Page 1

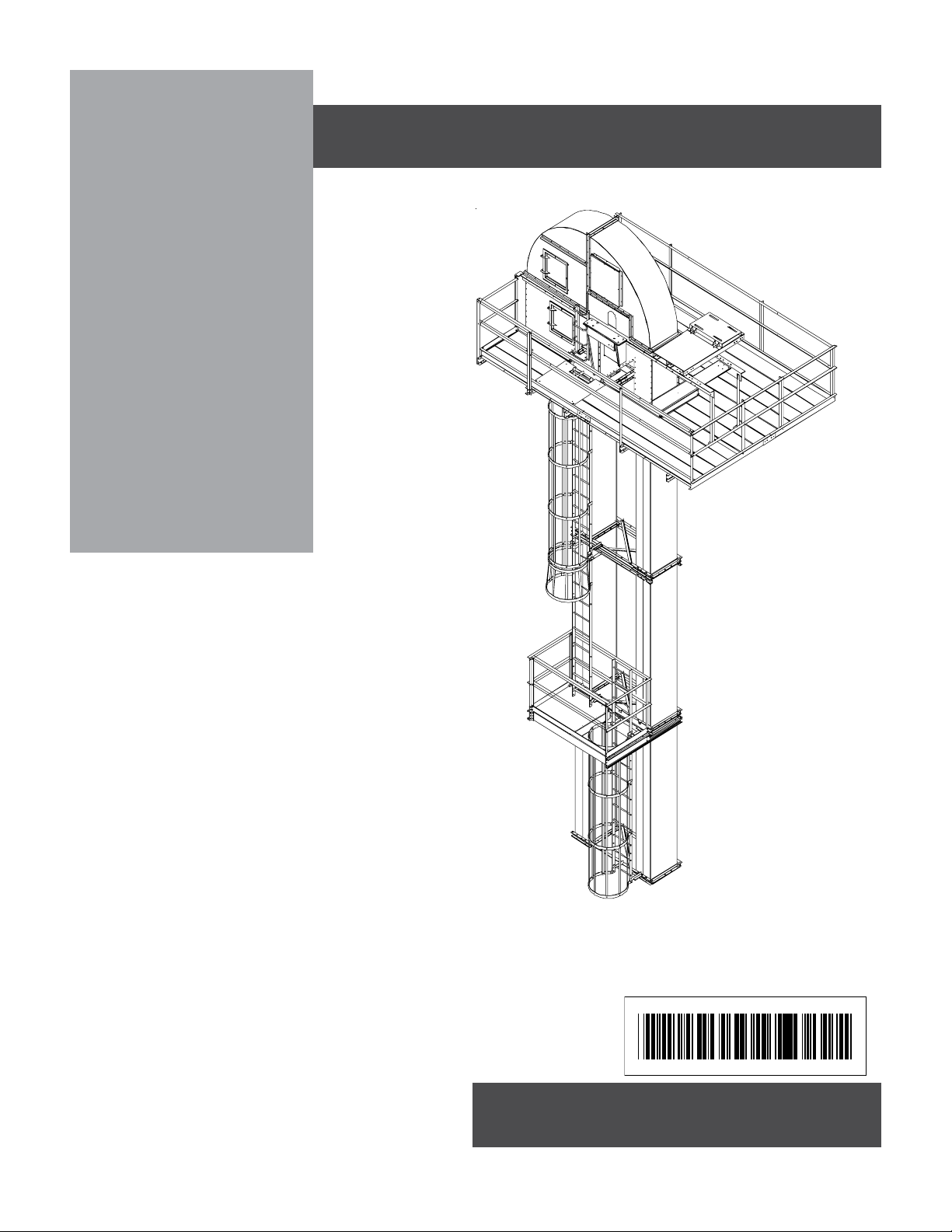

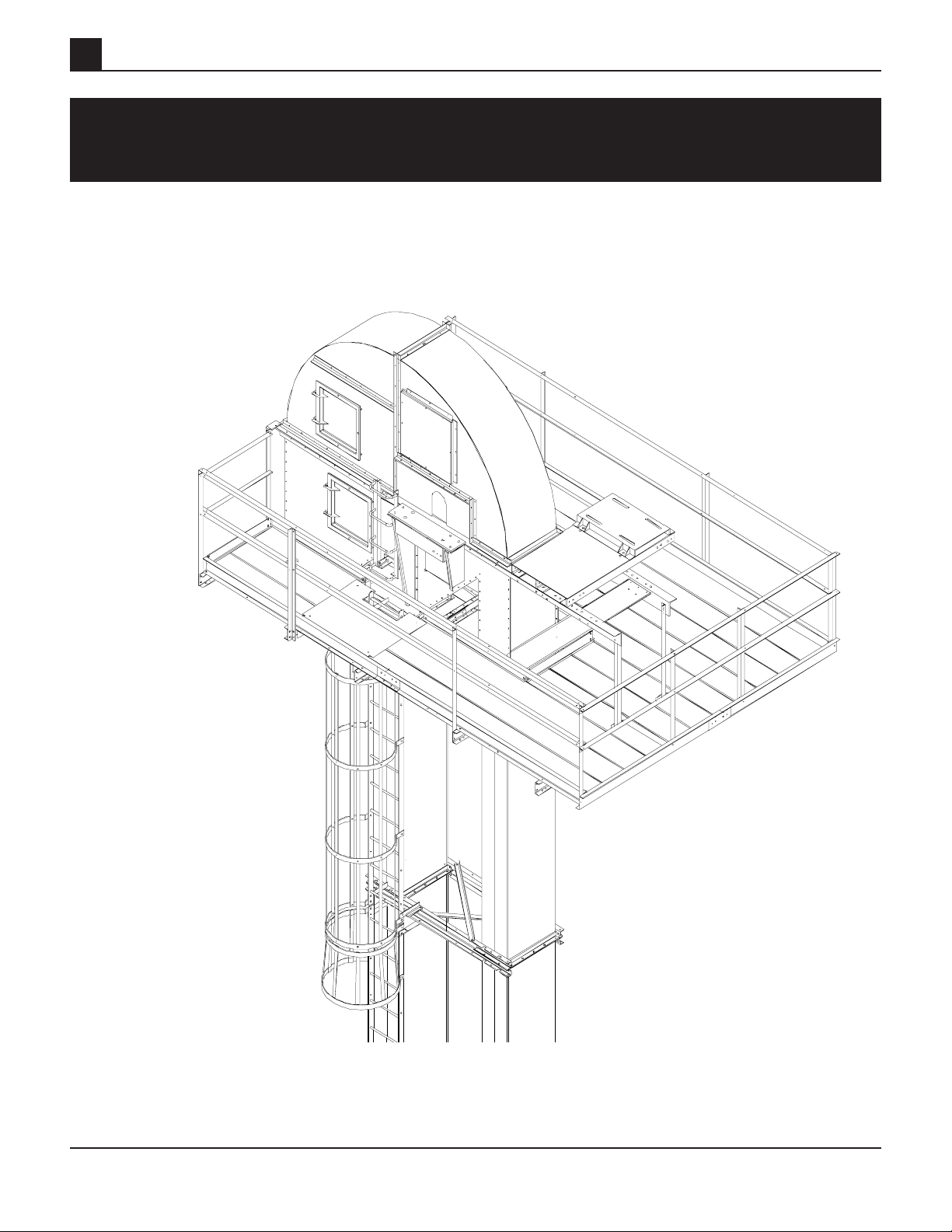

42" - 48"

Platform,

Safety Cage, &

Rest Platform

for Bucket Elevators

Installation Manual

PNEG-739

Revision Date: 10-16-2006

PNEG-739

Page 2

Page 3

Introduction

READ THIS MANUAL carefully to learn how to

properly use and install equipment. Failure to do

so could result in personal injury or equipment

damage.

INSPECT the shipment immediately upon arrival.

The Customer is responsible for ensuring that all

quantities are correct. Report any damage or

shortages by recording a detailed description on

the Bill of Lading to justify the Customer’s claim

from the Transport Firm. Our responsibility for

damage to the equipment ends with acceptance

by the delivering carrier. Save all paperwork and

documentation furnished with any of the equipment.

Introduction

When laying out the ladder, safety cage,

and platforms be sure and always start

from the head service platform and work

your way down the leg. Keep in mind a

rest platform needs to be located at every

30’ of vertical descent (OSHA Standards).

THIS MANUAL SHOULD BE CONSIDERED a

permanent part of your equipment and should be

easily accessible when needed.

WARRANTY is provided as part of the company’s

support program for customers who use and

properly maintain their equipment. The warranty is

explained on the warranty page located on the

inside back cover of this manual.

