into position, doing so will damage the edge

that the self-aligning wheels run on and result in poor performance.

7. Back off the adjustable standoffs on the pipe band. This is done by rotating the

adjustment screw counter clock-wise.

8. Finish tightening the top and bottom latch screws. The track must be sufficiently

fastened to remove any gaps between the ends of track at the joint. Do not over-tighten!

9. Verify track position on the pipe and then begin to tight each adjustable track standoff. It

is important that each standoff be adjusted by the same amount. By not doing this the

track will not be concentric with the pipe. See below for more details.

Track standoff assembly

Adjustment screw:

-Counter clock-wise to loosen

-Clock-wise to tighten

Adjustable range of

track mounting pad.

+/-0.157” [4mm]

7

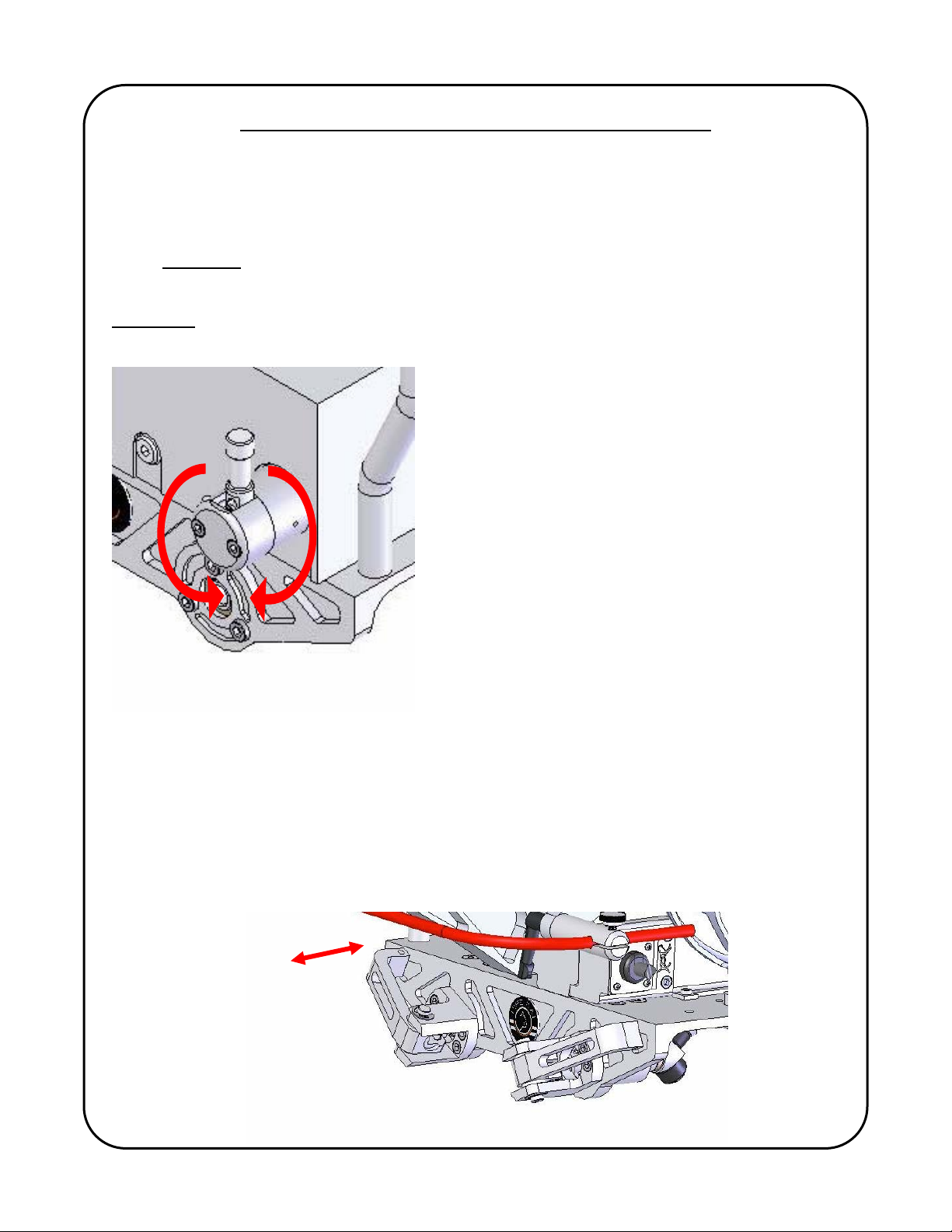

MOUNTING THE CARRIAGE ON THE PIPE BAND (TRACK)

