Page 1

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Wiring DiagramsWiring Diagrams

Wiring Diagrams

Wiring DiagramsWiring Diagrams

1999 Top Dry1999 Top Dry

1999 Top Dry

1999 Top Dry1999 Top Dry

PNEG-897

1

1

Page 2

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

2

Page 3

TABLE OF CONTENTSTABLE OF CONTENTS

y

TABLE OF CONTENTS

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Roof Damage and Disclaimer -------------------------------------------------------------- Page 4

Safety Decals ------------- ------------------------- ------------- ----------------------- ------- Page 5

Safety Precautions ---------------------- ----------------------- ------------- ----------------- Page 6

Safety Sign-Off Sheet ----------------------------------------------------------------------- Page 7

Electrical Power Supply -------------------------------------------------------------------- Page 8

Series 2000 Master Fan/Heater Wiring (Domestic & CGA Models)----------------- Page 9

Series 2000 Master Fan/Heater Wiring (European Models) --------------------------- Page 17

Series 2000 Slave Fan/Heater Wiring (All Models) ------------------------------------ Page 23

TABLE OF CONTENTSTABLE OF CONTENTS

Series 2000 Batch Control Box Wiring -------------------------------------------------- Page 29

Series 2000 Autoflow Control Box Wiring ---------------------------------------------- Page 35

Series 2000 Autoflow Actuator Wiring -------------------------------------------------- Page 41

Series 2000 Autoflow Fill System Control Box Wiring ------------------------------- Page 45

Warrant

------------------------------------------- ------------- ----------------------- ------- Page 57

3

Page 4

SAFETY SAFETY

SAFETY

SAFETY SAFETY

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

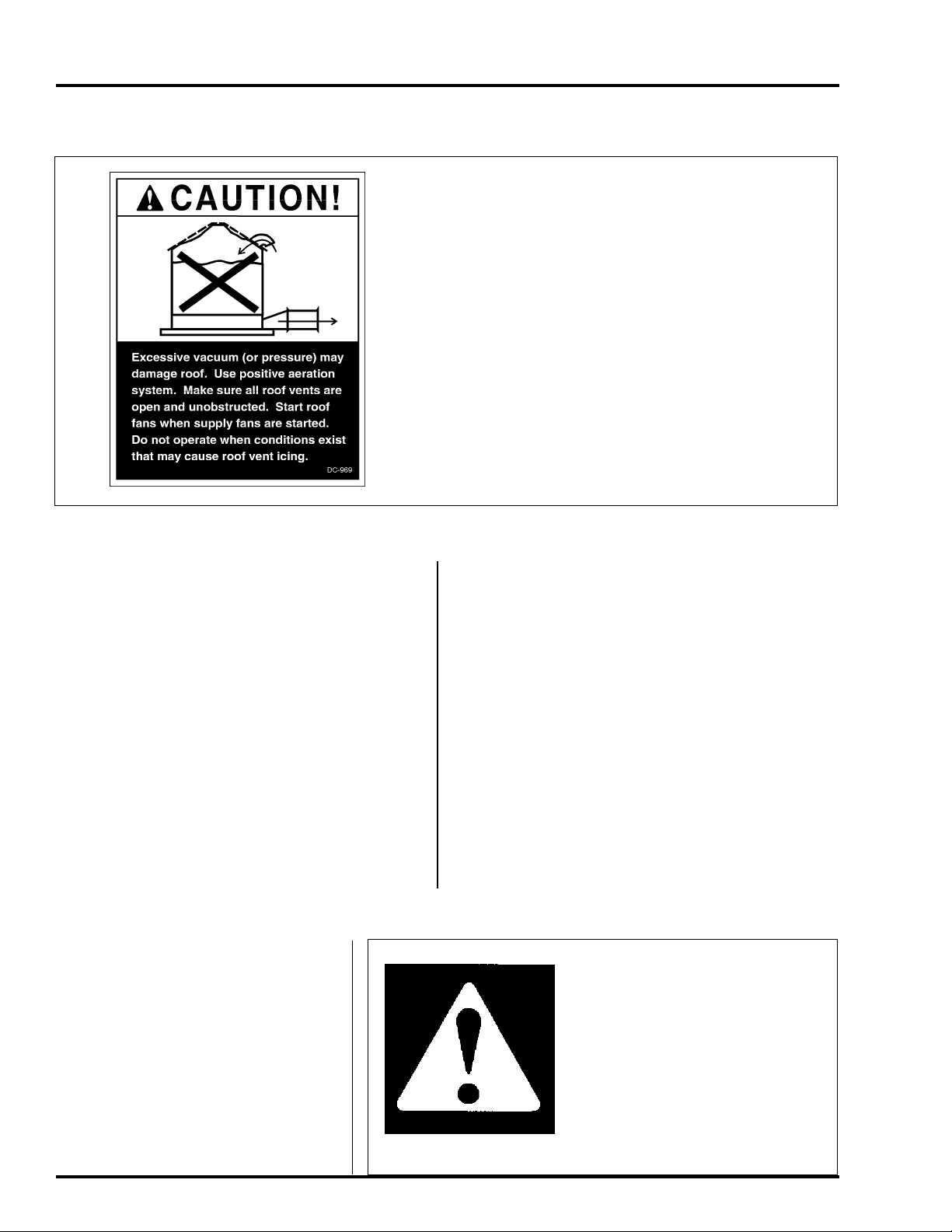

Roof Damage Warning and Disclaimer

GSI DOES NOT WARRANT ANY ROOF DAMAGE

CAUSED BY EXCESSIVE V ACUUM OR INTERNAL

PRESSURE FROM F ANS OR OTHER AIR MOVING

SYSTEMS. ADEQUATE VENTILATION AND/OR

"MAKEUP AIR" DEVICES SHOULD BE PROVIDED

FOR ALL POWERED AIR HANDLING SYSTEMS.

GSI DOES NOT RECOMMEND THE USE OF DOWNWARD FLOW SYSTEMS (SUCTION). SEVERE

ROOF DAMAGE CAN RESULT FROM ANY

BLOCKAGE OF AIR P ASSAGES. RUNNING FANS

DURING HIGH HUMIDITY/COLD WEA THER CONDITIONS CAN CAUSE AIR EXHAUST OR INT AKE

POR TS TO FREEZE.

Fan/Heater Installation & Operating Instructions

Thank you for choosing a T op Dry Series 2000 unit.

It is designed to give excellent performance and

service for many years.

This manual describes the wiring for all standard production Top Dry Series 2000 single fan,

multi-fan and 2000 Series Heater Control units. Different models are available for liquid propane or

natural gas fuel supply, with either single phase 230

volt, or three phase 208, 220, 380, 460 or 575 volt

electrical power.

The principal concern of the GSI Group, Inc.

("GSI") is your safety and the safety of others associated with grain handling equipment. This manual

is written to help you understand safe operating

procedures, and some of the problems that may be

en-countered by the operator or other personnel.

