Page 1

Autoflow Operation

Autoflow Operation

PNEG-728

1

1

Page 2

This page was left blank intentionally.

Autoflow Operation

2

Page 3

Autoflow Operation

Roof Damage Warning and Disclaimer.............................................................................4

Safety.............................................................................................................................5

Safety Precautions........................................................................................................6

Safety Sign-Off Sheet...................................................................................................7

Electrical Power Supply................................................................................................8

Electronic Monitoring Control System..............................................................................9

Dryer Control Panel..............................................................................................10

Set-Up Standard...................................................................................................14

Set-Up Extended...................................................................................................15

Fill System Control Box..............................................................................................18

Error Messages.............................................................................................................20

Pre-Season Checks......................................................................................................24

Top Dry Autoflow Theory of Operation.....................................................................27

Start Up Procedure......................................................................................................29

TopDry Autoflow Drying Rates for Shelled Corn......................................................32

TopDry Batch Drying Rates for Shelled Corn............................................................33

Warranty.....................................................................................................................34

TABLE OF CONTENTS

3

Page 4

SAFETY

Autoflow Operation

Roof Damage Warning and Disclaimer

GSI DOES NOT WARRANT ANY ROOF DAMAGE

CAUSED BY EXCESSIVE VACUUM OR INTER-

NAL PRESSURE FROM FANS OR OTHER AIR

MOVING SYSTEMS. ADEQUATE VENTILATION

AND/OR "MAKEUP AIR" DEVICES SHOULD BE

PROVIDED FOR ALL POWERED AIR HANDLING

SYSTEMS. GSI DOES NOT RECOMMEND THE

USE OF DOWNWARD FLOW SYSTEMS (SUC-

TION). SEVERE ROOF DAMAGE CAN RESULT

FROM ANY BLOCKAGE OF AIR PASSAGES.

RUNNING FANS DURING HIGH HUMIDITY/

COLD WEATHER CONDITIONS CAN CAUSE AIR

EXHAUST OR INTAKE PORTS TO FREEZE.

Fan/Heater Installation & Operating Instructions

Thank you for choosing a Top Dry Series Autoflow.

It is designed to give excellent performance and ser-

vice for many years.

This manual describes the installation for all

standard production Top Dry single fan, multi-fan

and Heater Control units. Different models are avail-

able for liquid propane or natural gas fuel supply,

with either single-phase 230 volt, or three-phase 208,

220, 380, 460 or 575 volt electrical power.

The principal concern of The GSI Group, Inc.

("GSI") is your safety and the safety of others asso-

The symbol shown is used to call your

attention to instructions concerning

your personal safety. Watch for this

symbol; it points out important safety

precautions. It means "ATTENTION",

"WARNING", "CAUTION", and

"DANGER". Read the message and

be cautious to the possibility of per-

sonal injury or death.

ciated with grain handling equipment. This manual

is written to help you understand safe operating pro-

cedures and some of the problems that may be en-

countered by the operator or other personnel.

As owner and/or operator, it is your responsi-

bility to know what requirements, hazards and pre-

cautions exist, and to inform all personnel associ-

ated with the equipment or who are in the fan area.

Avoid any alterations to the equipment. Such al-

terations may produce a very dangerous situation,

where serious injury or death may occur.

Safety Alert Symbol

WARNING! BE ALERT!

Personnel operating or working

around electric fans should read this

manual. This manual must be

delivered with the equipment to its

owner. Failure to read this manual

and its safety instructions is a

misuse of the equipment.

4

Page 5

Autoflow Operation

The GSI Group Inc. recom-

mends contacting your local

power company, and having a

representative survey your instal-

lation so the wiring is compatible

with their system, and adequate

power is supplied to your unit.

