Page 1

Series 2000 Downwind Heater

Downwind Series 2000

Centrifugal Heater

Installation And

Operating Instructions

MODEL # CH__ - __ __ - __ __ - 2 __ (HIGH)

MODEL # CL__ - __ __ - __ __ - 2 __ (LOW)

Owner's

Manual

PNEG-824

1

Page 2

Series 2000 Downwind Heater

THIS EQUIPMENT SHALL BE INSTALLED IN ACCORDANCE WITH THE CURRENT

INSTALLATION CODES FOR GAS BURNING APPLIANCES AND EQUIPMENT,

CAN1-B149.1 AND B149.2, OR APPLICABLE PROVINCIAL REGULATIONS WHICH

SHOULD BE CAREFULLY FOLLOWED IN ALL CASES. AUTHORITIES HAVING

JURISDICTION SHOULD BE CONSULTED BEFORE INSTALLATIONS ARE MADE.

2

Page 3

Series 2000 Downwind Heater

_____ 1. Check all wire connections

_____ 2. Spark plug and flame sensor tightness set plug gap to 1/8"

_____ 3. Check plug in terminal strips on back of circuit board to be sure they are plugged into

proper position.

_____ 4. Software settings correct for type of heater (hi-low, on-off)

_____ 5. Dip switch settings correct for heater model (slave, master)

_____ 6. Most current software version installed

_____ 7. Turn heater toggle switch on. Most current software version should be displayed first, fol-

lowed by temperature. Screen should read "NO AIRFLOW".

_____ 8. Turn fan on. Screen should read "AIRFLOW".

_____ 9. Program hi-limit set point to 140 degrees F.

_____ 10. Program cycle set point to 120 degrees F (only on hi-lo units).

_____ 11. Program differential to 10 degrees F/

_____ 12. Turn gas on to heater unit.

_____ 13. Press start switch on heater. Screen should flash "PURGE".

_____ 14. After 10 second purge heater should light screen, and should read "HI-FLAME".

"FLAME" should appear on lower right hand corner of screen.

_____ 15. Adjust pressure to 10 psi (lp units) 5 psi (ng units).

_____ 16. Check pipe train for leaks with soapy water.

_____ 17. Temperature should rise to 120 degrees. Screen should read "LO-FLAME" and unit

should cycle to lo-flame. (hi-lo units only)

_____ 18. Adjust pressure with ball valve to 2 psi (lp units) 1 psi (ng units). (hi-lo units only)

_____ 19. On standard units temperature will rise to 140 degrees. Screen will read "OFF-CYCLE".

Heater will shut off at this point.

_____ 20. Temperature will drop 10 degrees and unit will cycle back to hi-flame. Screen should read

"HI-FLAME".

_____ 21. Observe unit go through 3 cycles.

_____ 22. Pull wire off of housing hi-limit switch. Screen should read "ERROR 000" and "HOUSING

TEMP HI-LIMIT". Heater should shut down and lock out. Fan should shut off.

_____ 23. Turn heater toggle switch on. Most current software version should be displayed first,

followed by temperature. Screen should read "NO AIRFLOW".

_____ 24. Turn fan on. Screen should read "AIRFLOW".

_____ 25. Press start switch on heater. Screen should flash "PURGE".

_____ 26. After 10 second purge heater should light. Screen should read "HI-FLAME". "FLAME"

should appear on lower right hand corner of screen.

_____ 27. Shut gas off to heater and allow gas to burn out of system.

_____ 28. 2-4 seconds after flame goes out on heater, "FLAME" in lower right hand corner of screen

should go out. Unit should begin to spark.

_____ 29. After 10 seconds fan and heater should shut down and lock out. Screen should read

"ERROR 000" and "FLAME OUT".

_____ 30. Check heater visually to see that all decals are in place and correctly located.

_____ 31. Place owners manual in control box.

CHECKLIST

Tester Signature___________________________________________

Date____________________________________

3

Page 4

Series 2000 Downwind Heater

4

Page 5

Series 2000 Downwind Heater

Safety 6

Series 2000 Heater Installation

High Temperature Heater Specifications 8

Low Temperature Heater Specifications 8

Temperature Sensor Box 9

Transition Hi-Limit Installation 9

Bin Configuration/Operating Temperature Table 10

Heater Unit Wiring 11

Secondary Heater Unit Wiring 11

Machine To Earth Ground 12

Proper Installation Of The Ground Rod 12

Previously Installed Units 12

Fuel Connection For Liquid Propane Models 13

Fuel Connection For Propane Vapor Models 13

Fuel Connection For Natural Gas Models 13

Installing Optional Humidity Sensor 14

Series 2000 Operating Procedure

Power Up 15

Normal Operating Displays With Heater Not Running 16

Starting The Dryer 17

Setting Gas Pressure 17

BTU's Per Gauge Pressure (PSI) 10-15 hp Models (Approximate) 19

BTU's Per Gauge Pressure (PSI) 20-40 hp Models (Approximate) 20

BTU's Per Gauge Pressure (PSI) Lo-temp Models (Approximate) 22

Adjusting The Vaporizer 23

Running The Dryer 23

Programming Set Points 24

Programming Hours To Shutdown 25

Drying Grain In The Hours To Shutdown Mode 25

Run Hours Display 25

Multiple Heater Notes 25

Modulating Valve Operation 26

Factory Configuration

Configuration Dip Switches 27

Error Conditions

Limit Switches 28

Multiple Heater Error Conditions 28

Misc Error Numbers 28

Series 2000 Heater Service 29

Series 2000 Wiring Diagram 30

Warranty 32

TABLE OF CONTENTS

5

Page 6

SAFETY

SAFETY FIRST

General Safety Statements

The GSI Group Inc’s Principal concern is

your safety and the safety of others associated with

grain handling equipment. We want to keep you

as a customer. This manual is to help you understand safe operating procedures and some problems which may be encountered by the operator

and other personnel.

Series 2000 Downwind Heater

CAUTION

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

As owner and/or operator, it is your responsibility to know what requirements, hazards and

precautions exist and inform all personnel associated with, or in the area of the product. Safety

precautions may be required from the personnel.

This product is ideal for the conditioning of corn,

soy beans or other select grains. Avoid any alteration to the equipment, such alterations may produce a very dangerous situation, where serious injury or death may occur.

This is the safety alert symbol.

It is used to alert you to potential personal injury hazards.

Obey all safety messages that

follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury

CAUTION

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

If a decal is damaged or missing contact:

The GSI Group Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to you.

BE ALERT!

Danger!

Personnel operating or

working around electrical

equipment should read this

manual. This manual must be delivered with

equipment to its owner. Failure to read this

manual and its safety instructions is a misuse

of the equipment.

WARNING

WARNING indicates a potentially hazardous situation

which , if not avoided, could result in death or serious

injury.

6

The GSI Group Inc. recommends that you

contact your local power company and have a representative review your installation so your wiring will be compatible with their system and so

that you will have adequate power supplied to your

unit.

