Guardian CORE SERIES, 2211-L Owner's Manual

Owner’s Manual

● Please read and understand this manual and safety instructions carefully before installation.

● The Opener WILL NOT CLOSE until the Photo Eye Safety System is properly installed and aligned.

● REGULARLY CHECK and TEST the Opener according to the safety label to ENSURE SAFE OPERATION.

● Retain this manual for future reference.

GDO Manual Revised: 03-17

GDOMU10A-7

WARNING:

To reduce the risk of injury to persons - Use this operator only with Residential Sectional Garage doors.

Serial # __ __ __ __ __ __ __ Date Installed __ __ /__ __ /__ __ __ __

Located on the bar code label on top of your opener.

The illustrations used in this instruction manual may differ from the actual product you have purchased.

1

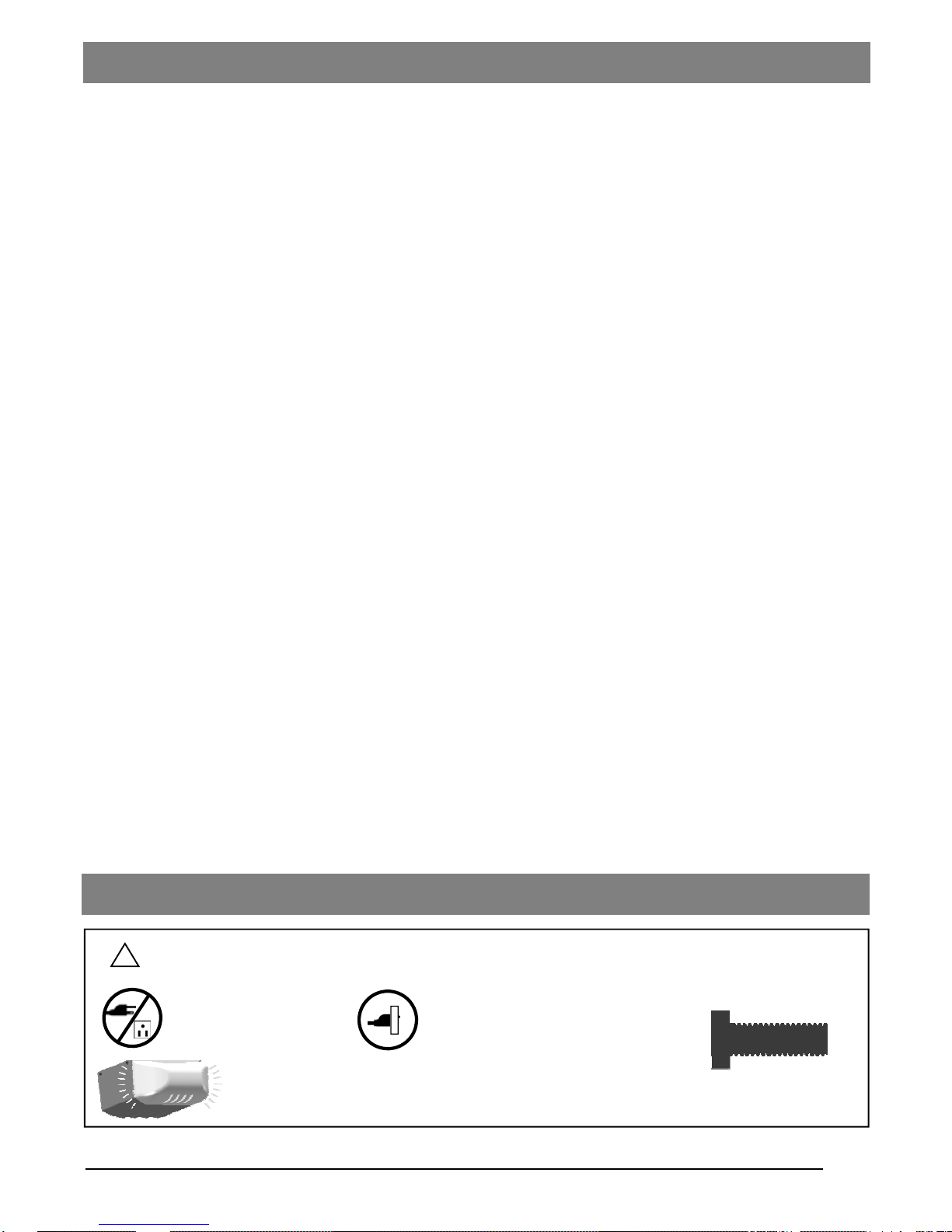

Courtesy light turns on/flashes with audible ‘click’.

