Page 1

MODEL # LTD - 18

LTD Heater

Owner's

Manual

MANUAL # PNEG-595

1

Page 2

LTD HEATER CHECK LIST

9OK

_____ 1. All wire connections

_____ 2. Electrical connection visual inspection and

fastener tightness

_____ 3. Spark plug gap .125

_____ 4. Pipe train tightness and gas leaks

_____ 5. Flame sensor tight

_____ 6. Fuse in place, extra fuse provided

_____ 7. Time delay reset

_____ 8. Indicator light

_____ 9. Pressure gauge

_____ 10.Regulator adjusted

_____ 11.Shut off valve operates correctly

_____ 12.Vapor high limit

_____ 13.Unit cycles on to off

_____ 14.Heat rise even across transition

_____ 15.Unit cycles hi to lo (hi-lo only)

_____ 16. Mod valve holds temperature within 1 degree

(mod units only).

_____ 17. All decals and serial number tag

_____ 18. Aesthetic appearance

_____ 19. Manual

Tester Signature___________________________________

Date_________________________

2

Page 3

LTD HEATER OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Warranty.......................................................................................................................4

Roof Warning, Operation & Safety...............................................................................5

Safety Alert Decals.......................................................................................................6

Standard Vane Axial Heater Installation.........................................................................7

Fuel Connection.....................................................................................................7

Heater Electrical Installation..................................................................................8

Second Heater Installation.....................................................................................8

Temperature Heater Specifications......................................................................10

Plenum Thermostat Mounting...............................................................................11

Transition Hi-Limit Installation...............................................................................11

Standard Vane Axial Heater Operation......................................................................12

Standard Heater Operation..................................................................................12

Hi-Lo Heater Operation.........................................................................................12

BTU's Per Gauge Pressure (PSI) Propane Models (Approximate)......................13

BTU's Per Gauge Pressure (PSI) Natural Gas Models (Approximate).................14

Adjusting The Vaporizor........................................................................................15

Standard Heater Troubleshooting Guide.....................................................................16

Standard Heater Wiring...............................................................................................17

Wiring Schematic..........................................................................................................18

3

Page 4

WARRANTY

THE GSI GROUP, INC. ("GSI") WARRANTS ALL PRODUCTS MANUFACTURED BY GSI TO BE FREE OF

DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND CONDITIONS FOR A

PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END USER OF SUCH PRODUCTS.

GSI'S ONLY OBLIGATION IS, AND PURCHASER'S SOLE REMEDY SHALL BE FOR GSI, TO REPAIR OR

REPLACE, AT GSI'S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI'S SOLE JUDGMENT, CON-

TAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP. ALL DELIVERY AND SHIPMENT

CHARGES TO AND FROM GSI'S FACTORY WILL BE PURCHASER'S RESPONSIBILITY. EXPENSES

INCURRED BY OR ON BEHALF OF THE PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION

FROM AN AUTHORIZED EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE ABOVE STATED EXPRESS LIMITED WARRANTIES, GSI MAKES NO WARRANTY

OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MER-

CHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION WITH (i) PROD-

UCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY ADVICE, INSTRUCTION, RECOMMENDATION OR

SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR

RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PUR-

POSE, OR DESIGN OF SUCH PRODUCT OR PRODUCTS.

IN NO EVENT SHALL GSI BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUEN-

TIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS OR BENEFITS.

PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO THAT STATED ABOVE, WHICH

SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS

NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE NO

OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIVE OR WARRANTIES MADE BY OR ON

BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS OR ERECTION DEFECTS WHICH

CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS. MODIFICATIONS TO THE PRODUCT

NOT SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NULLIFY ANY PRODUCT

WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT COVER PRODUCTS OR PARTS WHICH HAVE BEEN

DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY COVERS

ONLY PRODUCTS MANUFACTURED BY GSI. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES EXPRESS OR IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR

SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO RESEARCH AND COM-

PLY WITH ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION.

