Page 1

Vision N2 Controller

Models:

PORTABLE DRYERS

User Guide

PNEG-1851

Version 1.0

Date: 11-06-12

PNEG-1851

Page 2

All information, illustrations, photos, and specifications in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any

time without notice.

2 PNEG-1851 Vision N2

Page 3

Table of Contents

Contents

About This Guide......................................................................................................................... v

Chapter 1 Safety Precautions ....................................................................................................................7

Safety Guidelines for Portable Dryers............................................................................................7

Cautionary Symbols ....................................................................................................................9

Safety Decals for Portable Dryers ...............................................................................................10

Chapter 2 The Portable Dryer...................................................................................................................13

Overview of the Portable Dryer ................................................................................................... 13

Dryer Configurations..................................................................................................................15

The Control Panel .....................................................................................................................16

Overview of the User Interface.................................................................................................... 19

A Look at Parameter Fields ........................................................................................................23

Entering Parameter Values with the Keypad ................................................................................24

Chapter 3 Getting Started ........................................................................................................................ 27

Powering On the Dryer...............................................................................................................27

Configuring User Preferences.....................................................................................................28

Configuring Your Dryer’s Hardware ............................................................................................. 29

Setting the Dryer’s Timers and Delays......................................................................................... 30

Drying Grain in the Initial Run .....................................................................................................32

Unloading Grain in the Initial Run ................................................................................................33

Chapter 4 Basic Operations ..................................................................................................................... 35

Setting the Plenum Temperature Range ......................................................................................35

Resetting the Dry Grain Counters ...............................................................................................36

Shutting Off the Dryer at the End of the Day.................................................................................36

Shutting Off the Dryer at the End of the Drying Season .................................................................37

Monitoring Grain and Dryer Data in Real Time ............................................................................. 38

Downloading Dryer Data to a USB Flash Drive.............................................................................38

Chapter 5 The Drying Modes....................................................................................................................41

Continuous Flow Mode .............................................................................................................. 41

Continuous Flow Based on Grain Temperature ............................................................................42

Continuous Flow Based on Grain Moisture .................................................................................. 45

Staged Batch Mode ...................................................................................................................46

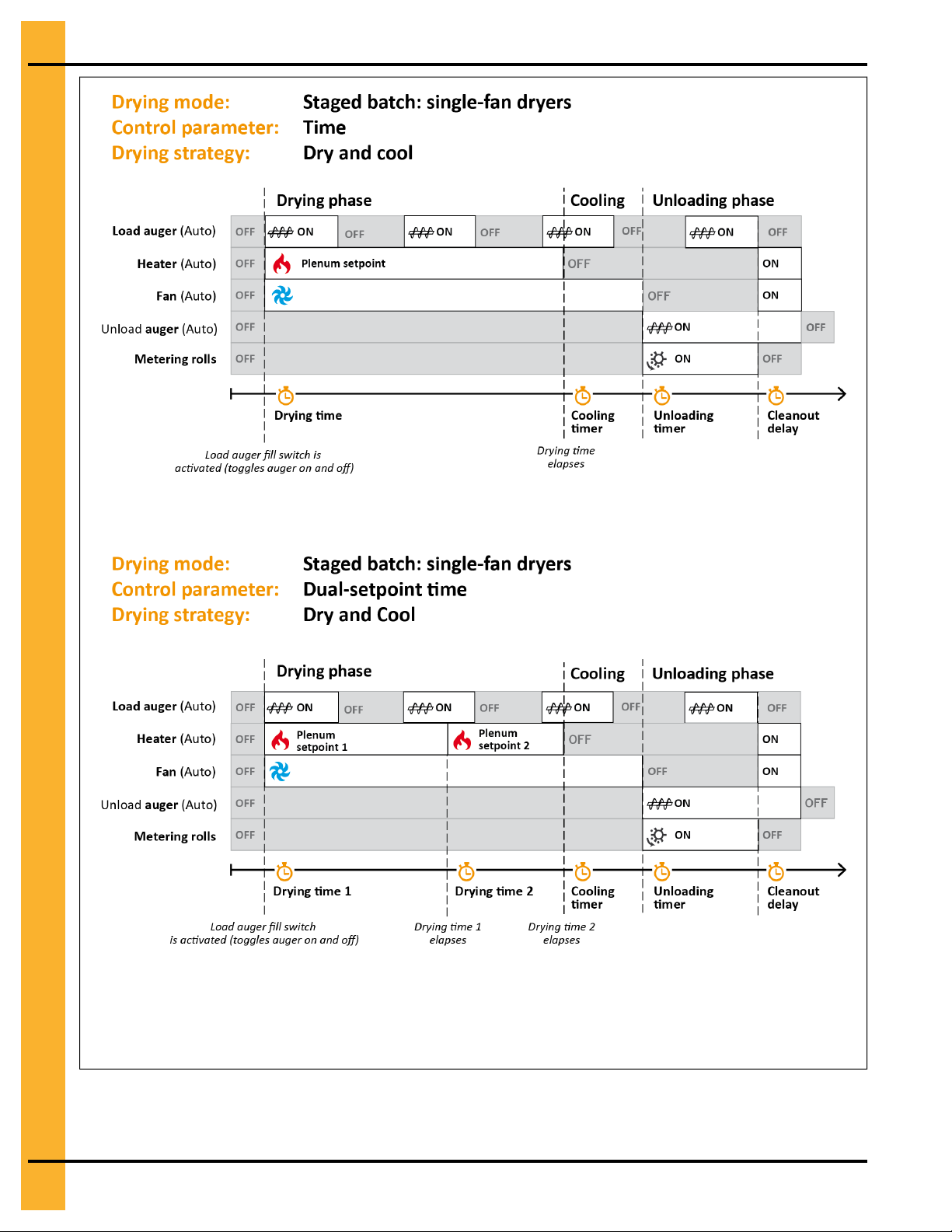

Staged Batch Based on Drying Time ...........................................................................................47

Staged Batch Based on Grain Temperature.................................................................................49

Staged Batch Based on Drying Time and Grain Temperature ........................................................51

Selecting a Drying Mode ............................................................................................................ 52

Chapter 6 The Wet Grain.......................................................................................................................... 53

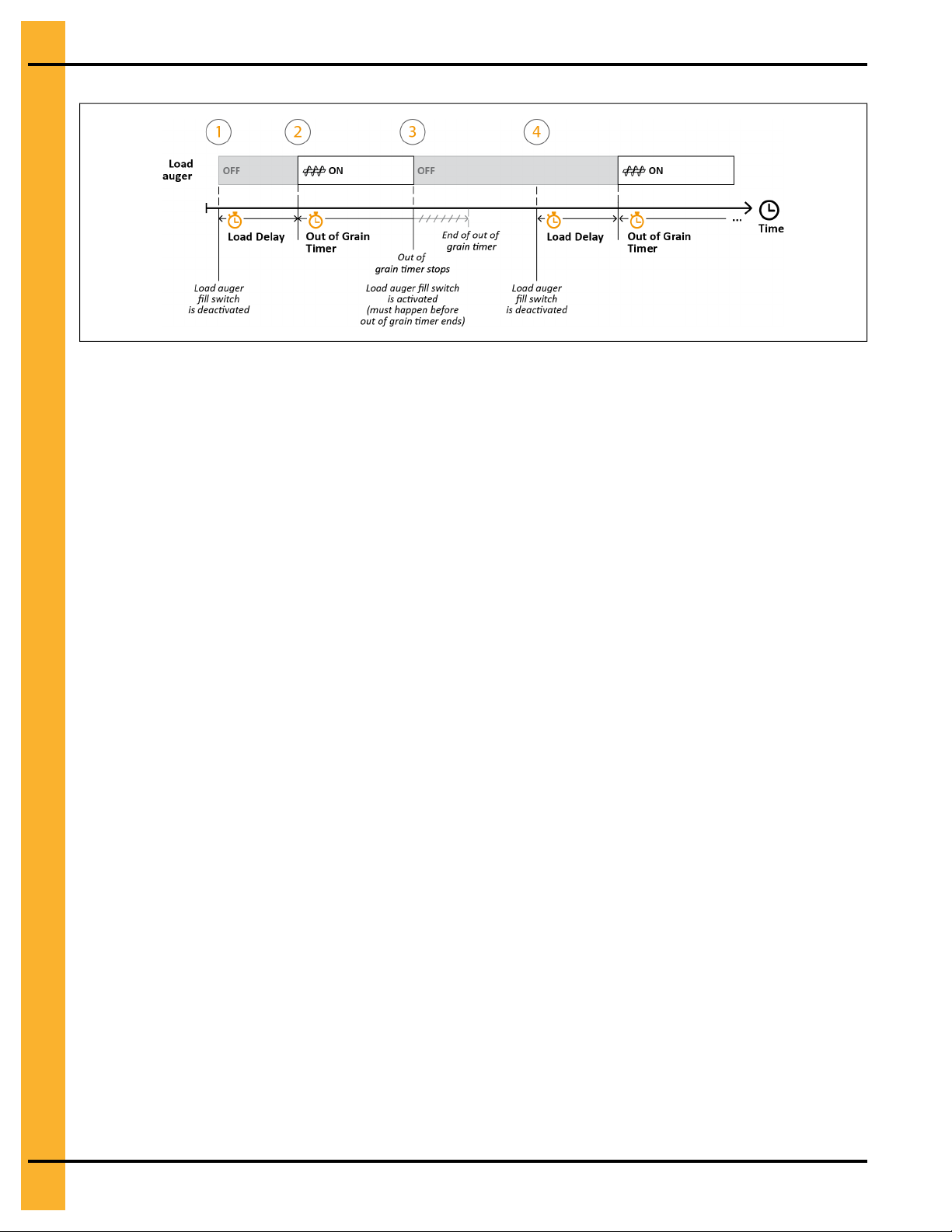

The Loading Process ................................................................................................................. 53

Ensuring Dryer Shutdowns When Supply Is Out of Grain .............................................................. 54

Minimizing Load Auger Startups .................................................................................................55

Validating Incoming Moisture and Temperature Readings ............................................................. 56

Chapter 7 The Continuous Flow Drying Process......................................................................................57

Drying Grain in Continuous Flow.................................................................................................57

Setting the 1-Speed Temperature Scheme in Continuous Flow......................................................58

Setting the 2-Speed Temperature Scheme in Continuous Flow......................................................59

Setting the 5-Speed Temperature Scheme in Continuous Flow......................................................60

Setting the 5-Speed Moisture Scheme in Continuous Flow............................................................ 61

Chapter 8 The Staged Batch Drying Process ...........................................................................................63

Drying Grain in Staged Batch .....................................................................................................63

Setting the Time Scheme in Staged Batch ................................................................................... 64

Setting the Temperature Scheme in Staged Batch ........................................................................65

Setting the Time and Temperature Scheme in Staged Batch .........................................................66

Setting the Dual-Setpoint Time Scheme in Staged Batch ..............................................................67

PNEG-1851 Vision N2 3

Page 4

Table of Contents

Setting the Dual-Setpoint Temperature Scheme in Staged Batch ................................................... 68

Chapter 9 The Dry Grain .......................................................................................................................... 71

Validating Outgoing Moisture And Temperature Readings ............................................................. 71

Cleaning the Dry Sensor ............................................................................................................ 72

Setting the Value Range for the Unload Speed.............................................................................73

Adjusting Unload Speeds in Real Time........................................................................................ 73

Ensuring Accurate Unload Speed Rates......................................................................................74

Appendix A Grain Drying Operations..........................................................................................................77

Drying Grain: A Quick Startup Procedure..................................................................................... 77

Initial Settings for Full-Heat and Dry and Cool .............................................................................. 78

The Burner Modes.....................................................................................................................79

Grain Drying: Full-Heat or Dry and Cool.......................................................................................80

A Glance at Cooling Processes ............................................................................................82

Appendix B Grain Drying Graphs................................................................................................................85

Temperature and Moisture Schemes in Continuous Flow ..............................................................86

Temperature Control Schemes in Staged Batch ........................................................................... 87

Time Control Schemes in Staged Batch.......................................................................................92

Appendix C Messages ................................................................................................................................ 97

The Status Messages ................................................................................................................97

Appendix D List of Parameters ................................................................................................................... 99

Vision N2 Parameters for Portable Dryers.................................................................................... 99

Glossary................................................................................................................................ 107

Index ..................................................................................................................................... 111

GSI Group, LLC Limited Warranty.......................................................................................... 115

4 PNEG-1851 Vision N2

Page 5

About This Guide

This guide contains information on operating portable dryers that are equipped with the Vision N2 Network

Dryer Control. It is intended for operators and service technicians, and can be used by both novice and

experienced users of GSI’s portable dryers.

