Page 1

Fan And Heater

Application

Guide

PNEG-501

Page 2

Page 3

Fan/Heater Application

Roof Warning, Operation & Safety................................................................................4

Safety Alert Decals........................................................................................................5

Fan Application Guide........................................................................................................6

Fan Application Guide......................................................................................................7

Fan Selection..................................................................................................................8

Aeration System Requirements.......................................................................................9

Example..............................................................................................................10

Situation..............................................................................................................11

Fan Performance Specifications..................................................................................12

Suggested Airflow Rates............................................................................................13

Static Pressure Charts....................................................................................................14

Beans w/ stirring........................................................................................................14

Corn w/ stirring......................................................................................................15

Rice w/ stirring.....................................................................................................16

Wheat w/ stirring....................................................................................................17

Barley..................................................................................................................18

Beans..................................................................................................................19

Clover..................................................................................................................20

White Popcorn.....................................................................................................21

Earcorn................................................................................................................22

Flax.....................................................................................................................23

Milo.....................................................................................................................24

Oats.....................................................................................................................25

Peanut.................................................................................................................26

Popcorn...............................................................................................................27

Rape....................................................................................................................28

Rice.....................................................................................................................29

Wheat..................................................................................................................30

Heater Application and Sizing....................................................................................31

Plenum Temperature........................................................................................................32

TABLE OF CONTENTS

3

Page 4

ROOF WARNING, OPERATION & SAFETY

Roof Damage Warning and Disclaimer

GSI DOES NOT WARRANT ANY ROOF DAMAGE

CAUSED BY EXCESSIVE VACUUM OR INTERNAL

PRESSURE FROM FANS OR OTHER AIR MOVING

SYSTEMS. ADEQUATE VENTILATION AND/OR

"MAKEUP AIR" DEVICES SHOULD BE PROVIDED

FOR ALL POWERED AIR HANDLING SYSTEMS.

GSI DOES NOT RECOMMEND THE USE OF DOWNWARD FLOW SYSTEMS (SUCTION). SEVERE

ROOF DAMAGE CAN RESULT FROM ANY BLOCKAGE OF AIR PASSAGES. RUNNING FANS DURING

HIGH HUMIDITY/COLD WEATHER CONDITIONS

CAN CAUSE AIR EXHAUST OR INTAKE PORTS TO

FREEZE.

Fan/Heater Application

Fuel Warning

Important! Do not use propane tanks which have previously been used for ammonia unless they

have been purged according to procedures of the National L. P. Association.

Be sure fuel supply system complies with all local codes for L. P. gas installations.

DO NOT USE FLAME FOR LEAK TESTING.

Power Warning

Be sure power is disconnected and locked out before installation!

Failure to do so may cause serious injury or death.

Important! Heater must be interlocked with fan for safe operation.

Important! Thermostat must be installed for safe operation.

Proper Use of Product

This product is intended for the use of grain drying only! Any other use is a misuse of this product.

This product has sharp edges! These sharp edges may cause serious injury. To avoid injury

handle sharp edges with caution and use proper protective clothing and equipment at all times.

Guards are removed for illustration only. All guards must be in place before and during operation.

4

Page 5

Fan/Heater Application

CAUTION! BE VERY

CAREFUL WHEN

CHECKING OUT 220V OR

460V CONTROL CIRCUIT.

SERIOUS INJURY OR

DEATH MAY OCCUR IF

PROPER PRECAUTIONS

ARE NOT TAKEN.

SAFETY ALERT DECALS

FAILURE TO INSTALL

THERMOSTAT INCREASES RISK OF FIRE IN BIN!

WARRANTIES ARE VOID ON HEATERS INSTALLED

WITHOUT THERMOSTATS.

The GSI Group, Inc. recommends contacting your local power

company, and having a representative survey your installation so the

wiring is compatible with their system, and adequate power is supplied to your unit.

Safety decals should be read

and understood by all people in

the grain handling area.

If a decal is damaged or is

missing contact:

The GSI Group, Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to

you.

BE SURE POWER IS

DISCONNECTED AND

LOCKED OUT BEFORE

INSTALLATION. FAILURE

TO DO SO MAY CAUSE

SERIOUS INJURY OR

DEATH

5

Page 6

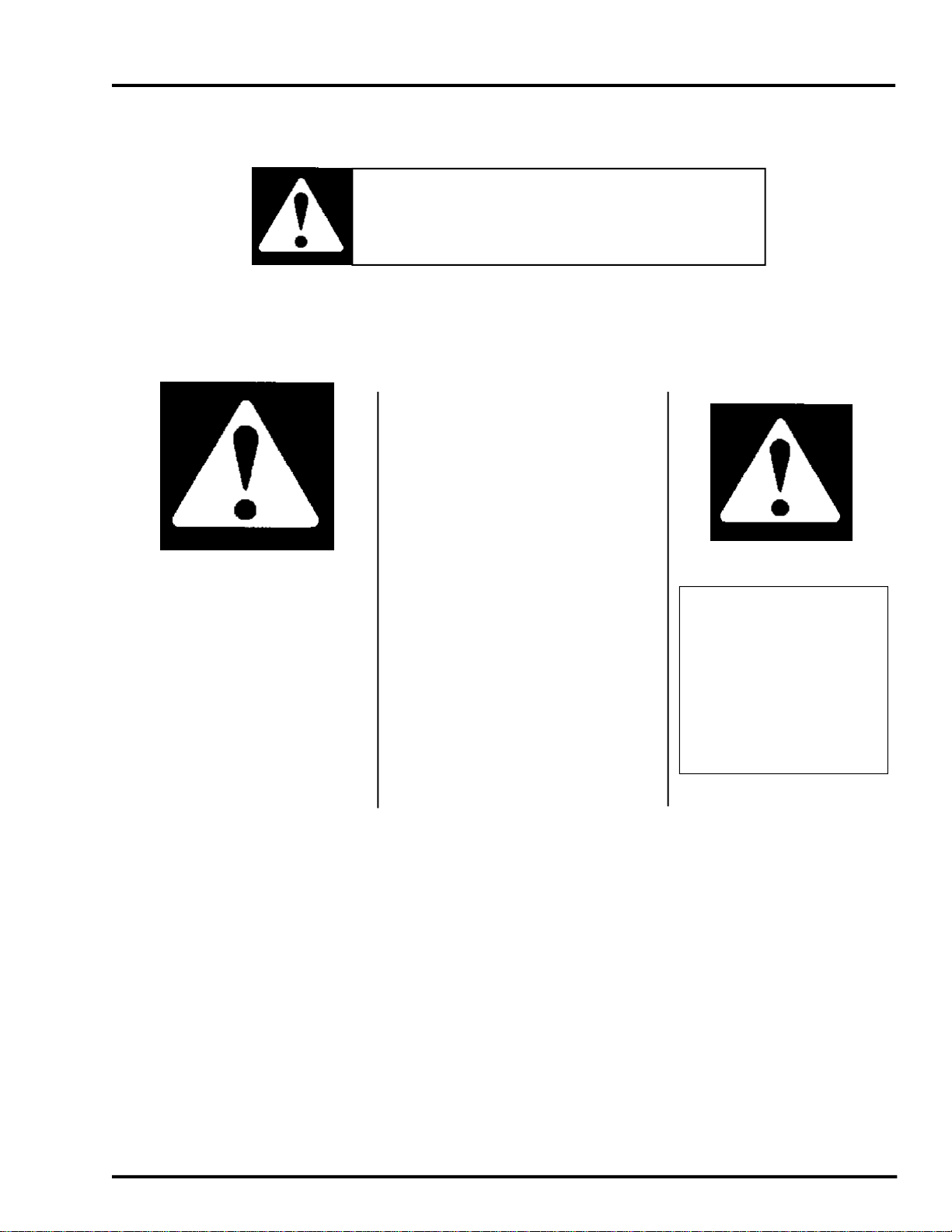

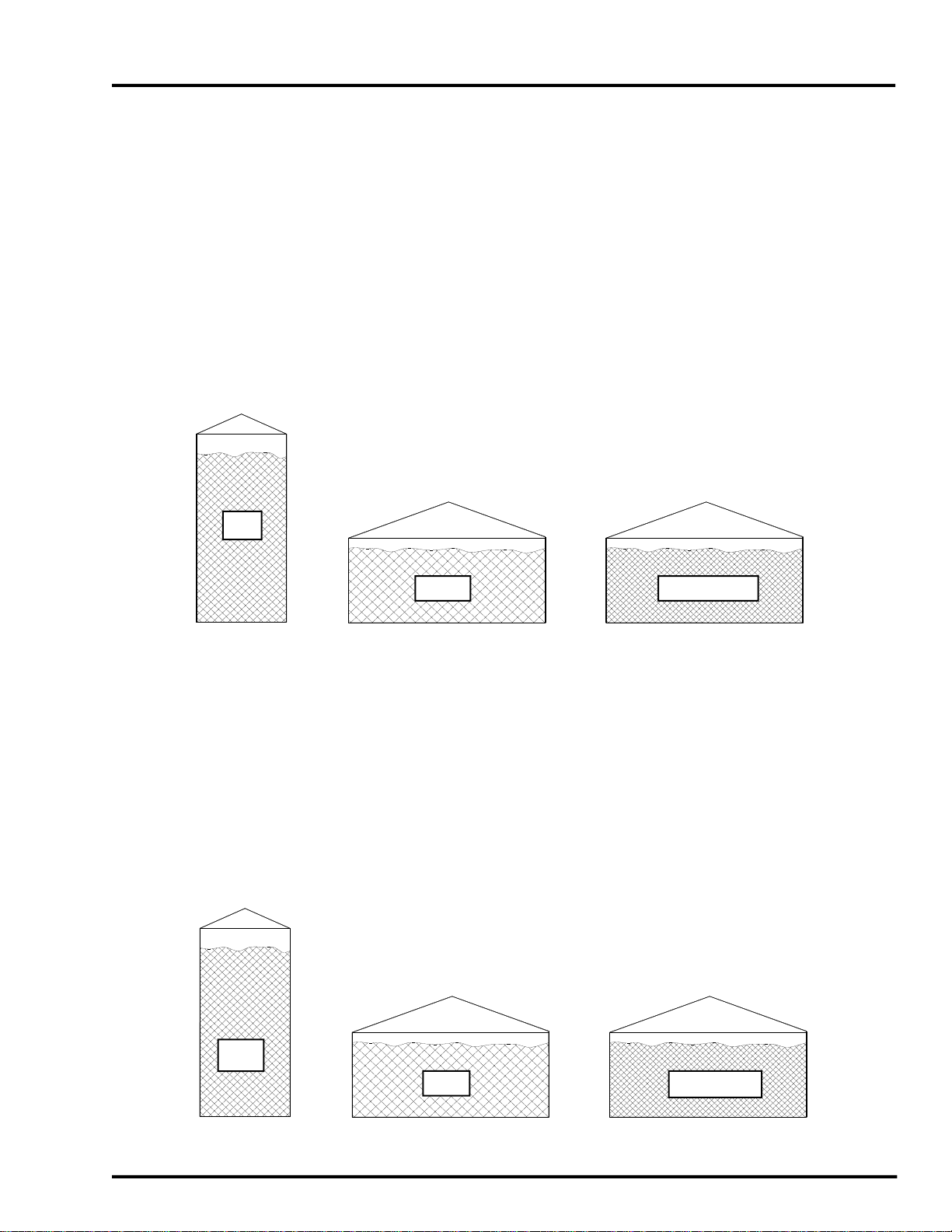

FAN APPLICATION GUIDE

3500RPM Vane Axial fans are normally high performance low static pressure

fans. They are normally used for inbin drying or aeration on shorter tanks or when

low resistance grains (corn, soybeans are processed. The application should be

looked at very closely when aerating unusually tall tanks or high resistance grains

NO

Vane Axial Fans

(wheat, milo).

