Page 1

MODEL ACS0

Residential Garage Door Opener

for Sectional and One Piece Track Garage Doors

up to 2.4M HIGH

Installation Instructions

and

Owner’s Manual

READ THIS MANUAL CAREFULLY BEFORE BEGINNING INSTALLATION

This Operator Must be installed by a Qualified Installer Only

HSOMU01A-1

Page 2

ACS0 Specifications

Electrical Rating

Input

AC 230 50Hz

Max. Current

2A

Power

375W

Standby Power

2W

Motor

Type

AC 230V Single Phase

Max. Capacity

75kg

Recommended Lifting Forces

Max. Lifting Force

60kg

Rated Lifting Force

15kg

Door travel rate

135mm/second

Door Type

Door Travel Limits

3.05 metres

Courtesy Light

Light bulb

E27 60W

Lighting Time

4.5 minutes

Transmitter

Frequency

433 MHz

Operation Range

50m (open field)

Coding Type

Fixed-code

Battery

12V (A23 Alkaline) x 1

Operation Features

Safety reverse on closing and stop on opening

Digital Force Adjustment

Auto-Closing (15/30/45s) with Photo Eye Installed

Miscellaneous

Operating Temperature

-20oC ~ +40oC

Dimension (mm)

344L x 240W x 173H

Weight

5.4kg approx.

Accessories (Optional)

Wall Push Button (Standard / Illuminated / Wireless)

Wall Control Box

Wireless Keypad

1 / 2 / 3 / 4 Button Transmitters

Safety Door Reversing System (PE)

Page 3

3

Contents

Specification 02

Contents 03

Safety Instructions 04

Before Starting 04

Pre-Assembly Check 04

Product Features/ Specifications 05

Door Test 06

Tools Required 06

Component Identification & Inventory 07

Fastener Identification 07

Assembly Instructions 08

Installation Notes 09

Step 1 Mounting the Front Bracket 09

Step 2 Attach the Rail Assembly to Front Bracket 10

Step 3 Position the Power Head for Mounting Bracket 10

Step 4 Mounting the Power Head to Ceiling 10

Step 5 Recheck all Fasteners for Tightness 10

Step 6 Door Arm, Bracket and Plate Installation 11

Step 7 Check Emergency Release 11

Step 8 Connecting Power 12

Step 9 Installing Light Bulb 12

Step 10 Installing Wireless Push Button

Step 11 Programming Transmitter Codes 12

Tilt Door Installation 13

Operation and Adjustment Instructions 15

Setting the Limits 15

Setting the Sensitivity Force 16

Testing the Openers Reversing System 17

Testing the Photo eye system 17

Final installation 18

Trouble Shooting 19

After the Installation 20

Parts Breakdown 21

Warranty 23

NOTICE

Guardian Garage Door Openers are designed and tested to offer safe operation, provided installation and use

of this product is followed in strict accordance with these instructions for assembly and installation. Failure to

comply with these instructions could cause property and/or bodily injury. The opener is intended only for the

use described in this manual and use other than intended will void any and all warranties herein described.

Page 4

4

Read and Follow These Important Safety Instructions

You will see Warning and Caution statements on the following Pages.

Read and follow these safety instructions carefully. Failure to do so could result in serious personal injury or death.

Warning means that severe injury or death may result from failure to follow instructions

Caution means that property damage or injury may result from failure to follow instructions

•

Be sure to read and follow all instructions carefully.

•

Locate lighted push button within sight of garage door, away from all moving parts and out of reach of children

(minimum 1.5M above floor). To reduce the risk of injury to persons, to use this operator only with a sectional

door.

•

Check to make sure the garage door is properly installed and balanced. Because of the extreme tension most

garage door parts are under do not attempt to adjust on your own. Have a qualified garage door service person

make repairs to cables, spring and other hardware before installing the opener.

•

Mount the Emergency Release Knob 2M from the floor. Use the manual release Only to disengage the trolley. Do

not use the Red Release Cord and Knob to pull door up or down. If possible, use the Emergency Release only

when the door is closed.

•

After installing opener, the door must reverse when it comes in contact with a 40mm high object. Check this safety

feature often.

•

Disengage all existing garage door locks to avoid damage to the garage door.

•

Aluminum and Steel Doors must be reinforced to Prevent Damage. Consult with Manufacturer for

Recommendations.

•

All installation and wiring must be done in strict compliance with local and state building and electrical codes.

Connect the power cord to a properly grounded outlet only. Do not in any way alter or remove the grounding pin.

•

Never operate the opener if the system is not operating properly.

•

Always disconnect electric power before making repairs or removing cover.

•

Activate opener only when the door is in full view and free from obstructions.

•

No one should enter or leave the garage while the door is moving. Do not allow children to play near, or operate

the door. Keep the remote control away from children.

•

After Installation is complete fasten this manual near the garage door. Perform periodic safety checks and

recommended maintenance and adjustments.

!

Page 5

5

Product Features

1.

Motor: Permanently lubricated, thermally protected, heavy-duty motor with automatic reset.

2.

Opener Lights: Turn on and off automatically with 2-1/2 minutes illumination for your safety and convenience.

3.

Sensing System: A built-in sensing system detects obstructions during door operation. If in the Downward (close)

travel mode, the Opener will sense an obstruction and reverse to the full open position. In the Open mode, the

Opener will stop. In both cases the light will start flashing and continue to flash for 60 seconds. Since all doors are

different, the Sensing System has independent adjustments for customising the level of force for the normal

opening and closing of specific door.

4.

Close Limit Switch: In winter months it’s common for small pieces of ice or packed snow to be trapped under the

door. Ground swelling may also affect the close limit setting of the Opener. The Close Limit Switch overrides the

Sensing System under the last 2.5cm of closing travel and prevents the door from reversing if it encounters an

obstruction at this point.

5.

Emergency Release: A pull cord allows manual disconnect and operation of door during power failure. Unit will

automatically reconnect when release is reset (the trolley release lever is snapped back to its original position),

power is restored and Opener is activated.

6.

Mechanical Door Lock: When properly adjusted, opener locks door in closed position preventing unwanted entry.

7.

Easy Connect Continuous Monitor Entrapment System: System allows quick and easy installation of Safety Door

Reversing System, (Photo Eye system Optional) while control circuitry monitors these devices continuously for

proper operation.

8.

Constant Contact to Close: For utmost safety if Photo Eye system (Optional) fails, constant contact of mechanical

push button is necessary to close door. In this mode of operation, a radio transmitter cannot be used to close door.

9.

Momentary Contact to Close: Single touch to Radio Transmitter or Wall Button will allow door to close as long as

Photo eye system (Optional) is operational.

10.

Safety Door Reversing System (Photo eye system Optional): An invisible infra-red beam of light guards the door

opening and reverses a downward moving door if the beam is broken by a stationary or moving object. If the beam

is broken, the opener light will flash for 30 seconds. Motor control circuitry constantly monitors the Photo Eye

system for proper operation.

11.

Digital Radio Control: Built in allowing over 1.6 million private codes, easily selected without use of tools. Bright

transmitter LED indicates operation and monitors battery condition.

