Gullco GK-200-RLx-L User Manual

“KAT”® CARRIAGE

COMPACT OSCILLATOR

SYSTEM

MODELS:

GK-200-RL*-L / GK-200-RM*-L / GK-200-RH*-L

GK-200-RL*-R / GK-200-RM*-R / GK-200-RH*-R

GK-200-FL*-L / GK-200-FM*-L / GK-200-FH*-L

GK-200-FL*-R / GK-200-FM*-R / GK-200-FH*-R

(* indicates voltage reference)

OPERATING

INSTRUCTIONS

Website: www.gullco.com

Distributed by:

Phone: 905-953-4140 Fax: 905-953-4138 e-mail: sales@gullco.com

Phone: 440-439-8333 Fax: 440-439-3634 e-mail: ussales@gullco.com

Phone: +44 1257-253579 Fax: +44 1257-254629 e-mail: uksales@gullco.com

Phone: 61 (0) 7 3348-5515 Fax: 61 (0) 7 3348-5510 e-mail: ausales@gullco.com

Phone: 91-20-65260382 Fax: 91-20-26836656 e-mail: indsales@gullco.com

GULLCO INTERNATIONAL LIMITED – CANADA

GULLCO INTERNATIONAL INC. – U.S.A.

GULLCO INTERNATIONAL [U.K.] LIMITED - EUROPE

GULLCO INTERNATIONAL PTY LIMITED - AUSTRALIA

GULLCO INTERNATIONAL LIMITED – INDIA

GULLCO INTERNATIONAL SHANGHAI – LIMITED

Phone: +8621-50460341 Fax: +8621-50463554 e-mail: c.zhang@gullco.com

Revised: March 18, 2014 GD-057-O GSP-2100

SAFETY INSTRUCTIONS

Although the “KAT”® Carriage/Compact Oscillator is manufactured for safe and dependable

operation, it is impossible to anticipate those combinations of circumstances which could result in

an accident. An operator of the “KAT”

"Safety First" during each phase of operation, set-up and maintenance.

Read and understand the operation manual before operating or performing service of this

equipment. Become familiar with the machines operation, applications and limitations. Keep the

operation manual in a clean and readily available location.

This equipment is normally used to automate / semi-automate welding or cutting processes. These

processes usually have any combination of the following; bright and hot arcs, flying sparks, fumes,

ultraviolet and infrared radiated energy, hot work-pieces, compressed gases, etc.. The onus is on

the operator of this equipment to know, understand and follow all the safety precautions associated

with the process being used.

A careless operator invites trouble, and failure to follow safety practices may cause serious injury or

even death. Important safety precautions are given in the following:

Electrical Shock Prevention

Do not use this equipment in damp or wet locations.

Do not expose this equipment to rain.

Never carry this equipment by the cables or pull the cables to disconnect from

the receptacle.

Keep all cables from heat, oil and sharp edges.

Inspect all cables periodically and replace if damaged.

Inspect the security of all cables periodically and repair if loose.

Disconnect the power cord when not in use.

Disconnect the power cord positively to prevent electrical shock before

repair and service of the equipment.

Carriage/Compact Oscillator is cautioned to always practice

®

Bodily Injury Prevention

Do not wear loose clothing, jewelry and loose, long hair which may get caught

into automatic systems or moving parts.

Ensure that the track is well secured when installed in any other position than

flat on a surface.

The track must have a method of safety back-up from falling when suspended,

i.e. chained at the ends, welded to work-piece, etc.

Keep lifting handle dry, clean and free from oil and grease.

Keep hands away from the underside of the “KAT”

carriage when there is the

®

slightest possibility of it moving.

If flex track is used, exercise extreme caution when mounting and handling the

track, as it is made of spring steel, and therefore poses a potential hazard of

injury due to “whipping”.

If flex track is used, always wear protective gloves when handling the track, to

prevent injury from sharp edges.