4

Page 5

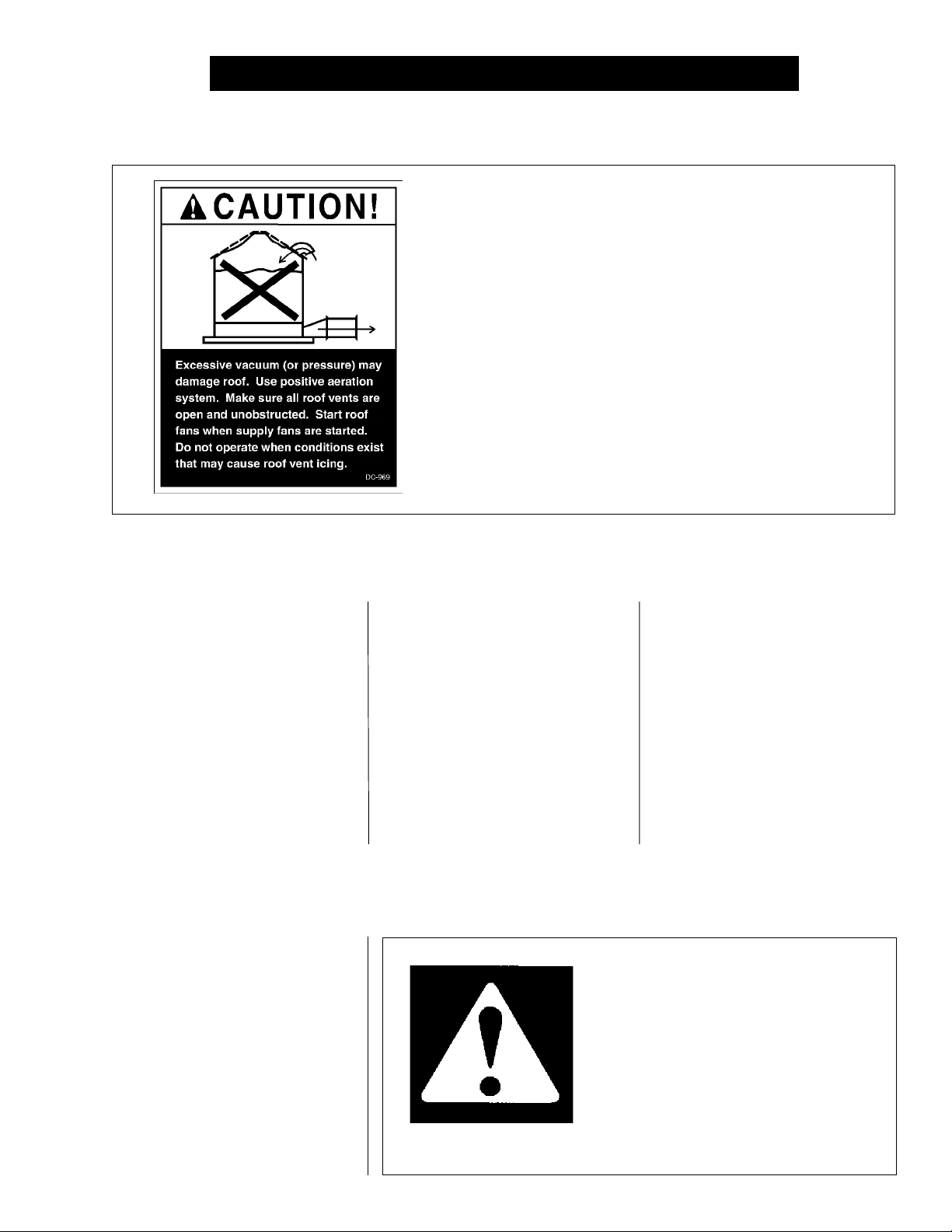

ROOF WARNING, OPERATION & SAFETY

ROOF DAMAGE WARNING AND DISCLAIMER

GSI DOES NOT WARRANT ANY ROOF DAMAGE CAUSED

BY EXCESSIVE VACUUM OR INTERNAL PRESSURE

FROM FANS OR OTHER AIR MOVING SYSTEMS. AD-

EQUATE VENTILATION AND/OR "MAKEUP AIR" DEVICES

SHOULD BE PROVIDED FOR ALL POWERED AIR HAN-

DLING SYSTEMS. GSI DOES NOT RECOMMEND THE USE

OF DOWNWARD FLOW SYSTEMS (SUCTION). SEVERE

ROOF DAMAGE CAN RESULT FROM ANY BLOCKAGE OF

AIR PASSAGES. RUNNING FANS DURING HIGH HUMID-

ITY/COLD WEATHER CONDITIONS CAN CAUSE AIR EX-

HAUST OR INTAKE PORTS TO FREEZE.

Thank you for choosing a GSI/Air-

stream product. It is designed to

give excellent performance and

service for many years.

This manual describes the op-

eration of the GSI/Airstream LTD

Heater. Many models are avail-

able to accommodate low, medium

or high temperature grain condi-

tioning.

The symbol shown is used to call

your attention to instructions con-

cerning your personal safety.

Watch for this symbol; it points out

important safety precautions. It

means "ATTENTION", "WARN-

ING", "CAUTION", and "DANGER".

Read the message and be cau-

tious to the possibility of personal

injury or death.

HEATER OPERATION

The principal concern of The

GSI Group, Inc. ("GSI") is your

safety and the safety of others as-

sociated with grain handling equip-

ment. This manual is written to help

you understand safe operating pro-

cedures, and some of the problems

that may be encountered by the op-

erator or other personnel.

As owner and/or operator, it is

SAFETY ALERT SYMBOL

WARNING! BE ALERT!

Personnel operating or working around

electric fans should read this manual.

This manual must be delivered with the

equipment to its owner. Failure to read

this manual and its safety instructions is

a misuse of the equipment.

your responsibility to know what

requirements, hazards and pre-

cautions exist, and to inform all

personnel associated with the

equipment, or who are in the

heater area. Avoid any alterations

to the equipment. Such alterations

may produce a very dangerous

situation, where serious injury or

death may occur.

