Page 1

PNEG-751-G2

12" Series II Sweep

131' and 135' Diameter

Owner ’s Manual

PNEG-751-G2

Version: 1.0

Date: 11-22-11

Page 2

Model Number of My Sweep:

__________________________________

Date Delivered:

__________________________________

Date Installed:

__________________________________

NOTE: The manufacturer reserves the right to improve its product whenever possible and practical to

do so. We reserve the right to change, improve and modify products at any time without

obligation to make changes, improvements and modifications on equipment sold previously.

Personnel operating or working around this equipment should read this manual. This manual

must be delivered with equipment to its owner. Failure to read this manual and its safety

instructions is a misuse of the equipment. Any misuse of the equipment may void the warranty.

2 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................5

Product Introduction .............................................................................................................................. 5

Chapter 2 Safety .....................................................................................................................................................7

Safety Guidelines .................................................................................................................................. 7

Safety Instructions ..................... ... .... .......................................... ... ... ..................................................... 8

Operator Qualifications ....................................................................................... .... ... ... ... ................... 12

Chapter 3 Safety Decals ......................................................................................................................................13

Chapter 4 General Product Information ............................... ....................... ...................... .................................17

Product Information ............................................................................................................................. 17

General Information ............................................................................................................................ 17

Capacities and Specifications ............................................................................................................. 18

Q-D Bushings - Reverse Mounting ..................................................................................................... 21

Chapter 5 Assembly ............................................................................................................................................23

Back Shield Assembly ......................... ... ... ... .... ... ... ... .... ... .......................................... ... ... ... ................ 23

Flighting Assembly .............................................................................................................................. 24

Hanger Bracket Assembly ...................... ... ... .... ... .......................................... ... ... .... ... ... ... ................... 25

Flange Bearing Assembly ...................... ... ... .... ... ... ... .... ... .......................................... ... ... ... ................ 26

Gear Reducer Assembly ............................................... ... ... .......................................... ... ... ................ 26

Drive Axle Assembly and Bearing Support ......................................................................................... 27

Install Reducer Mounting Plate and Reducer ...................................................................................... 29

Key Alignment ..................................................................................................................................... 30

Install Tractor Drive Motor ................................................................................................................... 31

Guard Assembly .................................................................................................................................. 32

Tractor Wheel Assembly ..................................................................................................................... 34

Weight Placement ............................................... ... ... .......................................... .... ... ... ...................... 35

Channel Extension Kit ............................... ... .... ... ... ... .... ... ... ... .... ... ... ................................................... 36

Motor Jack and Base Assembly .......................................................................................................... 37

Motor Installation ................................................................................................................................. 38

Sheave Installation .............................................................................................................................. 39

Electrical Assembly ............................................................................................................................. 42

Jack Support Assembly ....................................................................................................................... 46

Center Pivot Installation ...................................................................................................................... 48

Control Panel Setup ............................................................................................................................ 51

Calibration ........................................................................................................................................... 56

Operation ............................................................................................................................................ 57

Chapter 6 Start-Up ...............................................................................................................................................58

Perform Pre-Start Checks ......................................... .... .......................................... ... ... ... ................... 58

Start the Auger .................................................................................................................................... 59

Chapter 7 Operation ............................................................................................................................................60

Operating the Sweep Auger ............................................................................. ... .... ... ... ... ... .... . ........... 60

Operating the Sweep Auger Control Panel ......................................................................................... 61

Chapter 8 Shut Down ...........................................................................................................................................62

Normal Shut Down .............................................................................................................................. 62

Emergency Shut Down .................................................... ... ... .... ... ... ... ... .... ... ... ................................... 62

Storage Preparation .................................................. .... .......................................... ... ... ... ..

Chapter 9 Maintenance ........................................................................................................................................63

Maintain the Auger .............................................................................................................................. 63

Lubrication .............................. ............. ............. ............. ............. ............ ............. ................................ 64

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 3

................. 62

Page 4

Table of Contents

Chapter 10 Control Panel Diagrams ...................................................................................................................69

Control Panel Schematic (460/3/60) Pre-June 2010 ......................................................................... 69

Grain Sweep Schematic Post-June 2010 (S2PFA) ........................................................................... 70

Grain Sweep Schematic Post-June 2010 (S2PFB) ........................................................................... 71

Grain Sweep Schematic Post-June 2010 (S2PFC) ........................................................................... 72

Chapter 11 Troubleshooting ...............................................................................................................................73

FAQs ................................................................................................................................................. 74

Chapter 12 Parts List ...........................................................................................................................................81

Main Auger Components .................... ... ... ... .......................................... .... ... ... ... .... ... ... ... ... ............... 82

Flight Components ............................................................................................................................ 84

End Bearing Components ................................................................................................................. 85

Auger Drive Components .................................................................................................................. 86

Drive Assembly .................................................................................................................................. 88

Tractor Chain Guard Parts ................................................................................................................ 90

Motor Mount Jack and Base Assembly (GC09993) .......................................................................... 91

Jack Supports .................................................................................................................................... 92

Control Panel Components (S2PFA) ........... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ........................................ 94

Control Panel Components Post-June 2010 (S2PFA) ................................. ... ... .... ... ... ... ... .... ... ... ... .. 96

Control Panel Components Post-June 2010 (S2PFB) ................................. ... ... .... ... ... ... ... .... ... ... ... .. 98

Control Panel Components Post-June 2010 (S2PFC) ................................................................. ... 100

Weight Extension Kit (GC12311) . .... ... ... ... .......................................... ... .... ... ... ... .... ......................... 102

Chapter 13 Warranty ..........................................................................................................................................103

4 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 5

1. Introduction

Product Introduction

Congratulations. Your selection of the GSI Series II Sweep is a wise investment. It will give you years of

dependable service. The main function of the Series II Sweep is to clean out the remaining grain, from the

bin, after all gravity unloading has finished. The GSI Series II Sweep is a single pass sweep only. The unit

will only operate in a round grain bin equipped with a center sump in the bin floor. NOTE: The bin

manufacturer should be contacted for their recommendations on your bin’s structural integrity. The

following are sweep criteria recommendations.

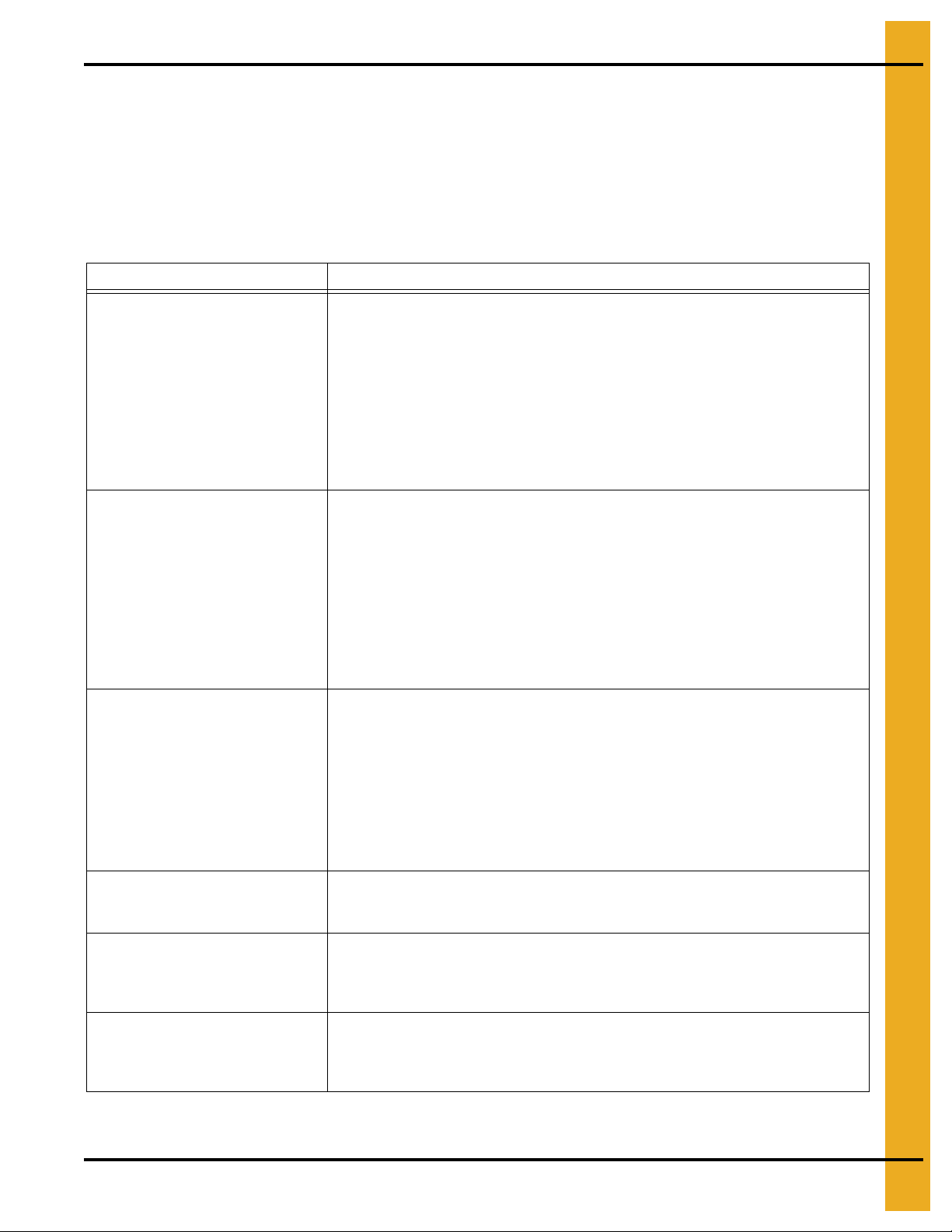

Issues Recommendations

A track is required under each of the sweep tires and jack wheels where they travel

over the aeration (steel) floor. This is the case for all steel flooring including full floor

and flush floor aeration. The track should be a minimum of 10 gauge thick and made

from steel. The steel can be galvanized for the jack wheel paths but needs to have a

non-slip coating for the drive tire paths. The drive tire track coating must not be course

Flooring.

enough to damage the drive tires. A Chart on Page 17 is included that shows radius

dimensions locating the points of contact between the sweep and the bin floor. The

dimensions may be used to figure the material quantities of track to support the sweep

across the aeration flooring. The track material is not supplied with the sweep and

must be supplied by the installer or purchased from GSI. The dimensions are

approximate and the assembled sweep should be checked for exact points of contact.

Center sump size.

Number of intermediate sumps.

Routing the power supply to

the sweep.

Floor level tolerance.

If installing a sump with collector ring, the opening will be 42" x 42" for 12" sweep size.

The sump hopper supplied by GSI was designed with sufficient clearance around

the collector ring housing to allow grain to gravity flow through the hopper and be

carried away by the material handling equipment below. 42-3/4" is the maximum

opening size to allow rolling clearance for the casters assembled to the head end jack.

If made smaller, grain flow may be decreased to an unacceptable level.

**Flow of grain is limited to 15000 BPH when using this sump and collector ring

housing assembly. The collector ring housing extends 22-1/2" down from the floor

surface and is approximately 14-1/4" x 14-1/4" in size.

Intermediate sump pumps must be installed on a maximum of 10' centers where the

sweep will be parked during storage. The first intermediate sump should be placed at

a maximum of 10' from the center sumps and the end sump should be no more than

4' from the bin wall.

The extra sumps will help clean out the grain in front of the sweep, reducing the

start-up load. Doing this will save labor dollars and hours of work to dig out the sweep

and will help the sweep during start-up. The sweep is not designed to start-up when

submerged in material. The sweep should be parked behind the intermediate sumps

with sumps on the auger side of the sweep.

The only option is to use the hopper sump with collector ring. This allows the power

to be transferred through a mechanical device in the center sump and does not twist

any cords.

The top edge of the sump hopper and the top edge of the “X” brace support must be

level with the floor. The floor must be level within 3/4" plus (or) minus, preferably less.

Any high or low points must be gradually sloped. The change in elevation should be

no more than 3/4" over 60".

Diameter tolerances are limited by foundation limits and sweep operation as well as

Bin roundness tolerance.

structural issues. For 72' diameter and larger, the overall tolerance would be plus or

minus 1-1/4" on the radius, plus or minus 1" on 42'-66' diameter bins and plus or

minus 3/4" on 30'-39' bins.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 5

Page 6

1. Introduction

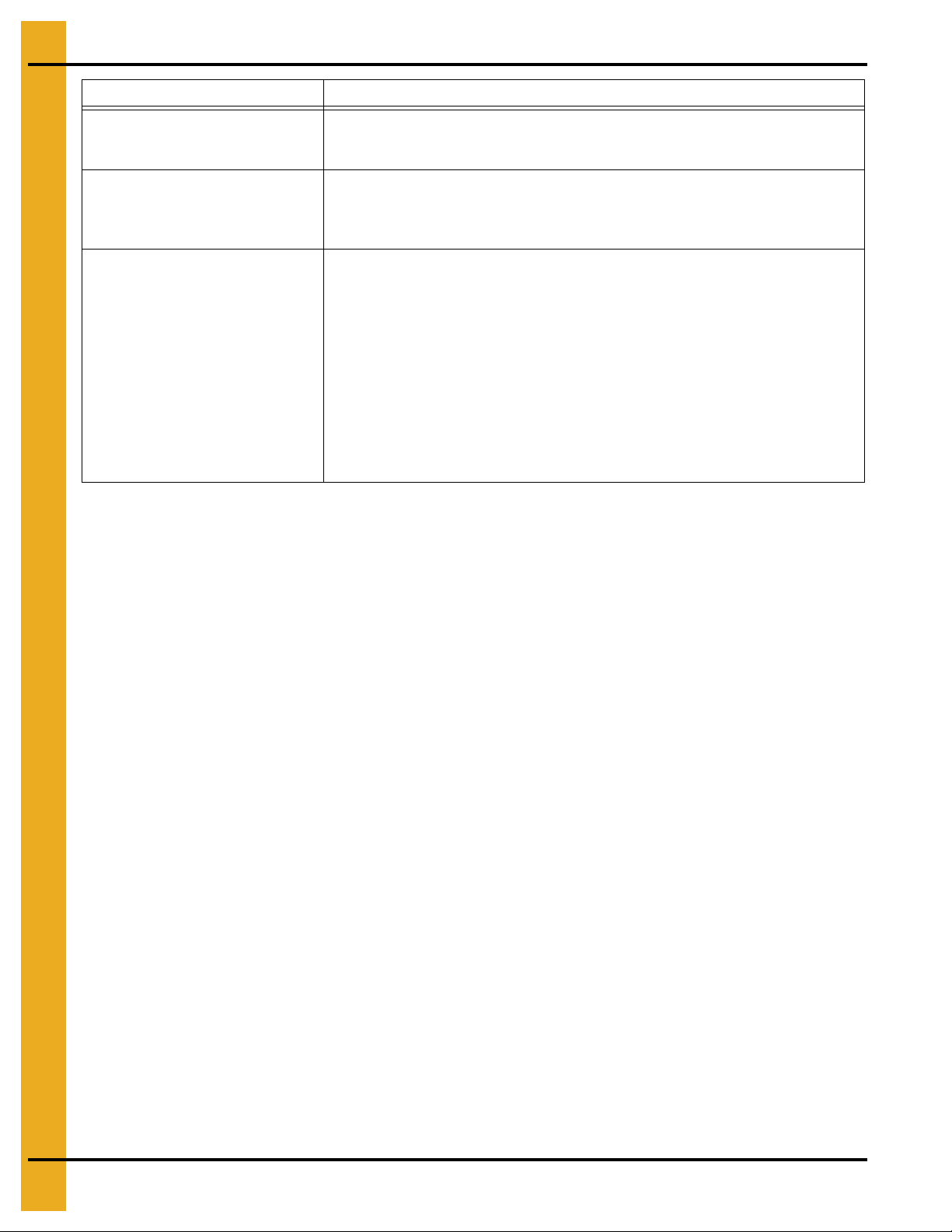

Issues Recommendations

Bin opening size required

for installation.

Vo ltage specification.

Electrical requirements.

The tail section is the largest piece of a standard Series II Sweep. The dimensions for a

12" tail section are 21-1/4" x 51-1/2". If the bin wall is not too thick, this unit should fit

through a 21-1/2" x 45" opening.

The Series II Sweep is designed to operate using 460 volt 3 phase 60 cycle power.

The voltage must be within plus or minus 4% for proper operation. Volt ages outside

of this range may cause excessive power draw or other operating problems. Please

contact the factory for applications outside of these parameters.

Electrical controls and wiring should be installed by a qualified electrician. The

conductor cables should comply with the National Electric Code and any local codes

which may apply.

Disconnect and lock out the power before servicing the equipment, entering the bin

or resetting the motor overloads.

The control panel MUST be mounted OUTSIDE the bin near the door. It must be

located so the operator has a full view of the equipment and can see that all personnel

are clear. It must NEVER be installed inside the bin. The foot switch has to be plugged

into the control panel and depressed before the sweep is operational. It has a 10' cord

so the sweep can only be monitored from OUTSIDE the bin. The thermal protection

cord must also be plugged in before the sweep will operate.

6 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 7

2. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 7

Page 8

2. Safety

Read and Understand Manual

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Keep Hands Away from Moving Parts

DO NOT put hand or arm in hopper. Rotating auger can

crush and dismember.

DO NOT put any kind of tool inside hopper to try and clear

debris while the auger is running. Damage to the equipment

will result.

ALWAYS turn off and lock out all power sources before

servicing equipment.

Keep all shields and covers in place during operation.

Rotating Auger

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

8 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 9

2. Safety

Operate Motor Properly

In an emergency, shut down the power source.

Turn OFF and lock out all power sources before performing

any maintenance.

Do not operate electric motor equipped units until motors are

properly grounded.

Disconnect power on electrical driven units before resetting

motor overloads.

Do not repetitively stop and start the drive in order to free a

plugged condition. Jogging the drive in this manner can damage

the equipment and/or drive components.

Electric Shock Hazard

Maintain Equipment

and Work Area

Practice Safe Maintenance

Understand service procedures before doing work. Keep area

clean and dry.

Never lubricate, service, or adjust machine while it is in operation.

Keep hands, feet, and clothing away from rotating parts.

Keep all parts in good condition and properly installed. Fix

damage immediately . Replace worn or broke n parts. Remove an y

built-up grease, oil, and debris.

Keep Emergency Equipment

Quickly Accessible

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 9

Page 10

2. Safety

Eye Protection

Gloves

Steel Toe Boots

Respirator

Hard Hat

Fall Protection

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

10 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 11

Operate Unload Equipment Properly

• Untrained operators subject themselves and others to SERIOUS INJURY

or DEATH. NEVER allow untrained personnel to operate this equipment.

• NEVER work alone.

• Keep children and other unqualified personnel out of the working

area at ALL times. Refer to the Start-Up section of this manual for

diagrams of the work area.

• Make sure ALL equipment is locked in position before operating.

• NEVER start equipment until ALL persons are clear of the work area.

• Keep hands and feet away from the auger intake and other moving parts.

• NEVER attempt to assist machinery operation or to remove trash from equipment while

in operation.

• Be sure all operators are adequately rested and prepared to perform all functions of operating

this equipment.

• NEVER allow any person intoxicated or under the influence of alcohol or drugs to operate

the equipment.

• Make sure someone is nearby who is aware of the proper shut down sequence in the event of an

accident or emergency.

• ALWAYS think before acting. NEVER act impulsively around the equipment.

• NEVER allow anyone inside a bin, truck or wagon which is being unloaded by an auger or

conveyor. Flowing grain can trap and suffocate in seconds.

• Use ample overhead lighting after sunset to light the work area.

