Page 1

PNEG-1895

V2 Electronic Distributor Control

Installation and Operation Manual

PNEG-1895

Date: 09-19-13

Page 2

2 PNEG-1895 V2 Electronic Distributor Control

Page 3

Table of Contents

Contents

Chapter 1 Safety ..................................................................................................................................................... 4

Safety Guidelines .................................................................................................................................. 4

Safety Instructions ..................... ... .... .......................................... ... ........................................................ 5

Chapter 2 Decals .................................................................................................................................................... 7

Chapter 3 Electrical Installation ........................................................................................................................... 8

Introduction ........................................................................................................................................... 8

Wire and Fitting Selection Requirements ................................... ... ... ............................................. ........ 8

Control Panel Cable to Distributor Fitting Connections ......................................................................... 9

Motor Cable to Motor Junction Box Fitting Connections ..................................... .... ... ... ... ... .... ... ... ... ... 10

Electric Motor Wiring Diagram ............................................................................................................ 11

Motor Wiring Electrical Connections ................................................................................................... 12

Sensor Wiring Connections to Connector Box .................................................................................... 13

Enclosure Covers Installation .............................................................................................................. 14

Control Panel Installation Guidelines .................................................................................................. 15

Electric Motor Connections at Control Panel ...................................................................................... 16

Sensor Terminations in Control Panel ................................................................................................ 17

Power Supply Wiring to Control Panel Electrical Connections ........................................................... 18

Chapter 4 Operation Procedures ........................................................................................................................ 19

Initializing Screen ...................................... ... .... ... ... .......................................... ... ................................ 19

Start-Up Checklist ........................................ .... .......................................... ... ...................................... 20

Main Screen ........................................................................................................................................ 21

Move Position Screen ................................................... ...................................... .... ... ... ... ... ....... ... ... ... 22

Setup Menu Screen ............................ ... ... ... .... ... ... ... .... .......................................... ... ......................... 23

Help Menu Screen .............................................................................................................................. 32

Manual Override ........................ ... .... ... .......................................... ... ............................................. ... ... 36

Chapter 5 Parts List ............................................................................................................................................. 38

12" 6 Hole 45° Distributor Assembly Electronic Control (DFB12645G-EC) ........................................ 38

Chapter 6 Retrofit Installation ..................................... .................... ...................... .............................................. 40

Electronic Distributor Control Shaft Installation ................................................................................... 40

Electronic Distributor Enclosure Installation ........................................... ............................................. 41

Sensor Plate Angle and Proximity Sensor Bracket Installation .................. ... ... ... ................................ 42

Proximity Sensor Location and Installation ......................................................................................... 43

Proximity Sensor Adjustment .............................................................................................................. 45

Encoder and Bracket Installation ........................................................................................................ 46

Installing the Connector Box and Cables ............................... .... ... ... ... .......................................... ...... 49

Motor Mounting Bracket Installation ................................. ................................................ ................... 50

Control Motor Installation .................................................................................................................... 51

Chapter 7 Troubleshooting ................................................................................................................................. 52

Error Messages ................................................................................................................................... 52

Fault Code Descriptions, Possible Causes and Solutions .................................................................. 54

Chapter 8 Schematic and Wiring Diagrams ...................................................................................................... 57

White Panel Layout ............................................................................................................................. 57

White Panel Electrical Schematic ..............................................................................................

Chapter 9 Warranty .............................................................................................................................................. 61

......... 58

PNEG-1895 V2 Electronic Distributor Control 3

Page 4

1. Safety

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

DANGER

WARNING

CAUTION

NOTICE

4 PNEG-1895 V2 Electronic Distributor Control

Page 5

1. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Practice Safe Maintenance

Understand service procedures before doing work. Keep area

clean and dry.

Never lubricate, service, or adjust machine while it is in operation.

Keep hands, feet and clothing away from rotating parts.

Keep all parts in good condition and properly installed. Fix

damage immediately . Replace worn or broken p arts. Remove any

built-up grease, oil, and debris.

Maintain Equipment

and Work Area

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may produce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

PNEG-1895 V2 Electronic Distributor Control 5

Page 6

1. Safety

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

6 PNEG-1895 V2 Electronic Distributor Control

Page 7

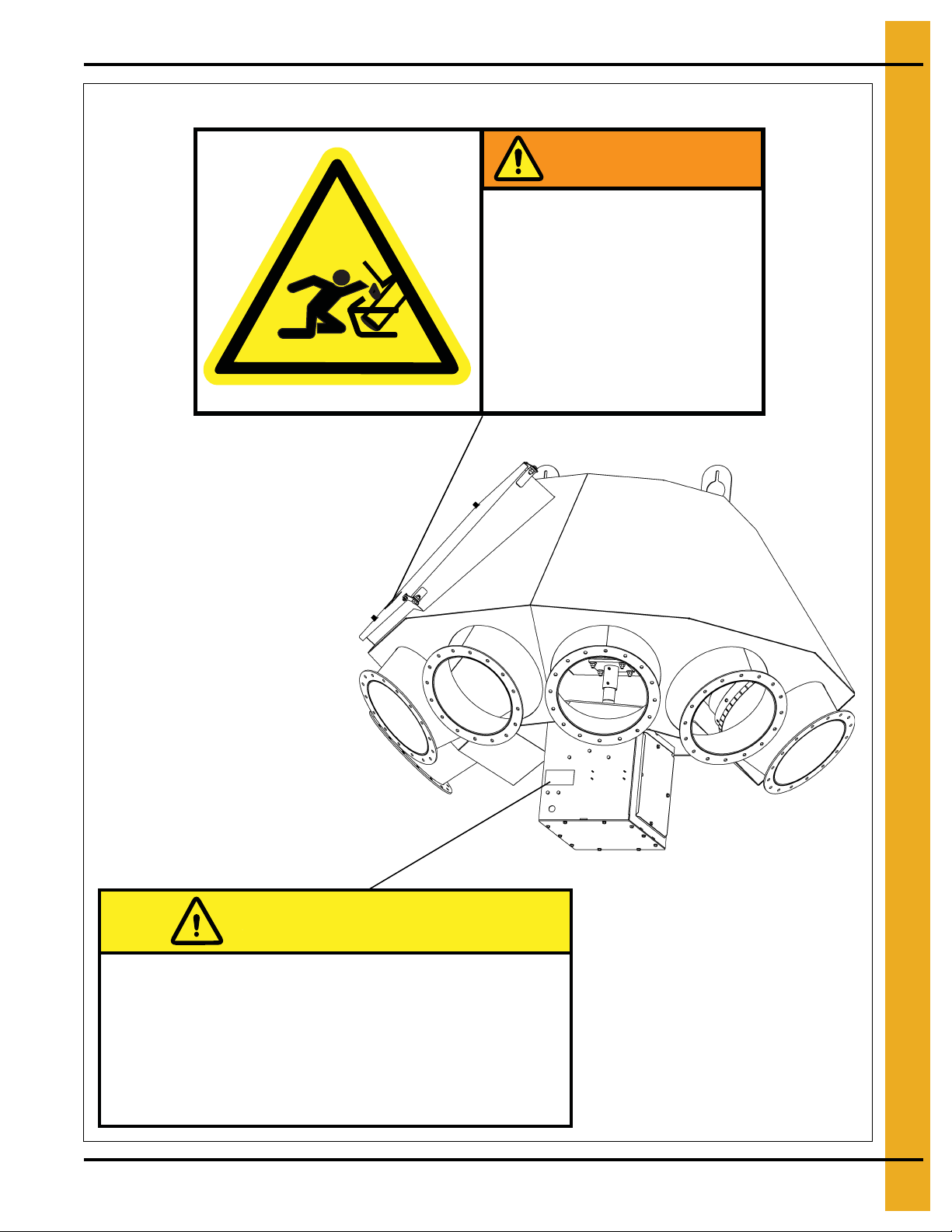

2. Decals

The decals are located as shown below:

DC-2159

WARNING

MOVING PARTS.

Rotating spout can

crush and cut.

Lock out power

before servicing.

CAUTION

Do not operate with access

panel removed.

Lock out power before servicing.

PNEG-1895 V2 Electronic Distributor Control 7

DC-2160

Page 8

3. Electrical Installation

Introduction

This section of the manual covers the electrical installation of your GSI electronically controlled distributor

and controller assembly. If your installation is an electronic controller retrofit being installed on an existing

GSI distributor, please begin with Section 6, Retrofit Installation on Page 40 and return to this section after

completion of mechanical component installation.

Wire and Fitting Selection Requirements

NOTE: The Sensor and VFD cables are supplied in 50' increments for a maximum length of 400'.

The Sensor cable has one unterminated end and one end has a connector. The VFD cable is

unterminated at both ends.

All sensor wiring should be run in its own conduit and this conduit should be kept at least 6" away from

other conduits. Any drain wires from shielded cable should be connected to ground in the panel.

VFD wiring should be run through appropriate conduit and the wiring for the motor must not be run in the

same conduit as the wiring for the sensors.

All conduit and fittings should be outdoor rated to keep things adequately sealed, rigid conduit

is required.

These shielding and conduit requirements must be followed for your GSI Electric Distributor Controller

to function properly. Failure to follow these guidelines may result in damage to equipment or

improper operation.

