Page 1

Owner’s Manual

Manual # PNEG-780

5-17-07

BIN STAIRS

& PLATFORM

ASSEMBLY

ASSEMBL Y MANUAL

PNEG-780

Page 2

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

2

Page 3

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Table of Contents

Safety First..............................................................................................3

Positioning Stairs and Platform..........................................................4

Platform Assembly.....................................................................5

Stair- Top Section Assembly............................................................6-8

Step Preassembly.....................................................................7

Step to Horizontal Bar Attachment......................................................7

Tie Strap Attachment..........................................................7

Handrail Post Attachment.............................................................8

Platform to Step Splice............................................................8

4.00” Standard Section.................................................................9

Handrail Installation....................................................................10

Top Handrail.....................................................................10

Intermediate Handrail................................................................10

Table of ContentsTable of Contents

Table of Contents

Table of ContentsTable of Contents

3

Page 4

Safety FirstSafety First

Safety First

Safety FirstSafety First

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

SAFETY FIRST

General Safety Statements

The GSI Group Inc’ s Principal concern is your

safety and the safety of others associated with grain

handling equipment. W e want to keep you as a customer . This manual is to help you understand safe

operating procedures and some problems which may

be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions exist and inform all personnel associated with,

or in the area of the equipment. Safety precautions

may be required from the personnel. Avoid any alteration to the equipment. Such alterations may produce a very dangerous situation, where serious injury

or death may occur.

BE ALERT!

Danger!

Personnel operating or working around electrical

equipment should read this manual. This manual

must be delivered with equipment to its owner.

Failure to read this manual and its safety instructions is a misuse of the equipment.

This product is intended for agricultural use to gain

access to grain bins only. Any other use is a misuse

of the product!

ATTENTION !

SAFETY ALERT

SYMBOL

The symbol shown is used to call your attention to

instructions concerning your personal safety.

W atch for this symbol; as it points out important

safety precautions. It means “ATTENTION,”

WARNING,” “CAUTION,” and “DANGER.”

Read the message that follows and be cautious to

the possibility of personal injury or death.

This product has sharp edges!

These sharp edges may cause serious injury. T o

avoid injury handle sharp edges with caution and

use proper protective clothing and equipment at

all times.

4

Page 5

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Positioning Stairs & Platform

Positioning Stair & PlatformPositioning Stair & Platform

Positioning Stair & Platform

Positioning Stair & PlatformPositioning Stair & Platform

Position the roof ladder and manhole

to allow for platform placement.

Refer to the table on this page to determine where stairs will end. Position the end of the stairs to avoid augers, doors, fans, and control boxes.