Page 7

Series 2000 Downwind Heater

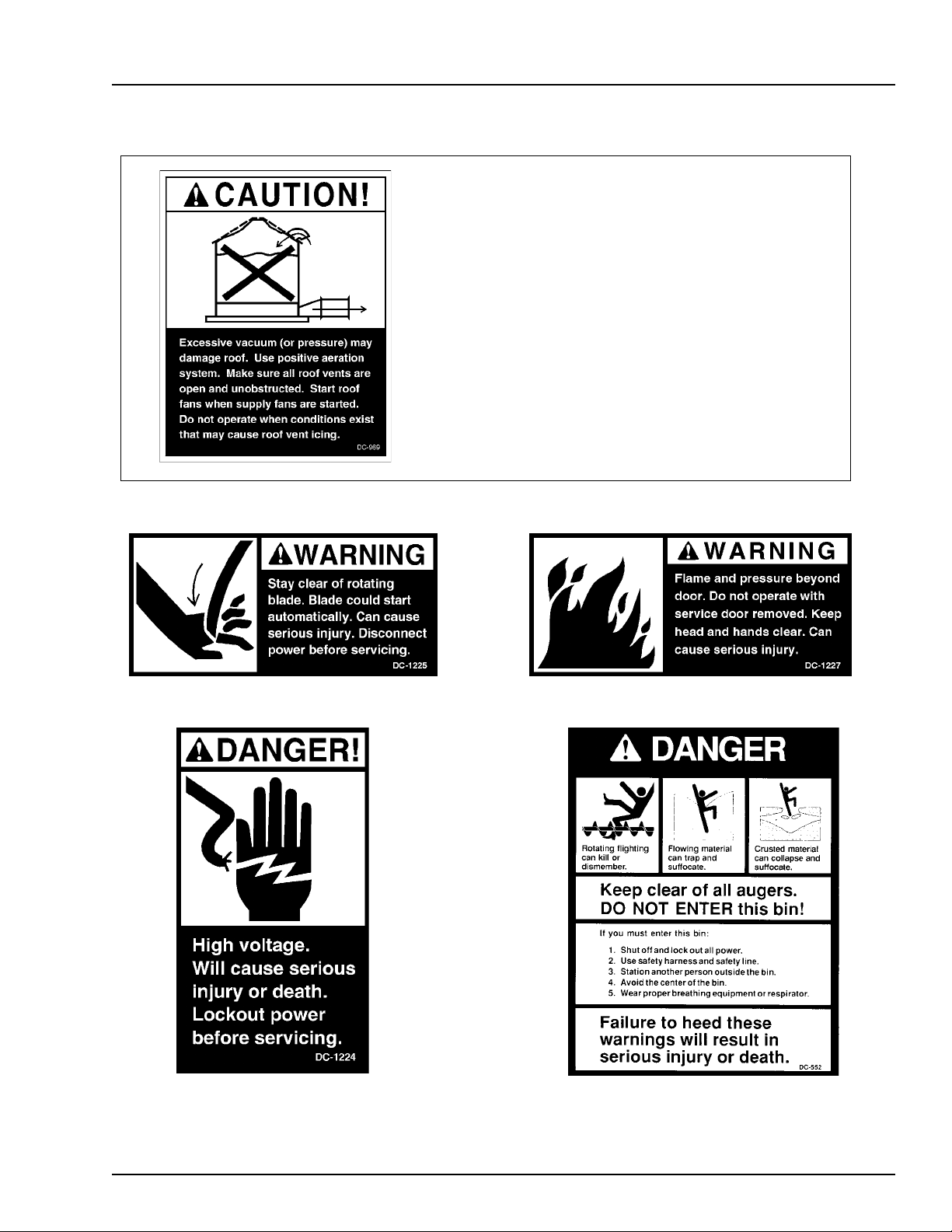

Roof Damage Warning And Disclaimer

SAFETY

GSI DOES NOT WARRANT ANY ROOF DAMAGE

CAUSED BY EXCESSIVE VACUUM OR INTERNAL PRES-

SURE FROM FANS OR OTHER AIR MOVING SYSTEMS.

ADEQUATE VENTILATION AND/OR "MAKEUP AIR" DE-

VICES SHOULD BE PROVIDED FOR ALL POWERED AIR

HANDLING SYSTEMS. GSI DOES NOT RECOMMEND

THE USE OF DOWNWARD FLOW SYSTEMS (SUCTION).