Page 6

6

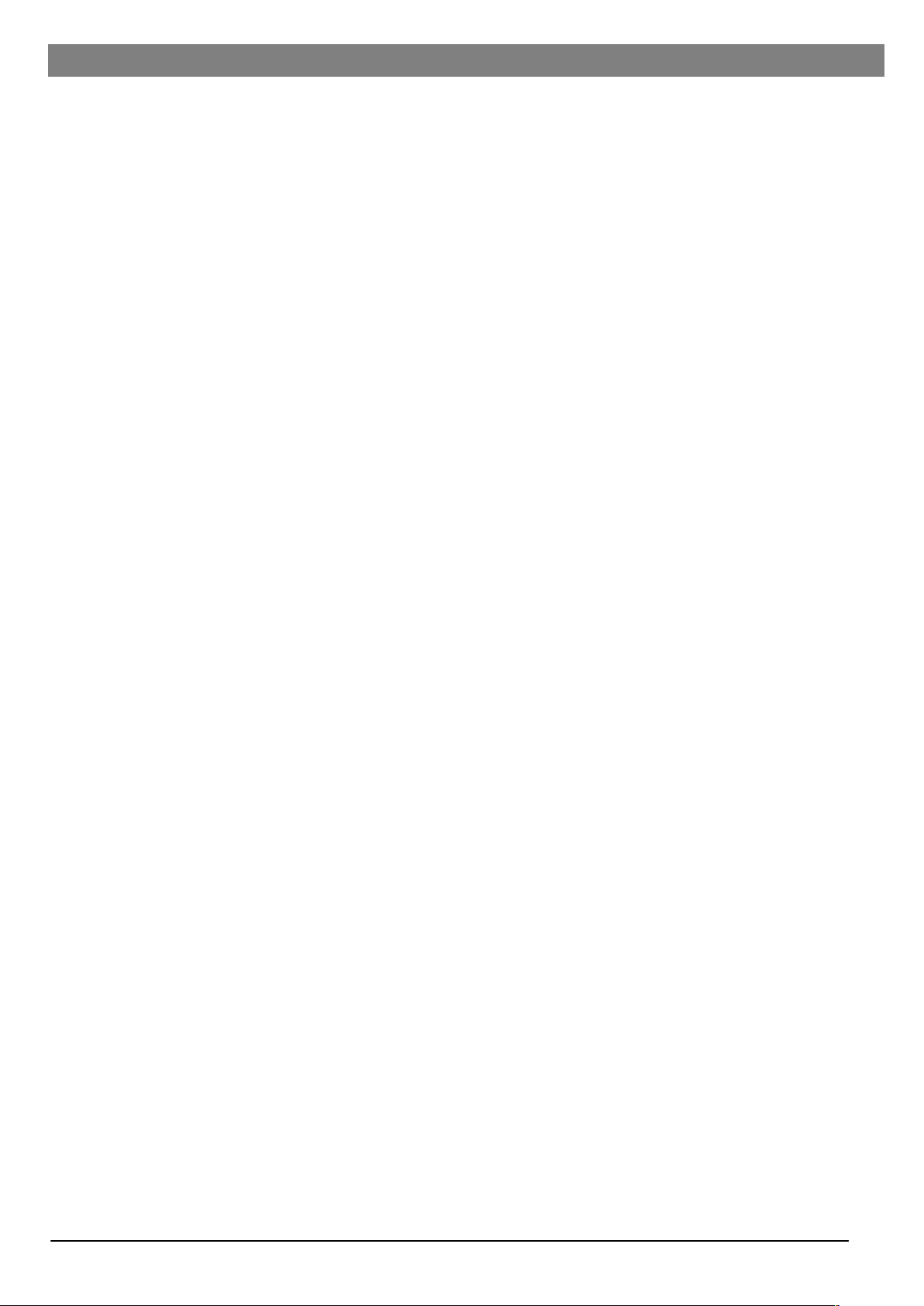

Door Test

Before beginning installation of the operator please complete the following test to insure that your door is balanced and

in good working condition. A poorly balanced door could cause severe personal injury and damage to the opener.

Always have a qualified garage door service person make any needed adjustments and/or repairs to your door before

proceeding with installation.

1.

Raise and lower the door and check closely for areas of

sticking and binding. Check for loose hinges, wobbly

rollers, frayed cables and damaged or broken springs.

Contact a qualified garage door service person to make

the necessary adjustments.

2.

Lift the door approximately halfway. When released, the

door should stay in that position. If door pulls open or

moves downward, the spring mechanism is not

adjusted properly. Contact a qualified garage door

service person to make the necessary adjustments.

3.

When properly installed and adjusted the door will

remain clear of the opening, when allowed to rest at its

natural full open position. If door drifts up or down the

door is not adjusted properly. Contact a qualified

garage door service person to make the necessary

adjustments.

Do Not Install the Opener Until These

Adjustments and Repairs Have Been Made.

Carefully follow the instructions for the assembly and

installation of the garage door opener contained in this

manual

Tools Required for Assembly and Installation

Sectional Door

One Piece Door w/ Track

!