How This Guide Works

The Vision N2 User Guide contains procedures, examples, references, and conceptual information. It also

includes a comprehensive table of contents and index, thus allowing you, the user, to navigate the document with greater ease and efficiency. This guide also contains a glossary of commonly used terms in the

grain drying environment.

Furthermore, an intuitive web version of this guide can be easily accessed via your Vision N2 controller.

Simply click on the Help icon located at the bottom left corner of your screen to access the web version.

The web version can also be accessed off-site via GSI’s remote web application. In addition, your user

interface contains information icons that are located next to parameter fields. Simply click on a parameter’s

information icon for a timely and concise description of that parameter.

Typographical Conventions

Typographical conventions are visual indicators for specific elements of text. These conventions are used

throughout this guide to indicate specific dryer functions and parameters, notes and warnings, or simply for

textual effect.

The following typographical conventions are used throughout this guide:

• Menus that are displayed in the following manner indicate the click sequence that is required to

access the desired menu or parameter:

System→Preferences→Language

• Text that is displayed in bold typeface indicates a button or switch on the dryer’s control panel, or

denotes a parameter in the Vision N2 user interface.

From the submenu pane, click Time and Date.

On the control panel, turn the Power switch to On.

• Text that is Italicized denotes a hyperlink.

For information on how to use the keypad, see Entering Parameter

Values with the Keypad, page 24.

In the PDF and web versions, hyperlinks are blue. Italics are also used to emphasize the italicized

word.

v

Page 6

Vision N2 Controller

Notes and Notices

The following notes and notices are used throughout this guide:

NOTE: Used to denote supplemental information that is directly related to the text that immediately pre-

cedes or follows it.

Tip

Used to provide advice on a particular subject.

Used to describe a real-life scenario that applies to the information that

precedes it. Examples can be displayed in contextual information to help

explain a concept, after an instructional step in a procedure, or following a

task (Task Example).

IMPORTANT: Used to alert you about a situation with potentially unfavorable consequences.

Used to call attention to a potentially hazardous situation which, if not avoided, might

CAUTION

result in minor, moderate, or serious injury.

DANGER

Used to alert you about an extremely hazardous or potentially lethal situation.

vi

Page 7

1 Safety Precautions

Topics Covered in this Chapter

▪ Safety Guidelines for Portable Dryers

▪ Cautionary Symbols

▪ Safety Decals for Portable Dryers

Safety Guidelines for Portable Dryers

Safety guidelines are general-to-specific rules that promote safe practices in the grain drying environment

and which must be respected at all times. Save these safety guidelines for future reference.

Make sure to read these safety guidelines carefully prior to installing, operating, or

CAUTION

Operation

• Read and fully understand this user guide before attempting to operate the grain dryer.

servicing your grain dryer.

• Never operate the grain dryer with its safety guards removed.

• Never operate the grain dryer by bypassing any safety device.

• Never exceed the maximum recommended drying temperature.

• Do not operate the grain dryer in an area where combustible material might be drawn into the fan.

• The operating and safety recommendations in this guide pertain to common cereal grains, as indicated. When drying other types of grain or products, contact the GSI Group, LLC for additional

recommendations.

Servicing

• The power supply must be disconnected when servicing electrical components. Always use extreme

caution when measuring voltage or performing procedures that require the dryer to be turned on.

• Before attempting to remove and reinstall a fan’s propeller, make sure to read the recommended procedure. If you are unsure about performing this procedure or cannot locate it, contact the GSI Group,

LLC before proceeding.

Pre-Season Mode

• When using a controller with Vision N2 software, the pre-season mode allows the fans and heaters to

operate under normal conditions, without the dryer being completely full of grain. In normal mode, the

dryer generates a Loss of Airflow shutdown if you operate the fans without having the dryer full of

grain.

• Following an extended period of inactivity—typically, at the beginning of the drying season, use preseason mode to fully test the dryer.

PNEG-1851 Vision N2

7

Page 8

Chapter 1: Safety Precautions

• To enable pre-season mode, click System→Control (Advanced)→Board Mode and then select

Pre-season Mode.

• Place the dryer in normal mode once inspections have been completed and you are ready to dry

grain.

IMPORTANT: If you power off the dryer while in pre-season mode, normal mode is automatically

enabled the next time you power on the dryer. Make sure to reselect pre-season

mode if further tests are required.

Cleanliness

• Keep the grain dryer clean at all times.

• Do not allow fine material to accumulate in the plenum chamber.

• An unclean plenum increases resistance to airflow, increases drying time, reduces drying efficiency,

and creates a fire hazard.

• Always keep the area around the fan’s air inlet clear of any obstacles and combustible material.

Augers/Auxiliary Conveyors

Always use extreme caution when working around augers and auxiliary conveyors

CAUTION

because they can start automatically.

• Always keep auger drive belts adequately tensioned to prevent slippage.

• Make sure that the technical specifications and capacities of the auxiliary conveyors are matched to

those of the dryer augers.

Burners/Gas Lines

• Regularly check for leaks at all gas line connections. If any leaks are detected, do not operate the

grain dryer. Shut off the main power and repair the leaks before operating. Gas lines must be

replaced regularly as required by the local gas regulations for your area.

• Routinely check for potential gas plumbing leaks. Check the liquid propane vaporizer for contact with

the burner vanes.

• Never use an open flame to locate gas leaks. Pour a solution of soap and water over the gas pipe

joints and connections, and check for the appearance of small bubbles.

• Set the pressure regulator to avoid applying excessive gas pressure to the burner during ignition or

when the burner is on.

• Do not use flammable or combustible materials in the dryer’s vicinity because explosive vapors can

be drawn into the fan and ignite.

• Always use extreme caution when working around high-speed fans and gas burners because they

can start automatically.

8 PNEG-1851 Vision N2

Page 9

Chapter 1: Safety Precautions

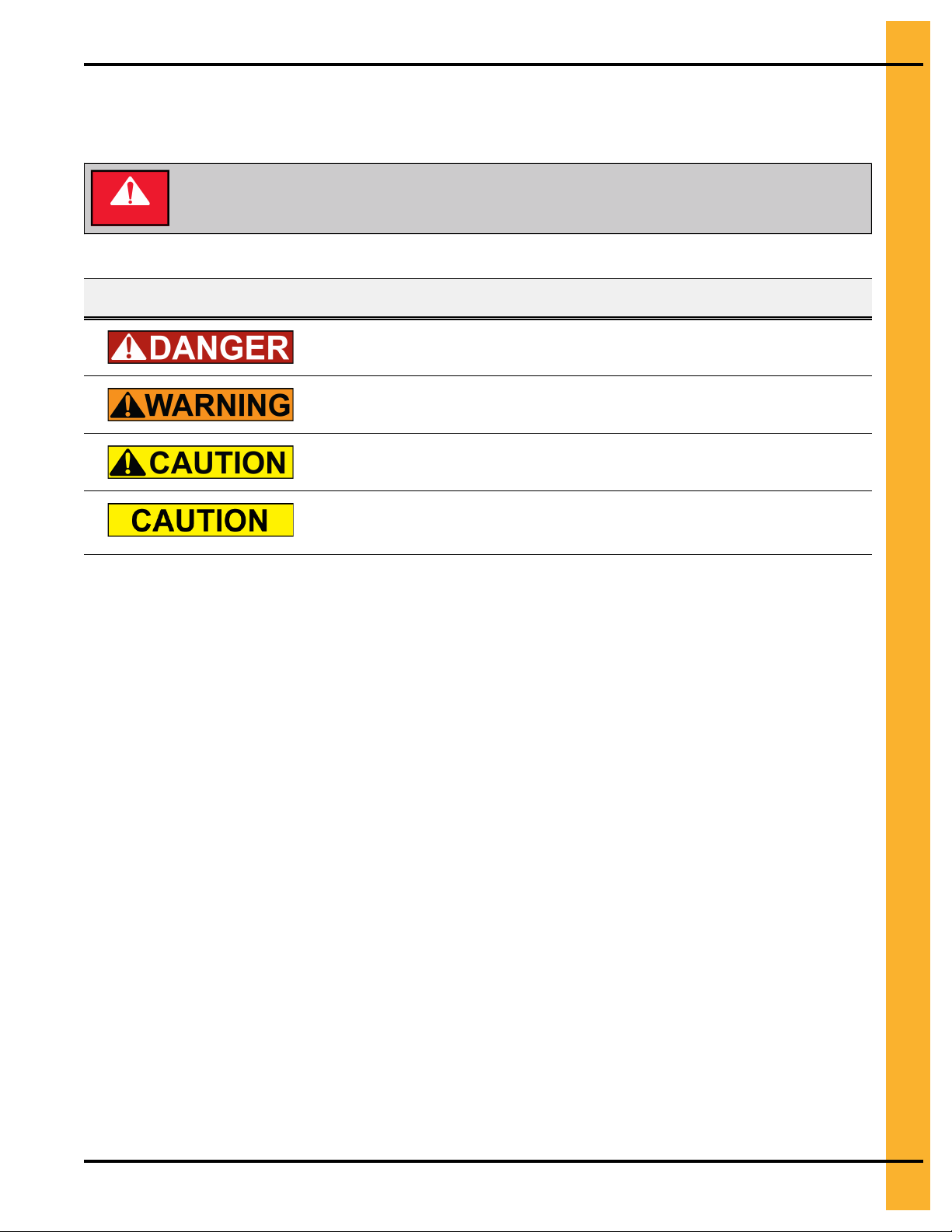

Cautionary Symbols

Cautionary symbols are present in the various decals of your equipment and alert you to the possible or

imminent risk of danger.

Make sure to familiarize yourself with the cautionary symbols prior to installing,

DANGER

Table 1-1 Overview of the different cautionary symbols

operating, or servicing your equipment. Failure to do so might lead to serious injury

or death.

Symbol Description

This symbol indicates an imminently hazardous situation which, if not avoided,

will result in serious injury or death.

This symbol indicates a potentially hazardous situation which, if not avoided,

might result in serious injury or death.

This symbol indicates a potentially hazardous situation which, if not avoided,

might result in minor or moderate injury.

This symbol indicates a potentially hazardous situation which, if not avoided,

might result in property damage.