YES

Fan/Heater Application

NO

Inline Centrifugal Fans

3500RPM Inline Centrifugal fans are normally medium performance medium

static pressure fans. They are normally used for aeration on taller tanks or when

high resistance grains (wheat, milo) are processed. Inlines may also be used in

drying applications however care should be taken to use correct adapters when

using gas heaters with these fans. These fans are often mis-applied and sold as a

quiet drying fan when a vane axial fan of equal horsepower will most likely out

perform it. The application should be looked at very closely when aerating unusu-

ally tall tanks or high airflow resistance grains (wheat, milo).

NO

YES

MAYBE

6

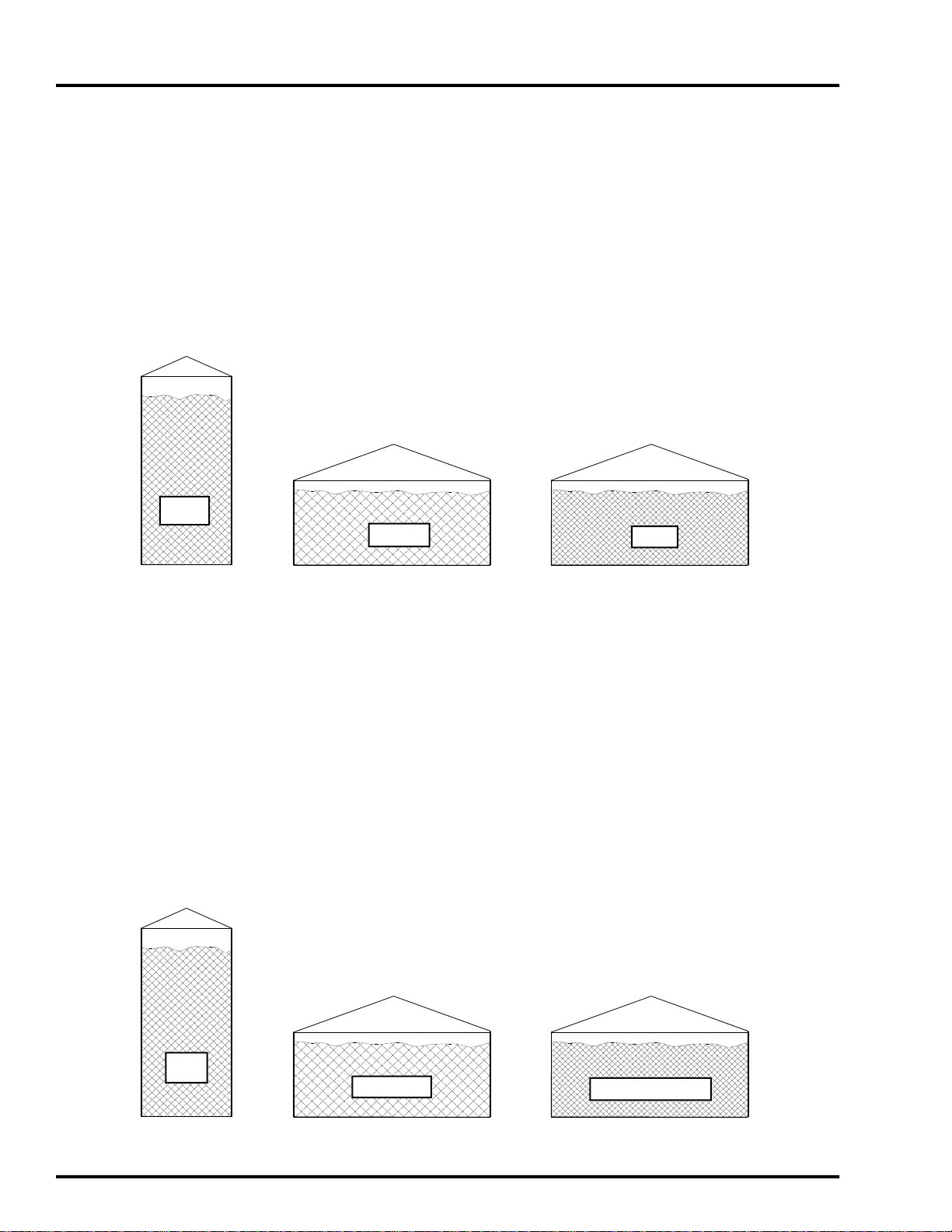

Page 7

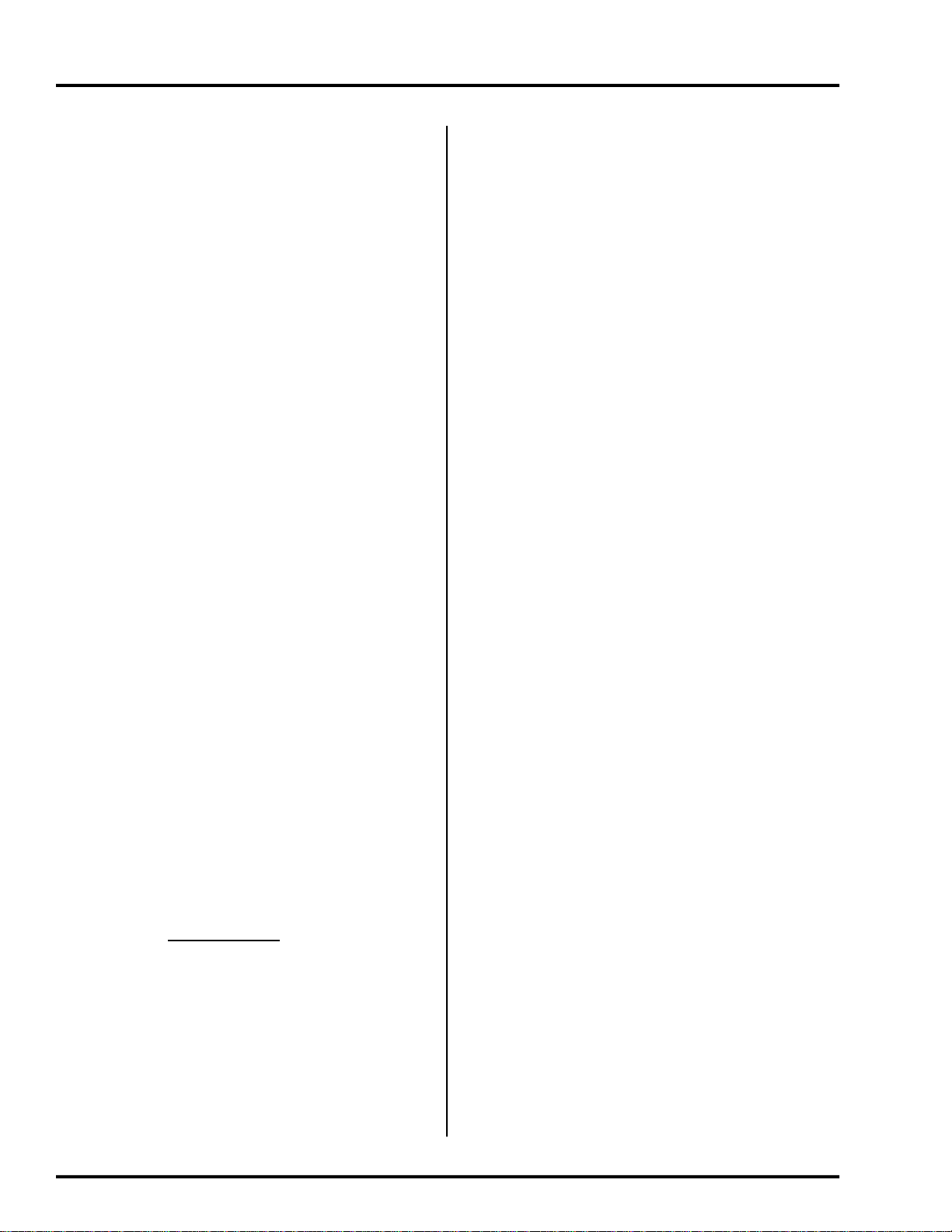

Fan/Heater Application

1750RPM Centrifugal fans are normally high performance, medium static pressure

fans. They are normally used for aeration or drying on shorter tanks or when low

resistance grains (corn, soybeans) are processed. These fans may be used with gas

heaters, either mounted on the inlet side of the fan or downwind on the outlet side.

Greater airflow is attained when the heaters are mounted downwind. Fans larger

than 30HP require a 17" tall plenum (floor) so the transition will clear. The

application should be looked at very closely when aerating unusually tall tanks or

FAN APPLICATION GUIDE

1750RPM Centrifugal Fans

high resistance grains (wheat, milo).

NO

YES

3500RPM Centrifugal Fans

3500RPM Centrifugal fans are normally medium preformance high static pressure

fans. They are normally used for aeration on taller tanks or when high resistance

grains (wheat, milo) are processed. These fans are not normally used with heaters.