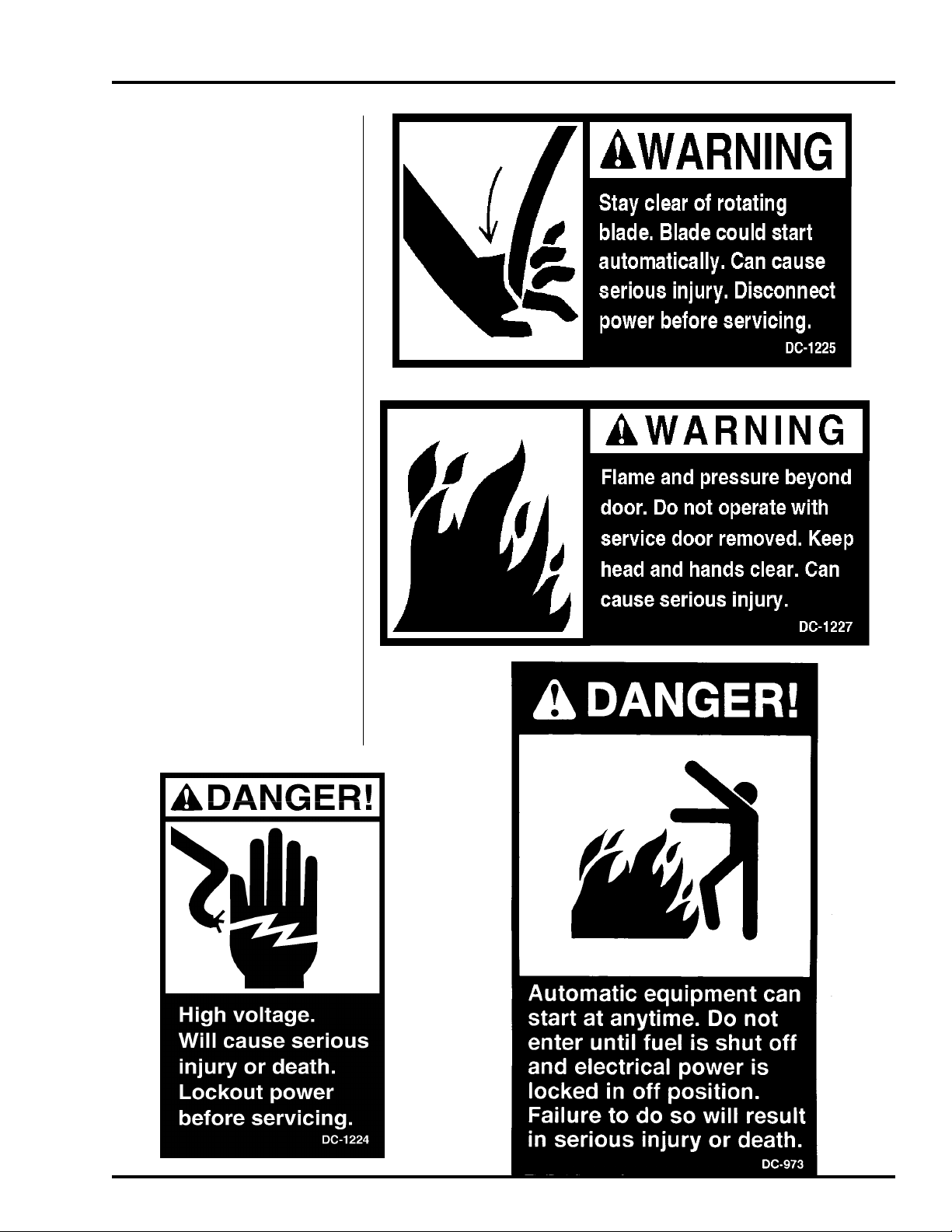

The symbol shown is used to call your

attention to instructions concerning your

personal safety. Watch for this symbol; it points out important safety precautions. It means "ATTENTION",

"WARNING", "CAUTION", and

"DANGER". Read the message and

be cautious to the possibility of personal injury or death.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions exist, and to inform all personnel associated with the equipment, or who are in the fan area.

A void any alterations to the equipment. Such alterations may produce a very dangerous situation,

where serious injury or death may occur.

Safety Alert Symbol

WARNING! BE ALERT!

Personnel operating or working

around electric fans should read this

manual. This manual must be

delivered with the equipment to its

owner. Failure to read this manual

and its safety instructions is a misuse

of the equipment.

4

Page 5

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Grain Systems, Inc. recommends contacting your local

power company , and having a representative survey your installation so the wiring is compatible

with their system, and adequate

power is supplied to your unit.

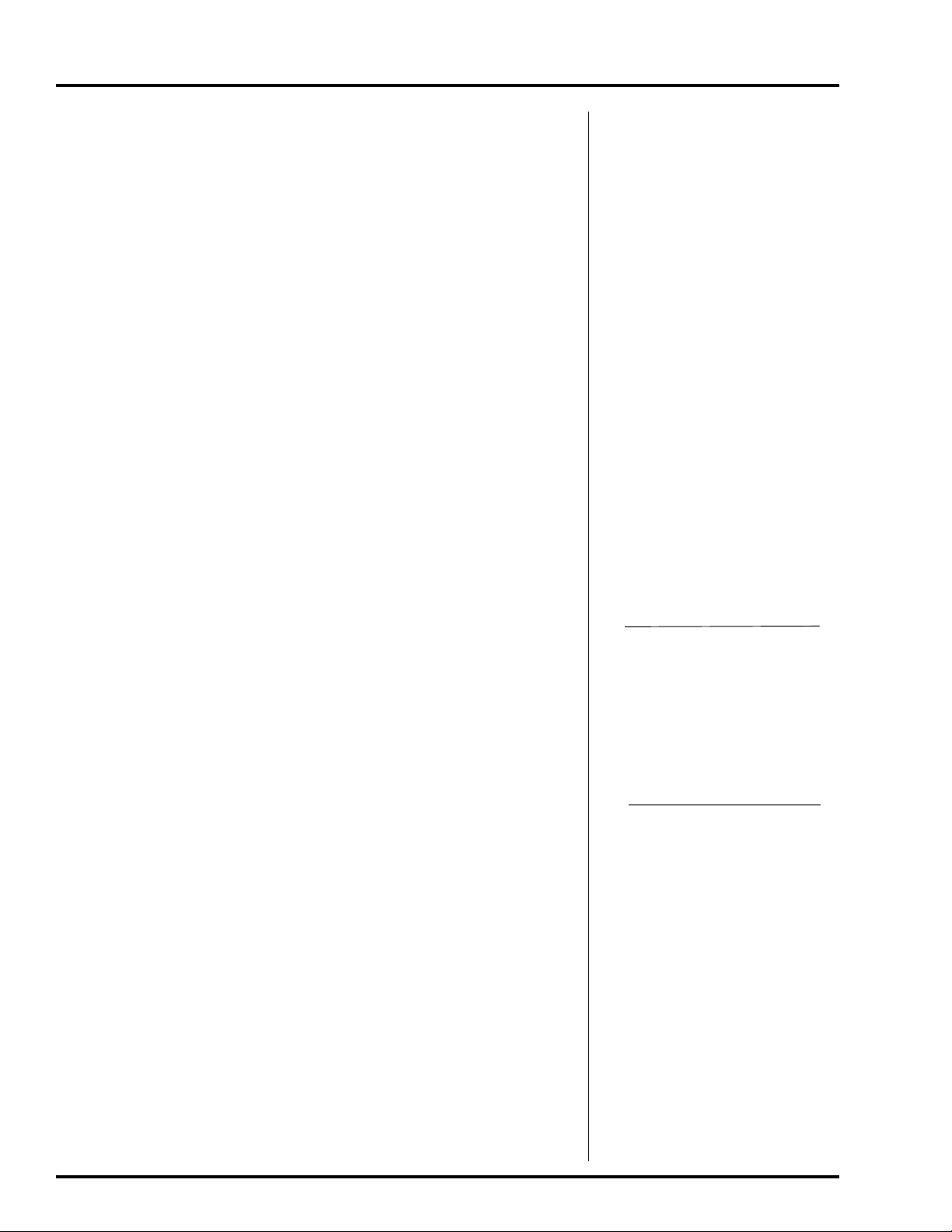

Safety decals should be read

and understood by all people in the

grain handling area. The rotating

blade, fire warning decals and

voltage danger decal must be displayed on the fan can. The bottom right decal should be present

on the inside bin door cover of the

two ring door, 24" porthole door

cover and the roof manway cover.

