Page 1

PNEG-1867

Concrete Foundation

Recommendations for

GSI CFL Grain Bins

Instruction Manual

PNEG-1867

Date: 05-31-12

Page 2

2 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 3

Table of Contents

Contents

Chapter 1 CFL Series Outside Universal Stiffened Anchor Bolt Charts ...........................................................6

CFL Series Outside Universal Stiffened Anchor Bolt Charts

4" Corrugation Commercial Farm Tanks ............................................................................................... 6

Chapter 2 Inverted “T” Foundation 4" Outside Stiffened (CFL Series) Commercial Farm Tanks ................ 10

3000 PSF Soil Bearing Capacity ......................................................................................................... 10

3500 PSF Soil Bearing Capacity ......................................................................................................... 12

4000 PSF Soil Bearing Capacity ......................................................................................................... 14

Chapter 3 T-Cap Foundation Outside Stiffened Commercial Farm Tanks ..................................................... 18

Chapter 4 Warranty .............................................................................................................................................. 21

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 3

Page 4

NOTES

4 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 5

CFL (4" Corrugation) Outside Stiffened

Anchor Bolt Chord Charts 2 Post

Commercial Farm Tanks

®

Section 1

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 5

Page 6

1. CFL Series Outside Universal Stiffened Anchor Bolt Charts

CFL Series Outside Universal Stiffened Anchor Bolt Charts

4" Corrugation Commercial Farm Tanks

Prior to setting any anchor bolts, you must be sure to have the correct anchor bolt placement chart. This

is very critical for stiffener alignment during erection.

The charts are divided up based on the following criteria:

• Does your bin have 2 or 3 stiffeners per sidewall sheet?

• Does your bin have stiffeners on the inside or outside?

• What diameter of bin do you have?

• What series of bin do you have (NC, WC, FC, CFL)?

Refer to proper chart on Page 7 to find the anchor chord that corresponds to the bin that is going to

be built.

