Page 1

GSI

Competitor

Portable Dryer

Models

Troubleshooting and

Reference Manual

& EMCS

2004 Revised Edition

PNEG-630

Competitor Series 2000 Dryer

Page 2

Portable Dryer Troubleshooting

Safety..................................................................................................................................................................... 3

Safety Sign Off Sheet ............................................................................................................................................ 8

EMCS Portable Dryer (1993-1998)

Safety Voltage Check Points .................................................................................................................................9

Programming Instructions for EMCS Grain Dryers .............................................................................................. 10

EMCS Display Board ............................................................................................................................................ 11

Input/Output Board Identification .......................................................................................................................... 12

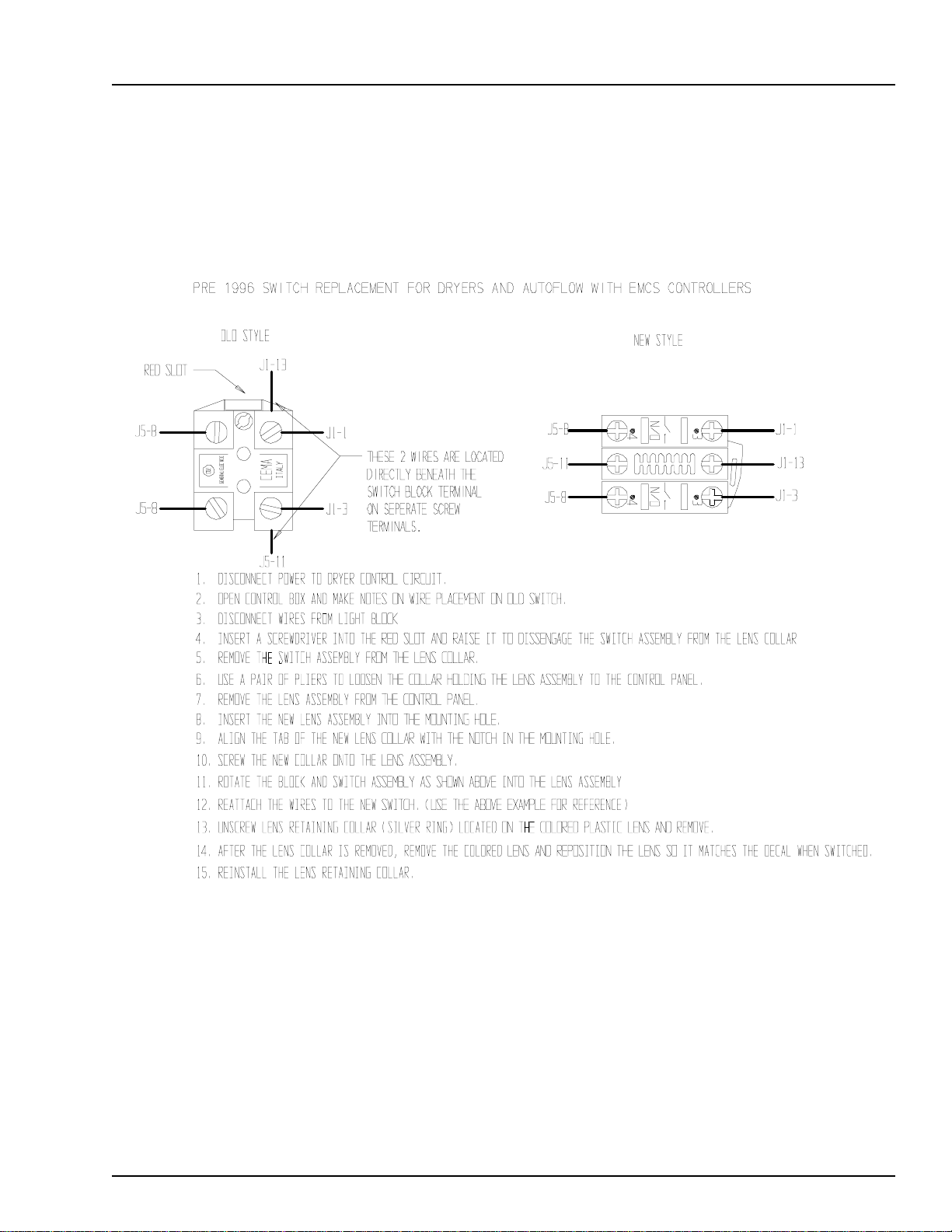

EMCS Switch Replacement.........................................................................................................................13

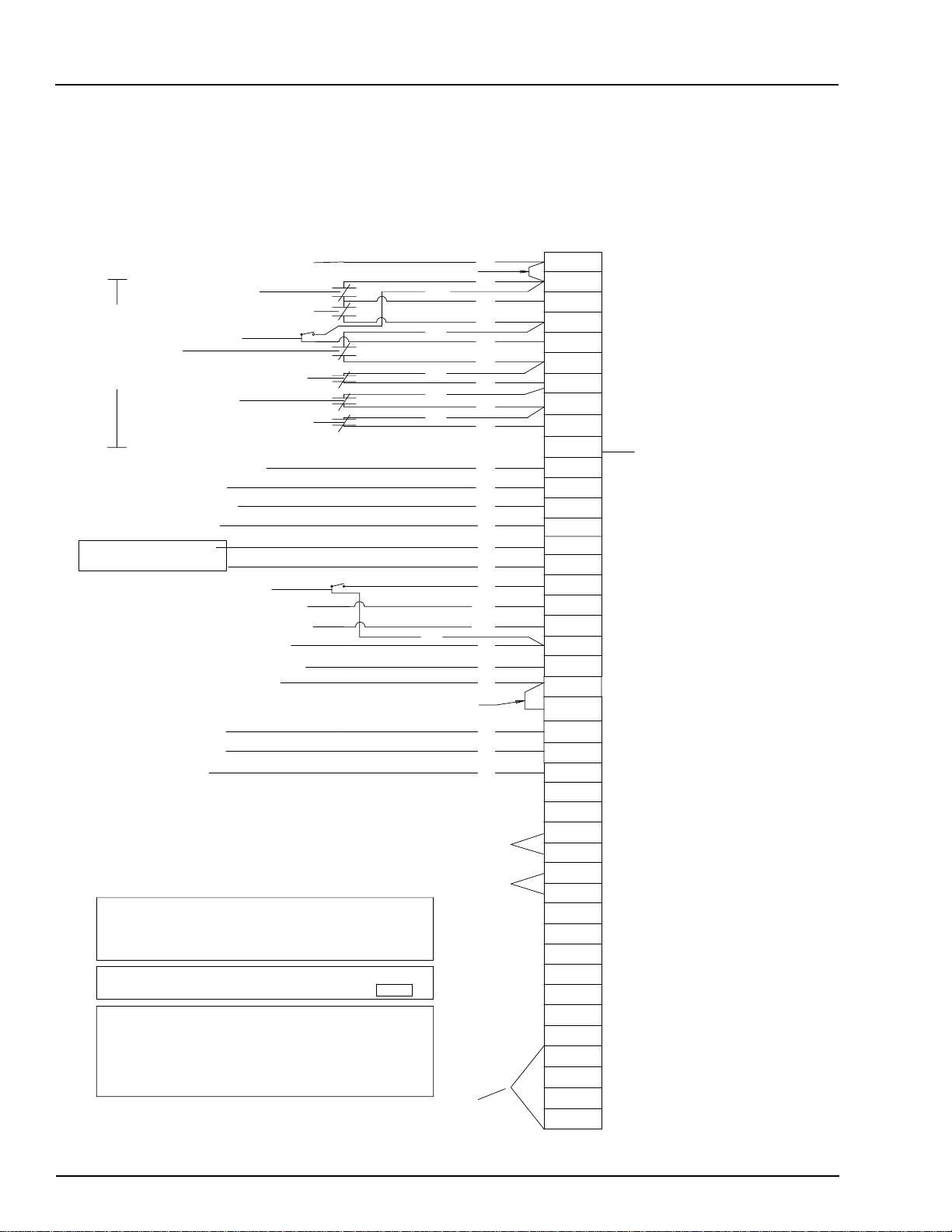

1100 Series Control Box W iring ............................................................................................................................. 14

1100 Series Control Box W iring (New) ................................................................................................................. 15

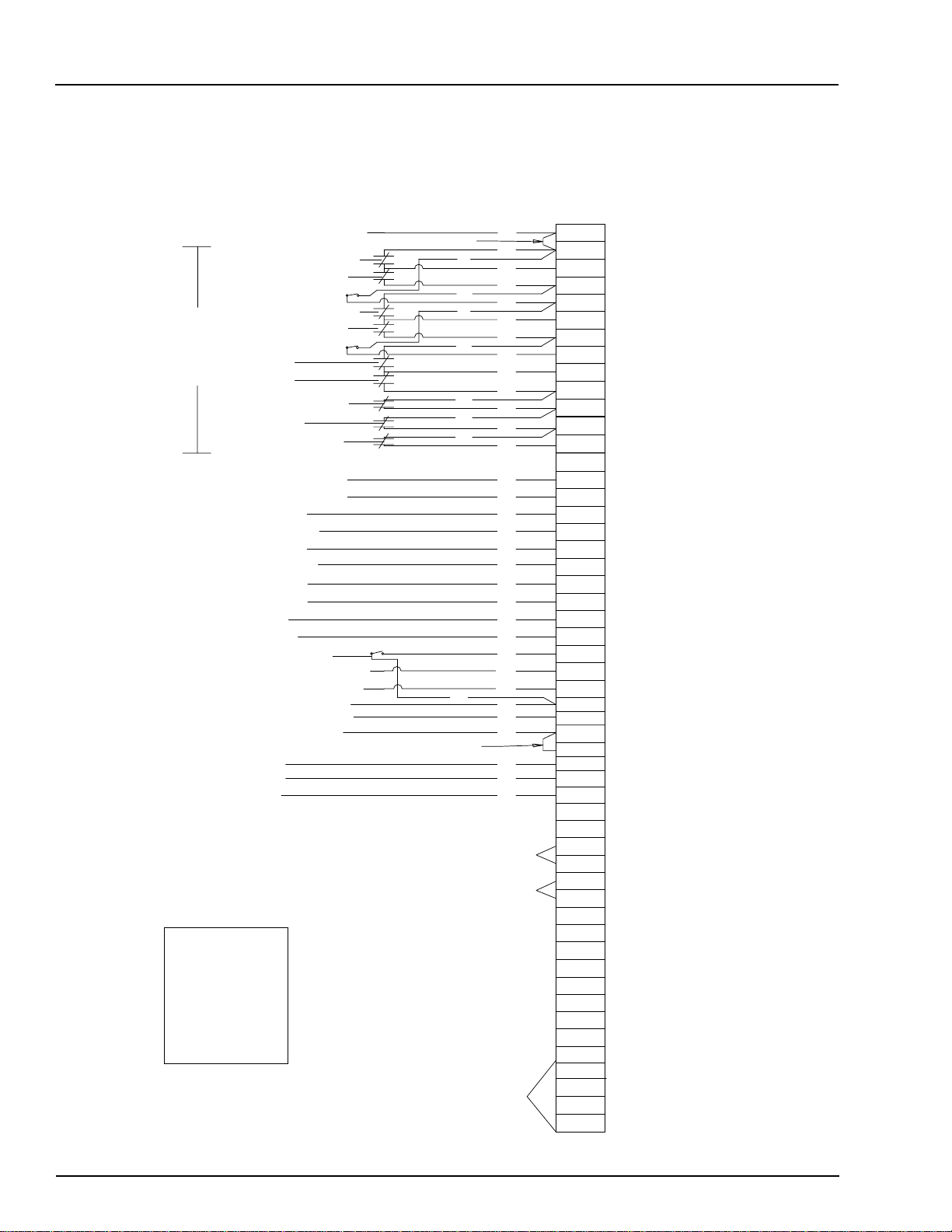

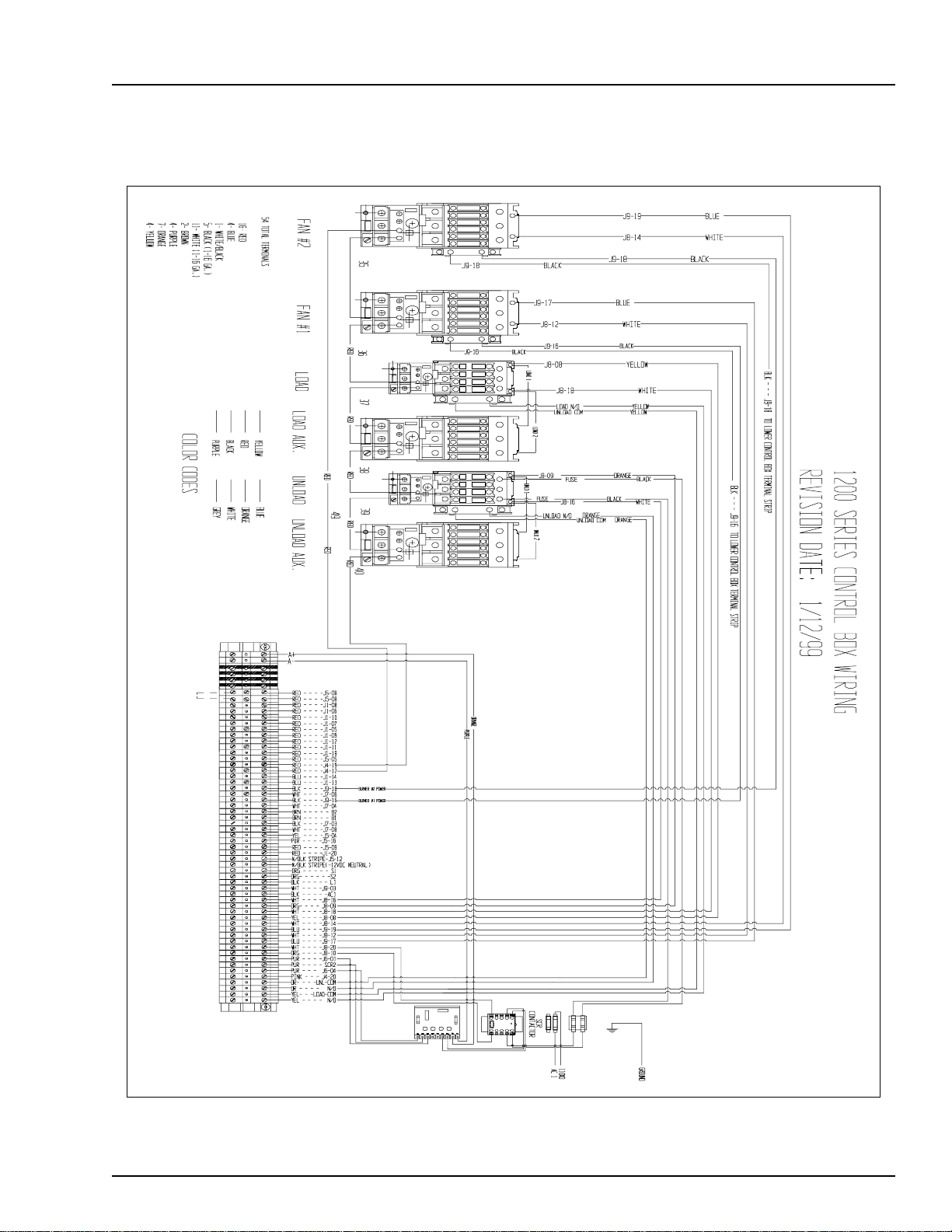

1200 Series Control Box Wiring............................................................................................................................. 16

1200 Series Control Box Wiring (New)................................................................................................................. 17

1100 Fan Lower Control Box Interconnect Strip................................................................................................... 18

1200 Fan Lower Control Box Interconnect Strip .................................................................................................. 19

Upper Control Box External Wiring....................................................................................................................... 20

Fan Housing and V apor Hi-Limit Circuit ............................................................................................................... 21

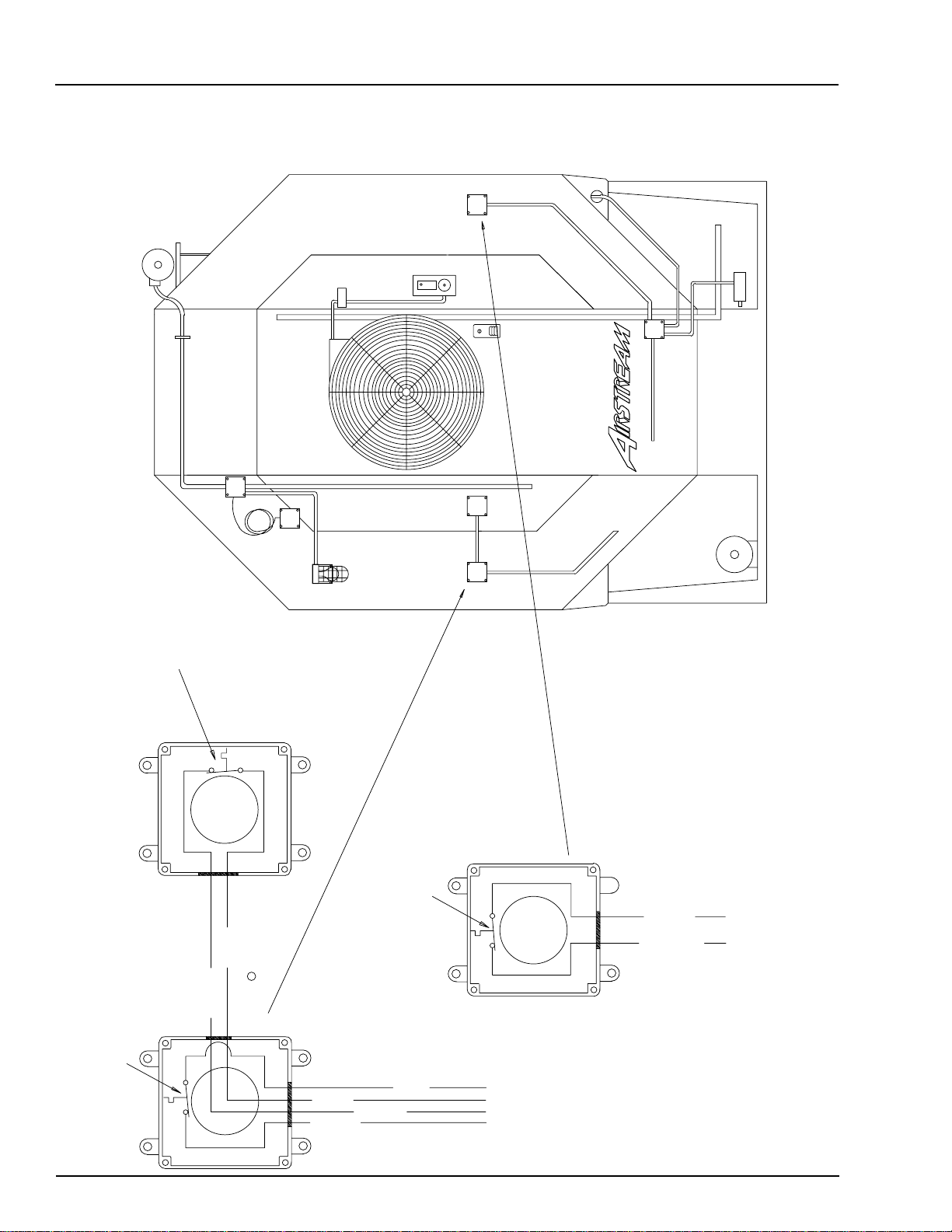

Plenum Hi-Temperature Switch ............................................................................................................................22