If a decal is damaged or is

missing contact:

Grain Systems, Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to

you.

SAFETYSAFETY

SAFETY

SAFETYSAFETY

5

Page 6

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

READ THESE INSTRUCTIONS

BEFORE OPERA TION AND SERVICE

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before trying to operate the

dryer.

2. Power supply should be OFF for service of electrical components. Use

CAUTION in checking voltage or other procedures requiring power to

be ON.

3. Check for gas leaks at all gas pipe connections. If any leaks are detected, do not operate the dryer. Shut down and repair before further

operation.

4. Never attempt to operate the dryer by jumping or otherwise bypassing

any safety devices on the unit.

5. Set pressure regulator to avoid excessive gas pressure applied to burner

during ignition and when burner is in operation. Do not exceed maxi-

mum recommended drying temperature.

6. Keep the dryer clean. Do not allow fine material to accumulate in the

plenum or drying chamber.

Use Caution in the

Operation of this

Equipment

The design and manufacture of this

dryer is directed toward operator

safety. However, the very nature

of a grain dryer having a gas burner,

high voltage electrical equipment and

high speed rotating parts, does

present a hazard to personnel, which

can not be completely safeguarded

against, without interfering with efficient operation and reasonable access to components.

Use extreme caution in working

around high speed fans, gas-fired

heaters, augers and auxiliary conveyors, which may start without warning when the dryer is operating on

automatic control.

7. Use CAUTION in working around high speed fans, gas burners, augers

and auxiliary conveyors which START AUTOMATICALLY.

8. Do not operate in any area where combustible material will be drawn into

the fan.

9. Before attempting to remove and reinstall any propellor, make certain to

read the recommended procedure listed within the servicing section of

the manual.

10. Clean grain is easier to dry. Fine material increases resistance to airflow

and requires removal of extra moisture.

This product is intended for the use of grain handling only. Any other

use is considered a misuse of the product.

Some edges of the product components can be sharp. It is recommended that each component of this product be examined to determine if there are any safety considerations to be taken. Any and all

necessary personal protective equipment should be worn at all tines

when handling, assembling, installing and operation of the product

and/or components.

Guards are removed for illustration purpose only. All guardsmust be

in place before/during operation.

KEEP THE DRYER CLEAN

DO NOT ALLOW FINE

MATERIAL TO ACCUMULATE

IN THE PLENUM CHAMBER

OR SURROUNDING THE OUT-

SIDE OF THE DRYER

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable

drying system, follow the recommendations within this manual, and make

it a practice to regularly inspect the

operation of the unit for any developing problems or unsafe conditions.

Take special note of the safety precautions listed above before attempting to operate the dryer.

6

Page 7

SAFETY SIGN-OFF SHEETSAFETY SIGN-OFF SHEET

SAFETY SIGN-OFF SHEET

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Date Employer’s Signature Employee

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

SAFETY SIGN-OFF SHEETSAFETY SIGN-OFF SHEET

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

7

Page 8

ELECTRICAL POWER SUPPLYELECTRICAL POWER SUPPLY

ELECTRICAL POWER SUPPLY

ELECTRICAL POWER SUPPLYELECTRICAL POWER SUPPLY

Power Supply

An adequate power supply and proper wiring are important factors for maximum performance and long life of

the dryer. Electrical service must be adequate enough to

prevent low voltage damage to motors and control circuits (see Electrical Load Information).

Transformer and Wiring Voltage Drop

It is necessary to know the distance from the unit to the

available transformer, and the horsepower of your fan

unit. Advise the service representative of your local power

supplier that an additional load will be placed on the line.

Each fan motor should be wired through a fused or circuit breaker disconnect switch. Check on KVA rating of

transformers, considering total horsepower load. The

power supply wiring, main switch equipment and transformers must provide adequate motor starting and operating voltage. Voltage drop during motor starting should

not exceed 14% of normal voltage, and after motor is

running at full speed it should be within 8% of normal

voltage. Check Electrical Load Information for HP ratings and maximum amp loads to properly size wire and

fusing elements. Standard electrical safety practices and

codes should be used. (Refer to National Electrical Code

Standard Handbook by National Fire Protection Association).

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

and the ignition system. The ground rod must be in

accordance with local requirements.

Proper Installation of Ground Rod

It is not recommended that the rod be driven into dry

ground.

Follow these instructions for proper installation:

1. Dig a hole large enough to hold 1 to 2 gallons

of water.

2.Fill hole with water.

3.Insert rod through water and jab it into the ground.

4.Continue jabbing the rod up and down. The wa

ter will work its way down the hole, making

it possible to work the rod completely into

the ground. This method of installing the

rod gives a good conductive bond with the sur

rounding soil.

5.Connect the bare, copper ground wire to

the rod with the proper ground rod

clamp. See Figure 8.

6. Connect the bare copper ground wire to the fan

control boxes with a grounding lug.

7. Ground wire must

not have any breaks

or splices.

Machine to Earth Grounding

It is very important that a Machine To Ear th Ground

Rod be installed at the fan. This is true even if there is

a ground at the pole 15 feet away. Place the ground

rod that comes standard, within 8 feet of the dryer and

attach it to the dryer control panel with at least a #6

solid, bare, copper ground wire and the clamp provided. The grounding rod located at the power pole

will not provide adequate grounding for the dryer . The

proper grounding will provide additional safety in case

of any short and will ensure long life of all circuit boards,

8

Dig a hole large

enough to hold 1

or 2 gallons of

water . W ork the

ground rod into

the earth until it

is completely in

the ground.