This warranty provides you the assurance that the

company will back its products where defects

appear within the warranty period. In some circumstances, the company also provides field

improvements, often without charge to the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to

change its performance beyond the factory specifications, the warranty will become void and field

improvements may be denied.

ALL SERVICE ACCESSORIES ARE

INTENDED FOR THE PROPER USE IN

WHICH THEY WERE DESIGNED. ANY

MISUSE OF THE EQUIPMENT OR

ACCESSORIES WILL VOID THE

WARRANTY. MISUSE CAN CAUSE

FAILURE, SEVERE INJURY OR DEATH TO

THE USER. THE MANUFACTURER

CANNOT BE RESPONSIBLE FOR THE

ERECTION OR USE OF THE BUCKET

ELEVATOR AND IT’S ACCESSORIES.

PNEG-739 42" - 48" Platforms & Safety Cages

3

Page 4

Equipment Information

Use of the Equipment Information page will help you identify your equipment in the case that you need to

call your dealer or installer. This information should be filled out and kept on record.

Equipment Information

Model Number:__________________________

Serial Number:___________________________

Material Handling

1004 East Illinois Street

Assumption, Illinois 62510 USA

Phone: (217) 226-4421

FAX: (888) 741-3004

e-mail: gsi@grainsystems.com

Date Purchased:____________________

Dealer/Distributor Name and Phone Number:

PNEG-739 42" - 48" Platforms & Safety Cages4

Page 5

Table of Contents

Table of Contents

Introduction ...................................................................................................3

Equipment Information ..................................................................................4

Safety Guidelines..........................................................................................6

Decal Locations ............................................................................................9

SECTION 1 - 42" Head Service Platform .......................................................10

Support Channels .......................................................................................11

Inside Toeboards ........................................................................................12

42" Platform Decking ..................................................................................13

Outside Toeboards .....................................................................................14

41-3/4" & 47-3/4" Handrail Posts.................................................................15

47-3/8" Handrail Posts ................................................................................16

Handrail & Vertical Support Angles.............................................................17

Handrail Retaining Clip ...............................................................................18

Hatch Access Door .....................................................................................19

SECTION 2 - 48" Head Service Platform .......................................................20

Cross Member Assembly............................................................................21

Toe Plates...................................................................................................22

Decking.......................................................................................................23

Handrails and Handrail Posts......................................................................24

Handrail Angles...........................................................................................25

Hatch Access Door .....................................................................................26

Two Rung Ladder........................................................................................26

Grab Bar Installation ...................................................................................27

SECTION 3 - Distributor Platform..................................................................28

Clamp Brackets...........................................................................................29

Distributor Platform Support and Brace Channels.......................................30

Distributor Platform Toeboards ...................................................................31

Distributor Decking and Toeboards.............................................................32

Handrail Posts and Handrail Angles ...........................................................33

Cross Knee Braces .....................................................................................34

SECTION 4 - Safety Cage Assembly .............................................................35

Tie Angle Attachment..................................................................................36

Tie Angle Dimensions .................................................................................37

Ladder Standoff Attachment........................................................................38

Ladder Attachment......................................................................................39

Safety Cage Hoop Assembly ......................................................................40

Safety Cage Vertical Bar Attachment..........................................................41

Safety Cage Flare Attachment ....................................................................42

SECTION 5 - Rest Platform Assembly ..........................................................43

Installing Side Mounting Channels ..............................................................44

Platform Corner Post ..................................................................................45

Front and Rear Mounting Channels ............................................................46

Center Support Channel .............................................................................47

Rest Platform Deck Plate ............................................................................48

Top and Mid Handrails ................................................................................49

Kickplates ...................................................................................................50

All information, illustrations, photos, and specifications in this manual

are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

PNEG-739 42" - 48" Platforms & Safety Cages

5

Page 6

Safety

SAFETY GUIDELINES

This manual contains information that is important for you, the owner/operator, to know and

understand. This information relates to protecting personal safety and preventing

equipment problems. It is the responsibility of the owner/operator to inform anyone

operating or working in the area of this equipment of these safety guidelines. To help you

recognize this information, we use the symbols that are defined below.

Please read the manual and pay attention to these sections. Failure to read this manual

and it’s safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention to.

PNEG-739 42" - 48" Platforms & Safety Cages6

Page 7

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual

and on your machine safety signs. Keep signs in

good condition. Replace missing or damaged

safety signs. Be sure new equipment components and repair parts include the current safety

signs. Replacement safety signs are available

from the manufacturer.

Learn how to operate the machine and how to

use controls properly. Do not let anyone operate

without instruction.

Keep your machinery in proper working condition. Unauthorized modifications to the machine

may impair the function and/or safety and affect

machine life. All service accessories are intended for the proper use in which they were

designed. Any misuse of the equipment or

accessories will void the warranty. Misuse can

cause failure, severe injury or death to the user.

The manufacturer cannot be responsible for the

erection or use of the bucket elevator and it’s

accessories.

Safety

If you do not understand any part of this manual

and need assistance, contact your dealer.

PRACTICE SAFE MAINTENANCE

Understand service procedures before doing

work. Keep area clean and dry.

Never lubricate, service, or adjust machine while

it is in operation. Keep hands, feet, and clothing

from rotating belt and idlers.

Keep all parts in good condition and properly

installed. Fix damage immediately. Replace

worn or broken parts. Remove any build up

grease, oil, or debris.

PNEG-739 42" - 48" Platforms & Safety Cages

7

Page 8

Safety

PREPARE FOR EMERGENCIES

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambu-

lance service, hospital, and fire department near

your telephone.

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment

appropriate to the job.

Safety glasses should be worn at all times to

protect eyes from debris.

Wear gloves to protect your hands from sharp

edges on plastic or steel parts.

A respirator may be needed to help prevent

breathing potentially toxic fumes and dust.

Wear hard hat and steel toe boots to help

protect your head and toes from falling debris.

Eye Protection

Gloves

Steel Toe Boots

Respirator

Hard Hat

PNEG-739 42" - 48" Platforms & Safety Cages8

Page 9

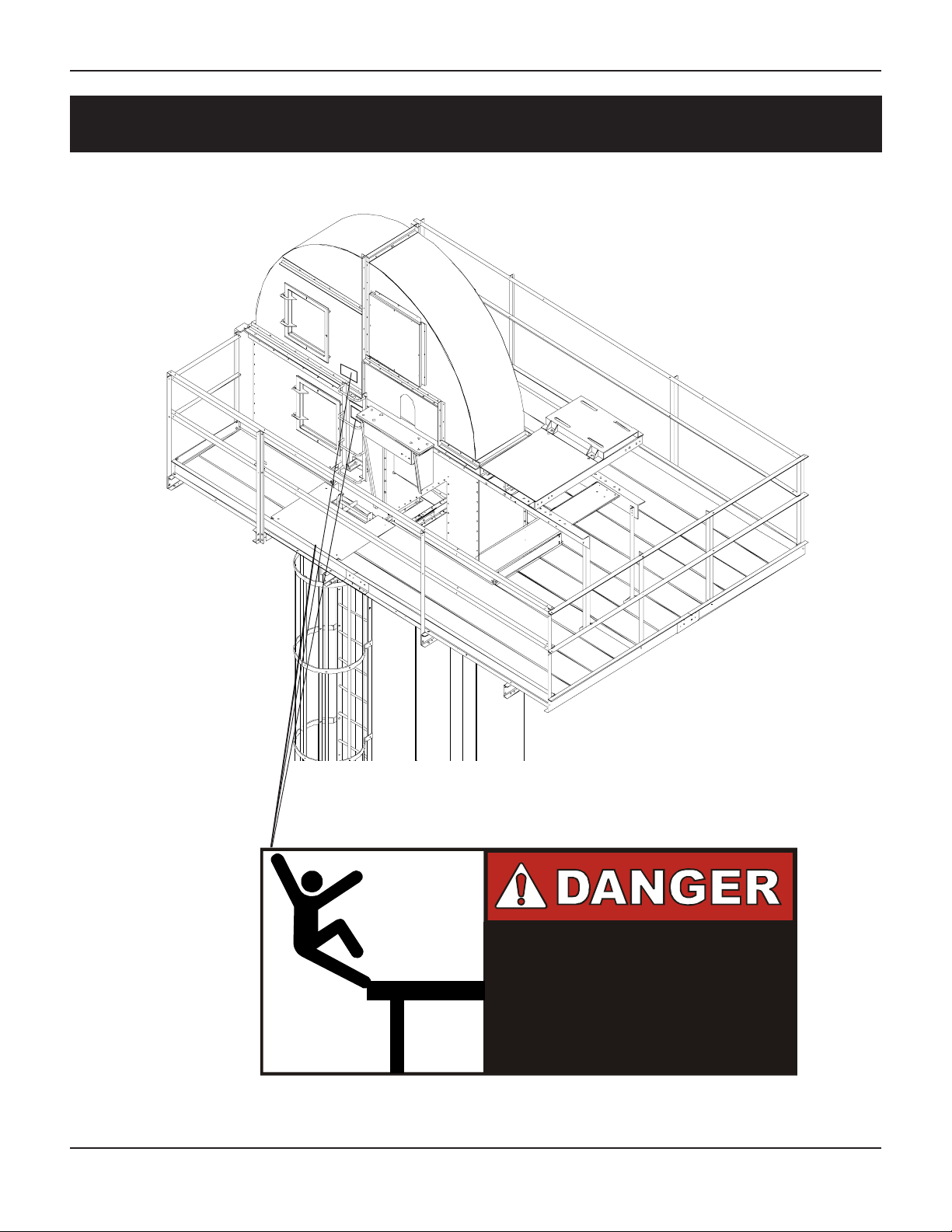

DECAL LOCATIONS

Decals

Decal located on bottom of platform access door and on

the side of the Head Assembly.

