Page 1

Instructions

PNEG-510

Improper installation methods of the hardware may cause permanent damage and

possible breakage of the boot.

CAUTION

1004 East Illinois Street • Assumption, IL 62510 • 1-217-226-4421

HR Unloader Restrictor Adjustment

Boot and Transfer Plate Installation

NOTE: Installation of the boot is the same whether the tank has the standard collar or the Sure-Flo

Feed Flow Control.

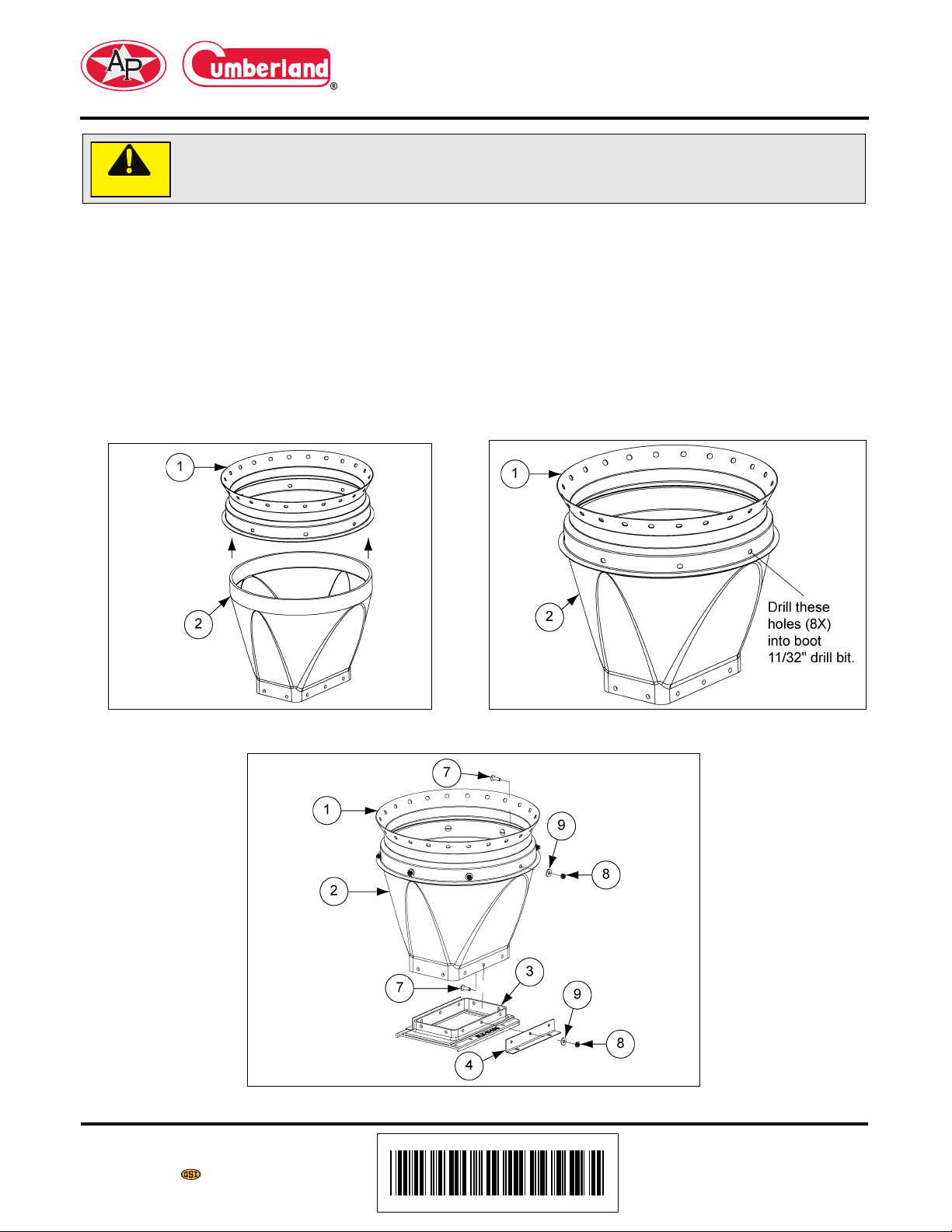

Slide the boot as far as possible into the tank collar or the Sure-Flo Feed Flow Control opening.