Claw Hammer

5mm and

8mm Drill Bit

Step Ladder

Hand Saw

Screw Driver

Drill

Tape

Measure

Pencil

Pliers

Open

End

Wrench

8mm

13mm and

11mm Socket

and Wrench

Level

Page 7

7

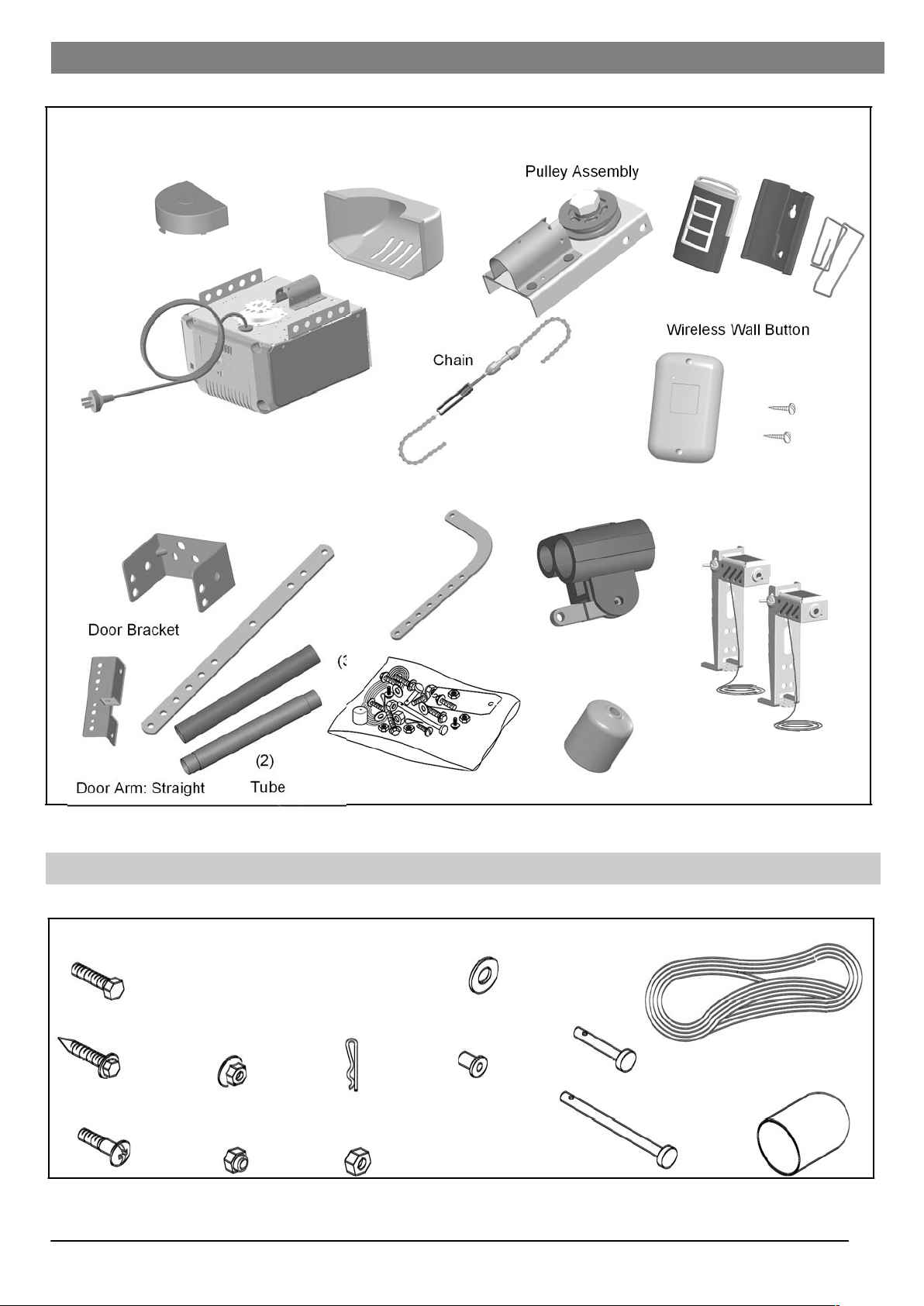

(3

Pulley Assembly

Wireless Wall

Button

Staples (20)

Door Bracket

(2)

Door Arm: Straight

Tube

Components Identification and Inventory

Fastener (parts in screw bag) Identification

Power Head w/ Sprocket Cover

Lamp Dome

Transmitter and Visor Clip

Header Bracket

Door Arm: Curved

Trolley Assembly

)

Trolley Stop

Screw Bag

Photo eye system (Optional)

Clevis Pin (1)

Long

Hex Nut (1)

6mm-20

Lock Nut (1)

8mm-18

CombHead Bolt(2)6mm-20

Rope Knob (1)

Well Nut (2)

Flange Nut (2)

8mm-18

Hitch Pin (2)

Lag Screw (6) 8mmx1-17mm

Clevis Pin (1)

Short

Rope (1)

Flat Washer (2) 8mm

Hex Bolt (3) 8mm-18x1”

Page 8

8

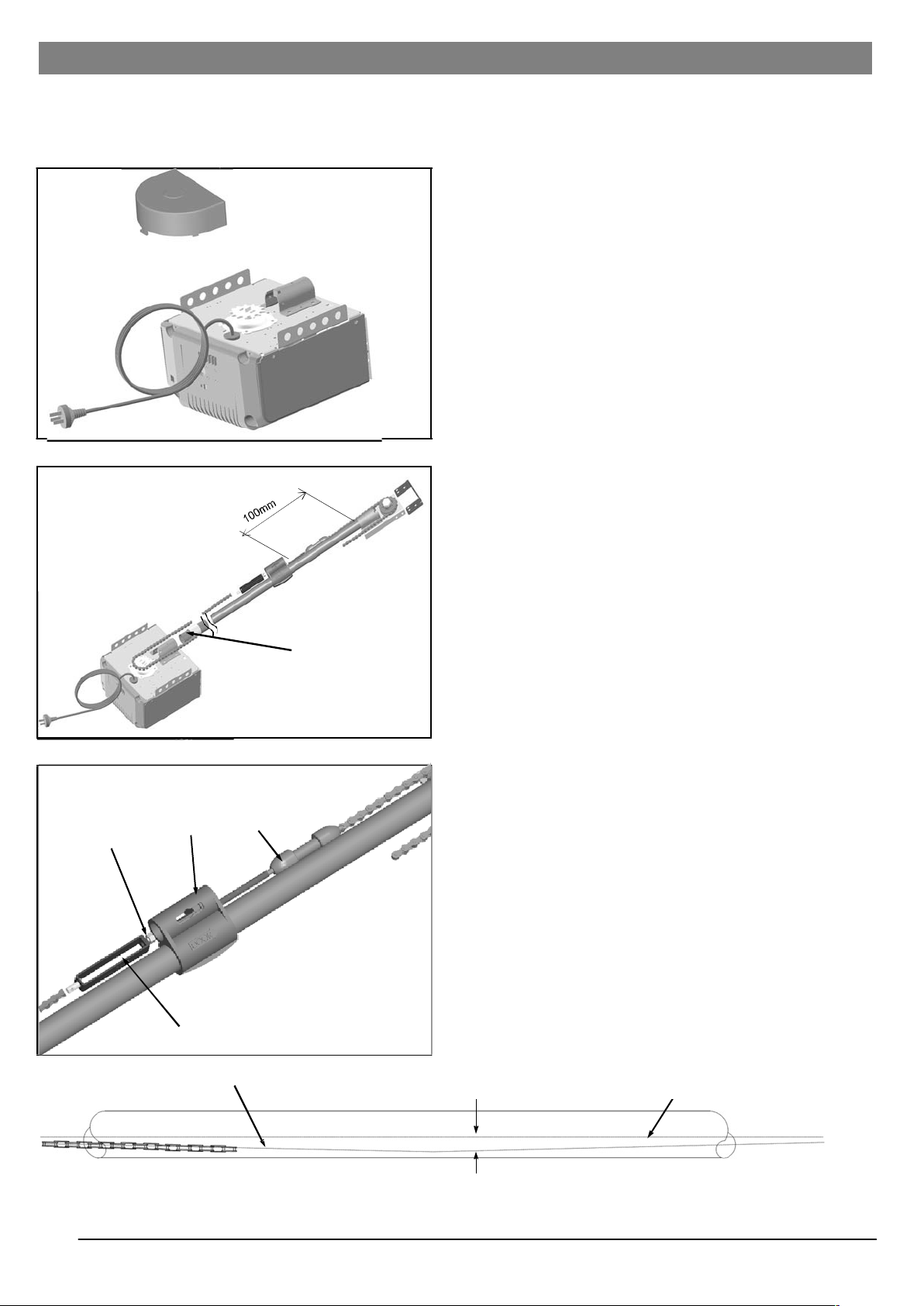

Assembly

Note: The Tube/Chain Speed Unit Assembly with Trolley and Front Idler Sprocket is packaged separately from the

Power Head Unit. Refer to Page 7 for package contents and identification.

Step 1.

Place Power Head Unit on discarded packing material/

cardboard.

Step 2.

Remove the sprocket cover, see figure 7A, and position

the trolley on the drive tube as illustrated figure 7B.

Step 3.

Roll out the chain assembly carefully to prevent tangling.

Connect the trolley release rod to the connecting link

through the drive trolley, but do not tighten. (Figure 7C)

Wrap the chain around the drive sprockets on the drive

unit ensuring the chain engages the teeth on the sprocket.

Extend the chain along the other side of the tube and

around the return pulley.

Ensure the trolley has not moved from the point as

indicated in the diagram (Figure 7B).