SEVERE ROOF DAMAGE CAN RESULT FROM ANY

BLOCKAGE OF AIR PASSAGES. RUNNING FANS DUR-

ING HIGH HUMIDITY/COLD WEATHER CONDITIONS

CAN CAUSE AIR EXHAUST OR INTAKE PORTS

7

Page 8

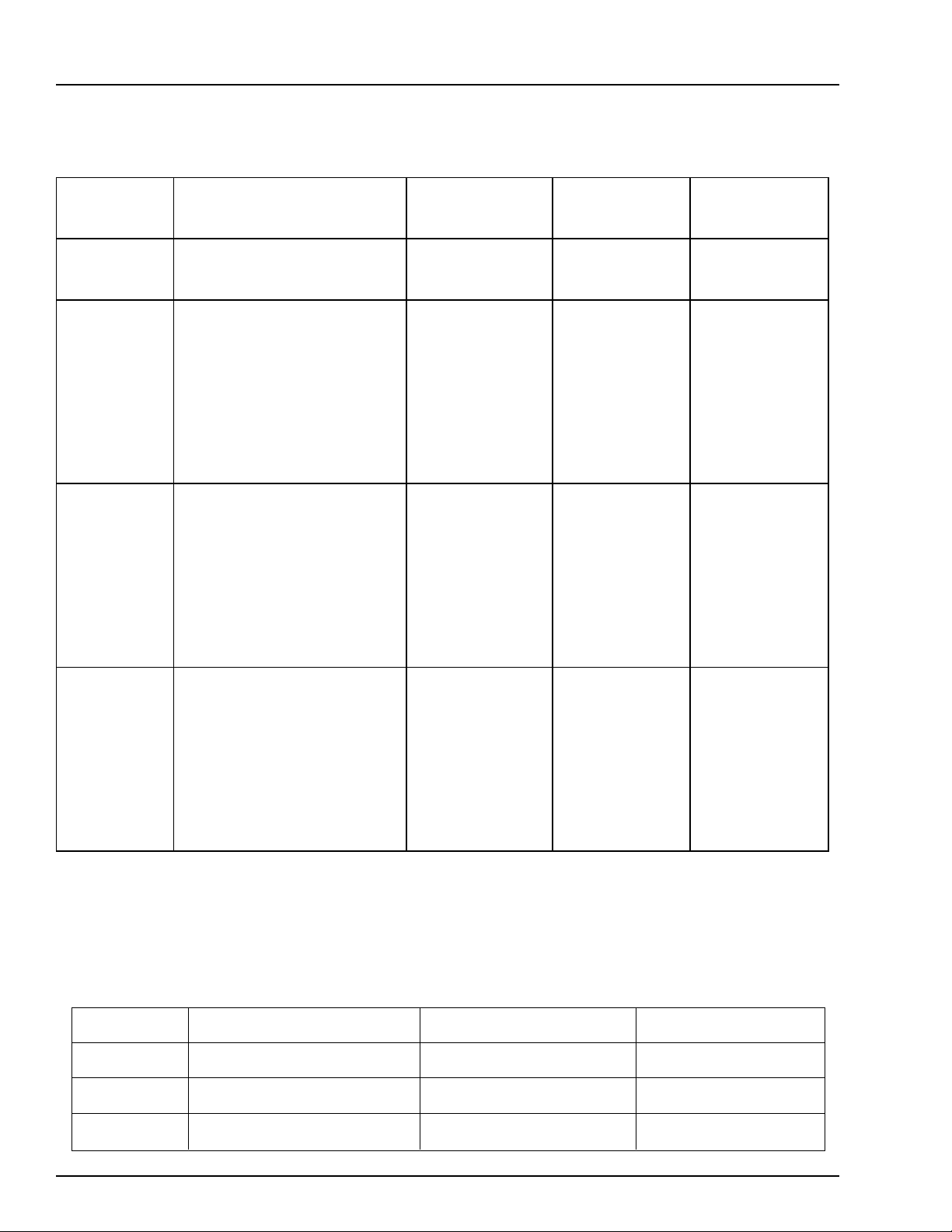

SPECIFICATIONS

Series 2000 Downwind Heater

Centrifugal Heater Specifications

Hi-Temp Hi-Temp Lo-Temp Model

10-15HP 20-40HP All units

All Models BTU Rating 2225000 4500000 500000

Weight 145 145 135

Liquid Mo dels Maximum Fuel flow (GPH) 24 49 N/A

Orifice size 0.2188 0.3125 N/A

Mod Valve Bypass Orifice Blue Aluminum Yellow

Minimum operating pre ssure 1 1 N/A

Maximum operating pressure 15 15 N/A

Minimum line size 3/8" 3/8" N/A

Vapor Models Maximum Fuel flow (CFH) 931 1898 210

Orifice size 0.2188 0.3125 0.109

Mod Valve Bypass Orifice Blue Aluminum Yellow

Minimum operating pre ssure 1 1 1

Maximum operating pressure 15 15 15

Minimum line size 3/8" 3/8" 1/2"

Natural Gas Maximum Fuel flow (CFH) 2496 4643 500

Models Orifice size 0.3438 0.4688 0.156

Mod Valve Bypass Orific e Aluminum Aluminum Gre en

Minimum operating pre ssure 0.5 0.5 1

Maximum operating pressure 7 7 7

Minimum line size 1.1/4" 1.1/4" 1"

Heater Dimensional Specifications

Heater Size

Inside Height

Inside Width

Inside length

8

10-15

30.1/4"

19.1/2"

24"

20-30

33.1/4"

21.3/4"

24"

40

33.1/4"

23.11/16"

24"

Page 9

Series 2000 Downwind Heater

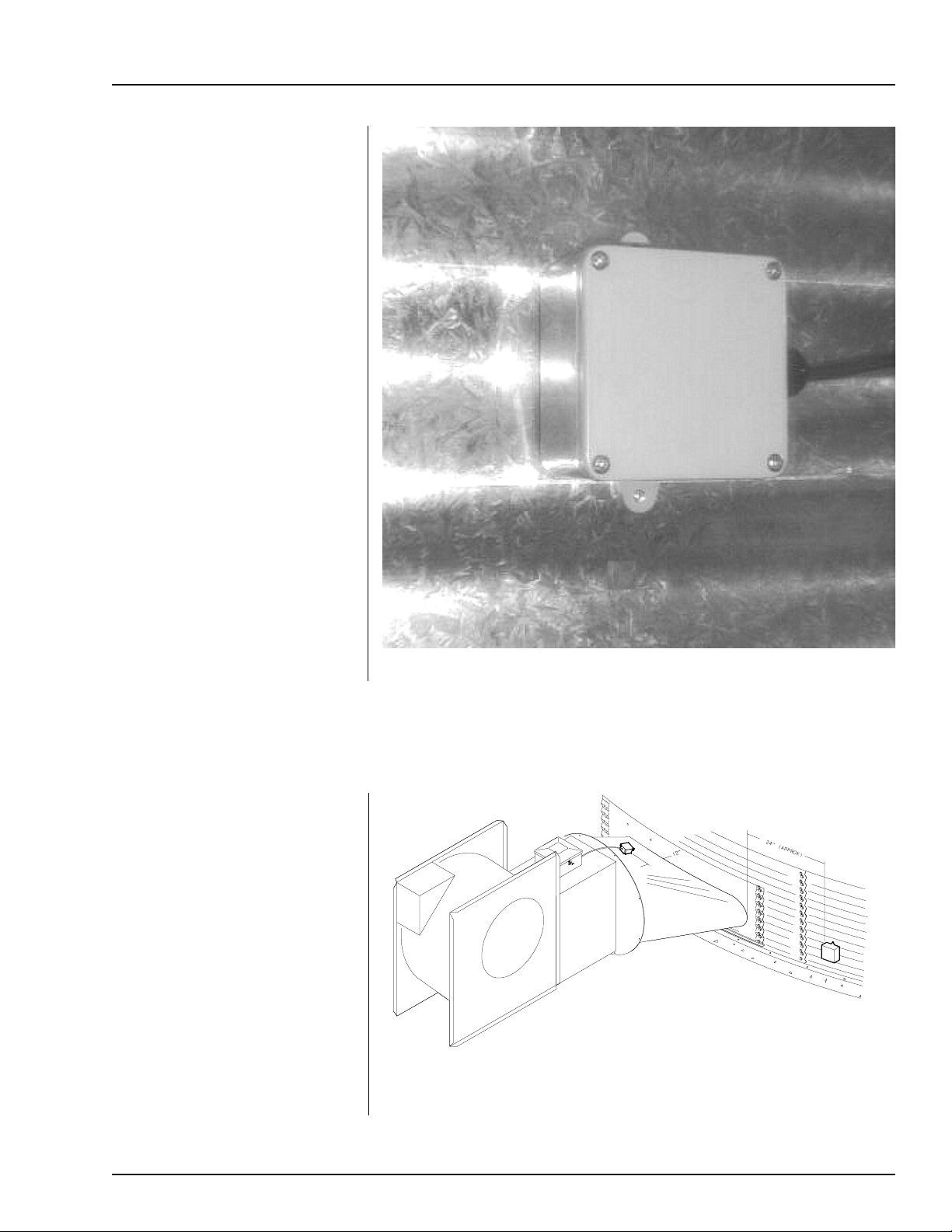

PLENUM TEMPERATURE

SENSOR MOUNTING

The plenum temperature sensor is

the white PVC junction box with bolt

extending from outside attached by

a cord to the fan/heater control box.

1. 24" to the right side of the transi

tion, drill one 3/8" hole in the cen

ter of the plenum in a valley on

the bin sidewall.

2. Insert the probe through the hole.

3. Position the housing so that the

tabs are vertical, and the cord

exits the housing horizontally.

HEATER INSTALLATION

4. Use two self drilling screws to

mount the housing to the bin

sidewall.

5. Caulk between the housing and

the sidewall to seal.

TRANSITION HI-LIMIT INSTALLATION

1. Mark location on transition one

(1) foot up from the bottom

(entrance collar) and centered

in the transition.

2. Drill or knock out 7/8" diameter

hole on marked location.

3. Install transition hi-limit using

supplied self drilling screws.

Plenum temperature sensor installation.

Figure 1: The transition connecting the heater to the bin with the plenum

thermostat in place.

9

Page 10

HEATER INSTALLATION

Bin Configuration

Series 2000 Downwind Heater

IMPORTANT! When

mounting (2) heaters on a

bin it is imperative that

they be situated as

illustrated in this drawing. Plenum thermostat

must be to the right of

master heater and master

heater must be to the

right of slave heater.