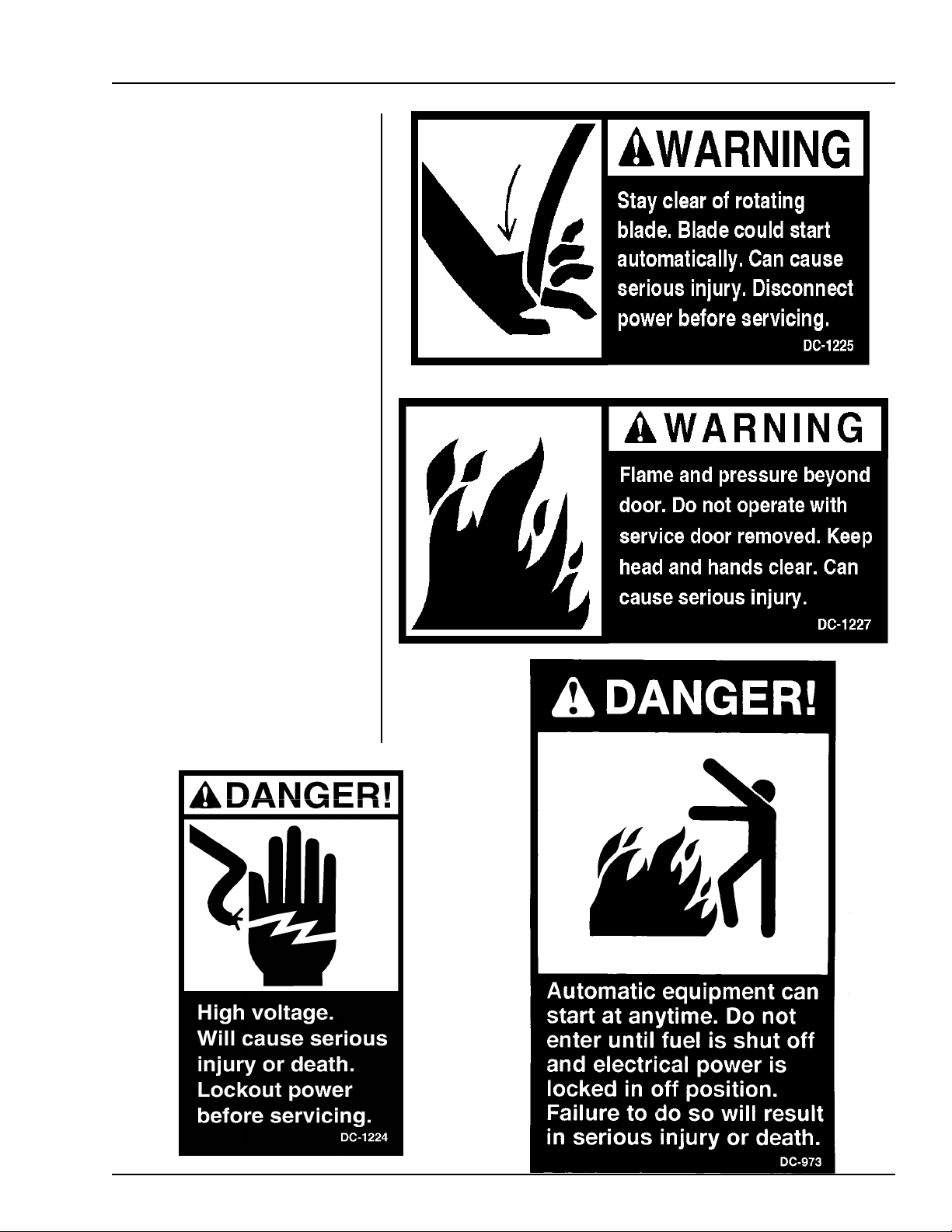

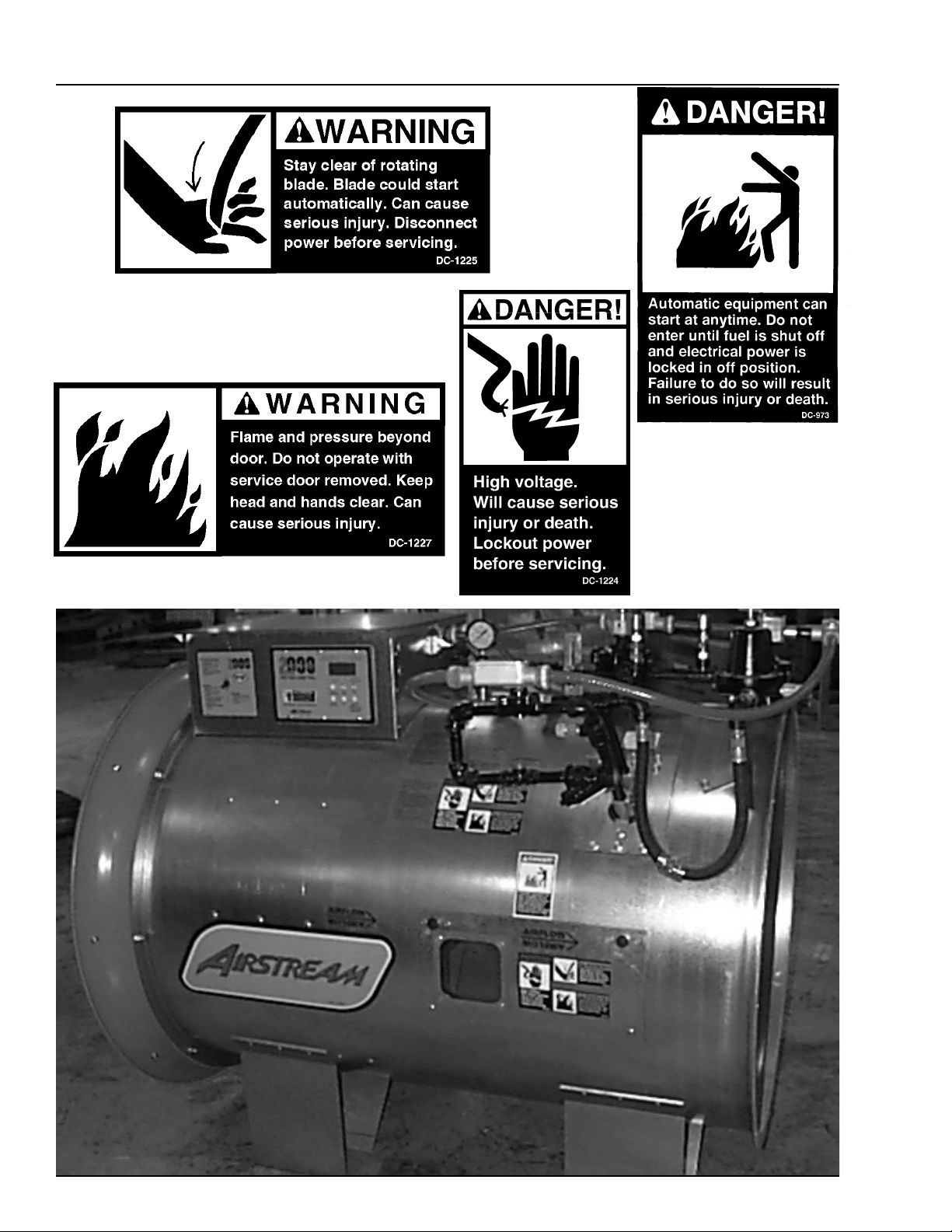

Safety decals should be read

and understood by all people in

the grain handling area. The ro-

tating blade, fire warning decals

and voltage danger decal must be

displayed on the fan can. The bot-

tom right decal should be present

on the inside bin door cover of

the two-ring door, 24" porthole

door cover and the roof manway

cover.

If a decal is damaged or is

missing,contact:

The GSI Group Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to

you.

SAFETY

5

Page 6

DECAL PLACEMENT

Autoflow Operation

6

Page 7

Autoflow Operation

SAFETY PRECAUTIONS

READ THESE INSTRUCTIONS

BEFORE OPERATION AND SERVICE

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before trying to operate the

dryer.

2. Power supply should be OFF for service of electrical components. Use

CAUTION in checking voltage or other procedures requiring power to

be ON.

3. Check for gas leaks at all gas pipe connections. If any leaks are de-

tected, do not operate the dryer. Shut down and repair before further

operation.

4. Never attempt to operate the dryer by jumping or otherwise bypassing

any safety devices on the unit.

5. Set pressure regulator to avoid excessive gas pressure applied to burner

during ignition and when burner is in operation. Do not exceed maxi-

mum recommended drying temperature.

6. Keep the dryer clean. Do not allow fine material to accumulate in the

plenum or drying chamber.

Use Caution in the

Operation of this

Equipment

The design and manufacture of this

dryer is directed toward operator

safety. However, the very nature of

a grain dryer having a gas burner,

high voltage electrical equipment

and high speed rotating parts, does

present a hazard to personnel which

cannot be completely safeguarded

against without interfering with ef-

ficient operation and reasonable ac-

cess to components.

Use extreme caution in working

around high-speed fans, gas-fired

heaters, augers and auxiliary con-

veyors, which may start without

warning when the dryer is operat-

ing on automatic control.

7. Use CAUTION in working around high speed fans, gas burners, augers

and auxiliary conveyors which START AUTOMATICALLY.

8. Do not operate in any area where combustible material will be drawn into

the fan.

9. Before attempting to remove and reinstall any propeller, make certain to

read the recommended procedure listed within the servicing section of

the manual.

10. Clean grain is easier to dry. Fine material increases resistance to airflow

and requires removal of extra moisture.

This product is intended for the use of grain handling only. Any other

use is considered a misuse of the product.

Some edges of the product components can be sharp. It is recommended

that each component of this product be examined to determine if there

are any safety considerations to be taken. Any and all necessary personal

protective equipment should be worn at all times when handling, assem-

bling, installing and operation of the product and/or components.

Guards are removed for illustration purpose only. All guards must be

in place before/during operation.

KEEP THE DRYER CLEAN

DO NOT ALLOW FINE

MATERIAL TO ACCUMULATE

IN THE PLENUM CHAMBER

OR SURROUNDING THE

OUTSIDE OF THE DRYER

Continued safe, dependable opera-

tion of automatic equipment de-

pends, to a great degree, upon the

owner. For a safe and dependable

drying system, follow the recom-

mendations within this manual, and

make it a practice to regularly in-

spect the operation of the unit for

any developing problems or unsafe

conditions.

Take special note of the safety pre-

cautions listed above before at-

tempting to operate the dryer.

7

Page 8

SAFETY SIGN-OFF SHEET

Autoflow Operation

Date Employers Signature Employee

________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________

8

Page 9

Autoflow Operation

Power Supply

ELECTRICAL POWER SUPPLY

An adequate power supply and proper wiring are impor-

tant factors for maximum performance and long life of

the dryer. Electrical service must be adequate enough to

prevent low-voltage damage to motors and control cir-

cuits (see Electrical Load Information). In 220V 1-phase

and 220V 3-phase systems, a separate neutral wire is

required for the 120V heater circuit, and should be

connected to terminal #1 in the master heater. Do not

run in conduit with motor power lines.

Transformer and Wiring Voltage Drop

It is necessary to know the distance from the unit to the

available transformer, and the horsepower of your fan

unit. Advise the service representative of your local power

supplier that an additional load will be placed on the line.

Each fan motor should be wired through a fuse or circuit

breaker disconnect switch. Check on KVA rating of trans-

formers, considering total horsepower load. The power

supply wiring, main switch equipment and transformers

must provide adequate motor starting and operating volt-

age. Voltage drop during motor starting should not ex-

ceed 14% of normal voltage, and after motor is running

at full speed, it should be within 8% of normal voltage.

Check Electrical Load Information for HP ratings and

maximum amp loads to properly size wire and fusing

elements. Standard electrical safety practices and codes

should be used. (Refer to National Electrical Code Stan-

dard Handbook by National Fire Protection Association).

Machine to Earth Grounding

It is very important that a Machine To Earth Ground

Rod be installed at the fan. This is true even if there is

a ground at the pole 15 feet (4.572 meters) away. Place

the ground rod that comes standard, within 8 feet

(2.438 meters) of the dryer, and attach it to the dryer

control panel with at least a #6 solid, bare, copper

ground wire and the clamp provided. The grounding

rod located at the power pole will not provide adequate

grounding for the dryer. The proper grounding will

provide additional safety in case of any short and will

ensure long life of all circuit boards, and the ignition

system. The ground rod must be in accordance with

local requirements.

Dave, any ideas what to put here,if anything?