(If light bulb is not installed, ‘click’ represents the light)

DO NOT connect power

Please connect power

Symbols and Icons

!

WARNING

Installation hardware

Introduction

Symbols and Icons 1

Inventory 2

Read and Follow These Important Safety Instructions 3

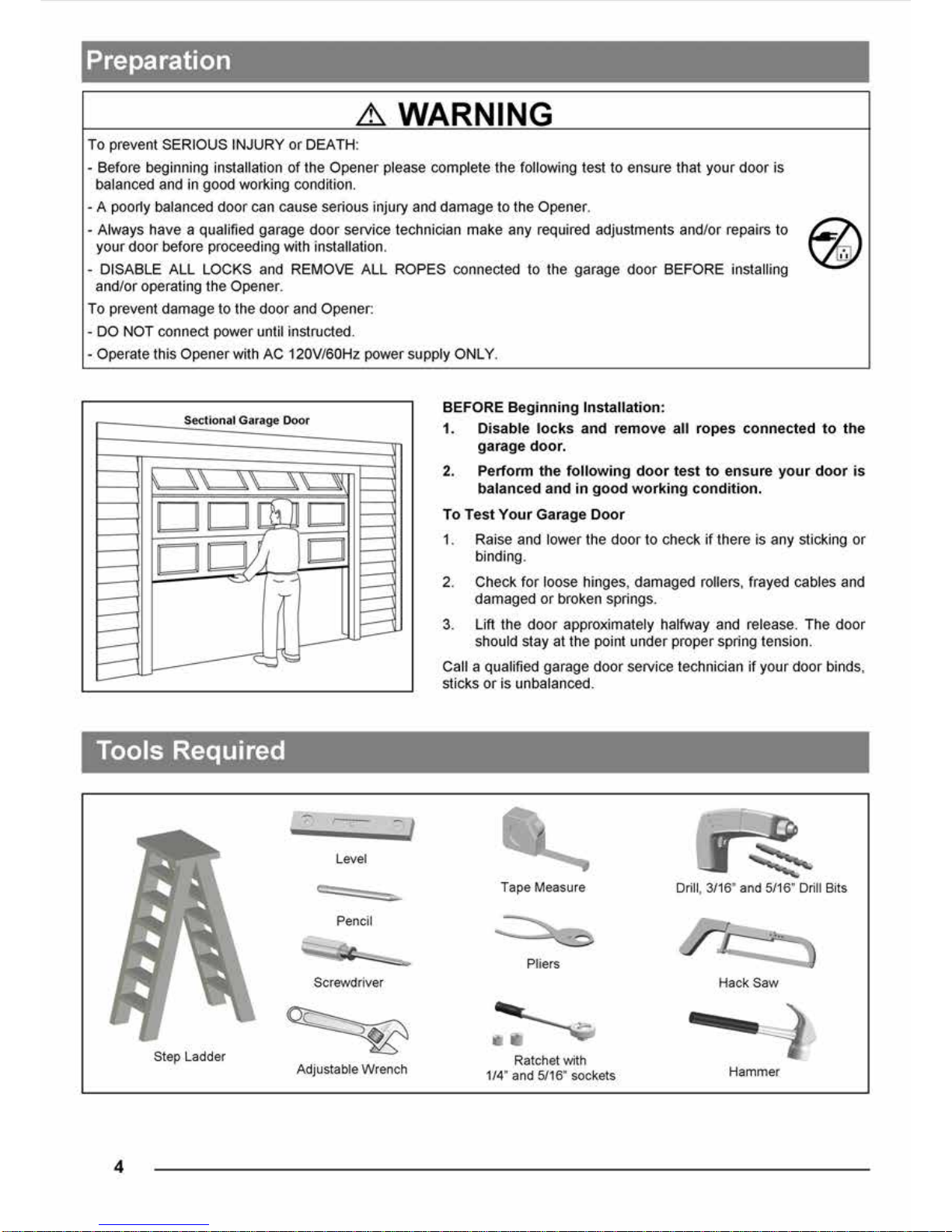

Preparation / Door Balance Test 4

Tools Required 4

Assembly

T-rail Assembly and Tensioning 5

Mounting Header Bracket 6

Installation

Attaching the Opener Assembly to Header Bracket 7

Mounting Door Bracket 7

Mounting Opener to Ceiling 8

Attaching Door Arms 9

Installing Light and Emergency Release Handle 10

Wiring

Wiring Instructions 11

Connecting Photo Eye Safety System 12

Connecting Push Button 13

Connecting Power 14

Adjustment

Aligning the Photo Eye Safety System 14

Travel Limit Adjustment 15

Force Adjustment 16

Final Adjustment and Testing 17

Operation

Programming Remote Controls* (OPTIONAL) 18

Operating the Opener 19-20

Maintenance 21

Troubleshooting 21

Repair Parts and Service

Installation and Accessory Parts 22

Opener Assembly parts 23

Warranty 24

Table of Contents

READ WARNINGS CAREFULLY to prevent SERIOUS INJURY or

DEATH caused by electrocution or mechanical hazard.

