Page 1

PNEG-588-04

Downwind Centrifugal Heater

Installation and Operation

Model #:_______________

Serial #:_______________

Owner ’s Manual

PNEG-588-04

Date: 05-30-13

Page 2

Check List

Personnel operating or working around this equipment should read this manual. This manual

must be delivered with equipment to its owner. Failure to read this manual and its safety

instructions is a misuse of the equipment. Any misuse of the equipment may void the warranty.

1. All wire connections

2. Spark plug gap 0.063 (1/16")

3. Pipe train tightness and gas leaks

4. Flame sensor tight

5. Fuse in place, extra fuse provided

6. Flame out light

7. Indicator light

8. Pressure gauge

9. Regulator adjusted

10. Shut off valve operates correctly

11. Vapor High-Limit

12. Unit cycles ON to OFF

13. Heat rise even across transition

14. Unit cycles HIGH to LOW (HIGH-LOW only)

15. Mod valve holds temperature within 1° (mod units only)

16. All decals and serial number tag

17. Aesthetic appearance

18. Manual

Tester Signature:

Date:_____________________________________

______________________________

2 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 3

Table of Contents

Contents

Chapter 1 Introduction .......................................................................................................................................... 4

Chapter 2 Safety ..................................................................................................................................................... 5

Safety Guidelines .................................................................................................................................. 5

Chapter 3 Decals .................................................................................................................................................... 6

Roof Damage Warning and Disclaimer ................................................................................................. 6

Chapter 4 Specifications ....................................................................................................................................... 9

Chapter 5 Installation .......................................................................................................................................... 11

Vertical Profile Angle Configuration .................................................................................................... 11

Deluxe Heater Electrical Installation ................................................................................................... 14

Deluxe Heater - Second Heater Installation ........................................................................................ 16

Fuel Connection .................................................................................................................................. 17

Liquid Propane Models .................................................... ... ... .... ... ... ... ... .... ... ...................................... 17

Propane Vapor Models ....................................................................................................................... 17

Natural Gas Models ............................................................................................................................ 17

Bin Configuration ................................................................................................................................. 18

Transition High-Limit Installation ......................................................................................................... 19

Plenum Thermostat Installation ........................ ............. ................ ................ ................ ...................... 20

Chapter 6 Operation ............................................................................................................................................ 21

Operating Temperature Table .......................... ... ... ... .... ... ... ... .... ... .......................................... ...... ...... 21

Cycling Heater Operation .................................................................................................................... 21

High-Low Heater Operation ................................................... .......................................... ... .... ...... ...... 22

Modulating Valve Operation ............................................................................................................. ... 23

BTU per Gauge Pressure - Propane ................................................................................................... 24

Gauge Pressure Required to Maintain Temperature Rise - Propane ................................................. 25

BTU per Gauge Pressure - Natural Gas ............................................................................................. 26

Gauge Pressure Required to Maintain Temperature Rise - Natural Gas ............................................ 27

Adjusting the Vaporizer ................................................................................................................. ... ... 28

Chapter 7 Service ................................................................................................................................................. 29

Seasonal Inspection and Service ........................................................................................................ 29

Chapter 8 Parts List ............................................................................................................................................. 31

Heater Housing: CHD-15 .............................................................................................................. ... ... 32

Heater Housing: CHD-30 and CHD-40 ............................................................................................... 33

Propane Vapor Pipe Train: All Models ................................................................................................ 34

Liquid Propane Pipe Train: All Models ................................................................................................ 35

Natural Gas Pipe Train: CHD-15 ......................................................................................................... 36

Natural Gas Pipe Train: CHD-30 and CHD-40 .......... .... ...................................... .... ... ... ... ... .... ............ 37

LP Supply Pipe Train .......................................................................................................................... 38

3/4" High-Low Pipe Train Option ......................................................................................................... 39

3/4" Modulating Pipe Train Option ................................................................................................... ... 40

1.0" Pipe Train Options: High-Low and Modulating ............................................................................ 41

Deluxe Heater Control Box ................................................................................................................. 42

Chapter 9 Test Fire Procedure ............................................................................................................................ 44

Test Firing Deluxe Burner Control ................................. ................... ................... .................... ............ 44

Chapter 10 Deluxe Heater Wiring Diagram ........................................................................................................ 45

Chapter 11 Miscellaneous Parts by Description ............................................................................................... 46

Chapter 12 Warranty ............................................................................................................................................ 49

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 3

Page 4

1. Introduction

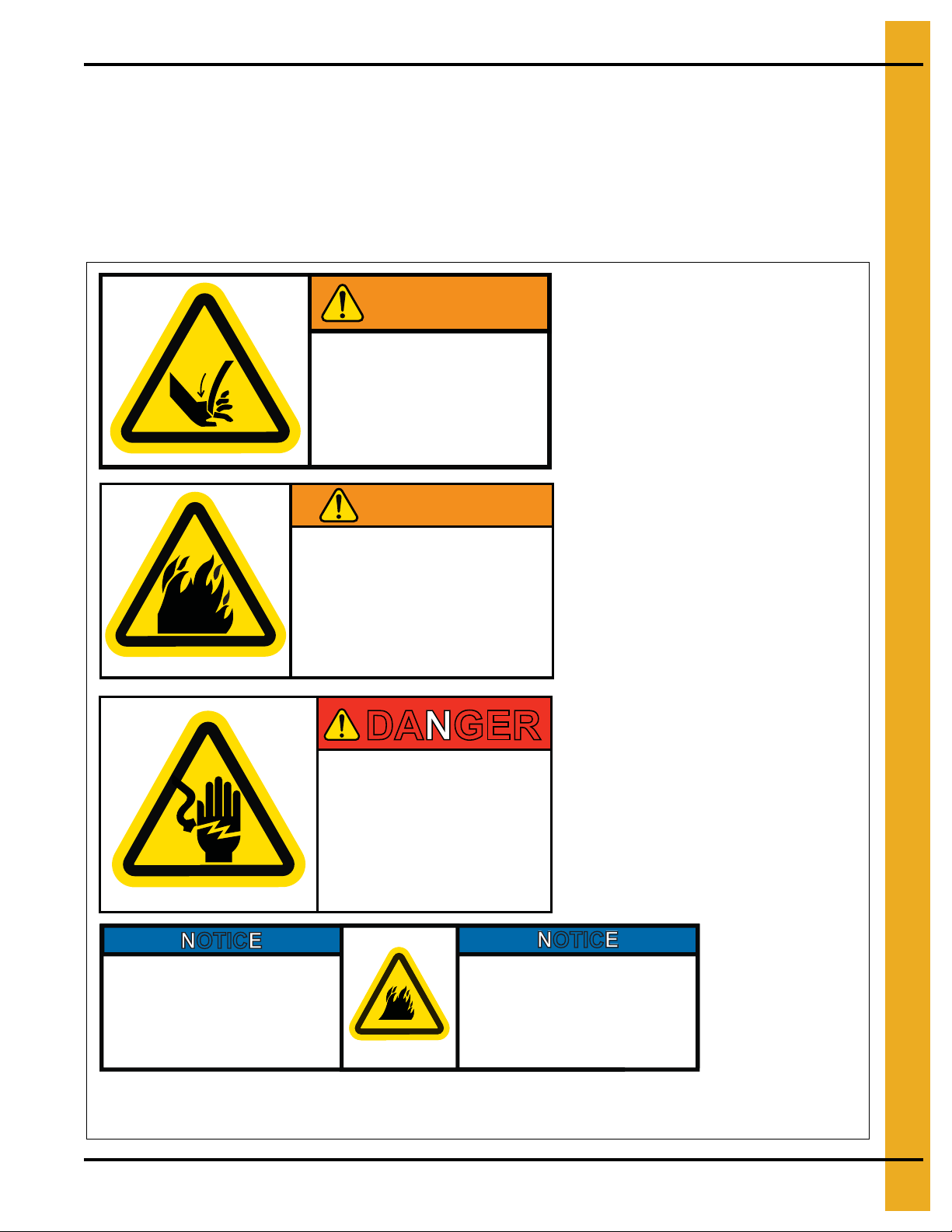

CAUTION

This product has sharp edges, which may cause serious injury. To avoid injury,

handle sharp edges with caution and always use proper protective clothing

and equipment.

Thank you for choosing a GSI Group product. It is designed to give excellent performance and service for

many years.

It is the plan of The GSI Group to improve its product whenever possible and practical to do so. We reserve

the right to change, improve and modify products at any time without obligation to make changes,

improvements and modifications on equipment sold previously.

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

THIS MANUAL DESCRIBES THE OPERATION OF THE CENTRIFUGAL DOWNWIND HEATER

DESIGNED FOR MEDIUM TO HIGH TEMPERATURE GRAIN CONDITIONING. ANY OTHER USE IS

CONSIDERED A MISUSE OF THE PRODUCT.

4 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 5

2. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 5

Page 6

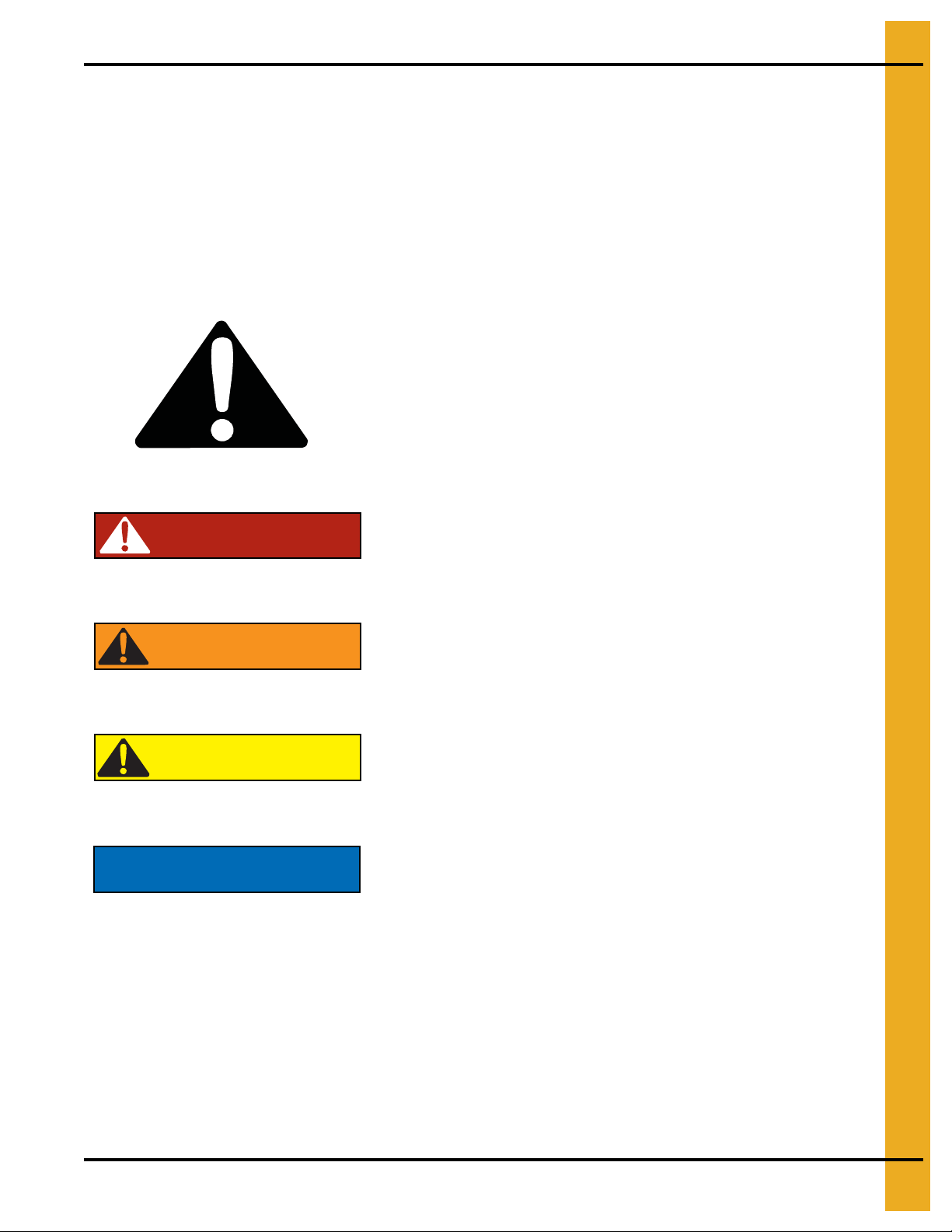

3. Decals

Excessive vacuum (or pressure) may

damage roof. Use positive aeration

system. Make sure all roof vents are

open and unobstructed. Start roof

fans when supply fans are started.

Do not operate when conditions exist

that may cause roof vent icing.

DC-969

CAUTION

GSI Group, Inc. 217-226-4421

Roof Damage Warning and Disclaimer

The manufacturer does not warrant any roof damage caused by excessive vacuum or internal

pressure from fans or other air moving systems. Adequate ventilation and/or “makeup air” devices

should be provided for all powered air handling systems. The manufacturer does not reco mmend

the use of downward flow systems (suction). Severe roof damage can result from any block age of

air passages. Running fans during high humidity/cold weather conditions can cause air exhaust

or intake ports to freeze.

6 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 7

3. Decals

Stay clear of rotating

blade. Blade could start

automatically. Can cause

serious injury. Disconnect

power before servicing.

DC-1225GSI Group 217-226-4421

WARNING

DANGER

HIGH VOLTAGE

Will cause injury

or death.