9

Page 10

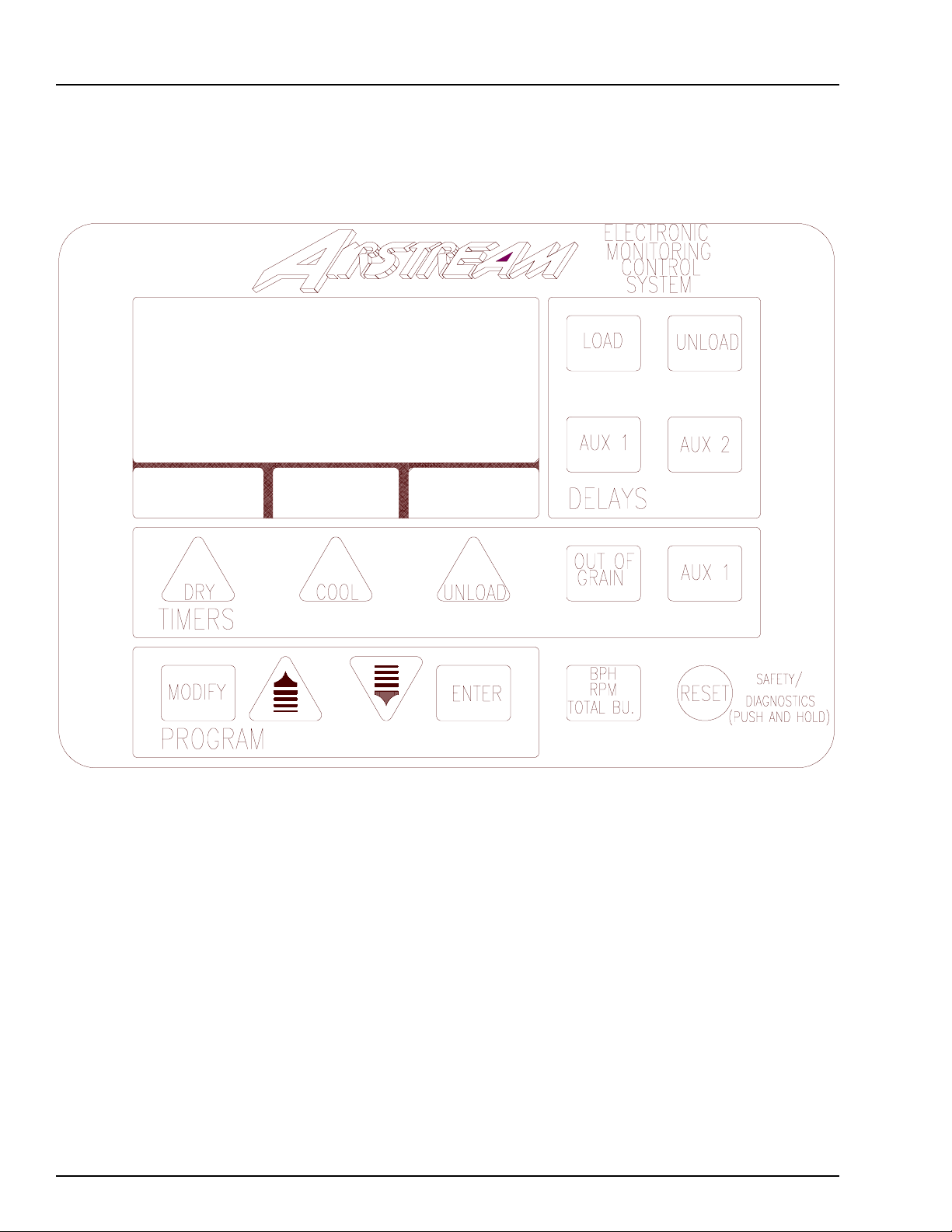

CONTROL SYSTEM

Electronic Monitoring Control System

Autoflow Operation

10

Page 11

Autoflow Operation

CONTROL SYSTEM

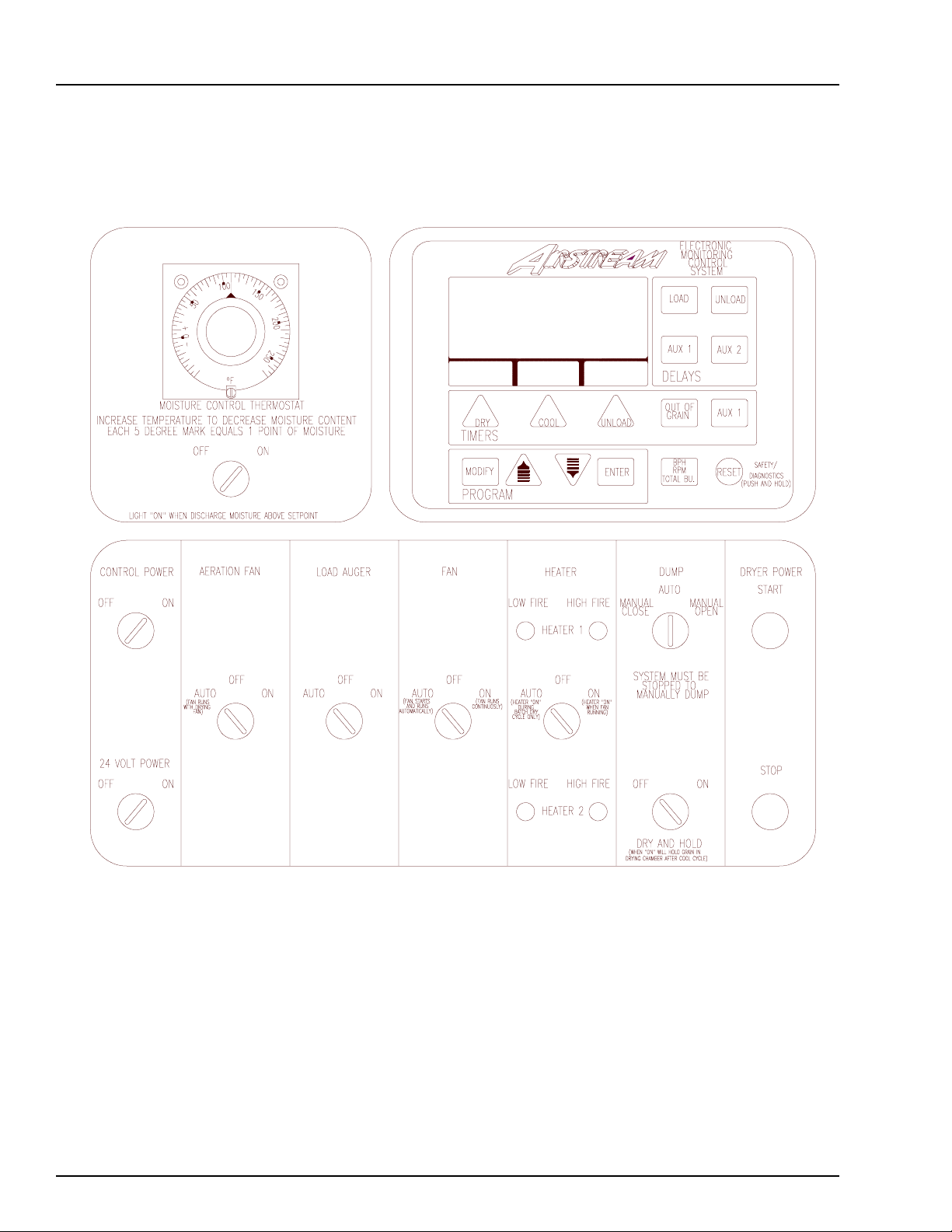

Dryer Control Panel Featuring the

Electronic Monitoring Control System

The control panel provides easy access to gauges

and controls, and the illuminated switches provide a

quick reference for every operating function. The

patent pending Electronic Monitoring Control

System is a computerized control system that gives

instant information regarding dryer operation.

Moisture Control Thermostat

This electronic thermostat controls the moisture

level of discharged grain by sensing grain column

temperature using the four (4) RTD temperature

sensors located in the drying chamber. The moisture

control thermostat indicates the current grain

temperature in the drying chamber with LEDs. The

grain temperature setpoint is set on the moisture

control thermostat. In the Autoflow mode, when the

grain temperature reaches the grain temperature

setpoint, and the dry timer has reached zero, the

dryer will dump the third driest portion of grain

from the drying chamber into the storage chamber.

In the Autobatch mode the dryer will dump all of the

grain into the storage chamber.

switch. The switch lights up when placed in the

on position. If the switch is placed in the on

position, and the light does not light up, make sure

that the emergency stop switches located on the

Autoflow control box is pulled out.

24-Volt Power Switch

This switch turns the power on or off to the actuator

control box. The switch lights up when placed in the

on position. If the switch is placed in the on

position, and the light does not light up, make sure

that the emergency stop switch located on the

actuator control box is pulled out (1997 model only).

Aeration Fan Switch

This switch controls the operation of the aeration fan

located at the bottom of the bin. The switch lights

up when the aeration fan comes on. When placed in

the auto position, the aeration fan starts and stops

with the main drying fans. When placed in the off

position, the aeration fan will not run. When placed

in the on position, the aeration fan comes on when

the dryer is running.

Load Auger Switch

Moisture Control Switch

This switch turns the power on or off to the moisture

control thermostat. When placed in the on

position, the dryer will not enter the dump cycle

until the grain temperature has reached the grain

temperature setpoint on the moisture control thermo-

stat and the dry timer has reached zero. When

placed in the on position, the moisture control

switch lights up when the grain temperature is below

the grain temperature set point on the moisture

control thermostat. When placed in the off

position, the dryer ignores the grain temperature and

operates strictly off the dry timer. When placed in

the off position, the moisture control switch does

not light up.

Control Power Switch

The power to the Electronic Monitoring Control

System is turned on or off with the control power

This switch controls the operation of the fill

system(s) that load grain into the drying chamber.

The switch lights up when the fill system(s) are

running. When placed in the auto position, the fill

system(s) start and stop automatically depending on

the level of grain relative to the drying chamber high

level rotary switch. When operating in the

Autobatch mode, the fill system(s) will shut off 2/3

(two-thirds) of the way through the dry cycle, even

if grain has not reached the drying chamber high

level rotary switch. When placed in the off

position ,the fill system(s) will not run. When

placed in the on position, the fill system(s) come

on and stay on when the dryer is running.

Fan Switch

This switch controls the operation of the main

drying fan(s). The switch lights up when the

airswitch located in the sidewall next to the master

11

Page 12

CONTROL SYSTEM

Dryer Control Panel, continued

Autoflow Operation

drying fan senses an increase in static pressure and

closes. In the Autoflow mode, when placed in the

auto position, the main drying fan(s) start when

grain reaches the drying chamber low level rotary

switch and do not stop until the dryer shuts down

or is stopped manually by pressing the stop switch.

