Page 1

-@SP-----TOPDRY----@

FANS &HEATERS

FAN MODEL NO.'s

TF·2024·1C

TF·2036-3C

TF-2024-3C

TF-2036-5C

TF·2024-5C

TF-2042-1C

TF-2028-1C

TF-2042-3C

TF-2028-3C

TF-2042-5C

TF-2028-5C

TF2042-33C

TF-2036·1C

TF2042-35C

1\(

1,,,4,,,,

~

APPROVED

®

HEATER

MODEL

NO.'s

THF-4024L,PC

THF~4036LPC

THF-4024VC

THF·4036VC

THF·4024NC

THF-4036NC

THF-4028LPC

THF-4042LPC

THF·4028VC

THF-4042NC

THF-4028NC

OWNER'S MANUAL

for CANADIAN MODELS

PNEG-121

Page 2

WARRANTY

·GRAIN

SYSTEMS,

INC.

warrants

all

products

manufactured

by

GRAIN

SYSTE~IS,

INC.

to

be

free

of

defects

in

materials

and

workmanship

under

usual

and

customary

service.

GRAIN

SYSTENS,

INC.

only

obligation

is

to

repair

or

replace

products

returned

on a

prepaid

basis

within

12

months

after

retail

sale,

and,

in

our

opinion,

found

to

be

defective

due

to

material

of

wor~nanship.

If

defective,

the

product

will

be

repaired

of

replaced

without

charge,

F.O.B.

factory,

this

constituting

and

fulfilling

our

warranty

obligation.

Expenses

incurred

without

authorization

of

GRAIN

SYSTEMS,

INC.

shall

be

the

sole

responsibility\

of

the

bearer.

Under no

circumstances

wiil

G~IN

SYSTH1S,

INC. be

liable

for

any

kind

of

special

of

consequential

damages,

nor

will

the

liabilty

ever

exceed

the

selling

price

of 'the

product.

This

warranty

does

not

cover

products

or

parts

which

have

been

damaged

by

negligent

use,

misuse,

alteration

of

accident.

All

products

supplied

by

outside

manufacturers

are

warranted

seperately

by

the

respectiv~

manufacturer.

This

war~anty

is

exclusive

and

in

lieu

of

all

other

warranties,

expressed

of

implied.

GRAIN

SYSTE~IS,

INC.

reserves

the

right

to

make

design

or

specification

changes

at

any

time,

without

an

contingent

obligation

to

purchasers

or

products

already

sold.

All

instructions

shall

be

construed

as

recommendations

only;

because

the

actual

installation

may

vary

according

to

local

conditions

and

GRAIN

SYSTENS,

INC.

assumes

no

liability

for

results

arising

from

the

use

of

such

recommendations.

GRAIN

SYSTEMS,

INC.

assumes

no

responsibility

for

field

modifi-

cations

or

erection

defects

which

create

structural

or

storage

quality

problems.

If

any

field

modifications

are

necessary

which

are

not

specifically

covered

by

the

contents

of

this

manual,

contact

GRAIN

SYSTENS,

INC.

for

recommendations

and

approval.

Any

unauthorized

modification

or

erection

defect

which

effects

th~

structural

integrity

of

the

G.S.I.

bin

will

be

cause

for

immediate

nullification

of

the

G.S.I.

bin

warranty.

ROO'

DAMAGE

WARNIM.G

GRAIN

SYSTENS,

INC.

cannot

warrant.

any

roof

damages due

to

excessive

vacuum

or

internal

pressure

caused

by

fans

or

other

air

moving

systems

Adequate

ventilation

and/or

"make-up

air"

devices

should

be

prov:..lted

for

all

powered

air

handling

systems.

GRAIN

SYSTEMS,

INC.

does

not

recommend

the

use

of

downward

flow

systems

(suction).

Severe

roof

structural

damage

can

result

from

any

blockage

of

air

passages.

Running

of

fans

during

certain

high

humidity/cold

weather

conditions

can

cause

freezing

over

of

air

exhaust

or

intake

ports.

THIS

EQUIPMENT

SHALL

BE

INSTALLED IN

ACCORDANCE

WITH

THE

CURRENT

INSTALLATION

CODES

FOR

GAS

BURNING

APPLIANCES

AND

EQUIP-

MENT,

CAN1-B149.1

AND

B149.2,

OR

APPLICABLE PROVINCIAL REGULATIONS

WHICH

SHOULD

BE

CAREFULLY

FOLLOWED

IN

ALL

CASES. AUTHORITIES

HAVING

JURISDICTION

SHOULD

BE

CONSULTED

BEFORE

INSTALLATIONS

ARE

MADE.

Page 3

CONTE1\fTS

PAGE

FAN

SPECIFICATIONS

1

FAN

INSTALLATION 2

FAN

SERVICE 2

FAN

TROUBLESHOOTING

CHART

4

24"

FAN

PARTS 5

24"

FAN 1 PHASE

WIRING

DIAGRAM

8

28"

FAN

PARTS 9

28"

FAN 1 PHASE

WIRING

DIAGRAM

12

36"

FAN

PARTS

13

42"

10-16

H.P.

FAN

PARTS

14

36"

&

42"

10-16

H.P.

FAN

1 PH. WIRING DIAG

17

42"

30 H. P .

FAN

PARTS

18

220

VOLT 3 PHASE

WIRING

DIAGRAM

20

440

VOLT 3 PHASE

WIRING

DIAGRAM

21

HEATER

SPECIFICATIONS

22

FUNCTION

OF

HEATER

PARTS

23

FUNCTION

OF

VAPORIZER PARTS

24

HEATER

INSTALLATION 24

HEATER

OPERATION

25

HEATER

SERVICE

26

ADJUSTING

PRIMARY

AIR

DAMPER

PLATE

27

HEATER

TROUBLESHOOTING

CHART

28

HEATER

WIRING

DIAGRAMS

29

HI-LO

THERMOSTAT

30

HI-LO

THERMOSTAT

WIRING

DIAGRAM

31

MOUNTING

TEMPLATE

FOR

THERMOSTAT

32

Page 4

--

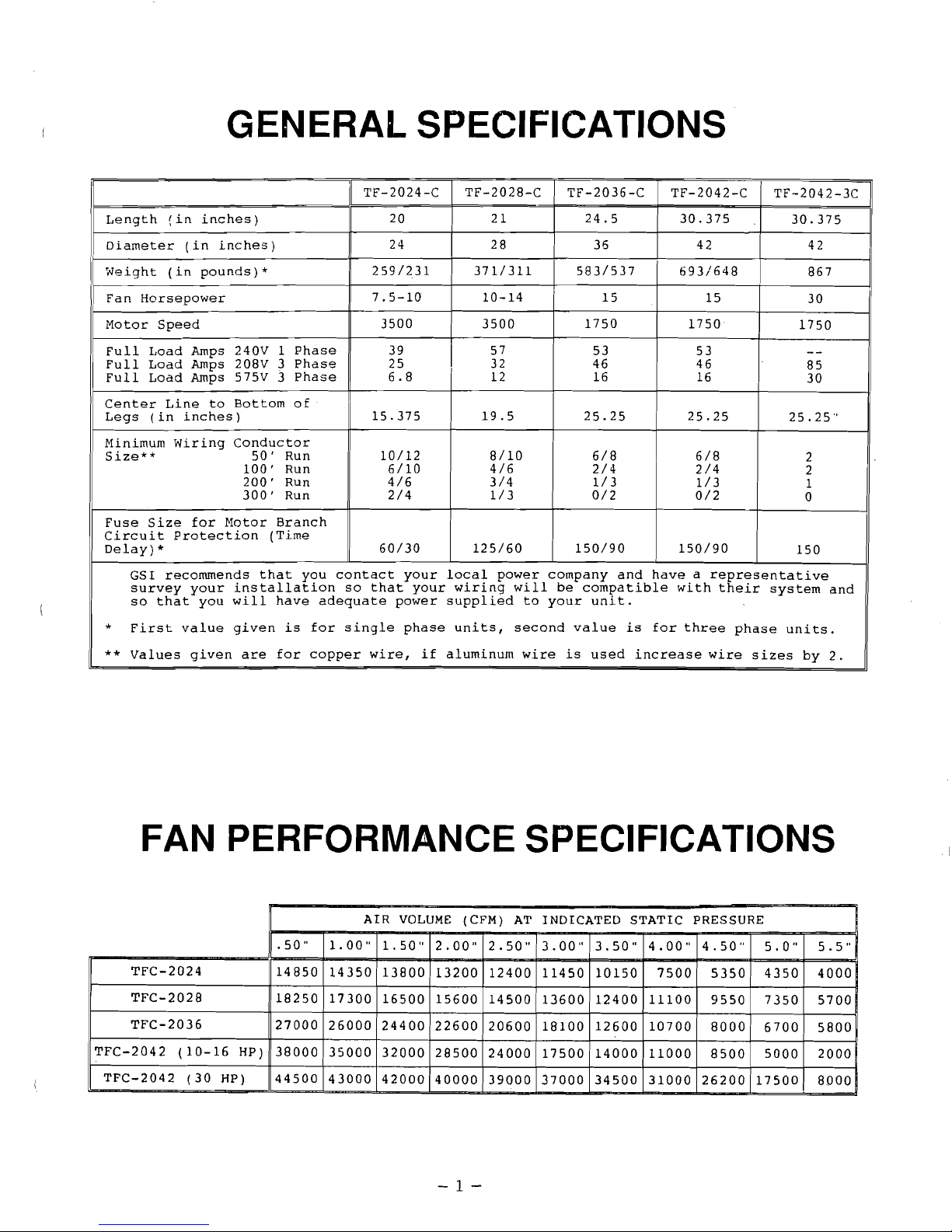

GENERAL SPECIFICATIONS

TF-2024-C

TF-2028-C

TF-2036-C

TF-2042-C

TF-2042-3C

20

21

24.5

30.375

Length

(in

inches)

30.375

24

28

36 42

Diameter

(in

inches)

42

259/231

371/311

583/537

693/648

Weight

(in

pounds)*

867

7.5-10

10-14

15

15

Fan

Horsepower

30

3500

1750

3500

1750

Motor

Speed

1750

39

57

Full

Load

Amps

240V

1

Phase

53 53

Full

Load

Amps

208V

3

Phase

25

I

32

46 46

85

Full

Load

Amps

575V

3

Phase

6.8

12 16 16

30

Center

Line

to

Bottom

of

Legs

(in

inches)

15.375

19.5

25.25

25.25

-.