Lockout power

before servicing.

DC-889

GSI Group Inc. 217-226-4421

Thermostat must be installed for

operation.

Failure to do so may damage

equipment and cause fire.

DC-1702

NOTICE

NOTICE

Le thermostat doit être installé

pour fonctionner.

Omettre cette installation peut

endommager l’équipement et

provoquer un feu.

GSI Group 217-226-4421

Part #: DC-1225

Size: 4-7/8" x 2-1/4"

Located above access door on heater housing.

(See Note Below.)

Part #: DC-1227

Size: 4-7/8" x 2-1/4"

Located above access door on heater housing.

(See Note Below.)

NOTE: May be substituted with

DC-1559 combination decals.

Part #: DC-889

Size: 2.813" x 1.375"

Located inside control box.

Part #: DC-1702

Size: 1-1/2" x 3-1/4"

Located on the outside of the control box lid.

Safety decals should be read and understood by all people in the grain handling area. If a decal is

damaged or is missing contact:

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

A free replacement will be sent to you.

GSI Group 217-226-4421

WARNING

Flame and pressure beyond

door. Do not operate with

service door removed. Keep

head and hands clear. Can

cause serious injury.

DC-1227

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 7

Page 8

3. Decals

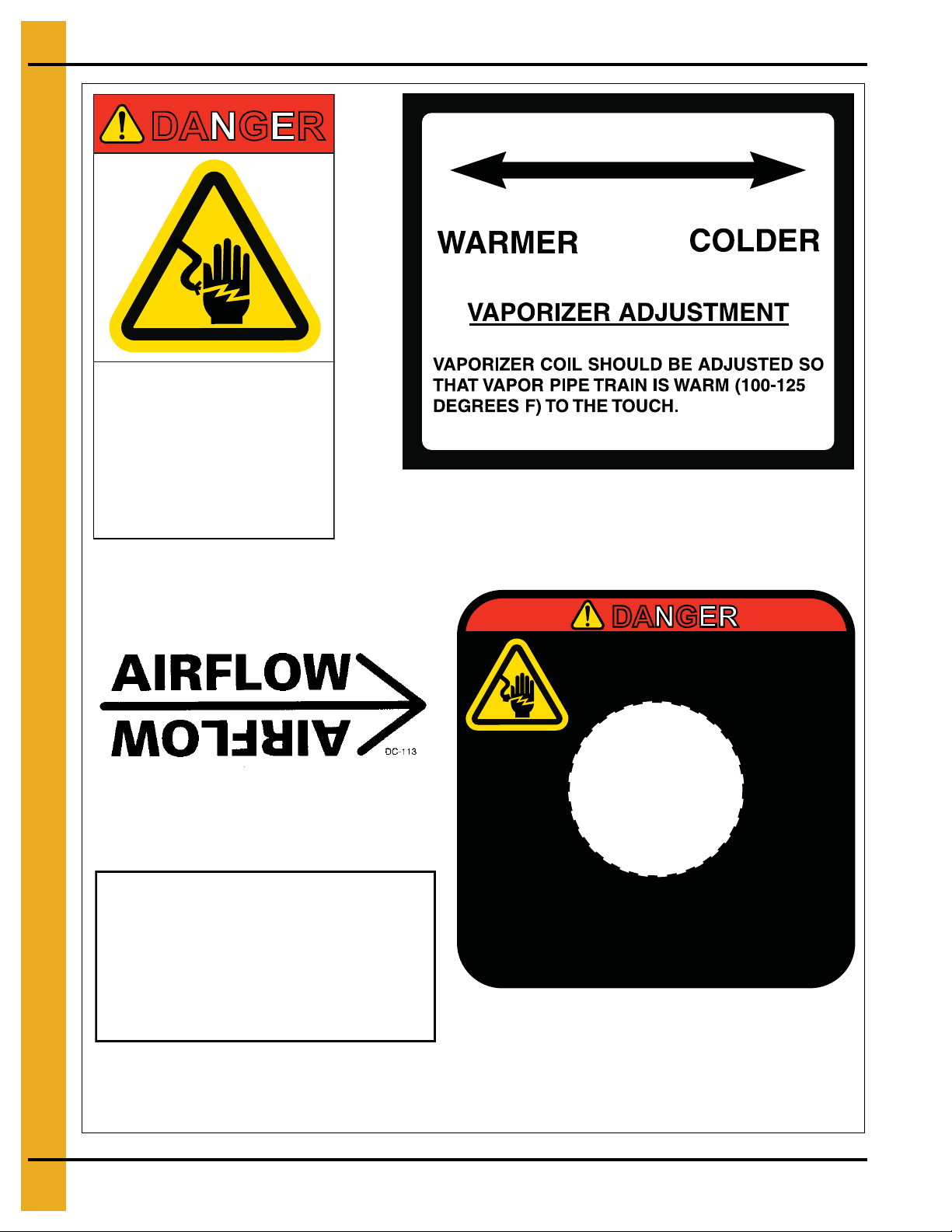

DANGER

DC-1224

High voltage.

Will cause serious

injury or death.

Lockout power

before servicing.

Part Number: DC-1224

Size: 2-5/8" x 4-5/8"

Located on the outside of the control box lid.

Part #: DC 113

Size: 4-3/4" x 1-5/8"

Located above access door on heater housing.

Part #: DC 1 165

Size: 3-1/4" x 3-1/4"

Located on the outside of the transition high-limit assembly.

DC-108

Hi-Limit

Reset Button

Part #: DC-108

Size: 1.0" x 2.0"

Located in control box next to housing high-limit switch.

DC-535

Part #: DC-535

Size: 2-1/2" x 3.0"

Located on the outside of the heater housing near

the vaporizer coil on LP units.

DANGER

HIGH VOLTAGE.

Will cause injury or death.

Lockout power before servicing.

HAUTE TENSION.

Causera des blessures ou la mort.

Fermez le courant avant l’entretien.

Remove plug to

reset high limit.

Enlevez le contact pour

reinitialiser la limite élévée.

DC-1165

8 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 9

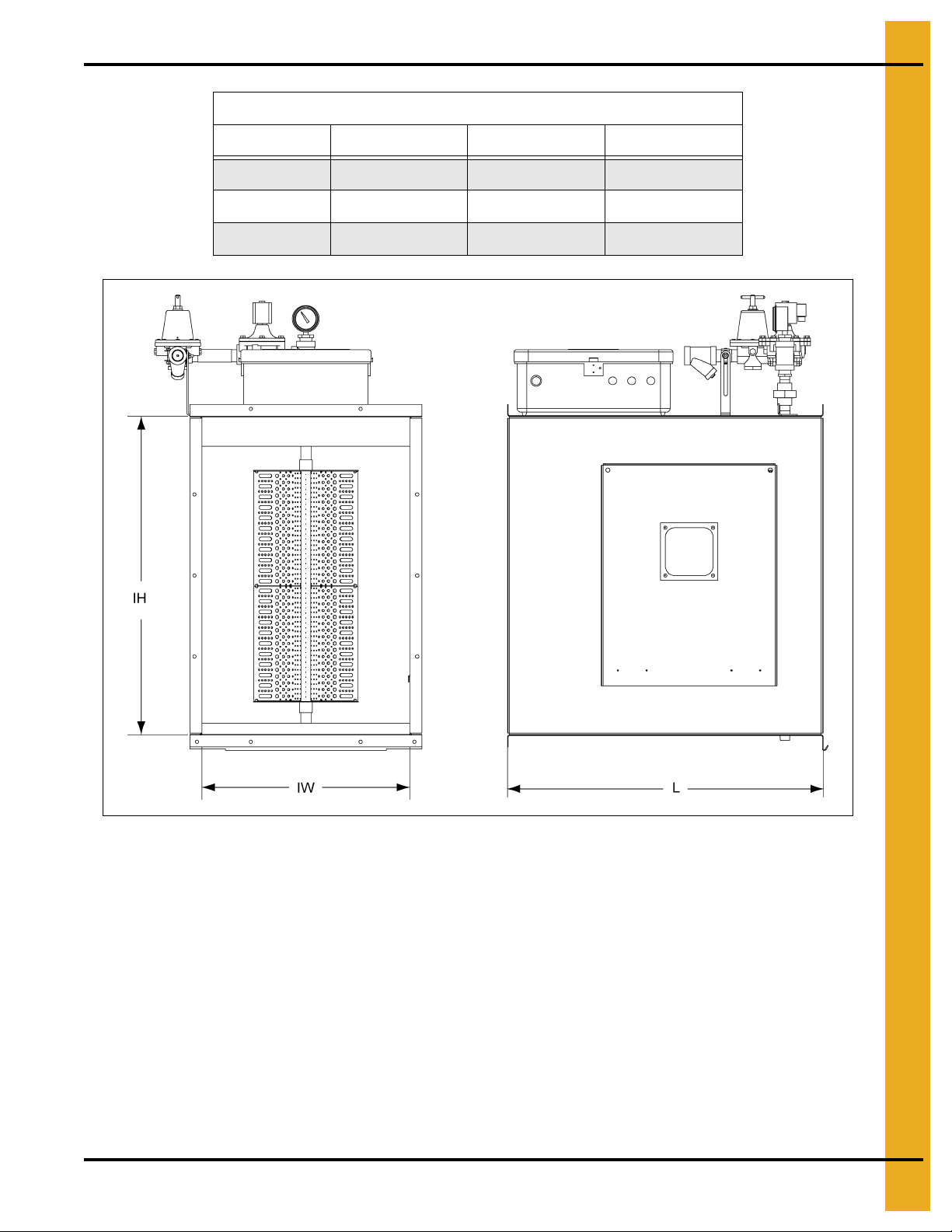

Heater Dimensions

Model # IH IW L

CHD-15 30-1/4" 19-1/2" 33.00"

CHD-30 33-1/4" 21-3/4" 33.00"

CHD-40 33-1/4" 23.69" 33.00"