Although these fans are less expensive than 1750RPM fans they are not normally

used on shallower grain depths because 1750RPM fans give much greater perfor-

mance for the horsepower at shallow depths thus less horsepower is required.

MAYBE

YES

NO

MAYBE

7

Page 8

FAN & ROOF VENT SELECTION

Fan/Heater Application

STEP 1

LEVEL FILL

PEAKED FILL

STEP 2.

Use SUGGESTED AIRFLOW RATES (page 13-30) for

desired drying or aeration conditions.

STEP 3.

For a selected grain, find the static pressure for the

corresponding AVE GRAIN DEPTH and AIRFLOW

RATE. Use the nearest height or approximate where

necessary. Where stirring machines are to be used, use

charts for stirring.

STEP 4.

BUSHELS = AVE GRAIN DEPTH (ft) x 0.6594 x

DIAMETER (ft) x DIAMETER (ft)

Since the calculation uses an average grain depth, the

capacity may vary from published sales capacities.

STEP 5.

TOTAL AIRFLOW (cfm) = AIRFLOW RATE x

BUSHELS

If more than one fan is desired for a system, divide the

TOTAL AIRFLOW by the number of fans to get the

CFM REQUIRED PER FAN for fan Selection.

STEP 6.

TABLE for vane axial or centrifugal fans, the TOTAL

. Determine the average grain depth

for a desired bin size:

-AVE GRAIN DEPTH (ft) =

EAVE HEIGHT (ft) - FLOOR HEIGHT ft)

- AVE GRAIN DEPTH (ft) =

EAVE HEIGHT (ft) + BIN DIAMETER

(ft) ÷12, Minus FLOOR HEIGHT (ft)

Select airflow rate in CFM/BU:

Using the STATIC PRESSURE

TABLES:

Determine bin capacity:

This capacity includes 5% compaction.

Find the required TOTAL AIR

FLOW in CFM:

IMPORTANT!

Using the FAN PERFORMANCE

STATIC PRESSURE from Step 3, and the CFM

PER FAN from Step 5, select the fan best

meeting the requirements. For best fan performance, a fan should run in the mid-range of is static

pressure ratings, if possible. Should excessive

static pressures be encountered, as with small grain

or very high airflows, consult GSI engineering for

the best fan choice.

NOTE:

tank aeration is in question.

Consult GSI engineering where hopper

Roof Vent Selection

STEP 7.

NUMBER ROOF VENTS = TOTAL AIRFLOW

(cfm) ÷ 1800 (cfm per vent)

If less than a full bin is intended an increased

number of roof vents will be necessary. The same

fan will produce a greater airflow when the bin is

less than full, due to less resistance from the grain.

An inadequate number of vents may have two

undesired effects

1) adding to the static pressure causing poor

fan performance and less air through the grain than

intended, and

2) possible structural damage to the roof

due to this increased pressure. Ideally, there should

be near zero static pressure in the space between the

grain and the roof.

A good estimate of vent numbers particularly in drying situations, would be using the CFM

from the FAN PERFORMANCE TABLE at onehalf the static pressure anticipated. This new value

should be divided by 1800 CFM/VENT.

Determine MINIMUM number of

roof vents:

8

Page 9

Fan/Heater Application

AERATION SYSTEM REQUIREMENTS

Full perforated floors are recommended in most DRYING situations. Floor

gauges

the grain load for a particular bin size. Please

inquire

(formed in concrete) systems are recommended when aeration only is desired. The

two most important aspects of aeration design

are the total perforated floor area and the

entrance duct cross-sectional area. Floors

should be sized for a maximum intended

airflow rate. To add larger fans or bin rings at

a later date may result in less than satisfactory

aeration performance.

mum requirement check for potential designs.

GSI floor designs will meet these requirements and be optimised for the best results.

STEP 8.

from

PERFORATED AREA (sq ft) = TOTAL

AIRFLOW ÷ 30cfm/sq ft.

and support spacing are dependent on

as to exact specifications. Flush floor

These steps are intended as a mini-

Determine MINIMUM re

quired perforated floor area

using TOTAL AIRFLOW

step 5.

STEP 9.

sectional area of air supply duct.

SUPPLY DUCT AREA (sq ft) = TOTAL

AIRFLOW ÷ 2000 cfm/sq ft

If more than one fan is used divide the

area by the number of fans. This is now the

area of each entrance tunnel.

To determine the inside width of the

supply ducts use the following formula. For

convenience it may be necessary to increase

this value to meet transition widths or "whole"

dimensions.

INSIDE DIMENSION OF SUPPLY DUCT

(ft) = SUPPLY DUCT AREA (sq ft) ÷

DESIRED TUNNEL DEPTH (ft)

STEP 10.

tween bin wall and nearest duct =

GRAIN DEPTH ÷ 4*

STEP 11.

tween ducts = AVE GRAIN DEPTH ÷ 2*

* These are starting values ONLY. Adequate

distribution of ducts may require smaller

distances.

Determine MINIMUM cross-

IMPORTANT!

MAXIMUM distance be-

AVE

MAXIMUM distance be-

9

Page 10

EXAMPLES

Fan/Heater Application

SITUATION:

1.

2.

3.

4.

5.

6.

On farm aeration of dry soybeans. 42" diameter, 9 rings, NSL series farm bin

with 24" eave height. A flush floor aeration system with one fan will be used.

AVE GRAIN DEPTH, peaked = 24' + (42' /12) = 27.5'

Select 1/10 CFM/BU aeration rate for beans

From the STATIC PRESSURE TABLE for BEANS at 28' (use the next

higher value or approximate) and 1/10 cfm/bu the static pressure is .91" of

water.

.91" water column

Bin capacity, BUSHELS

27.5' x 0.6594 x 42' x 42' = 31988 BUSHELS

Required TOTAL AIRFLOW, CFM

0.1 cfm/bu x 31988 bu = 3199 CFM

From the FAN PERFORMANCE TABLE for vane axial fans, at 1" (0.91")

static pressure and 3500 cfm (closest to 3199 cfm), the appropriate fan would

be a 1.5hp-18"

7.

8.

9.

10.

Number of ROOF VENTS

3500 CFM ÷ 1800 cfm/vent = 1.94, therefore 2 vents

PERFORATED AREA of floor, sq ft

3199 cfm ÷ 30 cfm/sq ft = 106.6 sq ft, minimum

SUPPLY DUCT AREA, sq ft

3199 cfm ÷ 2000 cfm/sq ft =1.60 sq ft, minimum

ID of supply duct for 12" deep tunnel = 1.6 sq ft ÷ 1.0 ft = 1.6 ft or 1.8"

Maximum distance between ducts and binwall = 27.5' ÷ 4 = 6.9'

10

Page 11

Fan/Heater Application

SITUATION

SITUATION:

1.

2.

3.

4.

5.

6. From the FAN PERFORMANCE TABLE for van axial fans, at 3.58" static

On farm in-bin drying of corn, 24' diameter, 6 ring, FCDL series farm bin with

22' eave height. Tank will be layer filled to level full. The drying systems

will consist of a full floor with 12" plenum, stirring device, one fan and heater.

AVE GRAIN DEPTH, level = (6 rings x 3.67) - 1 (floor) - 2 (stirring

device) = 19'.

Select 1 CFM/BU for heated air drying of corn.

From the STATIC PRESSURE TABLE for corn at 19' and 1cfm/bu the

static pressure is 3.58" of water.

3.58" water column

Bin operating capacity, BUSHELS

19' x 0.6594 x 24 x 24 = 7216

Required TOTAL AIRFLOW, CFM

1 cfm/bu x 7216 bu = 7216 CFM

pressure (4" on table) and 7216 cfm (10250 on table), the best choice would

be one 15 hp 26" fan.

7.

*

Number of ROOF VENTS

10250 cfm ÷ 1800 cfm/vent = 5.6, therefore 6 vents

NOTE!

Two fan/heater sets may be necessary to meet temperature requirements.

Two fan/heater sets may also be necessary to provide even air/heat distribution

when recirculating devices are in use.

It may be desired to increase the number of roof vents in a

drying situation to account for layers or batches as the effective

airflow will increase. In this example 8 vents should

accommodate the airflow at one-half the expected pressure:

12700÷1800 = 7

11

Page 12

CF-333000

2750

2450

2150

1750

800

CF-554900

4450

4000

3500

2900

1500

CF-7.5

7.5

5000

4700

4500

4200

3900

3700

3250

2300

CF-10

10

6650

6300

5900

5600

5300

4900

4300

3000

CF-15

15

10100

9500

9000

8400

7900

7400

6600

4600

CF-20

20

9400

9100

8800

8500

8200

8000

7400

6800

6500

5900

4000

CF-30

30

13200

12800

12400

11900

11500

10900

10400

9800

9100

8300

6000

CF-40

40

19000

18400

17750

17125

16500

15750

15000

14125

13125

12000

9000

CF-50

50

21600

21100

20500

19750

19000

18400

17600

16800

16000

15000

13500

11500

CF-336000

5500

5000

4500

4000

2200

CF-558750

8200

7300

6750

6100

5350

CF-7.5

7.5

12200

11600

10800

10000

9100

8000

CF-10

10

13450

12800

12050

11350

10700

9950

9000

7250

CF-15

15

17000

16000

15200

14400

13400

12200

10800

9200

CF-20

20

20500

19500

19000

18000

17000

16500

15750

14400

13300

CF-25

25

24000

23750

22750

21750

21000

20000

19000

17750

16000

12500

CF-30

30

28100

26900

25600

24600

23600

22500

21000

20100

19700

17800

16000

11500

CF-40

40

32750

31750

30750

29750

28750

27750

26750

25750

24250

22750

20250

15000

*CF-30D

30

32000

30500

29500

28000

27000

26000

25500

23000

20500

16500

*CF-40D

40

41000

39000

38000

37000

35000

33500

32000

30000

27000

24000

*CF-50D

50

49500

47500

45500

43500

42000

40000

38000

35500

32000

25000

FAN PERFORMANCE SPECIFICATIONS

STATIC PRESSURE IN INCHES

VANE AXIAL FANS

Fan/Heater Application

MODEL NO

AF-.75

AF-12

AF-14

AF-1.5

AF-3

AF-7

AF-10

AF-156

AF-158

MODEL NO

ILC-1.5

ILC-318

ILC-324

ILC-7

ILC-10

ILC-15

MODEL NO

H.P

1.5

H.P

3/4

1

1

3

7

10

15

15

FAN DIA

12"

12"

14"

18"

18"

24"

24"

26"

28"

0.0 1.0 2.0 3.0 4.0

2050 1050 500

2000 1100 650

3200 1850 1200

4650 3600 2300 1050

6300 5200 3700 2000 700

12750 11200 9500 7200 3600 950

13600 12300 10900 8900 5250

17000 15350 13700

19500 18000 16400

250

500

12000

14500

INLINE CENTRIFUGAL FANS

STATIC PRESSURE IN INCHES

H.P

1.5

3

3

7.0

10

15

FAN DIA

18"

18"

24"

24"

28"

28"

0.0 1.0 2.0

2650 2450 2300

4550 4300 4000

5000 4725 4450

5400 5150 4900

6150 5950 5800

7950 7700 7500

3.0

4.0 5.0 6.0 7.0 8.0 9.0

2100

1850 1500

3750

3500 3100 2700

4200

3950 3600 3200

4650

4400 4100 3800

5600

5450 5250 5050

7250

7000 6800 6500

1750 RPM CENTRIFUGAL FANS

STATIC PRESSURE IN INCHES

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0

5.0

3150

9500

12400

2900

3400

4850

6250

6400

9700

4650 4400 4200 3900

6000 5700 5400 5050

6.0

4500

6400

10.0 11.0

10.0 11.0

*

DOUBLE INLET FAN.