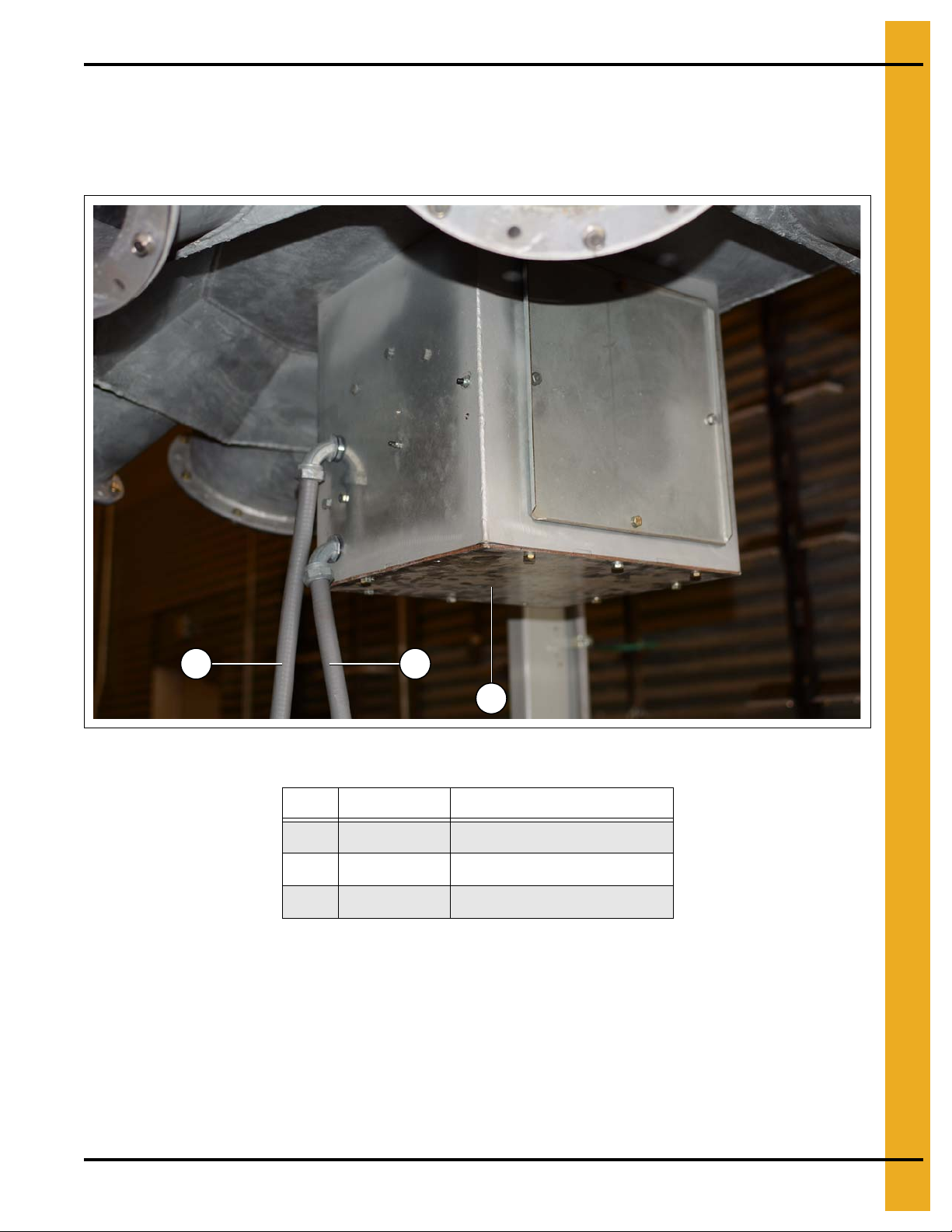

Figure 3A

8 PNEG-1895 V2 Electronic Distributor Control

Page 9

3. Electrical Installation

A

B B

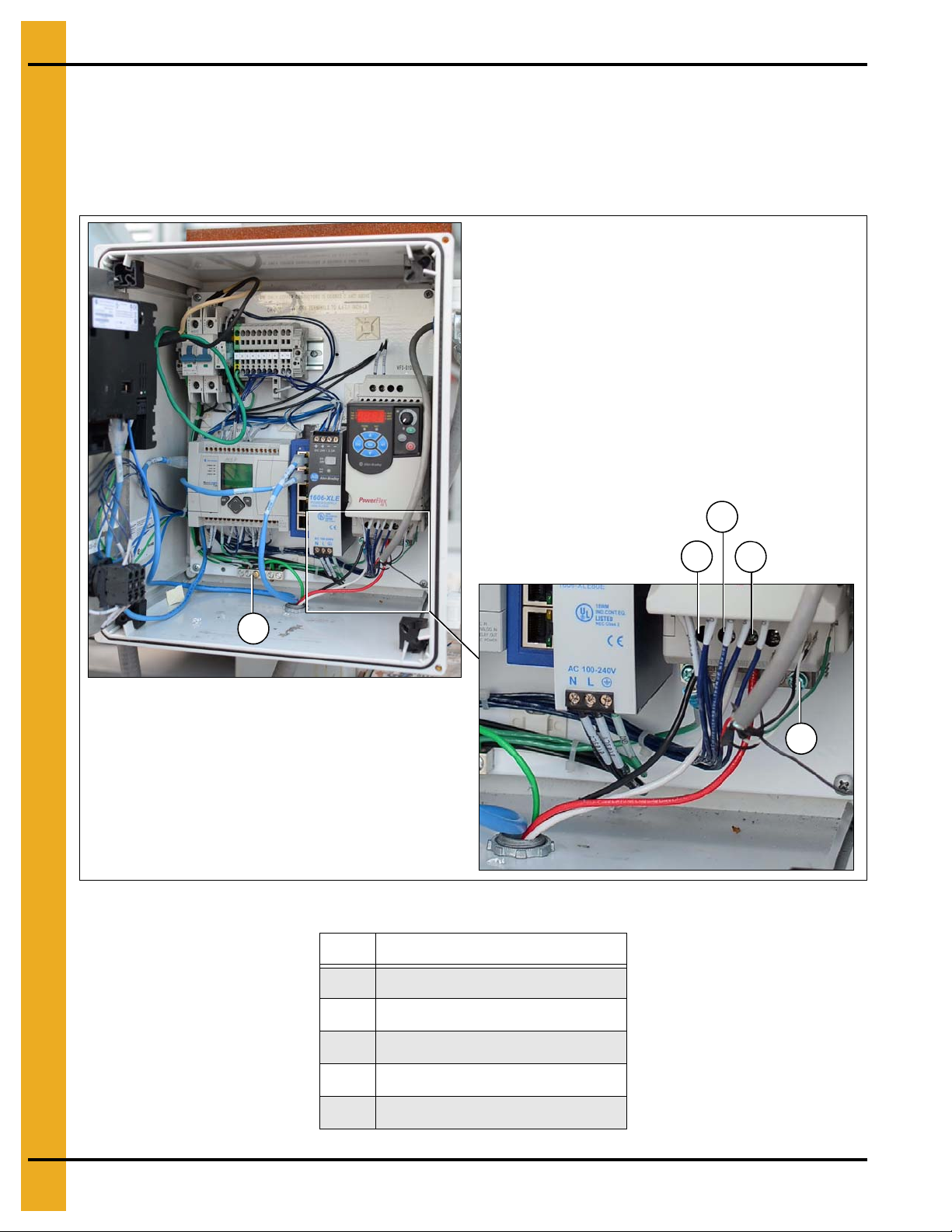

Control Panel Cable to Distributor Fitting Connections

Conduit for motor wiring should be run out of enclosure (DEC0005) (A) to the panel installed at ground

level. Conduit for sensor wiring should be run from enc losure (DEC0005) (A) to pan el installed at ground

level. Appropriate fittings for conduit selection must be used at all connections. (See Figure 3B.)

Figure 3B Cable Fitting Connections to Distributor Enclosure

Ref # Part# Description

A DEC0005 Enclosure

B DEC0026-XXX Sensor Cable

B DEC0025-XXX VFD Cable

NOTE: “XXX” represents the length of the cable.

PNEG-1895 V2 Electronic Distributor Control 9

Page 10

3. Electrical Installation

A

B

C

D

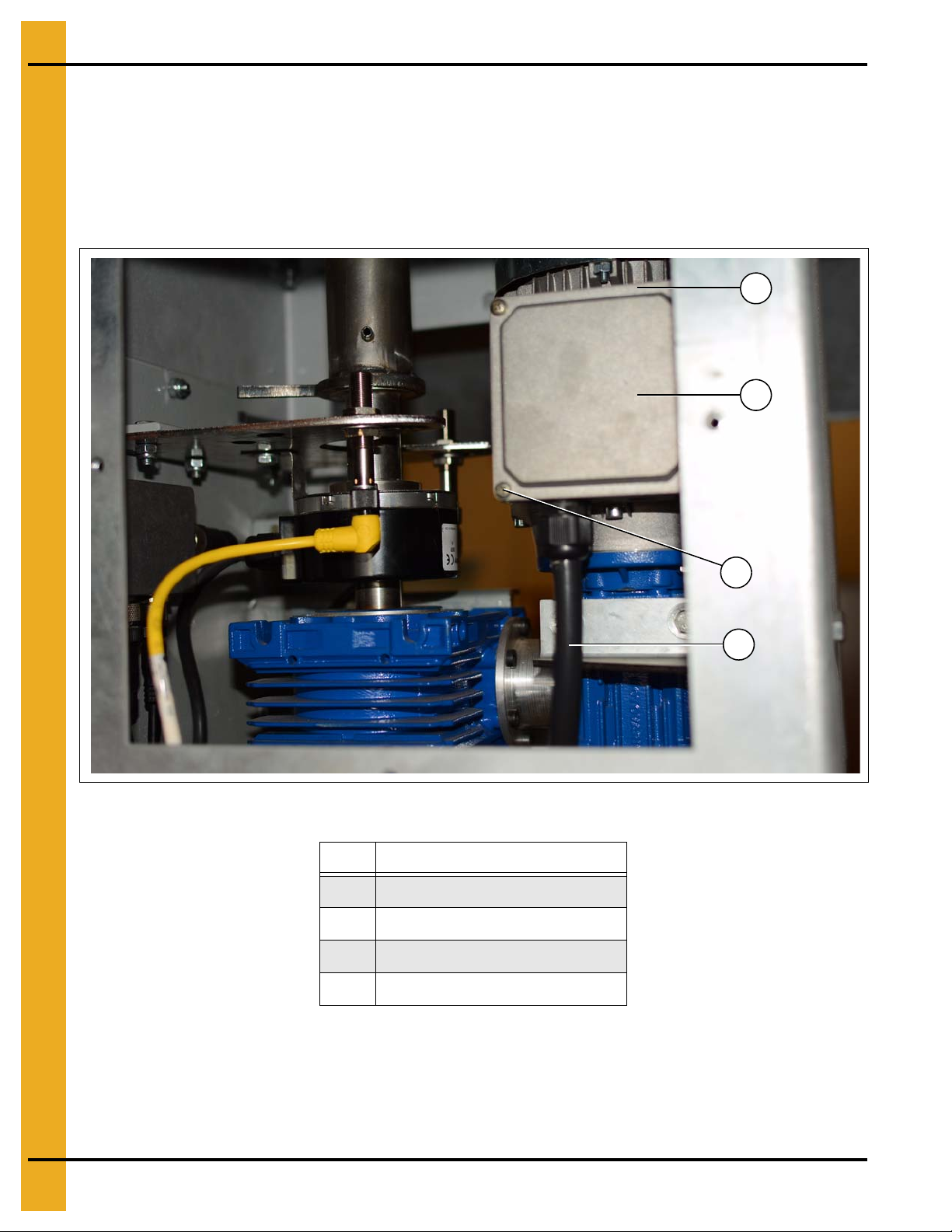

Motor Cable to Motor Junction Box Fitting Connections

Remove the four (4) motor junction box cover screws (C) and the motor junction box cover (A) as shown

in Figure 3C.