5

Page 6

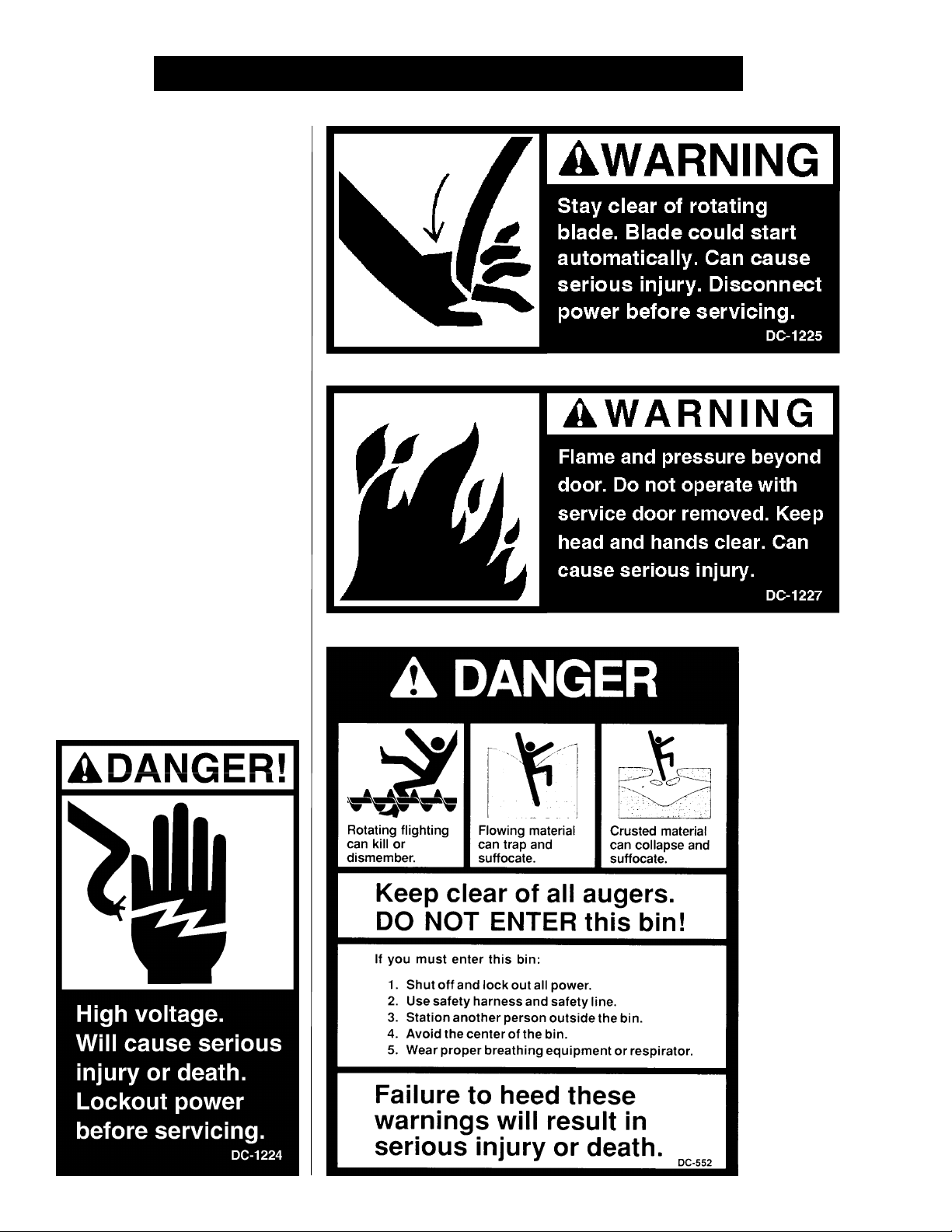

The GSI Group, Inc. recom-

mends contacting your local power

company, and having a represen-

tative survey your installation so the

wiring is compatible with their sys-

tem, and adequate power is sup-

plied to your unit.

Safety decals should be read

and understood by all people in the

grain handling area. The rotating

blade, fire warning decals and volt-

age danger decal must be displayed

on the fan/heater can. The danger

decal, DC-552, should be present

on the inside bin door cover of the

two ring door, 24" porthole door

cover and the roof manway cover.

If a decal is damaged or is miss-

ing contact:

The GSI Group, Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to you.

SAFETY ALERT DECALS

6

Page 7

LTD HEATER INSTALLATION

FUEL CONNECTION

Important! Do not use propane tanks which have previously

been used for ammonia unless they have been purged ac-

cording to procedures of the National L. P. Association.

Be sure fuel supply system complies with all local codes

for L. P. gas installations.

PROPANE VAPOR MODELS

1. Propane vapor models are de-

signed to run directly off of sup-

ply tank or from a separate ex-

ternal vaporizer.

2. Run proper size line (see speci-

fications) to pipe train on heater.

Have a qualified gas service

person inspect installation to be

sure everything is installed ac-

cording to local codes and ordi-

nances.

3. After installation is complete

check all connections for leaks.

DO NOT USE FLAME FOR

LEAK TESTING. (See above for

other precautions.)

NATURAL GAS MODELS

1. Natural gas models are similar

to vapor models, but have a

larger orifice to accommodate

lower pressure sometimes

found with natural gas.

2. Run proper size line (see speci-

fications) to pipe train on heater.

Have a qualified gas service

man inspect installation to be

sure everything is installed ac-

cording to local codes and ordi-

nances.

3. After installation is complete

check all connections for leaks.

DO NOT USE FLAME FOR

LEAK TESTING. (See above for

other precautions.)

7

Page 8

INSTALLING THE LTD HEATER WITH LTD MOUNTING BRACKETS

THESE INSTRUCTIONS ARE

FOR HEATER INSTALLATION

ON FAN UNITS WITH 230V

MOTORS.

BE SURE POWER IS

DISCONNECTED AND LOCKED

OUT BEFORE INSTALLATION!