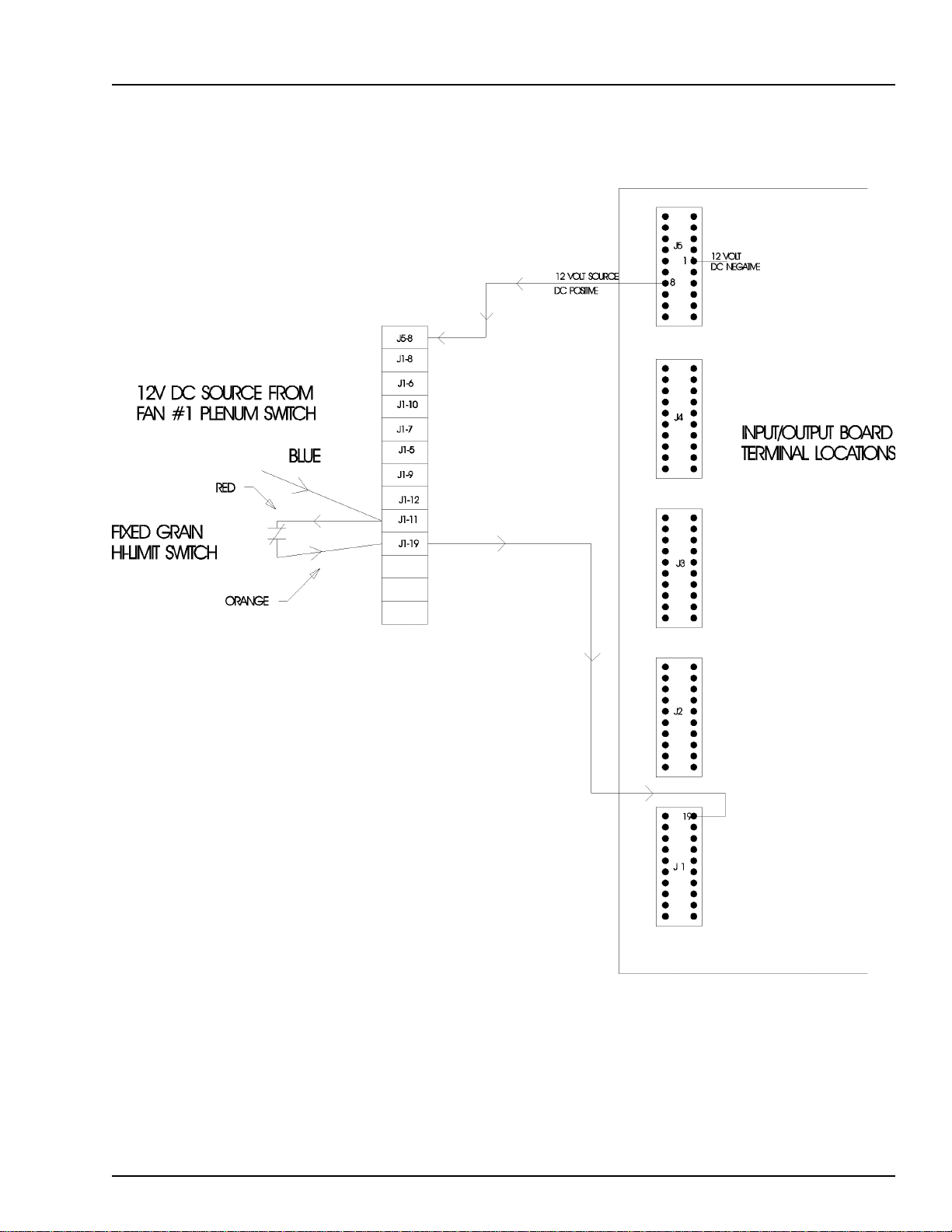

Fixed Grain Hi-Limit .............................................................................................................................................. 23

Grain & Plenum Hi-Limit Circuit........................................................................................................................... 24

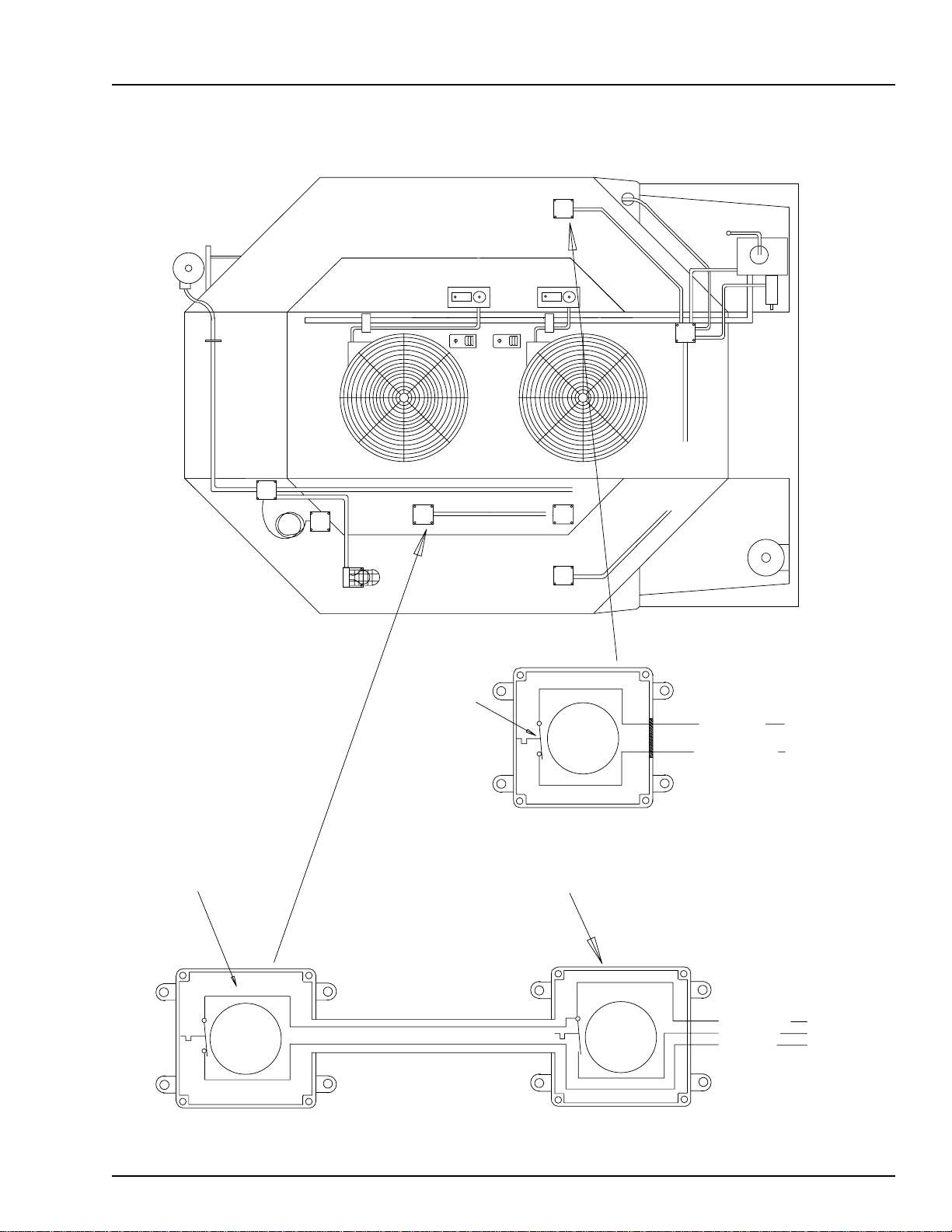

T wo Fan Plenum and Grain Limit Switch Wiring ..................................................................................................25

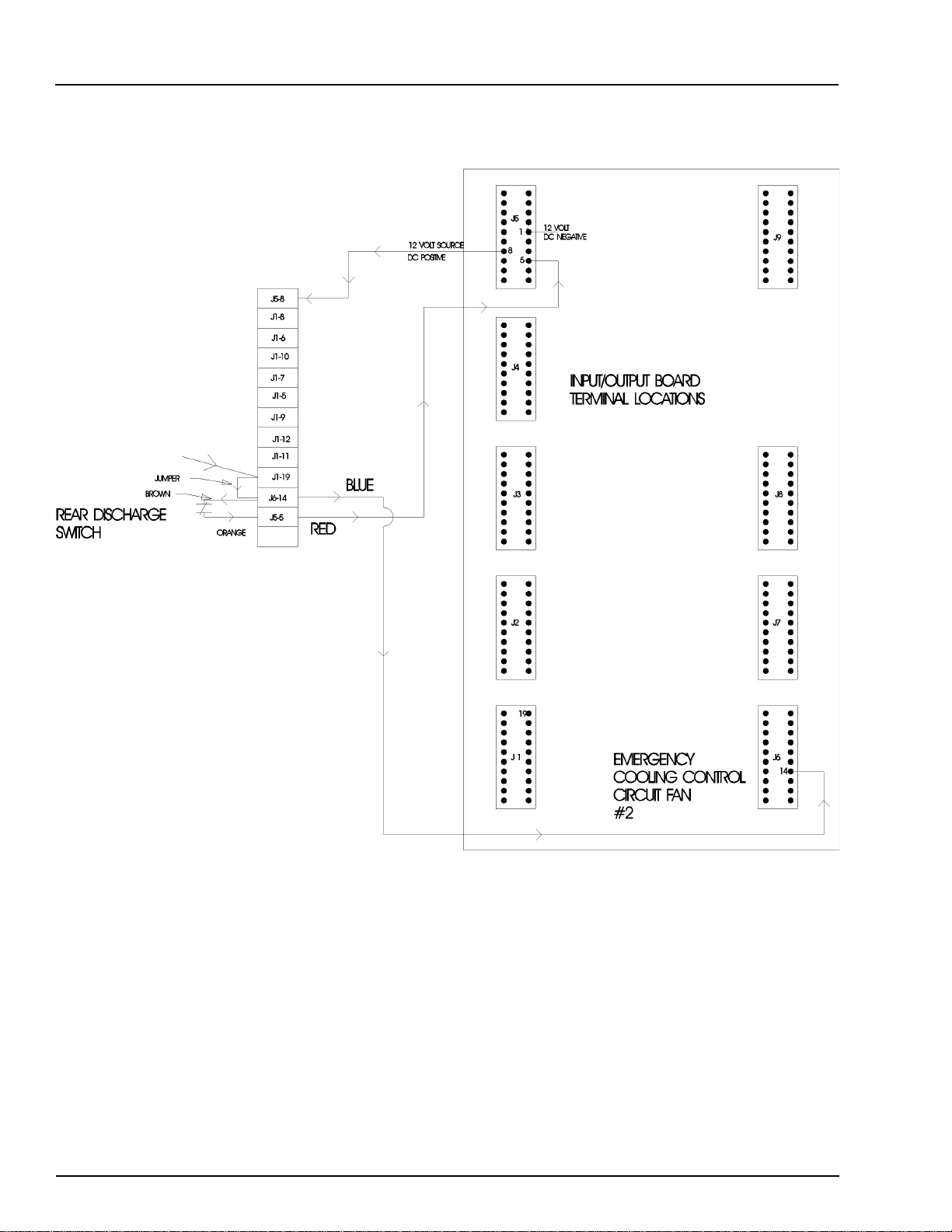

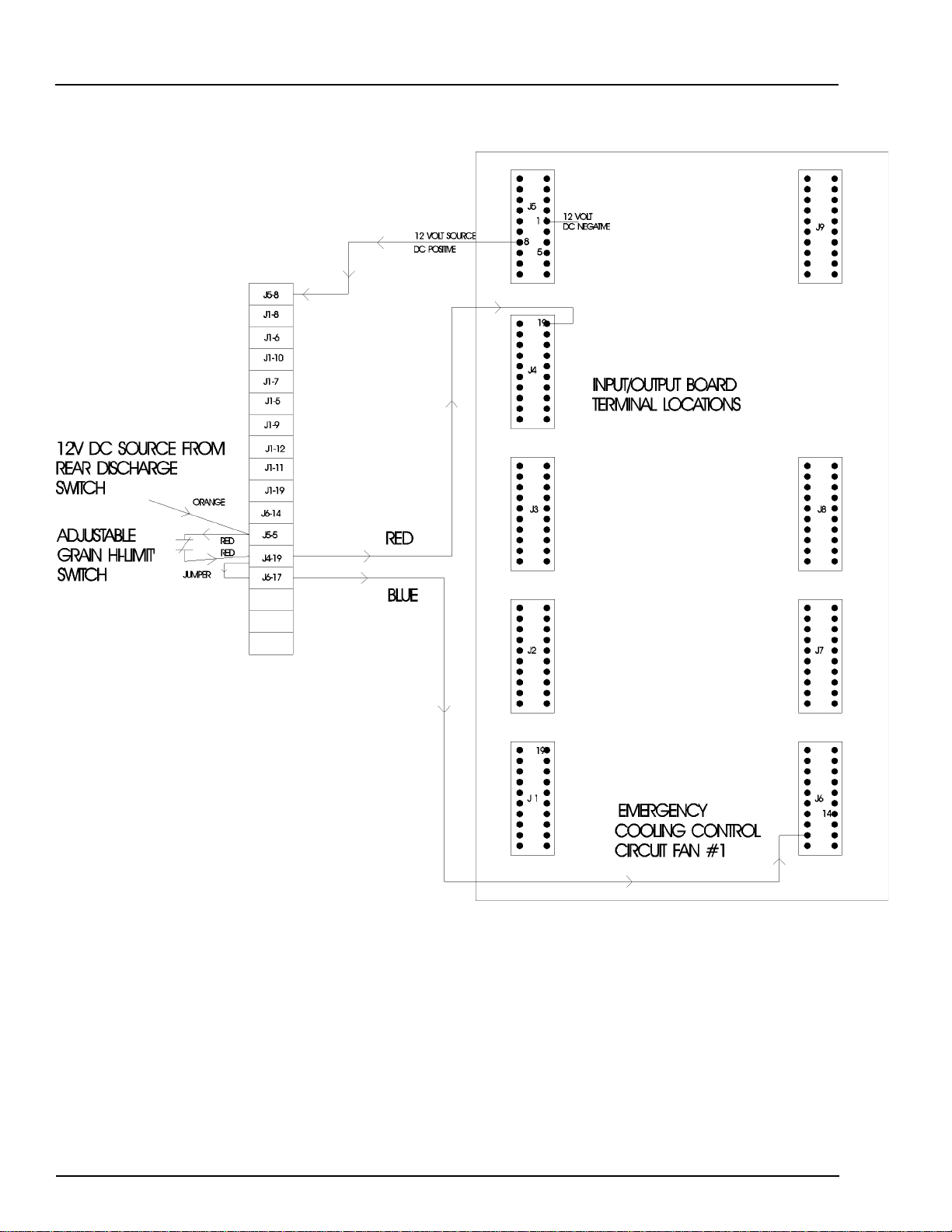

Rear Discharge & Emergency Cooling Circuit ..................................................................................................... 26

Rear Discharge Mercury Switch...........................................................................................................................27

Adjustable Hi-Limit & Emergency Cooling Circuit ............................................................................................... 28