DC-1568

PNEG-739 42" - 48" Platforms & Safety Cages

FALL HAZARD

Serious injury or death will result.

Keep access door closed

while on platform.

DC-1568

9

Page 10

1

42'' Head Service Platform

SECTION 1

42" HEAD SERVICE PLATFORM

PNEG-739 42" - 48" Platforms & Safety Cages10

Page 11

42'' Head Service Platform

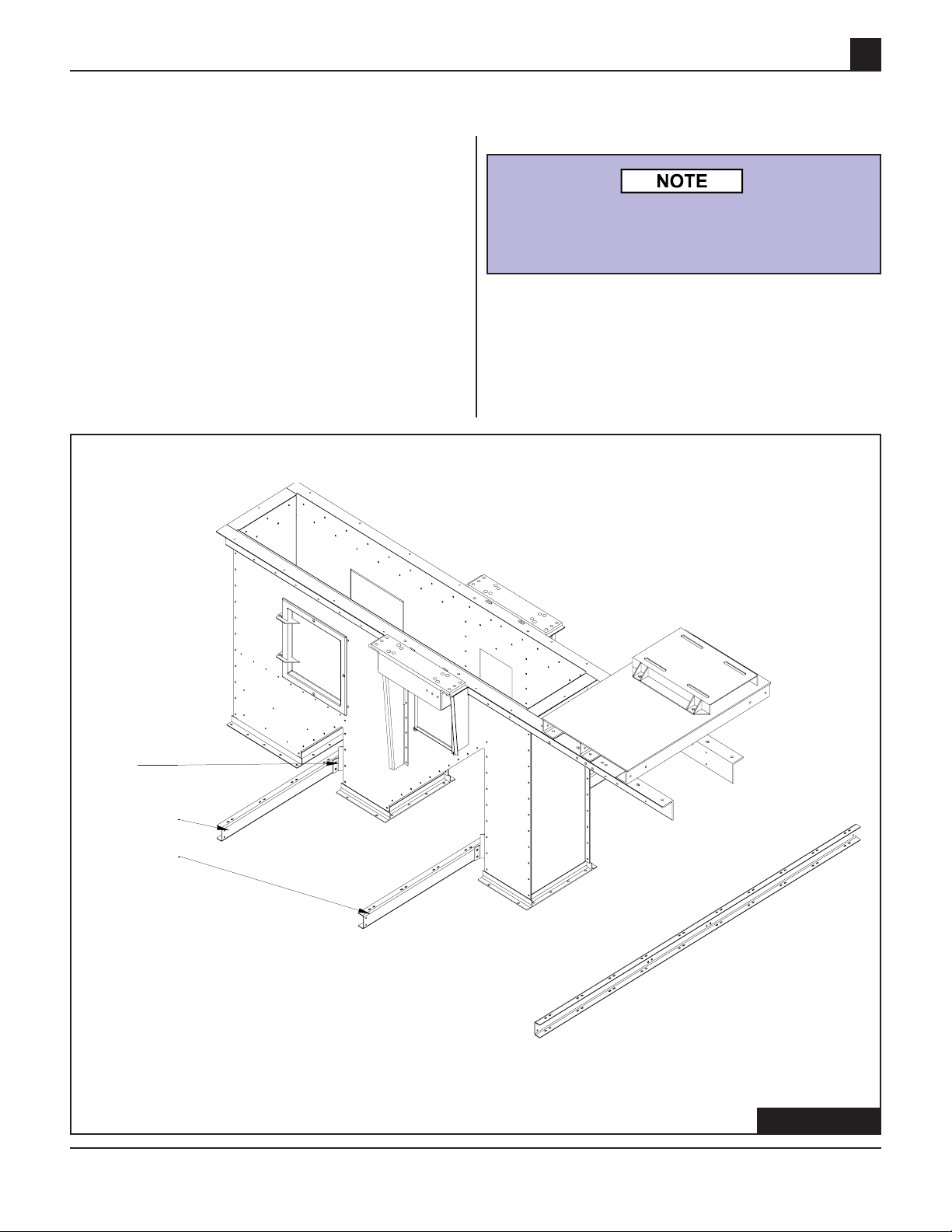

Suppor t Channels

Take time now and review all instructions and

drawings before attempting to assemble the platform. Layout all parts for easy identification.

Determine if the shaft will extend to the left or

right hand side of the platform. The long side of

the support channels must extend to the shaft

side of the head. Start the head service platform

assembly by attaching two support channels to

the head platform brackets using 1/2" x 1" hex

bolts. (See Figure 1-1.)

1

For entire platform assembly, use carriage bolts

at slot-to-hole connections and hex head cap

screws at hole-to-hole connections.

HSP42010

(Installed)

Left Hand Deck

Channel Support

Bracket

HSP42032 (2)

Platform Support

Channel 120"

HSP42012 (1)

Platform Support

Channel

FIGURE 1-1

FIGURE 1-1

PNEG-739 42" - 48" Platforms & Safety Cages

11

Page 12

1

Inside Toeboards

Place the side toeboards next to the head assembly on top of the support channels as shown

in Figure 1-2. The end platform support channel

must be placed below the two side toeboards.

Attach the toeboards to the support channels with

the 5/16" x 1" hex bolts supplied. Tighten all hardware in this assembly.

42'' Head Service Platform

Support

Channels

Toeboard Channel - 98.068"

End Platform Support Channel - 32"