Spaces around Bin

4.00” Corrugation

Rings Spaces

414

518

622

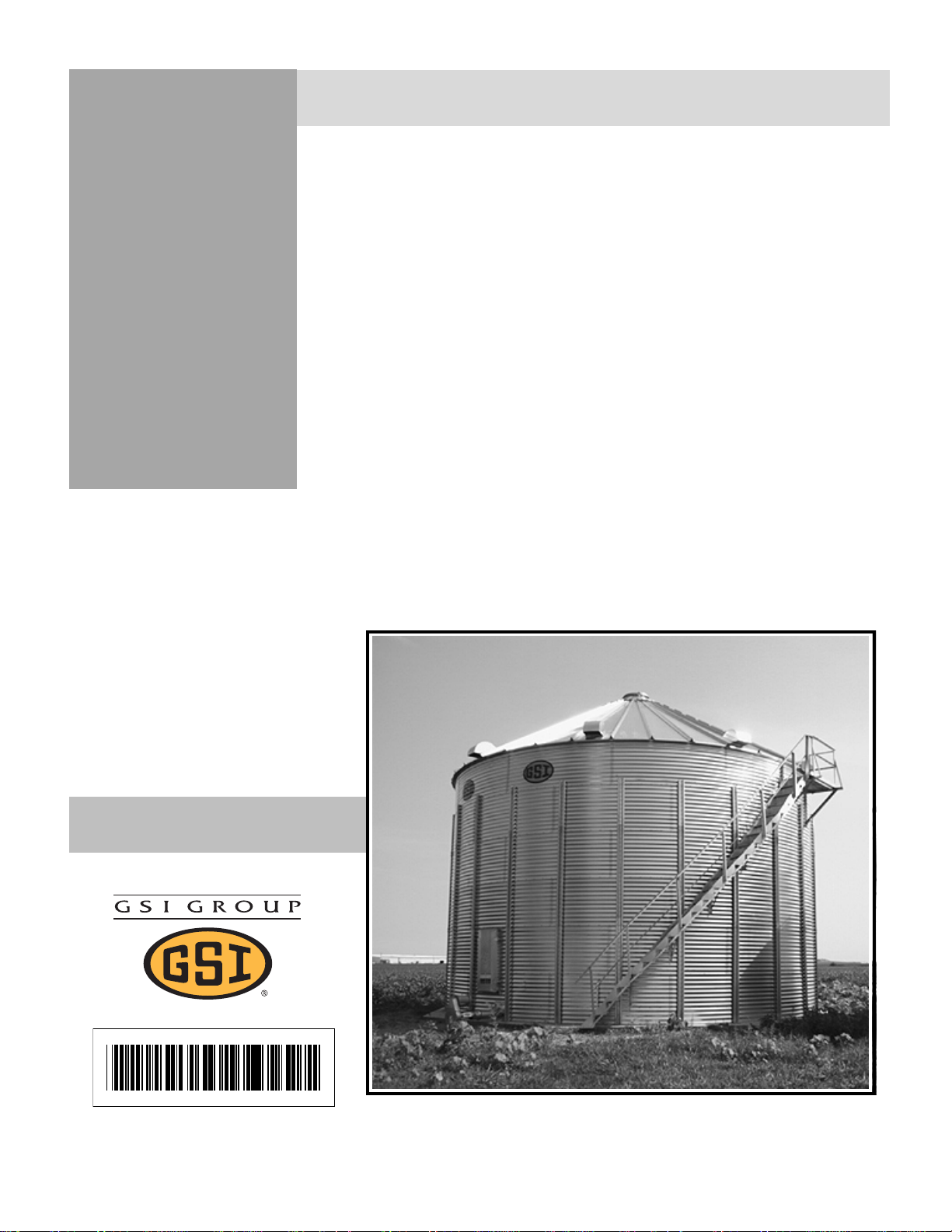

Figure 1: Orientation of Platform in relation to the manhole & roof

ladder.

Note: Stairs may be assembled in either a clockwise or counter

clockwise direction around the Bin. However, clockwise is

recommended.

2”