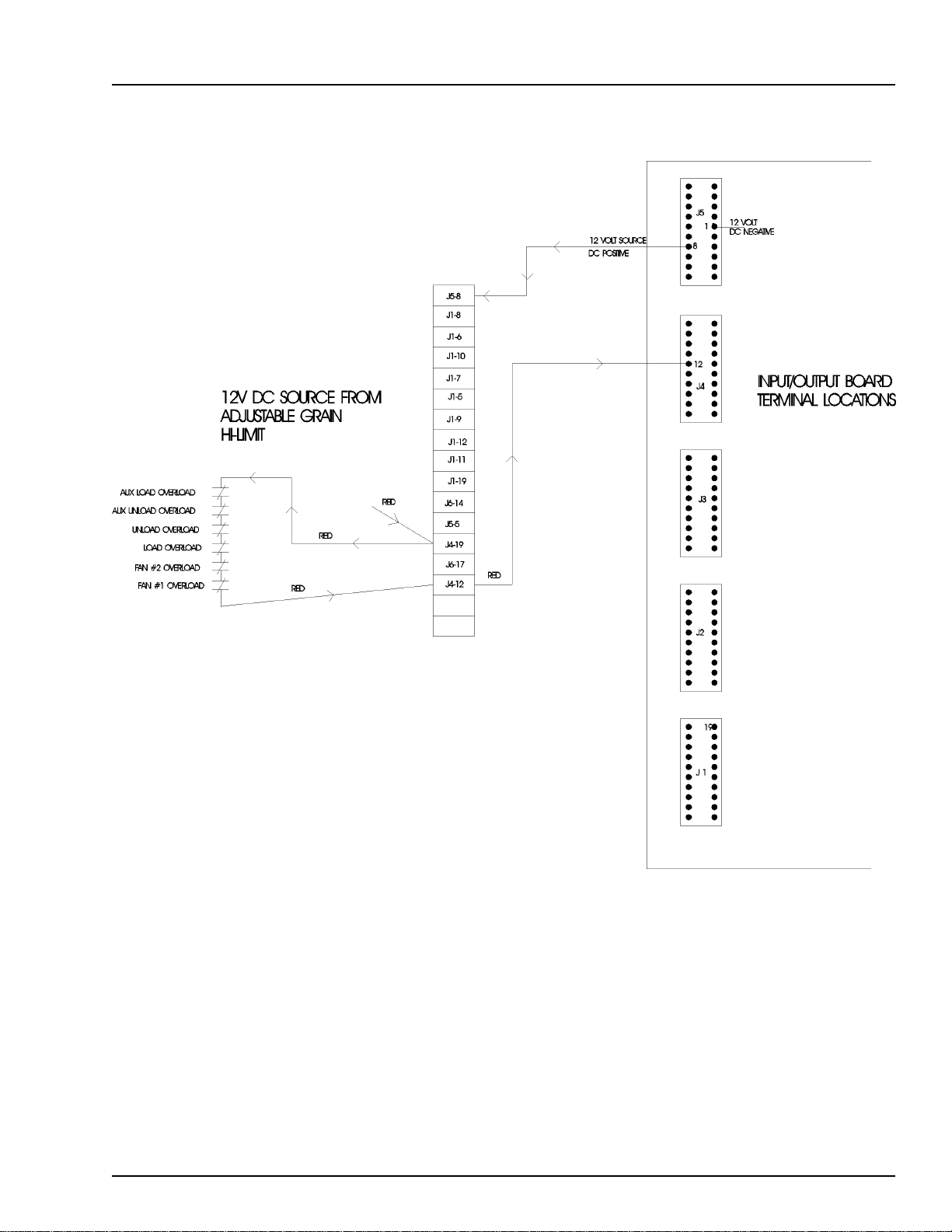

Motor Overloads .................................................................................................................................................... 29

Air Pressure Switch............................................................................................................................................... 30

Air Pressure Switch Drawing................................................................................................................................ 31

Out of Grain Safety Circuit....................................................................................................................................32

Out of Grain Safety Circuit Drawing..................................................................................................................... 33

Upper Junction Box Wiring.................................................................................................................................... 34

Meter Roll Sensor .................................................................................................................................................. 35

Meter Roll Sensor Wiring ......................................................................................................................................36

Meter Roll Reversing............................................................................................................................................. 37

Lower Junction Box Wiring ................................................................................................................................... 38

New Fenwal Board Wiring.......................................................................................................................... 39

New Fenwal Board Troubleshooting.............................................................................................................40

Flame Control Circuit............................................................................................................................................. 41

Fan Burner Circuit for Canadian Models .............................................................................................................. 42

Conversion Diagram for C Series Dryers to a Switchable Hi/Low or On/Off Burner ......................................... 43

Fan 28 LP Hi/Low-On/Off....................................................................................................................................44

Fan 28 LP On/Off Burner with Mercoid...............................................................................................................45

Fan 28 NG Hi/Low-On/Off ................................................................................................................................... 46

Fan 28 NG On/Off Burner with Mercoid .............................................................................................................. 47

Fan 42 LP Hi/Low-On/Off....................................................................................................................................48

Fan 42 LP On/Off Burner with Mercoid...............................................................................................................49

Fan 42 NG Hi/Low-On/Off ................................................................................................................................... 50

Fan 42 NG On/Off Burner with Mercoid .............................................................................................................. 51

SCR Drive Circuit.................................................................................................................................................. 52

RTD Temperature Sensor...................................................................................................................................... 53

Test Procedure for EMCS Dryers ......................................................................................................................... 54

Temperature Charts ............................................................................................................................................... 55

EMCS Troubleshooting Tips........................................................................................................................ 56

Table Of Contents

1

Page 3

Table Of Contents

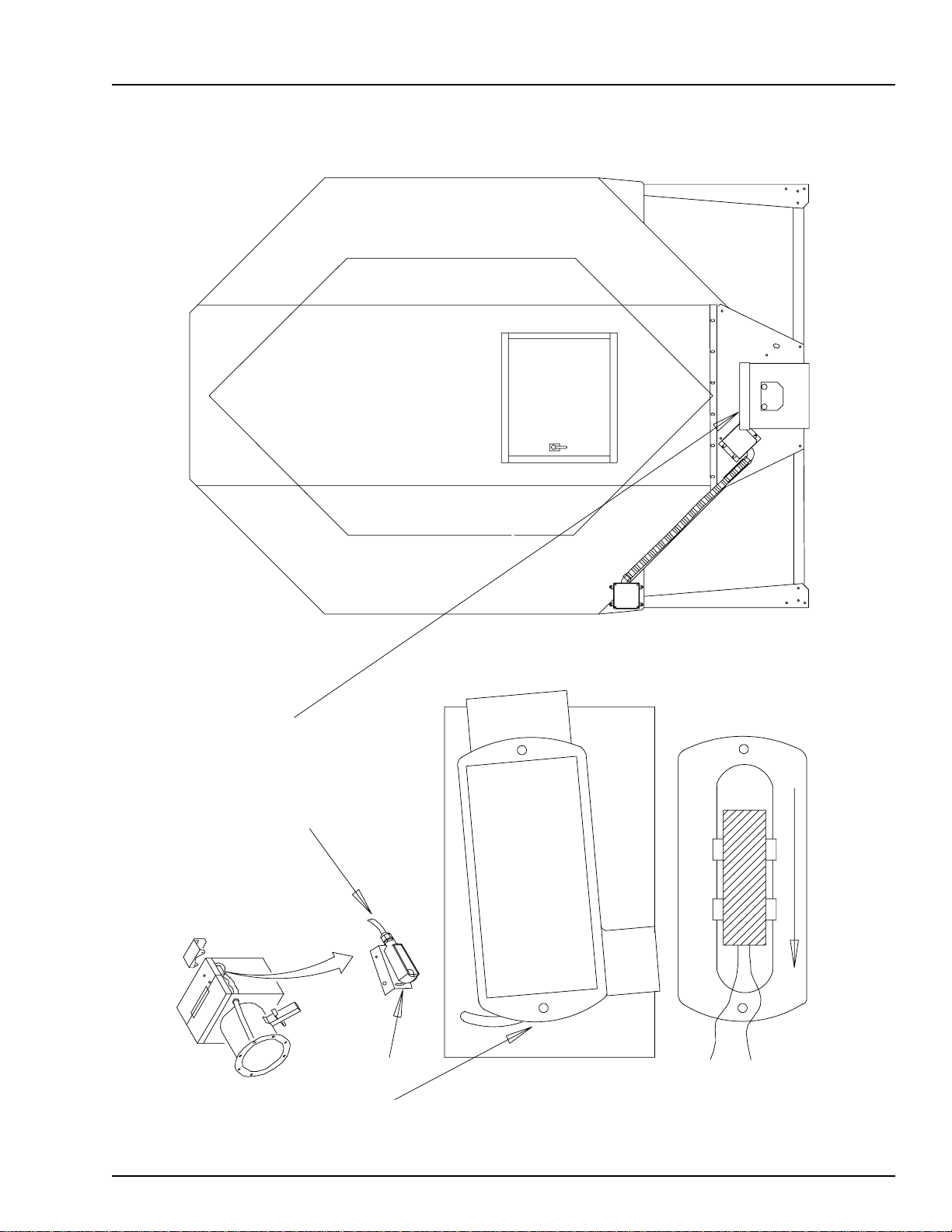

Competitor Series 2000 Dryer (Picture of Dryer)(1995 to Present)......................................................65

220 Volt Single (1) Phase Power Drawing ............................................................................................................ 66

220 Volt Single (1) Phase Power Drawing (New Version) .................................................................................. 67

220 Volt Three (3) Phase Power Drawing ............................................................................................................ 68

220 Volt Three (3) Phase Power Drawing (New Version) ................................................................................... 69

220 Volt 1 Phase Power Circuit (Ladder Diagram)........................................................................................70

220 Volt 3 Phase Power Circuit (Ladder Diagram)........................................................................................71

440 Volt 3 Phase Power Circuit (Ladder Diagram)........................................................................................72

Upper Control Box Internal Wiring........................................................................................................................ 73

Series 2000 Control Box Wiring (New Version) .................................................................................................... 74

Series 2000 Control Box Wiring............................................................................................................................. 75

Series 2000 Control Box Wiring (380-460-575 3 Phase).................................................................................76

Upper Terminal Strip...................................................................................................................................77

Upper Terminal Strip (Moisture Control Hook-Up)........................................................................................78

Upper Terminal Strip (Moisture Control Relay Hook-Up)...............................................................................79

Moisture Manager to Dryer Wiring...............................................................................................................80

Input/Output Board & T erminal Strip .................................................................................................................... 81

Control Circuit (CPU/Display)(Ladder Diagram)......................................................................................... 82

Control Circuit (I/O Board)(Ladder Diagram)...............................................................................................83

Control Circuit (SCR Drive Board)(Ladder Diagram)....................................................................................84

SCR Board (Installing & Calibrating)............................................................................................................85

Upper Control Box External Wiring....................................................................................................................... 88

Input/Output Board 12 Volt .................................................................................................................................... 89

CPU Board Wiring.................................................................................................................................................90

Programming Instructions for Competitor Series Grain Dryers ............................................................................91

Programming Hook Up Diagram...........................................................................................................................92

Back of Switch Panel Layout ................................................................................................................................ 95

Back of Switch Panel Wiring................................................................................................................................. 96

Air Switch Assembly ............................................................................................................................................. 97

Air Switch Adjusting...................................................................................................................................98

Fixed Grain Hi-Limit & T emperature Sensor ........................................................................................................ 99

Out of Grain Sensor...................................................................................................................................100

Grain Temperature Sensor..........................................................................................................................101

Grain Sensor Testing..................................................................................................................................102

Grain Sensor (Locating,Testing,& Replacing)...............................................................................................103

Sensor Resistance/Temperature Chart.........................................................................................................105

Plenum Sensor (Locating,Testing & Replacing)............................................................................................106

Stern and Capacitor Diagram......................................................................................................................108

Operation Hints..........................................................................................................................................109

Series 2000 Error Conditions.......................................................................................................................111

Heater Circuit............................................................................................................................................113

Fan Burner Circuit for Canadian Models Only..............................................................................................114

Series 2000 LP 26"/28" Fan ........................................................................................................................115

Series 2000 Natural Gas 26"/28" Fan............................................................................................................116

Series 2000 LP 36"/42" Fan.........................................................................................................................117

Series 2000 Natural Gas 36"/42" Fan............................................................................................................118

Warranty....................................................................................................................................................119

Portable Dryer Troubleshooting

2

Page 4

Portable Dryer Troubleshooting

Dryer Safety

Instructions and

Information

Thank you for choosing an GSI

Grain Dryer. It is designed to provide excellent performance and service for many years.

This manual refers to the troubleshooting of the E.M.C.S.and Series

2000 Competitor models. Different

models are available for liquid propane or natural gas fuel supply, with

either single phase 230 volt, or three

phase 230, 460, 575 volt electrical

power. (Also 380 volt 50Hz).

The GSI Group Inc. recommends

contacting your local power company, and having a representative

survey your installation so the wiring is compatible with your system

and adequate power is supplied.

The principal concern of the GSI

Group, Inc. ("GSI") is your safety

and the safety of others associated

with grain handling equipment. This

manual is written to help you understand safe operating procedures, and some of the problems

that may be encountered by the operator or other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions exist,

and to inform all personnel associated with the equipment, or who are in the dryer area. Avoid any alterations to

the equipment. Such alterations may produce a very dangerous situation, where serious injury or death may

occur.

Safety

WARNING! BE ALERT!

Personnel operating or working

around electric fans should read this

manual. This manual must be

delivered with the equipment to its

owner. Failure to read this manual

and its safety instructions is a

misuse of the equipment.

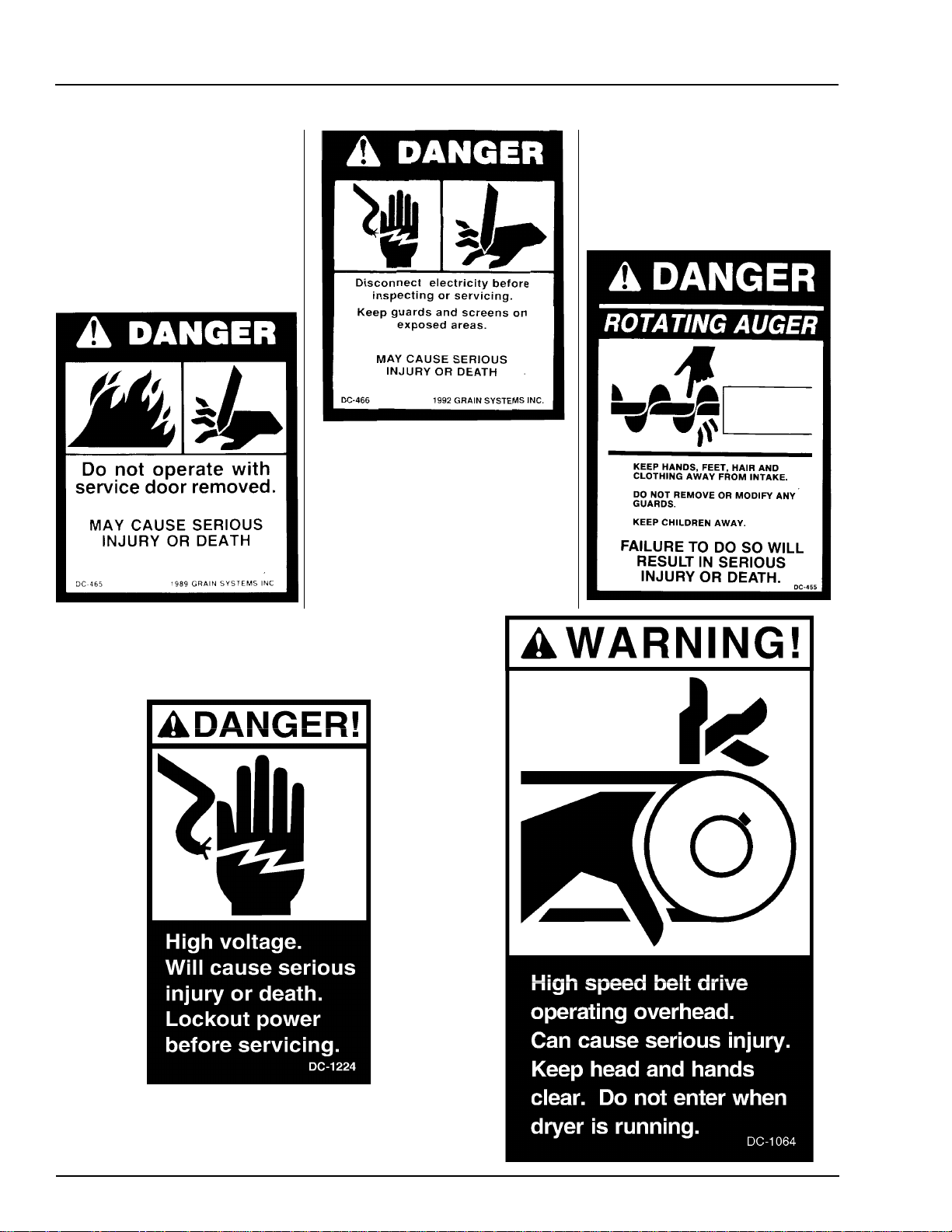

Safety Alert Symbol

The symbol shown is used to call your

attention to instructions concerning your

personal safety . Watch for this symbol;

it points out important safety precautions. It means "ATTENTION",

"WARNING", "CAUTION", and "DANGER". Read the message and be cau-

tious to the possibility of personal injury or death.

3

Page 5

Safety

Portable Dryer Troubleshooting

Grain Systems, Inc. recommends

you contact your local power company and have a representative survey your dryer installation, so your

wiring will be compatible with their

system and you will have adequate

power supplied to your unit.