Page 9

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Master Fan/Heater Wiring

Domestic & CGA Models

9

Page 10

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

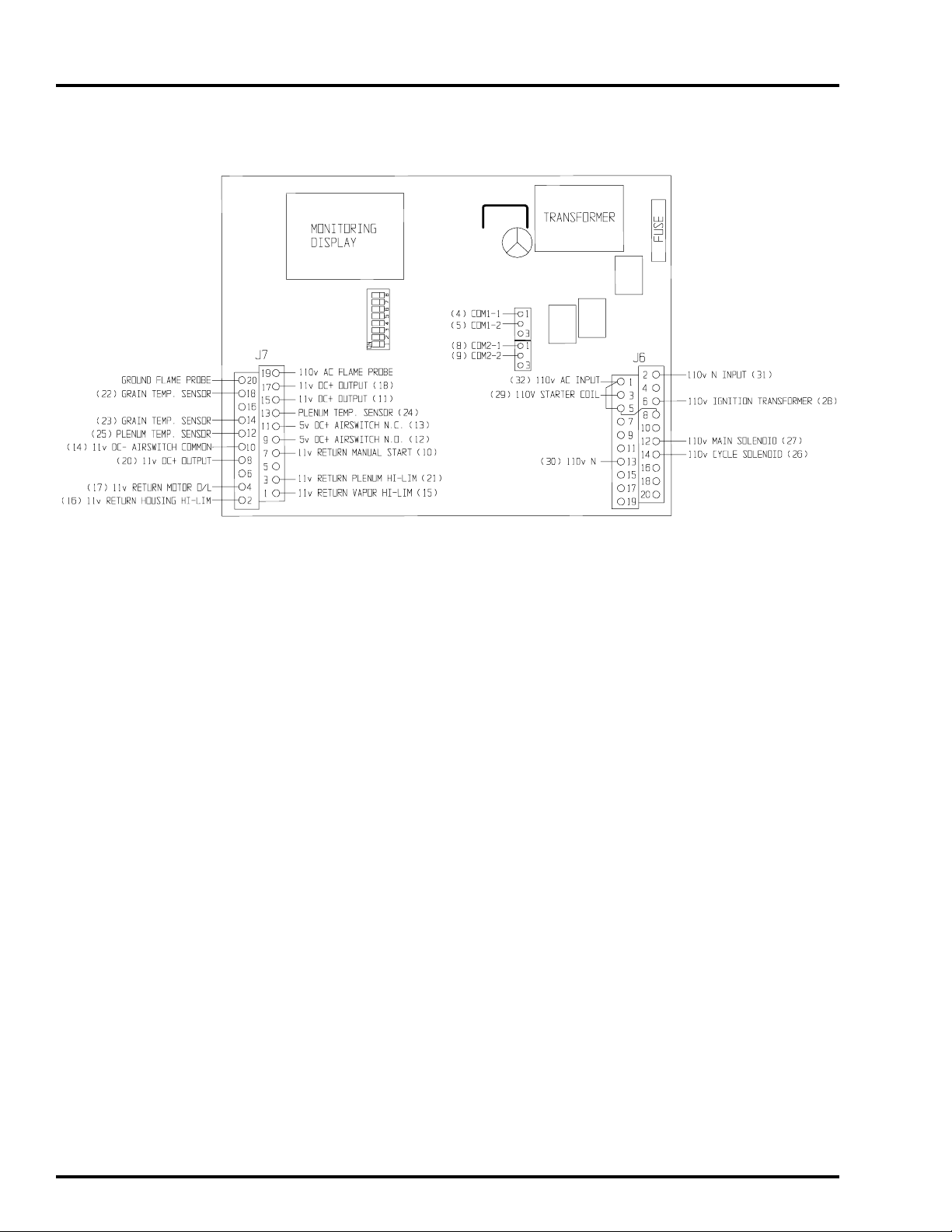

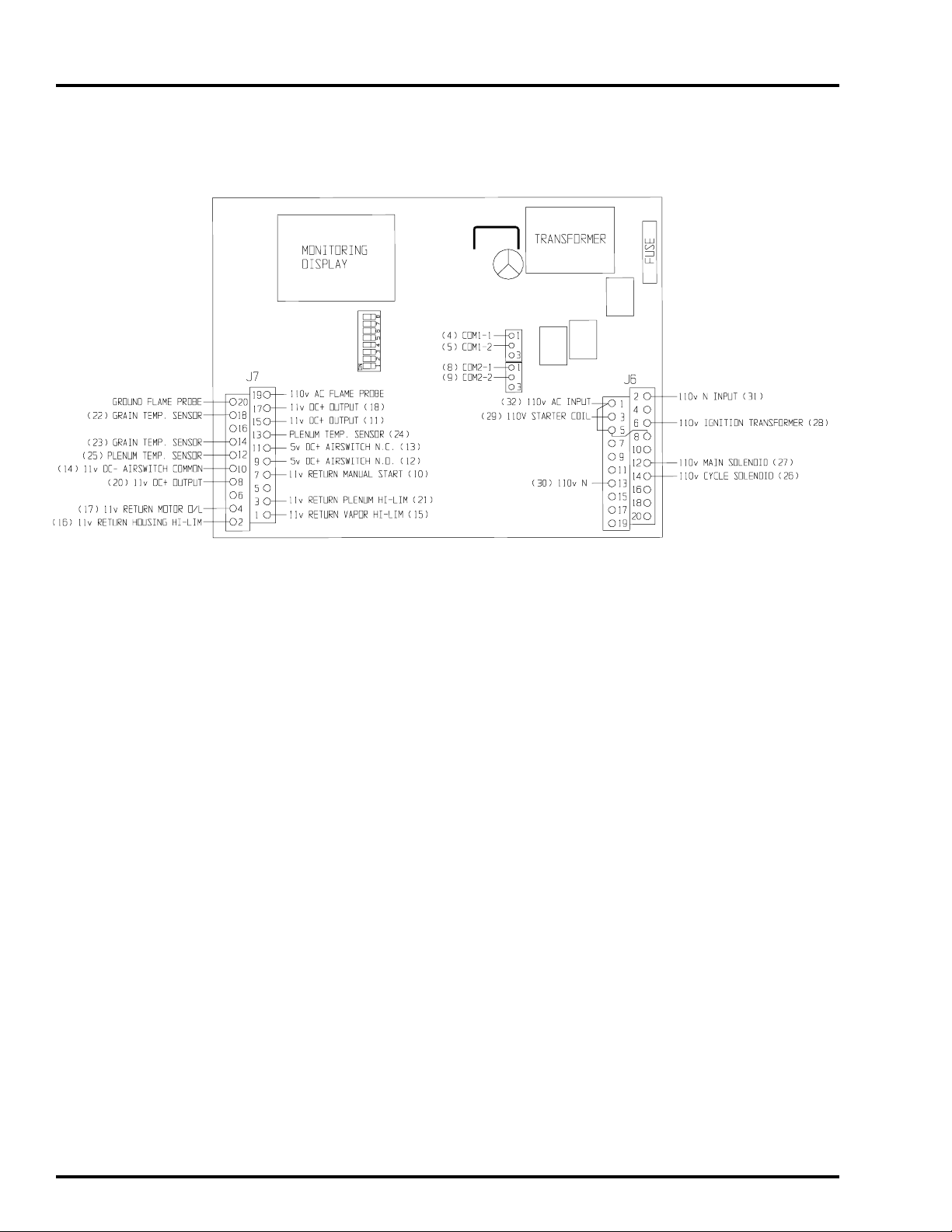

Series 2000 Master Heater Board Input/Output

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

10

Page 11

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