25.25

Minimum

Wiring

Conductor

Size**

50'

Run

10/12

8/10

6/8 6/8

2

100'

Run

6/10

4/6

2/4

2/4

2

200'

Run

4/6

1/3

3/4

1/3

1

300'

Run

2/4

1/3

0/2

0/2

0

Fuse

Size

for

Motor

Branch

Circuit

Protection

(Time

De1ay)*

60/30

125/60

150/90

150/90

150

GSI

recommends

that

you

contact

your

local

power

company

and

have a representative

survey

your

installation

so

that

your

wiring

will

be

compatible

with

their

system

and

so

that

you

will

have

adequate

power

supplied

to

your

unit.

First

value

given

is

for

single

phase

units,

second

value

is

for

three

phase

units.

*

**

Values

given

are

for

copper

wire,

if

aluminum

wire

is

used

increase

wire

sizes

by

2.

FAN PERFORMANCE SPECIFICATIONS

AIR

VOLUME

(CFM)

AT

INDICATED

STATIC

PRESSURE

.50

"

1.00

"

1.50"

2.00"

2.50"

3.00" 3.50"

4.00"

4.50"

5.0" 5.5"

TFC-2024

14850

14350

13800

13200 12400 11450

10150

7500

5350

4350 4000

TFC-2028

18250

17300

16500 15600

14500

13600

12400 11100

9550

7350

5700

TFC-2036

27000

26000 24400

22600

20600

18100

12600 10700

8000

6700

5800

TFC-2042

(10-16

HP)

38000

35000

32000

28500

24000

17500

14000

11000

8500

5000

2000

TFC-2042

(30

HP)

44500

43000

42000

40000

39000 37000 34500 31000

26200

17500

8000

-1-

Page 5

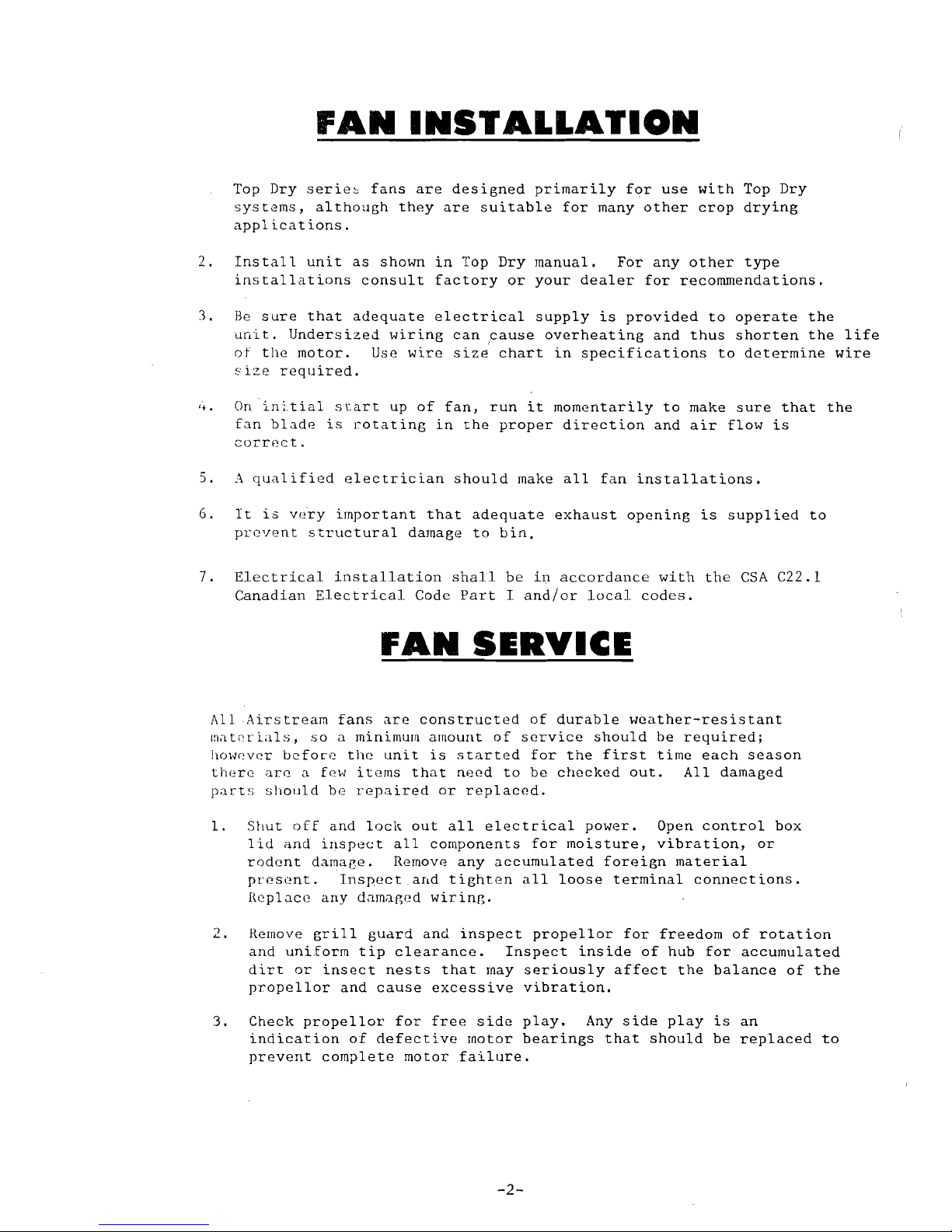

FAN

INSTALLATION

Top

Dry

serie~

fans

are

designed

primarily

for

use

with

Top

Dry

systems,

although

they

are

suitable

for

many

other

crop

drying

applications.

2.

Install

unit

as

shown

in

Top

Dry

manual.

For

any

other

type

installations

consult

factory

or

your

dealer

for

recommendations.

3.

Be

sure

that

adequate

electrical

supply

is

provided

to

operate

the

unit.

Undersized

wiring

can

cause

overheating

and

thus

shorten

the

life

of

tile

motor.

Use

wire

size

chart

in

specifications

to

determine

wire

~ize

required.

4.

On

initial

start

up

of

fan,

run

it

momentarily

to

make

sure

that

the

fan

blade

is

rotating

in

the

proper

direction

and

air

flow

is

correct.

5.

A

qualified

electrician

should

make

all

fan

installations.

6.

It

is

v~ry

important

that

adequate

exhaust

opening

is

supplied

to

prevent

structural

damage

to

bin.

7.

Electrical

installation

shall

be

in

accordance

with

the

CSA

C22.l

Canadian

Electrical

Code

Part

I

and/or

local

codes.

FAN

SERVICE

All

Airstream

fans

are

constructed

of

durable

weather-resistant

I~at~rials,

so a minimum

amount

of

service

should

be

required;

hOWl'vcr

bcfoLe

the

unit

is

started

for

the

first

time

each

season

there

are a few

items

that

need

to

be

checked

out.

All

damaged

parts

should

be

repaired

or

replaced.

1.

Shut

off

and

locl~

out

all

electrical

power.

Open

control

box

lid

and

inspect

all

components

for

moisture,

vibration,

or

rodent

damaGe.

Remove

any

accumulated

foreign

material

present.

Inspect

and

tighten

all

loose

terminal

connections.

Replace

any

damaRed

wiring.

2.

Remove

grill

guard

and

inspect

propellor

for

freedom

of

rotation

and

uniform

tip

clearance.

Inspect

inside

of

hub

for

accumulated

dirt

or

insect

nests

that

may

seriously

affect

the

balance

of

the

propel

lor

and

cause

excessive

vibration.

3.

Check

propel

lor

for

free

side

play.

Any

side

play

is

an

indication

of

defective

motor

bearings

that

should

be

replaced

to

prevent

complete

motor

failure.

-2-

Page 6

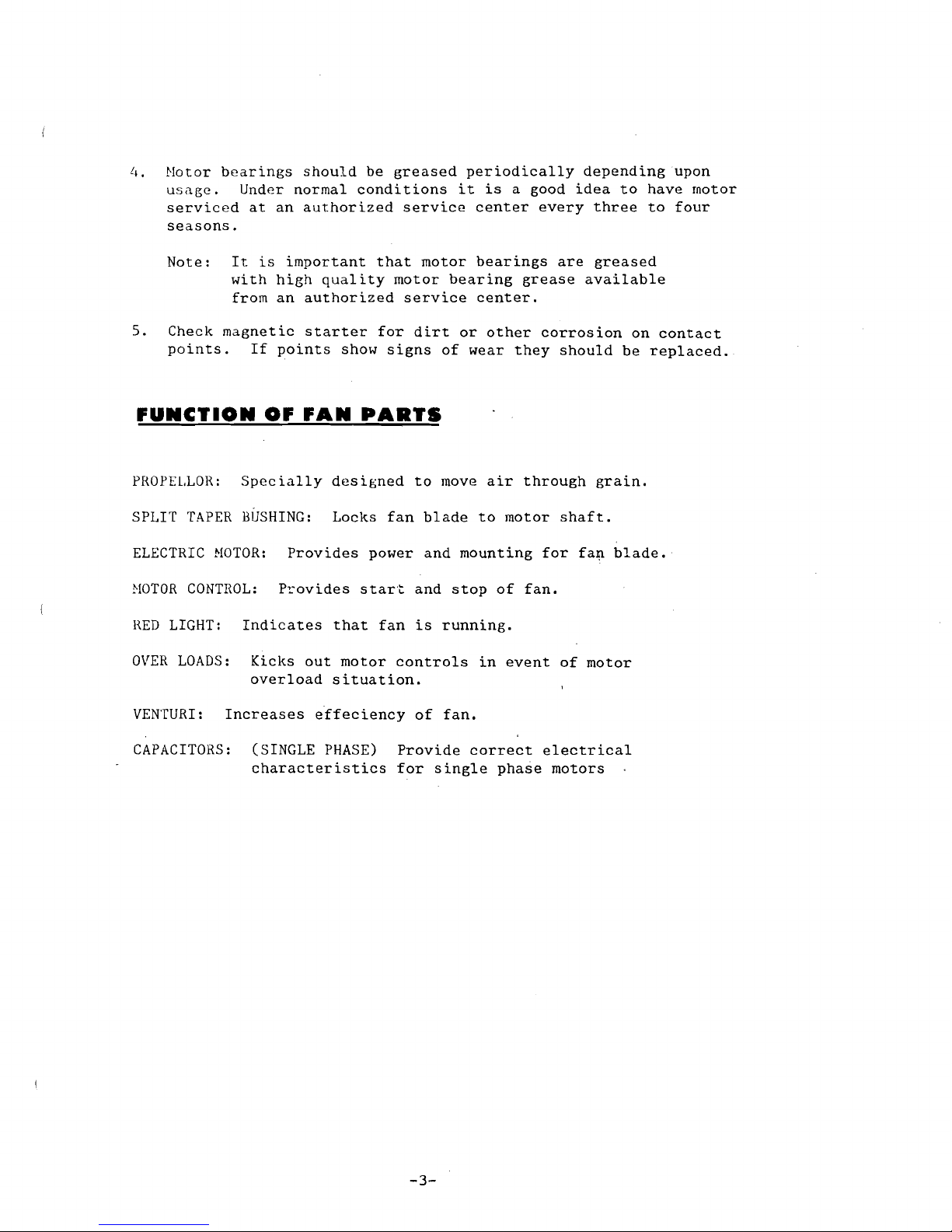

4.

