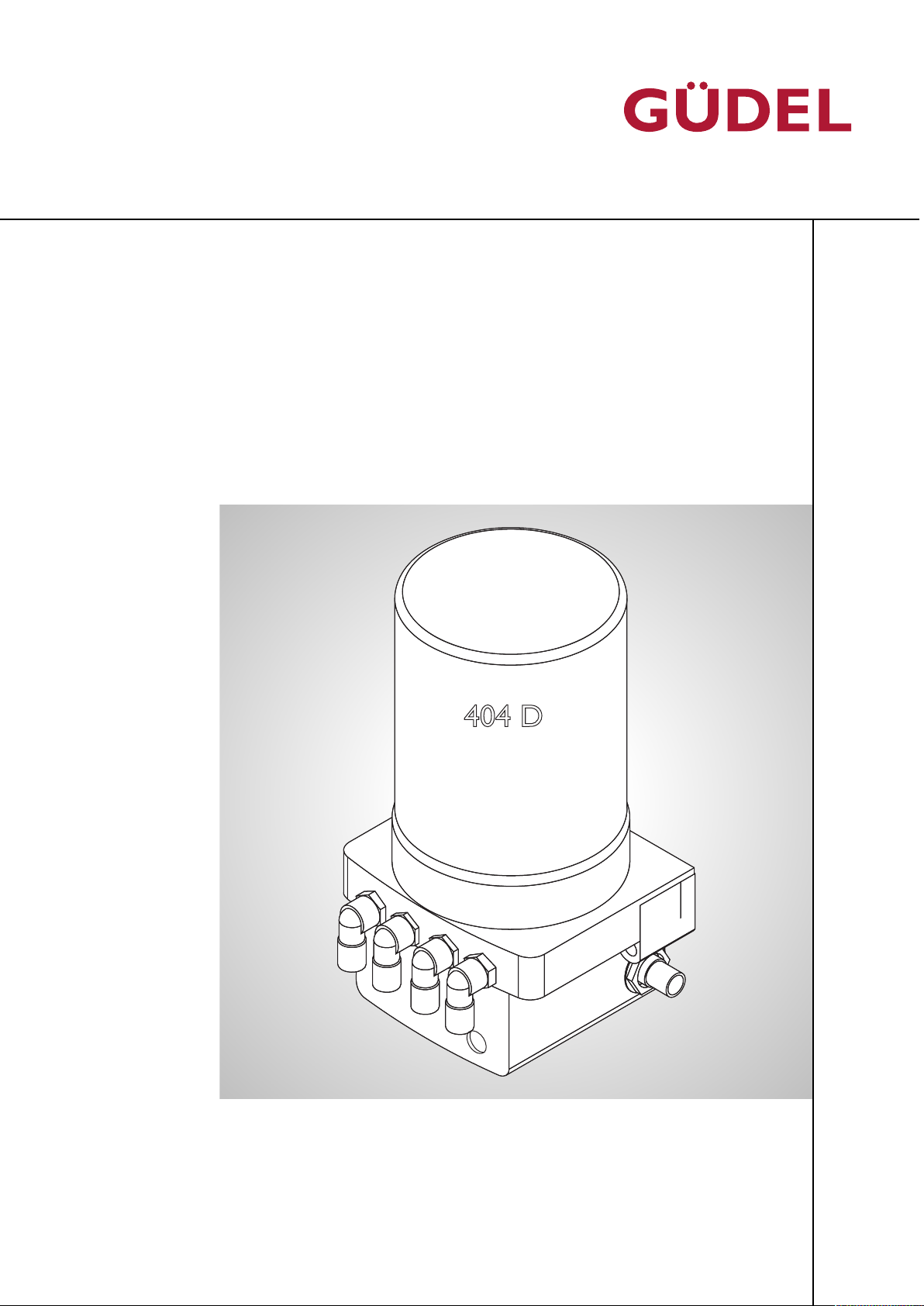

GUDEL 404DLS Operating Manual

404 DLS

OPERATING MANUAL

BETRIEBSANLEITUNG AUTOMATIC LUBRICATION SYSTEM FLEXXPUMP 404DLS72057594178931083_V7.0_EN-US

B1X.xxxxxxxxx-xxxx

09xxxxx

2018

Automatic lubrication system

FlexxPump 404DLS

Project / Order:

Bill of materials:

Serial number:

Year of manufacture:

© GÜDEL

Translation of the original instructions

This manual contains standard illustrations that may deviate from the original.

In the case of special models, options, or technical changes, the scope of delivery may differ from the descriptions here. Reprinting the instructions, in whole

or in part, requires our permission. Subject to change due to technical improvements.