THIS TABLE IS NOT INTENDED AS A DRYING GUIDE.

IT SHOULD BE USED AS A REFERENCE FOR SETTING MAXIMUM PLENUM

TEMPERATURE FOR SAFE OPERATION.

Operating Temperature Table

PMET-OL

HCTAB

0

02-5

NROC

ECIR

SNAEB

&

TAEHW

EVOBA

TNEIBMA

PMET

0

01-5

EVOBA

TNEIBMA

PMET

0

02-5

EVOBA

TNEIBMA

PMET

-HGIH

PMET

YRDHCTAB

GNIRRITSON

0

021

0

001

0

011

-HGIH

PMET

HTIW

GNIRRITS

0

041

SUOUNITNOC

WOLF

)GNITALUCRICER(

0

061

IMPORTANT!

DO NOT EXCEED

PLENUM

TEMPERATURES

0

001

0

021

TON

DEDNEMMOCER

TON

DEDNEMMOCER

LISTED IN TABLE

10

Page 11

Series 2000 Downwind Heater

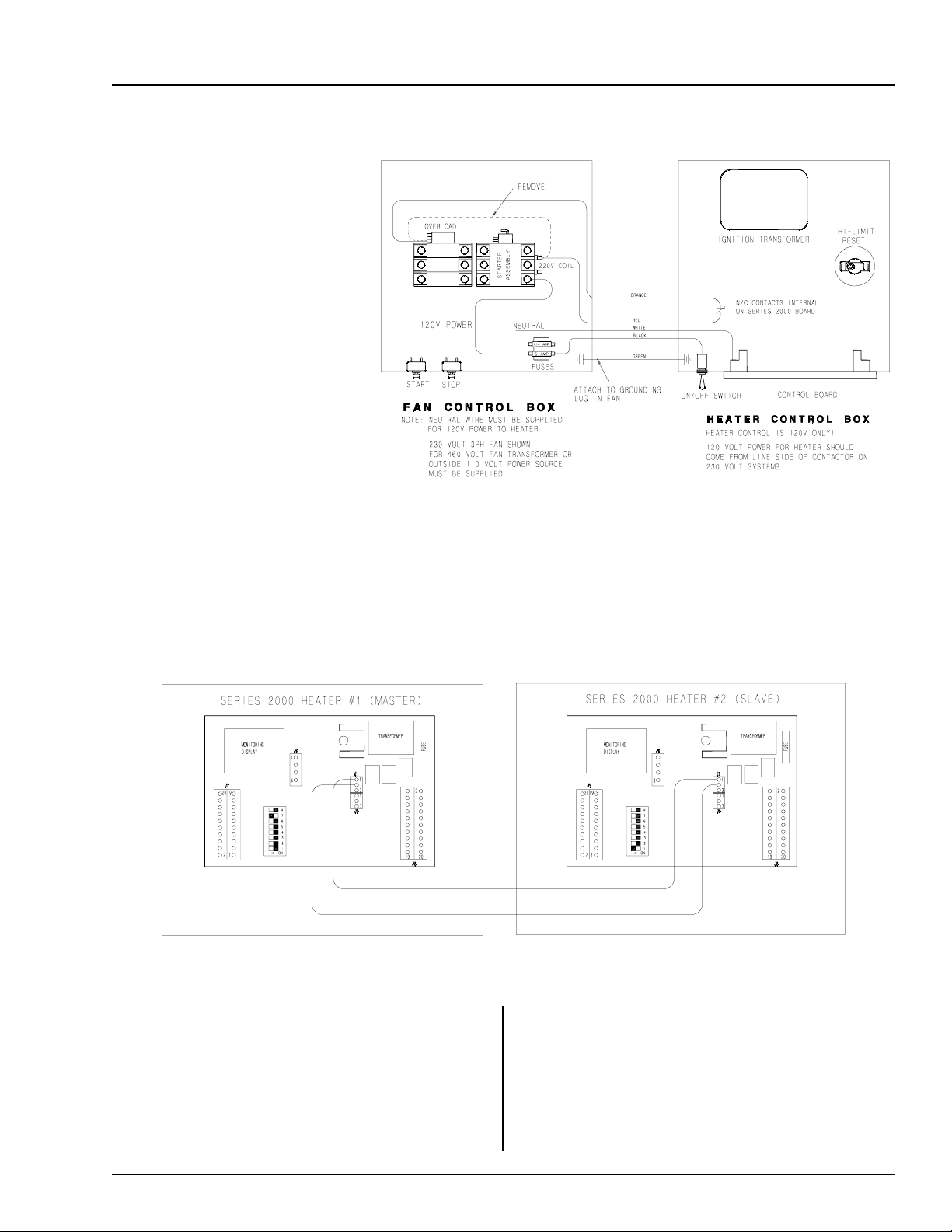

HEATER INSTALLATION

Heater Unit

1. Be sure fan unit is installed and

wired to meet local codes. Be

sure equipment is well grounded

(see page 10).

2. A separate neutral is required

for 120 volt heater circuit in 220

volt 1PH and 3PH fan units. For

460 volt fan units a separate 120

volt power supply or transformer

is required.

3. Run 5-wire black cord from

heater unit to fan unit and se-

cure to fan.

4. Orange and red wires should be

connected in series with coil in

fan. When contacts in heater be-

tween these wires open fan

Wiring

Figure 2: Wiring diagram for the fan and heater unit.

shuts down. Recommended wiring is shown in Figure 2.

5. Black and white wires should be connected to a fused 120V

power supply as shown. Green wire should be connected to

ground in fan. Heater should have power, even with fan off.

Figure 3: Secondary heater wiring diagram.

SECONDARY HEATER UNIT

1. Secondary heater unit runs as a slave of heater

unit #1 and requires no plenum temperature

sensor.

2. Run (2) 20 gauge (minimum) wires from sec-

ondary heater unit (slave) to heater unit #1

(master).

3.

Connect wires as shown in Figure 3.

4. Third heater unit may also be added to system.

If adding third unit, run connections to master

unit #1 and connect them in parallel with sec

ondary heater unit.

11

Page 12

HEATER INSTALLATION

Machine To Earth

Ground

It is very important that a machine

to earth ground rod be installed at

the fan. This is true even if there is

a ground at the pole 15 feet away.

This ground needs to be as close to

the fan as possible, but no more than

8 feet away. The ground rod should

be connected to the fan control panel

with at least a #6 solid bare copper

ground wire, or in accordance with

local requirements. The machine to

earth ground provides additional

safety if there is a short. It also pro-

vides the grounding necessary for

long life and operation of the solid

state circuit boards used on control

circuits and the electronic ignition

systems.

(Ground rods and wires are not supplied by Airstream). It is recommended that

the rod not be driven into dry ground. The following steps ensure proper ground

rod installation:

1. Dig a hole large enough to hold 1 to 2 gallons of water.

2. Fill hole with water.

Series 2000 Downwind Heater

Figure 4: Use a

#6 or approved

size bare copper

ground wire.

Install a 5/8"

diameter 8' long

copper-clad

ground rod, 2'

away from the

foundation and 1'

below the surface

of the ground or

in accordance

with local

requirements.

Proper Installation Of The Ground Rod

Dig a hole large enough to hold 1

or 2 gallons of water. Work the

ground rod into the earth until it is

completely in the ground.