MODEL NO

H.P

12

3500 RPM CENTRIFUGAL FANS

STATIC PRESSURE IN INCHES

0.0 2.0 4.0 6.0 8.0

10.0 12.0 14.0 16.0 18.0 20.0 22.0

Page 13

Fan/Heater Application

SUGGESTED AIRFLOW RATES

Aeration

This ventilation of stored grain to maintain

uniform moisture and temperature, uses low

airflow rates and unheated air. The lowest

rates are for dry grain and higher rates are for

higher moisture contents.

Corn

Wheat

Beans

Rice

1/10

1/13

1/10

1/10

to 1/5cfm/bu

to 1/8

to 1/7

to 1/7

cfm/bu

cfm/bu

cfm/bu

Dryeration and Cooling

Natural unheated air used to cool heated grain

and/or take out remaining few moisture points.

1/5

to 1/2

cfm/bu

Wet Holding

Higher airflow rate for maintaining wet grain

for short periods of time, generally one days'

conditioning capacity or no longer than the

recommended SAFE STORAGE TIME.

1/2

USE MAXIMUM BIN CAPACITY

TO SIZE FANS FOR APPLICATIONS IN

THIS COLUMN

to 1 cfm/bu

NOTE:

Natural Air Drying

Unheated air used on low moisture harvested

grain to remove remaining moisture points,

use layer method or full bin depending on

initial moisture, the airflow rate selected will

depend on geographic location and prevailing

weather conditions.

1 1/2

to 2 1/2cfm/bu

Low temperature Drying

5 to 20 degree F temperature rise, high airflow

rates, equilbrium drying system generally

employed with layer or full bin, stirring device

suggested.

1

to

2cfm/bu

High Temperature Drying

120-160 degree F plenum temperatures, high

airflow rates, batch or layers recommended

with stirring devices.

3/4

USE 1/2 TO 3/4 BIN CAPACITY TO SIZE

FANS FOR APPLICATION IN THIS

COLUMN. THIS WILL AVOID

UNREASONABLE FAN SIZES.

to

NOTE:

1 1/2cfm/bu

13

Page 14

PRESSURE CHART

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

0.55

0.53

0.52

0.51

0.5140.74

0.65

0.06

0.55

0.53

0.52

0.51

0.51

0.51

0.5161.11

0.86

0.66

0.61

0.57

0.55

0.53

0.53

0.52

0.51

0.51

0.5181.71

1.20

0.79

0.71

0.63

0.58

0.56

0.55

0.53

0.52

0.52

0.51102.56

1.68

0.98

0.84

0.71

0.63

0.60

0.58

0.55

0.54

0.52

0.52123.70

2.31

1.23

1.01

0.81

0.70

0.64

0.61

0.58

0.55

0.54

0.53145.17

3.12

1.53

1.22

0.94

0.77

0.70

0.66

0.61

0.57

0.55

0.54167.00

4.11

1.90

1.47

1.09

0.87

0.76

0.71

0.64

0.60

0.56

0.55189.23

5.30

2.34

1.77

1.26

0.97

0.84

0.76

0.68

0.62

0.58

0.562011.87

6.72

2.86

2.11

1.47

1.09

0.92

0.83

0.73

0.66

0.60

0.582214.96

8.36

3.45

2.51

1.70

1.23

1.02

0.90

0.78

0.69

0.62

0.592418.53

10.26

4.12

2.96

1.95

1.38

1.13

0.99

0.83

0.73

0.65

0.612612.41

4.88

3.46

2.24

1.55

1.25

1.08

0.90

0.77

0.67

0.632814.84

5.73

4.02

2.57

1.74

1.38

1.18

0.96

0.81

0.70

0.653017.55

6.68

4.64

2.92

1.95

1.52

1.29

1.04

0.86

0.73

0.67327.72

5.33

3.31

2.17

1.68

1.40

1.11

0.91

0.77

0.70348.86

6.08

3.73

2.42

1.85

1.53

1.20

0.97

0.80

0.723610.11

6.89

4.19

2.68

2.03

1.67

1.29

1.03

0.84

0.753811.47

7.78

4.68

2.96

2.22

1.82

1.39

1.09

0.88

0.784012.94

8.73

5.21

3.27

2.43

1.97

1.49

1.16

0.92

0.814214.52

9.76

5.78

3.59

2.65

2.14

1.60

1.23

0.97

0.844416.23

10.87

6.40

3.94

2.89

2.32

1.72

1.31

1.02

0.884618.06

12.05

7.05

4.31

3.14

2.51

1.84

1.39

1.07

0.914820.01

13.31

7.74

4.70

3.41

2.70

1.97

1.47

1.12

0.955014.65

8.48

5.12

3.69

2.91

2.11

1.56

1.17

0.995216.08

9.26

5.56

3.99

3.14

2.25

1.66

1.23

1.035417.60

10.09

6.02

4.30

3.37

2.41

1.75

1.29

1.085619.20

10.96

6.51

4.63

3.61

2.56

1.86

1.36

1.125811.88

7.02

4.98

3.87

2.73

1.96

1.42

1.176012.85

7.56

5.34

4.14

2.90

2.07

1.49

1.226213.87

8.12

5.72

4.42

3.08

2.19

1.56

1.276414.94

8.71

6.11

4.71

3.27

2.31

1.64

1.336616.05

9.33

6.52

5.01

3.47

2.44

1.71

1.386817.22

9.98

6.95

5.33

3.67

2.57

1.79

1.447018.45

10.65

7.40

5.66

3.88

2.70

1.88

1.507219.72

11.35

7.87

6.01

4.10

2.84

1.96

1.567412.08

8.36

6.36

4.33

2.98

2.05

1.627612.84

8.86

6.73

4.57

3.13

2.14

1.697813.63

9.38

7.12

4.81

3.29

2.23

1.758014.45

9.93

7.51

5.07

3.45

2.33

1.828215.29

10.49

7.92

5.33

3.61

2.43

1.898416.17

11.07

8.35

5.60

3.78

2.53

1.978617.09

11.67

8.79

5.88

3.96

2.64

2.048818.03

12.29

9.24

6.16

4.14

2.75

2.129019.00

12.93

9.71

6.46

4.32

2.86

2.209220.01

13.60

10.19

6.77

4.51

2.98

2.289414.28

10.69

7.08

4.71

3.09

2.369614.99

11.21

7.40

4.91

3.22

2.459815.71

11.74

7.74

5.12

3.34

2.54

100

16.46

12.28

8.08

5.33

3.47

2.63

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.15 Factor Applied to Shedd's Data

FEET

STATIC PRESSURE CHART FOR BEANS (W/STIRRING)

GRAIN

DEPTH

Fan/Heater Application

Static Pressure (inches of water column)

Airflow Rate (cfm per bushel)

