Page 1

1004 East Illinois Street • Assumption, IL 62510 • 1-217-226-4421

PNEG-1928

Tools you will need for this installation:

Instructions

UV Sensor Retrofit Instruction

Manual for Portable Dryers

Portable drill

7/8" Hole saw or step bit 1/8" Tip screwdriver

Phillips bit

Parts included with the UV-SENSE-KIT:

Part # Description

PNEG-1928 Installation Instructions (This Document)

D03-1168 UV Flame Sensor Relay

HF-7621 UV Flame Sensor Cable

9/64" Drill bit

Figure 1

GT3-1182 Time Delay Relay

GT3-1181 Time Delay Relay Base

FH-1310 Heyco Cord Connector

FH-1309 Lock Nut for Cord Connector

THH-4129 1/2" x 5" Nipple

D67-0005 1/2" Coupler

007-1149-9 1/2" to 1/8" Reducer Bushing

406-2293-8 Din Rail 3" Long

S-2786 Two (2) Self-Tapping Screws used to Mount Din Rail

Date: 06-27-13 PNEG-1928

Printed in the U.S.A.

Copyright © 2013 by GSI Group

www.gsiag.com

Page 1 of 9

CN-305799

Page 2

UV Sensor Retrofit Instruction Manual for Portable Dryers

Product Description

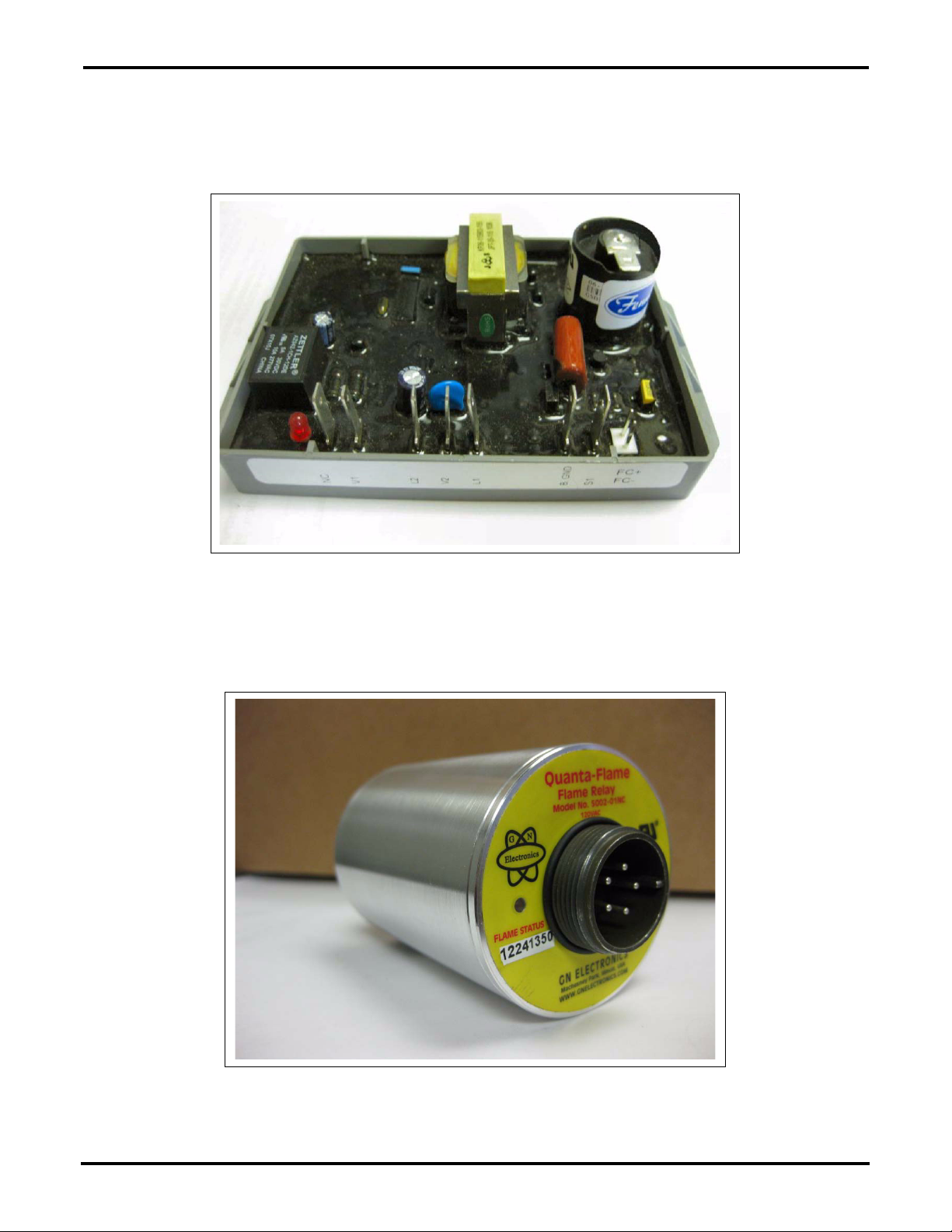

The UV flame detection kit was designed to replace the flame rod or probe that is used on Vision dryer

controls that utilize the HF-4624 fenwal flame control board. (See Figure 2.) This flame controller uses a

flame rectification circuit that in certain situations may not work reliably with certain gases.

Figure 2 Fenwal Flame Control (HF-4624) (HF-4624 not included)

The GSI part # D03-1168 UV flame relay sensor (See Figure 3) is more reliable since it picks up the

UV light (in the 180-230 nm) that is naturally emitted in the flame when using LP, natural gas or propane

as its fuel. It replaces the flame rod or probe located in the burner and re-produces the expected flame

signal to the fenwal board.

Figure 3 UV Flame Sensor Relay (D03-1168)

This kit will include all the parts necessary to change the flame rectification sensing on a fan/heater used

on portable dryers over to UV style flame sense.