Motor

bearings

should

be

greased

periodically

depending

upon

usage.

Under

normal

conditions

it

is

a good

idea

to

have

motor

serviced

at

an

authorized

service

center

every

three

to

four

seasons.

Note:

It

is

important

that

motor

bearings

are

greased

with

high

quality

motor

bearing

grease

available

from

an

authorized

service

center.

5.

Check

magnetic

starter

for

dirt

or

other

corrosion

on

contact

points.

If

points

show

signs

of

wear

they

should

be

replaced.

FUNCTION

OF

FAN

PARTS

PROPELLOR:

Specially

designed

to

move

air

through

grain.

SPLIT

TAPER

BUSHING:

Locks

fan

blade

to

motor

shaft.

ELECTRIC

NOTOR:

Provides

power

and

mounting

for

faJil

blade.

MOTOR

CONTROL:

Pl'ovides

start

and

stop

of

fan.

RED

LIGHT:

Indicates

that

fan

is

running.

OVER

LOADS:

Kicks

out

motor

controls

in

event

of

motor

overload

situation.

VENTURI:

Increases

effeciency

of

fan.

CAPACITORS:

(SINGLE

PHASE)

Provide

correct

electrical

characteristics

for

single

phase

motors

-3-

Page 7

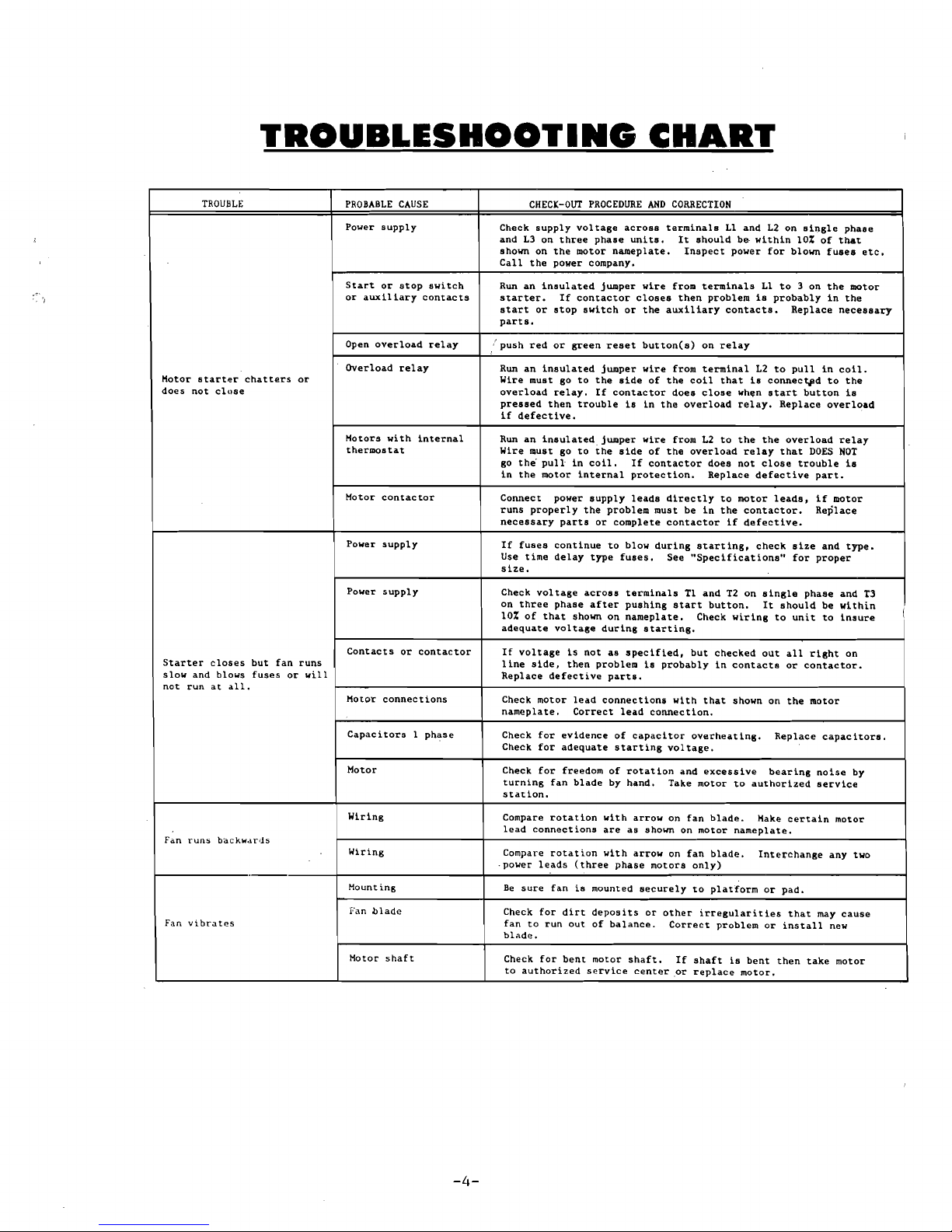

TROUBLESHOOTING

CHART

TROUBLE

PROBABLE

CAUSE

CHEC~-OUT

PROCEDURE

AND

CORRECTION

Power

supply

Check

supply

voltage

across

terminals

Ll

and

L2

on

single

phase

and

L3

on

three

phase

units.

It

should

be

within

lOt

of

that

shown on

the

motor

nameplate.

Inspect

power

for

blown

fuses

etc.

Call

the

power company.

Star.t

or

stop

switch

or

auxiliary

contacts

Run

an

insulated

jumper

wire

from

terminals

Ll

to

3 on

the

motor

starter.

If

contact

or

closes

then

problem

is

probably

in

the

start

or

stop

switch

or

the

auxiliary

contacts.

Replace

necessary

parts.

Hotor

starter

chatters

or

does

not

close

Open

overload

relay

Overload

relay

push

red

or

green

reset

button(s)

on

relay

Run

an

insulated

jumper

wire

from

terminal

L2

to

pull

in

coil.

Wire must go

to

the

side

of

the

coil

that

is

connec~d

to

the

overload

relay.

If

contactor

does

close

wh~n

start

button

is

pressed

then

trouble

is

in

the

overload

relay.

Replace

overload

if

defective.

Motors

with

internal

thermostat

Motor

contactor

Power

supply

Run

an

insulated.

jumper

wire

from

L2

to

the

the

overload

relay

Wire must go

to

the

side

of

the

overload

relay

that

DOES

NOT

go

the·

pull

in

coil.

If

contactor

does

not

close

trouble

is

in

the

motor

internal

protection.

Replace

defective

part.

Connect

power

supply

leads

directly

to

motor

leads,

if

motor

runs

properly

the

problem

must

be

in

the

contactor.

Replace

necessary

parts

or

complete

contactor

if

defective.

If

fuses

continue

to

blow

during

starting,

check

s

he

and

type.

Use

time

delay

type

fuses.

See

"Specifications"

for

proper

size.

Power

supply

Check

voltage

across

terminals

Tl

and

T2

on

single

phase

and

T3

on

three

phase

after

pushing

start

button.

It

should

be

within

(

lOt

of

that

shown

on

nameplate.

Check

wiring

to

unit

to

insure

adequate

voltage

during

starting.

Starter

closes

but

fan

runs

slow

and blows

fuses

or

will

not

run

at

all.

Contacts

or

contactor

Motor

connections

If

voltage

is

not

as

specified,

but

checked

out

all

right

on

line

side,

then

problem

is

probably

in

contacts

or

contactor.

Replace

defective

parts.

Check

motor

lead

connections

with

that

shown

on

the

motor

nameplate.

Correct

lead

connection.

Capacitors

1

phase

Motor

Check

for

evidence

of

capacitor

overheating.

Replace

capacitors.

Check

for

adequate

starting

voltage.

Check

for

freedom

of

rotation

and

excessive

bearing

noise

by

turning

fan

blade

by

hand.

Take

motor

to

authorized

service

station.

Fan

runs

ba.ckwards

Fan

vibrates

Wiring

Wiring

Mounting

Fan

blade

Compare

rotation

with

arrow

on

fan

blade.

Make

certain

motor

lead

connections

are

as

shown

on

motor

nameplate.

Compare

rotation

with

arrow

on

fan

blade.

Interchange

any

two

.

power

leads

(three

phase

motors

only)

Be

sure

fan

is

mounted

securely

to

platform

or

pad.

Check

for

dirt

deposits

or

other

irregularities

that

may

cause

fan

to

run

out

of

balance.

Correct

problem

or

install

new

blade.

Motor

shaft

Check

for

bent

motor

shaft.

If

shaft

is

bent

then

take

motor

to

authorized

service

center

or

replace

motor.