Pull motor wiring through conduit to enclosure and feed to motor junction box (B) and through provided

cord grip. Motor wiring should be routed within the enclosure to avoid close proximity to all sensor wiring.

Motor wiring should be kept at least 4" from any sensor wires. (See Figure 3C.)

Figure 3C Cable fitting connection to motor junction box.

Ref # Description

A Motor Junction Box Cover

B Motor Junction Box

C Motor Junction Box Cover Screw

D Motor Cable

10 PNEG-1895 V2 Electronic Distributor Control

Page 11

3. Electrical Installation

Electric Motor Wiring Diagram

The electric motor supplied with the GSI Electronic Distributor Control system is designed to be capable

of running on either low or high voltage. The variable frequency drive (VFD) supplied with the system

supplies 230V 3 phase power and requires that the electric motor be configured for low volta ge operation.

In order to ensure proper operation, verify the motor jumpers are configured in accordance with the wiring

diagram shown for low voltage operation. (See Figure 3D.)

Figure 3D

PNEG-1895 V2 Electronic Distributor Control 11

Page 12

3. Electrical Installation

A

B

C

D

E

F

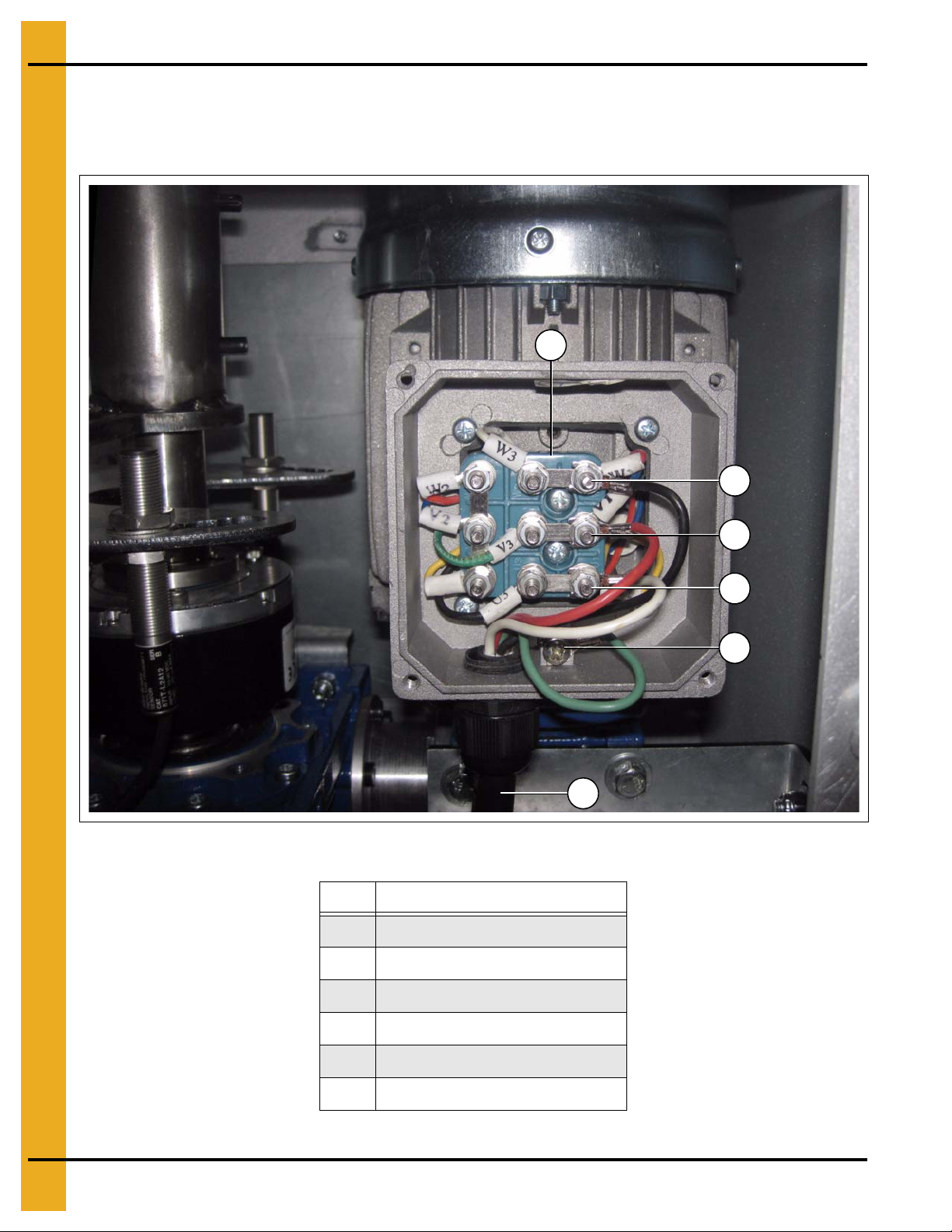

Motor Wiring Electrical Connections

Connect the motor wiring to the motor wiring terminals as shown in Figure 3E. Re-install the motor junction

box cover and screws before proceeding.

Figure 3E Motor Wiring to Motor Junction Box Electrical Connections

Ref # Description

A Motor Wiring Terminal Block

BWire W

C Wire V

DWire U

E Ground Wire

F Motor Cable

12 PNEG-1895 V2 Electronic Distributor Control

Page 13

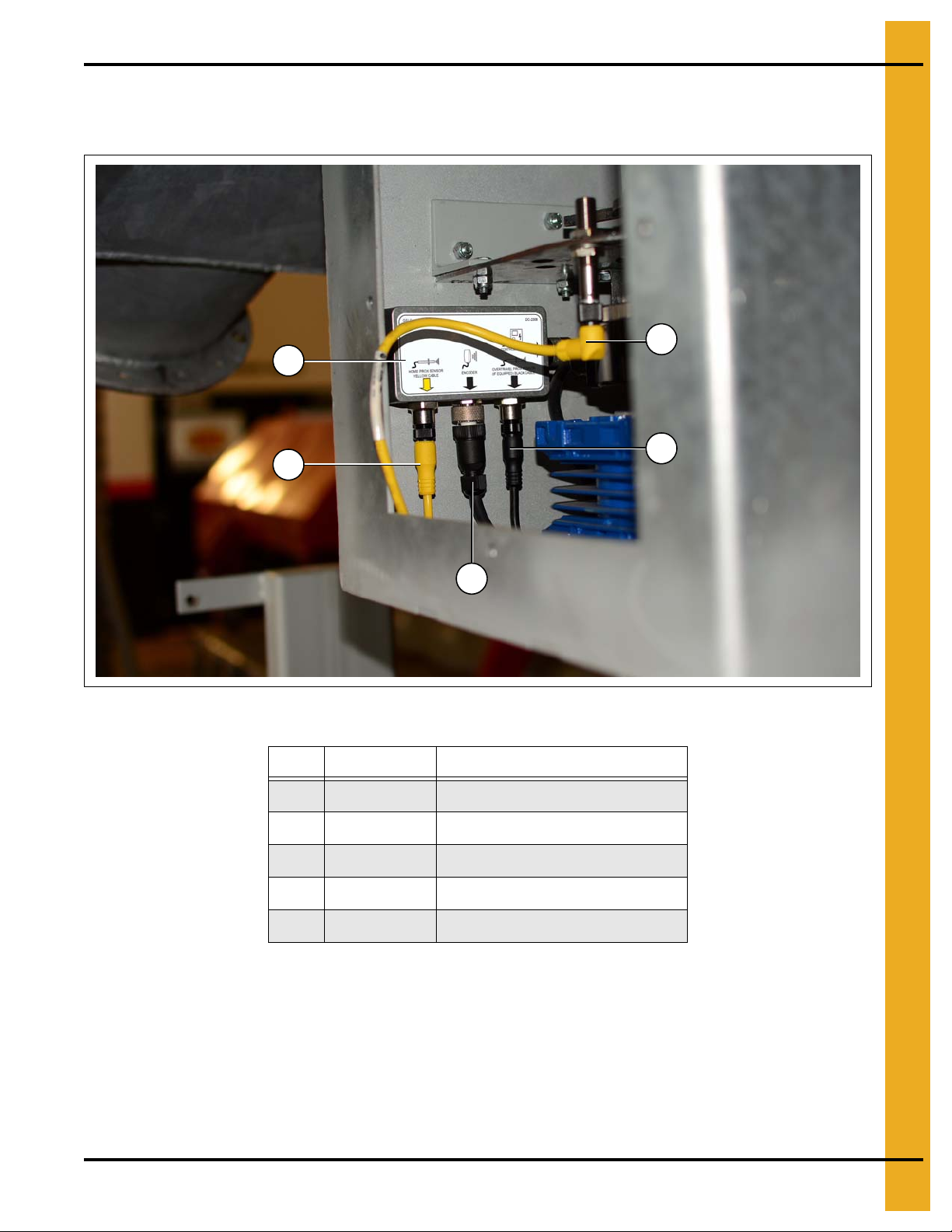

Sensor Wiring Connections to Connector Box

B

A

D

E

C

Pull sensor cable through conduit to enclosure. (See Figure 3F.)