14

Page 15

Fan/Heater Application

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

0.56

0.54

0.52

0.51

0.51

0.5140.80

0.68

0.58

0.55

0.53

0.52

0.52

0.51

0.51

0.5161.29

0.95

0.69

0.63

0.58

0.55

0.54

0.53

0.52

0.51

0.51

0.5182.10

1.40

0.86

0.75

0.65

0.60

0.57

0.55

0.54

0.53

0.52

0.51103.28

2.04

1.09

0.91

0.75

0.65

0.61

0.59

0.56

0.54

0.53

0.52124.90

2.90

1.41

1.12

0.87

0.73

0.66

0.63

0.59

0.56

0.54

0.53147.00

4.02

1.81

1.39

1.03

0.82

0.73

0.68

0.62

0.58

0.55

0.54169.63

5.41

2.30

1.71

1.21

0.93

0.80

0.73

0.66

0.61

0.57

0.551812.86

7.10

2.88

2.10

1.43

1.06

0.89

0.80

0.71

0.64

0.59

0.572016.72

9.11

3.58

2.55

1.69

1.21

1.00

0.88

0.76

0.67

0.61

0.582211.47

4.38

3.08

1.98

1.37

1.11

0.97

0.82

0.71

0.64

0.602414.20

5.31

3.68

2.32

1.57

1.24

1.07

0.88

0.75

0.66

0.622617.32

6.35

4.36

2.69

1.78

1.39

1.18

0.95

0.80

0.69

0.64287.53

5.12

3.11

2.02

1.55

1.30

1.03

0.85

0.72

0.66308.85

5.97

3.58

2.28

1.73

1.43

1.12

0.91

0.76

0.693210.31

6.91

4.09

2.57

1.92

1.57

1.21

0.97

0.80

0.723411.92

7.94

4.66

2.88

2.13

1.73

1.32

1.03

0.84

0.753613.69

9.07

5.27

3.22

2.36

1.90

1.42

1.11

0.88

0.783815.62

10.30

5.93

3.59

2.61

2.08

1.54

1.18

0.93

0.814017.72

11.63

6.65

3.99

2.88

2.28

1.67

1.26

0.98

0.854219.99

13.08

7.43

4.42

3.16

2.49

1.80

1.35

1.03

0.884414.63

8.27

4.87

3.47

2.71

1.95

1.44

1.08

0.924616.30

9.16

5.36

3.79

2.95

2.10

1.53

1.14

0.964818.09

10.11

5.88

4.13

3.20

2.26

1.63

1.20

1.015019.99

11.13

6.44

4.50

3.47

2.43

1.74

1.27

1.055212.21

7.02

4.89

3.75

2.61

1.85

1.34

1.105413.36

7.64

5.30

4.05

2.80

1.97

1.41

1.155614.57

8.30

5.73

4.37

2.99

2.09

1.48

1.205815.85

8.99

6.18

4.70

3.20

2.22

1.56

1.266017.20

9.72

6.66

5.04

3.42

2.36

1.64

1.326218.63

10.48

7.16

5.41

3.65

2.50

1.73

1.386420.13

11.29

7.69

5.79

3.89

2.65

1.81

1.446612.13

8.24

6.18

4.13

2.80

1.90

1.506813.01

8.81

6.60

4.39

2.96

2.00

1.577013.93

9.41

7.03

4.66

3.13

2.10

1.647214.90

10.04

7.49

4.94

3.30

2.20

1.717415.90

10.69

7.96

5.24

3.48

2.31

1.787616.95

11.37

8.45

5.54

3.67

2.42

1.867818.04

12.08

8.95

5.85

3.86

2.53

1.948019.17

12.81

9.48

6.18

4.06

2.65

2.028220.35

13.57

10.03

6.52

4.27

2.77

2.118414.36

10.60

6.87

4.48

2.89

2.198615.18

11.18

7.23

4.70

3.02

2.288816.03

11.79

7.60

4.93

3.15

2.379016.91

12.42

7.99

5.16

3.29

2.479217.82

13.07

8.39

5.40

3.43

2.579418.75

13.74

8.80

5.65

3.58

2.679619.72

14.43

9.22

5.91

3.72

2.779815.15

9.66

6.17

3.88

2.87

100

15.88

10.11

6.44

4.03

2.98

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.15 Factor Applied to Shedd's Data

STATIC PRESSURE CHART FOR CORN (W/STIRRING)

GRAIN

DEPTH

FEET

PRESSURE CHART

Static Pressure (inches of water column)

Airflow Rate (cfm per bushel)

15

Page 16

PRESSURE CHART

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

0.64

0.59

0.54

0.53

0.52

0.51

0.51

0.51

0.5141.14

0.89

0.68

0.63

0.58

0.56

0.54

0.53

0.52

0.52

0.51

0.5162.09

1.45

0.92

0.80

0.70

0.63

0.59

0.57

0.55

0.54

0.52

0.5283.59

2.32

1.28

1.06

0.86

0.73

0.67

0.63

0.59

0.57

0.54

0.53105.72

3.53

1.77

1.41

1.07

0.86

0.77

0.71

0.65

0.60

0.57

0.55128.57

5.13

2.41

1.85

1.34

1.03

0.89

0.81

0.72

0.65

0.60

0.571412.22

7.15

3.19

2.39

1.67

1.24

1.04

0.92

0.80

0.70

0.63

0.601616.73

9.63

4.14

3.04

2.06

1.48

1.21

1.06

0.89

0.77

0.68

0.631812.61

5.26

3.81

2.52

1.76

1.41

1.21

1.00

0.84

0.72

0.672016.11

6.56

4.69

3.05

2.08

1.64

1.39

1.12

0.92

0.78

0.712220.18

8.06

5.70

3.64

2.44

1.90

1.59

1.25

1.01

0.84

0.75249.76

6.85

4.31

2.84

2.18

1.81

1.40

1.12

0.90

0.802611.67

8.13

5.06

3.29

2.50

2.05

1.57

1.23

0.97

0.852813.80

9.55

5.88

3.78

2.84

2.31

1.75

1.35

1.05

0.913016.16

11.12

6.79

4.31

3.22

2.60

1.94

1.48

1.13

0.973218.76

12.85

7.78

4.90

3.63

2.91

2.15

1.62

1.22

1.043414.73

8.86

5.53

4.07

3.25

2.38

1.77

1.32

1.113616.78

10.02

6.21

4.54

3.61

2.62

1.93

1.42

1.183818.99

11.28

6.94

5.05

4.00

2.88

2.10

1.53

1.264012.63

7.73

5.59

4.41

3.16

2.28

1.65

1.354214.08

8.56

6.17

4.85

3.45

2.48

1.77

1.444415.63

9.46

6.78

5.31

3.76

2.68

1.90

1.534617.27

10.40

7.44

5.80

4.08

2.89

2.04

1.634819.02

11.41

8.12

6.32

4.42

3.12

2.18

1.735012.47

8.85

6.86

4.79

3.35

2.33

1.845213.59

9.62

7.44

5.16

3.60

2.48

1.955414.77

10.42

8.04

5.56

3.86

2.64

2.075616.01

11.27

8.67

5.98

4.13

2.81

2.195817.31

12.15

9.34

6.41

4.41

2.99

2.326018.67

13.08

10.03

6.86

4.71

3.17

2.466220.10

14.05

10.75

7.34

5.01

3.36

2.596415.06

11.51

7.83

5.33

3.56

2.746616.11

12.29

8.34

5.66

3.77

2.886817.21

13.11

8.87

6.00

3.98

3.047018.36

13.96

9.42

6.36

4.20

3.207219.54

14.84

9.99

6.73

4.43

3.367415.75

10.58

7.11

4.66

3.537616.70

11.20

7.50

4.90

3.707817.68

11.83

7.90

5.15

3.888018.70

12.48

8.32

5.41

4.078219.75

13.16

8.75

5.68

4.268413.86

9.20

5.95

4.458614.58

9.65

6.23

4.658815.32

10.13

6.52

4.869016.08

10.61

6.81

5.079216.87

11.11

7.12

5.299417.68

11.62

7.43

5.519618.51

12.15

7.75

5.749819.36

12.68

8.08

5.97

100

20.24

13.24

8.41

6.21

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.15 Factor Applied to Shedd's Data

STATIC PRESSURE CHART FOR RICE (W/ STIRRING)

GRAIN

DEPTH

FEET

Fan/Heater Application

Static Pressure (inches of water column)

Airflow Rate (cfm per bushel)

16

Page 17

Fan/Heater Application

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

0.73

0.65

0.57

0.55

0.53

0.52

0.52

0.51

0.51

0.5141.50

1.13

0.79

0.72

0.64

0.59

0.57

0.56

0.54

0.53

0.52

0.5162.94

2.00

1.18

1.00

0.82

0.71

0.66

0.63

0.59

0.56

0.54

0.5385.16

3.32

1.75

1.41

1.09

0.88

0.78

0.72

0.66

0.61

0.57

0.55108.27

5.13

2.52

1.96

1.43

1.10

0.95

0.85

0.75

0.67

0.61

0.591212.37

7.49

3.50

2.65

1.87

1.38

1.15

1.01

0.86

0.75

0.67

0.621417.56

10.45

4.70

3.50

2.39

1.71

1.39

1.20

1.00

0.84

0.73

0.671614.04

6.14

4.50

3.01

2.10

1.67

1.43

1.15

0.95

0.80

0.721818.31

7.82

5.67

3.73

2.55

2.00

1.68

1.33

1.07

0.88

0.78209.77

7.02

4.55

3.06

2.37

1.97

1.53

1.21

0.97

0.852211.98

8.54

5.47

3.63

2.78

2.29

1.75

1.36

1.06

0.922414.49

10.26

6.50

4.26

3.23

2.64

1.99

1.53

1.17

1.002617.29

12.17

7.64

4.96

3.73

3.03

2.26

1.71

1.29

1.092820.39

14.29

8.90

5.73

4.28

3.46

2.56

1.91

1.42

1.193016.61

10.28

6.56

4.88

3.92

2.87

2.12

1.56

1.293219.15

11.77

7.47

5.52

4.41

3.21

2.35

1.71

1.403413.40

8.44

6.21

4.95

3.58

2.60

1.87

1.523615.14

9.49

6.95

5.52

3.97

2.86

2.04

1.643817.02

10.61

7.75

6.13

4.38

3.14

2.22

1.774019.03

11.81

8.59

6.77

4.82

3.44

2.41

1.924213.09

9.49

7.46

5.29

3.75

2.61

2.064414.44

10.44

8.19

5.78

4.08

2.82

2.224615.88

11.44

8.96

6.30

4.42

3.04

2.384817.39

12.50

9.76

6.84

4.79

3.28

2.555018.99

13.62

10.61

7.41

5.17

3.52

2.735214.79

11.50

8.01

5.57

3.78

2.925416.02

12.44

8.64

5.98

4.04

3.115617.30

13.41

9.29

6.42

4.32

3.325818.65

14.43

9.98

6.87

4.60

3.536020.05

15.50

10.69

7.34

4.90

3.746216.61

11.43

7.82

5.21

3.976417.76

12.19

8.33

5.53

4.206618.96

12.99

8.86

5.87

4.456820.21

13.82

9.40

6.21

4.707014.67

9.96

6.56

4.957215.56

10.54

6.93

5.227416.48

11.14

7.31

5.507617.42

11.76

7.70

5.787818.40

12.40

8.10

6.078019.41

13.06

8.51

6.378220.45

13.74

8.94

6.688414.43

9.37

7.008615.15

9.82

7.328815.89

10.28

7.659016.64

10.75

8.009217.42

11.24

8.359418.22

11.74

8.719619.04

12.25

9.079819.88

12.77

9.45

100

13.30

9.84

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.15 Factor Applied to Shedd's Data

STATIC PRESSURE CHART FOR WHEAT (W/ STIRRING)

GRAIN

DEPTH

FEET

PRESSURE CHART

Static Pressure (inches of water column)

Airflow Rate (cfm per bushel)