-4-

Page 8

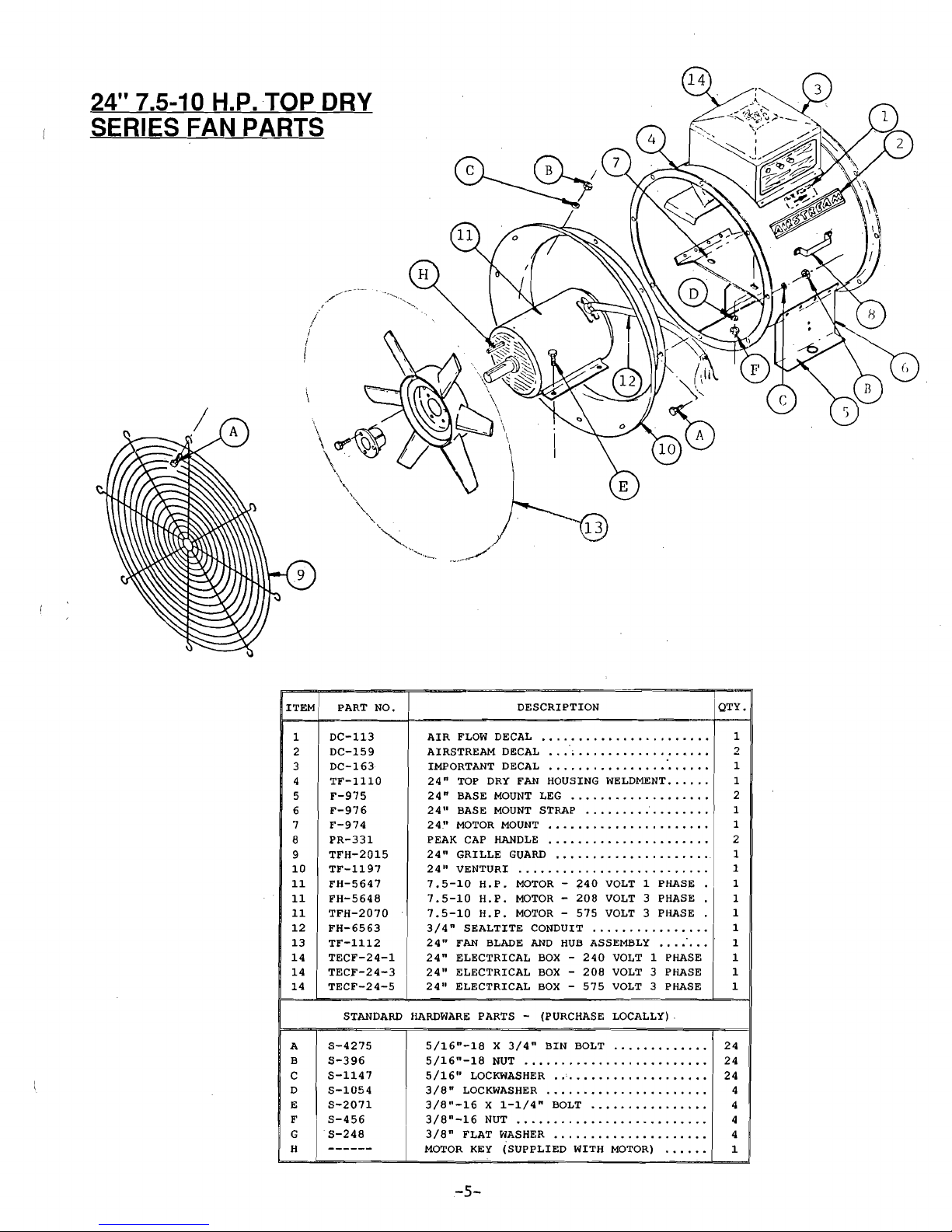

24" 7.5-10 H.P.

TOP

DRY

SERIES FAN PARTS

/

I

I

I

ITEM

PART

NO.

DESCRIPTION QTY.

1

DC-113

AIR

FLOW

DECAL

.

"-

...

"-.

"-

...............

1

2

DC-159

AIRSTREAM

DECAL

...

~

.............."- ..

"-

2

3

DC-163

IMPORTANT

DECAL

.............

"-

..................

"-

I

4

TF-I110

24"

TOP

DRY

FAN

HOUSING

WELDMENT

......

1

5

F-975

24"

BASE

MOUNT

LEG

............

"-

..........

2

6

F-976

24"

BASE

MOUNT

STRAP

............................

1

7

F-974

24"

MOTOR

MOUNT

................................

1

8

PR-331

PEAK

CAP

HANDLE

...............

"-

.....................

2

9

TFH-2015

24"

GRILLE

GUARD

....................................

1

10

TF-1197

24"

VENTURI .....................................

"-

I

11

FH-5647

7.5-10

H.P.

MOTOR -240

VOLT 1 PHASE

1

11

FH-5648

7.5-10

H.P.

MOTOR -208

VOLT 3 PHASE

1

11

TFH-2070

7.5-10

H.P.

MOTOR -575

VOLT 3 PHASE

1

12

FH-6563

3/4"

SEALTITE

CONDUIT

...

"-

...................

1

13

TF-1112

24"

FAN

BLADE

AND

HUB

ASSEMBLY

............ 1

14

TECF-24-1

24"

ELECTRICAL

BOX -240

VOLT 1 PHASE

1

14

TECF-24-3

24"

ELECTRICAL

BOX -208

VOLT 3 PHASE

1

14

TECF-24-5

I

24"

ELECTRICAL

BOX

-

575

VOLT 3 PHASE

1

STANDARD

HARDWARE

PARTS -

(PURCHASE

LOCALLY)

.

A

B

C

D

E

F

G

H

5-4275

5-396

5-1147

S-1054

S-2071

S-456

5-248

5/16"-18 X 3/4"

BIN

BOLT

'"

24

5/16"-18

NUT

..................•......

24

5/16"

LOCKWASHER ..'.

. . . . . . . . . . . . . . • • . .

24

3/8"

LOCKWA5HER

4

3/8"-16 X 1-1/4"

BOLT

4

3/8"-16

NUT

.....•....................

4

3/8"

FLAT

WASHER

4

MOTOR

KEY

(SUPPLIED

WITH

MOTOR)

1

-5-

Page 9

24"

7.5-10

~

1

PHASE

FAN

CONTROL

BOX

PARTS

ITEM PART NO. DESCRIPTION

QTY.

1

DC-381

CANADIAN

FAN

ELECTRICAL

BOX

DECAL

........

1

2

F-747

CAPAC~TOR

RETAINER

CLIP

............................

1

3

DC-437

24"

1 PHASE

WIRING

DIAGRAM

DECAL

..........

1

4

TFC-0028

STOP SWITCH

....................................................

1

5

TFC-0029

START

SWITCH

..................................................

1

6

TFC-0063

HEATER

STRIP

..................................................

1

7

TF-1185

24"

FAN

BOX

WELDMENT

..................................

1

8

TFC-0057

CONTACTOR

........................................................

1

9

TFC-0044

OVERLOAD

RELAY

..............................................

1

10

TFC-0018

TERMINAL

STRIP

.............................................. 1

11

TFH-2052

TERMINAL

STRIP

MARKER

................................ 1

12

---------

START

CAPACITORS

(BALDOR)

........................

AR

13

TFC-0012

RED

LIGHT

........................

.........

-

......................

1

STANDARD

HARDWARE

PARTS -(PURCHASE

LOCALLY)

A

S-6557

#8-32

X

3/4"

SHEET

METAL

SCREW

..............

2

B

S-1040

#8-32

X

1/4"

SHEET

METAL

SCREW

.............. 6

C

S-2605

1/4"-20

X

1-1/4"

SHEET

METAL

SCREW

...

1

-_.

_....

-_

..

-6-

Page 10

6

24"

7.5-10

H.P.

208 & 575

VOLT

3 PHASE

FAN

CONTROL

BOX

PARTS

Ie

QTY.

DESCRIPTION

PART NO.

1

CANADIAN

FAN

ELECTRICAL

BOX

DECAL

........

DC-381

1

208

VOLT

3

PHASE

WIRING

DIAGRAM

DECAL. 1

2

DC-379

575

VOLT

3

PHASE

WIRING

DIAGRAM

DECAL. 1

2

DC-380

1

STOP SWITCH

....................................................

TFC-0028

3

1

START SWITCH

..................................................

4

TFC-0029

HEATER

STRIP

(208

VOLT

ONLY)

..................

TFC-0041

5

~

HEATER

STRIP

(575

VOLT

ONLY)

.................. 3

TFC-0065

5

24"

FAN

CONTROL

BOX

WELDMENT

..................

1

TF-1185

6

CONTACTOR

........................................................ 1

7

TFC-0059

TERMINAL

STRIP

.............................................. 1

TFC-0018

8

TERMINAL

STRIP

MARKER

................................ 1

TFH-2052

9

RED

LIGHT

........................................................ 1

10

TFC-0012

TFC-0039

TRANSFORMER

575-120

V

(575

VOLT

ONLY)

.

1

11

TFC-0042

AUXILIARY POINTS

(575

VOLT

ONLY)

.......... 1

12

TFC-0043

COIL

-

120

VOLTS

(575

VOLT

ONLY)

.......... 1

13

STANDARD

HARDWARE

PARTS -(PURCHASE LOCALLY)

A

S-6557

#8-32

X

3/4"

SHEET

METAL

SCREW

..

... ........ " 4

B

S-1040

#8-32

X

1/4"

SHEET

METAL

SCREW

..............