4. Specifications

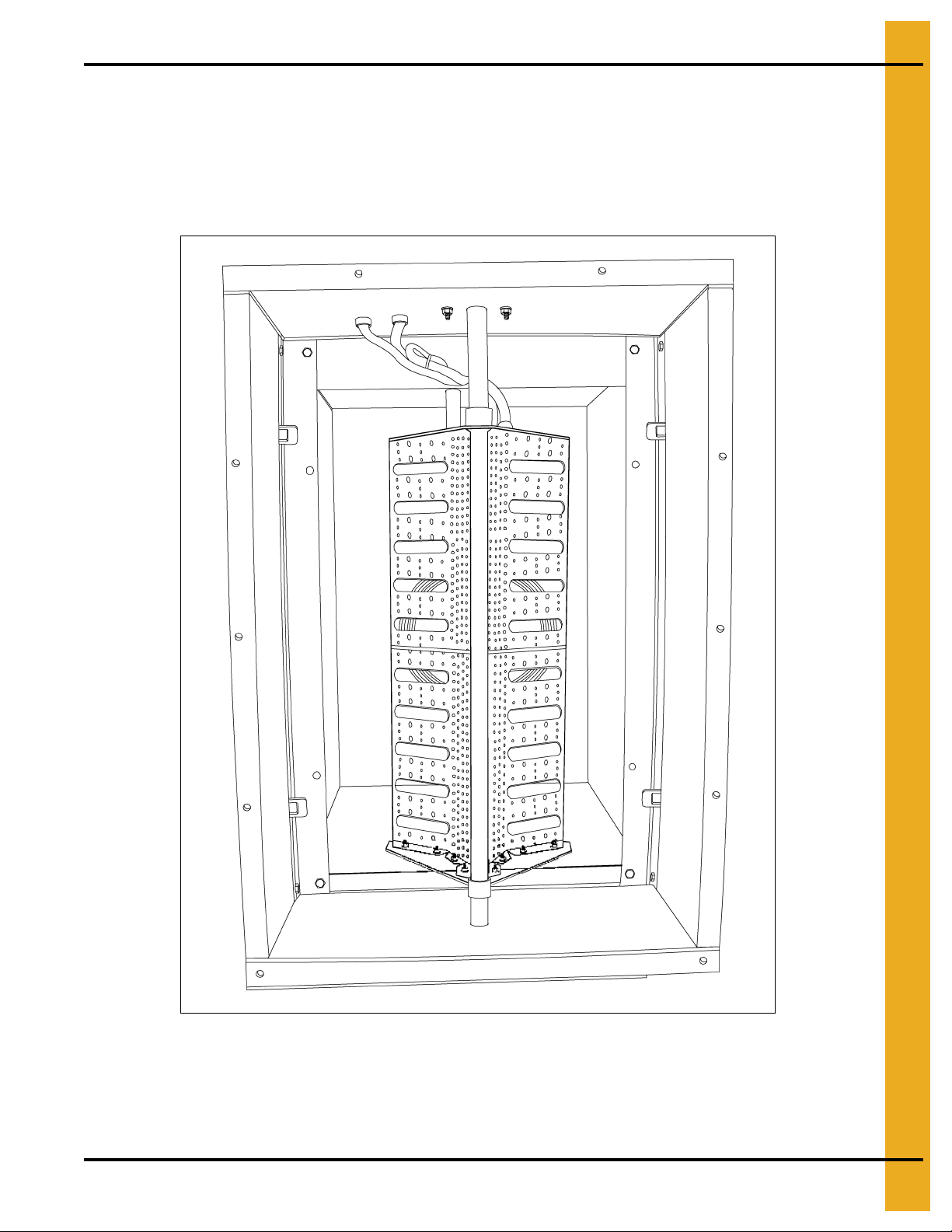

Figure 4A

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 9

Page 10

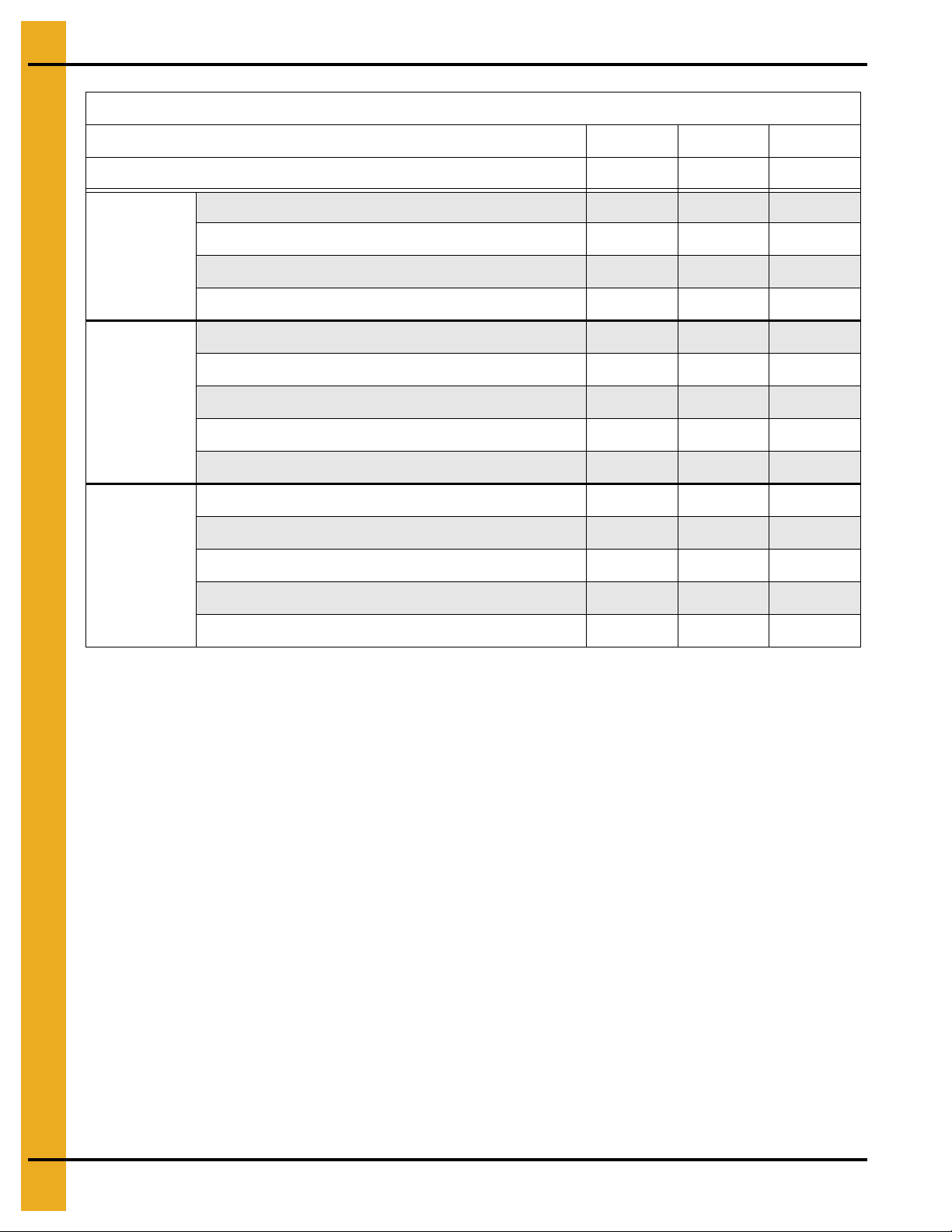

4. Specifications

Fuel Specifications and Recomme nd ati ons

Liquid

Propane

Models (LP)

Propane

Vapor

Models (VN)

Natural Gas

Models (VN)

Model #

BTU Rating

Orifice Size 7/32" 17/64" 5/16"

Operating Pressure Range, Heater Gauge Pressure (PSI) **

Typical Maximum Fuel Flow (GPH) * 25 36 46

Minimum Liquid Line Size 1/2" 1/2" 1/2"

Orifice Size 7/32" 17/64" 5/16"

Operating Pressure Range, Heater Gauge Pressure (PSI) **

Typical Maximum Fuel Flow (CFH) * 961 1379 1755

Minimum Line Size, 100' Run

Minimum Pressure to Heater at Connection (PSI) 20 20 20

Orifice Size

Operating Pressure Range, Heater Gauge Pressure (PSI) ** 1-7 1-7 1-7

Typical Maximum Vapor Fuel Flow (CFH) *

Minimum Line Size, 100' Run 1.0" 1.0" 1-1/4"

CHD-15 CHD-30 CHD-40

2,300,000 3,300,000 4,200,000

1-15 1-15 1-15

1-15 1-15 1-15

1.0" 1.0" 1-1/4"

21/64" 25/64" 7/16"

2212 3173 4038

Minimum Pressure to Heater at Connection (PSI)

* Maximum fuel flow rates listed assume full heat output for gas line sizing purposes. In normal operation, the fuel flow rates

would be substantially lower than indicated, due to actual pressure setting used and cycling of the burner.

** The gas pressures listed show the operating limits for each model heater and are not necessarily the recommended

operating pressure. The actual gas operating pressure should be within these limits, but will vary depending on the type

of grain and the drying system. The maximum setting assumes ideal conditions of relatively low static pressure conditions

with high fan airflow and good quality combustion. High static pressure conditions will require lower maximum gas pressure

setting than specified.

10 10 10

10 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 11

5. Installation

Vertical Profile Angle Configuration

Vertical profile angles have been added to the Downwind Centrifugal Heaters to increase burner

performance quality. These angles have been factory installed with the angle configuration of the smallest

horsepower fan rated for the heater. As a result, some changes will be require d at the time o f installation

once the fan and heater combination is known. This document describes the proper configurations of the

vertical angles inside the heater housing.

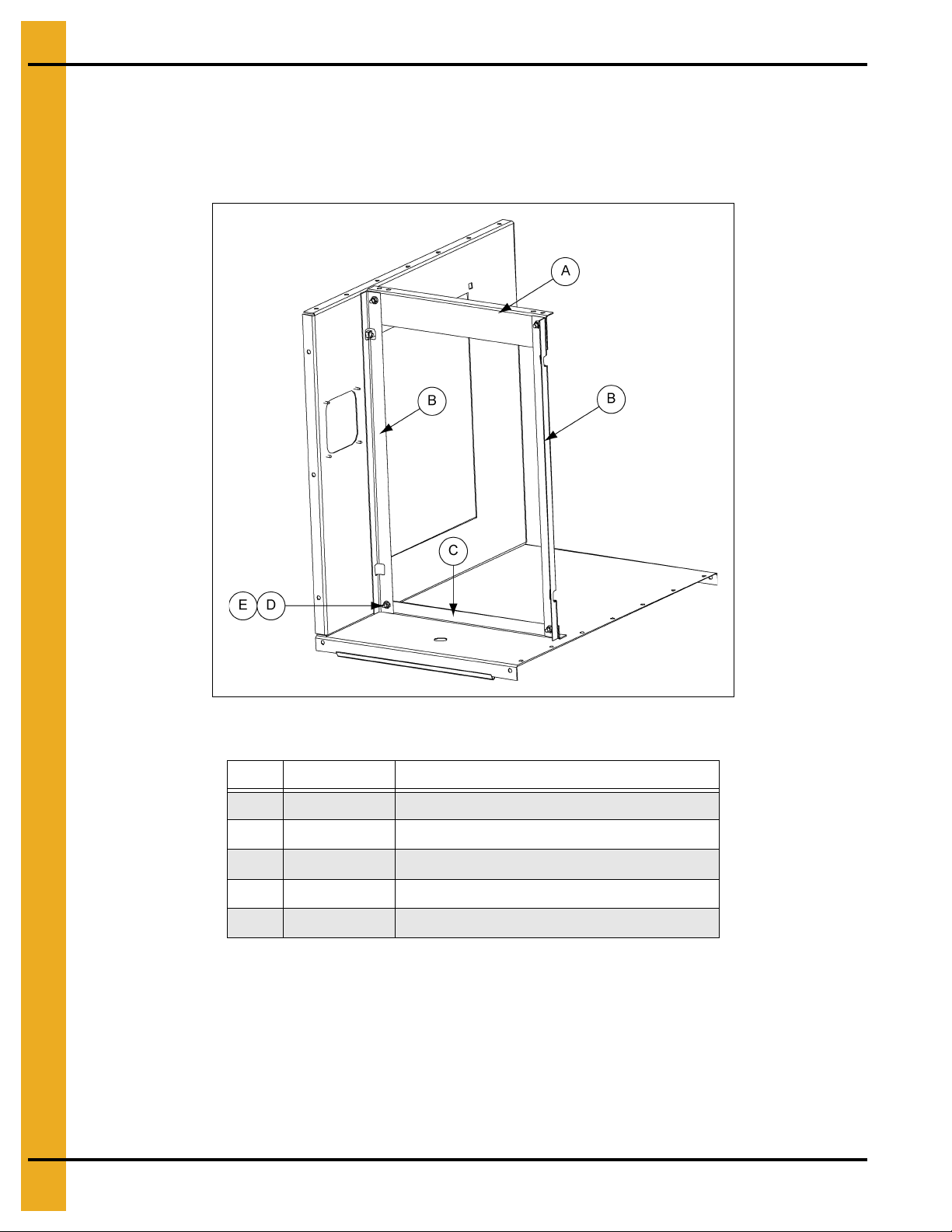

Figure 5A

IMPORTANT: Use of the vertical profile angles requires that the upper and lower pro file angles have their

90° bend on the window side of the heater as shown in Figure 5A.

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 11

Page 12

5. Installation

CF-10 Centrifugal Fan and CHD-15 Model Heater

Figure 5B shows the factory configuration. No change is required to the heater.

Retrofit applications require holes to be drilled in the upper and lower profile angles and the vertical angle

to be installed with the noted hardware.

Figure 5B CHD-15 Heater

Ref # Part # Description

A Upper Angle

B HF-8076 Profile Angle - Side for CHD-15 (2)

C Lower Angle

D S-3611 Flange Nut 5/16"-18 YDP Grade 2 (4)

E S-6606 Flange Bolt 5/16"-18 x 3/4" ZN Grade 5 (4)

CF-15 Centrifugal Fan and CHD-15 Model Heater

The vertical profile angles must be removed for correct operation of the heater.

12 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 13

5. Installation

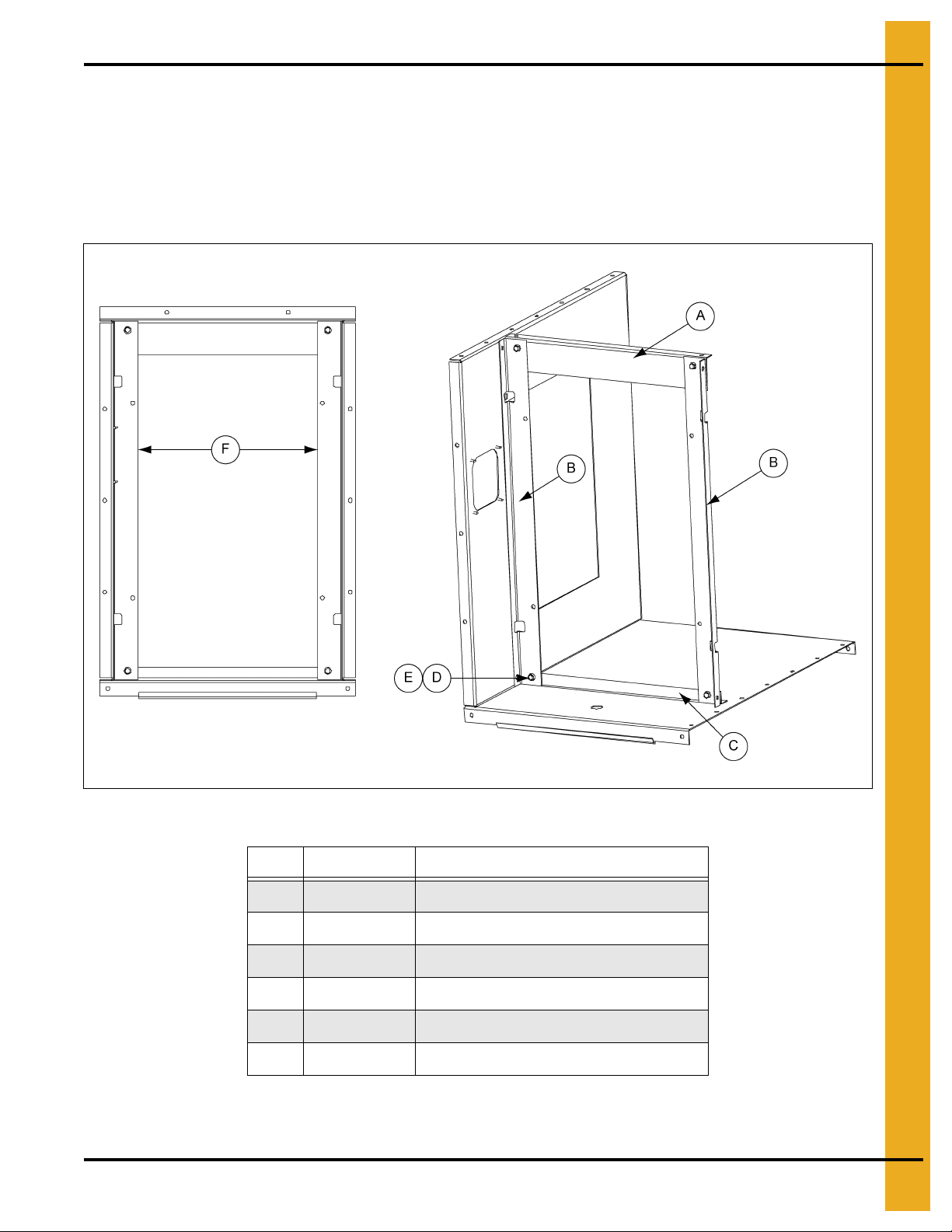

CF-20 Centrifugal Fan and CHD-30 Model Heater

Figure 5C shows the factory configuration for the 20 HP application. Here the long leg of the angle points

toward the center of the heater to provide a 17" wide opening across the housing at the location of the

angles. No change is required to the heater.

