Gullco GK-203-400-12 User Manual

(

)

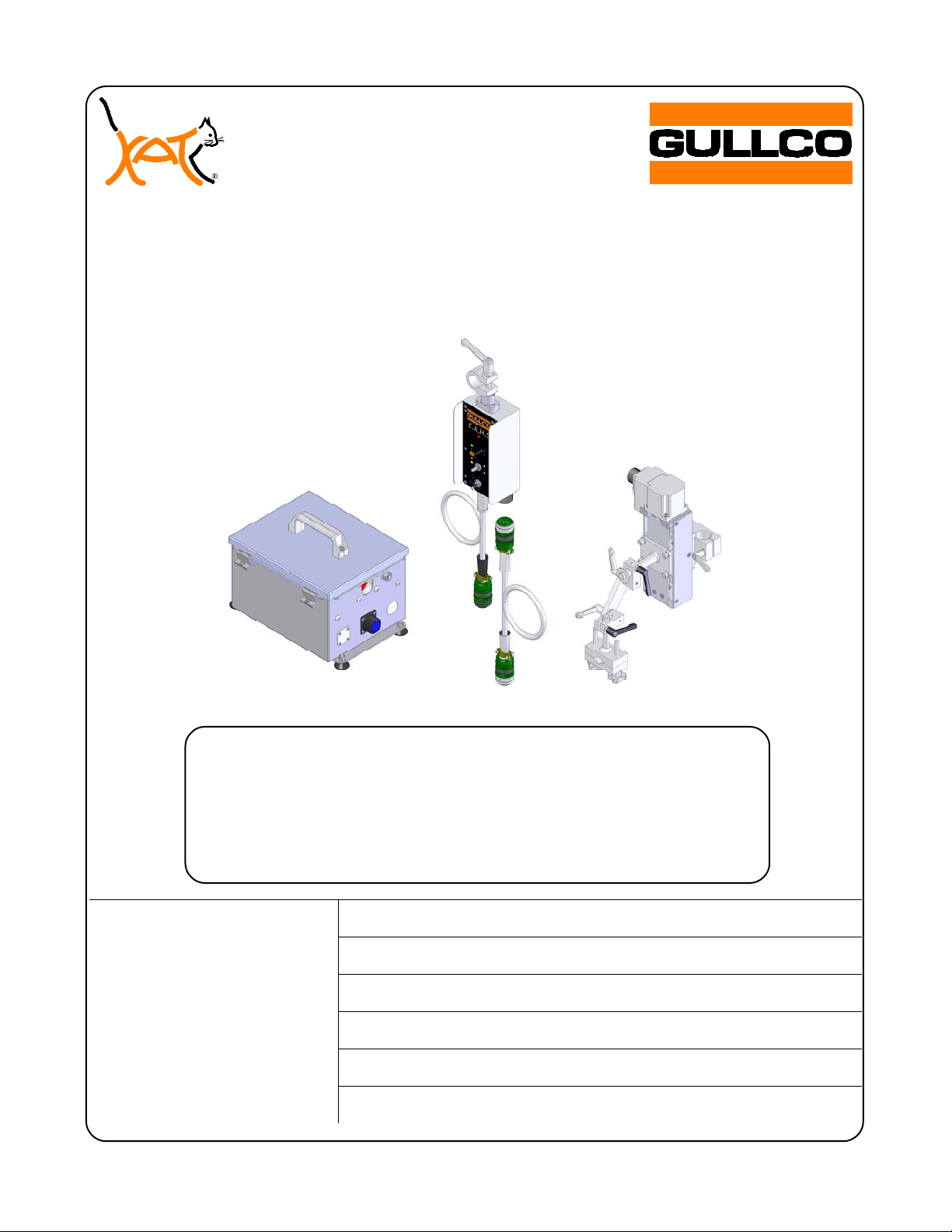

400 AMP ELECTRONIC ARC

HEIGHT SENSOR (E.A.H.S.)