In the Autobatch mode, the main drying fan(s)

shut off automatically in the dump cycle. When

placed in the off position, the main drying fan(s)

will not run. When placed in the on position, the

main drying fan(s) come on and stay on when the

dryer is running.

Fan Switch

This switch controls the operation of the main

drying fan(s). The switch lights up when the

airswitch located in the sidewall next to the master

drying fan senses an increase in static pressure and

closes. In the Autoflow mode, when placed in the

auto position, the main drying fan(s) start when

grain reaches the drying chamber low level rotary

switch and do not stop until the dryer shuts down

or is stopped manually by pressing the stop switch.

In the Autobatch mode the drying fan(s) will not

run. When placed in the on position, the main

drying fan(s) come on and stay on when the dryer

is running.

Dump Switch

This switch controls the operation of the linear

actuator housed in the actuator control box. The

switch lights up when the linear actuator is mov-

ing. When placed in the manual close position,

the linear actuator in the actuator control box

retracts, raising the dump chutes. When placed in

the auto position, the linear actuator extends at

the beginning of the dump cycle- lowering the

dump chutes, and retracts at the end of the dump

cycle, raising the dump chutes. When placed in

the manual open position, the linear actuator

extends, lowering the dump chutes. This switch is

disabled when the dryer is running. The dryer

must be stopped to manually dump.

Dry And Hold Switch

When placed in the on position, the grain in the

drying chamber will not be dumped into the

storage chamber at the end of the dry cycle, and

the dryer will stop. This switch can be used to

hold the last batch of grain in the drying chamber

and stop the dryer. When placed in the off

position, the dryer will operate normally. The

switch lights up when placed in the on position.

Heater Switch

This switch controls the operation of the

burner(s). The switch lights up when the burner is

on. When the burner is on, small lights above and

below the heater switch indicate if the burner(s)

are in high fire or low fire. In the Autoflow mode,

when placed in the auto position, the burner(s)

fire when grain reaches the drying chamber low

level rotary switch and do not stop until the dryer

shuts down or is stopped manually by pressing the

stop switch. In the Autobatch mode, the burner(s)

shut off automatically in the cool and dump cycle.

When placed in the off position, the burner(s)

will not fire. When placed in the on position,

the burner(s) fire anytime the main drying fan(s)

are running.

Dryer Power Start Switch

This switch starts and operates the dryer based on

switch settings. The switch lights up when the

dryer is running. The dump switch is disabled after

this switch has been pushed.

Dryer Power Stop Switch

This switch stops all dryer functions. If an auto-

matic dryer shutdown occurs, first determine and

correct the cause of the shutdown. Press the dryer

power stop switch to reset the dryer before starting.

12

Page 13

Autoflow Operation

CONTROL PANEL

13

Page 14

CONTROL SYSTEM

Electronic Monitoring Control System

Autoflow Operation

14

Page 15

Autoflow Operation

CONTROL SYSTEM

Electronic Monitoring

Control System

The Electronic Monitoring Control System

controls all timing functions and safety circuit

checks. It is designed to simplify dryer operation

by providing printed messages and warnings on its

liquid crystal display (LCD).

Turning On The Electronic Monitoring

Control System

Turn the control power switch to the on

position. The monitor will display a copyright

message, software version number, total running

time in hours and minutes and the model number,

and the serial number and current time and date.

When the serial number and current time and date

are displayed, press the reset button to activate the

controller and enter the main drying screen.

Setting The Dry, Cool And Unload Timers

These switches are used to set the dry, cool

and dump cycle times. The current settings on

these timers are displayed directly above their timer

button. To change the setting of these timers do the

following:

1) Press the dry, cool or unload timer

button.

2) Press the modify button.

3) Press the increase or decrease button to

adjust the settings.

4) Press the enter button.

5) To enter the new value into memory

immediately, press the reset button.

During operation, the remaining time on

each timer is displayed on the screen. If the power

goes out or the dryer is stopped, these times are

saved by the controller. When the dryer is restarted,

the timers will continue timing down. The timers

will return to their initial settings by pressing the

reset button. The cool timer is not used in an

Autoflow system.

Setting The Aux. 1 Timer

The value set on the aux. 1 timer acts as a

buffer to allow grain to fall away from the drying

chamber low level rotary switch after the drying

fans start without giving an error. When grain

reaches the drying chamber low level rotary

switch, the drying cycle starts (if the fan switch is

placed in the auto or on position) and the aux.

1 timer begins to time down. If grain falls away

from the drying chamber low level rotary switch

before the time on the aux 1 timer reaches zero, no

error is given and the dryer continues in the drying

cycle. If grain falls away from the drying chamber

low level rotary switch after the aux. 1 timer

reaches zero, a drying chamber no grain error is

given and the dryer shuts down. The aux. 1 timer

should be set long enough so that the fill system(s)

have sufficient time to make up the grain that falls

away from the drying chamber low level rotary

switch when the fan(s) and heater(s) start; but,

should not be set too long. If the linear actuator

fails to retract, the dump chutes and grain runs

directly from the drying chamber to the storage

chamber without being dried, then the grain would

fall away from the drying chamber low level

rotary switch and a drying chamber no grain error

would be given. If the aux. 1 timer is set too long

and the linear actuator failed to retract, an unac-

ceptable amount of wet grain could flow from the

drying chamber to the storage chamber before a

drying chamber no grain error is given and the

dryer shuts down. The aux. 1 timer is set using

the same procedure as the dry and unload timers,

but the reset button does not need to be pressed to

enter the new values into memory immediately.

Setting the Out of Grain Timer

The value set on the out of grain timer is

the amount of time that grain has to reach the

drying chamber low level rotary switch when the

dryer is refilling after the dump cycle in an

Autobatch system. When the dump cycle is

complete, the out of grain timer begins to count

down. If grain does not reach the drying chamber

low level switch before the out of grain timer

reaches zero, the dryer will give an out of grain

error and shut down. The out of grain timer is not

used in an Autoflow system.

15

Page 16

CONTROL SYSTEM

Autoflow Operation

Setting the Load Delay

The value set on the load delay is the amount

of time that fill system number two runs after grain

reaches the drying chamber high level rotary switch.

This delay is not used with only one fill system con-

trolled by the Autoflow. The load delay should be set

long enough so that the drying chamber high level

rotary switch is covered with enough grain that the fill

system do not start and stop frequently in the dry cycle

due to settling or shrinkage; but, the load delay should

be set short enough so that grain does not reach the

drying chamber overflow rotary switch. The load

delay is set using the same procedure as the dry and

unload timers, but the reset button does not need to be

pressed to enter the new values into memory immedi-

ately.

Setting the Aux. 1 Delay

In units that the Autoflow controls one fill

system, the value set on the aux. 1 delay is the amount

of time that fill system number one runs after grain

reaches the drying chamber high level rotary switch.

The aux.1 delay should be set long enough so that the

drying chamber high level rotary switch is covered

with enough grain that the fill system does not start and

stop frequently in the dry cycle due to settling or

shrinkage; but, the aux. 1 delay should be set short

enough so that grain does not reach the drying chamber

overflow rotary switch.

In units that the Autoflow controls two fill

systems, the value set on the aux. 1 delay is the amount

of time that fill system number one runs after fill

system number two shuts off. Fill system number one

is the fill system that directly puts grain in the drying

chamber. The aux. 1 delay should be set long enough

so that all grain present in fill system number one is

loaded into the drying chamber before it shuts off.

This will decrease the current required to start fill

system number one the next time the dryer calls for

grain. The aux. 1 delay is set using the same procedure

as the dry and unload timers, but the reset button does

not need to be pressed to enter the new values into

memory immediately.

Setting the Unload Delay

The value set on the unload delay is the

amount of time that both fill system number one

and fill system number two run after grain falls

away from the wet supply rotary switch before the

unit shuts down and gives a wet supply hopper

empty error. In units that the Autoflow controls

only one fill system, the value set on the unload

delay is the amount of time that fill system number

one runs after grain falls away from the wet supply

rotary switch. The unload delay should be set long

enough so that the fill system(s) clean out before

the dryer shuts down; but, should be set short

enough to avoid running the fill system (s) empty

for an excessive amount of time. The unload delay

is set using the same procedure as the dry and

unload timers, both the reset button does not need

to be pressed to enter the new values into memory

immediately.

Setting the Aux. 2 Delay

The aux. 2 delay is not currently being

used.

Viewing operation time and total cycles

The total operation time and total cycles

can be viewed at any time the dryer is in the main

drying screen by pressing the increase button.

Diagnostics Mode-Resetting Batch Counter

The Electronic Monitoring Control System

can perform a self-diagnostic exam. With the dryer

stopped and in the main drying screen, press and

hold down the reset button for several seconds.

After the self-diagnostic exam is complete, the

display will read the results of the exam and will

then give the user the option to reset the batch

counter. The batch counter can be cleared by

pressing the reset button or left as-so by pressing

the enter button. After choosing an option, the user

is taken to the shutdown history retrieval. To view

past shutdowns and the time and date the shutdown

occurred, press the decrease button. Press the enter

button at any time to return to the main drying

screen.