17

Page 18

PRESSURE CHART

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

0.67

0.61

0.55

0.54

0.52

0.52

0.51

0.51

0.5141.25

0.96

0.71

0.65

0.60

0.57

0.55

0.54

0.53

0.52

0.51

0.5162.36

1.62

1.00

0.86

0.73

0.65

0.61

0.59

0.56

0.54

0.53

0.5284.10

2.63

1.42

1.16

0.92

0.77

0.70

0.66

0.61

0.58

0.55

0.54106.58

4.05

2.00

1.57

1.17

0.93

0.82

0.75

0.68

0.62

0.58

0.56129.89

5.91

2.74

2.09

1.49

1.13

0.96

0.86

0.76

0.68

0.62

0.591414.11

8.25

3.66

2.72

1.88

1.37

1.14

1.00

0.85

0.74

0.66

0.621619.33

11.13

4.76

3.48

2.34

1.66

1.34

1.16

0.96

0.82

0.71

0.661814.58

6.07

4.38

2.88

1.99

1.58

1.35

1.09

0.90

0.77

0.702018.64

7.59

5.41

3.50

2.36

1.85

1.55

1.23

1.00

0.83

0.74229.34

6.60

4.19

2.79

2.15

1.79

1.39

1.11

0.90

0.802411.31

7.93

4.98

3.26

2.49

2.05

1.57

1.23

0.98

0.852613.53

9.42

5.85

3.78

2.86

2.33

1.76

1.36

1.06

0.922816.01

11.08

6.82

4.36

3.26

2.64

1.98

1.50

1.15

0.983018.75

12.91

7.87

4.99

3.70

2.98

2.21

1.66

1.25

1.063214.92

9.03

5.67

4.18

3.35

2.45

1.82

1.36

1.143417.10

10.29

6.41

4.70

3.74

2.72

2.00

1.47

1.223619.48

11.65

7.21

5.26

4.17

3.01

2.19

1.60

1.313813.11

8.07

5.85

4.62

3.31

2.39

1.72

1.404014.69

8.98

6.49

5.10

3.64

2.61

1.86

1.504216.37

9.96

7.17

5.62

3.98

2.84

2.01

1.614418.17

11.00

7.89

6.16

4.34

3.08

2.16

1.724620.09

12.11

8.65

6.74

4.72

3.33

2.32

1.844813.28

9.46

7.35

5.13

3.59

2.49

1.965014.52

10.31

7.99

5.55

3.87

2.66

2.095215.82

11.20

8.66

6.00

4.16

2.85

2.225417.20

12.14

9.37

6.47

4.47

3.04

2.365618.64

13.13

10.11

6.95

4.79

3.24

2.515820.16

14.17

10.88

7.46

5.12

3.45

2.666015.25

11.69

8.00

5.47

3.66

2.826216.38

12.54

8.55

5.83

3.89

2.986417.56

13.42

9.13

6.20

4.12

3.156618.79

14.34

9.73

6.59

4.36

3.326820.07

15.29

10.35

6.99

4.61

3.507016.29

10.99

7.41

4.87

3.697217.32

11.66

7.84

5.14

3.887418.38

12.36

8.29

5.42

4.087619.49

13.07

8.75

5.70

4.297813.82

9.22

6.00

4.508014.58

9.72

6.30

4.728215.37

10.22

6.61

4.948416.19

10.74

6.93

5.178617.03

11.28

7.26

5.418817.90

11.83

7.60

5.659018.79

12.40

7.95

5.909219.71

12.99

8.31

6.169413.59

8.68

6.429614.20

9.05

6.699814.84

9.44

6.96

100

15.48

9.83

7.25

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.5 Factor Applied to Shedd's Data

GRAIN

DEPTH

FEET

Fan/Heater Application

STATIC PRESSURE CHART FOR BARLEY

Static Pressure (inches of water column)

Airflow Rate (cfm per bushel)

18

Page 19

Fan/Heater Application

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

0.57

0.54

0.52

0.51

0.51

0.5140.82

0.69

0.59

0.56

0.54

0.53

0.52

0.52

0.51

0.51

0.5161.30

0.97

0.71

0.65

0.59

0.56

0.54

0.54

0.53

0.52

0.51

0.5182.07

1.41

0.88

0.77

0.67

0.61

0.58

0.56

0.54

0.53

0.52

0.52103.18

2.04

1.13

0.94

0.78

0.68

0.63

0.60

0.57

0.55

0.53

0.52124.68

2.86

1.45

1.16

0.91

0.76

0.69

0.65

0.60

0.57

0.55

0.53146.60

3.91

1.85

1.44

1.07

0.86

0.76

0.70

0.64

0.60

0.56

0.55168.98

5.21

2.33

1.76

1.27

0.98

0.84

0.77

0.69

0.63

0.58

0.561811.88

6.77

2.90

2.15

1.50

1.11

0.94

0.84

0.74

0.66

0.61

0.582015.33

8.61

3.57

2.60

1.76

1.27

1.05

0.93

0.80

0.70

0.63

0.602219.36

10.76

4.34

3.12

2.06

1.45

1.18

1.03

0.86

0.75

0.66

0.622413.23

5.22

3.70

2.40

1.65

1.32

1.13

0.94

0.80

0.69

0.642616.04

6.21

4.36

2.78

1.87

1.48

1.25

1.02

0.85

0.73

0.672819.20

7.32

5.09

3.19

2.12

1.65

1.38

1.10

0.91

0.76

0.69308.55

5.91

3.65

2.39

1.83

1.53

1.20

0.97

0.80

0.72329.91

6.80

4.16

2.68

2.04

1.68

1.30

1.04

0.85

0.763411.40

7.77

4.71

3.00

2.26

1.85

1.41

1.11

0.89

0.793613.03

8.84

5.31

3.34

2.49

2.02

1.53

1.19

0.94

0.833814.80

9.99

5.95

3.71

2.75

2.22

1.66

1.27

1.00

0.864016.72

11.24

6.65

4.11

3.02

2.42

1.79

1.36

1.05

0.904218.79

12.58

7.39

4.54

3.31

2.64

1.94

1.46

1.11

0.954414.02

8.19

4.99

3.62

2.87

2.09

1.56

1.17

0.994615.56

9.04

5.47

3.95

3.12

2.25

1.66

1.24

1.044817.21

9.95

5.98

4.30

3.38

2.42

1.77

1.31

1.095018.96

10.91

6.52

4.66

3.65

2.60

1.89

1.38

1.145211.93

7.10

5.05

3.94

2.79

2.01

1.46

1.205413.01

7.70

5.46

4.24

2.99

2.14

1.53

1.255614.15

8.34

5.89

4.56

3.19

2.27

1.62

1.315815.35

9.01

6.34

4.89

3.41

2.41

1.70

1.386016.61

9.71

6.81

5.24

3.64

2.55

1.79

1.446217.94

10.44

7.30

5.61

3.87

2.70

1.89

1.516419.33

11.21

7.82

5.99

4.12

2.86

1.98

1.586612.02

8.36

6.39

4.37

3.02

2.08

1.656812.86

8.92

6.80

4.64

3.19

2.19

1.727013.74

9.50

7.23

4.91

3.37

2.29

1.807214.65

10.11

7.68

5.20

3.55

2.41

1.887415.61

10.75

8.15

5.50

3.74

2.52

1.967616.59

11.40

8.63

5.81

3.94

2.64

2.057817.62

12.09

9.13

6.13

4.14

2.76

2.138018.69

12.79

9.65

6.46

4.34

2.89

2.228219.80

13.53

10.18

6.80

4.56

3.02

2.328414.29

10.74

7.15

4.78

3.15

2.418615.07

11.31

7.51

5.01

3.29

2.518815.88

11.90

7.89

5.24

3.43

2.619016.72

12.51

8.27

5.49

3.58

2.719217.58

13.15

8.67

5.74

3.73

2.829418.48

13.80

9.08

5.99

3.88

2.939619.40

14.47

9.50

6.26

4.04

3.049820.35

15.15

9.94

6.53

4.20

3.16

100

15.86

10.38

6.80

4.37

3.27

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.5 Factor Applied to Shedd's Data

GRAIN

DEPTH

FEET

PRESSURE CHART

STATIC PRESSURE CHART FOR BEANS

Static Pressure (inches of water column)

Airflow Rate (cfm per bushel)

19

Page 20

PRESSURE CHART

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

1.50

1.16

0.83

0.74

0.66

0.61

0.58

0.56

0.55

0.53

0.52

0.5244.63

3.19

1.82

1.48

1.15

0.93

0.82

0.76

0.68

0.63

0.59

0.56610.09

6.69

3.50

2.73

1.97

1.47

1.23

1.08

0.92

0.79

0.69

0.64818.06

11.75

5.89

4.49

3.13

2.24

1.80

1.54

1.24

1.02

0.84

0.761018.44

9.01

6.79

4.64

3.23

2.54

2.13

1.66

1.31

1.04

0.901212.89

9.64

6.49

4.45

3.44

2.85

2.17

1.67

1.28

1.081417.54

13.04

8.70

5.89

4.52

3.70

2.78

2.09

1.56

1.291617.02

11.27

7.57

5.77

4.69

3.48

2.58

1.88

1.531814.21

9.48

7.18

5.82

4.28

3.13

2.25

1.812017.52

11.63

8.78

7.08

5.17

3.75

2.66

2.122214.02

10.54

8.48

6.17

4.44

3.12

2.462416.64

12.49

10.02

7.25

5.20

3.62

2.832619.52

14.61

11.70

8.44

6.02

4.16

3.242816.91

13.52

9.72

6.91

4.75

3.683019.39

15.48

11.11

7.87

5.38

4.153217.58

12.59

8.89

6.06

4.663419.83

14.17

9.98

6.78

5.193615.85

11.14

7.55

5.773817.63

12.37

8.36

6.374019.51

13.67

9.21

7.014215.04

10.11

7.684416.47

11.06

8.394617.98

12.05

9.124819.56

13.09

9.905014.17

10.70

52

15.29

11.54

54

16.47

12.41

56

17.68

13.32

58

18.95

14.26

60

20.26

15.23

62

16.24

64

17.28

66

18.36

68

19.47

707274767880828486889092949698

100

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.5 Factor Applied to Shedd's Data

Fan/Heater Application

STATIC PRESSURE CHART FOR CLOVER

GRAIN

DEPTH

FEET

Static Pressure (inches of water column)

Airflow Rate (cfm per bushel)

