Page 1

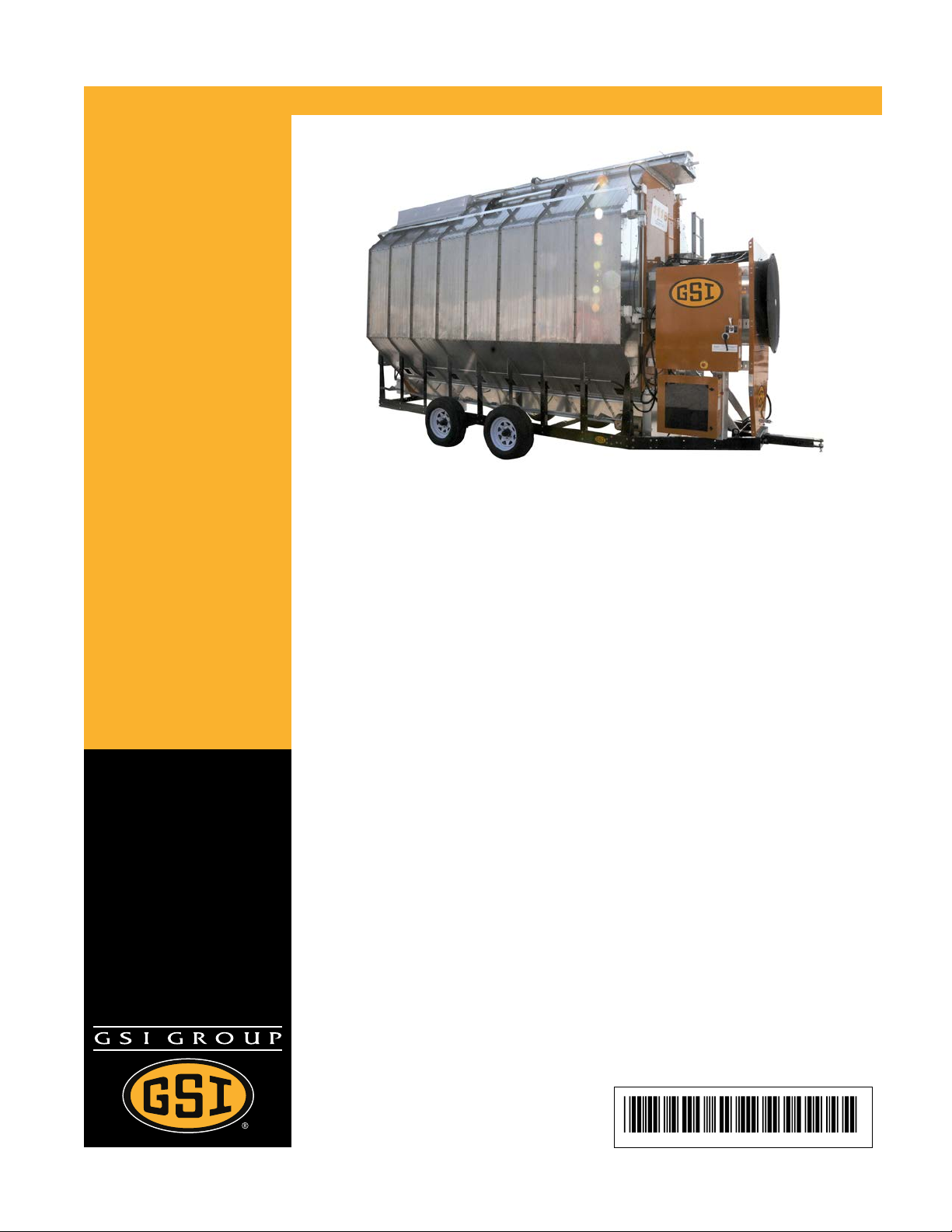

Single-Module Portable Dryer

Models:

1100, 1200, 1200S

CFAB-1 FAN, CFAB- 2 FAN, C2100A

Installation Guide

PNEG-1891

Date: 10-16-12

PNEG-1891

Page 2

All information, illustrations, photos, and specifications in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any

time without notice.

2 Pneg-1891 Portable Dryers

Page 3

Table of Contents

Contents

Chapter 1 Safety Precautions ....................................................................................................................5

Safety Guidelines for Portable Dryers............................................................................................5

Cautionary Symbols ....................................................................................................................6

Safety Decals for Portable Dryers .................................................................................................7

Chapter 2 Installation Guidelines............................................................................................................. 11

Guidelines for Transporting a Portable Dryer................................................................................ 11

Guidelines for Placing a Portable Dryer ....................................................................................... 12

Recommendations for a Single-Module Dryer Foundation............................................................. 12

Chapter 3 Dryer Supports ........................................................................................................................15

Guidelines for Supporting the Dryer with Concrete Blocks ............................................................. 15

Guidelines for Supporting the Dryer with Leg Stands .................................................................... 16

Leg Stand Spacing .................................................................................................................... 16

Installing Front and Rear Anchor Plates.......................................................................................17

Installing a Leg Stand to the Dryer Basket Corner.........................................................................18

Installing a Leg Stand Along the Dryer’s Frame ............................................................................ 19

Installing the Leg Stands Behind the Hitch Frame......................................................................... 20

Chapter 4 Hitch Ladder ............................................................................................................................ 23

Hitch Ladder Packages..............................................................................................................23

Installing the Hitch Ladder Support Bracket to the Hitch Channel ...................................................24

Installing the Ladder Standoff Bracket to the Hitch Ladder Support Bracket ....................................25

Installing the Ladder to the Ladder Standoff Brackets ................................................................... 26

Installing the End Cap to the Ladder............................................................................................ 26

Chapter 5 Rear Access Ladder ................................................................................................................ 29

Installing the Rear Ladder Support Brackets ................................................................................29

Installing the Ladder Standoff Brackets to the Rear Ladder Support Brackets ................................. 31

Chapter 6 Installing the Wet Bin............................................................................................................... 33

Raising the Load Auger.............................................................................................................. 33

Securing the Dryer Wet Bin Sides ...............................................................................................34

Installing the Belt Guard and Load Motor .....................................................................................36

Installing the Drive Sheaves and Belts......................................................................................... 37

Installing the Belt Guard Cover ................................................................................................... 38

Installing the Grain Intake Hopper ............................................................................................... 39

The Parts of the Dryer Wet Bin.................................................................................................... 39

Chapter 7 Power Supply .......................................................................................................................... 43

Guidelines for Supplying Adequate Power ................................................................................... 43

Installing the Machine-to-Earth Grounding Rod ............................................................................43

Guidelines for Powering Auxiliary Conveyors ...............................................................................45

Specifications for the Electrical Load on a Portable Dryer.............................................................. 45

Chapter 8 Fuel Supply .............................................................................................................................51

Guidelines for Connecting a Liquid Propane Supply Tank to a Dryer .............................................. 51

Specifications and Recommendations for Liquid Propane ............................................................. 52

Guidelines for Connecting Natural Gas to a Dryer.........................................................................53

Specifications and Recommendations for Natural Gas.................................................................. 53

Appendix A Dryer Specifications ................................................................................................................ 55

Specifications for GSI Dryers......................................................................................................55

Transport and Installation Dimensions for Single-Module GSI Dryers .............................................57

Specifications for FFI Dryers.......................................................................................................59

Transport and Installation Dimensions for Single-Module FFI Dryers ..............................................60

Specifications for X-Stream Dryers..............................................................................................62

Transport and Installation Dimensions for Single-Module X-Stream Dryers..................................... 64

Pneg-1891 Portable Dryers 3

Page 4

Table of Contents

Index .......................................................................................................................................65

GSI Group, LLC Limited Warranty............................................................................................ 67

4 Pneg-1891 Portable Dryers

Page 5

1 Safety Precautions

Topics Covered in this Chapter

▪ Safety Guidelines for Portable Dryers

▪ Cautionary Symbols

▪ Safety Decals for Portable Dryers

Safety Guidelines for Portable Dryers

Safety guidelines are general-to-specific rules that promote safe practices in the grain drying environment

and which must be respected at all times. Save these safety guidelines for future reference.

Make sure to read these safety guidelines carefully prior to installing, operating, or

CAUTION

Operation

• Read and fully understand this user guide before attempting to operate the grain dryer.

servicing your grain dryer.

• Never operate the grain dryer with its safety guards removed.

• Never operate the grain dryer by bypassing any safety device.

• Never exceed the maximum recommended drying temperature.

• Do not operate the grain dryer in an area where combustible material might be drawn into the fan.

• The operating and safety recommendations in this guide pertain to common cereal grains, as indicated. When drying other types of grain or products, contact the GSI Group, LLC for additional

recommendations.

Servicing

• The power supply must be disconnected when servicing electrical components. Always use extreme

caution when measuring voltage or performing procedures that require the dryer to be turned on.

• Before attempting to remove and reinstall a fan’s propeller, make sure to read the recommended procedure. If you are unsure about performing this procedure or cannot locate it, contact the GSI Group,

LLC before proceeding.

Pre-Season Mode

• When using a controller with Vision N2 software, the pre-season mode allows the fans and heaters to

operate under normal conditions, without the dryer being completely full of grain. In normal mode, the

dryer generates a Loss of Airflow shutdown if you operate the fans without having the dryer full of

grain.

• Following an extended period of inactivity—typically, at the beginning of the drying season, use preseason mode to fully test the dryer.

Pneg-1891 Portable Dryers

5

Page 6

Chapter 1: Safety Precautions

• To enable pre-season mode, click System→Control (Advanced)→Board Mode and then select

Pre-season Mode.

• Place the dryer in normal mode once inspections have been completed and you are ready to dry

grain.

IMPORTANT: If you power off the dryer while in pre-season mode, normal mode is automatically

enabled the next time you power on the dryer. Make sure to reselect pre-season

mode if further tests are required.

Cleanliness

• Keep the grain dryer clean at all times.

• Do not allow fine material to accumulate in the plenum chamber.

• An unclean plenum increases resistance to airflow, increases drying time, reduces drying efficiency,

and creates a fire hazard.

• Always keep the area around the fan’s air inlet clear of any obstacles and combustible material.

Augers/Auxiliary Conveyors

Always use extreme caution when working around augers and auxiliary conveyors

CAUTION

because they can start automatically.

• Always keep auger drive belts adequately tensioned to prevent slippage.

• Make sure that the technical specifications and capacities of the auxiliary conveyors are matched to

those of the dryer augers.

Burners/Gas Lines

• Regularly check for leaks at all gas line connections. If any leaks are detected, do not operate the

grain dryer. Shut off the main power and repair the leaks before operating. Gas lines must be

replaced regularly as required by the local gas regulations for your area.

• Routinely check for potential gas plumbing leaks. Check the liquid propane vaporizer for contact with

the burner vanes.

• Never use an open flame to locate gas leaks. Pour a solution of soap and water over the gas pipe

joints and connections, and check for the appearance of small bubbles.

• Set the pressure regulator to avoid applying excessive gas pressure to the burner during ignition or

when the burner is on.

• Do not use flammable or combustible materials in the dryer’s vicinity because explosive vapors can

be drawn into the fan and ignite.

• Always use extreme caution when working around high-speed fans and gas burners because they

can start automatically.

Cautionary Symbols

Cautionary symbols are present in the various decals of your equipment and alert you to the possible or

imminent risk of danger.

6 Pneg-1891 Portable Dryers

Page 7

Make sure to familiarize yourself with the cautionary symbols prior to installing,

operating, or servicing your equipment. Failure to do so might lead to serious injury

DANGER

Table 1-1 Overview of the different cautionary symbols

or death.

Symbol Description

This symbol indicates an imminently hazardous situation which, if not avoided,

will result in serious injury or death.

This symbol indicates a potentially hazardous situation which, if not avoided,

might result in serious injury or death.

This symbol indicates a potentially hazardous situation which, if not avoided,

might result in minor or moderate injury.

This symbol indicates a potentially hazardous situation which, if not avoided,

might result in property damage.

Chapter 1: Safety Precautions

Safety Decals for Portable Dryers

The safety decals on your grain dryer are safety indicators which must be carefully read and understood

by all personnel involved in the installation, operation, service, and maintenance of the grain dryer.