PNEG-1851 Vision N2 9

Page 10

Chapter 1: Safety Precautions

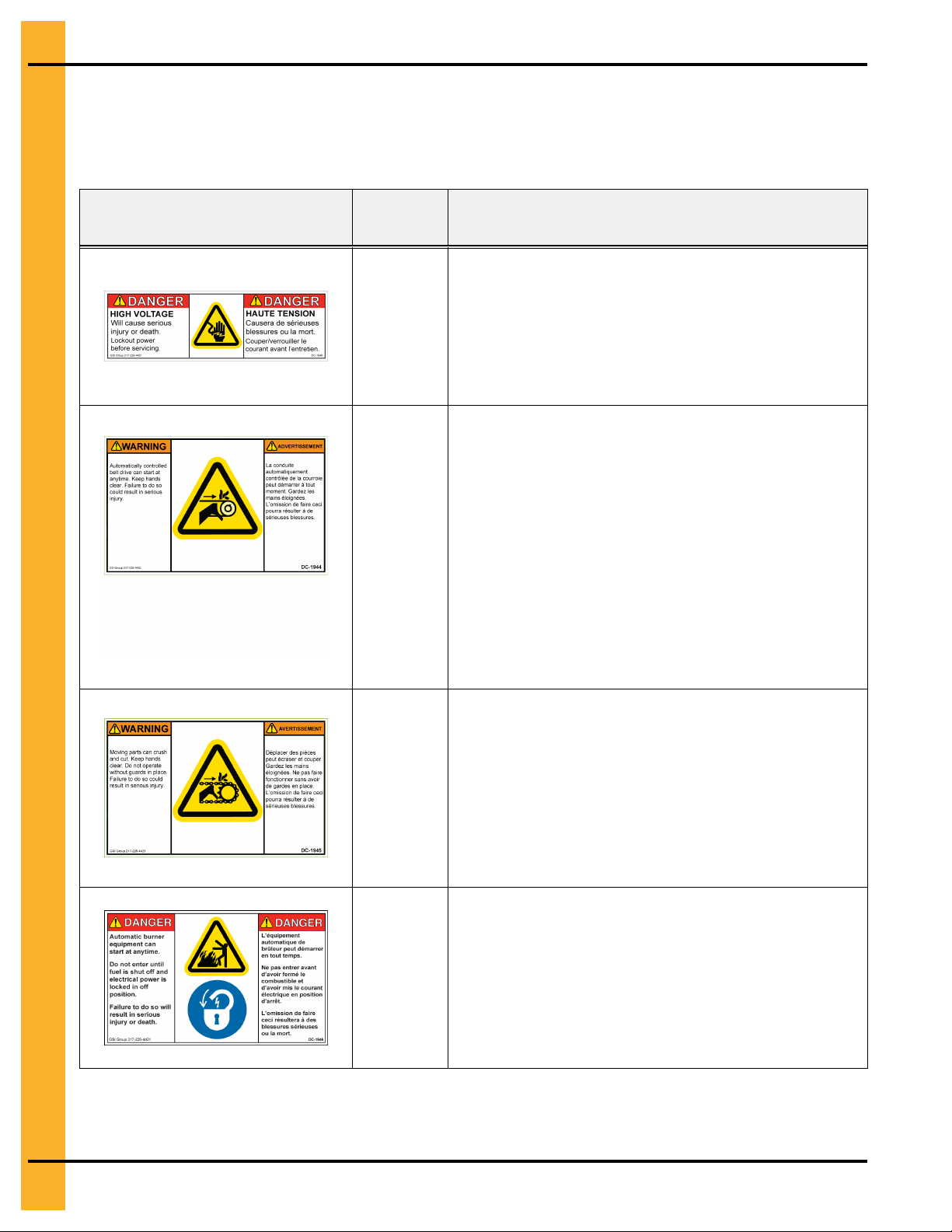

Safety Decals for Portable Dryers

The safety decals on your grain dryer are safety indicators which must be carefully read and understood

by all personnel involved in the installation, operation, service, and maintenance of the grain dryer.

Table 1-2 Description of the grain dryer’s decals

Decal Decal No. Location

This decal appears:

• On the lid of the fan/heater control box

DC-1948

• On the front of the fan/heater control box

• Inside the dryer’s upper control box

This decal appears:

• On the bottom auger belt guard

DC-1944

DC-1945

• On the front bearing plate (visible when the bottom

auger belt guard is removed)

• At the rear of the dryer (for dryers equipped with the

front discharge option)

• On the top auger belt guard

• On the inside belt guard body (visible when the top

auger belt guard is removed)

This decal appears:

• On the bottom auger belt guard

• On the front bearing plate (visible when the bottom

auger belt guard is removed)

• At the rear of the dryer (for dryers equipped with the

front discharge option)

This decal appears:

• On the inside of the rear plenum access door

DC-1946

10 PNEG-1851 Vision N2

• On the outside of the rear plenum access door

Page 11

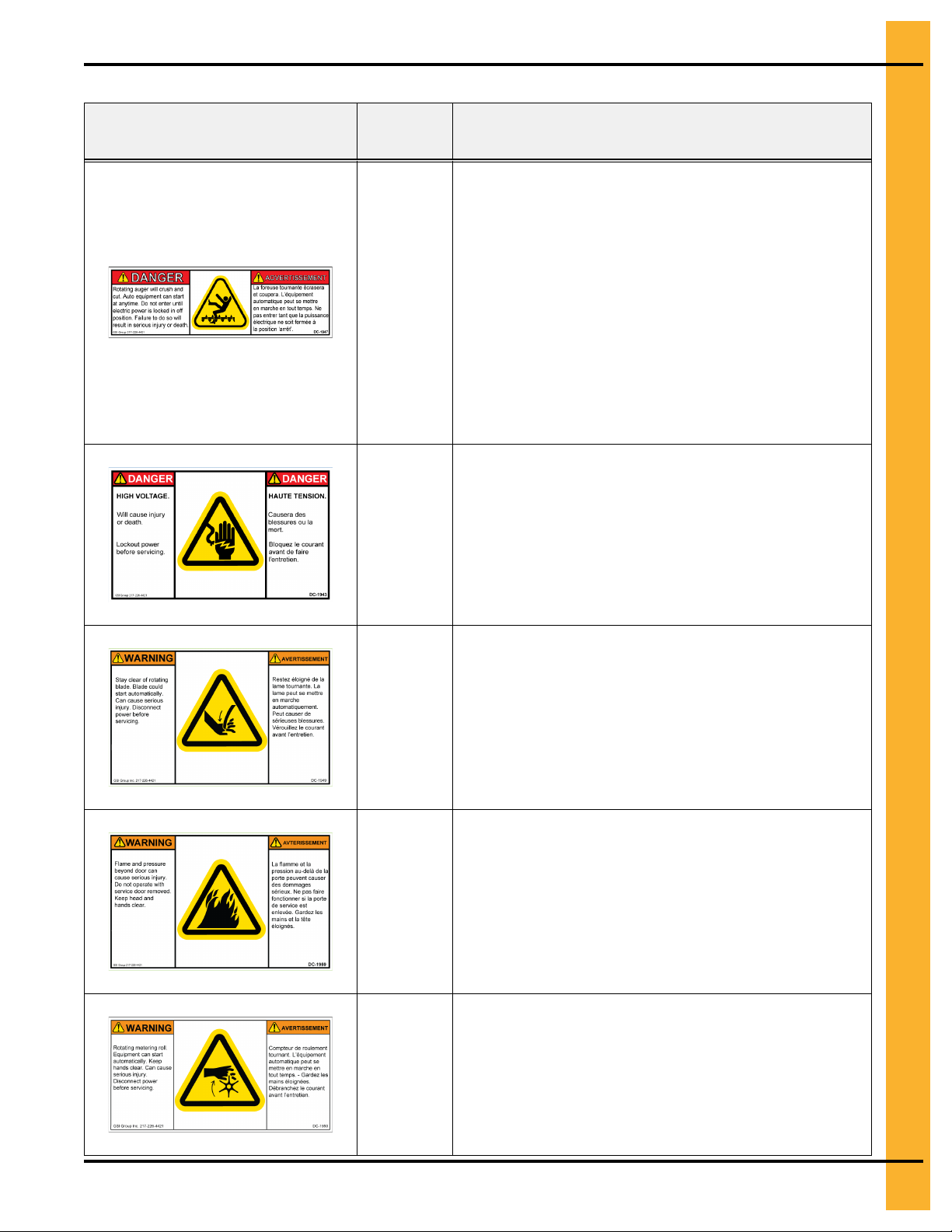

Table 1-2 Description of the grain dryer’s decals (cont'd.)

Decal Decal No. Location

Chapter 1: Safety Precautions

This decal appears:

• Twice on the front end panel, below the fan/heater

• Twice on the rear end panel, below the rear access

door

DC-1947

DC-1943

DC-1949

• On the auger discharge box

• On the inside of the auger discharge box’s flapper lid

(next to the discharge mercury switch)

• Inside the rear access door, on the rear plenum closure door (inside the plenum)

This decal appears:

• Inside the fan/heater control box

• On the door of the dryer’s upper control box

This decal appears on the fan/heater access door

This decal appears on the fan/heater access door

DC-1959

This decal appears on each of the metering roll access

doors

DC-1950

PNEG-1851 Vision N2 11

Page 12

Chapter 1: Safety Precautions

Table 1-2 Description of the grain dryer’s decals (cont'd.)

Decal Decal No. Location

This decal appears on the hitch tongue

DC-1956

This decal appears on the hitch tongue

DC-1954

Replacing Decals

All decals located on your grain dryer must remain legible and clearly visible at all times. To replace a damaged or missing decal, contact us to receive a free replacement.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Tel: 1–217–226–4421

12 PNEG-1851 Vision N2

Page 13

2 The Portable Dryer

Topics Covered in this Chapter

▪ Overview of the Portable Dryer

▪ Dryer Configurations

▪ The Control Panel

▪ Overview of the User Interface

▪ Entering Parameter Values with the Keypad

Overview of the Portable Dryer

Portable dryers are modular grain dryers that can operate in batch and continuous flow, and where wet

grain is dried in a drying column that is separate from the wet grain and dried grain storage bins.

GSI portable dryers are available in multiple module configurations. For details on the different dryer configurations, see Dryer Configurations, page 15.

NOTE: Images of the dryer, control panel, and user interface menus that are included in this guide are for

illustrative purposes only and might not entirely resemble the actual product.

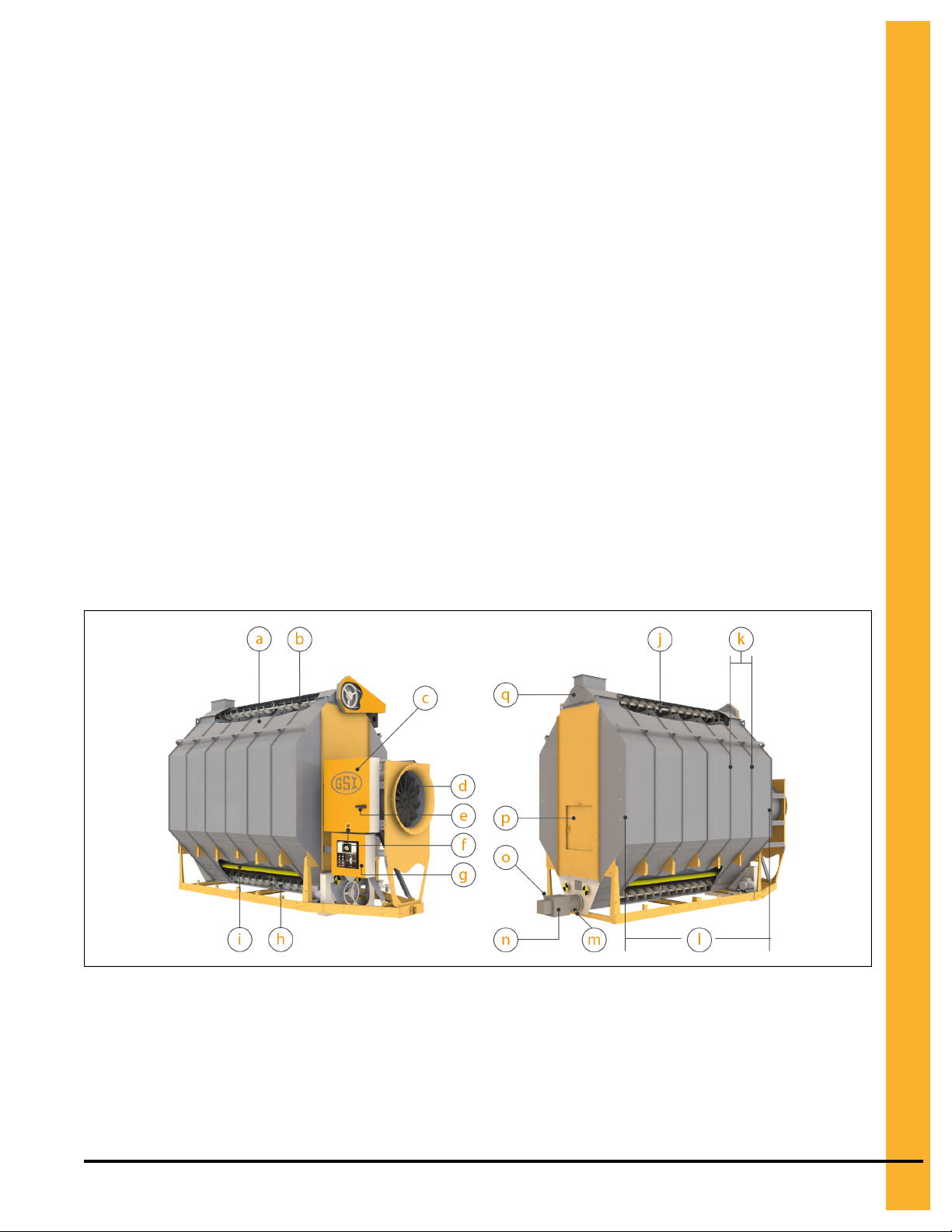

Figure 2-1 A 1-module, 1-fan portable dryer and its main components

NOTE: For definitions of the most commonly used grain drying terms, refer to this guide’s glossary.