Page 2 of 9 PNEG-1928

Page 3

UV Sensor Retrofit Instruction Manual for Portable Dryers

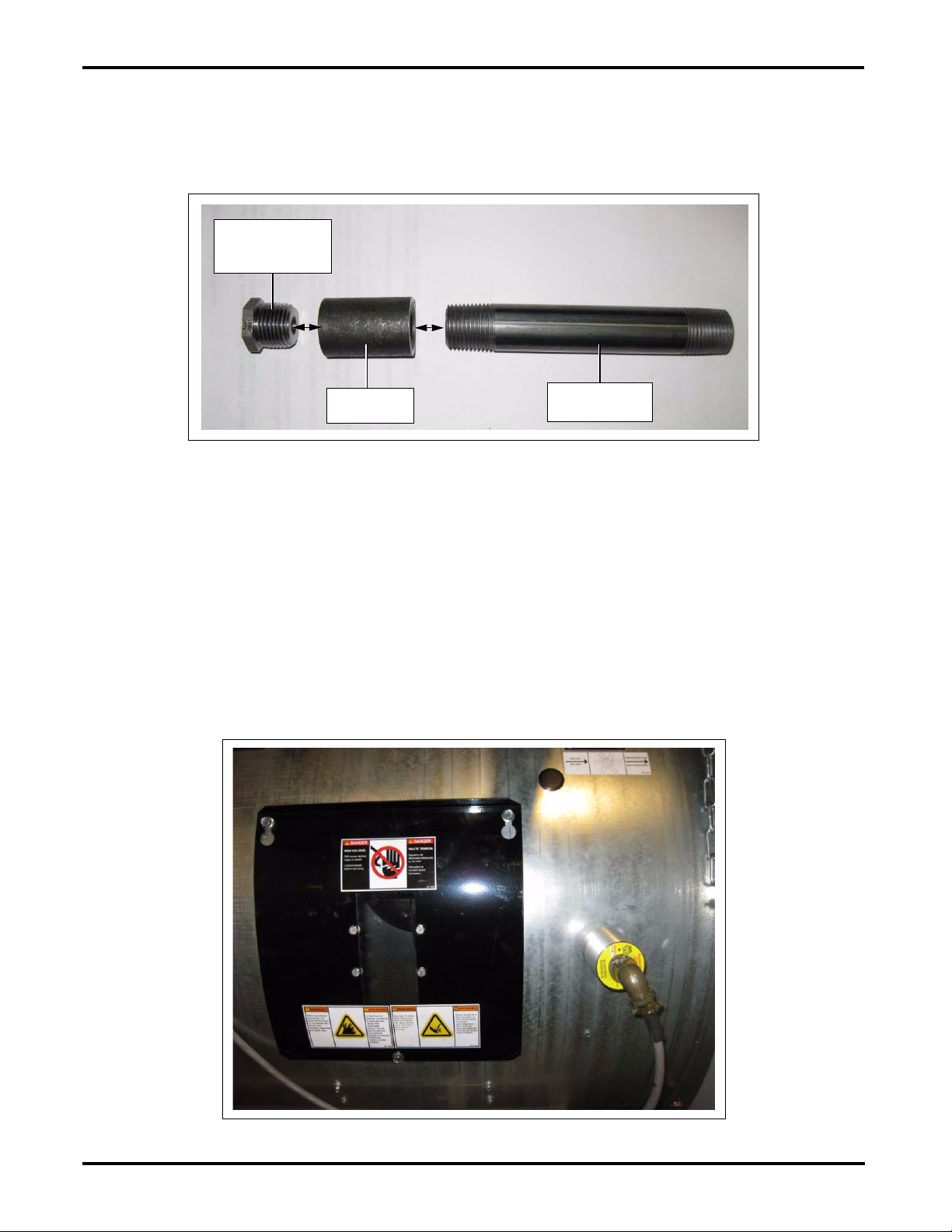

1/2" to 1/8"

Reducer bushing

(007-1149-9)

1/2" x 5" Nipple

(THH-4129)

1/2" Coupler

(D67-0005)

Sight Tube Assembly Instructions

Locate 1/2" x 5" nipple (THH-4129) and attach the 1/2" coupler (D67-0005) to one end of this nipple.

Then attach the 1/2" to 1/8" reducer bushing (007-1149-9) into the 1/2" coupling as shown in Figure 4.

(No sealant is necessary.)

Figure 4 Sight Tube Assembly

Sensor Mounting

The location to mount the sensor is critical in providing reliable flame sense. The sensor needs to

have a constant view to the flame of the burner during all burner modes and operations. Typically the

best location is just to the right of the inspection window plate as shown in Figure 5. The sensor tube

needs to be pointing between the burner veins as shown in Figure 6 on Page 4. It is best if the

sensor points slightly downward to allow any moisture that may be present to drain away from the

UV sensor component.

Once you have determined the sensors location drill a 7/8" hole into the side of the can and attach the

UV sight tube assembly into the hole using two (2) 1/2" lock nuts included with kit. Be sure to leave plenty

of thread sticking through the burner can to mount the UV sensor.

PNEG-1928 Page 3 of 9

Figure 5 Outside Sensor Location

Page 4

UV Sensor Retrofit Instruction Manual for Portable Dryers

Figure 6 Sensor Location Pointing between Burner Veins

Once UV sensor has been mounted to sight tube then attach the five (5) pin cable to sensor. Route the

cable through the black plastic heyco cord connector (FH-1310) then through either an existing hole in the

fan/heater control box or drill a new 7/8" hole. Try to keep the cable entrance location close to the relay

and fenwal board.

Find a location to mount the 3" aluminum din rail and relay base inside the fan/heater control box.

Drill two (2) 9/64" holes that will be used to mount the din rail to the heater back panel. Use the two (2)

supplied self-tapping phillip screws (S-2786) in the drilled holes to mount the din rail. Once the din rail is

secure snap the relay base to the din rail as shown in Figure 7.