Retrofit applications require holes to be drilled in the upper and lower profile angles and the vertical profile

angles to be installed with the noted hardware.

Figure 5C CHD-30 Heater for CF-20 Fan

Ref # Part # Description

A Upper Angle

B HF-8071 Profile Angle - Side for CHD-30 (2)

C Lower Angle

D S-3611 Flange Nut 5/16"-18 YDP Grade 2 (4)

E S-6606 Flange Bolt 5/16"-18 x 3/4" ZN Grade 5 (4)

F 17"

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 13

Page 14

5. Installation

Always disconnect and lock out power before working on or around heater.

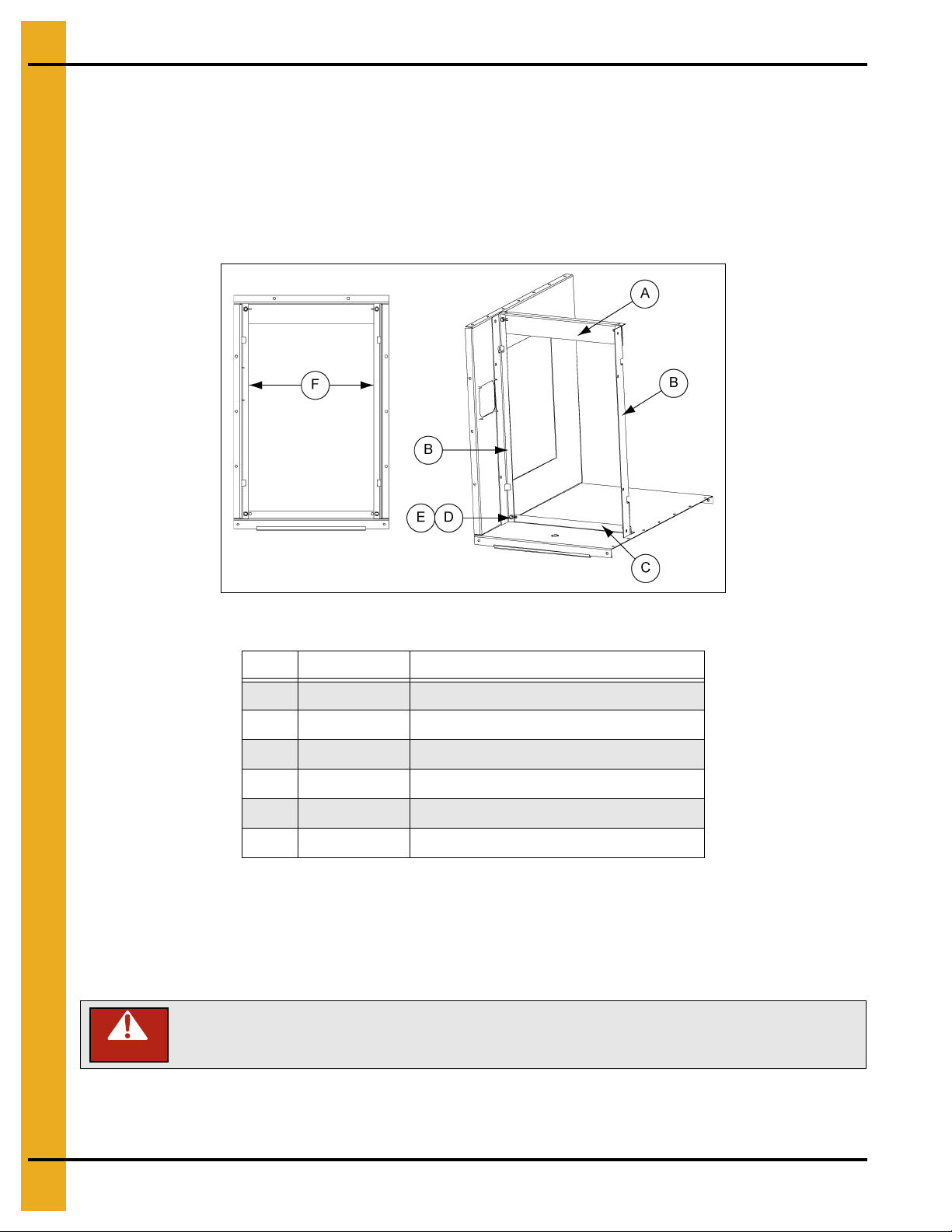

CF-25 Centrifugal Fan and CHD-30 Model Heater

Figure 5D shows the configuration for the 25 HP application. The vertical profile angles must be

repositioned. Flip each angle end for end and install it with the short leg of the angle pointing toward the

center of the heater. This provides a 19-1/2" wide opening across the heater housing at the location of

the angles.

Retrofit applications require holes to be drilled in the upper and lower profile angles and the vertical profile

angles to be installed with the noted hardware.

Figure 5D CHD-30 Heater for CF-25 Fan

Ref # Part # Description

A Upper Angle

B HF-8071 Profile Angle - Side for CHD-30 (2)

C Lower Angle

D S-3611 Flange Nut 5/16"-18 YDP Grade 2 (4)

E S-6606 Flange Bolt 5/16"-18 x 3/4" ZN Grade 5 (4)

F 19-1/2"

CF-30 Centrifugal Fan and CHD-30 Model Heater

The vertical profile angles must be removed for correct operation of the heater.

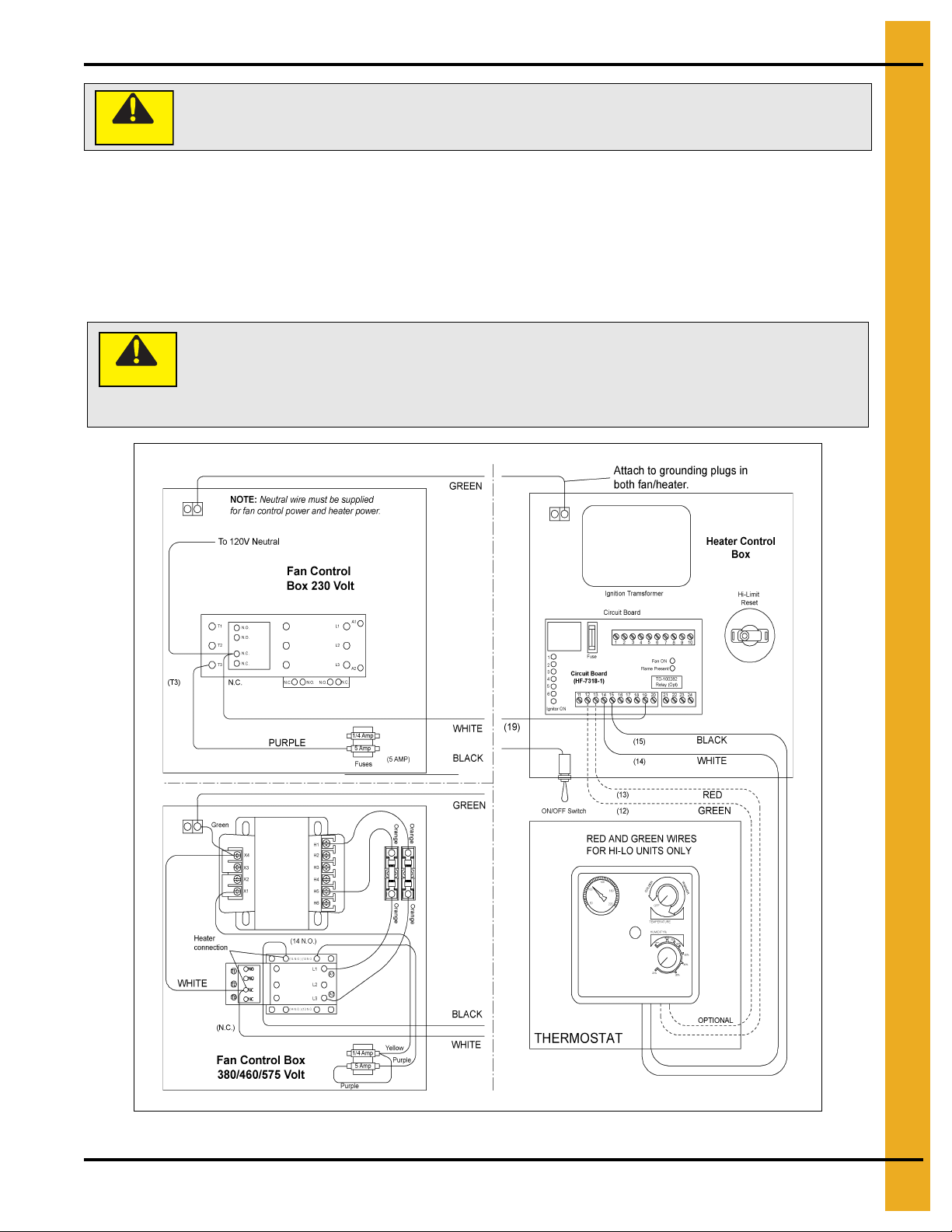

Deluxe Heater Electrical Installation

DANGER

Standard electrical safety practices and codes should be used when working with a heater. Refer to the

National Electric Code Standard handbook by the National Fire Protection Association. A qualified

electrician should make all wiring installations.

14 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 15

Heater Power Connection

CAUTION

Heater must be interlocked with fan for safe operation.

Thermostat must be installed for safe operation.

Heater power is 120 VAC. Damage will occur if connected to high voltage

power source.

1. Connect power cord to fan control box.

2. Make field connections in fan box as shown in Figure 5E.

3. Connect deluxe thermostat control as shown in Figure 5E.

NOTE: Heater control is 120V only.

CAUTION

5. Installation

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 15

Figure 5E

Page 16

5. Installation

Deluxe Heater - Second Heater Installation

For Deluxe Units Using HF-7318-1 Control Board

Two (2) Deluxe Heaters may be connected to one grain drying system and wired so they cycle together.

One of the heaters should have a thermostat connected to it as per the installation instructions. That

heater will be referred to as the master. The other heater (without the thermostat) will be referred to

as the slave.

Installation for ON/OFF Units

1. Install relay base (TD-100283) in master heater control box.

2. Connect wire between terminal 6 on circuit board and terminal 14 on relay base in master heater.

3. Connect wire between terminal 13 on relay base and terminal 8 on circuit board in master heater.

4. Run two (2) wires (18 gauge) between master and slave heaters.

5. Connect wires to terminal 5 and 9 (points A and B) on relay base in master heater.

6. Connect wire from terminal 9 in master to terminal 14 (point F) in slave unit.

7. Connect wire from terminal 5 in master to terminal 15 (point E) in slave unit.

8. Install relay (TD-100282) in relay base.

Additional Steps for High-Low Units

1. Run two (2) wires (18 gauge) between master and slave unit.

2. Connect wires to terminals 21 and 22 (points C and D) on circuit board in main heater.

3. Connect wire from terminal 21 in master to terminal 12 (point H) in slave unit.

4. Connect wire from terminal 22 in master to terminal 13 (point G) in slave unit.

5. Install relay (TD-100282) in relay base.

Figure 5F The Control Board (HF-7318-1)

16 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 17

5. Installation

Do not use propane tanks which have previously been used for ammonia unless

they have been purged according to procedures of the national LP association.

Investigate to be sure that the fuel supply sys tem complies with all loca l codes for

LP gas installations.

CAUTION

Do not use flame for leak testing.

Fuel Connection

Liquid Propane Models

1. LP models are designed to run on liquid propane, with liquid draw from the propane tank. Avoid using

propane supply tanks that have been use for vapor draw for long pe riods of time. When u sing liquid

draw systems any moisture that may be present in tank or lines may freeze when system is used in

cold weather. To avoid this, the usual precaution is to purge the system with methanol.

2. Run proper size line (See Specifications on Page 9) to pipe train on heater. Have a qualified gas

service person inspect installation to be sure everything is installed according to local codes

and ordinances.

3. After installation is complete, check all connections for leaks. Use liquid detergent or comparable

substance. Wear rubber gloves and eye protection. Avoid contact with liquid propane.

DANGER

Propane Vapor Models

1. Propane vapor models are designed to run directly off of supply tank or from a separate

external vaporizer.

