Page 1

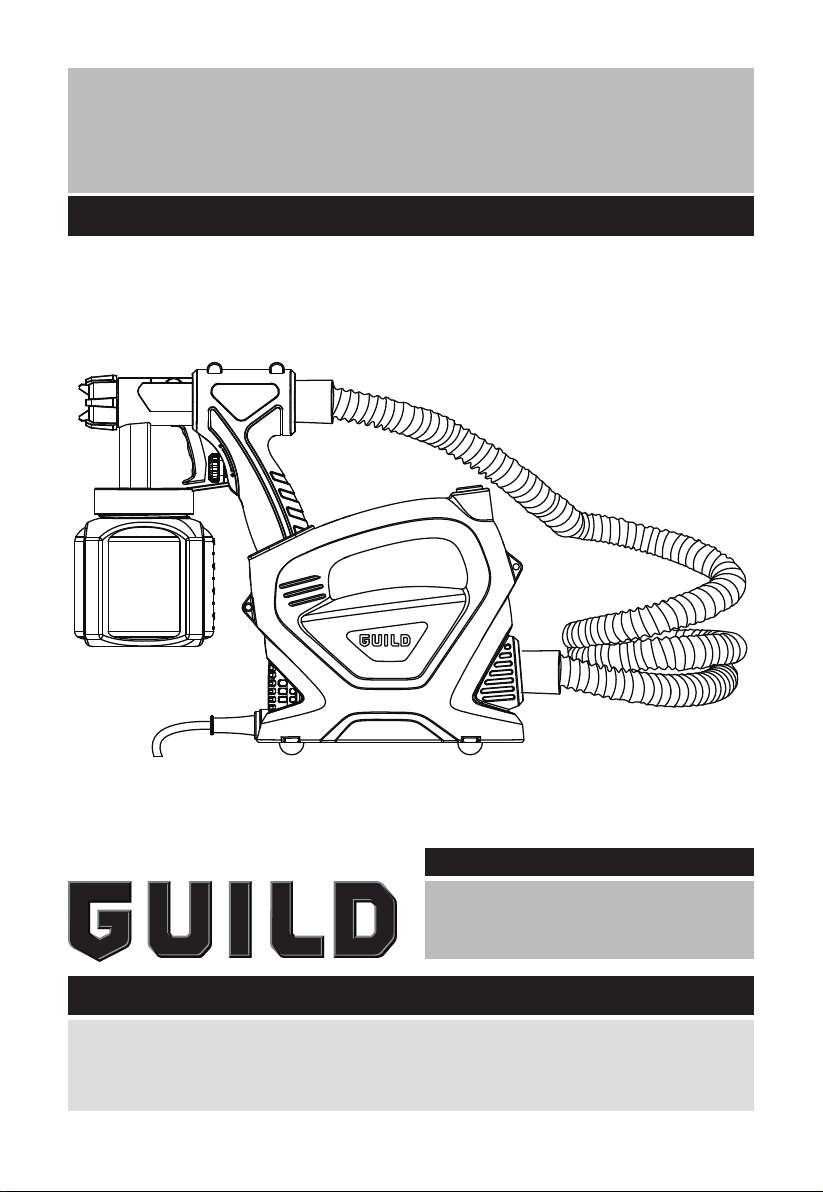

GUILD

500W Spray gun

Instruction Manual

PRG500G

After Sales Support

UK/Ireland 0333 3201989

Help@guildpowertools.co.uk

Important - Please read these instructions fully before operating or maintaining your Guild Spray gun

These instructions contain important information that will help you get the best from your Guild

Spray Gun, ensuring it remains safe to operate.

If you need help or have damaged or missing parts, call the Customer Helpline on 0333 3201989

Page 2

Contents

Safety Information.....................................................................................................3

In The Box..................................................................................................................6

Accessories................................................................................................................6

Operating Instructions...............................................................................................7

Troubleshooting.......................................................................................................12

Technical Data..........................................................................................................13

Environmental Protection........................................................................................14

Guarantee................................................................................................................15

2

Customer Helpline 0333 3201989

Page 3

Safety Information

Important - Please read these instructions fully before starting assembly

Warning Symbols

The following warning symbols appear throughout this assembly manual and

indicate the appropriate safety measures you should take when assembling and

operating the belt sander.

To reduce the risk of injury. Please read the instruction manual

Warning

Wear ear protection

Wear eye protection

Wear dust mask

Double insulation

Waste electrical products must not be disposed of with household waste. Please recycle

where facilities exist. Check with your local authorities or retailer for recycling advice.

Warning: Do not direct the jet at persons, animals and electrical equipment.

Customer Helpline 0333 3201989

3

Page 4

Safety Information

Important - Please read these instructions fully before starting assembly

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

4

Customer Helpline 0333 3201989

Original Instructions

Page 5

Safety Information

Important - Please read these instructions fully before starting assembly

General Power Tool Safety Warnings

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce

dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

5) Service

Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Spray gun safety warnings

1. Do not use guns for spraying flammable materials.

2. Do not clean guns with flammable solvents.

3. Warning! Be aware of any hazard presented by the material being sprayed

and consult the markings on the container or the information supplied by the

manufacturer of the material to be sprayed.