(See Figure 1.) Align the boot with the Flex-Flo System that will be installed. Using the holes in the

collars for guides, drill eight (8) 11/32" holes into the boot rim. (See Figure 2.)

Mount the boot to the collar with the hardware provided. Bolt the Transfer Plate and Unloader Braces to

the boot as shown. See Figure 3 for proper usage and assembly direction of hardware for mounting the

boot and the transfer plate. All connections should be tightened until they are “snug”.

Figure 1

Figure 3

Date: 04-28-11 PNEG-510

Printed in the U.S.A.

Copyright © 2011 by Group

www.gsiag.com

Figure 2

Page 1 of 5

Page 2

HR Unloader Restrictor Adjustment

Slide Gate Installation

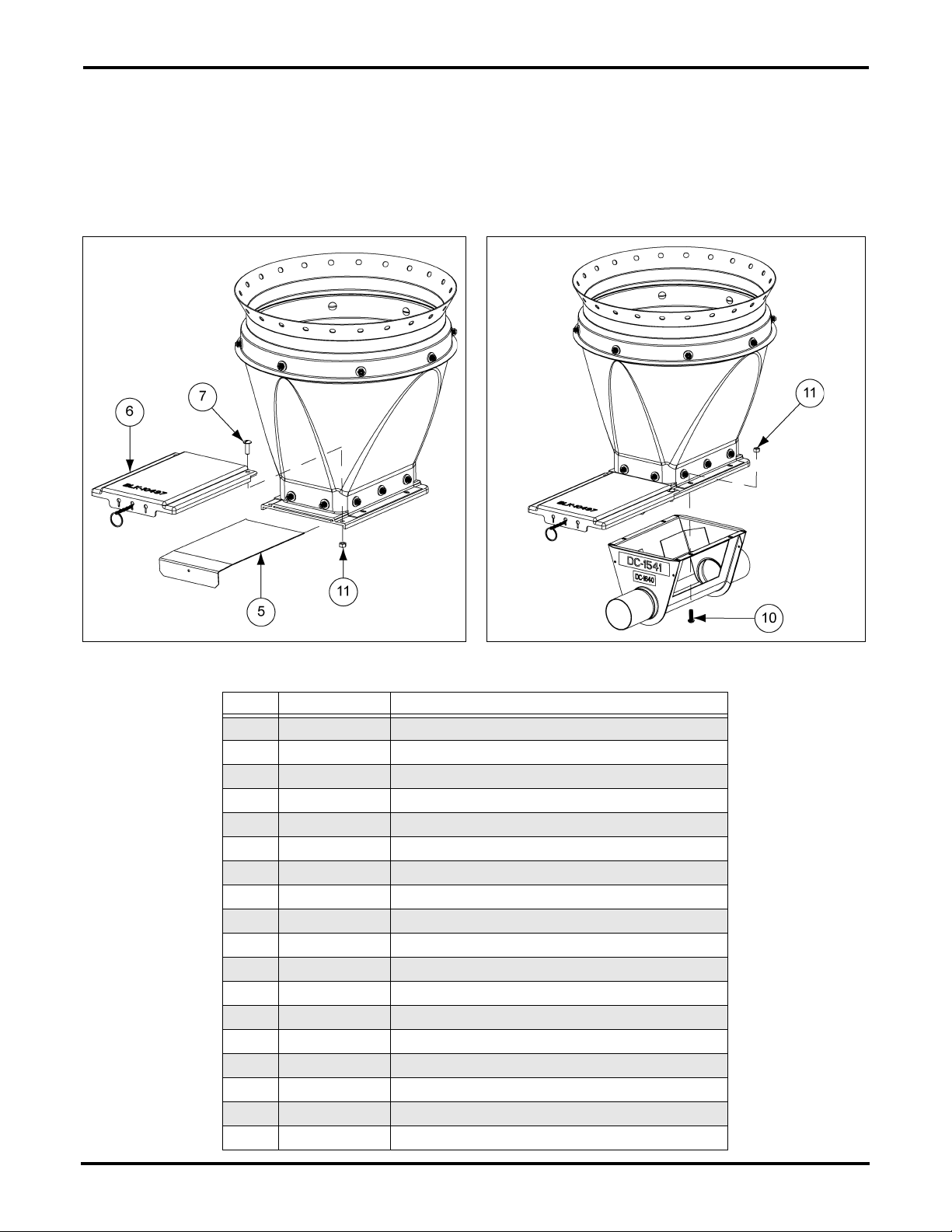

Insert the slide into the transfer plate. The slide must be in its operating position prior to attaching the slide

shield to the transfer plate. Use two (2) 5/16"-18 x 1" truss head tap bolts to mount the slide shield.