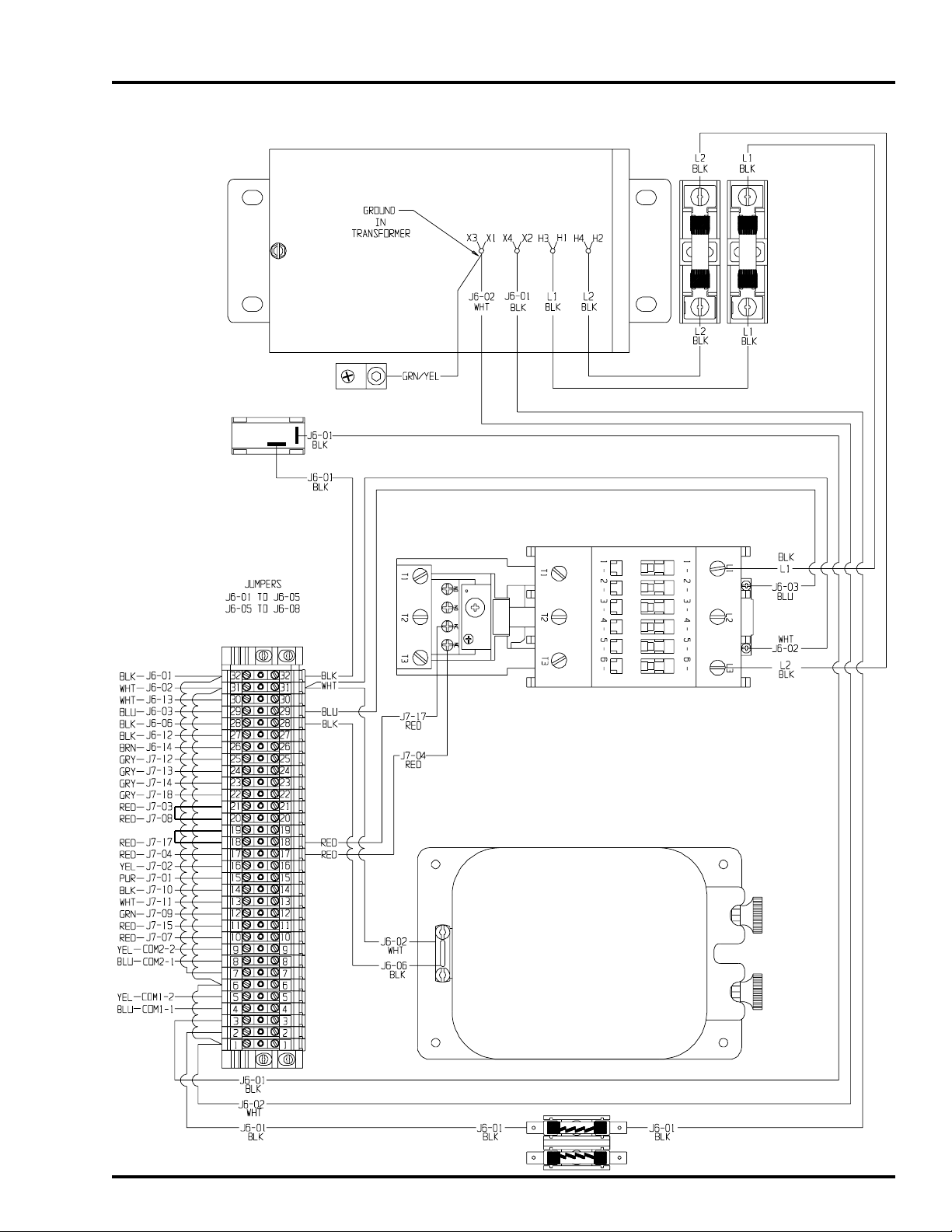

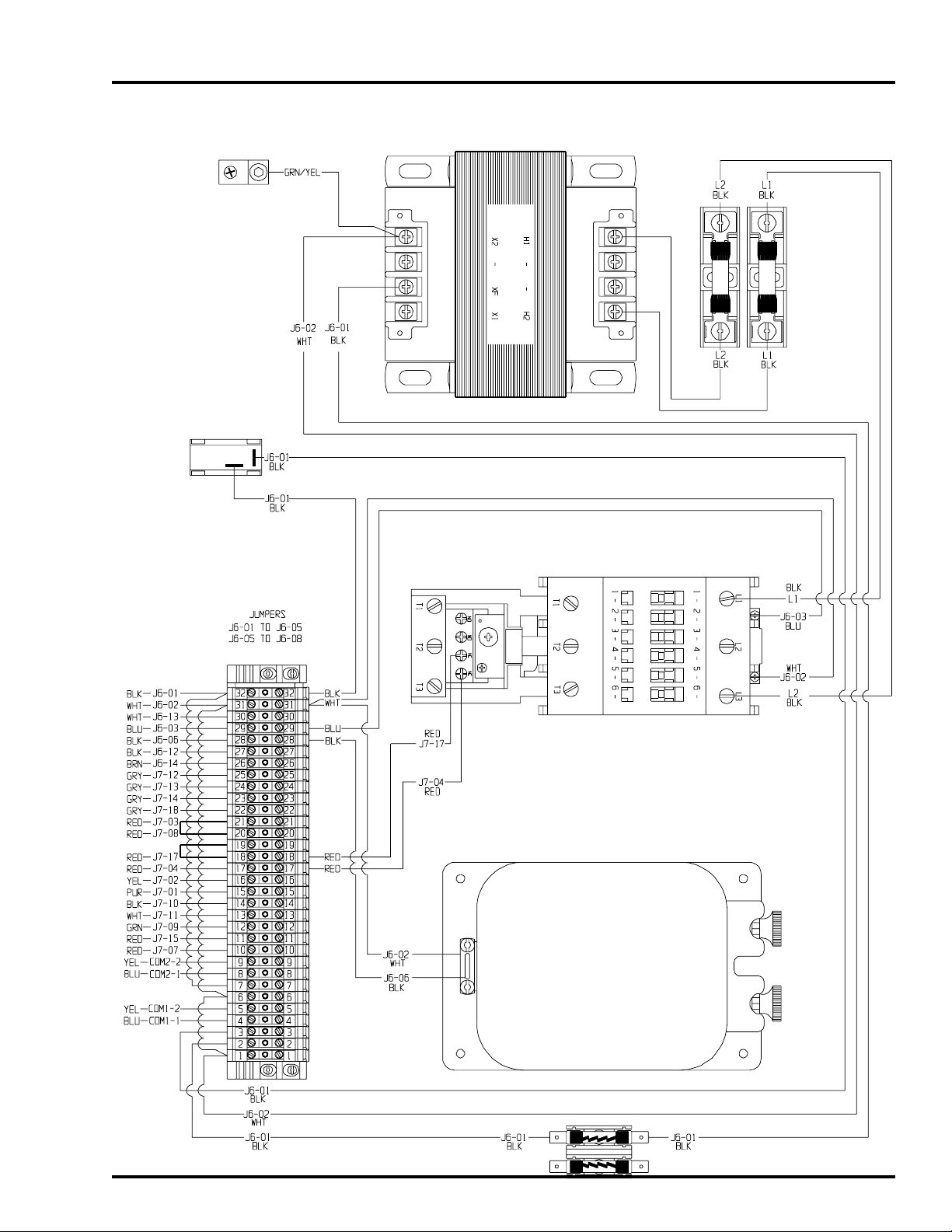

Series 2000 Master 220v1ph & 220v3ph Internal Wiring

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

11

Page 12

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

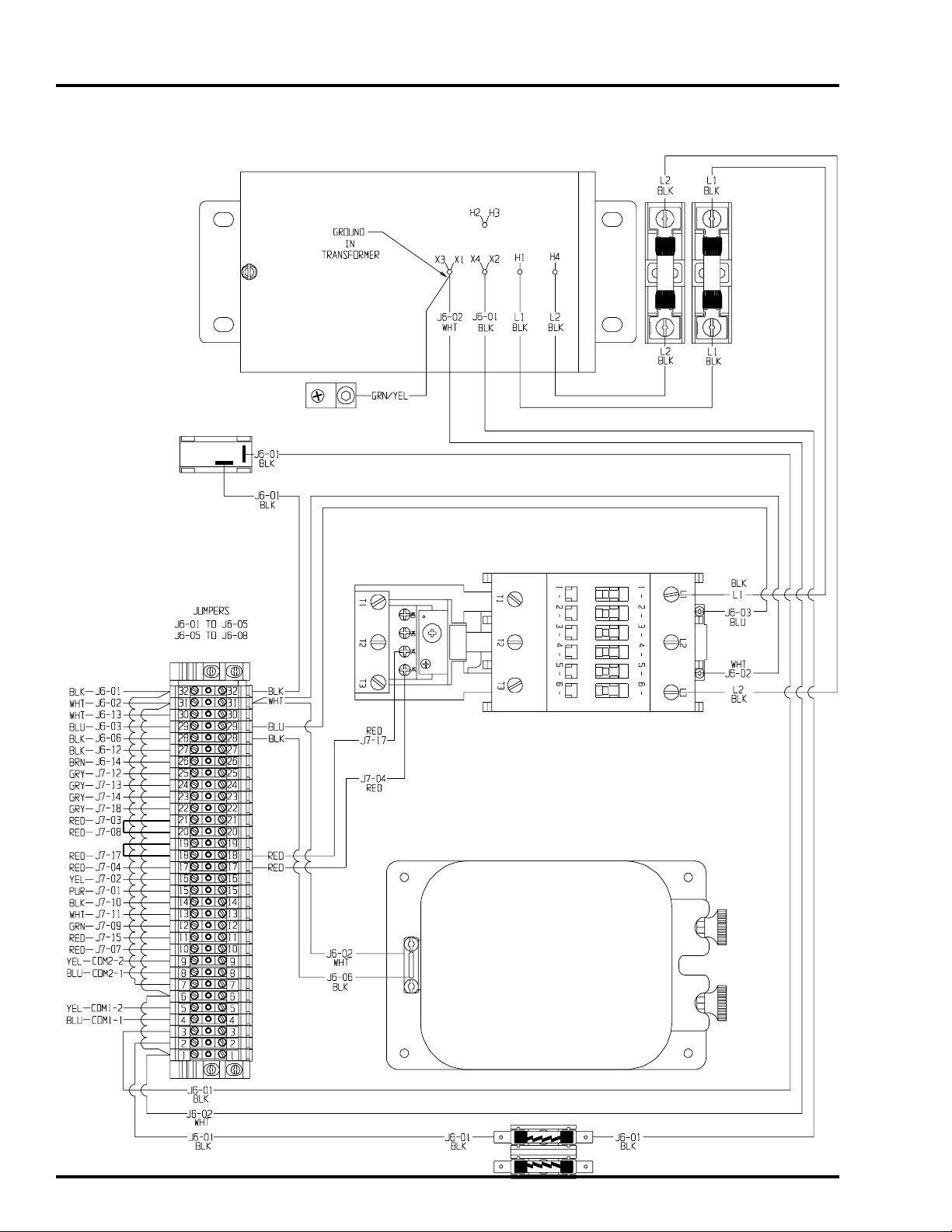

Series 2000 Master 460v3ph Internal Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