PNEG-1851 Vision N2 13

Page 14

Chapter 2: The Portable Dryer

Table 2-1 The main components of the portable dryer

Item Name Description

a

Dryer wet bin

b Load auger The auger that distributes grain inside the dryer wet bin

c

Main control box The electrical cabinet that serves as the dryer’s power distribution panel

d Fan and heater A one-piece unit that blows hot air inside the plenum when the fan and heater are

e

Main electrical disconnect switch/

handle

f Emergency stop (e-

stop) button

g

Control panel The panel that contains the graphical user interface and all dryer control switches

h Unload auger

The compartment that maintains an adequate level of wet grain to ensure proper

air seal; contains the load auger, wet sensor, and load auger fill switch

on, and blows cool air when the heater is off and the fan is on

A safety switch that is used to turn off and lock out the main power to the dryer

A safety device used to turn off the dryer’s control power and immediately stop all

of its functions (the main power, which is controlled by the main electrical disconnect, does not turn off when you press the Emergency Stop button)

and buttons

The auger that moves the dry grain out from the unload chamber

i Metering roll

j

Load auger fill

switch

k

Grain column The column upon which the grain travels down; each grain column is 2 ft (61 cm)

l Dryer length

m

Grain sampler A manually rotatable grain outlet from which a sample of dry grain can be collected

n

Grain discharge

box

o

Dry sensor

p

Plenum access

door

q

Wet sensor

A rotating device that controls the rate at which grain moves from the grain columns to the unload auger

The limit switch that is activated once the dryer wet bin is full

wide

The combined length of all grain columns (see Configuring Your Dryer’s Hardware,

page 29 to enter this setting)

(see Validating Outgoing Moisture And Temperature Readings, page 71)

The dry grain outlet that contains the grain discharge limit switch

The sensor that measures the dry grain’s moisture; requires regular and frequent

calibrations (see Validating Outgoing Moisture And Temperature Readings, page

71)

Allows you to access the plenum chamber

The sensor that measures the wet grain’s moisture and temperature; requires regular and frequent calibrations (see Validating Incoming Moisture and Temperature

Readings, page 56)

14 PNEG-1851 Vision N2

Page 15

Chapter 2: The Portable Dryer

Make sure to turn off the main electrical disconnect switch prior to servicing your

dryer. Only the main electrical disconnect switch turns off power to the dryer and all

DANGER

electrical cabinets. Failure to do so might lead to serious injury or death.

Pressing the Emergency Stop button stops dryer functions but does not turn off the

power that is present at the various electrical cabinets. Turn off the main electrical

DANGER

disconnect switch to shut off power to the dryer and all electrical cabinets. Failure to

do so might lead to serious injury or death.

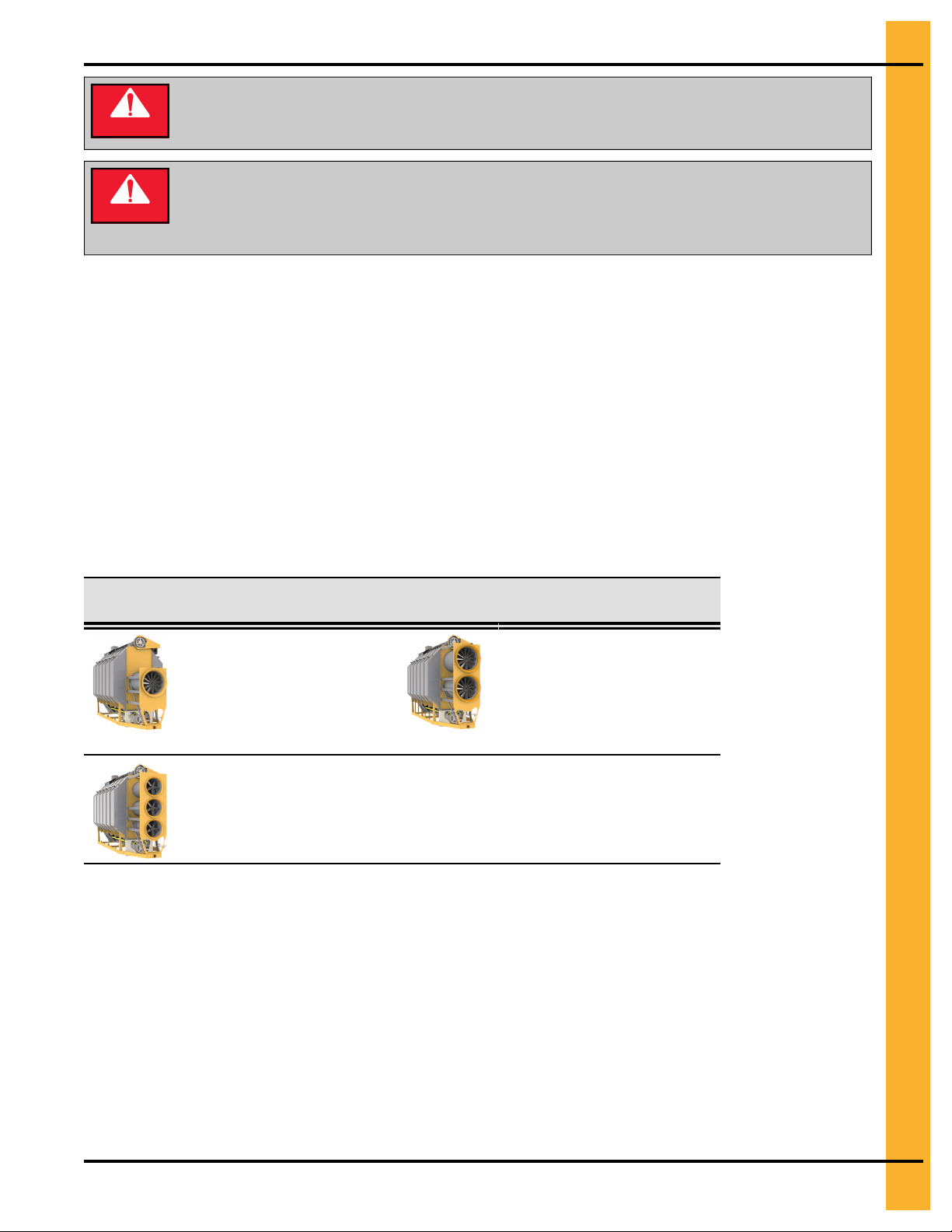

Dryer Configurations

As a result of their modular design, portable dryers are available in several fan and heater configurations,

thus making them practical in their functionality and customizable to your grain drying needs.

The following table outlines the different dryer configurations for portable dryers. Make sure to identify your

specific configuration before completing the hardware setup (see Configuring Your Dryer’s Hardware,

page 29 for details).

IMPORTANT: Make sure to enter the number of modules that corresponds to your actual dryer configura-

tion. If you enter a value that is greater or less than the actual number, the dryer will not

start because the system will search for missing or undeclared fans or heaters.

Table 2-2 The available configurations for portable dryers

Dryer configuration

Description Dryer con-

figuration

1-module, 1-fan portable

dryer

This single-module configuration includes one fan,

one heater, and one

plenum chamber

1-module, 3-fan portable dryer

This single-module configuration includes three fans, three heaters, and

three plenum chambers

Description

1-module, 2-fan portable

dryer

This single-module configuration includes two fans, two

heaters, and two plenum

chambers

PNEG-1851 Vision N2 15

Page 16

Chapter 2: The Portable Dryer

Table 2-2 The available configurations for portable dryers (cont'd.)

Dryer configuration

Description Dryer con-

figuration

2-module, 3-fan portable

dryer

This dual-module configuration includes three fans,

three heaters, and three

plenum chambers

3-module, 4-fan portable

dryer

This three-module configuration includes four fans,

four heaters, and four

plenum chambers

Description

2-module, 4-fan portable

dryer

This dual-module configuration includes four fans, four

heaters, and four plenum

chambers

3-module, 6-fan portable

dryer

This three-module configuration includes six fans, six

heaters, and six plenum

chambers

NOTE: Images of the dryer, control panel, and user interface menus that are included in this guide are for

illustrative purposes only and might not entirely resemble the actual product.

The Control Panel

Along with the touchscreen user interface, the control panel contains all buttons and switches that allow

you to set up and operate your dryer.

The following figure illustrates the Vision N2 control panel.

NOTE: Images of the dryer, control panel, and user interface menus that are included in this guide are for

illustrative purposes only and might not entirely resemble the actual product.

16 PNEG-1851 Vision N2

Page 17

Figure 2-2 The Vision N2 control panel

Chapter 2: The Portable Dryer

NOTE: The number of fan and heater switches on your control panel depends on the number of fans and

heaters that your dryer is equipped with.

Table 2-3 The components of the control panel

Item Name Description

a

b Heater switch

c

Touchscreen

Dryer configuration A visual representation of your particular dryer configuration

Allows you to access all of the user interface menus and set all parameters

(see Overview of the User Interface, page 19 for details)

Controls the heaters by way of the following modes:

• Off: the heaters do not run

• On: the heaters run when the fans are running and air pressure is

detected

• Auto: used in staged batch mode and controlled via a timer, temperature, or both, the heaters only run during the drying phase

PNEG-1851 Vision N2 17

Page 18

Chapter 2: The Portable Dryer

Table 2-3 The components of the control panel (cont'd.)

Item Name Description

d Fan switch

e

Unload auger switch

Controls the fans by way of the following modes:

• Off: the fans do not run

• On: the fans run continuously in both continuous flow and staged

batch modes

• Auto: used in staged batch mode and controlled via a timer, temperature, or both, the fans run during the drying and cooling phases, but

turn off once the unloading phase begins

Controls the metering rolls and unload auger by way of the following modes:

• Off: the metering rolls and unload auger do not run

• On: the metering rolls only turn at one speed (in both continuous flow

and staged batch), and the unload auger operates when the metering

rolls are running; also known as manual mode (see Unloading Grain in

the Initial Run, page 33)

• Auto: in continuous flow, the metering rolls turn at the speed dictated

by the selected moisture control scheme, and the unload auger runs

continuously; in staged batch mode, the metering rolls and unload

auger only run during the unloading phase

Note the following:

Load auger switch

f

• The Unload Auger switch is illuminated whenever the unload auger is

running

• If auxiliary unloading equipment is configured and connected to your

dryer, the Unload Auger switch also controls the operation of this additional equipment.

Controls the load auger by way of the following modes:

• Off: the load auger does not run

• On: the load auger runs when the dryer is low on grain and stops when

the dryer wet bin is full; in this mode, the load delay and out of grain

timer are disabled; also known as manual mode

• Auto: the load auger runs when the dryer is low on grain and stops

when the dryer wet bin is full; in this mode, the load delay and out of

grain timer are enabled (for the load delay, see Minimizing Load Auger

Startups, page 55; for the out of grain timer, see Ensuring Dryer Shut-

downs When Supply Is Out of Grain, page 54)

Note the following:

• The Load Auger switch is illuminated whenever the unload auger is

running

• If auxiliary loading equipment is configured and connected to your

dryer, the Load Auger switch also controls the operation of this additional equipment.

18 PNEG-1851 Vision N2

Page 19

Chapter 2: The Portable Dryer

Table 2-3 The components of the control panel (cont'd.)