3. Electrical Installation

Figure 3F Control Panel Wiring to Junction Box Electrical Connections

Ref # Part # Description

A DEC0108 Home Proximity Sensor Cable

B DEC0105 Connection Enclosure

C DEC0106 Encoder

D DEC0109 Over-Travel Proximity Sensor Cable

E DEC0026-XXX Sensor Cable

NOTE: “XXX” represent the length of the cable.

PNEG-1895 V2 Electronic Distributor Control 13

Page 14

3. Electrical Installation

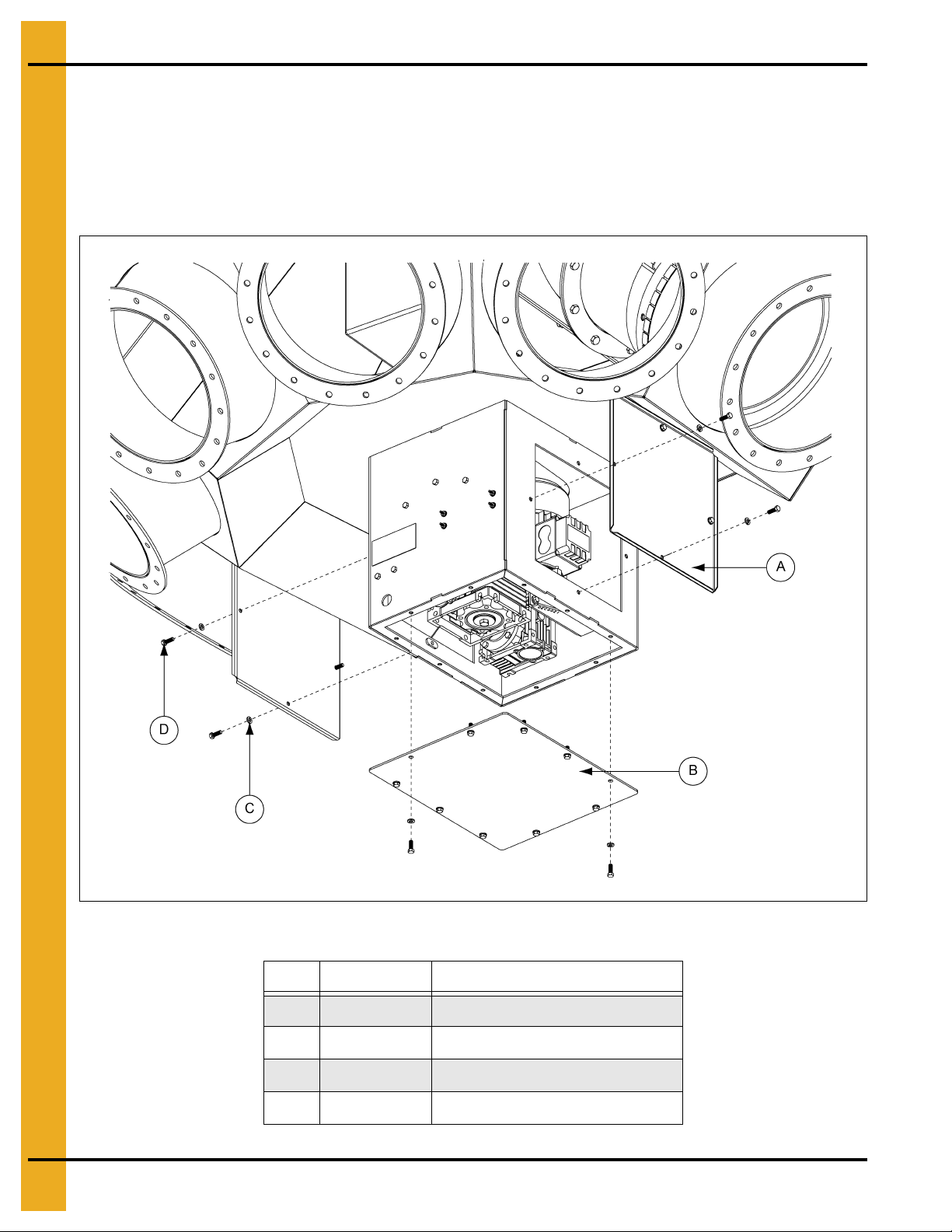

Enclosure Covers Installation

Once all wiring is complete, install the two (2) side access covers (DEC0012) (A) using four (4)

1/4"-20 x 3/4" HHCS bolts (S-1429) (D) and 1/4" lock washer (S-2041) (C) each and install the bottom

enclosure cover (DEC0013) (B) using ten (10) 1/4"-20 x 3/4" HHCS bolts (S-1429) (D) and 1/4" lock

washers (S-2041) (C) as shown in Figure 3G. Ensure that no wires are pinched or damaged when

installing access covers.

Figure 3G Enclosure Covers Installation

Ref # Part # Description

A DEC0012 Side Access Cover

B DEC0013 Bottom Enclosure Cover

C S-2041 1/4" Lock Washer

D S-1429 1/4"-20 x 3/4" HHCS Bolt

14 PNEG-1895 V2 Electronic Distributor Control

Page 15

3. Electrical Installation

Control Panel Installation Guidelines

The following requirements must be followed when installing and mounting the control panel:

All wiring should be performed by a licensed/qualified electrician in accordance with the National Electric

Code (NEC), state codes and local codes.

Never mount the control panel immediately beside or above heat generating equipment or directly below

water or steam pipes.

The atmosphere surrounding the control panel must be free of combustible vapors, chemical fumes and

corrosive materials.

The control panel must be easily accessible for maintenance and operation.

Mount the control panel on a flat, vertical surface using 1/4" fasteners.

Ensure that the mounting surface is sufficient to support the weight of the control panel.

Rigid conduit connections must be placed either at sides or bottom of the control panel.

PNEG-1895 V2 Electronic Distributor Control 15

Page 16

3. Electrical Installation

A

B

E

C

D

Electric Motor Connections at Control Panel

Connect the motor wiring to the terminals on the Variable Frequency Drive (VFD) in the control panel

as shown in Figure 3H. Please note that the U-V-W order of the wires is not configured as labeled on

the VFD. Motor wiring should be kept as far away from sensor wiring terminal blocks as the installation

configuration permits.

Figure 3H Control Panel Wiring from Motor Electrical Connections

Ref # Description

16 PNEG-1895 V2 Electronic Distributor Control

A Ground Terminal Block

BWire U

C Wire W

DWire V

E Ground Wire

Page 17

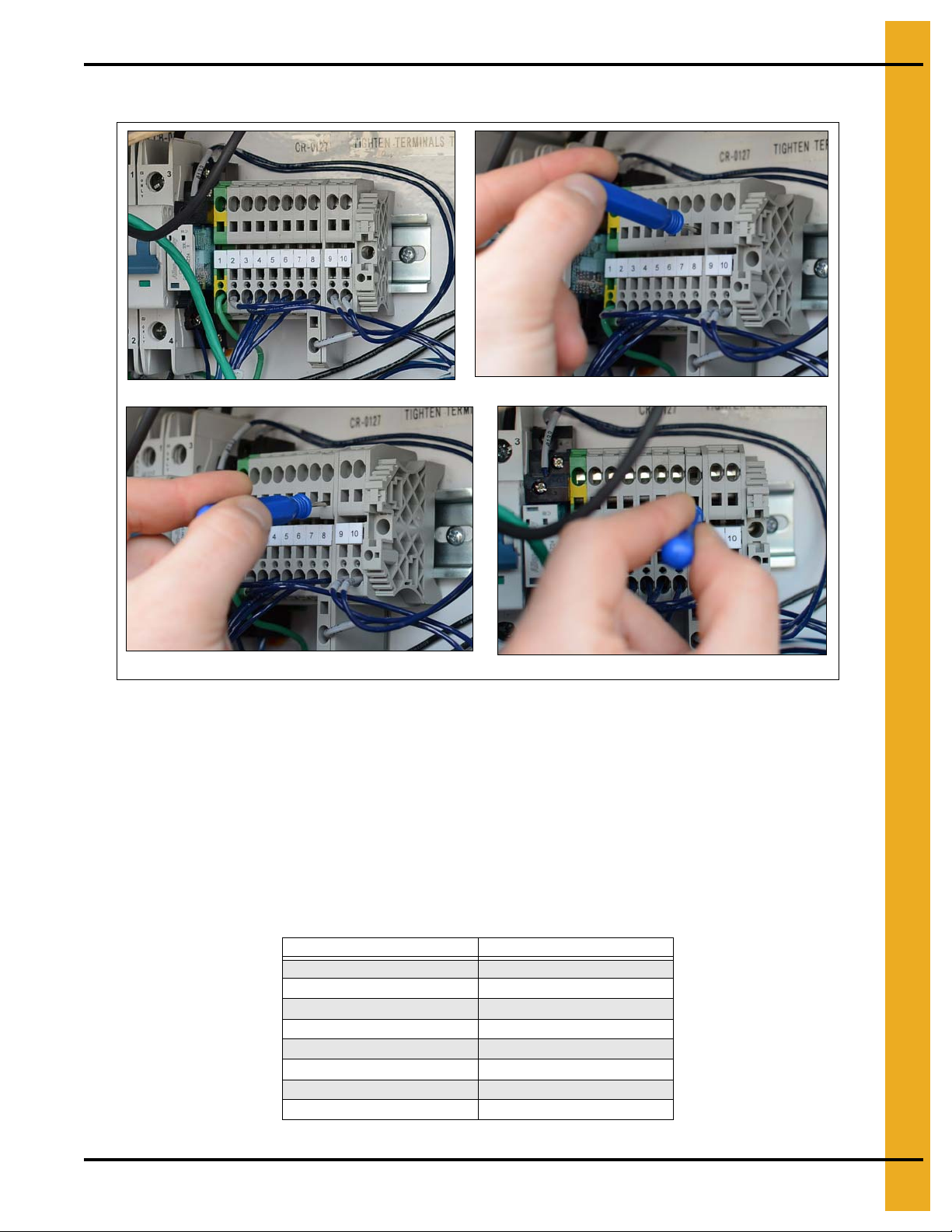

Sensor Terminations in Control Panel

1. Sensor terminal block

2. Push in screw driver

3. Push down on screw driver

4. Insert wire into open terminal

3. Electrical Installation

Figure 3I

Placing a wire into the terminal block.