Now install the connecting link to the trolley release rod as

illustrated. (Figure 7C).

Note: during the assembly the trolley release rod is

actually engaged in the trolley. It is shown here removed

for the sake of clarity.

Step 4.

Tension the chain by turning the adjusting nut. Hold the

trolley release rod and the connecting link to prevent from

turning. (Figure 7C).

The tension should be correct when the chain has a sag of

between 6 mm and 12 mm (Figure 7D).

Tighten lock nut against the connecting link, to lock

adjustment into place (Figure 7C)

Note:

The chain and its supporting equipment may stretch after a

period of time. The chain should be re-tightened after the

first three months’ use, and thereafter as required.

Step 5.

Re-check all nuts for tightness.

Assembly is now completed. You are ready to begin installation of the opener.

Figure 7A

Figure 7B

Safety Spacer

Figure 7C

Lock

Nut

Trolley

Trolley

Release

Rod

Connecting

Link

Figure 7D

Centre of Chain

6 mm to 12 mm

Centre of Tube

Page 9

9

Installation

Installation procedures will vary depending on type of garage door.

Identify your garage door from those illustrated below and follow procedure outlined for your type of door.

For tilt door (one-piece door), please refer to installation on page 12&13.

To determine high point of door. Raise the door slowly, until it reaches its highest point of travel. Place support block

under the door and measure the distance from the floor to the top edge of the door. Remove block and lower door.

Sectional Door with Curved Track

One-Piece Door with Horizontal Track

Springs, Pulleys, Cables and Mounting Hardware that balance your garage door are under

tremendous pressure at all times and can cause serious injury or death if disturbed. Do not

attempt adjustment!

Step 1.

Mounting the front Bracket (Sectional Doors and Onepiece with Track.) Mark a vertical centreline on the

header above the door. By manually raising the door,

determine the high point of the doors travel (see figure

8A and 8B) and using a level, transfer this

measurement to the header (See figure 8C) Draw a

horizontal line, crossing the previously drawn

centreline, at this point. Install the front Mounting

Bracket securely with lag screws as shown below. If

necessary, reinforce the header with steel or wood to

ensure a secure mount.

Support

Block

Track Point of

Door Travel

Door

Track

Ceiling

50mm Clearance

Header Wall

Header Bracket

Figure 8A

!

Figure 8C

Pre-Drawn

Vertical Line

Pre-Drawn

Horizontal Line

Header

Header

Lag Screws

Page 10

10

Installation

Warning: Aluminum or Lightweight Steel Doors Will Require Reinforcement before installation

of door mounting brackets. Contact your door manufacturer instructions. Failure to properly do so

may result in severe door damage.

Note: Reinforcing may affect the balance of your door. Check for proper manual operation after installation. If

necessary have your door re-balanced by a qualified garage door service person.

Step 2.

Place the power unit on the floor (use cardboard packing material

for protection) and raise Mounting Bracket align. Insert 8mm x 219mm Clevis Pin and Hitch Pin. See Figure 9A.

Step 3.

Raise the opener and rest the power unit on a ladder or other

support. Open the door to the full open position. See Figure 9B.

Note: Since the opener will be secured permanently in this

position, open and close the door a few times to be sure the door

does not rub on the rail and that you have allowed the proper

clearance before proceeding.

Step 4.

Mount Power Head to Ceiling:

Since there are many different ceiling designs, all possible

mounting illustrations cannot be shown. Primary concern is to

secure the power head to the ceiling so that operational strength,

rigidity and safety are achieved. The opener must be securely

fastened to a structural support of the garage. Although there are

a series of mounting holes provided on the power unit, try to

secure the mounting hangers to the slots closest to the front.

Mounting may usually be accomplished by using standard 32mm

perforated steel angle available at most hardware stores or from

your local garage door service person. If in doubt as to location

of, and attachment to, ceiling joists, a carpenter should be

contacted to provide assistance. A cross brace will be necessary

if power head is mounted 200 mm or more from the ceiling. See

figure 9C.

Fasteners Supplied: 2 ea. 8mm-18x 48mm8 Lags, 4 ea,

8mm - 18 x 28mm Hex Blots with Lock Washers and Nuts.

Step 5.

Re-check all Lags, Nuts and Bolts for Tightness.

!

Clevis-Long

Tube

Header Bracket

Hitch Pin

Figure 9A

Page 11

!

Installation

Step 6.

Door Arm, Bracket and Plate Installation:

Install the door mounting bracket in the centre and even, with the

top set of rollers on the door as illustrated Figure. 10A. (Fasteners

Supplied: 2 ea. Lag Screw. Connect the straight door arm section

(single hole section) to the trolley using a 8mm x 25.4mm Clevis

pin and clip. The door arm must pivot freely. Connect the two

Door arm pieces so that it leans toward the power unit as

illustrated fig. 10B. Do not install the door arm so that it is straight

up and down when the door is closed or the emergency release

will not function properly. Now attach Door Arm to Trolley using

8mm x 25.4mm Clevis pin and clip.

Step 7.

Tie a double overhand knot in one end of the Emergency Release

Rope and slip the other end through the Red Release Knob, the

Release Instruction Card and the hole at the end of the Release

Lever on the Trolley (Please take time now to read and familiarise

yourself with the instructions on the Emergency Release Label)

Figure 10C. Tie a second double overhand knot in the free end,

adjusting the Rope so that the Red Knob is 2M above the floor. If

the Rope must be cut, flame seal the cut end with a match or

lighter to prevent fraying or unraveling.

Figure 10C

Release

Knob

Double

Overhand

Knot

Double

Overhand

Knot

Release

Instruction

Card

Note: The Emergency Release Mechanism is engaged by pulling

the Release Knob down and towards the door, allowing the Trolley

Mechanism to separate freeing the door. To re-engage simply

move the Emergency Release Mechanism Lever upwards and

operate the Opener using the push button or Transmitter. The two

parts will automatically reconnect.

Note: This operation should be attempted only when the door is

fully closed. Disconnection when open or partially open can cause

the door to close quickly and cause personal injury or damage to

the door.

Use Manual Release Rope to Disengage Trolley Only. Do Not Use the Rope and Knob to

Pull the Door Open or Closed

Warning: A Child Operating the Door Controls Risks Injury - Or Death to themself and to

others. Do not Allow Children to Operate Any Door Controls. Mount the Push Button at least

1.5 M from the floor out of reach of children

Warning: Improper Door Operation can Cause Injury or Death. Caution Label Must Be

Mounted on Wall near The Push Button. All Warnings Should Be Strictly Adhered To.

11

Hex Bolts

and Nuts

(2)

Lag

Screw (2)

Curved

Hitch Pin

Clevis

Pin and

Door Arm

Door

Bracket at

Centre of

Door

Door Arm

Straight

Figure 10A

Page 12

12

Figure 11A

Figure 11C

Installation

Warning: Installation & Wiring Must Be in Compliance with Local Electrical and Building Codes.

Operation at other than 240V 50 Hz Will Cause Opener Malfunction and Damage.

Step. 8

Opener must be permanently wired or plugged into a grounded

3-prong receptacle wire according to local codes, within 1M of

the Power Unit.

Step. 9

Install an A19 100W Max Rough Service Bulb (available at most

hardware stores) firmly in the light socket. Light bulbs in Door

Openers are subject to vibration during normal operation, which

may shorten their life span. Fit Light Lens Cover and snap into

place.