16

Page 17

Autoflow Operation

Set-up Mode

The set-up mode is used to program the

computer with different variables that influence how

the dryer will operate. With the dryer stopped and in

the main drying screen, press the increase and

decrease buttons at the same time to enter the set-up

mode.

CONTROL SYSTEM

recommended.

3). The third variable to set is the

dryer model. Use the increase and de-

crease buttons to select one of the four

model types that fits your system. The four

models are as follows:

1). The first variable to be set is the

number of fill system that are to be con-

trolled by the dryer. Use the increase and

decrease buttons to toggle between one

or two fill systems. Press the enter button

when the number of fill systems displayed

on the screen equals the number of fill

systems that the computer will be control-

ling. If one fill system is selected, only one

fill system will be controlled by the

computer. The aux. 1 delay will be used to

delay the shut off of the fill system after

the drying chamber is full. The load delay

will have no effect on the operation of the

fill system. If two fill systems are selected,

two fill systems will be controlled by the

computer. Both the load delay and the aux.

1 delay are used by the computer to delay

the shut-off of the fill system(s) after the

drying chamber is full.

2). The second variable to set is

whether the drying fan(s) will start with the

drying chamber high level or drying

chamber low level rotary switch. Use the

increase and decrease buttons to toggle

between starting the fan(s) with the high or

low level rotary switch. Press the enter

button when the correct rotary switch is

displayed. In most situations, the fan(s)

should be started with the drying chamber

low level rotary switch. If the drying

chamber high level rotary switch is se-

lected to control the starting of the main

drying fan(s), the dry cycle and main drying

fan(s) will not start until grain reaches the

drying chamber high level rotary switch.

Again, this mode of operation is not

AF2-Autoflow with two main drying fans

AF1-Autoflow with one main drying fans

AB2-Autobatch with two main drying fans

AB1-Autobatch with one main drying fans

Most systems will be either an

Autoflow with one fan or an Autoflow with

two fans. Press the enter button when the

correct model number is displayed.

4). The fourth variable is the current

year. Use the increase and decrease

buttons to select the correct year. Press the

enter button when the correct year is

displayed.

5). The fifth variable is the current

month. Use the increase and decrease

buttons to select the correct month. Press

the enter button when the correct month is

displayed.

6). The sixth variable is the current

day of the month. Use the increase and

decrease buttons to select the correct day of

the month. Press the enter button when the

correct day is displayed.

7). The seventh variable is the current

hour. Use the increase and decrease

buttons to select the correct hour. Press the

enter button when the correct hour is

displayed.

8). The eighth variable is the current

minute. Use the increase and decrease

buttons to select the correct minute. Press

the enter button when the correct minute is

17

Page 18

CONTROL SYSTEM

displayed.

Autoflow Operation

9). The ninth variable is the airswitch

test. Use the increase and decrease buttons

to toggle between yes or no. If no is

selected, the dryer does not require proof

of airflow before the burner lights. If yes

is selected, the dryer requires proof of

airflow to light the burner. Each time the

dryer control power is shut off, the

airswitch test defaults to yes.

10). The tenth variable is the fan delay.

The fan delay is the delay in seconds

between the starting of the master fan unit

and the slave fan unit. In systems with

220v 1-ph electrical power, the fan delay

should be set at small value, less than 3

seconds. If the fan delay is set too long,

the slave fan could rotate fast enough

backwards to start in a reverse rotation.

Use the increase and decrease buttons to

select the fan delay. Press the enter button

when the correct fan delay is displayed. In

single fan units the fan delay is not appli-

cable.

12). The twelfth variable is the status

of the wet grain and drying chamber low

level rotary switches. By pressing the dry

timer switch, the user can directly enter the

shutdown history retrieval. By pressing the

unload timer switch, the status of these two

rotary switches can be altered. Use the

increase and decrease buttons to make the

selection. Press the enter button when the

correct selection is displayed. When the

wet supply test is on, the dryer monitors the

wet supply rotary switch. When the wet

supply test is off, the dryer does not

monitor the wet supply rotary switch. The

computer responds as though there is wet

grain in the wet storage tank. When the

chamber low test is off, the dryer does not

monitor the drying chamber low level

rotary switch. The computer responds as

though there is grain in the drying chamber

against the low level rotary switch. When

the chamber low test is off, the display on

the dryer control panel reads yes at the

grain low level status line.

11). The eleventh variable is the high

flame delay. The high flame delay is the

amount of time the burner remains in low

fire on ignition. In normal operation the

high flame delay is set at one second. Use

the increase and decrease buttons to select

the high flame delay. Press the enter

button when the correct high flame delay

is displayed.

After the set-up mode is complete

the user is taken directly to the shutdown

history retrieval. To view past shutdowns

and the time and date the shutdown oc-

curred, press the decrease button. Press the

enter button at any time to return to the

main drying screen.

18

Page 19

Autoflow Operation

CONTROL SYSTEM

19

Page 20

CONTROL SYSTEM

Autoflow Operation

20

Page 21

Autoflow Operation

CONTROL SYSTEM

21

Page 22

CONTROL SYSTEM

Autoflow Operation

22

Page 23

Autoflow Operation

CONTROL SYSTEM

Dryer Status

By viewing the display on the dryer control

panel the user can quickly determine what mode of

operation the dryer is in, what cycle the dryer is in,

the location of grain relative to the drying chamber

rotary switches, and the current status of the dryer.

The Electronic Monitoring Control System flashes

the current status of the dryer on the display on the

dryer control panel. When the system is running,

information about the operation of the dryer and

the location of grain can be obtained with a quick

glance at the dryer control panel. The displayed

dryer conditions are as follows:

Batch Mode

When the display on the dryer control

panel reads batch mode, the dryer has been

programmed to operate as an automatic batch

dryer. When operating as an automatic batch dryer

all the grain in the drying chamber is dumped into

the storage chamber during the dump cycle, and a

cooling cycle is available after the dry cycle. This

is not the standard mode of operation. The user

must enter the set-up mode to change the dryer

model from AB1 or AB2 to AF1 or AF2, to

change from Autobatch to Autoflow.

Auto Mode

When the display on the dryer control

panel reads auto mode, the dryer has been

programmed to operate as an automatic staged

batch dryer. When operating as an automatic

staged batch dryer, only the driest third of grain is

removed from the drying chamber during the

dump cycle, and once the drying process starts it

does not stop until the dryer is stopped. This is the

standard mode of operation.

drying chamber has reached the drying chamber

high level rotary switch. If the load switch on the

dryer control panel is in the auto position, the fill

system(s) should be stopped or in the process of

stopping.

Grain High Level NO

When the display on the dryer control

panel reads grain high level no, the grain in the

drying chamber has not reached the drying

chamber high level rotary switch. If the load

auger switch on the dryer control panel is in the

on or auto position, the fill system(s) should

be running.

Grain Low Level YES

When the display on the dryer control

panel reads grain low level yes, the grain in the

drying chamber has reached the drying chamber

low level rotary switch. If the fan switch on the

dryer control panel is in the auto or on

position the dry timer begins to count down and

the dry cycle begins.

Grain Low Level No

When the display on the dryer control

reads grain low level no, the grain in the

drying chamber has not reached the drying

chamber low level rotary switch and the drying

process has not started.

Stopped

When the display on the dryer control

panel is flashing stopped the dryer is not

running. The set-up mode can be entered into

when the dryer status is stopped.

Grain High Level YES

When the display on the dryer control

panel reads grain high level yes, the grain in the

Purging

When the display on the dryer control

panel is flashing purging, the dryer is running,

23

Page 24

CONTROL SYSTEM

Autoflow Operation

the fan is running and there is proof of airflow, the

burner is getting ready to ignite.

Unload

When the display is flashing unload, the

dump chutes have been lowered and the dryer is in

the dump cycle.

Temp HLD

When the display on the dryer control

panel is flashing temp hld the dryer is in the dry

cycle, the dry timer has reached zero, and the

current grain temperature is below the grain

temperature setpoint on the moisture control

thermostat. If the dryer is stopped when temp

hld is flashing on the screen, two minutes will be

entered into the dry timer when the dryer is re-

started.

The Electronic Monitoring Control System dis-

plays the error message and sounds a warning

signal to alert the user. The displayed error condi-

tions and their electrical cause are as follows:

Burner 1 Warning Flame Not Detected

The flame sensor in burning number one

has failed to detect flame. Either the burner failed

to light or the flame sensor needs to be adjusted.

The flame sensor is the sensor attached to the

burner, and has a single lead. If the burner is

lighting but the unit it still shutting down; due to

loss of flame, the flame sensor needs to be ad-

justed. The flame sensor can be adjusted by

bending it so it is immersed in flame. If the burner

is not lighting, make sure that the dryer is getting

fuel, all solenoids are opening, and the ignitor is

sparking. Electrically there is a loss of 12vDC+ on

J1-9 on the input/output board.

Loading

When the display on the dryer control

panel is flashing loading, the fill system(s) are

running.