72057594178931083_v7.0_EN-US

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

Revision history

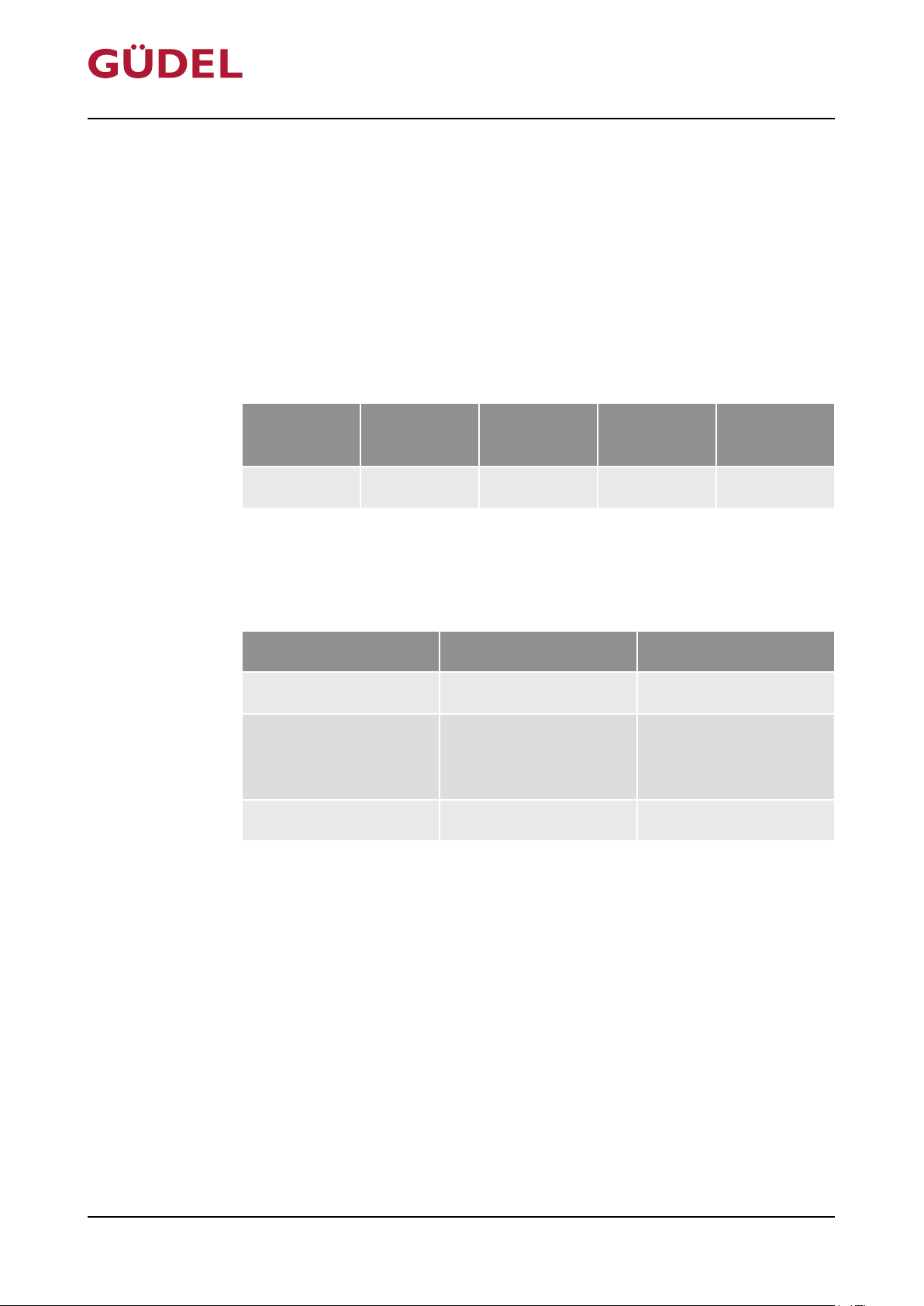

Version Date Description

7.0 01.06.2018 Valid as of FlexxPump serial number

Revision history

1601929

Updated:

• Actuate ÜChapter6.4,243

• Lubrication recommendation Ü255

New:

• Splitter Ü229

ÜChapter5.2.3.1,233

6.0 12.04.2018 Updated:

5.0 12.12.2017 Updated:

4.0 08.08.2017 Added:

3.0 27.02.2017 Corrected:

2.0 29.11.2016 Updated:

1.0 29.07.2016 Basic version

Table-1 Revision history

• Lubrication check Ü261

• Lubrication check Ü261

• Lubrication check Ü261

• Standards and guidelines of the Declaration of conformity ÜChapter1,211

• New signatures on Declaration of conformity ÜChapter1,211

• Entire manual updated

72057594178931083_v7.0_EN-US

3

Revision history

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

72057594178931083_v7.0_EN-US

4

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

Table of contents

Table of contents

1 EC declaration of conformity 11

2 General 13

2.1 Further applicable documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Purpose of the document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.3 Explanation of symbols/abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Safety 15

72057594178931083_v7.0_EN-US

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1.1 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.2 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.2.1 Operating companies. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.2.2 Transport specialists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.2.3 Fitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.2.4 Commissioning technicians . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.2.5 Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.2.6 Manufacturer's technicians. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1.2.7 Maintenance technicians . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.1.2.8 Service technicians . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.2.9 Disposal specialists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.3 Disregarding safety regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.4 Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Hazard symbols in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.1 Hazard warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.2 Explanation of warning symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Fundamentals of safety. . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 23

3.3.1 Product-specific hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.3.2 Material safety data sheets (MSDS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5

OPERATING MANUAL Automatic lubrication system

Table of contents

FlexxPump 404DLS

4 Product description 25

4.1 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1.2 Non-intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.2 Product designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.1 FlexxPump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.1.1 Dimensions and connections 404DLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.1.2 Temperature ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3.1.3 IP protection class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3.1.4 Operating pressure. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3.2 Splitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.3.2.1 Temperature ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3.2.2 Accuracy of the lubricant distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3.2.3 Minimum lubrication quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3.2.4 Maximum pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3.3 Lubricant amount . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.3.4 Shelf life of Güdel H1 lubricant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 Design, function 31

5.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.1 Detailed design of FlexxPump 404DLS . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . .32

5.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2.1 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.2.2 FlexxPump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2.2.1 404DLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2.3 Splitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

72057594178931083_v7.0_EN-US

5.2.3.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

Table of contents

6 Commissioning 35

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1.1.1 Personnel qualifications. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.1 Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.2 Installing the FlexxPump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.3.3 Connect hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.3.1 404DLS 3-fold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.3.2 404DLS 6-fold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3.3.3 404DLS 10-fold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.3.4 Connecting electrical equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.3.4.1 Connecting the 404DLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.4 Actuate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.4.1 Recommended solution, software programming . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.4.2 Switching the FlexxPump on and off. . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . 45

6.4.3 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.4.4 Filling hydraulic lines / venting the FlexxPump. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.4.5 Error message: Empty . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .51

6.4.6 Error message: General. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 53

6.4.7 Lubrication recommendation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.4.7.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.4.7.2 Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.4.7.3 Minimum lubrication quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.4.7.4 Calculation formulas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

72057594178931083_v7.0_EN-US

6.5 Initial commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.5.1 Carrying out a lubrication check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

7

OPERATING MANUAL Automatic lubrication system

Table of contents

FlexxPump 404DLS

7 Operation 66

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

7.2 Personnel .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

8 Maintenance 69

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.1.2 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 69

