Page 1

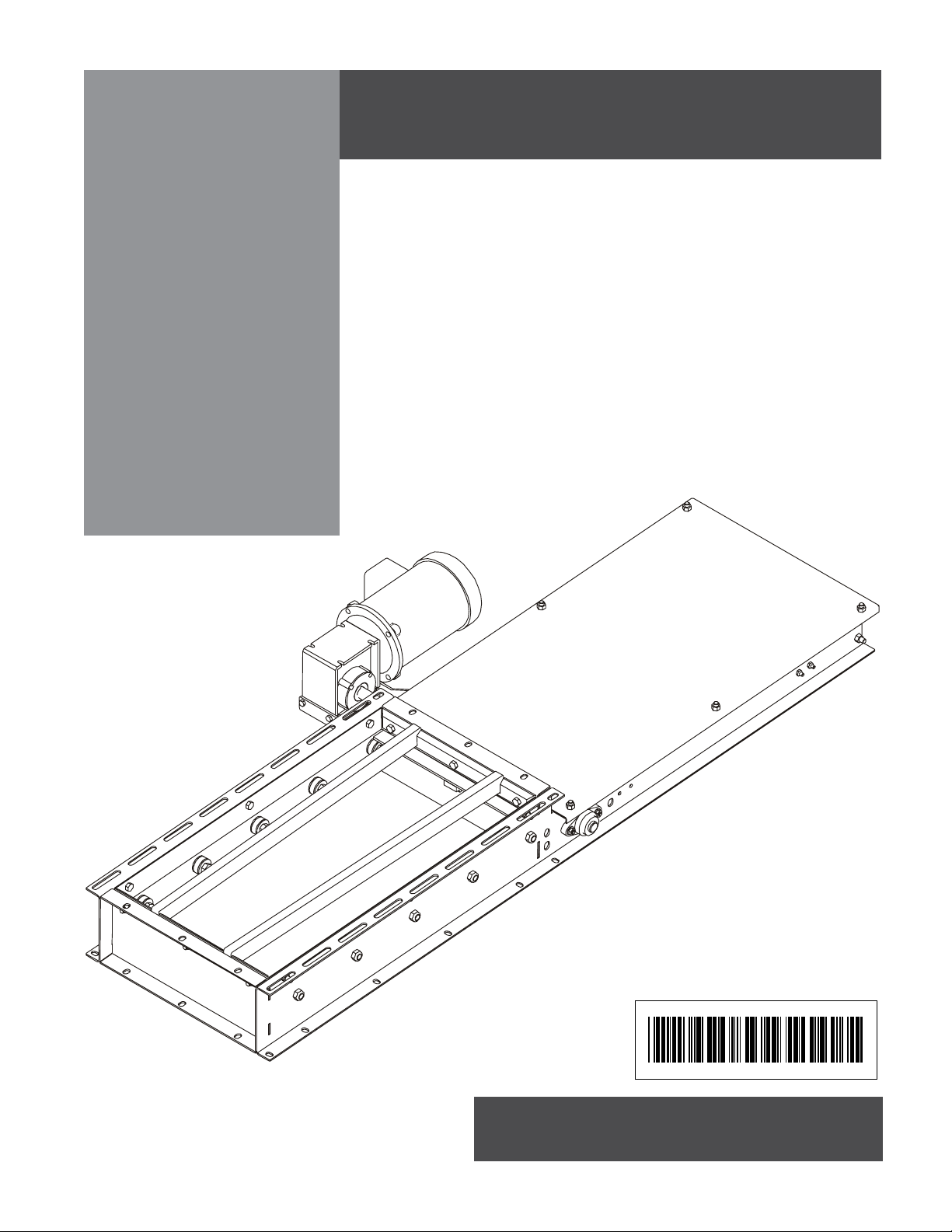

In-line Intermediate

Discharge Gates

Installation Manual

PNEG-765

Date: 9-2-05

PNEG-765

Page 2

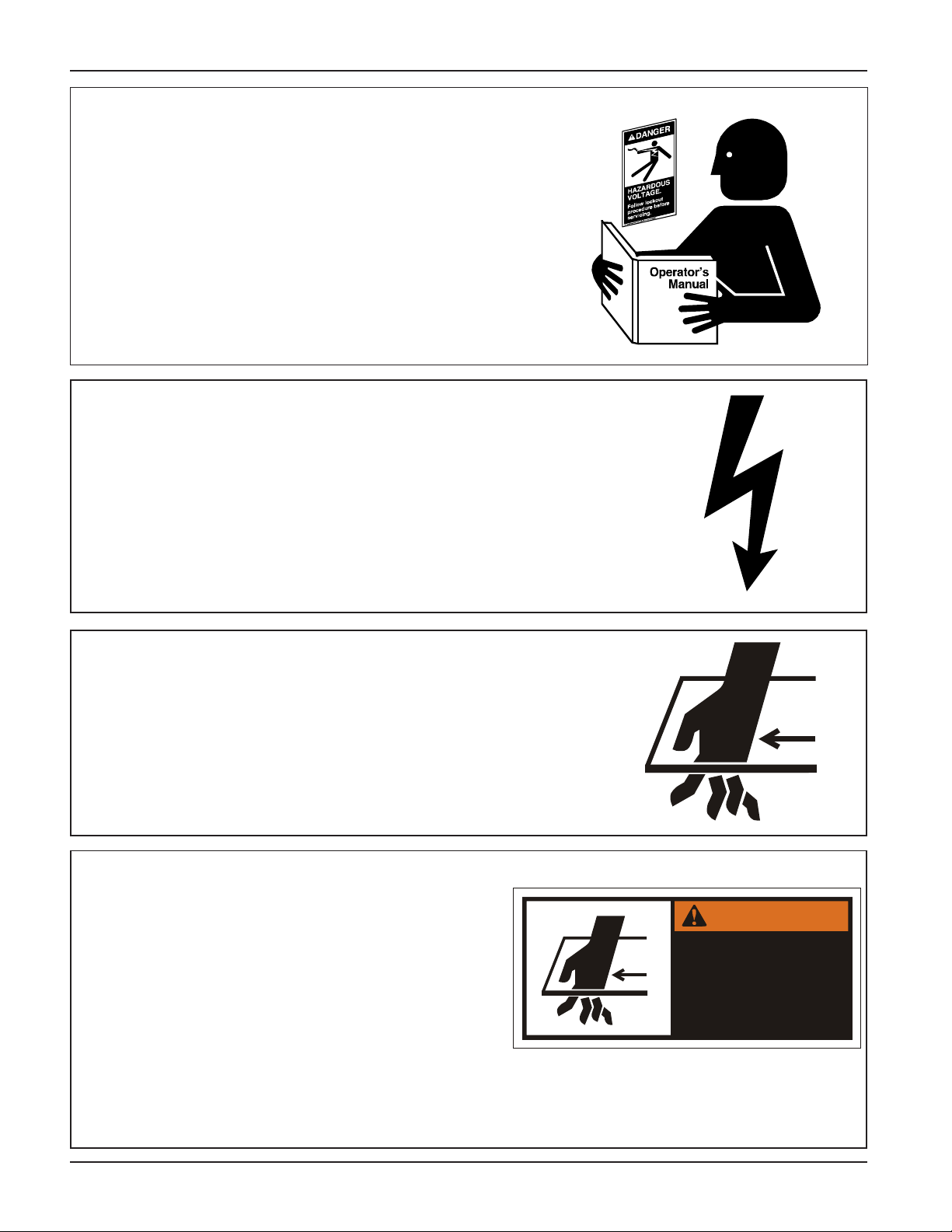

SAFETY

FOLLOW SAFETY INSTRUCTIONS

Learn how to operate the machine and how to use controls properly . Do not let anyone operate without instruction.

Keep your machinery in proper working condition. Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

If you do not understand any part of this manual and need

assistance, contact your dealer.

INSTALL & OPERATE ELECTRICAL

EQUIPMENT PROPERLY

Electrical controls should be installed by a qualified

electrician and must meet the standards set by the

national electrical code and all local and state

codes.

Electric Shock

Hazard

Disconnect and lock out all power sources before

installing wires/cables or servicing equipment .

STAY CLEAR OF MOVING PARTS

Keep arms and hands away from slide gate opening.

Slide Gate can crush and dismember. Motor may

start at any time.

Always stop and lock out power source before making adjustments, cleaning, or maintaining equipment.

DECALS

Please remember, safety decals provide important

safety information for people working near equipment that is in operation. If a safety sign cannot be

easily read for any reason or has been painted

over , replace it immediately . Additional Safety signs

may be obtained from your dealer, distributor , or

ordered from the factory free of charge.

Crush

Hazard

WARNING

Moving side plate.

Auto equipment can

start at any time.

Disconnect and lockout

before servicing.

DC-1248

CONT ACT : The GSI Group

1004 E. Illinois St.

Decal #: DC-1248

(Not to scale.)

