Page 1

T H E G S I G R O U P , I N C.

1 9 9 81 9 9 8

1 9 9 8

1 9 9 81 9 9 8

S

ERVICE SCHOOLERVICE SCHOOL

ERVICE SCHOOL

ERVICE SCHOOLERVICE SCHOOL

GSI DRYING SYSTEMSGSI DRYING SYSTEMS

GSI DRYING SYSTEMS

GSI DRYING SYSTEMSGSI DRYING SYSTEMS

PNEG-573PNEG-573

PNEG-573

PNEG-573PNEG-573

PORTABLE DRYERS,PORTABLE DRYERS,

PORTABLE DRYERS,

PORTABLE DRYERS,PORTABLE DRYERS,

FANS & HEATERSFANS & HEATERS

FANS & HEATERS

FANS & HEATERSFANS & HEATERS

1

Page 2

2

Page 3

AIRSTREAM DRYER SERVICEAIRSTREAM DRYER SERVICE

AIRSTREAM DRYER SERVICE

AIRSTREAM DRYER SERVICEAIRSTREAM DRYER SERVICE

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

Warranty............................................................................................................................5

Safety First........................................................................................................................6

Safety Alert Decals............................................................................................................6

Safety Precautions............................................................................................................8

C-Series Dryer Control Panel Featuring The Electronic Monitoring Control System........9

Safety Circuit Shutdown Messages..........................................................................15

Series 2000 Dryer Control Panel Featuring The Competitor Series 2000 Control System.....16

Special Features.................................................................................................................21

Safety Circuit Shutdown Messages...................................................................................21

Series 2000 Error Conditions.....................................................................................................22

Error Code Breakdown.......................................................................................................22

Pre Start Checks For All Portable Dryers...................................................................23

Pre Season Inspection.............................................................................................24

Startup & Operation For All Portable Dryers...............................................................28

Continuous Flow And Continuous Batch Startup Procedures.................................29

120 & 1200 Series Continuous Flow Metering Roll Settings-Full Heat.....................30

120 & 1200 Series Continuous Flow Metering Roll Settings-Dry & Cool..................31

1200S Series Continuous Flow Metering Roll Settings-Full Heat.............................32

1200S Series Continuous Flow Metering Roll Settings-Dry & Cool..........................33

Fan & Heater Switch Settings...................................................................................35

120 & 1200 Series Batch Timer Settings..............................................................36

120 & 1200 Series Staged Batch Timer Settings......................................................37

1200S Series Batch Timer Settings..........................................................................38

1200S Series Staged Batch Timer Settings..............................................................39

Operating Tips...........................................................................................................39

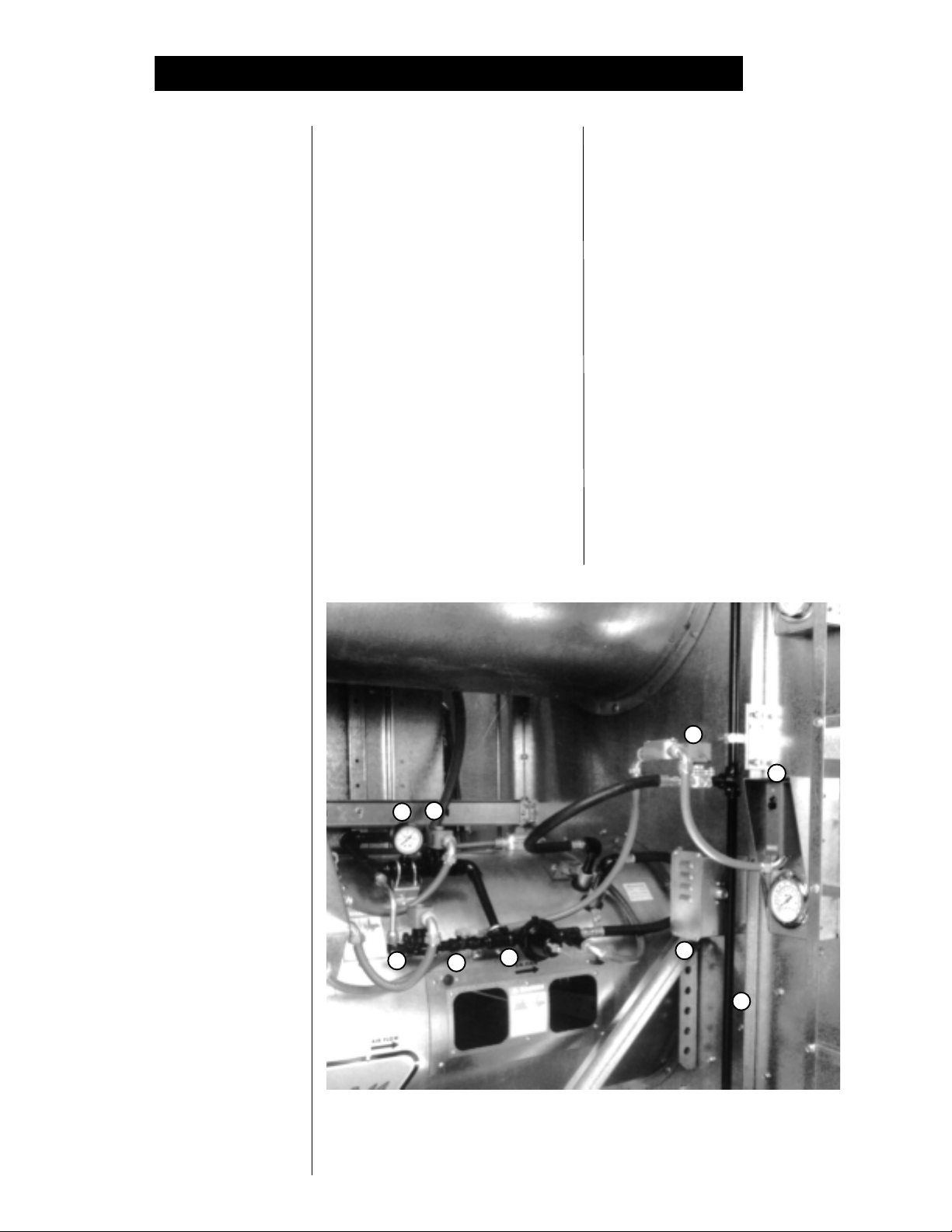

Operating Pressures.................................................................................................40

Burner Temperatures................................................................................................41

Moisture Control Setting............................................................................................41

Moisture Control Tips...............................................................................................41

20-30% Moisture Corn (Continuous Flow)................................................................42

Drying Corn Using The All Heat Process..................................................................42

Dryeration Process...................................................................................................43

Startup With Dryer Full Of Wet Grain.......................................................................44

3

Page 4

AIRSTREAM DRYER SERVICEAIRSTREAM DRYER SERVICE

AIRSTREAM DRYER SERVICE

AIRSTREAM DRYER SERVICEAIRSTREAM DRYER SERVICE

TABLE OF CONTENTS(con't)TABLE OF CONTENTS(con't)

TABLE OF CONTENTS(con't)

TABLE OF CONTENTS(con't)TABLE OF CONTENTS(con't)

End Of Season Dryer Shutdown................................................................................44

SCR Speed Information.............................................................................................45

Capacity Information.................................................................................................45

Fuel Formula Constants............................................................................................46

Maintaining Grain Quality..........................................................................................47

Equilibrium Moisture Chart........................................................................................47

Approximate Allowable Holding Time.......................................................................48

Approximate Hours Of Fan Operation To Change Bin Temperature.........................48

Service Guide For All Portable Dryers.............................................................................49

Seasonal Inspection And Service..............................................................................50

Lubrication Instructions For Ball Bearing Motors......................................................50

Suggested Lubricants..............................................................................................51

Fan Propellor Removal And Installation.................................................................52

Fan Motor Removal And Installation.........................................................................53

Heater Parts Removal And Installation.....................................................................54

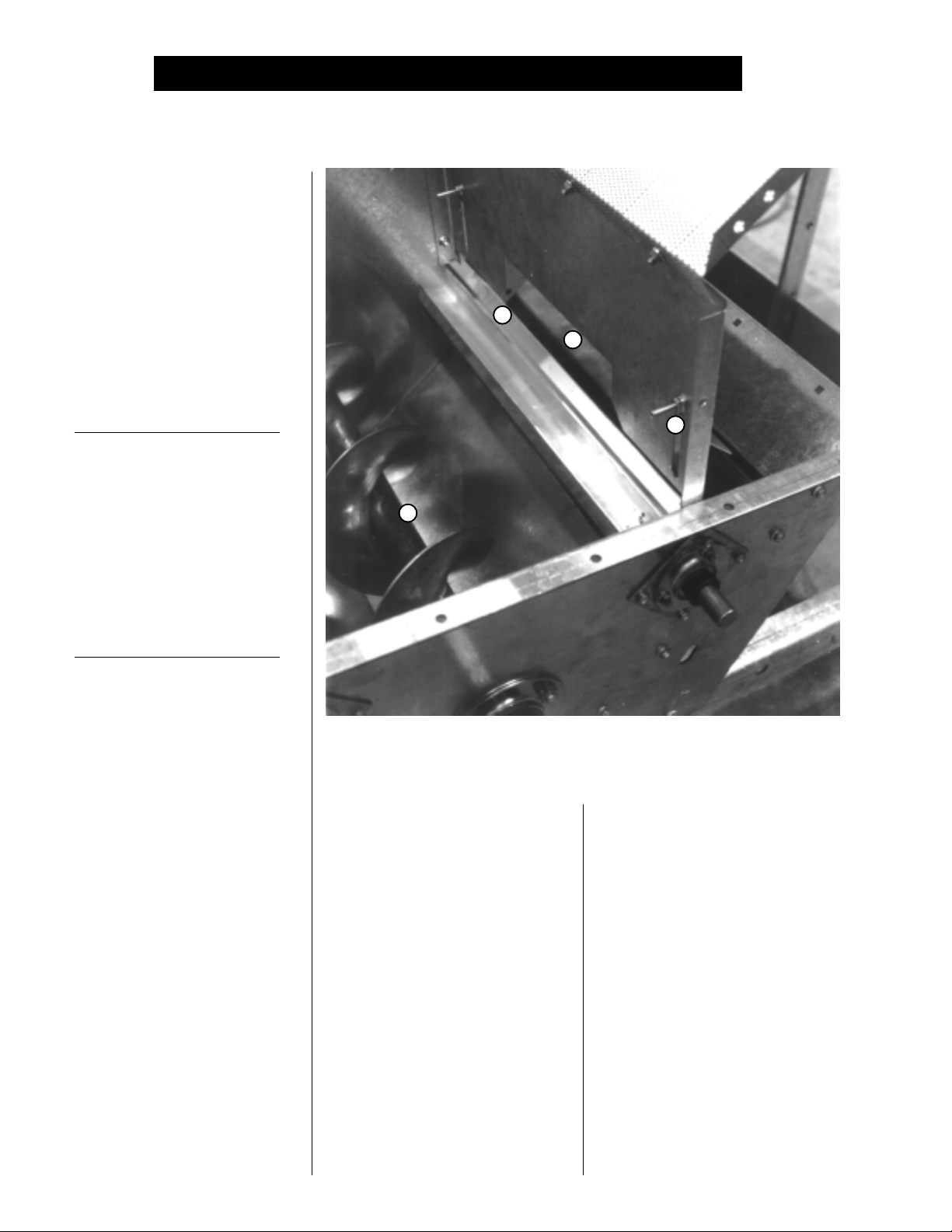

Metering Roll Servicing............................................................................................55

How To Determine A Metering Roll Problem............................................................56

1200 & 1200S C-Series Wiring Diagrams......................................................................57

Competitor Series 2000 Wiring Diagrams...................................................................69

Trouble Analysis For All Portable Dryers.......................................................................78

C-Series Quick Reference Guide-Electronic Monitoring Control System.......................84

Notes.......................................................................................................................................85

4

Page 5

AIRSTREAM DRYER SERVICEAIRSTREAM DRYER SERVICE

AIRSTREAM DRYER SERVICE

AIRSTREAM DRYER SERVICEAIRSTREAM DRYER SERVICE

Thank you for choosing an Airstream

product. These products are the fin-

est built on the market today, and are

designed to give excellent perfor-

mance and service for many years.

Grain Systems, Inc. warrants its

products to be free of defects in ma-

terial and workmanship. The only

obligation of the manufacturer is to

repair or replace components which

have been submitted and found to

be defective within 24 months after

installation of the dryer, and within

12 months of a fan or heater pur-

chase. If so found to be defective,

the components will be repaired or

replaced without charge, this con-

stituting and entirely fulfilling the

warranty obligation. Grain Systems,

Inc. assumes no liability for ex-

penses incurred without written au-

This service school manual de-

scribes the operation and service for

all portable grain dryers, including

general grain drying information.

Dryer models are available

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

thorizations; in no event shall liabil-

ity include special or consequen-

tial damages, or exceed the sell-

ing price of the product.

This warranty does not cover

products or parts which have been

damaged by negligent use, mis-

use, alteration or accident. Elec-

tric motors, tires, and other com-

ponents supplied by outside manu-

facturers have separate warran-

ties, from those suppliers. This

warranty is exclusive and in lieu of

all other warranties, expressed or

implied. Grain Systems, Inc. re-

serves the right to make design or

for liquid propane or natural gas fuel

supply, with either single phase 230

volt, or three phase 220 or 440 volt

electrical power (diesel and 380 volt

options also available).

specification changes at any time,

without any contingent obligations

to purchasers of products al-

ready sold.

All instructions shall be con-

strued as recommendation only.

Because of the many variable con-

ditions in actual installation, Grain

Systems, Inc. assumes no liability

for results arising from the use of

such recommendations. Any alter-

ation in design or operation of any

Grain Systems, Inc. product must

be submitted and approved in writ-

ing by Grain Systems, Inc. before

the alteration is made.