A CAREFUL OPERATOR

IS THE BEST INSURANCE

AGAINST AN ACCIDENT

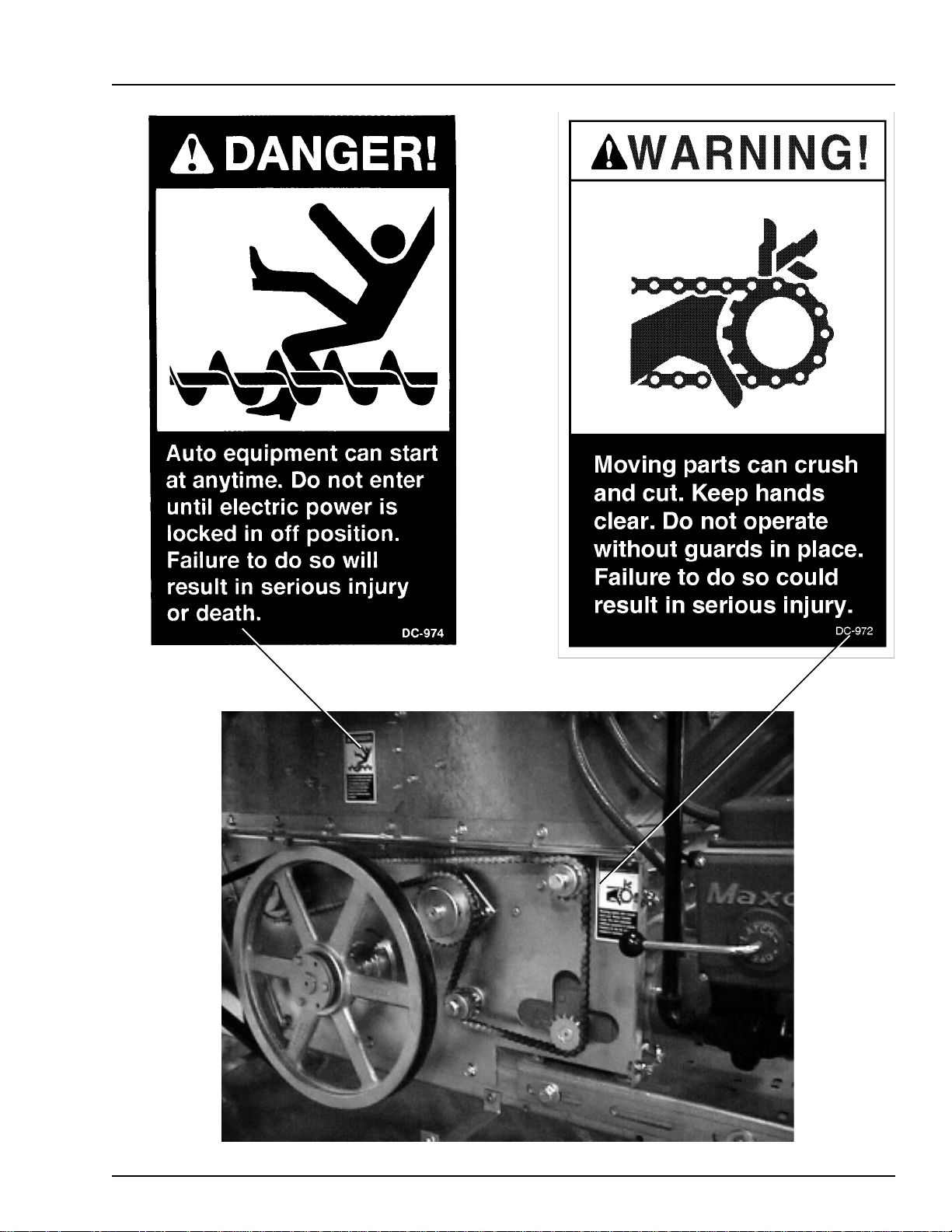

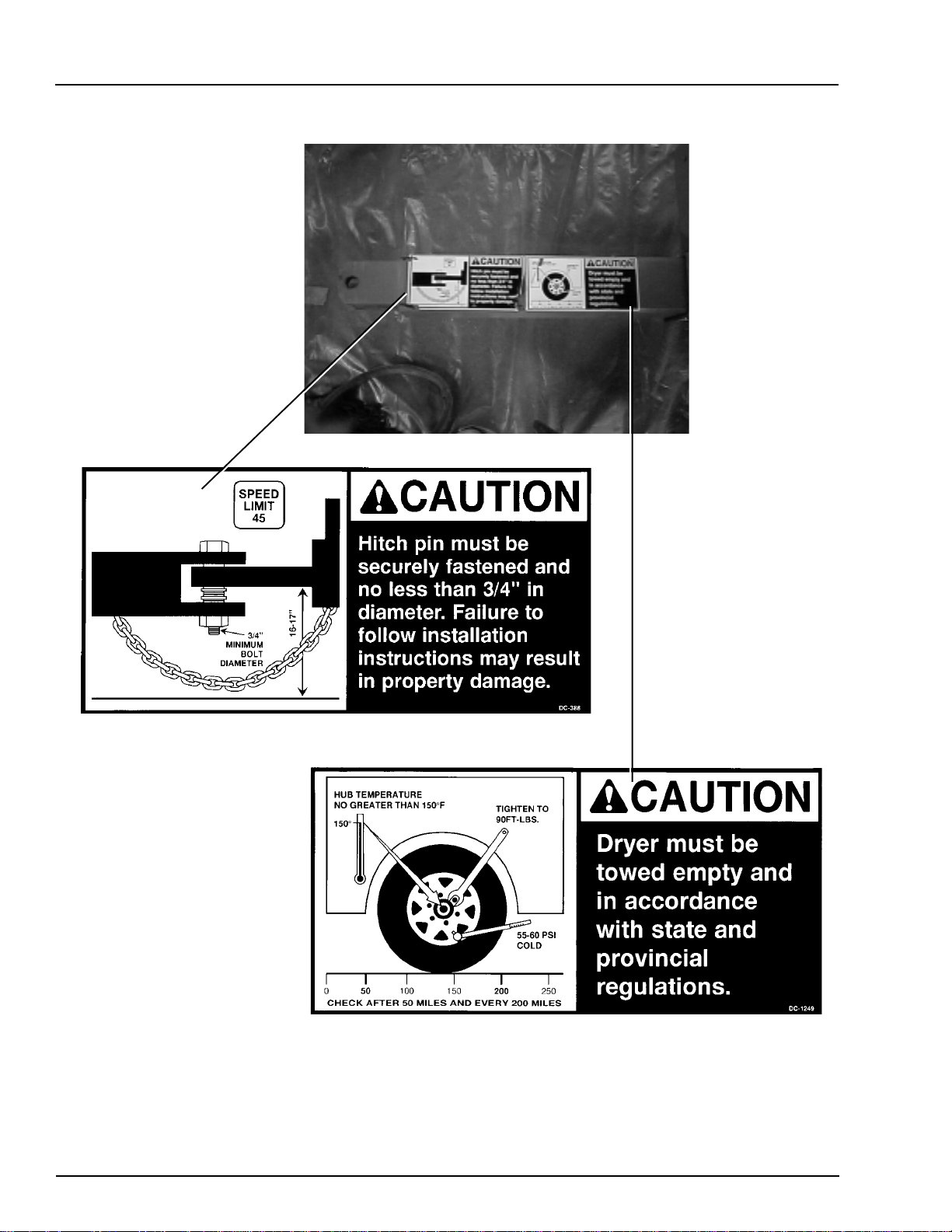

Safety decals should be read and

understood by all people in and

around the dryer area. If the following safety decals are not displayed

on your dryer, or if they are damaged, contact Grain Systems, Inc. for

replacement.

4

Page 6

Portable Dryer Troubleshooting

Safety

5

Page 7

Safety

Portable Dryer Troubleshooting

6

Page 8

Portable Dryer Troubleshooting

READ THESE INSTRUCTIONS

BEFORE OPERATION AND SERVICE

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before trying to operate the

dryer.

2. Power supply should be OFF for service of electrical components. Use

CAUTION in checking voltage or other procedures requiring power to

be ON.

3. Check for gas leaks at all gas pipe connections. If any leaks are detected, do not operate the dryer. Shut down and repair before further

operation.

4. Never attempt to operate the dryer by jumping or otherwise bypassing

any safety devices on the unit.

5. Set pressure regulator to avoid excessive gas pressure applied to burner

during ignition and when burner is in operation. Do not exceed maximum recommended drying temperature.

6. Keep the dryer clean. Do not allow fine material to accumulate in the

plenum or drying chamber.

Safety Precautions

Use Caution in the

Operation of this

Equipment

The design and manufacture of this

dryer is directed toward operator

safety. However, the very nature of

a grain dryer having a gas burner,

high voltage electrical equipment

and high speed rotating parts, does

present a hazard to personnel, which

can not be completely safeguarded

against, without interfering with efficient operation and reasonable access to components.

Use extreme caution in working

around high speed fans, gas-fired

heaters, augers and auxiliary conveyors, which may start without

warning when the dryer is operating on automatic control.

7. Use CAUTION in working around high speed fans, gas burners, augers

and auxiliary conveyors which START AUTOMATICALLY.

8. Do not operate in any area where combustible material will be drawn into

the fan.

9. Before attempting to remove and reinstall any propeller, make certain to

read the recommended procedure listed within the servicing section of

the manual.

10. Clean grain is easier to dry. Fine material increases resistance to airflow

and requires removal of extra moisture.

This product is intended for the use of grain handling only. Any other

use is considered a misuse of the product.

Some edges of the product components can be sharp. It is recommended

that each component of this product be examined to determine if there

are any safety considerations to be taken. Any and all necessary personal

protective equipment should be worn at all tines when handling, assembling, installing and operation of the product and/or components.

Guards are removed for illustration purpose only. All guards must be

in place before/during operation.

KEEP THE DRYER CLEAN

DO NOT ALLOW FINE

MATERIAL TO ACCUMULATE

IN THE PLENUM CHAMBER

OR SURROUNDING THE

OUTSIDE OF THE DRYER

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable

drying system, follow the recommendations within this manual, and

make it a practice to regularly inspect the operation of the unit for

any developing problems or unsafe

conditions.

Take special note of the safety precautions listed at left before attempting to operate the dryer.

7

Page 9

Safety Sign-Off Sheet

Portable Dryer Troubleshooting

Date Employer’s Signature Employee

________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________

8

Page 10

Portable Dryer Troubleshooting

Safety Voltage Check Points

Wiring Reference

123456

FAN #

Error Message - + - + - + - + - + - + RESULT

Plenum # High Temperature J5-12 J1-11 J5-12 J1-12 J5-12 J2-11 J5-12 J2-12 J5-12 J3-11 J5-12 J3-12 12VDC

Burner # Flame not Detected J5-12 J1-9 J5-12 J1-10 J5-12 J2-9 J5-12 J2-10 J5-12 J3-9 J5-12 J3-10 12VDC

Fan # Housing High Tempera ture J5-12 J1-7 J5-12 J1-8 J5-12 J2-7 J5-12 J2-8 J5-12 J3-7 J5-12 J3-8 12VDC

Burner # Vapor High Temperature J5-12 J1-5 J5-12 J1-6 J5-12 J2-5 J5-12 J2-6 J5-12 J3-5 J5-12 J3-6 12VDC

Burner # Shutdown Loss of Airflow J5-12 J1-13 J5-12 J1-14 J5-12 J2-13 J 5-12 J2-14 J5-12 J3-13 J5-12 J3-14 Note 1

Fan # Failure No Airflow J5-12 J1-13 J5-12 J1-14 J5-12 J2-13 J 5-12 J2-14 J5-12 J3-13 J5-12 J3-14 Note 2

the fan is on.

in the closed postition. No voltage should be present if the

dryer is stopped.

3 The condition for this error will occur if the air switch is stuck

1100/1200/1300 2200/2300/2400 3300/3400/3600

Motor Ov er lo a d J5-12 J4-12 1 T his error will occur if the fan and bur ner were both operating and

Upper Fixed Grain J5-12 N/A J5-12 J 4-4 J5-12 J4-2

Middle Fixed Grain J5-12 N/A J5-12 N /A J5-12 J4-4

Misc E r rors

Upper Adjustable Grain J5-12 N/A J5-12 J4-8 J5-12 J4-6

Middle Adjustable Grain J5-12 N/A J5-12 N/A J5-12 J4-8

Lower or Left Fixed Grain J5-12 J1-19 J5-12 J1-19 J5-12 J1-19

Fan # cannot Start Check Air Switch J5-12 J1-13 J5-12 J1-14 J5-12 J2-13 J5-12 J2-14 J5-12 J3-13 J5-12 J3-14 Note 3

Lower Adjustable or Right Fixed Grain J5-12 J4-19 J5-12 J4-19 J5-12 J4-19

Auxilliary Safety Shutd o w n J5-12 J1-20 Note:

Grain Discharge Warning J5-12 J5-5 the air switch opens which indicates loss of static pressure.

Maxon Valve Shut Warning J5-12 J5-2 12 volts should be present if the fan is on.

Unknow n S a fe ty Er ror J5-12 J5-10 2 This error will occ ur if after the fan has started the air switc h does

20 Second Safety Circuit Failure J5-12 J5-6 not detect any static pressure. 12 volts should be present if

9

Page 11

Programming

Portable Dryer Troubleshooting

Programming Instructions for EMCS Grain Dryers

1. Turn Control Power on dryer to off.

2. Locate programming jack (P7) on back of computer. (See page 13).

3. Plug the DB-9 jack of the programmer into the computer's jack.

4. Be sure that the rotary switch on the programmer is set to position 8.

5. Turn on Control Power to the dryer .

6. The four (4) lights on the programmer will come on, then three (3) will go out leaving the power light still on.

7. Push the start button on the programmer to start the transfer of Software.

8. The busy light will flash until the transfer process is complete.

9. When completed the pass light will flash indicating a successful transfer.

10. If the fail light flashes then check your connections and repeat the above process.

11. T urn Control Power on dryer to off and remove the cable.

12. Turn on the dryer and the opening screens should indicate the newer version of software.

10

Page 12

Portable Dryer Troubleshooting

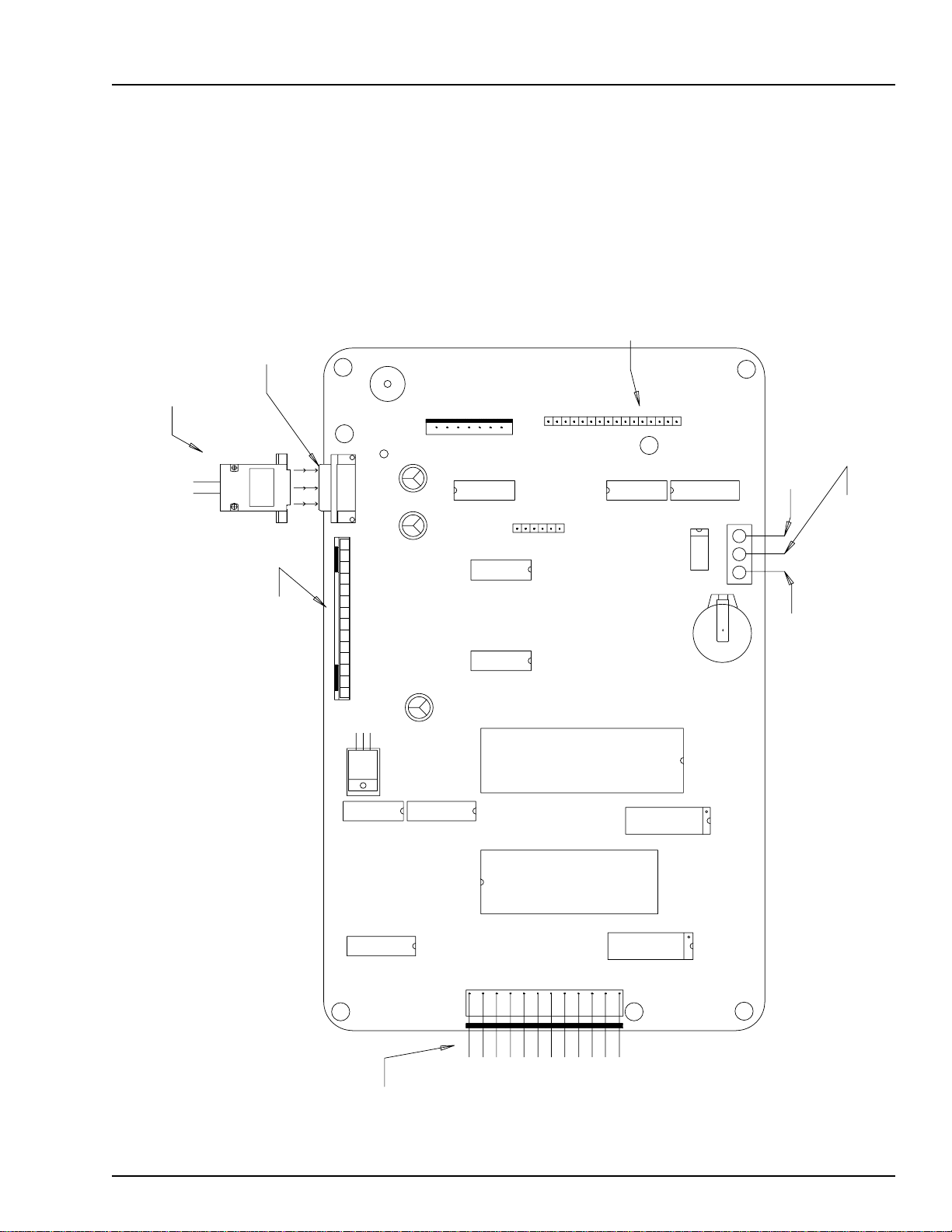

EMCS Display Board

COMPUTER

PROGRAMMING

JACK

PROGRAMMER

JACK (DB9)

SOUND

S1

P5

Programming

KEY PAD RIBBON

P4

P7

P8

COMMUNICATIONS CABLE

TO I/O BOARD

P6

TO STOP SW.

P3

3

21

U12

BATTERY (TIC)

TO START &

TO START SW.

STOP SWS.