WITH STANDARD SLIDE

GK-203-400-12-*

* INDICATES VOLTAGEREFERENCE

PARTS LIST

&

OPERATING INSTRUCTIONS

Website: www.gullco.com

Distributed by:

Phone: 905-953-4140 Fax: 905-953-4138 e-mail: sales@gullco.com

Phone: 440-439-8333 Fax: 440-439-3634 e-mail: ussales@gullco.com

Phone: +44 1257-253579 Fax: +44 1257-254629 e-mail: uksales@gullco.com

Phone: 61 (0) 7 3348-5515 Fax: 61 (0) 7 3348-5510 e-mail: ausales@gullco.com

Phone: 91-20-65260382 Fax: 91-20-26836656 e-mail: indsales@gullco.com

GULLCO INTERNATIONAL LIMITED – CANADA

GULLCO INTERNATIONAL INC. – U.S.A.

GULLCO INTERNATIONAL [U.K.] LIMITED - EUROPE

GULLCO INTERNATIONAL PTY LIMITED - AUSTRALIA

GULLCO INTERNATIONAL INDIA PRIVATE LIMITED

GULLCO INTERNATIONAL SHANGHAI – LIMITED

Phone: +8621-50460341 Fax: +8621-50463554 e-mail: c.zhang@gullco.com

Revised: December 23, 2014 GD-063

SAFETY INSTRUCTIONS

Although the Electronic Arc Height Sensor (E.A.H.S.) is manufactured for safe and dependable

operation, it is impossible to anticipate those combinations of circumstances, which could result in

an accident. An operator of this equipment is cautioned to always practice "Safety First" during

each phase of operation, setup and maintenance.

Read and understand the whole operating instructions before operating or performing service of this

equipment. Become familiar with the machine operation, applications and limitations. Keep the

operating instructions in a clean and readily available location.

This equipment is normally used to automate / semi-automate welding processes. These

processes usually have any combination of the following; bright and hot arcs, flying sparks, fumes,

ultraviolet and infrared radiated energy, hot work-pieces, compressed gases, etc. The onus is on

the operator of this equipment to know, understand and follow all the safety precautions associated

with the process being used.

A careless operator invites troubles, and failure to follow safety practices may cause serious injury

or even death. Important safety precautions are given in the following:

Electrical Shock Prevention

Do not use this equipment in damp or wet locations.

Do not expose this equipment to rain.

Never carry this equipment by the cables or pull the cables to disconnect from the

receptacle.

Keep all cables from heat, oil and sharp edges.

Inspect all cables periodically and replace if damaged.

Inspect the secureness of all cables periodically and repair if loose.

Disconnect the power cord when not in use.

Disconnect the power cord positively to prevent electrical shock before repair and service

of the equipment.

Bodily Injury Prevention

Do not wear loose clothing, jewellery and loose, long hair, which may get caught into

automatic systems or moving parts.

Do not operate this equipment if ill or drowsy from medication or fatigue.

Always keep the Electronic Arc Height Sensor (E.A.H.S.) clean and in good working order.

Report any unsafe condition for immediate correction.

ALL THE SAFE PRACTICES AND PRECAUTIONS MAY NOT BE GIVEN IN WRITING. SOME

ARE BASED ON COMMON SENSE, BUT OTHERS MAY REQUIRE TECHNICAL

BACKGROUND TO EXPLAIN.