FIGURE 1-2

FIGURE 1-2

PNEG-739 42" - 48" Platforms & Safety Cages12

Page 13

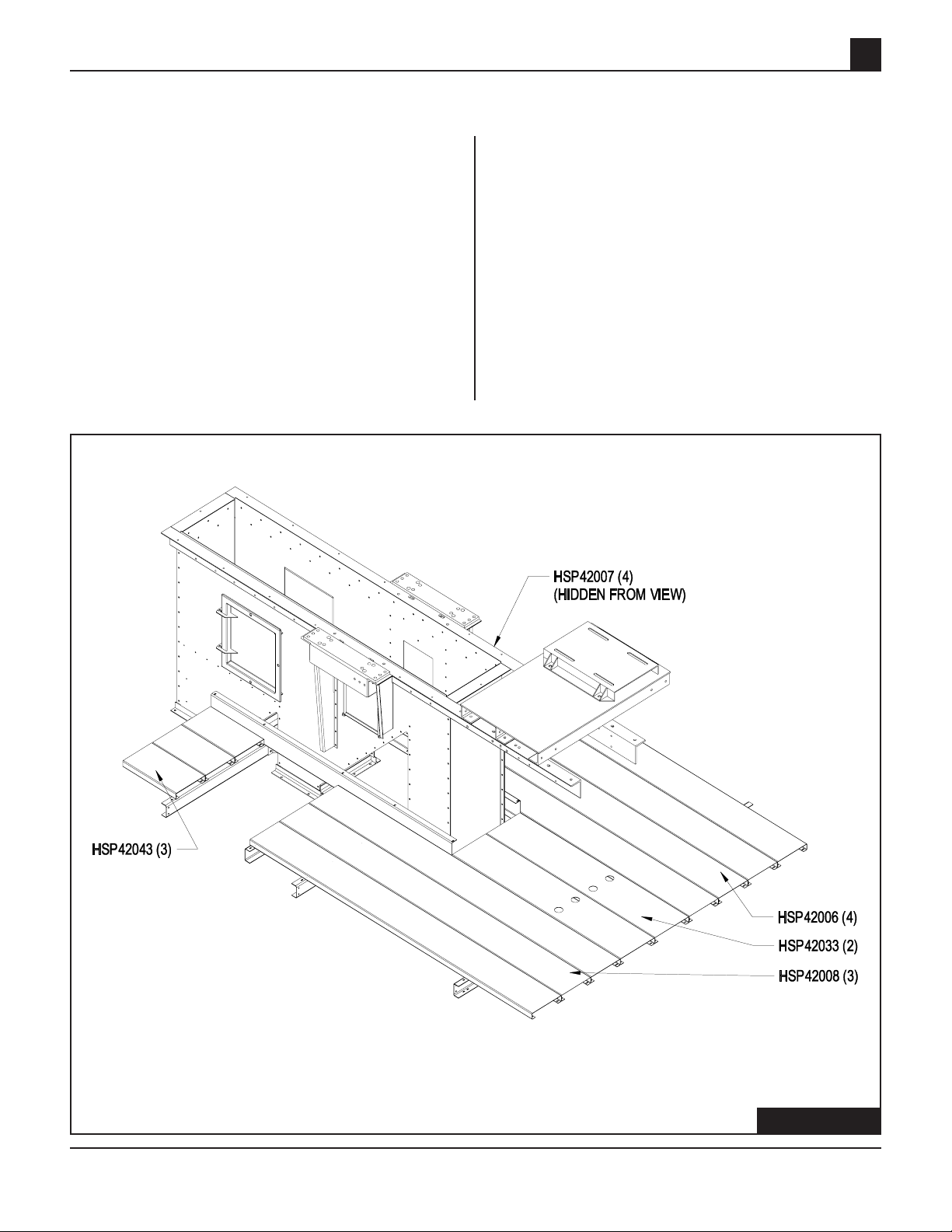

42'' Head Service Platform

42" Platform Decking

Layout all floor deck panels according to position

on platform (Figure 1-3). Remember to layout

for right hand (standard) or left hand shaft. Attach

floor panels to support channels (as shown in

Figure 1-3) using 5/16" x 1" carraige bolts and

5/16" nuts.

1

Platform

Decking - 21.65"

Platform Decking - 73.625"

Platform Decking - 93"

Platform Decking - 68.607"

Platform Decking - 114.812"

FIGURE 1-3

NOTE: This layout is for a RIGHT hand drive setup.

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE 1-3

13

Page 14

1

Outside Toeboards

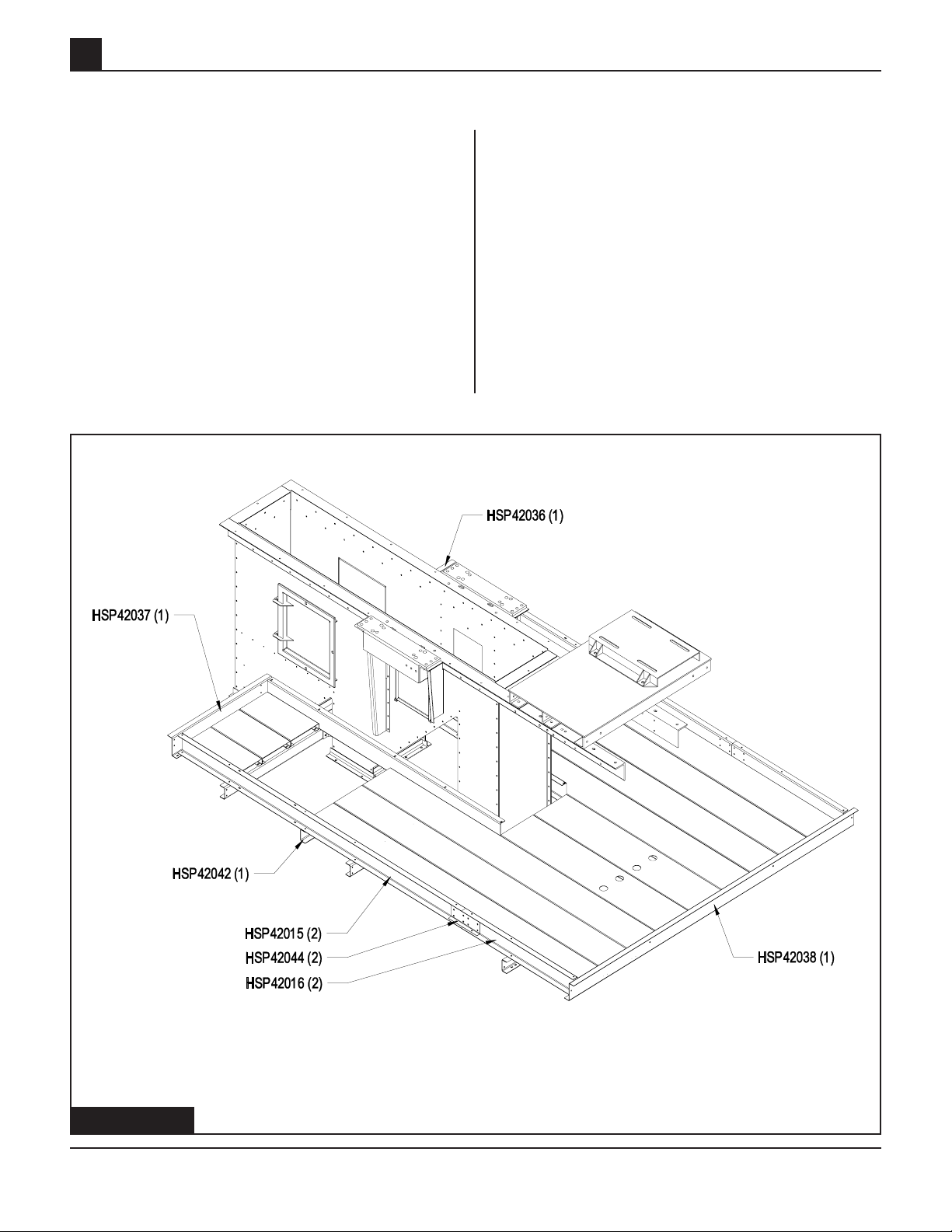

Attach support channel, HSP42042, to underside

of floor panels at the hatch opening (Figure 1-4).

Small floor panels may be left off until the outside

toeboards are attached. Use the 5/16" x 1" hex

bolts during this assembly. Attach toeboards to

the ends of the deck panels and to the support

channels as shown in (Figure 1-4). Be sure and

use splice channel on side toe boards. Tighten

all hardware.

42'' Head Service Platform

Z Toeboard - 54"

Platform Support

Channel - 40"

Toeboard Channel - 120"

Toeboard Splice Plate

Toeboard Channel 46.976"

Z Toeboard - 42"

Z Toeboard 120"

FIGURE 1-4

FIGURE 1-4

PNEG-739 42" - 48" Platforms & Safety Cages14

Page 15

42'' Head Service Platform

41-3/4" & 47-3/4"

Handrail Posts

Attach short handrail posts to toeboards using

the 5/16" hardware as shown in Figure 1-5. There

are different lengths of handrail posts, so be sure

and use the (6) 41- ¾" lengths on the outside

and the 47-3/4" lengths next to the head as noted

in Figure 1-5.

1

Handrail Upright

Angle - 47.75"

Handrail

Upright Angle -

41.813"

FIGURE 1-5

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE1-5

15

Page 16

1

47-3/8" Handrail Posts

Attach long handrail posts to the support channels using 5/16" x 1" hex bolts as shown in Figure 1-6. Be sure and use the longer 47-3/8" handrail posts for this assembly.

42'' Head Service Platform

Handrail Upright

Angle - 47.402"

FIGURE 1-6

FIGURE 1-6

PNEG-739 42" - 48" Platforms & Safety Cages16

Page 17

42'' Head Service Platform

Handrail & Vertical

Suppor t Ang les

Attach platform hatch latch assembly, GSB30120,

to handrail as shown, using 5/16" x 1" hex bolts.

Locate all handrail angles and attach to the handrail posts, as shown in Figure 1-7, using the

5/16" hardware. Attach the two deck channel support angles, HSP42014, to the rear of the head

angles and to the support channel through the

holes provided in the center decking uisng 3/8" x

1" hex bolts.

Handrail Angle - 38.63"

1

Handrail Angle -

50.625"

Latch

Assembly

Latch

Assembly

Handrail Angle - 167.289"

Deck Channel

Support Angle

Handrail

Angle - 120"

FIGURE 1-7 FIGURE 1-7

PNEG-739 42" - 48" Platforms & Safety Cages

17

Page 18

1

Handrail Retaining Clip

Attach the two HSP36027 handrail support clips

to the handrail uprights next to the head bearing

angle on the discharge end of head as shown in

Figure 1-8. Field drill the hole in each head bearing angle and attach using the 5/16" x 1" hex bolts

supplied.

