Gullco KBM-28U User Manual

KBM®-28U

INVERTED PORTABLE PLATE

EDGE BEVELLING MACHINE

Adjustable bevel head produces

bevel angles from 22.5º through 55º

Supplied with angle bevel pins for

22.5º, 30º, 37.5º, 45º and 55º

Other bevel angle pins are available

upon request.

NOTE: Machine shipped with the 30º

bevel pin in place.

PARTS LIST

&

OPERATING INSTRUCTIONS

Website: www.gullco.com

Distributed by:

Phone: 905-953-4140 Fax: 905-953-4138 e-mail: sales@gullco.com

Phone: 440-439-8333 Fax: 440-439-3634 e-mail: ussales@gullco.com

Phone: +44 1257-253579 Fax: +44 1257-254629 e-mail: uksales@gullco.com

Phone: 61 (0) 7 3344-5515 Fax: 61 (0) 7 3348-5510 e-mail: ausales@gullco.com

Phone: 91-20-65260382 Fax: 91-20-26836656 e-mail: insales@gullco.com

GULLCO INTERNATIONAL LIMITED – CANADA

GULLCO INTERNATIONAL INC. – U.S.A.

GULLCO INTERNATIONAL [U.K.] LIMITED – EUROPE

GULLCO INTERNATIONAL PTY LIMITED – AUSTRALIA

GULLCO INTERNATIONAL INDIA PRIVATE -LIMITED

GULLCO INTERNATIONAL SHANGHAI – LIMITED

Phone: +8621-50460341 Fax: +8621-50463554 e-mail: c.zhang@gullco.com

Revised: December 18, 2014 GD-055

READ BEFORE USING THE KBM®-28U BEVELLER

Please refer to the KBM®-28 Portable Plate Edge Bevelling Machine Parts

List & Operating Instructions document (GD-047) for all other information

not contained within this supplemental manual, as it contains all of the

major wear components used in the KBM®-28U machine along with similar

principles of operational procedure, safety instruction, maintenance etc.

KBM®-28U PLATE EDGE BEVELLING MACHINE DETAILS

This manual (in combination with the KBM®-28 manual, GD-047) covers the operation instructions,

maintenance requirements and provides parts lists for the Gullco Inverted Plate Edge Bevelling

Machine, part number: KBM

DECLARATION OF CONFORMITY - CE - designed and manufactured in compliance with

-28U.

®

2006/42/EC provisions and further amendments.

MACHINE SPECIFICATIONS

Maximum Bevel Width: 1.10" [28 mm] at standard 30° bevel angle on material with a

tensile strength of 64,000 lb/in² [45 Kg/mm²] (multiple passes)

Maximum Bevel Depth: 0.95" [24.2 mm] at standard 30° bevel angle on material with a

tensile strength of 64,000 lb/in² [45 Kg/mm²] (multiple passes)

Minimum Plate Thickness: 5/16" (8.0 mm)

Maximum Plate Thickness: 2" (50 mm)

†

Bevel Speed: 10’ [3 m] per minute

Motor: 3 H.p., 3 phase, available for 230, 460 and 575 V at 60 Hz. and

also 380 and 400/415 V at 50 Hz. supply

Gearbox Oil: 4.8 US Gallon (18 Litres) of Shell Tivera S 320 (See section

“Periodic Inspection & Maintenance” for further details)

Weight: 924 lbs. [420 Kg.] including hydraulic undercarriage assembly

†

Top speed can vary depending on variations of bevel depth, voltage and frequency.