Figure 7 Relay Base

Page 4 of 9 PNEG-1928

Page 5

UV Sensor Retrofit Instruction Manual for Portable Dryers

Disconnect power and lock out prior to performing this service.

DANGER

Wiring Instructions

The factory and the UV wirings diagram are included (Figure 9 on Page 6 and Figure 12 on Page 8) which

will help show the difference between the current and modified versions.

1. Cut the supplied red wire into two (2) equal pieces. Strip the insulation off both ends of each wire.

Attach one wire between terminals 10 and 11. Attach the other wire between terminals 5 and 6.

2. Locate the V1 wire on the fenwal board as shown in Figure 8. Leave the wire connected to the

fenwal board and follow it to the terminal strip. Disconnect the wire which will be in terminal

number 21 on the terminal strip.

Figure 8 Locating the V1 grey wire on the fenwal board and terminal 21.

3. Re-locate the grey wire to the relay base terminal 11 which will also contain a jumper wire between

terminals 10 and 11.

4. Strip the insulation off both ends of the supplied grey wire. Attach one end of the grey wire to the

terminal number 21 on the terminal strip (where you removed the grey wire above) and attach the

other end to the relay base terminal 9.

PNEG-1928 Page 5 of 9

Page 6

UV Sensor Retrofit Instruction Manual for Portable Dryers

J5-04 12 VDC Positive

J5-03 12 VDC Negative

J5-02 4-20ma In

J5-01 4-20ma Return

120 VAC Input Power

120 VAC Neutral

12 Volt DC Negative for Testing

12 Volt DC to Housing High-Limit

Housing High-Limit 12 Volt DC Return

12 Volt DC to Vapor High-Limit

Vapor High-Limit 12 Volt DC Return

12 Volt DC for Plenum High-Limit

Plenum High-Limit 12 Volt DC Return

Right Grain High-Limit Yellow

Right Grain High-Limit Yellow

Left Grain High-Limit Orange

Left Grain High-Limit Orange

12 Volt DC to Mercoid (CGA Only)

Mercoid 12 Volt DC Return

12 Volt DC to Air Switch

Air Switch 12 Volt Return

Grain Temp Sensor Input

Temperature Sensor Ground

Temperature Sensor Ground

Plenum Temp Sensor Input

Jumper

21 22 23 24

LOCATE V1 WIRE ON FENWAL, DISCONNECT OTHER

END OF WIRE FROM TERMINAL STRIP #21 LEAVE OTHER

WIRE INTACT THAT RUNS TO J1-01.

GREY WIRE

LEAVE THIS WIRE INTACT

12

345678910111213141516 17181920

FENWAL

LIGHT

N.C.

V1

L2 V2

L1

B.GROUND

S1

FC +

FC -

FLAME

PROBE

PINK

BROWN

RED

GREEN

BLUE

WHITE/BLACK STRIPE

GREY

WHITE

BLACK

ORANGE

YELLOW

PURPLE

REMOVE FLAME PROBE

WIRE FROM S1 (NO

LONGER USED)

COLOR LEGEND

J1-04 120 VAC Neutral

J1-03 120 VAC Input

J1-02 Cycle Solenoid Power

J1-01 Fenwal Terminal V1

J2-05 Fan Power

J2-04 AC Neutral

J2-03 Burner (L1) Power

J2-02 Relay N.O.