1

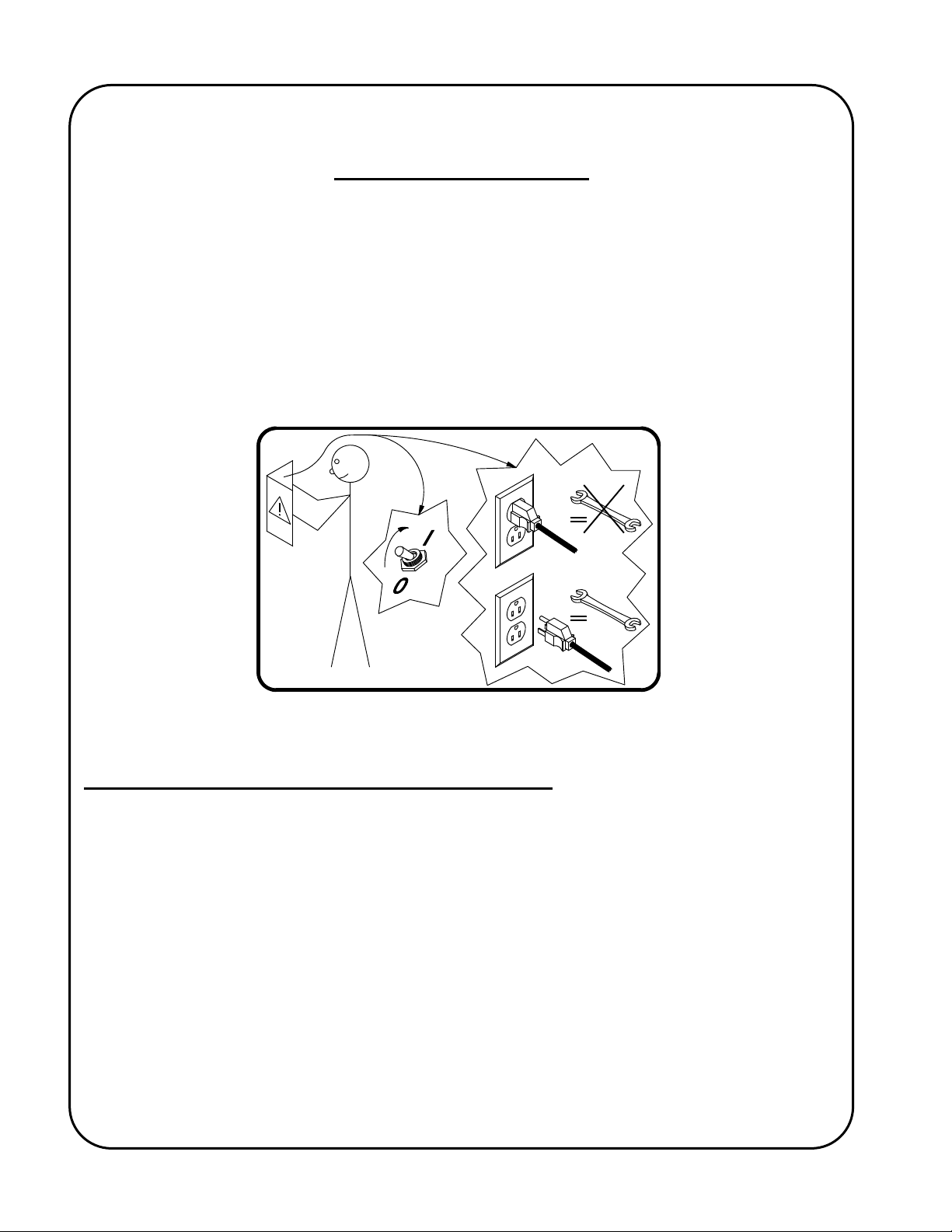

SAFETY INSTRUCTIONS

The following cautionary/warning label is attached to each Electronic Arc Height Sensor (E.A.H.S.):The below label pictorially represents the following:

“Warning:Read the manual before turning the unit on and before performing service.

Also, positively disconnect the unit from all power supplies before servicing!”

READ THIS BEFORE OPERATING THE E.A.H.S. UNIT

Always turn the main power off before connecting/disconnecting the cables to/from the Remote

Control Pendant, slide and control box. Failure to comply may result in control

damage.

The control must not be continually started and stopped by the removal and re-applying of power.

Allow ten (10) seconds after the removal of power before re-applying the power to the control.

Ensure that an adequate and well-maintained weld return path is provided with good electrical

contact. Failure to do so may result in the welding current passing through the equipment and

damaging the wiring and electrical components.