• Keep area around intake free of obstacles such as electrical cords, blocks, etc., that might

trip workers.

• NEVER drive, stand or walk under the equipment.

• Use caution not to hit the auger when positioning the load.

• ALWAYS lock out ALL power to the equipment when finished unloading a bin.

• Be aware of pinch points. A pinch point is a narrow area between two surfaces t hat is likely to trap or

catch objects and so is a potential safety hazard.

Operate Unload

Equipment Safely

2. Safety

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 11

Page 12

2. Safety

Operator Qualifications

A. The User/Operator must be competent and experienced to operate auger equipment. Anyone who

works with or around augers must have good common sense in order to be qu alified. These persons

must also know and meet all other qualifications, such as:

i. Any person who has not read and/or does not understand all operation and safety procedures

is not qualified to operate any auger systems.

ii. Certain regulations apply to personnel operating power machinery. Personnel under the age of

18 years may not operate power machinery, including augers. It is your responsibility, as owner

and/or supervisor, to know what these regulations are in your area or situation.

iii. Unqualified or incompetent persons are to remain out of the work area.

iv. O.S.H.A. (Occupational Safety and Health Administration) regulations state: “At the time of

initial assignment and at least annually thereafter, the employer shall instruct every employee

in the safe operation and servicing of all equipment with which the employee is, or will be

involved”. (Federal Occupational Safety and Health Standards for Agriculture. Subpart D,

Section 1928.57 (a) (6)).

B. As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe

operating and safety procedures for this auger. The sign-off sheet is provided for your convenience

and personal record keeping. All unqualified persons are to stay out of the work area at all times. It

is strongly recommended that another qualified person who knows the shut down procedure is in the

area in the event of an emergency.

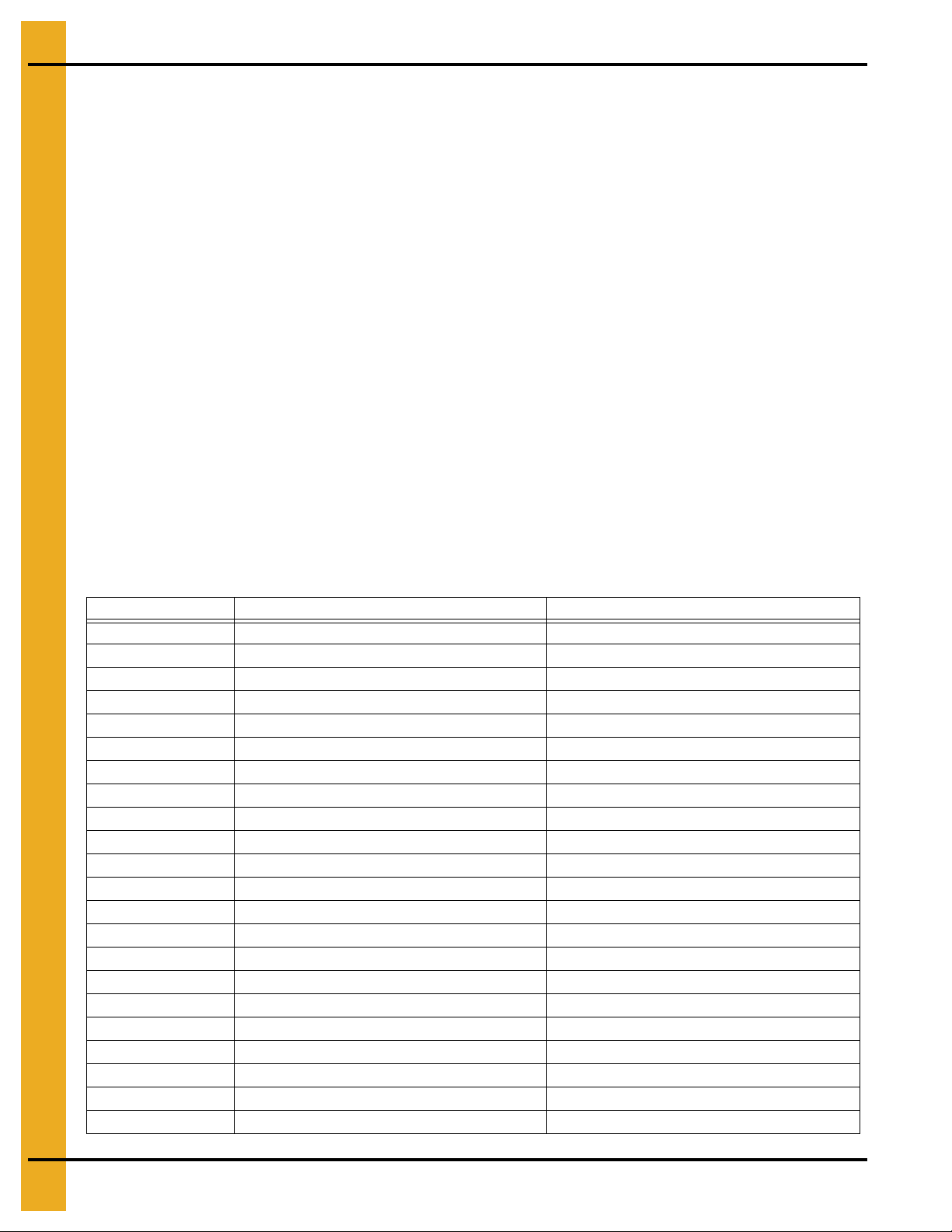

Date Employee Name Supervisor Name

12 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 13

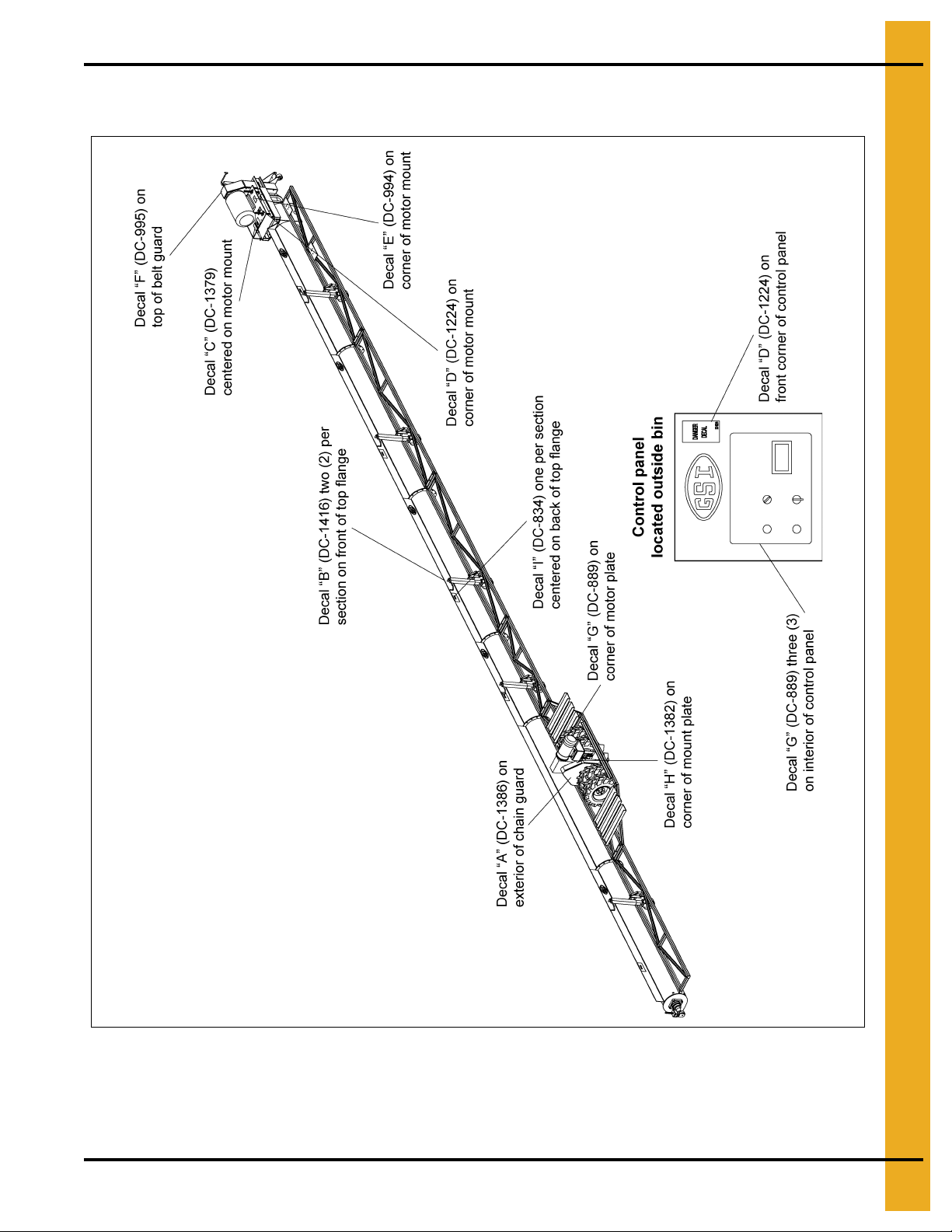

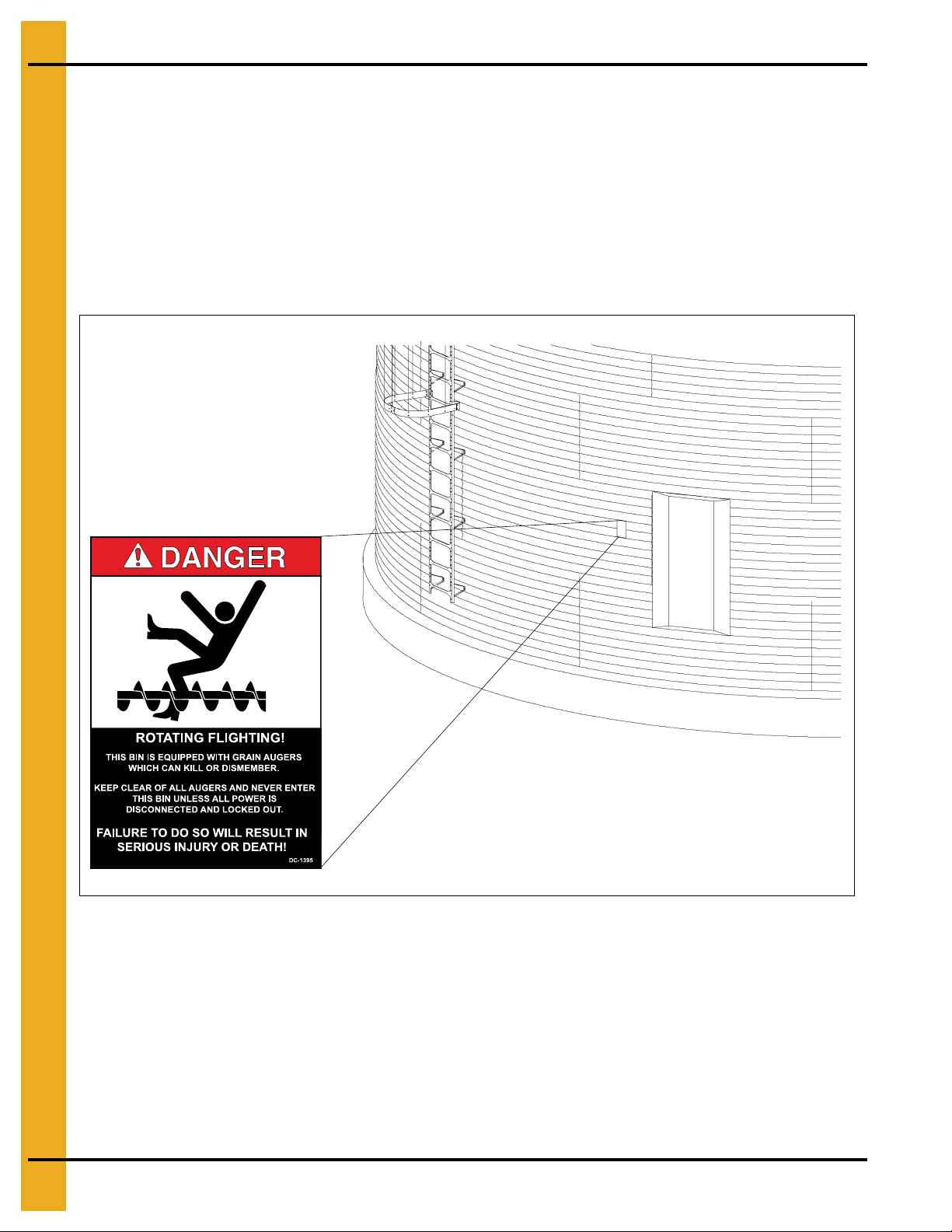

3. Safety Decals

The images below show the location of the decals and safety signs which should appear on the

Series II Sweep. (Refer to Pages 14-16 for decals.)

NOTE: Please remember safety signs provide important safety information for people working near bin

unloading equipment that is in operation.

Any safety signs that are worn, missing, illegible or painted over should be replaced immediately.

Obtain FREE replacements by contacting GSI.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 13

Page 14

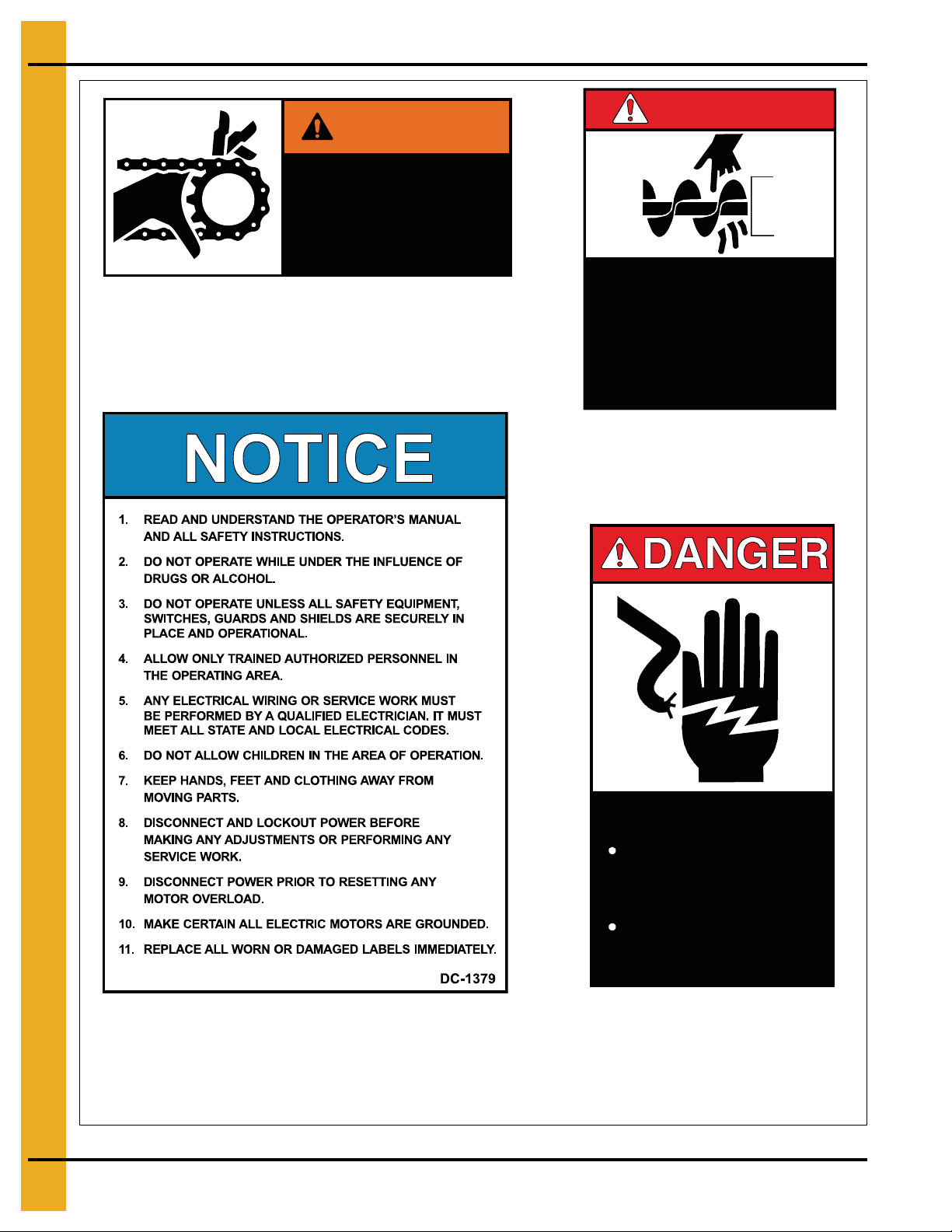

3. Safety Decals

SHEAR POINT

Moving parts can

crush and cut. Keep

hands clear of

sprocket and chain.

DC-1386

WARNING

ROTATING AUGER!

• DISCONNECT AND LOCKOUT P OWER BEFORE

SERVICING, ADJUSTING OR CLEANING.

• KEEP HANDS, FEET, HAIR AND LOOSE

CLOTHING AWAY FROM ROTATING AUGER AND

MOVING PARTS AT ALL TIMES.

• NEVER REMOVE O R MODIFY GUARDS OR

SHIELDS.

FAILURE TO HEED WILL RESULT IN

SERIOUS INJURY OR DEATH!

DC-1416

DANGERDANGER

Decal “A”

Location: Exterior of chain guard

Size: 2" x 4-1/2"

Part #: DC-1386

Decal “B”

Location: Two (2) per section on

front of top flange

Size: 4-5/16" x 5-7/16"

Part #: DC-1416

Decal “C”

Location: Centered on motor mount

Size: 5-1/2" x 7-3/8"

Part #: DC-1379

Decal “D”

Location: Corner of motor mount

Size: 2-7/8" x 5"

Part #: DC-1224

HIGH VOLTAGE.

Will cause serious

injury or death.

Lockout power

before servicing.