4

-7-

Page 11

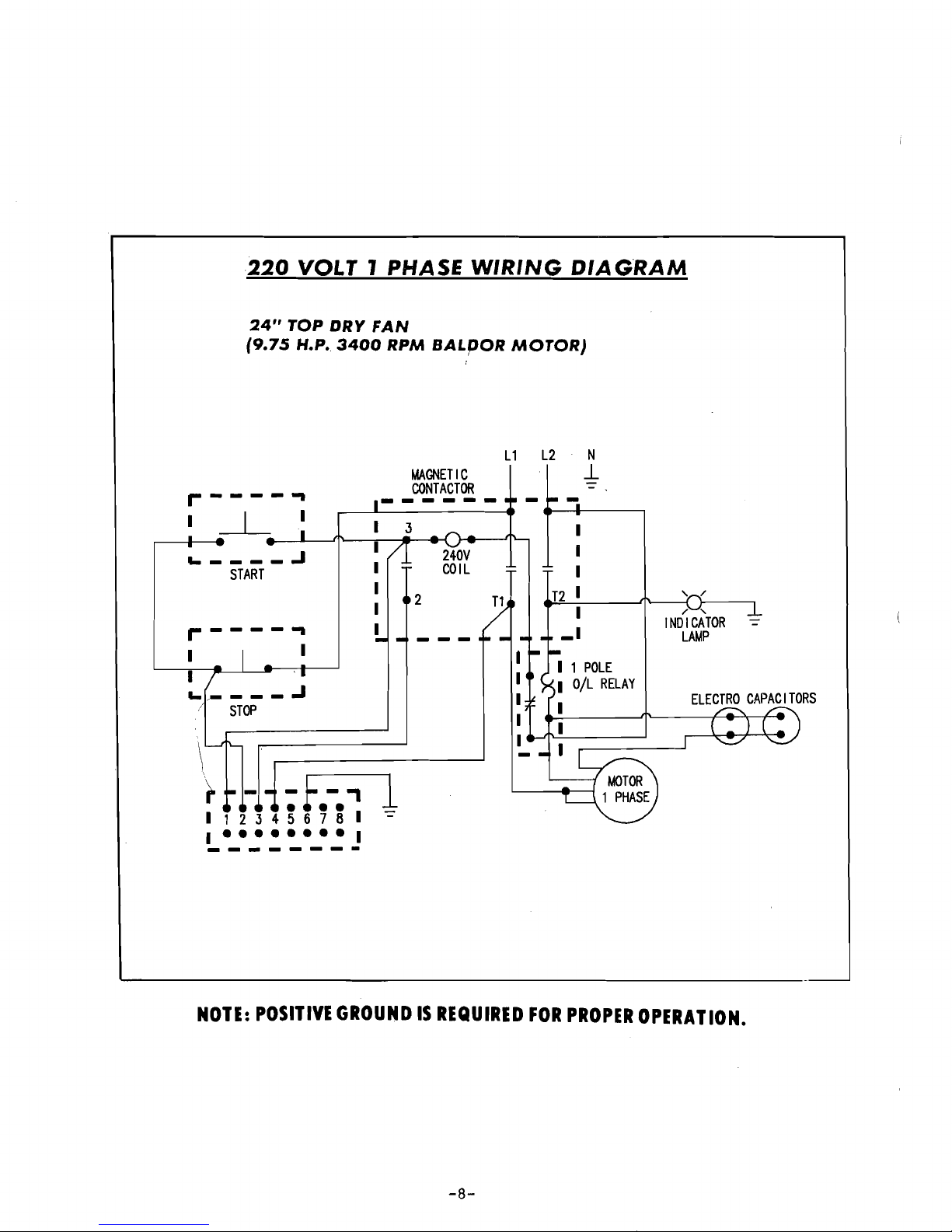

220

VOLT

1 PHASE

WIRING

DIAGRAM

24"

TOP

DRY

FAN

(9.75

H.P.

3400

RPM

BALpOR

MOTOR)

L1

L2

N

MAGNETIC

JL

CONTACTOR

/ ,

INDICATOR

LAMP

_I

1 1

POLE

lOlL

RELAY

1

START

- :

f.-.'

1

I

123

4 5 6 7 8 I

~

1

••••••••

1

--------

,.----

...

1

1

... .J

!

STOP

NOTE:

POSITIVE

GROUND

IS

REQUIRED

FOR

PROPER

OPERATION.

-8-

Page 12

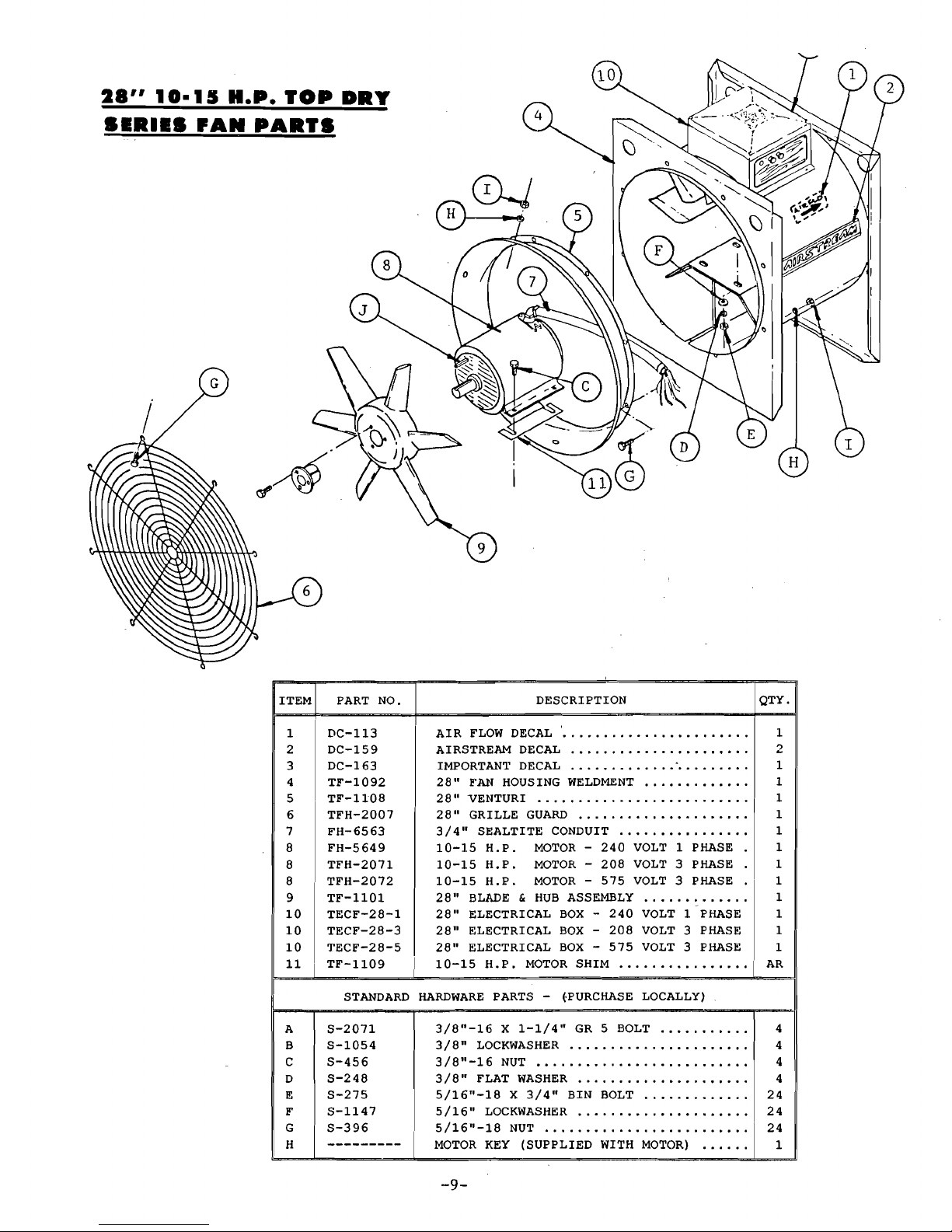

28"

10-15

R.P.

TOP

DRY

SIRIIS

'AN

PARTS

G

DESCRIPTION QTY.

1

DC-113

ITEM

PART

NO.

AIR

FLOW

DECAL

. 00000000.. ... •.•. .•.. . 1

AIRSTREAM

DECAL

2

2

DC-159

3

DC-163

IMPORTANT

DECAL

..

1

28"

E'AN

HOUSING

WELDMENT

1

4

TF-1092

5

TF-1108

28"

VENTURI 10 • • • • • • • • • • • • • • • •

28"

GRILLE

GUARD

.0...................

1

6

TFH-2007

3/4"

SEALTITE

CONDUIT

1

7

FH-6563

10-15

H.P.

MOTOR -240

VOLT 1 PHASE

1

8

FH-5649

10-15

H.P.

MOTOR -208

VOLT 3 PHASE

1

8

TFH-2071

8

TFH-2072

10-15

HoP.

MOTOR -575

VOLT 3 PHASE

1

28"

BLADE & HUB

ASSEMBLy.............

1

9

TF-1101

28"

ELECTRICAL

BOX -240

VOLT 1 PHASE

1

10

TECF-28-1

28"

ELECTRICAL

BOX -208

VOLT 3 PHASE

1

10

TECF-28-3

28"

ELECTRICAL

BOX -575

VOLT 3 PHASE

1

10

'J'ECF-28-5

10-15

H.P.

MOTOR

SHIM................

AR

STANDARD

HARDWARE

PARTS -(·PURCHASE

LOCALLY)

A

11

TF-1109

3/8"-16

X

1-1/4"

GR 5 BOLT

4

S-2071

3/8"

LOCKWASHER

4

B

S-1054

C

S-456

3/8"-16

NUT

0.................

4

S-248

3/8"

FLAT

WASHER

0

.....•.•.•

00•. 4

D

S-275

5/16"-18

X

3/4"

BIN

BOLT

24

E

F

S-1147

5/16"

LOCKWASHER

00

0............

24

G

5/16"-18

NUl'

....

0

........•...

0.0.....

24

S-396

H

MOTOR

KEY

(SUPPLIED

WITH

MOTOR)

1

-9-

Page 13

~

10 15

~

~

PHASE

FAN

CONTROL

BOX

PARTS

-

. .

ITEM

PART

NO.

1

DC-381

2

DC:-436

3

TFC-0028

4

TFC-0029

5

TFC-0045

6

TF-1187

7

TF-1096

8

TFC-0044

9

TFC-0001

10

TFC-0018

11

TFH-2052

12

---------

13

TFC-0012

14

---------

STANDARD

A

S-6557

B

S-1040

C

S-1102

D

S-4627

DESCRIPTION

CANADIAN

FAN

ELECTRICAL

BOX

DECAL

........

28" 1 ,PHASE

WIRING

DIAGRAM

DECAL

..........

'---

/'

.

STOP SWITCH .................. ...

..............................

"

START SWITCH

..................................................

HEATER

STRIP

..................................................

28"

FAN

CONTROL

BOX

WELDMENT

..................

CAPACITOR

HALF

CLAMP

(BALDOR)

................

OVERLOAD

RELAY

..............................................

CONTACTOR

........................................................

TERMINAL

STRIP

..............................................

TERMINAL

STRIP

MARKER

................................

BALDOR

RUN

CAPACITORS

(OIL)

....................

RED

LIGHT

D

......................................................

BALDOR

START CAPACITORS (ELECTRO)

........

HARDWARE

PARTS

-

(PURCHASE

LOCALLY)

#8-32

X

5/8"

SHEET

METAL

SCREW

..............

#8-32

X

1/4"

SHEET

METAL

SCREW

..............

1/4"-20

NUT

....................................................

1/4"-20

X

2-1/2"

MACHINE

SCREW

..............

-10-

-

QTY.

1

1

1

1

1

1

2

1

1

1

1

AR

1

AR

2

8

2

2

Page 14

28"

10-15

H.P.

208 & 575

VOLT 3 PHASE

FAN

CONTROL

BOX

PARTS

r

QTY.

ITEM

PART

NO.

DESCRIPTION

1

1

CANADIAN

FAN

ELECTRICAL

BOX

DECAL

........