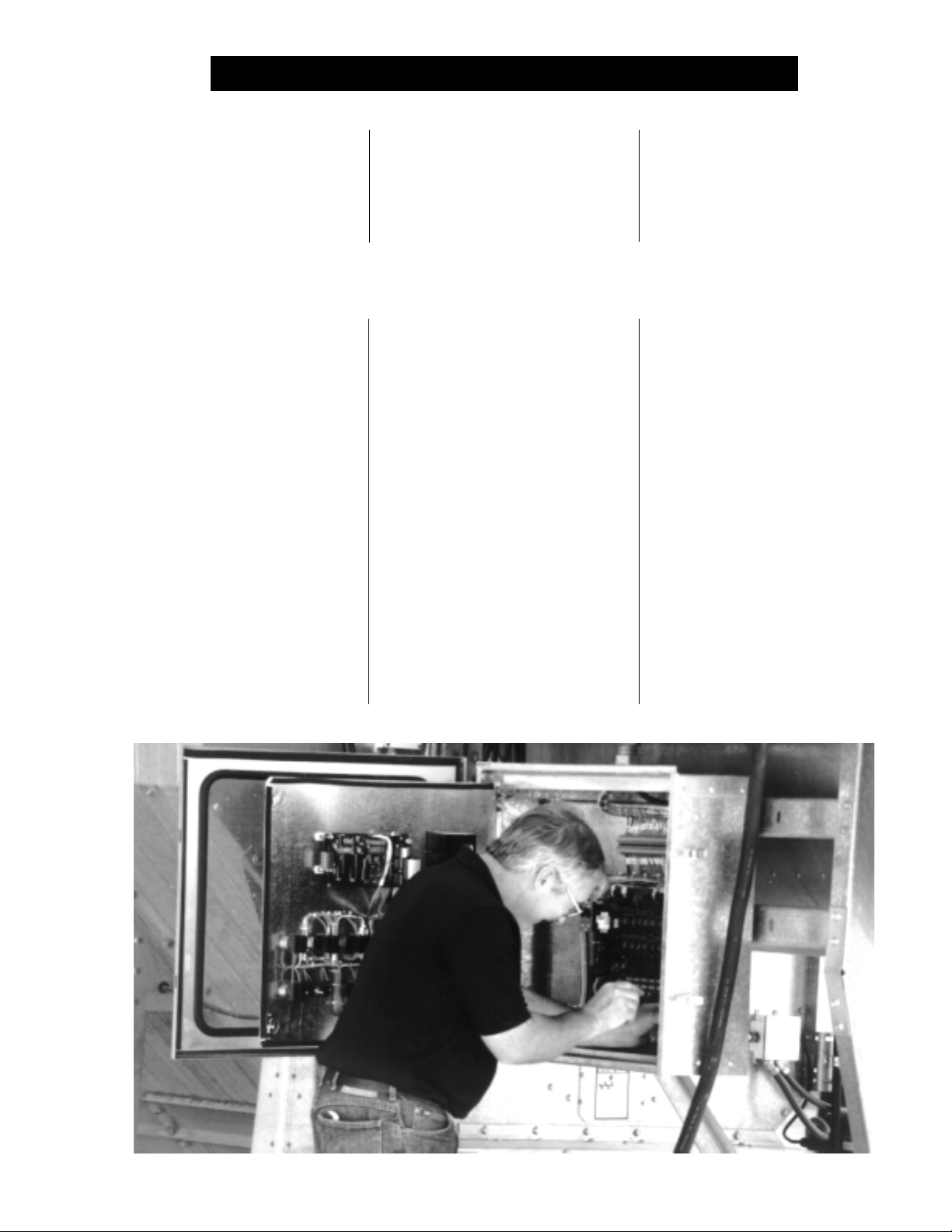

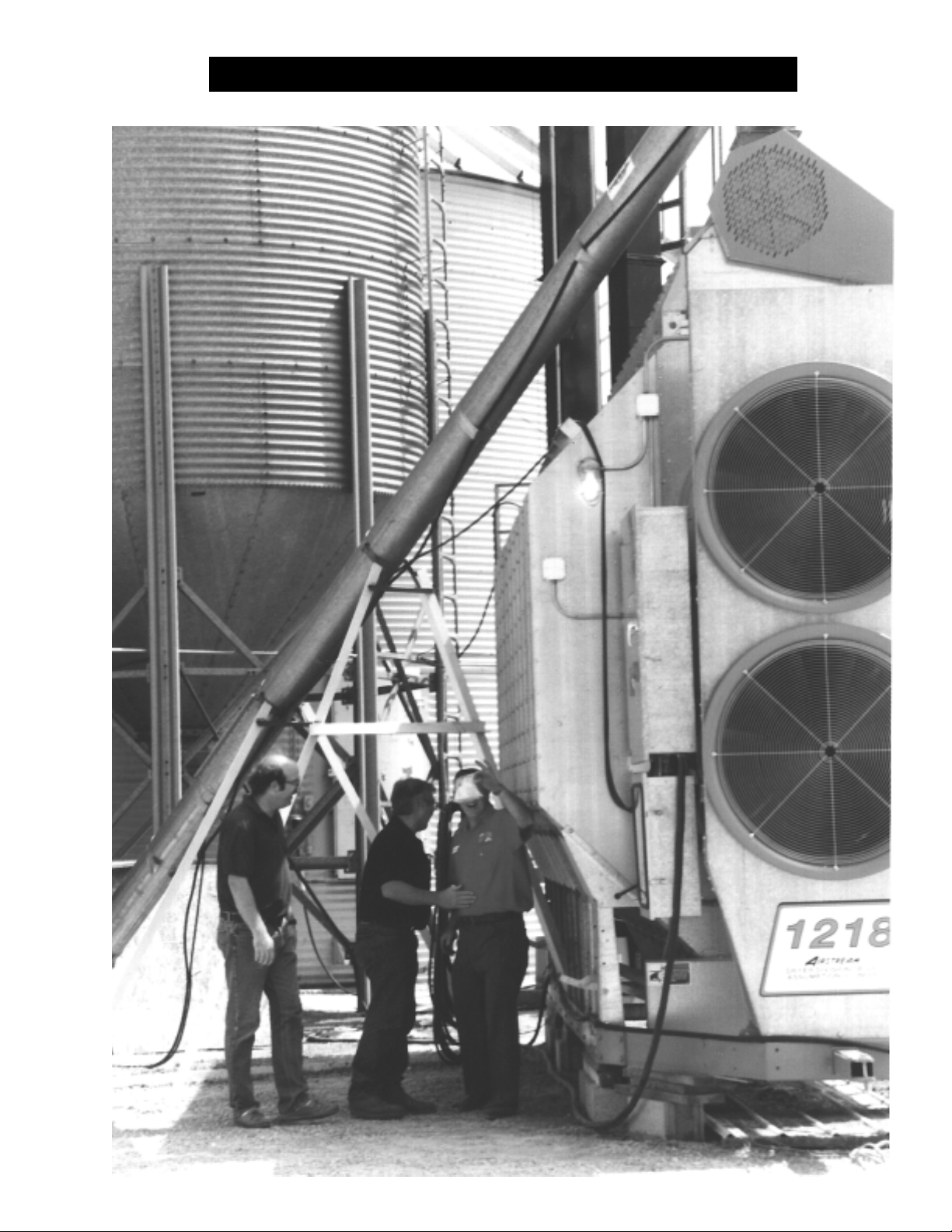

Airstream Service Technician checks the wiring on a single module grain dryer.Airstream Service Technician checks the wiring on a single module grain dryer.

Airstream Service Technician checks the wiring on a single module grain dryer.

Airstream Service Technician checks the wiring on a single module grain dryer.Airstream Service Technician checks the wiring on a single module grain dryer.

5

Page 6

SAFETY FIRSTSAFETY FIRST

SAFETY FIRST

SAFETY FIRSTSAFETY FIRST

Grain Systems, Inc.'s principle con-

cern is your safety and the safety of

others associated with grain han-

dling equipment. This manual was

written with that thought in mind. We

want to keep you as a customer.

This manual is to help you under-

The symbol shown below is used to

call your attention to instructions

concerning your personal safety.

Watch for this symbol; it points out

important safety precautions. It

means "ATTENTION", "WARNING",

"CAUTION", and "DANGER". Read

the message that follows and be

cautious to the possibility of per-

sonal injury or death.

stand safe operating proceedures

and some problems which may be

encountered by the operator and

other personnel.

As owner and/or operator, it is

your responsibility to know what re-

quirements, hazards and precau-

SAFETY ALERT SYMBOLSAFETY ALERT SYMBOL

SAFETY ALERT SYMBOL

SAFETY ALERT SYMBOLSAFETY ALERT SYMBOL

WARNING! BE ALERT!WARNING! BE ALERT!

WARNING! BE ALERT!

WARNING! BE ALERT!WARNING! BE ALERT!

Personnel operating or working around

grain drying equipment should read this

manual. This manual must be delivered

with equipment to its owner. Failure to

read this manual and its safety instruc-

tions is a misuse of the equipment.

tions exist, and to inform all person-

nel associated with the equipment

or who are in the area. Avoid any

alterations to the equipment. Such

alterations may produce a very dan-

gerous situation, where serious in-

jury or death may occur.

Grain Systems, Inc. recommends

that you contact your local power com-

pany and have a representative sur-

vey your equipment installation so

your wiring will be compatible with

their system and you will have ad-

equate power supplied to your unit.

6

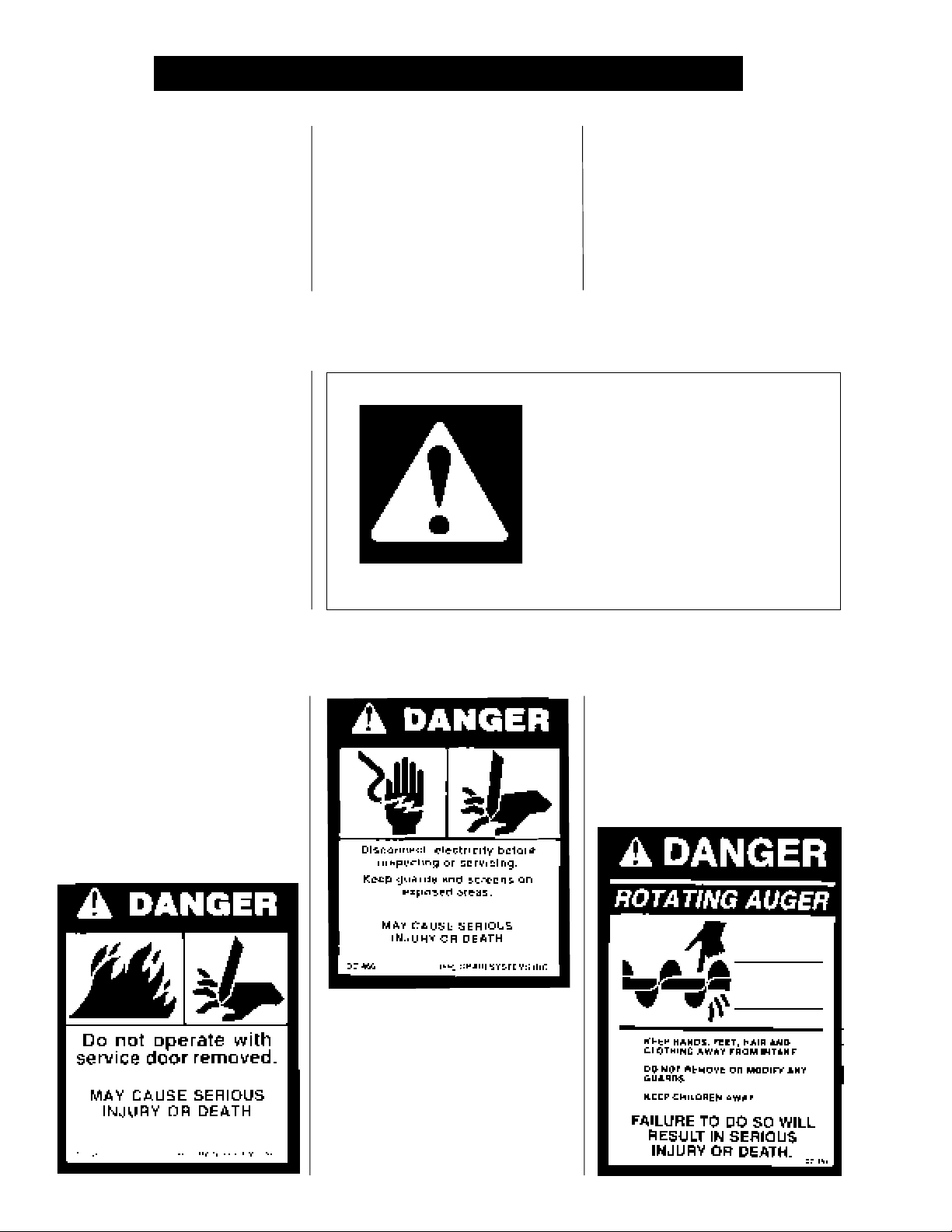

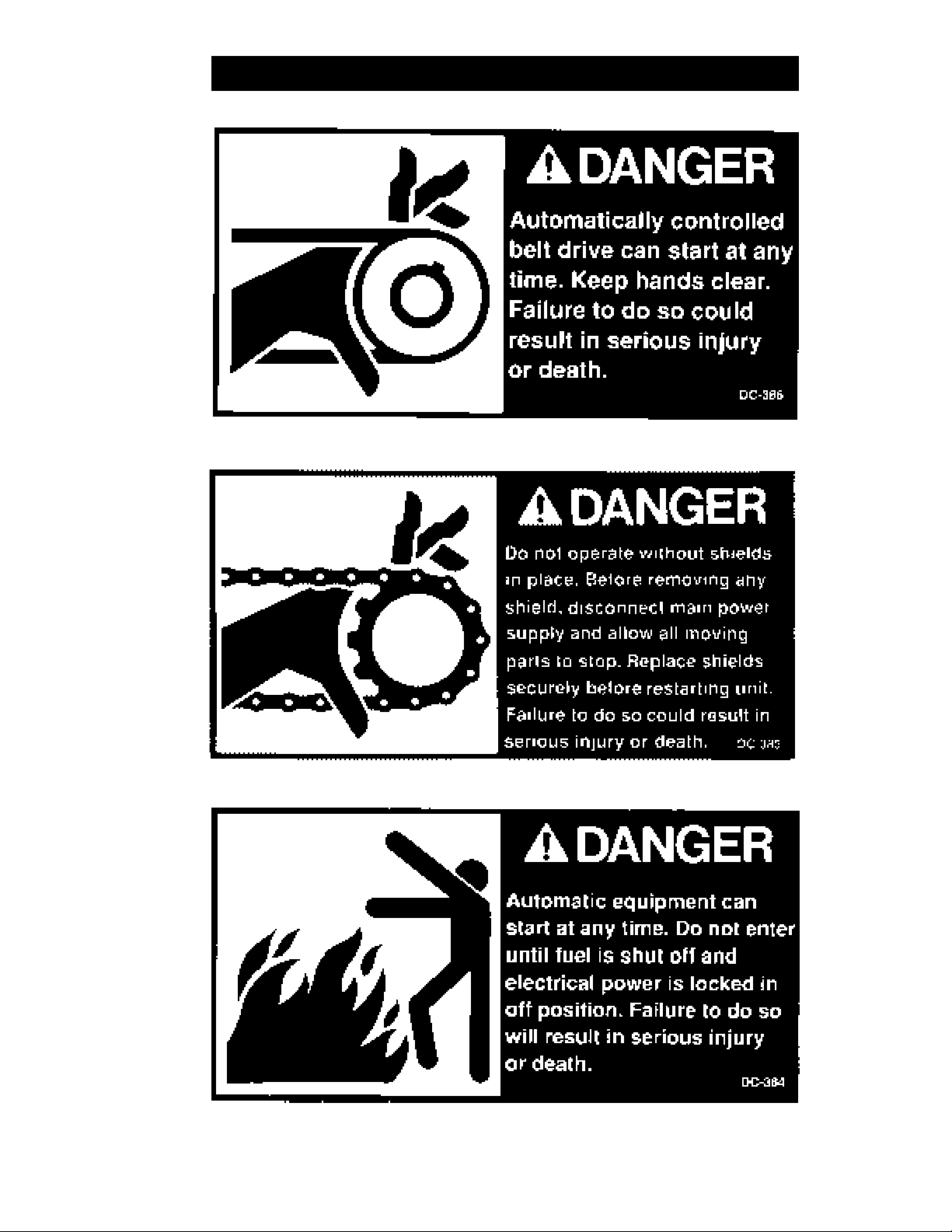

SAFETY ALERT DECALSSAFETY ALERT DECALS

SAFETY ALERT DECALS

SAFETY ALERT DECALSSAFETY ALERT DECALS

Safety decals should be read and

understood by all people in and

around the grain drying area. If the

following safety decals are not dis-

played on your dryer, or if they are

damaged, contact Grain Systems,

Inc. for replacement.