Item Name Description

g

Stop button Stops all dryer functions; not to be confused with Stop Dryer, which is

included in the user interface’s main menu (see Overview of the User Inter-

face, page 19 for details)

h

Start button Starts the grain drying cycle

i Power switch

j Light switch

Turns the dryer’s control power on or off

Turns the dryer’s service light on or off; in auto mode, the light remains lit

while the dryer is in operation and turns off if a shutdown situation occurs

The Power switch controls dryer functions but does not control the power that is

CAUTION

present at the various electrical cabinets. Turn off the main electrical disconnect

switch to shut off power to the dryer and all electrical cabinets.

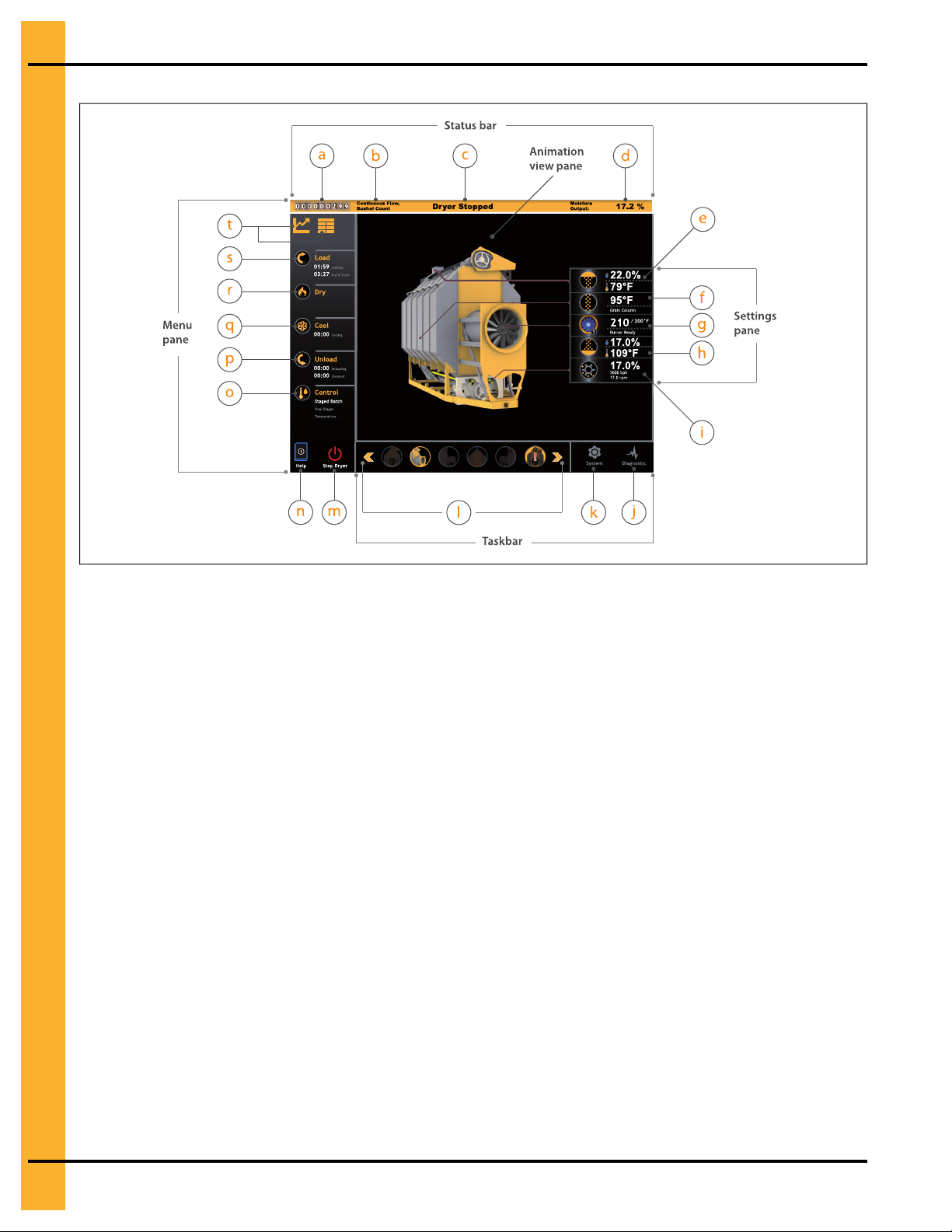

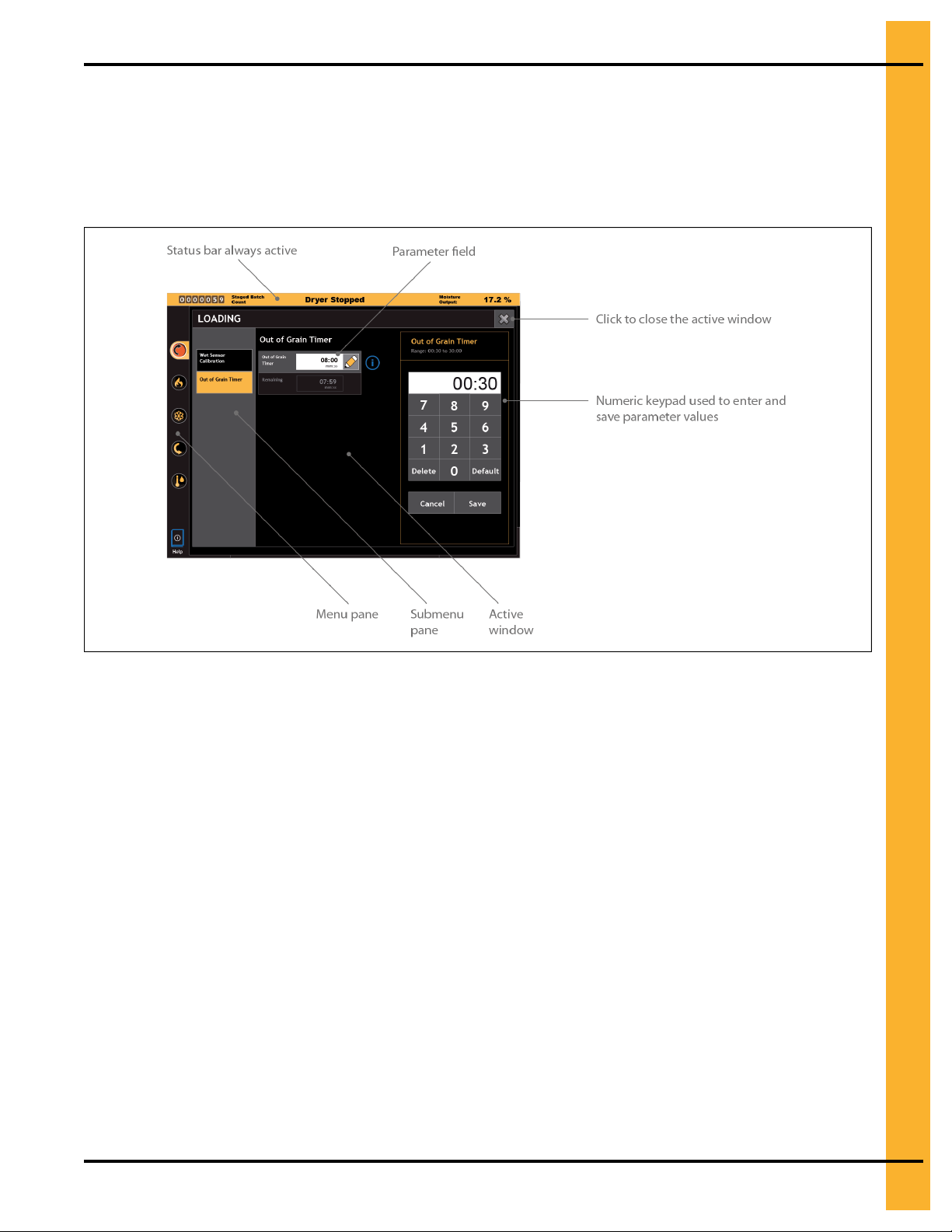

Overview of the User Interface

The user interface allows you to access all operation and information windows via a touch-sensitive

screen. The interface includes an intuitive menu structure that allows you to easily locate parameter settings and system information.

The Main Menu

The main menu serves as a starting point for all your dryer-related operations. In addition to providing

access to all parameter settings, the main menu is easily customizable and displays essential, real-time

temperature and moisture readings. If you think that a touchscreen calibration is required while you navigate the various menus, simply access the Touchscreen Calibration submenu in the System menu and

follow the onscreen instructions. The Touchscreen Calibration submenu is not accessible when you are

operating the dryer via GSI’s remote web application.

PNEG-1851 Vision N2 19

Page 20

Chapter 2: The Portable Dryer

Settings

pane

Menu

pane

Status bar

Taskbar

01: 59

Loading

03: 27

Out of Grain

00: 00

Unloading

00: 00

Clea

nout

Tempe ratu re

Dual Sta ges

Stage d Bat ch

00: 00

Cooling

Load

Dry

Cool

Unloa d

Cont ro l

Sys

te m

Dia

gnost ic

Stop DryerHelp

95°F

22.0%

79°F

17.0%

109°F

17.0%

2000 bp h

17.0 r pm

Grain Colum n

210

/ 2 00° F

Burner Ready

1

Continuous F lo w,

Bushel Count

Moi st u re

Ou tp ut :

Dr ye r S t o ppe d 17 .2 %

9

00

a

b

c

d

s

t

e

i

j

k

f

g

h

r

q

p

o

mn

Animation

view pane

l

Figure 2-3 The main menu

NOTE: Due to the numerous configurations and options available, images of the dryer and its user inter-

face that are included in this guide might differ from the actual product.

20 PNEG-1851 Vision N2

Page 21

Table 2-4 Description of the main menu’s buttons and displays

Chapter 2: The Portable Dryer

Menu Area Item Name

Dry grain and staged batch

a

counter

Drying mode display

b

Status bar

Settings pane

c Dryer status display Displays the dryer’s current status

Outgoing moisture or grain

d

column temperature display

Incoming grain’s temperature/

e

moisture display

Grain column temperature

f

display

Plenum setpoint shortcut and

g

burner status display

Outgoing grain’s temperature

h

and moisture display

Description

In continuous flow, displays the total grain output; in

staged batch, displays the total batch count

Displays the selected drying mode and its associated output counter

Depending on the selected control scheme, displays

either the outgoing moisture level or the temperature

reading inside the dryer’s grain columns

Shortcut that allows you to quickly calibrate the

moisture value and the grain temperature of the wet

grain; displays the wet grain’s temperature and

moisture readings

Displays the average temperature of the grain

Shortcut that allows you to quickly modify the

plenum setpoint; displays current plenum temperature reading and burner status

Shortcut that allows you to quickly calibrate the

moisture value and the grain temperature of the dry

grain; displays the dry grain’s temperature and moisture readings

Taskbar

Shortcut that allows you to quickly modify the meter-

Metering roll speed display

i

j Diagnostic menu button Allows you to access the Diagnostic menu

System menu button Allows you to access the System menu

k

Dryer view toolbar

l

ing roll speed; displays the actual metering roll

speed

Allows you to select the dryer view that is displayed

in the animation view pane

PNEG-1851 Vision N2 21

Page 22

Chapter 2: The Portable Dryer

Table 2-4 Description of the main menu’s buttons and displays (cont'd.)

Menu Area Item Name

Stop Dryer button (remote

m

access only)

Dryer documentation button

n

o Control menu button and display

p

Menu pane

Unload menu button and display

q

Cool menu button and display

Dry menu button and display Allows you to access the Drying menu

r

s Load menu button and display

Dryer data buttons (Dryer Data:

Graph View; Dryer Data: Table

t

View)

Description

Allows you to stop the dryer via a remote connection; this button is only available on your dryer’s

remote web application, not the actual dryer

Allows you to consult the dryer’s user

documentation

Allows you to access moisture control settings; displays selected drying mode, control scheme, countdown of drying time (in staged batch only),

temperature setpoints, or a combination thereof

Allows you to access the Unloading menu; displays

a countdown of the unload time (in staged batch

only) and cleanout delay

Allows you to access the Cooling menu; displays a

countdown of the cooling timer (in staged batch

only)

Allows you to access the Loading menu; displays a

countdown of the load delay and out of grain timer

Allows you to monitor dryer data in either graph

format (on the left) or table format (on the right)

Animation

view pane

Displays the dryer view selected from the animation view toolbar; the alarm window opens here

when a shutdown fault occurs

NOTE: Regardless of which menu or submenu you are in, the status bar is always displayed atop the

active window. This allows you to constantly keep track of your dryer’s status.