20

Page 21

Fan/Heater Application

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

0.69

0.62

0.56

0.54

0.53

0.52

0.51

0.51

0.51

0.5141.35

1.03

0.74

0.68

0.62

0.58

0.56

0.55

0.53

0.52

0.51

0.5162.59

1.77

1.07

0.92

0.77

0.67

0.63

0.60

0.55

0.53

0.5384.52

2.90

1.55

1.26

0.99

0.82

0.73

0.69

0.63

0.59

0.56

0.55107.25

4.48

2.21

1.72

1.28

1.00

0.87

0.79

0.71

0.64

0.59

0.571210.87

6.53

3.04

2.31

1.64

1.23

1.04

0.92

0.80

0.71

0.64

0.601415.47

9.12

4.07

3.03

2.08

1.51

1.24

1.08

0.91

0.78

0.69

0.641612.28

5.31

3.89

2.61

1.83

1.47

1.27

1.04

0.87

0.74

0.681816.05

6.76

4.89

3.22

2.21

1.75

1.48

1.18

0.97

0.81

0.732020.48

8.45

6.05

3.91

2.64

2.05

1.72

1.35

1.08

0.88

0.792210.38

7.37

4.70

3.12

2.40

1.99

1.53

1.21

0.97

0.852412.57

8.85

5.58

3.66

2.78

2.28

1.74

1.35

1.06

0.912615.01

10.51

6.56

4.25

3.20

2.61

1.96

1.50

1.15

0.992817.74

12.35

7.64

4.90

3.67

2.97

2.21

1.66

1.26

1.063014.37

8.82

5.61

4.17

3.35

2.47

1.84

1.38

1.153216.59

10.12

6.38

4.71

3.77

2.76

2.03

1.50

1.243419.00

11.52

7.22

5.30

4.22

3.06

2.24

1.63

1.343613.03

8.11

5.93

4.70

3.39

2.46

1.77

1.443814.66

9.07

6.60

5.22

3.74

2.69

1.92

1.554016.40

10.10

7.32

5.77

4.11

2.94

2.08

1.674218.27

11.20

8.09

6.35

4.50

3.20

2.25

1.794420.27

12.36

8.90

6.97

4.91

3.47

2.42

1.924613.60

9.76

7.62

5.35

3.76

2.61

2.054814.91

10.66

8.30

5.81

4.07

2.80

2.205016.29

11.62

9.03

6.29

4.39

3.00

2.345217.74

12.62

9.79

6.80

4.72

3.22

2.505419.27

13.68

10.58

7.33

5.07

3.44

2.665614.78

11.42

7.88

5.43

3.67

2.835815.94

12.29

8.46

5.81

3.91

3.006017.15

13.20

9.06

6.21

4.16

3.186218.41

14.15

9.69

6.62

4.42

3.376419.73

15.14

10.34

7.05

4.68

3.576616.17

11.02

7.49

4.96

3.776817.24

11.72

7.95

5.25

3.987018.35

12.45

8.42

5.55

4.197219.50

13.21

8.91

5.85

4.427413.99

9.42

6.17

4.657614.80

9.94

6.50

4.887815.63

10.48

6.83

5.128016.50

11.04

7.18

5.388217.39

11.62

7.54

5.638418.30

12.21

7.90

5.908619.25

12.82

8.28

6.178820.22

13.44

8.67

6.459014.08

9.06

6.739214.75

9.47

7.039415.42

9.89

7.339616.12

10.32

7.649816.84

10.76

7.95

100

17.57

11.21

8.27

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.5 Factor Applied to Shedd's Data

GRAIN

DEPTH

FEET

PRESSURE CHART

STATIC CHART FOR WHITE POPCORN

Static Pressure (inches of water column)

Airflow Rate (cfm per bushel)

21

Page 22

PRESSURE CHART

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

0.51

0.5140.57

0.53

0.51

0.5160.69

0.60

0.53

0.52

0.51

0.5180.92

0.71

0.57

0.54

0.52

0.51

0.51

0.51101.28

0.89

0.62

0.58

0.54

0.52

0.51

0.51

0.51121.78

1.13

0.70

0.62

0.56

0.53

0.52

0.52

0.51

0.51142.45

1.46

0.79

0.68

0.59

0.55

0.53

0.52

0.51

0.51163.33

1.89

0.92

0.76

0.63

0.57

0.54

0.53

0.52

0.51

0.51184.41

2.42

1.08

0.86

0.68

0.59

0.56

0.54

0.53

0.52

0.51

0.51205.74

3.06

1.27

0.97

0.74

0.62

0.58

0.56

0.53

0.52

0.51

0.51227.33

3.83

1.50

1.11

0.81

0.66

0.60

0.57

0.54

0.52

0.51

0.51249.20

4.74

1.77

1.27

0.89

0.70

0.63

0.59

0.55

0.53

0.52

0.512611.37

5.79

2.07

1.46

0.98

0.75

0.66

0.61

0.56

0.54

0.52

0.512813.87

6.99

2.43

1.67

1.09

0.80

0.69

0.63

0.58

0.55

0.53

0.523016.71

8.36

2.83

1.92

1.21

0.86

0.73

0.66

0.59

0.55

0.53

0.523219.91

9.91

3.28

2.19

1.34

0.93

0.77

0.69

0.61

0.56

0.53

0.523411.63

3.78

2.49

1.49

1.00

0.81

0.72

0.63

0.57

0.54

0.533613.55

4.34

2.83

1.66

1.08

0.86

0.75

0.65

0.59

0.55

0.533815.67

4.95

3.20

1.84

1.18

0.92

0.79

0.67

0.60

0.55

0.534018.00

5.63

3.60

2.04

1.28

0.98

0.83

0.69

0.61

0.56

0.54426.36

4.05

2.26

1.38

1.05

0.88

0.72

0.63

0.57

0.54447.17

4.53

2.50

1.50

1.12

0.93

0.75

0.64

0.58

0.55468.04

5.05

2.75

1.63

1.20

0.98

0.78

0.66

0.59

0.56488.98

5.61

3.03

1.76

1.28

1.04

0.81

0.68

0.59

0.56509.99

6.22

3.33

1.91

1.37

1.10

0.85

0.70

0.61

0.575211.08

6.87

3.65

2.07

1.47

1.17

0.89

0.72

0.62

0.585412.24

7.57

3.99

2.24

1.57

1.24

0.93

0.74

0.63

0.585613.49

8.32

4.35

2.42

1.68

1.31

0.97

0.76

0.64

0.595814.81

9.11

4.74

2.61

1.80

1.39

1.01

0.79

0.65

0.606016.23

9.96

5.15

2.81

1.92

1.48

1.06

0.82

0.67

0.616217.72

10.85

5.59

3.02

2.05

1.57

1.11

0.84

0.68

0.626419.31

11.80

6.05

3.25

2.19

1.66

1.17

0.87

0.70

0.636612.81

6.54

3.49

2.33

1.76

1.22

0.90

0.71

0.646813.86

7.06

3.74

2.49

1.86

1.28

0.94

0.73

0.657014.98

7.60

4.01

2.65

1.97

1.34

0.97

0.75

0.667216.16

8.17

4.29

2.82

2.09

1.41

1.01

0.77

0.677417.39

8.77

4.58

3.00

2.21

1.48

1.04

0.79

0.687618.69

9.40

4.89

3.19

2.34

1.55

1.08

0.81

0.707820.04

10.06

5.21

3.38

2.47

1.62

1.12

0.83

0.718010.75

5.55

3.59

2.61

1.70

1.17

0.85

0.728211.48

5.90

3.80

2.76

1.78

1.21

0.87

0.748412.23

6.27

4.02

2.91

1.87

1.26

0.90

0.758613.02

6.65

4.25

3.06

1.96

1.31

0.92

0.778813.84

7.05

4.50

3.23

2.05

1.36

0.95

0.789014.69

7.47

4.75

3.40

2.15

1.41

0.97

0.809215.58

7.90

5.01

3.58

2.25

1.47

1.00

0.829416.50

8.35

5.28

3.76

2.35

1.52

1.03

0.849617.46

8.82

5.56

3.95

2.46

1.58

1.06

0.859818.45

9.30

5.85

4.15

2.57

1.64

1.09

0.87

100

19.48

9.80

6.16

4.36

2.68

1.70

1.12

0.89

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.5 Factor Applied to Shedd's Data

GRAIN

DEPTH

FEET

Fan/Heater Application

STATIC PRESSURE CHART FOR EARCORN

Static Pressure (inches of water column)

Airflow Rate (cfm per bushel)

22

Page 23

Fan/Heater Application

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

1.50

1.16

0.83

0.74

0.66

0.61

0.58

0.56

0.55

0.53

0.52

0.5244.63

3.19

1.82

1.48

1.15

0.93

0.82

0.76

0.68

0.63

0.59

0.56610.09

6.69

3.50

2.73

1.97

1.47

1.23

1.08

0.92

0.79

0.69

0.64818.06

11.75

5.89

4.49

3.13

2.24

1.80

1.54

1.24

1.02

0.84

0.761018.44

9.01

6.79

4.64

3.23

2.54

2.13

1.66

1.31

1.04

0.901212.89

9.64

6.49

4.45

3.44

2.85

2.17

1.67

1.28

1.081417.54

13.04

8.70

5.89

4.52

3.70

2.78

2.09

1.56

1.291617.02

11.27

7.57

5.77

4.69

3.48

2.58

1.88

1.531814.21

9.48

7.18

5.82

4.28

3.13

2.25

1.812017.52

11.63

8.78

7.08

5.17

3.75

2.66

2.122214.02

10.54

8.48

6.17

4.44

3.12

2.462416.64

12.49

10.02

7.25

5.20

3.62

2.832619.52

14.61

11.70

8.44

6.02

4.16

3.242816.91

13.52

9.72

6.91

4.75

3.683019.39

15.48

11.11

7.87

5.38

4.153217.58

12.59

8.89

6.06

4.663419.83

14.17

9.98

6.78

5.193615.85

11.14

7.55

5.773817.63

12.37

8.36

6.374019.51

13.67

9.21

7.014215.04

10.11

7.684416.47

11.06

8.394617.98

12.05

9.124819.56

13.09

9.905014.17

10.70

52

15.29

11.54

54

16.47

12.41

56

17.68

13.32

58

18.95

14.26

60

20.26

15.23

62

16.24

64

17.28

66

18.36

68

19.47

707274767880828486889092949698

100

.50" Water Column have been Added To Static Pressure to Account for System Loss

Static Pressures are Calculated Using a 1.5 Factor Applied to Shedd's Data

Airflow Rate (cfm per bushel)

GRAIN

DEPTH

FEET

PRESSURE CHART

STATIC PRESSURE CHART FOR FLAX

Static Pressure (inches of water column)