3. Insert rod through water and jab it into the ground.

4. Continue jabbing the rod up and down, the water will work its way

down the hole, making it possible to work the rod completely

into the ground. This method of installing the rod gives a good

conductive bond with the surrounding soil.

5. Connect the bare copper ground wire to the rod with the proper

ground rod clamp.

6. Connect the bare ground wire to the fan control boxes with a

grounding lug. See figure 4.

7. Ground wire must not have any breaks or splices. Insulated

wire is not recommended for grounding.

Previously Installed Units

It is recommended that previously installed units be checked to see

that a machine to earth ground has been installed by an electrician.

12

Page 13

Series 2000 Downwind Heater

HEATER INSTALLATION

Standard electrical safety prac-

tices and codes should be used

when working with a heater.

Refer to the National Electric

ALWAYS DISCONNECT

AND LOCK OUT POWER

WARNING

BEFORE WORKING ON OR

Code Standard Handbook by

the National Fire Protection

Association. A qualified elec-

trician should make all wiring

installations.

AROUND HEATER

Fuel Connection

Liquid Propane Models

1. L.P. models are designed to run on liquid pro

pane with liquid draw from the propane tank.

Avoid using propane supply tanks that have been

used for vapor draw for long periods of time.

When using liquid draw systems any moisture

that may be present in tank or lines may freeze

when system is used in cold weather. To avoid

this situation, purge the system with methanol.

2. Run proper size line (see specification on page

7) to liquid pipetrain on heater. Have a qualified

gas service person inspect installation to be sure

that everything is installed according to local

codes and ordinances.

IMPORTANT! Do not use pro-

pane tanks that have previ-

ously been used for ammonia

unless they have been purged

according to procedures of the

National L.P. Association.

Fuel supply system must

comply with local codes for L.P.

gas installation.

external vaporizer.

2. Run proper size line (see specifications on page

7) to pipetrain on heater. Have a qualified gas

service person inspect installation to be sure that

everything is installed according to local codes

and ordinances.

3. After installation is complete check all connec-

tions for leaks. DO NOT USE FLAME FOR

LEAK TESTING.

Natural Gas Models

1. Natural gas models are designed to run directly

off of a supply tank or from a separate

external vaporizer.

3. After installation is complete check all connec-

tions for leaks with liquid detergent or compa-

rable. Wear rubber gloves and eye protection.

Avoid contact with liquid propane. DO NOT

USE FLAME FOR LEAK TESTING.

Propane Vapor Models

1. Propane vapor models are designed to run di-

rectly off of a supply tank or from a separate

2. Run proper size line (see specification on page 7)

to pipetrain on heater. Have a qualified gas

service person inspect installation to be sure ev-

erything is installed according to local codes

and ordinances.

3. After installation is complete check all connec-

tions for leaks. DO NOT USE FLAME FOR

LEAK TESTING.

13

Page 14

HEATER INSTALLATION

Figure A

Series 2000 Downwind Heater

Installing Optional Humidity Sensor

1. Humidity sensor should be mounted 6-8"

right of the airswitch/temperature sensor

box. See Figure A.

2. Using sensor as a guide drill or knock-out

7/8" diameter hole in the center of the

plenum on the bin sidewall. If you are

using sensor to sense drying air humidity.

3. Insert pipe nipple from sensor housing

through hole in side wall and use selfdrilling screws to mount to sidewall.

Figure B

4. Do not caulk sensor box openings on side

of box, they are for air escape.

14

Figure B

Page 15

Series 2000 Downwind Heater

OPERATING PROCEDURE

The control panel display showing initial start up.

Standard electrical safety practices and codes should

be used when working with a heater. Refer to the

National Electric Code Standard Handbook by

the National Fire Protection Association. A quali-

fied electrician should make all wiring installa-

tions.

WARNING

ALWAYS DISCONNECT AND LOCK OUT

POWER BEFORE WORKING ON OR

AROUND HEATER

Power Up

All safety and high limit switches are checked upon

power up. If a safety or limit is open, the control dis-

plays it. The control cannot operate with a safety switch

error, and the fan cannot turn on with an error condi-

tion. There is no way to bypass an error condition. It

must be fixed. (See errors on page 21)

The air switch is also checked on power up.

The air switch must indicate no airflow. This is

necessary to check the function of the air switch.

However, if the operator forgets and turns the fan

on before the controller has been powered up,

The controller locks up with the main display alter-

nating between a "FAN" and "ON" message. This

may be bypassed by depressing and holding the

"FAN BYPASS" switch (lower right switch). Nor-

mal operating procedure should be to power up the

controller with the fan off.

If multiple heaters are tied together, and the

master detects that the slave fan is on (the air

switch stuck?), the master will lock up display-

ing "SLA ERROR". This condition may be by-

passed with the "FAN BYPASS" switch.

15

Page 16

OPERATING PROCEDURE

Normal Operating Displays With Heater Not Running

Series 2000 Downwind Heater

The main display shows the plenum temperature. If

the dryer has not been running, the display should

show outside temperature. The control is preset at

the factory to display temperature in centigrade or

fahrenheit.

"AIRFLOW" or "NO AIRFLOW" is displayed

if air is flowing or not flowing. "RX TX" (receive,

transmit) is displayed if multiple heaters are con-

nected.

All safeties or high limits are continuously

checked during the off mode. A limit switch open,

or any other error condition will cause the display

to show the limit or error condition.

When drying is not occurring, and the limit

or error condition is corrected, the display returns

to its normal output. This is not the case with an

error or limit condition during the drying opera-

tion. This causes the display to lock up in the er-

ror display mode. This is to keep the display

locked up with the condition illuminated. ( see

section on "Running the Dryer" for mode expla-

nation on page 17).

16

The heater display with fan on (airflow).

Page 17

Series 2000 Downwind Heater

Starting The Dryer

After heater power is turned on, the fan must be

turned on. Attempting to start the dryer without the

air switch indicating there is airflow will cause an air-

flow alarm to go off when the start switch is depressed.

The airflow alarm is simply the entire display going

blank, and the "NO AIRFLOW" message flashing for

a few seconds. The display must show "AIRFLOW"

before the dryer can be started.

To start the dryer, just push the "START" switch.

The first message to come up will be the "PURGE"

message--the drying process begins with a 10 sec-

ond purge.

When multiple heaters are connected together,

drying may be started from any heater control.

OPERATING PROCEDURE

Programming the temperature differential.

7. Press the "PROGRAM TEMPERATURE" but

ton to continue to set the "TEMPERATURE

DIFFERENTIAL".

8. Use the increase or decrease buttons to set the

"TEMPERATURE DIFFERENTIAL" to 10°*.

Setting Gas Pressure

1. At heater turn toggle switch to "ON" position.

2. Press the "PROGRAM TEMPERATURE" but-

ton.

3. Use the increase or decrease button to set the

"PLENUM HIGH LIMIT SET POINT" to de-

sired setting (100°-160°*).

4. Press the "PROGRAM TEMPERATURE" but-

ton to continue to set the "CYCLE SETPOINT".

(hi-lo units only)

5. Use the increase or decrease buttons to set the

"CYCLE SET POINT" to desired setting (90°-

150°*) (hi-lo units only).

9. Press "progam temperature" button to continue

to set "relative humidity differential". Use ar-

row keys to adjust to 5%. ( Hudidity sensor units

only).

10. Open all manual gas shut off valves, on and to

the heater unit.