2. Run proper size line (See Specifications on Page 9) to pipe train on heater. Have a qualified gas

service person inspect installation to be sure everything is installed according to local codes

and ordinances.

3. After installation is complete, check all connections for leaks.

Natural Gas Models

1. Natural gas models are similar to vapor models, but have a larger orifice to accommodate lower

pressure, sometimes found with natural gas.

2. Run proper size line (See Specifications on Page 9) to pipe train on heater. Have a qualified gas

service person inspect installation to be sure everything is installed according to local codes

and ordinances.

3. After installation is complete, check all connections for leaks.

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 17

Page 18

5. Installation

Bin Configuration

Figure 5G

Ref # Description

A Unload Auger

B Plenum Thermostat

C Master Heater

D Slave Heater

IMPORTANT: When mounting two (2) heaters on a bin it is imperative that they be situated as shown in

Figure 5G. Plenum thermostat must be to the right of master heater and master heater must

be to the right of slave heater.

18 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 19

Transition High-Limit Installation

1. Mark location on transition one foot up from the bottom (entrance collar) and centered in

the transition.

2. Drill or knock out 7/8" diameter hole on marked location.

3. Install transition high-limit using supplied self-drilling screws.

5. Installation

Figure 5H Sensor placement on transition connecting heater to the bin.

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 19

Page 20

5. Installation

CAUTION

Thermostat must be installed to operate as plenum high-limit safety.

Plenum Thermostat Installation

The plenum thermostat must be ordered separately from the heater unit.

1. Follow installation instructions provided with the thermostat assembly.

2. Position the housing so that the bolt flanges are vertical and the cord exits the housing from the

bottom. Mark position.

3. Use six (6) (4.00") or eight (8) (2.66") self-drilling screws to mount the housing to the bin sidewall.

DO NOT TIGHTEN COMPLETELY. Insert corrugation seal into gap between housing and sidewall.

Tighten screws.

4. Caulk between the housing and the sidewall to seal.

Heater control device (thermostat or humidistat) is required for heater warranty on all heaters.

Figure 5I Plenum thermostat mounted on bin wall.

Figure 5J Side view of thermostat showing

corrugation seal.

20 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 21

6. Operation

CAUTION

Do not exceed plenum temperatures listed in table

Do not operate above rated maximum BTU output. Fire damage to grain product

and drying structure will occur. Refer to burner specifications for maximum BTU.

Operating Temperature Table

NOTE: This table is not intended as a d rying guide. It should be used as a reference for setting maximum

plenum temperature for safe operation.

Grain

Corn

Rice

Beans and

Wheat

Low Temperature

Batch

5-20°Above

Ambient Temperature

5-10°Above

Ambient Temperature

5-20°Above

Ambient Temperature

High Temperature

Batch Dry No Stirring

120° 140° 140°

100° 100° Not Recommended

110° 120° Not Recommended

High Temperature

with Stirring

CAUTION

Cycling Heater Operation

1. Thermostat must be wired into heater control box for heater to operate.

Continuous Flow

(Recirculating)

2. Open all manual shut off valves to heater unit.

3. Start fan. This will supply power to heater.

4. Turn thermostat dial to its highest setting.

5. Turn toggle switch ON.

6. Heater should now be lit. If not check to see that all gas is ON.

7. Watch thermometer on plenum and when it reaches desired temperature turn thermostat back slowly

until heater cycles OFF.

8. Gas pressure should be adjusted, so burner is on 75% of the time.

9. Watch plenum temperature as burner goes through a few cycles, to be sure that it is

operating properly.

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 21

Page 22

6. Operation

High-Low Heater Operation

1. High-limit and cycling thermostat must be wired into heater control box for heater to operate.

2. Open all manual shut off valves to heater unit.

3. Start fan. This will supply power to heater.

4. Turn thermostat dial to its highest setting.

5. Turn toggle switch ON. Both indicator lights should illuminate indicating power to the control circuit.

6. Heater should now be lit. If not check to see that all gas is ON.

7. Loosen the retaining nut holding bypass valve screw in place. Open the bypass valve all the way.

8. Turn thermostat dial back slowly until heater cycles to low flame.

9. Adjust bypass valve so that low-flame pressure is at desired setting. (As low as possible.)

10. Turn thermostat dial to desired setting and wait for bin plenum to come up to temperature. Heater

should cycle to low flame after a few minutes.

11. If heater does not cycle to low flame increase high flame gas pressure by adjusting the regulator.

12. High flame should be adjusted, so the heater cycles at least once a minute. Low flame should be

adjusted so there is enough flame for unit to keep operating.

13. Watch as burner goes through a few cycles, to be sure that it is o perating properly back to high flame.

Figure 6A

Ref # Description

A Bypass Valve

B Retaining Nut

C Bypass Valve Screw

22 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 23

6. Operation

Modulating Valve Operation

1. The modulating valve regulates gas flow through the heater based on sensing unit in the plenum and

maintains a constant drying air temperature.

2. The sensing bulb of the modulating valve should be mounted through the bin wall with the side

reading “top” up. The bulb reacts to temperature. It changes the amount of gas (increase or

decrease), burning warmer or cooler depending on the position of the valve SET POINT. If the bulb

is cooler than it was at the SET POINT, the bulb senses the cooler temperature and opens the valve

further so more heat is applied to the drying air. If the bulb is warmer than it was at the SET POINT,

the valve closes further and reduces the temperature until the air is at the valve SET POINT.

3. It is important that the pressure regulator be set high enough to allow the modulating valve to deliver

enough gas to maintain the plenum temperature necessary. The regulat or is normally factory set at

15 PSI (propane units). To set the regulator, run the heater and turn the mo dulating valve T-handle

in. This gets full line pressure to the burner. Then adjust regulator to read 15 PSI (depending on the

plenum temperature needed).

4. Turn the fan and heater ON. To set the modulating valve, turn the T-handle out (counterclockwise)

until loose and wait a few minutes for the plenum temperature to equalize. When the temperature

under the bin has equalized, gradually turn T-handle in (clockwise) about 1/2 turn at a time. Wait until

temperature under bin has equalized as before. If temperature under bin is less than the desired

temperature, continue turning T-handle in, increasing gas flow and waiting for plenum temperature

to equalize until the desired temperature is the stable temperature of the plenum. If temperature

under bin is the same 10 minutes after you last made any adjustments to the T-handle you can be

certain that the temperature under the bin is the SET POINT of the valve. 1 Turn of the T-handle

equals approximately 7°F of temperature.

5. The valve will now keep the plenum temperature at the set point regardless of ambient conditions as

long as humidistat or thermostat do not shut down the heater. A bypass orifice is used to maintain a

small flame when outside temperature is near or above the set point of the valve. The bypass insures

steady application of heat at minimum gas flow operation. By pass orifice will only operate correctly

if pressure regulator is set correctly.

6. To observe how the modulating valve increases the efficiency of bin drying, check the gas pressure

of the unit in the morning and compare to the pressure read mid-afternoon. If the ambient (outside)

temperature is significantly greater later in the day (as normal), the ga s p r essure will be less. Sin ce

less heat is required to maintain the same temperature in the plenum, the modulating valve will have

reduced the amount of gas used by the heater.

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 23

Page 24

6. Operation

BTU per Gauge Pressure - Propane

BTU Per Gauge Pressure - Propane (Approximate)

Gauge Pressure (PSI) 10-15 20-30 40-50

1 576,713 847,122 1,174,963

2 816,013 1,203,679 1,663,135

3 997,881 1,469,302 2,034,050

4 1,148,640 1,694,244 2,345,140

5 1,287,434 1,895,256 2,622,728

6 1,409,477 2,077,124 2,878,779

7 1,524,341 2,244,634 3,108,507

8 1,632,026 2,404,965 3,328,663

9 1,725,353 2,541,366 3,520,103

10 1,825,859 2,687,339 3,721,115

11 1,995,762 2,938,604 4,068,100

12 2,153,700 3,173,118 4,393,548

13 2,227,883 3,280,803 4,541,914

24 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 25

6. Operation

Gauge Pressure Required to Maintain Temperature Rise - Propane

Gauge Pressure (PSI) Required to Maintain Temperature Rise (Approximate)

Propane - High Temperature Units Only

Fan Model

10

15

20

25

Static Pressure

(Inches)

2 2 4 6 8 11

4 23569

6 2 2 3 5 6

2 36911

4 3 5 7 10 13

6 23579

2 3 4 6 9 11

4 245710

6 2 3 4 6 8

2 46913

4 3 5 8 11 15

6 346911

60 80 100 120 140

Heat Rise °F

30

40

50

2 4 7 10 15

4 46913

6 3 5 8 11 15

2 36911

4 3 5 8 11 13

6 347913

2 4 6 9 13

4 3581115

6 3 5 7 10 13

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 25

Page 26

6. Operation

BTU per Gauge Pressure - Natural Gas

BTU Per Gauge Pressure - Natural Gas (Approximate)

Gauge Pressure (PSI) 10-15 20-30 40-50

1 893,360 1,264,640 1,587,040

2 1,266,720 1,794,000 2,250,560

3 1,548,560 2,192,320 2,750,800

4 1,785,680 2,529,280 3,173,040

5 1,996,800 2,827,760 3,548,480

6 2,191,280 3,102,320 3,891,680

7 2,367,040 3,351,920 4,204,720

26 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 27

Gauge Pressure Required to Maintain Temperature Rise Natural Gas

Gauge Pressure (PSI) Required to Maintain Temperature Rise (Approximate)

Natural Gas - High Temperature Units Only

6. Operation

Fan

Model

10

15

20

25

Static Pressure

(Inches)

2 1 2 3 4 5

4 12234

6 1 1 2 2 3

2 23457

4 1 2 3 4 6

6 12234

2 1 2 3 4 5

4 12345

6 1 2 2 3 4

2 2346

4 2 3 4 5 7

6 12346

60 80 100 120 140

Heat Rise °F

30

40

50

2 2 3 5 7

4 2346

6 2 3 4 5 7

2 2357

4 2 3 4 6

6 23457

2 2 4 5 7

4 2356

6 2 3 4 5 7

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 27

Page 28

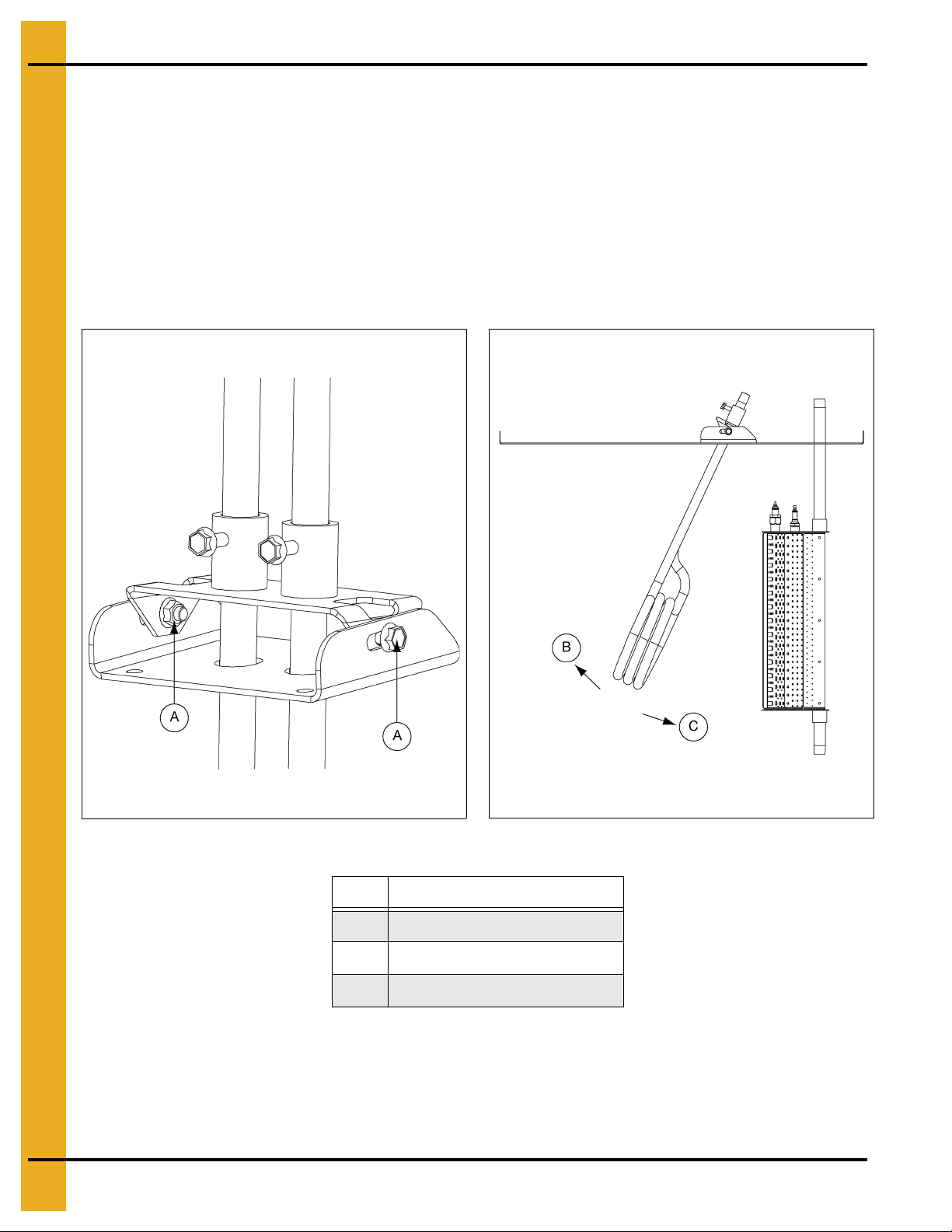

6. Operation

Adjusting the Vaporizer

1. Vaporizer should be adjusted so the vapor pipe train runs warm to the touch (100°-120°F).

2. Loosen 5/16" pivot bolts on adjustment bracket.

3. Tilt vaporizer away from burner to cool. Tilt toward burner to heat. Vaporizer may be raised or lowered

for vertical adjustments.