2

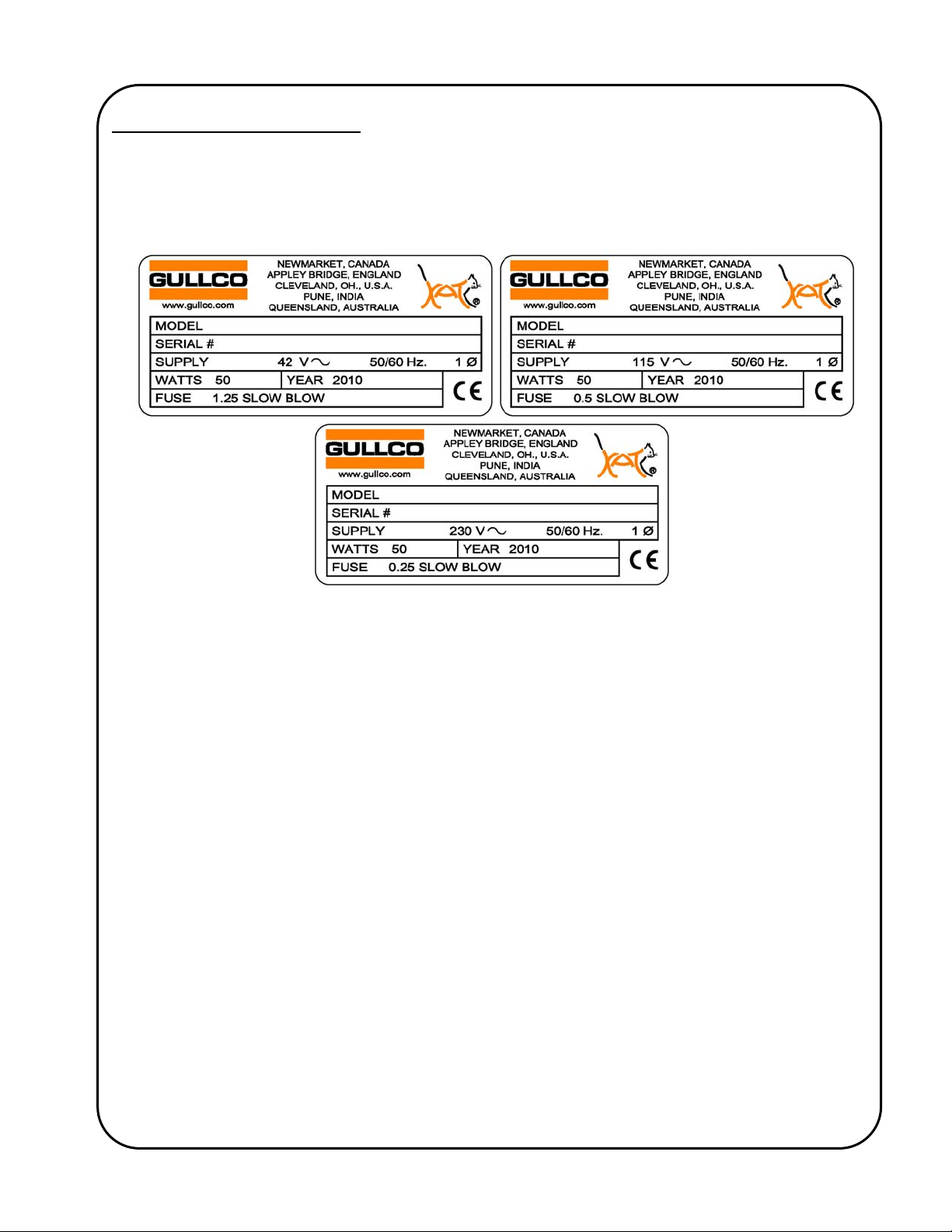

ELECTRICAL CONNECTION

WARNING! Before connecting the E.A.H.S. to a power source (receptacle, outlet, etc.,) be sure

that the voltage supplied is the same as that specified on the product label. If in

doubt, DO NOT PLUG IN THE E.A.H.S. Copies of the possible product labels are

shown below:

As the colours of the wires in the mains lead of this equipment may not correspond with the

coloured markings identifying the terminals in your plug, proceed as follows:

The Green & Yellow or Green wire must be connected to the terminal in the plug which is

allocated for “Earth” / “Ground”.

The Blue or White wire must be connected to the terminal that is allocated for “Neutral”.

The Brown or Black wire must be connected to the terminal that is allocated for “Live”.

230V Equipment must be installed in accordance with CEC, NEC or other applicable electrical

code.

WARNING! Ensure proper AC earth grounding of the Gullco E.A.H.S. and all auxiliary equipment

(where applicable), before applying power. Failure to do so may invalidate the

Gullco Warranty.

Note: If other torch mounting hardware is used that was not supplied by Gullco to mount the torch

to the slide, it is important that the torch is electrical isolated from the slide. i.e. no welding current

from the torch must be allowed to pass through the slide. Failure to do so will result in damage to

the E.A.H.S. controls. It is recommended that you consult your local Gullco representative when

considering other torch mounting hardware.