12

Page 13

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Master 575v3ph Internal Wiring

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

13

Page 14

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

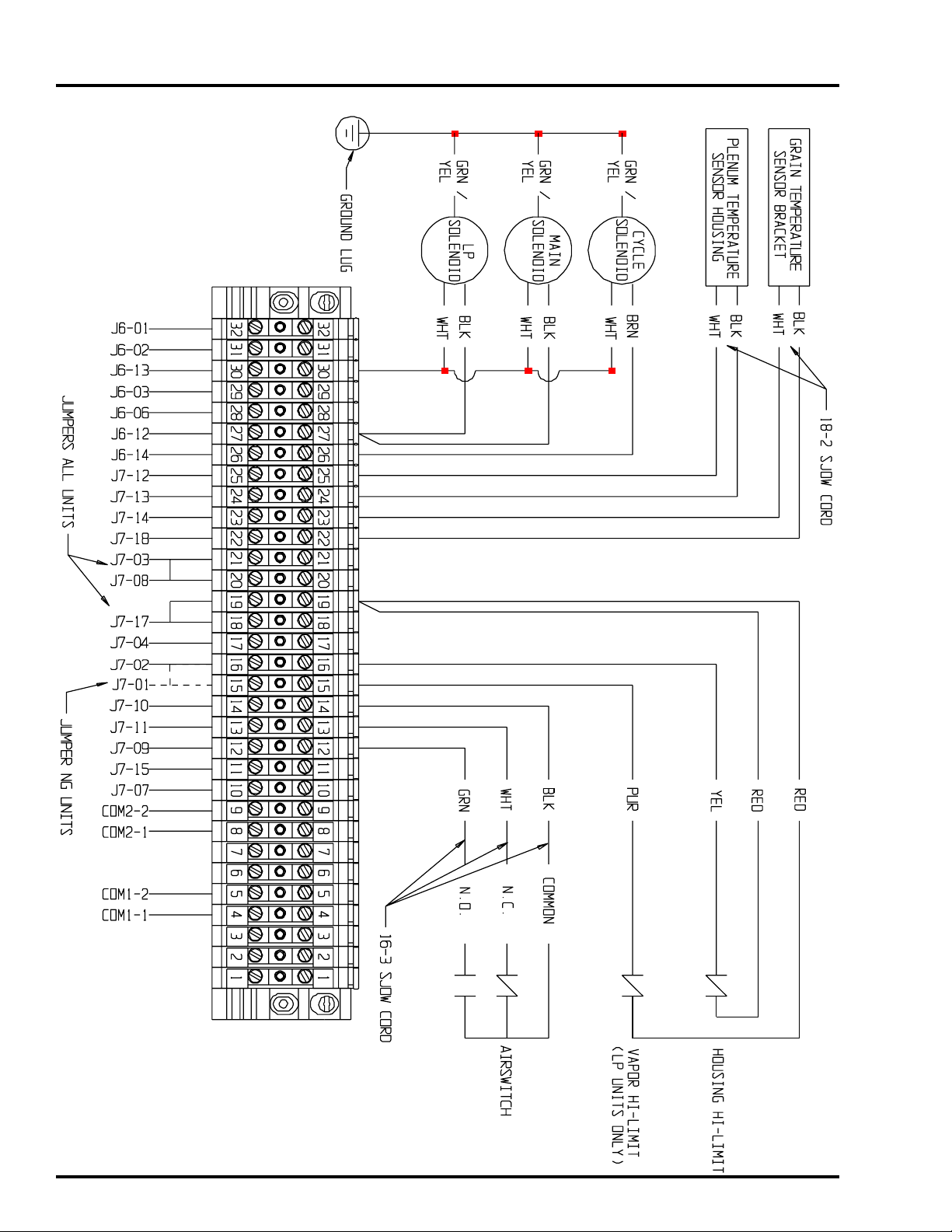

Series 2000 Master External Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

14

Page 15

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

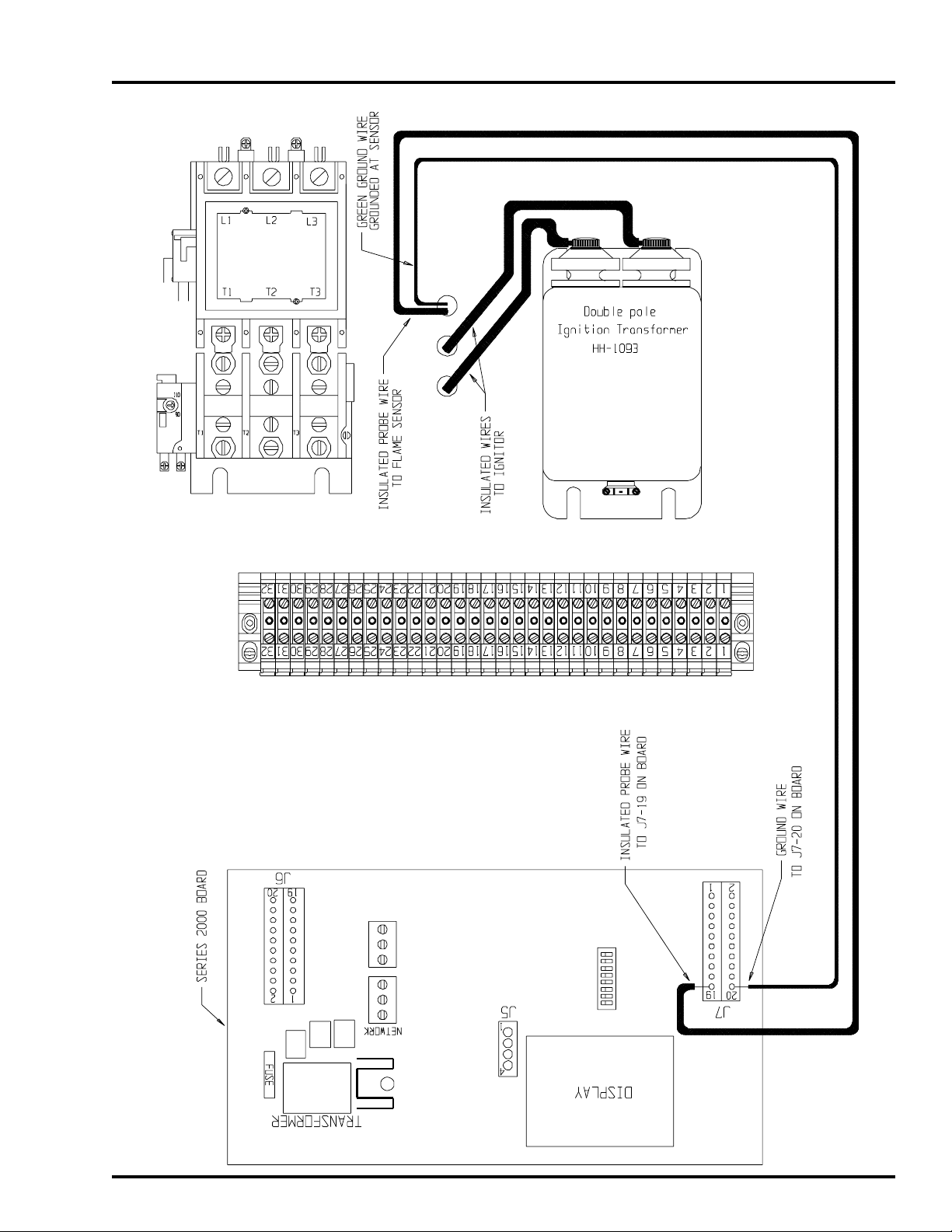

Series 2000 Master Ignitor/Probe Wiring

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

15

Page 16

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGA

SERIES 2000 DOMESTIC & CGASERIES 2000 DOMESTIC & CGA

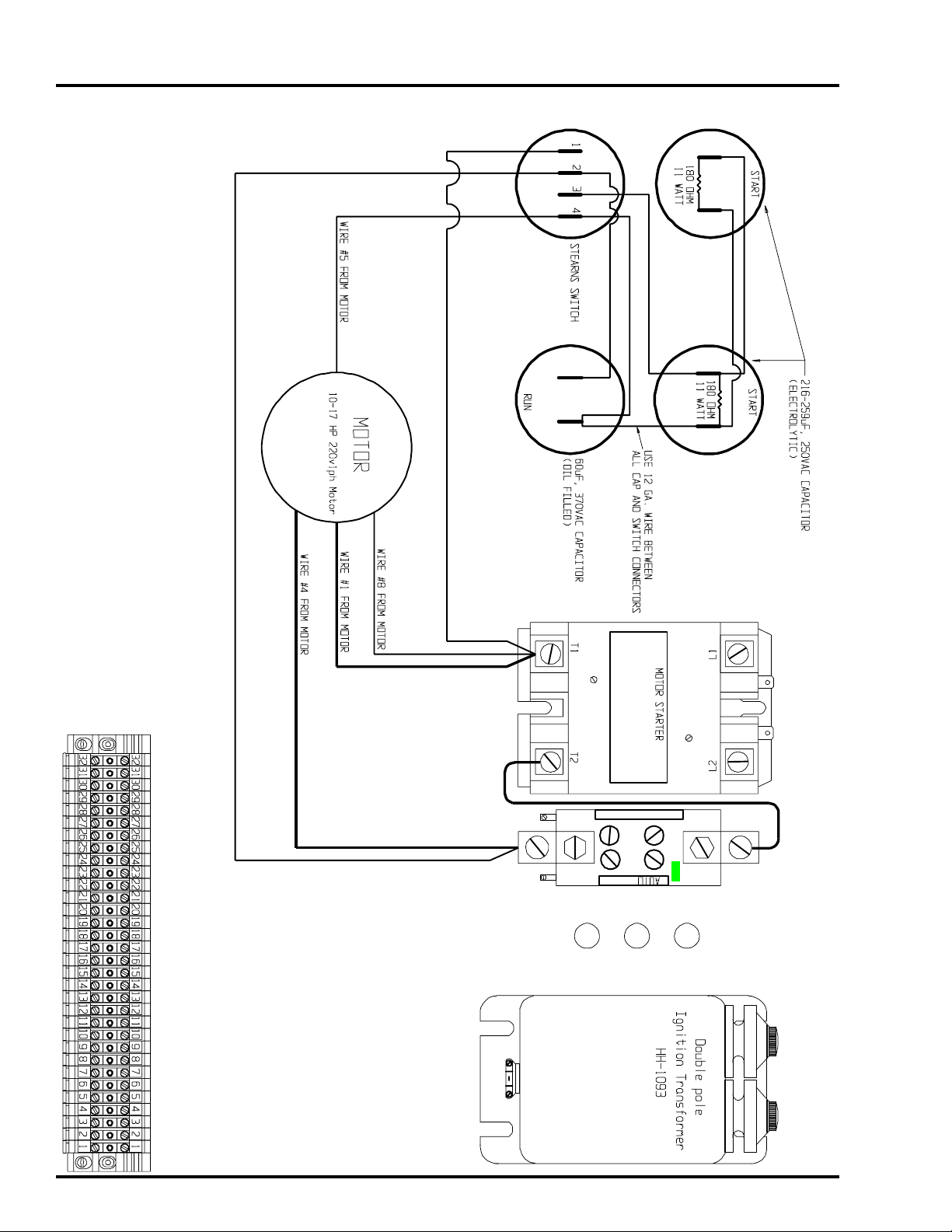

Series 2000 Master 15 Hp 220v1ph Capacitor Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

16

Page 17

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Master Fan/Heater Wiring

European Models

17

Page 18

SERIES 2000 EUROPEANSERIES 2000 EUROPEAN

SERIES 2000 EUROPEAN

SERIES 2000 EUROPEANSERIES 2000 EUROPEAN

Series 2000 Master Heater Board Input/Output

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

18

Page 19

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Master 380v3ph Internal Wiring - European Models

SERIES 2000 EUROPEANSERIES 2000 EUROPEAN

SERIES 2000 EUROPEAN

SERIES 2000 EUROPEANSERIES 2000 EUROPEAN

19

Page 20

SERIES 2000 EUROPEANSERIES 2000 EUROPEAN

SERIES 2000 EUROPEAN

SERIES 2000 EUROPEANSERIES 2000 EUROPEAN

Series 2000 Master 380v3ph External Wiring - European Models

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

20

Page 21

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Master Ignitor/Probe Wiring.

SERIES 2000 EUROPEANSERIES 2000 EUROPEAN

SERIES 2000 EUROPEAN

SERIES 2000 EUROPEANSERIES 2000 EUROPEAN

21

Page 22

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

22

Page 23

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Slave Fan/Heater Wiring

Domestic, CGA, and European Models