How the Main Menu Works

As defined by the menu pane, grain drying is performed in the following five steps:

1. Loading the grain (Loading menu)

2. Drying/heating the grain (Drying menu)

3. Cooling the grain (Cooling menu)

4. Unloading the grain (Unloading menu)

5. Adapting dryer functions to modify the grain’s moisture content (Control menu)

NOTE: Cooling the grain inside the dryer is an optional step. Depending on your preference or grain drying

setup, you can choose to cool grain in dedicated cooling bins. See A Glance at Cooling Processes,

page 82 for more information.

To help you navigate the user interface or find the submenu for a particular setting, consider a logical,

sequenced approach to grain drying and its related tasks. Begin by answering the question: Which of the

five steps of grain drying does the topic I’m searching for apply to? For example, to configure anything pertaining to the dryer’s loading operation (out of grain timer, wet sensor calibration, etc.), simply click Load

and then choose the desired parameter from the submenu.

22 PNEG-1851 Vision N2

Page 23

Chapter 2: The Portable Dryer

The Submenu Window

Via the various submenus, you can access and set all parameters that are required in the daily operation

of your dryer. The figure that follows illustrates a typical submenu.

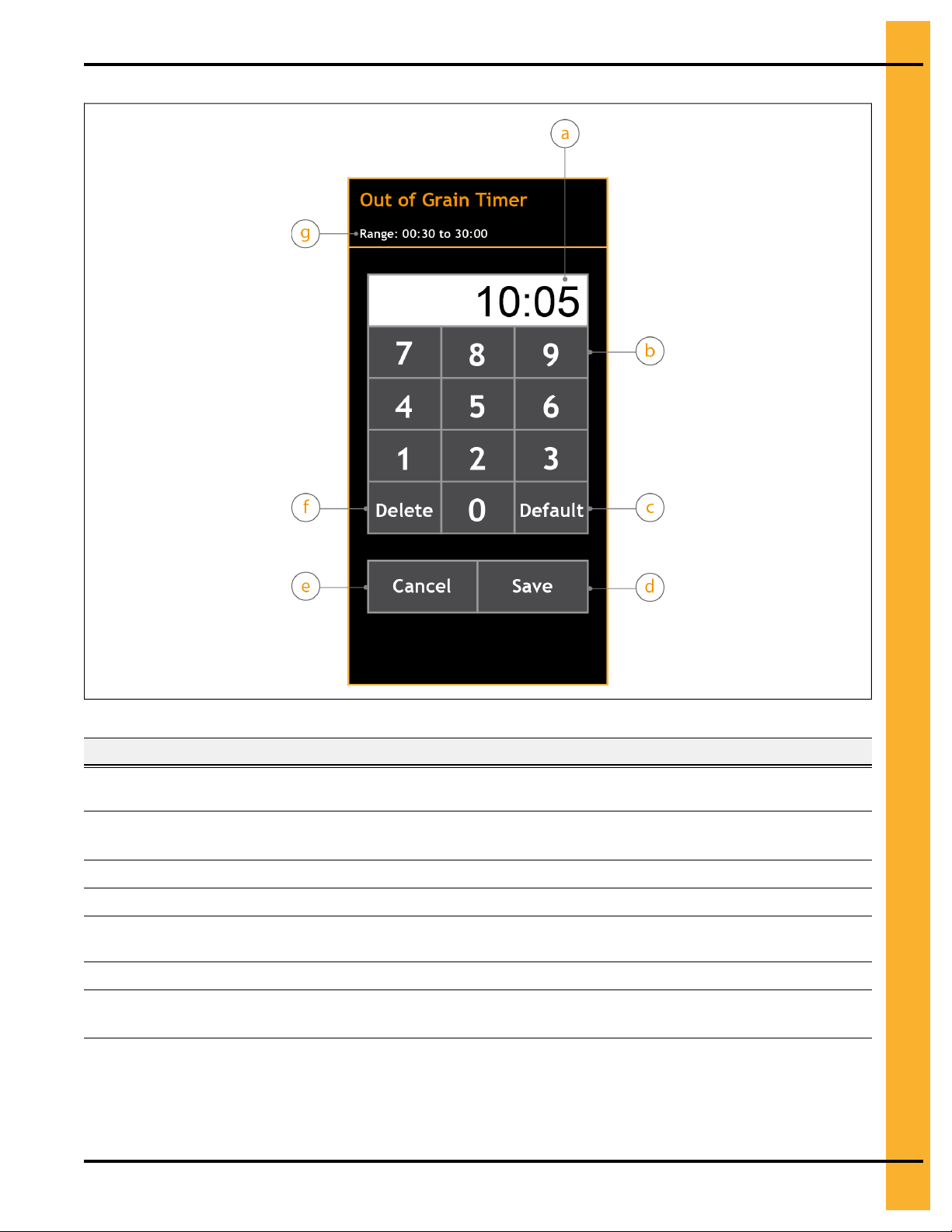

Figure 2-4 The Out of Grain Timer submenu

How the Submenu Window Works

When working in submenu windows, remember the following:

• You can only access and modify parameter settings through their respective parameter fields.

• The numeric keypad is only displayed when you click the parameter field’s Edit icon, and remains

onscreen until you either save or cancel your entry. For information on how to use the keypad, see

Entering Parameter Values with the Keypad, page 24.

• When the numeric keypad is not active, a view of your dryer’s configuration is displayed.

• You must close the active submenu window to return to the main menu.

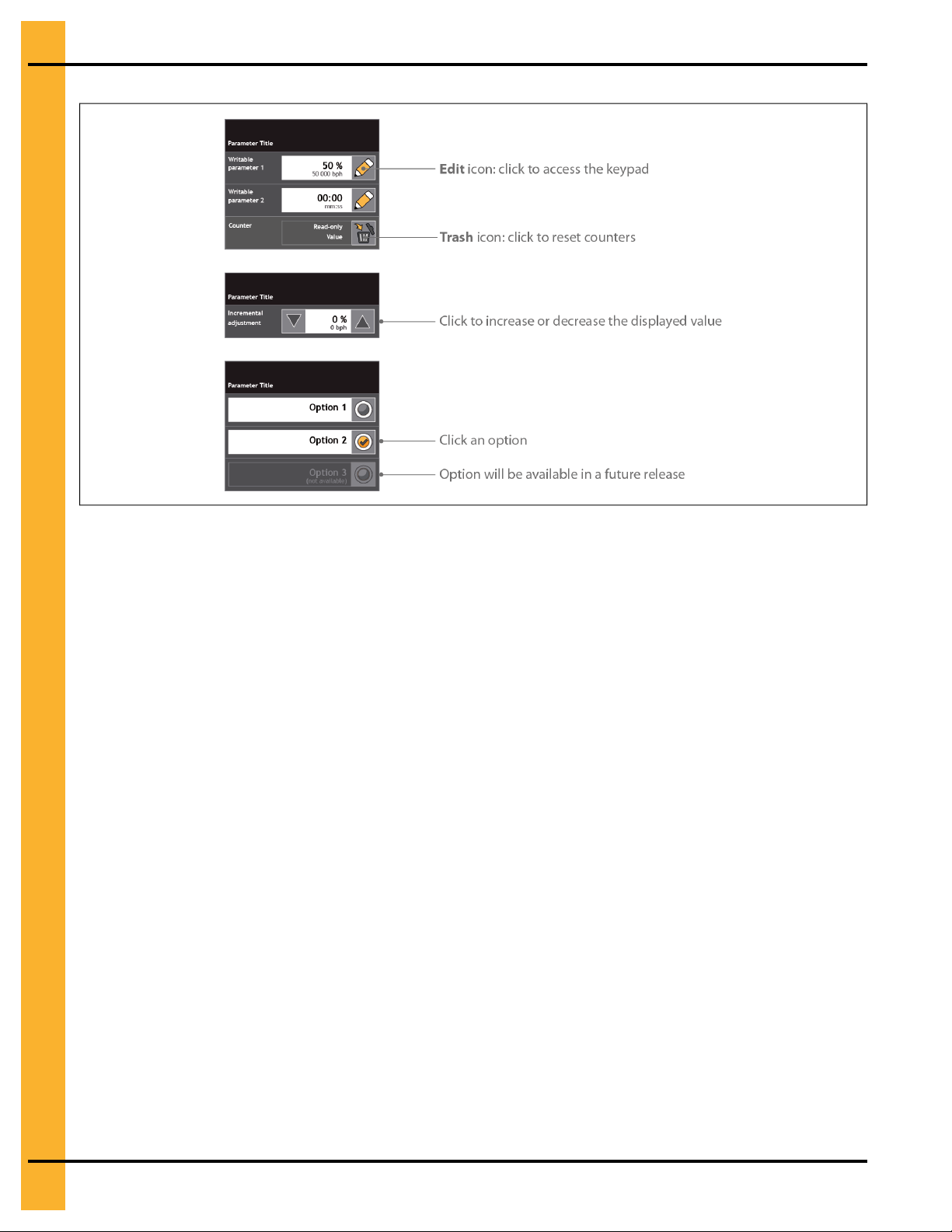

A Look at Parameter Fields

Parameter fields fall into two main categories: writable or read-only. The former allows you to enter and

modify values for specific parameters, whereas the latter merely displays a value that cannot be edited.

The figure that follows illustrates the different types of parameter fields that are available in your dryer’s

user interface.

PNEG-1851 Vision N2 23

Page 24

Chapter 2: The Portable Dryer

Figure 2-5 Samples of the various parameter fields

NOTE: Images of the dryer, control panel, and user interface menus that are included in this guide are for

illustrative purposes only and might not entirely resemble the actual product.

What You Should Know

When entering parameter values, remember the following:

• Except for the parameter shortcuts in the main menu’s system pane, the keypad is only accessible

through the Edit icon.

• The Remaining field always displays a countdown of the timer or delay that is directly above it.

Simply click its Edit icon to interrupt the countdown and enter a new value.

• When you click the Trash icon in counter fields, the displayed count is permanently erased and

cannot be retrieved.

• Not all entries made using the incremental adjustment buttons take immediate effect; some require

you to click Save to store your settings.

• In some instances, the up/down arrow buttons used for incremental adjustments might be replaced

by + and – buttons.

Entering Parameter Values with the Keypad

For parameters whose values are modifiable via the Edit icon, you can enter and save their values using

the numeric keypad.

What You Should Know

The keypad is used to enter numeric values pertaining to speed, timers or delays, and temperature or

moisture content, in a format that is unique to each type. For example, some temperature parameters

require you to enter one digit to the right of the decimal separator and others do not. Always refer to the

parameter range appearing at the top of the keypad for the required format. The following figure shows a

typical numeric keypad.

24 PNEG-1851 Vision N2

Page 25

Figure 2-6 The numeric keypad for the out of grain timer

Chapter 2: The Portable Dryer

Table 2-5 Description of the keypad

Item Name

a Value display

b

c Default key Enters the parameter’s default value

d

e Cancel key

f

g

Numeric keys (0 to 9)

Save key Allows you to store the newly entered value

Delete key Allows you to clear the displayed value

Parameter range

Description

Shows the parameter’s current value once the keypad is displayed

and the new value once it is entered

Allows you to enter parameter values; entries start from the far right

of the decimal separator and move left

Allows you to exit the keypad without saving the value and return to

the active window

Displays the parameter’s allowable value range; an error message

is displayed when the entered value is out of range

To enter parameter values using the keypad:

1. From the parameter’s submenu window, click the parameter’s Edit icon.

PNEG-1851 Vision N2 25

Page 26

Chapter 2: The Portable Dryer

The keypad is displayed and the submenu window is no longer active. The parameter’s current value

is shown in the keypad’s value display.

2. Using the numeric keys, enter a new value that is within its allowable range. To enter the parameter’s

default value, click Default.

To enter 10 minutes and 5 seconds for the out of grain timer parameter,

click 1, 0, 0, 5.

The value is displayed in the keypad’s value display. If the entered value is out of range, an error

message is displayed.