A CAREFUL OPERATORA CAREFUL OPERATOR

A CAREFUL OPERATOR

A CAREFUL OPERATORA CAREFUL OPERATOR

IS THE BEST INSURANCE IS THE BEST INSURANCE

IS THE BEST INSURANCE

IS THE BEST INSURANCE IS THE BEST INSURANCE

AGAINST AN ACCIDENTAGAINST AN ACCIDENT

AGAINST AN ACCIDENT

AGAINST AN ACCIDENTAGAINST AN ACCIDENT

Page 7

SAFETY ALERT DECALSSAFETY ALERT DECALS

SAFETY ALERT DECALS

SAFETY ALERT DECALSSAFETY ALERT DECALS

Three decals displayed on all Airstream Dryers. Belt drives, chain driven meter rollsThree decals displayed on all Airstream Dryers. Belt drives, chain driven meter rolls

Three decals displayed on all Airstream Dryers. Belt drives, chain driven meter rolls

Three decals displayed on all Airstream Dryers. Belt drives, chain driven meter rollsThree decals displayed on all Airstream Dryers. Belt drives, chain driven meter rolls

and combustible fuels must be treated with caution.and combustible fuels must be treated with caution.

and combustible fuels must be treated with caution.

and combustible fuels must be treated with caution.and combustible fuels must be treated with caution.

7

Page 8

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

1. Read and understand the operating manual before trying to operate the

dryer, fan or heater.

2. Never operate a dryer while the

3. Power supply should be OFF for service of

Use CAUTION in checking voltage or other procedures requiring power

to be ON.

4. Check for gas leaks at all

detected, do not operate dryer. Shut down and repair before further

operation.

5. Never attempt to operate a dryer by jumping or otherwise bypassing

any safety devices on the unit.

6. Set

7. Keep the dryer clean. Do not allow fine material to accumulate in the

8.

pressure regulatorpressure regulator

pressure regulator to avoid excessive gas pressure applied to burner

pressure regulatorpressure regulator

during ignition and

ing procedures. Do not exceed maxi

perature.

num chambernum chamber

num chamber. Also occasionally clean the

num chambernum chamber

auger drive beltsauger drive belts

Keep

auger drive belts tight

auger drive beltsauger drive belts

when burner is in operation. See chart for operat-

guardsguards

guards are removed.

guardsguards

electrical componentselectrical components

electrical components.

electrical componentselectrical components

gas pipegas pipe

gas pipe connections. If any leaks are

gas pipegas pipe

mum recommended drying tem-

outside screensoutside screens

outside screens of the dryer.

outside screensoutside screens

enough to prevent slippage.

ple-ple-

ple-

ple-ple-

USE CAUTIONUSE CAUTION

USE CAUTION

USE CAUTIONUSE CAUTION

IN THE OPERATIONIN THE OPERATION

IN THE OPERATION

IN THE OPERATIONIN THE OPERATION

OF THIS EQUIPMENTOF THIS EQUIPMENT

OF THIS EQUIPMENT

OF THIS EQUIPMENTOF THIS EQUIPMENT

The design and manufacture of a

dryer is directed toward operator

safety. However, the very nature of

a grain dryer having a

high voltage

and high speed

present a hazard to personnel which

can not be completely safeguarded

against, without interfering with effi-

cient operation and reasonable ac-

cess to components.

Use extreme caution in working

around high speed

heaters, augers and auxiliary con-heaters, augers and auxiliary con-

heaters, augers and auxiliary con-

heaters, augers and auxiliary con-heaters, augers and auxiliary con-

veyorsveyors

veyors, which may start without

veyorsveyors

warning when the dryer is operating

on automatic control.

electrical equipmentelectrical equipment

electrical equipment

electrical equipmentelectrical equipment

rotating partsrotating parts

rotating parts, does

rotating partsrotating parts

gas burnergas burner

gas burner,

gas burnergas burner

fans, gas firedfans, gas fired

fans, gas fired

fans, gas firedfans, gas fired

KEEP THE DRYER CLEAN

DO NOT ALLOW FINE

9. Use CAUTION in working around high speed

and auxiliary conveyorsand auxiliary conveyors

and auxiliary conveyors which START AUTOMATICALLY.

and auxiliary conveyorsand auxiliary conveyors

10. Do not operate in any area where combustible material will be drawn into

fanfan

the

fan.

fanfan

11. Before attempting to remove and reinstall any

read the recommended procedure listed within the servicing section of

the manual.

12. Be certain that capacities of

augerauger

auger capacities.

augerauger

13. Clean grain is easier to dry. Fine material increases resistance to airflow

and requires removal of extra moisture.

READ THESE INSTRUCTIONSREAD THESE INSTRUCTIONS

READ THESE INSTRUCTIONS

READ THESE INSTRUCTIONSREAD THESE INSTRUCTIONS

BEFORE OPERATION AND SERVICEBEFORE OPERATION AND SERVICE

BEFORE OPERATION AND SERVICE

BEFORE OPERATION AND SERVICEBEFORE OPERATION AND SERVICE

SAVE FOR FUTURE REFERENCESAVE FOR FUTURE REFERENCE

SAVE FOR FUTURE REFERENCE

SAVE FOR FUTURE REFERENCESAVE FOR FUTURE REFERENCE

8

auxiliary conveyorsauxiliary conveyors

auxiliary conveyors are matched to dryer

auxiliary conveyorsauxiliary conveyors

fans, gas burners, augersfans, gas burners, augers

fans, gas burners, augers

fans, gas burners, augersfans, gas burners, augers

propellerpropeller

propeller, make certain to

propellerpropeller

MATERIAL TO ACCUMULATE

IN THE PLENUM CHAMBER

OR SURROUNDING THE

OUTSIDE OF THE DRYER

Continued safe, dependable opera-

tion of automatic equipment de-

pends, to a great degree, upon the

owner. For a safe and dependable

drying system, follow the recom-

mendations within this manual, and

make it a practice to regularly in-

spect the operation of the unit for any

developing problems or unsafe con-

ditions.

Take special note of the safety

precautions listed before attempting

to operate a dryer, fan or heater.

Page 9

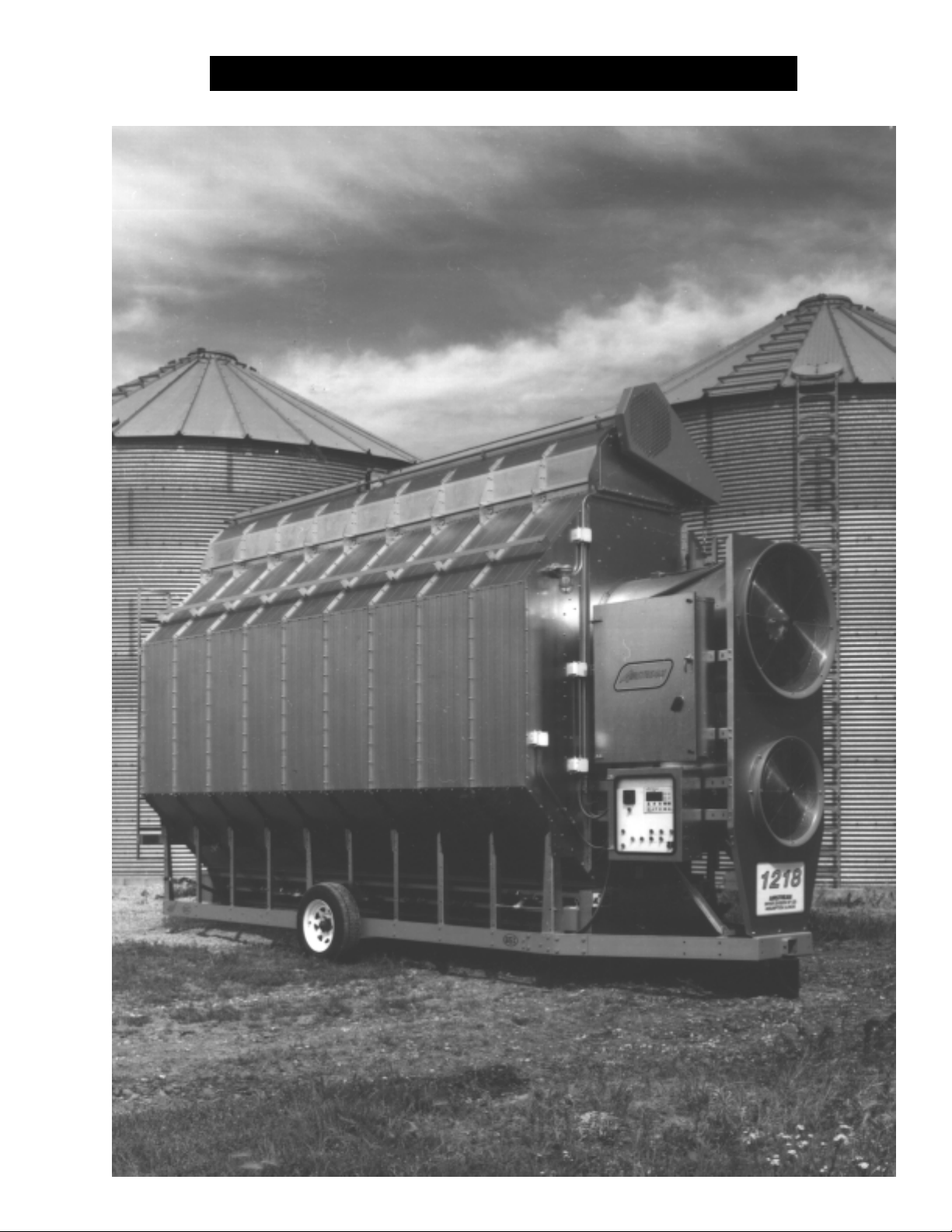

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

9

Page 10

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

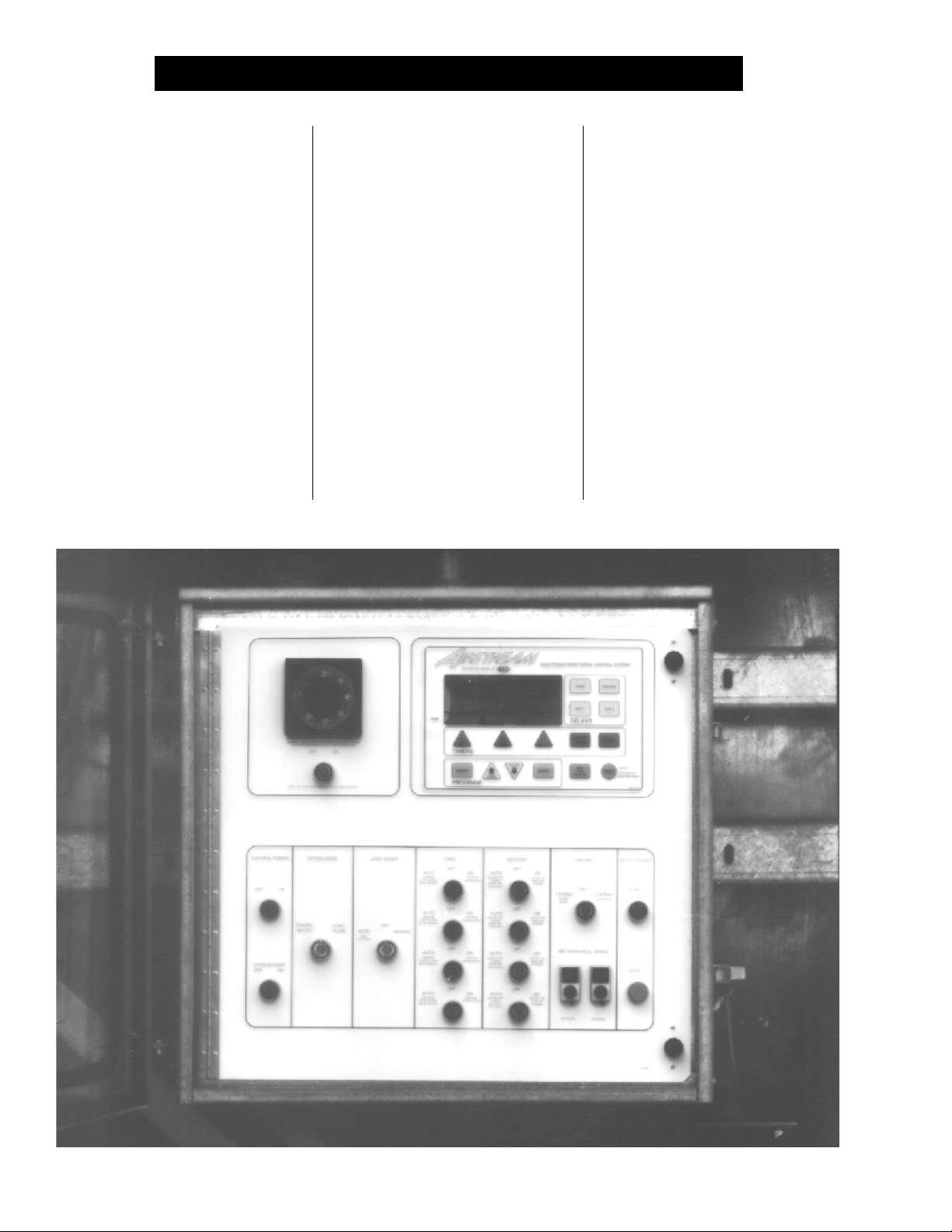

Figure 1: The C-Series grain dryer control panel with the Electronic Monitoring Control System in the upper right panel.Figure 1: The C-Series grain dryer control panel with the Electronic Monitoring Control System in the upper right panel.

Figure 1: The C-Series grain dryer control panel with the Electronic Monitoring Control System in the upper right panel.

Figure 1: The C-Series grain dryer control panel with the Electronic Monitoring Control System in the upper right panel.Figure 1: The C-Series grain dryer control panel with the Electronic Monitoring Control System in the upper right panel.