8.2 Consumables and auxiliary agents. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . 70

8.2.1 Cleaning agents . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

8.2.1.1 Table of cleaning agents . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 70

8.2.2 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.2.2.1 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Automatic lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2.2.2 Lubricant table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.3 Maintenance tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.3.1 Checking automatic lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.3.2 Replacing the cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8.4 Maintenance table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9 Repairs 79

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9.1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9.1.2 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 79

9.2 Malfunctions / Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

72057594178931083_v7.0_EN-US

9.3 Service departments .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

Table of contents

10 Decommissioning, storage 81

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.1.1 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 81

10.2 Storage conditions . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .81

10.3 Decommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 82

10.3.1 Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.3.2 Cleaning, rust-proofing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.3.3 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.4 Recommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11 Disposal 85

11.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11.1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11.1.2 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 85

11.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.3 Waste management compliant assemblies . . . . . . . . . . . . . . . . . . . . . . . . 86

11.3.1 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.3.2 Material groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

11.4 Disposal facilities, authorities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

12 Accessories 89

12.1 PLC connecting cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13 Spare parts supply 91

72057594178931083_v7.0_EN-US

13.1 Service departments .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

13.2 Explanations regarding the spare parts list . . . . . . . . . . . . . . . . . . . . . . . . 99

13.2.1 Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.2.2 Position drawings . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .99

9

OPERATING MANUAL Automatic lubrication system

Table of contents

FlexxPump 404DLS

14 Torque tables 100

14.1 Tightening torques for screws. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

14.1.1 Zinc plated screws . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . 101

14.1.2 Black screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

14.1.3 Stainless steel screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Illustrations 105

List of tables 107

Index 109

Appendix

Layout

Spare parts lists

72057594178931083_v7.0_EN-US

10

OPERATING MANUAL Automatic lubrication system

Automatic lubrication system FlexxPump 404DLS

09xxxxx

2018

xx.xx.20xx

FlexxPump 404DLS

Declaration of conformity, declaration of incorporation

1 EC declaration of conformity

The manufacturer: GÜDEL AG

Industrie Nord

CH-4900 Langenthal

hereby declares that the machine:

Product, type

Serial number

Parts list

Year of manufacture

corresponds to the applicable requirements of the Machinery Directive

(2006/42/EC).

72057594178931083_v7.0_EN-US

Authorized representative responsible for compiling the technical documentation:

Michael Marti Tel. +41 (0)62 916 91 37

The machine complies with the following other EC directives:

• Low Voltage Directive2014/35/EU

• EMC Directive2014/30/EU

The following harmonized standards have basically been applied:

EN ISO 12100:2010; EN ISO 13850:2015; EN 60204-1:2006; EN ISO

14119:2013; EN ISO 4413:2010; EN ISO 4414:2010; EN ISO 13849-1:2015

Langenthal,

Markus Ruprecht

CEO

Michael Marti

Director R&D

11

Declaration of conformity, declaration of incorporation

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

12

72057594178931083_v7.0_EN-US

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

2 General

Read the entire manual before working with the product. The manual contains important information for your personal safety. The manual must be

read and understood by all persons who work on the product in any of the

product life phases.

2.1 Further applicable documentation

All documents delivered with this manual are further applicable documentation. They must be observed in addition to this operating manual for the safe

handling of the product.

General

2.2 Purpose of the document

This manual describes all the product life phases of the product:

• Transport

• Commissioning

• Operation

• Maintenance

• Repairs

• Disposal

The manual contains the information required for using the product as intended. It is an essential component of the product.

The manual must be available at the product site throughout the entire service life of the product. If the product is sold, the manual must be transferred

to the new owner.