23

Page 24

SERIES 2000 SLAVE

Series 2000 Slave Heater Board Input/Output

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

24

Page 25

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Slave Internal Wiring

SERIES 2000 SLAVE

25

Page 26

SERIES 2000 SLAVE

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Slave External Wiring

26

Page 27

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Slave Ignitor/Probe Wiring

SERIES 2000 SLAVE

27

Page 28

SERIES 2000 SLAVE

Series 2000 Slave 15 Hp 220v1ph Capacitor Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

28

Page 29

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Batch

Control Box Wiring

29

Page 30

SERIES 2000 BATCH CONTROLS

Series 2000 Batch Remote Display Wiring - Domestic & CGA Units

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

30

Page 31

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Batch Remote Display Wiring - European Units

SERIES 2000 BATCH CONTROLS

31

Page 32

SERIES 2000 BATCH CONTROLS

Series 2000 Batch Economy Control Wiring - Domestic & CGA Units

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

32

Page 33

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Batch Economy Control Wiring - European Units

SERIES 2000 BATCH CONTROLS

33

Page 34

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Autoflow Front Panel

34

Page 35

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Autoflow

Control Box Wiring

35

Page 36

SERIES 2000 AUTOFLOW CONTROLS

Series 2000 Autoflow Input/Output Board Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

36

Page 37

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000Autoflow Terminal Strip Wiring

SERIES 2000 AUTOFLOW CONTROLS

37

Page 38

SERIES 2000 AUTOFLOW CONTROLS

Series 2000 Autoflow Door Internal Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

38

Page 39

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000Autoflow Door External Wiring