C-SERIES DRYER CONTROL PANEL FEATURINGC-SERIES DRYER CONTROL PANEL FEATURING

C-SERIES DRYER CONTROL PANEL FEATURING

C-SERIES DRYER CONTROL PANEL FEATURINGC-SERIES DRYER CONTROL PANEL FEATURING

THE ELECTRONIC MONITORING CONTROL SYSTEMTHE ELECTRONIC MONITORING CONTROL SYSTEM

THE ELECTRONIC MONITORING CONTROL SYSTEM

THE ELECTRONIC MONITORING CONTROL SYSTEMTHE ELECTRONIC MONITORING CONTROL SYSTEM

MOISTURE CONTROLMOISTURE CONTROL

MOISTURE CONTROL

control panel control panel

The

control panel provides easy

control panel control panel

access to gauges and controls, and

the ILLUMINATED SWITCHES pro-

vide a quick reference for every op-

erating function. The patent pend-

Electronic Monitoring ControlElectronic Monitoring Control

ing

Electronic Monitoring Control

Electronic Monitoring ControlElectronic Monitoring Control

SystemSystem

System is a computerized control

SystemSystem

10

system that gives instant information

regarding dryer operation.

MOISTURE CONTROLMOISTURE CONTROL

MOISTURE CONTROL

MOISTURE CONTROLMOISTURE CONTROL

THERMOSTAT(1)THERMOSTAT(1)

THERMOSTAT(1)

THERMOSTAT(1)THERMOSTAT(1)

This electronic

the moisture level of discharged grain

by sensing grain column temperature.

THERMOSTAT controls

MOISTURE CONTROLMOISTURE CONTROL

SWITCH(2)SWITCH(2)

SWITCH(2)

SWITCH(2)SWITCH(2)

This switch turns the power ON or

OFF to the MOISTURE CONTROL

THERMOSTAT. It lights up when

the grain column temperature is be-

low the thermostat set point.

Page 11

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

CONTROL POWERCONTROL POWER

CONTROL POWER

CONTROL POWERCONTROL POWER

SWITCH(3)SWITCH(3)

SWITCH(3)

SWITCH(3)SWITCH(3)

The power to the

toring Control Systemtoring Control System

toring Control System is turned

toring Control Systemtoring Control System

ON or OFF with this switch.

OUTSIDE LIGHT(4)OUTSIDE LIGHT(4)

OUTSIDE LIGHT(4)

OUTSIDE LIGHT(4)OUTSIDE LIGHT(4)

The dryer

or OFF here. It also may be set on

AUTO, which turns the light on while

the dryer is running and off if a shut-

down occurs.

DRYING MODE SWITCH(5)DRYING MODE SWITCH(5)

DRYING MODE SWITCH(5)

DRYING MODE SWITCH(5)DRYING MODE SWITCH(5)

This is used to select STAGED

BATCH or CONTINUOUS FLOW

drying. The switch will light only

after the

Control SystemControl System

Control System has been turned

Control SystemControl System

ON, the safety circuit is okay and

the RESET button on the control

panel has been pressed.

LOAD AUGER SWITCH(6)LOAD AUGER SWITCH(6)

LOAD AUGER SWITCH(6)

LOAD AUGER SWITCH(6)LOAD AUGER SWITCH(6)

This is used to select the operation

of the

and MANUAL position the

gerger

ger will operate if the dryer is low

gerger

on grain and will automatically shut

off when the dryer is full. In the

AUTO position only, the dryer will

shutdown after a preset period of

time set on the OUT OF GRAIN

TIMER, or if grain flow is interrupted

to the dryer. The switch will light

whenever the

ing.

to AUTO or MANUAL it also controls

the operation of any

equipmentequipment

equipment being utilized, such as

equipmentequipment

an

service lightservice light

service light is turned ON

service lightservice light

Electronic MonitoringElectronic Monitoring

Electronic Monitoring

Electronic MonitoringElectronic Monitoring

load augerload auger

load auger. In both the AUTO

load augerload auger

(Note: When this switch is set

auxiliary auger or conveyor.auxiliary auger or conveyor.

auxiliary auger or conveyor.

auxiliary auger or conveyor.auxiliary auger or conveyor.

Electronic Moni-Electronic Moni-

Electronic Moni-

Electronic Moni-Electronic Moni-

load au-load au-

load au-

load au-load au-

load augerload auger

load auger is operat-

load augerload auger

auxiliary loadauxiliary load

auxiliary load

auxiliary loadauxiliary load

FAN SWITCHES(7)FAN SWITCHES(7)

FAN SWITCHES(7)

FAN SWITCHES(7)FAN SWITCHES(7)

fanfan

Each

fan is turned ON or OFF with

fanfan

this switch. The ON position oper-

ates the

STAGED BATCH and CONTINU-

OUS FLOW modes. The AUTO po-

sition operates the

BATCH during the dry and cool

cycle. The switch will light up when-

ever the airflow switch is sensing

airflow and the dryer is full of grain.

This switch is used to turn the

burner burner

burner ON or OFF. The AUTO po-

burner burner

sition operates the

STAGED BATCH during the dry

cycle. The ON position will operate

the

ning. The switch will light up only when

the flame sensor detects the flame.

The UNLOAD switch turns the

tering rolls and discharge augertering rolls and discharge auger

tering rolls and discharge auger

tering rolls and discharge augertering rolls and discharge auger

ON or OFF, and selects the opera-

tion of the

• In the

MOISTURE CONTROL switch is

ON, and the DRYING MODE

switch is turned to CONTINUOUS

FLOW, the METERING ROLL

SPEED will alternate between the

HIGH speed metering roll potenti-

ometer setting and the LOW

speed metering roll potentiometer

setting depending on the control

signal from the MOISTURE CON-

TROL THERMOSTAT. The

charge augercharge auger

charge auger will operate con-

charge augercharge auger

tinuously.

fanfan

fan continuously during

fanfan

fan fan

fan in STAGED

fan fan

HEATER SWITCHES(8)HEATER SWITCHES(8)

HEATER SWITCHES(8)

HEATER SWITCHES(8)HEATER SWITCHES(8)

burnerburner

burner in

burnerburner

burnerburner

burner only when the

burnerburner

UNLOAD SWITCH(9)UNLOAD SWITCH(9)

UNLOAD SWITCH(9)

UNLOAD SWITCH(9)UNLOAD SWITCH(9)

metering rollsmetering rolls

metering rolls.

metering rollsmetering rolls

2 SPEED

position if the

fanfan

fan is run-

fanfan

me-me-

me-

me-me-

dis-dis-

dis-

dis-dis-

• In the 1 SPEED position, if the

MOISTURE CONTROL switch is

ON, and the DRYING MODE

switch is turned to CONTINUOUS

FLOW, the METERING ROLL

SPEED will operate at the HIGH

speed metering roll potentiometer

setting or turn OFF depending on

the control signal from the MOIS-

TURE CONTROL THERMOSTAT.

discharge augerdischarge auger

The

discharge auger will operate

discharge augerdischarge auger

whenever the

erating.

• In both the 1 SPEED or the 2

SPEED position, if the MOIS-

TURE CONTROL THERMOSTAT

is OFF, and the DRYING MODE

switch is turned to CONTINUOUS

FLOW, the METERING ROLL

SPEED can be manually con-

trolled by adjusting the HIGH

speed metering roll potentiometer.

discharge auger discharge auger

The

discharge auger will operate

discharge auger discharge auger

continuously.

• If the DRYING MODE switch is

turned to STAGED BATCH, the

UNLOAD switch should be set to

the 1 SPEED position. The

charge auger and meteringcharge auger and metering

charge auger and metering

charge auger and meteringcharge auger and metering

rollsrolls

rolls will only operate during

rollsrolls

the unload cycle of the staged

batch operation, and the ME-

TERING ROLL SPEED is ad-

justed using the HIGH speed

metering roll potentiometer.

Note: When this switch is set to

AUTO or MANUAL it also controls

the operation of any

equipmentequipment

equipment being utilized, such as

equipmentequipment

auxiliary auger or conveyorauxiliary auger or conveyor

an

auxiliary auger or conveyor.

auxiliary auger or conveyorauxiliary auger or conveyor

metering rolls metering rolls

metering rolls are op-

metering rolls metering rolls

dis-dis-

dis-

dis-dis-

auxiliary loadauxiliary load

auxiliary load

auxiliary loadauxiliary load

11

Page 12

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

LOW SPEED METERINGLOW SPEED METERING

LOW SPEED METERING

LOW SPEED METERINGLOW SPEED METERING

ROLL POTENTIOMETER(10)ROLL POTENTIOMETER(10)

ROLL POTENTIOMETER(10)

ROLL POTENTIOMETER(10)ROLL POTENTIOMETER(10)

This is used to adjust the LOW

speed of the

2 SPEED and MOISTURE CON-

TROL THERMOSTAT are in use.

HIGH SPEED METERINGHIGH SPEED METERING

HIGH SPEED METERING

HIGH SPEED METERINGHIGH SPEED METERING

ROLL POTENTIOMETER(11)ROLL POTENTIOMETER(11)

ROLL POTENTIOMETER(11)

ROLL POTENTIOMETER(11)ROLL POTENTIOMETER(11)

This is used to:

• Set the HIGH speed of the

ing rolling roll

ing roll when the 2 SPEED auto-

ing rolling roll

matic moisture control feature of the

dryer is utilized.

• Set the speed of the

when the 1 SPEED automatic

metering rollmetering roll

metering roll when the

metering rollmetering roll

meter-meter-

meter-

meter-meter-

metering rollsmetering rolls

metering rolls

metering rollsmetering rolls

moisture control feature of the

dryer is utilized.

• Set the speed of the

rolls rolls

rolls during continuous flow op-

rolls rolls

eration when the moisture control

is not used.

• Set the rate of grain discharge from

the dryer during the unload cycle of

staged batch dryer operation.

DRYER POWERDRYER POWER

DRYER POWER

DRYER POWERDRYER POWER

START SWITCH(12)START SWITCH(12)

START SWITCH(12)

START SWITCH(12)START SWITCH(12)

This switch starts and operates the

dryer based on switch settings. If

other switch settings are in the OFF

position, individual dryer compo-

meteringmetering

metering

meteringmetering

nents can be operated by turning the

DRYING MODE switch to CON-

TINUOUS FLOW, pressing the

DRYER POWER START button and

then turning ON the desired dryer

component.

DRYER POWERDRYER POWER

DRYER POWER

DRYER POWERDRYER POWER

STOP SWITCH(13)STOP SWITCH(13)

STOP SWITCH(13)

STOP SWITCH(13)STOP SWITCH(13)

This switch stops all dryer func-

tions. If an automatic dryer shut-

down occurs, first determine and

correct the cause of the shutdown.

Then, press the DRYER POWER

STOP button to reset the dryer be-

fore restarting.

12

An Airstream C-Series Dryer Control Panel (four fan model) mounted on the dryer.An Airstream C-Series Dryer Control Panel (four fan model) mounted on the dryer.

An Airstream C-Series Dryer Control Panel (four fan model) mounted on the dryer.

An Airstream C-Series Dryer Control Panel (four fan model) mounted on the dryer.An Airstream C-Series Dryer Control Panel (four fan model) mounted on the dryer.