Head Bearing Angle

42'' Head Service Platform

FIGURE 1-8

Handrail Retaining Clip

HSP42035

Handrail Upright Angle

FIGURE 1-8

PNEG-739 42" - 48" Platforms & Safety Cages18

Page 19

42'' Head Service Platform

Hatch Access Door

Assemble the deck hatch access door by attaching the left and right hand hinges to bottom side

of the outside toeboard, using 5/16" x 1" carraige

bolts. Leave hardware loose until the assembly

is complete. Attach the hinges & hatch decking

to the angle frame weldment and double nut the

hinge bolts - do not overtighten. (See Figure 1-9)

1

Right Hand

Hatch Hinge

Left Hand

Hatch Hinge

Decking Hatch

Frame Weldment

GSB36222 (1)

Hatch Service

Hatch Decking

FIGURE 1-9

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE 1-9

19

Page 20

2

48'' Head Service Platform

SECTION 2

48" HEAD SERVICE PLATFORM

PNEG-739 42" - 48" Platforms & Safety Cages20

Page 21

48'' Head Service Platform

Mainframe & Cr oss Member Assembl y

2

Before attempting any assembly of the platform,

read and follow all directions. Lay out all parts

associated with the assembly. Due to the

assembly of the head service platform, the lower

head assembly may need to be blocked up under

the head and discharge flanges approximately

12" to provide clearance for assembly. Look at

the head assembly to determine the drive side,

which will be the wide side of platform.

First, attach the left and right mainframe

assemblies to the head using 1/2" x 1" hex bolts.

Then attach the cross members to the mainframe

assemblies with the long end of channels

extending towards the drive side, use the ½" x 1"

hex bolts supplied. (See Figure 2-1)

The middle cross member HSP48x106 has a

double hole pattern. Be sure to orientate the

cross members according to Figure 2-1. Right

Drive platform layout shown in all figures.

When items with more than one part# are shown you

will only use the one relevant to your service platform.

Example: HSP482xxx single row 48" elevator,

HSP484xxx double row 38"- 42" wide 48" elevator,

HSP485xxx double row 50" wide 48" elevator.

HSP482106 (1) - Cross Member Assembly Double Hole - 26"

HSP484106 (1) - Cross Member Assembly Double Hole - 38"-42"

HSP485106 (1) - Cross Member Assembly Double Hole - 50"

FIGURE 2-1

PNEG-739 42" - 48" Platforms & Safety Cages

HSP48401 (1) - Right

Mainframe Assembly

HSP48402 (1) - Left

Mainframe Assembly

HSP482105 (1) - Cross Member Assembly - 26"

HSP484105 (1) - Cross Member Assembly - 38"-42"

HSP485105 (1) - Cross Member Assembly - 50"

FIGURE 2-1

21

Page 22

2

Toe Plates

48'' Head Service Platform

Now that cross members are attached to head

assembly, the toe board channel assemblies

(HSP484117) can be attached to the ends of the

cross members using 1/2" x 1" hex bolts. After

both toe board channels are in place the Z-board

channels (HSP48x121) can be placed on the end

of the toe board channels and bolted in place

using 3/8" x 1" hex bolts. Now tighten all hardware. Attach the (8) toe guard mounting angles

(HSP484024) to the cross members then attach

the inner toe boards to the angles using 1/2" x 1"

NOTE: Some parts may have been

eliminated for clarity of assembly.

Toe Plate, Platform

End (38-42)

hex bolts. The inboard mounting for toe board

HSP484036 – HSP484037 will be done when the

hand rail post are assembled. (See Figure 2-2)

The lower head assembly has been

removed from figure below to help clarify

the assembly process.

HSP484029 (1) Toe Plate, Inner

Down Leg (38"-42")

HSP484117 (2) Toeboard Channel

Assembly (38"-42"-50")

Toe Guard Mounting

Angle (38-42)

HSP484037 (1)

Toe Plate Platform

End (38-42)

Toe Plate, Inner

Down Leg

Toe Plate, Inner

Upleg (38-42)

8

HSP482028 (1) Toe Plate Inner Upleg-26"

HSP484028 (1) Toe Plate Inner Upleg-38"-42"

HSP485028 (1) Toe Plate Inner Upleg-50"

HSP484026 (1) Toe Plate,

Inner Upleg (38"-42")

HSP482121 (1) Z-Board Channel Assembly - 26"

HSP484121 (1) Z-Board Channel Assembly - 38"-42"

HSP485121 (1) Z-Board Channel Assembly - 50"

FIGURE 2-2

FIGURE 2-2

PNEG-739 42" - 48" Platforms & Safety Cages22

Page 23

48'' Head Service Platform

Decking

With all support channels in place and hardware

tightened, locate all floor deck panels. Position

the floor deck panels onto the support channels

as shown below. Use the 5/16" x 1" carriage

bolts to attach ends of the deck panels to the

support channels. (See Figure 2-3)

NOTE: Some parts may have been

eliminated for clarity of assembly.

2

The quantity of HSP484013 will be

determined by the width of the service platform.

SP-4826 = 1, SP-483842 = 2, SP-4850 = 3.

Platform Decking -

48.625"

Platform Decking - 123"

FIGURE 1-12

Platform

Decking - 86"

Platform

Decking - 122"

Platform Decking -

69.313"

Platform Decking -

69.313"

NOTE: HSP48013 can have up to 5

planks depending on the size of platform.

FIGURE 2-3

PNEG-739 42" - 48" Platforms & Safety Cages

23

Page 24

2

Handrails and Handr ail

Posts

Bolt all handrail posts to the cross members and

Z board channels. Post that attach to cross members will use 1/2" hardware, post that attach to

the Z board will use 3/8" hardware. Leave all

hardware loose until all posts and handrails are

in place. With all post in place attach hand rails

with 3/8" hardware. Review Figure 2-4 for proper

placement of post and handrails. HSP 484040

posts are attached to Z-board channel only.

HSP484045 (2) 60.250"

Handrail (38"-50")

48'' Head Service Platform

HSP484042 (2) 49.000"

Discharge Post (38"-50")

HSP484046 (2) 30"

Handrail (38"-50")

HSP484041 (6) Handrail Angle (38"-50")

HSP484044 (4) Side Handrail (38"-50")

HSP484040 (4) 42"

Angle Post (38"-50")

FIGURE 2-4

HSP482043 (2) End Handrail (26")

HSP484043 (2) End Handrail (38"-42")

HSP485043 (2) End Handrail (50")

FIGURE 5-1

PNEG-739 42" - 48" Platforms & Safety Cages24

Page 25

48'' Head Service Platform

Handrail Ang les

Attach HSP484047 and HSP484048 handrail attachment angles to the post next to the head

bearing angle on the discharge end of the lower

head (Figure 2-5) Field drill the hole in each head

bearing angle and use 3/8" x 1" hex bolts supplied.

Attach the two service platform support angles,

HSP484038, to rear of head angles and to the

support channel through the holes provided in

the center decking using 3/8" x 1" hex bolts. (See

Figure 2-5)

HSP484048 Right Attachment Angle for Handrail

2

HSP484047 Left Attachment Angle for Handrail

Service Platform

Support Angle

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE 2-5

25

Page 26

2

48'' Head Service Platform

Hatch Access Door

Assemble the deck hatch access door by

attaching the left and right hand hinges to bottom

side of the outside toeboard (HSP484117) using

5/16" x 1" hex bolts. Leave hardware loose until

the assembly is complete. Attach hatch assembly

(HSP484055) to the hinges and double nut the

hinge bolts. Do not over tighten.

NOTE: Only applicable for 38" - 72"

wide bucket elevators.

Two Rung Ladder

Attach the ladder standoff angles as shown

below using 1/2" x 1" hex bolts. Then attach two

rung ladder to the standoff angles using

1/2" x 1" hex bolts. The top rung of the ladder

should be even with the top of the decking when

installed.Tighten all hardware. (See Figure 2-6)

HSP484117 Toeboard

Channel Assembly (38"-50")

HSP36003 Left Hand

Hatch Hinge

HSP36002 Right

Hand Hatch Hinge

HSP484055 Platform Hatch

HSP484051 Two Rung Ladder

(See Note.)

BE-PLAT1 (2) Ladder

Standoff Angle

(See Note.)

BE-PLAT2 (2) Ladder

Standoff Angle

(See Note.)