72057594178931083_v7.0_EN-US

13

Ü

2

OPERATING MANUAL Automatic lubrication system

General

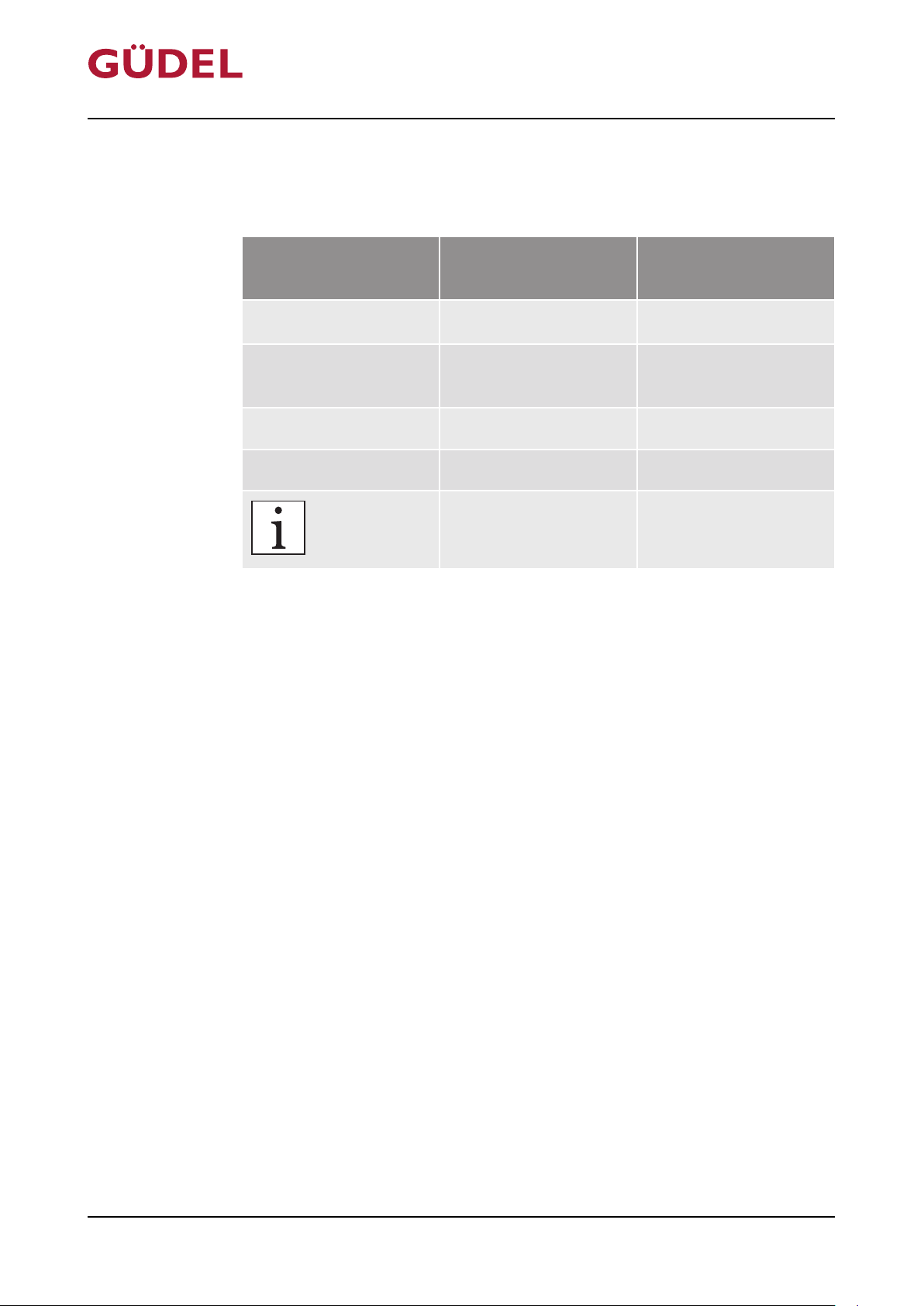

2.3 Explanation of symbols/abbreviations

The following symbols and abbreviations are used in this manual:

FlexxPump 404DLS

Symbol/Abbreviation

Fig. Designation of graphics Figure

Table Designation of tables Table

Table2-1 Explanation of symbols/abbreviations

Use Explanation

For cross-reference See

Possibly for cross-ref-

Page

erence

In the tip Information or tip

72057594178931083_v7.0_EN-US

14

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

3 Safety

3.1 General

Read the entire manual before working with the product. The manual contains important information for your personal safety. The manual must be

read and understood by all persons who work on the product in any of the

product life phases.

3.1.1 Product safety

Safety

Residual danger

Operation

The product is built using state-of-the-art technology. It was designed and

constructed in accordance with the accepted safety regulations. However,

some residual danger remains during its operation.

There is danger to the personal safety of the operator as well as for the product and other property.

When operating the product, always observe this manual and ensure that the

system is always in perfect working order.

72057594178931083_v7.0_EN-US

15

Safety

3.1.2 Personnel qualifications

Lack of safety training

Incorrect behavior of untrained or insufficiently trained technicians can result

in severe or fatal injuries!

Before technicians work on safety-related aspects of the product:

• Ensure that the technicians are trained with regard to safety

• Train and instruct the technicians specifically for their area of responsibility

Only appropriately trained and authorized technicians are allowed to work on

the product.

Persons are authorized if:

• they are familiar with the relevant safety regulations for their area of responsibility

• they have read and understood this manual

• they meet the requirements for an area of responsibility

• they were assigned an area of responsibility by the operator

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

WARNING

The technician is responsible to third parties in his area of responsibility.

During a training session or instruction, the technician may only work on the

product under the supervision of an experienced manufacturer's technician.

3.1.2.1 Operating companies

The operating company is responsible for ensuring that:

• the product is used as intended

• the product is sufficiently lubricated at all times

• all safety aspects are complied with

• the product is put out of operation if the functioning of the safety equipment is not fully guaranteed

• the technician working on the product is appropriately trained

• the technician is provided with personal protective equipment

• the operating manual is available to the technician at the operation site of

the product at all times

• the technicians are kept up-to-date regarding best practice

• the technicians are informed about technical progress, modifications, and

the like.

• the contracted cleaning staff only work under the supervision of a maintenance technician

72057594178931083_v7.0_EN-US

16

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

3.1.2.2 Transport specialists

The transport specialist:

• is able to transport loads safely

• is able to use slings safely and properly

• is able to secure the load properly

• has experience in transportation

3.1.2.3 Fitters

The fitter:

• has very good mechanical and/or electrical knowledge

• is flexible

• has assembly experience

3.1.2.4 Commissioning technicians

Safety

72057594178931083_v7.0_EN-US

The commissioning technician:

• has good programming knowledge

• has mechanical and/or electrical knowledge

• is flexible

The commissioning technician is responsible for the following tasks:

• commissioning the product

• testing the functions of the product

3.1.2.5 Operators

The operator:

• was trained and instructed by the operating company or the manufacturer

• has very good knowledge of the user interface and the operating elements

• has process knowledge which is specifically geared to the product

The operator is responsible for the following tasks:

• switching the control system of the product on and off

• creating production readiness

• monitoring the production process

• localizing minor malfunctions

17

Safety

3.1.2.6 Manufacturer's technicians

The manufacturer's technician:

• is employed on site at the premises of the manufacturer or representative

• has very good mechanical and/or electrical knowledge

• has good software knowledge

• has maintenance, service and repair experience

• has experience with Güdel products

The manufacturer's technician is responsible for the following tasks:

• performing mechanical and electrical maintenance work in accordance with

the manual

• performing mechanical and electrical service work in accordance with the

manual

• cleaning the product

• replacing spare parts

• localizing and fixing malfunctions

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

3.1.2.7 Maintenance technicians

The maintenance technician:

• was trained by the operating company or the manufacturer

• has very good mechanical and/or electrical knowledge

• has software knowledge

• has maintenance experience

• bears responsibility for the safety of the cleaning staff

The maintenance technician is responsible for the following tasks:

• performing mechanical and electrical maintenance work in accordance with

the manual

• cleaning the product

• replacing spare parts

• monitoring and instructing the cleaning staff in the safety zone during the

cleaning process

72057594178931083_v7.0_EN-US

18

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

3.1.2.8 Service technicians

The service technician:

• was trained by the operating company or the manufacturer

• has very good mechanical and/or electrical knowledge

• has software knowledge

• has service and repair experience

• is flexible

The service technician is responsible for the following tasks:

• performing mechanical and electrical service work in accordance with the

manual

• replacing spare parts

3.1.2.9 Disposal specialists

The disposal specialist:

• is able to separate waste

• is familiar with the country-specific disposal regulations

• has experience in environmentally-friendly disposal

• works carefully and safely

Safety

72057594178931083_v7.0_EN-US

19

OPERATING MANUAL Automatic lubrication system

Safety

3.1.3 Disregarding safety regulations

DANGER

Disregarding safety regulations

Disregarding safety regulations can result in damage to property, severe or

fatal injuries.