Page 13

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

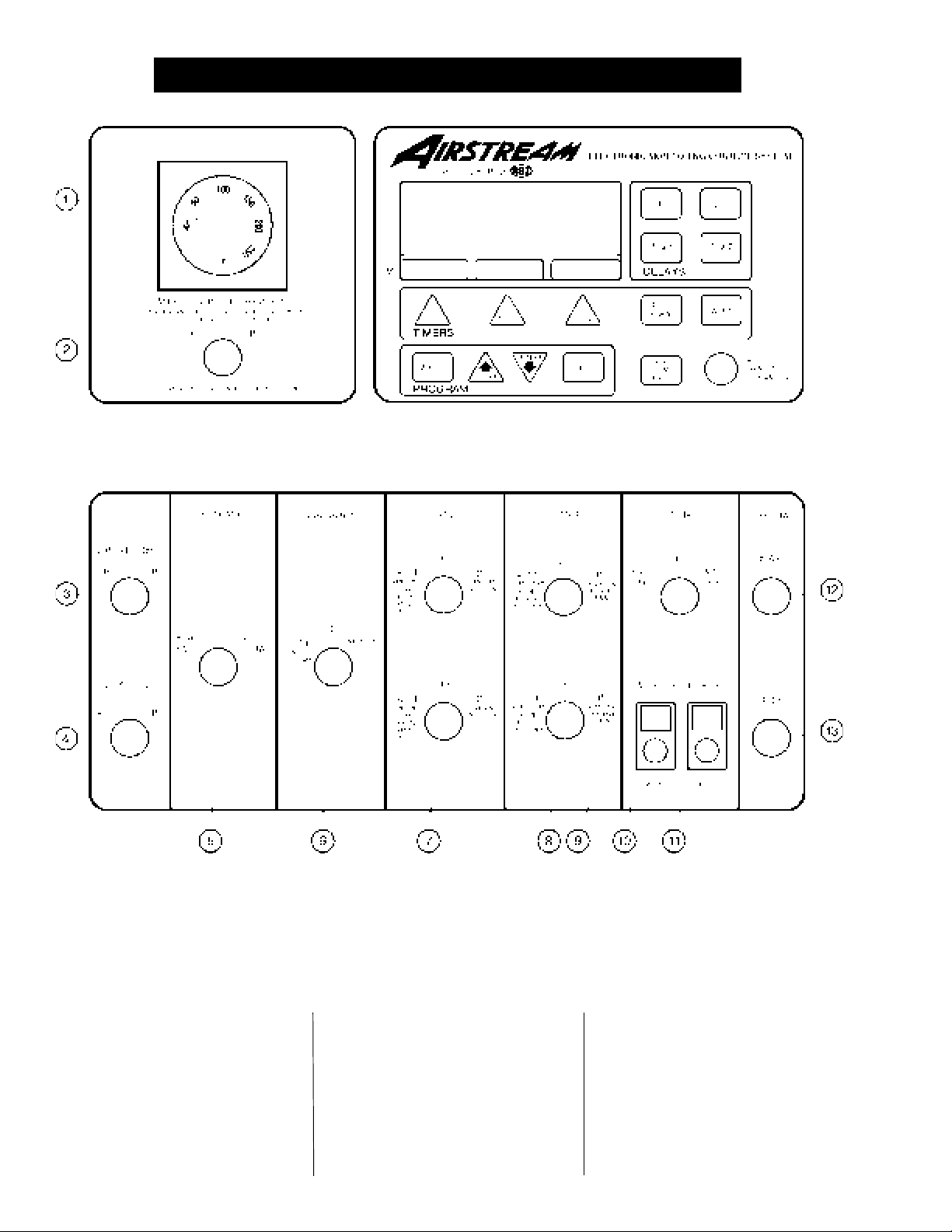

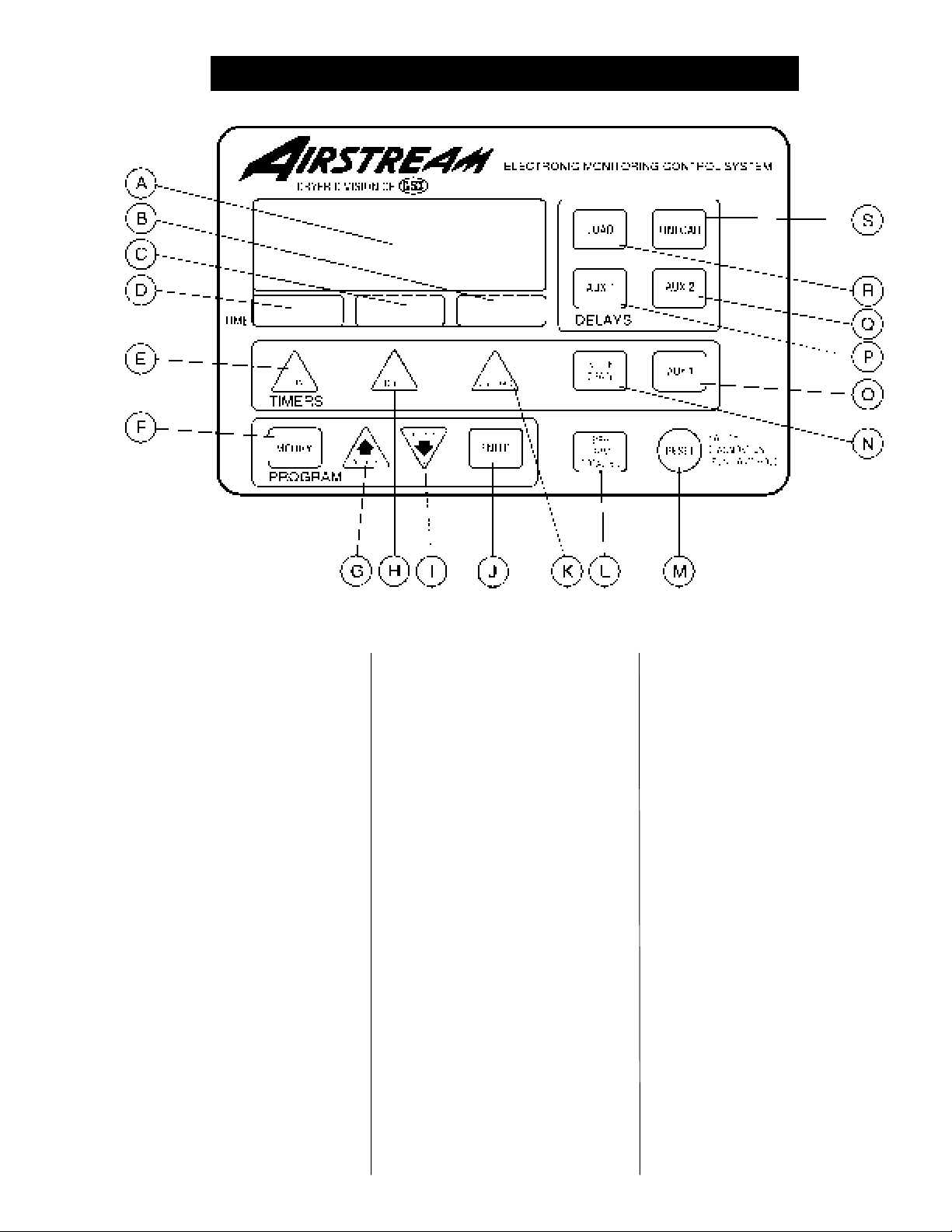

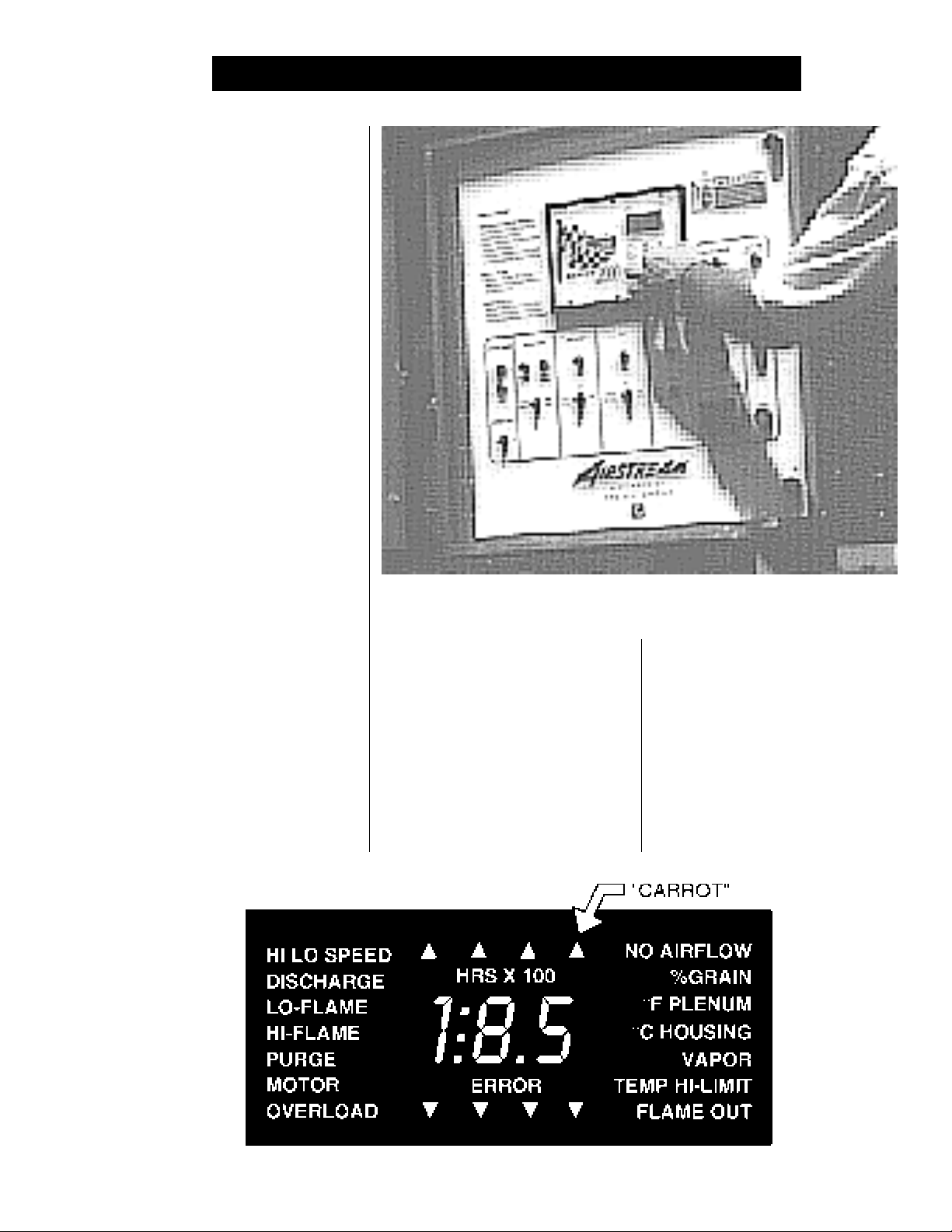

Figure 2: The C-Series Airstream Electronic Monitoring Control System.Figure 2: The C-Series Airstream Electronic Monitoring Control System.

Figure 2: The C-Series Airstream Electronic Monitoring Control System.

Figure 2: The C-Series Airstream Electronic Monitoring Control System.Figure 2: The C-Series Airstream Electronic Monitoring Control System.

ELECTRONICELECTRONIC

ELECTRONIC

ELECTRONICELECTRONIC

MONITORING CONTROLMONITORING CONTROL

MONITORING CONTROL

MONITORING CONTROLMONITORING CONTROL

SYSTEMSYSTEM

SYSTEM

SYSTEMSYSTEM

Electronic Monitoring ControlElectronic Monitoring Control

The

Electronic Monitoring Control

Electronic Monitoring ControlElectronic Monitoring Control

SystemSystem

System (fig. 2) controls all timing

SystemSystem

functions and safety circuit checks.

It is designed to simplify dryer op-

eration by providing printed mes-

sages and warnings on its liquid

crystal display (LCD).

TURNING ON THETURNING ON THE

TURNING ON THE

TURNING ON THETURNING ON THE

ELECTRONICELECTRONIC

ELECTRONIC

ELECTRONICELECTRONIC

MONITORING CONTROLMONITORING CONTROL

MONITORING CONTROL

MONITORING CONTROLMONITORING CONTROL

SYSTEMSYSTEM

SYSTEM

SYSTEMSYSTEM

Turn the CONTROL POWER switch

to ON. The monitor will display a

copyright message and model num-

ber, total running time in hours and

minutes and the current time and

date (fig. 2-A). To activate the control-

ler press the RESET button (fig. 2-M).

SETTING THE DRY, COOL,SETTING THE DRY, COOL,

SETTING THE DRY, COOL,

SETTING THE DRY, COOL,SETTING THE DRY, COOL,

UNLOAD AND BATCHUNLOAD AND BATCH

UNLOAD AND BATCH

UNLOAD AND BATCHUNLOAD AND BATCH

TIMERSTIMERS

TIMERS

TIMERSTIMERS

The DRY, COOL and UNLOAD tim-

ers (fig. 2-E, H, K) are used to set

the cycle times in the STAGED

BATCH DRYING MODE only. To

use and display the settings on

these three TIMERS, the DRYING

MODE switch (fig. 1-6) must be in

the STAGED BATCH position. The

current setting on these three TIM-

ERS is displayed directly above

each TIMER button (fig. 2-B, C, D).

To change the setting of these TIM-

ERS follow these instructions:

1. Press the DRY, COOL or UN-

LOAD TIMER button (fig. 2-E,

H, K).

2. Press the MODIFY button (fig.

2-F).

3. Press the INCREASE or DE-

CREASE (fig. 2-G, I) button to

adjust the settings.

4. Press the ENTER button to en-

ter new setting into the control-

ler (fig. 2-J).

After the DRY, COOL or UNLOAD

button is pressed, screen messages

on the LCD display of the

Monitoring Control SystemMonitoring Control System

Monitoring Control System direct

Monitoring Control SystemMonitoring Control System

the dryer operation through the proper

sequence for setting the TIMERS.

During operation the remaining time

on each TIMER is displayed. If the

power goes out or if the dryer is

stopped, these times are saved by the

controller. When the dryer is restarted

the TIMERS will continue timing

down from these times. They will

return to their initial setting if the

RESET button (fig. 2, M) is pushed.

ElectronicElectronic

Electronic

ElectronicElectronic

13

Page 14

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

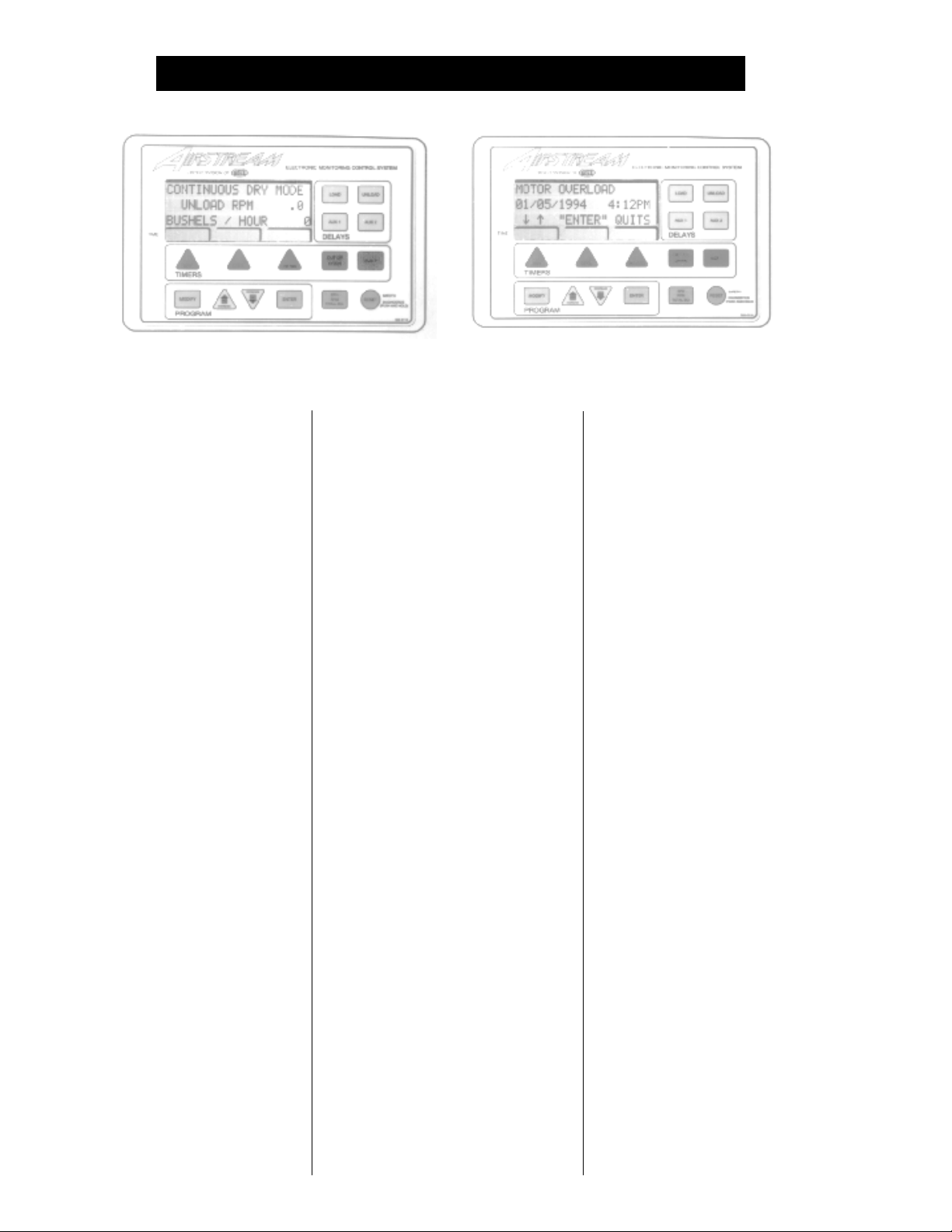

The Airstream Electronic Monitoring Control System showing several different LCD displays.The Airstream Electronic Monitoring Control System showing several different LCD displays.

The Airstream Electronic Monitoring Control System showing several different LCD displays.

The Airstream Electronic Monitoring Control System showing several different LCD displays.The Airstream Electronic Monitoring Control System showing several different LCD displays.

SETTING THE OUT OFSETTING THE OUT OF

SETTING THE OUT OF

SETTING THE OUT OFSETTING THE OUT OF

GRAIN TIMERGRAIN TIMER

GRAIN TIMER

GRAIN TIMERGRAIN TIMER

If the dryer runs out of grain while

the LOAD AUGER switch (fig. 1-7)

is in the AUTO position, the OUT OF

GRAIN timer (fig. 2-N) automatically

shuts OFF the dryer after the period

of time preset on the TIMER. When

pressed, the display will show the

amount of time left on the TIMER

and the percentage of time used by

the last load. A second screen will

appear with the TIMER'S setting,

and may be modified as described

in the BATCH TIMER section.