FIGURE 2-6

PNEG-739 42" - 48" Platforms & Safety Cages26

Page 27

48'' Head Service Platform

Grab Bar Installation

Attach the grab bar attachment angles

(HSP484035) to the grab bar mounting angle

using 3/8" x 1" hex bolts. Then fasten the grab

bar weldment to the attachment angles and the

head bearing angle using 3/8" x 1" hex bolts.

Recheck assembly to be sure all hardware is

secure.

NOTE: Only applicable for 38" - 72"

wide bucket elevators.

2

Head Bearing Angle

HSP484033 Grab

Bar Weldment

HSP484034 Grab

Bar Mounting Angle

HSP484035 Grab

Bar Attachment Angle

GSB30120 Latch

Assembly

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE 2-7

27

Page 28

3

Distributor Platform Assembly

SECTION 3

DISTRIBUTOR PLATFORM

PNEG-739 42" - 48" Platforms & Safety Cages28

Page 29

Distributor Platform Assembly

Clamp Brackets

3

This assembly is designed to be located at any

elevation on trunking that’s needed to provide access to other equipment. Determine elevation of

platform surface and work from there. Locate all

parts required for assembly by using the charts

shown in the following figures.

Locate all clamp halves, clamp brackets, threaded

rods, and hardware to assemble clamps onto the

trunking. Measure the distance between the

clamps to assure proper location for support channels and knee brace attachment. See clamp

detail in FIgure 3-1 for hardware orientation.

Place 5/8" nuts and lock washers on a threaded

rod (one from each end). Place a clamp half on

each end of the rod and thread another nut and

lock washer to hold clamp in place. Now place

that assembly around trunk and place a clamp

bracket onto the opposite end of the clamp assembly and use ½" hardware to fasten parts together. Adjust the position of the inside nuts of

the rod assembly to allow the clamps to be tightened onto the trunking.

TIGHTEN CLAMPS ONTO TRUNKING, DO NOT

OVERTIGHTEN AND COLLAPSE THE TRUNKING.

Position inside nuts back to the clamp and tighten.

42" SINGLE TRUNKING

DSP42007 (6) Platform Brace Clamp Half

DSP42008 (3) Brace Clamp Rod

DSP42006 (3) Clamp Half, 42" (22)

48" SINGLE TRUNKING

DSP42007 (6) Platform Brace Clamp Half

DSP48008 (3) Brace Clamp Rod

DSP48006 (3) Clamp Half, 48" (26)

FIGURE 3-1

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE 3-1

29

Page 30

3

Distributor Platform

Suppor t and Br ace

Channels

With clamps fastened securely to the trunk, attach

the platform support channels to the middle

clamp, use ½" hardware with this assembly. The

platform brace channels will attach in the upper

set of holes on side of support channel and to

the lower clamp. Before tightening hardware, the

support channels must be perpendicular to the

trunk, now tighten all hardware. (See Figure 3-2)

Distributor Platform Assembly

FIGURE 3-2

Platform Support Channel (2)

Platform Brace Channel (2)

FIGURE 3-2

PNEG-739 42" - 48" Platforms & Safety Cages30

Page 31

Distributor Platform Assembly

Distributor Platform

Toeboards

The toeboards will not be centered on trunking

but should be offset to the ladder side. Platform

is designed to work for either side of trunking

access.

With support assembly attached to trunk and

hardware tightened, proceed by attaching the

notched toe board and unnotched toeboard to

the top of the support channel using the 5/16"

hardware provided. (Leave hardware loose). See

Figure 3-3.

3

Notched Toeboard Angle

Toeboard Angle

FIGURE 3-3

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE 3-3

31

Page 32

3

Distributor Decking and

Toeboards

Attach the floor deck panels to the support channels using 5/16" x 1" hex bolts. Then attach decking to end toe boards with the 5/16" x 1" hex bolts

provided. After all pieces have been attached,

tighten all hardware. (See Figure 3-4)

Distributor Platform Assembly

Toeboard Angle (2)

Platform Decking (6)

FIGURE 3-4

FIGURE 3-4

PNEG-739 42" - 48" Platforms & Safety Cages32

Page 33

Distributor Platform Assembly

Handrail Posts and

Handrail Ang les

Locate the toe board cover plate and bolt over

the unused notched toe board area 5/16" x 1"

hex bolts. Attach handrail posts to the toe

boards as shown using the 5/16" x 1" hex bolts

provided. (Leave hardware loose until all

handrails are in place.) Attach all handrail

angles and brace angle 5/16" x 1" hex bolts.

(See Figure 3-5.) After all pieces have been

attached go back and tighten all hardware.

3

Handrail Clip

Bracket

Toeboard Plate

Handrail Brace

Handrail Angles

Handrail Angles

Handrail Angles

FIGURE 3-5

PNEG-739 42" - 48" Platforms & Safety Cages

Handrail Upright

Angle (5)

FIGURE 3-5

33

Page 34

3

Cross Knee Br aces

Attach cross knee brace diagonals to bottom side

of the knee braces 1/2" x 1" hex bolts. This will

add extra stability to the distributor platform. (See

Figure 3-6.)

Distributor Platform Assembly

FIGURE 3-6

Cross Knee Brace

FIGURE 3-6

PNEG-739 42" - 48" Platforms & Safety Cages34

Page 35

Safety Cage Assembly

SAFETY CAGE ASSEMBLY

4

SECTION 4

PNEG-739 42" - 48" Platforms & Safety Cages

35

Page 36

4

Tie Angle Attachment

Attach the up and down legs together with the tie

angles. Position the tie angles around the trunking

joint as shown. Fasten the tie angles to the

trunking angles using 1/2"-13 x 1" bolts. (See Fig.

4-1)

Safety Cage Assembly

1/2"-13 x 1" Hex Bolt

Trunking Section

1/2" -13 Hex Nut

Trunking

Angles

FIGURE 4-1

Tie Angle

PNEG-739 42" - 48" Platforms & Safety Cages36

Page 37

Safety Cage Assembly

4

Tie Angle Dimensions

See Figure 4-2B for 42" & 48" tie angle dimensions. Only the 42" and 48" elevators have tie

angle cross braces that brace the two tie angles

diagonally. (One per pair of tie angles.) (See Figure 4-2A)

BECT4204 42" Tie Angle

Tie Angle Cross Braces

FIGURE 4-2A

.000

2.000

.000

1.000

8.500

10.000

16.500

23.500

29.000

Ø .563

(8 PL.)

49.000

54.500

61.500

69.500

68.000

77.000

78.000

BECT4833 48" Tie Angle

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE 4-2B

37

Page 38

4

Ladder Standoff

Attachment

Attach the ladder standoff brackets to the tie

angles using 1/2" x 1" hex bolts as shown in Figure 4-3.

Safety Cage Assembly

1/2"-13

Hex Nut

Ladder Standoff

Bracket

Left - (BE-PLAT1)

1/2"-13 x 1" Hex Bolt

Ladder Standoff

Bracket

Right - (BE-PALT2)

FIGURE 4-3

PNEG-739 42" - 48" Platforms & Safety Cages38

Page 39

Safety Cage Assembly

Ladder Attachment

Attach the ladder to the standoffs using 1/2"-13 x

1" hex bolts. When attaching the ladder to the

standoffs, the ladder is attached through the second hole down the front end of the ladder. The

first hole is for the safety cage hoop. Attach the

safety hoop to the ladder using 1/2" x 1"hex bolts.

(See Figure 4-4)

4

27" Safety Cage

Hoop (27Hoop)

**NOTE: A ten foot section is used at

anytime the ladder continues on to

another section of ladder. A fourteen

foot section is used anytime the ladder

extends through any platform deck.

1/2"-13 x 1"

Hex Bolt

1/2"-13 Hex Nut

PNEG-739 42" - 48" Platforms & Safety Cages

10' Ladder

Section** (10foot)

FIGURE 4-4

39

Page 40

4

Safety Cage Hoop

Assembly

Bolt all safety cage hoops to ladder as shown

below using 1/2" x 1" hex bolts. Leave all bolts

loose until the vertical bars are in place and then

tighten all hardare. (See Figure 4-5)

Safety Cage Assembly

FIGURE 4-5

PNEG-739 42" - 48" Platforms & Safety Cages40

Page 41

Safety Cage Assembly

Safety Cage Vertical Bar

Attachment

Bolt all safety cage vertical bars to the cage hoops

shown below. The vertical bars should be installed

to the inside of the hoops using 1/2" x 1" hex

bolts. (See Figure 4-6)

4

PNEG-739 42" - 48" Platforms & Safety Cages

1/2-13 x 1" Hex Bolt

1/2"-13 Hex Nut

Safety Cage Vertical

Bar (10Foot-V)

FIGURE 4-6

41

Page 42

4

Safety Cage Flar e

Attachment

Attach the safety cage tapper vertical bars to the

inside of the 27" & 30 " safety hoops using 1/2" x

1" hex bolts. (See Figure 4-6) Then fasten the

27" safety cage hoop through the top hole on the

ladder using 1/2" x 1" hex bolts. Install the 30"

Hoop to the ladder using 1/2" x 1" hex bolts.