11 Start the fan unit.

12. Make sure that the blade is spinning in the right

direction. If not place the toggle switch in the

"OFF" position and correct the problem.

13. After the fan reaches full speed the display should

read "AIRFLOW" in the upper right hand corner.

If not adjust air switch. (See page 19)

14. Press the start button on the heater control.

6. Press "programs temperature" button to continue

to set the desired "relative humidity" setting,

lower setting will run heater longer. (humidity

sensor units only) Use arrow keys to set.

15. After 10 seconds the burner should ignite. If not,

turn "OFF" the toggle switch and then back "ON".

Repeat 12-15.

*Temperatures are fahrenheit.

17

Page 18

OPERATING PROCEDURE

Series 2000 Downwind Heater

16. When the burner ignites the display should read

"HI-FLAME " at the left of the display. Loosen

the nut on the main regulator and turn screw in, to

increase pressure and out to decrease pressure.

The pressure gauges should be set at 10-15 lbs.

for LP units, or 4-6 lbs.. for natural gas units. (use

the charts on the following pages to set pressure)

17. Press the "PROGRAM TEMPERATURE" but-

ton to change the high limit set point. Press it

again to change the "CYCLE SET POINT". (hi-

lo units only)

18. Decrease the "CYCLE SET POINT TEM

PERATURE" until the heater cycles to low

flame. (hi-lo units only)

19. Open or close the low cycle ball valve until

the gas pressure is 3-5 lbs. for LP, or 1-2 lbs.

for natural gas. (hi-lo units only)

20. Increase the cycle set point to return to high

flame. (hi-lo units only)

21. Watch heater run several minutes to make

sure it cycles between hi and lo flame or on

and off properly.

22. Hi-flame pressure should be adjusted so ple-

num reaches cycling temperature easily.

23. Adjust pressure on on/off units so that unit is

on approximately 75% of the time.

18

Page 19

Series 2000 Downwind Heater

g

)

(°F)

)

g

g

)

(°F)

)

BTUs Per Gauge Pressure (psi) PROPANE MODELS (Approximate

Hi

2 4 6 8 10 12 14 15

ALL

MODELS

816,013 1,148,640 1,409,477 1,632,026 1,825,859 1,995,762 2,153,700 2,227,883

Gau

e Pressure (psi) Required to Maintain Temperature (Approximate

(10-15 hp High Temperature Propane Units Only)

OPERATING PROCEDURE

10-15 hp Units

h Temperature 10-15hp 7/32" (0.219") Orifice

OPERATING PRESSURE (psi)

Fan Static

Model Pressure 60 80 100 120 140 160 180

2"24681013

10 hp4"135681114

6"11356810

2" 3 6 9 12 15

15 hp 4" 3 5 7 10 13

6"235691114

Heat Rise

10-15 hp Units

BTUs Per Gauge Pressure (psi) NATURAL GAS MODELS (Approximate

High Temperature 10-15hp 11/32" (0.344") Orifice

OPERATING PRESSURE (psi)

1234567

ALL

MODELS

859,104 1,218,432 1,489,296 1,718,208 1,921,584 2,107,632 2,276,352

Gau

e Pressure (psi) Required to Maintain Temperature (Approximate

(10-15 hp High Temperature Natural Gas Units Only)

Fan Static

Model Pressure 60 80 100 120 140 160 180

2" 1 1.75 2.5 3.5 4.75 6

10 hp 4" 0.75 1.25 2 2.75 3.75 4.75 6

6" 0.5 1 1.5 2 2.75 3.5 4.25

2" 1.5 2.5 3.75 5.5

15 hp 4" 1.25 2 3 4.25 5.75

6" 0.75 1.25 2 2.75 3.75 5 6

Heat Rise

19

Page 20

OPERATING PROCEDURE

g

)

(°F)

)

g

BTUs Per Gauge Pressure (psi) PROPANE MODELS (Approximate

Hi

h Temperature 20-40hp 5/16" (0.313") Orifice

OPERATING PRESSURE (psi)

2 4 6 8 10 12 14 15

ALL

MODELS

1,663,135 2,345,140 2,878,779 3,328,663 3,721,115 4,068,100 4,393,548 4,541,914

Gau

e Pressure (psi) Required to Maintain Temperature (Approximate

(20-40 hp High Temperature Propane Units Only)

Series 2000 Downwind Heater

20-40 hp Units

Fan Static

Model Pressure 60 80 100 120 140 160 180

2"22457810

20 hp 4" 1 2 3 4 5 7 8

6"1234567

2" 2 3 5 7 9 12 15

25 hp 4" 2 3 4 6 8 10 13

6"22456810

2"24681115

30 hp 4" 2 4 5 7 10 13

6" 2 3 4 6 8 10 13

2" 3 6 8 12

40 hp 4" 3 5 7 11 14

6"347912

Heat Rise

20

Page 21

Series 2000 Downwind Heater

g

)

(°F)

)

BTUs Per Gauge Pressure (psi) NATURAL GAS MODELS (Approximate

High Temperature 20-40hp 15/32" (0.469") Orifice

OPERATING PRESSURE (psi)

1234567

ALL

MODELS

1,597,824 2,266,320 2,770,656 3,195,648 3,573,216 3,919,776 4,234,416

Gau

e Pressure (psi) Required to Maintain Temperature (Approximate

(20-40 hp High Temperature Natural Gas Units Only)

OPERATING PROCEDURE

20-40 hp Units

Fan Static

Model Pressure 60 80 100 120 140 160 180

2" 0.75 1.25 1.75 2.5 3.25 4.25 5.5

20 hp 4" 0.5 1 1.5 2 2.75 3.5 4.5

6" 0.5 0.75 1.25 1.75 2.25 3 3.75

2" 1 1.75 2.25 3.5 4.75 6.25

25 hp 4" 0.75 1.5 2.25 3.25 4 5.25 6.25

6" 0.5 1.25 1.75 2.5 3.25 4.25 5.5

2" 1.25 2 3 4.5 6

30 hp 4" 1 1.75 2.75 3.75 5 7

6" 0.75 1.5 2.25 3 4 5.25 7

2" 1.75 3 4.5 6.25

40 hp 4" 1.5 2.5 4 5.5

6" 1.25 2.25 3.5 4.75 6.75

Heat Rise

21

Page 22

OPERATING PROCEDURE

)

(App

)

p

g

)

(App

)

Lo-Temp Units

BTUs Per Gauge Pressure (psi

PROPANE MODELS

Series 2000 Downwind Heater

roximate

ALL

MODELS

Low Tem

2 4 6 8 10 12 14 15

203,405 287,160 351,771 409,203 457,063 497,744 538,425 555,176

erature All hp 7/64" (0.109") Orifice

OPERATING PRESSURE (psi)

Lo-Temp Units

BTUs Per Gau

NATURAL GAS MODELS

e Pressure (psi

roximate

22

Low Temperature All hp 5/32" (0.156") Orifice

OPERATING PRESSURE (psi)

1234567

ALL

MODELS

177,840 251,712 308,256 355,680 397,632 435,936 470,592

Page 23

Series 2000 Downwind Heater

OPERATING PROCEDURE

Adjusting The Vaporizor

1. Vaporizer should be adjusted so

the vapor pipetrain runs warm

to the touch (100°-120°F).

2. Loosen 5/16" bolt on adjust-

ment bracket.

