Gullco GP-200 User Manual

WELDING

POSITIONER

(USING GULLCO GSP-1000

SERIES CONTROLS)

MODELS:

GP-200

GPP-200

GP-300

OPERATING

INSTRUCTIONS

Website: www.gullco.com

Distributed by:

Phone: 905-953-4140 Fax: 905-953-4138 e-mail: sales@gullco.com

Phone: 440-439-8333 Fax: 440-439-3634 e-mail: ussales@gullco.com

Phone: +44 1257-253579 Fax: +44 1257-254629 e-mail: uksales@gullco.com

Phone: 61 (0) 7 3348-5515 Fax: 61 (0) 7 3348-5510 e-mail: ausales@gullco.com

Phone: 91-20-56260382 Fax: 91-20-26836656 e-mail: India.lo@gullco.com

Revised: February 27, 2013 GD-044-O

GULLCO INTERNATIONAL LIMITED – CANADA

GULLCO INTERNATIONAL INC. – U.S.A.

GULLCO INTERNATIONAL [U.K.] LIMITED - EUROPE

GULLCO INTERNATIONAL PTY LIMITED - AUSTRALIA

GULLCO INTERNATIONAL LIMITED – INDIA

GULLCO INTERNATIONAL SHANGHAI – LIMITED

Phone: +8621-50460341 Fax: +8621-50463554 e-mail: c.zhang@gullco.com

SAFETY INSTRUCTIONS

Although the Gullco welding positioner is manufactured for safe and dependable operation, it is

impossible to anticipate those combinations of circumstances, which could result in an accident. An

operator of the welding positioner is cautioned to always practice "Safety First" during each phase

of operation, setup and maintenance.

Read and understand the whole Operating Instructions manual (as well as the additional Technical

manual complete with the supplementary GSP-1000 Control Manual, “GD-042”) before operating or

performing service of this equipment. Become familiar with the machines operation, applications

and limitations. Keep the operation manual in a clean and readily available location.

This equipment is normally used to automate / semi-automate welding or cutting processes. These

processes usually have any combination of the following; bright and hot arcs, flying sparks, fumes,

ultraviolet and infrared radiated energy, hot work-pieces, compressed gases, etc.. The onus is on

the operator of this equipment to know, understand and follow all the safety precautions associated

with the process being used.

A careless operator invites troubles, and failure to follow safety practices may cause serious injury

or even death. Important safety precautions are given in the following:

Electrical Shock Prevention

Do not use this equipment in damp or wet locations.

Do not expose this equipment to rain.

Do not touch electrically live parts or electrode with skin or wet clothing.

Insulate yourself from the work and ground.

Never carry this equipment by the cables or pull the cables to disconnect from the receptacle.

Keep all cables from heat, oil and sharp edges.

Inspect all cables periodically and replace if damaged.

Inspect the security of all cables periodically and repair if loose.

Disconnect the power cord when not in use.

Disconnect the power cord positively to prevent electrical shock before repair and service of the

equipment.

Bodily Injury Prevention

Do not wear loose clothing, jewellery or loose, long hair which may get caught into automatic systems

or moving parts.

Keep equipment (especially lifting handles) dry, clean and free from oil & grease.

Ensure that the positioner is well secured to the bench, tabletop, etc., to prevent it from tipping over

when subjected to over hung loading.

Never loosen the tilt-locking lever, nor try to tilt the rotary welding table, when there is a load mounted

to the table generating large radial moments.

Keep hands away from the rotary table when it is in motion, or when there is the slightest possibility of

motion.

Wherever possible, avoid mounting devices, etc., that protrude from the rotating mass, and pose

possible pinch-points.

Make certain that work-piece/mounting device protrusions will not strike the floor, positioner frame or

any other object during rotation.

There should only ever be one (1) operator working at the machine at any given time.

Do not operate this equipment if drowsy from medication or fatigue.

Do not lift the machine with heavy accessories or cables attached and only lift using adopted safe

lifting standards and practices.