Table 1-2 Description of the grain dryer’s decals

Decal Decal No. Location

This decal appears:

• On the lid of the fan/heater control box

DC-1948

• On the front of the fan/heater control box

• Inside the dryer’s upper control box

This decal appears:

• On the bottom auger belt guard

• On the front bearing plate (visible when the bottom

auger belt guard is removed)

Pneg-1891 Portable Dryers

DC-1944

• At the rear of the dryer (for dryers equipped with the

front discharge option)

• On the top auger belt guard

• On the inside belt guard body (visible when the top

auger belt guard is removed)

7

Page 8

Chapter 1: Safety Precautions

Table 1-2 Description of the grain dryer’s decals (cont'd.)

Decal Decal No. Location

This decal appears:

• On the bottom auger belt guard

DC-1945

DC-1946

DC-1947

• On the front bearing plate (visible when the bottom

auger belt guard is removed)

• At the rear of the dryer (for dryers equipped with the

front discharge option)

This decal appears:

• On the inside of the rear plenum access door

• On the outside of the rear plenum access door

This decal appears:

• Twice on the front end panel, below the fan/heater

• Twice on the rear end panel, below the rear access

door

• On the auger discharge box

DC-1943

• On the inside of the auger discharge box’s flapper lid

(next to the discharge mercury switch)

• Inside the rear access door, on the rear plenum closure door (inside the plenum)

This decal appears:

• Inside the fan/heater control box

• On the door of the dryer’s upper control box

8 Pneg-1891 Portable Dryers

Page 9

Table 1-2 Description of the grain dryer’s decals (cont'd.)

Decal Decal No. Location

DC-1949

DC-1959

Chapter 1: Safety Precautions

This decal appears on the fan/heater access door

This decal appears on the fan/heater access door

This decal appears on each of the metering roll access

doors

DC-1950

This decal appears on the hitch tongue

DC-1956

This decal appears on the hitch tongue

DC-1954

Replacing Decals

All decals located on your grain dryer must remain legible and clearly visible at all times. To replace a damaged or missing decal, contact us to receive a free replacement.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Tel: 1–217–226–4421

Pneg-1891 Portable Dryers 9

Page 10

NOTES

10 Pneg-1891 Portable Dryers

Page 11

2 Installation Guidelines

Topics Covered in this Chapter

▪ Guidelines for Transporting a Portable Dryer

▪ Guidelines for Placing a Portable Dryer

▪ Recommendations for a Single-Module Dryer Foundation

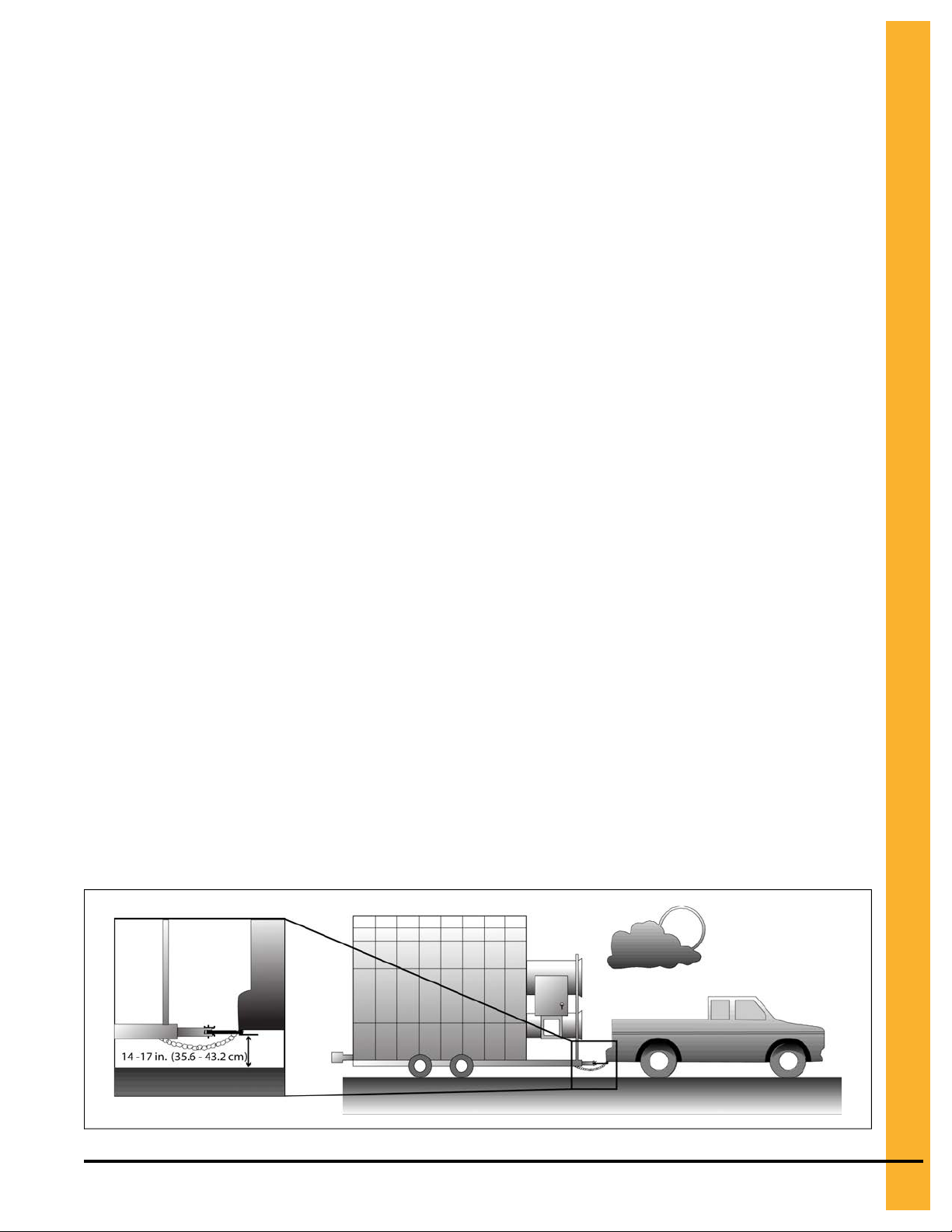

Guidelines for Transporting a Portable Dryer

To transport the dryer safely, follow the recommended guidelines and adhere to all state or provincial

towing regulations.

• Refer to Appendix A for the dryer transportation dimensions.

• Ensure that the hitch height is between 14 and 17 in. (35.6 and 43.2 cm), see Figure 2-1, page 11).

• The hitch bolt must be at least 0.75 in. (1.9 cm) in diameter and securely fastened with a locking nut,

(see Figure 2-2, page 12).

• Use washers to minimize the vertical hitch movement

• Always use a safety chain.

• Dryer must be towed empty and in accordance with applicable state or provincial regulations.

NOTE: NEVER tow dryer with grain or any other material inside of it.

• Recommended tire pressure is 55-60 PSI (3.8 bar) cold.

• Ensure the wheel lug nuts are torqued at 115 to 120 ft-lb (160 Nm).

• Maximum towing speed is 45 mph (70 km/h) or the speed limit, whichever is lower.

• After the first 50 miles (80 km) and every 200 miles (300 km) thereafter, examine the dryer wheel hub

and the spindle temperature immediately after stopping

NOTE: Temperature must not exceed 150° F (65° C) or lubricant will melt.

Figure 2-1 14 and 17 in. (35.6 and 43.2 cm) towing hitch height and safety chain

Pneg-1891 Portable Dryers 11

Page 12

Chapter 2: Installation Guidelines

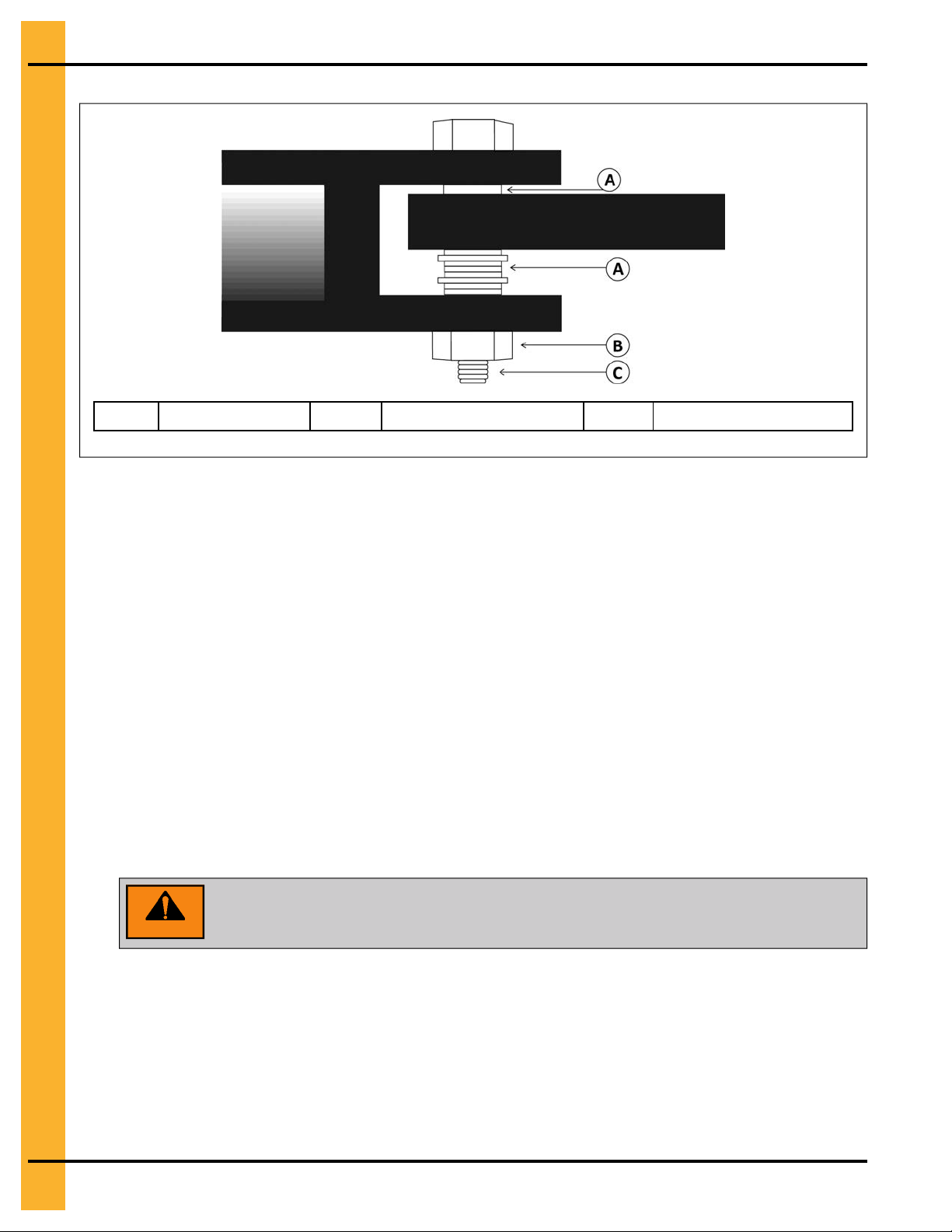

Figure 2-2 Hitch bolt with washer used for spacing

A Washers B Locking nut C 0.75 in. (1.9 cm)

Guidelines for Placing a Portable Dryer

The location of existing equipment and local code requirements must be evaluated before installing the

dryer.

Things to consider when choosing a location:

• Refer to Appendix A for dryer installation dimensions.

• Consult all national and local electrical and gas codes to ensure dryer is located correctly.

• Consider the location of the wet grain supply and dry grain discharge in relationship to the dryer.

• Consider the location of the storage bins and other grain handling equipment in relationship to the

dryer.

• Consider the location of the fuel supply and electrical sources in relationship to the dryer.

• Maintain a minimum distance of at least three feet between the dryer and other structures, otherwise

air flow problems may occur.

Do not operate dryer in an area where combustible materials can be drawn into

WARNING

the fans or where load and unload augers can come into contact with power

lines.

Recommendations for a Single-Module Dryer Foundation

A reinforced concrete pad or similar permanent foundation is required to keep the dryer stable during

operation.

Minimum Bag Mix for Concrete Strength per Model Weight

Consider the location of the gas and electrical service locations and how the pipe and the wire need to be

positioned before pouring the concrete.

12 Pneg-1891 Portable Dryers

Page 13

Chapter 2: Installation Guidelines

To prevent the dryer from overturning or moving laterally, the dryer must be secured to the foundation

using anchor bolts or cables. Anchor bolts can be cast into the concrete slab and secured to the dryer

legs. The dryer can also be secured using cables and turnbuckles that are fastened to the anchors that are

installed at the edge of the concrete slab.

Table 2-1 General reference for concrete materials needed for each size dryer foundation.