3. Click Save to store the value, or click Cancel to exit without saving and return to the active window.

The keypad is no longer onscreen and the newly entered value is displayed in the respective parameter field.

NOTE: If the newly entered value is not displayed in its respective parameter field once you exit the

keypad, the value has not been stored and is not active.

26 PNEG-1851 Vision N2

Page 27

3 Getting Started

Topics Covered in this Chapter

▪ Powering On the Dryer

▪ Configuring User Preferences

▪ Configuring Your Dryer’s Hardware

▪ Setting the Dryer’s Timers and Delays

▪ Drying Grain in the Initial Run

▪ Unloading Grain in the Initial Run

Powering On the Dryer

After it has been thoroughly inspected, you can turn on your dryer to perform a touchscreen calibration, set

all of the required parameters, and begin drying grain.

Before You Begin

• Make sure that all dryer functions were properly verified and all motors, augers, belts, gear boxes,

electrical boxes, and other components were inspected by authorized maintenance personnel.

• Make sure that the Emergency Stop button on the main control box is in its fully-retracted position

(unlocked).

• If using GSI’s remote web application, make sure that the hardware setup is configured prior to starting the application (System→Hardware Setup). You must complete the hardware setup on-site

before accessing the dryer off-site.

The dryer and all of its components and functions must be in good working order

CAUTION

To power on the dryer:

1. On the control panel, turn off the following:

2. On the dryer’s main control box, place the safety disconnect switch in the On position.

3. On the control panel, turn the Power switch to On.

prior to starting the dryer. Perform thorough inspections at regular intervals,

especially when the dryer has not been in use for extended periods.

• All Fan switches

• All Heater switches

• The Load Auger switch

• The Unload Auger switch

The switch is illuminated, the controller turns on, and the startup window is displayed. During this

time, no onscreen area is active.

PNEG-1851 Vision N2 27

Page 28

Chapter 3: Getting Started

NOTE: The Configuration Status dialog box is displayed in certain situations, most notably upon

startup and after clearing shutdown messages. It remains active for a few seconds before

closing automatically.

4. Once the software is ready, click the Start Software button.

If the touchscreen is calibrated, the software starts immediately and the main menu is displayed. If

not calibrated, the Touchscreen Calibration window automatically opens. Follow the onscreen instructions to successfully calibrate the touchscreen.

IMPORTANT: If the screen is too slow in reacting or your touches seem to be constantly off target,

you can calibrate the touchscreen by accessing the Touchscreen Calibration submenu in the System menu. The Touchscreen Calibration submenu is not accessible

when you are operating the dryer via GSI’s remote web application.

After You Finish

With the controller turned on, proceed as follows:

• If configuring your controller for the first time, see Configuring User Preferences, page 28.

• If performing pre-season tests, click System→Control (Advanced)→Board Mode and select Pre-

season Mode (see Pre-Season Mode, page 7 for details on this mode).

• If drying grain, see Drying Grain in the Initial Run, page 32.

IMPORTANT: If the dryer detects a fault with one or more of its components upon startup, the correspond-

ing shutdown messages are displayed onscreen. Correct them immediately before starting

the dryer.

Configuring User Preferences

Once you power on the dryer, you can set user preferences such as the system’s language and its clock,

so that onscreen content appears as desired and system logs are accurate.

To configure user preferences:

1. From the taskbar, click System→Preferences→Language.

2. Set the following parameter:

Language — The system’s language. Content in all menus and submenus appear in this language.

3. Click Save.

IMPORTANT: To store your settings, make sure to click Save before closing the active window.

28 PNEG-1851 Vision N2

Page 29

Chapter 3: Getting Started

4. From the submenu pane, click Time and Date.

5. Set the following parameters:

Time — The current time (hour; minute; a.m./p.m.).

Date — The current date (month; day; year).

IMPORTANT: Setting the correct time and date is important because the system’s clock is used by

other processes, such as your dryer’s shutdown history. As a result, incorrect time

and date settings lead to inaccurate system logs. Be sure to check the time and date

at the beginning of each drying season or when restarting the dryer after a long period

of inactivity.

6. Click Save.

7. Click Units of Measure.

8. Set the following parameter:

System Selection — The system of measurement used for all onscreen temperature, speed, and

grain measure values. The available systems of measurement are the American (or United States

customary system) and the International System (SI).

9. Click Save and close the active window.

After You Finish

Once the system settings are set, configure your dryer’s hardware setup so that the controller can properly

validate your dryer’s configuration.

Configuring Your Dryer’s Hardware

The hardware setup is a series of tangible settings that ensure your dryer’s onscreen representation accurately reflects the actual product. You can configure the hardware before the initial loading cycle, thus

avoiding potential startup faults.

Before You Begin

• Make sure that you are on-site. You cannot configure your dryer's hardware when you are operating

your dryer via GSI’s remote web application.

• Make sure that the dryer is stopped.

To configure your dryer’s hardware:

1. From the taskbar, click System→Hardware Setup.

2. Set the following parameters:

Dryer Type — The type of grain dryer that you are using (portable; tower; top).

IMPORTANT: Make sure to enter the dryer type that corresponds to your actual dryer. If you enter a

dryer type that is incorrect, a shutdown message will be displayed onscreen and you

will not be able to start the dryer.

Number of Modules — The number of modules corresponding to your portable dryer’s configuration

(1: single module; 2: two modules; 3: three modules).

PNEG-1851 Vision N2 29

Page 30

Chapter 3: Getting Started

IMPORTANT: Make sure to enter the number of modules that corresponds to your actual dryer con-

figuration. If you enter a value that is greater or less than the actual number, the dryer

will not start because the system will search for missing or undeclared fans or

heaters.

Number of Fans and Heaters — The total number of fans and heaters that are present on your portable dryer (1, 2, 3, 4, or 6).

NOTE: A portable dryer setup can contain up to three stacked modules, and each module can

include one or two fans and heaters.

Dryer Length — The length of your portable dryer (8, 12, 14, 16, 18, 20, 22, 26 ft). The dryer length

is the combined length of all grain columns and each column is 2 ft (61 cm) wide.

Loading System — The type of loading systems that is used to load grain. The available loading

systems are the following:

• Dual fill: Loads grain at both ends of the dryer wet bin and two load augers move the grain

towards the center of the dryer

• Center fill: Loads grain at the center of the dryer wet bin and two load augers move the grain

towards the front and back of the dryer

• End fill: Loads grain at one end of the dryer wet bin and one load auger evenly fills the bin

Type of Fuel — The type of fuel used to ignite the burner (diesel; vapor; natural gas; liquid propane).

Metering Roll Diameter — The diameter of your dryer’s metering rolls (4 or 7 in.). Setting the correct

diameter ensures accurate unload speeds and proper functioning in auto mode. The standard metering roll diameter is 7 in.

Metering Roll Drive Type — The drive used to control the speed and rotational force of the metering

rolls’ electric motor (DC Motor; Modbus VFD; Analog VFD).

3. Click Save and close the active window.

IMPORTANT: To store your settings, make sure to click Save before closing the active window.

Setting the Dryer’s Timers and Delays

Your dryer settings include several timers and delays pertaining to all phases of the drying process. You

can set all timers and delays before the initial run and adjust them accordingly throughout the drying

process.

What You Should Know

Certain timers and delays (for example, the unload timer) are exclusive to the staged batch drying mode

and are disabled when running in continuous flow mode. In addition, the drying time parameter is a moisture control setting specific to the time-based control schemes of the staged batch mode; as a result, the

drying time parameter is not included below. See Drying Grain in Staged Batch, page 63 for details on

accessing the staged batch control schemes.

NOTE: The Cool menu is only enabled in staged batch mode. In continuous flow mode, this menu is not

displayed in the menu pane.

30 PNEG-1851 Vision N2

Page 31

Chapter 3: Getting Started

Tip

Unless otherwise advised, it is recommended to start drying grain using the default settings for the timers

and delays. If necessary, adjust these values only after having carefully monitored all phases of the drying

cycle.

To set the timers and delays:

1. Whether in continuous flow or staged batch, click System→Cool (Advanced)→Fan Delay from the

taskbar, and set the following parameter:

Fan Delay — The delay between each fan activation. The fan delay is only available in a multiple-fan

configuration.

A fan startup draws a lot of current from the electrical grid and might cause lights to flicker in nearby

buildings. Multiple fans starting simultaneously can create even greater problems. To minimize the

voltage drop in a multi-fan configuration, set the fan delay to allow fans to start one at a time. This creates many small voltage drops instead of one big drop, thus preventing possible damage to sensitive

devices that are connected to the same electrical grid.

2. From the submenu pane, click Unload (Advanced)→Cleanout Delay and set the following

parameter:

Cleanout Delay — The length of time that the unload auger and the auxiliary unloading equipment

continue to run once the metering rolls stop. When the dryer is stopped and the cleanout delay is

counting down, pressing Stop on the control panel stops the cleanout delay.

Running the unload auger after the metering rolls have stopped ensures that the unload auger is

adequately emptied.

3. Close the active window. If running in continuous flow mode, go to step 8; if running in staged batch,

go to the next step.

4. Click Cool→Cooling Timer from the menu pane, and set the following parameter:

Cooling Timer — The length of time that the fans run to cool the grain. This timer is only available in

staged batch mode.

Tip

If running full-heat operation in staged batch mode, set the cooling timer to zero seconds to bypass

the cooling phase.

5. From the submenu pane, click Cool-Down Time and set the following parameter:

Cool-Down Time — The length of time that the fans run following a shutdown error, except when

shutdowns related to the plenums, high grain temperatures, and fan motor overloads occur; in these

instances, the cool-down time is not in effect. This timer is only available in staged batch mode.

Allowing the fans to continue to run when inconsequential shutdowns occur allows you to keep cooling the grain despite the dryer’s status. Once the shutdown message is cleared, press Start on the

control panel to restart the dryer.

6. Close the active window.

7. From the menu pane, click Unload→Unload Timer and set the following parameter:

PNEG-1851 Vision N2 31

Page 32

Chapter 3: Getting Started

Unload Timer — The length of time that the unload auger runs to unload the grain. This timer is only

available in staged batch mode.

8. To set the load delay, see Minimizing Load Auger Startups, page 55; for the out of grain timer, see

Ensuring Dryer Shutdowns When Supply Is Out of Grain, page 54.

NOTE: The Remaining field displays a countdown of the set delay or timer. Click it to interrupt the count-

down and enter a new value.

Drying Grain in the Initial Run

For the initial run, load your grain in manual mode so that you can validate its incoming moisture and

select an appropriate drying time.

Before You Begin

• Make sure that your grain loading equipment is ready to load wet grain, and that the Unload Auger

switch is in the Off position.

• Make sure that your user preferences (see Configuring User Preferences, page 28) and the hardware

setup (see Configuring Your Dryer’s Hardware, page 29) are configured.

• Set all timers and delays (see Setting the Dryer’s Timers and Delays, page 30).

• Select the moisture control mode (see Selecting a Drying Mode, page 52).

• Set the plenum temperature (see Setting the Plenum Temperature Range, page 35).

• Select the burner mode (see The Burner Modes, page 79).

To dry grain in the initial run:

1. To begin loading grain, turn the Load Auger switch to On.

The switch is illuminated, the load auger starts, and the grain loading equipment also starts after a

brief delay. Manual mode is enabled for the loading phase.

NOTE: To avoid out of grain shutdowns, the load delay and out of grain timer are bypassed in

manual mode.

2. As the wet grain enters the dryer wet bin, obtain a sample to measure the actual incoming moisture

(see Validating Incoming Moisture and Temperature Readings, page 56 for details).

When the dryer is full of grain (the load auger fill switch is activated), the load auger and grain loading

equipment stop.

3. Open the following valves:

• The tank’s main fuel supply valve (if using liquid propane as a fuel source); or the valve in the

fuel supply line (if using natural gas as a fuel source)

• The automatic electric shutoff valve or the manual shutoff valve (depending on which one your

dryer is equipped with)

4. Turn the Load Auger switch to Auto.

With the Load Auger switch in either the Auto or On positions, the controller and load auger fill

switch ensure that the dryer is always kept full of grain.