DC-381

1

208

VOLT

3

PHASE WIRING

DIAGRAM

DECAL

2

DC-379

1

575

VOLT 3 PHASE

WIRING

DIAGRAM

DECAL

2

DC-380

1

STOP SWITCH

.......................................... "

....

"

..

3

TFC-0028

1

TFC-0029

4

START

SWITCH

..................

""

............

""

............

TFC-0061

HEATER

STRIP

(208

VOLT

ONLY)

.................. 3

5

HEATER

STRIP

(575

VOLT

ONLY)

..................

TFC-0064

3

5

1

TF-1187

28"

FAN

CONTROL

BOX

WELDMENT

.............. "

..

6

1

CONTACTOR

(208

VOLT

ONLY)

........................

7

TFC-0050

1

CONTACTOR

(575

VOLT

ONLY)

........................

7

TFC-0059

1

8

TFC-0018

TERMINAL

STRIP

..............................................

TFH-2052

9

TERMINAL

STRIP

MARKER

................................ 1

TFC-0012

1

10

RED

LIGHT ........................................................

TFC-0039

TRANSFORMER

575-120V

(575

VOLT

ONLY)

11

1

I

12

TFC-0042

AUXILIARY POINTS

(575

VOLT

ONLY)

..........

1

I

13

TFC-0043

J

COIL -120

VOLTS

(575

VOLT

ONLY)

.......... 1

I

STANDARD

HARDWARE

PARTS -(PURCHASE

LOCALLY)

S-6557

#8-32 X 3/4"

SHEET

METAL

SCREW

.......

~I

~

S-10<10

!

#8-32

X

1/4"

SHEET

METAL

SCREW

.......

i 6

.-

-_.-

J

-

---

-

-.-

-~-

-11-

I

Page 15

-12-

220

VOLT 1 PHASE

WIRING

DIAGRAM

28"

TOP

DRY

FAN

PO-15

H.P.

3400

RPM

SALDOR

MOTOR}

OIL

CAPACITORS

1

POLE

lOlL

RELAY

1

L1

L2

N

MAGNETIC

~

CONTACTOR

1-

- f

-,

l

-

--

1123456781

L

-_-

.=. ~-

.:

:.

-_I

_____

1

START

1-----

1 1

NOTE:

POSITIVE

GROUND

IS

REQUIRED

FOR

PROPER

OPERATION.

Page 16

36"

10-16

H.P.

TOP

DRY

SIRIIS

'AN

PARTS

/

/

®-Jr'

o

.~

/

9

lTEM

PART

NO.

1

2

3

4

5

6

7

8

8

8

9

10

10

10

11

12

DC-113

DC-159

DC-163

TF-1017

TF-1050

TFH-2002

FH-6564

TFH-2054

TFH-2068

TFH-2066

TF-1053

TECF-36-1

TECF-36-3

TECF-36-5

TF-1116

TF-1037

DESCRIPTION QTY.

AIR

FLOW

DECAL .'.

. . . . . . . . . . . . . . • . . . . . • 1

AIRSTREAM

DECAL

2

iMPORTANT

DECAL

..............•.......

1

36"

FAN

HOUSING

WELDMENT

1

36"

VENTURI 1

36"

GRILLE

GUARD

1

1"

SEALTITE

CONDUIT

.....•............

'1

10-16

H.P.

MOTOR -240

VOLT 1 PHASE

1

10-16

H.P.

MOTOR -208

VOLT 3 PHASE

1

10-16

H.P.

MOTOR -575

VOLT 3 PHASE

1

36"

FAN

BLADE & HUB

ASSEMBLy.........

1

36"

ELECTRICAL

BOX -240

VOLT 1 PHASE

1

36"

ELECTRICAL

BOX -208

VOLT 3 PHASE

1

36"

ELECTRICAL

BOX -575

VOLT

3 PHASE 1

3

PHASE

ADAPTOR

(3

PHASE

ONLY)

...•...

1

10-16

H.P.

MOTOR

SHIM

AR

STANDARD

HARDWARE

PARTS -

(PURCHASE

LOCALLY)

A

B

C

D

E

F

G

H

S-4275

S-1147

S-396

S-1054

S-456

S-2071

S-248

5/16"-18

X

3/4"

BIN

BOLT

24

5/16"

LOCKWASHER

.................•...

24

5/16"-18

NUT.........................

24

3/8"

LOCKWASHER

...........•..••......

4

3/8"-16

NUT

4

3/8"-16

X

1-1/4"

BOLT

4

3/8"

FLAT

WASHER.....................

4

MOTOR

KEY

(SUPPLIED

WITH

MOTOR)

..

....

1

-13-

Page 17

42"

10-16

R.P.

TOP

DRY

SIRIIS

'AN

PARTS

/

CD

-J

CiJ1

/

/

A

DESCRIPTION QTY.

ITEM PART NO.

1

2

3

4

5

6

7

8

8

8

9

10

11

11

11

12

13

DC-113

DC-159

DC-163

TF-1121

TF-I082

TFH-2003

FH-6564

TFH-2054

TFH-2068

TFH-2066

TF-I086

FH-1108

TECF-42-1

TECF-42-3

TECF-42-5

'XF-1116

TF-I037

AIR

FLOW

DECAL

.

AIRSTREAM

DECAL

.

IMPORTANT

DECAL

....................•.

42"

10-16

H.P.

FAN

HOUSING

WELDMENT

..

42"

VENTURI .

42"

GRILLE

GUARD

.

1"

SEALTITE CONDUIT .

10-16

H.P.

MOTOR -240

VOLT

1 PHASE

..

10-16

H.P.

MOTOR -208

VOLT

3 PHASE

..

10-16

H.P.

MOTOR -575

VOLT

3 PHASE

..

42"

FAN

BLADE & HUB

ASSEMBLy .

BLADE

HUB

CAP

.

42"

ELECTRICAL

BOX -240

VOLT

1 PHASE

42"

ELECTRICAL

BOX

- ·208

VOLT

3 PHASE

42"

ELECTRICAL

BOX -575

VOLT

3 PHASE

3 PHASE ADAPTER

(3

PHASE

ONLY)

.

10-16

H.P.

MOTOR

SHIM .

I

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

AR

STANDARD

HARDWARE

PARTS - (PURCHASE

LOCALLY)

A

S-4275

5/16"-18

X

3/4"

BIN

BOLT

24

B

S-l147

5/16"

LOCKWASHER

24

C

S-396

5/16"-18

NUT

24

D

S-1054

3/8"

LOCKWASHER

4

E

S-456

3/8"-16

NUT..........................

4

F

S-2071

3/8"-16

X

1-1/4"

BOLT

4

G

S-248

3/8"

FLAT

WASHER.............

.. ..

4

H

MOTOR

KEY

(SUPPLIED

WITH

MOTOR)

1

I

HH-1830

1/4"-20

X

1-1/2"

FLAT

HD

MACH.

SCREW

2

-14-

Page 18

---------

---------

---------

~ £ ~

10-16

~

~

PHASE

EAN

C0NTROL

aQX

PARTS

PART

NO. QTY.

ITEM DESCRIPTION

DC-325

1

1

TOP

DRY

FAN

ELECTRICAL

BOX

DECAL

..........

MOTOR

START

RELAY

........................................ 1

2

1

DC-435

36"/42"

1 PHASE WIRING

DIAGRAM

DECAL

3

1

TFC-0028

4 STOP SWITCH

....................................................

5

TFC-0029

START SWITCH .................................................. 1

6

TFC-0047

HEATER

STRIP

................................................. 1

7

TF-1189

36"

FAN

CONTROL

BOX

WELDMENT

.................. 1

7 1

TF-1191

42"

FAN

CONTROL

BOX

WELDMENT

..................

8

TF-I096

2CAPACITOR

HALF

CLAMP

(BALDOR)

................

1

9

TFC-0044

OVERLOAD

RELAY

..............................................

10

TFC-0018

1

TERMINAL

STRIP

..............................................

11

TFH-2052

1

TERMINAL

STRIP

MARKER

................................

12

AR

BALDOR

RUN

CAPACITORS

(OIL)

....................

13

TFC-0002

1

CONTACTOR

........................................................

14

TFC-0012

1

RED

LIGHT ........................................................

15

AR

BALDOR

START CAPACITORS

(ELECTRO)

........

STANDARD

HARDWARE

PARTS -(PURCHASE

LOCALLY)

S";6557

A

*8-32

X

3/4"

SHEET

METAL

SCREW

.............. 2

B

S-4805

*8-32

X

1-1/4"

MACHINE

SCREW

.................. 2

C

8-4627

1/4"-20

X

2-1/2!'

MACHINE

SCREW

.............. 2

D

S-1040

*8-32

X

1/4"

SHEET

METAL

SCREW

..... , .......

8

E

S-1102

2

1/4"-20

NUT

....................................................

-15-

Page 19

~ & ~

~~

~

J

PHASE

EAN

CONTROL

BOX

PARTS

-

. .

IE

,,·~RT

NO.

DC-325

1

2

DC-379

2

DC-380

TFC-0028

3

4

TFC-0029

TFC-0058

5

5

TFC-0046

TF-1189

6

TF-1191

6

7

TFC-0060

7

TFC-0059

8

TFC-0018

TFH-2052

9

TFC-0012

10

11

TFC-0039

TFC-0042

12

13

TFC-0043

STANDARD

A

S-6557

B

S-1040

DESCRIPTION

TOP

DRY

FAN

ELECTRICAL

BOX

DECAL

..........

208

VOLT

3

PHASE

WIRING

DIAGRAM

DECAL

575

VOLT

3

PHASE

WIRING

DIAGRAM

DECAL

STOP

S~ITCH

....................................................

START SWITCH

..................................................

HEATER

STRIP

(208

VOLT

ONLY)

..................

HEATER

STRIP

(575

VOLT

ONLY)

..................

36"

FAN

CONTROL

BOX

WELDMENT

..

" ..............

42"

FAN

CONTROL

BOX

WELDMENT

..................

CONTACTOR

(208

VOLT

ONLY)

........................

CONTACTOR

(575

VOLT

ONLY)

........................

TERMINAL

STRIP

..............................................

TERMINAL

STRIP

MARKER

................................

RED

LIGHT

........................................................

TRANSFORMER

575-120V

(575

VOLT

ONLY)

AUXILIARY POINTS

(575

VOLT

ONLY)

..........

COIL

-

120

VOLTS

(575

VOLT

ONLY)

..........

HARDWARE

PARTS - (PURCHASE

LOCALLY)

#8-32

X

3/4"

SHEET

METAL

SCREW

..............