The drive engagement lever (shown below) extends out the side of the carriage drive assembly

and allows the operator to engage or disengage the drive gear the rack on pipe band. The drive

gear can either be engaged or disengaged when mounting the carriage on the track. It also

permits free-wheeling for rapid positioning of the PIPE KAT

carriage. To engage the drive, pull

®

the lever away from the carriage body and turn in either direction until the lever arm is facing

down. Important: always make sure the drive is properly engaged by verifying the lever is

locked into position.

WARNING Never disengage the drive when there is a possibility that this action may result in

the equipment moving expectantly and causing injury.

MOUNTING PROCEDURE:

1) With both Carriage Locking Handles open, both handles have a built in detent to

hold them open, place the carriage directly over the Pipe Band/track.

2) Rest the carriage so that the top shoulder of all four wheel assemblies is resting

on the outer face of the band.

3) Close the locking handles securing the carriage to the track.

8

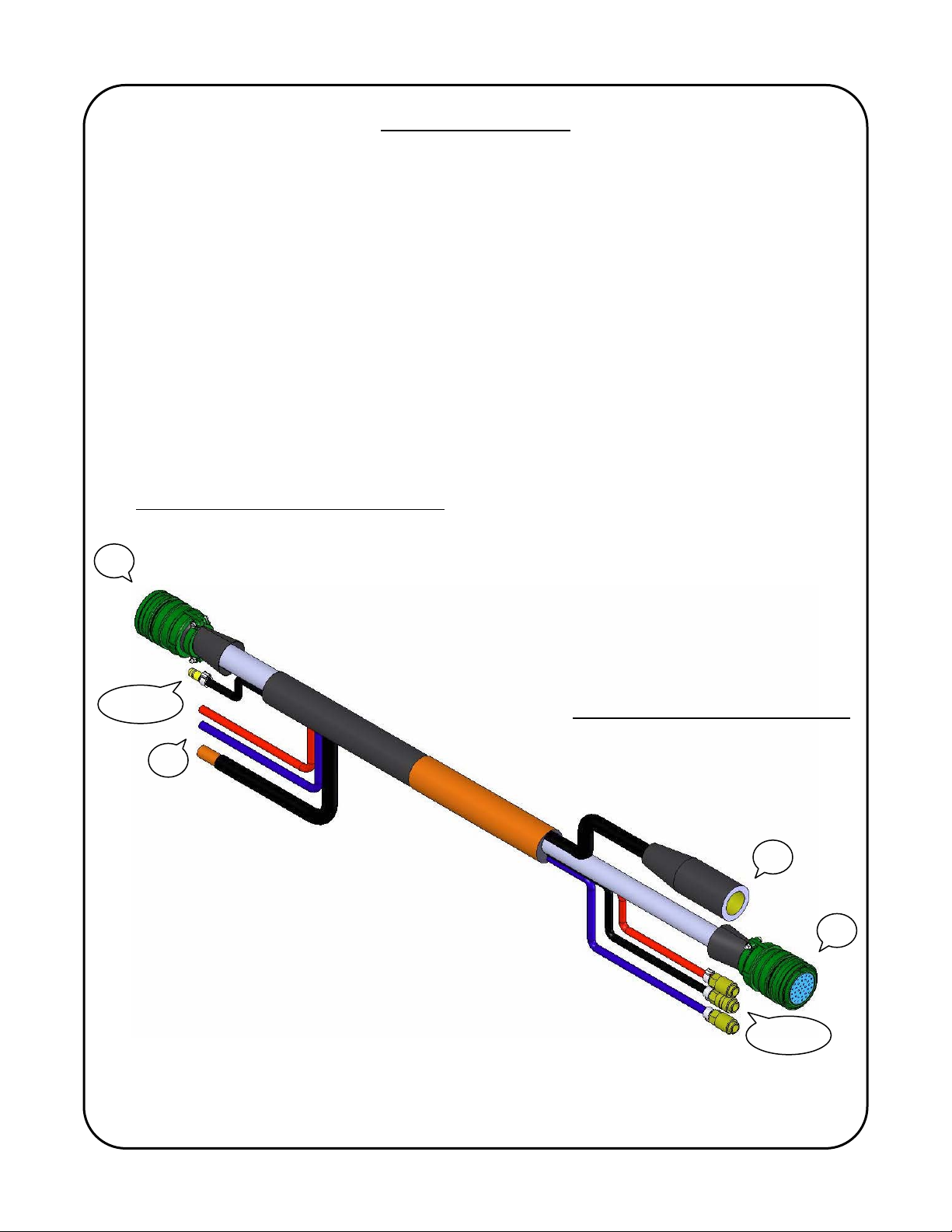

CARRIAGE UMBILICAL

The umbilical assembly provides communication between the Main Control Box and the

PIPE KAT

carriage, in addition to supplying cooling water, shielding gas and electrical welding

®

power to the torch.

The umbilical comprises of one control cable that provides power and communication to