Drying

When the display on the dryer control

panel is flashing drying, the dryer is in the dry

cycle, the main drying fan(s) are running, and the

load augers are not running.

Cooling

When the display on the dryer control

panel is flashing cooling, the dryer has been set-

up as an Autobatch unit and is in the cool cycle.

Error Messages

When the dryer shuts down, the user can

quickly determine what caused the shutdown by

viewing the display on the dryer control panel.

Burner 2 Warning Flame Not Detected

The flame sensor in burner number two has

failed to detect flame. Either the burner failed to

light or the flame sensor needs to be adjusted. The

flame sensor is the sensor attached to the burner,

and has a single lead. If the burner is lighting but

the unit is still shutting down; due to loss of flame,

the flame sensor needs to be adjusted. The flame

sensor can be adjusted by bending it so it is im-

mersed in flame. If the burner is not lighting,

make sure that the dryer is getting fuel, all sole-

noids are opening, and the ignitor is sparking.

Electrically there is a loss of 12vDC+ on J1-10 on

the input/output board.

Burner 1-Vapor High Temperature

The LP gas vapor temperature sensor,

located on the gas pipe train downstream from the

vaporizer coil, on fan and heater number one has

opened, indicating that the vaporizer coil is run-

ning too hot and must be adjusted. This sensor is

set at 200 degrees Fahrenheit and automatically

24

Page 25

Autoflow Operation

CONTROL SYSTEM

resets itself when cool. The vaporizer is adjusted

by loosening the bolt and moving the vaporizer

coil away from the flame. Electrically there is a

loss of 12vDC+ on J1-5 on the input/output board.

Burner 2 Vapor High Temperature

The LP gas vapor temperature sensor

located on the gas pipe train downstream from the

vaporizer coil, on fan and heater number two has

opened, indicating that the vaporizer coil is run-

ning too hot and must be adjusted. This sensor is

set at 200 degrees Fahrenheit and automatically

resets itself when cool. The vaporizer is adjusted

by loosening the bolt and moving the vaporizer

coil away from the flame. Electrically there is a

loss of 12vDC+ on J1-6 on the input/output board.

Fan 1 Housing High Temperature

The temperature high limit, located on the

housing, on the fan and heater number one opened,

indicating that the housing towards the bin has

overheated. The high limit sensor is set at 200

degrees Fahrenheit and must be manually reset.

Electrically there is a loss of 12vDC+ on J1-7 on

the input/output board.

needs to be lowered, or the cycle setpoint on the

Hi-lo thermostat needs to be increased, if the error

is displayed frequently. Electrically there is a loss

of 12vDC+ on J1-11 on the input/output board.

12 volt power supply warning

The right circuit breaker, located on the

input/output board, has tripped.

L1 Voltage Lost

The left circuit breaker, located on the

input/output board, has tripped or one of the

hardware timers has shut down the dryer. The

overload must be reset manually. Electrically

there is a loss of 12vDC+ on J5-6, or J5-10 on the

input/output board.

Fan 1 Motor Overload

The thermal overload in the control box on

fan number one, has tripped, indicating an

overcurrent condition. The overload must be reset

manually. Electrically there is a loss of 12vDC+

on J4-12 on the input/output board.

Fan 2 Motor Overload

Fan 2 Housing High Temperature

The temperature high limit, located on the

housing, on fan and heater number two opened,

indicating that the housing towards the bin has

overheated. This high limit sensor is set at 200

degrees Fahrenheit and must be manually reset.

Electrically there is a loss of 12vDC+ on J1-8 on

the input/output board.

Plenum High Temperature

An over temperature condition has oc-

curred inside the dryer plenum. The plenum high

limit is set automatically on the Hi-Lo thermostat

when the cycle set-point is adjusted and resets

automatically when cooled. The lo-fire pressure

The thermal overload in the control box on

fan number two has tripped, indicating an

overcurrent condition. The overload must be reset

manually. Electrically there is a loss of 12vDC+

on J4-18 on the input/output board.

Fan Shutdown Loss of Airflow

The contacts on the airswitch, located in

the bin sidewall and attached to fan and heater

number one, have opened due to the fan not

turning, or the airswitch may need to be adjusted.

Electrically there is a loss of 12vDC+ on J1-13 on

the input/output board.

25

Page 26

CONTROL SYSTEM

Autoflow Operation

Drying Chamber Overflow

The grain level in the drying chamber has

reached the drying chamber overflow rotary

switch. Grain will have to be dumped from the

drying chamber to the storage chamber before the

unit can be restarted. This error indicates that

either the drying chamber high level rotary switch

is faulty or the time on the Load delay or Aux.1

delay needs to be lowered. Electrically there is the

presence of 12vDC+ on J4-6 on the input/output

board.

Storage Chamber Full

The grain level in the storage chamber has

reached the storage chamber high level rotary

switch located 3 feet(.91 meters) below the fan and

heater(s). Grain will have to be removed from the

storage chamber before the unit can be restarted.

Electrically there is the presence of 12vDC + on

J4-4 on the input/output board.

Wet Supply Hopper Empty

The grain in the wet supply tank has fallen

below the wet supply rotary switch. If there is

grain against the drying chamber low level rotary

switch, the dryer can be restarted by pressing the

stop switch to clear the error and then the start

switch. Electrically there is a loss of 12vDC+ on

J4-2 on the input/output board.

Wet Supply Empty Press<Enter>to

Dry Remaining Grain

This message is displayed when the start

button is pushed and grain has fallen away from

the wet supply rotary switch and there is still grain

against the drying chamber low level rotary

switch. If the enter button is pushed, the dryer will

restart, but the fill system(s) will not restart.

Electrically there is a loss of 12vDC+ on J4-2 and

the presence of 12vDC+ on J4-8 on the input/

output board.

Out of Grain Warning

This message is displayed after the dump cycle

when the dryer has been restarted by pressing the

enter button, after a wet supply empty error has

been given.

Cannot Start Dryer Wet Supply Empty

This message is displayed when the start button is

pushed and grain has fallen away from the wet

supply rotary switch and there is no grain against

the drying chamber low level rotary switch. Grain

will have to be put into the wet supply tank or the

drying chamber to start the dryer. Electrically

there is a loss of 12vDC on J4-2 and a loss of

12vDC+ on J4-8 on the input/output board.

Drying Chamber Low Grain

This message is displayed when grain falls

away from the drying chamber low level rotary

switch after the Aux. 1 timer has reached zero. If

the error is being caused due to the settling of

grain after the fans start, the time on the Aux.1

timer can be lengthened. Electrically there is a

loss of 12vDC+ on J4-8 on the input/output board.

Load Auger Motor Overload

The thermal overload in the fill system control box

for fill system number one has tripped, indicating

an overcurrent condition. Make sure the emer-

gency stop switch on the fill system control box is

pulled out as this will inhibit the motor starter

from engaging. The overload must be reset manu-

ally. Electrically there is a loss of 12vDC+ on J4-

16 on the input/output board.

26

Page 27

Autoflow Operation

CONTROL SYSTEM

Auxiliary Fill Motor Overload

The thermal overload, in the fill system control

box for fill system number two; has tripped,

indicating an over current condition. Make sure

the emergency stop switch on the fill system

control box is pulled out as this will inhibit the

motor starter from engaging. The overload must

be reset manually. Electrically there is a loss of

12vDC on J4-16 on the input/output board.

Aeration Fan Motor Overload

The thermal overload, in the fill system

control box for the aeration fan; has tripped,

indicating an overcurrent condition. Make sure the

emergency stop switch on the fill system control

box is pulled out as this will inhibit the motor

starter from engaging. The overload must be reset

manually. Electrically there is a loss 12vDC+ on

J4-17 on the input/output board.

Autoflow Fan and Heater Control Box

The Autoflow fan and heater control box

mounted on the fan heater unit(s), houses the

motor starter, Fenwall ignition-flame detection

board, and all circuitry involved with the control of

the fan and heater unit. Two service switches are

located on the front panel of the Autoflow fan and

heater control box.

Fan

This switch allows the user to turn off the

drying fan while at the fan and heater unit. It the

Autoflow is running, and the fan is running, the

fan will stop when the fan service switch is placed

in the off position, but the dryer will continue

running as though the fan was on. If the burner is

running when the fan service switch is placed in

the off position, the burner will shut off also.

The fan service switch light on the master fan

lights up when the airswitch closes. In normal

operation the fan service switch should be left in

the on position.

Heater

This switch allows the user to turn off the

burner while at the fan and heater unit. If the

Autoflow is running, and the burner is running, the

burner will stop when the heater service switch is

placed in the off position, but the dryer will

continue running as though the burner was on.

When the heater service switch is placed in the

off position, the fan does NOT shut off. When

the heater service switch is placed back to the on

position, the unit reignites after the purge delay.

The heater service switch light lights up when the

burner is on. In normal operation, the heater

service switch should be left in the on position.

27

Page 28

FILL SYSTEM CONTROL BOX

Autoflow Operation

28

Page 29

Autoflow Operation

Fill System Control Box

FILL SYSTEM CONTROL BOX

The fill system control box houses the

motor starters for fill system #1, fill system #2 and

the aeration fan. Start and stop switches are

located on the front of the fill system control box

and the emergency stop, and aeration fan lockout

switches are located on the side of the control box.