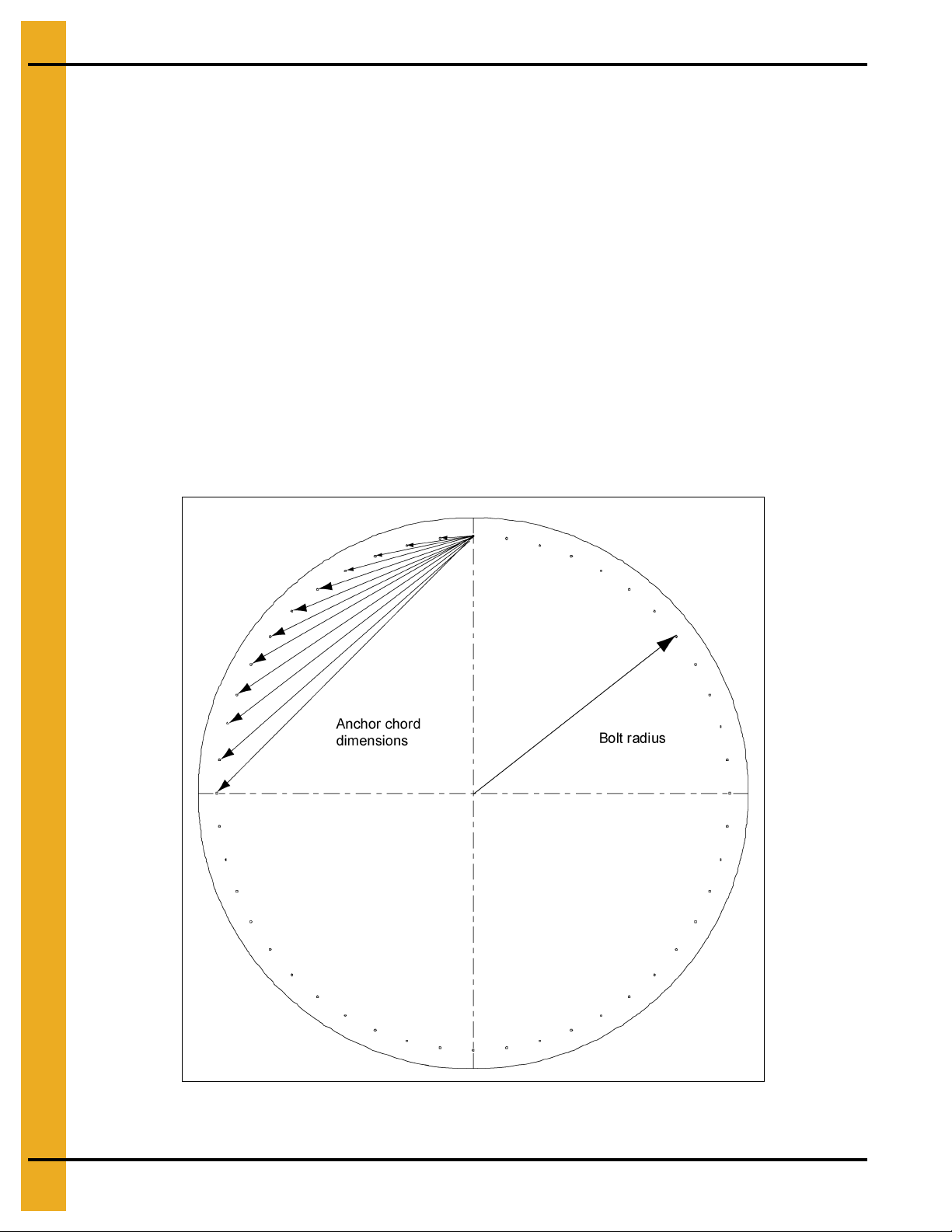

Start with one anchor bolt and work from it to the left to locate one quarter of the anchor bolts the n to the

right to locate another quarter of the bolts. Now work off of the last anchor bolt s in each quarter t o lo cate

remaining anchor bolts in the last two (2) quarters.

Figure 1A

6 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 7

1. CFL Series Outside Universal Stiffened Anchor Bolt Charts

CFL Series Outside Stiffened Tanks 2 Stiffeners per

Sidewall Sheet 4" Commercial Anchor Bolt Placement Charts

Nominal 36 Anchors

Diameter

Bolt Radius

Anchor Chord

Nominal 40 Anchors

Diameter

Bolt Radius

= 54' 2 Post

= 27' - 2-1/2"

4' - 8-15/16"

9' - 5-7/16"

14' - 1-1/16"

18' - 7-3/8"

23' - 0-1/16"

27' - 2-9/16"

31' - 2-5/8"

34' - 1 1 -1 3/16"

38' - 5-13/16"

= 60' 2 Post

= 30' - 2-3/8"

4' - 8-7/8"

9' - 5-3/8"

14' - 1-3/16"

18'-8"

Anchor Chord

23' - 1-3/8"

27' - 5-1/16"

31' - 6-11/16"

35'-6"

39' - 2-11/16"

42' - 8-1/2"

NOTE: These tables are for 2 post CFL series outside stiffened bins only.

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 7

Page 8

NOTES

8 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 9

Inverted “T” Foundation Recommendations

for 4" Corrugation Out side Stiffened

Commercial Farm Tanks (CFL Series)

®

Section 2

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 9

Page 10

2. Inverted “T” Foundation 4" Outside Stif fened (CFL Series) Commercial Farm Tanks

All foundation specifications shall be construed as

recommendations only. Because of the many

variable conditions in actual installation, GSI

assumes no liability for results arising from the use

of such recommendations.

3000 PSF Soil Bearing Capacity

Inverted “T” Foundation Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3000 PSF. Bearing

capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

Figure 2A

10 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 11

2. Inverted “T” Foundation 4" Outside Stiffened (CFL Series) Commercial Farm Tanks

Diameter of Bin: 54'

Soil Bearing Capacity: 3000 PSF

Ring # 8 10 11 13 14 16 17

A 1'-0" 1'-0" 1'-0" 1'-0" 1'-0" 1'-0" 1'-1"

B 2'-9" 3'-5" 4'-3" 5'-1" 6'-0" 6'-9" 7'-8"

C 27'-10" 27'-10" 27'-10" 27'-10" 27'-10" 27'-10" 27'-10"

D 28'-2" 28'-6" 28'-10" 29'-2" 29'-6" 29'-10" 30'-2"

M 5 #4's 6 #4's 6 #4's 7 #4's 7 #4's 5 #5's 5 #5's

N 3 #5's 4 #5's 4 #5's 5 #5's 6 #5's 6 #5's 7 #5's

P #5 @ 14" c/c #5 @ 14" c/c #5 @ 14" c/c #5 @ 14" c/c #5 @ 13" c/c #6 @ 13" c/c #6 @ 9" c/c

#4 (ft.) 6500 6900 6900 7200 7200 4800 4800

Rerod

Cu. Yds.