Step. 10 Installing the Standard Wireless Wall Button

(1)

Select a convenient place near an access door, 1.5m above

the floor and out of reach of children for mounting. (2) Mount the

Wireless Wall Button with screws supplied as shown in Figure

11A.

Step. 11 Programming Transmitter Codes

Programming Wireless Wall Button

Press the “Radio Set Button” on the opener as shown in figure

11B. The courtesy light will stay on for 30 seconds.

During this 30 second period, press the button on the Wireless

Wall Button, the courtesy light will flash twice this will indicate

that the receiver has accepted the code.

If the code is not accepted the courtesy light will stay on for 30

seconds, flash 4 times and then stay on for 2 1/2 minutes.

Programming Handset

Repeat above procedure to program handset code by pressing

the desired button you wish to program on a transmitter.

Adding Handsets

Up to 20 handset codes (including wireless keypad) can be

programmed into the receiver repeating the above process.

Each button on a handset has its own code and must be

programmed separately. In case of more than 20 codes are

programmed, the very first code will be replaced by the latest

code programmed.

Erase ALL Codes

To erase all transmitter codes from memory, press and hold the

“Radio Set Button” for above 5 seconds. The courtesy light will

then flash 7 times, indicating all codes have been erased from

memory.

!

Figure 11B

Figure 11C

Holster

Transmitter

Visor Clip

Page 13

13

Installation (Tilt Door)

Step 1:

Locate the centre of the top edge of the garage door and mark it on the inside face. With a level set plumb at this mark,

draw a vertical line on the mounting surface above the door. (IF a ceiling surface suitable for marking exists, extend the

line to the ceiling and mark the ceiling. Open the door and plumb up from the centre mark made on the door to the

ceiling, if one exists, and mark the ceiling. Determine the rise of the high arc of the door. Use level to measure rise on

mounting surface above door. Use the table below to determine the distance the front end bracket should be mounted

above the top of the door when closed.

HIGH ARC RISE MOUNTING DISTANCE

100 cm 200cm

100-200 cm 330 cm

200-300 cm 450 cm

Make the appropriate measurement and mark the

vertical line at this point.

Step 2:

Attach the bracket provided directly to the structure or the addition with lag screws or bolts and self locking nuts so that

one leg of the bracket provides a shelf upon which the front end of the rail may be rested and subsequently attached.

The leg of the bracket forming the shelf should be at the horizontal mark made in Step 1. The centre hole in this leg

should be aligned with the centre of the door opening or the vertical line. The other leg of the bracket, which is to be

attached to the structure may be above or below the mark as the situation may require.

Step 3:

Place the front end of the rail on the bracket attached in Step 2, and drop one of the 6mm x 50mm carriage bolts

through the hole in the end of the rail and the centre hole in the bracket. Run one of the 6mm nuts on the end of the bolt

a few turns. This will temporarily hold the rail in place while the back end is swung upward and rested on a step ladder.

CAUTION: IF ADDITIONAL HEIGHT IS REQUIRED, BE CERTAIN THAT THE MEANS USED PROVIDES A STURDY

AND STABLE NON-SKID PLATFORM. PULL THE CARRIER RELEASE ARM TO A VERTICAL POSITION AND

SLIDE THE OUTER HALF OF THE CARRIER TO THE REAR OF THE RAIL. THIS WILL PREVENT THE DOOR

FROM STRIKING THE LEVER. At this time the door can be opened to its high arc position. It will be

necessary to support the door so that it will remain in this position. Position the rail over the centre of the top

section of the door.

Lower the back end of the operator so that the bottom of the rail is about 13mm above the door edge at the high arc

position (Fig 13A). Do not allow the door to support the operator, as this will cause a false measurement to be taken

and possibly damage the door. Support the operator in the same fashion as before and measure the distance from the

ceiling to the selected frame mounting slot. The length of the rear vertical supports will not be greater than this

dimension.

Step 4:

A rear mount must be constructed to secure the rear of the operator to the ceiling. The distance from the operator to the

ceiling structure has already been determined in STEP 3. Measure and cut the appropriate length of perforated angle

iron or other suitable metal required to suspend the operator. The operator frame plate is 165mm wide. The vertical

supports should be 82mm from each side of the centre line. Construct the mount and secure it to the structure in the

ceiling. Secure the operator to the mount. The mount must be braced to minimise lateral movement in all directions.

Page 14

14

Door Arm

Curved

Door Arm

Straight

Installation (Tilt Door)

Step 5:

After the rear of the operator is suspended, remove the door

support and close the door. Remove the 6mm x 50mm carriage

bolt and nut that was used to temporarily hold the front end of

the rail to the bracket and secure with a 8mm x 25.4mm bolt

and lock nut. Attach the straight portion of the door arm to the

carrier by means of the 10mm x 25.4mm bolt and self-locking

nut already on the carrier. Assemble the angled portion of the

door arm to the door bracket with a 10mm x 25.4mm bolt and

self-locking nut from the hardware bag. This connection should

be made to the top round hole on the door bracket with the

door arm on the INSIDE of the angle. (See Fig 13B). Next,

connect the two sections of the arm together with three holes

overlapping using two 8mm x 25.4mm bolts. (Make the nuts

only finger tight at this time).

Step 6:

Release the carrier for manual operation of the door. Swing the

door arm and door bracket forward until the door bracket rests

against the inside surface of the door with the arm attachment

point close to the top edge of the door (See Fig 13B). Note the

position of the outer slide of the carrier on the rail and make a

mark for later reference. Prepare the operator for electrical

operation.

Step 8:

Step 7:

With the disconnect still in the release position, start the opera-

tor in the closing direction (carrier forward) by means of the

pushbutton and allow it to stop on the DOWN limit setting.

Should the position of the inner carrier slide not coincide with

the position of the outer slide determined in STEP 6., it will be

necessary to re-position the DOWN limit cam so that the outer

slide of the carrier stops as close as possible to this point.

Move the DOWN limit roller assembly on the chain toward the

door if more travel is needed; toward the operator head to re-

connect.

When the DOWN limit position of the inner carrier slide and the position of the outer slide determined as in STEP 6,

coincide as closely as possible following the DOWN limit adjustment, re-connect the carrier slides. Swing the door arm up

forward until the door bracket rests against the inside face of the door. If the point of attachment of the door arm on the

door bracket is within 25.4mm of the top edge of the door, check vertical alignment of the door arm then mark the door for

mounting holes. Use centre hole and bottom of the lower slot. Drill two 6mm holes and secure the bracket to the door with

the carriage bolts provided. (NOTE: When drilling these holes, make sure that the drill, exiting through the front surface of

the door, does not damage any overlapping trim.) Tighten the two 8mm x 25.4mm nuts and bolts which hold the two

sections of the door arm together.

Step 9:

Again, release the carrier for manual operation. Using the pushbutton, run the carrier to its fully open (rear) position.

Manually, raise the door to its fully open position and note the relative positions of the inner and outer carrier slides. If the

two halves of the carrier do not coincide exactly, re-position the UP limit roller assembly on the chain until the inner slide

stops, during electrical operation, just AHEAD of the outer slide (toward the door). Do not permit the inner slide to attempt

to travel beyond the maximum rearward travel of the outer slide with the door in the fully open position.