1

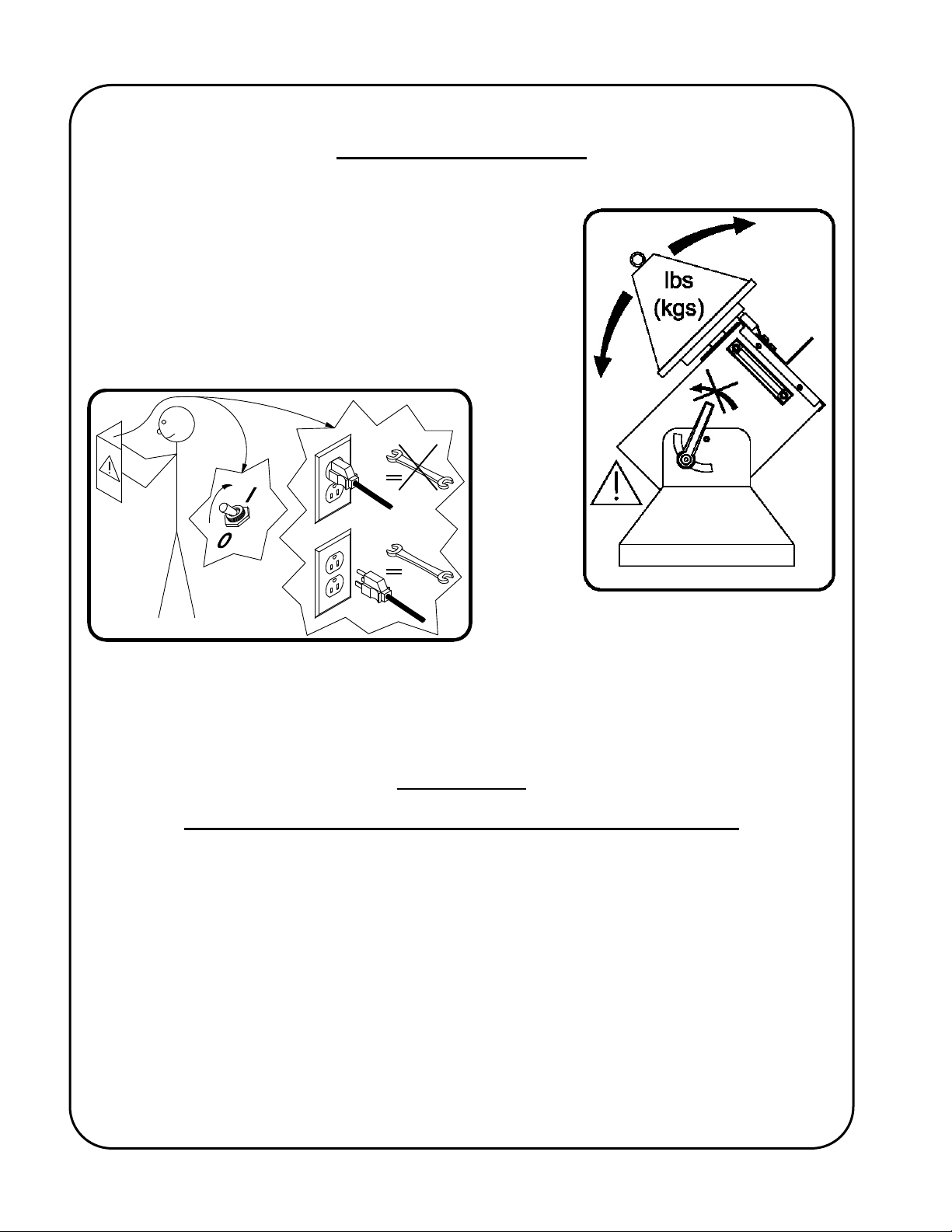

SAFETY PRECAUTIONS

The following cautionary/warning labels are attached to each welding positioner:-

The adjacent label pictorially represents the following:

Warning:-

Do not loosen the tilt clamp lever when there is a load

applied to the table. This may result in an unexpected

radial movement!

The above label pictorially represents the following:

Warning:-

Read the manual before turning the unit on and before performing service. Also, positively

disconnect the unit from all power supplies before servicing!

IMPORTANT

READ THIS BEFORE OPERATING THE WELDING POSITIONER

When used with electric arc welding or cutting equipment, ensure that an adequate and wellmaintained power return path is provided with good electrical contact. Failure to do so may result in

the welding/cutting current passing through the Positioner and damaging the wiring and electrical

components.

Important information regarding safety and operation of the “GSP-1000” motor control used in the

Positioner is contained in a supplemental manual attached at the end of the Technical Manual. It is

equally important to read, understand and apply the information contained within that manual. The

supplemental manual (GD-042) has a title “Technical Information For The Gullco “GSP-1000”

Microprocessor Based Motor Control”, and it’s pages are numbered with a prefix of “T-“.

ALL THE SAFE PRACTICES AND PRECAUTIONS MAY NOT BE GIVEN IN WRITING. SOME

ARE BASED ON COMMON SENSE, BUT OTHERS MAY REQUIRE TECHNICAL

BACKGROUND TO EXPLAIN.

2

Loading...

Loading...