Dryer basket length

Concrete pad size (ft x ft)

Concrete pad size (m x m)

Concrete yards (meters)

Quantity of reinforcing rods

20 in. (50.8 cm) each

Wire mesh sq—ft (sq m )

Steel legs (minimum

quantity)

Anchors

Blocks

Feet (Meters) of 2 x 6

boards

Quantity of turnbuckles

Estimated man-hours

Quantities are approximate and requirements might vary due to site elevations.

Setup times do not include site preparations and the pouring of the concrete pad.

8 12 14 16 18 20 22 26

12 x 18 12 x 22 12 x 24 12 x 26 12 x 28 12 x 30 12 x 32 12 x 36

3.7 x 5.5 3.7 x 6.7 3.7 x 7.3 3.7 x 7.9 3.7 x 8.5 3.7 x 9.1 3.7 x 9.8 3.7 x 11

5.9 (5.4) 7.1 (6.5) 7.7 (7.0) 8.3 (7.6) 8.9 (8.1) 9.2 (8.4) 10.1 (9.2)

6 7 7 8 8 8 9 10

20.0

(216)

8 10 12 12 14 14 16 18

4 6 6 6 8 8 8 10

14 18 18 18 22 22 26 30

14 (4.3) 18 (5.5) 18 (5.5) 18 (5.5) 22 (6.7) 22 (6.7) 26 (7.9) 30 (9.1)

4 6 6 6 8 8 8 10

10 14 18 18 20 22 24 28

24.5

(264)

26.7

(288)

29.0

(312)

31.2

(336)

33.4

(360)

35.7

(384)

11.3

(10.3)

40.1

(432)

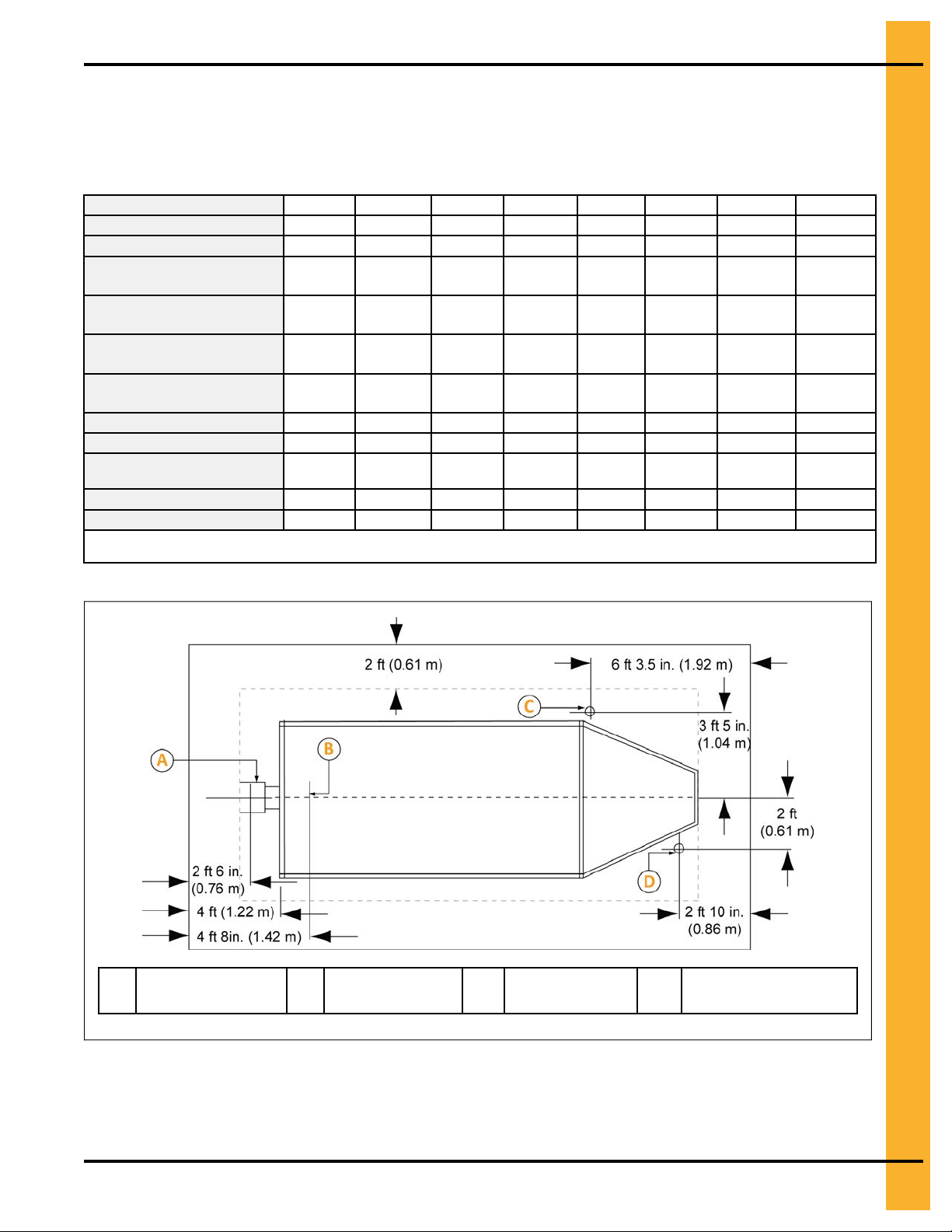

Figure 2-3 Recommended locations for external equipment

A

Grain discharge

area

B Fill-hopper

C Gas pipe

location

D Electrical service

location

Pneg-1891 Portable Dryers 13

Page 14

Chapter 2: Installation Guidelines

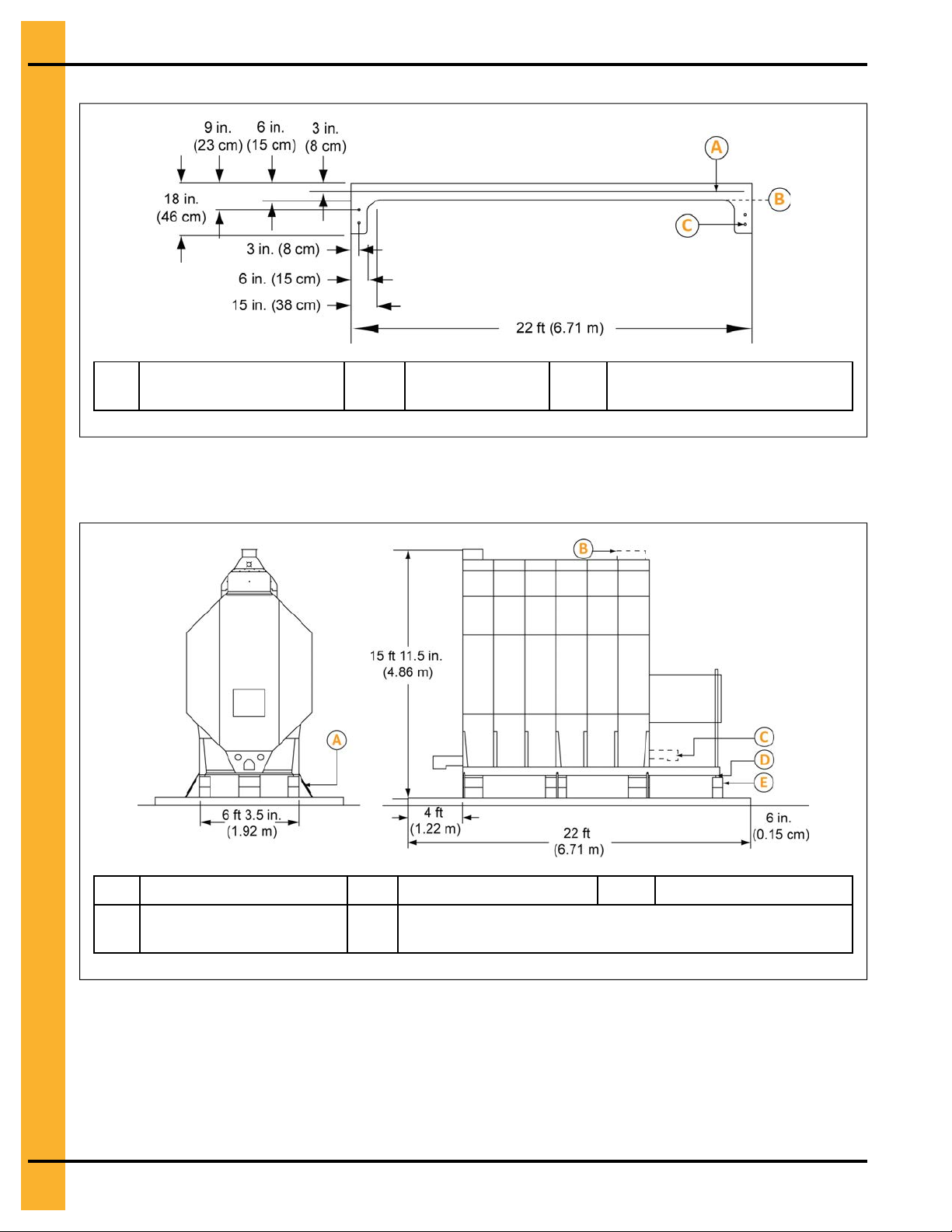

Figure 2-4 Cross-section of the concrete for single-module dryers

A

6 in. x 6 in. (15.2 cm x 15.2

cm) reinforcing mesh wire

Figure 2-5 Side and rear view of the portable dryer

B

Grade level C 0.5 in. (1.3 cm) number 4 rein-

forcing bar

A Turnbuckle B

D 2 in. x 6 in. (5.8 cm x 15.2

cm) board

14 Pneg-1891 Portable Dryers

Front fill option C

E 8 in. X 8 in. X 16 in. (20.3 cm x 20.3 cm x 40.6 cm) concrete

blocks

Front discharge option

Page 15

3 Dryer Supports

Topics Covered in this Chapter

▪ Guidelines for Supporting the Dryer with Concrete Blocks

▪ Guidelines for Supporting the Dryer with Leg Stands

▪ Leg Stand Spacing

▪ Installing Front and Rear Anchor Plates

▪ Installing a Leg Stand to the Dryer Basket Corner

▪ Installing a Leg Stand Along the Dryer’s Frame

▪ Installing the Leg Stands Behind the Hitch Frame

Guidelines for Supporting the Dryer with Concrete Blocks

Before filling the dryer with grain, the dryer frame must be supported with either concrete blocks or leg

stands. If choosing concrete blocks, follow these guidelines for proper installation:

• Place a 2 x 6 or 2 x 8 board between the dryer frame and the concrete blocks to prevent the dryer

frame from fracturing the concrete blocks.

• To prevent the dryer from overturning, it must be secured to the foundation using cables and turnbuckles that are fastened to anchors in the concrete foundation.

• Do not use the wheels as supports. Wheels are for transporting the dryer when it is empty.

• Place concrete blocks six feet apart on each side of the dryer to support the dryer frame.

NOTE: A minimum of one support for every six feet of basket length is required on each side.

• The blocks must be able to support the weight of a dryer that is filled with grain.

• With the hitch tongue removed, place a concrete block under the hitch mount location.

• The hitch assembly and the fan support must remain in place during operation. The hitch assembly

and fan support are not part of the transport tie down assembly.

• Use shims to provide uniform, level support for all blocks.

• The dryer should be 16 in. (40.6 cm) off the concrete pad to accommodate for clean-out and the use

of auxiliary grain handling equipment.

Pneg-1891 Portable Dryers 15

Page 16

Chapter 3: Dryer Supports

Guidelines for Supporting the Dryer with Leg Stands

Before filling the dryer with grain, the dryer frame must be supported with either concrete blocks or leg

stands. Leg stands are optional and available in seven different sizes to accommodate various dryer

heights.

Leg Stand Height Options

Leg stands are optional and must be ordered separately from your dryer. If you do not have leg stands,

you must support the dryer with concrete blocks.