Warranty will be void if genuine Gullco replacement parts are not used.

3

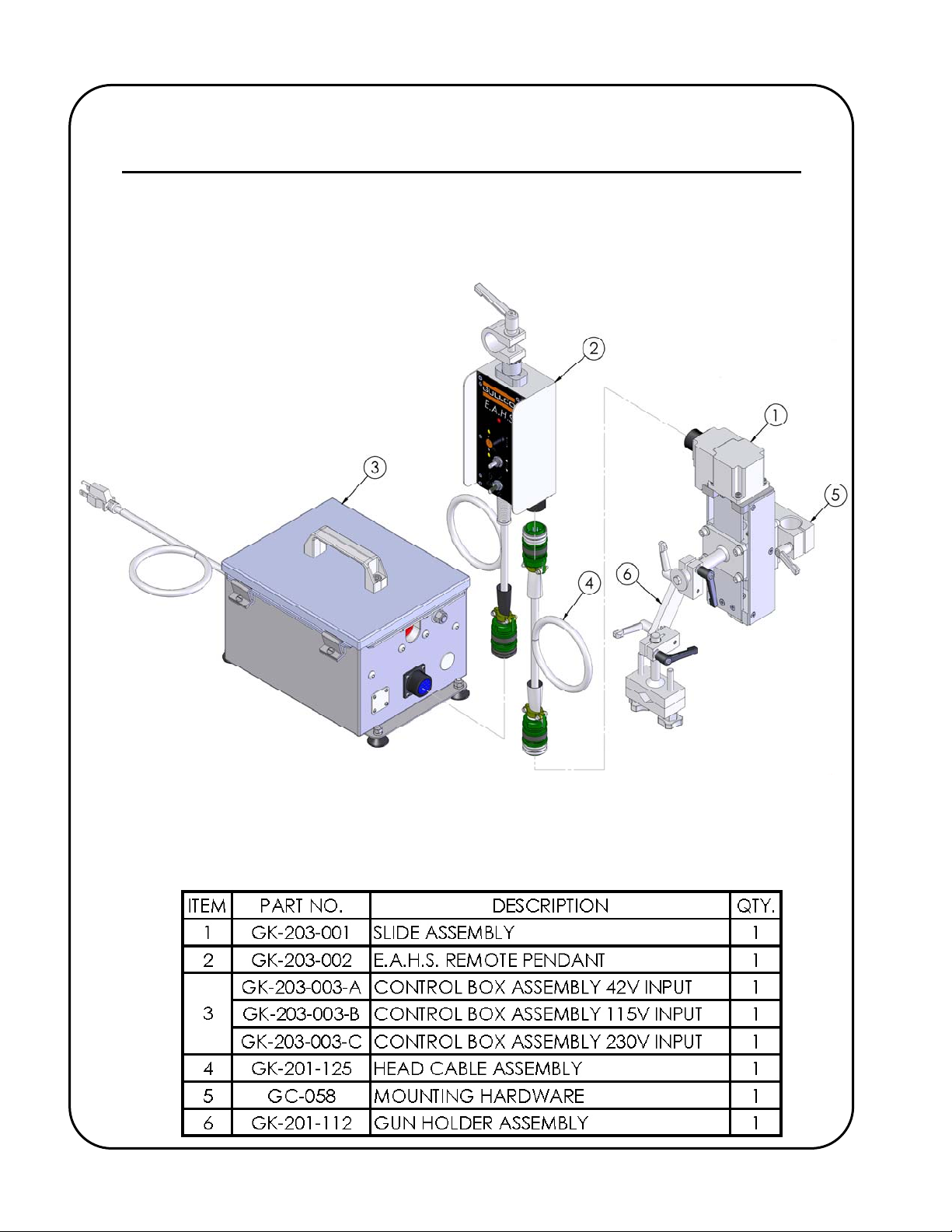

ELECTRONIC ARC HEIGHT SENSOR (E.A.H.S.)