Concrete

Diameter of Bin: 60'

Soil Bearing Capacity: 3000 PSF

#5 (ft.) 900 1200 1300 1600 2000 2800 3100

#6 (ft.) 0 0 0 0 0 1100 1700

Footing 18 23 28 33 38 43 52

Wall 33 33 33 33 33 33 33

Floor 42 42 42 42 42 42 42

Total 93 98 103 108 113 118 127

Ring #12141618

A 1'-0" 1'-0" 1'-0" 1'-0"

B 4'-7" 6'-0" 7'-1" 8'-5"

C 30'-9" 30'-9" 30'-9" 30'-9"

D 32'-3" 32'-8" 33'-4" 33'-11"

M 5 #5's 6 #5's 7 #5's 5 #6's

N 5 #5's 6 #5's 7 #5's 9 #5's

P #5 @ 14" c/c #5 @ 11" c/c #6 @ 9" c/c #6 @ 6" c/c

#4 (ft.) 5700 5900 5900 5900

Rerod

Cu. Yds.

Concrete

#5 (ft.) 3600 4700 4100 1800

#6 (ft.) 0 0 1700 5000

#7 (ft.) 0 0 0 0

Footing32425064

Wall 36 36 36 36

Floor51515151

Total 119 129 139 151

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 11

Page 12

2. Inverted “T” Foundation 4" Outside Stif fened (CFL Series) Commercial Farm Tanks

All foundation specifications shall be construed as

recommendations only. Because of the many

variable conditions in actual installation, GSI

assumes no liability for results arising from the use

of such recommendations.

3500 PSF Soil Bearing Capacity

Inverted “T” Foundation Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3500 PSF. Bearing

capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

Figure 2B

12 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 13

2. Inverted “T” Foundation 4" Outside Stiffened (CFL Series) Commercial Farm Tanks

Diameter of Bin: 54'

Soil Bearing Capacity: 3500 PSF

Ring # 8 10 11 13 14 16 17 19

A 1'-0" 1'-0" 1'-0" 1'-0" 1'-0" 1'-0" 1'-0" 1'-2"

B 2'-3" 2'-10" 3'-6" 4'-3" 5'-1" 5'-9" 6'-6" 8'-9"

C 27'-10" 27'-10" 27'-10" 27'-10" 27'-10" 27'-10" 27'-10" 27'-10"

D 28'-2" 28'-6" 28'-10" 29'-2" 29'-6" 29'-10" 30'-2" 30'-6"

M 5 #4's 6 #4's 6 #4's 7 #4's 7 #4' s 5 #5's 5 #5's 6 #5's

N 2 #5's 3 #5's 4 #5's 5 #5's 5 #5's 6 #5's 7 #5's 10 #5's

P #5 @ 14" c/c #5 @ 14" c/c#5 @ 14" c/c #5 @ 14" c/c #5 @ 14" c/c#5 @ 12" c/c #6 @ 11" c/c #6 @ 10" c/c

#4 (ft.) 6500 6900 6900 7200 7200 4800 4800 4900

Rerod

Cu. Yds.

Concrete

Diameter of Bin: 60'

Soil Bearing Capacity: 3500 PSF

#5 (ft.) 700 900 1200 1500 1600 3700 3000 3400

#6 (ft.) 0 0 0 0 0 0 1200 1700

Footing 15 19 23 28 33 37 42 63

Wall 33 33 33 33 33 33 33 33

Floor 42 42 42 42 42 42 42 42

Total 90 94 98 103 108 112 117 138

Ring #12141618

A 1'-0" 1'-0" 1'-0" 1'-0"

B 3'-10" 4'-11" 6'-2" 7'-1"

C 30'-9" 30'-9" 30'-9" 30'-9"

D 32'-3" 31'-11" 32'-4" 33'-7"

M 5 #5's 6 #5's 7 #5's 5 #6's

N 4 #5's 5 #5's 6 #5's 8 #5's

P #5 @ 14" c/c #5 @ 14" c/c #6 @ 11" c/c #6 @ 7" c/c

#4 (ft.) 5700 5900 590 0 5900

Rerod

Cu. Yds.

Concrete

#5 (ft.) 3300 4100 3900 1600

#6 (ft.) 0 0 1200 4200

#7 (ft.) 0 0 0 0

Footing27354354

Wall 36 36 36 36

Floor 51 51 51 51

Total 114 122 130 141

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 13

Page 14

2. Inverted “T” Foundation 4" Outside Stif fened (CFL Series) Commercial Farm Tanks

All foundation specifications shall be construed as

recommendations only. Because of the many

variable conditions in actual installation, GSI

assumes no liability for results arising from the use

of such recommendations.