FAILURE TO DO SO MAY CAUSE

SERIOUS INJURY OR DEATH.

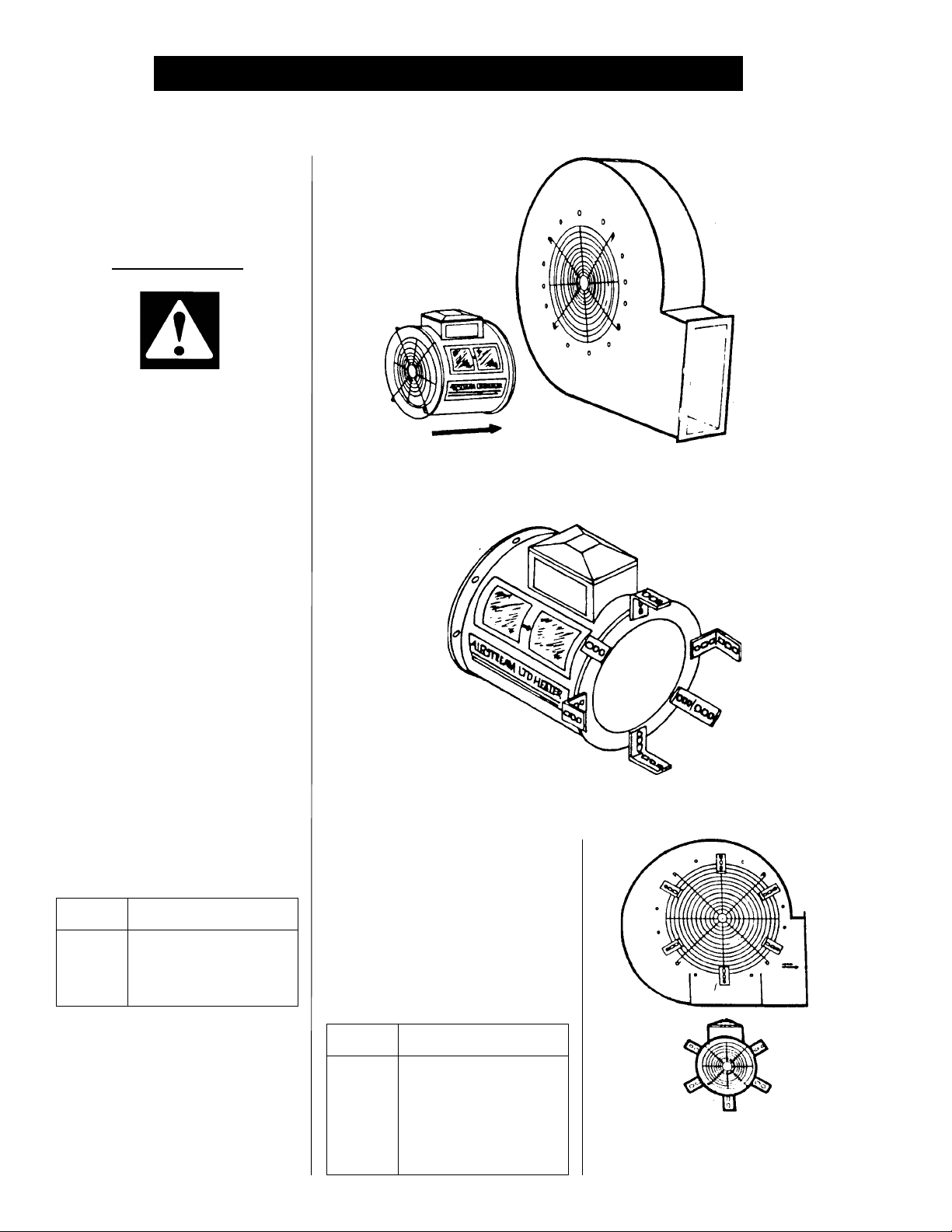

LTD HEATER INSTALLATION

IMPORTANT!

Note: Heater Direction

Figure 1: Make sure the LTD Heater is positioned in the right direction.

1. Place heater on the ground next

to the inlet of the centrifugal fan.

The LTD heater is designed to

mount upwind. Be sure airflow

decal is pointing towards the in-

let of the fan.

2. Bolt LTD mounting brackets to

each of the six holes in the

downstream angle ring of the

heater. Snug tighten bolts such

that they can still pivot with little

force applied. See chart for slots

to bolt through in bracket.

Slot

End

Middle

Fan Inlet Bolt Circle

31" to 35"

Less than 31"

Figure 2: The six(6) mounting brackets positioned on the LTD Heater.

six(6) bolts and bolt the remain-

ing six(6) brackets to fan using

nuts removed. It may be neces-

sary to remount the fan grill

guard so mounting brackets will

seat properly. Slots to use for

fan mounting bolts are below.

3. Pivot brackets so they are nearly

radial from center of heater.

Stand behind heater and deter

mine which bolts on fan inlet

best line up with the brackets.

Remove the nuts from those

8

Slot

End

Middle

Inner

Fan Inlet Bolt Circle

35"

31 3/4"

29"

Figure 3: The LTD Heater brackets

pivoted so they are radial from the

center of the heater.

Page 9

4. Lift heater and align paired

brackets as shown and insert

bolts in corresponding slots as

in table below. Be sure to place

washer provided between tap

and bracket. Tighten bolts snug

but loose enough to slide heater

in and out.