This manual covers the operating instructions of the following Electronic Arc Height Sensor

(E.A.H.S.):- GK-203-400-12* (* indicates input voltage, A = 42V, B = 115V, C = 230V)

GENERAL DESCRIPTION

The Model GK-203-400-12 is a standalone unit meaning it does not interface with the customer’s

wire feeder. The arc activation trigger signal of the customer’s welding equipment that is used to

start/stop the welding process must come from a separate piece of equipment, i.e. customer

supplied control or other Gullco equipment. This advanced Electric Arc Height Sensor package

uses Gullco’s sophisticated, yet easy to use, E.A.H.S. remote pendant control, in conjunction with a

4” linear slide assembly and current sensing control box, to provide precision arc height control

during the welding process.

The Gullco linear slide is compact, light weight, yet durable, linear motion device with high torque,

high resolution and low vibration stepper motor. The slide imparts a linear motion to the welding

gun. The low voltage E.A.H.S. control provides user friendly functions while minimizing set-up and

welding down time. The Gullco E.A.H.S. system offers the following functions and features:

Lightweight and durable components to reduce operator fatigue.

The 4” standard slide features engraved top, bottom and center marks for quick slide

position reference to aid setup.

Standard 25 feet of remote pendant control cable means the current sensor main control

box can be kept away from the work area reducing trip hazards; an additional 25ft extension

is available.

Easy setup and torch height calibration (teach mode).

Sensor control box design allows the operator to use their standard existing welding cables

without any cutting or splicing that would be needed for a shunt type sensor.

Extremely accurate arc detection within 2% to 97% of the nominal amp range.

Slide travel speed factory set at 10 IPM [25.4cm/min], programmable range of 3 IPM

[7.6cm/min] to 17 IPM [43.2cm/min].

Easy to use remote pendant interface.

Coarse and fine slide adjustment.

Built in fault code diagnostics.

These features enable precise control over the torch height, generating accurate and repetitive high

quality results.

The E.A.H.S. sensor main control box is available in three line voltage inputs; 42, 115 and 230

VAC, single phase, 50/60 Hz.

Supplied adjustable torch bracketry allows for easy mounting of any semi-automatic and automatic

machine torches.

4

5

INTENDED / FORESEEN USAGE

The Gullco Electronic Arc Height Sensor (E.A.H.S.) system is used throughout the world to

automate and improve the quality and efficiency of the weld produced in automatic mechanized

welding operations. This is achieved through minimizing weld defects such as poor penetration,

incomplete fusion, overlap and undercut. Also, detrimental factors such as poor or awkward

accessibility, operator fatigue, or inconsistent workmanship are eliminated. Required quality levels

are consistently attained and productivity and profitability increased.

Welding guns are readily mounted on the linear slide. This equipment is intended to automatically

control the torch height throughout the welding process. The longitudinal movement can be

obtained from either the work piece traveling whilst the linear remains stationary, or, by a travel

carriage such as the Gullco “KAT”

work piece, which is the norm. By combining welding gun height control with the precision

controlled travel speed of the “KAT”

carriage carrying the E.A.H.S. equipment down the length of the

®

carriage high quality workmanship can be produced.