• Always comply with the safety regulations

FlexxPump 404DLS

Liability

Güdel shall not be held liable under any of the following circumstances:

• The installation regulations were disregarded

• Included protective equipment was not installed

• Included protective equipment was modified

• Included monitoring equipment was not installed

• Included monitoring equipment was modified

• The product was not used as intended

• The maintenance work was not performed in the specified intervals, or

was carried out incorrectly.

3.1.4 Installation instructions

Protective mea-

sures

The operating company is responsible for ensuring safe conditions in the vicinity of the product. In particular, he must ensure compliance with the general

safety regulations, guidelines and standards. Before commissioning the system

the operating company must check whether all the protective measures have

been implemented. These must cover all hazards. This is the only way to ensure that application of the product conforms to CE regulations.

Modifications

General rules for

occupational

20

As stipulated by the Machinery Directive, the protective measures must:

• Correspond to best practices

• Comply with the required safety category

The product must never be modified or used in a manner contrary to its intended use. Ü225

72057594178931083_v7.0_EN-US

The generally accepted occupational safety rules must be observed and implemented.

safety

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

3.2 Hazard symbols in the manual

3.2.1 Hazard warnings

The hazard warnings are defined for the following four types of danger levels:

DANGER

DANGER

DANGER refers to hazards with a high risk of severe physical injury or immediate fatality.

WARNING

WARNING

Safety

WARNING refers to hazards with a moderate risk of severe physical injury

or potential fatality.

CAUTION

CAUTION

CAUTION refers to hazards with a slight risk of moderate physical injury.

NOTE

NOTE

NOTE refers to hazards that can lead to property damage.

72057594178931083_v7.0_EN-US

21

OPERATING MANUAL Automatic lubrication system

Safety

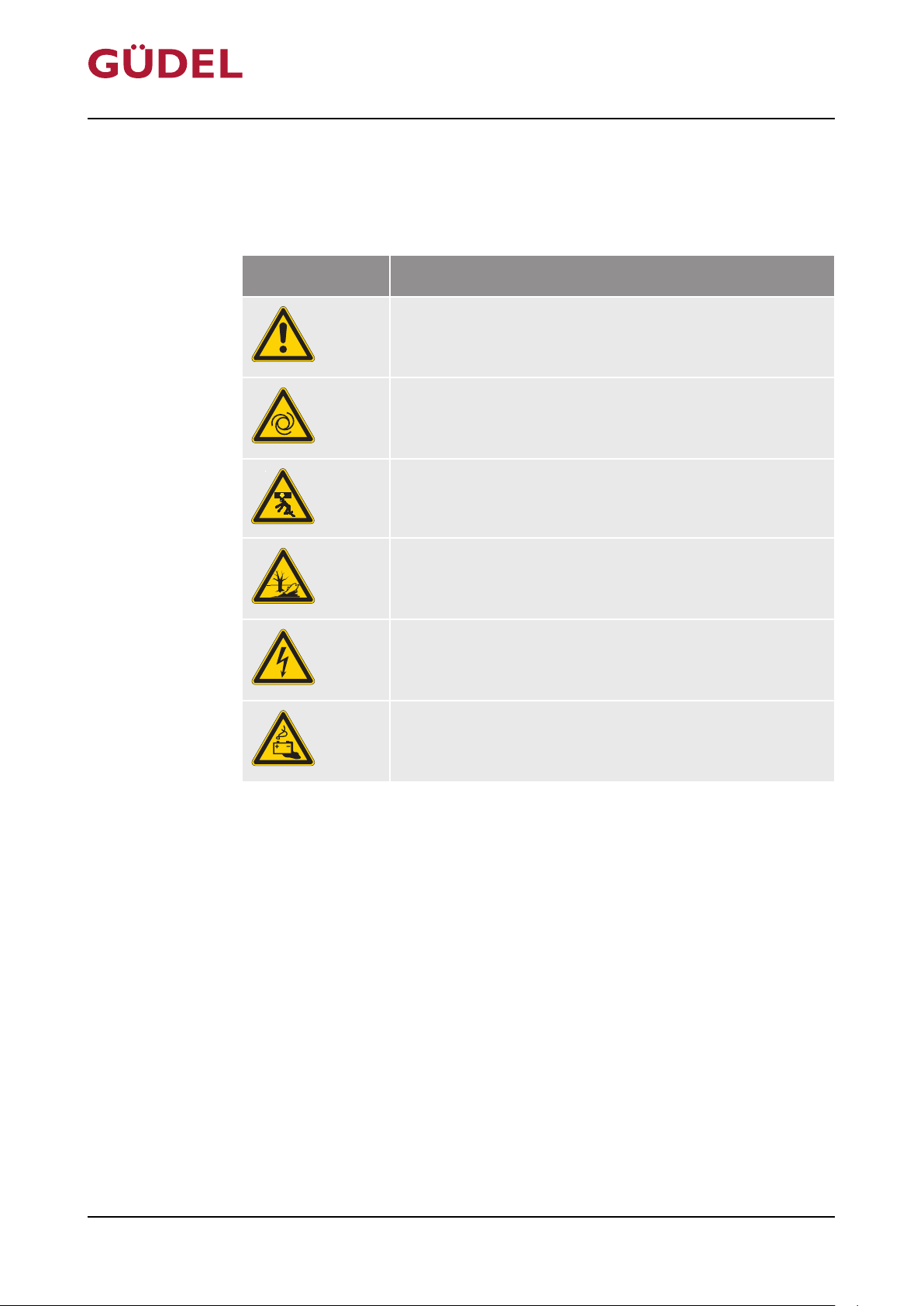

3.2.2 Explanation of warning symbol

Hazard warnings for personal injuries contain the symbol of the corresponding hazard.