DISPLAY

RIBBON

P1

11

Page 13

Wiring Reference

0

Portable Dryer Troubleshooting

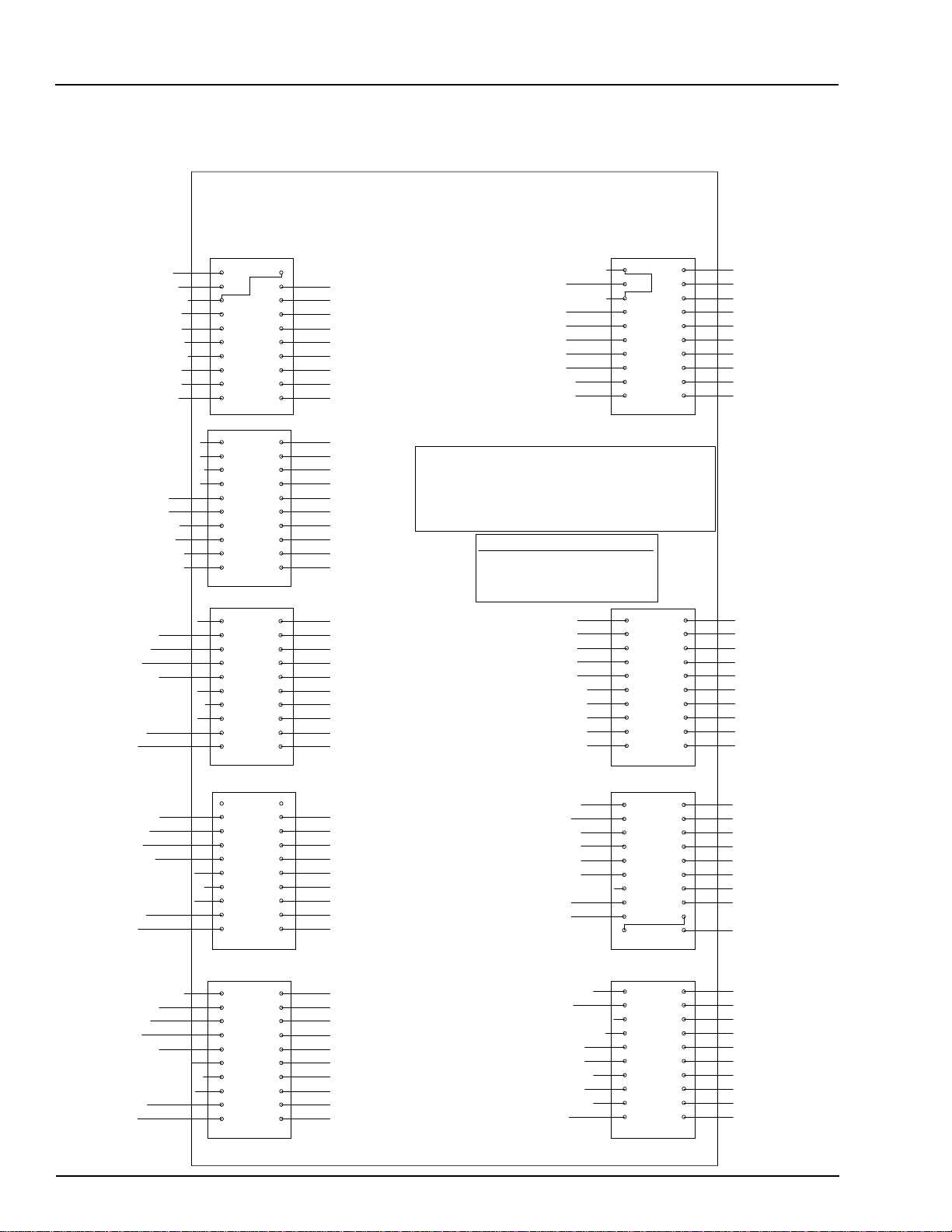

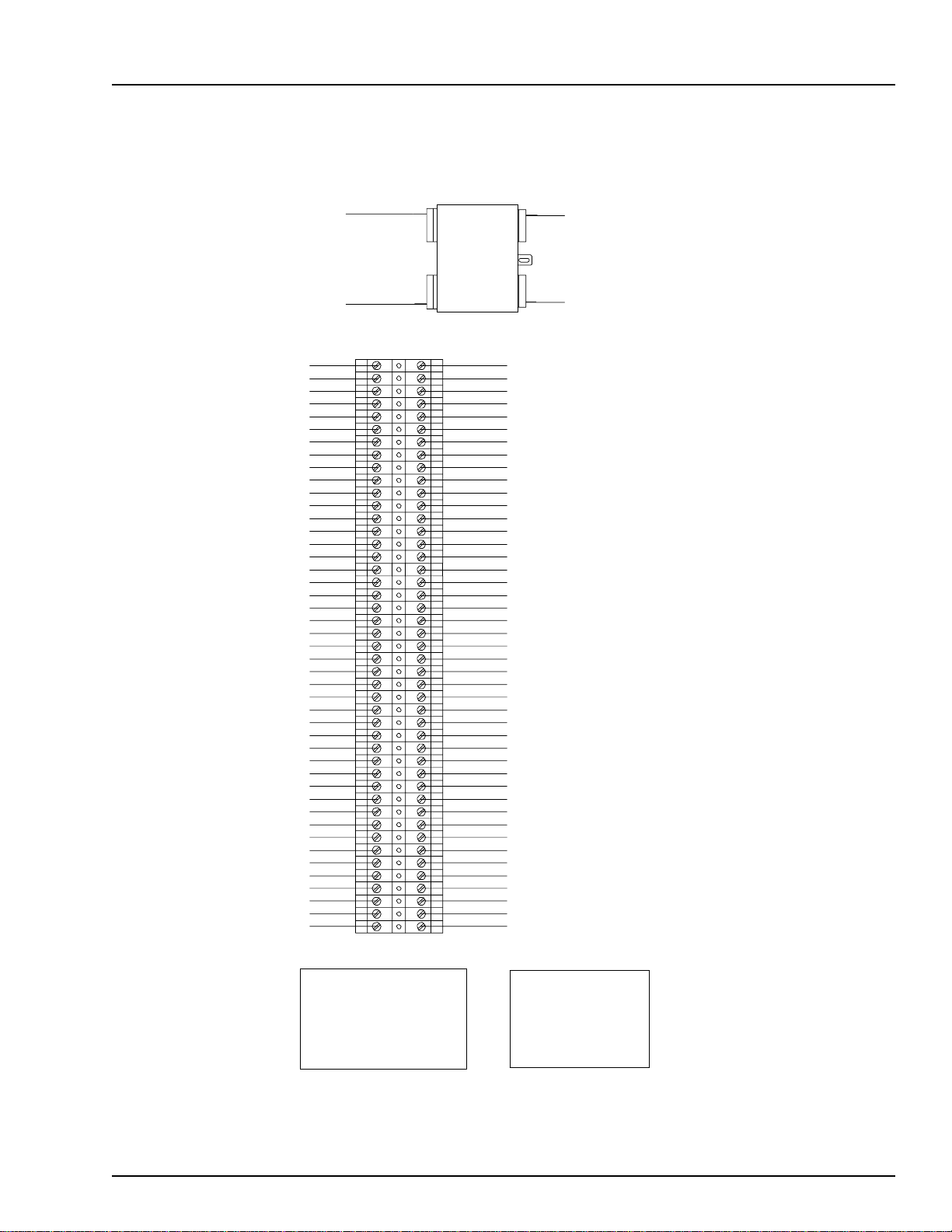

Input/Output Board Identification

120 VOLT AC OUTPUTS12 VOLT DC INPUTS

+12 LIMIT OUTPUT

12 VOLT DC NEUTRAL

METERING ROLL INPUT

12 VOLT DC NEGATIVE

12 VOLT DC NEGATIVE

SAFETY CIRCUIT INPUT

+12 VOLT LIMIT OUTPUT

FLAME SENSOR RETURN

OUT OF GRAIN SENSOR

MAXON VALVE SENSOR

MERCOID SFTY FAN#1 (CAN)

MERCOID SFTY FAN#2 (CAN)

MERCOID SFTY FAN#4 (CAN)

LOW MERCURY SWITCH (BO)

MOTOR OVERLOADS

MOISTURE CONTROL

ADJ. GRAIN (MIDDLE)

ADJ. GRAIN (UPPER)

FIXED GRAIN (MIDDLE)

FIXED GRAIN (UPPER)

BURNER #6 AUTO

BURNER #6 ON

FAN #6 AIR

FAN #6 PLENUM

FAN #6 FLAME DETECTION

FAN #6 HOUSING HIGH LIMIT

FAN #6 VAPOR HIGH LIMIT

FAN #6 AUTO

FAN #6 ON

20

19

18

17

15

16

14

13

12

11

J5

9

10

7

8

6

5

3

4

2

1

20

19

18

17

16

15

14

13

12

11

J4

10

9

7

8

6

5

3

4

1

2

20

19

18

17

16

15

14

13

12

11

J3

9

10

8

7

5

6

3

4

2

1

+12 LIMIT OUTPUT

12 VOLT DC NEGATIVE

12 VOLT DC NEGATIVE

12 VOLT DC NEGATIVE

+12 VOLT LIMIT OUTPUT

+12 VOLT LIMIT OUTPUT

REAR DISCHARGE

M.C. THERMOSTAT N.O. TERM #4

M.C. THERMOATAT N.C. TERM #6

LOWER ADJ. GRAIN HIGH LIMIT

2 SPEED UNLOAD

1 SPEED UNLOAD

UNLOAD BYPASS

LOAD SWITCH AUTO

LOAD SWITCH ON

BATCH MODE

CONTINUOUS FLOW

MERCOID SAFTY FAN#3 (CAN)

OUT OF GRAIN FOR LOAD #2

LO-HEAT THERMOSTAT (BO)HI-HEAT THERMOSTAT (BO)

BURNER #5 AUTO

BURNER #5 ON

FAN #5 AIR

FAN #5 PLENUM

FAN #5 FLAME DETECTION

FAN #5 HOUSING HIGH LIMIT

FAN #5 VAPOR HIGH LIMIT

FAN #5 AUTO

FAN #5 ON

JUMPER J1-9 TO J5-6 IS A HARDWARE TIMER FOR THE FLAME SENSOR SHUTDOWN

JUMPER J5-2 TO J5-20 IS A CONNECTION FOR THE MAXON VALVE SENS0R

JUMPER J4-12 TO J5-10 IS A HARDWARE TIMER FOR THE SAFETY SHUTDOWNS

JUMPER J1-20 TO J5-8 IS A CONNECTION FOR THE USER SUPPLLIED SAFETY

JUMPERS MUST BE INSTALLED FOR THE INPUT/OUTPUT BOARD TO OPERATE!!

120VAC POWER (INPUT)

AC NEUTRAL

120VAC POWER (INPUT)

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

FAN #1 POWER

FAN #2 POWER

JUMPERS TO BE INSTALLED FOR E-COOL

INSTALL JUMPER FROM J6-13 TO J1-5

INSTALL JUMPER FROM J6-14 TO J1-19

INSTALL JUMPER FROM J6-16 TO J5-5

INSTALL JUMPER FROM J6-17 TO J4-19

FAN #3 POWER

FAN #4 POWER

FAN #5 POWER

FAN #6 POWER

UNLOAD POWER

BUR # 4 NEUTRAL

BUR # 3 NEUTRAL

FAN # 4 NEUTRAL

FAN # 3 NEUTRAL

LOAD #2 NEUTRAL

1

2

3

4

5

6

7

8

9

10

J9

12

11

13

14

16

15

18

17

20

19

1

2

3

4

5

6

7

8

9

10

J8

11

12

13

14

15

16

18

17

20

19

120VAC POWER (OUTPUT)

AC NEUTRAL

120VAC POWER (OUTPUT)

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

BURNER #1 POWER

BURNER #2 POWER

BURNER #3 POWER

BURNER #4 POWER

BURNER #5 POWER

BURNER #6 POWER

LOAD POWER

SCR POWER

FAN #1 NEUTRAL

FAN #2 NEUTRAL

UNLOAD NEUTRAL

LOAD NEUTRAL

SCR NEUTRAL

12

BURNER #4 AUTO

BURNER #4 ON

FAN #4 AIR

FAN #4 PLENUM

FAN #4 FLAME DETECTION

FAN #4 HOUSING HIGH LIMIT

FAN #4 VAPOR HIGH LIMIT

FAN #4 AUTO

FAN #4 ON

USER SUPPLIED SAFETY

BURNER #2 AUTO

BURNER #2 ON

FAN #2 AIR

FAN #2 PLENUM

FAN #2 FLAME DETECTION

FAN #2 HOUSING HIGH LIMIT

FAN #2 VAPOR HIGH LIMIT

FAN #2 AUTO

FAN #2 ON

20

19

18

17

16

15

14

13

12

11

J2

10

9

7

8

5

6

3

4

1

2

20

19

18

17

16

15

14

13

12

11

J1

10

9

8

7

6

5

3

4

1

2

** IMPORTANT--JUMPERS LISTED ABOVE MUST BE INSTALLED

BURNER #3 AUTO

BURNER #3 ON

FAN #3 AIR

FAN #3 PLENUM

FAN #3 FLAME DETECTION

FAN #3 HOUSING HIGH LIMIT

FAN #3 VAPOR HIGH LIMIT

FAN #3 AUTO

FAN #3 ON

LOWER GRAIN HIGH LIMIT

BURNER #1 AUTO

BURNER #1 ON

FAN #1 AIR

FAN #1 PLENUM

FAN #1 FLAME DETECTION

FAN #1 HOUSING HIGH LIMIT

FAN #1 VAPOR HIGH LIMIT

FAN #1 AUTO

FAN #1 ON

LOAD #2 POWER

MAXON POWER

BUR #6 NEUTRAL

BUR #5 NEUTRAL

FAN #6 NEUTRAL

FAN #5 NEUTRAL

THERMOSTAT 110VAC (BO)

NC

NC

SCR P1 &

V1 FROM BR#1 (BO)

M.R.H POT 2

M.R.L POT 2 & HI SOLENOID BUR#2 (BO)

THERMOSTAT SENSOR S1

SENSOR 2 LOWER.

SENSOR 2 UPPER

ENERGENCY COOLING

AUX #6 B-COMMON

EMERGENCY COOLING

NC

1

2

3

4

5

6

7

8

9

10

J7

12

11

13

14

16

15

18

17

20

19

1

2

3

4

5

6

7

8

9

10

J6

12

11

14

13

16

15

18

17

19

20

PROCESS LIGHT

BURNER #1 NEUTRAL

BURNER #2 NEUTRAL

MAXON NEUTRAL

AC NEUTRAL

LO-HEAT POWER (BO)

HI-HEAT POWER (BO)

NC

M.R.H POT 3

M.R.L POT 3 &

HIGH SOLENOID BUR#1 (BO)

SCR P3 & V1 FROM BR#2 (B

SENSOR 1 LOWER

SENSOR 1 UPPER

THERMOSTAT SENSOR S2

AUX #6 A-N.C.

EMERGENCY COOLING

EMERGENCY COOLING

NC

NC

Page 14

Portable Dryer Troubleshooting

Switch Replacement for EMCS Dryer

Switch Replacement

Switch N/O Contact Block - Part No. D63-0006

Switch Light Block - D01-0455

13

Page 15

Wiring Reference

Portable Dryer Troubleshooting

1100 Series Control Box Wiring

1100 FAN TO CONTROL BOX WIRING

AIR PRESSURE SWITCH +12VDC

HOUSING HIGH LIMIT

VAPOR HIGH LIMIT (LP ONLY)

FLAME DETECTION

PLENUM

LEFT FIXED GRAIN HI LIMIT

SAFETY CIRCUIT

*REAR DISCHARGE

RIGHT FIXED GRAIN HI LIMIT

AIR PRESSURE SWITCH

BURNER POWER

BURNER NEUTRAL

BURNER LIGHT

USED ON SINGLE FAN

NAT GAS ONLY

K OTHER SIDE

N/C) SAFETY

5-8 OR J5-9 --

MAXON POWER

MAXON NEUTRAL

OUT OF GRAIN SENSOR

*

LEFT METERING ROLL SENSOR

*

RIGHT METERING ROLL SENSOR

METERING ROLL 12 VOLTS

CUSTOMER SUPPLIED SAFETY

METERING ROLL NEUTRAL

TEMP SENSORS

TEMP SENSORS

WORK LIGHT

DRYER SAFETY CIRCUIT ALWAYS STARTS ON J5-8 AND ENDS

ON J4-12.USING THE J5-12 TERMINAL FOR NEGATIVE,

THERE SHOULD BE 12 VOLTS DC ON EACH TERMINAL FROM

J5-8 TO J4-12.

WHEN CHECKING FOR 12 VOLTS DC ALWAYS PUT THE

NEGATIVE PROBE OF VOLT METER TO TERMINAL J5-12

SAFETY CIRCUIT IN BOLD IS FOR FLAME DETECTION ONLY.

EACH OF THE TERMINALS CONNECTED TO IT CAN LOOSE

12 VDC FOR 20 SECONDS BEFORE A SHUTDOWN OCCURS.

THIS GIVES THE BURNER CIRCUIT TIME TO SENSE FLAME.

ALL OTHER SAFETY CONNECTIONS MUST HAVE 12 VDC

PRESENT AT ALL TIMES TO OPERATE PROPERLY.