Slot

LTD HEATER INSTALLATION

Fan HP

5

7.5

10

15

20

25

5. Align mating bracket pairs so

that they are in a straight line.

Tighten bolts on fan and heater

rigid.

6. Make sure the heater stand off

dimension is correct for the fan

used. Refer to the table below.

Slide the heater to meet the

stand off dimension all around.

Tighten mating brackets rigid.

The heater should now be se-

curely fastened to the fan. If not

tighten all loose connections.

Heater

Middle

End

End

End

End

End

Fan

Middle

Middle

Middle

End

End

End

Figure 4: Heater aligned with paired brackets and bolts inserted.

Figure 5: Align mating bracket pairs in a straight line.

IMPORTANT!

Fan HP

5

7.5

10

15

20

25

Stand Off

5"

7"

7"

7 1/2"

8 1/2"

8 1/2"

Figure 6: Check the heater stand off distance, based on fan horsepower.

9

Page 10

LTD HEATER INSTALLATION

Note: The optimum distance the

heater should stand away from the

fan inlet has been experimently de-

termined. If there are any ignition

problems, or flame quality is not as

desired, move heater in or out, cali-

brating heater to actual field condi-

tions. Variation from table may be

required to adjust for grain depth,

fan performance and bin size.

8. The LTD stand off bracket can

increase the efficiency of the fan

and heater dramatically com-

pared to using an upwind

mounting plate. Moreover, by

applying the heat to the air up-

wind, the air will be a constant

temperature discharging into

the plenum resulting in more

uniform drying.

9. After heater is securely

mounted, connect gas lines as

required per the installation re-

quirements.

10

Page 11

LTD HEATER INSTALLATION

LTD HEATER ELECTRICAL INSTALLATION (230V FANS)

1. Connect power cord to fan con-

trol box.

2. Make field connections of wires

in fan box as shown in Figure

1.

IMPORTANT! HEATER MUST

BE INTERLOCKED WITH FAN

FOR SAFE OPERATION.

3. Connect deluxe thermostat con-

trol (optional) in heater box as

shown in Figure 1. IMPOR-

TANT! THERMOSTAT MUST

BE INSTALLED FOR SAFE

OPERATION.

Figure 7: 230 volt fan control box.

11

Page 12

LTD HEATER INSTALLATION

LTD HEATER ELECTRICAL INSTALLATION (460V FANS)

1. Connect power cord to fan con-

trol box.

2. Make field connections of

wires in fan box as shown in

Figure 2. 110V power supply

or .5KVA 460V to 110V trans-

former must be used to

supply power for heater. IM-

PORTANT! HEATER MUST

BE INTERLOCKED WITH

FAN FOR SAFE OPERATION.

3. Connect deluxe thermostat con-

trol (optional) as shown in Fig-

ure 2. IMPORTANT! THERMO-

STAT MUST BE INSTALLED

FOR SAFE OPERATION.

12

Figure 8: 460 volt fan control box.

Page 13

LTD HEATER INSTALLATION

AIRSTREAM SURFACE MOUNT HUMIDISTAT (EDS SYSTEMS ONLY)

1. The humidistat can be used to

directly control the operation of

a heater for drying, or with addi-

tional equipment, the operation

of a fan for aeration.

2. The humidistat closes on a

humidity rise. If the humidistat

is set at 50% relative humidity

and the humidity of the air sur-

rounding the sensing unit on the

humidistat is greater than 50%

relative humidity, the micro-

switch remains closed. When

the humidity drops below 50%

relative humidity the micro-

switch opens. Power then

ceases to travel through the hu-

midistat, simultaneously shut-

ting off the heater. If the humi-

distat is used as an aeration

control or fan control for natural

air drying, additional equipment

is required to control the fan

power supply, so it runs when

the humidistat is open.

3. The housing of the humidistat

has a perforated bottom allow-

ing air to surround the sens-

ing element. The perforated

bottom insures accurate sens-

ing of the (outside) humidity.

The housing also incorporates

a vent hole at the top of one

side. This guards against heat

build up in the box, changing

the relative humidity and de-

stroying the heat sensing abil-

ity of the unit. Also, air is drawn

through the perforated bottom

and across the sensing ele-

ment of the humidistat. These

design features insure accurate

sensing of relative humidity.

4. The humidistat should be

mounted with the back plate,

corner holes on a corrugation

hill. It should be positioned ap-

proximately three feet from the

ground or grade line as shown

in the illustration.

5. The humidistat is used in con-

junction with a temperature

sensing control device (thermo-

stat), which senses the drying

air temperature. If the plenum air

temperature exceeds the setting

of the thermostat, the thermostat

opens and the heater shuts off.

When the plenum temperature

drops below the setting of the

thermostat, the thermostat

closes and the heater turns on

again. The thermostat is a safety

device keeping the grain tem-

perature equal to the thermostat

setting. Some grains are more

sensitive to temperature. Qual-

ity, germination and value are

lost due to high temperatures.

Grains used for seed, rice and

popcorn are adversely effected

by high temperatures.