Fill System #1

These start and stop switches are used to

start and stop fill system #1 manually. In order to

use the start and stop switches for fill system #1,

the control power switch on the Autoflow control

box must be placed in the on position, and the

dryer must be stopped. When the start switch for

fill system #1 is pushed, fill system #1 starts and

will not shut off until the stop switch for fill

system #1 or the emergency stop switch is pushed.

When the dryer is running, the start and stop

switches for fill system #1 are disabled.

fan, the control power switch on the Autoflow

control box must be placed in theon position,

and the dryer must be stopped. When the start

switch for the aeration fan is pushed the aeration

fan is pushed, the aeration fan starts and will not

shut off until the stop switch for the aeration fan or

the emergency stop switch is pushed. When the

dryer is running, the start and stop switches for the

aeration fan are disabled.

Aeration Fan Lockout

This switch controls how the aeration fan

will operate in the event the Autoflow unit

stopped. If the aeration fan lockout switch is

placed in the continuos position, the aeration fan

will remain running after the Autoflow unit shuts

down. If the aeration fan lockout switch is placed

in the automatic position, the aeration fan shuts

off when the dryer stops.

Fill System #2

These start and stop switches are used to

start and stop fill system #2 manually. In order to

use the start and stop switches for fill system #2,

the control power switch on the Autoflow control

box must be placed in the on position, and the

dryer must be stopped. When the start switch for

fill system #2 is pushed, fill system #2 starts and

will not shut off until the stop switch for fill

system #2 or the emergency stop switch is pushed.

When the dryer is running the start and stop

switches for fill system #2 are disabled.

Aeration Fan

These start and stop switches are used to

start and stop the aeration fan manually. In order

to use the start and stop switches for the aeration

Emergency Stop Switch

This switch will stop all fill systems and

aeration fan(s) that are running when the emer-

gency stop switch is pushed. Note: that the emer-

gency stop switch only stops fill systems and

aeration fans that are controlled by the fill system

control box. If the dryer is running when the

emergency stop switch is pushed, the dryer will

stop along with any fill systems or aeration fans

that are running.

Pre-Season Check

Before the dryer is filled, thoroughly

inspect the unit and check the operation of the

dryer as follows on page 29. When entering the

bin take great caution. Never enter a bin where

grain is present.

29

Page 30

FILL SYSTEM CONTROL BOX

Set Control Switches

♦ MOISTURE CONTROL Switch On

♦ AERATION FAN Switch Off

♦ LOAD AUGER Switch Off

♦ FAN Switch Off

♦ HEATER Switch Off

♦ DUMP Switch Auto

♦ DRY and HOLD Switch Off

♦ Autoflow Emergency Stop Switch Out

♦ Actuator Emergency Stop Switch Out

♦ Fill System Control Box Emergency Stop Switch Out

♦ 24 VOLT POWER Switch On

Autoflow Operation

Control Power Switch

Turn the control power switch on. The

switch will light up. The screen will display a

copyright message and software version number,

total running time in hours and minutes and the

model number, and the serial number and current

time and date. At this time, the controller will lock

out all other dryer functions. Once the date and

time are displayed, press the reset button and the

dryer will perform its safety circuit check. If a

fault is found, an error message will be displayed

on the screen. If all are found safe, the main

drying screen will be displayed.

Drying Chamber

Enter the drying chamber and inspect each

dump hopper for obstructions that may inhibit the

flow of grain into the dump chutes. Make sure that

the gap between the discharge flow plates and the

floor sheets is a minimum of 1-1/2. All discharge

flow plates should be adjusted evenly around the

bin. Inspect each discharge flow plate and make

sure that the bottom brackets on each flow plate

have not collapsed, due to pressure from walking

around the drying chamber. Inspect the leveling

bands. Make sure that all leveling bands are

installed properly and are in good shape.

Rotary Switches

View the drying chamber switches from

the peak hole on top of the dryer. Make sure that

all three rotary switches are spinning freely.

Double check the seal on each rotary switch top.

The number one cause of switch failure is water.

Make sure when the electricain replaced the top on

the rotary switch that no creases formed in the

gasket. Inspect both the storage and wet supply

rotary switches for operation and proper seal.

Dump Chutes

Enter the storage chamber. Make sure that

all dump chutes are adjusted evenly. When one

chute is level, make sure that all chutes are level.

This is very critical to the correct operation of the

dryer. The center plate, that all the dump chute

chains attach to, should be no greater than 12

from the pulley when the chutes are level. If the

center plate is further than 12 from the pulley

when the chutes are closed, the chains must be

lengthened.

Linear Actuator

Turn the dump switch on the Autoflow

control box to the manual open position. Use a

30

Page 31

Autoflow Operation

FILL SYSTEM CONTROL BOX

tape measure to measure the stroke on the linear

actuator. The stroke should be between 12 and

14. If the stroke on the actuator is not 12 to 14,

the actuator should be adjusted. Make sure that all

pulleys and cables are able to move freely when

the actuator is moving. With the actuator ex-

tended, enter the storage chamber. View each

dump chute individually. Make sure that each

dump chute opened completely when the actuator

extended. If a dump chute does not open com-

pletely, the double nuts on the bolt that the chutes

hinge on, needs to be loosened. The dump chutes

should hinge smoothly. After the chutes have

been inspected turn the dump switch on the

Autoflow control box to the Auto position and

press the stop switch. The chutes should raise.

Power Start Button

Before the dryer start button is pushed,

make sure there is grain in the wet supply tank. If

there is no grain in the wet supply tank, the dryer

will not start. Push the dryer start button. The

screen should no longer be flashing STOPPED.

can easily be reversed by first turning off the

power at the main disconnect, then interchanging

any two of the three power supply wires coming

into the motor starter in the fan control box.

Reverse the two outside wires, L1 and L3, and

leave the middle one in the same position. If the

dryer is empty, the unit will not operate. The fans

cannot create enough static pressure to engage the

airswitch. You will receive a loss of airflow

message.

Aeration Fan

Bump the aeration fan switch on the

autoflow control box and observe the aeration fan

rotation. The aeration fan should run counter-

clockwise. Sometimes on three phase models the

motor will run backwards. This can easily be

reversed by first turning off the power at the main

disconnect, then interchanging any two of the three

power supply wires coming into the motor starter

in the fill system control box. Reverse the two

outside wires, L1 and L3, and leave the middle one

in the same position.

Fuel Check

If using LP gas, make sure the tank has

plenty of fuel. If using natural gas, make sure

adequate supply is available. If using LP gas,

slowly open the main fuel supply valve at the tank.

If using natural gas, turn on the valve along the

supply line. Then open the ball valve on the fan

heater unit(s). Inspect all gas lines and connec-

tions for possible leaks. Any gas leaks need to be

fixed immediately!

Fan

Make sure that the fan and heater service

switches on the main drying fan(s) are in the on

position. Bump the fan switch on the Autoflow

control box and observe the fan rotation. The fan

should run counterclockwise. Sometimes on three

phase models the motor will run backwards. This

Fill System

Prepare the wet storage tank to deliver

grain to the dryer. Make sure all personnel are

away from any machinery that is controlled by the

Autoflow. Place the load auger switch in the

Auto position. The fill system(s) should begin

to load grain from the wet supply tank to the dryer.

When the display on the Autoflow control box

reads GRAIN LOW LEVEL YES, close the

valve that supplies the fill system(s) with wet grain

from the wet supply tank. After the fill system(s)

have cleaned out, place the load auger switch in

the off position.

Airswitch

Place the fan and heater service switches

on the main drying fan(s) in the off position.

Place the fan switch on the Autoflow control box

31

Page 32

FILL SYSTEM CONTROL BOX

Autoflow Operation

in the on position. Place the aeration fan switch

on the Autoflow control box in the on position.

Go to the master fan and heater unit. Place the fan

service switch in the on position. The master

fan should start. In two fan, units the slave fan

should start after the fan delay. In single fan units

the light on the master fan service switch should

light up after the master fan reaches half speed. If

the service switch light lights up before the fan

reaches half speed, adjust the airswitch by turning

it clockwise. If the service switch light does not

light up, adjust the airswitch by turning it counter-

clockwise. In two fan units, the light on the master

fan service switch should light up after the slave

fan reaches half speed. If the service switch light

lights up before the fan reaches half speed, adjust

the airswitch by turning it clockwise. If the ser-

vice switch light does not light up, adjust the

airswitch by turning it counterclockwise.

Burner Test Fire

natural gas units. At this time adjust the Hi-Lo

thermostat all the way to the right. Watch the

thermometers. When the temperature in dryer gets

to the desired setpoint (160°-180°), turn the knob

back to the left until the heater cycles from high

fire to low fire. While the heater is in low fire,

adjust the low fire gas pressure by opening or

closing the valve located on top of the pipetrain.