726

830

934

10 38

11 42

12 46

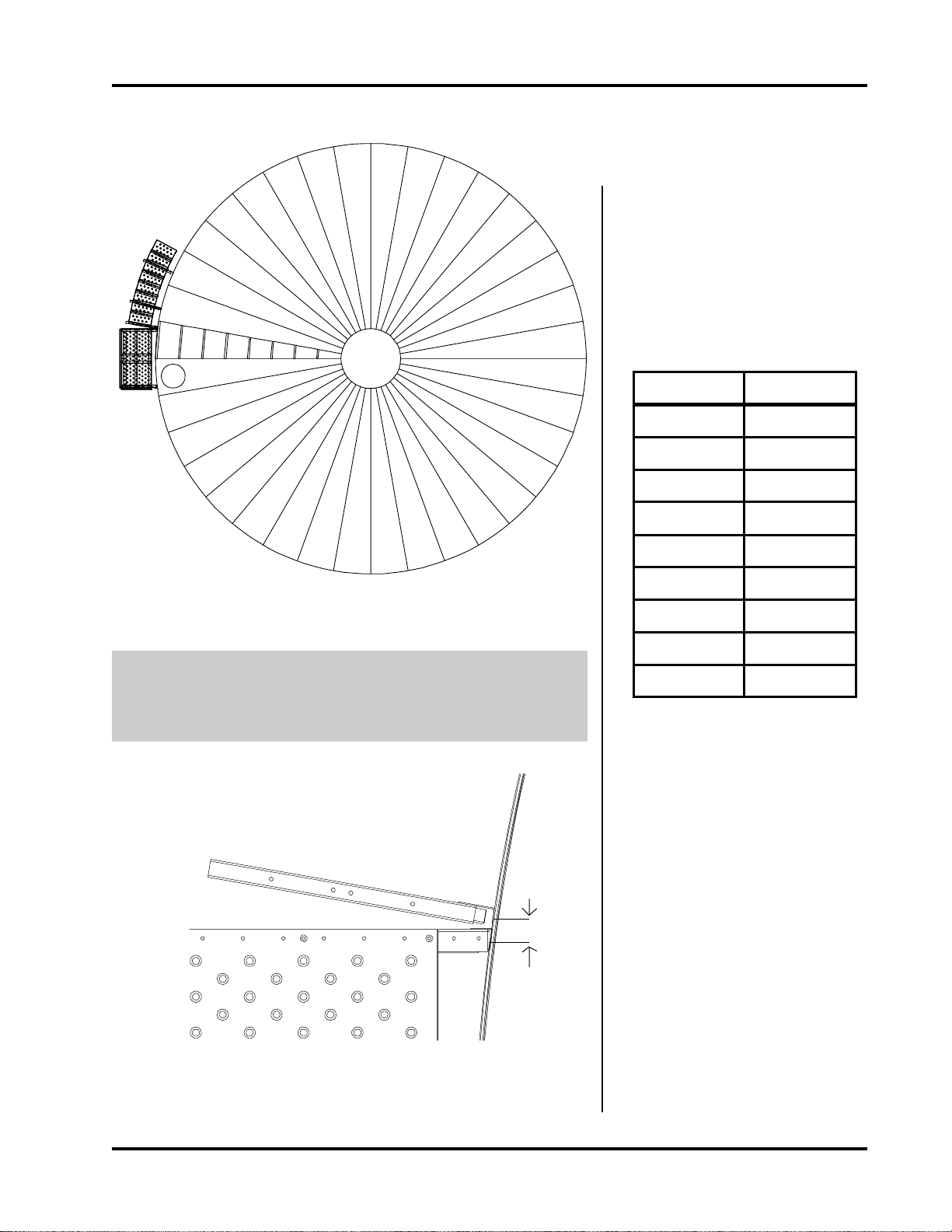

Once you determine the platform location, position the platform wall

bracket 2” from the horizontal seam

bolt where the stairs will begin. Field

drill the bolt hole on the horizontal

seam and 4-5 more from top to bottom on the wall bracket and secure.

Use 5/16” x 1 1/4” bolt to attach wall

bracket.

Firgure 2: Bracket Distance from Step Bracket.

Note: The top of the wall bracket

should line up with the corrugation at the eave.

5

Page 6

Platform AssemblyPlatform Assembly

Platform Assembly

Platform AssemblyPlatform Assembly

Platform Assembly

When attaching the sidewall access platform to the

tank wall, vertical wall brackets need to be mounted

to the bin wall with 5/16” x 3/4” bin bolts (see Fig.

3). To insure the proper placement of the second

wall bracket, preassemble platform support (see Fig.

4) and mark the hole positions for drilling. Field drill

and assemble the platform support with 5/16” truss

head bolts. Now , proceed to the platform floor and

floor splice. Align holes on platform floor with the

holes on platform supports and bolt together using

5/16” x 3/4” truss head bolts and nuts. Be sure and

attach platform toe plate at the same time you attach

the platform floor (see Fig.6).

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Figure 3: Wall Brackets to Bin W all.

(2) Wall Bracket

LDR-4092

LS-6623 (2)

Platform Support

TDP-5005 (Lt Blue/Black)

Floor Brace (3)

Diagonal Support Angle (2)

LDR-4142

Figure 4: Platform Support Assembly

TDP-5002 (Pink/Black)

30” Hand Rail

TDP-5000 (Brown)

59” Hand Rail

TDP-5011

Platform

Toe Plate

TDP-5010 Platform

Splice Plate

TDP-5006

Platform Floor

Figure 5: Platform Assembly

6

Page 7

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Stair - Top Section Assembly

LDR-4092

Wall Bracket

(I) LDR-4082

Stair Wall Bracket

(II)LDR-4083

Horizontal Bar

Bracket

(III) LDR-4084

Knee Brace

Stair - Top Section AssemblyStair - Top Section Assembly

Stair - Top Section Assembly

Stair - Top Section AssemblyStair - Top Section Assembly

LDR-4142

Diagonal Support Angle

Figure 6: Stair - T op Section Assembly

I. The stair wall bracket (LDR-4082) should be

placed on a horizontal seam and bolted vertically .