Symbol Explanation of symbols

Hazards due to general causes

Hazards resulting from automatic startup

Hazards due to falling axles

FlexxPump 404DLS

Hazards due to environmental pollution

Hazards due to dangerous electrical voltage

Hazards from leaking batteries

72057594178931083_v7.0_EN-US

22

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

3.3 Fundamentals of safety

3.3.1 Product-specific hazards

Leaking batteries

Battery fluids and their fumes are hazardous to the environment, corrosive

and poisonous! They cause injury to persons and damage to property!

Observe the following points:

• Make sure there is good ventilation in closed rooms before repairing leaks

• Wear safety goggles and gloves

• Prevent battery fluids from getting into the drinking water supply

• Use only dry cleaning cloths without detergents

Safety

CAUTION

72057594178931083_v7.0_EN-US

• Dispose of batteries in an environmentally friendly manner

CAUTION

Oil, greases

Oils and greases are harmful to the environment!

• The oils and greases must not get into the drinking water supply. Take appropriate measures

• Observe the country-specific safety data sheets

• Oils and greases must be disposed of as hazardous waste, even if the total

quantity is small

23

OPERATING MANUAL Automatic lubrication system

Safety

3.3.2 Material safety data sheets (MSDS)

Safety data sheets contain safety information about the materials. They are

country-specific. Safety data sheets are issued, for example, for materials such

as oils, greases, cleaning agents, etc. The operating company is responsible for

obtaining safety data sheets for all materials used.

Safety data sheets can be obtained as follows:

• Suppliers of chemicals usually supply their substances together with safety

data sheets

• Safety data sheets are available on the Internet.

(Enter "msds" and the name of the material in a search engine. Safety information about the material will be displayed.)

Read the safety data sheets carefully. Follow all the instructions. We recommend that you store the safety data sheets for future reference.

FlexxPump 404DLS

The safety data sheet for Güdel H1 can be found in the download area of our

company Web site http://www.gudel.com

24

72057594178931083_v7.0_EN-US

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

4 Product description

4.1 Use

4.1.1 Intended use

The automatic lubrication system is designed exclusively for lubricating Güdel

guideways and Güdel gear teeth. Be sure the hydraulic system is installed correctly ÜChapter6.3.3,238

Any other or additional use is not considered to be use in the intended manner. The manufacturer assumes no liability for any resulting damage. All risks

are borne solely by the user.

Product description

4.1.2 Non-intended use

The product is not intended for:

• Lubrication of runners, bearings, or other elements

• Operation in potentially explosive areas

• Lubrication of elements in or on automobiles

• Operation outside of specified performance data

• Operation outside of permissible temperature range

• Using lubricants with properties other than the ones specified

Any use other than the specified intended use will be considered improper

use and is prohibited!

Do not make any modifications to the product.

72057594178931083_v7.0_EN-US

25

D003061

www.gudel.com Made in Germany

Artikelnummer 0193906

GÜDEL

A

B

C

D003063

A

B

Product description

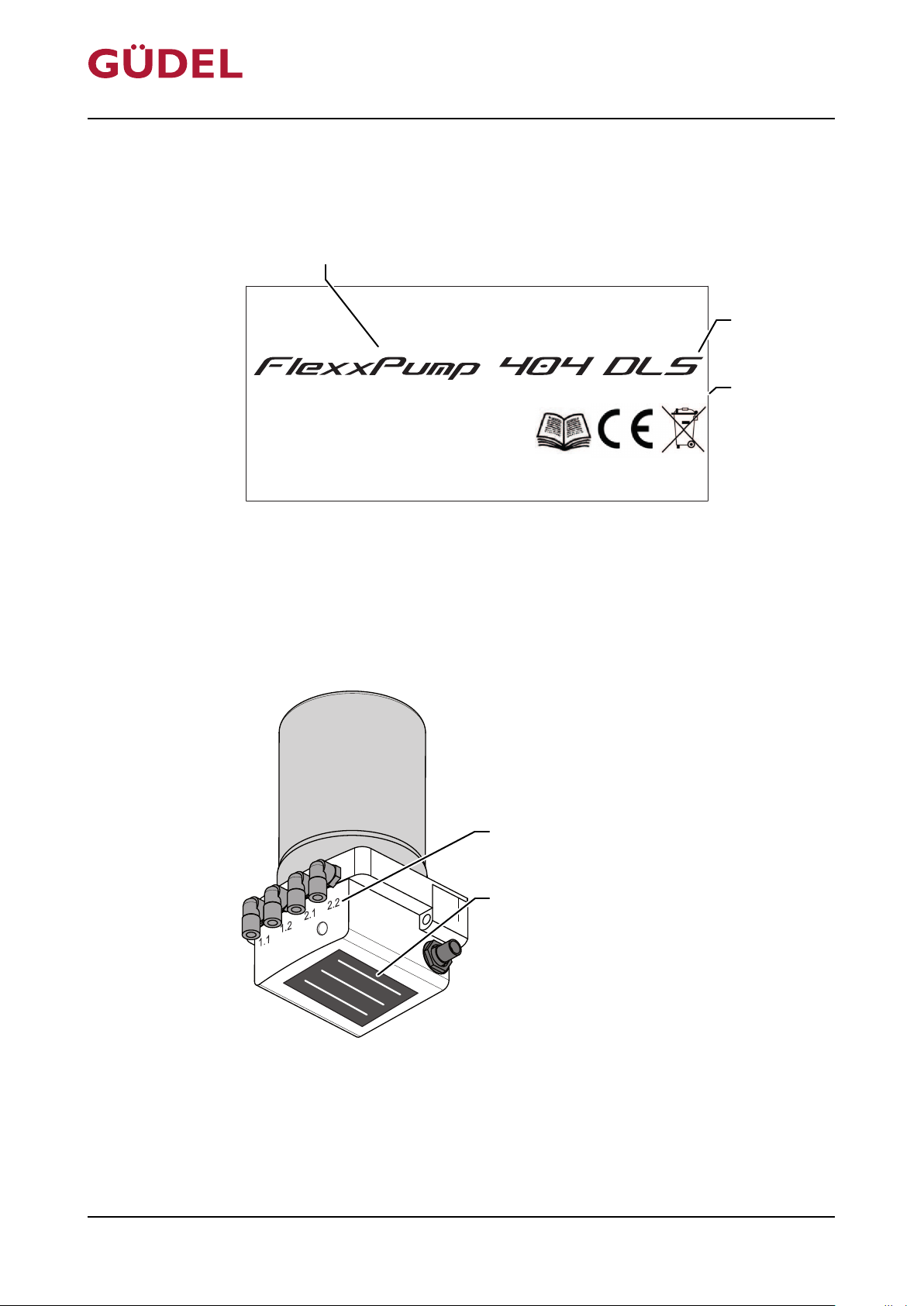

4.2 Product designation

The product has a type plate. It contains the following information:

Fig.4-1 Type plate

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

A Product name

B Pump type

C Item number

The type plate is attached to the bottom of the casing. The hydraulic outputs

are indicated by engraved numbers.