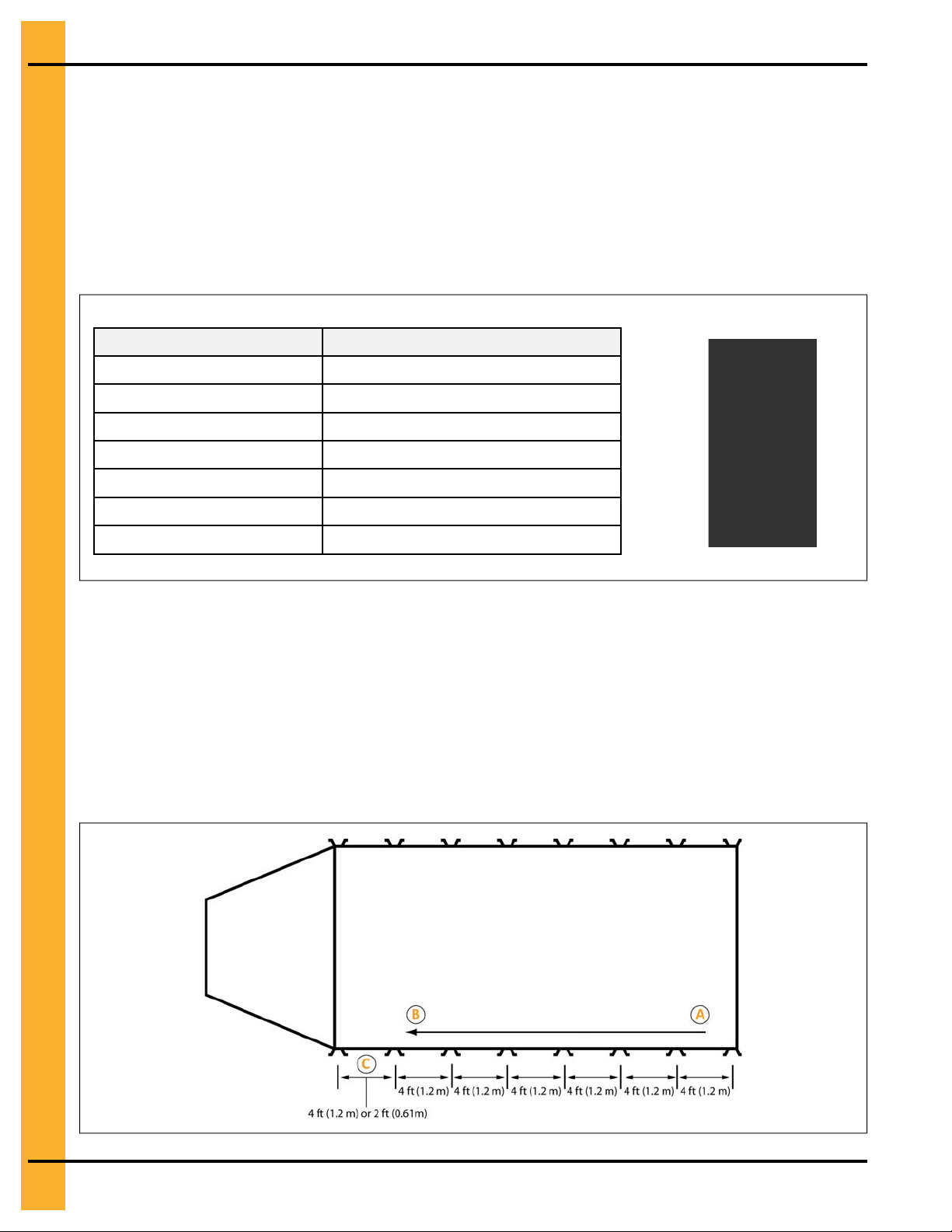

Figure 3-1 Leg stand heights

Part number Leg stand height

D01–0408 16 in. (406.4 mm)

D01–1046 18 in. (457.2 mm)

D01–0398 24 in. (609.6 mm)

D01–0399 30 in. (762 mm)

D01–1047 36 in. (914.4 mm)

D01–0582 42 in. (1066.8 mm)

D01–0761 48 in. (1219.2 mm)

Leg Stand Spacing

Correct leg spacing is important to adequately support the dryer during operation. Incorrect spacing might

result in unstable operating conditions.

Leg Spacing for Standard Dryers

Starting at the back corner of the dryer (A), space legs 4 ft (1.22 m) apart and move towards the front (B).

Spacing between the front legs (C) can be 2 ft (0.61 m) or 4 ft (1.22 m), depending on the length of the

dryer.

Figure 3-2 Leg spacing on a standard dryer

16 Pneg-1891 Portable Dryers

Page 17

Chapter 3: Dryer Supports

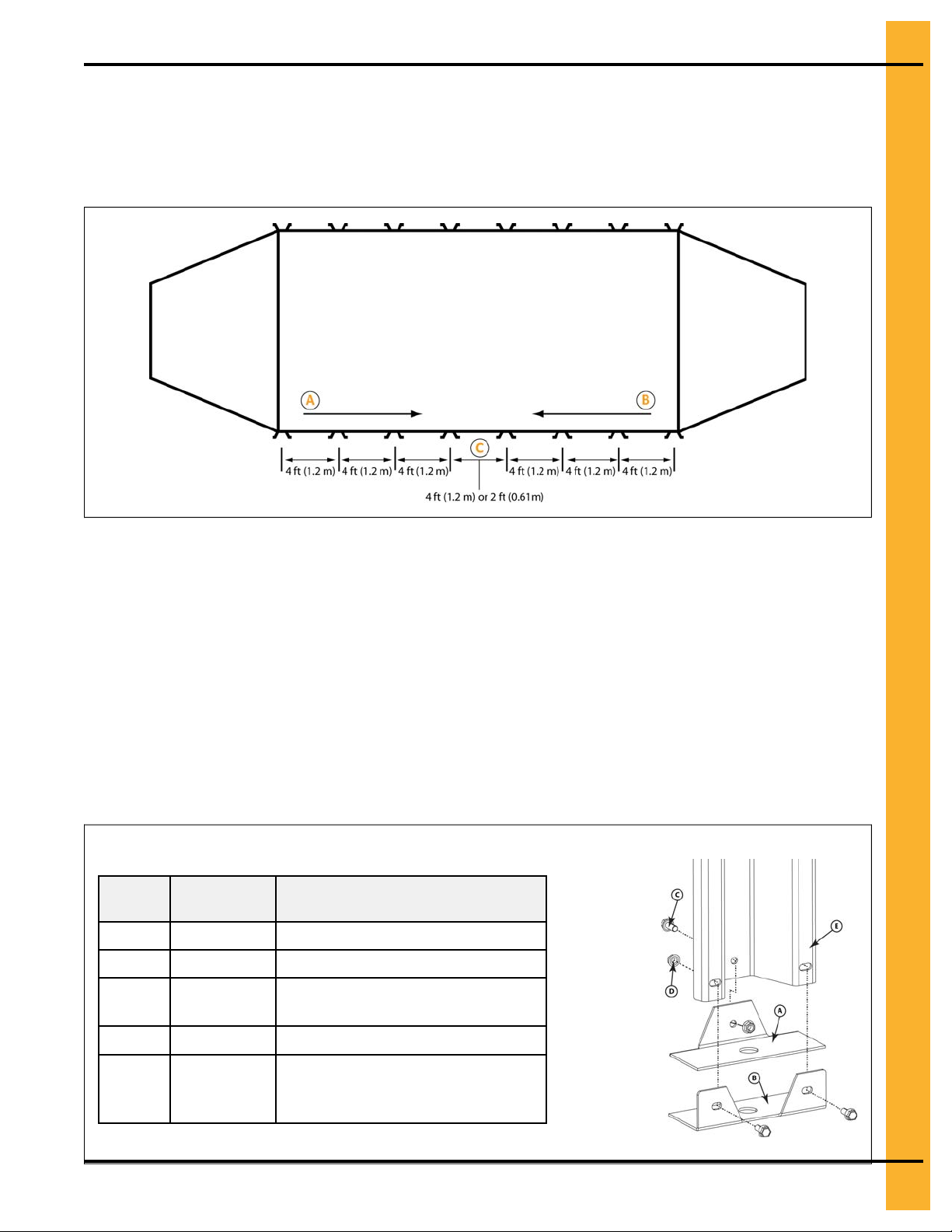

Leg Spacing for X-Stream Dryers

Starting at both the front and back ends of the dryer (A and B), space legs 4 ft (1.22 m) apart working

towards the center of the dryer. Spacing between center legs (C) can be 2 ft (0.61 m) or 4 ft (1.22 m),

depending on the length of the dryer.

Figure 3-3 Leg spacing on an X-Stream dryer

NOTE: The number of dryer legs varies depending on the length of the dryer.

Installing Front and Rear Anchor Plates

To secure the dryer, you must install the front and rear anchor plates to the leg stand bottoms, thereby enabling the legs to be anchored to the concrete foundation.

1. Use a flange bolt (C) and a flange nut (D) to attach the rear leg anchor plate (A) to the bottom of the

leg stand (E).

2. Position the front leg anchor plate (B) below the rear leg anchor plate (A), and use two flange bolts

(C) and flange nuts (D) to attach the anchor plate to the front of the leg stand (E).

3. Secure the leg stand (E) to the concrete foundation using concrete anchor bolts (not supplied).

Figure 3-4 Leg anchor plate assembly

Callout

A

B

C S-6606 5/16 in. - 18 X 3/4 in. zinc grade 5

Part

number

BLK-10057

BLK-10058

Description

Rear leg anchor plate

Front leg anchor plate

flange bolt

D

E

Pneg-1891 Portable Dryers 17

S-3611 5/16 in. –18 grade 2 flange nut

D01–xxxx For leg stand, refer to Guidelines for

Supporting the Dryer with Leg

Stands, page 16.

Page 18

Chapter 3: Dryer Supports

Installing a Leg Stand to the Dryer Basket Corner

If not using concrete blocks, you must install leg stands to the dryer frame at the dryer basket corners to

support the dryer.

What You Should Know

The additional width of the hitch bracket requires the use of an extra shim to install the legs located at the

dryer frame corners.

To install a leg stand to the dryer basket corner:

1. Remove the two existing bolts and nuts from the dryer frame corner (E and F).

2. Align the holes in leg stand (H) with the holes in the dryer frame corner, and fasten in place using the

bolts and nuts that were previously removed (E and F).

3. Align the top hole in the leg stand with the hole in the basket corner leg (G).

4. Fasten the legs together using bolt (B), washer (C), two shims (A), and nut (D).

Figure 3-5 Installing a leg stand to the dryer basket corner

Callout Part number Description

A D01–1221 Shim dryer stand to dryer

B

C S-2121 1/2 in. X 1 3/8 in. flat washer

D S-8506 1/2 in. - 13 zinc flange nut

18 Pneg-1891 Portable Dryers

S-8856 1/2 in. - 13 X 1 3/4 in. zinc grade 5 flange bolt

Page 19

Chapter 3: Dryer Supports

E S-3883 Original bolts installed on dryer (1/2 in. - 13 X 1 3/4 in. zinc

grade 8 HHCS bolt)

F S-6493 Original nuts installed on dryer (1/2 in. - 13 zinc grade 2

deformed lock nut)