SETTING THE LOAD ANDSETTING THE LOAD AND

SETTING THE LOAD AND

SETTING THE LOAD ANDSETTING THE LOAD AND

UNLOAD DELAYSUNLOAD DELAYS

UNLOAD DELAYS

UNLOAD DELAYSUNLOAD DELAYS

Electronic Monitoring ControlElectronic Monitoring Control

The

Electronic Monitoring Control

Electronic Monitoring ControlElectronic Monitoring Control

System System

System has four built in TIMER de-

System System

lays. The LOAD DELAY (fig. 2-R) is

used to delay the starting of the

augerauger

auger when the dryer is unloading

augerauger

to prevent the

ing and stopping. The UNLOAD

DELAY (fig. 2-S) is used to control

the amount of time the

gerger

ger runs after the

gerger

stop to allow for

Both the LOAD and UNLOAD DE-

LAYS are set using the same pro-

load augerload auger

load auger from start-

load augerload auger

metering rollsmetering rolls

metering rolls

metering rollsmetering rolls

auger auger

auger cleanout.

auger auger

loadload

load

loadload

unload au-unload au-

unload au-

unload au-unload au-

cedure as the TIMERS. The AUX 1

(fig.2-P) and AUX 2 (fig. 2-Q) DE-

LAYS are presently not being used.

UTILIZING THEUTILIZING THE

UTILIZING THE

UTILIZING THEUTILIZING THE

BUSHEL COUNTERBUSHEL COUNTER

BUSHEL COUNTER

BUSHEL COUNTERBUSHEL COUNTER

When the dryer is operating, the

LCD display (fig. 2-A) shows the

DRYER MODE OF OPERATION on

the first line, the BUSHELS PER

HOUR or the METERING ROLL

RPM on the second line and the

TOTAL BUSHELS DRIED on the

third line. By pressing the BPH/

RPM/TOTAL BU button (fig. 2-L) the

second line will alternate between

the METERING ROLL RPM's or the

BUSHEL PER HOUR rate that the

metering rollsmetering rolls

metering rolls are removing grain

metering rollsmetering rolls

from the dryer. The TOTAL BUSH-

ELS DRIED reading is the total since

the bushel counter was last reset.

To reset the BUSHEL COUNTER,

press and hold the RESET button

(fig. 2-M) for five seconds. Press the

ENTER button (fig. 2-J) through the

date and time settings, and follow

the instructions displayed on the

LCD for resetting the counter.

In the BATCH MODE, the first

line of the LCD display tells which

TIMER is being used, and the sec-

ond line switches between TOTAL

BATCHES, UNLOAD RPM or TOTAL

BUSHELS. The third line indicates

TOTAL DRY TIME, and the fourth line

is TIME REMAINING on the TIMERS.

DRYER SAFETY CIRCUITDRYER SAFETY CIRCUIT

DRYER SAFETY CIRCUIT

DRYER SAFETY CIRCUITDRYER SAFETY CIRCUIT

Electronic Monitoring ControlElectronic Monitoring Control

The

Electronic Monitoring Control

Electronic Monitoring ControlElectronic Monitoring Control

System System

System continuously checks all

System System

safety circuits on the dryer, and will

automatically shut the dryer down

should a problem occur. The cause

of the dryer shutdown will be dis-

played on the LCD display (fig. 2-

A), and a beeper will sound on the

controller. To restart the dryer after

a safety shutdown, first correct the

reason for the shutdown, and then

press the DRYER POWER STOP

(FIG. 1-14) button to reset the circuit.

Press the START button (fig. 1-13).

Electronic Monitoring Electronic Monitoring

The

Electronic Monitoring

Electronic Monitoring Electronic Monitoring

Control System Control System

Control System stores in its

Control System Control System

memory the time, date and cause for

the last 25 dryer safety shutdowns.

To review this information, hold the

RESET button in for five seconds.

The procedure for reviewing the

safety circuit shutdown log will be

displayed on the LCD display.

14

Page 15

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANELC-SERIES DRYER CONTROL PANEL

SAFETY CIRCUIT SHUTDOWN MESSAGESSAFETY CIRCUIT SHUTDOWN MESSAGES

SAFETY CIRCUIT SHUTDOWN MESSAGES

SAFETY CIRCUIT SHUTDOWN MESSAGESSAFETY CIRCUIT SHUTDOWN MESSAGES

BURNER VAPOR HIGHBURNER VAPOR HIGH

BURNER VAPOR HIGH

BURNER VAPOR HIGHBURNER VAPOR HIGH

TEMPERATURETEMPERATURE

TEMPERATURE

TEMPERATURETEMPERATURE

The LP gas vapor

sorsor

sor located in the

sorsor

downstream from the vaporizer, has

opened indicating that the vaporizer

is running too hot and must be read-

justed. This sensor is set at 200°F

and automatically resets itself when

cool. The message will distinguish

between burners.

BURNER WARNING FLAMEBURNER WARNING FLAME

BURNER WARNING FLAME

BURNER WARNING FLAMEBURNER WARNING FLAME

NOT DETECTEDNOT DETECTED

NOT DETECTED

NOT DETECTEDNOT DETECTED

flame sensorflame sensor

The

flame sensor has failed to de-

flame sensorflame sensor

tect a burner flame indicating that the

burner has failed to light. There is a

problem with the flame sensing cir-

cuitry or the dryer is not getting

burner fuel. The message will dis-

tinguish between burners.

FAN HOUSING HIGHFAN HOUSING HIGH

FAN HOUSING HIGH

FAN HOUSING HIGHFAN HOUSING HIGH

TEMPERATURETEMPERATURE

TEMPERATURE

TEMPERATURETEMPERATURE

temperature high limittemperature high limit

The

temperature high limit located

temperature high limittemperature high limit

on the

opened, indicating an over tempera-

ture condition has occurred towards

the rear of the

This control is set at 200°F and must

be manually reset. The message will

distinguish between fans.

The contacts in the

opened due to insufficient airflow for

the

will distinguish between burners.

The

has opened, indicating that grain is

backing up into the

fan/burner housingfan/burner housing

fan/burner housing has

fan/burner housingfan/burner housing

BURNER SHUTDOWNBURNER SHUTDOWN

BURNER SHUTDOWN

BURNER SHUTDOWNBURNER SHUTDOWN

LOSS OF AIRFLOWLOSS OF AIRFLOW

LOSS OF AIRFLOW

LOSS OF AIRFLOWLOSS OF AIRFLOW

burnerburner

burner to operate. The message

burnerburner

GRAIN DISCHARGEGRAIN DISCHARGE

GRAIN DISCHARGE

GRAIN DISCHARGEGRAIN DISCHARGE

WARNINGWARNING

WARNING

WARNINGWARNING

lid on the grain discharge box lid on the grain discharge box

lid on the grain discharge box

lid on the grain discharge box lid on the grain discharge box

temperature sen-temperature sen-

temperature sen-

temperature sen-temperature sen-

gas pipe traingas pipe train

gas pipe train

gas pipe traingas pipe train

fan/heater housingfan/heater housing

fan/heater housing.

fan/heater housingfan/heater housing

air switchair switch

air switch have

air switchair switch

discharge boxdischarge box

discharge box.

discharge boxdischarge box

LOWER ADJUSTABLELOWER ADJUSTABLE

LOWER ADJUSTABLE

LOWER ADJUSTABLELOWER ADJUSTABLE

GRAIN HIGHGRAIN HIGH

GRAIN HIGH

GRAIN HIGHGRAIN HIGH

TEMPERATURETEMPERATURE

TEMPERATURE

TEMPERATURETEMPERATURE

An over temperature condition has oc-

curred in the

as viewed from behind the dryer)

grain column grain column

grain column causing the control to

grain column grain column

shut down the dryer. This control is

adjustable from 80° to 220°F, and au-

tomatically resets itself when cool.

LOWER FIXED GRAINLOWER FIXED GRAIN

LOWER FIXED GRAIN

LOWER FIXED GRAINLOWER FIXED GRAIN

HIGH TEMPERATUREHIGH TEMPERATURE

HIGH TEMPERATURE

HIGH TEMPERATUREHIGH TEMPERATURE

An over temperature condition has oc-

curred in the

viewed from behind the dryer)

umn umn

umn causing the control to shutdown

umn umn

the dryer. This control is set at 210°F

and automatically resets itself when cool.

MOTOR OVERLOADMOTOR OVERLOAD

MOTOR OVERLOAD

MOTOR OVERLOADMOTOR OVERLOAD

One of the

either the

iliary motorsiliary motors

iliary motors has opened, indicat-

iliary motorsiliary motors

ing an overcurrent condition. The

overloadsoverloads

overloads must be manually reset.

overloadsoverloads

OUT OF GRAIN WARNING/OUT OF GRAIN WARNING/

OUT OF GRAIN WARNING/

OUT OF GRAIN WARNING/OUT OF GRAIN WARNING/

UNLOAD CLEANOUTUNLOAD CLEANOUT

UNLOAD CLEANOUT

UNLOAD CLEANOUTUNLOAD CLEANOUT

The dryer has run low on grain, and

the OUT OF GRAIN TIMER has

timed out, shutting the dryer down.

unload augerunload auger

The

unload auger will clean out the

unload augerunload auger

dryer if it is in continuous flow op-

eration with the unload switch on.

SUPPLY WARNINGSUPPLY WARNING

SUPPLY WARNING

SUPPLY WARNINGSUPPLY WARNING

right circuit breakerright circuit breaker

The

right circuit breaker on the

right circuit breakerright circuit breaker

put/output boardput/output board

put/output board has tripped.

put/output boardput/output board

L1 VOLTAGE LOSTL1 VOLTAGE LOST

L1 VOLTAGE LOST

L1 VOLTAGE LOSTL1 VOLTAGE LOST

left circuit breakerleft circuit breaker

The

left circuit breaker located on

left circuit breakerleft circuit breaker

input/output board input/output board

the

input/output board of the

input/output board input/output board

tronic Monitoring Control Systemtronic Monitoring Control System

tronic Monitoring Control System

tronic Monitoring Control Systemtronic Monitoring Control System

has tripped, or one of the hardware

timers has shut down the dryer.

right sideright side

right side (left and right

right sideright side

left side left side

left side (left and right as

left side left side

grain col- grain col-

grain col-

grain col- grain col-

thermal overloadsthermal overloads

thermal overloads on

thermal overloadsthermal overloads

fan, load, unload fan, load, unload

fan, load, unload or

fan, load, unload fan, load, unload

12 VOLT POWER12 VOLT POWER

12 VOLT POWER

12 VOLT POWER12 VOLT POWER

aux-aux-

aux-

aux-aux-

in-in-

in-

in-in-

Elec-Elec-

Elec-

Elec-Elec-

METERING ROLL DRIVEMETERING ROLL DRIVE

METERING ROLL DRIVE

METERING ROLL DRIVEMETERING ROLL DRIVE

SYSTEM FAILURESYSTEM FAILURE

SYSTEM FAILURE

SYSTEM FAILURESYSTEM FAILURE

metering roll drive metering roll drive

The

metering roll drive

metering roll drive metering roll drive

failed to turn. A broken chain or jammed

metering roll is a possible cause.

RIGHT METERING ROLLRIGHT METERING ROLL

RIGHT METERING ROLL

RIGHT METERING ROLLRIGHT METERING ROLL

FAILUREFAILURE

FAILURE

FAILUREFAILURE

right right

The

right (as viewed from behind the

right right

metering roll metering roll

dryer)

metering roll has stopped turn-

metering roll metering roll

ing, or the sensor has been damaged.

LEFT METERING ROLLLEFT METERING ROLL

LEFT METERING ROLL

LEFT METERING ROLLLEFT METERING ROLL

FAILUREFAILURE

FAILURE

FAILUREFAILURE

left left

The

left (as viewed from behind the

left left

metering rollmetering roll

dryer)

metering roll has stopped turn-

metering rollmetering roll

ing, or the sensor has been damaged.

PLENUM HIGHPLENUM HIGH

PLENUM HIGH

PLENUM HIGHPLENUM HIGH

TEMPERATURETEMPERATURE

TEMPERATURE

TEMPERATURETEMPERATURE

An over temperature condition has

occurred inside the

This control is a 300°F limit and au-

tomatically resets itself when cool.

The message will distinguish be-

tween plenums.

AUXILIARY SAFETYAUXILIARY SAFETY

AUXILIARY SAFETY

AUXILIARY SAFETYAUXILIARY SAFETY

SHUTDOWNSHUTDOWN

SHUTDOWN

SHUTDOWNSHUTDOWN

A shutdown has occurred due to an

auxiliary installed safety feature.

FAN FAILURE NO AIRFLOWFAN FAILURE NO AIRFLOW

FAN FAILURE NO AIRFLOW

FAN FAILURE NO AIRFLOWFAN FAILURE NO AIRFLOW

air switchair switch

The

air switch contacts have opened.

air switchair switch

fanfan

The

fan may not be turning, or the

fanfan

switchswitch

switch may need adjustment. The mes-

switchswitch

sage will distinguish between fans.