72057594178931083_v7.0_EN-US

Fig.4-2 Product designations

A Numbers of the hydraulic outputs

B Type plate

26

D003135

94

110

96

107

112

35,3

196

A

B

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

4.3 Technical data

For specific information on the product, refer to the respective drawings as

well as the documentation on the complete plant.

Product description

Emission sound

pressure level

The emission sound pressure level depends on the machine properties and

the operating conditions. Generally the emissions sound pressure level LpA is

≤ 80dB(A), measured at a distance of 1 m from the safety fence and 1.6 m

above ground level. The measurement is performed according to the ISO

11202 standard. The measured value is time-averaged over a machine specific

cycle and offset with correction factors for room and environment noise correction. The measured value contains measuring uncertainty of +/- 4dB(A)

(accuracy grade 3) and applies for a single machine, measured separately.

4.3.1 FlexxPump

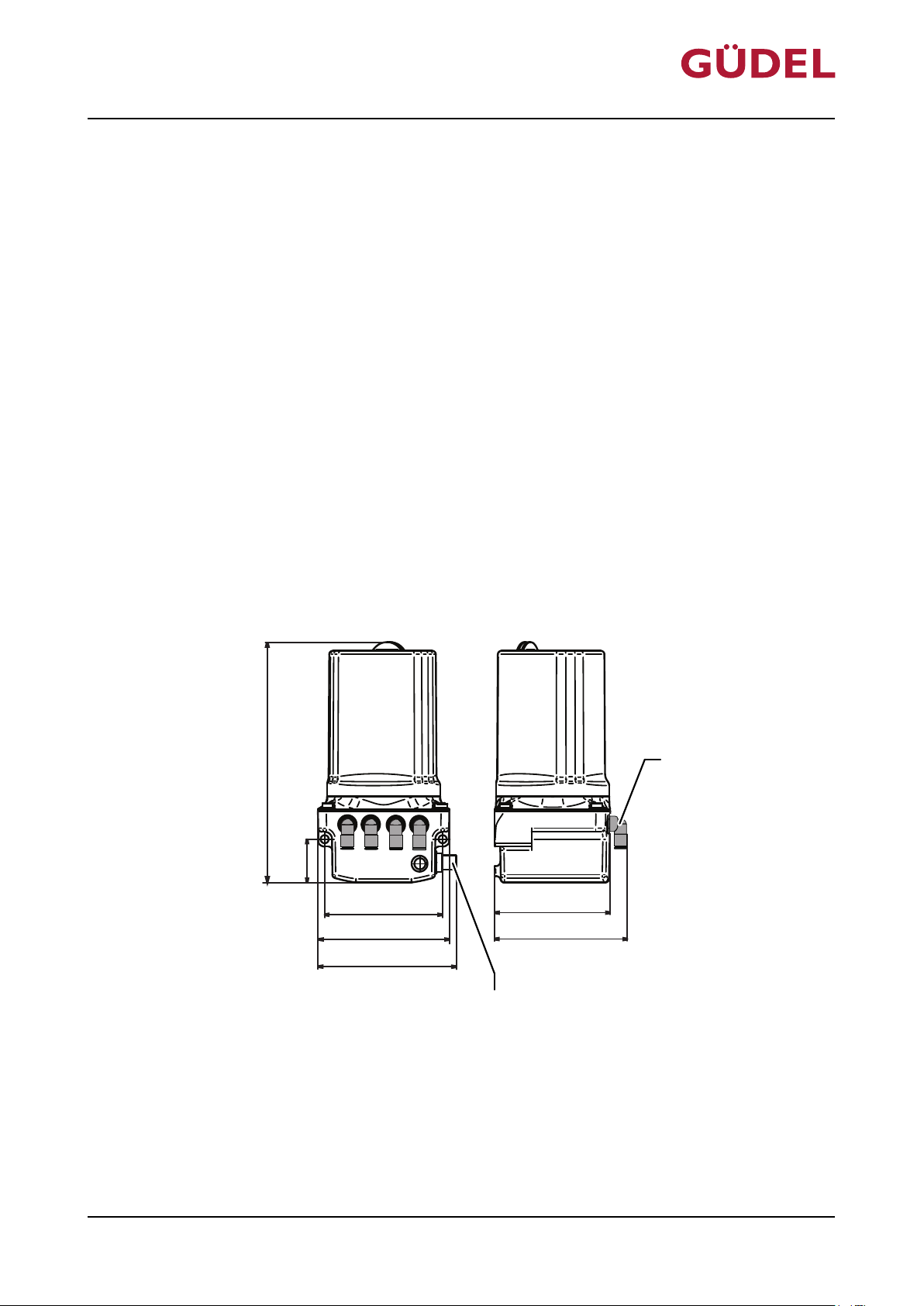

4.3.1.1 Dimensions and connections 404DLS

The FlexxPump 404DLS weighs approx. 1500 g and has the following dimensions:

72057594178931083_v7.0_EN-US

Fig.4-3 Dimensions and connections 404DLS

A Hydraulic outputs

B Connection plug M12x1

27

Product description

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

Connections

Hydraulic:

• Four connections for hydraulic hoses with diameter of 6/3 mm

Electrical: The four-pole connection size M12x1 transmits the following signals:

• Control signals

• Operating voltage

Interfaces

The FlexxPump 404DLS features an integrated microprocessor. It is controlled via a programmable logic controller (PLC).