*LOCATED AT REAR OF DRYER

1100EW98.PRT REV. DATE 4/10/98

RELAY CONTACTS LOCATED

IN DRYER FAN CAN BOX

MERCURY SWITCH LOCATED

ON TOP OF DRYER

120VAC FOR AUX UNLOAD CONTACTOR COIL

120VAC FOR AUX LOAD CONTACTOR COIL

AUX CONTACT POINTS FOR LOAD AND UNLOAD SYSTEMS

ALL VOLTAGE SUPPLIED BY USER

42 TOTAL TERMINALS

WIRINGDESCRIPTION

NEED JUMPER

OR

YEL

RED

BRN

RED

BLK

NEED JUMPER

RED

RED

YEL

PUR

OR

BLU

OR

OR

OR

BLU

BLK

WHT

BRN

PUR

WHT

BLK

YEL

BLU

RED

BLK

WHT

BLK

RED

ALL SAFETIES MUST BE CLOSED FOR DRYER TO OPERATE

J5-8

J5-8

J1-7

J1-5

J1-9

J1-11

J1-19

J5-5

J4-19

J4-12

J1-13

J9-16

J7-4

B1

J7-3

J7-8

J5-4

J5-16

J5-19

J5-9

J1-20

J5-12

-12VDC

S1

S2

L1

J8-16

J8-9

J8-18

J8-8

J8-12

J9-17

J8-20

J8-10

J6-1

SCR 2

J6-4

U-COM

U-N/O

L-COM

L-N/O

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

MOTOR OVERLOADS

12 VOLTS DC (BLUE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

120 VAC (BLUE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

12 VOLTS DC (YELLOW)

METER ROLL PULSE (PUR)

NO LONGER USED

12 VOLTS DC (RED)

12 VOLTS DC (RED)BLK

12 VOLTS DC NEG (WHITE)

TEMP SENSOR (ORANGE)

TEMP SENSOR (ORANGE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)J9-3

120 VAC (BLACK)AC 1

120 VAC NEUT (WHITE)

120 VAC (ORANGE)

120 VAC NEUT (WHITE)

120 VAC (YELLOW)

120 VAC NEUT (WHITE)

120 VAC (BLUE)

120 VAC NEUT (WHITE)

120 VAC (ORANGE)

CONTROL POT P1 (PUR)

CONTROL POT P2 (PUR)

CONTROL POT P3 (PUR)

UNLOAD AUX COM(ORANGE)

UNLOAD AUX N/O(ORANGE)

LOAD AUX COM (YELLOW)

LOAD AUX N/O (YELLOW)

COLORVOLTAGE

14

Page 16

Portable Dryer Troubleshooting

1100 Series Control Box Wiring (New Version)

Wiring Reference

15

Page 17

Wiring Reference

1200 Series Control Box Wiring

DESCRIPTION

WIRING

Portable Dryer Troubleshooting

52 TOTAL TERMINALS

TERMINAL

COLORVOLTAGE

HOOK OTHER SIDE

OF (N/C) SAFETY

TO J5-8 OR J5-9 --

53 TOTAL TERMINALS

15 - RED

4 - BLUE

1 - WHITE/BLACK

3 - BLACK (1-16GA)

9 - WHITE (1-16GA

2 - BROWN

4 - PURPLE

4 - ORANGE)

*LOCATED AT REAR OF DRYER

1200EW98.PRT REV. DATE 3/5/98

AIR PRESSURE SWITCH +12VDC

FAN #2 HOUSING HIGH LIMIT

FAN #2 VAPOR HIGH LIMIT

FAN #2 FLAME DETECTION

FAN #1 HOUSING HIGH LIMIT

FAN #1 VAPOR HIGH LIMIT

FAN #1 FLAME DETECTION

FAN #2 PLENUM

SAFETY CIRCUIT

FAN #1 PLENUM

FIXED GRAIN HIGH LIMIT

*REAR DISCHARGE

ADJ. GRAIN HIGH LIMIT

FAN #2 PRESSURE SWITCH

FAN #1 PRESSURE SWITCH

BURNER #2 POWER

BURNER #2 NEUTRAL

BURNER #1 POWER

BURNER #1 NEUTRAL

BURNER #2 LIGHT

BURNER #1 LIGHT

MAXON POWER

MAXON NEUTRAL

OUT OF GRAIN SENSOR

*LEFT METERING ROLL SENSOR

*RIGHT METERING ROLL SENSOR

METERING ROLL 12 VOLTS

CUSTOMER SUPPLIED SAFETY RED

METERING ROLL NEGATIVE

TEMP SENSOR

TEMP SENSOR

RELAY CONTACTS LOCATED

IN FAN CAN CONTROL BOX

RELAY CONTACTS LOCATED

IN FAN CAN CONTROL BOX

MERCURY SWITCH LOCATED

ON TOP OF DRYER

120VAC FOR AUX UNLOAD CONTACTOR COIL

120VAC FOR AUX LOAD CONTACTOR COIL

AUX CONTACT POINTS FOR LOAD AND UNLOAD SYSTEMS

ALL VOLTAGE SUPPLIED BY USER

NEED JUMPER

RED

RED

RED

BRN

RED

BLK

NEED JUMPER

RED

RED

OR

YEL

PUR

OR

OR

YEL

PUR

OR

YEL

BLU

OR

OR

RED

MOTOR OVERLOADS

BLU

BLU

BLK

WHT

BLK

WHT

BRN

BRN

PUR

WHT

BLK

YEL

BLU

RED

BLK

WHT

BLK

RED

ALL SAFETIES MUST BE CLOSED FOR DRYER TO OPERATE

J5-8

J5-8

J1-8

J1-6

J1-10

J1-7

J1-5

J1-9

J1-12

J1-11

J1-19

J5-5

J4-19

J4-12

J1-14

J1-13

J9-18

J7-6

J9-16

J7-4

B2

B1

J7-3

J7-8

J5-4

J5-16

J5-19

J5-9

J1-20

J5-12

-12VDC

S1

S2

L1 WORK LIGHT

J9-3

J8-16

J8-9

J8-18

J8-8

J8-14

J9-19

J8-12

J9-17

J8-20

J8-10

J6-1

SCR 2

J6-4

U-COM

U-N/O

L-COM

L-N/O

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (BLUE)

12 VOLTS DC (BLUE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

120 VAC (BROWN)

120 VAC (BROWN)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

12 VOLTS DC (YELLOW)

METER ROLL PULSE (PUR)

NO LONGER USED

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC NEG (WHITE)

TEMP SENSOR (ORANGE)

TEMP SENSOR (ORANGE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

120 VAC (BLACK)AC 1

120 VAC NEUT (WHITE)

120 VAC (ORANGE)

120 VAC NEUT (WHITE)

120 VAC (YELLOW)

120 VAC NEUT (WHITE)

120 VAC (BLUE)

120 VAC NEUT (WHITE)

120 VAC (BLUE)

120 VAC NEUT (WHITE)

120 VAC (ORANGE)

CONTROL POT P1 (PUR)

CONTROL POT P2 (PUR)

CONTROL POT P3 (PUR)

UNLOAD AUX COM(ORANGE)

UNLOAD AUX N/O(ORANGE)

LOAD AUX COM (YELLOW)

LOAD AUX N/O (YELLOW)

16

Page 18

Portable Dryer Troubleshooting

1200 Series Control Box Wiring (New Version)

Wiring Reference

17

Page 19

Wiring Reference

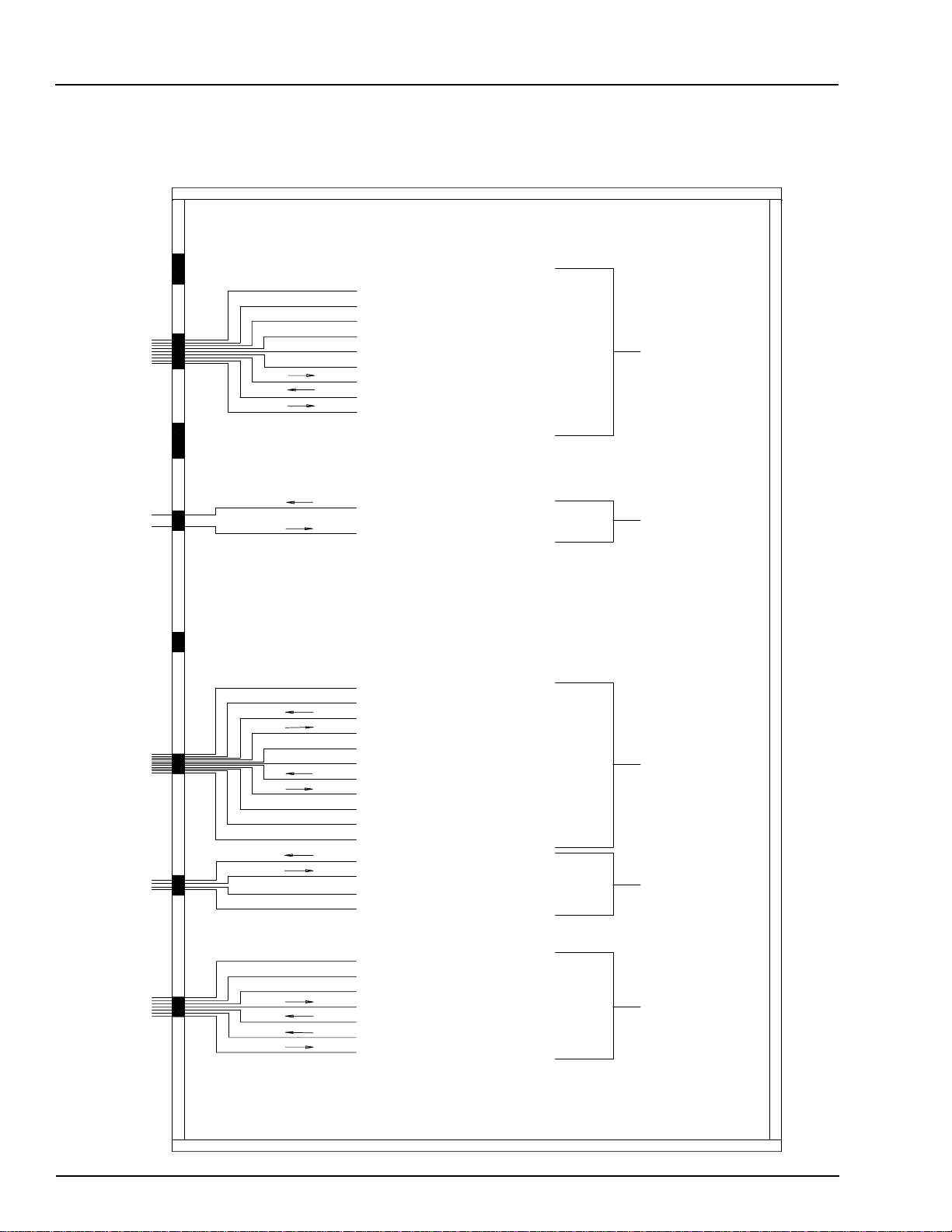

1100 Fan Lower Control Box Interconnect Strip

Portable Dryer Troubleshooting

J9-1

LOAD

LINE

AC-1

EMERGENCY COOLING JUMPERS

INSTALL J6-13 TO J1-5

INSTALL J6-14 TO J1-19

INSTALL J6-16 TO J5-5

INSTALL J6-17 TO J4-19

L1

B1

S1

S2

SCR2

J1-5

J1-7

J1-9

J1-11

J1-13

J1-19

J1-20

J4-12

J4-19

J5-4

J5-5

J5-8

J5-9

J5-12

J5-16

J5-19

J6-1

J6-4

J7-3

J7-4

J7-8

J8-8

J8-9

J8-10

J8-12

J9-3

EMI FILTER

D03-0181

BLACK - 120 VAC - OUTSIDE LIGHT

BROWN - 120 VAC - BURNER #1 LIGHT

ORANGE - TEMPERATURE SENSOR

ORANGE - TEMPERATURE SENSOR

PURPLE - CONTROL POT P2

RED - 12 VDC - FAN #1 VAPOR HIGH LIMIT

RED - 12 VDC - FAN #1 HOUSING HIGH LIMIT

RED - 12 VDC - FAN #1 FLAME DETECTION

RED - 12 VDC - FAN #1 PLENUM HIGHT LIMIT

BLUE - 12 VDC - FAN #1 AIR SWITCH

RED - 12 VDC - LOWER FIXED GRAIN LIMIT

RED - 12 VDC - USER SUPPLIED SAFETY

RED - 12 VDC - MOTOR OVERLOADS

RED - 12 VDC - LOWER ADJUSTABLE GRAIN HIGH LIMIT

YELLOW - 12 VDC - OUT OF GRAIN SENSOR

RED - 12 VDC - REAR DISCHARGE SWITCH

RED - 12 VDC - 12 VOLT SUPPLY

RED - 12 VDC - 12 VOLT SUPPLY

WHITE - 12 VDC NEG - 12 VOLT SUPPLY NEGATIVE

PURPLE -TIMING PULSE- LEFT METERING ROLL PULSE

PURPLE -TIMING PULSE- RIGHT METERING ROLL PULSE

PURPLE - CONTROL POT P1

PURPLE - CONTROL POT P3

BLACK - 120 VAC - MAXON POWER

WHITE - AC NEUTRAL - BURNER NEUTRAL

WHITE - AC NEUTRAL - MAXON NEUTRAL

YELLOW - 120 VAC - LOAD POWER

ORANGE - 120 VAC - UNLOAD POWER

ORANGE - 120 VAC - SCR POWER

WHITE - AC NEUTRAL - FAN #1 NEUTRAL

5VB1

J9-3

J8-16 WHITE - AC NEUTRAL - UNLOAD NEUTRAL

J8-18

J8-20

J9-16

J9-17

WHITE - AC NEUTRAL - LOAD NEUTRAL

WHITE - AC NEUTRAL - SCR NEUTRAL

BLACK - 120 VAC - BURNER #1 POWER

BLUE - 120 VAC - FAN #1 POWER

18

35 - D01-0531 ENTRELEC TERMINALS

2 - D01-0533 END STOPS

1 - D01-0532 BLANK PROTECTOR END

I/O BOARD JUMPERS

INSTALL J1-9 TO J5-6

INSTALL J5-2 TO J5-20

INSTALL J4-12 TO J5-10

INSTALL J1-20 TO J5-8

Page 20

Portable Dryer Troubleshooting

1200 Fan Lower Control Box Interconnect Strip

Wiring Reference

J9-1

LOAD

J9-3

L1

B1

B2

S1 ORANGE - TEMPERATURE SENSOR

S2 ORANGE - TEMPERATURE SENSOR

SCR2

J1-5

J1-6

J1-7

J1-8

J1-9

J1-10

J1-11

J1-12

J1-13

J1-14

J1-19

J1-20

J4-12

J4-19

J5-4

J5-5

J5-8

J5-9

J5-12

J5-16

J5-19

J6-1

J6-4

J7-3

J7-4

J7-8

J8-8

J8-9

J8-10

J8-12

J8-18

J8-20

J9-16

LINE

5VB1

EMI FILTER

D03-0181

BLACK - 120 VAC - OUTSIDE LIGHT

BROWN - 120 VAC - BURNER #1 LIGHT

BROWN - 120 VAC - BURNER #2 LIGHT

PURPLE - CONTROL POT P2

RED - 12 VDC - FAN #1 VAPOR HIGH LIMIT

RED - 12 VDC - FAN #2 VAPOR HIGH LIMIT

RED - 12 VDC - FAN #1 HOUSING HIGH LIMIT

RED - 12 VDC - FAN #2 HOUSING HIGH LIMIT

RED - 12 VDC - FAN #1 FLAME DETECTION

RED - 12 VDC - FAN #2 FLAME DETECTION

RED - 12 VDC - FAN #1 PLENUM HIGHT LIMIT

RED - 12 VDC - FAN #2 PLENUM HIGHT LIMIT

BLUE - 12 VDC - FAN #1 AIR SWITCH

BLUE - 12 VDC - FAN #2 AIR SWITCH

RED - 12 VDC - LOWER FIXED GRAIN LIMIT

RED - 12 VDC - USER SUPPLIED SAFETY

RED - 12 VDC - MOTOR OVERLOADS

RED - 12 VDC - LOWER ADJUSTABLE GRAIN HIGH LIMIT

YELLOW - 12 VDC - OUT OF GRAIN SENSOR

RED - 12 VDC - REAR DISCHARGE SWITCH

RED - 12 VDC - 12 VOLT SUPPLY

RED - 12 VDC - 12 VOLT SUPPLY

WHITE - 12 VDC NEG - 12 VOLT SUPPLY NEGATIVE

PURPLE -TIMING PULSE- LEFT METERING ROLL PULSE

PURPLE -TIMING PULSE- RIGHT METERING ROLL PULSE

PURPLE - CONTROL POT P1

PURPLE - CONTROL POT P3

BLACK - 120 VAC - MAXON POWER

WHITE - AC NEUTRAL - BURNER #1 NEUTRAL

WHITE - AC NEUTRAL - BURNER #2 NEUTRALJ7-6

WHITE - AC NEUTRAL - MAXON NEUTRAL

YELLOW - 120 VAC - LOAD POWER

ORANGE - 120 VAC - UNLOAD POWER

ORANGE - 120 VAC - SCR POWER

WHITE - AC NEUTRAL - FAN #1 NEUTRAL

WHITE - AC NEUTRAL - FAN #2 NEUTRALJ8-14

WHITE - AC NEUTRAL - UNLOAD NEUTRALJ8-16

WHITE - AC NEUTRAL - LOAD NEUTRAL

WHITE - AC NEUTRAL - SCR NEUTRAL

BLACK - 120 VAC - BURNER #1 POWER

BLUE - 120 VAC - FAN #1 POWERJ9-17

BLACK - 120 VAC - BURNER #2 POWERJ9-18

BLUE - 120 VAC - FAN #2 POWERJ9-19

AC-1

J9-3

EMERGENCY COOLING JUMPERS

INSTALL J6-13 TO J1-5

INSTALL J6-14 TO J1-19

INSTALL J6-16 TO J5-5

INSTALL J6-17 TO J4-19

45 - D01-0531 ENTRELEC TERMINALS

2 - D01-0533 END STOPS

1 - D01-0532 BLANK PROTECTOR ENDS

I/O BOARD JUMPERS

INSTALL J1-9 TO J5-6

INSTALL J5-2 TO J5-20

INSTALL J4-12 TO J5-10

INSTALL J9-1 TO J9-5

19

Page 21

Wiring Reference

Portable Dryer Troubleshooting

Upper Control Box External Wiring

BLACK FROM J9-16 TO L1 ON FENWAL BOARD 120VAC POWER

WHITE FROM J7-04 TO L2 ON FENWAL BOARD 120VAC NEUTRAL

BROWN TO B1 FROM V1 ON FENWAL BOARD 120VAC

ORANGE FROM J1-09 TO FLAME DETECTION RELAYS

ORANGE FROM J5-08 TO FLAME DETECTION RELAYS

WHITE/BLACK STRIP J5-12 12VDC NEGATIVE

YELLOW TO J1-07 FROM HOUSING HIGH LIMIT SWITCH

RED FROM J5-08 TO HOUSING & VAPOR HIGH LIMIT SWITCHES

PURPLE TO J1-05 FROM VAPOR HIGH LIMIT SWITCH

TO FAN CONTROL BOX

BLUE FROM J5-08 TO AIRSWITCH COMMON TERMINAL

BLUE TO J1-13 FROM AIRSWITCH N.O. TERMINAL

WHITE TO S1 FROM RIGHT GRAIN TEMPERATURE SENSOR

BLACK TO S2 FROM RIGHT GRAIN TEMPERATURE SENSOR

RED FROM J1-11 TO LEFT GRAIN HIGH LIMIT SWITCH

ORANGE TO J1-19 FROM LEFT GRAIN HIGH LIMIT SWITCH

PURPLE J7-03 MAXON POWER 120VAC (NATURAL GAS ONLY)

WHITE J7-08 MAXON 120VAC NEUTRAL (NATURAL GAS ONLY)