1

y

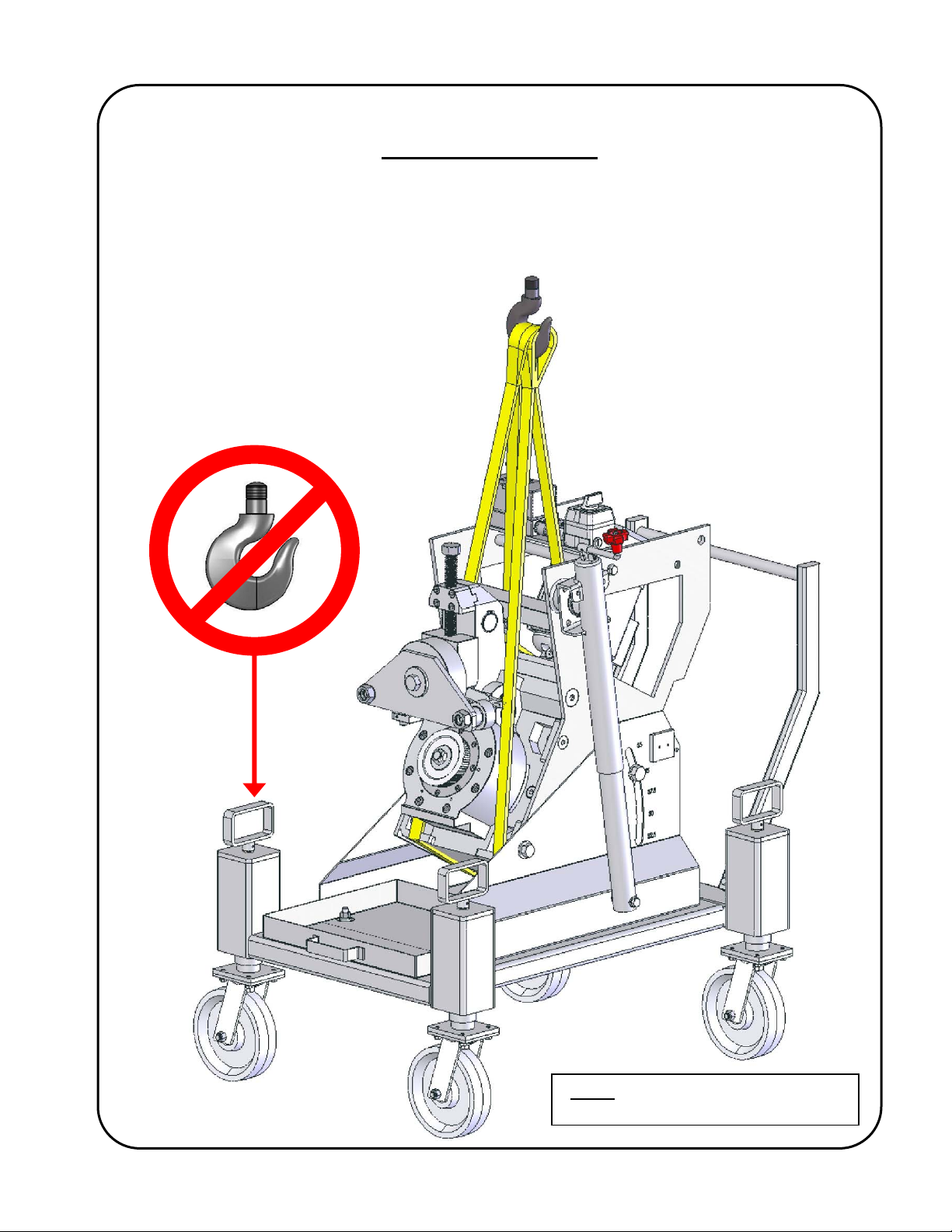

LIFTING (HOISTING)

The recommended method of lifting (hoisting) the Gullco KBM®-28U Inverted Portable Plate Edge

Bevelling machine is to use two (2) equal length slings of sufficient capacity (924 lbs [420 Kg]

minimum), fed through the machine as shown below. All lifting (hoisting) equipment must be

suitably rated and clearly identified to be of adequate capacity. Never raise the machine any higher

than necessary and never transport it over the top of people!

WARNING! Do not lift the machine by the

wheel adjusting handles, or any

other such component(s) that

could result in machine damage

and/or bodily injury due to

mechanical failure during the

lifting (hoisting) process.