DC-1224

14 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 15

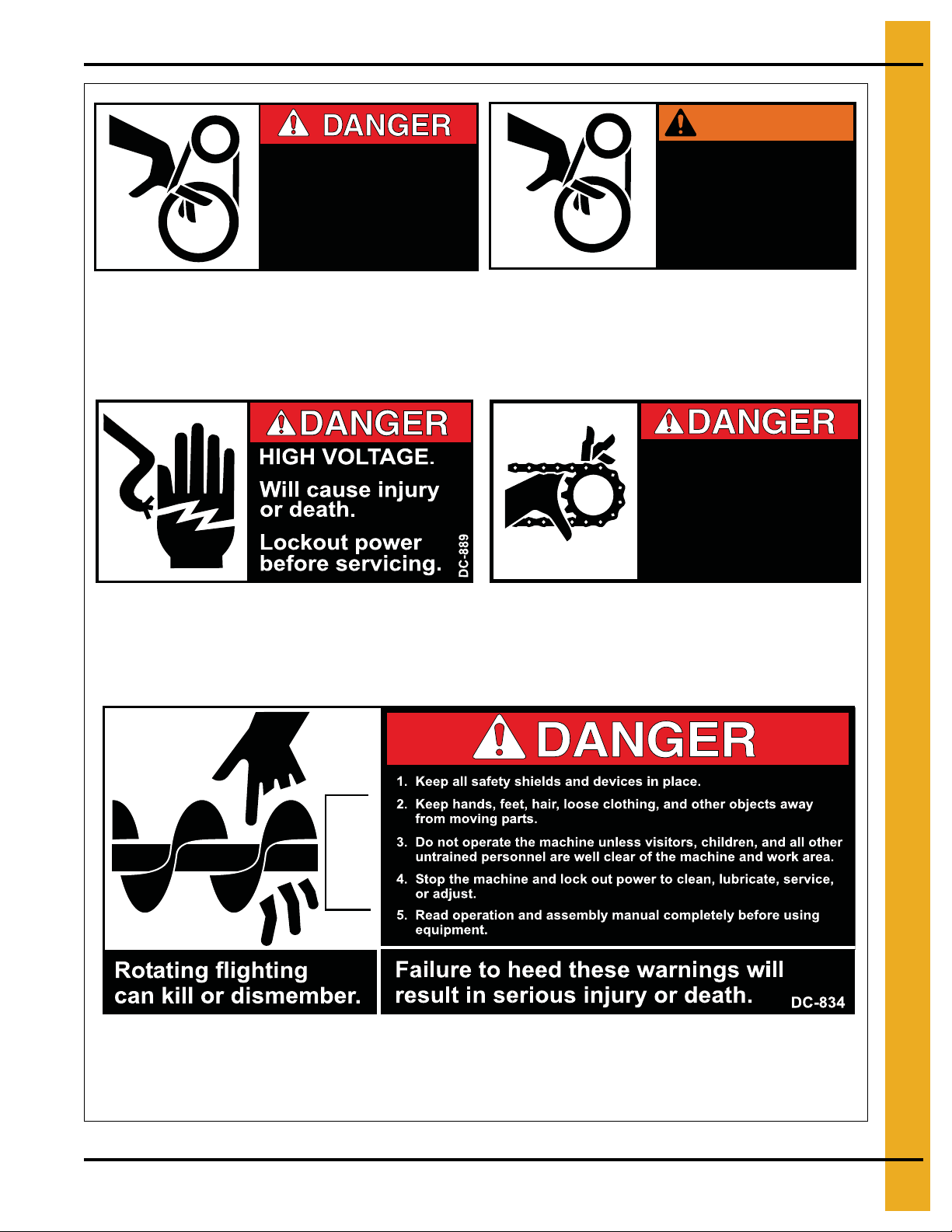

SHEAR POINT

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

DC-995

WARNING

Decal “G”

Location: Corner of motor mount

Size: 2-13/16" x 17/16"

Part #: DC-889

Decal “F”

Location: Top of belt guard

Size: 4-1/2" x 2"

Part #: DC-995

Decal “E”

Location: Corner of motor mount

Size: 4-1/2" x 2"

Part #: DC-994

Decal “H”

Location: Corner of mount plate

Size: 4" x 1-3/4"

Part #: DC-1382

Decal “I”

Location: One per section centered on back of top flange

Size: 9" x 3-3/4"

Part #: DC-834

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

3. Safety Decals

DC-994

SHEAR POINT

Moving parts can

crush and cut. Keep

hands clear of

sprocket and chain.

DC-1382

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 15

Page 16

3. Safety Decals

A. DANGER Sign No. DC-1395 was supplied with your bin unloading equipment. This safety sign

should be applied to the side of the bin near the bin opening, so it will be viewed by people entering

into the bin storage building. Do not cover any safety signs or any other signs that are already there.

B. If the safety sign location suggested is not in full view because of equipment modifications, other

equipment in the area or any reason, then locate the safety sign in a more suitable location.

C. Be certain the surface is clean, dry and free of dirt and oil. Peel paper backing from decals and stick

into place. The adhesive backing will bond on contact.

NOTE: Please remember, safety signs provide important safety information for people working near bin

unloading equipment that is in operation.

NOTE: If the Safety Sign cannot be easily read for any reason or has been painted over, replace it

immediately. Additional Safety Signs may be obtained free of charge from your dealer, distributor

or ordered from the factory.

Order SAFETY SIGN NO. DC-1395

16 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 17

4. General Product Information

This Series II Sweep is a single pass sweep. Consult the manufacturer of the

storage tank regarding the requirements or restrictions of the sweeping process.

The manufacturer may require a multiple pass sweep.

WARNING

NEVER enter a grain bin unless ALL power driven equipment has been shut down.

Disconnect and lock out power before entering the bin or servicing the equipment.

Product Information

CAUTION

A. The Series II Sweep includes the following components.

• Control panel

• Two (2) motors

•Motor covers

• Motor mount

• Auger flighting

• Auger back shield assembly

• Jack supports

B. The unit will operate only in a round grain bin equipped with a center sump in the bin floor.

General Information

A. GSI reserves the right to improve its product whenever possible and practical to do so. We reserve

the right to change, improve and modify products at any time without obligation to make changes,

improvements and modifications on equipment sold previously.

B. This new bin sweep auger has been engineered and manufactured to give years of dependable

service. The care and maintenance of this equipment will affect the satisfaction and service

obtained. By following the instructions and recommendations, the owner should receive quality

service for many years. If additional information or assistance is required, please contact GSI.

C. It is important to check both the quantity of parts and their descriptions with the packing list enclosed

within each package. All claims for freight damage or shortage must be made by the consignee

within ten (10) days of the date of the occurrence. The consignee should accept the shipment after

noting the damage or loss on the bill of lading.

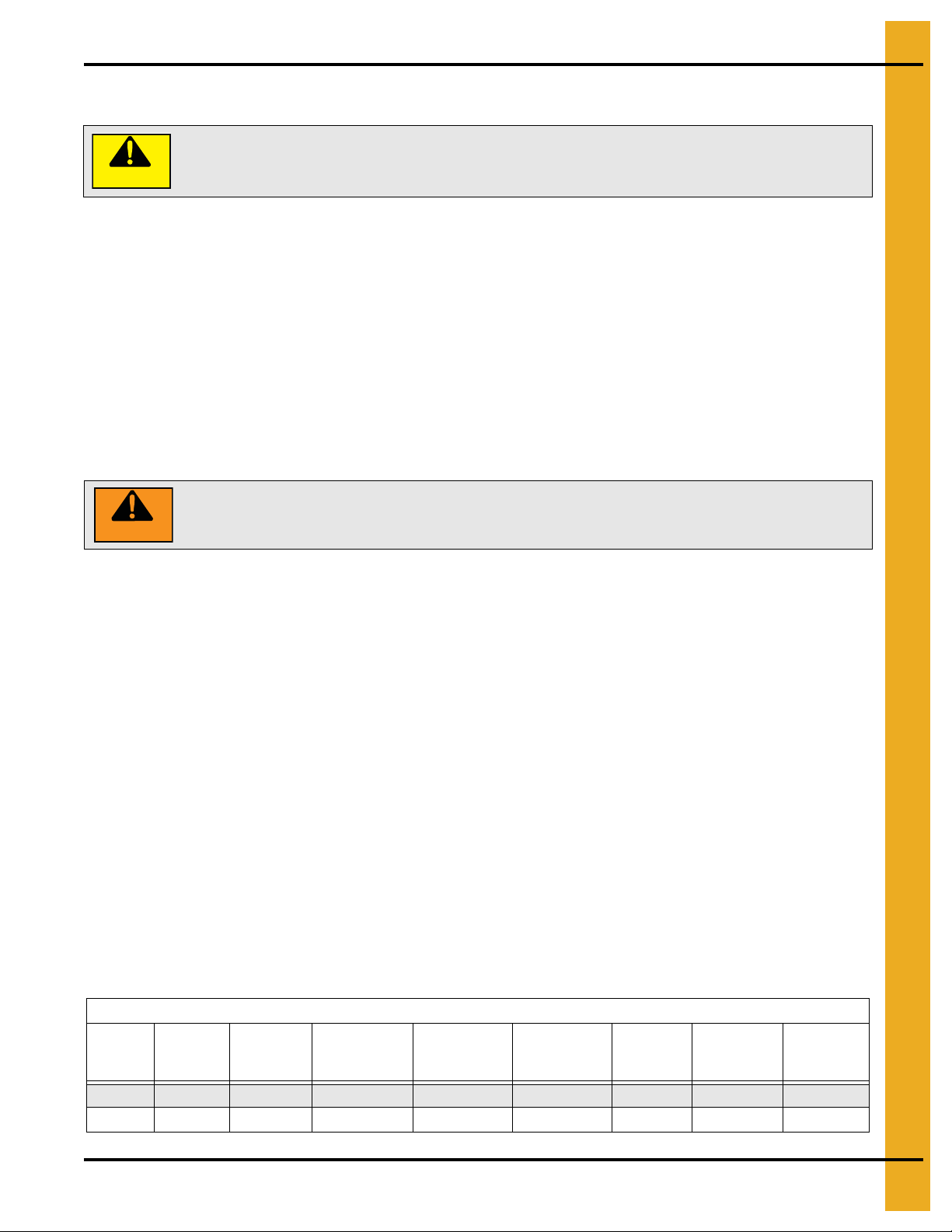

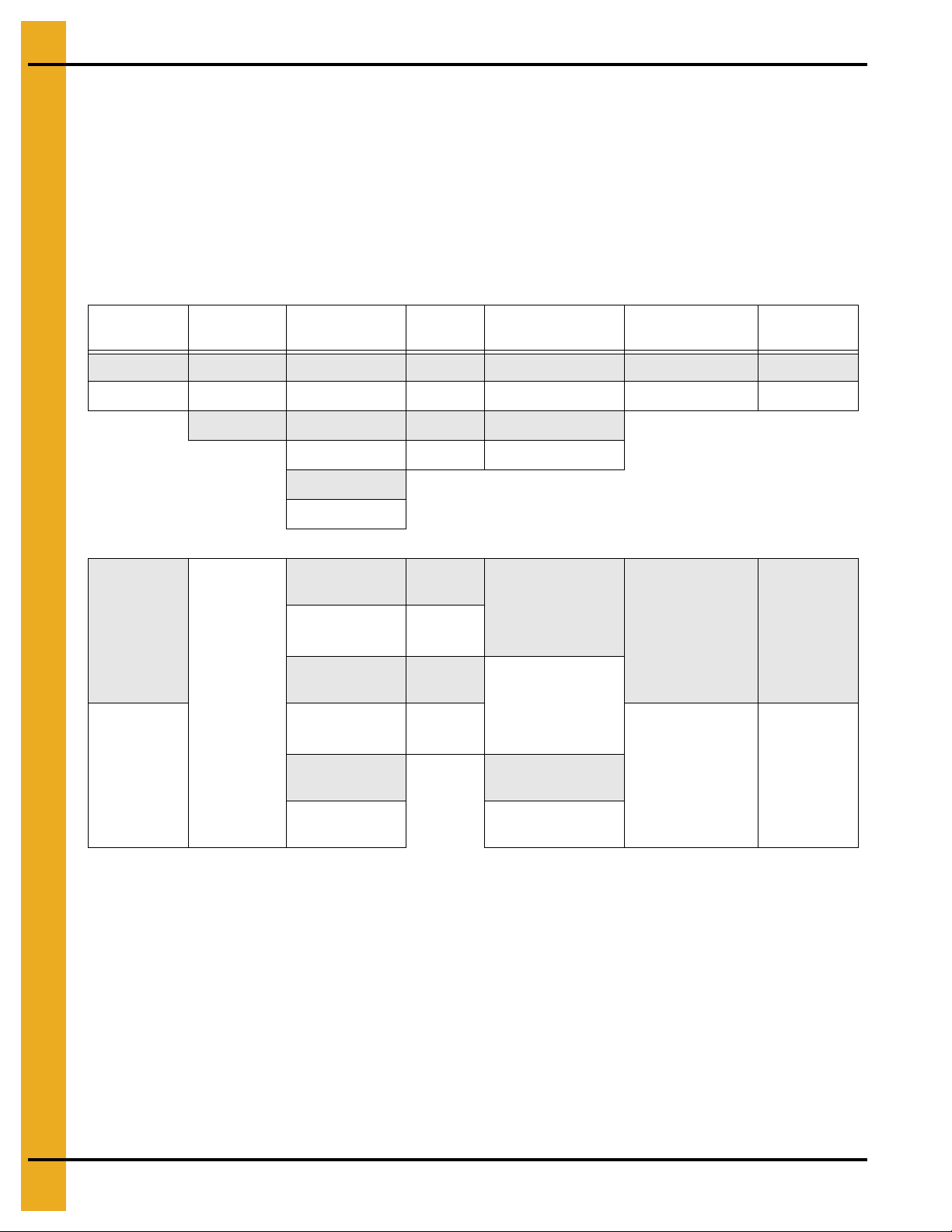

D. The Chart below shows radius dimensions locating the points of contact between the sweep and the

bin floor. The dimensions may be used to figure material quantities of track to support the sweep

across the aeration flooring. The track material is not supplied with the sweep and must be supplied

by the installer. The dimensions are approximate and the assembled sweep should be checked for

exact points of contact.

Radius Dimensions from Center of Bin

Bin

Diameter

131' 6 92" 236" 380" 468" 537-1/4" 574-1/2" 677"

135' 6 92" 236" 380" 484" 561-1/4" 598-1/2" 701"

# of

Sections

Head Jack

Wheel

2" Wide

Intermediate

Jack Wheel

3" Wide

Intermediate

Jack Wheel

3" Wide

Intermediate

Jack Wheel

3" Wide

Inside Tire

18" Wide

Outside Tire

18" Wide

Extension

Jack Wheel

3" Wide

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 17

Page 18

4. General Product Information

Electrical controls and wiring should be installed by a qualified electrician. The

motor disconnect switches and conductor cables should comply wit h the National

Electrical Code and any local codes. Locate reset and motor starting stations so

the operator can see that all personnel are clear of the equipment.

There should ALWAYS be two (2) people in the work area.

A main power disconnect switch capable of being locked only in the OFF position

should be used. It should be locked in the OFF position whenever work is being

done on the Series II Sweep.

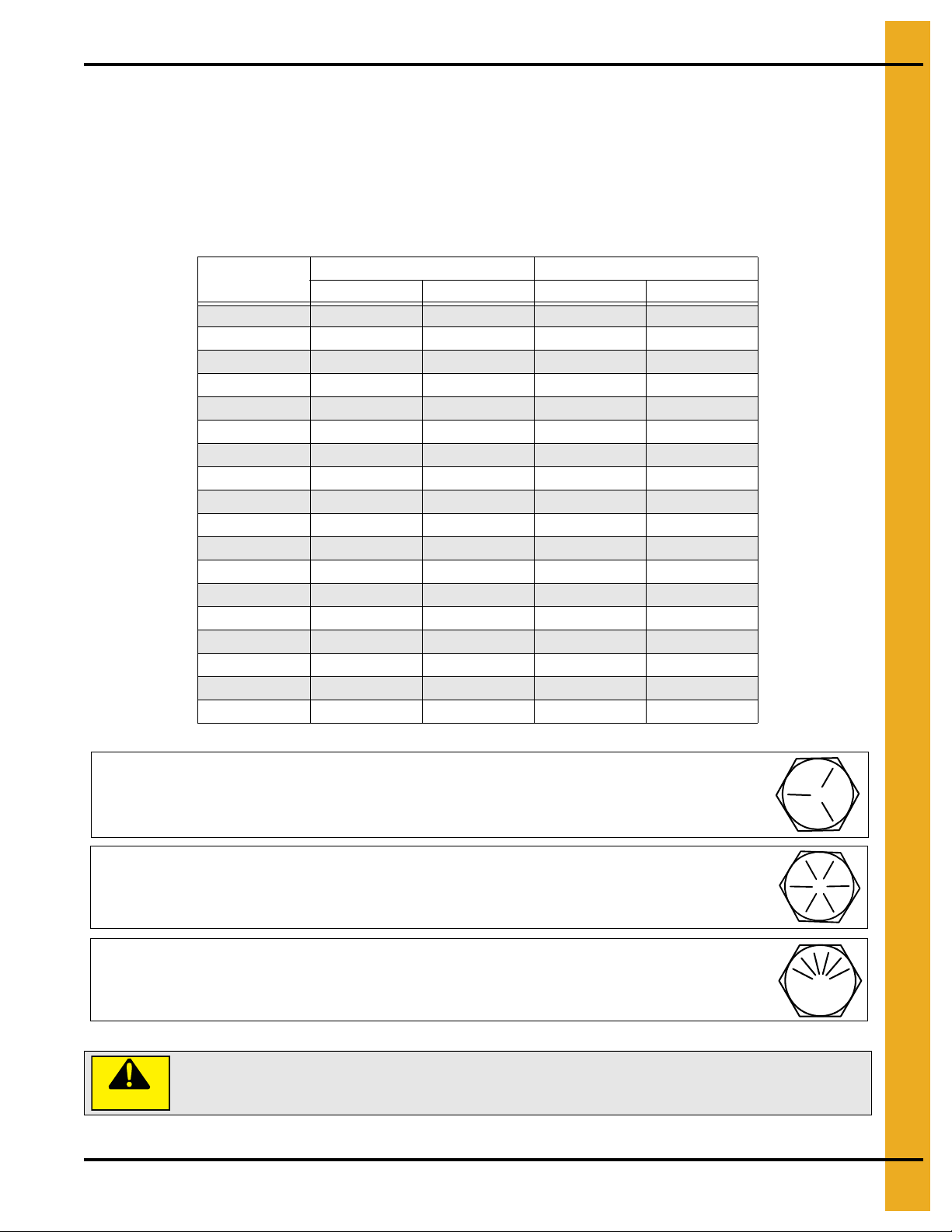

Capacities and Specifications

WARNING

A. Use the Chart below to determine the horsepower required.

NOTE: Sweep is not designed to start under full load.

12" Series II Sweep

Bin

Diameter

131' 5 N/A 20 N/A 63.84' (19.46 m)

135' 5 N/A 20 N/A 65.84' (20.07 m)

Drive HP

Bushel/MT per Hour Horsepower

Length Pivot to End

5000/125 6000/155 7000/180

NOTE: The horsepower recommendations are for augering reasonably dry grain. High moisture grain

(greater than 15%) will require greater power for maximum capacity.

NOTE: Sweep drive and carrier wheels require plates or track over aeration flooring for travel and supports

not supplied with the sweep unit. Contact the installer or flooring provider for possible sources

and details.

B. A magnetic starter should be used to protect the motor when starting and stopping. It should stop the

motor in case of power interruption, conductor fault, low voltage, circuit interruption or motor

overload. The motor must be restarted manually. Some motors have built-in thermal overload

protection. If this is the type of motor being used, use only those with a manual reset.

C. The motor starting controls must be located outside the bin. They must NEVER be installed on the

Series II auger inside the bin.

D. Disconnect and lock out the power before resetting motor overloads.

E. Disconnect and lock out the power before entering the bin.

F. Disconnect and lock out the power before servicing the equipment.

G. Position the reset and motor starting controls so that the operators have full view of the equipment.

WARNING

H. Make sure electric motors are grounded.

WARNING

18 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 19

4. General Product Information

Grade 5 Bolts

Grade 5 bolts are designated by three (3) slash marks on the head.

Grade 8 Bolts

Grade 8 bolts are designated by six (6) slash marks even l y spaced on the he ad of th e bo lt.

Grade 8.2 Bolts

Grade 8.2 bolts are designated by six (6) slash marks on the head in a sunrise pattern.

Under no condition shall any other fasteners be substituted for those supplied

by the manufacturer.