4. Do not spray any material where the hazard is not known.

5. Use appropriate personal protective equipment, such as dust mask, protective

clothing.

6. Do not clean guns with flammable solvent.

7. Recommendation that the tool always be supplied via a residual current device with a

rated residual current of 30mA or less.

Customer Helpline 0333 3201989

5

Page 6

In The Box

2

Parts

1

Trigger

2

Flow rate adjustment screw

3

Spray gun

4

Air hose

5

On / Off switch

6

Blower

7

Container

8

Air cap

9

Nozzle

10

Cap nut

11

Viscosity cup

12

Nozzle cleaning needle

Shoulder strap

13

1 2

3

4 5

9 108

67

11 12 13

Accessories

Viscosity cup 1pc

Nozzle cleaning needle 1pc

Shoulder strap 1pc

6

Customer Helpline 0333 3201989

Page 7

Operating Instructions

NOTE: Before using the tool, read the instruction book carefully.

Intended Use

The spray gun is for spraying non-flammable and non-hazardous paints and varnishes

suitable. The tool could not be used for spraying of flammable liquids. Do not use the tool

for the food, pharmacy or other purposes that are not mentioned in the manual.

1. COATING MATERIALS

Solvent-based and water-based paints, finishes, primers, two-component paints,

varnishes, automotive topcoats, stains and wood preservatives.

2. UNSUITABLE COATING MATERIALS

Wall colors (dispersion), etc., alkali and acidic paints.

3. PREPAREDNESS THE COATING MATERIAL

Measuring the viscosity using the viscosity cup. (See Fig. A)

1) Stir well coating material before the start of the measurement.

2) Fill the viscosity cup with coating material (100 cm3).

3) Lift viscosity cup and measure the time in seconds, until the coating material finish

dripping.

4) These are called run-DIN-seconds (DIN-s)

Coating material viscosity DIN-s

Solvent-based paints-------------------------------15-50

Primers--------------------------------------------25-50

Pickling----------------------------------------undiluted

2 Combination paints-------------------------------20-50

Varnishes------------------------------------------15-40

Waterborne paints---------------------------------20-40

Automotive topcoats-------------------------------20-40

Wood protection center l ----------------------undiluted

A

�╚└� 25.400

Customer Helpline 0333 3201989

7

Page 8

Operating Instructions

4. CONNECT THE AIR HOSE TO THE TOOL.

1) Insert the air hose end to the guide at side of device firmly. (See Fig. B1)

2) Insert another side of air hose to the connector of gun side firmly. (See Fig. B2)

5. THE RISER

1) Unscrew the container of the spray gun.

2) Assemble the riser correctly according to different situation to reduce the liquid in the

container as much as possible.

Spraying with underlying objects

- rotating riser forward. (SEE FIG. C1)

NOTE: Don’t tilt it at a large angle.

Spray job with overhead objects

- rotating riser backwards. (SEE FIG. C2)

Note: Don’t tilt it at a large angle.

3) Place one paper under the container. Pour the prepared coating material into the container.

4) After you pour liquid into the container, screw the container back into the spray gun. And

tighten it.

B1

C1

8

B2

C2

Customer Helpline 0333 3201989

Page 9

Operating Instructions

6. ON/OFF SWITCH (SEE FIG. D)

To start the tool, depress the protective cover over the switch indicated by the mark “I”.

To stop the tool, depress the protective cover indicated by the mark “O”.

7. TAKE THE SPRAY GUN OUT OF THE GUN HOLDER (SEE FIG. E)

This tool is equipped with 1.8m air hose. The spray gun can be taken out of the gun holder to

make work more convenient.

8. TRIGGER (SEE FIG. F1)

Depress the trigger for spraying work.

9. ASSEMBLE THE SHOULDER STRAP.(SEE FIG F2)

There are two holes on the blower,you can use the shoulder strap pothook to install it.

D E

F1 F2

Customer Helpline 0333 3201989

9

Page 10

Operating Instructions

10. ADJUSTMENT OF THE SPRAY GUN

Selection spray patterns

1) Unscrew the cup nut.

2) Setting the position of air cup to the desired situation.

The Horizontal position of air cup(SEE FIG. G1)=the spraying shape is vertical: for vertical surface.

The vertical position of air cup (SEE FIG. G2)=the spraying shape is horizontal: for horizontal

surface.

The oblique position of air cup (SEE FIG. G3)=the spraying shape is circular: for corners,

edges and others.

3) Screw the cup nut and tighten it.

WARNING! Never change the setting of the air cup when pulling the trigger.

Adjustment of the rate of flow (SEE FIG. H)

The material volume by turning the flow rate adjustment screw.