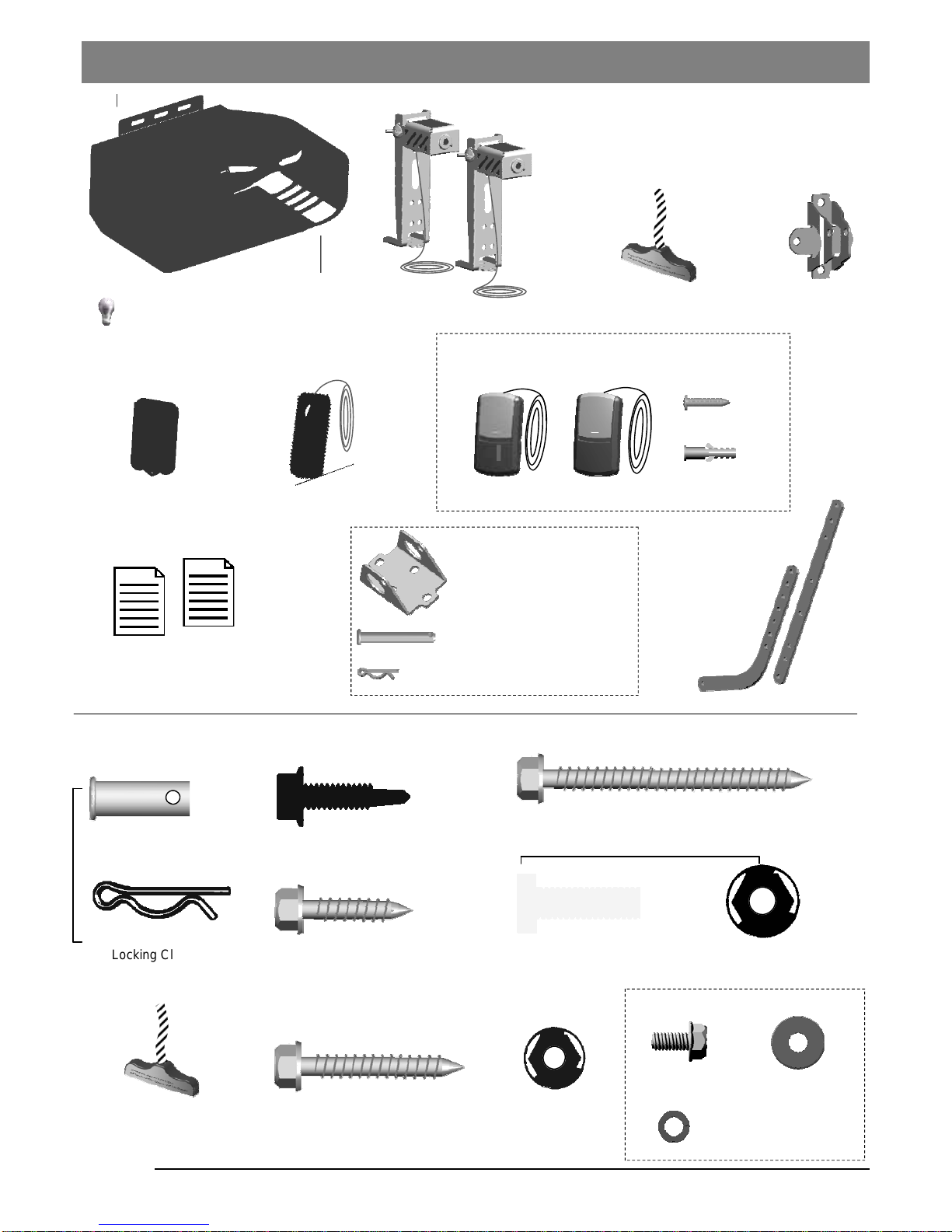

2

Emergency Release Handle

+ Rope

Literature + Safety Labels

Photo Eye Safety System

Door Bracket

Door Arms

Inventory

Remote Control

Push Button

Header Bracket

Clevis Pin Long x1

5/16’’ x 2-1/4’’

Hitch Pin — Locking Clevis Pins x1

x 2

Hitch Pin

— Locking Clevis Pins

x 2

Lag Screw 5/16” x 1-5/8”

— Door Bracket / Mounting Opener

Bolt 5/16” -18 x 1”

5/16” Flange Nut

x 6

x 6

x 4

x 2

Clevis Pin — Door arms

5/16” x 1”

INSTALLATION HARDWARE, LOCATED IN HARDWARE BAG (SHOWN IN ACTUAL SIZE 1:1)

Lag Screw 5/16” x 2 1/2”

— Header Bracket / Mounting Opener

x 2

x 4

Emergency Release Handle

+ Rope

Flange Nut

1/4” -20

Lag Screw 1/4” x 1”

— Door Bracket

x 2

Lag Screw 1/4” x 1”

— Photo Eye System

Opener Unit + Lamp Dome

( Light bulb are not included )

Hexagonal Screw

#

10 - 24 x 1/2”

Spring Washer

#

10

Washer #10

x 1

x 1

x 1

x 1

— Door arms / Mounting Opener

T-rail Assembly

Drywall Anchor

x 2

x 2

Screw #6 x 1”