13

Page 14

LTD HEATER INSTALLATION

SURFACE MOUNT HUMIDISTAT (AS A HEATER CONTROL)

REDRAW

BOTH HUMIDISTAT AND THERMOSTAT MUST BE CLOSED FOR HEATER

OPERATION

REDRAW

14

Page 15

LTD HEATER INSTALLATION

LOW TEMPERATURE HEATER SPECIFICATIONS

18"

All models

Vapor models

Natural gas

models

Inside diameter

Bolt circle diameter

Length

BTU rating

Weight

Maximum fuel flow (GPH)

Orifice

Modulating valve bypass orifice

Minimum operating pressure

Maximum operating pressure

Minimum line size

Maximum fuel flow (CFH)

Orifice

Modulating valve bypass orifice

Minimum operating pressure

Maximum operating pressure

Minimum line size

18.5/16"

19.7/16"

22"

400000

81

167

5/64"

Red

2

20

3/8"

421

9/64"

Yellow

1

7

1/2"

15

Page 16

LTD HEATER OPERATION

1. Check to see if high limit con-

trol is in the down position.

2. Open fuel valves between tank

and heater.

3. Turn the heater power switch to

ON by toggling the ON/OFF

switch to ON position.

BTU'S PER GAUGE PRESSURE (PSI) PROPANE MODELS (APPROXIMATE)

Diameter

18"

2

102900

4

14597061818708208190102345101225366014275200162943401831109020335020

4. For prolonged shutdown close the

tank or supply valve and allow

flame to burn until all the gas is

out of the line (the flame dies out).

5. If any problems occur refer to

the service section of this

manual and follow the proce-

dure described. Some common

LOW TEMPERATURE

Operating Pressure (PSI)

problems are:

a. Humidistat and /or ther-

mostat is not set high

enough.

b. Pressure regulator is not

open.

c. Supply valve is not open.

d. High limit button is not

pushed in.

BTU'S PER GAUGE PRESSURE (PSI) NATURAL GAS MODELS (APPROXIMATE)

LOW TEMPERATURE

Operating Pressure (PSI)

Diameter

18"

1

144100

2

205200

3

250800

4

289100

5

322850

6

353860

7

383040

16

Page 17

LTD HEATER OPERATION

MODULATING VALVE OPERATION

Your LTD heater is equipped with

a modulating valve. The following

material should be read thor-

oughly.

1. The modulating valve regulates

gas flow through heater based

on sensing unit in the plenum,

and maintains a constant drying

air temperature.

2. The sensing bulb of the modu-

lating valve should be mounted

through the bin wall with the

reading side top up. The bulb

reacts to temperature. It

changes the amount of gas (in

crease or decrease), burning

warmer or cooler depending on

the position of the valve SET

POINT. If the bulb is cooler than

it was at the SET POINT, the

bulb senses the cooler tempera-

ture and opens the valve further

so more heat is applied to the

drying air. If the bulb is warmer

than it was at the SET POINT,

the valve closes further and re

duces the temperature until the

air is at the valve SET POINT.

3. It is important that the pressure

regulator be set high enough to

allow the modulating valve to

deliver enough gas to maintain

the plenum temperature neces-

sary. The regulator is normally

factory set at 15 psi. To set the

regulator, run the heater and turn

the modulating valve T-handle

in. This gets full line pressure to

the burner. Then adjust regula-

tor to read 15 psi (depending on

the plenum temperature needed).

4. Turn the fan and heater on. To

set the modulating valve, turn the

T-handle out (counterclockwise)

until loose and wait a few min-

utes for the plenum temperature

to equalize. When the tempera-

ture under the bin has equalized,

gradually turn T-handle in (clock

wise) about 1/2 turn. Wait until

temperature under bin has

equalized as before. If tempera-

ture under bin is less than the

desired temperature, continue

turning T-handle in, increasing

gas flow and waiting for plenum

temperature to equalize until the

desired temperature is the

stable temperature of the ple-

num. If temperature under bin is

the same 10 minutes after you

last made any adjustments to

the T-handle you can be certain

that the temperature under the

bin is the SET POINT of the

valve. 1 turn of the T-handle

equals approximately 7 de-

grees F of temperature.

5. The valve will now keep the ple-

num temperature at the set point

regardless of ambient condi-

tions as long as humidistat or

thermostat do not shut down the

heater. A bypass orifice is used

to maintain a small flame when

outside temperature is near or

above the set point of the valve.

The bypass insures steady

application of heat at minimum

gas flow operation.

6. The modulating valve may re-

quire minor adjustment periodi-

cally if a certain temperature rise

over ambient (outside) tempera-

ture is desired.

7. To observe how the modulating

valve increases the efficiency of

bin drying, check the gas pres-

sure of the unit in the morning

and compare to the pressure

read mid-afternoon. If the ambi-

ent (outside) temperature is sig-

nificantly greater later in the day

(as normal), the gas pressure

will be less. Since less heat is

required to maintain the same

temperature in the plenum, the

modulating valve will have re-

duced the amount of gas used

by the heater. This is preferred

to cycling the application of heat

as is commonly done. The grain

is not shocked and cooled

quickly and then reheated,

which is a waste of fuel in con-

ventional bin drying systems.

17

Page 18

LTD HEATER OPERATION

The following tables are general

values for equilibrium moisture con-

tent. The equilibrium moisture con-

tent is the moisture content that the

grain will eventually arrive at if ex-

posed to specific air conditions for

a long enough period of time. The

equilibrium moisture content does

not tell us how fast the grain will lose

moisture to get to its equilibrium

moisture content. Generally, drying

air conditions with a lower equilib-

rium moisture content are used to

increase the rate of moisture re-

moval. The drying process is then

stopped before the grain can reach

equilibrium with the drying air. The

following tables should only be used

as a guide for management of grain

conditioning systems, possible de-

viations may occur due to varieties

and grain condition. (Values calcu-

lated from the Henderson-Thomp-

son equation.)