4. Tighten 5/16" pivot bolts to fix vaporizer position.

IMPORTANT: Only move vaporizer 1" at a time. Allow heater to run a few minutes for temperature

to equalize.

Figure 6B

Ref # Description

A Pivot Bolts

BCooler

C Warmer

Figure 6C

Vaporizer adjustment: Away from burner to cool. Toward burner to heat.

28 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 29

7. Service

Seasonal Inspection and Service

All parts are made of weather-proof construction and are designed to require a minimum of service;

however, we recommend the following items be checked and serviced, as described, before the unit is

used each season. Replace any damaged or questionable parts.

THESE CHECKS WILL HELP ELIMINATE POSSIBLE MINOR FAULTS AND ASSURE DEPENDABLE

OPERATION OF THE EQUIPMENT WHEN IT IS NEEDED.

1. Check fan and service it as described within the fan installation and operation manual.

2. Shut off electrical power. Remove heater control box cover and inspect for moisture, rodent damage

or accumulated foreign material remove any foreign material present. INSPECT AND TIGHTEN ALL

LOOSE TERMINAL CONNECTIONS. Replace any damaged or deteriorated wiring.

3. Shut off fuel and remove and clean gas line strainer.

4. Remove the orifice from the burner venturi and inspect for obstructions. Also, inspect and clean out

the burner venturi and the ports within the burner cup. Blow out with compressed air or disassemble

and thoroughly clean these parts. Foreign material in the venturi or burner cup will impair heater

operation and cannot be expected to burn out when the heater is started.

5. Inspect and clean the electrodes on the ignitor plug. Use an ignition point file to remove carbon and

rust between the electrode surfaces.

6. Inspect flame rod and ignitor plug wires for possible damage or poor connections.

7. After completing all checks and performing any necessary service, check the control device, as

described under the following appropriate heading.

Heaters Equipped with a Humidistat Control

Temporarily remove humidistat control from air plenum chamber of bin. Rotate the knob through the

20% to 80% humidity range. The switch within the humidistat should produce a small “click” when the le ver

passes the point of prevailing humidity.

NOTE: For additional information, refer to instructions that accompanied the humidistat.

Heaters Equipped with a Thermostat Control

Slowly rotate the thermostat dial through its temperature range. The switch within the thermostat should

produce a small “click” when the dial passes the point of prevailing temperature. Set the dial to a setting

at least 10°F above the prevailing temperature and proceed to the next step.

8. Test operate the fan and heater. Make sure to follow operating instructions, INCLUDING. After fan

starts operating and the heater purge interval has elapsed (approximately 20 seconds delay), the

heater should come ON and start operating.

9. Slowly change the humidistat or thermostat setting and cycle the heater OFF and ON to make sure

the device is controlling the heater and is operating properly.

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 29

Page 30

7. Service

10. LP MODELS ONLY - After heater has been operating for some time and temperatures have

stabilized, check temperature of the gas line between outlet side of vaporizer and the gas regulator.

If gas line becomes “frosted” with an accumulation o f ice build-u p, adjust vaporize r slightly closer to

the flame. If line reaches a high temperature where it is hot to the touch, adjust vaporizer further away

from the flame.

NOTE: If gas temperature exceeds approximately 220°F, the vapor high-limit thermostat will

open the electrical circuit to the liquid gas solenoid valve and shut off fuel flow to stop the

heater. This condition can be verified by temporarily connecting a jumper wire across the

connections of the high-limit and observing that the burner re-lights. If high-limit vapor

thermostat causes the burner to stop operating, it may also cause the burner to go into a

safety lock out condition. Refer to heater operating instructions for restarting procedure.

11. Vaporizers should be inspected and serviced prior to each season of operation, including

the following:

a. Carefully inspect the surfaces of the vaporizer coil and the inlet and vapor outlet pipes for

evidence of severe corrosion or abrasion of metal which could cause subsequent leakage of

liquid propane, gross overheating and fire hazard.

b. Insecure mounting of either the vaporizer or burner, due to loosened bolts, can cause interference

between burner vanes and vaporizer pipes, with the natural vibration of the unit causing erosion

of the pipe metal at the point of maintained contact.

c. If there has been significant abrasion of the steel vaporizer pipe, it must be replaced.

12. When satisfied that heater is operating properly, make sure to reset the control d evice to the p roper

setting and restore the fan and heater for normal type operation.

IMPORTANT: Use care when troubleshooting this product. Limit exposure to potential hazards by

following all recommended safety practices.

30 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 31

1. Heater Housing: CHD-15 - (See Page 32.)

2. Heater Housing: CHD-30 and CHD-40 - (See Page 33.)

3. Propane Vapor Pipe Train: All Models - (See Page 34.)

4. Liquid Propane Pipe Train: All Models - (See Page 35.)

5. Natural Gas Pipe Train: CHD-15 - (See Page 36.)

6. Natural Gas Pipe Train: CHD-30 and CHD-40 - (See Page 37.)

7. LP Supply Pipe Train - (See Page 38.)

8. 3/4" High-Low Pipe Train Option - (See Page 39.)

8. Parts List

9. 3/4" Modulating Pipe Train Option - (See Page 40.)

10. 1.0" Pipe Train Options: High-Low and Modulating - (See Page 41.)

11. Deluxe Heater Control Box - (See Pages 42-43.)

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 31

Page 32

8. Parts List

Heater Housing: CHD-15

Heater Housing: CHD-15 Parts List

Ref # Part # Description

1 HF-7653 Downwind Housing Bottom: 10-15

2 HF-7654 Downwind Housing Side: R.H. 10-15

3 HF-7652 Downwind Housing Top: 10-15

4 HF-7655 Downwind Housing Side: L.H. 10-15

5 HF-7854 Access Panel Downwind Heater - Blank

6 HF-7287 Access Panel Bracket - Downwind Heaters

7 HF-7379 Heater Cover Plate 1996<

8 HF-7380 Window Access 0.060 x 6 x 6 Plastic

9 HF-7662 Downwind Housing Profile Bottom: 10-15

10 HF-7661 Downwind Housing Profile Top: 10 -15

11 401-5369-4 Burner Mounting Bracket - CFDH

12 HF-7796 Cover Plate - Downwind Vaporizer Hole

13 415-4312-5 Burner Sub-Assembly CFDH27

14 THH-4179 Flame Sensor 6" Long Rod

15 HH-1650 Spark Plug Auburn #I-31

32 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 33

Heater Housing: CHD-30 and CHD-40

8. Parts List

Heater Housing: CHD-30 Parts List Heater Housing: CHD-40 Parts List

Ref # Part # Description Ref # Part # Description

1 HF-7781 Downwind Housing Bottom: 20-30 1 HF-7803 Downwind Housing Bottom: 40

2 HF-7783

3 HF-7780 Downwind Housing Top: 20-30 3 HF-7802 Downwind Housing Top: 40

4 HF-7784

5 HF-7854 Access Panel Downwind Heater - Blank 5 HF-7854 Access Panel Downwind Heater - Blank

6 HF-7287

7 HF-7379 Heater Cover Plate 1996< 7 HF-7379 Heater Cover Plate 1996<

8 HF-7380

9 HF-7786 Downwind Housing Profile Bottom: 20-30 9 HF-7805 Downwind Housing Profile Bottom: 40

10 HF-7785

11 401-5369-4 Burner Mounting Bracket - CFDH 11 401-5369-4 Burner Mounting Bracket - CFDH

12 HF-7796

13 415-4434-7 Burner Sub-Assembly CFDH30/33 13 415-4434-7 Burner Sub-Assembly CFDH30/33

14 THH-4179

Downwind Housing Side: R.H. 20-30/40 2 HF-7783 Downwind Housing Side: R.H. 20-30/40

Downwind Housing Side: L.H. 20-30/40 4 HF-7784 Downwind Housing Side: L.H. 20-30/40

Access Panel Bracket - Downwind Heaters 6 HF-7287 Access Panel Bracket - Downwind Heaters

Window Access 0.060 x 6 x 6 Plastic 8 HF-7380 Window Access 0.060 x 6 x 6 Plastic

Downwind Housing Profile Top: 20-30 10 HF-7804 Downwind Housing Profile Top: 40

Cover Plate - Downwind Vaporizer Hole 12 HF-7796 Cover Plate - Downwind Vaporizer Hole

Flame Sensor 6" Long Rod 14 THH-4179 Flame Sensor 6" Long Rod

15 HH-1650 Spark Plug Auburn #I-31 15 HH-1650 Spark Plug Auburn #I-31

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 33

Page 34

8. Parts List

Propane Vapor Pipe Train: All Models

Propane Vapor Pipe Train: All Models Parts List

Ref # Part # Description Ref # Part # Description

1 HH-1251 Strainer, 1/2" Y 250# WOG SCH 80 12 707-1175-9 Union, 3/4" SCH 40 Black

2 007-1747-0 Plug, Pipe 1/4"

3 THH-4088 Nipple, 1/2" x 4" SCH 40 Black 14 HF-7794 Orifice Holder - Quad Heater - 3/4"

4 HH-1096 Clamp, 1/2" Conduit

5 HF-7575 Pipe Train Bracket: Downwind Unipipe 15 HF-7749 Orifice Plug (3/4) Drill: 17/64" (CHD-30)

6 TFC-0023-50 Regulator, 1/2" NPT - CSA 50 PSI

7 THH-4032 Nipple, 1/2" Close SCH 40 Black 16 007-1106-9 Tee, 1" x 1" x 3/4"

8 THH-4149 Elbow, 3/4"-1/2" Reduce SCH 40

9 HH-7101 Nipple, 3/4" x 6" SCH 40 Black 18 HH-2984 Gauge, Pressure 0-30# LP

10 056-2223-8 Solenoid Valve 3/4" NPT 115V Din

11 THH-4121 Nipple, 3/4" Close SCH 40 Black (CHD-15)

11 HH-7102 Nipple, 3/4" x 2-3/4" SCH 40 Black (CHD-30)

13 THH-4121 Nipple, 3/4" Close SCH 40 Black

15 HF-7 701 Orifice Plug (3/4) Drill: 7/32" (CHD-15)

15 HF-7 809 Orifice Plug (3/4) Drill: 5/16" (CHD-40)

17 THH-4001 Reducer, 1" x 1/4" Hex Bushing S40 BL

11 THH-4122 Nipple, 3/4" x 4-1/2" SCH 40 Black (CHD-40)

34 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 35

Liquid Propane Pipe Train: All Models

8. Parts List

Liquid Propane Pipe Train: All Models Parts List

Ref # Part # Description Ref # Part # Description

1 HF-7686 Pipe Train Asembly, LP Supply DW 04 17 THH-4149 Elbow, 3/4"-1/2" Reduce SCH 40

2 HF-7509 Hose, 1/2" x 18" LP Gas Assembly

3 HH-4847 Elbow, 1/2"-90° SCH 80 Black 19 056-2223-8 Solenoid Valve 3/4" NPT 115V Din

4 CD-0197 Vaporizor Coil for Downwind Heaters

5 410-1783-1 Vaporizer Adjusting Weldment 20 HH-7102 Nipple, 3/4" x 2-3/4" SCH 40 Black (CHD-30)

6 HF-7795 Pivot Bracket: Downwind Vaporizer 04

7 THH-4058 Tee, 1/2" x 1/2" x 1/2" SCH 80 Black 21 THH-4001 Reducer, 1" x 1/4" Hex Bushing S40 BL

8 HH-7013 Switch, Screw-In Vapor High-limit

9 THH-4071 Elbow, 1/2"-90° SCH 40 Black 23 007-1106-9 Tee, 1" x 1" x 3/4"

10 D07-0009 Hose, 3/8" x 24" LG LP Gas 350 Max

11 HH-1096 Clamp, 1/2" Condui t 25 THH-4121 Nipple, 3/4" Close SCH 40 Black

12 HF-7575 Pipe Train Bracket: Downwind Unipipe

13 THH-4071 Elbow , 1/2"-90° SCH 40 Black 27 HF-7701 Orifice Plug (3/4) Drill: 7/32" (CHD-15)

14 THH-4088 Nipple, 1/2" x 4" SCH 40 Black

18 D08-0020 Nipple, 3/4" x 6" SCH 80 Black

20 THH-4121 Nipple, 3/4" Close SCH 40 Black (CHD-15)

20 THH-4122 Nipple, 3/4" x 4-1/2" SCH 40 Black (CHD-40)

22 HH-2984 Gauge, Pressure 0-30# LP

24 707-1175-9 Union, 3/4" SCH 40 Black

26 HF-7794 Orifice Holder - Quad Heater - 3/4"

27 HF-7749 Orifice Plug (3/4) Drill: 17 /64" (CHD-30)

15 TFC-0023-50 Regulator, 1/2" NPT - CSA 50 PSI 27 HF-7809 Orifice Plug (3/4) Drill: 5/16" (CHD-40)

16 THH-4032 Nipple, 1/2" Close SCH 40 Black

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 35

Page 36

8. Parts List

Natural Gas Pipe Train: CHD-15

Natural Gas Pipe Train: CHD-15 Parts List

Ref # Part # Description

1 D67-0008 Strainer, 3/4" Y 250# WOG SCH 80 Black

2 D07-0024 Plug, 1/2" Pipe Solid Black

3 D08-0018 Nipple, 3/4" x 4" SCH 40 Black

4 D62-0005 Clamp, 3/4" Conduit

5 HF-7575 Pipe T rain Bracket: Downwind Unipipe

6 D58-0002 Valve, 3/4" NPT Ball Shut Off

7 THH-4066 Elbow, 3/4"-90° Street SCH 40 Black

8 HH-7101 Nipple, 3/4" x 6" SCH 40 Black

9 056-2223-8 Solenoid Valve 3/4" NPT 115V Din

10 THH-4121 Nipple, 3/4" Close SCH 40 Black

11 707-1175-9 Union, 3/4" SCH 40 Black

12 THH-4121 Nipple, 3/4" Close SCH 40 Black

13 HF-7794 Orifice Holder - Quad Heater - 3/4"

14 HF-7708 Orifice Plug (3/4) Drill: 21/64"

15 007-1106-9 Tee, 1" x 1" x 3/4"