the carriage, two water hoses (supply and return), shielding gas hose and welding electrode

cable. The umbilical is wrapped in a heat and abrasion resistant cover and uses a clamp to

secure the umbilical assembly to the carriage (see pages 13 & 14 to see where the umbilical

attaches to the PIPE KAT

carriage).

®

Note: It is important that the umbilical does not become tangled, coiled, or caught in

anyway that would impede the motion of the carriage and possibly damage electrical cables and

restrict water supply and/or shielding gas supply to the torch.

It is good practice to frequently inspect the carriage umbilical for damage and worn

components, any suspect parts should be replaced immediately to prevent further damage to

the PIPE KAT

system.

®

Connection to the Pipe KAT main control

3 & 4

Connection to the Pipe KAT carriage

3 & 4

9

Connection to the PIPE KAT

1) Additional 15 ft welding power supply electrode cable

2) One (1) large electrical connector for communication supply to the carriage

3) One (1) male plug for the shielding gas supply to the torch

4) Additional 15 ft of water cooling hoses (supply & return)

Connection to the PIPE KAT

1) One (1) twist connect welding power supply cable connection

2) One (1) large electrical connector for carriage communication

3) One (1) quick-disconnect fitting for the torch shielding gas

4) Two (2) quick-disconnect fittings cooling water, supply (blue) and return (red)

Main Control includes:

®

carriage includes:

®

10

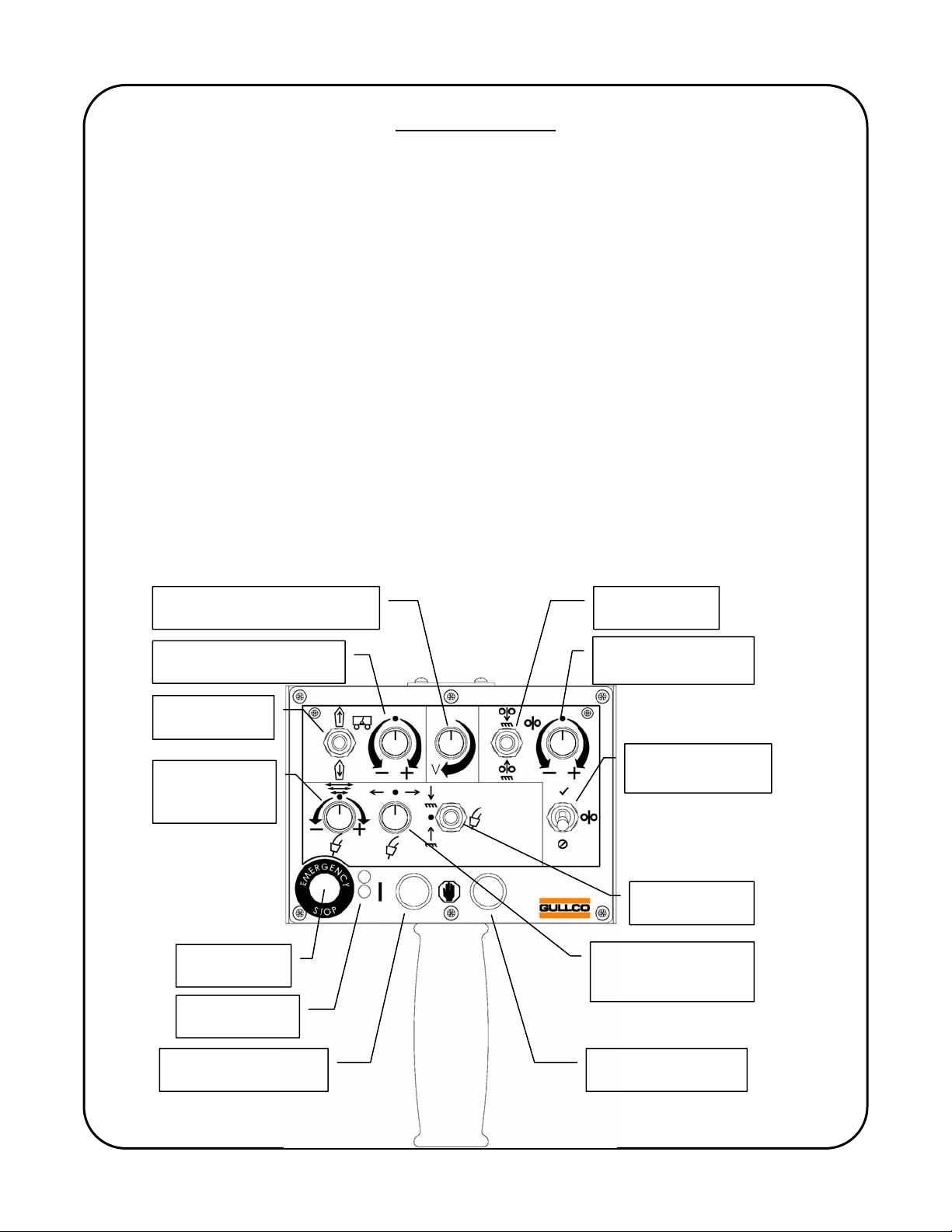

REMOTE PENDANT

The Remote pendant is used in conjunction with the main control to provide adjustment

during setup, initiate the weld cycle, provide fine adjustment during welding, and to stop the

weld cycle.

During setup the pendant is used to provide the following:

Position the carriage to the welding start position

Adjust oscillator center position

Adjust torch height in relation to the pipe

Advance the wire towards and back from the pipe

Set welding voltage

During the welding operation the pendant can be used to provide the following fine adjustments:

Carriage speed

Wire feed speed

The torch height in relation to the pipe (tip-to-work distance)

Oscillation center position

Oscillation width adjustment

Adjust welding voltage

The remote pendant is supplied with a 35ft communication cable that connects to the

right side panel of the PIPE KAT

Main Control. The functions of the Remote Pendant are

®

discussed in detail below.

WELDING VOLTAGE

CONTROL

WIRE FEED

JOG

CARRIAGE WELD SPEED

TRIM OVERRIDE

WIRE FEED SPEED

TRIM OVERRIDE

CARRIAGE

JOG

OSCILLATION

WIDTH

ADJUSTMENT

WELD ENABLED/

DISABLED

TORCH SLIDE

JOG

EMERGENCY

STOP

RED & GREEN

L.E.D.s

OSCILLATOR

CENTER POSITION

ADJUSTMENT

AUTO CYCLE START

PUSH BUTTON

AUTO CYCLE STOP

PUSH BUTTON

11

RED POWER LED: The red LED is illuminated to indicate there is power to the pendant. It also

flashes whenever there is an error code displayed on the controls.

WIRE FEED SPEED TRIM OVERRIDE: This speed adjustment knob allows for fine adjustment

in wire feed when the PIPE KAT

is in auto cycle mode (welding), this serves as a fine

®

adjustment to control and maintain the quality of the welding process. Adjustment range: +/- 19

inches/minute or +/- 48 cm/minute.