NOTE: Insulation must be removed from the end of the wire for a good connection.

1. Insert a small screw driver into the square opening under the terminal.

2. Push down on the small screw driver.

3. Insert the wire into the open terminal block above the small screw driver.

4. Remove the small screw driver to secure the wire.

5. Repeat for remaining wires. (See Figure 3I.)

Wire Connections for Terminal Block

Terminal Block # Wire Connection

1 Shield

2Black

3 White

4Red

5 Green

6Orange

7 Blue

8-11 Used for Safety Interlocks

NOTE: #11 Not shown here.

PNEG-1895 V2 Electronic Distributor Control 17

Page 18

3. Electrical Installation

A

B

C

D

Power Supply Wiring to Control Panel Electrical Connections

NOTE: Ensure the power supply voltage source is OFF before installation.

Install power supply cable through the control panel using suitable hardware as shown in F igure 3J.

Connect the power supply hot wires (B) to the control panel circuit breakers (C) as shown in Figure 3J.

Connect the power supply ground wire (D) as shown in Figure 3J to the ground terminal block as shown

in Figure 3H on Page 16.

Figure 3J Control Panel Wiring from Motor Electrical Connections

Ref # Description

A Power Cable Hardware

BHot Wires

C Control Panel Circuit Breakers

D Power Supply Ground Wire

18 PNEG-1895 V2 Electronic Distributor Control

Page 19

4. Operation Procedures

Initializing Screen

When powering up the distributor the first screen that appears is the “Initializing” screen. (See Figure 4A.)

During a first time start-up, press the “Diagnostic Screen” button to proceed to the diagnostic screen in

order to complete start-up checklist. If the start-up checklist has already been completed, press OK to

initialize system. Distributor will move to “HOME POSITION” to verify positioning, then display the

MAIN screen.

Figure 4A Initial Start-Up Screen

PNEG-1895 V2 Electronic Distributor Control 19

Page 20

4. Operation Procedures

Start-Up Checklist

Press “Diagnostic Screen” button to enter diagnostic menu to complete the following checklist:

Check Procedure

Insert key into key switch override on front of control panel. Rotate switch to forward “FWD” position

Motor Direction

Encoder Function

Home Prox Test

Overtravel Test

for 4 seconds. Verify that “DIRECTION” in bottom right hand corner reads “FORWARD” during this.

If “REVERSE” is displayed after 4 seconds, reverse any two (2) motor leads on motor or VFD to

correct rotation direction.

Using key switch, rotate switch to reverse “REV” position for 4 seconds. Verify that inputs 0 and 1.

(Labeled ENCODER CHANNEL A and ENCODER CHANNEL B in top left hand corner of screen.)

Toggle ON and OFF while switch is held in reverse position. If either channel fails to toggle ON or OFF ,

verify that encoder is wired correctly.

Using a second person as a spotter, use key switch to rotate spout in reverse direction until the “flag”

welded to the drive shaft is positioned over the top of the “home” proximity switch. (Located on side of

sensor mounting plate labeled “RED”.) Verify that when flag is positioned above proximity switch, input

2 labeled “HOME PROX SWITCH” turns green and shows “ON” on diagnostic screen. If input does not

show “ON”, check that gap between switch and flag is 0.050" ± 0.010".

Using a second person as a spotter, use key switch to rotate spout in forward direction until the “flag”

welded to the drive shaft is positioned over the top of the “overtravel” proximity switch. (Located on

side of sensor mounting plate labeled “GREY”.) Verify that when flag is positioned above proximity

switch, input 2 labeled “OVERTRAVEL PROX” turns green and shows “ON” on diagnostic screen.

If input does not show “ON”, check that gap between switch and flag is 0.050" ± 0.010".

Figure 4B Diagnostic Screen

20 PNEG-1895 V2 Electronic Distributor Control

Page 21

4. Operation Procedures

CURRENT SPOUT SELECTION:

BIN 1

CURRENT SPOUT SELECTION:

BIN 1

CURRENT SPOUT SELECTION:

BIN 1

CURRENT SPOUT SELECTION:

BIN 1

Main Screen

Depending on the number of spouts in the current configuration, one of the following screens will be

displayed. (See Figure 4C, Figure 4D, Figure 4E and Figure 4F.) The display depicts a view of your

distributor as it would appear if looking down from above, with lower spout numbers to the le ft and higher

spout numbers to the right. The name of the current spout is indicated at the top of the screen and is

indicated in the graphic with a green circle. At the bottom of the screen are three (3) buttons to navigate

to either the Help Menu, Move Position Screen or Setup Menu.

Figure 4C Four (4) Spout Main Screen

Figure 4D Six (6) Spout Main Screen

Figure 4E Eight (8) Spout Main Screen

Figure 4F Ten (10) Spout Main Screen

PNEG-1895 V2 Electronic Distributor Control 21

Page 22

4. Operation Procedures

Move Position Screen

This screen allows the user to change the distributor’s current spout position. The green highlig hted spout

number indicates the current selection. A spout number with a red circle with a line through it indicates a

position that is currently locked-out. (See “Position Lock-Out Screen” on Page 29.) (See Figure 4G.)

NOTE: The default names for each spout will be “BIN #”, see “Position Names Screen” on Page 25 for

instructions for customizing the spout names.

Figure 4G Move Position Screen

Moving Spout Position

1. On the “Move Position” screen, select the position you want the spout to move to by pressing the

button displaying the desired spout name on the screen.

2. The “Main Menu” screen will now display a flashing message “Moving to” at the top of the screen,

the selected spout number will flash yellow while the pointer is moving to the selected spout. The

destination spout number will turn green when the move is complete.

Verifying Spout Alignment

NOTE: In the following steps, the distributor must be in a position to view the spout location in the

distributor to verify that it lines up correctly. If the distributor is installed above ground level,

two (2) people will be needed; one to verify the alignment of the distributor spout and one to

operate the controller.

1. From the “Main” screen or the “Setup Menu”, select “MOVE” to view the “Move Position” screen.

(See Figure 4G.)

2. On the “Move Position” screen, select the position you want the spout to move to by pressing the

spout name on the screen.

3. The “Main Menu” screen will now display a flashing message “Moving to” at the top of the screen,

the selected spout number will flash yellow while the pointer is moving to the selected spout. The

destination spout number will turn green when the move is complete.

4. Once the spout has finished moving, visually check and verify the spout is centered with the

distributor discharge spout. If alignment requires adjustment, see “Position Locations Screen”

on Page 27 to adjust the positioning.

5. Repeat procedure for all other spouts.

22 PNEG-1895 V2 Electronic Distributor Control

Page 23

Setup Menu Screen

4. Operation Procedures

Figure 4H Setup Menu Screen

Configuration Setup: Displays the machine setup screen that allows the user to change the distributor’s

parameters or reload default values. See “Configuration Setup Screen” on Page 24.

Position Names: Allows the user to assign or change the name of each spout position and to create or

change a name for the distributor. See “Position Names Screen” on Page 25.

Position Locations: Displays the positioning screen which allows the user to set the value that aligns the

spouts with the distributor. See “Position Locations Screen” on Page 27.

Position Lock-Out: Allows the user to lock or unlock spouts from being used. See “Position Lock-Out

Screen” on Page 29.

Homing Interval: Allows the user to set the number of times before the “Perform Homing Now” warning

appears. See “Homing Interval Screen” on Page 30.

Perform Homing Now: Press this to perform the homing operation to re-calibrate the distributor.

PNEG-1895 V2 Electronic Distributor Control 23

Page 24

4. Operation Procedures

Configuration Setup Screen

This screen allows the user to change the distributor’s spout diameter property, total of number of spouts

and for resetting the distributor back to the default settings. (See Figure 4I.)

Figure 4I Configuration Setup Screen

Diameter of Spouts: Press the button that matches the size of the spout that is currently installed on the

distributor. The diameter that is selected will turn green and the number of spouts available for that

diameter will be displayed.

Number of Spouts: Press the button that matches the current configuration of the distributor. The number

that is selected will turn green. The number of spout options will change according to the diameter of

spout selected.

Reload Defaults: If during operation, any configuration par ameters are altered from the original settings,

pressing this button will revert settings to the default values.

OK: Press this button to save the current configuration and be brought back to the Setup Menu.

NOTE: A warning message will appear if distributor has already been previously configured.

(See Figure 4J.)

Figure 4J

24 PNEG-1895 V2 Electronic Distributor Control

Page 25

4. Operation Procedures

Position Names Screen

This screen allows the user to individually name each of the distributor discharge spouts and is also used

to create or modify a distributor name. (See Figure 4K.)

Figure 4K Create/Modify Spout Names

PNEG-1895 V2 Electronic Distributor Control 25

Page 26

4. Operation Procedures

Create/Modify Spout Name

1. From the “Setup Menu”, select “Position Names” to bring up the “Create/Modify Spout

Names” screen.

2. Press the spout name to be modified to display an alphanumeric keypad. (See Figure 4L.)

Figure 4L Alphanumeric Keypad

3. Type in the desired name for the spout position and press “enter”.

4. Select “OK” to return to “Setup Menu”.

Create/Modify Distributor Name

1. From the “Setup Menu”, select “Position Names” to bring up the “Create/Modify Spout

Names” screen.

2. Next to ochre “Distributor Name” label, press the distributor name to display an alphanumeric keypad.

(See Figure 4L.)

3. Type in the desired name for the spout position and press “enter”.

4. Select “OK” to return to “Setup Menu”.

26 PNEG-1895 V2 Electronic Distributor Control

Page 27

4. Operation Procedures

Position Locations Screen

This screen allows the user to adjust the spout positioning so it lines up with the center of the distributor

discharge. Adjustments can be made individually or an offset can be used to adjust all spouts by the same

amount. (See Figure 4M.)

Figure 4M Modify Spout Positioning

Modify Spout Positioning

1. From the “Setup Menu”, select “Position Locations” to bring up the “Modify Spout Positioning” screen.

2. In the “Modify Spout Positioning” screen select the spout that requires adjustment by touching the

value pad next to the spout number balloon. A number keypad will display. (See Figure 4N.)