The vertical location must be field drilled to match

up with platform location. Use 5/16” x 1 1/4”

bolt to secure LDR-4082 to the sidewall. Field

drill 3 more holes and attach the bracket.

II. Using the two end holes of horizontal step bracket

attach it to LDR-4082 with (2) 3/8” x 1”flanged

head bolts and nuts.

III. Using the same bolts and nuts as step II connect

the knee brace (LDR-4084) to LDR-4083 and

LDR-4082.

IV . Continue to raise bin adding sidewall sheets until

the top hole of the next sidewall bracket can be

attached to a horizontal seam. Each step will

cover 9 3/8” on the horizontal seam. Two steps

will be added before the next brace assembly can

be mounted. There should be a distance of 18 3/

4” along the horizontal seam between brackets.

Fasten the lower end of the bracket to the seam

with a seam bolt. You will need to field drill

extra holes (2) as needed to finish fastening

the bracket to the seam. (Use 5/16” x 1 1/4”

Bin Bolts).

V. Complete the second wall support assembly as

previously instructed in step II and III

7

Page 8

Stair Top Section AssemblyStair Top Section Assembly

Stair Top Section Assembly

Stair Top Section AssemblyStair Top Section Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Step Preassembly

Figure 7: Step Assembly

LDR-4079 -- Step

LDR-4080 -- Right End

LDR-4081 -- Left End

Preassemble ends to step with 5/16” truss head bolts.

Put all bolts in the bottom of the step and install the

bottom two bolts on the back of the step and tighten.

Step to Horizontal Bar Attachment

Attach step assembly to the top horizontal bracket

with two 5/16” x 3/4” T russ head bolts. Use the outer

set of holes in the horizontal bracket. Attach another

step to the lower horizontal bracket. Maneuver the

next step in between the others and attach the top

side tabs to the outside of the upper steps with truss

head bolts see Figure 8. Attach lower step tabs in

the same manner.

Tie Strap Attachment

Attach the steps to each other with the tie straps (LDR-

4090). Use 5/16 x 3/4” truss head bolts and nuts to

attach the strap to the holes provided on the ends of

the step. Align the step slots and level the steps before tightening. The steps will align to curvature and

wall brackets. When all the parts of the top section

are in place tighten all the bolts.

5/16” x 3/4”

Truss head

bolt and nut

Figure 9: Brace Strap Connection

Attachment

Tab

Tie Strap

(LDR-4090)

T op S tair Assembly

5/16 x 3/4” Truss head bolts

Horizontal

Bracket

Figure 8: Horizontal Bracket to Step

8

Figure 10: T op Stair Assembly

Page 9

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Handrail Post Attachment

Handrail Post

(LDR-4085)

(2) 3/8” x 1” Flange

head bolts and nuts.

Stair - Top Section AssemblyStair - Top Section Assembly

Stair - Top Section Assembly

Stair - Top Section AssemblyStair - Top Section Assembly

The handrail post (LDR-4085) connects

to the end of the horizontal wall bracket

with (2) 3/8” x 1” Flange head bolts and

nuts. Tighten the bolts and move on to the

next section. The handrail will be installed

after all stair sections are on the tank. (See

figure 10 on page 7 for a detailed drawing

of the first few steps and the hand railing.)

Figure 11: Handrail Post Connection

Cut out notches to fit

around handrail posts.

Platform to Step Splice

Platform Splice

TDP-5010

Use platform splice (TDP-5010) to cover

the gap between the platform and the stair

section. Since the gap changes with bin

diameter, field drilling and cutting are required for proper placement of the splice.

The attachment tabs on the top of the step

may need to be trimmed to allow fit (refer

to figure 9 on page 7). The splice will also

need to be notched to fit around the handrail post. Secure to the step and platform

with truss head bolts and nuts.