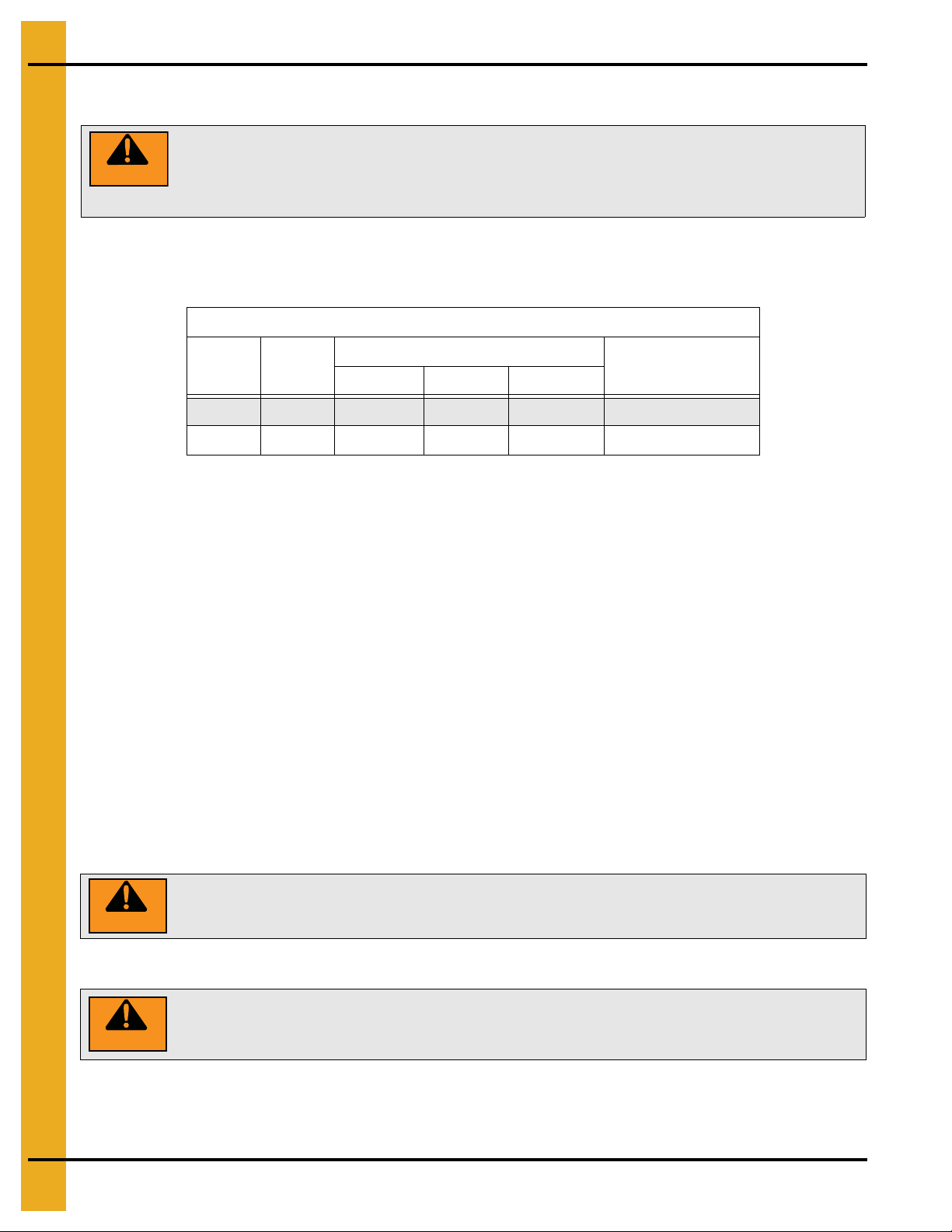

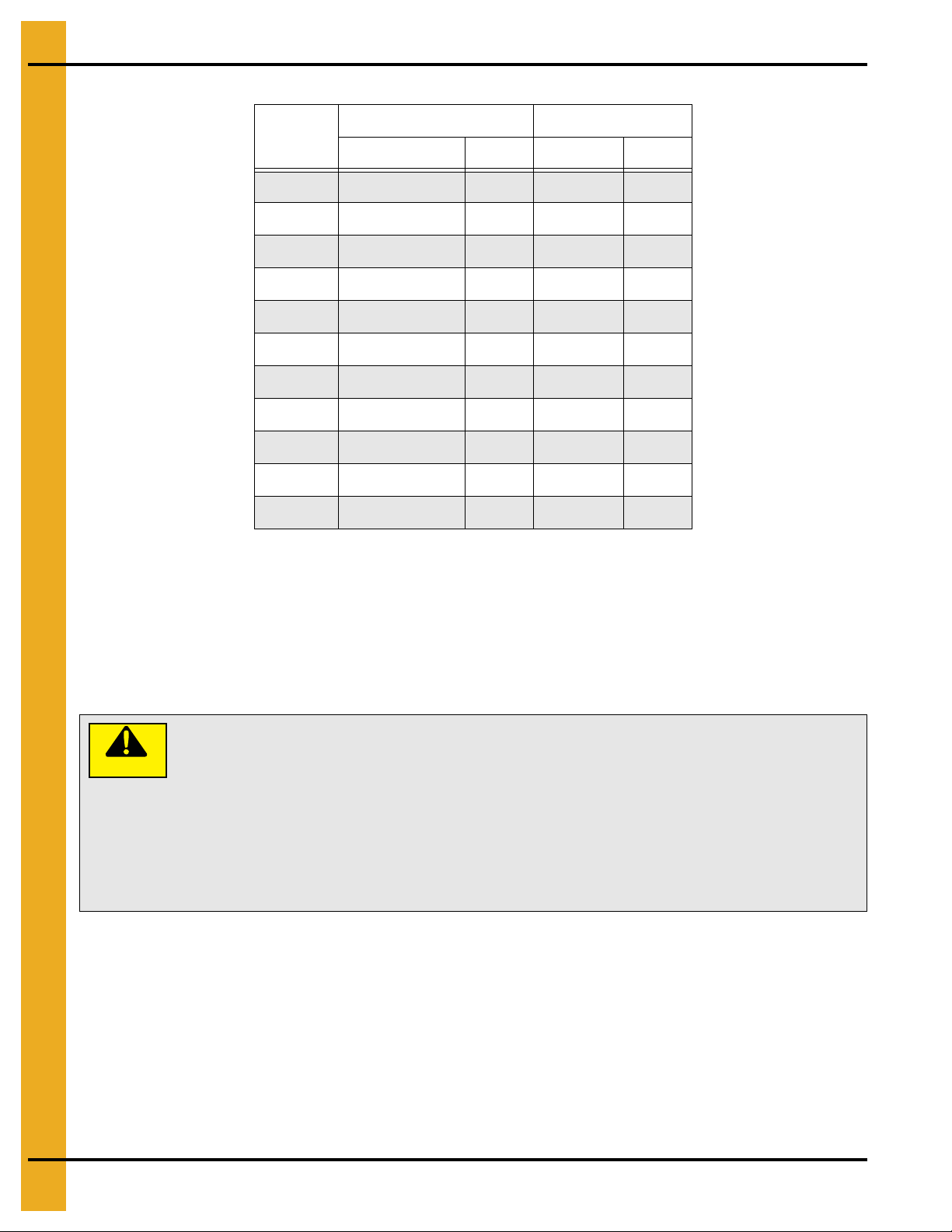

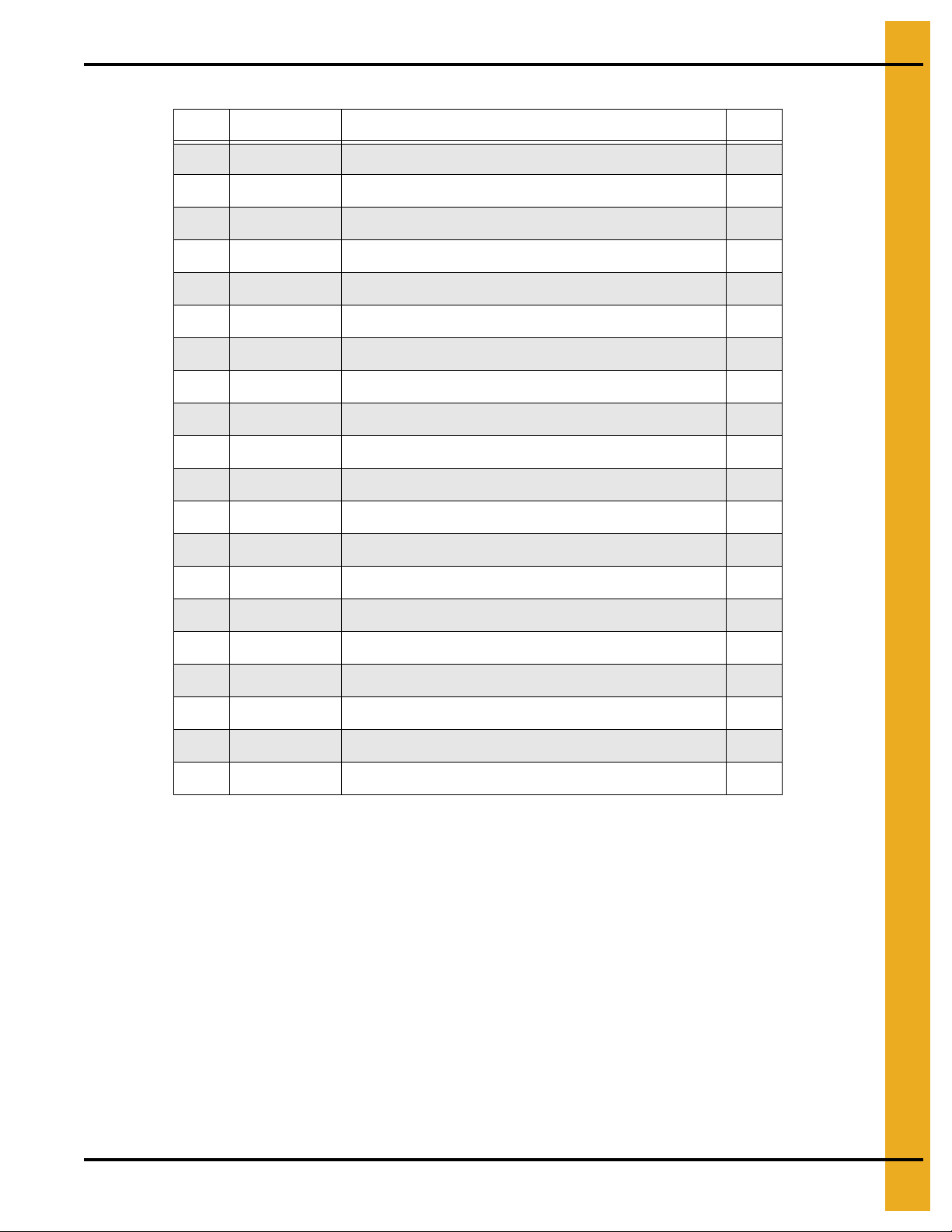

Torque Values to be used when Tightening the Bolts on the Series II Sweep

It takes more force to tighten a 3/4"-10 bolt than to tighten a 1/2"-13 bolt because of its larger diameter. It

also takes more force to tighten a grade 8 bolt than it does to tighten a g rade 5 bolt because of the greater

material strength. A bolt that is waxed or otherwise lubricated requires much less force to tighten. If the

same amount of force is used with a lubricated bolt as with a non-lubricated bolt, the lubricated bolt often

will break.

A suggested initial tightening torque is listed in the Chart below.

Size

1/4"-20 8 ft. lbs. 75 in. lbs. 12 ft. lbs. 9 ft. lbs.

1/4"-28 10 ft. lbs. 86 in. lbs. 14 ft. lbs. 10 ft. lbs.

5/16"-18 17 ft. lbs. 13 ft. lbs. 25 ft. lbs. 18 ft. lbs.

5/16"-24 19 ft. lbs. 14 ft. lbs. 25 ft. lbs. 20 ft. lbs.

3/8"-16 30 ft. lbs. 23 ft. lbs. 45 ft. lbs. 35 ft. lbs.

3/8"-24 35 ft. lbs. 25 ft. lbs. 50 ft. lbs. 35 ft. lbs.

1/2"-13 75 ft. lbs. 55 ft. lbs. 110 ft. lbs. 80 ft. lbs.

1/2"-20 90 ft. lbs. 65 ft. lbs. 120 ft. lbs. 90 ft. lbs.

5/8"-11 150 ft. lbs. 110 ft. lbs. 220 ft. lbs. 170 ft. lbs.

5/8"-18 180 ft. lbs. 130 ft. lbs. 240 ft. lbs. 180 ft. lbs.

3/4"-10 260 ft. lbs. 200 ft. lbs. 380 ft. lbs. 280 ft. lbs.

3/4"-16 300 ft. lbs. 220 ft. lbs. 420 ft. lbs. 320 ft. lbs.

7/8"-9 320 ft. lbs. 320 ft. lbs. 600 ft. lbs. 460 ft. lbs.

1"-8 640 ft. lbs. 480 ft. lbs. 900 ft. lbs. 680 ft. lbs.

1-1/8" - 7 800 ft. lbs. 600 ft. lbs. 1280 ft. lbs. 960 ft. lbs.

1-1/4" - 7 1120 ft. lbs. 840 ft. lbs. 1820 ft. lbs. 1360 ft. lbs.

1-3/8" - 6 1460 ft. lbs. 1100 ft. lbs. 2380 ft. lbs. 1780 ft. lbs.

1-1/2" - 6 1910 ft. lbs. 1460 ft. lbs. 3160 ft. lbs. 2360 ft. lbs.

Grade #5 Assembly Torque Grade #8 Assembly Torque

Dry Lubricated Dry Lubricated

CAUTION

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 19

Page 20

4. General Product Information

Insert set screws to install

Insert set screw to remove

Wedging forces in the bushing saw slot, such as that exerted by a narrow edged

regular screw driver, may damage or break the bushing. This damage would not

be covered under the GSI warranty.

Do not lubricate the bushing taper , bushing bore, hub taper or the shaft. Doing so

could result in breakage of the product.

Do not use worn hex key wrenches. Doing so may result in a loose assembly or

may damage the screws.

CAUTION

Taper-Lock Bushings

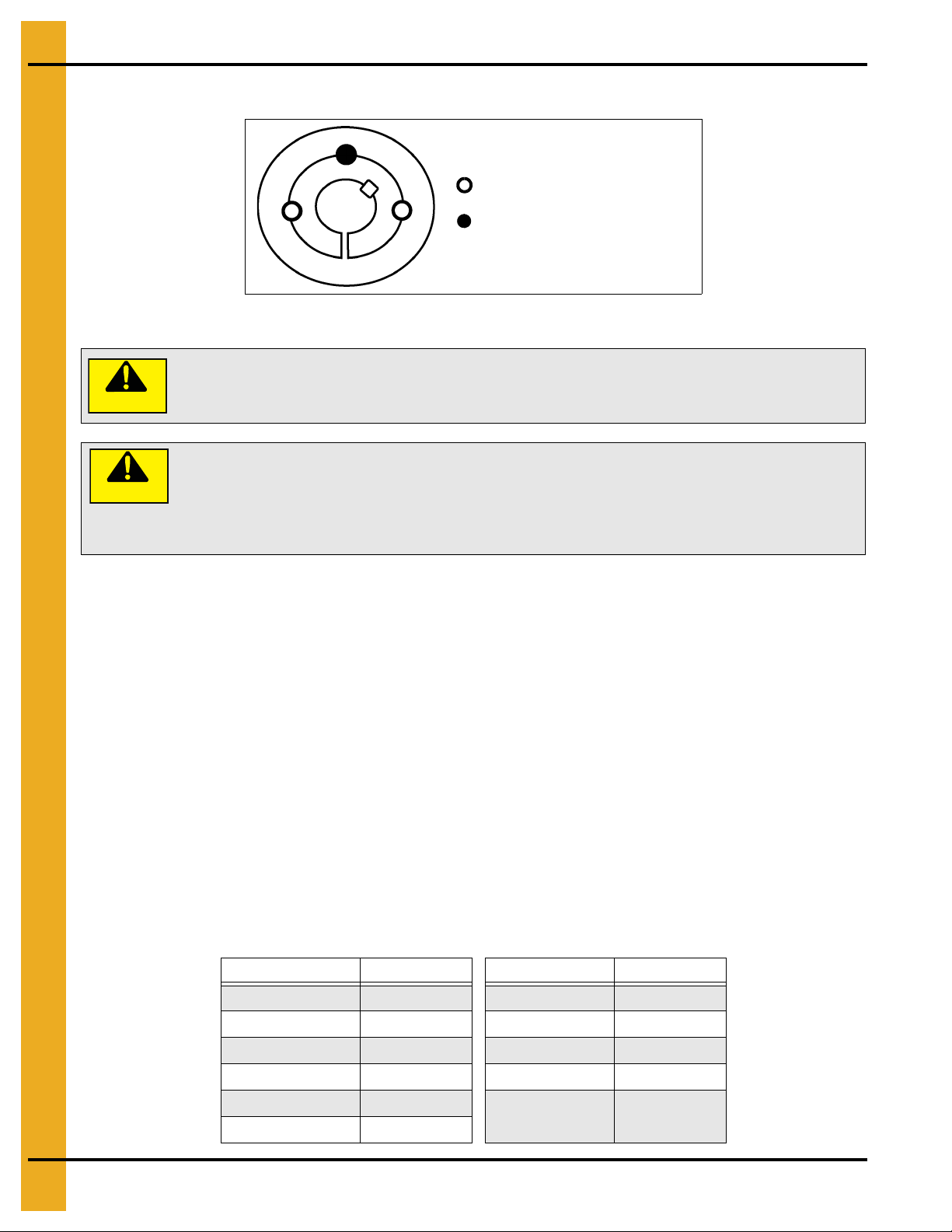

Figure 4A Number 1008 to 3030 Bushing

CAUTION

To Install

1. Clean shaft, bore and outside of bushing and hub bore of all oil, paint and dirt. File away burrs.

2. Insert bushing in hub. Match the hole pattern, not threaded holes (each complete hole will be

threaded on one side only).

3. Lightly oil set screws and thread into the half-threaded holes indicated as in Figure 4A.

4. Position the assembly onto the shaft allowing for the small axial movement which will occur during

the tightening procedure.

5. Alternately torque set screws to recommended torque setting listed in the Chart below.

6. To increase the gripping force, hammer the face of the bushing using a drift or sleeve. (Do not hit the

bushing directly with the hammer.)

7. Re-torque the screws after hammering.

8. Re-check the screw torques after the initial run-in and periodically thereafter. Repeat Steps 5, 6

and 7 if loose.

Recommended Installation Wrench Torque

Bushing # lbs.-in Bushing # lbs.-in

1008, 1108 55 3535 1000

1210, 1215, 1310 175 4040 1700

1610, 1615 175 4545 2450

2012 280 5050 3100

2517, 2525 430

20 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

3020, 3030 800

6050, 7060, 8065 7820

Page 21

To Remove

1. Remove all screws.

4. General Product Information

2. Insert screws in hole or holes indicated on

the screw(s).