Figure 13B

Page 15

15

Adjustment

Warning: If Limits are not adjusted properly, the emergency release mechanism may not work

properly and door operation could result in door damage or serious injury.

Note: It is now necessary to turn on the power in order to run the opener to check limit settings. Before doing so,

ensure that all mounting hardware is installed and has been properly tightened, that all electrical connections are per

local code requirements. Double Check that all ropes have been removed and that the doorway is clear.

•

Up (Open) and Down (Close) Limits

•

Limit adjustments settings regulate the total amount of

distance the door will travel while opening and/or

closing.

•

Setting the Up Down Limits

•

Note: Run the Opener through a complete travel cycle

after each adjustment.

•

Note: Repeated Operation of Opener may cause the

motor to Overheat and the Thermal Overload

Protection System will shut off the Opener. Please wait

approximately 15 minutes for the Opener to cool down

and automatically reset.

•

If the door opens completely and closes completely

without reversing: No adjustment is necessary.

•

If the door does not open completely but opens at least

1.5M: Increase Up travel by turning UP LIMIT screw

Clockwise

•

If the door does not open 1.5M: Adjust Up FORCE/

SENSITIVITY Setting Page 16.

•

If Door does not close completely: Increase Down

Travel by turning DOWN LIMIT screw CounterClockwise.

•

If Door reverses in full closed position: Decrease Down

travel by turning Down LIMIT screw Clockwise.

•

If Door Continues to Reverse: Disconnect Door from

Opener use manual release. Check for binding while

working door manually. If door binds or is out of

balance call a qualified garage door service person. If

no binding is found and balance seems correct. Adjust

FORCE/SENSITIVITY Setting Page 16.

!

Figure 14B

Page 16

16

Force/Sensitivity Adjustment

Warning: Improper Adjustment of Sensitivity System Force Could Cause Entrapment, Injury or

Death. Set Adjust For Just Enough Force To Operate The Door Reliably, But No Stronger. Do

Not Over-Adjust Force/Sensitivity System To Compensate For A Poorly Working, Sticking or

Binding Door (Contact a qualified Garage Door Service Person to Correct any binding, sticking

and/or other door problems).

Force/Sensitivity Adjustment

•

Force/Sensitivity Adjustment Controls are located on the

Back Panel of the Opener (See Figure 15A). Up and Down

sensitivity adjustment are independent of one another (+

indicates more force) and ( indicates more sensitivity).

Never change the Force/Sensitivity setting by more than 1

increment at a time.

•

Note: Force/Sensitivity is set at level 1 at the factory both

for the up and down adjustments. The size and operating

conditions of the garage door will determine the correct

level of Force/Sensitivity. Weather conditions may also

affect the operation of the door requiring further

adjustments as needed.

•

Note: If the down pressure adjustment is set too light the

operator will reverse in the down cycle. If the up pressure

adjustment is set too light the operator will stop in the up

cycle.

•

Note: There are 12 levels (increments) of up and down

force/sensitivity setting. When either the maximum or

minimum setting is reached the light will flash 6 times.

Setting Force/Sensitivity Adjustment

Down force/Sensitivity Adjustment

•

In the down or close direction the operator will reverse if the

force required to close is exceeded. If the operator

completes a full closure without reversing decrease the

amount of pressure in increments of one push of the down

button until the operator reverses. Once the operator does

reverse in the down direction increase down pressure by

pushing the down + button once.

Up Force/Sensitivity Adjustment

•

In the up or open direction the operator will stop if the force

required to open the door is exceeded. If the operator

completes a full open cycle without stopping decrease the

amount of force in increments of one push of the up –

button until the operator stops during the up cycle. Once

the operator does stop increase the up force by pushing the

up + button once. For safety the force setting should always

be set at the least amount necessary to run the door

properly.

!

Figure 15A

Page 17

17

Testing the Safety Reverse System

Warning: Failure to Test Reversing System Could Result in Death or Serious Injury. Test This

System Once A Month.

To test the Opener Reversing Feature at floor level, place a

solid object 100 mm thick on the ground so that the centre of

the door will contact it. Close the Door. If the Down force

Adjustments are Correct, the door will reverse within one and

a half (1-1/2) seconds of contacting the object and travel to the

Full Open Position. Light will also start flashing and continue to

flash for 30 seconds. If this does not occur, re-check Limit

Adjustments Page 15 and Force/Sensitivity Adjustments Page

16.

Note: Any time any adjustments are made to Limits or Sensitivity, You Must Retest the opener for the Reversing

Feature at Floor Level as outlined above.

Warning: The Sensitivity System Reversing Test Should Be Performed Monthly to Ensure

That This Important System Remains in Proper Adjustment

Warning: A Damaged or Malfunctioning Photo eye system could enable a Garage Door to

Close on People or Property, Causing Serious Injury or Death. Perform this Test

Monthly to Ensure Proper Operation.

Testing the Photo Eye System *

Start the door down and then place an obstacle approximately

200 mm high by 300 mm wide in the path of the beam. The

Red Pilot Light on the Photo eye system should go off. The

door should stop for 1-1/2 seconds and reverse to the full

open position. The Opener light will also begin flashing and

continue to flash for 30 seconds. IF the door is moving up and

the beam is broken, the door will continue up to full open.

With the door fully open and at rest, place the obstacle in the

path of the beam once again. Activate the Wall Push Button,

The Opener will revert to and remain in the safety. Push And

Hold Operation for close travel. See Page 13.

NOTE: If the Garage Door Travels More Than 25mm in a Downward Path After Releasing the Button, the Photo

eye system is Malfunctioning. Check All Electrical connections and Alignment of the Photo eye system.

* Optional

!

100 mm Board

Laid Flat

!

Sensor Beam 100150 mm above Floor

Invisible Light Beam

Protection Area

Sensor Beam 100-150

mm above Floor

Page 18

18

Final Installation

Make Sure That:

1.

The front and rear mounts for the opener are sound and secure and the rail is positioned correctly above the

high arc of the door and that the opener is positioned over the door action centreline.

2.

For sectional doors and one-piece doors with tracks, the position of the door arm with the opener closed, is such

that its connecting point on the trolley is 125 to 200 mm behind its connecting point on the door bracket. The

door arm should never be perfectly vertical when the door is in the closed position.

For one-piece doors without tracks, the position of the door arm, with the door closed, is such that its connecting

point on the trolley is 500 mm to 550 mm behind its connecting point on the door bracket. The straight portion of

the door arm should be at an angle of 15-20 degrees with respect to the floor when the door is closed.

3.

The emergency release knob and cord are secured to the emergency release lever on the trolley. The knob is

located 2M above the floor and requires no more than 20 KGs. pull to actuate. Ensure the trolley and release

mechanism are properly lubricated.

4.

The standard lighted wireless wall button is in such a position and at such a height that an adult can only actuate

it. The caution label is prominently displayed next to the push button.

5.

All wiring is correct to code. There is ground continuity in the supply. The ground prong on the power cord is

intact.

6.

All ropes and door locks have been removed from the door. The door moves freely without binding when

operated manually. The door is correctly balanced and lubricated. All door hardware is secure and sound. The

sensitivity has been adjusted to minimum force. The appropriate warning sticker has been affixed to the door.