Safety Cage Assembly

27" Safety Cage

Hoop (27hoop)

1/2"-13

Hex Nut

30" Safety

Cage Hoop

(30hoop)

1/2"-13 x 1" Hex Bolt

Safety Cage Tapper

Vertical Bar (taper-v)

FIGURE 4-6

PNEG-739 42" - 48" Platforms & Safety Cages42

Page 43

Rest Platf orm Assembly

REST PLATFORM ASSEMBLY

5

SECTION 5

PNEG-739 42" - 48" Platforms & Safety Cages

43

Page 44

5

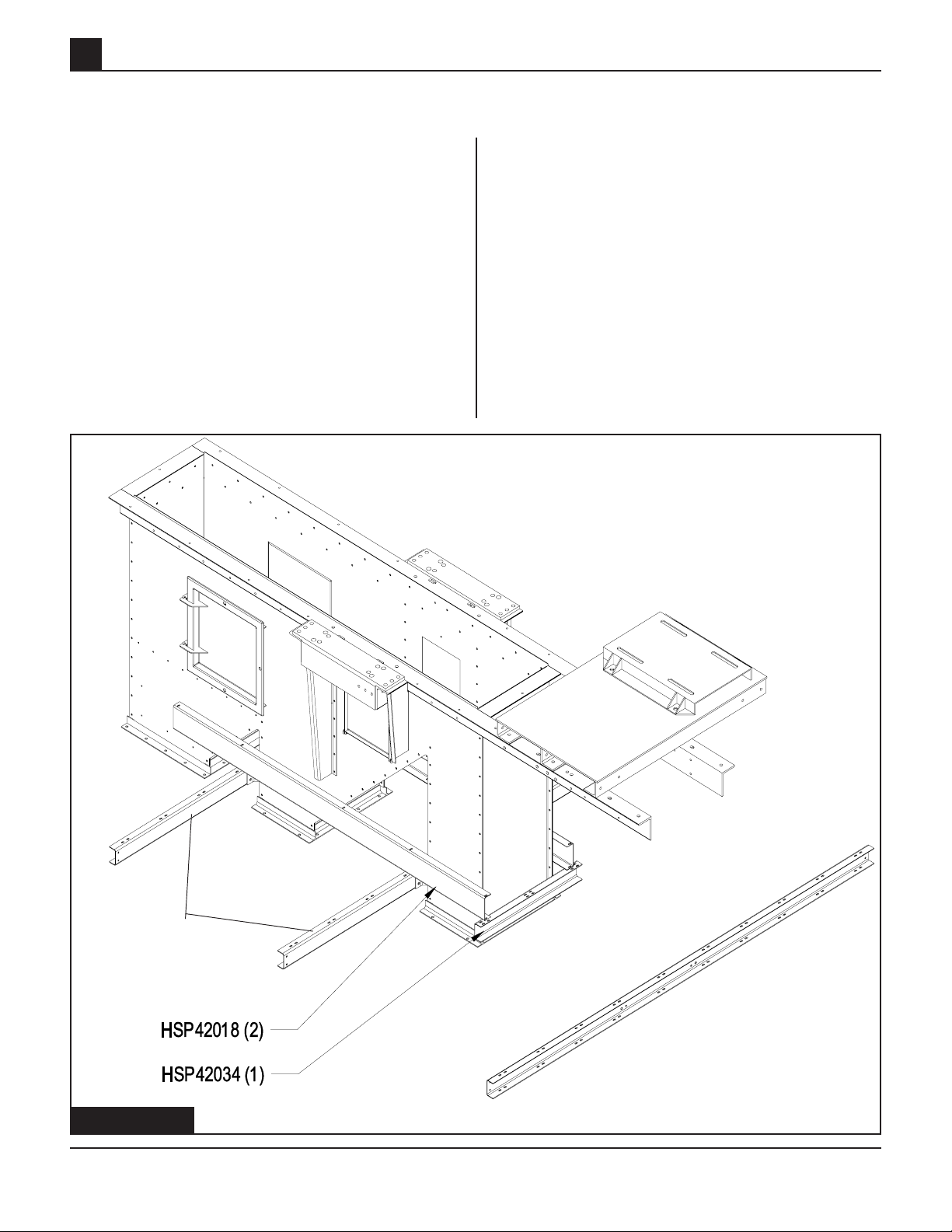

Installing Side Mounting

Channels

The first step to assemble the rest platform is to

attach the side mounting channels to the tie

angles using 1/2" x 1" hex bolts. (See Figure 5-1)

Rest Platf orm Assembly

LEFT SIDE

MOUNTING CHANNEL

RSP48203 - 26"

RSP484003 - 30" & 42"

RSP485003 - 50"

RSP486003 - 60"

FIGURE 5-1

1/2"-13 Hex Nut

1/2"-13 x 1" Hex Bolt

RIGHT SIDE

MOUNTING CHANNEL

RSP48202 - 26"

RSP484002 - 30" & 42"

RSP485002 - 50"

RSP486002 - 60"

FIGURE 5-1

PNEG-739 42" - 48" Platforms & Safety Cages44

Page 45

Rest Platf orm Assembly

Platform Corner Post

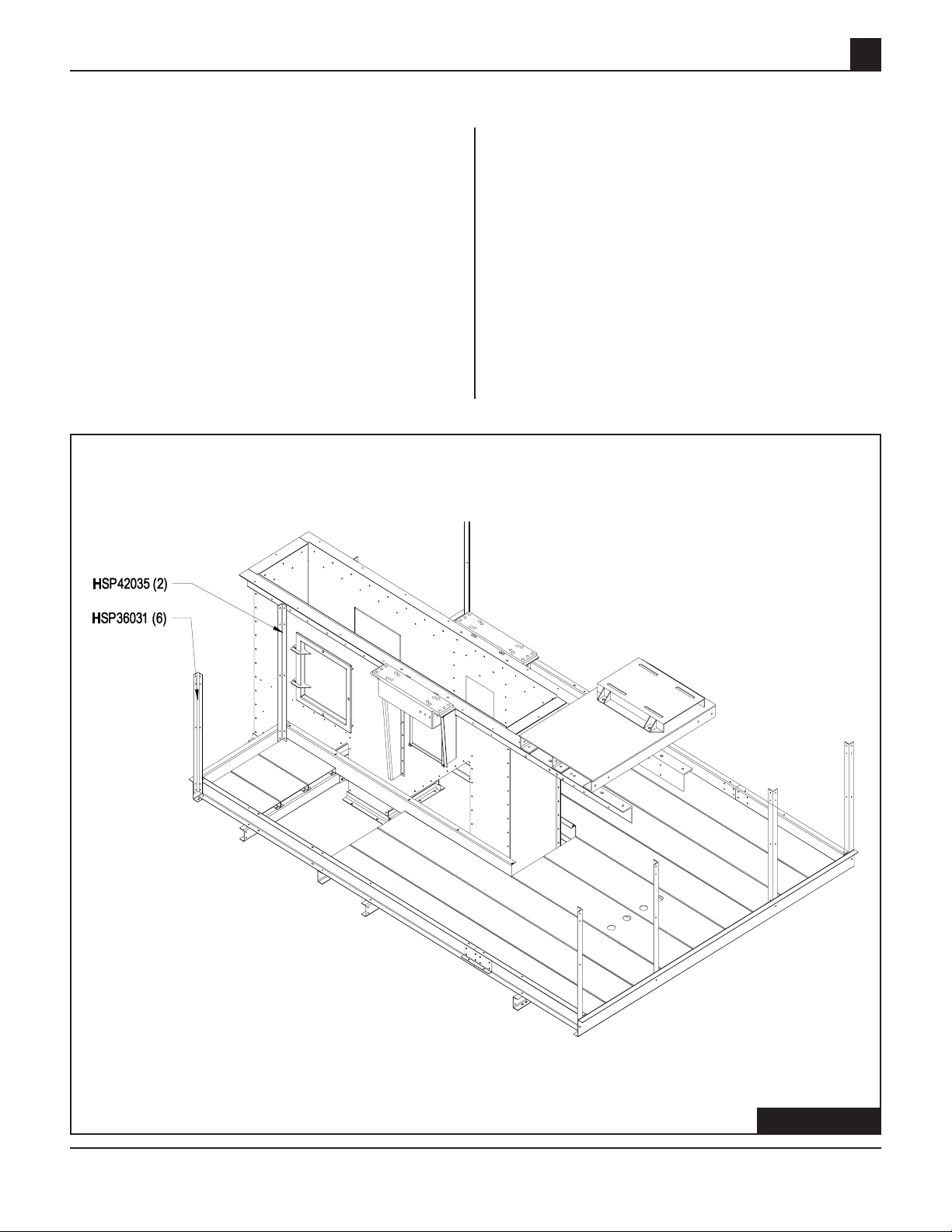

Next attach the platform corner posts to the

mounting channels as shown below using 1/2" x

1" hex bolts. Leaving hardware loose will help fit

other parts in place. (See Figure 5-2)