J2-01 Relay Com

J3-04 SENSOR GROUND

J3-03 GRAIN SENSOR

J3-02 SENSOR GROUND

J3-01 PLENUM SENSOR

J4-01 12 VDC Positive

J4-02 Extra #1

J4-03 Extra #2

J4-04 Air Switch

J4-05 Mercoid

J4-06 Grain High-Limit

J4-07 Plenum High-Limit

J4-08 Vapor High-Limit

J4-09 Housing High-Limit

J4-10 Fan Overload

Figure 9 Wires to be Moved in Stock Fan/Heater Box (Original Wiring)

Page 6 of 9 PNEG-1928

Page 7

UV Sensor Retrofit Instruction Manual for Portable Dryers

Relay terminals:

1 = No Connection

2 = AC Neutral for Relay

3 = No Connection

4 = No Connection

5 = Jumper to 6

6 = Jumper to 5

7 = No Connection

8 = No Connection

9 = To Main Solenoids and V1 Input on Heater

Figure 10 Flame Sensor Wire Location

5. Disconnect the flame probe or sensor wire from terminal S1 which is shown in Figure 10. It is the

thin red 18 gauge high temperature wire (Teflon) and tie it back out of the way. Attach the red wire

from the UV sensor cable with the spade terminal attached to the S1 terminal of the fenwal. (You

may need to peel back more of the grey sheathing of the UV cable to gain more length of the

wire conductors to reach all the connection points.)

10. Insert time delay relay into its socket and set the timer using the settings as shown in Figure 11.

6. Strip the insulation off both ends of the supplied white wire and insert one end into either terminal

22 or 24 (whichever of the white terminals that contains a single wire) and the other end into

terminal 2 of the relay base.

7. Attach the black wire from the UV sensor cable into terminal 2 of the relay base. This will provide

the grounding path to the flame signal through neutral.

8. Attach the yellow wire from the UV sensor cable into terminal 1 (black terminal) of the terminal strip

in the fan/heater box.

9. Attach the orange wire from the UV sensor cable into terminal 2 (white terminal) of the terminal strip

in the fan/heater box.

PNEG-1928 Page 7 of 9

Figure 11 Timer Settings and Connections

Page 8

UV Sensor Retrofit Instruction Manual for Portable Dryers

1

2

3

4

567

8

9

10

11

ORANGE

YELLOW

BLACK

BROWN

RED

ABCDE

AC Neutral

120 VAC

COM SWITCH

NOT Used

RECTIFIED OUTPUT

Quanta-Flame

UV Scanner System

Series 5002-01NC

FENWAL

LIGHT

N.C.

V1 L2

L1

V2

B.GROUND

S1

FC +

FC -

PINK

BROWN

RED

GREEN

BLUE

WHITE/BLACK STRIPE

GREY

WHITE

BLACK

ORANGE

YELLOW

PURPLE

COLOR LEGEND

TDRSRXP-120V

TIMER SETTINGS

DIP SWITCH FOUR = ON

TURN DIAL TO MAXIMUM (10)

TIME DELAY RELAY = GT3-1182

RELAY BASE = GT3-1181

UV SENSOR = D03-1168

TIMER WILL SHUT OFF

UV SENSOR EVERY 10 HOURS.

DIP SWITCH ONE = ON

DIP SWITCH TWO = ON

DIP SWITCH THREE = ON

120 VAC Input Power

120 VAC Neutral

12 Volt DC Negative for Testing

12 Volt DC to Housing High-Limit

Housing High-Limit 12 Volt DC Return

12 Volt DC to Vapor High-Limit

Vapor High-Limit 12 Volt DC Return

12 Volt DC for Plenum High-Limit

Plenum High-Limit 12 Volt DC Return

Right Grain High-Limit Yellow

Right Grain High-Limit Yellow

Left Grain High-Limit Orange

Left Grain High-Limit Orange

12 Volt DC to Mercoid (CGA Only)

Mercoid 12 Volt DC Return

12 Volt DC to Air Switch

Air Switch 12 Volt Return

Grain Temp Sensor Input

Temperature Sensor Ground

Temperature Sensor Ground

Plenum Temp Sensor Input

Jumper

12

345 6789

10 11 12 13 14 1516

1718 1920

21 22 23 24

Main Solenoid (V1)

Main Sol Neutral

Cycle Sol Neutral

Cycle Solenoid

J5-04 12 VDC Positive

J5-03 12 VDC Negative

J5-02 4-20ma In

J5-01 4-20ma Return

J1-04 120 VAC Neutral

J1-03 120 VAC Input

J1-02 Cycle Solenoid Power

J1-01 Fenwal Terminal V1

J2-05 Fan Power

J2-04 AC Neutral

J2-03 Burner (L1) Power

J2-02 Relay N.O.