Figure 4N Number Keypad

PNEG-1895 V2 Electronic Distributor Control 27

Page 28

4. Operation Procedures

3. Insert the desired value and press “enter”.

NOTE: Entering a value larger than the existing value will move spout positio n to the left, entering a

smaller value will move the position to the right.

4. Select “OK” to return to “Setup Menu”.

5. Verify spout alignment with distributor. See “Verifying Spout Alignment” on Page 22.

Offset All

1. From the “Setup Menu”, select “Position Locations” to bring up the “Modify Spout Positioning” screen.

2. In “Modify Spout Positioning” screen select the “0” key pad next to “OFFSET ALL”. A number keypad

will display. (See Figure 4O.)

Figure 4O Help Menu Screen

3. Insert the desired value and press “enter”.

To offset the spouts to the left, use a positive value and to offset to the right, use a negative value.

NOTE: A maximum offset at any one time is ± 20.

4. Select “OK” to return to “Setup Menu”.

5. Verify each spout alignment with distributor. See “Verifying Spout Alignment” on Page 22.

28 PNEG-1895 V2 Electronic Distributor Control

Page 29

4. Operation Procedures

Position Lock-Out Screen

The position lock-out allows you to lock-out a distributor discharge spout position so it can not be used

until it is manually unlocked. (See Figure 4P.)

Figure 4P Lock/Unlock Position

Lock/Unlock Position

1. From the “Setup Menu”, select “Position Lock-Out” to display the “Lock/Unlock Position”

setup screen.

2. Press name of spout to toggle between locked and unlocked. When in the locked position the number

balloon will change to a red circle with a line through it.

NOTE: The position that the distributor is currently located, indicated by a green number balloon

icon, can not be locked out. Move the spout position to a different location then try again.

See “Move Position Screen” on Page 22.

3. Select “OK” to apply changes and return to “Main Menu”.

PNEG-1895 V2 Electronic Distributor Control 29

Page 30

4. Operation Procedures

Homing Interval Screen

The homing interval screen allows the user to set the number of times the distributor position may be

moved before a warning displays for home position re-calibration. A default value of 50 is standard.

(See Figure 4Q.)

Figure 4Q Homing Interval Screen

Setting Homing Interval

1. To access the homing interval from the “Setup Menu”, select “Homing Interval” to display the “Homing

Interval” setup screen.

2. Press the button under the “Homing Interval” label. A number keypad will display. (See Figure 4R.)

Figure 4R

3. Insert the desired value and press “enter”.

4. Select “OK” to apply changes and return to “Main Menu”.

30 PNEG-1895 V2 Electronic Distributor Control

Page 31

4. Operation Procedures

Homing Warning

To help ensure accurate positioning of the distributor a homing warning will display when the number of

times the distributor is re-positioned is equal to the homing interval. This message will occur every time

that a spout move is attempted until the homing procedure is completed. The user will be given two (2)

options: “Home Now” and “Home Next Move”. (See Figure 4S.)

Figure 4S Homing Warning

Home Now

Select to perform the homing calibration immediately. The user interface will return to the “MAIN”

screen and “Homing” will be shown in yellow. After homing is complete, the spout will return to the

selected position.

Home Next Move

Select “Home Next Move” to skip the homing operation and move to the selected position. The user

interface will continue to prompt you to home the unit during every subsequent move until homing

is performed.

PNEG-1895 V2 Electronic Distributor Control 31

Page 32

4. Operation Procedures

Help Menu Screen

The help menu has six (6) options for displaying troubleshooting information for different faults that may

appear during the operation of the distributor and for checking diagnostic parameters. (See Figure 4T.)

Figure 4T Help Menu Screen

Encoder Fault: Displays the “Encoder Fault” screen which displays fault codes and solutions for faults

related to the function of the encoder during movement. (See Figure 4U on Page 33.)

Drive Fault: Displays the “VFD” Fault screen which offers pos sible causes and solutions to f aults caused

by the variable frequency drive. (See Figure 4V on Page 33.)

Homing Fault: Displays the “Homing Fault” screen which offers possible causes and solutions to faults

caused by a timeout of the homing procedure. (See Figure 4W on Page 34.)

Overtravel Fault: Displays the “Overtravel Fault” screen which offers possible causes and solutions to

faults caused by the an overtravel condition. (See Figure 4X on Page 34.)

Direction Fault: Displays the “Direction Fault” screen which offers possible causes and solu tions to faults

caused by the detection of a rotation direction conflict. (See Figure 4Y on Page 35.)

Diagnostic Screen: Displays the status of the inputs and outputs of the Programmable Logic Controller

(PLC) as well as the current encoder position count and rotation direction. (See Figure 4Z on Page 35.)

32 PNEG-1895 V2 Electronic Distributor Control

Page 33

Encoder Fault Screen

4. Operation Procedures

Drive Fault Screen

Figure 4U Encoder Fault Screen

Figure 4V Drive Fault Screen

PNEG-1895 V2 Electronic Distributor Control 33

Page 34

4. Operation Procedures

Homing Fault Screen

Overtravel Fault Screen

Figure 4W Homing Fault Screen

Figure 4X Overtravel Fault Screen

34 PNEG-1895 V2 Electronic Distributor Control

Page 35

Direction Fault Screen

4. Operation Procedures

Diagnostic Screen

Figure 4Y Direction Fault Screen

Figure 4Z Diagnostic Screen

PNEG-1895 V2 Electronic Distributor Control 35

Page 36

4. Operation Procedures

A

Manual Override

Located on the front of the controller is a manual/jog dial (A). This manual override is key locked and

should only be used in case of a major equipment failure. It allows for manually moving the spout in the

direction you turn the dial when the key is inserted.

It is recommended that two (2) people perform this procedure. One person to operate the manual/jog

dial (A) and another to look through the distributor and verify alignment of the spout. (See Figure 4AA.)

NOTE: Panel will not close with key inserted in the manual/jog dial (A). Always keep key in a safe location

for access by authorized personnel only.

Figure 4AA

Ref # Description

36 PNEG-1895 V2 Electronic Distributor Control

A Manual/Jog Dial

Page 37

NOTES

PNEG-1895 V2 Electronic Distributor Control 37

Page 38

5. Parts List

Assembly Procedure:

1. Install shaft (DEC0009) with provided roll

pins (S-9288).

2. Install enclosure (DEC0005) with 3/8" bolts and

nylock nuts.

3. Install junction box (DEC0105) with self-drilling

screws.

4. Install sensor mounting angle (DEC0014) and

plate (DEC0006).

5. Install sensors (DEC0107) and set clearance.

(See detail A.)

6. Install encoder (DEC0106), torque set screw to

8 in-lbs.

7. Install motor (DEC0015) and mount brackets

(DEC0003 and DEC0021).

8. Install bottom (DEC0021) and side (DEC0013)

covers.

NOTE: Install sensors in #3 hole on both sides.

Set 0.050" ± 0.01" clearance from face of each

sensor to flag on shaft.

See detail A

Detail A

12" 6 Hole 45° Distributor Assembly Electronic Control

(DFB12645G-EC)

38 PNEG-1895 V2 Electronic Distributor Control

Page 39

5. Parts List

12" 6 Hole 45° Distributor Assembly Electronic Control (DFB12645G-EC) Parts List

Ref # Part # Description Qty

1 DFB12645G 12" 6 Hole 45° Distributor Assembly 1

2 DEC0009 Weldment, Shaft and Flag, 1/2 HP Distributor Control 1

3 DEC0005 Weldment, Enclosure, 1/2 HP Distributor Control 1

4 DEC0014 Angle, Sensor Plate Mounting, 1/2 HP Distributor Control 1

5 DEC0006 Bracket, Proximity Sensor, 1/2 HP Distributor Control 1

6 DEC0015 Gear Motor, DBL WRM, 1/2 HP, 400:1, Distributor Control 1

7 DEC0003 Bracke t, Motor Mount, 1/2 HP Distributor Control 1

8 DEC0016 Bracket, Encoder Mount, Distri butor Control 1

9 DEC0106 Encoder, with Connector 2048 PPR, 30 mm, Distributor Control 1

10 DEC0107 Sensor, Prox, Threaded, Inductive, 12 mm, S=4 2 2

11 DEC0105 Connector Box, Farm Distributor Control 1

12 DEC0013 Cover, Side Access, 1/2 HP Distributor Control 2

13 DEC0012 Cover, Enclosure Bottom, 1/2 HP Distributor Control 1

14 S-2041 Split Lock Washer 1/4" ZN 18

15 S-1429 Bolt, HHCS 1/4"-20 x 3/4" ZN Grade 2 29

16 S-2126 Flat Washer 1/4" x 2-5/8" SAE ZN Grade 2 11

17 S-6998 Bolt, HHCS 1/4"-20 x 1" ZN Grade 5 4

18 S-7025 Nylock Nut 1/4"-20 ZN Grade 5 15

19 S-9288 Spring Pin 1/4" x 2-1/2" Plain Steel Slotted Rolled 2

20 S-7469 Bolt, HHCS 3/8"-16 x 1" ZN Grade 5 5

21 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 4

22 S-10200 Fender Washer 3/8" x 1-1/2" O.D. ZN 1

23 S-7223 Split Lock Washer #10 ZN 3

24 S-10167 Bolt, SHCS #10-32 x 1/4" ZN 3

25 DEC0021 Bracket, Motor Mount Short, 1/2 HP Distributor Control 1

26 DC-2160 Decal, Caution, Do not Operate with Access Panel 1

27 DC-2159 Decal, Warning, Rotating Spout can Crush and Cut 1

28 DEC0108 Cable, Home Proximity Sensor Cable Yellow 1

29 DEC0109 Cable, Overtravel Proximity Sensor Cable Black 1

30 DEC0011 Key, 1/4" x 3" L 1

N/S DEC0110 Panel, V2 Electric Distributor Control 1

N/S PNEG-1895 Manual, V2 Distributor Electric Control 1

PNEG-1895 V2 Electronic Distributor Control 39

Page 40

6. Retrofit Installation

Electronic Distributor Control Shaft Installation

Install the shaft (DEC0009) (A) to the distributor shaft (D) using two (2) roll pins (S-9288) (B). NOTE: Flag

extension (C) should be installed in line with the spout to ensure proper alignment with the sensor.