G D01–0007 Basket corner leg

H D01–xxxx For leg stand, refer to Guidelines for Supporting the Dryer with

Leg Stands, page 16

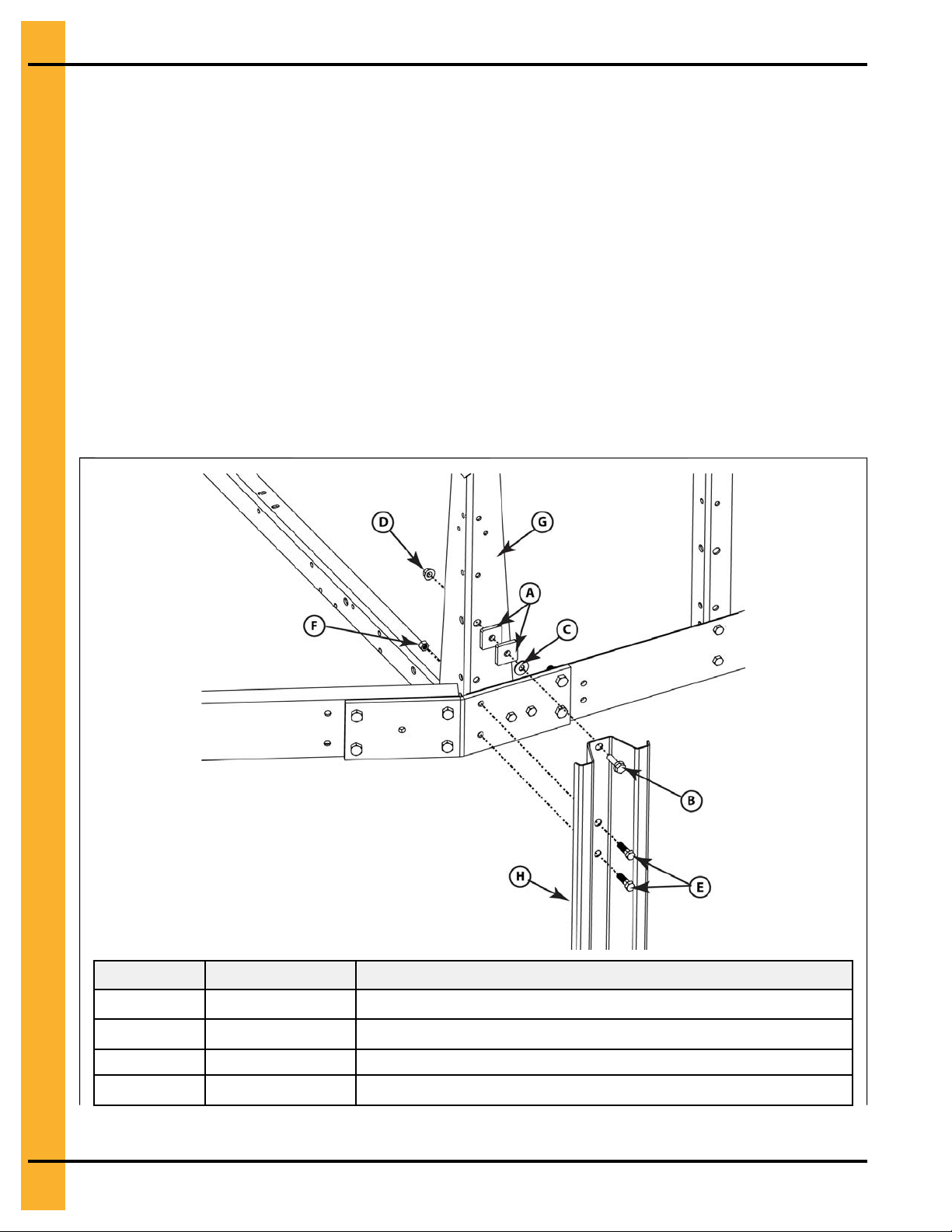

Installing a Leg Stand Along the Dryer’s Frame

If not using concrete blocks, you must install leg stands to the dryer frame to support the dryer.

1. Remove the two bolts and nuts from the dryer frame at the location where the leg stand is to be

installed (A and B).

2. Align the holes in the leg stand (G) with the holes in the dryer frame, and fasten in place using the

bolts and nuts that were previously removed (A and B).

3. Align the top hole in the leg stand (G) with the hole in the basket leg (F).

4. Fasten the legs together using a bolt (E), shim (C), and nut (D).

5. For a secure fit, use the shim plates (H) to make any minor adjustments to the leg height.

Pneg-1891 Portable Dryers 19

Page 20

Chapter 3: Dryer Supports

Figure 3-6 Installing leg stands along dryer frame

Callout Part number Description

A S-3883 Original bolts installed on dryer (1/2 in. - 13 X 1 3/4 in. zinc

grade 8 HHCS bolt)

B S-6493 Original nuts installed on dryer (1/2 in. - 13 zinc grade 2

deformed lock nut)

C D01–1221 Shim dryer stand to dryer

NS S-2121 1/2 in. X 1 3/8 in. flat washer

D S-8506 1/2 in. -13 zinc flange nut

E S-8856 1/2 in. - 13 X 1 3/4 in. zinc grade 5 flange bolt

F D01–0007 Basket corner leg

G D01–xxxx For leg stand, refer to Guidelines for Supporting the Dryer with

Leg Stands, page 16

H FC-42077 Shim plate

Installing the Leg Stands Behind the Hitch Frame

Use leg stands behind the hitch frame to appropriately support the dryer.

20 Pneg-1891 Portable Dryers

Page 21

Chapter 3: Dryer Supports

1. Position the leg stands (E) behind the hitch frame, and align them with the holes in the rear hitch

cross channel (D).

2. Fasten the legs to the channel using two bolts (B), four washers (C), and two nuts (A) per each leg.

Figure 3-7 Installing leg stands to the hitch assembly

Callout

A

B

C S-2121 1/2 in. X 1 3/8 in. type A plated flat washer

D

E

Part number Description

S-8506 1/2 in. - 13 zinc flange nut

S-8856 1/2 in. - 13 X 1 3/4 in. zinc grade 5 flange bolt

D01–2481

D01–xxxx For leg stand, refer to Guidelines for Supporting the Dryer with

Rear hitch cross channel

Leg Stands, page 16

Pneg-1891 Portable Dryers 21

Page 22

NOTES

22 Pneg-1891 Portable Dryers

Page 23

4 Hitch Ladder

Topics Covered in this Chapter

▪ Hitch Ladder Packages

▪ Installing the Hitch Ladder Support Bracket to the Hitch Channel

▪ Installing the Ladder Standoff Bracket to the Hitch Ladder Support Bracket

▪ Installing the Ladder to the Ladder Standoff Brackets

▪ Installing the End Cap to the Ladder

Hitch Ladder Packages

Hitch ladders are available in three different sizes. You must use the ladder package that is specific to your

dryer size.

Table 4-1 Available hitch ladder packages

Part number Description

2FOOTRF 2 foot roll formed ladder assembly used for 16,18, and 24 inch dryer heights

3FOOTRF 3 foot roll formed ladder assembly used for 30 and 36 inch dryer heights

4FOOTRF 4 foot roll formed ladder assembly used for 42 and 48 inch dryer heights

Pneg-1891 Portable Dryers 23

Page 24

Chapter 4: Hitch Ladder

Installing the Hitch Ladder Support Bracket to the Hitch Channel

The hitch ladder is used to access the front of the dryer opposite of the control box side of the dryer.

1. Install the hitch ladder support bracket (A) to the center hole pattern on the hitch channel.

2. Fasten bracket (A) to the hitch channel, using flange bolts (B) and flange nuts (C).

Figure 4-1 Installing the hitch ladder support bracket to the hitch channel

Callout

A

B

C S-8506 1/2 in. - 13 zinc flange nut

24 Pneg-1891 Portable Dryers

Part number Description

D01–2755

S-9062 1/2 in. - 13 X 1 1/4 in. zinc grade 5 flange bolt

Hitch ladder support bracket

Page 25

Chapter 4: Hitch Ladder

Installing the Ladder Standoff Bracket to the Hitch Ladder Support Bracket

The ladder standoff brackets secures the ladder to the ladder support bracket, thus ensuring safe access

to the front of the dryer.

1. Align the holes in the ladder standoff brackets (B) with the holes on the side of the hitch ladder support bracket (A).

2. Fasten the four standoff brackets (B) to the hitch ladder support bracket (A) using flange bolts (C)

and flange nuts (D.)

Figure 4-2 Installing the ladder standoff bracket to the hitch ladder support bracket

Callout

A

B

C S-6606 5/16 in. - 18 X 3/4 in. zinc grade 5 flange bolts

D

Pneg-1891 Portable Dryers 25

Part number Description

D01–2755

LDR-4341 Ladder standoff bracket

S-3611 5/16 in. - 18 grade 2 flange nut

Hitch ladder support bracket

Page 26

Chapter 4: Hitch Ladder

Installing the Ladder to the Ladder Standoff Brackets

Standoff brackets are used to support the ladder along it’s vertical length and secure the ladder to the

equipment.

1. Install the carriage bolt (C) through the standoff wedge (B).

2. Hook the standoff wedge assembly (B) under the ladder edge (E).

3. Place the standoff bracket (A) onto the carriage bolt (C) and fasten in place with flange nut (D). Leave

the flange nut (D) loose to allow the ladder to slide into position before fully tightening.

4. Install all standoff brackets (A) and adjust the ladder vertically into position.

5. Fully tighten the carriage bolts (C) and flange nuts (D).

Figure 4-3 Detail of the standoff bracket

Callout

A LDR-4314 Ladder standoff bracket

B LDR-4198 Ladder standoff wedge

C S-3550 5/16 in. x 1 in. carriage bolt

D S-3611 5/16 in. flange nut

Part

Number

Description

Installing the End Cap to the Ladder

The end cap helps to protects your hands from the sharp edges on the ends of the ladder.

1. Install the end caps (A) to both the right and left side of the ladder by snapping the end caps (A) into

the top of the ladder.

2. Secure the end cap (A) in place using a flange bolt (B) and flange nut (C).

26 Pneg-1891 Portable Dryers

Page 27

Figure 4-4 End cap assembly

Callout Part number Description

Chapter 4: Hitch Ladder

A

B S-7470 5/16 in. - 18 X 1 in. zinc grade 5

C S-3611 5/16 in. - 18 grade 2 flange nut

LDR-5011

Ladder end cap

flange bolt

Pneg-1891 Portable Dryers 27

Page 28

NOTES

28 Pneg-1891 Portable Dryers

Page 29

5 Rear Access Ladder

Topics Covered in this Chapter

▪ Installing the Rear Ladder Support Brackets

▪ Installing the Ladder Standoff Brackets to the Rear Ladder Support Brackets

Installing the Rear Ladder Support Brackets

The rear ladder support brackets attach directly to the dryer and support the ladder standoff brackets.

1. Locate the two upper rear ladder bracket installation locations (A) and remove the existing hardware

(B and C).

2. Install one upper rear ladder bracket (A) by aligning it with the bottom bolt in the door frame (B), and

fasten with the previously removed hardware.

3. Install the second upper rear bracket (A) by aligning it with the middle bolt in the gusset plate (C), and

fasten with the previously removed hardware.

4. Align the holes in the lower rear bracket (D) with the holes in the dryer frame and fasten with three

flange bolts (E) and flange nuts (F).

Pneg-1891 Portable Dryers 29

Page 30

Chapter 5: Rear Access Ladder

Figure 5-1 Installing the rear ladder support brackets

Callout Part number Description

A

B NA Existing hardware — bottom bolt in door frame

C NA Existing hardware — lower rear bracket

D

E

F

30 Pneg-1891 Portable Dryers

D01–2691

D01–2692

S-9067 3/8 in. - 16 X 3/4 in. zinc grade 5 flange bolt

S-968 3/8 in. -16 zinc grade 5 flange nut

Upper rear ladder bracket

Lower rear bracket

Page 31

Chapter 5: Rear Access Ladder

Installing the Ladder Standoff Brackets to the Rear Ladder Support Brackets

The ladder standoff brackets allow the ladder to be easily adjusted and secured to the dryer.

1. Install the ladder standoff brackets (A) to the lower rear ladder support bracket (D), using carriage

bolts (B) and flange nuts (C).

2. Install the ladder standoff brackets (A) to the upper rear ladder support brackets (E), using carriage

bolts (B) and flange nuts (C).

3. Install the ladder to standoff brackets, (see Installing the Ladder to the Ladder Standoff Brackets,

page 26).

4. Install the end caps to the ends of the ladder, (see Installing the End Cap to the Ladder, page 26).

Figure 5-2 Installing the ladder standoff bracket to rear ladder support bracket

Callout

A

B

C S-3611 5/16 in. - 18 grade 2 flange nut

D

E

Pneg-1891 Portable Dryers 31

Part number Description

LDR-4341 Standoff bracket

S-3550 5/16 in. X 1 in. carriage bolt

D01–2692

D01–2691

Lower rear ladder bracket

Upper rear ladder bracket

Page 32

NOTES

32 Pneg-1891 Portable Dryers

Page 33

6 Installing the Wet Bin

Topics Covered in this Chapter

▪ Raising the Load Auger

▪ Securing the Dryer Wet Bin Sides

▪ Installing the Belt Guard and Load Motor

▪ Installing the Drive Sheaves and Belts

▪ Installing the Belt Guard Cover

▪ Installing the Grain Intake Hopper

▪ The Parts of the Dryer Wet Bin

Raising the Load Auger

You must raise the load auger before you can install the dryer wet bin.

1. To raise the load auger:

• For dryers eight ft (2.44 m) use the handrails (A)

Figure 6-1 Handrail location for dryers eight ft (2.44 m) in length.

A

• For dryers twelve ft (2.66 m) or longer, turn the turnbuckles on the lift kit (B)

Pneg-1891 Portable Dryers 33

Handrails for 8 ft (2.44 m) dryer

Page 34

Chapter 6: Installing the Wet Bin

Figure 6-2 Turnbuckle location for dryers twelve ft (2.66 m) and longer

B

Lift kit turnbuckles for twelve ft (2.66 m) and longer dryers

2. Bolt the top angle brackets (D) to the angle brackets already installed, positioning the brackets backto-back. Brackets are located on the front and rear of the dryer, (see Figure 6-3, page 34).