®

6

GK-203-400-12 E.A.H.S. SYSTEM COMPONENTS AND GENERAL ASSEMBLY

7

(

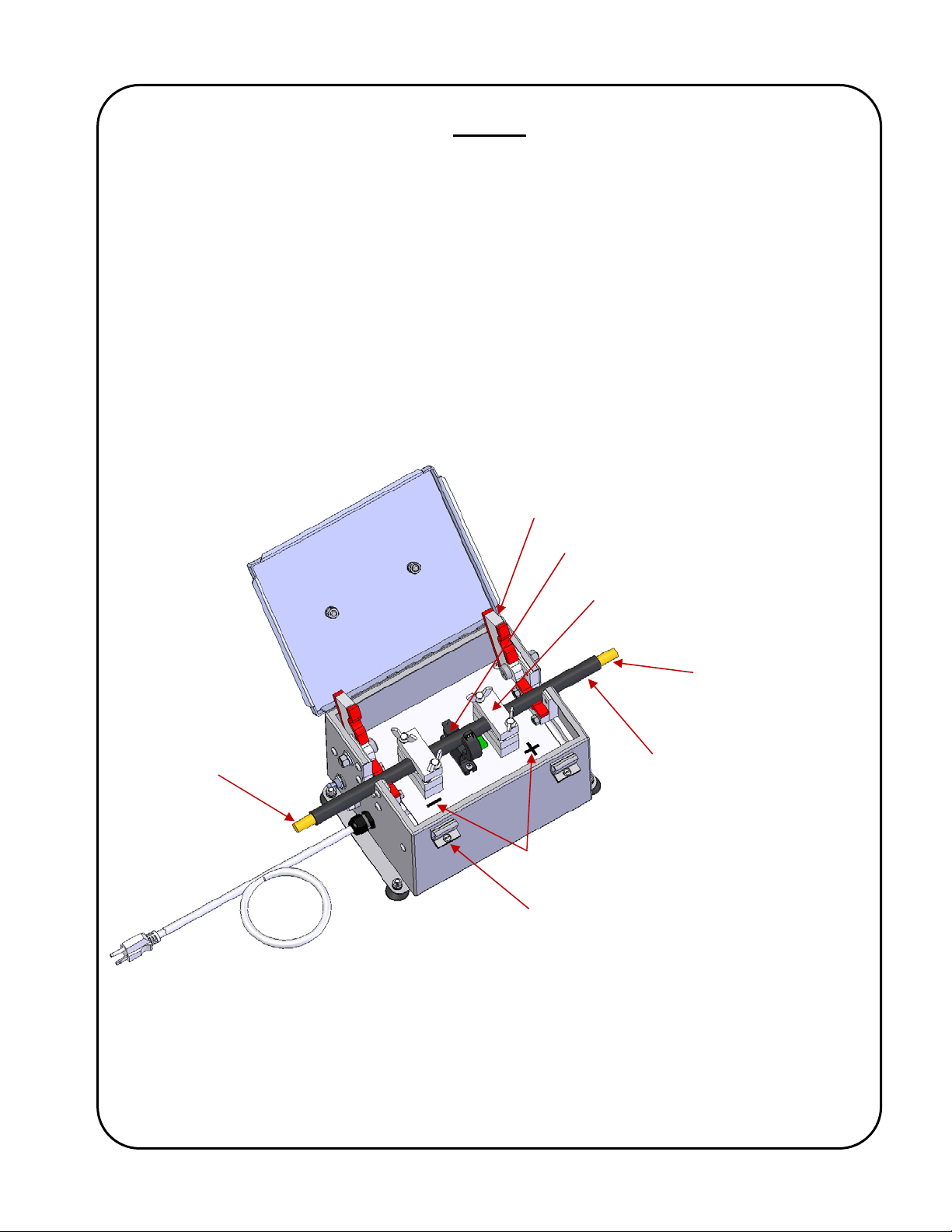

SETUP

Before powering up the E.A.H.S. make sure all components and cables are properly

connected. There are three (3) major components to the E.A.H.S. system; the sensor

control box, the remote pendant and the 4” linear slide. In order for the E.A.H.S. system to

operate, the welding ground cable must be routed through the sensor control box. The

direction of current flow or polarity is important or the E.A.H.S. will not be able detect

current thus not allowing it to track the arc height automatically. To open the sensor control

box loosen the lid clamping screws until the lid can be opened. Inside the control box there

are two (2) cable dust covers, two (2) cable clamps and the current sensor. To install the

welding ground cable open both dust covers and remove the wing screws on both cable

clamps. Remove small Phillips screw from the current sensor and open it. Place the

welding ground cable inside, shown below. Then close the current sensor reinstalling the

Phillips screw and tightening the cable clamps. Close the dust covers and the lid, then

tighten the lid clamp screws.

Electrode positive setup

“+” torch)

Dust cover

Current sensor

Cable clamp

Work piece ground

connection

Return path back to

welding power

source “-“ terminal

Welding ground

cable

Polarity reference

marks

Lid clamp

screw

For electrode negative setup (“-“ torch), flip the orientation of the welding ground in relation

the control box, the “+” reference will face welding power source while the “-“ reference will

face the work piece.

Note: Care should be taken to ensure that no foreign debris enters the main control box,

periodically check the condition of the foam gaskets and replace any that are damaged or

defective.

Loading...

Loading...