Gullco 350 User Manual

PARTS LIST

&

OPERATING INSTRUCTIONS

Self Propelled Portable Plate Edge Bevellers

Gullco has two new Portable Plate Edge Bevelling

Machines with

adjustable angle bevelling heads enabling bevel angles

of 22-1/2°

to 55°. They provide clean machined bevels with no

thermal

distortion. The KBM-18 and KBM-28 are both capable of

beveling any length of mild steel, stainless steel or

aluminum plate. The KBM -18 has a maximum bevel

width capacity of 0.70” (18mm) and can handle plate

thickness 1/4” to 1-1/2” (6.3 mm to 38.1 mm).The KBM-

28 has a maximum bevel width capacity of 1.10” (28mm)

and can handle plate thicknesses from 5/16” to 2” (7.93

mm to 50.8 mm).

*Both of the above machines have an adjustable angle

bevelling head 22-1/2° through 55°

ALL GULLCO PORTABLE

PLATE EDGE BEVELLERS...

- are designed for one man

operation

- are self-propelled

- are mounted on exclusive under

carriages

- have a spring loaded self-aligning

mechanism that automatically

compensates for uneven work

surfaces

- produce clean machined bevels

with no thermal distortion

- bevel any length of mild steel,

stainless steel or aluminum plate

“KAMEL’’ PIPE

TURNING ROLLS

Reduce pipe preparation

costs with this rugged,

portable equipment which

rotates pipe from 2” to 16” (51

- 406mm) diameter. Gullco

Kamel Rolls come complete

with a protected on/off foot

switch on a 10’ (3m) cable.

Electronic controls are

immune to damage from high frequency electromagnetic

interference.

Two models of Power Rolls are available;

Model KR-200-M...has a turning capacity of 1500 lbs

(680 kg), and an infinitely variable forward/reverse

speed

range of 1-40 ipm (2.5-102 cm/min).

Model KR-200-H...has a turning capacity of 1000 lbs

(454

kg) and an infinitely variable forward/reverse speed

range of

2-80 ipm (5-203 cm/min).

Idler Rolls:

Model KR-750...load capacity is 750 lbs. (340 kg) with a

pipe

diameter range of 2” - 6” (51 - 406 mm).

KATBAK

Ceramic Weld Backing

-Impart X-ray

Quality Back

Beads On Root

Pass

-Weld One Side

Only

-Deposit More

Weld Metal

-Root Weld And Fill In One

Pass

-Eliminate Defects And Rework

-Eliminate Costly Unnecessary

Gouging And Grinding

...available in a wide range of sizes

and shapes for a variety of applications

GULLCO CERAMIC WELD BACKINGS.....A

COST EFFECTIVE

CANTILEVERED

welding

positioners

Gullco Cantilevered Welding

Positioners are widely applied to

reduce the cost of welding pipe

flanges and fittings. They are comp

-act, portable and provide fast

positioning and smooth rotation.

Standard or Purge-Equipped

units are available...and each can

be supplied in one of two "speed range" models to suit specific

application requirements

- rotation speeds are electronically -150 lb (68 kg) capacity in the

controlled and infinitely vertical position and 300 lb (136

variable in either direction kg) in horizontal (Model GP-150-6)

- table tilt manually set at any - stop/start foot switch on 8’