BROWN FROM J1-19 TO REAR DISCHARGE SWITCH

ORANGE TO J5-05 FROM REAR DISCHARGE SWITCH

RED 16 GA. A+ SCR DRIVE MOTOR

BLACK 16 GA. A- SCR DRIVE MOTOR

GREEN 16 GA. SCR DRIVE MOTOR GROUND

BLACK FROM J5-09 TO LOAD MERCURY SWITCH

BLACK TO J5-04 FROM LOAD MERCURY SWITCH

WHITE FROM J9-03 TO OUTSIDE LIGHT AC NEUTRAL

RED FROM L1 120VAC TO OUTSIDE LIGHT POWER

TO AIRSWITCH ASSEMBLY

TO LOWER JUNCTION BOX

TO UPPER JUNCTION BOX

20

YELLOW FROM J1-05 TO PLENUM HIGH LIMIT SWITCH

WHITE TO S1 FROM GRAIN TEMPERATURE SENSOR

BLACK TO S2 FROM GRAIN TEMPERATURE SENSOR

BLUE TO J1-11 FROM PLENUM HIGH LIMIT SWITCH

YELLOW FROM J1-05 TO PLENUM HIGH LIMIT SWITCH

RED FROM J5-05 TO RIGHT GRAIN HIGH LIMIT SWITCH

ORANGE TO J4-19 FROM RIGHT GRAIN HIGH LIMIT SWITCH

TO PLENUM AND RIGHT

FIXED GRAIN HIGH LIMIT

SWITCHES AND TEMPERATURE

SENSORS

Page 22

Portable Dryer Troubleshooting

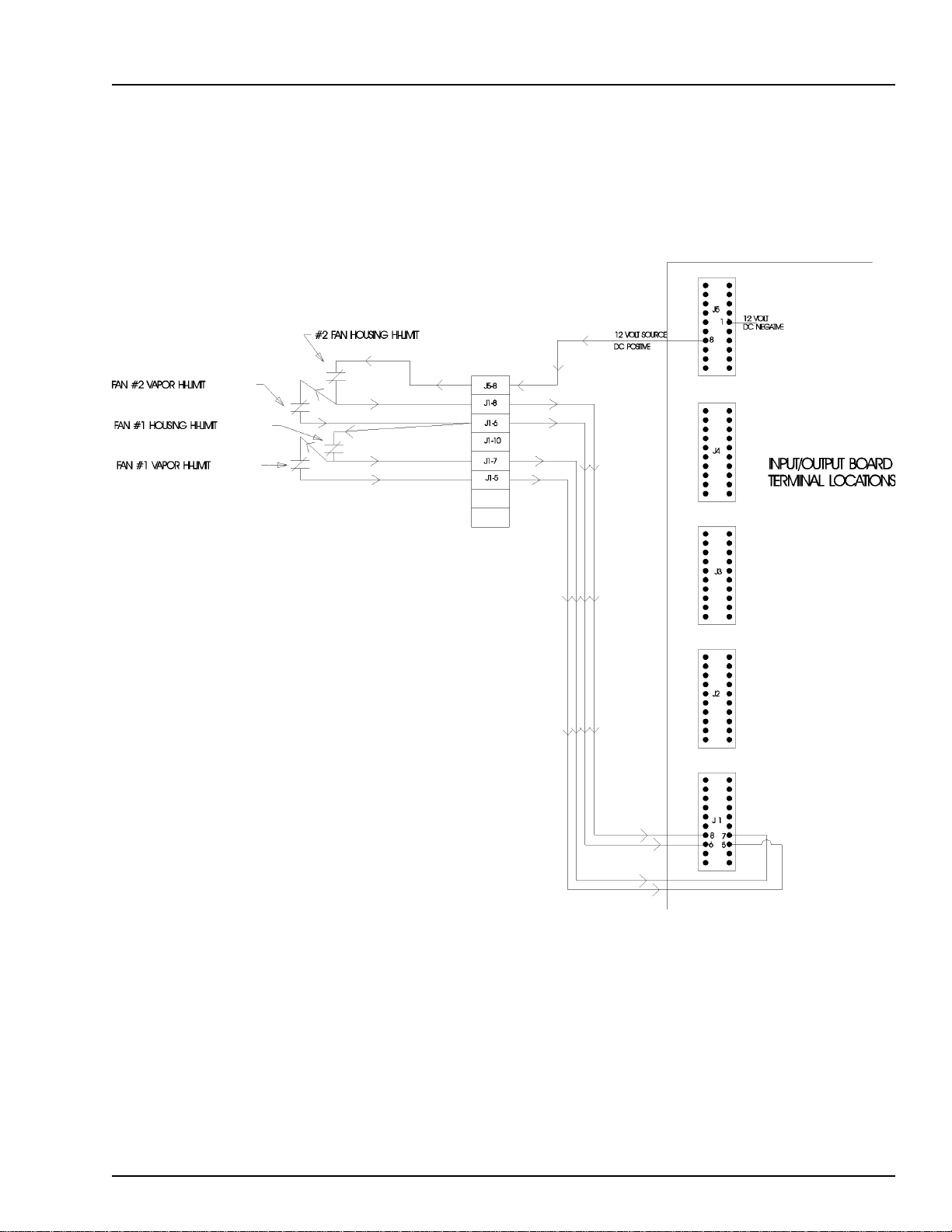

Fan Housing and Vapor Hi-Limit Circuit

Wiring Reference

21

Page 23

Wiring Reference

Portable Dryer Troubleshooting

Plenum Hi-Temperature Switch

22

Page 24

Portable Dryer Troubleshooting

Fixed Grain Hi-Limit

Wiring Reference

23

Page 25

Wiring Reference

LOAD

MOTOR

Portable Dryer Troubleshooting

Grain & Plenum Hi-Limit Locations

LIMIT

GRAIN HIGH

LEFT FIXED

TEMP. SENSORS

GAS PIPE TRAIN

11XX

BOX

UPPER

JUNCTION

OUTSIDE LIGHT

LOAD MERCURY SWITCH

PLENUM HIGH LIMIT SWITCH

D03-0004 300 DEGREE

SOLENOID

BURNER

HI-LOW

THERMO

PLENUM

LIMIT

GRAIN HIGH

RIGHT FIXED

TEMP. SENSORS

AIR SWITCH

FAN

BOX

LOWER

JUNCTION

SCR

MOTOR

UNLOAD

24

BLUE J1-11

YELLOW J1-05

RIGHT GRAIN HIGH LIMIT SWITCH

D03-0005 210 DEGREE

BLUE J1-11

YELLOW J1-05

ORANGE J4-19

LEFT GRAIN HIGH LIMIT SWITCH

D03-0005 210 DEGREE

RED J5-05

TO UPPER CONTROL BOX

RED J1-11

ORANGE J1-19

TO LOWER JUNCTION BOX

Page 26

Portable Dryer Troubleshooting

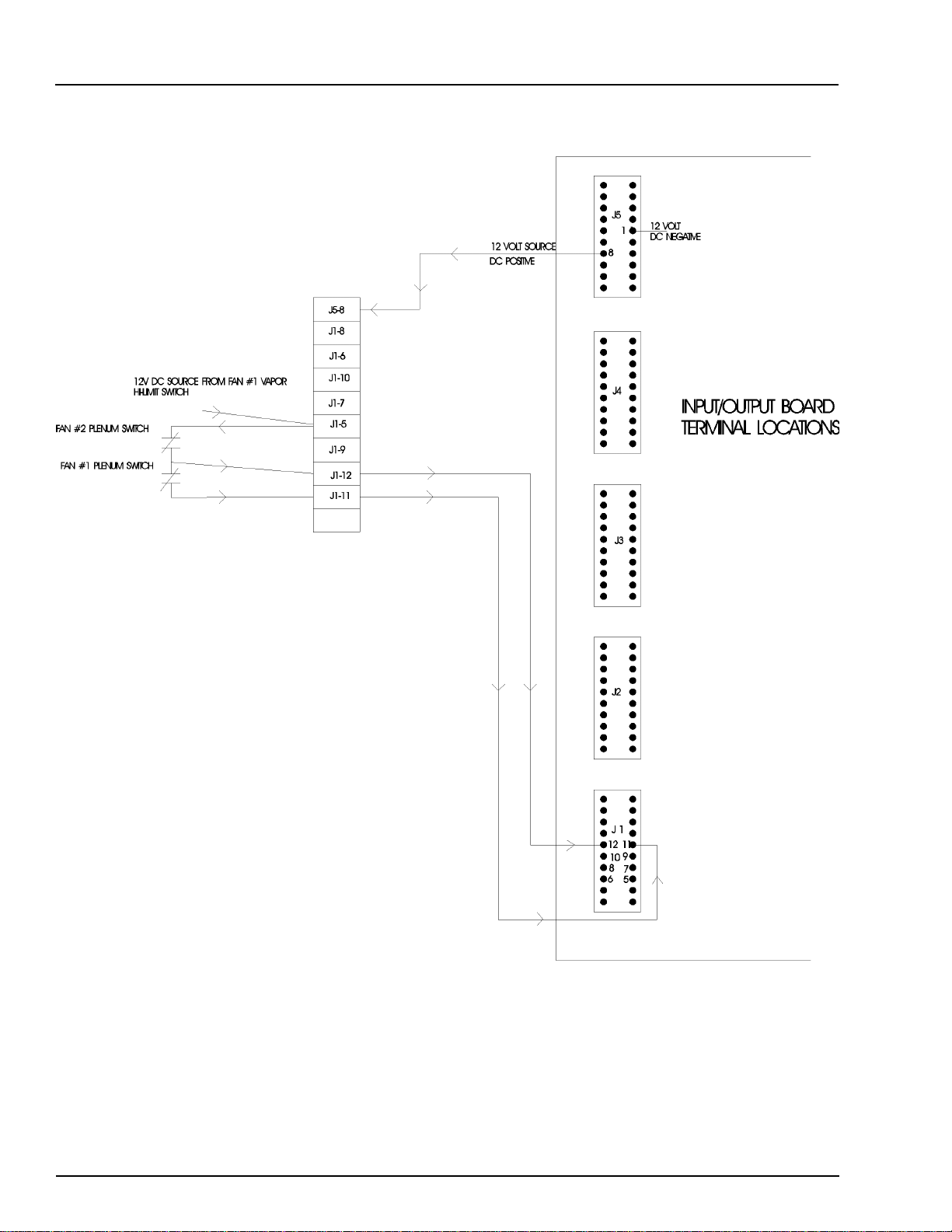

Two Fan Plenum and Grain Limit Switch Wiring

LOAD

MOTOR

FIXED GRAIN

HI-LIMIT AND

THERMO SENSORS

Wiring Reference

MAXON

12XX

BOX

UPPER

JUNCTION

SOLENOID

LOAD MERCURY SWITCH

OUTSIDE LIGHT

BURNER #2

PLENUM #2

HI-LOW

THERMO

HI-LOW

BURNER #1

AIR

SWITCHES

FAN #2

THERMO

SOLENOID

PLENUM #1

LIMIT

ADJUSTABLE

GRAIN HIGH

TEMP. SENSORS

FAN #1

RED TO J1-11

SCR

MOTOR

UNLOAD

2FNLMTSW98.PRT REV. DATE 4/5/98

FAN #2

PLENUM HIGH LIMIT SWITCH

D03-0004 300 DEGREE

FIXED GRAIN HIGH LIMIT SWITCH

D03-0005 210 DEGREE

FAN #1

PLENUM HIGH LIMIT SWITCH

D03-0004 300 DEGREE

ORANGE TO J1-19

YELLOW TO J1-12

BLUE TO J1-11

RED TO J1-05

TO LOWER JUNCTION BOX

25

Page 27

Wiring Reference

Rear Discharge & Emergency Cooling Circuit

Portable Dryer Troubleshooting

26

Page 28

Portable Dryer Troubleshooting

Rear Discharge Mercury Switch

Wiring Reference

POSITIONED WITH LID CLOSED AND

SJOW 18/2 CORD POINTED TOWARDS

THE FRONT OF THE DRYER CONNECT

INSIDE METER ROLL BOX TO BROWN

AND ORANGE WIRES.

LOOSEN SCREWS ON BRACKET

TO CHANGE SENSITIVITY

OF REAR DISCHARGE SWITCH

CONNECT TO SJOW CORD

INSIDE LRL BOX

27

Page 29

Wiring Reference

Adjustable Hi-Limit & Emergency Cooling Circuit

Portable Dryer Troubleshooting

28

Page 30

Portable Dryer Troubleshooting

Wiring Reference

Motor Overloads

29

Page 31

D

S

Wiring Reference

12V DC SOURCE FROM

MOTOR OVERLOADS

FAN #2 PRESSURE SWITCH

FAN #1 PRESSURE SWITCH

Air Pressure Switch

J5-8

J1-8

J1-6

J1-10

J1-7

J1-5

J1-9

J1-12

J1-11

J1-19

J6-14

J5-5

J4-19

BLUE

BLUE

J6-17

J4-12

J1-14

J1-13

BLUE

BLUE

Portable Dryer Troubleshooting

J5

12 VOLT

1 1

12 VOLT SOURCE

DC POSITIVE

DC NEGATIVE

8

12

J4

INPUT/OUTPUT BOAR

TERMINAL LOCATION

J3

J2

PRESSURE SWITCH SAFETY

CIRCUIT

14

13

J 1

30

Page 32

Portable Dryer Troubleshooting

Air Pressure Switch Drawing

LOAD

MOTOR

LIMIT

LEFT FIXED

GRAIN HIGH

TEMP. SENSORS

Wiring Reference

GAS PIPE TRAIN

11XX

BOX

UPPER

JUNCTION

SOLENOID

LOAD MERCURY SWITCH

OUTSIDE LIGHT

PLENUM

LIMIT

GRAIN HIGH

RIGHT FIXED

TEMP. SENSORS

AIR SWITCH

FAN

BOX

LOWER

JUNCTION

SCR

MOTOR

UNLOAD

TO UPPER CONTROL BOX

BLUE J5-08 12VDC POSITIVE

BLUE J1-13 AIRFLOW (N.O.)

CALIBRATED WITH

DIAPHRAGM VERTICAL

C N.C. N.O.

HIGH

BACKVIEW OF AIR SWITCH ASSEMBLY

31

Page 33

Wiring Reference

Portable Dryer Troubleshooting

Out of Grain Safety Circuit

32

Page 34

Portable Dryer Troubleshooting

Out of Grain Safety Circuit Location

LOAD

MOTOR

LIMIT

GRAIN HIGH

LEFT FIXED

TEMP. SENSORS

Wiring Reference

GAS PIPE TRAIN

11XX

BOX

UPPER

JUNCTION

SOLENOID

LOAD MERCURY SWITCH

OUTSIDE LIGHT

BURNER

THERMO

HI-LOW

PLENUM

LIMIT

GRAIN HIGH

RIGHT FIXED

TEMP. SENSORS

AIR SWITCH

FAN

BOX

LOWER

JUNCTION

SCR

MOTOR

UNLOAD

LEADS MUST BE IN THIS POSITION

FOR PROPER OPERATION

SJOW 18/2 WIRE

EXITS THROUGH

BLACK

BOX COVER

WHITE

FRONT VIEW OF OPEN BOX

UP

REMOVE THESE EARS

33

Page 35

Wiring Reference

LOAD

MOTOR

Portable Dryer Troubleshooting

Upper Junction Box Drawing

LIMIT

GRAIN HIGH

LEFT FIXED

TEMP. SENSORS

GAS PIPE TRAIN

11XX

BOX

UPPER

JUNCTION

SOLENOID

OUTSIDE LIGHT

LOAD MERCURY SWITCH

BURNER

HI-LOW

THERMO

PLENUM

LIMIT

GRAIN HIGH

RIGHT FIXED

TEMP. SENSORS

AIR SWITCH

FAN

BOX

LOWER

JUNCTION

SCR

MOTOR

UNLOAD

34

BLACK

WHITE

TO LOAD MERCURY SWITCH

WHITE

RED

J9-03

BLACK

L1

BLACK

WHITE

TO 12VDC J5-09

BLACK

J5-04

TO UPPER CONTROL BOX

TO OUTSIDE LIGHT FIXTURE

Page 36

Portable Dryer Troubleshooting

Wiring Reference

Meter Roll Sensor

RIGHT METER

ROLL SENSOR

RED

BLACK

BLUE

J5-19

J5-12

J5-09

NOTE:

RIGHT SENSOR IS

NO LONGER USED ON

DRYERS MANUFACTURED

AFTER MARCH 1, 1997

RED 12VDC POS

BLACK OR WHITE/BLACK STRIP 12VDC NEG

YELLOW LEFT METER PULSE RETURN

BLUE RIGHT METER PULSE RETURN

J5-19

J5-12

YELLOW

BLACK

LEFT METER

ORANGE REAR DISCHARGE RETURN

ROLL SENSOR

BROWN 12VDC TO DISCHARGE SWITCH

TO REAR

ORANGE

J5-09

RED

BROWN

J5-16

JUNCTION BOX

TO REAR DISCHARGE SWITCH

J1-19

J5-05

35

Page 37

Wiring Reference

Portable Dryer Troubleshooting

Meter Roll Sensor Wiring

19

9

J5

16

12

J5-8

J1-7

J1-5

J1-9

J1-11

J1-19

J5-5

J4-19

J4

J1-13

J4-12

J9-16

J7-4

J3

J5-16

J5-19

J5-4

J7-8

J7-3

B1

J5-9

J1-20

J5-12

J2

S1

S2

J 1

Pulse

12 Volt +

12 Volt -

Pulse

Board

Meter Roll

Board

Meter Roll

36

T-2

T-1

T-3

METER ROLL SENSOR

12 Volt +

T-1

12 Volt -

T-2

T-3

1997 Dryers have only 1 meter roll board.

Remove one meter roll board and tie the

2 T-3 wires together.

Page 38

Portable Dryer Troubleshooting

Meter Roll Reversing

Wiring Reference

YOU MUST ENTER INTO THE DRYER

PARMETER MODE BY PRESSING THE

INCREASE AND DECREASE BUTTONS

SIMULTANIOUSLY. YOU WILL HAVE

THE FOLLOWING OPTIONS LISTED:

SHUTDOWN HISTORY (PRESS ENTER)

DRYER MODEL # (IE. 1112)

FAN DELAY (DEFAULT = 5)

FILL AUGER (DEFAULT = END)

BPH FACTOR (DEFAULT = 1.0)

TEST METER ROLL (DEFAULT = YES)

TEST AIR SWITCH (DEFAULT = YES)

M.R. REVERSE (DEFAULT = NO) <- CHANGE TO YES

* REVERSE DELAY (DEFAULT = 60)

* REVERSE TIME (DEFAULT = 1)

* DISPLAYED ONLY IF M.R. REVERSE

IS CHANGED TO YES

REVERSE DELAY = METER ROLLS NORMAL ROTATION TIME

(AMOUNT OF TIME METER ROLLS WILL OPERATE BEFORE

THEY WILL BEGIN REVERSE ROTATION)

REVERSE TIME = METER ROLLS REVERSE ROTATION TIME

(AMOUNT OF TIME METER ROLLS WILL OPERATE IN THE

REVERSED ROTATION MODE)

EXAMPLE: REVERSE DELAY = 10 MINUTES

REVERSE TIME = 1 MINUTE

NOTE:

WHEN INSTALLING RELAY

BASE NOTE POSITION OF

SLOTS FOR RELAY!!