Figure 12: Platform Stair Splice Connection

9

Page 10

4.00” Standard Section4.00” Standard Section

4.00” Standard Section

4.00” Standard Section4.00” Standard Section

4.00” Standard Section

Continue raising the bin until the next wall

bracket can be attached to the wall 3

spaces (2.66” Corrugation) or 4 spaces

(4.00” Corrugation) along the horizontal

seam. Bolt the rest of the assembly in place

and field drill to secure. Place a step over

the wall bracket and secure. Hang the three

steps between brackets to finish the section. Align steps level with tie straps and

tighten section. Add the handrail post and

continue adding sections.

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

4.00” Corrugation

Standard Section

The bottom wall bracket will need to be

field drilled in order to attach the last horizontal bracket. The top of the horizontal

bracket should be a distance of 11” up

from the base of the tank. Attach the bottom step as previously directed. The front

lip of the bottom step may need to be

trimmed off to allow fitup. Add the two

other steps, level and tighten all bolts and

tie straps. Install the bottom handrail post.

Figure 13: 4.00” Corrugation Standard Section

Bottom Section

Wall Bracket to

Horizontal Bracket

Attachment

A distance of 11” must be measured

from the top of the horizontal bracket

to the base of the tank.

10

Figure 14: Last Step

Page 11

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Handrail Installation

5/16” x 1 1/4”

Bolt and Nut

Handrail InstallationHandrail Installation

Handrail Installation

Handrail InstallationHandrail Installation

T op Handrail Installation

Start at the top handrail post and align the

bottom slot with the second post, mark

top post location. T rim off the narrow end

and drill for top connection. Connect with

5/16” x 1 1/4” bolt and nut. Slide the next

narrow end into the upper wide end of the

next rail. Align the slots and attach to post

with 5/16” x 1 1/4” bolt.

Note: Keep post plumb as you tighten

the bolt.

Figure15a: Handrail Connection

5/16” x 1 1/4”

Bolt and Nut

Figure15b: Handrail Connection

Continue down the stairs installing handrail sections. Extra force maybe needed

to curve the handrail for attachment to the

post. W ith smaller diameter tanks the bottom section of the handrail will require a

field drilled hole for the attachment to the

last post.

ATTENTION!

P A Y CLOSE A TTENTION

TO SHARP EDGES AND

GRIND SMOOTH ANY SHARP

POINTS. SHARP EDGES CAN

CAUSE SERIOUS INJURY!

5/16” x 1 1/4”

bin bolt and nut

Figure 16: Intermediate Handrail

Intermediate Handrail

After installing top handrail bolt the intermediate handrail in place. The handrail

section consists of a large tube and a small

telescoping tube. The large tube is located

on top. Bolt the rail in place with a 5/16”

x 1 1/4” bin bolt and nut. Continue up the

steps adding the handrail. The top middle

handrail section will need to be shortened

to fit and to complete the installation.

11

Page 12

NOTES

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

12

Page 13

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

Bin Stairs and Platform Assembly

Bin Stairs and Platform AssemblyBin Stairs and Platform Assembly

WarrantyWarranty

Warranty

WarrantyWarranty

The GSI Group, Inc. Warranty

THE GSI GROUP, INC. (“GSI”) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END

USER. THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE TO

REPAIR OR REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S SOLE

JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP.

ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI’S FACTORY WILL BE

PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE

PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED

EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR

USE IN CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE,

OR DESIGN OF SUCH PRODUCTS.

GSI SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED

PROFITS OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY IS AS SET FORTH

IN THE LIMITED WARRANTY EXPRESSED ABOVE, WHICH SHALL NOT EXCEED THE

AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE

NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIONS OR WARRANTIES

MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION DEFECTS

OR UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT MANUFACTURED.

MODIFICATIONS TO PRODUCTS NOT SPECIFICALLY DELINEATED IN THE MANUAL

ACCOMPANYING THE EQUIPMENT AT INITIAL SALE WILL NULLIFY THE PRODUCT

WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH

HAVE BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS

WARRANTY EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR

IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT

ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH

ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

13

Page 14

1004 E. Illinois St.

P.O. Box 20

Assumption, Il. 62510-0020

Phone: 217.226.4421

Fax: 217.226.4420

e-mail: gsi@grainsystems.com

internet: http://www .grainsystems.com

Loading...

Loading...