Figure 4A on Page 20

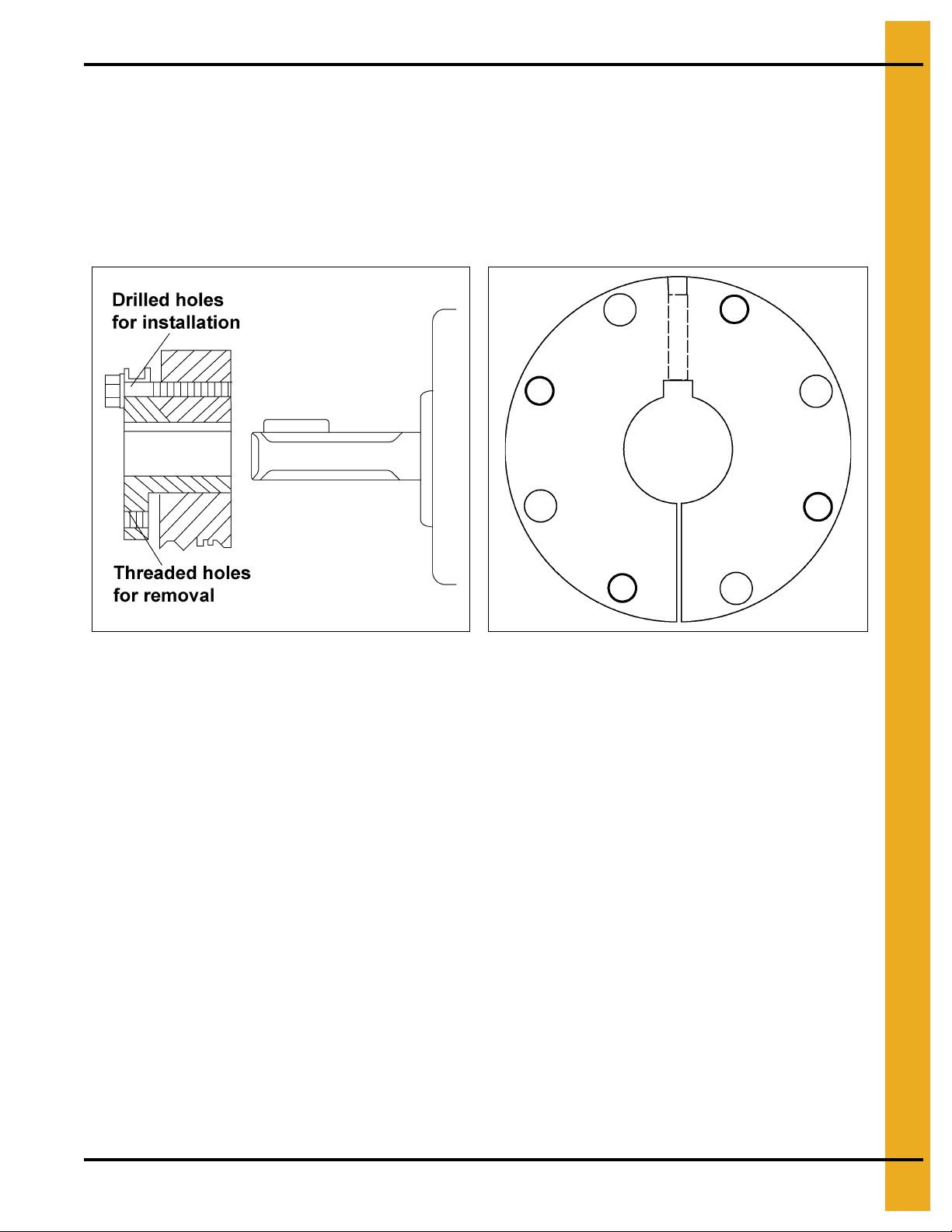

Q-D Bushings - Reverse Mounting

. Loosen the bushing by tightening

Figure 4B

Figure 4C Overhead View of Q-D Bushing

To Install

1. Clean shaft, bore of bushing, outside of bushing and hub bore of all oil, paint and dirt. File

away burrs.

2. Reverse mounting: Place the bushing in hub and insert the cap screws through the drilled holes in

the bushing flange. Tighten the cap screws, finger tight into threaded holes in the hub.

3. With the key on the shaft, slide the loosely assembled unit onto the shaft so that the cap screw

heads are on the outside. Place the unit in the desired position on the shaft.

4. Tighten the cap screws alternately and evenly to the wrench torque specified in the

NOTE: When tightened, there will be a gap of 1/8" to 1/4" between the bushing flange and the hub.

Should this gap be less, either undersize shafting or the wrong bushing shaft size was used.

5. Tighten the set screw (if supplied) over the key to the torque value listed in the Chart on Page 22.

Chart on Page 22

.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 21

Page 22

4. General Product Information

Do not lubricate the bushing taper , bushing bore, hub taper or the shaft. Doing so

could result in breakage of the product.

Excessive screw torque may cause damage to either the bushing and/or the

sheave. Uneven pressure on the jack screws may also damage the bushing

flange making removal difficult without damage to the bushing and/or sheave.

Do not use worn hex keys and/or wrenches. Doing so may result in a loose

assembly or may damage the screws.

CAUTION

Recommended Installation Wrench Torque

Bushing

H 1/4"-20 x 7/8" 90 N/A N/A

JA #10-24 x 1" 60 N/A N/A

SH 1/4"-20 x 1-3/8" 108 1/4"-20 87

SDS 1/4"-20 x 1-3/8" 108 1/4"-20 87

SD 1/4"-20 x 1-7/8" 108 1/4"-20 87

SK 5/16"-18 x 2" 180 1/4"-20 87

SF 3/8"-16 x 2" 360 3/8"-16 290

E 1/2"-13 x 2-3/4" 720 3/8"-16 290

F 9/16"-12 x 3-5/8" 900 3/8"-16 290

J 5/8"-11 x 4-1/2" 1620 1/2"-13 620

Cap Screw Key Seat Set Screw

Size lbs.-in Size lbs.-in

M 3/4"-10 x 6-3/4" 2700 1/2"-13 620

To Remove

1. Remove all cap screws.

2. Insert the cap screws into the threaded jack hole or holes.

3. Tighten all the jack screws alternately and evenly beginning with the screw farthest from the bushing

saw slot. Tighten until the bushing grip is released. Slide the unit off the shaft.

22 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 23

5. Assembly

The section sizes are total length given in inches. The head section has 8"

subtracted from the shield length due to the pivot pipe location.

The 12" tail section has 5-1/2" added to the shield length due to the end shaft length.

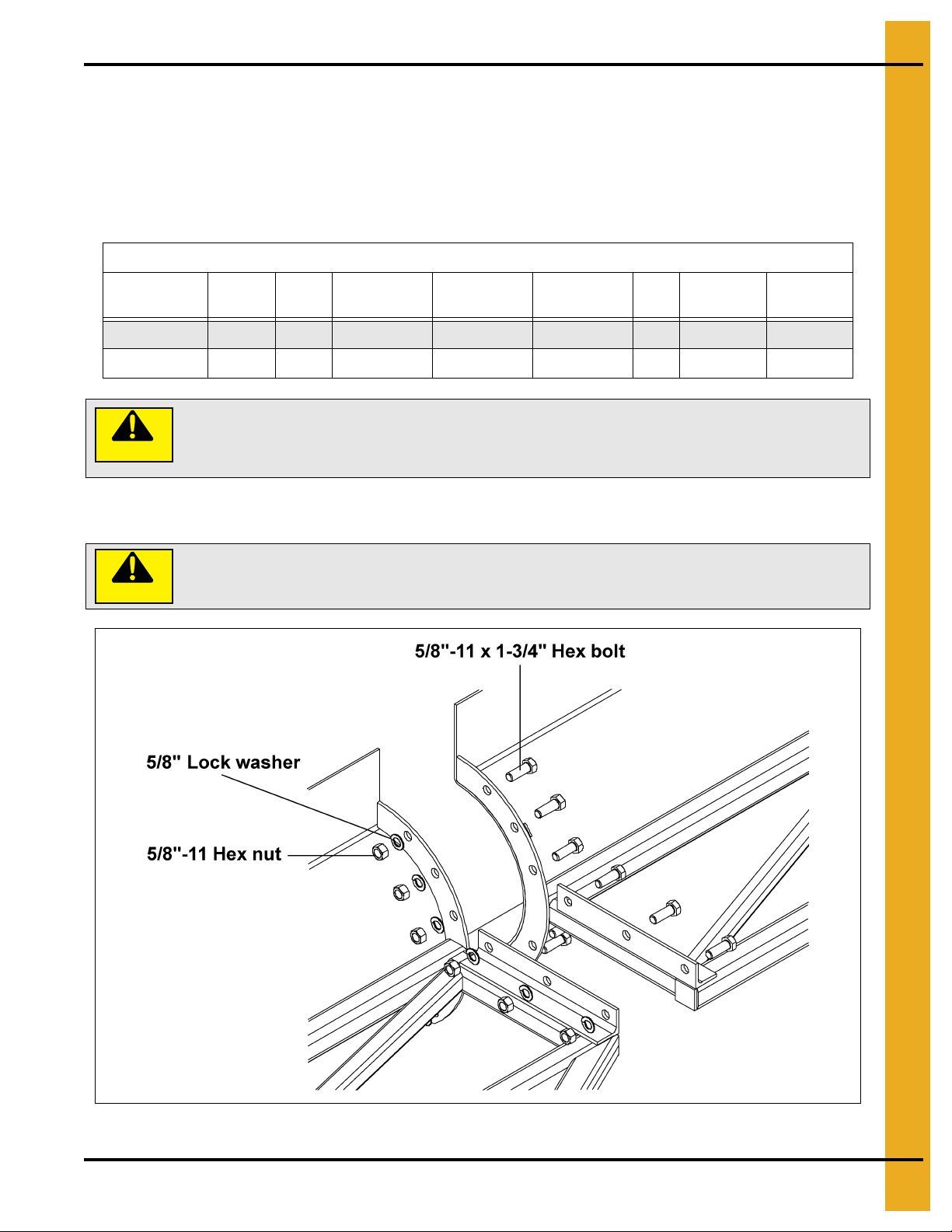

The bolts MUST be installed as shown in Figure 5A.

Back Shield Assembly

A. The sweep has been broken down into four (4) different section types: the head, intermediate, tail

and extension sections.

NOTE: Use the Chart below to determine the identification and the order of assembly of the individual

sweep sections.

12" Series II Sweep Sections

Bin Diameter

131' 6 136" 144" 144" 60" 144" 137-1/2" 63.84'

135' 6 136" 144" 144" 84" 144" 137-1/2" 65.84'

CAUTION

# of

Sections

Head Intermediate Intermediate Intermediate Tail Extension Pivot to End

B. Use eight (8) 5/8"-11 x 1-3/4" grade 8 hex bolts, lock washers and hex nuts at each

section connection.

CAUTION

Figure 5A

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 23

Page 24

5. Assembly

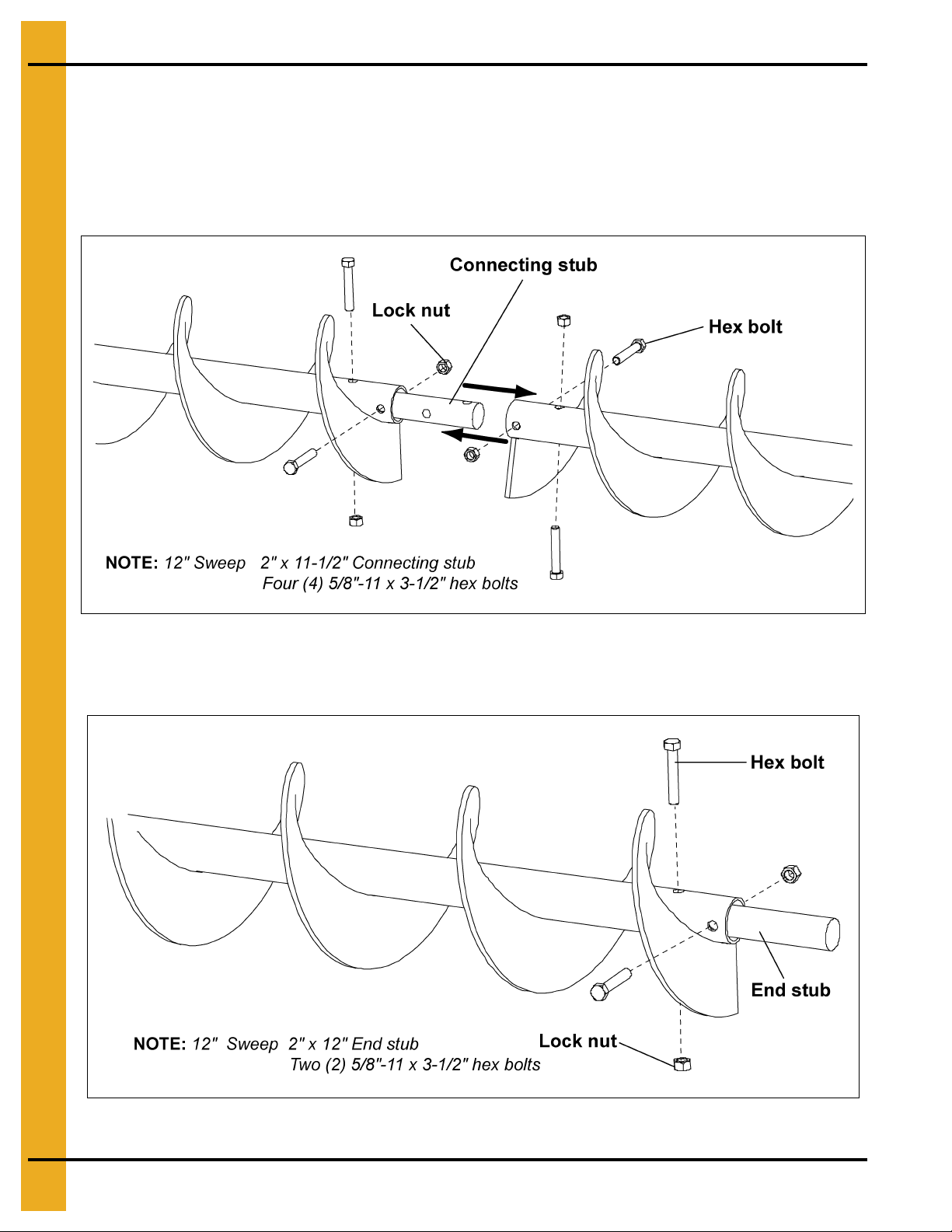

Flighting Assembly

A. Lay out the flight sections in order of assembly starting with the head flight working towards the

tail flight.

B. Using the connecting stubs, bolt the flight sections together with hex bolts and lock nuts. Make sure

the flight ends are in time with each other.

Figure 5B

C. Slide the end stub through the bearing plate on the tail section and into the tail flight securing it with

hex bolts and lock nuts.

Figure 5C

24 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 25

5. Assembly

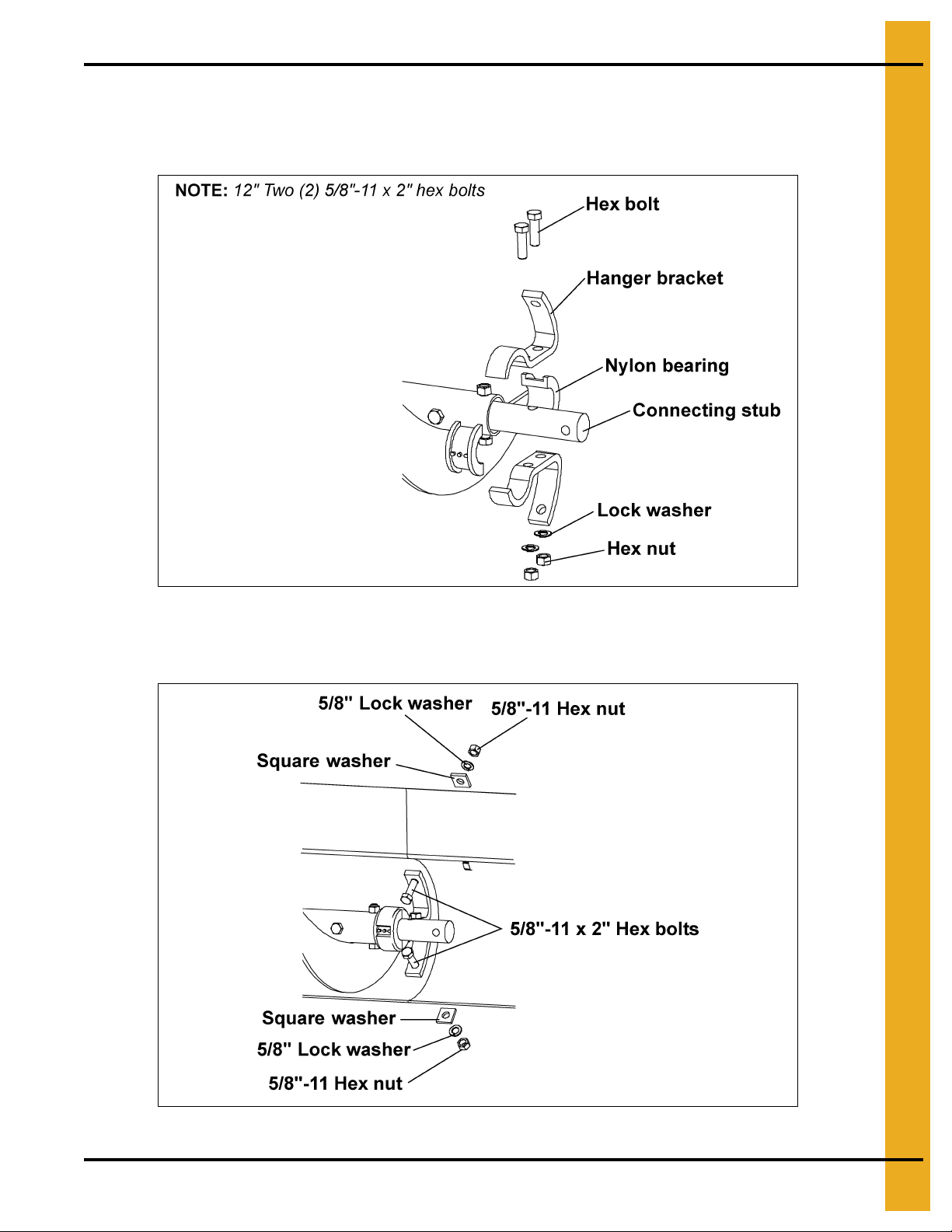

Hanger Bracket Assembly

A. Bolt the nylon bearings and hanger brackets to the connecting stubs using hex bolts, lock washers

and hex nuts as shown in Figure 5D.

Figure 5D

B. Bolt the hanger brackets to the back shields using two (2) 5/8"-11 x 2" hex bolts, two (2) square

washers, two (2) lock washers and two (2) hex nuts as shown in Figure 5E.