(See Figure 4.)

Bolt unloader to transfer plate/unloader brace assembly as shown in Figure 5. Note orientation of these

bolts. (See Figure 5.)

Figure 4 Figure 5

Ref # Part # Description

1 BLK-10488 16" 67° 16" Hopper Collar (24 Holes)

1 BLK-10489 16" 60° Hopper Collar (24 Holes)

1 BLK-11463 16" 60° Hopper Collar (27 Holes)

1 BLK-12342 16" 60° Hopper Collar (18 Holes)

2 FLX-2194 16" 30° Black Plastic Boot

2 FLX-2194C 16" 30° Clear Plastic Boot

2 FLX-2195 16" Straight Black Plastic Boot

2 FLX-2195C 16" Straight Clear Plastic Boot

2 FLX-4869 16" Double Straight Black Boot

3 BLK-10496 Transfer Plate

4 FLX-4819 Unloader Brace

5 FLX-4782 Slide Gate

6 BLK-10497 Slide Gate Shield

7 S-4336 5/16" x 1" Truss Head Machine Screw

8 S-4337 5/16"-18 Nylon Insert Nut

9 S-4338 5/16" Nylon Washer

10 S-8328 Screw, MS 5/16"-18 x 1" RHS ZN Grade 2

11 S-396 Hex Nut 5/16"-18 YDP Grade 2

Page 2 of 5 PNEG-510

Page 3

HR Unloader Restrictor Adjustment

Inspection/Clean-Out Plate Installation

Once the installation of the auger tubes and auger is complete, insert the inspection/clean-out plate

or the optional unloader switch.

The inspection/clean-out plate is to be installed per the following instructions (See Figure 6):

1. Back off both wing nuts to the stud ends.

2. Slide the plate onto the lower side of the unloader opening.

3. Move the plate first against the side of the unloader then upward toward the top of the unloader.

4. Tighten the wing nuts while holding the plate steady.

Figure 6 Clean-Out Plate Installation

PNEG-510 Page 3 of 5

Page 4

HR Unloader Restrictor Adjustment

Restrictor Adjustment

The restrictor may be adjusted to allow more feed flow. Do not modify the restrictor until the system is

completely operational and the auger has been polished by running feed through the system.

Instructions:

1. Remove the restrictor tube from the unloader.

2. Cut 1" (2.5 cm) from the restrictor. (See Figure 7.)

3. Install the restrictor and the bearing assembly into the unloader.

4. Test the feed flow.

5. If the desired feed flow rate is not attained, repeat the above procedure until the desired rate

is reached.

Figure 7 Restrictor Adjustment

Page 4 of 5 PNEG-510

Page 5

HR Unloader and Anchor Assembly

HR Unloader Restrictor Adjustment

HR Unloader

Ref # Part # Description

1 FLX-2195 16" Straight Black Plastic Boot

1 FLX-2195C 16" Straight Clear Plastic Boot

2 FLX-2194 16" 30° Black Plastic Boot

2 FLX-2194C 16" 30° Clear Plastic Boot

N/S FLX-4869 16" Double Straight Black Boot

3 BLK-11137A Transfer and Slide Gate Kit

4 404238 Iron Ball 3" Hollow - 1-1/2 #

5 FLX-4461 Clean-out Plate Assembly

6 S-4319 3-1/2" Tube Clamp

7 FLX-4648HR Anchor and Bearing Assembly

8 FLX-2605 Model HR Flex-Flo Single through Unloader Body Assembly

9 S-4443 4" Tube Clamp

10 FLX-2217 Model 220, 300, 350 Flex Seal Ring

11 FLX-3422 Neoprene Seal

12 FLX-2116HR HR Twin Unloader Body with Baffle

13 FLX-4819 Unloader Brace

PNEG-510 Page 5 of 5

Loading...

Loading...