3. Bolt the load auger housing channel (C) to the front and rear of the ends of the dryer wet bin.

Figure 6-3 Angle brackets and housing channels

C

Top auger housing channel D Top angle bracket

4. Once the auger assembly is securely bolted, unbolt the lift kit legs and lower them back into their

shipping position.

Securing the Dryer Wet Bin Sides

After having raised the load auger, you must install the side panels so that the dryer wet bin can receive

and hold the incoming grain.

34 Pneg-1891 Portable Dryers

Page 35

Chapter 6: Installing the Wet Bin

1. At each end of the dryer, attach the end plate connectors to the corners of the dryer wet bin, (see

Figure 6-4, page 35).

2. Raise the dryer wet grain bin sides (B) and secure them to the end plate connectors (A), (see Figure

6-5, page 36).

NOTE: Do not connect the side of the dryer wet bin that is adjacent to the load auger motor. Leave

this side open to allow for easy access when attaching the belt guard body.

Figure 6-4 The end plate connectors of the dryer wet bin

A End plate connector

Pneg-1891 Portable Dryers 35

Page 36

Chapter 6: Installing the Wet Bin

Figure 6-5 Connections for the dryer wet bin sides

B Dryer wet bin side

Installing the Belt Guard and Load Motor

To protect you from the load motor belt, you must install the belt guard after installing the load motor.

1. Install the belt guard mounting bracket to the top of the dryer wet bin.

2. Lift the load motor and install 0.50 in. x 6 in. turnbuckles to the motor mount (D01–0173) and motor

mount anchor bracket (D01–0170) with two turnbuckle pins and two cotter pins.

3. Install the three bolts for the belt guard body.

4. Place the belt guard body onto the bolts, centering the cutout in the belt guard body over the drive

shaft of the load motor.

5. Loosely secure with nuts. These bolts will be tightened after the belt is adjusted for clearance.

36 Pneg-1891 Portable Dryers

Page 37

Figure 6-6 Bolt locations for Belt Guard Body

Chapter 6: Installing the Wet Bin

Installing the Drive Sheaves and Belts

To ensure that the load auger rotates, you must install the drive sheaves and belts. The motor turns the

drive sheaves and belts, and the drive sheaves and belts turn the load auger.

1. Insert the key into the keyway on the auger drive shaft.

2. Place 16 inch sheave (D52–0001) on the auger drive shaft.

Pneg-1891 Portable Dryers 37

Page 38

Chapter 6: Installing the Wet Bin

3. Insert the 1–1/2 inch split tapered Q1 bushing on the auger drive shaft and infix the bushing with a

wooden or non-metal mallet.

4. Install three bolts into the bushing. If necessary, smooth the load auger drive shaft with hardware

cloth.

5. Insert the key into keyway and slide the motor drive sheave onto the drive shaft of the load motor.

6. Secure the drive sheave with the setscrew.

7. Thread the two BX97 belts from the motor drive pulley to the 16 inch sheave.

8. Check the alignment of the belts and sheaves to ensure that they are aligned.

9. To tighten belts, turn the turnbuckle on the anchor bracket of the motor mount.

10.Adjust the clearance of the belt guard body so that there is no contact with moving parts and tighten

the adjustment hardware.

Figure 6-7 Load motor sheave and motor adjustment turnbuckle

A Load motor sheave B

Motor adjustment turnbuckle

Installing the Belt Guard Cover

To easily remove the cover when performing maintenance to the drive belts and sheaves, you must install

the belt guard cover using its latches.

1. Insert the tabs on the belt guard cover into the slots on the belt guard body.

2. Engage the latches, one on the top and two on the bottom, (see Figure 6-8, page 39).

3. Install the dryer wet bin side that was left open to allow for easy access to the belt guard body.

38 Pneg-1891 Portable Dryers

Page 39

Chapter 6: Installing the Wet Bin

Figure 6-8 Latches for the belt guard cover

Installing the Grain Intake Hopper

To ensure that the dryer receives the incoming wet grain, you must connect the grain intake hopper

between the dryer wet bin and the equipment that supplies the wet grain.

1. Locate the hopper assembly (D01–0193) over the grain intake opening at the top rear of the dryer.

2. Connect the hopper assembly to the dryer wet grain bin by using six 1/4 in. x 3/4 in. self-drilling

screws (S-6497), six 5/16 in. x 3/4 in. flange bolts (S-6606), and six 5/16 in. flange nuts (S-3611).

Figure 6-9 Hopper assembly and hopper installation location

A

Hopper assembly (D01–0193)

B

Hopper installation location on load auger

assembly

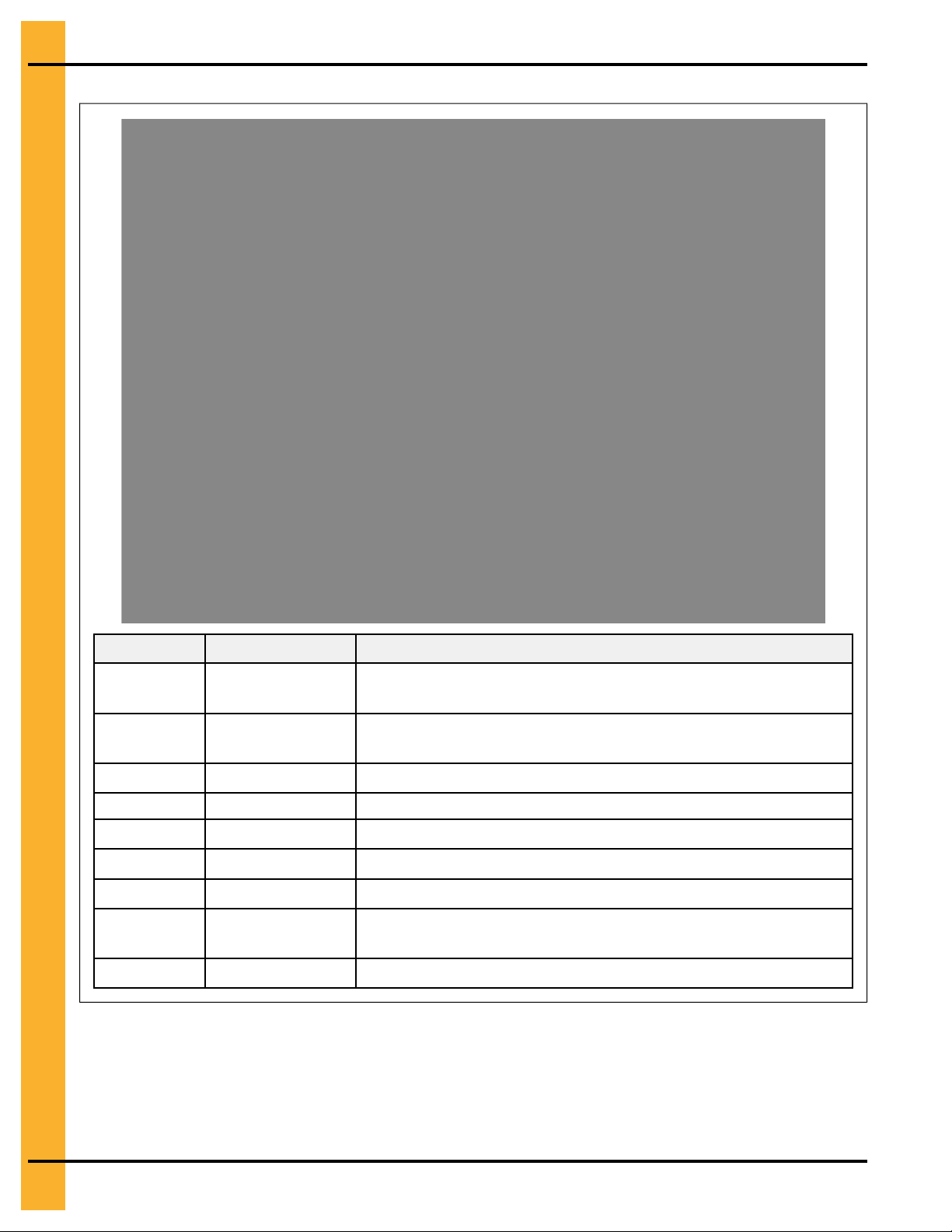

The Parts of the Dryer Wet Bin

Shows the dryer wet bin parts for easy identification of parts.

Pneg-1891 Portable Dryers 39

Page 40

Chapter 6: Installing the Wet Bin

Figure 6-10 The parts that make up the dryer wet bin

40 Pneg-1891 Portable Dryers

Page 41

Table 6-1 Part descriptions of the dryer wet bin

Chapter 6: Installing the Wet Bin

Part

Callout

1

2

3 & 4 D01-1182-Y

3 D01-0452-Y

4 D01-0453

5

6 D01-0044

7 D01-0156

8 D01-1526

9 D01-0155

10 NA

11 D01-0464 Belts BX97 2

12 D32-0019

13 D52-0001

Number

D01-0465

Description

Dryer wet bin hardware package

Turnbuckle, 0.50 in. X 6 in.

Top auger belt guard assembly (includes #3, #4, and #5)

Top auger belt guard cover (not shown)

Top auger belt guard body

Belt guard assembly mounting hardware (see Table 6-2, page 41)

Top angle bracket, front and rear

Top auger housing channel

Wet bin end plate connector

Belt guard mounting bracket

Motor shaft sheave (determined by the dryer model)

Bushing Q1 - 1.50 in. split taper (for auger shaft sheave and includes

hardware)

Sheave, 16 in. grip-belt 2 groove

Qua-

ntity

1

1

1

1

1

2

2

4

1

1

1

1

14 D01-0193-Y

Table 6-2 Hardware packages for the belt guard of the dryer wet bin

Part

number

S-6501 3/8 in. - 16 X 4 in. bolt 3

S-968

S-248 3/8 in. flat washer 4

S-6606

S-3611

S-3949 3/8 in. - 16 X 1 in. bolt 2

S-4663

Description

3/8 in. - 16 flange whiz nut

5/16 in. - 18 X 3/4 in. flange bolt

5/16 in. - 18 flange nut

3/8 in. - 16 locking nut

Hopper assembly

Quantity

9

3

3

2

1

Pneg-1891 Portable Dryers 41

Page 42

NOTES

42 Pneg-1891 Portable Dryers

Page 43

7 Power Supply

Topics Covered in this Chapter

▪ Guidelines for Supplying Adequate Power

▪ Installing the Machine-to-Earth Grounding Rod

▪ Guidelines for Powering Auxiliary Conveyors

▪ Specifications for the Electrical Load on a Portable Dryer

Guidelines for Supplying Adequate Power

An adequate power supply and proper wiring are important factors for ensuring maximum performance

and long life of the dryer.

• Ensure that electrical service is adequate to prevent low-voltage damage to motors and control circuits. Refer to Specifications for the Electrical Load on a Portable Dryer, page 45 for power supply

requirements.

• Power supply for single-phase models must include a neutral wire.

All dryers are equipped with a main electrical disconnect switch on the main

WARNING

dryer.

control box. This switch turns off the main power to the dryer. Make sure to turn

off the main electrical disconnect switch before inspecting or servicing the

• Advise the service representative of the local power supplier that an additional load will be placed on

the line.

• Considering the total horsepower load, check the KVA rating of transformers.

• The voltage drop during a motor start must not exceed 14% of the normal voltage. The power supply

wiring, main switch equipment, and transformers must provide adequate motor startup and operating

voltage.

• Verify that the motor is within 8% of the normal voltage when it is operating at full speed.

• Check the electrical load information for HP ratings and the maximum amp loads.

Installing the Machine-to-Earth Grounding Rod

To help protect circuit boards, the variable frequency drive (VFD), and the ignition system if electrical short

circuits occur, you must install a machine-to-earth grounding rod.

What You Should Know

The machine-to-earth grounding rod that is located at the power pole does not provide adequate grounding

for the dryer. The grounding rod that you install must be in accordance with local requirements.

Pneg-1891 Portable Dryers 43

Page 44

Chapter 7: Power Supply

Do not install the machine-to-earth grounding rod into dry soil. The soil must be wet

CAUTION

1. Place the machine-to-earth grounding rod within 8 feet (2.4 meters) of the dryer.

2. Dig a hole large enough to hold 2 gallons (7.6 liters) of water.

3. Fill the hole with water and insert the rod through the water and into the ground.

4. Move the rod up and down, working the water into the ground.

The rod is fully inserted into the ground and an appropriate contact with the surrounding soil is

assured.