Figure 5E

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 25

Page 26

5. Assembly

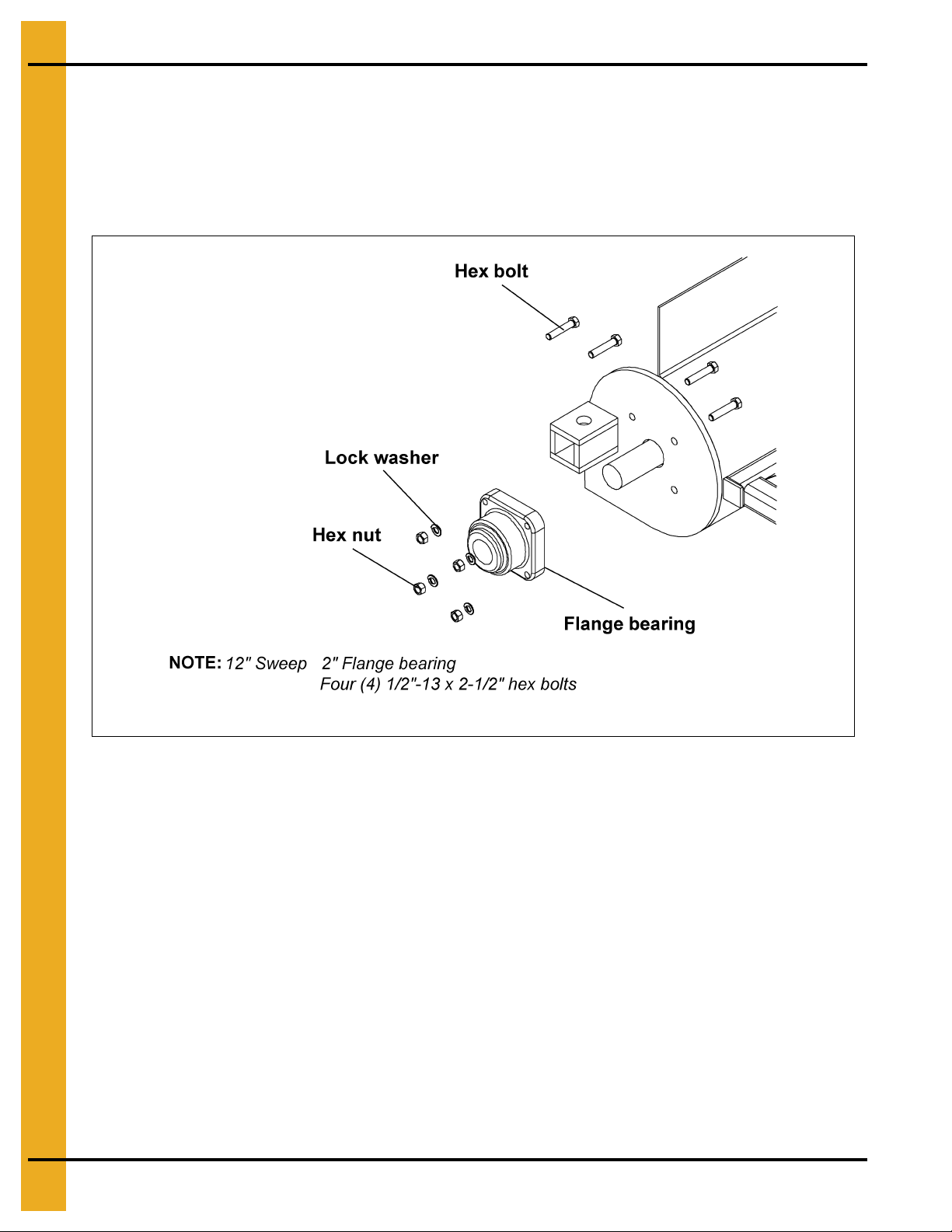

Flange Bearing Assembly

A. Slide the flange bearing onto the end stub and bolt it to the end pla te using hex bolts, lock washers

and hex nuts as shown in Figure 5F.

NOTE: Do not tighten the set screws on the bearing at this time. This can be done after t he gear reducer

is installed.

Figure 5F

Gear Reducer Assembly

A. Slide the output shaft of the reducer through the end plate of the head section and into the end of the

head flight. Secure the reducer output shaft to the head flight with hex bolts and lock nuts.

(See Figure 5G on Page 27.)

B. Bolt the reducer to the end plate of the head section using hex bolts, flat washers and lock washers,

supplied with the reducer. (See Figure 5G on Page 27.)

NOTE: The input shaft of the reducer MUST be to the top of the reducer. Refer to Owner’s manual

supplied with the reducer for proper vent plug, fill plug and drain plug locations.

26 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 27

Figure 5G

The gear reducer is NOT filled with oil from the factory. For gear reducer

specifications and oil fill recommendations, refer to lubrication section o n Page 64

of this manual.

5. Assembly

NOTICE

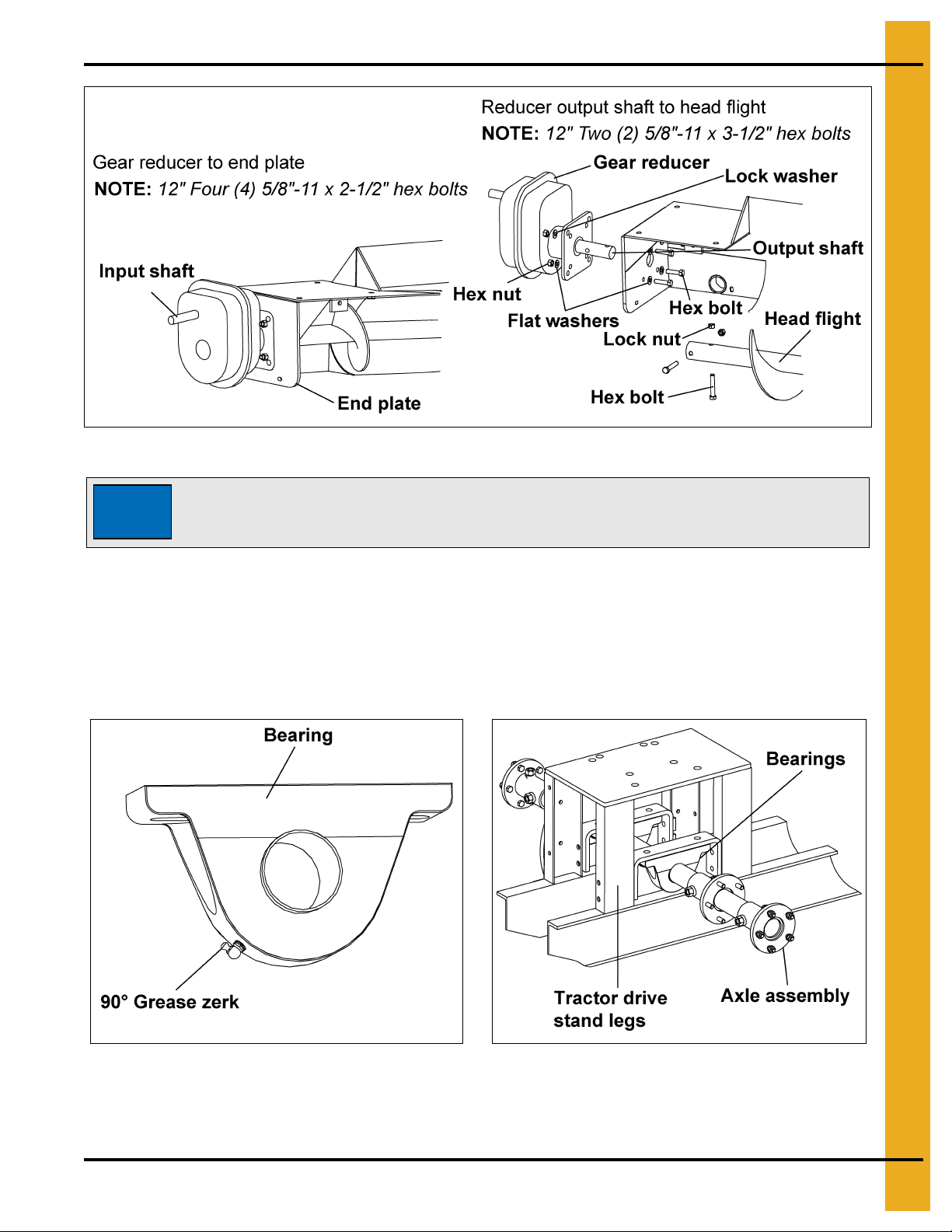

Drive Axle Assembly and Bearing Support

A. Loosen set screws on bearings.

B. Replace standard grease zerks with 90° grease zerks on both bearings. Make sure the 90° grease

zerk is turned as shown in Figure 5H, so the zerks are accessible from the center of the tractor

drive stand.

Figure 5H

C. Slide the axle assembly between the legs of the tractor drive stand as shown in Figure 5I.

D. Rotate the pillow block bearings until the bases are facing up. (See Figure 5I.)

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 27

Figure 5I

Page 28

5. Assembly

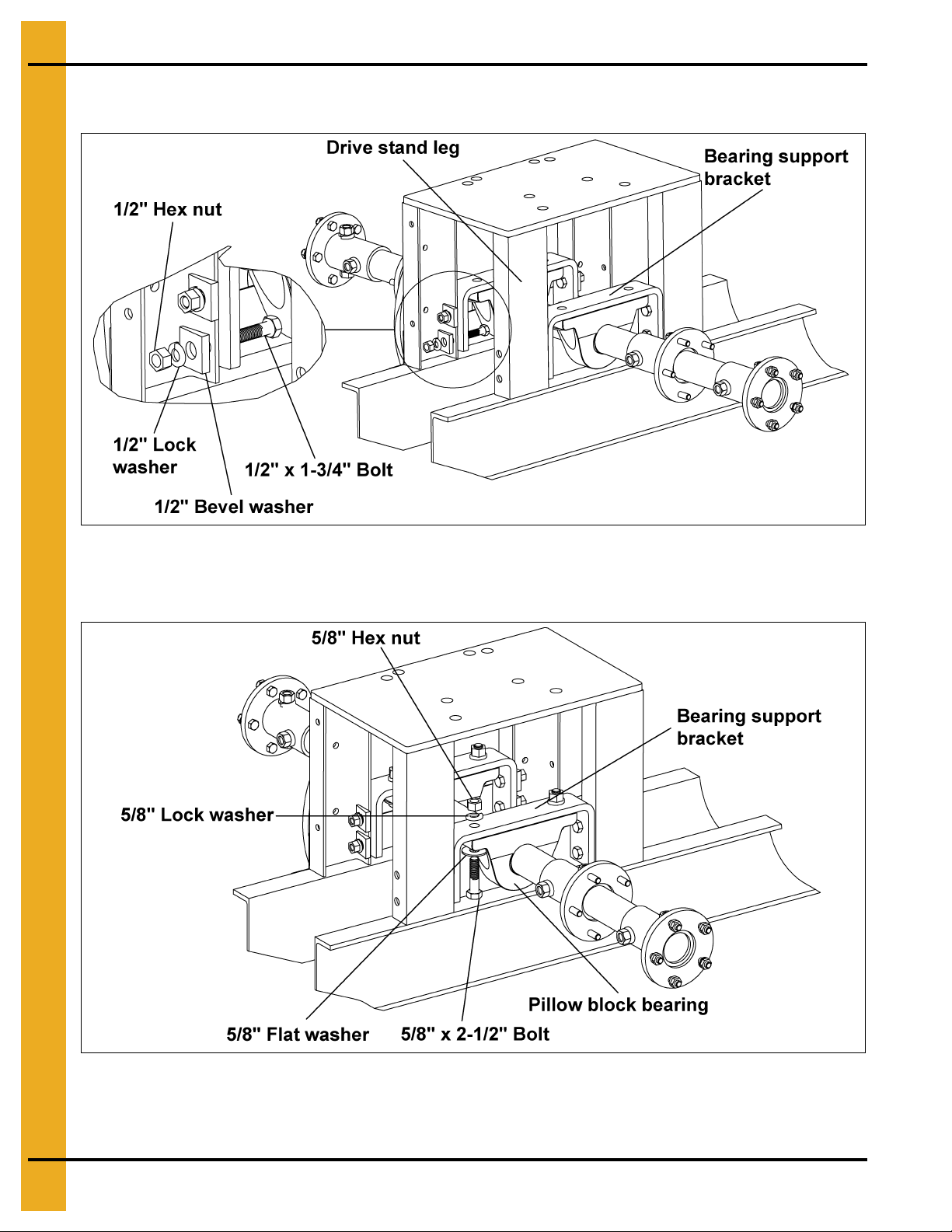

E. Bolt the bearing support brackets to the legs of the tractor drive stand using 1/2" x 1-3/4" bolts,

1/2" lock washers, 1/2" bevel washers and 1/2" hex nuts. (See Figure 5J.)

Figure 5J

F. Attach pillow block bearings to the bearing support brackets using 5/8" x 2-1/2" bolts, 5/8" lock and

flat washers and 5/8" hex nuts. (See Figure 5K.)

Figure 5K

G. Tighten set screws on pillow block bearings.

H. Tighten all hardware.

28 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 29

5. Assembly

CAUTION

The gear reducer is NOT filled with oil from the factory. For gear reducer

specifications and oil fill recommendations, refer to Owner’s manual supplied

with the reducer or the lubrication information in the lubrication section on

Page 64 of this manual.

The tractor drive gear reducer has a drain plug in the bottom of the housing. Make

sure the drain plug is flush or slightly under the surface of the mounting face. If it

is not, the plug will not allow the reducer to set flat on the mounting plate and

could cause the motor to seize.

THIS TYPE OF DAMAGE IS NOT COVERED BY THE WARRANTY.

Install Reducer Mounting Plate and Reducer

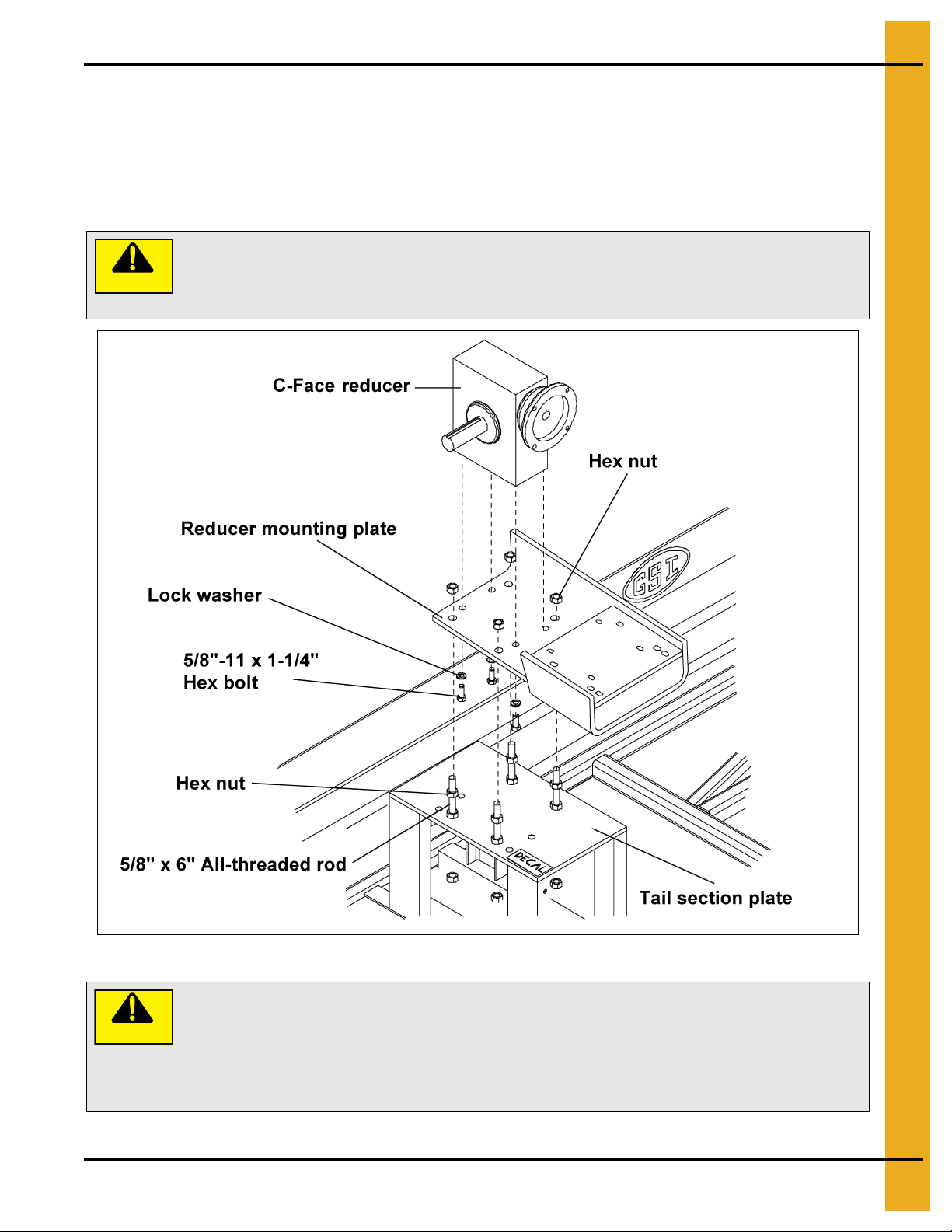

A. Attach the C-face reducer to the mounting plate using four (4) 5/8"-11 x 1-1/4" hex bolts and

lock washers. (See Figure 5L.)

B. Fasten the reducer mounting plate to the tail section plate using four (4) 5/8"-11 x 6" all-thread rods

and sixteen (16) hex nuts. Adjust the mounting plate as close as possible to the tail section plate.

Figure 5L

CAUTION

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 29

Page 30

5. Assembly

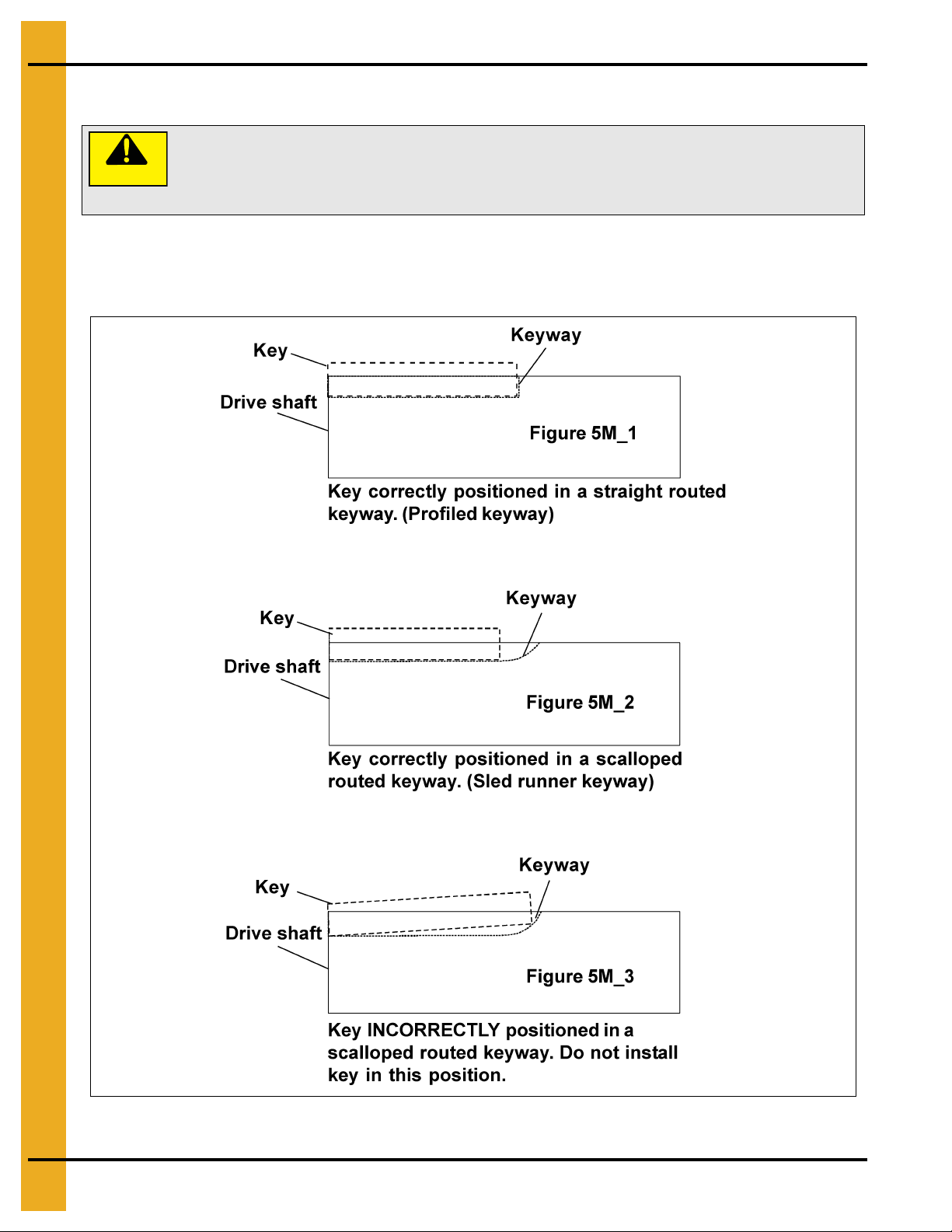

CAUTION

All keys should be parallel to the drive shaft. If the key is not straight (parallel) the

gearbox quill sleeve will crack.