ORANGE

TO

SCR DRIVE

BOARD

A+

85

4

A-

PURPLE

JUMPER WIRES SHOULD

GO BETWEEN:

TERMINALS 4 AND 5

TERMINALS 1 AND 8

1

LOCATE THE ORANGE AND

PURPLE WIRES COMING FROM

THE SCR DRIVE BOARD GOING

TO THE TERMINAL STRIP AND

INSERT THE RELAY AS SHOWN

BLACK

J7-17

(110 VAC CONTROL)

PURPLE

IMPORTANT

YOU MUST ADD A JUMPER WIRE

FROM J9-09 TO J7-16 IN THE

LOWER CONTROL BOX.

14

12

A-

TO

DC DRIVE

MOTOR

13

9

(110 VAC NEUTRAL)

ORANGE

A+

WHITE

J8-20

37

Page 39

Wiring Reference

LOAD

MOTOR

Portable Dryer Troubleshooting

Lower Junction Box Wiring

LIMIT

GRAIN HIGH

LEFT FIXED

TEMP. SENSORS

GAS PIPE TRAIN

11XX

BOX

UPPER

JUNCTION

SOLENOID

LOAD MERCURY SWITCH

OUTSIDE LIGHT

WHITE S1

RED J1-11

BURNER

HI-LOW

THERMO

PLENUM

LIMIT

GRAIN HIGH

RIGHT FIXED

TEMP. SENSORS

AIR SWITCH

FAN

BOX

LOWER

JUNCTION

SCR

MOTOR

UNLOAD

38

TO LEFT FIXED

GRAIN HIGH LIMIT

AND TEMPERATURE

SENSORS

SJOW 18/2 WIRE

BLACK TO MAXON

PURPLE J7-03

WHITE TO MAXON

WHITE J7-08

NATURAL GAS DRYERS ONLY

WIRES GO TO UPPER

CONTROL BOX

BLACK S2

ORANGE J1-19

RED FROM J5-09 TO 12VDC POSITIVE TERMINAL ON METER ROLL SENSOR

BLACK FROM J5-12 TO 12V NEGATIVE TERMINAL ON METER ROLL SENSOR

YELLOW FROM J5-16 TO LEFT METER ROLL SENSOR

BLUE FROM J5-19 TO RIGHT METER ROLL SENSOR

BROWN FROM J1-19 TO DISCHARGE SWITCH

ORANGE FROM J5-05 TO DISCHARGE SWITCH

RED 16 GA. A+ TO SCR DRIVE MOTOR

BLACK 16 GA. A- TO SCR DRIVE MOTOR

GREEN 16 GA. TO SCR DRIVE GROUND

TO SCR

DRIVE MOTOR

TO REAR

OF DRYER

Page 40

Portable Dryer Troubleshooting

Wiring Reference

New Fenwal Board Wiring

The B. GND terminal is used to ground the burner and to complete the flame current signal circuit. This terminal is

new for systems that used the older version of the Fenwal board. This terminal must be connected to the burner

(chassis) ground not only to ensure the best, long term, stable flame signal, but also to ground the burner for

proper sparking.

The use of a burner ground terminal eliminates the problem of loss of flame sense signal due to a missing or loose

neutral or ground (green) wire at the 120 V AC power source. The new board has been designed such that reversing

the polarity of the 120 V AC line does not cause a loss of flame signal. Thus providing a more reliable flame signal

along with a reduction of nuisance lockouts, due to its design and the use of the B. GND terminal.

NEU.

HOT

BURNER

120

VAC

H.V.

S1

B. GND

L1

V2

L2

GAS

VALVE

BURNER

HOT

NEU.

120

VAC

S1

E2

L2

V2

(A) L1

(B) V1

H.V.

E1

GAS

VALVE

V1

NC

Old version with Remote Flame Sense.

New version with Remote Sense using existing

spark and remote sense electrodes.

Note that terminal E2 on the old version has been replaced by terminal B.GND on the new board.

IGNITOR

Part No. HF-4624

Flame Safety Board

BURNER

GROUND

(B. GND)

FLAME ROD

39

Page 41

Wiring Reference

Portable Dryer Troubleshooting

Fenwal Board Troubleshooting

On-Board Diagnostics

The LED will flash on for 0.2 seconds then off for 0.2 seconds to indicate an error condition.

The pause time between error codes will be 2.5 to 3.0 seconds. During power-up, the LED will light

for one second and then turn off to indicate normal operation.

LED Indication Fault Mode

Steady on Internal Control Failure

2 Flashes Flame Fault**

3 Flashes Ignition Lockout Fault

** May indicate either that a flame was detected during

pre- or post-purge, or that there is a flame sensing error.

If a lockout occurs, the board will have to be reset

by shutting off the power to the board.

Measure Flame Current

Micro Amp Meter

BURNER

YES NO

BURNER

Flame

Test

S1

Flame

Test

S1

+

-

FC+

FC-

BURNER

NO

40

Page 42

Portable Dryer Troubleshooting

Flame Control Circuit

TER. 6-8 (110 VOLTS AC)

6

7

8

WHT

OR

TER. 1-5 (12 VOLTS DC)

2

3

4

5

OR

OR

1

WHT

OR

BRN

WHT

Coil

BRN

COIL

COMMON

BLK

Normal Closed

Wiring Reference

COMMON

OR

OR

BLK

Coil

Neutral

WHT

Normal Closed

FLAME

SENSOR

IGNITOR

TIME

DELAY

S1

FENWAL BOARD

E2

L2

V2

L1

V1

WHT

Neutral

WHT

WHT

BLK

BRN

BLK

BRN

WHT

120 VOLTS AC

NEUTRAL

120 VOLTS AC

BURNER LIGHT

OR

OR

12 VOLTS DC

20 SEC SAFETY

20 SEC INPUT

MAIN CONTROL BOX

ALL WIRES COME FROM

41

Page 43

Wiring Reference

Fan Burner Circuit for Canadian Models Only

* MERCOID TERMINALS

J4-20 FOR 1 FAN DRYERS

J4-18 FOR 2 FAN DRYERS

SOLENOIDS

HIGH

BROWN

VAPOR

o

HONEYWELL THERMOSTAT

PART# D03-0047

t

RB

LOW

Portable Dryer Troubleshooting

HOUSING

GREY BROWN

FLAME

SENSOR

MERCOID

SWITCH

WIRING

TIME

DELAY

BLACK

LIQUID

WHITE

BROWN

8

9

WHT

BLK

TER. 1-7 (12 VOLTS DC)

TER. 8-10 (110 VOLTS AC)

BLK

L1 BURNER

L2

WHITE

V2

BROWN

YELLOW

YELLOW

BLACK

PURPLE

PURPLE

7654321

ORG

YEL

BRN

PUR

PUR

VAPOR LIMIT

ORG

RED

RED

YEL

ORG

ORG

12 VOLTS DC

20 SEC INPUT

20 SEC SAFETY

HOUSING LIMIT

PNK

MERCOID SAFETY PNK

ORG

ORG

MERCOID SAFETY

RELAY

GREY

WHITE

BROWN

ORG

BLK

ORG

WHITE WHITE

BLACK

42

IGNITOR

E2 S1

FENWAL PART# HF-4624

E1

110 VOLTS AC

110 VOLTS AC

NEUTRAL- - - - WHT

TO BURNER CIRCUIT

L1V1

BURNER LIGHT - BRN

BLK

BRN

N/C

N/O

COM

MERCOID

PRESSURE SWITCH

SWITCH CLOSES WHEN

BROWN

PRESSURE IS SENSED

Page 44

Portable Dryer Troubleshooting

Conversion Diagram For C Series Dryers To A Switchable

Hi/Low Burner Or A On/Off Burner

Wiring Reference

43

Page 45

Wiring Reference

Portable Dryer Troubleshooting

Fan 28 LP Hi/Low-On/Off

44

Page 46

Portable Dryer Troubleshooting

Fan 28 LP Hi/Low-On/Off Burner With Mercoid

Wiring Reference

45

Page 47

Wiring Reference

Portable Dryer Troubleshooting

Fan 28 NG Hi/Low-On/Off

46

Page 48

Portable Dryer Troubleshooting

Fan 28 NG Hi/Low-On/Off Burner With Mercoid

Wiring Reference

47

Page 49

Wiring Reference

Portable Dryer Troubleshooting

Fan 42 LP Hi/Low-On/Off

48

Page 50

Portable Dryer Troubleshooting

Fan 42 LP Hi/Low-On/Off Burner With Mercoid

Wiring Reference

49

Page 51

Wiring Reference

Portable Dryer Troubleshooting

Fan 42 NG Hi/Low-On/Off

50

Page 52

Portable Dryer Troubleshooting

Fan 42 NG Hi/Low-On/Off Burner With Mercoid

Wiring Reference

51

Page 53

Wiring Reference

Portable Dryer Troubleshooting

SCR Drive Circuit

To Coil

BLK

SCR

CONTACTOR

T2 L2

6

8

A2 A1

COIL

BLK

1

2

3

F +

F L 1

L 2

A +

A -

L 1

L 2

Fuse

220 Volt

L1T1

5

7

OR

S C R Board

52

OR

P

P

W

J6-1

SCR 2

J8-10

J8-20

SCR P2

SCR P1

SCR POWER

SCR NEUTRAL

P

J6-4

SCR P3

To SCR Drive Motor

OR

PUR

A -

A +

TO TERMINAL ON

WITH POWER WIRES

UPPER POWER STRIP

Page 54

Portable Dryer Troubleshooting

RTD Temperature Sensor

LOAD

MOTOR

LIMIT

GRAIN HIGH

LEFT FIXED

TEMP. SENSORS

Wiring Reference

GAS PIPE TRAIN

11XX

BOX

UPPER

JUNCTION

SOLENOID

OUTSIDE LIGHT

LOAD MERCURY SWITCH

BLACK S2

WHITE S1

BURNER

HI-LOW

THERMO

PLENUM

LIMIT

GRAIN HIGH

RIGHT FIXED

TEMP. SENSORS

TO UPPER CONTROL BOX

AIR SWITCH

FAN

BOX

LOWER

JUNCTION

BLACK S2

SCR

MOTOR

UNLOAD

WHITE S1

TO LOWER JUNCTIONL BOX

BLACK 20 GA.

WHITE 20 GA.

FRONT

INSIDE GRAIN COLUMN CONDUIT

SOLDERED AND INSULATED INSIDE CONDUIT

REAR

BLACK 20 GA.

WHITE 20 GA.

FRONT

INSIDE GRAIN COLUMN CONDUIT

SOLDERED AND INSULATED INSIDE CONDUIT

REAR

53

Page 55

)

Wiring Reference

USING OHM METER BEGIN CHECKING

THE SENSORS FOLLOWING FIG. 1

Portable Dryer Troubleshooting

Test Procedure for E.M.C.S. Dryers

IF OHMS DOES NOT = 3.4 K

CHECK LOWER AND UPPER TERMINAL

STRIP (ON SINGLE MODULES CHECK S1 & S2

(ON DOUBLE OR TRIPLE MODULES

CHECK J6-9 TO J6-6 = 3.4 AND

CHECK J6-11 TO J6-8 = 3.4)

IF MEASUREMENTS DO NOT = 3.4 K

CHECK CONNECTIONS IN WHITE

JUNCTION BOX ON FAR LEFT AND

RIGHT SIDES FACING THE FAN END.

IF NONE OF THE MEASUREMENTS = 3.4 K,

THEN CHECK EACH INDIVIDUAL SENSOR.

FIG.1

J5-3

4

E.M.C.S. PORTABLE DRYERS

5

6

CONTROL

MOISTURE

THERMOSTAT

9

8

7

3

2

1

S2

S1

3.4 ON 20K

SCALE AT

70 DEGREES

54

Page 56

Portable Dryer Troubleshooting

Temperature Charts

We use two (2) different types of sensors (NTC thermistor on the Competitor Series 2000, and an

encapsulated sensor on the E.M.C.S dryer) in our dryers. The resistance of the sensors varies according to the

outside temperature. For example, on the E.M.C.S. dryers, for every one (1) degree rise in temperature the

resistance increases 4.8 ohms. However, on the Competitor Series 2000 dryer , the sensor reacts just the opposite,

the resistance rises with colder temperatures. The charts displayed above will help when troubleshooting any

sensor problems.

55

Page 57

Troubleshooting Tips

Portable Dryer Troubleshooting

DC Drive Metering Roll System

Symptoms: Metering Roll will not turn,

dryer shutdown-"Metering Roll Drive Failure"

Metering Roll Operation

• The DC drive system on the portable

dryer is used to control the output of grain

from the dryer. It is adjusted from the

front of the control box using the high and

low metering roll potentiometers. Components used in this circuit are the SCR

contactor, SCR drive board, DC motor/

gear box, and the input/output board from

the Electronic Monitoring Control System.

• All voltage for the drive system comes

from terminals 1-(L1) and 3-(L2) of the

SCR contactor. There should be 220 volts

AC across these two points even if the

unload system is turned off. If this voltage

is zero, check your incoming main power.

in the 2 Speed position. If this is present

then the SCR contactor and input/output board

are okay.

• If 220 volts AC is present across input of

the SCR drive board (L1 and L2) then

check for voltage across the output of the

board. Change your voltmeter to check for

DC voltage at a range above the 200 volt

scale. Put the leads across A+ and A-. The

voltage across these two points will vary

depending on where the speed control potentiometer is turned. Also try turning the potentiometer up and down. The voltage should go

from zero to approximately 180 Volts DC. If

zero voltage is present across the A+ and Aterminal, first try to disconnect the wires from

these two points and then check for DC volts

again. If the voltage returns, suspect a bad

motor or a problem in the wiring to the motor.

If the voltage does not return, suspect a bad

DC drive board.

• When the unload system is turned on you

should be able to observe the SCR

contactor energizing. The power to the

contactor should turn on and off with the

unload switch. You can check for power by

putting an AC voltmeter across terminals

A1 and A2. Across these points you

should read 120 Volts AC. Also on the top

of the contactor you can see a plunger pulling

in whenever the contactor coil gets power. When

the contactor is energized, power is transferred

from terminals L1 and L2 to terminals T1 and

T2. Understand that L1 and L2 are the Input

of the SCR contactor and T1 and T2 are the

Output of the contactor.

Check the SCR Drive Board

• Next if all the above checks out okay, put

your voltmeter across terminal L1and L2 of the

SCR drive board. You should get 220 Volts AC

across these points when the Unload Switch Is

Check the Motor

• The wires attached to A+ and A- go directly to

the DC drive motor on the dryer. You may

remove the top cover of the motor and check

for the same DC voltages mentioned above at

the motor. If the voltage is not present try to

disconnect the wires, then check for DC volts

again. If you do not get any voltage then look

for a broken or loose wire between the motor

and the drive board terminals.

• If the voltage is present suspect the motor

or the gear box. Removing the motor from

the gear box and trying to run the motor only

is one way of narrowing down the problem, or

you may want to remove the chain and see if

the metering rolls are froze up. Using a pipe

wrench is an easy way to try and rotate the

metering rolls.

56

Page 58

Portable Dryer Troubleshooting

Troubleshooting Tips

Fenwal Ignition System

Symptoms: Burner will not light, dryer

shutdown for "Loss of Flame"

Fenwal Ignition Operation

• The Fenwal Ignition System ignites the

Fenwal Ignition Operation

burner and monitors the flame. Once 120

VAC is applied to the Fenwal, the solenoids

are powered up and the transformer begins

ignition through the ignitor. If flame is

sensed during the ignition period (about

4 seconds), the transformer is turned off,

but the solenoids stay on. If no flame is detected after the ignition period, both the solenoids

and transformer lose power and the dryer

begins a shutdown sequence.

• All voltage for the Fenwal Ignition

System is derived from the input/output

board of the Electronic Monitoring

Control System. For ignition to occur:

1. The fan must be turned on.

2. The pressure switch in the plenum

must indicate the fan is operating.

3. The burner switch must be in the

auto or manual position.

4. The dryer must go through a 10

second purge delay, which is indicated

ing

on the LCD screen.

These steps must take place before troubleshooting

of the Fenwal System can occur. The following

assumes the above steps have been taken.

Fenwal Troubleshooting

• The Fenwal Board located in the fan can

control box on the dryer has seven(7)

terminals. They are L1, L2, V1, V2, S1, S2

and E2. L1 and L2 are considered the input

to the board. After the 10 second purge delay,

an AC voltmeter connected Across L1 and

L2 should read 120 Volts AC. If this is true,

you can assume the input/output board is

operating properly and the problem is in the

Fenwal Ignition System. If no voltage is

present after the 10 second purge delay,

check for voltage going through the auxiliary switch mounted on the side of the fan

contactor for that burner. This switch has

to close before the Fenwal gets power. If

this is OK, check the appropriate output

on the input/output board for that burner.

• If voltage is present across L1 and L2,

check for voltage across the Output of

the Fenwal board. The output terminals

are V1 and V2, and they will also have

120 VAC across them for approximately four(4) seconds. The four(4)

seconds is the amount of time the Fenwal

has to ignite and sense flame or it concludes

no flame is detected and begins a "Loss of

Flame" shutdown. If you have power on the in