5. Using an appropriate clamp, connect the bare, copper ground wire to the grounding rod.

6. Connect the ground wire to the control panel using the ground lug that is provided in the control box.

NOTE: Use a minimum grade of number six solid, bare, copper wire. The ground wire must not have

Figure 7-1 Grounding rod installation

to ensure good contact with the surrounding soil, thereby making an appropriate

ground.

any breaks or splices. Do not use insulated wire for grounding applications.

A Bare, copper ground wire B

44 Pneg-1891 Portable Dryers

Clamp C

Machine-to-earth grounding rod

Page 45

Chapter 7: Power Supply

Guidelines for Powering Auxiliary Conveyors

Before you can operate the auxiliary conveyors, you must ensure that adequate power is available.

• The auxiliary load and auxiliary unload augers or conveyors can be wired directly to the dryer.

• If an auxiliary motor is larger than recommended, it must be powered from a source outside the dryer

and must use a separate contactor and overload protection device for each motor. However, you can

operate the auxiliaries through the control panel.

• Refer to Specifications for the Electrical Load on a Portable Dryer, page 45 for the maximum horse-

power and amps that can be wired to the dryer.

Specifications for the Electrical Load on a Portable Dryer

These charts provide information for you to ensure that the grain dryer and the auxiliary equipment are

supplied with adequate power.

It is recommended that you contact the local power company and have a representative verify the installation to make sure that the wiring is compatible with their system and adequate power is supplied to the

unit. The only equipment connected to the recommended service amps must be the grain dryer. You must

adhere to all national and local electrical regulations. (Refer to the National Electrical Code Standard handbook created by the National Fire Protection Association). A qualified electrician must make all electrical

wiring installations.

Table 7-1 Specifications for the electrical load on a portable dryer

Dryer

model

1108

D190

1112

D270

Voltage

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

Motor HP

Load auger

Unload auger

Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Fan 10 to 12 33 60

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Fan 10 to 12 16.5 60

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Fan 10 to 17 78 100

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Fan 15 39 60

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Fan 15 19.5 60

(2) Auxiliary (2) 7.5

Fuel Load

Amps

1.5 8

1 6.5 60

62 *

1.5 5

1 3.4 50

40 *

1.5 2.5

1 1.7 60

20 *

2 14

1.5 8 60

62 *

2 6.2

1.5 5 50

40 *

2 3.1

1.5 2.5 60

20 *

Maximum amps

with auxiliaries

153 62.5 200

104 41.4 150

57 20.7 150

196 100 300

114 50.2 175

62 25.1 150

Minimum

amps

Recommended

service in amps

Branch breaker

in amps

60

50

60

60

50

60

Pneg-1891 Portable Dryers 45

Page 46

Chapter 7: Power Supply

Table 7-1 Specifications for the electrical load on a portable dryer (cont'd.)

Dryer

model

1114

D320

1116

D370

1118

D400

1120

D460

Voltage

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

Motor HP

Load auger

Unload auger

Fan 10 to 17 78 100

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Fan 15 39 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Fan 15 19.5 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Fan 10 to 17 78 100

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Fan 15 39 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Fan 15 19.5 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Fan 20 50 90

(2) Auxiliary (2) 10

Load auger

Unload auger

Fan 20 25 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Fan 25 64 90

(2) Auxiliary (2) 15

Load auger

Unload auger

Fan 25 32 60

(2) Auxiliary (2) 15

7.5 20

7.5 20 90

7.5 10

7.5 10 60

Fuel Load

Amps

5 26

5 26 100

62 *

5 13.2

5 13.2 60

52 *

5 6.6

5 6.6 60

26 *

5 26

5 26 100

62 *

5 13.2

5 13.2 60

52 *

5 6.6

5 6.6 60

26 *

5 13.2

5 13.2 60

52 *

5 6.6

5 6.6 60

26 *

78 *

39 *

Maximum amps

with auxiliaries

231 130 350

145 65.4 200

78 32.7 150

231 130 350

145 65.4 200

78 32.7 150

158 76.4 250

84 38.2 150

219 104 300

115 52 200

Minimum

amps

Recommended

service in amps

Branch breaker

in amps

100

60

60

100

60

60

60

60

90

60

46 Pneg-1891 Portable Dryers

Page 47

Table 7-1 Specifications for the electrical load on a portable dryer (cont'd.)

Dryer

model

1122

D511

1126

D601

1214

2120

1216

2122

Voltage

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

Motor HP

Load auger

Unload auger

Fan 30 74 90

(2) Auxiliary (2) 15

Load auger

Unload auger

Fan 30 37 60

(2) Auxiliary (2) 15

Load auger

Unload auger

Fan 40 102 125

(2) Auxiliary (2) 15

Load auger

Unload auger

Fan 40 51 90

(2) Auxiliary (2) 15

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 10

10 to 12 48 100

10 to 17 78 100

Fuel Load

Amps

7.5 20

7.5 20 90

78 *

7.5 10

7.5 10 60

39 *

10 26

10 26 90

78 *

10 13

10 13 60

39l *

5 26

5 26 100

62 *

5 13.2

5 13.2 60

10 28 60

52 *

5 6.6

5 6.6 60

10 14 60

26 *

5 26

5 26 100

62 *

5 13.2

5 13.2 60

15 39 60

52 *

5 6.6 60

5 6.6

15 19.5 60

26 *

Maximum amps

with auxiliaries

231 114 300

120 57 200

277 154 400

143 77 250

252 148 300

170 87.4 225

90 43.7 150

286 178 400

183 98.4 225

96 49.2 150

Minimum

amps

Chapter 7: Power Supply

Recommended

service in amps

Branch breaker

in amps

90

60

90

60

100

60

60

100

60

60

Pneg-1891 Portable Dryers 47

Page 48

Chapter 7: Power Supply

Table 7-1 Specifications for the electrical load on a portable dryer (cont'd.)

Dryer

model

1218

2125

1220

2130

1222

2132

Voltage

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

Motor HP

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 10

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5

Load auger

Unload auger

Top Fan

Bottom Fan 10 to12 33 60

(2) Auxiliary (2) 15

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 15

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 15

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 15

10 to 17 78 100

7.5 31

7.5 31 100

10 to 17 78 100

7.5 20

7.5 20 90

7.5 10

7.5 10 60

7.5 20

7.5 20 90

7.5 10

7.5 10 60

Fuel Load

Amps

5 26

5 26 100

62 *

5 13.2

5 13.2 60

15 39 60

52 *

5 6.6

5 6.6 60

15 19.5 60

26 *

62 *

15 39 60

78 *

15 19.5 60

39 *

20 50 90

78 *

20 25 60

39 *

Maximum amps

with auxiliaries

286 178 400

183 98.4 225

96 49.2 150

298 188 400

229 112 300

123 59 200

241 123 350

129 64.5 200

Minimum

amps

Recommended

service in amps

Branch breaker

in amps

100

60

60

100

90

60

90

60

48 Pneg-1891 Portable Dryers

Page 49

Table 7-1 Specifications for the electrical load on a portable dryer (cont'd.)

Dryer

model

1226

2140

1214S

2141

1218S

2181

Voltage

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

Motor HP

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 15

Load auger

Unload auger

Top Fan

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 15

Load auger

Unload auger

(2) Fans

(2) Auxiliary (2) 7.5

Load auger

Unload auger

(2) Fans

(2) Auxiliary (2) 10

Load auger

Unload auger

(2) Fans

(2) Auxiliary (2) 10

Load auger

Unload auger

(2) Fans

(2) Auxiliary (2) 7.5

Load auger

Unload auger

(2) Fans (2) 10

(2) Auxiliary (2) 10

Load auger

Unload auger

(2) Fans (2) 10

(2) Auxiliary (2) 10

(2) 10 to

(2) 10 to

(2) 10 to

(2) 10 to

Fuel Load

Amps

10 26

10 26 90

25 64 90

78 *

10 13

10 13 60

25 32 60

39 *

5 26

5 26 100

12

5 13.2

5 13.2 60

12

5 6.6

5 6.6 60

12

5 26

5 26 100

12

5 13.2

5 13.2 60

5 6.6

5 6.6 60

96 100

62 *

66 60

52 *

33 60

26 *

96 100

62 *

56 60

52 *

28 60

26 *

Maximum amps

with auxiliaries

271 149 350

144 77.5 200

252 148 350

176 92.4 225

93 46.2 150

252 148 350

165 82.4 225

87 41.2 150

Minimum

amps

Chapter 7: Power Supply

Recommended

service in amps

Branch breaker

in amps

90

60

100

60

60

100

60

60

Pneg-1891 Portable Dryers 49

Page 50

Chapter 7: Power Supply

Table 7-1 Specifications for the electrical load on a portable dryer (cont'd.)

Dryer

model

1220S

1220H

1220SX

1220HX

500H

500HX

490

490X

1222S

1222H

1222SX

1222HX

2221

2221X

510

510X

1226S

1226H

1226SX

1226HX

650M

650MX

600

600X

Voltage

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

Motor HP

Load auger

Unload auger

(2) Fans

(2) Auxiliary (2) 7.5

Load auger

Unload auger

(2) Fans (2) 15

(2) Auxiliary (2) 15

Load auger

Unload auger

(2) Fans (2) 15

(2) Auxiliary (2) 15

Load auger

Unload auger

(2) Fans

(2) Auxiliary (2) 7.5

Load auger

Unload auger

(2) Fans (2) 15

(2) Auxiliary (2) 15

Load auger

Unload auger

(2) Fans (2) 15

(2) Auxiliary (2) 15

Load auger

Unload auger

(2) Fans (2) 25

(2) Auxiliary (2) 15

Load auger

Unload auger

(2) Fans (2) 25

(2) Auxiliary (2) 15

7.5 31

7.5 31 100

(2) 10 to

17

7.5 20

7.5 20 90

7.5 10

7.5 10 60

7.5 31

7.5 31 100

(2) 10 to

17

7.5 20

7.5 20 90

7.5 10

7.5 10 60

10 26

10 26 90

10 13

10 13 60

Fuel Load

Amps

156 100

62 *

78 60

78 *

39 60

39 *

156 100

62 *

78 60

78 *

39 60

39 *

128 90

78 *

64 60

39 *

Maximum amps

with auxiliaries

332 218 400

235 118 300

123 59 200

332 218 400

235 118 300

123 59 200

307 180 400

158 90 200

Minimum

amps

Recommended

service in amps

Branch breaker

in amps

100

90

60

100

90

60

90

60

50 Pneg-1891 Portable Dryers

Page 51

8 Fuel Supply

Topics Covered in this Chapter

▪ Guidelines for Connecting a Liquid Propane Supply Tank to a Dryer

▪ Specifications and Recommendations for Liquid Propane

▪ Guidelines for Connecting Natural Gas to a Dryer

▪ Specifications and Recommendations for Natural Gas

Guidelines for Connecting a Liquid Propane Supply Tank to a Dryer

When initially installing the dryer, you must connect a fuel source before you can operate the dryer. Liquid

propane (LP) is one of the fuel sources you can use to fuel your dryer.

The dryers have internal vaporizers and are designed to operate on liquid draw from the supply tank. Consult your liquid propane gas dealer for proper fittings, connection hose, and safety controls that are

required to meet local standards and conform with the National Fire Protection Association standards. The

piping train on the dryer includes the strainer, pressure relief valve, electronic safety shutoff valve (on

some models), and a pressure regulator between the vaporizer and the burner.

When long gas lines are installed between the liquid propane fuel tank and the dryer,

CAUTION

CAUTION

CAUTION

accumulation of oil or heavy hydrocarbon, resulting from extensive use on a vapor withdrawal

system.

Guidelines for connecting the liquid propane fuel tank to the dryer:

• Verify that the tank is 1000 gallons or larger and does not have a regulator mounted to it.

• Connect a flexible hose that is designed for liquid propane gas to supply tank. See Table 8-1, page

52 to determine the correct size of fuel line and heater orifice to use for your installation.

• Consult your liquid propane gas dealer for correct fittings, connection hoses, and safety controls that

are required to meet all local and national code standards.

the fuel can vaporize in the fuel lines causing the vaporizer to over heat.

Do not use tanks that have previously been used for ammonia or fertilizer solutions.

These substances are extremely corrosive and can damage fuel supply and burner

parts.