Operating voltage

Operating

voltage

24 V DC 200 mA 350 mA <20 mA 300 mA

Table4-1 Operating voltage

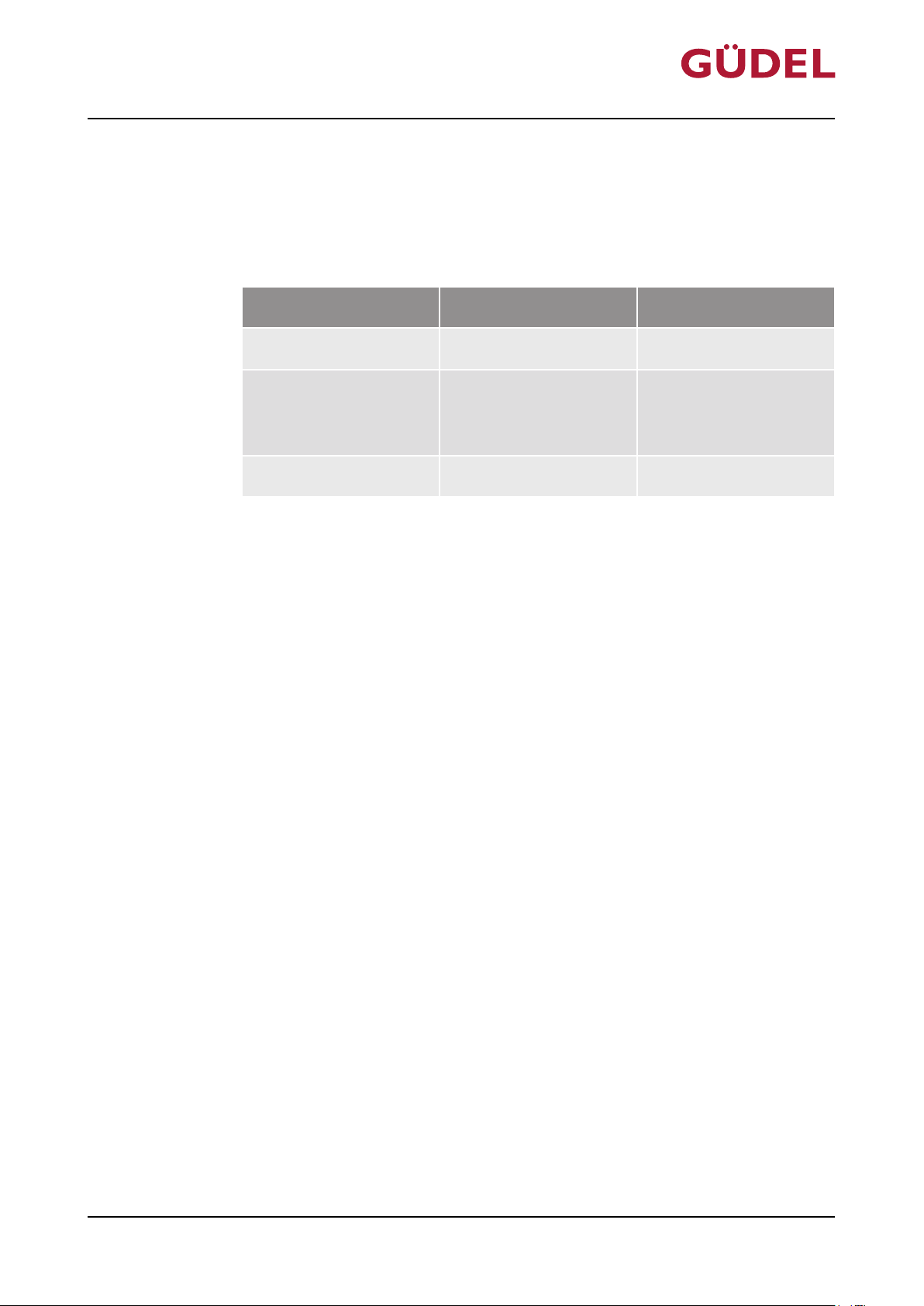

4.3.1.2 Temperature ranges

The following temperature ranges and humidity apply:

Operating

power

Peak

power I

max

Standby

current

Peak output power

Product life phase Temperature range Air humidity

Transport -10 to +60 °C

Operation -20 to +70 °C Up to and at 85 %,

Storage -10 to +40 °C Up to 75 %

Table4-2 Temperature ranges: FlexxPump

4.3.1.3 IP protection class

The product conforms to the protection class IP65.

4.3.1.4 Operating pressure

The operating pressure is 70bar and is monitored electronically by counterpressure measuring. The maximum pressure is 150bar.

condensation formation is not permissible

72057594178931083_v7.0_EN-US

28

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

4.3.2 Splitter

4.3.2.1 Temperature ranges

The following temperature ranges and humidity apply:

Product life phase Temperature range Air humidity

Transport -10 to +60 °C

Operation +10 to +80°C Up to and at 85 %,

Storage -10 to +40°C Up to 75 %

Table4-3 Temperature ranges: Splitter

Product description

condensation formation is not permissible

72057594178931083_v7.0_EN-US

4.3.2.2 Accuracy of the lubricant distribution

The accuracy of the lubricant distribution is ±10%. The accuracy is valid up to

a pressure difference of less than 6 bar.

4.3.2.3 Minimum lubrication quantity

Splitters only function correctly if > 0.5 cm3 of lubricant is produced at their

input per lubrication cycle.

4.3.2.4 Maximum pressure

The maximum pressure at the input of splitters is 110 bar.

4.3.3 Lubricant amount

The cartridge contains 400cm3 of lubricant. The empty level is monitored by

an integrated reed contact.

4.3.4 Shelf life of Güdel H1 lubricant

The date of filling of the lubricant is shown on the lubricant cartridge. The

Güdel H1 lubricant has a shelf life of two years from date of filling. This applies to sealed original containers stored under the required storage conditions.

29

Product description

OPERATING MANUAL Automatic lubrication system

FlexxPump 404DLS

30

72057594178931083_v7.0_EN-US

Loading...

Loading...