+ Rotate anticlockwise: reduce the rate of flow

- Rotate clockwise : increase the rate of flow

G1

G3

G2

H

10

Customer Helpline 0333 3201989

Page 11

Operating Instructions

11. SPRAY TECHNOLOGY

1) The intended surface should be smooth and clean. And the surface must be pretreated and dust-free.

2) Surface not to be sprayed must be covered with tape and newspaper.

3) Cover screw or similar at the object need to be covered.

4) It is important to perform on cardboard or a similar surface spray sample to find the right spray gun setting.

Correct directional length

Hold the spray gun at straight distance of about 5 -15 cm from the object being sprayed. (SEE FIG. I1)

Incorrect

Overspray, unevenly even surface quality. (SEE FIG. I2)

NOTE: Cleanness is necessary as coating material buildup on the nozzle and air cap A B,

both parts with solvents or water. (SEE FIG. I3)

12. WORK STOPPAGES

1) Switch off the device.

2) Back spray gun to the spray gun holder.

13. CLEANING

1) Switch off the device. Press the trigger, so that the coating material in the spray gun

passes back into the container.

2) Unscrew the container. Empty the remaining coating material.

3) Clean containers and tubing with brush.

4) Screw the container. Always keep container seal free of paint residue and check for damage.

5) Clean spray gun and container exterior with a cloth soaked in solvent and water cloth.

NOTE: Never clean the nozzle or air holes in the spray gun with sharp metal objects.

I1

I3

5-15cm

I2

A

B

Customer Helpline 0333 3201989

11

Page 12

Troubleshooting

Problem Cause Remedy

Nozzle clogged Clean

Riser clogged Clean

Small holes on the riser

No coating

material come out

from Nozzle

Dropping coating

material at nozzle

Spray too thick

Spray unstable

Drip in spraying

pipe clogged

Flow setting is at min level Rotate the ow rate adjustment

Riser loose

Container loose

The viscosity is too high

Nozzle loose

Worn nozzle

Coating material

accumulated at air cap and

nozzle

The viscosity is too high

Flow setting is at max level

Too little pressure in the

container

Litter coating material in

container

The lter is too dirty

Flow setting is at max level

Clean

screw clockwise

Tighten the riser

Tighten the container

Dilution

Tighten nozzle

Replace

Clean

Dilution

Rotate the flow rate adjustment

screw anticlockwise

Tighten the container

Add more coating material

Clean or replace

Rotate the flow rate adjustment

screw anticlockwise

12

Customer Helpline 0333 3201989

Page 13

Technical Data

Technical Data Table

Voltage

Power consumption 500 W

Nozzle size 2.5mm

Max air volume ow 600ml/min

Max viscosity 60DIN-s

Air hose length 1.8m

Tank capacity 800 ml

Spraying pressure

Protection degree

Weight

220-240V~50Hz

0.1-0.2bar

/II

1.82kg

Noise Information

A weighted sound pressure LpA :83dB(A)

A weighted sound power LwA : 94dB(A)

KpA & KwA=3.0dB(A)

Wear ear protection

Vibration Information

Vibration total values (triax vector sum) determined according to EN 60745 & EN50580:

Vibration emission value ah = 2.687m/s

Uncertainty K = 1.5m/s²

2

WARNING: The vibration emission value during actual use of the power tool can

differ from the declared value depending on the ways in which the tool is used

dependant on the following examples and other variations on how the tool is used:

How the tool is used.

The tool being in good condition and well maintained

Using the correct accessory for the tool and ensuring it is in good condition.

The tightness of the grip on the handles and if any anti vibration accessories are used.

And the tool is being used as intended by its design and these instructions.

This tool may cause hand-arm vibration syndrome if its use is not adequately

managed

WARNING: To be accurate, an estimation of exposure level in the actual conditions

of use should also take account of all parts of the operating cycle such as the times

when the tool is switched off and when it is running idle but not actually doing the job. This

may signicantly reduce the exposure level over the total working period.

Customer Helpline 0333 3201989

13

Page 14

Technical Data

Vibration Information

Helping to minimise your vibration exposure risk.

Maintain this tool in accordance with these instructions and keep well lubricated (where

appropriate)

If the tool is to be used regularly then invest in anti vibration accessories.

Plan your work schedule to spread any high vibration tool use across a number of days.

Environmental Protection

Waste electrical products must not be disposed of with household waste. Please

recycle where facilities exist. Check with your local authorities or retailer for

recycling advice.

14

Customer Helpline 0333 3201989

Page 15

Guarantee

This product is selected for DOMESTIC USE ONLY and not for business use.

This product is guaranteed against manufacturing defects for a period of 24 months. This

does not cover the product where the fault is due to misuse, abuse, use in contravention of

the instructions, or where the product has been the subject of unauthorised modifications

or alterations, or has been the subject of commercial use. In the event of a problem with

the product within the guarantee period please return it to your nearest store. If the item is

shown to have an inherent defect present at the time of sale, the store will provide you with

a replacement. Your statutory rights remain unaffected.

Issue1 08/2018

Customer Helpline 0333 3201989

15

Page 16

Loading...

Loading...