(See Figure 6A.)

Figure 6A Electronic Distributor Control Shaft

Ref # Part # Description

A DEC0009 Shaft

B S-9288 Roll Pin

C Flag Extension

D Distributor Shaft

E Spout

40 PNEG-1895 V2 Electronic Distributor Control

Page 41

6. Retrofit Installation

Electronic Distributor Enclosure Installation

Install the enclosure (DEC0005) to the distributor (C) using four (4) 3/8 bolts (S-7469) (B) and nylock nuts

(S-7383) (A). (See Figure 6B.) Note the orientation of the enclosure; the side with th e two (2) large holes

must face away from back wall of distributor. Controller will not work if installed backwards.

Figure 6B Electronic Distributor Enclosure

Ref # Part # Description

A S-7383 3/8" Nylock Nut

B S-7469 3/8" Bolt

C Distributor

PNEG-1895 V2 Electronic Distributor Control 41

Page 42

6. Retrofit Installation

Sensor Plate Angle and Proximity Sensor Bracket Installation

Assemble the sensor plate angle (DEC0014) (A) to the proximity sensor bracket (DEC0006) (D) using

three (3) 1/4"-20 x 3/4" HHCS bolts (S-1429) (B) and 1/4"-20 nylock nuts (S-7025) (C) as shown in

Figure 6C.

Attach the proximity sensor bracket (DEC0006) (D) to the inside of the enclosure (DEC0005) (E) using

three (3) 1/4"-20 x 3/4" HHCS bolts (S-1429) (B) and 1/4"-20 nylock nuts (S-7025) (C). (See Figure 6C.)

Bracket must be installed with note markings facing down.

Figure 6C Sensor Plate Angle and Proximity Sensor Bracket

Ref # Part # Description

A DEC0014 Sensor Plate Angle

B S-1429 1/4"-20 x 3/4" HHCS Bolt

C S-7025 1/4"-20 Nylock Nut

D DEC0006 Proximity Sensor Bracket

E DEC0005 Enclosure

42 PNEG-1895 V2 Electronic Distributor Control

Page 43

6. Retrofit Installation

Diameter # Spouts Prox Ref #

6

4 2

65

8 6

8

65

8 7

10 9

10

6 4

810

10 9

12

41

6 3

88

10 9

14

41

6 3

8 8

Proximity Sensor Location and Installation

NOTE: The location of the proximity sensor will be determined by the configuration of the distributor.

Using the table shown in Figure 6D, locate the diameter and number of spouts of the distributor being

used and note the proximity sensor reference number. This reference number is marked on the bottom

of the proximity sensor bracket (DEC0006) (B) and identifies the location for installing the proximity

sensors (DEC0107) (A).

Install the two (2) proximity sensors (DEC0107) (A) into the proximity sensor bracket (DEC0006) (B) at the

appropriate locations determined from the table. (See Figure 6D below and Figure 6E on Page 44.)

PNEG-1895 V2 Electronic Distributor Control 43

Figure 6D Proximity Sensor Location

Ref # Part # Description

A DEC0107 Proximity Sensor

B DEC0006 Proximity Sensor Bracket

Page 44

6. Retrofit Installation

Proximity Sensor Location and Installation (Continued)

Figure 6E Proximity Sensor Installation

Ref # Part # Description

A DEC0107 Proximity Sensor

B DEC0006 Proximity Sensor Bracket

44 PNEG-1895 V2 Electronic Distributor Control

Page 45

6. Retrofit Installation

Proximity Sensor Adjustment

Set the clearance of the two (2) proximity sensors (DEC0107) (A) to 0.050" ± 0.01" from the face of each

sensor to the flag (B) on the shaft (DEC0009). (See Figure 6F.) This adjustment may need to be made

after motor is wired by using manual key switch to locate flag above each proximity sensor.

Figure 6F Proximity Sensor Adjustment

Ref # Part # Description

A DEC0107 Proximity Sensor

BFlag

PNEG-1895 V2 Electronic Distributor Control 45

Page 46

6. Retrofit Installation

Encoder and Bracket Installation

Install the encoder (DEC0106) (A) to the encoder mounting bracket (DEC0016) (B) using the three (3)

#10-32 bolts (S-10167) (D) and #10 washers (S-7223) (C) as shown in Figure 6G.

Tighten the encoder collar set screw (E) as shown in Figure 6H on Page 47 to 8 in-lbs.

Install the encoder mounting bracket (DEC0016) (B) to the proximity sensor bracket (DEC0006) (H) using

the 1/4"-20 x 3/4" HHCS bolt (S-1429) (I), 1/4" washer (S-2126) (J) and 1/4"-20 nylock nut (S-7025) (K) as

shown in Figure 6I on Page 48.

Figure 6G Encoder to Mounting Bracket

Ref # Part # Description

A DEC0106 Encoder

B DEC0016 Encoder Mounting Bracket

C S-7223 #10 Washer

D S-10167 #10-32 Bolt

46 PNEG-1895 V2 Electronic Distributor Control

Page 47

Encoder and Bracket Installation (Continued)

6. Retrofit Installation

Figure 6H Encoder Collar Set Screw

Ref # Part # Description

A DEC0106 Encoder

E Encoder Collar Set Screw

F Encoder Collar

PNEG-1895 V2 Electronic Distributor Control 47

Page 48

6. Retrofit Installation

Encoder and Bracket Installation (Continued)

Figure 6I Connector Box Install, Sensor Connectors to Encoder Connection

Ref # Part # Description

B DEC0016 Encoder Mounting Bracket

G DEC0107 Proximity Sensor

H DEC0006 Proximity Sensor Bracket

I S-1429 1/4"-20 x 3/4" HHCS Bolt

J S-2126 1/4" Washer

K S-7025 1/4"-20 Nylock Nut

48 PNEG-1895 V2 Electronic Distributor Control

Page 49

6. Retrofit Installation

E

D

G

H

F

Installing the Connector Box and Cables

1. Install the connector box to the inside of the enclosure using four (4) bolts (B) and nuts (C).

Make sure nuts are located on the outside of the enclosure. (See Figure 6J.)

Figure 6J

2. Pull sensor cable through the conduit connected to the enclosure.

3. Connect cables to the connector enclosure. (See Figure 6K.)

Figure 6K Control Panel Wiring to Junction Box Electrical Connec tio ns

Ref # Part # Description Ref # Part # Description

A Enclosure E DEC0105 Connection Enclosure

BBolts

C Nuts G DEC0109 Over-Travel Proximity Sensor Cable

D DEC0108 Home Proximity Sensor Cable

NOTE: “XXX” represent the length of the cable.

PNEG-1895 V2 Electronic Distributor Control 49

F DEC0106 Encoder

H DEC0026-XXX Sensor Cable

Page 50

6. Retrofit Installation

Motor Mounting Bracket Installation

Install the motor mounting bracket (DEC0003) (A) to the enclosure (DEC0005) (E) using two (2)

1/4"-20 x 3/4" HHCS bolts (S-1429) (D), 1/4" washers (S-2126) (C) and 1/4"-20 nylock nuts (S-7025) (B)

as shown in Figure 6L.

Figure 6L Motor Mounting Bracket

Ref # Part # Description

A DEC0003 Motor Mounting Bracket

B S-7025 1/4"-20 Nylock Nut

C S-2126 1/4" Washer

D S-1429 1/4"-20 x 3/4" HHCS Bolt

E DEC0005 Enclosure

50 PNEG-1895 V2 Electronic Distributor Control

Page 51

6. Retrofit Installation

Control Motor Installation

Install the motor (DEC0015) (A) to the motor mounting bracket (DEC0003) (F) using two (2) 1/4"-20 x 1"

HHCS bolts (S-6998), four (4) 1/4" washers (S-2126) (D) and two (2) 1/4"-20 nylock nuts (S-7025) (C) as

shown in Figure 6M.

Install second motor mounting bracket (DEC0021) (B) to the enclosure (DEC0005) using two (2)

1/4"-20 x 3/4" HHCS bolts (S-1429) (E), 1/4" washers (S-2126) (D) and 1/4"-20 nylock nuts (S-7025) (C).

Then install the motor to the motor mounting bracket (DEC0021) (B) using two (2) 1/4"-20 x 1" HHCS

bolts (S-6998), four (4) 1/4" washers (S-2126) (D) and two (2) 1/4"-20 nylock nuts (S-7025) (C) as shown

in Figure 6M.

Figure 6M Control Motor Installation

Ref # Part # Description

A DEC0015 Motor

B DEC0021 Motor Mounting Bracket - Short

C S-7025 1/4"-20 Nylock Nut

D S-2126 1/4" Washers

E S-1429 1/4"-20 x 1" HHCS Bolt

F DEC0003 Motor Mounting Bracket

G DEC0011 Key

PNEG-1895 V2 Electronic Distributor Control 51

Page 52

7. Troubleshooting

Error Messages

Figure 7A

Cause: When using the supplied interlock function, this message will appear when a move is attempted

while the contact closure that indicates that upstream equipment is running is closed. The move will

complete once the contact closure opens indicating the upstream equipment is no longer running.

Figure 7B

Cause: This message will appear if the user attempts to move to the position where the distributor is

currently located. If a different position is desired, the user must select a different position.

Figure 7C

Cause: This message will appear if the user attempts to move to a position that has been configured as

“locked-out.” If this position is desired, it must first be unlocked by navigating to “Position Lock-Out” screen

in the setup menu.

52 PNEG-1895 V2 Electronic Distributor Control

Page 53

7. Troubleshooting

Figure 7D

Cause: This message will appear if the user attempts to enter a po sition location value that is outside the

range of values allowed by the controller. This range exists to protect the equipment. To prevent this

message, user should enter a value that is within the range of values displayed in the error message.

(These values will vary for each controller; the values shown in Figure 7D will not be representative of

all configurations.)