3. Swivel vaporizer away from

flame if running too hot, closer

to flame if too cold.

4. Move vaporizer only 1" at a time

and allow a few minutes for

tem perature to equalize.

Adjusting the vaporizer coil on a liquid propane model. The top photo

shows the setting in, and the bottom photo shows the coil out.

5. Tighten 5/16" bolt and watch

heater run for several minutes

to verify adjustment.

Running The Dryer

The display will indicate "FLAME"

when flame is sensed. If no flame

is sensed, the "FLAME" message

will be off. The display indicates

what part of the cycle it is in. If the

unit is a hi-lo dryer, the display will

indicate whether it is in the "HI-

FLAME" or "LO-FLAME" part of

the cycle. (See "programming set

points" page 21 for setting the hi-lo

flame temperature). If the tempera-

ture is above the high temperature set-

ting, the flame will be off, the

"FLAME" message will be out and the

display will be flashing "OFF-

CYCLE".

If the flame is shut off because

of the humidity sensor (humidistat),

the display flashes "OFF-CYCLE

HUMIDISTAT".

23

Page 24

OPERATING PROCEDURE

Series 2000 Downwind Heater

The limits are continuously

checked during the drying operation.

A limit switch open or any other er-

ror condition will cause the dryer to

shutdown, and the fan will be shut-

down. If a limit opens, or an er-

ror condition occurs during dry-

ing, the control will lockup in the

error display mode. Power must

be shut off and back on to the con-

trol to clear the error condition--

even if the error or limit that

caused the shutdown has been

corrected. This is to keep the dis-

play locked up with the condition

that caused the error, allowing the

operator time to determine what

caused the shutdown.

Multiple heaters may be done at any heater control console. The informa-

tion programmed is automatically transmitted to all other heaters when the

programming is complete.

Hi Limit Set Point--The upper left cursor is flashing indicating the

mode. If the plenum temperature increases above this point, the flame is

shut off--"OFF-CYCLE" is displayed on screen.

Cycle Set Point--The upper 2nd from left cursor is flashing indicating

the mode. If the dryer is not a hi-lo dryer, this function is skipped. If

the plenum temperature increases above this point, the flame reduces to

"LO-FLAME".

Humidity Set Point--The upper 2nd from right cursor is flashing indi-

cating the mode. If the humidity is above this point the dryer operates

normally--flame on and off at the high limit and cycle set points. If the

humidity is below this point the dryer goes into the "OFF-CYCLE" mode.

Temperature Differential--The upper right cursor is flashing indicating

the mode. If the flame shuts off because the temperature is greater than the

high limit set point, the temperature must fall below the (Set Point minus

Temperature Differential) for the flame to come back on.

Programming Set Points

Depressing the "PROGRAM"

switch (lower left) causes the dis-

play to enter the program mode.

Each item below is programmed by

using the up and down arrow

switches. Holding down these up

and down arrow switches for about

2 seconds will cause the numbers to

increase/decrease rapidly until the

switch is released. When finished

programming an item, depressing

the "PROGRAM" switch again will

cause the new setting to be entered

into memory, and the display will

advance to the next function to be

programmed.

Programming may be done at

anytime (unless an error condition

exists) even while the dryer is in

operation.

Programming a system with

Programming the high-limit set point.

24

Page 25

Series 2000 Downwind Heater

OPERATING PROCEDURE

On hi-lo units when the unit reaches cycle set point, the flame will

switch to lo-flame and unit will not cycle back to hi-flame until (Set

Point minus Temperature Differential) is reached.

Temperature differential would normally be set for 10-15 degrees F

for high temp units, and 2-5 degrees F for lo-temp units.

Humidity Differential--The upper right cursor is flashing indicat-

ing the mode. If the flame shuts off because the humidity set point, the

humidity must rise above the ( Set Point plus Humidity Differential) for

the flame to come back on. (Normally set to 5%)

Programming Hours To Shutdown

To change the hours to shutdown, depress and hold the "SHUTDOWN

HOURS" switch. While holding in on the switch, depress the up and

down arrow switches to alter the

hours. Setting range is 0 to 200

hours.

Drying Grain In The

Hours To Shutdown

Mode

While drying grain, depress and

hold the "SHUTDOWN HOURS"

switch. While holding in on that

switch, depress the "START"

switch. After depressing the start

switch one time, the heater is in the

shutdown mode. Then, the fan and

heater shutdown when the time ex-

pires. This is indicated by the lower

left cursor flashing.

Depressing the start switch

again (while holding in on the

"SHUTDOWN HOURS" switch)

will cause only the heater to shut off.

This leaves the fan on when the time

expires. This is indicated by the 2nd

from lower left cursor flashing. De-

pressing the start switch one more

time returns the heater into the con-

tinuous--non-shutdown mode.

Setting the cycle set point.

Run Hours Display

Run hours are recorded when the

controller detects that the fan is on

(airflow). The hours may be viewed

by depressing the "HOURS" to get

hours and "HOURS X 1000" to get

the number of 1000 hours accumu-

lated.

Multiple Heater Notes

When multiple heaters are con-

nected together, the temperature and

humidity sensors must be connected

to the master.

25

Page 26

OPERATING PROCEDURE

Modulating Valve Operation

Series 2000 Downwind Heater

1. The modulating valve regulates gas flow through

the heater based on sensing unit in the plenum,

and maintains a constant drying air temperature.

2. The sensing bulb of the modulating valve should

be mounted through the bin wall with the side

reading "top" up. The bulb reacts to temperature. It changes the amount of gas (increase or

decrease), burning warmer or cooler depending

on the position of the valve SET POINT. If the

bulb is cooler than it was at the SET POINT, the

bulb senses the cooler temperature and opens

the valve further so more heat is applied to the

drying air. If the bulb is warmer than it was at

the SET POINT, the valve closes further and reduces the temperature until the air is at the valve

SET POINT.

3. It is important that the pressure regulator be set

high enough to allow the modulating valve to

deliver enough gas to maintain the plenum temperature necessary. The regulator is normally

factory set at 15 psi (propane units). To set the

regulator, run the heater and turn the modulat

ing valve T-handle in. This gets full line pressure to the burner. Then adjust regulator to read

15 psi (depending on the plenum temperature

needed).

4. Turn the fan and heater on. To set the modulating valve, turn the T-handle out (counterclockwise)

until loose and wait a few minutes for the plenum temperature to equalize. When the temperature under the bin has equalized, gradually turn

T-handle in (clockwise) about 1/2 turn at a time.

Wait until temperature under bin has equalized as

before. If temperature under bin is less than the

desired temperature, continue turning T-handle

in, increasing gas flow and waiting for plenum

temperature to equalize until the desired temperature is the stable temperature of the ple

num. If temperature under bin is the same 10

minutes after you last made any adjustments

to the T-handle you can be certain that the

temperature under the bin is the SET POINT

of the valve. 1 turn of the T-handle equals

approximately 7 degrees F of temperature.

5. The valve will now keep the plenum temperature at the set point regardless of ambient

conditions as long as humidistat or thermostat

do not shut down the heater. A bypass orifice

is used to maintain a small flame when outside temperature is near or above the set point

of the valve. The bypass insures steady application of heat at minimum gas flow operation.

Bypass orifice will only operate correctly if

pressure regulator is set correctly.