1

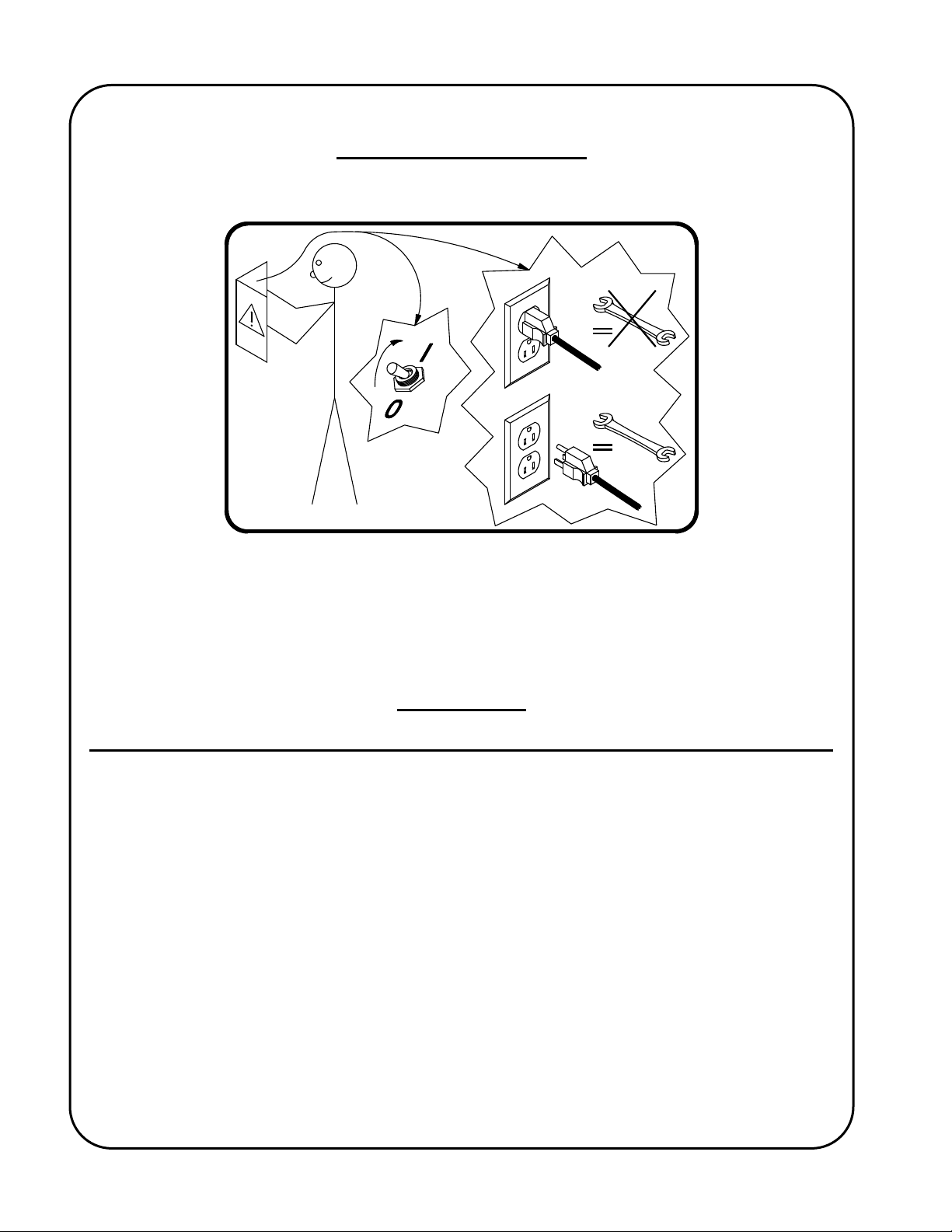

SAFETY PRECAUTIONS

The following cautionary/warning label is attached to each “KAT”® carriage:-

The above label pictorially represents the following:

“Warning:Read the manual before turning the unit on and before performing service.

Also, positively disconnect the unit from all power supplies before servicing!”

IMPORTANT

READ THIS BEFORE OPERATING THE “KAT”® CARRIAGE/COMPACT OSCILLATOR

WARNING! Always turn the main power off before connecting/disconnecting the oscillator head

cable to/from the “KAT”

Ensure that an adequate and well-maintained weld return path is provided with good electrical

contact. Failure to do so may result in the welding current passing through the carriage and

damaging the wiring and electrical components.

Important information regarding safety and operation of the “GSP-2100” motor control used in the

“KAT”

Manual. It is equally important to read, understand and apply the information contained within the

manual. The supplemental manual (GD-075) has a title “Technical Information For The Gullco

“GSP-2100” Micro-Processor Based, 24 Volt DC Motor Control”, and it’s pages are numbered with

a prefix of “T-“.

carriage is contained in a supplemental manual attached at the end of the Technical

®

carriage. Failure to comply may result in control damage.