CARRIAGE WELD SPEED OVERRIDE: This speed adjustment knob allows for fine adjustment

in carriage weld speed when the PIPE KAT

is in auto cycle mode (welding), this serves as a

®

fine adjustment to control and maintain the quality of the welding process. Adjustment range: +/-

1.32 inches/minute or +/- 3.36 cm/minute.

WELDING VOLTAGE CONTROL: This adjustment knob allows for adjustment of the welding

voltage during setup or in auto mode. Note: welding voltage control is only available when the

PIPE KAT

is interfaced with the welding power source; see “Welding power source calibration”

®

on page 37 for more details.

WIRE FEED JOG: This 3-position momentary switch (Forward/Auto/Reverse) allows for

manual forward and reverse feeding of the welding wire when not in the auto cycle mode. The

switch is automatically disabled during the auto cycle.

CARRIAGE JOG: This 3-position momentary switch (Forward/Auto/Reverse) allows for manual

forward and reverse motion of the carriage when not in the auto cycle mode. Use the carriage

jog switch to establish the proper position of the carriage to the work prior to welding. When the

forward or reverse jog direction is selected, the carriage will travel at the set carriage (weld)

travel speed for three (3) seconds then it will progressively ramp up to maximum travel speed.

The switch is automatically disabled during the auto cycle.

EMERGENCY STOP: The emergency stop button serves as a safety feature that will terminate

all operations and shut down the PIPE KAT

unit when pressed. The emergency stop will

®

remain activated until it is reset by turning the button in a clock-wise motion. There are two (2)

other such emergency stop buttons; one (1) on the PIPE KAT

carriage assembly and one (1)

®

on the Main Control Box. These three (3) Emergency Stop buttons are wired in series, so any

one (1) will shut down the PIPE KAT

system when activated, and all three have to be released

®

in order for the system to power-up.

GREEN LED: The green LED is illuminated when the PIPE KAT

is operating in the auto cycle

®

mode.

AUTO CYCLE START PUSH BUTTON: This green button is used to initiate the auto cycle

mode. The button must be held for a minimum of two (2) seconds to reduce the possibility of

accidentally starting an automatic operation.

AUTO CYCLE STOP PUSH BUTTON: This red button is used to terminate the auto cycle

mode. The button must be held for a minimum of two (2) seconds to reduce the possibility of

accidentally aborting the automatic operation.

OSCILLATION WIDTH ADJUSTMENT: This adjustment knob allows the operator to adjust the

torch oscillation width while in the auto cycle mode (welding). This serves as a fine adjustment

12

to control and maintain the quality of the welding process. Width is increased or decreased in

0.01 Inch/CM increments.

OSCILLATION CENTER POSITION ADJUSTMENT: This adjustment knob allows the operator

to adjust the center position of the torch oscillation while in the auto cycle mode (welding) or to

jog the torch to the desired position prior to welding. This serves as a fine adjustment to control

and maintain the quality of the welding process. To make adjustments (steering) while welding,

rotate the knob in the appropriate direction until the center of the oscillation has moved to the

desired location. The size of these centre adjustment (steering) increments can be programmed

to be as large or small as preferred (see the “2

nd

Field” details on page 25).

TORCH SLIDE JOG: This 3-position momentary switch (In/Stop/Out) allows the operator to

adjust the In/Out distance of the torch relative to the work. The torch slide provides 2” or

[50.8mm] of motorized travel and can be used in both auto and manual modes. This serves as a

fine adjustment to control and maintain the tip-to-work distance. The linear speed of the slide

can be programmed through the Carriage Control (see page 36).

WELD ENABLED/DISABLED: This 2-position maintained switch allows the user to perform

simulated auto cycles, without actually welding, when in the Disable (

) position (i.e. when an

auto cycle is initiated the wire feeder, the welding power source, and the shielding gas flow are

disabled). When in the Enabled (

) position the auto cycle will perform a weld cycle (see page

45).