EQUILIBRIUM MOISTURE TABLE FOR SHELLED CORN % WET BASIS

Temp.

degrees

35

40

45

50

55

60

65

70

75

80

85

90

95

100

10

5.2

5.0

4.9

4.8

4.7

4.6

4.5

4.4

4.3

4.2

4.2

4.1

4.0

3.9

20

7.6

7.4

7.2

7.0

6.9

6.7

6.6

6.4

6.3

6.2

6.1

6.0

5.9

5.8

30

9.5

9.3

9.0

8.8

8.6

8.5

8.3

8.1

8.0

7.8

7.7

7.6

7.4

7.3

Relative Humidity (percent)

40

11.3

11.0

10.8

10.5

10.3

10.1

9.9

9.7

9.5

9.3

9.2

9.0

8.9

8.7

50

13.0

12.7

12.4

12.2

11.9

11.7

11.4

11.2

11.0

10.8

10.6

10.5

10.3

10.1

60

14.8

14.5

14.2

13.9

13.6

13.3

13.0

12.8

12.6

12.4

12.1

12.0

11.8

11.6

70

16.8

16.4

16.0

15.7

15.4

15.1

14.8

14.5

14.3

14.0

13.8

13.6

13.4

13.2

80

19.1

18.7

18.3

17.9

17.5

17.2

16.9

16.6

16.3

16.0

15.8

15.5

15.3

15.1

90

22.2

21.7

21.3

20.9

20.5

20.1

19.7

19.4

19.1

18.8

18.5

18.2

17.9

17.7

Temp.

degrees

35

40

45

50

55

60

65

70

75

80

85

90

95

100

18

EQUILIBRIUM MOISTURE TABLE FOR ROUGH RICE % WET BASIS

Relative Humidity (percent)

10

6.3

6.1

6.0

5.9

5.8

5.7

5.6

5.6

5.5

5.4

5.3

5.3

5.2

5.1

20

8.3

8.2

8.0

7.9

7.7

7.6

7.5

7.4

7.3

7.2

7.1

7.0

6.9

6.8

30

9.9

9.7

9.6

9.4

9.2

9.1

9.0

8.8

8.7

8.6

8.5

8.4

8.3

8.2

40

11.3

11.1

10.9

10.7

10.5

10.4

10.2

10.1

9.9

9.8

9.7

9.6

9.4

9.3

50

12.6

12.4

12.2

12.0

11.8

11.6

11.4

11.3

11.1

11.0

10.8

10.7

10.6

10.4

60

13.9

13.7

13.4

13.2

13.0

12.8

12.6

12.5

12.3

12.1

12.0

11.8

11.7

11.6

70

15.3

15.1

14.8

14.6

14.3

14.1

13.9

13.7

13.5

13.4

13.2

13.1

12.9

12.8

80

16.9

16.6

16.4

16.1

15.9

15.6

15.4

15.2

15.0

14.8

14.6

14.5

14.3

14.1

90

19.1

18.8

18.5

18.2

17.9

17.7

17.4

17.2

17.0

16.8

16.6

16.4

16.2

16.0

Page 19

LTD HEATER OPERATION

EQUILIBRIUM MOISTURE TABLE FOR SORGHUM % WET BASIS

Temp.

degrees

35

40

45

50

55

60

65

70

75

80

85

90

95

100

Temp.

degrees

35

40

45

50

55

60

65

70

75

80

85

90

95

100

Relative Humidity (percent)

10

6.2

6.1

6.1

6.0

6.0

5.9

5.9

5.8

5.8

5.7

5.7

5.7

5.6

5.6

20

8.2

8.1

8.1

8.0

7.9

7.9

7.8

7.7

7.7

7.6

7.6

7.5

7.5

7.4

30

9.8

9.7

9.6

9.5

9.4

9.4

9.3

9.2

9.1

9.1

9.0

8.9

8.9

8.8

40

11.1

11.0

10.9

10.8

10.7

10.7

10.6

10.5

10.4

10.3

10.3

10.2

10.1

10.1

50

12.4

12.3

12.2

12.1

12.0

11.9

11.8

11.7

11.6

11.5

11.5

11.4

11.3

11.2

60

13.7

13.5

13.4

13.3

13.2

13.1

13.0

12.9

12.8

12.8

12.7

12.6

12.5

12.4

70

15.0

14.9

14.8

14.7

14.5

14.4

14.3

14.2

14.1

14.0

13.9

13.8

13.8

13.7

80

16.6

16.4

16.3

16.2

16.1

15.9

15.8

15.7

15.6

15.5

15.4

15.3

15.2

15.1

EQUILIBRIUM MOISTURE TABLE FOR SOYBEANS % WET BASIS

Relative Humidity (percent)