Door Control included in some models

3-FDCC

1-FDCC

Standard Door Control

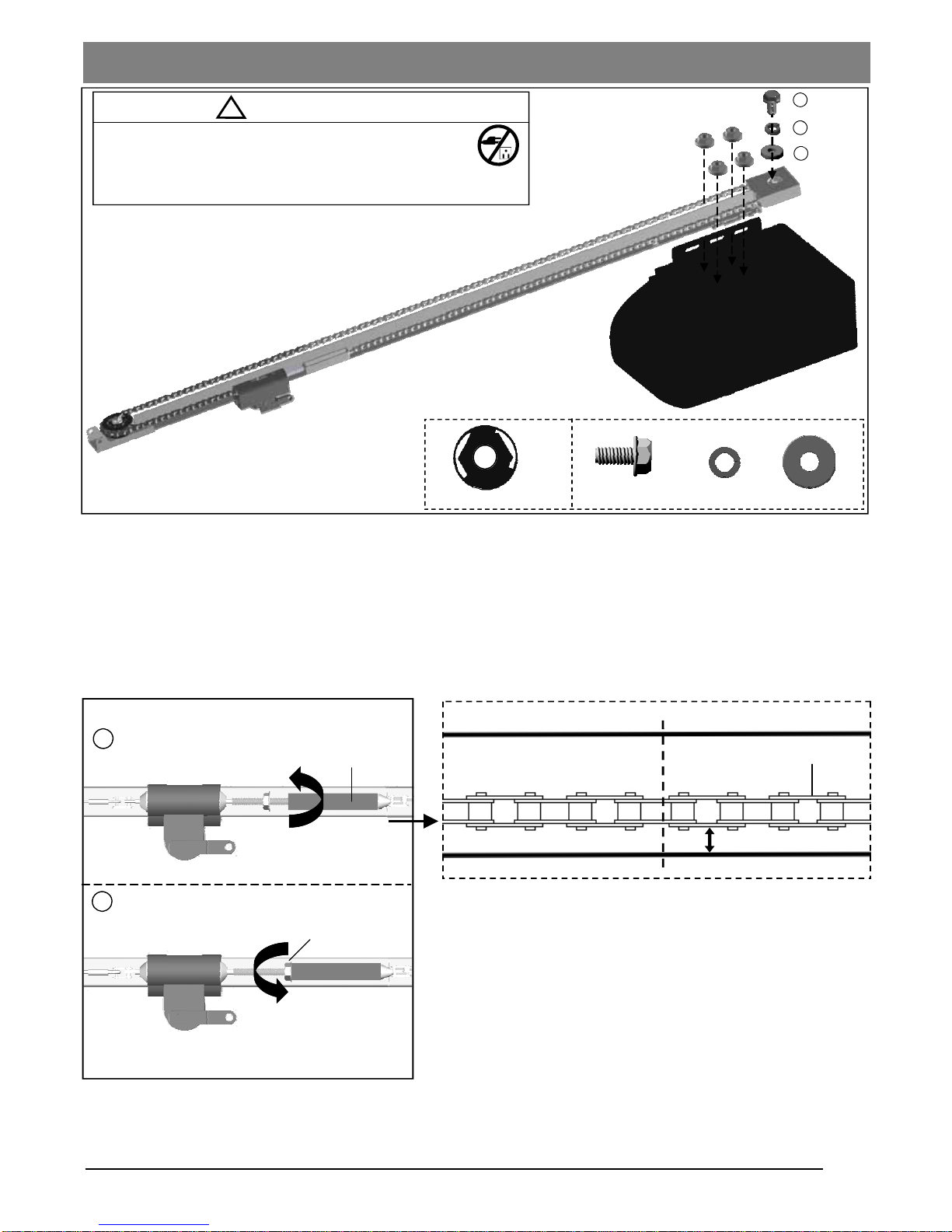

5

Fig.2

1

Tighten until...

2

Tighten nut

Flange Nut

Chain to Cable Connector

To Tighten the Chain:

Follow steps shown in Fig.2 to tighten the chain:

1. Turn the Chain-to-Cable Connector on the Trolley Shaft

until the chain is about 1/4” (6mm) above the base of the

rail. Compare with the illustration below.

2. Tighten the Flange Nut on Trolley Shaft against the Chain-to

-Cable Connector.

Notice

During operation, it is normal for the chain to appear loose when

the door is closed. If the chain returns to the position as shown

below when the door is opened, the chain is adjusted properly.

DO NOT re-tighten the chain.

When performing maintenance, always PULL the Emergency

Release to DISCONNECT the door from Opener before adjusting

the chain.

1/4” (6mm)

Base of Rail

Mid-point of rail assembly

Chain

Top of Rail

Actual Size

T-rail Assembly and Tensioning

Fig.1

!

CAUTION

- DO NOT connect power until instructed.

- To prevent INJURY, keep hands and fingers away

from joints and possible sharp edges.

- Wear gloves when installing chain and cable.

2

3

4

1/4” Flange Nut x 4

Screw

Spring Washer Washer

To Assemble the Rail

Align the pre-assembled T-rail on the top of opener in the direction as shown in Fig.1.

Secure the T-rail to the opener firmly using 1/4” flange nut x 4.

Final Step to T-Rail Installation

Fasten the Screw(2) to the motor shaft with spring washer(3) and washer(4) in between.

Note: The chain or belt rail assembly comes pre-tensioned from the factory. If installing with the optional belt rail,

follow the same adjustment steps.

#

10 - 24 x 1/2”

Loading...

Loading...