Assumption, IL 62510

217-226-4421

2 PNEG-765 Gate Manual

Page 3

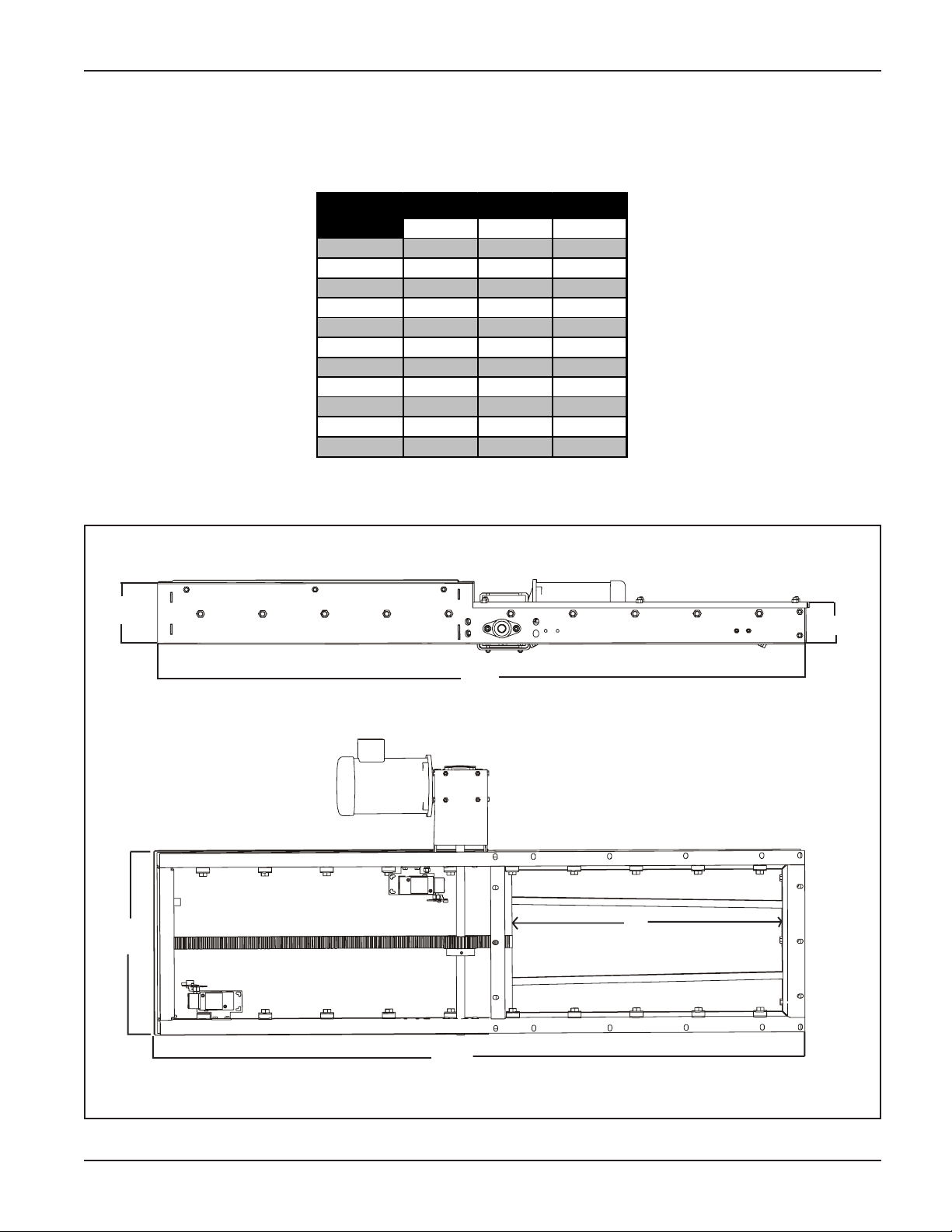

OVERALL GATE DIMENSIONS

Overall Gate Dimensions

Conv. Size

0912

1212

1612

1214

1614

2114

1420

1620

2020

2620

3220

ABC

9.00 30.00

12.00 30.00

16.00 30.00

12.00 30.00

16.00 30.00

21.00 30.00

14.00 36.00

16.00 36.00

20.00 36.00

26.00 36.00

32.00 36.00 81.125

68.125

68.125

68.125

68.125

68.125

68.125

81.125

81.125

81.125

81.125

6.50"

A

4.31"

C

B

C

Overall Gate Dimensions

3PNEG-765 Gate Manual

Page 4

Cut Out Discharge Hole in Trough Bottom

1. T o find where to cut hole in trough bottom, start by locating the center of the purposed discharge.

Dimension “A”. (Refer to Figure 1.)

2. When locating discharges try to position opening so that gate flange hole pattern and conveyor

hole pattern lineup. The gate has slotted holes to allow for adjustment to nearest 1".