THIS TYPE OF DAMAGE IS NOT COVERED BY WARRANTY.

Key Alignment

A. Place key in keyway on drive shaft.

B. Make sure key is flat (parallel to drive shaft) in keyway as in Figure 5M_1 and Figure 5M_2. NOT

like Figure 5M_3.

Figure 5M

30 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 31

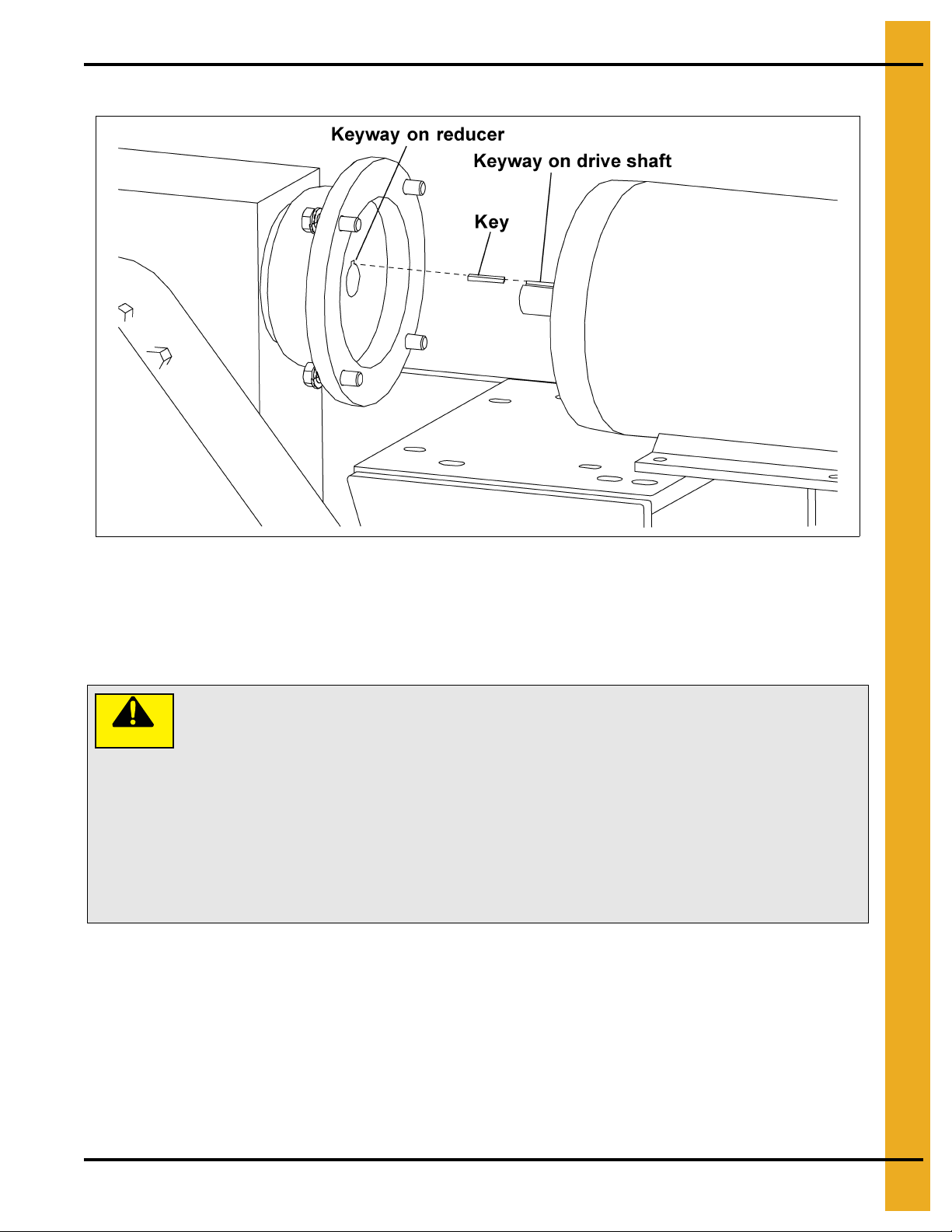

5. Assembly

Do not use the motor mounting bolts to pull the motor down to the motor mount

plate. Instead, add shims (GC09838) between the motor feet and the motor mount

plate to fill any gap. If these shims are not used as required, the motor front

bearing may be pushed out of alignment and the motor will lock up. If the gap

seems unusually large, over 1/4", check to make sure the gear reducer is setting

flat on its mounting base. The tractor drive gear reducer has a drain plug in the

bottom of the housing. Make sure the drain plug is flush or slightly under the

surface of the mounting face. If it is not, the plug will not allow the reducer to set

flat on its mounting plate, causing damage to the motor.

THIS TYPE OF DAMAGE IS NOT COVERED BY WARRANTY.

C. Line up keyway on shaft with keyway on reducer and insert shaft into motor. (See Figure 5N.)

Figure 5N

Install Tractor Drive Motor

A. Bolt the C-face motor to the reducer using hex bolts, lock washers and a key. (See Figure 5O on

Page 32.) (See the note on Page 32 for bolt size.)

CAUTION

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 31

Page 32

5. Assembly

182TC Frame Four (4) 1/2"-13 x 1-1/4" hex bolts and 1/4" x 1/4" x 1" key

NOTE:

Figure 5O

Guard Assembly

A. Attach the guard plate to the tractor drive stand legs using 3/8" bolts and nuts before attaching the

drive sprocket. (See Figure 5P on Page 33.)

B. Slide the fourteen (14) tooth (teeth N/S) drive sprocket, bushing and key (see key chart on

Page 33 for the size key) onto the output shaft of the reducer, make sure both sprockets line up.

(See Figure 5P and Figure 5P_A on Page 33.)

C. Assemble the bottom chain guard trap to the bottom chain guard weldment using 1/2" x 3" HHCS

bolts, 1/2" split lock washers and 1/2" hex nuts.

D. Attach bottom chain guard weldment to tractor drive stand using 3/8" x 1-1/4" HHCS bolts,

3/8" split lock washers and 3/8" hex nuts. (See Figure 5P on Page 33.)

E. Attach top chain guard assembly to tractor drive stand using 3/8" x 1" bolts, 3/8" split lock washers

and 3/8" hex nuts. (See Figure 5P on Page 33.)

(See Figure 5P on Page 33.)

32 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 33

5. Assembly

Key chart

5 HP - 3/8" x 2" Key

Wedging forces in the bushing saw slot, such as that exerted by a narrow edged

regular screw driver, may damage or break the bushing. This damage would not

be covered under the GSI warranty.

CAUTION

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 33

Figure 5P

Page 34

5. Assembly

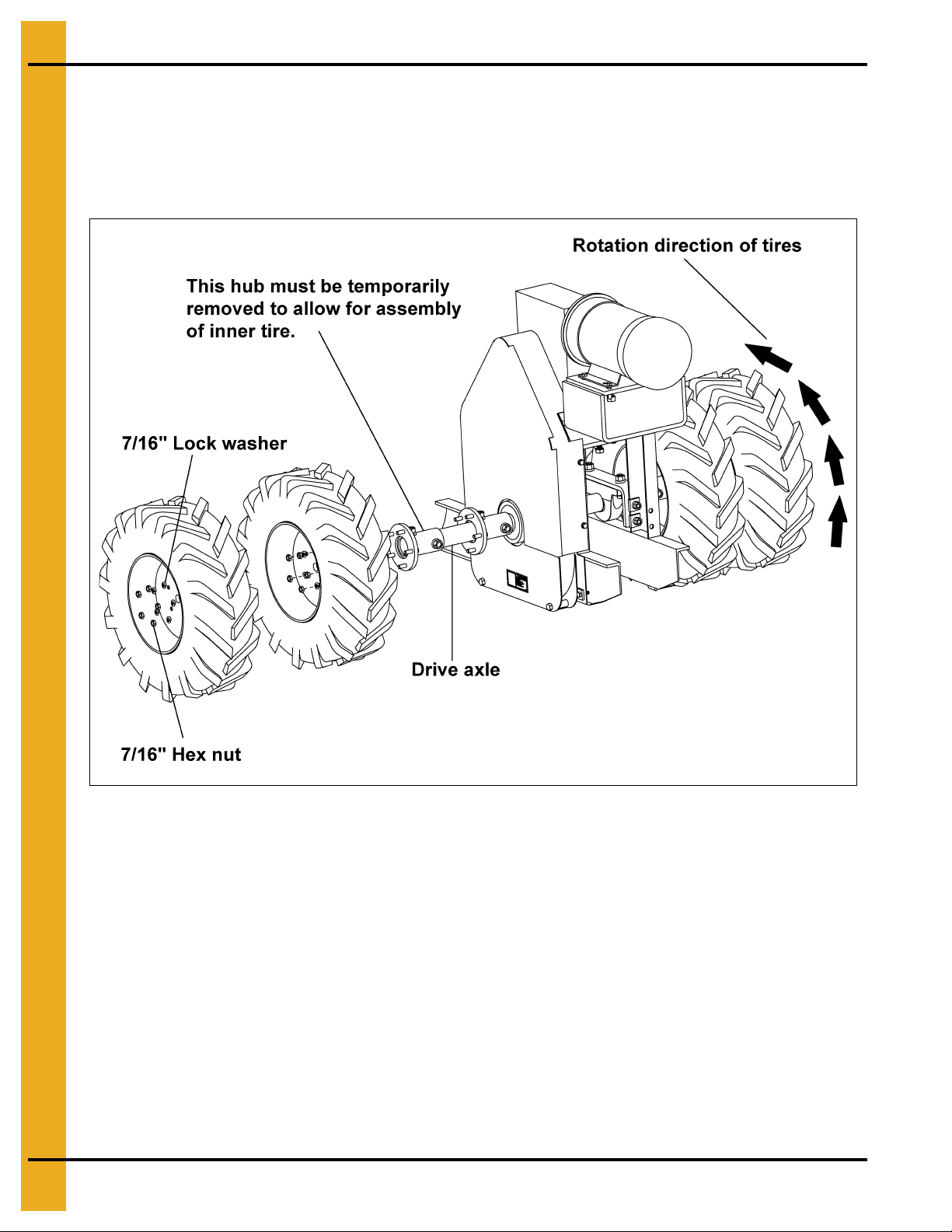

Tractor Wheel Assembly

A. Assemble the tires to the drive axle assembly using twenty (20) 7/16" lock washers and hex nuts.

(See Figure 5Q.)

NOTE: Tires go on backwards as shown in Figure 5Q.

Figure 5Q

34 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 35

5. Assembly

CAUTION

Use proper lifting procedures and equipment when lifting the weights. Each

weight weighs 175 pounds.

Weight Placement

A. Place an equal number of weights on each side of the drive assembly on the six inch (6") channels

that are welded to the tail section.

Figure 5R

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 35

Page 36

5. Assembly

Channel Extension Kit

A. 131' and 135' Sweeps need an extension kit installed.

B. Attach the center weight weldments to the adjustable center weight channel using eight (8)

1/2" x 1-1/4" bolts, split lock washers and hex nuts. The adjustable center weig ht has thre e (3) sets

of holes for the center weight weldments to adjust the weights. (See Figure 5S.)

Figure 5S

C. Place assembly on top of the back tail section, around the tires. The end of the adjustable center

weight should be placed under the tail frame. (See Figure 5T.)

Figure 5T

D. Fasten assembly to tail section using two (2) 3/8" x 2-7/16" U-bolts, four (4) 3/8" lock washers and

four (4) 3/8" hex nuts.

36 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 37

5. Assembly

Motor Jack and Base Assembly

A. Attach the motor mount base assembly to the head section using four (4) 3/4" x 2" bolts,

lock washers and hex nuts. (See Figure 5U.)

B. Attach the motor jack assembly to the motor mount base assembly using four (4) 1/2"-13 x 1-1/2"

bolts, 1/2" flat washers and 1/2" hex nuts.

Figure 5U

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 37

Page 38

5. Assembly

Motor bolt

(See chart below for size)

Motor Installation

A. Level the top plate assembly by adjusting the 1" nuts and washers on the adjustment rods.

(See Figure 5V.)

B. Line up the end face of the shafts as closely as possible before bolting motor to mounting plate.

(See Figure 5V-A.)

Figure 5V

C. Fasten the motor to the motor mount using hex bolts, lock washers and hex nuts. (See Motor Bolt

Chart for bolt sizes.)

Motor Bolt Chart

Motor Size Hex Bolt Size Qty

213T 3/8"-16 x 1-1/4" 4

215T 3/8"-16 x 1-1/4" 4

254T 1/2"-13 x 1-3/4" 4

256T 1/2"-13 x 1-3/4" 4

284T 1/2"-13 x 1-3/4" 4

286T 1/2"-13 x 1-3/4" 4

38 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 39

Sheave Installation

WARNING

To ensure that the drive is not unexpectedly started, turn OFF and lock out the

power source before proceeding. Failure to observe these precautions could

result in bodily injury.

Wedging forces in the bushing saw slot, such as that exerted by a narrow edged

regular screw driver, may damage or break the bushing. This damage would not

be covered under the GSI warranty.

CAUTION

5. Assembly

Figure 5W

A. Loosely bolt the bushing and large sheave together with the screws provided with the bushing.

B. Slide the bushing and large sheave onto the auger gear reducer input shaft with a key.

(See Figure 5W.)

C. Loosely bolt the bushing and small sheave together with the screws provided with the bushing.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 39

Page 40

5. Assembly

D. Slide the bushing and small sheave onto the motor shaft with a key. (See Figure 5X.)

Figure 5X

E. Align the sheaves with a straight edge to assure proper alignment and tighten the screws on the

bushings. (See Figure 5X.)

F. Carefully install the belts onto the large and small sheaves. (See Figure 5Y on Page 41.)

NOTE: Adjust the hex nuts on the motor mount adjustment rod to attain correct belt tension while

making sure the motor mount is level on both rods. The motor mount must be parallel to the

auger screw to allow for proper sheave alignment.

40 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 41

5. Assembly

G. Loosely bolt the bottom belt guard to the motor mount using four (4) 3/8"-16 x 1" hex bolts, flat

washers and lock washers. (See Figure 5Y.)

Figure 5Y

H. Slide the top belt guard over the bottom belt guard as shown in Figure 5Y and tighten bolts.

I. Install belt guard bottom back plate.

J. Slide belt guard bottom pan and bolt into place.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 41

Page 42

5. Assembly

WARNING

All electrical wiring and service work must be performed by a qualified

electrician and must meet all state and local electrical codes.

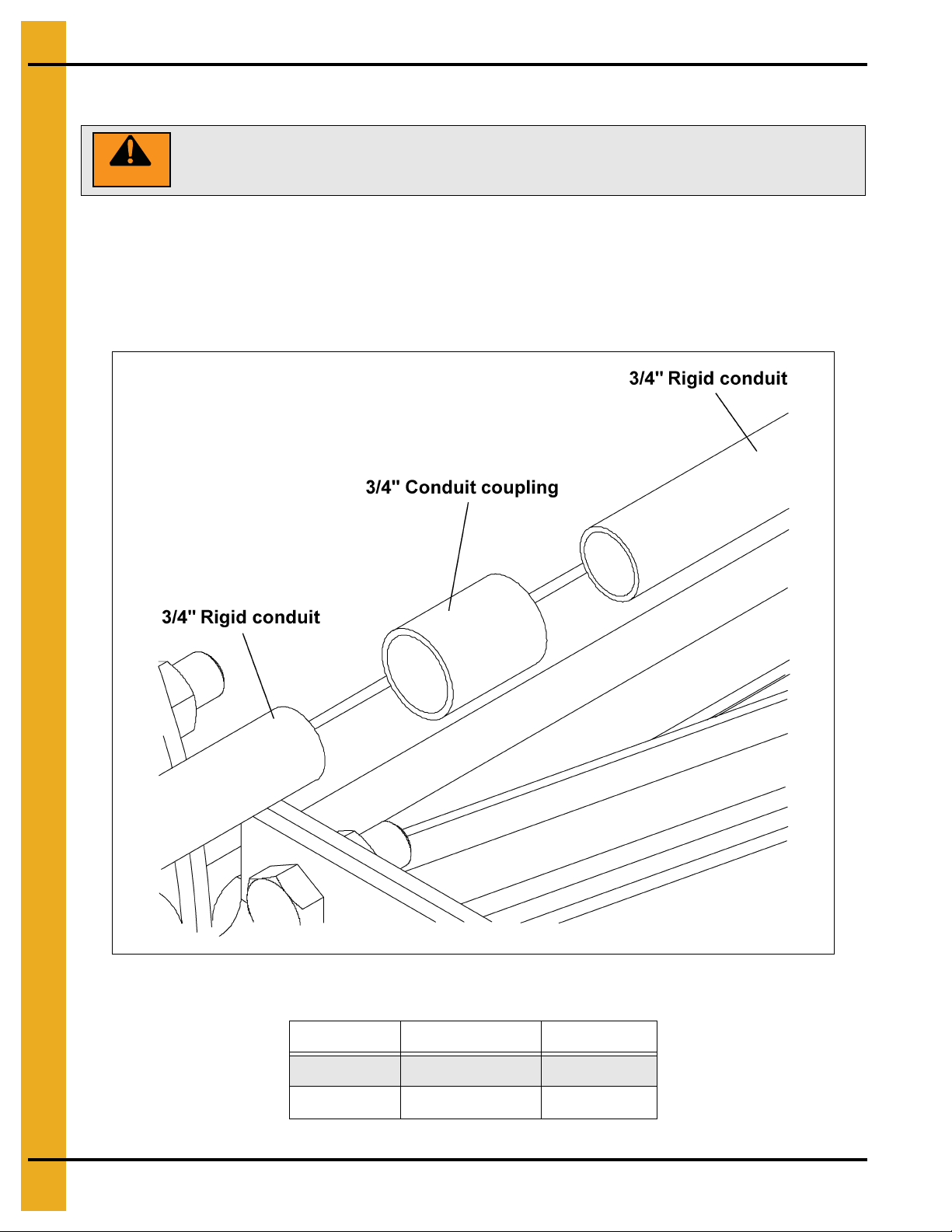

Electrical Assembly

NOTE: See Chart below for the correct size of conduit with the corresponding sweep size.

A. Place the 3/4" rigid conduits in order starting with the head section and working towards the tail or

extension section.

B. Connect the rigid conduit together using one 3/4" conduit coupling between each piece of conduit.

(See Figure 5Z.)

Figure 5Z

Sweep Section Conduit Sizes

Bin Diameter 10' Conduit Pieces Other Pieces

131' 4 1 at 5'

135' 4 1 at 7'

42 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 43

5. Assembly

C. Connect the 3/4" x 48" liquid-tight flex conduit to the drive end of the 3/4" rigid conduit using one

3/4" conduit coupling and one 3/4" liquid-tight flex conduit coupling. (See Figure 5AA.)

1. Thread a 3/4" conduit coupling onto the 3/4" rigid conduit. (See Figure 5AA.)

2. Thread a 3/4" flex conduit coupling body onto the 3/4" conduit coupling. (See Figure 5AA.)

3. Slide a 3/4" flex conduit coupling cap onto the 3/4" flex conduit followed by a plastic ring.

(See Figure 5AA.)

4. Thread a steel ring into the 3/4" flex conduit. (See Figure 5AA.)

5. Thread the 3/4" flex conduit coupling cap onto the 3/4" flex conduit coupling body.

(See Figure 5AA.)