7.

The door reverses on obstructions to within 40 mm of the floor. The floor beneath the closed door provides

uniform contact.

Page 19

19

Trouble Shooting

Symptoms

Probable Cause/Solution

Opener does not work from either the transmitter or push button.

1,2,3,5,6,9,11,17,23,24

Opener does not start on command and light flashes for 30 seconds

1,4,5,7,8,11,12,13,15,16,17,18,22,23,24

Opener stops during cycle and light flashes 5 times

6

Opener operates from push button but not radio

9,14,20,21,25

Stops before reaching full open or closed

10,15

Reverses when the door makes contact with the floor

10

Light flashes 5 times but the opener does not start

26

Light does not come on

5,19

Light will not turn off (Light stays on)

5

Probable Cause

1.

Mechanical garage door lock is engaged

2.

Power is not present at outlet.

3.

Shorted or defective wireless wall button.

4.

Bell-wire is shorted

5.

Malfunctioning logic board

6.

Thermal overload breaker protection has been

activated.

7.

Garage door springs are out of balance

8.

Garage door is jammed.

9.

Weak transmitter battery

10.

Travel limits are out of adjustment

11.

Photo eyes* are obstructed (light flashes 30

seconds)

12.

Photo eyes*are out of alignment (light flashes 30

seconds)

13.

Photo eye*bell wire is shorted (light flashes 30

seconds)

14.

Defective transmitter or receiver

15.

Up force/sensitivity out of adjustment

16.

Down force/sensitivity out of adjustment

17.

Bottom of garage door frozen to the ground

18.

Foreign object on the floor such as ice or snow.

19.

Defective light bulb

20.

Radio receiver is not receiving the radio signal

21.

Location of radio transmitter

22.

Defective RPM counter board.

23.

Defective programming board

24.

Defective photo eyes*

25.

Defective transmitter

Solution

1.

Remove all locks from the garage door

2.

Check circuit breakers, fuse box and GFI receptacle

3.

Remove wireless wall button from wall and disconnect

wires from the push button (activate transmitter). If the

operator works from transmitter replace push button.

4.

Disconnect bell wire from the terminal stripe on the back

of the power head (activate transmitter).

5.

Unplug operator at power outlet and then reconnect.

Consult repairman to replace logic board.

6.

Allow time for motor to cool down (15 to 30 minutes

depending on temperature in the garage). Thermal

breaker automatically resets itself.

7.

Consult service repairman to balance or replace springs.

8.

Operate garage door manually; disconnect opener by

pulling red cord on the trolley. Look for binding or

jamming of the garage door. Consult service repairman.

9.

Replace 12-volt battery in the transmitter by removing

the screws on the backside of the transmitter case and

pulling the case open to expose battery.

10.

Refer to page 15 in the installation manual.

11.

Check for obstructions between the photo eyes* and

remove obstruction.

12.

Check red LED inside the lens of the receiver photo

eye*(photo eye with 4 wires). Led will light up when

photo eyes* are aligned properly, refer to page 13 & 14

in the installation manual.

13.

Replace existing bell wire with new. Make sure that

insulated staples do not short wire.

14.

Contact your local dealer.

15.

Adjust up force/sensitivity see page 16.

16.

Adjust down force/sensitivity see page 16.

17.

Free bottom of the door from the ice.

18.

Clear all foreign objects from under the door.

19.

Replace with rough service bulb of A19 100W Max.

20.

Point wire antenna straight down towards the floor.

Ensure radio signal (transmitter) has a direct line of site

to the receiver. Radio signals do not pass through metal

objects but do penetrate glass.

21.

Contact your local dealer.

22.

Contact your local dealer.

23.

Contact your local dealer.

24.

Contact your local dealer.

25.

Contact your local dealer.

* Optional

Page 20

20

After the Installation

1.

Never permit children to play with or operate the garage door opener either from the wall station or the remote

controls. Keep radio transmitter locked in the car. Misuse of the push button or transmitter could result in serious

injury or even death.

2.

Open the garage door with the remote controls only when the garage door is fully visible to you and clear of all

obstructions. The garage door should be kept in sight until it is completely open or closed and you are certain that the

garage door opener has shut off.

3.

Attempting to exit the garage through the garage door opening, while the door is in motion, is a very dangerous

activity that could result in serious injury or even death.

4.

Children and pets should always be clear of the door opening while the garage door is in motion.

5.

Check the safety reverse mechanism at least once a month to make sure that it will reverse with the minimum amount

of force. Also check to be sure that the door will reverse within 100 mm of the floor. See page 16.

6.

Check the manual operation of your garage door at least every 90 days to be sure that it is operating smoothly and

does not bind or stick. Tighten all bolts on the door and visually check all hardware including springs for wear of

damage. Caution: If service is needed contact your local garage door service person.

7.

Do not decrease the safety reversing sensitivity mechanism to overcome a damaged or poorly operating door. This

will adversely affect the operation of the safety reverse mechanism, which could result in damage to the door,

personal injury or even death.

Caution: Never operate the door opener if the reversing mechanism is not functioning properly.

8.

Whenever possible, the manual disconnect should only be used when the door is fully closed. Caution: Extreme care

must be taken whenever the disconnect cord is pulled with the door partially open. Weak or broken springs may allow

the door to fall rapidly resulting in property damage, personal injury or death. If a broken spring is evident, contact

your local garage door service person immediately before disconnecting the door from the opener. Never attempt

servicing a broken spring.

9.

Always disconnect electrical power supply to the opener when performing any maintenance or service to the opener

or garage door. Failure to do so could result in electrical shock, property damage, personal injury or death.

10.

If any damage to any mechanical or structural component of the opener is observed, discontinue use and contact

your local garage door service person immediately.

Page 21

21

A-

A-5

A-6

A-28

Drive Shaft Assembly w/ Helical Gear

A-10

Motor Shaft Bushing

A-19

Limit Shaft Clip

A-2

Chassis

A-11

Roll Pin

A-20

Limit Screws

A-3

Logic Board

A-12

Motor Mounting Bracket

A-21

RPM Reader Wheel

A-4

Capacitor

A-13

Up Limit

A-22

RPM Reader Board

A-5

Capacitor Mounting Bracket

A-14

Limit Actuator (Traveler)

A-23

RPM Reader Board Bracket

A-6

Wiring Harness

A-15

Down Limit

A24

Power Cord

A-7

Thermal Block

A-16

Light Socket

A-25

Programming Board

A-8

Motor

A-17

Front Panel

A-26

Back Panel

A-9

Worm Gear

A-18

Wrap Cover Assembly

A-27

Light Lens

A-28

250V 5A Slow-Blow Fuse

Page 22

22

Rail and Hardware Parts List

B-1

Chain

B-6

Emergency Pull-Cord with Knob

B-11

Straight Door Arm

B-2

Header Bracket

B-7

Trolley Assembly

B-12

Curved Door Arm

B-3

Pulley Assembly

B-8

Chain Tension Assembly

B-13

Door Bracket

B-4

Tube

B-9

Trolley Release Rod

B-14

Sprocket Cover

B-5

Chain Connecting Link

B-10

Trolley Stop

B15

Well nut and bolt

B16

Manual Push Button

Page 23

Guardian Automation

Warranty Policy

Important document: To be kept by the user of the Product

If you are a consumer under the Australian Consumer Law, Guardian Automation will provide you, the original purchaser of this

Garage Door Opener (Product), with this limited warranty in addition to any rights that you have under Australian consumer

protection laws. This warranty is in addition to, and does not exclude, restrict or modify your guarantees and other legal

rights under Australian Consumer law. Our goods come with guarantees that cannot be excluded under the Australian

Consumer Law.