16 THH-4001 Reducer, 1" x 1/4" Hex Bushing S40 BL

17 D08-0022 Gauge, Pressure 0-15#

36 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 37

Natural Gas Pipe Tr ain: CHD-30 and CHD-40

8. Parts List

Natural Gas Pipe Train: CHD-30 and CHD-40 Parts List

Ref # Part # Description

1 TF-1283 Strainer, 1" Y

2 D07-0024 Plug, 1/2" Pipe Solid Black

3 THH-4059 Nipple, 1" x 5-1/2" SCH 40 Black

4 THH-4170 Clamp, 1" Conduit

5 HF-7575 Pipe Train Bracket: Downwind Unipipe

6 TFC-0093 Valve, 1" NPT Bronze Ball - CGA

7 THH-4164 Elbow, 1"-90° Street SCH 40 Black

8 THH-4059 Nipple, 1" x 5-1/2" SCH 40 Black (CHD-30)

8 007-11 10-1 Nipple, 1" x 7" (CHD-40)

9 056-2224-6 Solenoid Valve 1" NPT 115V Din

10 THH-4117 Nipple, 1" Close SCH 40 Black

11 707-1175-9 Union, 3/4" SCH 40 Black

12 THH-4121 Nipple, 3/4" Close SCH 40 Black

13 HF-7794 Orifice Holder - Quad Heater - 3/4"

14 HF-7750 Orifice Plug (3/4) Dr ill: 25/64" (CHD-30)

14 HF-7810 Orifice Plug (3/4) Drill: 7/16" (CHD-40)

15 THH-4137 Tee, 1" x 1" x 1" NPT SCH 40 Black

16 THH-4001 Reducer, 1" x 1/4" Hex Bushing S40 BL

17 D08-0022 Gauge, Pressure 0-15#

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 37

Page 38

8. Parts List

LP Supply Pipe Train

LP Supply Pipe Train Parts List

Ref # Part # Description

1 HH-1251 Strainer, 1/2" Y 250# WOG SCH 80

2 007-1747-0 Plug, Pipe 1/4"

3 D07-0019 Nipple, 1/2" x 1-1/2" SCH 80 Black

4 007-1226-5 Ball Valve 1/2" w/ Lever Handle

5 HF-7586 Nipple, 1/2" x 2" SCH 80 Black

6 HH-1096 Clamp, 1/2" Conduit

7 HF-1026 Pipe Train Bracket: Vane Axial Heaters

8 TFC-0100 Valve, 1/2" NPT Solenoid LP w/ Din

9 TFC-0027 Valve, 1/4" NPT 250 PSI Relief

10 HH-4846 Tee, 1/2" x 1/2" x 1/4" SCH 80 Black

11 HH-1932 Elbow, 1/2" Pipe/1/2" Flare Brass

38 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 39

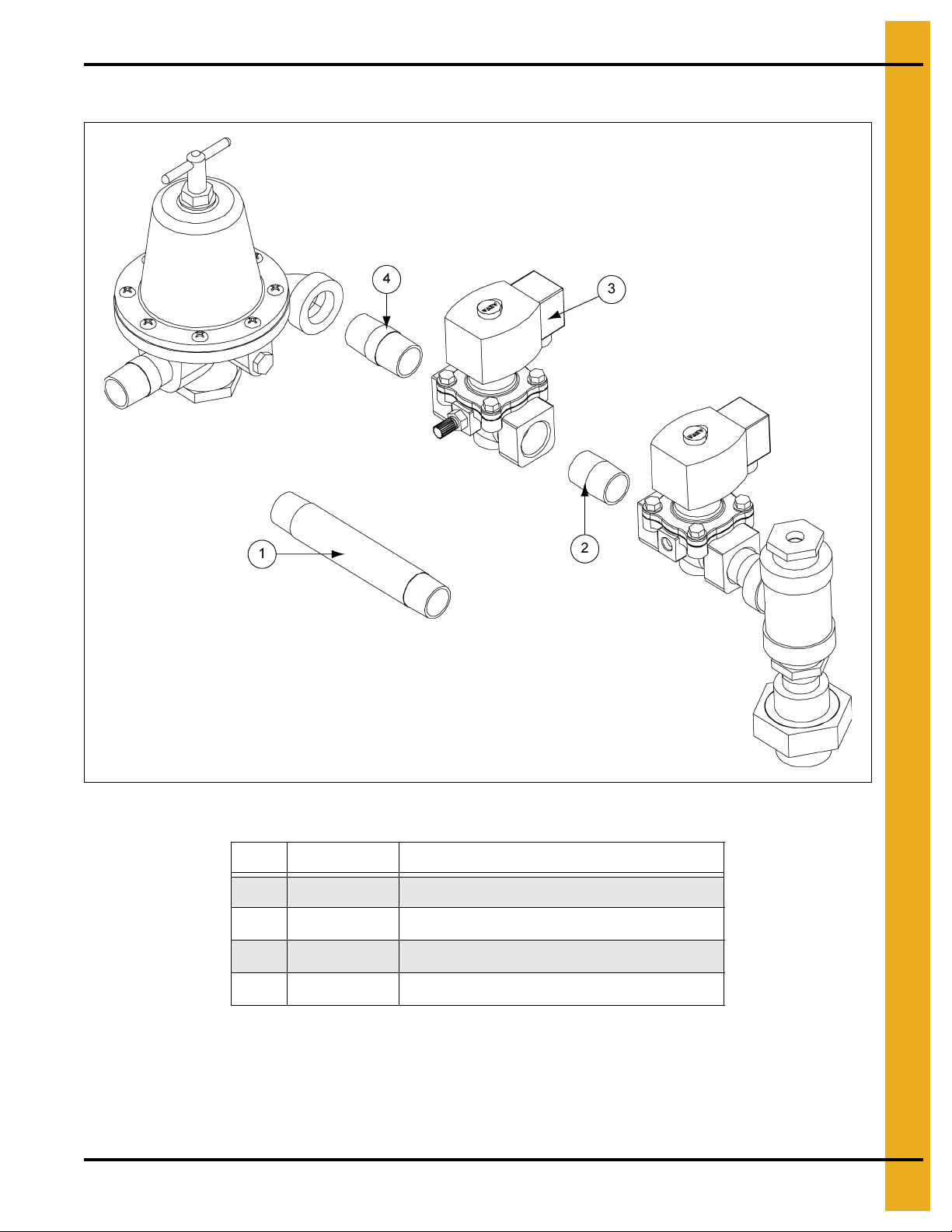

3/4" High-Low Pipe Train Option

8. Parts List

3/4" High-Low Pipe Train Option Parts List

Ref # Part # Description

1 D08-0020 Nipple, 3/4" x 6" SCH 40 Black

2 THH-4125 Nipple, 3/4" x 2" SCH 40 Black

3 056-2228-7 Solenoid Valve 3/4" NPT 115V Bypass

4 THH-4121 Nipple, 3/4" Close SCH 40 Black

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 39

Page 40

8. Parts List

3/4" Modulating Pipe Train Option

3/4" Modulating Pipe Train Option Parts List

Ref # Part # Description

1 THH-4164 Elbow, 1"-90° Street SCH 40 Black

2 THH-4115 El bow, 1"-90° SCHED SCH 40 Black

3 THH-4151 Nipple, 1" x 3" SCH 40 Black

4 THH-4059 Nipple, 1" x 5-1/2" SCH 40 Black

High-Low or Modulating Valves can be ordered factory installed or added in the field. Field installation

requires the removal of the long pipe nipple (See Ref #1 on Page 39 ). Once removed, the components

for the appropriate valve should be added in the same location. Pipe sealant should always be used to

prevent leaks.

40 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 41

8. Parts List

1.0" Pipe Train Options: High-Low and Modulating

High-Low or Modulating Valves can be ordered factory installed or added in the field. Field installation

requires the removal of the 1" 90° street elbow (Ref #1). Once removed, the components for the

appropriate valve should be added in the same location. 1.0" Pipe train options will require additional

support brackets: HF-7575 and THH-4170. Pipe sealant should always be used to prevent leaks.

1.0" Pipe Train Options: High-Low and Modulating Parts List

Ref # Part # Description

1 THH-4164 Elbow, 1"-90° Street SCH 40 Black

2 THH-4115 Elbow, 1"-90° SCHED SC H 40 Bla ck

3 THH-4151 Nipple, 1" x 3" SCH 40 Black

4 THH-4059 Nipple, 1" x 5-1/2 " SCH 40 Black

5 THH-4151 Nipple, 1" x 3" SCH 40 Black

6 056-2230-3 Solenoid Valve 1" NPT 115V w/ Bypass

7 HF-7847 Valve, Mod 1-1/4" 90/210F 15' Cap

8 THH-4083 Reducer, 1-1/4 -1" Hex Bushing SCH

9 HF-7575 Pipe Train Bracket: Downwind Unipipe

10 THH-4170 Clamp, 1" Conduit

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 41

Page 42

8. Parts List

Deluxe Heater Control Box

42 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 43

Deluxe Heater Control Box Parts List

Ref # Part # Description

1 HF-7719 Downwind Heater Box - CNC OPS

2 069-1376-8 Control Box Lid - Poly Blank

3 D03-0696 Latch, Farm Fans Control Box

4 DC-1695 Decal, Heater Plastic Control Box Deluxe

5 90-0009 Lamp, Oil Tight 1/4" TAB 120V

6 HF-7696 Switch 2 Position Selector: Lever

7 D63-0006 Block, Contact N.O.

8 HF-7318-1 Deluxe Circuit Board

9 HF-7211 Snap Track 4" x 6" (Ciruit Board)

10 HH-1487 Transformer Single Pole 120V

11 HH-1092 Switch, High-Limit 180°

8. Parts List

12 HF-7698 Backing Plate - Heater Controls

13 FH-7404 Fuse, 2 Amp 1/4" x 1-1/4" Slow Blow

14 E160-1137 Lug Ground, #TA-2 (CSA)

15 DC-1165 Decal, Danger Transition High-Limit

16 HF-7439 Switch, High-Limit 250° (Not Shown)

17 HF-7454 High-Limit Box Body - Transition High-Limit

18 HF-7455 High-Limit Box Lid - Transition High-Limit

19 HF-7414 Plug, Plastic 7/8" Recessed

20 FH-1310 Connector, Cord HEYCO #3231

21 FH-1309 Lock Nut 1/2" with Pipe Threads

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 43

Page 44

9. Test Fire Procedure

Test Firing Deluxe Burner Control

1. Turn ON power and fuel to the fan and heater. Set the controlling thermostat to call for heat.

2. Start fan and move heater switch to the “ON” position.

a. The “FAN ON” indicator light on the board should now be lit.

b. If light is not ON, confirm 120V at terminals 19 and 20. If no power exists, check for power at

the fuse in the fan control box and all safety high-limit switches. Make the needed repairs to

restore power to the terminals 19 and 20.

c. If power exists at terminals 19 and 20, be sure the circuit between 17 and 18 for the air switch

is closed.

3. With the “FAN ON” indicator lit, the troubleshooting lights 1 through 5 should be ON at the end of a

20 second purge cycle. The “IGNITOR ON” indicator will now light.

4. Heater should ignite, and “FLAME PRESENT” indicator should be lit. If flame is present and light not

ON. Adjust sensor into flame until light is ON when flame is burning. It may be necessary to adjust

sensor after changing gas pressure settings.

5. If heater does not light, follow the troubleshooting lights on the wiring schematic decal and correct

faults. Be aware that light #1 relates to the fuse on the board and not the fuse in the fan cont rol box.

If the fuse in the fan box is blown, no lights on the board will be ON.

6. Cycle the controlling thermostat to ensure the heater responds to the call for heat. If the unit is

HIGH-LOW fire, the #6 light will indicate during high-fire.

7. Heater is now ready for normal operation. Set the desired temperature on the thermostat and check

fuel pressure settings.