SERIES 2000 AUTOFLOW CONTROLS

39

Page 40

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Autoflow Actuator

40

Page 41

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Autoflow

Actuator Wiring

41

Page 42

SERIES 2000 AUTOFLOW ACTUATOR

Series 2000 Autoflow Actuator Schematic

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

42

Page 43

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Autoflow Actuator Wiring

SERIES 2000 AUTOFLOW ACTUATOR

43

Page 44

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Autoflow Fill System Control Box

44

Page 45

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

Series 2000 Autoflow

Fill System Control Box Wiring

45

Page 46

FILL SYSTEM CONTROL BOX

0 - Fill Systems, 1 - Aeration Fan Internal Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

46

Page 47

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

0 - Fill Systems, 1 - Aeration Fan Door Wiring

FILL SYSTEM CONTROL BOX

47

Page 48

FILL SYSTEM CONTROL BOX

1 - Fill Systems, 0 - Aeration Fan Internal Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

48

Page 49

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1 - Fill Systems, 0 - Aeration Fan Door Wiring

FILL SYSTEM CONTROL BOX

49

Page 50

FILL SYSTEM CONTROL BOX

1 - Fill Systems, 1 - Aeration Fan Internal Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

50

Page 51

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1 - Fill Systems, 1 - Aeration Fan Door Wiring

FILL SYSTEM CONTROL BOX

51

Page 52

FILL SYSTEM CONTROL BOX

2 - Fill Systems, 0 - Aeration Fan Internal Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

52

Page 53

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

2 - Fill Systems, 0 - Aeration Fan Door Wiring

FILL SYSTEM CONTROL BOX

53

Page 54

FILL SYSTEM CONTROL BOX

2 - Fill Systems, 1 - Aeration Fan Internal Wiring

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

54

Page 55

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

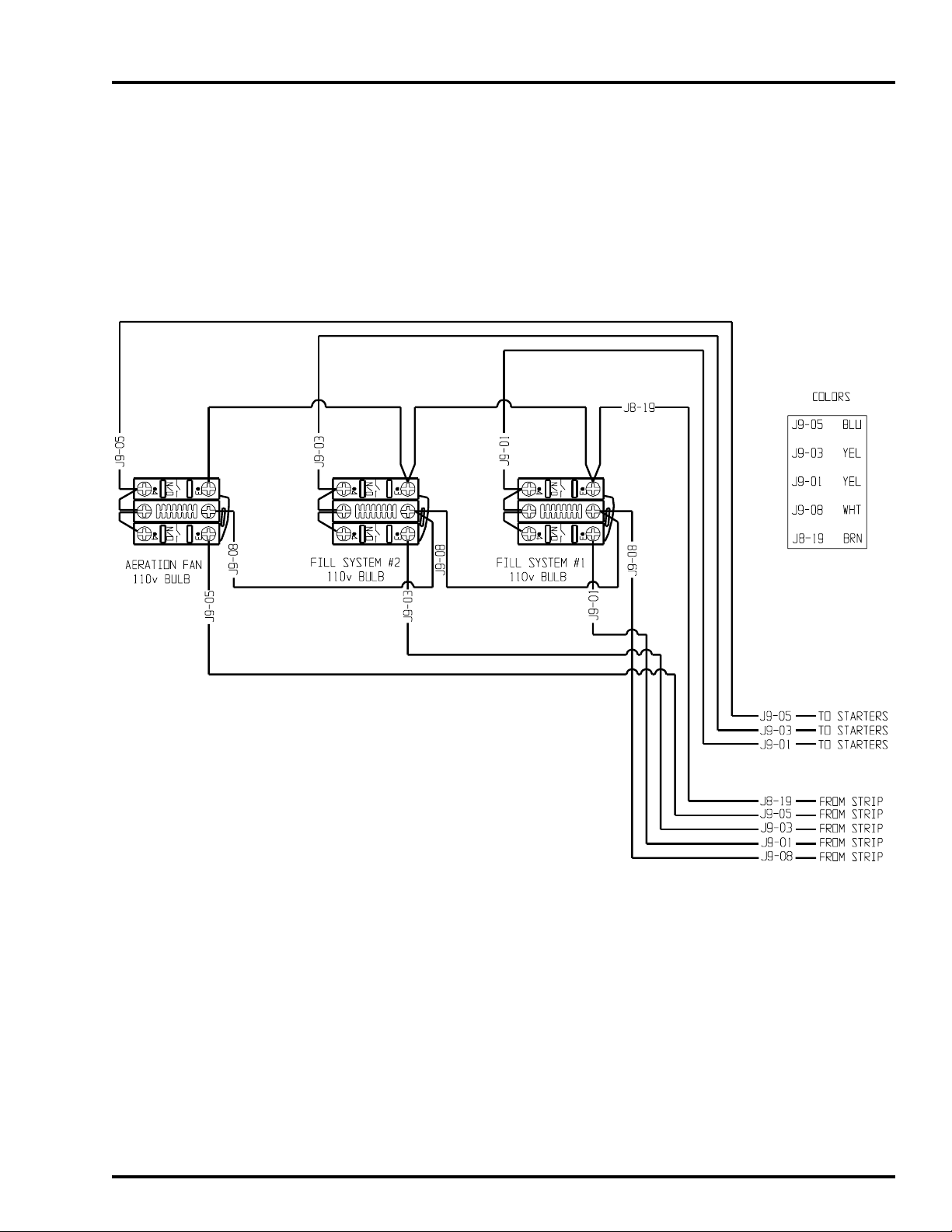

2 - Fill Systems, 1 - Aeration Fan Door Wiring

FILL SYSTEM CONTROL BOX

55

Page 56

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

56

Page 57

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

THE GSI GROUP , INC. ("GSI") WARRANTS ALL PRODUCTS MANUF ACTURED BY GSI TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE

AND CONDITIONS FOR A PERIOD OF TWEL VE MONTHS AFTER RET AIL SALE T O THE

ORIGINAL END USER OF SUCH PRODUCTS. GSI'S ONLY OBLIGATION IS, AND

PURCHASER'S SOLE REMEDY SHALL BE FOR GSI, TO REPAIR OR REPLACE, AT GSI'S

OPTION AND EXPENSE, PRODUCTS THA T , IN GSI'S SOLE JUDGMENT , CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP . ALL DELIVER Y AND SHIPMENT CHARGES TO AND FROM GSI'S FACTORY WILL BE PURCHASER'S RESPONSIBILITY . EXPENSES INCURRED BY OR ON BEHALF OF THE PURCHASER WITHOUT PRIOR

WRITTEN AUTHORIZA TION FROM AN AUTHORIZED EMPLOYEE OF GSI SHALL BE THE

SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE ABOVE STATED EXPRESS LIMITED WARRANTIES, GSI MAKES NO WARRANTY

OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION WITH

(i) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR EMPLOYEE OF GSI

REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR

A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCT OR PRODUCTS.

IN NO EVENT SHALL GSI BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS OR

BENEFITS. PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO THAT STATED

ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS

WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI

SHALL HAVE NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIVE OR WARRANTIES MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICA TIONS OR ERECTION DEFECTS WHICH

CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS. MODIFICATIONS TO THE PRODUCT

NOT SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NULLIFY ANY PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT COVER PRODUCTS OR PARTS WHICH HAVE BEEN

DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY COVERS ONLY PRODUCTS MANUFACTURED BY GSI. THIS WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE REPONSIBILITY TO RESEARCH AND COMPLY WITH ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION

AND INSTALLATION

57

Page 58

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams

1999 Top Dry Wiring Diagrams1999 Top Dry Wiring Diagrams

58

1004 E. Illinois

St.

Assumption, IL

62510

Phone 217-226-

4421

Fax 217-226-4498

July 1999

Loading...

Loading...