angle through 180° (2438mm) cable

FOR MORE INFORMATION

MODELS

SPEED RANGE

Standard

GP-200-M

.025 to 6.5 RPM

GP200-H

0.50 to 15 RPM

Purge-

GPP-200-M

.025 to 6.5 RPM

Equipped

GPP-200-H

0.50 to 15 RPM

MODEL 350

350 LB (159 kg) CAPACITY

ELECTRODE STABILIZING OVEN

Tel: +44 1257 253 579 Fax: +44 1257 254 629 Email: sales@gullco.co.uk

GULLCO INTERNATIONAL LIMITED CANADA

Tel: 905-953-4140 Fax: 905-953-4138 E-mail: sales@gullco.com

GULLCO INTERNATIONAL INC U.S.A

Tel: 440-439-8333 Fax: 905-953-4138 Email: ussales@gullco.com

GULLCO INTERNATIONAL (U.K.) LIMITED EUROPE

GULLCO INTERNATIONAL PTY LIMITED AUSTRALIA

Tel: 61 (07) 5496 9555 Fax: 61 (07) 5496 9522 Email: ausales@gullco.com

GULLCO INTERNATIONAL LIMITED INDIA

Tel: 91 (20) 4272212 Fax: 91 (20) 4272212 Email: india.lo@gullco.com

April, 2009 GD-019

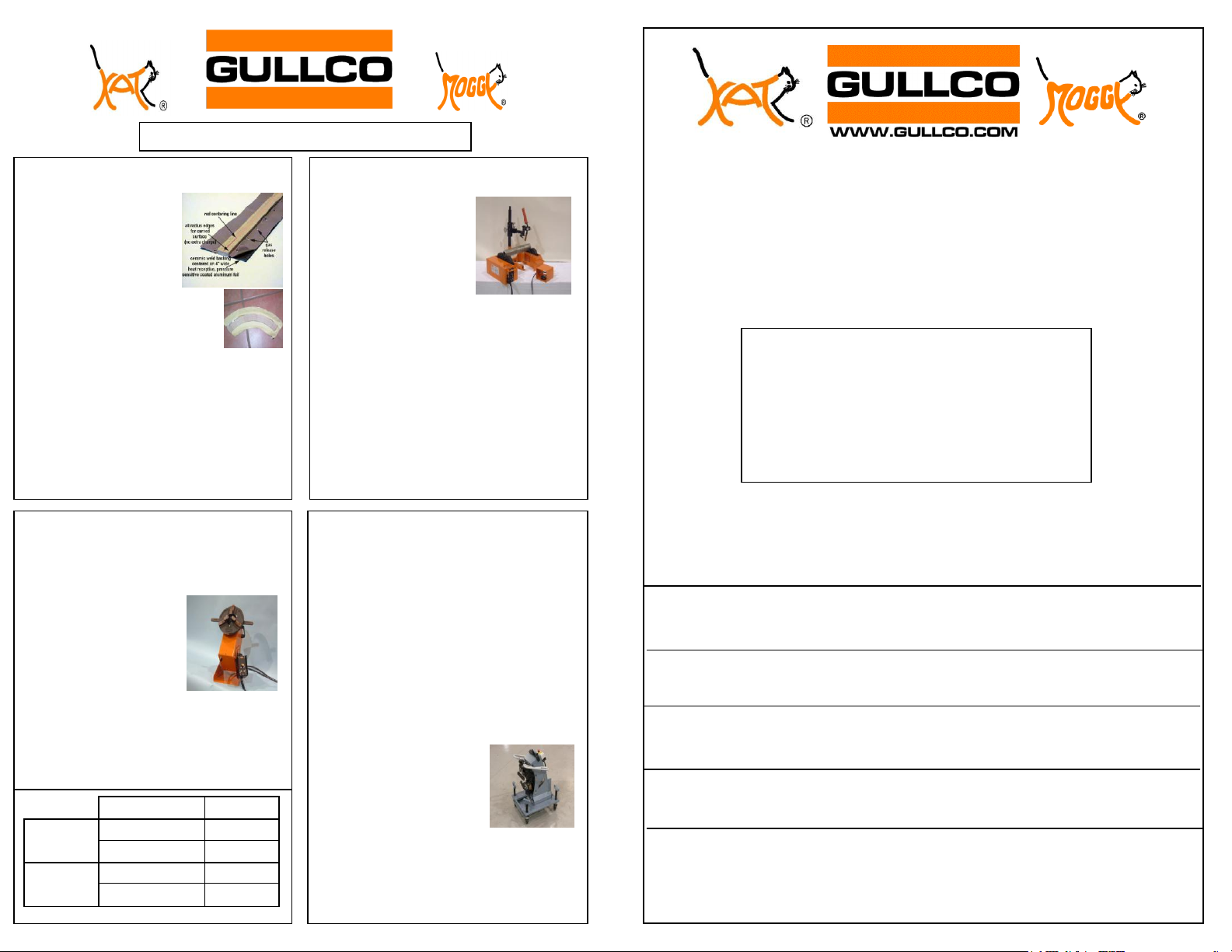

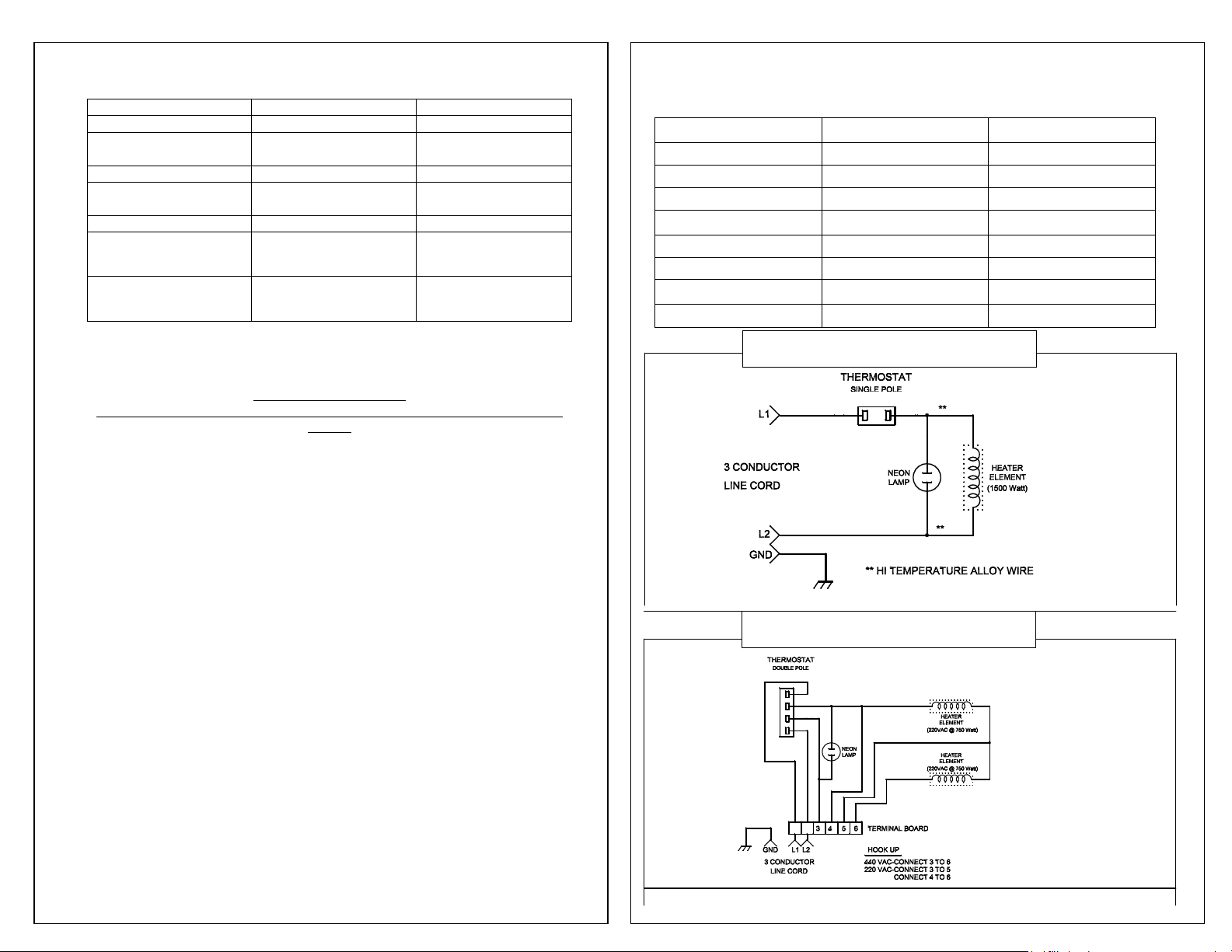

MODEL 350A

MODEL

350

350A

CAPACITY

350 LBS / 159 kg

350 LBS / 159 kg

VOLTAGE

(SEE RATING PLATE)