FAN CANNOT FAN CANNOT

FAN CANNOT

FAN CANNOT FAN CANNOT

CHECK AIR SWITCHCHECK AIR SWITCH

CHECK AIR SWITCH

CHECK AIR SWITCHCHECK AIR SWITCH

air switchair switch

The

air switch contacts have closed

air switchair switch

prior to the

freewheeling

ting of the

will distinguish between fans.

fan fan

fan starting, indicating a

fan fan

bladeblade

blade or improper set-

bladeblade

air switchair switch

air switch. The message

air switchair switch

systemsystem

system has

systemsystem

dryer plenumdryer plenum

dryer plenum.

dryer plenumdryer plenum

airair

air

airair

STARTSTART

START

STARTSTART

15

Page 16

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

16

Page 17

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

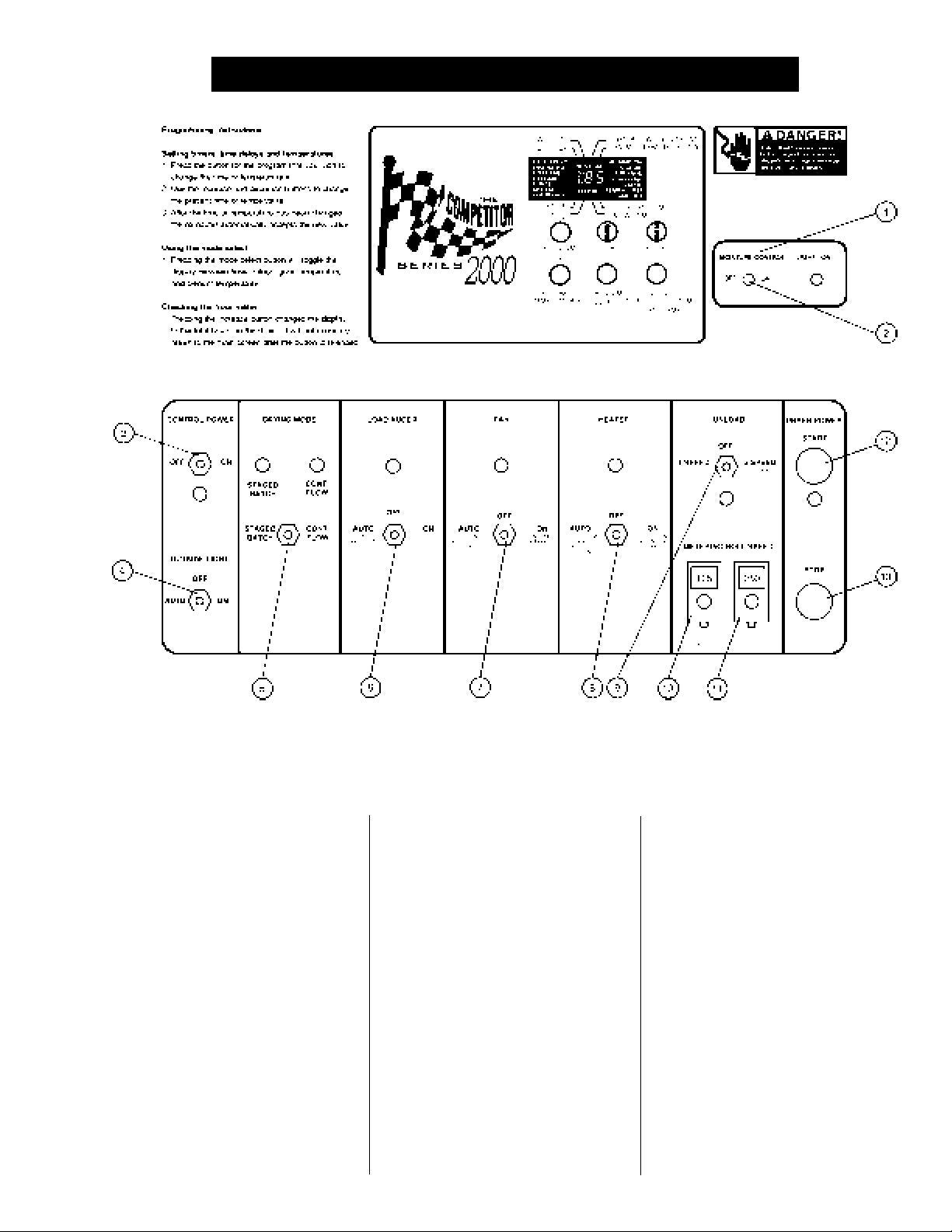

DRYER CONTROL PANEL FEATURING THE COMPETITORDRYER CONTROL PANEL FEATURING THE COMPETITOR

DRYER CONTROL PANEL FEATURING THE COMPETITOR

DRYER CONTROL PANEL FEATURING THE COMPETITORDRYER CONTROL PANEL FEATURING THE COMPETITOR

SERIES 2000 CONTROL SYSTEMSERIES 2000 CONTROL SYSTEM

SERIES 2000 CONTROL SYSTEM

SERIES 2000 CONTROL SYSTEMSERIES 2000 CONTROL SYSTEM

control panelcontrol panel

The

control panel provides easy

control panelcontrol panel

access to gauges and controls. The

Competitor Series 2000 Control

System is a computerized control

system that gives instant information

regarding dryer operation.

MOISTURE CONTROL(1)MOISTURE CONTROL(1)

MOISTURE CONTROL(1)

MOISTURE CONTROL(1)MOISTURE CONTROL(1)

The Series 2000 Dryer has a built in

moisture control. It controls the

moisture level of discharged grain

by sensing grain column temperature.

MOISTURE CONTROLMOISTURE CONTROL

MOISTURE CONTROL

MOISTURE CONTROLMOISTURE CONTROL

SWITCH(2)SWITCH(2)

SWITCH(2)

SWITCH(2)SWITCH(2)

This switch turns the power ON or

Figure 3: The grain dryer control panel.Figure 3: The grain dryer control panel.

Figure 3: The grain dryer control panel.

Figure 3: The grain dryer control panel.Figure 3: The grain dryer control panel.

OFF to the moisture control. The light

beside the switch is illuminated when

the grain column temperature is be-

low the moisture control set point.

CONTROL POWERCONTROL POWER

CONTROL POWER

CONTROL POWERCONTROL POWER

SWITCH(3)SWITCH(3)

SWITCH(3)

SWITCH(3)SWITCH(3)

The power to the Competitor 2000

Control System is turned on or off

with this switch.

OUTSIDE LIGHT(4)OUTSIDE LIGHT(4)

OUTSIDE LIGHT(4)

OUTSIDE LIGHT(4)OUTSIDE LIGHT(4)

The dryer outside light is turned on

or off here. In auto the light turns

off if the dryer has a shutdown.

DRYING MODE SWITCH(5)DRYING MODE SWITCH(5)

DRYING MODE SWITCH(5)

DRYING MODE SWITCH(5)DRYING MODE SWITCH(5)

This is used to select staged batch

or continuous flow drying.

LOAD AUGER SWITCH(6)LOAD AUGER SWITCH(6)

LOAD AUGER SWITCH(6)

LOAD AUGER SWITCH(6)LOAD AUGER SWITCH(6)

This is used to select the opera-

tion of the

AUTO and MANUAL position the

load auger load auger

load auger will operate if the dryer

load auger load auger

is low on grain and will automati-

cally shut off when the dryer is full.

In the AUTO position only, the

dryer will shut down after a preset

period of time set on the OUT OF

GRAIN TIMER.

load augerload auger

load auger. In both the

load augerload auger

17

Page 18

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

Note: When this switch is set to

AUTO or MANUAL it also controls

the operation of any

equipmentequipment

equipment being utilized, such as

equipmentequipment

auxiliary auger or conveyorauxiliary auger or conveyor

an

auxiliary auger or conveyor.

auxiliary auger or conveyorauxiliary auger or conveyor

FAN SWITCH(7)FAN SWITCH(7)

FAN SWITCH(7)

FAN SWITCH(7)FAN SWITCH(7)

fanfan

The

fan is turned ON or OFF with this

fanfan

switch. The ON position operates the

fan fan

fan continuously during STAGED

fan fan

BATCH and CONTINUOUS FLOW

modes. The AUTO position operates

fan fan

the

fan in STAGED BATCH during the

fan fan

dry and cool cycle. The light comes

on only when air pressure is sensed.

HEATER SWITCH(8)HEATER SWITCH(8)

HEATER SWITCH(8)

HEATER SWITCH(8)HEATER SWITCH(8)

This switch is used to turn the

ON or OFF. The AUTO position op-

erates the

during the dry cycle. The ON posi-

tion will operate the

the

comes on only when flame is detected.

The UNLOAD switch turns the

tering rolls and discharge augertering rolls and discharge auger

tering rolls and discharge auger

tering rolls and discharge augertering rolls and discharge auger

ON or OFF, and selects the opera-

tion of the

• In the

MOISTURE CONTROL switch is

ON, and the DRYING MODE

switch is turned to CONTINUOUS

FLOW, the METERING ROLL

SPEED will alternate between the

HIGH speed metering roll potenti-

ometer setting and the LOW

speed metering roll potentiometer

setting depending on the control sig-

nal from the MOISTURE CONTROL

THERMOSTAT. The

gerger

ger will operate continuously.

gerger

burnerburner

burner in STAGED BATCH

burnerburner

fanfan

fan is running. The burner light

fanfan

UNLOAD SWITCH(9)UNLOAD SWITCH(9)

UNLOAD SWITCH(9)

UNLOAD SWITCH(9)UNLOAD SWITCH(9)

metering rollsmetering rolls

metering rolls.

metering rollsmetering rolls

2 SPEED position if the

auxiliary loadauxiliary load

auxiliary load

auxiliary loadauxiliary load

burnerburner

burner

burnerburner

burner burner

burner only when

burner burner

me-me-

me-

me-me-

discharge au-discharge au-

discharge au-

discharge au-discharge au-

• In the 1 SPEED position, if the

MOISTURE CONTROL switch is

ON, and the DRYING MODE

switch is turned to CONTINUOUS

FLOW, the METERING ROLL

SPEED will operate at the HIGH

speed metering roll potentiometer

setting or turn OFF depending on

the control signal from the MOIS-

TURE CONTROL THERMO-

STAT. The

operate whenever the

rolls rolls

rolls are operating.

rolls rolls

• In both the 1 SPEED or the 2

SPEED position, if the MOIS-

TURE CONTROL THERMOSTAT

is OFF, and the DRYING MODE

switch is turned to CONTINUOUS

FLOW, the METERING ROLL

SPEED can be manually con-

trolled by adjusting the HIGH

speed metering roll potentiometer.

discharge auger discharge auger

The

discharge auger will operate

discharge auger discharge auger

continuously.

• If the DRYING MODE switch is

turned to STAGED BATCH, the UN-

LOAD switch should be set to the 1

SPEED position. The

auger and metering rollsauger and metering rolls

auger and metering rolls will only

auger and metering rollsauger and metering rolls

operate during the unload cycle of

the staged batch operation, and the

speed of the

justed using the HIGH speed me-

tering roll potentiometer.

Note: When this switch is set to

AUTO or MANUAL it also controls

the operation of any

equipment equipment

equipment being utilized, such as

equipment equipment

auxiliary auger or conveyorauxiliary auger or conveyor

an

auxiliary auger or conveyor.

auxiliary auger or conveyorauxiliary auger or conveyor

discharge augerdischarge auger

discharge auger will

discharge augerdischarge auger

meteringmetering

metering

meteringmetering

dischargedischarge

discharge

dischargedischarge

metering rollsmetering rolls

metering rolls is ad-

metering rollsmetering rolls

auxiliary loadauxiliary load

auxiliary load

auxiliary loadauxiliary load

LOW SPEED METERINGLOW SPEED METERING

LOW SPEED METERING

LOW SPEED METERINGLOW SPEED METERING

ROLL POTENTIOMETER(10)ROLL POTENTIOMETER(10)

ROLL POTENTIOMETER(10)

ROLL POTENTIOMETER(10)ROLL POTENTIOMETER(10)

This is used to adjust the LOW

speed of the

2 SPEED automatic MOISTURE

CONTROL is in use.

HIGH SPEED METERINGHIGH SPEED METERING

HIGH SPEED METERING

HIGH SPEED METERINGHIGH SPEED METERING

ROLL POTENTIOMETER(11)ROLL POTENTIOMETER(11)

ROLL POTENTIOMETER(11)

ROLL POTENTIOMETER(11)ROLL POTENTIOMETER(11)

This is used to:

• Set the HIGH speed of the

roll roll

roll when the 2 SPEED automatic

roll roll

MOISTURE CONTROL is utilized.

• Set the speed of the

when the 1 SPEED automatic MOIS-

TURE CONTROL is utilized.

• Set the speed of the

during CONTINUOUS FLOW

operation when the MOISTURE

CONTROL is not used.

• Set the rate of grain discharge from

the dryer during the unload cycle of

staged batch dryer operation.

START SWITCH(12)START SWITCH(12)

START SWITCH(12)

START SWITCH(12)START SWITCH(12)

This switch starts and operates the

dryer based on switch settings. If

other switch settings are in the OFF

position, individual dryer compo-

nents can be operated by turning the

DRYING MODE switch to CON-

TINUOUS FLOW, pressing the

DRYER POWER START button and

turning ON the desired dryer com-

ponent.

STOP SWITCH(13)STOP SWITCH(13)

STOP SWITCH(13)

STOP SWITCH(13)STOP SWITCH(13)

This switch stops all dryer functions.

If an automatic dryer shutdown oc-

curs, first determine and correct the

cause of the shutdown. Press the

DRYER POWER STOP button to re-

set the dryer before restarting.

metering roll metering roll

metering roll when the

metering roll metering roll

metering rollsmetering rolls

metering rolls

metering rollsmetering rolls

metering rollsmetering rolls

metering rolls

metering rollsmetering rolls

DRYER POWERDRYER POWER

DRYER POWER

DRYER POWERDRYER POWER

DRYER POWERDRYER POWER

DRYER POWER

DRYER POWERDRYER POWER

meteringmetering

metering

meteringmetering

18

Page 19

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

SERIES 2000SERIES 2000

SERIES 2000

SERIES 2000SERIES 2000

CONTROL SYSTEMCONTROL SYSTEM

CONTROL SYSTEM

CONTROL SYSTEMCONTROL SYSTEM

2000 Control System2000 Control System

The

2000 Control System controls

2000 Control System2000 Control System

all timing functions and safety cir-

cuit checks. It is designed to sim-

plify dryer operation by providing

messages and warnings on its liq-

uid crystal display (LCD).

TURNING ON THE SERIESTURNING ON THE SERIES

TURNING ON THE SERIES

TURNING ON THE SERIESTURNING ON THE SERIES

2000 CONTROL SYSTEM2000 CONTROL SYSTEM

2000 CONTROL SYSTEM

2000 CONTROL SYSTEM2000 CONTROL SYSTEM

Turn the CONTROL POWER switch

to ON. The monitor will display "GSI"

and the current software version num-

ber.