As a result of liquid draw from the supply tank, any water or oil present in the tank

can freeze in the pipe train or the controls and cause damage. To make sure that the

tank is free of moisture, it can be purged with methanol. Avoid tanks containing an

• Connect a liquid propane flexible hose to the manifold on the dryer.

• Open the liquid propane shutoff valves slowly to prevent accidental closing of the excess flow valves.

Pneg-1891 Portable Dryers 51

Page 52

Chapter 8: Fuel Supply

Figure 8-1 Grain dryer connected to a liquid propane tank

A Liquid propane gas

supply tank

B

Liquid manifold connection C

Liquid propane gas

fuel line

Specifications and Recommendations for Liquid Propane

The liquid propane (LP) fuel line size and heater orifice size are determined by the dryer model heat

capacity and fuel flow rate. Use the specifications chart that follows to select the appropriate equipment for

your dryer.

Table 8-1 Specifications for liquid propane (LP)

Dryer Model # Maximum Heat Capacity

GSI FFI

1108

1112

1114

1116

1118

1120

1122

1126

1214

1216

1218

1220

1222

1226

1214S

1218S

1220HX

1220SX

1222HX

1222SX

1226HX

1226SX

* Minimum line size for a 100 ft (30.5 m) distance.

190

270

320

370

400

460

511

601

2120

2122

2125

2130

2132

2140

2141

2181

490

500HX

510

2221

600

650MX

BTU Per

Hour

3,000,000

4,500,000

5,750,000

5,750,000

6,750,000

7,500,000

8,750,000

10,250,000

6,200,000

7,200,000

7,200,000

8,500,000

9,750,000

10,500,000

6,000,000

7,000,000

8,500,000

8,500,000

9,750,000

9,750,000

10,500,000

10,500,000

Kilowatt

Hours

879 33 124.9 0.50 25.4

1319 49 185.5 0.50 25.4

1685 63 238.5 0.50 25.4

1685 63 238.5 0.50 25.4

1978 74 280.1 0.50 25.4

2198 82 310.4 0.50 25.4

2564 96 363.4 0.75 76.2

3004 112 424 0.75 76.2

1817 68 257.4 0.75 76.2

2110 79 299 0.75 76.2

2110 79 299 0.75 76.2

2491 93 352 0.75 76.2

2857 107 405 0.75 76.2

3077 115 435.3 0.75 76.2

1759 66 250 0.75 76.2

2052 77 291 0.75 76.2

2491 93 352 0.75 76.2

2491 93 352 0.75 76.2

2857 107 405 0.75 76.2

2857 107 405 0.75 76.2

3077 115 435.3 0.75 76.2

3077 115 435.3 0.75 76.2

Maximum Fuel Flow

Gallons Per

Hour (gph)

Liters Per Hour

(l/hour)

Fuel Line Size*

Inches Millimeters

52 Pneg-1891 Portable Dryers

Page 53

Chapter 8: Fuel Supply

Guidelines for Connecting Natural Gas to a Dryer

When initially installing the dryer, you must connect a fuel source before you can operate the dryer. Natural

gas (NG) is one possible fuel choice.

• Operate the dryer on natural gas with a heat value of approximately 1000 BTU (880 kWper cubic

foot).

NOTE: The dryer is equipped with a natural gas supply pipe system connected to the heater solenoid

valves.

• You must provide a regulated pressure of 15 PSI at the connection to the dryer with sufficient gas

available to maintain this operating pressure.

Figure 8-2 Grain dryer connected to a natural gas supply tank

A

Gas meter and regulator

B

Natural gas manifold C

Fuel supply pipe

Specifications and Recommendations for Natural Gas

The fuel line size and heater orifice size are determined by the dryer model heat capacity and fuel flow

rate. Use the specifications chart that follows to select the appropriate equipment for your dryer.

Table 8-2 Specifications for natural gas (NG)

Dryer Model # Maximum Heat Capacity

GSI FFI

1108

1112

1114

1116

1118

1120

1122

1126

1214

1216

1218

1220

190

270

320

370

400

460

511

601

2120

2122

2125

2130

BTU Per

Hour

3,000,000

4,500,000

5,750,000

5,750,000

6,750,000

7,500,000

8,750,000

10,250,000

6,200,000

7,200,000

7,200,000

8,500,000

Kilowatt

Hours

879 33 124.9 0.50 25.4

1319 49 185.5 0.50 25.4

1685 63 238.5 0.50 25.4

1685 63 238.5 0.50 25.4

1978 74 280.1 0.50 25.4

2198 82 310.4 0.50 25.4

2564 96 363.4 0.75 76.2

3004 112 424 0.75 76.2

1817 68 257.4 0.75 76.2

2110 79 299 0.75 76.2

2110 79 299 0.75 76.2

2491 93 352 0.75 76.2

Maximum Fuel Flow

Gallons Per

Hour (gph)

Liters Per

Hour (l/hour)

Fuel Line Size*

Inches Millimeters

Pneg-1891 Portable Dryers 53

Page 54

Chapter 8: Fuel Supply

Table 8-2 Specifications for natural gas (NG) (cont'd.)

Dryer Model # Maximum Heat Capacity

GSI FFI

1222

1226

1214S

1218S

1220HX

1220SX

1222HX

1222SX

1226HX

1226SX

* Minimum line size for a 100 ft (30.5 m) distance.

2132

2140

2141

2181

490

500HX

510

2221

600

650MX

BTU Per

Hour

9,750,000

10,500,000

6,000,000

7,000,000

8,500,000

8,500,000

9,750,000

9,750,000

10,500,000

10,500,000

Kilowatt

Hours

2857 107 405 0.75 76.2

3077 115 435.3 0.75 76.2

1759 66 250 0.75 76.2

2052 77 291 0.75 76.2

2491 93 352 0.75 76.2

2491 93 352 0.75 76.2

2857 107 405 0.75 76.2

2857 107 405 0.75 76.2

3077 115 435.3 0.75 76.2

3077 115 435.3 0.75 76.2

Maximum Fuel Flow

Gallons Per

Hour (gph)

Liters Per

Hour (l/hour)

Fuel Line Size*

Inches Millimeters

54 Pneg-1891 Portable Dryers

Page 55

A Dryer Specifications

Topics Covered in this Appendix

▪ Specifications for GSI Dryers

▪ Transport and Installation Dimensions for Single-Module GSI Dryers

▪ Specifications for FFI Dryers

▪ Transport and Installation Dimensions for Single-Module FFI Dryers

▪ Specifications for X-Stream Dryers

▪ Transport and Installation Dimensions for Single-Module X-Stream Dryers

Specifications for GSI Dryers

The specifications that follow list the detail information for each dryer model. You can reference these

charts for items such as capacities, electrical loads, fan sizes, and auger dimensions.

Figure A-1 Profiles for GSI portable dryers

A

1100 series profile

Table A-1 Specifications for the 1100 series portable dryers

Model # 1108 1112 1114 1116 1118 1120 1122 1126

Total Holding

Capacity

(Bushels)

Grain

Column

Holding

Capacity

(Bushels)

Fans

Pneg-1891 Portable Dryers

190 327 381 436 490 544 599 708

160 282 329 376 423 470 517 611

28 in.

(71 cm)

10-13 HP

36 in.

(91 cm)

15 HP

B

1200SH series profile C 1200 series profile

40 in.

(102 cm)

15 HP

40 in.

(102 cm)

15 HP

42 in.

(107 cm)

20 HP

42 in.

(107 cm)

25 HP

(107 cm)

42 in.

30 HP

42 in.

(107 cm)

40 HP

55

Page 56

Appendix A: Dryer Specifications

Table A-1 Specifications for the 1100 series portable dryers (cont'd.)

Model # 1108 1112 1114 1116 1118 1120 1122 1126

Top Auger

8 in.

(20 cm)

diameter

Capacity

(BPH)

Bottom

Auger

8 in.

(20 cm)

diameter

Meter Roll

Drive

Capacity -

Maximum

1

(BPH)

Rate

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

Table A-2 Specifications for the 1200 series portable dryers

Model # 1214 1216 1218 1220 1222 1226

Total Holding

Capacity (Bushels)

Grain Column

Holding Capacity

(Bushels)

Fans

Top Auger

8 in.

(20 cm) diameter

Capacity (BPH)

Bottom Auger

8 in.

(20 cm) diameter

Meter Roll Drive

Capacity - Maxi-

mum Rate

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2 HP 2 HP 3 HP 5 HP 5 HP 7.5 HP 7.5 HP 10 HP

2900 2900 3800 3800 3800 3800 3800 3800

1.5 HP 1.5 HP 3 HP 5 HP 5 HP 7.5 HP 7.5 HP 10 HP

VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP

1120 1680 1960 2240 2520 2800 3080 3640

381 436 490 544 599 708

329 376 423 470 517 611

28 in. (66 cm)

10–13 HP/

36 in. (91 cm)

10–13 HP

28 in. (66 cm)

10–13 HP/

36 in. (91 cm)

15 HP

28 in. (66 cm)

10–13 HP/

36 in. (91 cm)

15 HP

28 in. (71 cm)

10–13 HP/

40 in. (102 cm)

15 HP

28 in. (71 cm)

10–13 HP/

42 in. (107

cm) 20 HP

28 in. (71 cm)

10–13 HP/

42 in. (107

cm) 25 HP

5 HP 5 HP 5 HP 7.5 HP 7.5 HP 10 HP

3800 3800 3800 3800 3800 3800

5 HP 5HP 5 HP 7.5 HP 7.5 HP 10 HP

VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP

1

(BPH)

1960 2240 2520 2800 3080 3640

Table A-3 1Specifications for the 1200S series portable dryers

Model #

1214(S or H) 1218(S or H) 1220(S or H) 1222(S or H) 1226(S or H)

Total Holding

Capacity

381 490 544 599 708

(Bushels)

Grain Column

Holding Capacity

329 423 470 517 611

(Bushels)

Fans

28 in. (71 cm)

10–13 HP (2)

36 in. (91 cm)

10–13 HP (2)

36 in. (91 cm)

15 HP (2)

36 in. (91 cm)

15 HP (2)

40 in. (102 cm)

25 HP (2)

56 Pneg-1891 Portable Dryers

Page 57

Appendix A: Dryer Specifications

Table A-3 1Specifications for the 1200S series portable dryers (cont'd.)

Model #

Top Auger

8 in. (20 cm)

diameter

Capacity (BPH)

Bottom Auger

8 in. (20 cm)

diameter

Meter Roll Drive

Capacity - Maxi-

mum Rate

(BPH)

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum

rate.

1214(S or H) 1218(S or H) 1220(S or H) 1222(S or H) 1226(S or H)

5 HP 5 HP 7.5 HP 7.5 HP 10 HP

3800 3800 3800 3800 3800

5 HP 5 HP 7.5 HP 7.5 HP 10 HP

VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP VFD, 1 HP

1

1960 2520 2800 3080 3640

Transport and Installation Dimensions for Single-Module GSI Dryers

The dryer dimensions that follow help you determine the area that is needed for transporting and installing

the dryer.

Figure A-2 Diagram of dryer dimensions

Table A-4 GSI portable dryer transport and installation dimensions

A B C E F G H

Dryer

Basket

1108

1112

1114

Pneg-1891 Portable Dryers

Transport

Height

13 ft 5 in. 8 ft 14 ft 6 in. 6 ft 5 in. 8 ft 15 ft 2 in. 17 ft 2 in.

(409 cm) (244 cm) (442 cm) (196 cm) (244 cm) (462 cm) (523 cm)

13 ft 5 in. 8 ft 14 ft 6 in. 6 ft 5 in. 8 ft 19 ft 2 in. 21 ft 2 in.

(409 cm) (244 cm) (442 cm) (196 cm) (244 cm) (584 cm) (645 cm)

13 ft 5 in. 8 ft 14 ft 6 in. 6 ft 5 in. 8 ft 21 ft 2 in. 23 ft 2 in.

(409 cm) (244 cm) (442 cm) (196 cm) (244 cm) (645 cm) (706 cm)

Installed

Width

Installed

Height

Wet Bin

Frame

Width

Transport

Width

Installed

Length

Transport

Length

57

Page 58

Appendix A: Dryer Specifications

Table A-4 GSI portable dryer transport and installation dimensions (cont'd.)

A B C E F G H

Dryer

Basket

1116

1118

1120

1122

1126

1214

1216

1218

1220

1222

1226

1214S

1218S

1220SH

1222SH

1226SH

Transport

Height

13 ft 5 in. 8 ft 14 ft 6 in. 6 ft 5 in. 8 ft 23 ft 2 in. 25 ft 2 in.