44 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 45

10. Deluxe Heater Wiring Diagram

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 45

Page 46

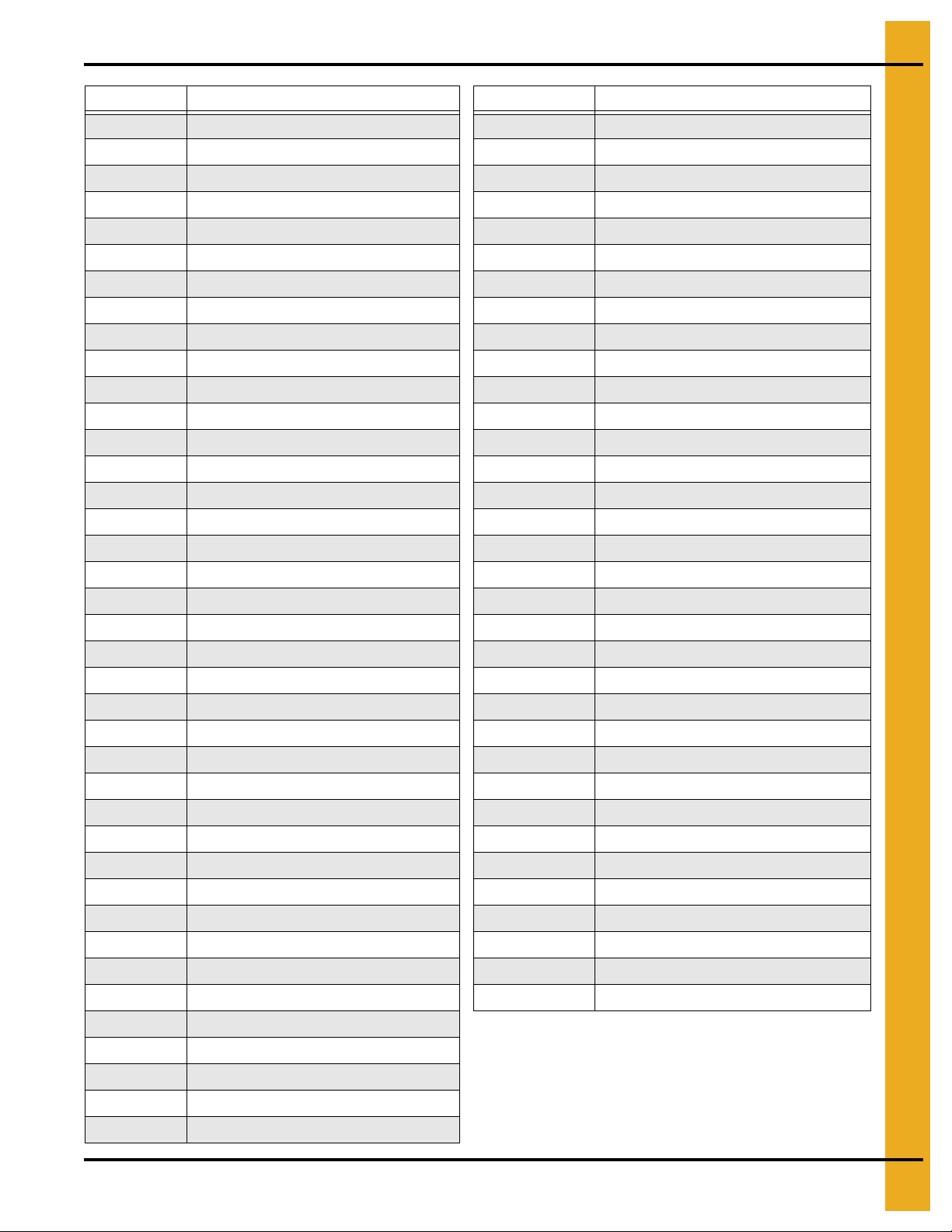

11. Miscellaneous Parts by Description

Part # Description Part # Description

HF-7200 250° Bin High-Limit Assembly HF-7719 Downwind Heater Box - CNC OPS

HF-7431 Access Panel Assembly Dow nwind Heater HF-7653 Downwind Housing Bottom: 10-15

HF-7287 Access Panel Bracket - Do wnwind Heaters HF-7781 Downwind Housing Bottom: 20-30

HF-7288 Access Panel Do wnwind Heater HF-7803 Downwind Housing Bottom: 40

D03-0099 Adapter Tab 0.187" x 0.187" HF-7662 Downwind Housing Profile Bottom: 10-15

HF-7698 Backing Plate - Heater Controls HF-7786 Downwind Housing Profile Bottom: 20-30

D63-0006 Block, Contact N.O. HF-7805 Downwind Housing Profile Bottom: 40

S-6606 Flange Bolt 5/16"-18 x 3/4" ZN Grade 5 HF-7661 Downwind Housing Profile Top: 10-15

S-1 101 Bolt, HHCS 1/4"-20 x 1/2" ZN Grade 2 HF-7785 Downwind Housing Profile Top: 20-30

756-1485-9 Boot - For Flame Rod and Igniter-A HF-7804 Downwind Housing Profile T op: 40

HF-7665 Burner Mounting Grip: Downwind Heater FH-7050 Elbow, 3/8" 90° PVC w/ Nut

415-4312-5 Burner Sub-Assembly CFDH27 HF-7655 Downwind Housing Side: L.H. 10-15

415-4434-7 Burner Sub-Assembly CFDH30/33 D03-0696 Latch, Farm Fans Control Box

HH-1096 Clamp, 1/2" Conduit HF-7784 Downwind Housing Side: L.H. 20-30/40

HF-7710 Conduit Assembly - Downwind Flame Rod Wire HF-7654 Downwind Housing Side: R.H. 10-15

415-4222-6 Conduit Assembly - Downwind Heater to Fan HF-7783 Downwind Housing Side: L.H. 20-30/40

HF-7709 Conduit Assembly - Downwind Ignition Wire FH-7404 Fuse, 2 Amp 1/4" x 1-1/4" Slow Blow

HF-7723 Conduit Assembly - Liquid Solenoid w/ Din DW HF-7652 Downwind Housing T op: 10-15

HF-7722 Conduit Assembly - Main Solenoid w/ Din DW HF-7780 Downwind Housing Top: 20-30

FH-1310 Con nector, Cord HEYCO #3231 HF-7802 Downwind Housing Top : 40

069-1376-8 Control Box Lid - Poly Blank 025-1203-6 Plug, Hole - 7/8" Diameter Liquid Tight

HF-7694 Control Box Sub-Assembly: Downwind Deluxe THH-4071 Elbow, 1/2"-90° SCH 40 Black

HF-7796 Cover Plate - Downwind Vaporizer Hole HH-4847 Elbow, 1/2"-90° SCH 80 Black

DC-889 Decal, Danger High Voltage THH-4153 Elbow, 1" x 1/2" - 90° Reducing SCH 40

420-1422-5 Decal, 115 Volt 1 Phase FH-1309 Lock Nut 1/2" with Pipe Threads

DC-113 Decal, Air Flow THH-4149 Elbow, 3/4"-1/2" Reduce SCH 40

DC-1224 Decal, Danger High Voltage (LG) 90-0009 Lamp, Oil Tight 1/4" TAB 120V

DC-1254 Decal, Ground Lug 24 Per Sheet E160-1137 Lug Ground, #TA-2 (CSA)

DC-108 Decal, High-Limit Button THH-4179 Flame Sensor 6" Long Rod

DC-1718 Decal, Warning Heater Fire S-2052 Foam Strip 1/8" Thread x 1/2" Wide

DC-1559 Decal, Warning: DC-1225/DC-1227 025-1202-8 Gasket - Adapter Plate/Motor C

DC-1170 Decal, Deluxe Heater Wiring HH-2984 Gauge, Pre s sure 0-30# LP

DC-1702 Decal: Caution Use TSTAT w/ Heater HF-7379 Heater Cover Plate 1996<

FH-7038 Fitting, Sealtite PVC 3/8" HF-7509 Hose, 1/2" x 18" LP Gas Assembly

DC-1695 Decal, Heater Plastic Control Box Deluxe D07-0009 Hose, 3/8" x 24" LG LP Gas 350 Max

HF-7318-1 Deluxe Circuit Board HH-7014 Jumper J6-2 Terminal Strip

FH-7049 Ada pter, Connector PVC 3/8" Straight w/ Nut PNEG-588-04 Ma nual, Heater Deluxe Downwind 04

006-1354-7 Din Connector - 1/2" NPT 090-1705-4 Screw, MS #8-32 x 3/8" Phillip s PHSEMS

HH-7046 Crimp, Disconnect 0.187" Female 007-1110-1 Nipple, 1" x 7"

46 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 47

11. Miscellaneous Parts by Description

Part # Description Part # Description

090-1701-3 Screw, MS #10-24 x 1/2" PHS ZN S-7192 Screw, MS #8-32 x 5/8" PHP ZN

THH-4117 Nipple, 1" Close SCH 40 Black D03-0247 Wire Tie 5" Panduit #PLT 1.5M-M

THH-4059 Nipple, 1" x 5-1/2" SCH 40 Black WR-18GRN/YLW Wire, 18 Gauge Green/Yellow Stranded

THH-4032 Nipple, 1/2" Close SCH 40 Black 07098556 Shroud 16" Motor Cord

090-1699-9 Rivet, Pop 1/8" Diameter x 0.775" Long CH-6873 Silicone Cartridge Clear RTV

THH-4088 Nipple, 1/2" x 4" SCH 40 Black WR-18BLU Wire, 18 Gauge Blue Stranded

THH-4121 Nipple, 3/4" Close SCH 40 Black WR-18FPGR Wire, 18 Gauge GR Teflon Flame SNS

HH-7098 Nipple, 3/4" x 12" SCH 40 Black WR-18GRN/YLW Wire, 18 Gauge Green/Yellow Stranded

D08-0020 Nipple, 3/4" x 6" SCH 40 Black WR-18FPRD Wire, 18 Gauge RD Teflon Flame SNS

S-7215 Flange Nut 1/4"-20 ZINC WR-7MM Wire, 7 MM Silicone Ignitor

S-280 Screw, SDS #10-16 x 5/8" HWH ZN E105-1102 Wire Kit - VA/DW Heaters Deluxe

S-968 Flange Nut 3/8"-16 ZN Grade 5 D02-0039 Wire Tie Anchors

S-2786 Screw, TCSF #8-32 x 3/8" RHP ZN E305-0282 WR 126" (18 Black) 1/4 Spade/3/8"

S-3611 Flan ge Nut 5/1 6-18 ZN YDP HH-1650 Spark Plug Auburn #I-31

S-8927 Jam Nut M14 x 1-1/4" Black HH-1251 Strainer, 1/2" Y 250# WOG SCH 80

07098556 Shroud 16" Motor Cord DC-1461 Decal, Tag Attention Pre ssure Gauges

HF-7794 Orifice Holder- Quad Heater - 3/4" HH-1092 Switch, High-Limit 180°

HF-7749 Orifice Plug (3/4) Drill: 17/64" HH-7013 Switch, Screw-In Vapor High-Limit

006-1363-8 Sealing Washer 0.85 I.D. Black 707-1175-9 Union, 3/4" SCH 40 Black

HF-7708 Orifice Plug (3/4) Drill: 21/64" 007-1106-9 Tee, 1" x 1" x 3/4"

HF-7750 Orifice Plug (3/4) Drill: 25/64" THH-4137 Tee, 1" x 1" x 1" NPT SCH 40 Black

HF-7809 Orifice Plug (3/4) Drill: 5/16" THH-4058 Tee, 1/2" x 1/2" x 1/2" SCH 80 Black

HH-1 1 06 Terminal, 3/16" Eyelet HH-1487 Transformer Single Pole 120V

HF-7211 Snap Track 4" x 6" (Ciruit Board) HF-7705 Piping Sub-Assembly 1.0 (CHD-30)

HF-7810 Orifice Plug (3/4) Drill: 7/16" HF-7808 Piping Sub-Assembly 1.0 (CHD-40)

S-4764 Spade Terminal MV14-6FBX Fork HF-77 04 Pipin g Sub-Assembly 3/4 (CHD-15)

HF-7701 Orifice Plug (3/4) Drill: 7/32" 056-2224-6 Solenoid Valve 1" NPT 115V Din

S-7598 Paint, Black Spray 056-2223-8 Solenoid Valve 3/4" NPT 115V Din

HF-7696 Switch 2 Position Selector: Lever 410-1783-1 Vaporizer Adjusting Weldment

007-1747-0 Plug, Pipe 1/4" CD-0197 Vaporizor Coil for Downwind Heaters

HF-7686 Pipe Train Assembly: LP Supply DW 04 S-3674 Flat Washer #10 SAE ZN

HF-7575 Pipe Train Bracket: Downwind Unipipe HF-7380 Window Access 0.060 x 6 x 6 Plastic

HF-1026 Pipe Train Bracket: Vane Axial Heaters WR-18BRN Wire 18 Gauge Brown Stranded

WR-18WHT Wire 18 Gauge White Stranded WR-18YLW Wire 18 Gauge Yellow Stranded

HF-7795 Pivot Bracket: Downwind Vaporizer 04

045-1068-1 Terminal Strip Assembly 20A 2 Position W

THH-4001 Reducer, 1" x 1/4" Hex Bushing S40 BL

TFC-0023-50 Regulator, 1/2" NPT - CSA 50 PSI

090-1709-6 Retainer Nut 5/16"-18 x 0.120" ZN

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 47

Page 48

NOTES

48 PNEG-588-04 Deluxe Downwind Heater Installation and Operation

Page 49

12. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions of

use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-588-04 Deluxe Downwind Heater Installation and Operation 49

Page 50

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2013 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-302062

Loading...

Loading...