J2-01 Relay Com

J3-04 SENSOR GROUND

J3-03 GRAIN SENSOR

J3-02 SENSOR GROUND

J3-01 PLENUM SENSOR

J4-01 12 VDC Positive

J4-02 Extra #1

J4-03 Extra #2

J4-04 Air Switch

J4-05 Mercoid

J4-06 Grain High-Limit

J4-07 Plenum High-Limit

J4-08 Vapor High-Limit

J4-09 Housing High-Limit

J4-10 Fan Overload

Page 8 of 9 PNEG-1928

Figure 12 UV Sensor and Relay Wiring

Page 9

UV Sensor Retrofit Instruction Manual for Portable Dryers

Operation

The UV sensor is highly sensitive to only UVC light that is present in flame. It can detect a small flame

from a lit match over 6' away. Because the particular wavelength “C” band of UV light this sensor is

sensitive to (180-230 nm) is normally absorbed by the ozone present in our atmosphere the sensor will

not be affected by normal sunlight.

The UV Sensor is powered up whenever the dryer controls are energized (orange and yellow wires). The

rectified output (black and red wires) of the UV flame sensor is only active when the sensor senses flame

through an internal relay. This is provided to the fenwal flame board between terminal S1 and the burner

ground or AC Neutral.

The Time delay relay provides a means of self checking to test whether or not the sensor has possibly

burned in a flame sense state. Or in other words the sensor has locked itself up by sensing UV flame

even when flame is not present. So every ten (10) hours the timer will open up the internal contacts that

provide the flame signal to the Vision Flame board J1-01. This interruption will force the controls to cycle

power to the fenwal board in an attempt to relight the burner.

Normally, if the UV sensor stops sensing flame then the fenwal will resume by relighting the burner. This

will cause a brief interruption in burner flame which will last for about five (5) seconds or so until the next

timer relay cycle (ten (10) hours).

If the UV sensor has burned in and continues to sense flame even with no flame present then the fenwal

board will go into a fault condition and will not allow the burner to relight. If the fenwal has a fault condition

then the LED will repeatedly flash two (2) times then pause then flash two (2) times again until power is

lost to the fenwal or the controls system shuts down with an error. This will occur after three (3) failed

relight attempts to the burner.

Life expectancy of the UV sensor is rated for approximately 10000 hours of continuous operation which

should provide many years of reliable use.

Testing

The sensor contains two (2) red LED lamps that will aid in troubleshooting flame sensing issues. One is

labeled “FLAME STATUS” and the other “FLAME RELAY”.

FLAME STATUS indicates the strength of the flame signal. The brighter the LED, the stronger the

flames signal.

FLAME RELAY turns on once the FLAME STATUS becomes strong enough. This is what activates the

flame rectification circuit going to the fenwal board used in the Vision control system.

If the sight tube is positioned too close to the spark or the reducing bushing is not used then the flame

sensor will falsely sense flame and activate the flame relay. This can be tested by dry firing the burner

with the gas turned OFF. You may rarely see the FLAME STATUS light flicker briefly during this test but

it should never be strong enough for the flame relay to become active.

If everything is working correctly the burner should attempt to relight three (3) times then controls will shut

the system down with an ignition failure warning on the screen.

NOTE: The ignition source (spark) is very rich in Ultraviolet light. This can cause the UV sensor to sense

flame if it can see the light that is emitted from the spark. This is the reason we choked the sight

tube down to a 1/8" NPT opening is to reduce this effect.

Do not reverse the Yellow and Orange wires on the UV sensor

The sensor is polarity sensitive and reversing these wires can destroy the sensor.

PNEG-1928 Page 9 of 9

when hooking it up to 120 VAC.

Loading...

Loading...