SETTING THE DRY, COOL,SETTING THE DRY, COOL,

SETTING THE DRY, COOL,

SETTING THE DRY, COOL,SETTING THE DRY, COOL,

UNLOAD AND OUT OFUNLOAD AND OUT OF

UNLOAD AND OUT OF

UNLOAD AND OUT OFUNLOAD AND OUT OF

GRAIN TIMERSGRAIN TIMERS

GRAIN TIMERS

GRAIN TIMERSGRAIN TIMERS

The DRY, COOL and UNLOAD tim-

ers set cycle times in the STAGED

BATCH drying mode only. The DRY-

ING MODE switch must be in the

STAGED BATCH position. OUT OF

GRAIN sets the length of time the

dryer will run before shutting down

when the LOAD switch is in the AUTO

position. To change the setting of

these timers follow these instructions:

1. Press the PROGRAM (TIMERS)

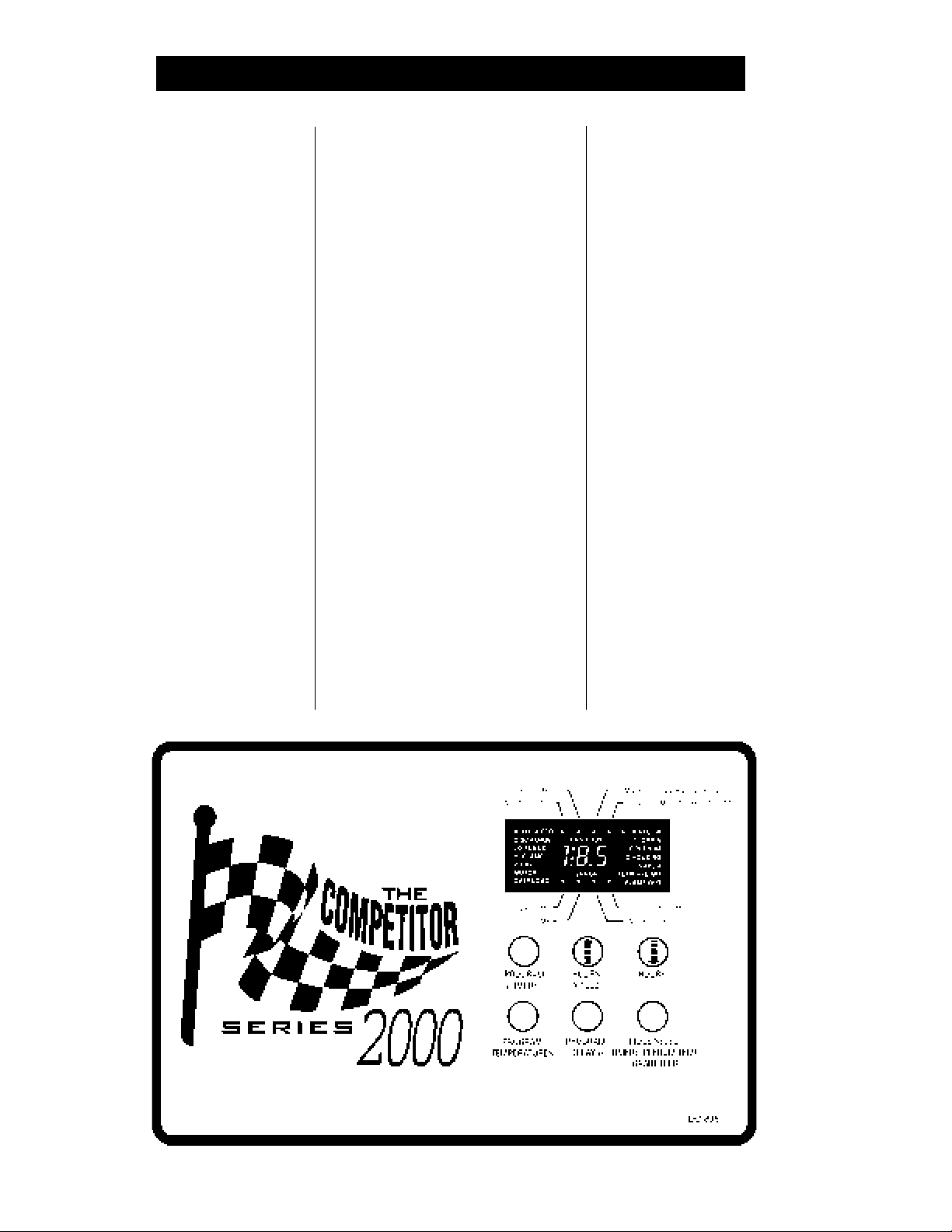

The Airstream Competitor Series 2000 Dryer Control Panel.The Airstream Competitor Series 2000 Dryer Control Panel.

The Airstream Competitor Series 2000 Dryer Control Panel.

The Airstream Competitor Series 2000 Dryer Control Panel.The Airstream Competitor Series 2000 Dryer Control Panel.

button until the "carrot" is above

the timer you want to modify.

2. Use the UP and DOWN arrow

keys to change the present time

to the desired setting. The new

time is automatically accepted.

3. Keep pressing the PROGRAM

(TIMERS) button until the carrot

disappears or press the MODE

SELECT button once to exit.

During the operation the remaining

time on each timer is displayed on

the screen. If the power goes out or

if the dryer is stopped, these times

are saved by the controller. When

Figure 4: The dryer LCD display.Figure 4: The dryer LCD display.

Figure 4: The dryer LCD display.

Figure 4: The dryer LCD display.Figure 4: The dryer LCD display.

19

Page 20

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

the dryer is restarted the timers will

continue timing down. The timers

will return to their initial settings by

pressing and holding the STOP

button for 5 seconds.

SETTING THE LOAD ANDSETTING THE LOAD AND

SETTING THE LOAD AND

SETTING THE LOAD ANDSETTING THE LOAD AND

UNLOAD DELAYSUNLOAD DELAYS

UNLOAD DELAYS

UNLOAD DELAYSUNLOAD DELAYS

The LOAD DELAY is used to delay the

starting of the

dryer is unloading to prevent the

augerauger

auger from starting and stopping too

augerauger

often. The UNLOAD DELAY is used to

control the amount of time the

augerauger

auger runs after the

augerauger

stop to allow for auger cleanout.

1. Press the PROGRAM (DELAYS)

button until the carrot is under the

time delay to be changed.

2. Use the UP and DOWN arrow

keys to change the present time

to the new one. The new time is

load augerload auger

load auger when the

load augerload auger

loadload

load

loadload

unloadunload

unload

unloadunload

metering rollsmetering rolls

metering rolls

metering rollsmetering rolls

automatically entered.

3. Keep pressing the PROGRAM

(DELAYS) button until the car-

rot disappears or press the MODE

SELECT button once to exit.

SETTING THE MOISTURESETTING THE MOISTURE

SETTING THE MOISTURE

SETTING THE MOISTURESETTING THE MOISTURE

CONTROL AND PLENUMCONTROL AND PLENUM

CONTROL AND PLENUM

CONTROL AND PLENUMCONTROL AND PLENUM

SET POINTSET POINT

SET POINT

SET POINTSET POINT

1. Press the PROGRAM (TEM-

PERATURES) button until the

carrot is under the temperature

setting to be changed.

2. Use the UPand DOWN arrow

keys to change the present tem-

perature to the new one. The

new time is automatically entered.

3. Keep pressing the PROGRAM

(TEMPERATURES) button until

the carrot disappears or press the

MODE SELECT button once to exit.

DRYER SAFETY CIRCUITDRYER SAFETY CIRCUIT

DRYER SAFETY CIRCUIT

DRYER SAFETY CIRCUITDRYER SAFETY CIRCUIT

Competitor Series 2000 Con-Competitor Series 2000 Con-

The

Competitor Series 2000 Con-

Competitor Series 2000 Con-Competitor Series 2000 Con-

trol Systemtrol System

trol System continuously checks all

trol Systemtrol System

safety circuits on the dryer, and will

automatically shut the dryer down

should a problem occur. The cause

of the dryer shutdown will be shown

on the LCD display. To restart the

dryer after a safety shutdown, first

correct the reason for the shutdown,

and then press the DRYER POWER

STOP button to reset the circuit.

Press the START button.

MONITORING GRAINMONITORING GRAIN

MONITORING GRAIN

MONITORING GRAINMONITORING GRAIN

TEMPERATURES, PLENUMTEMPERATURES, PLENUM

TEMPERATURES, PLENUM

TEMPERATURES, PLENUMTEMPERATURES, PLENUM

TEMPERATURE OR TIMERSTEMPERATURE OR TIMERS

TEMPERATURE OR TIMERS

TEMPERATURE OR TIMERSTEMPERATURE OR TIMERS

Use the mode select to decide which

of the modes you want to view.

CHECKING THE HOURCHECKING THE HOUR

CHECKING THE HOUR

CHECKING THE HOURCHECKING THE HOUR

METERMETER

METER

METERMETER

Press the UP arrow key and the total

hours on the machine are displayed.

20

Figure 5: The Competitor Series 2000 Control SystemFigure 5: The Competitor Series 2000 Control System

Figure 5: The Competitor Series 2000 Control System

Figure 5: The Competitor Series 2000 Control SystemFigure 5: The Competitor Series 2000 Control System

Page 21

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANEL

SERIES 2000 DRYER CONTROL PANELSERIES 2000 DRYER CONTROL PANEL

EMERGENCY COOLINGEMERGENCY COOLING

EMERGENCY COOLING

EMERGENCY COOLINGEMERGENCY COOLING

MODEMODE

MODE

MODEMODE

An emergency cooling mode can be

entered by switching the next to the

top switch (number seven) on the dip

switch located inside the

boxbox

box on the back of the

boxbox

control boardcontrol board

control board. This will enable a

control boardcontrol board

mode, allowing the operator to run

the dryer

is a plenum temperature or grain

high limit warning. When either of

these safeties shuts down the dryer,

fanfan

fan only, in the case there

fanfan

controlcontrol

control

controlcontrol

computercomputer

computer

computercomputer

SAFETY CIRCUIT SHUTDOWN MESSAGESSAFETY CIRCUIT SHUTDOWN MESSAGES

SAFETY CIRCUIT SHUTDOWN MESSAGES

SAFETY CIRCUIT SHUTDOWN MESSAGESSAFETY CIRCUIT SHUTDOWN MESSAGES

SPECIAL FEATURESSPECIAL FEATURES

SPECIAL FEATURES

SPECIAL FEATURESSPECIAL FEATURES

you can run the

grain and/or plenum high limit back

down to a safe level. After changing

the switch press the START button

and only the

mately five minutes.

BURNER ON/OFFBURNER ON/OFF

BURNER ON/OFF

BURNER ON/OFFBURNER ON/OFF

The need has developed for an ON/

burnerburner

OFF

burner in recent years, due to

burnerburner

changing fuel conditions, and also

to aid in drying wheat or other low

temperature grains in hot weather.

fanfan

fan to help cool the

fanfan

fanfan

fan will run for approxi-

fanfan

OPERATIONOPERATION

OPERATION

OPERATIONOPERATION

By moving the third switch (num-

ber six) on the dip switch located in-

side the

the

burner can be changed from a HI-LO

burnerburner

burner to an ON/OFF

burnerburner

tion. The

the same as the HI-LO

ever, when the set point is reached

the

ing to a lower pressure. The vapor-

izer cools quicker and allows a closer

tolerance on the set point.

control boxcontrol box

control box on the back of

control boxcontrol box

computer control boardcomputer control board

computer control board, the

computer control boardcomputer control board

burnerburner

burner opera-

burnerburner

burnerburner

burner will operate exactly

burnerburner

burnerburner

burner, how-

burnerburner

burner burner

burner is cycled off instead of go-

burner burner

VAPOR HIGHVAPOR HIGH

VAPOR HIGH

VAPOR HIGHVAPOR HIGH

TEMPERATURETEMPERATURE

TEMPERATURE

TEMPERATURETEMPERATURE

The LP gas vapor

sensorsensor

sensor located in the

sensorsensor

train train

train downstream from the vapor-

train train

izer, has opened indicating that the

vaporizor is running too hot and

must be readjusted. This

is set at 200°F and automatically

resets itself when cool.

LOSS OF FLAMELOSS OF FLAME

LOSS OF FLAME

LOSS OF FLAMELOSS OF FLAME

flame sensor flame sensor

The

flame sensor has failed to de-

flame sensor flame sensor

tect a burner flame indicating that the

burnerburner

burner has failed to light, there is a

burnerburner

problem with the flame sensing cir-

cuitry or the dryer is not getting

burner fuel.

sition the flame probe, turn off thesition the flame probe, turn off the

sition the flame probe, turn off the

sition the flame probe, turn off thesition the flame probe, turn off the

incoming power to the dryer at theincoming power to the dryer at the

incoming power to the dryer at the

incoming power to the dryer at theincoming power to the dryer at the

main safety disconnect.main safety disconnect.

main safety disconnect.

main safety disconnect.main safety disconnect.

temperature high limit temperature high limit

The

temperature high limit located

temperature high limit temperature high limit

on the

Before trying to repo-Before trying to repo-

Before trying to repo-

Before trying to repo-Before trying to repo-

HOUSING HIGHHOUSING HIGH

HOUSING HIGH

HOUSING HIGHHOUSING HIGH

TEMPERATURETEMPERATURE

TEMPERATURE

TEMPERATURETEMPERATURE

fan/burner housing fan/burner housing

fan/burner housing has

fan/burner housing fan/burner housing

temperaturetemperature

temperature

temperaturetemperature

gas pipegas pipe

gas pipe

gas pipegas pipe

sensorsensor

sensor

sensorsensor

opened, indicating an over tempera-

ture condition has occurred toward

the rear of the

in an oblong covered electrical box.

This control is set at 200°F and must

be manually reset.

REAR DISCHARGEREAR DISCHARGE

REAR DISCHARGE

REAR DISCHARGEREAR DISCHARGE

lid on the grain discharge boxlid on the grain discharge box

The

lid on the grain discharge box

lid on the grain discharge boxlid on the grain discharge box

has opened, indicating that grain is

not being taken away fast enough

at the

One of the

ther the

iary motorsiary motors

iary motors has opened, indicating

iary motorsiary motors

an overcurrent condition. The

loadsloads

loads must be manually reset.

loadsloads

An over temperature condition has

occurred in one of the

umns umns

umns causing the control to shut-

umns umns

down the dryer. This control is set

discharge boxdischarge box

discharge box.

discharge boxdischarge box

MOTOR OVERLOADMOTOR OVERLOAD

MOTOR OVERLOAD

MOTOR OVERLOADMOTOR OVERLOAD

fan, load, unload fan, load, unload

fan, load, unload or

fan, load, unload fan, load, unload

GRAIN HIGHGRAIN HIGH

GRAIN HIGH

GRAIN HIGHGRAIN HIGH

TEMPERATURETEMPERATURE

TEMPERATURE

TEMPERATURETEMPERATURE

fan/heater housingfan/heater housing

fan/heater housing

fan/heater housingfan/heater housing

WARNINGWARNING

WARNING

WARNINGWARNING

thermal overloadsthermal overloads

thermal overloads on ei-

thermal overloadsthermal overloads

auxil-auxil-

auxil-

auxil-auxil-

over-over-

over-

over-over-

grain col-grain col-

grain col-

grain col-grain col-

at 210°F and automatically resets

itself when cool.

OUT OF GRAINOUT OF GRAIN

OUT OF GRAIN

OUT OF GRAINOUT OF GRAIN

The dryer has run low on grain, and

the OUT OF GRAIN TIMER has timed

out, shutting the dryer down. The

load augerload auger

load auger will clean out the dryer if

load augerload auger

in CONTINUOUS FLOW operation.

PLENUM HIGHPLENUM HIGH

PLENUM HIGH

PLENUM HIGHPLENUM HIGH

TEMPERATURETEMPERATURE

TEMPERATURE

TEMPERATURETEMPERATURE

An over temperature condition has

occurred inside the

This control is a 300°F limit and auto-

matically resets itself when cool. See

emergency cooling mode above.

NO AIRFLOWNO AIRFLOW

NO AIRFLOW

NO AIRFLOWNO AIRFLOW

The contacts in the

opened due to insufficient airflow for the

burnerburner

burner to operate, the

burnerburner

air switchair switch

or the

air switch may need adjusting.

air switchair switch

air switchair switch

The

air switch contacts have closed

air switchair switch

prior to the

freewheeling

ting of the

fanfan

fan starting, indicating a

fanfan

blade blade

blade or improper set-

blade blade

air switch air switch

air switch.

air switch air switch

dryer plenumdryer plenum

dryer plenum.

dryer plenumdryer plenum

air switchair switch

air switch have

air switchair switch

fan fan

fan not turning,

fan fan

AIRAIR

AIR

AIRAIR

un-un-

un-

un-un-

21

Page 22

SERIES 2000 ERROR CONDITIONSSERIES 2000 ERROR CONDITIONS

SERIES 2000 ERROR CONDITIONS

SERIES 2000 ERROR CONDITIONSSERIES 2000 ERROR CONDITIONS

ERROR CODE BREAKDOWNERROR CODE BREAKDOWN