®

ALL THE SAFE PRACTICES AND PRECAUTIONS MAY NOT BE GIVEN IN WRITING. SOME

ARE BASED ON COMMON SENSE, BUT OTHERS MAY REQUIRE TECHNICAL

BACKGROUND TO EXPLAIN.

2

“KAT”® CARRIAGE/COMPACT OSCILLATOR COMBINATION

This manual covers the operation instructions of the following “KAT”® Carriage/Compact Oscillator

systems, using Rigid or Flex “KAT”

or Radial Oscillator heads (* indicates input voltage: ‘A’ = 42 VAC; ‘B’ = 115 VAC; ‘C’ = 230 VAC):

GK-200-RL*-L / GK-200-RM*-L / GK-200-RH*-L

GK-200-RL*-R / GK-200-RM*-R / GK-200-RH*-R

GK-200-FL*-L / GK-200-FM*-L / GK-200-FH*-L

GK-200-FL*-R / GK-200-FM*-R / GK-200-FH*-R

, all position, variable speed travel carriages and either Linear

®

GENERAL DESCRIPTION

This advanced Gullco oscillation package combines the Gullco “KAT”® all position, travel carriage

with either the Linear or Radial compact oscillator head and oscillator control which is incorporated

into the carriage.

The Gullco “KAT”

is a heavy duty, all position travel carriage. It is an electrically powered, self

®

propelled carriage that travels in a forward or reverse direction, at precisely controlled speeds,

along a special track. The self aligning wheel system of the carriage grips the top and bottom of the

track, enabling it to travel along any plane. The bogey wheel assembly keeps the carriage snug to

the track, while allowing it to be easily mounted and removed from the track at any point. The

positive drive of the “KAT”

is obtained from either a pinion that engages with the rack of the rigid

®

track, or a spherical sprocket gear that engages with slots in the flex track. Both of these systems

are driven by a low voltage permanent magnet motor and gear-head power unit assembly. Safety

is greatly enhanced by the use of Gullco’s low voltage (24 V), highly advanced control/power supply

system that is available in three line voltage inputs... 42, 115 and 230 VAC, single phase, 50/60 Hz,

3

or any unregulated 24 VDC power supply at 220 watts of power. The micro-processor carriage

motor control offers operator interface of forward, stop, reverse and infinitely variable control of the

speed, within the range of the model, as well as an L.E.D. display indicating speed in either in/min.

or cm/min.

The Gullco Linear and Radial oscillator heads are compact, light weight, yet durable, reciprocating

devices with high torque, high resolution and low vibration stepper motors. They impart a linear,

pendulum or tangential motion to the welding gun. The low voltage Oscillator Control provides a

large, easy to read, multi-page graphical display and offers programmable and electronic

adjustment over the following functions:

Oscillation width

Oscillation speed

Independent Left, centre and right dwells

Oscillation centre positioning (steering)

Automatic wire feed activation

Automatic and Manual carriage travel activation

Weld travel start delay and weld crater fill delay

Standard (angular) or step (square) pattern oscillation

Multiple oscillation program storage

These features enable precise control over the automated cycle generating accurate and repetitive

weld oscillation.

Adjustable bracketry as well as vertical and horizontal Micro Fine Adjustable Rack Boxes, allow the

welding gun and the oscillator head to be easily mounted, adjusted and accurately positioned, in

virtually any plane, off the front or back of the “KAT”

carriage.

®

INTENDED / FORESEEN USAGE

The Gullco “KAT”® Carriage/Compact Oscillator combination is used throughout the world to

automate and improve the quality and efficiency of the weld produced in automatic mechanized

welding operations. This is achieved through minimizing weld defects such as poor penetration,

incomplete fusion, overlap and undercut. Also, detrimental factors such as poor or awkward

accessibility, operator fatigue, or inconsistent workmanship are eliminated. Required quality levels

are consistently attained and productivity and profitability increased.

Welding guns are readily mounted on the oscillator head and either a linear, pendulum or tangential

motion is used to produce either a standard angular or step (square) weld pattern. The track that

the “KAT”

carriage is going to travel along, is positioned so that the “KAT”® will move the oscillator

®

head and welding gun along the desired path and then securely held in place using magnetic or

vacuum activated mounting devices. Safety back-up devices such as chains at the ends of the

track; or welding some track mounting devices to the work-piece; must be implemented whenever

there is a possibility that the equipment may fall due to gravity. By combining welding gun

oscillation movement with the precision controlled travel speed of the “KAT”

carriage, a wide range

®

of weld patterns can be produced....as described on the following pages.

4

Loading...

Loading...