#8-32 X 1/4"

SHEET

METAL

SCREW

..............

-16-

QTY. J

1

1

1

1

1

3

3

1

1

1

1

1

1

1

1

1

1

2

6

Page 20

__

220

VOLT 1 PHASE

WIRING

DIAGRAM

36" & 42"

TOP DRY

FANS

(70-76

H.P.

7725

RPM

BALDOR

MOTOR)

L1

L2

N

..L

MAGNETIC

,.

-f-,

l

•••

1123456781

1

••••••••

1

--------

...

----.,

1

'----

START

.-----,

I

'----_-1

STOP

CONTACTOR

---

--

OIL

CAPACITORS

~T~T.iEJJY

,.JJ'-----..

______

1

I

1

1

.J

NOTE:

POSITIVE

GROUND

IS

REQUIRED

FOR

PROPER

OPERATION.

-17-

Page 21

42"

30

R.P.

TOP

DRY

SIRIIS

FAN

PARTS

':>

5

l~

DESCRIPTION QTY.

1

DC-113

ITEM

PART

NO.

AIR

FLOW

DECAL

1

AIRSTREAM

DECAL

2

2

DC-159

3

DC-163

IMPORTANT

DECAL

1

42"

30

H.P.

FAN

HOUSING

WELDMENT

1

4

TF-1000

5

TF-1082

42 ~ VENTURI 1

6

TFH-2003

42

~

GRILLE

GUARD

1

42"

FAN

ELECTRIC

BOX

1

7

TF-1011

ELECTRIC

BOX

COVER

1

8

TF-1012

9

FH-6564

1"

SEALTITE

CONDUIT

1

30

H.P.

MOTOR -208

VOLT 3 PHASE.

1

10

TFH-2073

10

TFH-2074

30

H.P.

MOTOR -575

VOLT 3 PHASE

1

42"

30

H.P.

FAN

BLADE & HUB

ASSEMBLY

1

11

TF-1087

12

TF-1036

30

H.

P.

MOTOR

SHIM...................

AR

30

H.P.

ELECTRICAL

BOX -208

VOLT

....

1

13

TECF-42-33

13

TECF-42-35

30

H.P.

ELECTRICAL

BOX -575

VOLT....

1

STANDARD

HARDWARE

PARTS -(PURCHASE

LOCALLY)

A

5/16"-18

X

3/4"

BIN

BOLT

24

S-4275

S-1147

5/16"

LOCKWASHER

24

B

S-396

5/16"-18

NUT

24

C

D

S-1054

3/8"

LOCKWASHER

4

E

S-456

3/8"-16

NUT

4

po

S-2071

3/8"-16

X

1-1/4"

BOLT

4

S-248

3/8"

FLAT

WASHER.....................

4

G

H

MOTOR

KEY

(SUPPLIED

WITH

MOTOR)

1

-18-

Page 22

~

1Q H P

.

.

ITEM

1

2

3

3

4

5

6

6

7

7

8

9

10

11

12

13

14

I A

B

PART

NO.

DC-325

TF-1191

DC-379

DC-380

TFC-0028

TFC-0029

TFC-0066

TFC-0063

TFC-0052

TFC-0050

TFC-0018

TFH-2052

TFC-0012

TFC-0056

TFC-0039

TFC-0043

TFC-0042

STANDARD

HARDWARE

PARTS

-

(PURCHASE

LOCALLY)

#8-32 X 3/4"

SHEET

METAL

SCREW

.............. 2

S-6557

p

#8-32

X

1/4"

SHEET

METAL

SCREW

S-1040

.... e ........

1

PHASE

FAN

CONTROL

BOX

PARTS

DESCRIPTION

QTY

TOP

DRY

FAN

ELECTRICAL

BOX

DECAL

.......... 1

42"

30

H.P.

FAN

CONTROL

BOX

WELDMENT

1

208

VOLT 3 PHASE

WIRING

DIAGRAM

DECAL

1

575

VOLT 3 PHASE

WIRING

DIAGRAM

DECAL

1

STOP

SWITCH

.................................................... 1

START

SWITCH

.................................................. 1

HEATER

STRIP

(208

VOLT

ONLY)

.................. 3

HEATER

STRIP

(575

VOLT

ONLY)

..................

3

CONTACTOR

(208

VOLT

ONLY)

........................ 1

CONTACTOR

(575

VOLT

ONLY)

........................ 1

TERMINAL

STRIP

..............................................

1

TERMINAL

STRIP

MARKER

................................ 1

1

RED

LIGHT ........................................................

1

OVERLOAD

RELAY

(208

VOLT

ONLY)

..............

1

575-120V

TRANSFORMER

(575

VOLT

ONLY)

120V

COIL

(575

VOLT

ONLY)

........................ 1

1

AUXILIARY POINTS

(575

VOLT

ONLY)

..........

-19-

Page 23

208 VOLT 3 PHASE WIRING DIAGRAM

24",

28",

36" & 42"

TOP

DRY

FANS

(BALDOR

MOTORS)

L1

L2

L3

N

r-----.

MAGNETIC

_L

CONTACTOR

--L

L

.J

START

r-----.

J/

/2,

LAMP

INDICATOR

!. -

STOP

- - .Jir=

1_

I I:

~i''-I:>--O_/L_REL]

1E

=E-

1~ -------

r

.-----,

•

••

I

'------{

112345678

....

\

'------1

I

••••••••

I

.--------------\

L.. ....

NOTE:

POSITIVE

GROUND

IS

REQUIRED

FOR

PROPER

OPERATION.

-20-

Page 24

--

575 VOLT 3 PHASE WIRING DIAGRAM

24",

28",

36" & 42"

TOP

DRY

FANS

(BALDOR

MOTORS}

575

TO

120

VOLT

TRAI~SFORMER

.------------,

...-------,

H1

-----I---------tI~

r------a---____+_____

1

I

III----

-

L

L

._..__

._

..

~_.~

r--------

I

:

~

I

'---~

I

~

~

sTiiRT

- - J-

I

r--------

I

I

I

INDICATOR

-1-

~I~

" /

LAMP

I

••

•.

I

112345678

I

I

••••••••

I

'-----

1

H2

H3

H~

_I

. I

------I

1---------'

'-----------,

L3

MAGI~ET

IC

L2

COI~TACTOR

L--_.;

-t-=-;--------J-

- - -

--

- T

-1

I I

I I

I I

L

_J

,

NOTE:

POSITIVE

GROUND

IS

REQUIRED'FOR

PROPER

OPERATION.

-21-

Page 25

SPICIPICATIONS

DL\JILTER

24"

28"

36"

42"

bTU

RATING

2000000

3000000

4000000 5000000

\HEGlIT

110

145

228 286

~lAX

FUEL

FLOI..J

tGPH) 21

32

43

59

LIQUID

OlUfICE SIZE

.177"

.25"

.25"

.438"

mN

OPERATING

PRESSURE

1

3

5

1

~10DELS

HAX

OPERATING

PRESSURE

30 18

30

6

mN

LINE

SIZE

3/8"

3/8"

1/2"

1/2"

MAX

FUEL

FLOW

(CU

FT/HR)

800 118S 1590

----

VAPOR

ORIFICE SIZE

.177"

•25'

.25"

----

~IIN

OPERATING

PRESSURE

1

3

5

----

HODELS

HAX

OPERATING

PRESSURE

30

18

30

----

mN

LINE

SIZE

3/4"

1"

1"

----

HAX

FUEL

FLOIl

(CU

FT/HR)

2100 3000

4200

5000

NAT

GAS

ORIfICE SIZE

.25"

.375

• 375'

.500

mN

OPERATING

PRESSURE

1 1

3

1

~10DELS

HAX

OPERATING

mN

LINE

SIZE

PRESSURE

10

1"

6

10

5

1-1/4" 1-1/2"

2"

HIATER

CONTROL

SPECIFICATIONS

SPARK

PLUG

fUSES

tlI-LHJIT

HOUSING

lII-LHlIT

VAPOR

SOLID

STATE

IGNITION

BOARD

Double

electrode

1/8"

gap

5

amp

250

volt

Opens

circuit

at

200

degrees

f

Opens

circuit

at

180

degrees

f

110 v works

on

flame

rectification

principle

to

prove

flame.

supplys

15000 v

to

spark

plUB

for

iBnition.

-22-

Page 26

FUNCTION OF

HIATIR

PARTS

HEATER

HIGH

LHIIT -

Shuts

down

heater

in

event

housing

temperature

exceeds

200

degrees.

(This

might

occur

if

fan

motor

were

to

fail.)

PRESSURE

GAUGE -Allows

the

manifold

pressure

to

be

monitored

for

regulator

adjustment.

HI-FLANE

SOLENOID

VALVE

--When

closed

forces

gas

to

go

to

bypass

and

tJlrough

adjustable

flow

control

for

low

flame.

When

opened

it

allows

gas

to

flow

straight

through

to

orifice.

LU-FLM1E

SOLENOID

VALVE -Closes

in

event

that

the

low

flame

would

get

to

hot.

SPARK

PLUG -Provides

electric

spark

for

ignition.

BUENEE

SIHTClI -Switches

on

power

to

heater

unit.

l'UWJE

HELAY -Provides

a

ten

second

delay

to

allow

all

gas

to

be

pur~ed

from

heater

and

fan

to

come up

speed

before

first

igniting

burner.

ELECTRONIC

IGNITION

BOARD -Provides

high

voltage

to

spark

plug

for

ignition

and

also

provides

flame

proving

through

flame

rectification.

l'LM1E

SENSOR -Senses

flame

and

sends

:signal

back

ito

ignition

board.

EESEl' -

Locks

out

system

after

repeated

trials

for

ignition.

RED

LIGIIT -Indicates

that

electronic

ignition

board

is

recieving

power.

FUNCTION OF

YAPORIZIR

PARTS

STRAINER -Filters

out

any

foreign

matter

from

gas

line

that

could

lodge

in

gas

solenoid

valve.

SHUT-OFF

VALVE -Starts

or

Stops

flow

of

liquid

to

vaporizer.

SAFETY

RELIEF

VALVE -Releases

pressure

should

blockage

or

pressure

build

up

occur.

SOLENOID

VALVE -Shuts

off

flow

of

liquid

should

vapor

get

overheated

in

cooling

coil.

VAPOR

HIGH

LIHIT -

Senses

overheating

in

cooling

coil

and

sends

signal

to

solenoid

valve

to

close,

shutting

off

flow

of

liquid

to

heater.