Figure 7E

Cause: This message will appear if the controller has sensed that the spout has drifted from its desired

position while not being commanded to move. This may be caused by mechanical lash within the drive

mechanism or by the use of the manual key switch override on the front of the panel. User should execute

a “Move” command (see moving positions on Page 22) before attempting to move material through

distributor. Controller should force a homing operation before completing the move command.

Figure 7F

Cause: This message will be displayed if the user attempts to select the position where the distributor is

currently located to be locked-out. If this position is desired for lock-out, a “Move” command (see mo ving

positions on Page 22) should be performed to change to another position before selecting the position

for lock-out.

PNEG-1895 V2 Electronic Distributor Control 53

Page 54

7. Troubleshooting

Fault Code Descriptions, Possible Causes and Solutions

Code Fault Type Description Cause Solution

Using manual key switch, verify that forward command

produces counter-clockwise (as observed from above)

101 Direction

102 Direction

201 Encoder

Motor Direction

Forward, Encoder

Reading Reverse

Motor Direction

Reverse, Encoder

Reading Forward

Encoder Channel A

is OFF, Encoder

Channel B is OFF

Motor wiring or

encoder signal

wiring is reversed.

Motor wiring or

encoder signal

wiring is reversed.

Controller is

detecting no signal

from encoder

channel A or

encoder channel B.

distributor rotation. If distributor rotates clockwise (as

observed from above), swap any two (2) motor leads to

reverse motor rotation direction. If motor direction is

correct, check blue terminals 3 and 4 for correct wiring

both at junction box and control panel.

Using manual key switch, verify that forward command

produces counter-clockwise (as observed from above)

distributor rotation. If distributor rotates clockwise (as

observed from above), swap any two (2) motor leads to

reverse motor rotation direction. If motor direction is

correct, check blue terminals 3 and 4 for correct wiring

both at junction box and control panel.

Verify encoder wiring per instructions in this manual.

Encoder connections are blue terminal blocks. Blue

terminal block #1 should be connected to red encoder

wire. Blue terminal block #2 should be connected to

blue encoder wire. Blue terminal block #3 should be

connected to pink encoder wire. Blue terminal block #4

should be connected to white encoder wire.

202 Encoder

203 Encoder

204 Encoder

Encoder Channel A

is OFF, Encoder

Channel B is ON

Encoder Channel A

is ON, Encoder

Channel B is OFF

Encoder Channel A

is ON, Encoder

Channel B is ON

Controller is

detecting no signal

from encoder

channel A,

channel B is always

ON.

Controller is

detecting encoder

channel A always

ON, channel B no

signal.

Controller is

detecting encoder

channel A and

channel B always

ON.

Controller is receiving no signal from channel A (blue

terminal block #3) and a constant signal from channel B

(blue terminal block #4). Verify encoder wiring as

referenced above and ensure all terminal blocks are

secure with proper electrical continuity. If wiring is

correct and all terminals have continuity, check for 24V

across terminals 1 and 2. If encoder has 24V power

and problem persists the encoder has likely failed.

Replace encoder.

Controller is receiving a constant signal from channel A

(blue terminal block #3) and no signal from channel B

(blue terminal block #4). Verify encoder wiring as

referenced above and ensure all terminal blocks are

secure with proper electrical continuity. If wiring is

correct and all terminals have continuity, check for 24V

across terminals 1 and 2. If encoder has 24V power

and problem persists the encoder has likely failed.

Replace encoder.

Controller is receiving a constant signal from channel A

(blue terminal block #3) and a constant signal from

channel b (blue terminal block #4). Verify that encoder

ground (blue terminal block #2) is secure with proper

electrical continuity at all terminations. If wiring is

correct and all terminals have continuity, check for 24V

across terminals 1 and 2. If encoder has 24V power

and problem persists the encoder has likely failed.

Replace encoder.

54 PNEG-1895 V2 Electronic Distributor Control

Page 55

7. Troubleshooting

Fault Code Descriptions, Possible Causes and Solutions

(Continued)

Code Fault Type Description Cause Solution

Controller is receiving no signal from channel A (blue

terminal block #3) and a normal pulsing signal from

channel B (blue terminal block #4). Verify that blue

terminal block #3 has proper electrical continuity and

that connections are secure. If wiring is correct and

all terminals have continuity, check for 24V across

terminals 1 and 2. If encoder has 24V power and

problem persists the encoder has likely failed.

Replace encoder.

Controller is receiving a constant signal from

channel A (blue terminal block #3) and a normal

pulsing signal from channel B (blue terminal block #4).

Verify that blue terminal block #3 has no short present

in that circuit and that connections are secure. If wiring

is correct and all terminals have continuity, check for

24V across terminals 1 and 2. If encoder has 24V

power and problem persists the encoder has likely

failed. Replace encoder.

205 Encoder

206 Encoder

Encoder Channel A

is OFF, Encoder

Channel B is OK

Encoder Channel A

is ON, Encoder

Channel B is OK

Controller is detecting no

signal from encoder

channel A, channel B is

functioning normally.

Controller is detecting

encoder channel A

always ON, channel B

is functioning normally.

207 Encoder

208 Encoder

301 VFD

Encoder Channel A

is OK, Encoder

Channel B is OFF

Encoder Channel A

is OK, Encoder

Channel B is ON

Variable frequency

electric motor drive

has faulted.

Controller is detecting

encoder channel A

functioning normally,

channel B no signal.

Controller is detecting

encoder channel A

functioning normally,

channel B always ON.

VFD has detected a

malfunction while driving

the electric motor.

Controller is receiving a normal pulsing signal from

channel A (blue terminal block #3) and no signal from

channel B (blue terminal block #4). Verify that blue

terminal block #4 has proper electrical continuity and

that connections are secure. If wiring is correct and

all terminals have continuity, check for 24V across

terminals 1 and 2. If encoder has 24V power and

problem persists the encoder has likely failed.

Replace encoder.

Controller is receiving a normal pulsing signal from

channel A (blue terminal block #3) and a constant

signal from channel B (blue terminal block #4). Verify

that blue terminal block #4 has no short present in that

circuit and that connections are secure. If wiring is

correct and all terminals have continuity, check for 24V

across terminals 1 and 2. If encoder has 24V power

and problem persists the encoder has likely failed.

Replace encoder.

Open control panel and observe red LCD display

screen on power flex Variable Frequency Drive (VFD).

this display should show a numbered fault code

corresponding to the malfunction. Press red button

to reset fault and consult manufacturer’s technical

manual for full description of fault.

PNEG-1895 V2 Electronic Distributor Control 55

Page 56

7. Troubleshooting

Fault Code Descriptions, Possible Causes and Solutions

(Continued)

Code Fault Type Description Cause Solution

Controller has received a signal from proximity sensor

on home side of assembly (noted as “red” on sensor

mounting plate and run to red terminal blocks) during a

position move, indicating spout has overtraveled

expected position. Verify that proximity sensors are

401 Overtravel

402 Overtravel

Overtravel left

(home side)

detected during

position move.

Overtravel right

detected during

position move.

Controller has detected

signal indicating spout

has traveled past position

#1 toward back wall.

Controller has detected

signal indicating spout

has traveled past last

position toward back wall.

in correct numbered positions on mounting plate

(See Page 43), are wired to the correct terminal blocks

and that no metal objects are within 2 mm (0.080") of

the black plastic sensing surface. Metal flag welded to

shaft should only pass over home proximity sensor

during a homing procedure. Flag should trigger

proximity sensor after passing position #1 toward back

wall of distributor, just before internal spout makes

contact with back wall.

Controller has received a signal from proximity sensor

on far side of assembly (noted as “grey” on sensor

mounting plate and run to grey terminal blocks)

during a position move, indicating spout has

overtraveled expected position. Verify that proximity

sensors are in correct numbered positions on

mounting plate (See Page 43), are wired to the correct

terminal blocks and that no metal objects are within

2 mm (0.080") of the black plastic sensing surface.

Metal flag welded to shaft should never pass over

overtravel proximity sensor during normal operation.

Flag should trigger sensor only if spout has traveled

past the last position.

501 Encoder

601 Encoder

Homing operation

has timed out

before completion.

System has

detected a change

in position without

a move command

from PLC.

Controller did not receive

signal from home

proximity sensor within

the maximum allowable

time limit.

Controller has measured

movement of spout

assembly without user

input. This may be caused

by use of the manual/key

switch override or by other

mechanical issue.

Homing operation rotates distributor spout to a

position between the back wall of the distributor and

the center of the #1 position to set a constant zero

point. If controller does not receive signal from home

proximity sensor within a pre-defined time limit,

homing operation fails. this may be caused by a

mechanical obstacle stopping rotation or by the

sensor not being triggered by the metal flag welded

to the drive shaft. If the gap between the proximity

sensor and the flag welded to the drive shaft is too

large, the sensor will not trigger and homing will fail.

Verify that the gap between sensor and flag is

0.050" ± 0.010". Manual key switch may be used to

check this. If gap is correct and red LED light on

sensor illuminates in presence of shaft flag, verify that

the sensor is wired to the correct red terminal blocks,

and that diagnostic screen shows home prox “on”

when flag is over top of sensor.

If fault is caused by use of key switch, distributor may

be returned to a position by performing a “move”

command from move screen. Distributor will force a

homing operation before completing move command

to ensure accurate positioning. Controller should

return spout to the selected position on completion

of homing.

56 PNEG-1895 V2 Electronic Distributor Control

Page 57

White Panel Layout

8. Schematic and Wiring Diagrams

Figure 8A

PNEG-1895 V2 Electronic Distributor Control 57

Page 58

8. Schematic and Wiring Diagrams

White Panel Electrical Schematic

Figure 8B

58 PNEG-1895 V2 Electronic Distributor Control

Page 59

8. Schematic and Wiring Diagrams

White Panel Electrical Schematic (Continued)

Figure 8C

PNEG-1895 V2 Electronic Distributor Control 59

Page 60

NOTES

60 PNEG-1895 V2 Electronic Distributor Control

Page 61

9. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1895 V2 Electronic Distributor Control 61

Page 62

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Copyright © 2013 by GSI Group

Printed in the USA

GSI is a worldwide brand of AGCO Corporation.

CN-302694

Loading...

Loading...