5

FIGURE 5-2

RSP48007 Platform

Corner Post - 42" & 48"

1/2"-13 Hex Nut

1/2"-13 x 1" Hex Bolt

FIGURE 5-2

PNEG-739 42" - 48" Platforms & Safety Cages

45

Page 46

5

Front and Rear Mounting

Channels

The next step is to attach the front and rear

support channel to the platform corner posts as

shown below using 1/2" x 1" hex bolts. (See

Figure 5-3)

Rest Platf orm Assembly

1/2"-13 Hex Nut

1/2"-13 x 1" Hex Bolt

RSP48005 Front Support Channel - 42" & 48"

RSP48206 Rear Mounting Channel - 42" & 48"

FIGURE 5-3

FIGURE 5-3

PNEG-739 42" - 48" Platforms & Safety Cages46

Page 47

Rest Platf orm Assembly

Center Suppor t Channel

To complete the support frame, bolt on the center

support channel to the front and rear support

channel using 1/2" x 1" hex bolts. (See Figure 5-4)

5

1/2"-13 Hex Nut

1/2"-13 x 1" Hex Bolt

RSP48204 Center Support Channel - 42" & 48"

FIGURE 5-4

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE 5-4

47

Page 48

5

Rest Platfor m Deck Plate

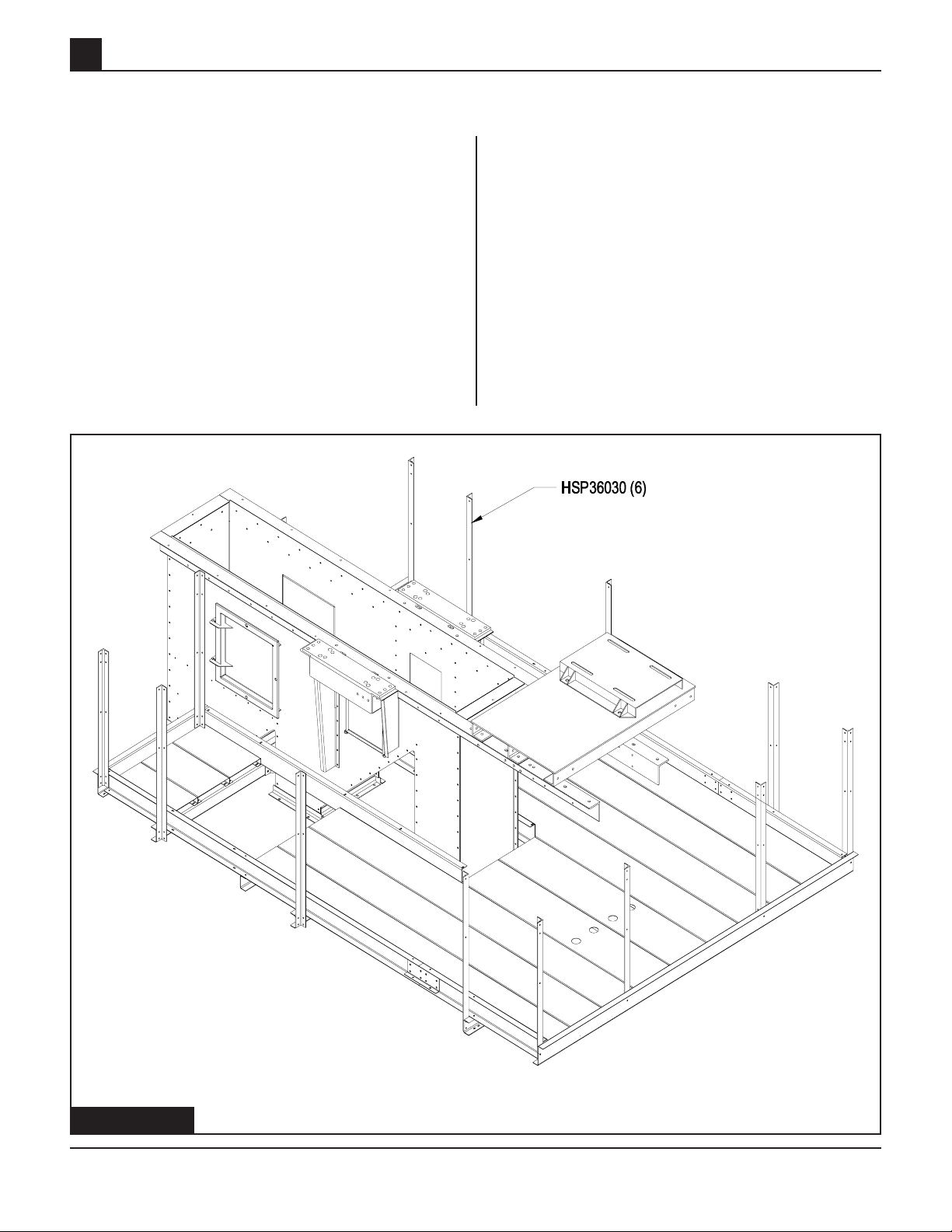

Using the 1/4" hardware, bolt the deck tread plate

to the mounting and support frames. (See Figure

5-5)

Rest Platf orm Assembly

FIGURE 5-5

1/4"-20 x 1" Hex Bolt

1/4"-13 Hex Nut

1/4" Flat Washer

RSP48201 Rest Platform

Deck Tread Plate - 42" & 48"

FIGURE 5-5

PNEG-739 42" - 48" Platforms & Safety Cages48

Page 49

Rest Platf orm Assembly

Top and Mid Handr ails

Bolt on all the top and mid handrails following

picture below using 1/2" x 1" hex bolts. (See

Figure 5-6)

5

1/2"-13 x 1" Hex Bolt

1/2"-13 Hex Nut

RPS48209

Top & Mid Hand Rail (Left

and Right) - 42" & 48"

RPS48008

Top & Mid Hand Rail (Front

and Rear) - 42" & 48"

FIGURE 5-6

PNEG-739 42" - 48" Platforms & Safety Cages

FIGURE 5-6

49

Page 50

5

Kickplates

To complete the rest platform, bolt on all

toeboards to the platform corner posts as shown

using the hardware in figure 5-7. Recheck all

hardware in assembly to ensure proper tightness.

Rest Platf orm Assembly

RSP48012

Kick Plate (Left & Right) - 42" & 48"

1/2"-13 x 1" Hex Bolt

1/2"-13 Hex Nut

RSP48210

Front Kick Plate - 42" & 48"

RSP48211

Rear Kick Plate - 42" & 48"

FIGURE 5-7

1/4"-20 x 1" Hex Bolt

1/4"-20 Hex Nut

FIGURE 5-7

PNEG-739 42" - 48" Platforms & Safety Cages50

Page 51

The GSI Group, Inc. Warranty

THE GSI GROUP, INC. (“GSI”) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END

USER. THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE TO

REPAIR OR REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S SOLE

JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP.

ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI’S FACTORY WILL BE

PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE

PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED

EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE

IN CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE,

OR DESIGN OF SUCH PRODUCTS.

GSI SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED

PROFITS OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY IS AS SET FORTH

IN THE LIMITED WARRANTY EXPRESSED ABOVE, WHICH SHALL NOT EXCEED THE

AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE

NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIONS OR WARRANTIES

MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION DEFECTS

OR UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT MANUFACTURED.

MODIFICATIONS TO PRODUCTS NOT SPECIFICALLY DELINEATED IN THE MANUAL

ACCOMPANYING THE EQUIPMENT AT INITIAL SALE WILL NULLIFY THE PRODUCT

WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH

HAVE BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS

WARRANTY EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR

IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT

ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH ALL

FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

Page 52

This Equipment shall be installed in accordance

with the current installation codes and applicable

regulations which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installation occurs.

Copyright © 2005 by The GSI Group

Printed in the USA

1004 East Illinois Street

Assumption, IL 62510

217-226-4421 Phone

800-800-5329 FAX

Loading...

Loading...