You are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

This warranty only applies to Product sold by Guardian Automation or an authorised dealer in Australia. An approved and

authorised dealer meaning an approved reseller of Guardian Automation' products purchased from Guardian Automation for the

purpose of supplying those products to the end consumer. This warranty document is not intended to create a contract between

Guardian Automation and the purchaser.

Except for this warranty, Guardian Automation gives no warranties of any kind whatsoever (whether express or implied) in

relation to the Product and all warranties relating to the Product are hereby excluded to the extent permissible by law. Guardian

Automation will not accept any additional warranties or conditions provided by others that attempt to modify the terms of this

warranty.

Subject to your non-excludable rights under the Australian Consumer Law, Guardian Automation expressly excludes any liability

for consequential loss, incidental or indirect damages (including but not limited to damages for loss of business profits, business

interruption and loss of business information) due to a defect of the Product. In particular, any loss or damage caused to other

equipment or accessories used with the Product or any loss resulting from a delay in repair, is excluded to the extent permitted

by law.

Conditions of Warranty

Subject to the terms of this warranty, Guardian Automation warrants to the original purchaser that:

1.

the Product will be free from defects in materials and workmanship for a period of 5 years from the date of purchase or

10,000 cycles (whichever occurs first) for the motor, and 3 years from the date of purchase or 6,000 cycles (whichever

occurs first) for the electronics and mechanics. A cycle means one opening and closing cycle of the door.

2.

the remote-controlled transmitters and accessories included with the Product will be free from defects in materials and

workmanship for a period of 12 months from the date of purchase.

3.

where the Product is installed by Guardian Automation, the installation service is covered for a period of twelve

months from defects in materials and workmanship.

Subject to the following conditions and any non-excludable statutory rights, Guardian Automation will, at its option, either

repair or replace any proven defects in materials or workmanship;

(a)

The garage door to which the Product is fitted must be "spring balanced" and able to be opened and closed by a force not

exceeding 15 kilograms.

(b)

Proof of purchase must be presented.

(c)

The Product must have been serviced by a professional authorised by Guardian Automation at intervals not exceeding 12

months (the cost of servicing is not covered by this warranty).

(d)

The Product is well maintained and kept in good working condition.

(e)

The supplier must be notified as soon as practicable of any defect covered by this warranty. If the Product was supplied by

an authorised Guardian Automation dealer and this dealer cannot be contacted, then notification must be made as soon as

practicable to Guardian Automation.

(f)

This Warranty is limited to Return-to-Base (RTB) repair and does not cover labour or associated costs for on-site

attendance. The purchaser is responsible for the cost of returning the Product to the supplier or to Guardian Automation.

The purchaser is responsible for the cost of labour and any travel or other additional expenses incurred for any on-site

attendance.

(g)

Any Product repaired or replaced during the warranty period will be covered by the terms of this warranty until the

expiration of the original warranty period.

(h)

Where Guardian Automation, or its Authorised Dealer, in its absolute discretion determines that a warranty claim is not

being covered under the conditions of this warranty, then Guardian Automation or its authorised dealer (as the case

may be) reserves the right to charge for reasonable reimbursement of expenses for assessing the claim, and these

must be paid by the purchaser before the Product will be returned (at the purchaser’s expense)

(i)

This warranty is not transferrable.

j) Repairs may be conducted using refurbished components, and Products presented for repair may be replaced with

refurbished products of similar type.

(k)

Products must be returned in original or suitably safe packaging.

(I)

This warranty is only applicable for repairs to Products in Australia.

Page 24

What this warranty does not cover:

(a)

Corrosion: Damage from salt, water or any other form of corrosion.

(b)

Installation: damage or defect due to faulty installation of the Product (except where installed by Guardian Automation).

(c)

Service: damage or defect due to a failure to properly service, care for or maintain the Product in accordance with the

instruction manual.

(d)

Damage due to misuse (including failure to follow the instruction manual) or deliberate, negligent or accidental damage of

any sort.

(e)

Modifications: Guardian Automation will not be required to incorporate any modifications made to existing or future models.

(f)

Electrical Power: Any damage, issues or faults caused by electrical surge or fluctuation.

(g)

Problems that are directly or indirectly caused by or relate to the garage door or garage door hardware, which could include

but are not limited to door springs, rollers, curtain wear, fixings and alignment.

(h)

Normal wear and tear.

(i)

Non-authorised repairs.

j) Acts or omissions of any person, including approved dealers, other than Guardian Automation and its staff.

(k) Travel Expenses: Expenses incurred by Guardian Automation or its authorised dealer in travelling and or transporting

Products to and from the location of the Product are not included and will be paid for by the purchaser.

(I)

(m)

(n)

Additional access or equipment required: Expenses incurred by Guardian Automation or its authorised dealer required to

provide clear access, or the equipment used to access the Product (for example: Lifting hardware such as forklift or scissor

lift) are not covered by this warranty and must be paid for by the purchaser.

Frequency Interference: Where remote transmitters cannot operate the opener due to frequency interference at the location

where the Product is installed.

Damage due to matters outside of the reasonable control of Guardian Automation including, but not limited to, rain, hail,

flood, water, fire, insects or any other event beyond the reasonable control of Guardian Automation.

(o) Consumer Goods: Components such as globes, accessories, batteries and other consumable parts are not covered

by this warranty.

What will void this warranty:

Guardian Automation will be relieved of all obligations, responsibilities and liabilities under this warranty if, in the opinion of

Guardian Automation, the defects in the Product result from:

(a)

Any modifications, repairs or works carried out to the Product, which are not authorised by Guardian Automation.

(b)

The fitment of any device to the Product, which is not approved by Guardian Automation.

(c)

Misuse or unreasonable use of the Product, as determined by Guardian Automation.

(d)

Any use of the Product other than for residential application only (i.e. for use in a single-family dwelling or individual

garages within an apartment complex).

(e)

Failure to follow any directions or instructions, including any warning notifications in instruction manuals or signs on or

provided with the Product.

If any part of this warranty is or becomes illegal, void or unenforceable, this does not invalidate the rest of the warranty.

How to make a claim

Please be aware you are responsible for the expense of making a claim under this warranty.

To make a claim, if the Product was supplied to you directly from Guardian Automation please forward a copy of your original

receipt as proof of purchase and a completed warranty claim form to Guardian Automation directly. If the Product was supplied

by an authorised Guardian Automation dealer, please provide the copy of your original receipt along with a completed warranty

claim form to that dealer. If the authorised dealer cannot be contacted, then please contact Guardian Automation and provide the

copy of the receipt and the completed warranty claim form and Guardian Automation will forward these to the relevant authorised

dealer.

This warranty is supplied by Guardian Automation Ply Ltd

WARRANTY CERTIFICATE

Invoice No:

Installation Date:

Your Name:

Phone No:

Address:

State:

Installed by:

Motor Serial #:

Door Model:

www.guardianautomation.com.au

Loading...

Loading...