10

3.0

2.9

2.8

2.7

2.6

2.5

2.4

2.3

2.3

2.2

2.1

2.1

2.0

2.0

20

5.1

4.9

4.7

4.5

4.4

4.2

4.1

4.0

3.8

3.7

3.6

3.5

3.5

3.4

30

7.1

6.8

6.5

6.3

6.1

5.9

5.7

5.5

5.3

5.2

5.1

4.9

4.8

4.7

40

9.0

8.6

8.3

8.0

7.7

7.5

7.3

7.0

6.8

6.7

6.5

6.3

6.2

6.0

50

11.0

10.6

10.2

9.8

9.5

9.2

8.9

8.7

8.4

8.2

8.0

7.8

7.6

7.4

60

13.2

12.7

12.2

11.8

11.4

11.1

10.7

10.4

10.1

9.9

9.6

9.4

9.2

8.9

70

15.6

15.1

14.5

14.1

13.6

13.2

12.8

12.5

12.1

11.8

11.5

11.2

11.0

10.7

80

18.7

18.0

17.4

16.8

16.3

15.8

15.4

15.0

14.6

14.2

13.9

13.5

13.2

12.9

90

18.7

18.5

18.4

18.2

18.1

18.0

17.9

17.7

17.6

17.5

17.4

17.3

17.2

17.1

90

23.0

22.2

21.5

20.8

20.2

19.7

19.1

18.6

18.2

17.7

17.3

16.9

16.5

16.2

19

Page 20

LTD HEATER OPERATION

EQUILIBRIUM MOISTURE TABLE FOR WHEAT (SOFT) % WET BASIS

Temp.

degrees

35

40

45

50

55

60

65

70

75

80

85

90

95

100

10

6.3

6.2

6.1

6.0

5.9

5.9

5.8

5.7

5.7

5.6

5.5

5.5

5.4

5.4

20

8.3

8.1

8.0

7.9

7.8

7.7

7.6

7.5

7.4

7.4

7.3

7.2

7.1

7.1

30

9.8

9.6

9.5

9.4

9.2

9.1

9.0

8.9

8.8

8.7

8.6

8.5

8.4

8.4

Relative Humidity (percent)

40

11.1

10.9

10.8

10.6

10.5

10.4

10.2

10.1

10.0

9.9

9.8

9.7

9.6

9.5

50

12.3

12.1

12.0

11.8

11.7

11.5

11.4

11.3

11.1

11.0

10.9

10.8

10.7

10.6

60

13.5

13.3

13.2

13.0

12.8

12.7

12.5

12.4

12.3

12.1

12.0

11.9

11.8

11.7

70

14.8

14.6

14.4

14.2

14.1

13.9

13.7

13.6

13.4

13.3

13.2

13.0

12.9

12.8

80

16.3

16.1

15.9

15.7

15.5

15.3

15.2

15.0

14.8

14.7

14.5

14.4

14.3

14.1

90

18.3

18.1

17.9

17.6

17.4

17.2

17.0

16.9

16.7

16.5

16.4

16.2

16.1

15.9

20

Page 21

LTD HEATER WIRING DIAGRAM

21

Page 22

LTD HEATER PARTS

18" GAS HEATER

22

Key

1

2

3

4

5

6

7

8

9

10

11

12

13

14

NS

NS

NS

15

16

Part Number

HF-6785

HH-3933

HH-4410

HF-7073

HF-6062-18

HF-7380

HF-7379

TFH-2046

HF-983

HF-978

HH-4416

HH-4421

F-953

HH-1650

HF-1810

HF-7260

HF-7262

THH-4179

CD-0187

Description

18" Heater Housing

18" Burner Casting

18" Lo-Temp Flame Spreader

18" Lo-Temp Flame Diverter

18" Access Panel

Plastic View Window

Access Panel Cover Plate

Access Panel Latch

18/24" Burner Collector

18/24/26" Burner Collector Plate

Drum Grill Guard (LTD)

Stand-Off Bracket (LTD)

18" Grill Guard (LTD)

Spark Plug

Spark Plug Nut

18-28" Heater Spark Plug Wire

18-28" Heater Flame Probe Wire

Flame Sensor

Flame Sensor Bracket

Page 23

LTD HEATER PARTS

AXIAL PROPANE VAPOR & NATURAL GAS PIPETRAIN

Key

1

2

3

4

5

6

7

8

8

9

Part Number

HH-1077

HH-3670

TFC-0032

HH-2029

HH-2984

S-3853

HH-1083

CD-0149

HF-7085

HH-2653

Description

1/2" regulator

1/2" x 2-1/2" nipple

1/2" solenoid

1/2" x 1-1/2" nipple

1/4" gauge 30PSI

1/2" x 1/4" x 1/2" tee

18/24/28" Orifice pipe

5/64" Orifice plug (propane)

9/64" Orifice plug (natural gas)

Modulating valve

23

Page 24

LTD HEATER PARTS

CONTROL BOX PARTS

24

Key

1

2

3

4

5

6

7

8

9

10

Part Number

F-942

HH-1487

HF-7318

HH-1092

FH-4429-1

HF-7211

HF-7046

DC-1166

TFH-2021

HH-1442

Description

Control Box Lid

Ignition Transformer

Deluxe Control Board

Housing Hi-Limit

Latch

Snap Track

18" Control Box Housing

Control Box Decal

110V Red Light

Toggle Switch

Page 25

25

Page 26

I R S T R E A M

A

R A I N

G

O N D I T I O N I N G

C

Y S T E M S

S

26

1004 E. Illinois St.

Assumption, IL 62510

phone 217-226-4421

fax 217-226-4498

October 1997

Loading...

Loading...