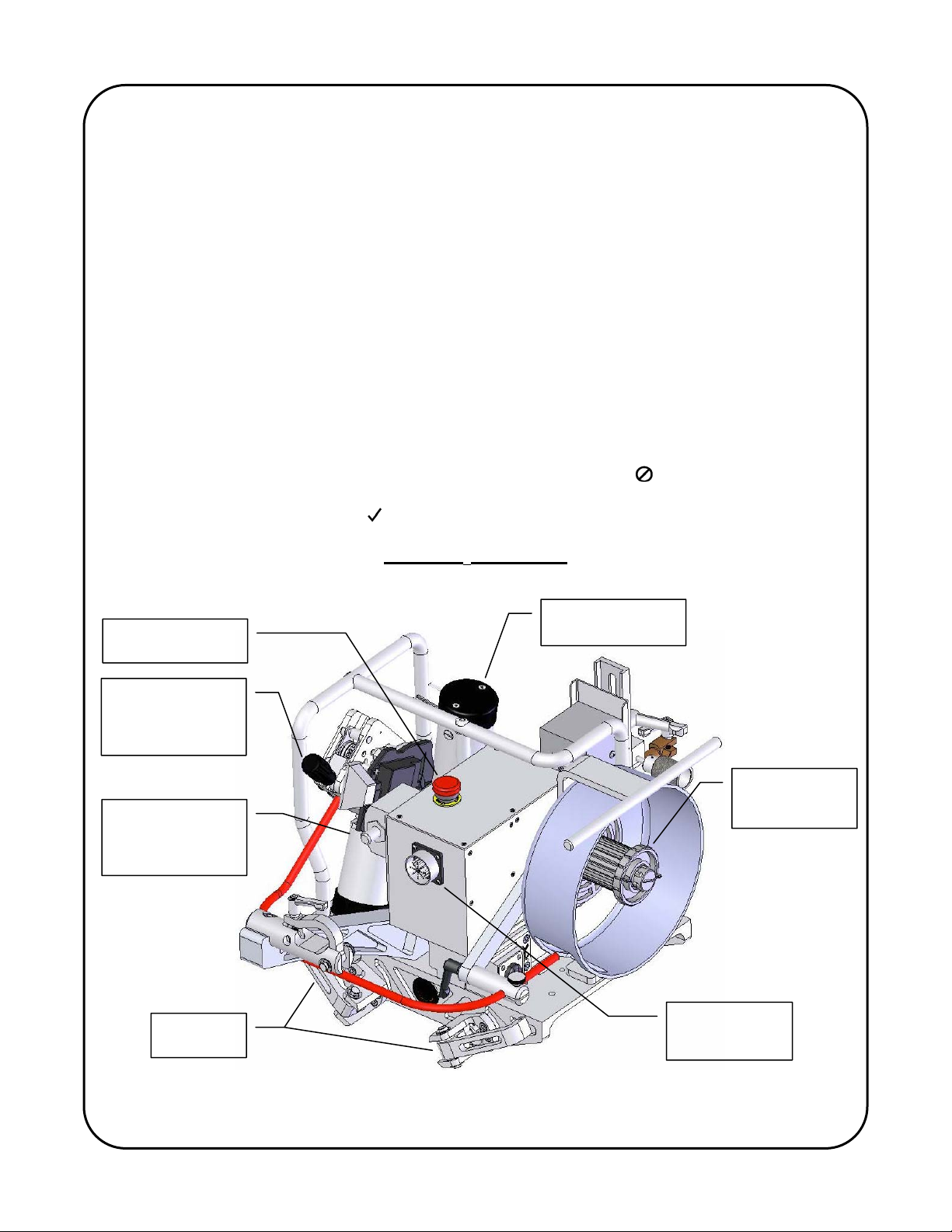

PIPE KAT

CARRIAGE

®

EMERGENCY

STOP

CARRIAGE DRIVE

MOTOR

WIRE FEED

PINCH ROLLER

PRESSURE

ADJUSTMENT

CARRIAGE

ELECTRODE

CABLE

CONNENCTION

WIRE SPOOL

TENSION

ADJUSTMENT

LOCKING

HANDLES

CARRIAGE

CONTROL

CONNECTION

13

Loading...

Loading...