Note: Undercarriage may not be as

shown, for illustrative purposes onl

2

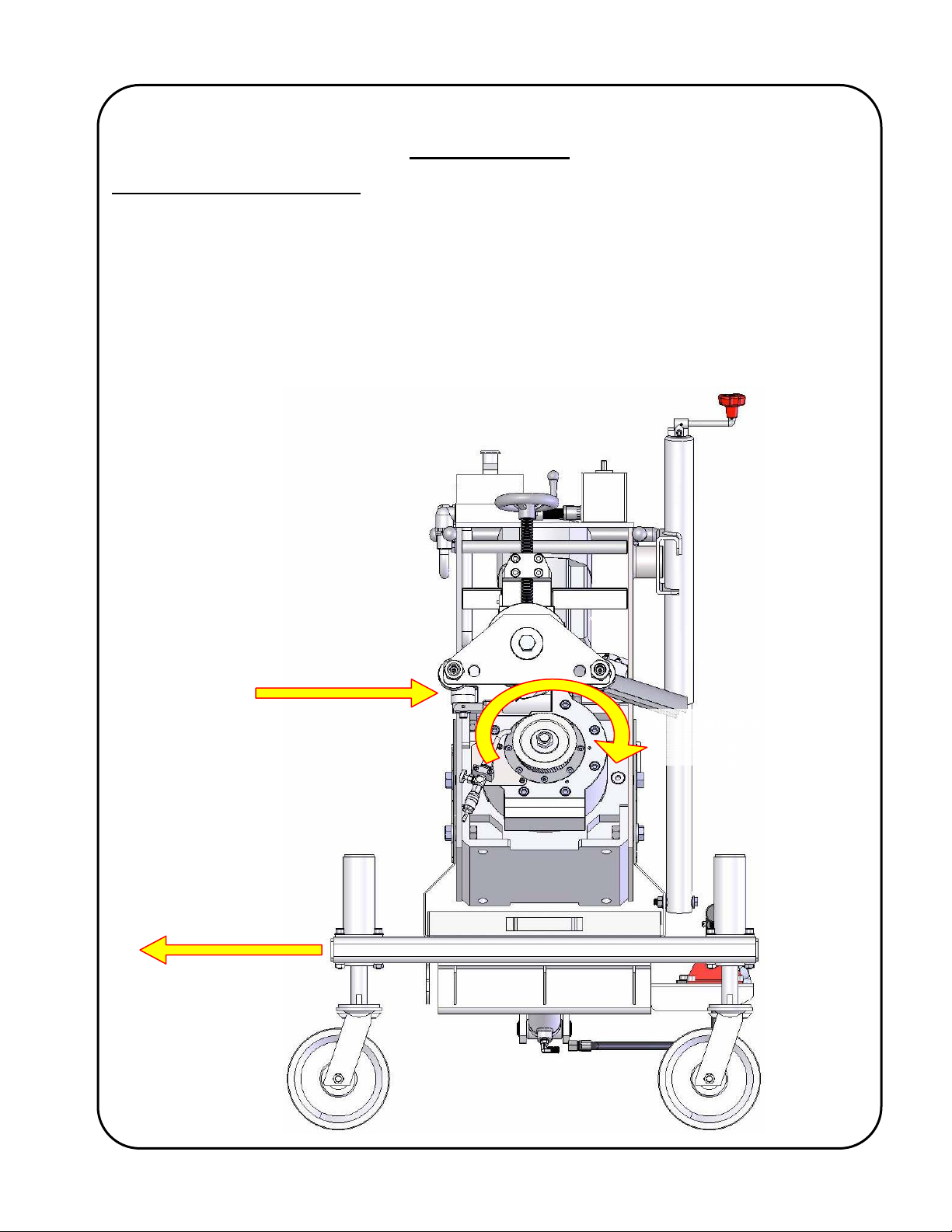

INSTALLATION

ELECTRICAL CONNECTION

WARNING! As shown in the accompanying drawing, the cutter rotation MUST be clockwise (as

viewed from the front). IT IS IMPORTANT THAT THIS ROTATION DIRECTION BE

CORRECT OTHERWISE DAMAGE TO THE MACHINE MAY OCCUR AND

WARRANTY WILL BE VOID. Be certain to check the cutter rotation before

operating the machine. The plate should be fed in the direction shown if the machine

is static and the material is being manually fed, alternatively, the bevelling machine

should travel in the direction shown if the plate is static and the machine is running

along the plate. If the cutter rotation is incorrect, it means that the 3 phase AC

connection is incorrect and two out of the three Live wires must be swapped.

PLATE TRAVEL

MACHINE TRAVEL

CUTTER

ROTATION

3

Loading...

Loading...