6. To observe how the modulating valve increases

the efficiency of bin drying, check the gas pressure of the unit in the morning and compare to

the pressure read mid-afternoon. If the ambient (outside) temperature is significantly

greater later in the day (as normal), the gas pres

sure will be less. Since less heat is required to

maintain the same temperature in the plenum,

the modulating valve will have reduced the

amount of gas used by the heater.

26

Page 27

Series 2000 Downwind Heater

FACTOR Y CONFIGURATION

Configuration Dip

Switches (Normally Done

At GSI)

These switches are used to config-

ure the heater control for various

types of heaters.

Stand alone heater

with no slaves, all

dip switches in the

off state.

Multiple heaters connected together through the serial link.

Master with one

slave-dip switch 7

on/all others off.

Master with two

slaves-dip switch 8

on/all others off.

Slave #1-dip switch

one and three on/all

others off.

Slave #2-dip switch

two and three on/all

others off.

Master with 3

slaves-dip switch 7

& 8 on/all others

off.

Slave #3-dip switch

one, two and three

on/all others off.

The backside of the control board, showing the dip switch placement.

27

Page 28

ERROR CONDITIONS

Limit Switches

Series 2000 Downwind Heater

The following limit switch errors light up individually on the heaters

LCD screen: PLENUM, HOUSING, VAPOR, TEMP HI LIMIT.

Note: When a shutdown does occur due to an error condition, the amount

of time elapsed since the shutdown can be viewed by pressing the down

arrow switch (up to 218 Hours).

"SLA" on the main display

and the "RX" "TX" symbols will be

flashing.

If a limit switch error or one of

the error numbers 1 through 8

occurs, that error is displayed on

Multiple Heater Error Conditions

If two or more heaters are connected together through the serial link, and the

master cannot communicate with a slave controller, the master will display

the slave where the error origi-

nates. The master displays

"SLA ERROR".

Misc Error Numbers

1 2 3 4 5 6

Temperature

probe 1 open.

7

Temperature

probe 1 short.

8 9 10 11 12

Temperature

probe 2 open.

Temperature

probe 2 short.

Airflow open.

Airflow short.

Illegal flame

sense.

Error 7 is

most likely

caused by stuck

open solenoid.

Error 7 will not

shutdown fan

until loss of

flame is detected

by control.

13

+11 volt DC

shorted to

ground.

The heater

control display

showing error

#7.

Flame probe

short error.

000

This indicates

that one of the

other on screen

errors (vapor,

plenum or

housing temp hilimit or flame out

or no airflow has

occurred).

Slave #1 inconsistent with master with either

the drying grain

flag or the LP

main solenoid or

cycle solenoid.

Most likely

the slave got reset powering up

with the solenoids off.

(Errors 9 through 11 are displayed only if multiple heaters

are tied together through serial link).

Note: Temperature sensor connection-the temperature

sensor (bolt) must always be connected to the master.

Slave #2

inconsistent.

Same as

error 9 for slave

#1.

Slave #3

inconsistent.

Same as

error 9 for slave

#1.

Wrong voltage.

Dip switch

#5 is the voltage

selector switch.

If dip switch #5

in "ON" that selects 240 VAC.

If the unit has

only 120 VAC

applied, error 12

will show up. If

dip switch #5 is

"OFF" that selects 120 VAC. If

the unit has 240

VAC applied error 12 will show

up.

This is important because

if the fan heater

is set up at GSI

for 120 VAC and

the customer

connects to 240

VAC the heater

control will work,

but if allowed to

operate the solenoids will have

240 VAC applied

to them which

will damage solenoids.

28

Page 29

Series 2000 Downwind Heater

HEATER SERVICE

All Airstream heaters are constructed of durable

weather-resistant materials, so a minimum

amount of service should be required; however

before the unit is started for the first time each

season there are a few items that need to be

checked out. All damaged parts should be repaired

or replaced.

1. Disconnect and lock out power to fan and heater.

Open control box lid and inspect all compo-

nents for moisture, vibration or rodent damage.

Inspect and tighten all loose terminal con-

nections. Replace any damaged wiring.

2. Remove burner orifice tube and inspect for dirt

or foreign material. Clean out if necessary.

3. Inspect burner for wear or foreign material in

any of the ports. Clean or replace parts if necessary.

4. Inspect the spark plug and flame probe for cor

rosion and damage. Clean or replace if necessary.

The Series 2000 control box.

29

Page 30

WIRING DIAGRAM

Series 2000 Downwind Heater

30

Page 31

Series 2000 Downwind Heater

______________________________________________________________________________________________________________

_____________________________________________________________________________________________________

__________________________________________________________________________________________________________

______________________________________________________________________________________________________

______________________________________________________________________________________________________

____________________________________________________________________________________________________________

_________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

_____________________________________________________________________________________________________

__________________________________________________________________________________________________________

______________________________________________________________________________________________________

______________________________________________________________________________________________________

NOTES

____________________________________________________________________________________________________________

_________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

_____________________________________________________________________________________________________

__________________________________________________________________________________________________________

______________________________________________________________________________________________________

______________________________________________________________________________________________________

____________________________________________________________________________________________________________

_________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

_____________________________________________________________________________________________________

__________________________________________________________________________________________________________

______________________________________________________________________________________________________

______________________________________________________________________________________________________

____________________________________________________________________________________________________________

_________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________

__________________________________________________________________________________________________________

31

Page 32

WARRANTY

THE GSI GROUP, INC. ("GSI") WARRANTS ALL PRODUCTS MANUFACTURED BY GSI TO BE FREE

OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND CONDITIONS

FOR A PERIOD OF 36 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END USER OF SUCH

PRODUCTS. GSI'S ONLY OBLIGATION IS, AND PURCHASER'S SOLE REMEDY SHALL BE FOR

GSI, TO REPAIR OR REPLACE, AT GSI'S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI'S SOLE

JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP. ALL

DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI'S FACTORY WILL BE PURCHASER'S

RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE PURCHASER WITHOUT

PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED EMPLOYEE OF GSI SHALL BE THE

SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE ABOVE STATED EXPRESS LIMITED WARRANTIES, GSI MAKES NO WARRANTY

OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION

WITH (i) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY ADVICE, INSTRUCTION,

RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR EMPLOYEE

OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUIT-

ABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCT OR PRODUCTS.

Series 2000 Downwind Heater

IN NO EVENT SHALL GSI BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSE-

QUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS

OR BENEFITS. PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO THAT

STATED ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT PUR-

CHASED. THIS WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL

PURCHASER. GSI SHALL HAVE NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTA-

TIVE OR WARRANTIES MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR

OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS OR ERECTION DEFECTS

WHICH CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS. MODIFICATIONS TO THE

PRODUCT NOT SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NUL-

LIFY ANY PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT COVER PRODUCTS OR PARTS WHICH HAVE BEEN

DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY COV-

ERS ONLY PRODUCTS MANUFACTURED BY GSI. THIS WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED. GSI RESERVES THE RIGHT TO MAKE

DESIGN OR SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO RESEARCH AND COM-

PLY WITH ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION

AND INSTALLATION.

32

Page 33

Series 2000 Downwind Heater

33

Page 34

Series 2000 Downwind Heater

34

1004 E. Illinois St.

Assumption, IL 62510

Phone 217-226-4421

Fax 217-226-4498

March 2000

Loading...

Loading...