23

Page 24

PRESSURE CHART

Fan/Heater Application

Static Pressure Chart For Milo

Grain depth Static Pressure (inches of water column) Airflow Rate (cfm per bushel)

in feet 3 2 1 3/4 1/2 1/3 1/4 1/5 1/7 1/10 1/15 1/20

2

4

6

8

10

12

14 19.58 11.51 5.08 3.75 2.54 1.80 1.45 1.25 1.03 0.86 0.74 0.68

16

18

20

22

24

26 19.05 13.31 8.27 5.32 3.98 3.21 2.38 1.79 1.34 1.13

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64 19.28 13.14 8.92 5.89 4.45

66

68

70

72

74

76 18.85 12.64 8.22 6.14

78

80

82

84

86

88

90

92

94

96

98

100

0.74 0.66 0.58 0.56 0.54 0.52 0.52 0.51 0.51 0.51

1.59 1.18 0.81 0.73 0.65 0.60 0.57 0.56 0.54 0.53 0.52 0.51

3.17 2.13 1.23 1.03 0.85 0.73 0.67 0.63 0.59 0.57 0.54 0.53

5.64 3.58 1.85 1.48 1.13 0.91 0.80 0.74 0.67 0.62 0.58 0.56

9.12 5.59 2.69 2.07 1.50 1.14 0.98 0.88 0.77 0.68 0.62 0.59

13.73 8.21 3.76 2.82 1.97 1.44 1.19 1.05 0.88 0.77 0.68 0.63

15.54 6.66 4.84 3.21 2.22 1.75 1.49 1.19 0.98 0.81 0.73

20.34 8.52 6.13 3.99 2.70 2.10 1.76 1.38 1.11 0.90 0.80

10.68 7.61 4.88 3.25 2.50 2.07 1.60 1.25 0.99 0.87

13.14 9.30 5.89 3.87 2.94 2.41 1.83 1.41 1.10 0.95

15.93 11.19 7.02 4.56 3.44 2.79 2.10 1.59 1.22 1.03

15.66 9.65 6.15 4.57 3.67 2.70 2.00 1.48 1.23

18.24 11.17 7.06 5.22 4.17 3.04 2.23 1.63 1.34

12.82 8.05 5.91 4.71 3.40 2.48 1.79 1.45

14.61 9.12 6.67 5.28 3.80 2.74 1.96 1.58

16.54 10.27 7.48 5.90 4.22 3.02 2.14 1.71

18.62 11.50 8.34 6.56 4.66 3.32 2.33 1.86

12.81 9.26 7.27 5.14 3.64 2.54 2.00

14.22 10.24 8.01 5.64 3.97 2.75 2.16

15.71 11.28 8.81 6.17 4.33 2.98 2.33

17.29 12.38 9.64 6.74 4.70 3.21 2.50

18.96 13.54 10.52 7.33 5.09 3.46 2.69

14.76 11.45 7.95 5.50 3.73 2.88

16.04 12.42 8.59 5.93 4.00 3.08

17.39 13.44 9.27 6.38 4.28 3.28

18.81 14.51 9.99 6.85 4.58 3.50

20.29 15.63 10.73 7.34 4.89 3.73

16.79 11.50 7.84 5.21 3.96

18.01 12.30 8.37 5.54 4.20

14.01 9.49 6.24 4.71

14.91 10.07 6.61 4.98

15.85 10.68 6.99 5.26

16.81 11.31 7.39 5.54

17.81 11.96 7.80 5.84

19.92 13.33 8.65 6.46

14.04 9.09 6.78

14.78 9.55 7.11

15.54 10.02 7.45

16.32 10.51 7.80

17.12 11.00 8.16

17.95 11.52 8.52

18.80 12.04 8.90

19.67 12.58 9.29

13.13 9.68

13.69 10.09

14.27 10.50

24

Page 25

Fan/Heater Application

100

17.12

10.82

7.95

PRESSURE CHART

Static Pressure Chart For Oats

Grain depth Static Pressure (inches of water column) Airflow Rate (cfm per bushel)

in feet 3 2 1 3/4 1/2 1/3 1/4 1/5 1/7 1/10 1/15 1/20

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38 14.56 8.90 6.43 5.06 3.60 2.59 1.85 1.49

40

42

44

46

48

50

52 17.57 12.39 9.55 6.58 4.55 3.09 2.40

54

56

58

60

62

64

66 15.88 10.73 7.23 4.76 3.61

68

70

72

74

76

78

80 16.13 10.70 6.90 5.15

82

84

86

88

90

92

94 15.00 9.54 7.03

96

98

0.68 0.62 0.56 0.54 0.53 0.52 0.51 0.51 0.51 0.51

1.33 1.01 0.73 0.67 0.61 0.57 0.55 0.54 0.53 0.52 0.51 0.51

2.57 1.74 1.05 0.90 0.75 0.67 0.62 0.60 0.57 0.55 0.53 0.52

4.53 2.87 1.52 1.23 0.96 0.80 0.72 0.67 0.62 0.59 0.56 0.54

7.31 4.46 2.16 1.68 1.24 0.98 0.85 0.78 0.69 0.63 0.59 0.57

11.03 6.54 2.99 2.26 1.60 1.20 1.01 0.90 0.78 0.69 0.63 0.60

15.78 9.18 4.01 2.96 2.03 1.46 1.20 1.05 0.89 0.77 0.68 0.63

12.41 5.25 3.81 2.54 1.78 1.43 1.23 1.01 0.85 0.73 0.67

16.29 6.71 4.81 3.14 2.14 1.69 1.43 1.15 0.94 0.79 0.72

8.41 5.97 3.82 2.56 1.99 1.66 1.31 1.05 0.86 0.77

10.36 7.29 4.60 3.03 2.32 1.92 1.48 1.17 0.94 0.83

12.58 8.78 5.47 3.56 2.69 2.21 1.68 1.30 1.02 0.89

15.07 10.45 6.45 4.14 3.10 2.52 1.89 1.45 1.12 0.96

17.85 12.31 7.52 4.78 3.55 2.87 2.13 1.61 1.22 1.03

14.35 8.70 5.48 4.05 3.24 2.38 1.78 1.33 1.11

16.60 10.00 6.24 4.58 3.65 2.66 1.96 1.45 1.20

19.06 11.40 7.06 5.15 4.09 2.95 2.15 1.57 1.29

12.92 7.95 5.77 4.56 3.27 2.36 1.71 1.39

16.32 9.93 7.14 5.60 3.96 2.83 2.00 1.60

18.21 11.02 7.90 6.17 4.34 3.08 2.16 1.72

20.23 12.18 8.70 6.77 4.75 3.34 2.33 1.84

13.42 9.55 7.41 5.17 3.62 2.50 1.97

14.72 10.44 8.09 5.62 3.91 2.69 2.11

16.11 11.39 8.80 6.09 4.22 2.88 2.25

19.11 13.44 10.34 7.10 4.88 3.30 2.55

14.54 11.16 7.64 5.24 3.52 2.71

15.70 12.03 8.21 5.61 3.75 2.88

16.91 12.93 8.80 5.99 3.99 3.05

18.17 13.87 9.42 6.39 4.24 3.23

19.49 14.85 10.06 6.80 4.50 3.42

16.94 11.42 7.68 5.04 3.81

18.05 12.14 8.14 5.33 4.02

19.20 12.88 8.62 5.62 4.23

20.39 13.65 9.12 5.93 4.45

14.45 9.63 6.24 4.68

15.28 10.16 6.57 4.91

17.01 11.26 7.25 5.40

17.92 11.84 7.61 5.65

18.86 12.44 7.97 5.91

19.83 13.05 8.35 6.18

13.69 8.73 6.46

14.34 9.13 6.74

15.69 9.95 7.33

16.39 10.38 7.63

25

Page 26

PRESSURE CHART

321

3/4

1/2

1/3

1/4

1/5

1/7

1/10

1/15

1/20

2

0.5140.53

0.52

0.5160.60

0.55

0.52

0.51

0.5180.71

0.61

0.54

0.52

0.51

0.51

0.51100.88

0.70

0.57

0.54

0.52

0.51

0.51

0.51121.12

0.82

0.60

0.57

0.54

0.52

0.51

0.51

0.51141.44

0.98

0.66

0.60

0.55

0.53

0.52

0.51

0.51

0.51161.85

1.18

0.72

0.64

0.58

0.54

0.53

0.52

0.51

0.51

0.51182.35

1.43

0.80

0.69

0.60

0.56

0.54

0.53

0.52

0.51

0.51202.96

1.74

0.89

0.75

0.63

0.57

0.55

0.53

0.52

0.51

0.51

0.51223.69

2.10

1.00

0.82

0.67

0.59

0.56

0.54

0.53

0.52

0.51

0.51244.54

2.52

1.13

0.90

0.71

0.61

0.57

0.55

0.53

0.52

0.51

0.51265.53

3.01

1.28

0.99

0.76

0.64

0.59

0.57

0.54

0.53

0.51

0.51286.66

3.56

1.45

1.10

0.81

0.67

0.61

0.58

0.55

0.53

0.52

0.51307.95

4.19

1.65

1.21

0.87

0.70

0.63

0.59

0.56

0.54

0.52

0.51329.39

4.90

1.86

1.35

0.94

0.73

0.65

0.61

0.57

0.54

0.52

0.523411.00

5.69

2.10

1.49

1.01

0.77

0.68

0.63

0.58

0.55

0.53

0.523612.79

6.57

2.36

1.66

1.10

0.81

0.70

0.64

0.59

0.55

0.53

0.523814.76

7.53

2.65

1.83

1.19

0.86

0.73

0.67

0.60

0.56

0.54

0.524016.93

8.59

2.97

2.03

1.29

0.91

0.76

0.69

0.61

0.57

0.54

0.534219.29

9.74

3.32

2.24

1.39

0.97

0.80

0.71

0.63

0.58

0.54

0.534411.00

3.69

2.47

1.51

1.03

0.84

0.74

0.65

0.59

0.55

0.534612.36

4.10

2.72

1.63

1.09

0.88

0.77

0.66

0.60

0.56

0.544813.83

4.54

2.98

1.77

1.16

0.92

0.80

0.68

0.61

0.56

0.545015.41

5.01

3.27

1.91

1.23

0.97

0.83

0.70

0.62

0.57

0.555217.11

5.51

3.58

2.07

1.31

1.02

0.86

0.72

0.63

0.57

0.555418.93

6.05

3.91

2.23

1.39

1.07

0.90

0.74

0.64

0.58

0.55566.62

4.26

2.41

1.48

1.12

0.94

0.76