4000 PSF Soil Bearing Capacity

Inverted “T” Foundation Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 4000 PSF. Bearing

capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

Figure 2C

14 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 15

2. Inverted “T” Foundation 4" Outside Stiffened (CFL Series) Commercial Farm Tanks

Diameter of Bin: 54'

Soil Bearing Capacity: 4000 PSF

Ring # 8 10 11 13 14 16 17

A 1'-0" 1'-0" 1'-0" 1'-0" 1'-0" 1'-0" 1'-1"

B 1'-11" 2'-5" 2'-11" 3'-7" 4'-3" 5'-0" 5'-8"

C 27'-9" 27'-9" 27'-9" 27'-9" 27'-9" 27'-9" 27'-9"

D 28'-0" 28'-3" 28'-7" 28'-10" 29'-1" 29'-5" 29'-9"

M 5 #4's 6 #4's 6 #4's 7 #4's 5 #5's 5 #5's 5 #5's

N 2 #5's 3 #5's 3 #5's 4 #5's 4 #5's 5 #5's 6 #5's

P #5 @ 14" c/c #5 @ 14" c/c #5 @ 14" c/c #5 @ 14" c/c #5 @ 14" c/c #5 @ 14" c/c #5 @ 10" c/c

#4 (ft.) 6700 7000 7000 7300 4900 4900 4900

Rerod

Cu. Yds.

Concrete

Diameter of Bin: 60'

Soil Bearing Capacity: 4000 PSF

#5 (ft.) 700 900 1000 1200 3100 3400 4000

#6 (ft.)0000000

Footing 13 16 19 23 27 32 36

Wall 31 31 31 31 31 31 31

Floor 41 41 41 41 41 41 41

Total8588919599104108

Ring #12141618

A 1'-0" 1'-0" 1'-0" 1'-0"

B 3'-3" 4'-2" 5'-2" 6'-2"

C 30'-9" 30'-9" 30'-9" 30'-9"

D 31'-8" 32'-1" 32'-6" 32'-11"

M 5 #5's 6 #5's 7 #5' s 5 #6's

N 4 #5's 4 #5's 5 #5's 6 #5's

P #5 @ 14" c/c #5 @ 14" c/c #5 @ 10" c/c #6 @ 8" c/c

#4 (ft.) 5900 5900 5900 5900

Rerod

Cu. Yds.

Concrete

#5 (ft.) 3300 3800 4800 1200

#6 (ft.) 0 0 0 3600

#7 (ft.) 0 0 0 0

Footing23303643

Wall 36 36 36 36

Floor51515151

Total 110 117 123 130

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 15

Page 16

NOTES

16 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 17

T-Cap Foundation Recommendations for

CFL 4" Corrugation Outside Stiffened

Commercial Farm Tanks

®

Section 3

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 17

Page 18

3. T-Cap Foundation Outside Stiffened Commercial Farm Tanks

All foundation specifications shall be construed as

recommendations only. Because of the many

variable conditions in actual installation, GSI

assumes no liability for results arising from the use

of such recommendations.

T-Cap Foundation Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity as specified on each

chart. Bearing capacity of the soils should be determined by geotechnical investigation and be of

uniform bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

Figure 3A

18 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 19

3. T-Cap Foundation Outside Stiffened Commercial Farm Tanks

Diameter of Bin: 54'

Soil Bearing Capacity: 4000 PSF

Rings 20 21

A 1'-5" 1'-7"

B8'-0" 9'-0"

C 27'-11" 27'-11"

D 31'-3" 31'-9"

E 1'-4" 1'-4"

F1'-1" 1'-3"

G 0'-8" 0'-8"

M 5 #5's 5 #5's

N 10 #5's 10 #6's

P #5 @ 8" c/c #6 @ 9" c/c

Q #5 @ 16" c/c #6 @ 18" c/c

R #4 @ 12" c/c #5 @ 12" c/c

#4 (ft.) 2900 0

Rebar

Cu. Yds.

Concrete

#5 (ft.) 12600 11200

#6 (ft.) 0 7100

Footing 73 92

Wall 35 35

Floor 78 86

Total 186 213

Diameter of Bin: 60'

Soil Bearing Capacity: 4000 PSF

Rings 20 21

A 1'-6" 1'-8"

B 8'-6" 9'-10"

C 30'-10" 30'-10"

D 34'-5" 35'-1"

E 1'-4" 1'-4"

F 1'-3" 1'-5"

G 0'-8" 0'-8"

M 5 #5's 6 #5's

N 9 #6's 11 #6's

P #5 @ 8" c/c #6 @ 9" c/c

Q #5 @ 16" c/c #6 @ 18" c/c

R #4 @ 12" c/c #5 @ 12" c/c

#4 (ft.) 3200 0

Rebar

Cu. Yds.

Concrete

#5 (ft.) 13900 13600

#6 (ft.) 3500 8500

Footing 91 1 17

Wall 39 39

Floor 101 111

Total 231 267

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 19

Page 20

NOTES

20 PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins

Page 21

4. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions of

use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1867 Concrete Foundation Recommendations for GSI CFL Grain Bins 21

Page 22

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2012 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-210072

Loading...

Loading...