3. If this cannot be achieved then holes must be drilled on site.

4. Find dimensions “B” and “C” corresponding to your conveyor size. Use “D” dimensions as a

reference. (See Figure 1 and chart below.)

5. Mark the cut out from outside the conveyor on the trough bottom.

6. Cut opening into the bottom being careful not to damage other components of the Conveyor .

Remove all burrs and rough edges from the opening.

Trough Hole Dim ensi ons

Conv. S i ze

0912

1212

1612

1214

1614

2114

1420

1620

2020

2620

3220

2626

3226

3232

3632

BCD

9.00 30.125

12.00 30.125

16.00 30.125

12.00 30.125

16.00 30.125

21.00 30.125

14.00 36.125

16.00 36.125

20.00 36.125

26.00 36.125

32.00 36.125

26.00 36.125 2.00

32.00 36.125 2.00

32.00 36.125 2.00

36.00 36.125 2.00

1.50

1.50

1.50

1.50

1.50

1.50

2.00

2.00

2.00

2.00

2.00

D

Conveyor

Bottom

C

B

Figure 1

A

4 PNEG-765 Gate Manual

Page 5

Manual Gate Installation

Manually Operated Gate

1. Install the specified wheel to the shaft by aligning the key and key way , then tighten the set

screw. This gate can be operated by a chain, cable, or hand wheel.

2. Manual gates up to 16" wide are fitted with a single rack. Manual gates larger than 16" wide

have a double rack.

3. The slide gate plate rides on 1-3/8" double shielded radial bearings for smooth operation.

Hand Wheel

Key

Shaft

Figure 2

Gate Frame

5PNEG-765 Gate Manual

Page 6

Motor Driven Gate Installation

Install Motor Bracket

1. Install the motor bracket to the gate. Then

attach the motor to the bracket as shown

in Figure 3, using the provided hardware.

Install Limit Switch

1. Using limit switches that are available in

Nema 4 or explosion proof standards,

achieves accurate positioning of these

gates. Limit Switches are located on both

sides of the frame to detect when the gate

is totally open or closed.

2. Attach the switch brackets to the inside of

the gate as shown using hardware

provided. (See Figure 4.) Att ach limit

switch to the bracket as shown. (See

Figure 5.)

3. After switches are securely fastened.

Adjust lever arms so they come in contact

with tripper blocks on underneath side of

slide plate.

4. Disconnect the power at the electrical

panel, run the proper gauge electrical wire

to the motors and limit switches. (See

Wiring Diagram on page 9.) Be sure that

the limit switches are adjusted

properly before operating the gate!

Turn the power back on and CAUTIOUSL Y

operate the gate, opening and closing the

gate slide, making the necessary

adjustments to the limit switch arms to

assure complete opening and closing of

the gate.

5. Motor driven gates are available in both

TEFC and explosion proof configurations.

Motor

Bracket

Limit

Switch

Switch

Bracket

Motor

Shaft

Key

Keyway

Figure 3

Figure 4

Switch

Bracket

Figure 5

6 PNEG-765 Gate Manual

Page 7

Side View with side

removed for clarity .

Figure 6

Tripper Block

Actuator Arm

Limit Switch

Cover

Slide Gate

Tripper Block

EXPLODED VIEW shown

without side for clarity .

Slide Gate

GATE CLOSED POSITION

shown without side for clarity .

GATE OPENED POSITION

shown without side for clarity .

Actuator

Arm

Limit

Switch

Tripper Block

Actuator Arm

Slide Gate

Actuator Arm

Figure 7

Figure 8

Tripper Block

Figure 9

7PNEG-765 Gate Manual

Page 8

Install Gate Frame to Trough

1. Assemble the gate frame to the bottom of the trough section using the existing hardware in

the trough bottom.

2. Adjust the carry over bars flush to the bottom of your conveyor . (Note: Failure to adjust carry

over bars properly will cause severe damage to chain and/or gate.

3. It is preferred that the gate is oriented so it closes towards the head section.

Trough Section

Gate Assembly

Carry Over Bars

Figure 10

8 PNEG-765 Gate Manual

Page 9

Typical Wiring Diagram

OPEN

CLOSE

STOP

1

1

O

N.C.

C

N.C.

2

2

4

6

3

7

5

2

1

G

N

I

S

R

E

V

E

R

R

E

T

R

A

T

S

L1

L2

L3

T1

T2

T3

M

Remove internal jumpers 3 to 6, 5 to 7.

O

C

Open position switch.

Closed position switch.

Break for momentary operation.

9PNEG-765 Gate Manual

Page 10

Copyright © 2005 by The GSI Group

Printed in the USA

The GSI Group

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

Loading...

Loading...