110 OR 220 VAC, 1PH.,

50/60 HZ

220 OR 440 VAC,

50/ 60 HZ

WATTAGE

1500 WATTS

1500 WATTS

TEMPERATURE

RANGE

100-550º F.

38-288°C

100-550º F.

38-288ºC

WEIGHT

105 LBS (47.6 KG)

105 LBS (47.6 KG)

EXTERNAL

DIMENSIONS

H-22”, W-22”, D--24½”,

H-559mm,W-559mm D622mm

H-22”, W-22”, D--24½”,

H-559mm,W-559mm D622mm

INTERNAL

DIMENSIONS

H-14”, W-16”, D-19”

H-355mm, W- 406mm, D482mm

H-14”, W-16”, D-19”

H-355mm, W- 406mm, D482mm

MODEL

350

350A

ELEMENT 110 VOLTS

1015

N/A

ELEMENT 220 VOLTS

1020

1015A

THERMOSTAT

EA-5

D1

THERMOSTAT KNOB

EA-5K

D1K

PILOT LIGHT 110 VOLT

1010A1

N/A

PILOT LIGHT 220 VOLT

2010-A1

1090-G1

LINE CORD

10-LC

N/A

THERMOMETER KIT

T-23

T-23

SCHEMATIC MODEL 350

SCHEMATIC MODEL 350A

SPECIFICATIONS

PARTS LIST

THE FOLLOWING INSTRUCTIONS AND SAFTEY WARNINGS MUST BE READ

BEFORE THIS EQUIPMENT IS CONNECTED AND PLACED INTO SERVICE

ENSURE THAT SUPPLY VOLTAGE MATCHES THAT SHOWN ON RATING

The Model 350 and the Model 350A are 350 Lbs. (159 kg) capacity electrode

stabilizing ovens used to maintain welding electrodes in their dry state or to dry

electrode which have absorbed moisture. The Model 350 operated on single phase

power with heat being supplied by a single element. The Model 350A connects to three

phase power with heat being supplied by two elements. The ovens are normally located

in a central storage area. They are complete with recessed controls, removable shelves,

full insulation pilot light and a heating system incorporating low watt density elements.

Temperature is thermostatically controlled. Nesting feet and sockets ensure safe, easy

stacking of up to four ovens.

Ensure adequate free space is provided around the ovens for safe loading and

unloading of the electrodes. Users should exercise caution when loading and unloading

the oven. Certain parts of the oven and the electrodes may reach temperatures

exceeding 550º F (288°C). All exposed body parts must be protected against accidental

contact with hot materials. Safety glasses, gloves, overalls, and protective footwear

must be worn when using the over. Hot electrodes must be unloaded into a suitable

container capable of withstanding the heat and of containing the load safely.

To minimize the risk of electrical shock the Model 350 and Model 350A

should not be exposed to rain or placed in a wet location. Liquids should not be placed

in the oven. The oven should be connected to a suitable, fused power supply using a

recognised connector. The oven must be properly earth grounded. Before performing

ensure it cannot be restored. To minimise the risk of fire do not place food, beverages

or other combustible items in the oven.

USING THE OVEN

The oven is loaded and unloaded via the front door. Avoid contact with hot

surfaces during this operating. The load should be distributing securely and evenly

within the oven to ensure even heating. The shelves may be removed to accommodate

larger loads if required.

BEFORE CONNECTION:

PLATE

Loading...

Loading...