The low fire gas pressure should be approximately

2-6 lbs. for LP units and 1-3 lbs. for natural gas

units. If the burner remains in low fire and does

not cycle, slightly decrease the gas pressure at the

low fire gas valve. Any time the high fire gas

pressure is adjusted, the low fire gas pressure

needs to be checked. The basic rule-of-thumb for

setting gas pressure is as follows: make sure that

the temperature in the bin is increasing at a rapid

rate when in high fire, and the temperature in the

bin is falling at a rapid rate while in the low fire.

Dryer Shutdown

Make sure the heater service switch on the

main drying fan(s) is in the off position. Place

the heater switch on the Autoflow control box in

the on position. Start the main drying fan(s), if

they are not already running. Make sure the fuel

supply is on. Go to the fan and heater unit(s) and

place the heater service switch in the on posi-

tion. The burner should ignite after a short purge

delay. Gas pressure should be shown on the

gauge. Adjust the high fire gas pressure by turning

the regulator in and out on LP units; or, by open-

ing and closing the main ball valve on natural gas

units. The high fire pressure should be approxi-

mately 6-15 lbs. for LP units and 6-10 lbs. for

To shut down the dryer, first close the fuel

supply valve at the tank or the valve along the fuel

supply line. If the burner is operating, let the dryer

run out of fuel. It should shut down due to loss of

flame. Press the dryer stop button to clear the

error, and turn off the main power disconnect at

the entrance panel.

Emergency

In case of an emergency push the emer-

gency stop switch located on the side of the

Autoflow control box. This will shut everything,

that is controlled by the dryer, off immediately.

32

Page 33

Autoflow Operation

Top Dry Autoflow Theory of Operation

THEORY OF OPERATION

Control Panel Switches Status:

Control Power: On

24v Power: On

Moisture Control Thermostat: On

Aeration Fan: Auto

Load Auger: Auto

Fan: Auto

Heater: Auto

Dump: Auto

Dry & Hold: Off

When the Top Dry is in a ready state; that

is, with no grain the Drying Chamber and wet

grain in the Wet Storage Tank, Fill System #1 and

Fill System #2 will start to fill the Drying Chamber

with wet grain when the start switch is pressed on

the Dryer Control Panel. In single fill system

units on Fill System #1 will start. When grain

reaches the Drying Chamber Low Level Rotary

Switch the Aeration Fan, and the Master Drying

Fan will come on, and the Fan Delay will start to

count down. When the Fan Delay reaches zero the

Slave Drying Fan will start, the Airswitch will

close, and the Dry Timer will start to count down.

In single fan units the Fan Delay will not count

down and the Airswitch will close after the Master

Drying Fan starts. After a twenty second Purge

Delay the fan/heater unit(s) will ignite. When the

Plenum Temperature reaches the Cycle Setpoint on

the Hi-Lo Thermostat the fan/heater unit(s) will

cycle to Low-Fire. When the Plenum Temperature

falls ten degrees below the Cycle Setpoint the fan/

heater unit(s) will cycle back to High-Fire. The

fan/heater unit(s) will continue to cycle throughout

the drying.

When grain reaches the Chamber High

Level Rotary Switch the Load Delay will begin to

count down. When the Load Delay reaches zero

Emergency Stop Switches Status

Autoflow Control Box Emergency Stop: pulled out

Fill System Control Box Emergency Stop: pulled out

Actuator Control Box Emergency Stop: pulled out

Aeration Fan Bypass: Continuos

Fill System #2 will shut off and the Aux. 1 Delay

will begin to count down. When the Aux. 1 Delay

reaches zero Fill System #1 will shut off.

If the Chamber High Level Rotary Switch

becomes exposed due to shrinkage of grain in the

Drying Chamber, the fill system(s) will start and

refill the Drying Chamber. When grain reaches

the Chamber High Level Rotary Switch the fill

system(s) will shut off after the delays.

When the Dry Timer reaches zero and the

Grain Temperature Setpoint on the Moisture

Control Thermostat has not been reached the unit

will go into Temperature Hold. When the grain

temperature reaches the Grain Temperature

Setpoint on the Moisture Control Thermostat the

unit will continue to the Dump Cycle. In the

Dump Cycle the Linear Actuator in the Actuator

Control Box extends, the dump chutes lower, and

grain is dumped from the Drying Chamber into

Storage Chamber. Immediately after the dump

chutes open the Unload Timer begins to count

down. When the Unload Timer reaches zero the

dump chutes raise and grain stops dumping from

the Drying Chamber into the Storage Chamber.

During the Dump Cycle, 1/3 of the grain is

dumped into the Storage Chamber.

33

Page 34

THEORY OF OPERATION

Autoflow Operation

After the Dump Cycle, the unit returns to

the beginning of the Dry Cycle, the Fill system(s)

refill the Drying Chamber and the process begins

again. If the Dry Timer reaches zero after the

grain temperature reaches the Grain Temperature

Setpoint on the Moisture Control Thermostat the

unit does not enter Temperature Hold. It goes

right to the Dump Cycle.

The unit continues with the same operation

until either no grain is present against the Wet

Supply Rotary Switch, or the Storage Chamber

becomes full.

If the Wet Storage Tank becomes empty

while the fill systems are running, the Unload

Delay starts to count down. When the Unload

Delay reaches zero the fill system(s) shut off

along with the dryer and a Wet Supply Hopper

Empty error is displayed on the Dryer Control

Panel screen. If there is grain against the Drying

Chamber Low Level Rotary Switch the unit can be

restarted by pressing the start switch. When the

start switch is pressed the screen on the Dryer

Control Panel will read Press Enter to Dry

Remaining Grain. If the enter button is pushed

the dryer will restart without running the fill

system(s). The dryer will remain running until the

completion of the next Dump Cycle, after which an

out of Grain error is displayed on the Dryer

Control Panel and the dryer stops.

If the Storage Chamber High-Limit Rotary

Switch becomes covered with grain during the

Dump Cycle the dryer will continue through the

Dump Cycle and will continue to the next Dry

Cycle. When the Dry Cycle is complete the unit

will not continue to the Dump Cycle. A Storage

Chamber Full error will be displayed on the

screen and the dryer will stop. The unit will not

dump automatically until grain has been removed

from the Storage Chamber.

If the dryer stops for any reason the Aera-

tion Fan Bypass switch is placed in the

continuos position. The Aeration Fan Bypass

switch is located in the side of the Fill System

Control Box. If the Aeration Fan Bypass switch is

placed in the automatic position the Aeration

Fan stops whenever the dryer stops.

Items In Italics Are Defined In the

Dryer Terminology Section.

Top Dry Autobatch

Theory of Operation

Control Panel Switches Status:

Control Power: On

24v Power: On

Moisture Control Thermostat: On

Aeration Fan: Auto

Load Auger: Auto

Fan: Auto

Heater: Auto

Dump: Auto

Dry & Hold: Off

34

Emergency Stop Switches Status

Autoflow Control Box Emergency Stop: pulled out

Fill System Control Box Emergency Stop: pulled out

Actuator Control Box Emergency Stop: pulled out

Aeration Fan Bypass: Continuos

continued on page 35

Page 35

Autoflow Operation

THEORY OF OPERATION

When the Top Dry is in a ready state; that

is, with no grain in the Drying Chamber and wet

grain in the Wet Storage Tank, Fill System #1 and

Fill System #2 will start to fill the Drying Chamber

with wet grain when the start switch is pressed on

the Dryer Control Panel. In single fill system

units only Fill System #1 will start. When grain

reaches the Drying Chamber Low Level Rotary

Switch the Aeration Fan , and the Master Drying

Fan will come on, and the Fan Delay will start to

count down. When the Fan Delay reaches zero the

Slave Drying Fan will start, the Airswitch will

close, and the Dry Timer will start to count down.

In single fan units the Fan Delay will not count

down and the Airswitch will close after the Master

Drying Fan starts. After twenty second Purge

Delay the fan/heater unit(s) will ignite. When the

Plenum Temperature reaches the Cycle Setpoint on

the Hi-Lo Thermostat the fan/heater unit(s) will

cycle to Low-Fire. When the Plenum Temperature

falls ten degrees below the Cycle Setpoint the fan/

heater unit(s) will cycle back to High-Fire. The

fan/heater unit(s) will continue to cycle throughout

the drying process.

When grain reaches the Chamber High

Level Rotary Switch the Load Delay will begin to

count down. When the Load Delay reaches zero

Fill System #2 will shut off and the Aux. 1 Delay

reaches zero Fill System #1 will shut off. If grain

does not reach the drying chamber high level

rotary switch before 2/3rds. of the dry cycle is

complete the fill systems will shut off automati-

cally.

If the Chamber High Level Rotary Switch

becomes exposed due to shrinkage of grain in the

Drying Chamber, the fill system(s) will start and

refill the Drying Chamber. When grain reaches

the Chamber High Level Rotary Switch the fill

system(s) will shut off after the delays.

When the Dry Timer reaches zero and the

Grain Temperature Setpoint on the Moisture

Control Thermostat has not been reached, the unit

will go into Temperature Hold. When the grain

temperature reaches the Grain Temperature

Setpoint on the Moisture Control Thermostat the