Figure 5AA

D. Attach the 3/4" x 12" liquid-tight flex conduit to the other end of the rigid conduit using one 3/4"

conduit coupling and one 3/4" liquid-tight flex conduit coupling. (See Figure 5AB.)

E. Connect the two (2) junction boxes together using the 1" x 4-3/4" conduit nipple. (See Figure 5AB.)

F. Connect the 3/4" x 12" liquid-tight flex conduit to the left junction box using one 3/4" liquid-tight flex

conduit coupling and one 1" to 3/4" reducer bushing. (See Figure 5AB.)

G. Attach the 3/4" x 40" liquid-tight flex conduit to the right junction box using one 3/4" liquid-tight flex

conduit coupling and one 1" to 3/4" reducer bushing. (See Figure 5AB.)

Figure 5AB

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 43

Page 44

5. Assembly

H. Feed each of the six (6) 14 AWG stranded wires through the 3/4" rigid conduit assembly and cut

them off, leaving six inches (6") at both the left junction box and drive motor.

I. Feed each of the six (6) 10 AWG stranded wires cord through the 3/4" x 40" liquid-tight flex conduit

and cut four (4) of them off, leaving six inches (6") at both the right junction box and auger motor.

Cut the 10 AWG blue and yellow wires longer so they can be connected to the 14 AWG blue and

yellow wires in the left junction box.

J. Place the 3/4" rigid conduit assembly onto the back frame of the sweep between the connecting

angle and connecting flange.

Figure 5AC

K. Fasten the junction boxes to the mounting plate using two (2) 3/8"-16 x 1-3/8" U-bolts, four (4) lock

washers and hex nuts.

Figure 5AD

44 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 45

5. Assembly

L. Attach the 3/4" rigid conduit assembly to the sweep using the 5/16"-18 x 3/4" studs welded to the

sweep using 1" conduit clamps, lock washers and hex nuts.

M. Run the 14 AWG stranded wires into the drive motor and fasten the 3 /4" x 48" liquid-tight flex conduit

to the motor using one 3/4" liquid-tight flex conduit coupling. Some motors may require a reducer

bushing not supplied with the sweep. Connect the leads as required.

Figure 5AE

N. Run the 10 AWG stranded wires into the auger motor and fasten the 3/4" x 40" liquid-tight flex

conduit to the motor using one 3/4" liquid-tight flex conduit coupling. Some motors may require a

reducer bushing not supplied with the sweep. Connect the leads as required.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 45

Page 46

5. Assembly

Jack Support Assembly

NOTE: Be sure to use the spanner bushings, supplied with the caster wheels, between the caster and the

caster plate on each side.

Jack Support (See Figure 5AF below and Figure 5AG on Page 47.)

A. Attach one caster wheel to the jack caster assembly using one 3/4" x 5-1/2" hex bolt, lock washer

and hex nut.

B. Locate the 2" x 2" x 12" tube to the right of each connecting angle and fasten the jack mount

assembly to the sweep frame using one jack mount plate, four (4) 1/2"-13 x 3-3/4" hex bolts, lock

washers and hex nuts.

C. Attach the jack caster assembly to the jack assembly using one pin.

D. Bolt the jack assembly to the jack mount assembly using four (4) 1/2"-13 x 2" hex bolts, lock washers

and hex nuts.

Figure 5AF Current Production Sweep Sh own

46 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 47

5. Assembly

Figure 5AG

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 47

Page 48

5. Assembly

CAUTION

The center pipe of the pivot assembly MUST be in the center of the bin. If it is

not, the sweep could hit the bin wall.

Center Pivot Installation

A. Center pivot with pivot kit

1. Use the pivot assembly supplied with the sweep pivot kit and cut it to fit, if needed.

2. Feed the multi-conductor cord through the hole in the back of the sweep head section leaving

five feet (5') of cord outside the hole. (See Figure 5AH.)

Figure 5AH

48 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 49

5. Assembly

3. Feed the power cord through the pivot tube. (See Figure 5AI.)

4. Align the hole in the back shield with the pivot tube and push the sweep onto the pivot tube.

(See Figure 5AI.)

5. Connect the pivot plate to the back shield using two (2) 1/2"-13 x 1-3/4" hex bolts, flat washers,

lock washers and hex nuts. (See Figure 5AI.)

6. Fasten the pivot rod to the back shield and pivot plate using two (2) 1/2"-13 x 2" hex bolts, lock

washers and hex nuts. (See Figure 5AI.)

7. Screw the 45° grease fitting into the pivot assembly pipe. (See Figure 5AI.)

Figure 5AI

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 49

Page 50

5. Assembly

8. Connect the 1" x 48" liquid-tight flex conduit to the pivot tube using one 1" conduit coupling and

one 1" liquid-tight flex conduit coupling. (See Figure 5AJ.)

9. Connect the 1" x 48" liquid-tight flex conduit to one of the junction boxes using one 1" liquid-tight

flex conduit coupling. Connect the leads as required. (See Figure 5AJ.)

10. The customer is to provide proper power cord protection between the pivot assembly and the

sump transition. (See Figure 5AJ.)

Figure 5AJ

11. The multi-conductor power cord can be connected with the 14 AWG/3 wire, 14 AWG/4 wire and

10 AWG/4 wire cords in an explosion proof junction box.

12. Hardwire foot switch to terminal 3 and terminal 4 in control panel.

(See Schematic on Pages 69-72.)

13. Hardwire motor thermostat J-wires to terminal 1 and terminal 2 in control panel. (See Schematic

on Pages 69-72.)

14. Hardwire motors to starters in control panel. (See Schematic on Pages 69-72.)

50 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 51

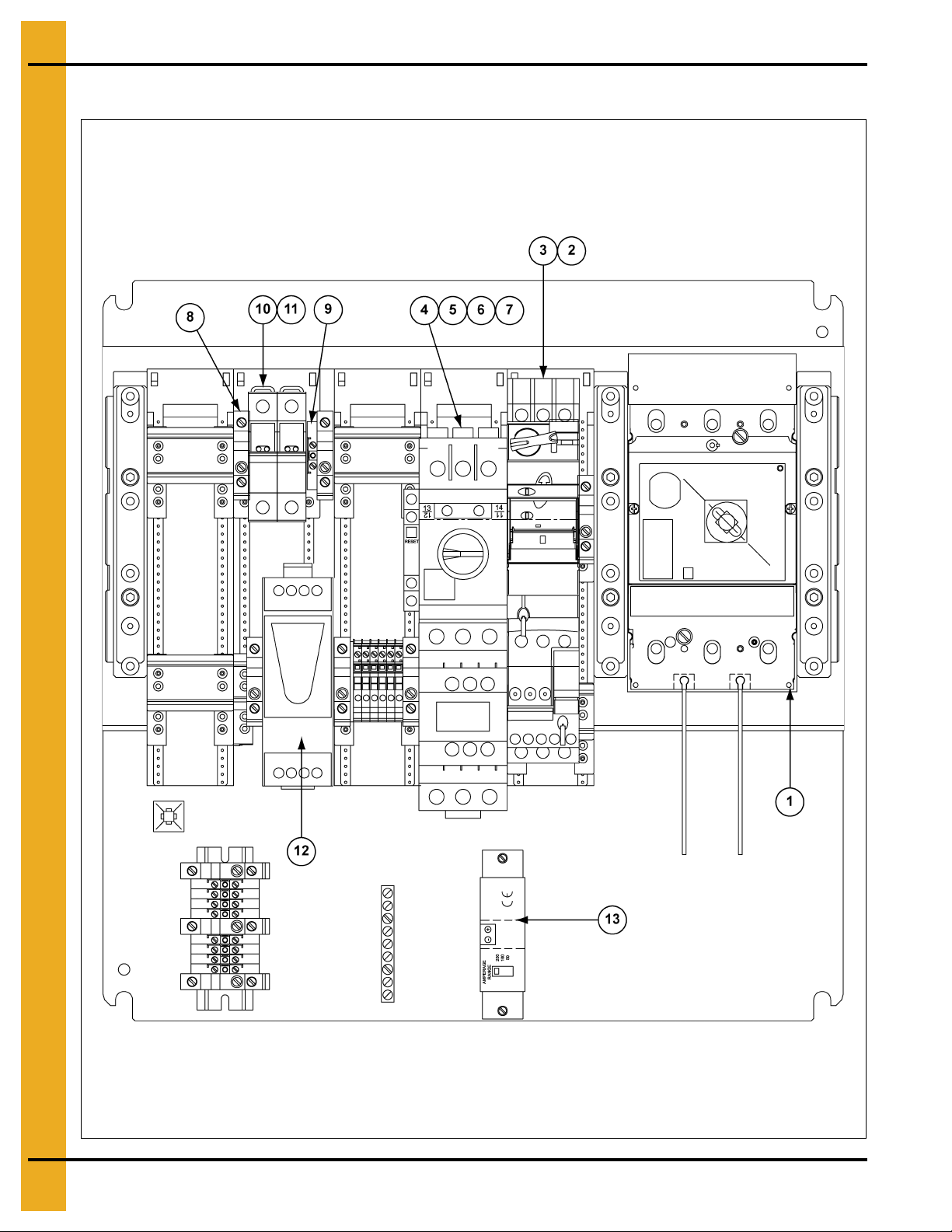

Control Panel Setup

If the meter looks like this:

5. Assembly

Figure 5AK

Follow these instructions:

The control panel is intended for hard wired connections for power in, auger drive motor wiring,

tractor drive motor wiring and the thermal overload wiring for both the auger drive motor and the tractor

drive motor.

If the system that this control panel is designed to have the cables for the auger drive motor and the tractor

drive motor run inside the bin on the floor and exit through the bin door, a plug package is available to

allow the panel to connect to the cords without hard wiring. This package is GC20117. This package is

only standard in the center pin style sweep systems and not in the protected cord center swee p systems.

Control Panel Calibration

Observe the tractor drive motor nameplate and the auger drive motor nameplate.

Record the full load amp (FLA) value for the specific voltage on each motor.

Auger drive motor full load amps: ____

Tractor drive motor full load amps: ____

Switch the disconnect switch on the panel to OFF (not ON).

Unlock and open the control panel.

Adjust the FLA dial screw on the tractor drive motor contactor (M1) and the auger drive motor contactor

(M2) so that the indicator arrowhead is set slightly higher than the full load amp value listed on

the nameplates.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 51

Page 52

5. Assembly

Tractor drive motor contactor (M1) FLA adjustment dial: ____

Auger drive motor (M2) FLA adjustment dial value: ____

Close and lock the control panel.

Switch the disconnect switch on the panel to ON (not OFF).

Initial Display Setup

NOTE: If no keys are activated for 2 minutes, the display returns to the default state without saving any

configuration changes. At each value, after 5 seconds of inactivity, a description of the current

state will scroll across the display.

NOTE: Pressing and hold OK will re turn to the previous menu or return to t he default state without saving

the changed values or parameters.

Press OK on the display unit.

(IN) should be displayed on the unit.

Press or on the display unit until (CURR) is shown (not VOLT, POTM or TEMP).

Press OK.

(RANG) should be displayed on the unit.

Press or on the display unit until 4-20 is shown (not 0-20).

Press OK.

(DEC.P) should be displayed on the unit.

Press or on the display unit until 11.11 is shown (not 1111, 111.1, 1.111 or .1111).

Press OK.

(DI.LO) should be displayed on the unit.

Press or on the display unit until 0 is shown.

Press OK.

(DI.HI) should be displayed on the unit.

The DI.HI value is 2x the value that the FLA dial on the auger drive motor (M2) that was set earlier.

2x FLA dial: ____

Press or on the display unit until the correct value is shown.

Press OK repeatedly until “-----” is displayed. This indicates the programming described above has

been saved.

Make sure no individual is inside the bin.

Make sure the sweep will not contact any obstruction and cause damage.

Have an employee observe the sweep from outside the bin, through the open door.

The person observing the sweep is meant to have control over the safety foot switch.

Have another employee operate the control panel.

52 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 53

5. Assembly

Switch the Run Mode switch so that Manual is selected (not Auto).

Switch the Manual Mode switch to Idle (not reverse or forward).

Depress the pedal in the safety foot switch.

Press the Start button on the control panel.

NOTE: If any damage is observed or t here is abnormal operation of the sweep, shut it down immediately.

There are three (3) ways to accomplish this. 1) Remove the pressure on the safety foot switch.

2) Press the Stop button on the control panel. 3) Press in on the Enable/Disable button so that it

collapses appropriately. Switch the disconnect switch on the panel to OFF (not ON). Lock out the

panel before entering the bin to service the sweep.

Observe the no load amps (NLA) displayed on the meter on the front of the panel.

Auger drive motor no load amps: ____

The tractor motor operation (forward and stop) in automatic is dictated by the amp reading on the auger

drive motor.

The tractor drive motor is meant to shut off (idle) when the auger drive motor reaches 90% of the

nameplate FLA.

90% of full load amps: ____

The tractor motor is meant to reactivate (forward) when the auger drive motor reaches 110% of the

no load amps (amperage observed when the auger flight turns freely in absence of grain).

110% of no load amps: ____

Final Display Setup

NOTE: If no keys are activated for 2 minutes, the display returns to the default state without saving any

configuration changes. At each value, after 5 seconds of inactivity, a description of the current

state will scroll across the display.

Press OK repeatedly until RELU is displayed on the unit.

Press or on the display unit until DISP is shown (not PERC).

Press OK.

REL1 should be displayed on the unit.

Press or on the display unit until SET is shown (not SKIP or OFF).

Press OK.

SETP should be displayed on the unit.

Press or on the display unit the 90% of FLA value is shown.

Press OK.

ACT1 should be displayed on the unit.

Press or on the display unit until INCR is shown (not DECR).

Press OK.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 53

Page 54

5. Assembly

HYS1 should be displayed on the unit.

For this control panel hysteresis (HYS1) is measured as the different between 90% of full load amps and

110% of no load amps.

90% of full load amps: ____ minus 110% of no load amps: ____

Press or on the display unit until the correct value is shown.

Press OK.

ERR1 should be displayed on the unit.

Press or on the display unit until DEAC is shown (not HOLD, ACTI or NONE).

Press OK.

ON.DE should be displayed on the unit.

Press or on the display unit until 0 is shown.

Press OK.

OF.DE should be displayed on the unit.

Press or on the display unit until 20 is shown.

Press OK.

REL2 should be displayed on the unit.

Press or on the display unit until OFF is shown (not SET or SKIP).

Press OK.

E.PAS should be displayed on the unit.

Press or on the display unit until NO is shown.

Press OK.

This function will allow the values that were entered to be locked.

NOTE: Using a password will stop access to the menu and parameters. There are two (2) levels of

password protection. Passwords between 0000 and 4999 allow access to the fast set point

adjustment and relay test. (Using this password stops access to all other parts of the menu.)

Passwords between 5000 and 9999 stop access to all parts of the menu, fast set point adjustment

and relay test. (Current set point is still shown.) By using the master password 2008, all

configuration menus are available.

If you select NO, press OK.

If you select YES, N.PAS will be displayed. Press or on the display unit until your password is shown.

Press OK. Document this password.

The password will be necessary if there needs to be changes to many of the configuration values.

54 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 55

If the meter looks like this:

NEVER program the “High Amp Set Point” greater than the full load running

amps of the auger motor.

Follow these instructions:

5. Assembly

Figure 5AL

NOTE: In order to fine tune the control panel, the bin must have grain in it.

The Series II Sweep is supplied with adjustable overloads that are not set at the factory. These should be

set slightly higher than the Full Load Amp (FLA) value listed on the motor nameplates.

A. Find the desired “High” Amp and “Low” Amp set points.

1. High Amp Set Point: The Amp load the auger draws when the auger flighting is 90% loaded.

This will turn OFF the tractor drive motor. Initially, set the value to 90% of the Full Load Amps

(FLA) listed on the motor nameplate.

2. Low Amp Set Point: The Amp load the auger motor draws when the auger flighting is 10%

loaded. This will turn ON the drive motor. Initially, set this value to 10% over the Amp draw of the

sweep running empty.

CAUTION

B. Programming the Amp Meter.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 55

Page 56

5. Assembly

Calibration

1. Setting Input

a. Press “PRGM” to “inPut”.

b. Press “ENTER”.

c. Press “PRGM” to “i4-20”.

d. Press “ENTER” to RUN MODE.

2. Setting Setup

a. Press “PRGM” to “SEtuP”.

b. Press “ENTER” to “rdEC”

Use arrow buttons to change the decimal placement. Show .0 Amps.

c. Press “ENTER” to “SETLO”.

d. Press “ENTER”

Value = 0.0

e. Press “ENTER” to “SEtHi”.

f. Press “Enter”

Value = 50.0

Use arrow buttons to change value.

g. Press “ENTER” to “LoCut”.

Press “ENTER”

This value = 0

h. Press “ENTER” to RUN MODE.

56 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 57

Operation

1. Setting Presets

a. Press “Pre A”.

b. Press “PRGM”

This value = “High Amp Set Point”.

Use arrow buttons to change value.

c. Press “ENTER”.

2. Setting Relays

a. Press “PRGM” to “rELAYS”.

b. Press “ENTER” to “HYS A”.

c. Press “PRGM”

This value = “High Amp Set Point”-“Low Amp Set Point”

Use arrow buttons to change value.

5. Assembly

d. Press “ENTER” to RUN MODE.

EXAMPLE: Full Load Running Amps = 21 Amps

High Amp Set Point = 20 Amps

Low Amp Set Point = 12 Amps

Then “HYS A” = 8 Amps

And “Pre A” = 20 Amps

NOTE: This is the difference between the High Amp Set Point and the Low Amp Set Point.

[20 Amps-12 Amps = 8 Amps]. Low Amp Set Point is only used to calculate this value.

C. Locking the Amp Meter

1. Locking the Amp meter is not required but prevents the meter from being tampered with once it

is programmed.

2. In RUN MODE, press “LOCK” three (3) times within five (5) seconds.

This value = A number that is easily remembered.

Use arrow buttons to change value.

a. Press “ENTER”.

D. Unlocking the Amp Meter

1. In RUN MODE, press “LOCK” three (3) times within five (5) seconds.

a. Enter the “LoC” value.

Use arrow buttons to change value.

b. Press “ENTER”.

NOTE: It is recommended to write down the “LoC” value and keep it in a safe place in case it

is forgotten.

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter 57

Page 58

6. Start-Up

WARNING

To ensure that the drive is not unexpectedly started, turn OFF and lock out the

power source before proceeding. Failure to observe these precautions could

result in bodily injury.

DANGER

Failure to perform any or all of these pre-start checks may cause damage to the

equipment and/or cause SERIOUS INJURY or DEATH to those in the work area.

Failure to perform any or all of these pre-start checks may also be a misuse of

the equipment. Any misuse of the equipment may void the warranty.

WARNING

ALWAYS keep ALL guards and shields in place, until all the power is

disconnected and locked out.

CAUTION

Be sure to remove the grain from the drive chain and sprockets. If this is not

done, damage can occur to the drive system.

WARNING

Make certain ONLY trained operators are in the work area before operating or

moving the machine. Two (2) people must always be in position to monitor the

operation of the equipment from outside the bin.

Perform Pre-Start Checks

A. Make sure ALL shields are in place.

B. Inspect the drive unit for any problems or potential problems.

C. Be aware of any emergency shut down procedures. Two (2) people must always be in position to

monitor the operation of the equipment from outside the bin.

D. Before starting the auger for the first time, make sure that all parts are assembled correctly according

to the instructions in this manual.

58 PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Page 59

6. Start-Up

CAUTION

DO NOT start or stop the auger while it is under load.

CAUTION

Failures may occur if the auger is run full before it has been “polished” during