COOLING

COIL -Allows

hot

vapor

to

cool

slightly

before

combustion.

VAPORIZER

SUPPORT

WELDMENT -Provides

lateral

and

vertical

movement

of

vaporizer

coil.

-23-

Page 27

HEATER

INSTALLATION

1.

Top Dry

series

heaters

are

designed

primarily

for

use

with

Top

Dry

systems,

although

they

are

suitable

for

many

other

crop

drying

applications.

Instructions

given

in

this

manual

will

assume

that

heater

is

being

installed

on

a Top

Dry.

L.

Bolt

heater

to

downwind

side

of

fan.

(If

required)

Use

3/8"

x

1-1/4"

bolts,

nuts

and

lockwashers.

(not

included)

3.

Hoist

fan

and

heater

unit

up

onto

fan

and

heater

platform.

4.

If

fan

and

heater

unit

is

36"

or

42"

then

the

unit

should

bolt

directly

to

transition

sheeL,

For a 24"

or

28"

fan

and

heater,

unit

must

be

shimmed

under

the

legs

in

order

to

gain

height

required

to

bolt

to

transition.

5.

Wire

fan

as

per

fan

manual

and

CSA

C22.l

Canadian

Electrical

Code

Part I and/or

local

codes.

6.

Wire

heater

to

fan

as

shown

on

the

wiring

diagram.

This

should

be

all

that

is

required

for

wiring

on

heater.

(see

dual

heater

control

instructions

for

wiring

more

than 1 fan

and

heater.)

FUEL

CONNECTION

HIPonTANT -

DO

NOT

USE

pnOPANE

TANKS

WHICH

HAVE

PREVIOUSLY

BEEN

USED

FOn

MU·IONIA

UNLESS

THEY

HAVE

BEEN

PURGED

ACCORDING

TO

PROCEDURES

OF

THE

NATIONAL

L.P. ASSOCIATION.

INVESTIGATE

TO

BE

SUnE

THAT

FUEL

SUPPLY

SYSTEM

COMPLYS

WITH

ALL

LOCAL

CODES

FOR

1.

P.

GAS

INSTALLATIONS.

LIQUID

pnOPANE

MODELS

1.

LP

models

are

designed

to

run

on

liquid

propane,

with

liquid

dra\.]

from

the

propane

tank.

Avoif--using

propane

supply

tanks

that

have

been

used

for

vapor

draw

for

long

periods

of

time.

~~hen

using

liquid

draw

systems

any

moisture

that

may

be

present

in

tank

or

lines

r.lay

freeze

when

system

used

in

cold

weather.

To

avoid

this

the

usual

precaution

is

to

purge

the

system

with

methanol.

2.

nun

proper

size

line

(see

specifications)

to

liquid

pipe

train

on

heater.

Have

qualified

gas

service

man

inspect

installation

to

be

sure

that

every

thing

is

installed

according

to

local

codes

and

ordinances.

3.

After

installation

is

complete

check

all

connections

for

leaks.

-24-

Page 28

,

•

,

PROPANE

VAPOR

NODELS

1.

Propane

vapor

models

are

designed

to

rurr

either

directly

off

of

supply

tank

of

from a separate

external

vaporizer.

2.

!I.

lli~h

pressure

(0-30

lbs.)

regulator

should

be

installed

in

line

to

regulate

gas

flow

to

heater.

24"

model

heaters

have

regulator

installed

on

heater

at

factory.

3.

Run

proper

size

line

(see

specifications)

to

pipe

train

on

heater.

Have a

qualified

gas

service

man

inspect

installation

to

be

sure

that

everything

is

installed

according

to

local

codes

and

ordinances.

4.

!I.Lter

installation

is

complete

check

all

connections

for

leaks.

Ni\TUl:!I.L

G!l.S

r'lOlJU,S

1.

Natural

gas

models

are

similar

to

vapor

models.

but

have a larger

orifice

to

accomodate

lower

pressures

sometimes

found

with

Natural

gas.

2.

?ressure

regulator

must

be

installed

ahead

of

heater

to

adjust

gas

flow.

This

regulator

must

be

capable

of

supplying

the

required

pressure

and

maximum

gas

flow.

(seespecificati6ns)

3.

Run

proper

size

lines

(see

specifications)

to

pipe

train

on

heater.

Have

qualified

gas

service

man

inspect

installation

to

be

sure

that

everything

is

installed

according

to

local

codes

and

ordinances.

4.

After

installation

is

complete

check

all

co~nections

for

leaks.

HEATER

OPERATION

All

Top Dry

heaters

have

standard

a HI-LO

type

pipe

train.

This

style

of

burner

should

burn

constantly

cycling

in

and

out

the

high

flame.

Follow

these

instructions

when

first

starting

up

your

unit

•

1.

The

thermostat

plugs

must

be

plugged

into

heater

control

box

for

heater

to

operate.

(see

thermostat

instructions)

2.

Ope~

all

manual

shut-off

valves

to

heater

unit.

3.

Start

fan.

This

should

supply

power

to

heater

on/off

switch.

4.

Depress

heater

on/off

switch.

Switch

should

stay

in.

To

release_

push

up

on

red

tab

below

the

button.

5.

After

10

seconds

red

indicator

light

should

light

up.

indicating

that

there

is

power

to

the

ignition

board.

-25-

Page 29

6.

Heater

should

now

be

lit.

If

not

check

to

see

that

all

gas

is

on

and

both

thermostats

are

plugged

in.

7.

Turn

thermostat

dial

to

its

highest

setting

so

that

heater

should

be

on

high

flame.

8.

Open

adjustable

flow

control

valve

all'the

way. (On

propane

models

this

is

the

small

red

top

adjustable

valve,

on

natural

gas

models

this

is

the

ball

valve

with

the

lever

handle.)

9.

Turn

thermostat

dial

to

lowest

setting

so

that

heater

should

be

on

10101

flame.

10.

Adjust

flow

control

valve

so

that

low

flame

pressure

is

at

desired

setting.

.

11.

Turn

thermostat

dial

back

to a very

high

setting

and

wait

for

bin

plenum

to

com~

up

to

temperature.

Then

turn

thermostat

bacik

slowly

until

h\~ater

goes

to

low

flame.

12.

Lo\,

flame

should

be

adjusted

so

that

it

drops

slowly

until

burner

goes

back

to

high

flame.

13.

l~atch

plenllin

temperature

as

burner

goes

through a few

cycles,

to

be

sure

that

it

is

operating

properly.

ILl.

1{e;,'er

to

Top Dry

Control

Center

manual

for

further

instructions

on

drying

with

a Top Dry

System.

HEATER

SERYICE

All

AIRSTREAM

heaters

are

constructed

of

durable

weather-resistant

materials,

so

a minimum

amount

of

service

should

be

required;

however

before

the

unit

is

started

for

the

first

time

each

season

there

are a few

items

that

need

to

be

checked

out.

All

damaged

parts

should

be

repaired

or

~eplaced.

1.

Disconnect

main

power

supply.Open

control

box

lid

and

inspect

all

components

for

moisture,

vibration,

or

rodent

damage.

Inspect

and

tighten

all

loose

terminal

connections.

Replace

any

damaged

wiring.

2.

1{emove

burner

orifice

tube

and

inspect

for

dirt

or

foreign

material.

Clean

out

if

necessary.

3.

Remove

burner

cup

from

burner

venturi

and

inspect

for

foreign

I~aterial

in

any

of

the

ports.

Clean

these

parts

out

if

necessary.

Any

foreign

material

blocking

burner

cup

ports

may

seriously

impair

the

performance

of

the

heater.

[I.

Inspect

the

spark

plue

and

flame

sensor

for

corrosion

and

danage.

Clean

or

replace

if

necessary.

-26-

Page 30

ADJUSTING

PRIMARY

AIR

DAMPIR

PLAT.

(42"

HIATIR

ONLY)

The

42"

heater

is

equipped

with

an

air

damper

plate.

It

is

located

on

top

of

the

heater

inside

of

the

can.

The

brass

orifice

tube

goes

down

through

this

plate.

This

plate

is

adjustable

up

and

down

to

control

the

quality

of

the

flame.

1.

With

heater

on

adjust

gas

pressure

to

desired

setting.

Observe

flame

through

access

door.

If

flame

is a clear

blue

color

air

damper

is

adj.usted

correctly.

2.

Stop

fan

and

heater.

Damper

plate

may

be

adjusted

from

heater

outlet

or

from

access

cover.

J.

Loosen

wingnuts

and

readjust

damper.

Secure

again

with

wingnuts.

4.

Uperate

heater

and

rechecl(

flame.

Readjust

plate

if

necessary.

flame

should

be

checked

periodically

through-out

drying

season

and

adjusted

if

necessary.

-27-

Page 31

TROUBLESHOOTING

CHART

TkOUBLE

PROBABLE

CAUSE

CRECK-OUT

PROCEDURE

AND

CORRECTION

Heater

not

plul~ect1

ill.

Piue

heater

cord

into-

[an

canrntrol

box.

Burner

will

not

firc

no

~as

pressure

to

orifice

after

30

seconds

of

fan

operation.

(Red

licht

does

not

co~e

on

at

all.)

Purge

relay

Blown

fuse

Remove

wires

from

purge

relay

and

tie

then

to~ether.

If

purge

relay

was bad

red

light

should

come on

immediately

after

pressing

on/off

switch.

If

purge

relay

is

bad

replace

Check

fuse

visually

or

with

ohm

meter

if

bad

replace.

High

limit

(heater

housing)

Press

red

reset

button

on

hi-limit

if

this

docs

not

correct

situation

check

hi-limit

with

ohm

meter.

If

hi-limit-shows

open

circuit

then

replace.

(Remove

wires

before

checking.)

fan

and

lIeat

unit

not

grounded

properly.

fan

and

Ileat

operation.

unit

must

be

~rounded

for

proper

IIi-limit

reset

thermostat

on III-LO

Depress

red

button

on Ill-LO

thermostat.

If

thi6

does

not

correct

sitiuation

jump arounrt

thermosta't

to

determine

whether

thermostat

is

bad.

Burner

will

not

firc.

no

r,as

pressure

to

orifice.

(Red

li~ht

cones

on

aft~r

15

seconds

of

operation.)

Vapor

Hi-limit

Time

Delay

Heset

control

box)

(on

Jump

around

the

Hi-limit

and

situation

replace

Iii-limit.

Reset

button

if

this

corrects

Liquid

solenoid

valve

Feel

top

of

valve

to

see

if it

clicks

tllis

would

indicate

that