IMPORTANT: When the Load Auger switch is in the On position, the out of grain timer is bypassed.

As a result, out of grain shutdowns do not occur.

32 PNEG-1851 Vision N2

Page 33

Chapter 3: Getting Started

5. Turn all Fan switches to On.

The fans start and the switches are illuminated once air pressure is detected.

Tip

It is recommended to start fans one at a time, and to let each fan attain their respective speed before

starting the next one.

6. Turn all Heater switches to On, and confirm that all plenum setpoints are set (see Setting the Plenum

Temperature Range, page 35).

After a 15-second purge for safety reasons, the burners ignite and the switches are illuminated.

7. Run the burners for the drying time indicated in the drying operation’s respective startup settings (see

Initial Settings for Full-Heat and Dry and Cool, page 78).

When establishing drying times, the rule of thumb is to dry grain for five to seven minutes for each point of

moisture you need to remove. Let’s assume that the wet grain has a moisture content of 25%, a target of

15%, and that you are running a full-heat operation. According to the startup settings, you need to dry

grain for 54 minutes.

If running dry and cool, turn off the bottom heater once the drying time elapses, and run the dryer for an

additional 10 minutes so that the grain can cool.

After You Finish

Unload grain in manual mode before switching to auto mode (see Unloading Grain in the Initial Run, page

33). For information on drying grain in auto mode, see Drying Grain in Continuous Flow, page 57 (for con-

tinuous flow) or Drying Grain in Staged Batch, page 63 (for staged batch).

Unloading Grain in the Initial Run

For the initial run, unload the dry grain in manual mode so that you can validate the outgoing moisture content and establish an appropriate unload rate prior to switching to auto mode.

Before You Begin

• Make sure to set all required parameters; see Powering On the Dryer, page 27 for information on

which parameters to set.

• If running dry and cool, ensure that the set drying time and cooling time have elapsed (see Drying

Grain in the Initial Run, page 32 for details).

What You Should Know

In manual mode, only one unload speed is available, regardless of the chosen control scheme; whereas in

auto mode (Unload Auger switch in the Auto position), you can enter unload speeds in the settings

window of the chosen control scheme.

To unload grain in the initial run:

1. From the menu pane, click Unload→Unload Speed.

The Unload Speed in Manual Mode window opens.

2. Set the following parameters:

Unload Speeds Entered in — The units of measure (bushels or metric tons per hour, or metering

roll speed %) that the unload speed value is entered in.

PNEG-1851 Vision N2 33

Page 34

Chapter 3: Getting Started

Adjusted Speed — The speed that the metering rolls turn at when the Unload Auger switch is in the

On position. Enter the speed value that corresponds to your dryer’s configuration and your chosen

drying operation (full-heat or dry and cool).

See Setting the Value Range for the Unload Speed, page 73 for information on the minimum and

maximum limits for the unload speed.

Incremental Adjustment — The incremental adjustment of the metering roll speed in manual mode.

NOTE: See Initial Settings for Full-Heat and Dry and Cool, page 78 for startup settings for both the

full-heat and dry and cool operations.

3. Turn the Unload switch to On.

Manual mode is enabled for the unloading phase and dry grain begins to unload.

4. As dry grain exits the dryer, obtain a sample to measure the actual outgoing moisture (see Validating

Outgoing Moisture And Temperature Readings, page 71 for details).

5. If running in continuous flow, run a second complete cycle and repeat step 4 before proceeding. If

running in staged batch, proceed to step 6.

6. Based on the resulting moisture content, adjust the plenum temperature according to your dryer

configuration.

If running in full-heat with a three-fan dryer, you can stage the plenum temperatures 30 degrees apart

—highest temperature at the top plenum and lowest at the bottom (for example, from top to bottom:

230°F, 200°F, 170°F).

7. Obtain another sample of dry grain as it exits the dryer and re-validate its moisture content.

8. Once you are outputting the desired moisture content, turn the Unload Auger switch to Auto.

Let’s assume that the wet grain has a moisture content of 25%, a target of 15%, and that you are running a

full-heat operation with a two-module dryer configuration. According to the startup settings, set an unload

speed of 390 bph after having dried the grain for 54 minutes.

34 PNEG-1851 Vision N2

Page 35

4 Basic Operations

Topics Covered in this Chapter

▪ Setting the Plenum Temperature Range

▪ Resetting the Dry Grain Counters

▪ Shutting Off the Dryer at the End of the Day

▪ Shutting Off the Dryer at the End of the Drying Season

▪ Monitoring Grain and Dryer Data in Real Time

▪ Downloading Dryer Data to a USB Flash Drive

Setting the Plenum Temperature Range

The plenum setpoint and burner differential settings establish the temperature range inside the plenum.

You can set this range before the initial run and adjust if the grain temperature rises or drops excessively.

To set the plenum temperature range:

1. From the menu pane, click Dry→Plenum Setpoints.

NOTE: The plenum setpoint window that opens is dependent on the chosen drying mode. For exam-

ple, the second group of plenum setpoints is only displayed when a dual-setpoint control

scheme is selected within the staged batch drying mode.

2. Set the following parameter:

Plenum Setpoints — The desired temperature inside the plenum. In a multi fan and heater configuration, plenum 1 always refers to the one that is closest to ground level.

NOTE: To access and enter plenum setpoints from the main menu quickly, click the plenum’s respec-

tive setpoint shortcut that is located in the settings pane.

3. Close the active window.

4. From the taskbar, click System→Dry (Advanced)→Burner Differential.

5. Set the following parameter:

Burner Differential — The offset from the target temperature that establishes the minimum and maximum plenum setpoint limits. When these limits are attained, the burner’s reaction is dependent on

the chosen burner mode.

Let’s assume that you enter a plenum setpoint of 210°F, a burner differential value of +/- 1°F, and choose

either the high/low or on/off burner operating mode. When the plenum’s actual temperature reaches 211°F,

the burner switches to either low fire (high/low mode) or shuts off (on/off mode). In both modes, the burner

switches back to high fire when the plenum temperature drops to 209°F.

After You Finish

Select a burner mode to help you establish and maintain a uniform plenum temperature (see The Burner

Modes, page 79).

PNEG-1851 Vision N2 35

Page 36

Chapter 4: Basic Operations

Resetting the Dry Grain Counters

The dry grain and staged batch counters keep track of unloaded grain. You can reset these counters at

any time, allowing you to keep count of grain unloaded for a particular harvest or work period.

IMPORTANT: Resetting a counter permanently erases its total count and it cannot be retrieved.

To reset the dry grain counters:

1. From the menu pane, click System→Unload (Advanced)→Dry Grain Counter.

2. Reset the following count:

Total Dry Grain Count — The total count of dry grain tallied from the last grain counter reset. The

total count also includes that from the staged batch counter.

The counter displays 0.

NOTE: The units of measure selection (bushels or metric tons per hour) that is displayed in this field

is dependent on the chosen system of measurement (System→Preferences→Units of

Measure).

3. If in staged batch mode, click Staged Batch Counter from the submenu pane.

4. Reset the following count:

Total Batch Count — The total number of batches tallied from the last batch counter reset. Available

only in staged batch mode, a batch is the quantity of grain that is discharged in one unloading

operation.

The counter displays 0.

Shutting Off the Dryer at the End of the Day

A proper daily shutoff procedure prolongs the life of your equipment and ensures your safety. You can shut

off the dryer according to your established policies or when instructed to do so for maintenance purposes.

What You Should Know

To properly shut off the dryer at the end of the day you must be present at the control panel. However, it is

also possible to stop the dryer when you are off-site, via GSI’s remote web application. To stop your dryer

through this remote application, simply click Stop Dryer from the main menu, and then click Yes when

prompted to confirm your action.

IMPORTANT: Once you have stopped the dryer via the remote web application, you cannot restart it

remotely. The dryer can only be restarted on-site.

The ensuing procedure assumes that you will continue to dry grain in the days that follow, and that the

dryer will not be off for an extended period. To shut off the dryer at the end of the drying season, see Shut-

ting Off the Dryer at the End of the Drying Season, page 37.

To shut off the dryer at the end of the day:

1. Turn off the following, in sequence:

a. The Load Auger switch

b. All Heater switches, from top to bottom

c. The Unload Auger switch

2. Run the fans for 15 to 20 minutes to cool the dryer.

36 PNEG-1851 Vision N2

Page 37

Chapter 4: Basic Operations

3. Once the dryer has cooled off, close the dryer’s fuel valve.

4. On the control panel, press Stop .

All dryer functions stop.

Shutting Off the Dryer at the End of the Drying Season

You can shut off the dryer at the end of the drying season to ensure that your equipment can safely remain

inactive until the start of the next drying season.

Before You Begin

Make sure that there is no grain in the dryer and in the wet grain storage bin.

The ensuing procedure assumes that you will not dry grain in the days that follow, and that the dryer will be

off for an extended period. To shut off the dryer at the end of the day, see Shutting Off the Dryer at the End

of the Day, page 36.

To properly shut off the dryer at the end of the drying season you must be present at

CAUTION

the control panel. Stopping the dryer via GSI’s remote web application only stops

dryer functions—the dryer’s main power is still on.

To shut off the dryer at the end of the drying season:

1. Turn off the following, in sequence:

a. The Load Auger switch

b. All Heater switches, from top to bottom

c. All Fan switches, from top to bottom

d. The Unload Auger switch

2. If using liquid propane, close the tank’s fuel supply valve; if using natural gas, close the fuel line

valve.

3. If the burner is on, let the dryer run out of fuel.

Once it is out of fuel, the burner automatically shuts off because it no longer detects a flame.

4. Close the dryer’s fuel valve, and then press Stop on the control panel.

All dryer functions stop.

5. Turn the Power switch to Off.

The control power turns off and the controller shuts down.

6. Place the main electrical disconnect switch in the Off position, and then turn off the dryer’s main

power.

The main power that is present at the electrical cabinets turns off.

The Power switch controls dryer functions but does not control the power that is

CAUTION

After You Finish

PNEG-1851 Vision N2 37

present at the various electrical cabinets. Turn off the main electrical disconnect

switch to shut off power to the dryer and all electrical cabinets.

Page 38

Chapter 4: Basic Operations

Make sure to thoroughly inspect and clean the dryer’s various components such as the metering rolls,

augers, and motors. You can follow your established procedures or contact the GSI Group, LLC for specific

instructions.

Monitoring Grain and Dryer Data in Real Time

To obtain a graphical or tabular representation of grain drying statistics in real time, you can set your

desired data monitoring parameters, and also transfer the data to your personal computer or local network

to keep a record of these statistics.

What You Should Know

You can monitor various grain and dryer data through either the Dryer Data: Table View or Dryer Data:

Graph View windows, both of which are available in continuous flow and staged batch mode. However,

you can only set the time and date that you want to start collecting data by, in the Dryer Data: Table View

window. Access these windows by clicking on their respective buttons in the main menu (see Overview of

the User Interface, page 19).

To monitor grain and dryer data in real time:

1. From the menu pane, click on the Dryer Data: Table View button.

2. Click on Date.

3. Set the time and date to start collecting data by, then click Apply.

The window closes and Live is now displayed at the bottom left corner of the active window.

4. Click Live to get the current data.

The data within the table is updated and Live is no longer displayed.

5. Set the following parameters:

Interval — The length of interrupted time that the controller collects grain and dryer data.

Sampling Rate — The frequency at which the controller collects grain and dryer data.

NOTE: The sampling rate varies according to the chosen interval. For example, you can only select a

sampling rate of 10 minutes for an interval setting of 48 hours; however, for a interval setting

of 4 hours, you can choose sampling rates of 1 minute, 5, minutes, or 10 minutes.

6. Click the check mark to apply the settings.

Let’s assume that you want to monitor the moisture content of the wet grain over a 24-hour period, and you

want samples to be collected every 5 minutes. Set the interval at 24 hr. and the sampling rate at 5 min.

Downloading Dryer Data to a USB Flash Drive

To keep a record of statistics, such as the grain’s moisture content over a set interval of time, you can

download dryer data from the controller and then transfer the information to your personal computer or

local network.

Before You Begin

38 PNEG-1851 Vision N2

Page 39

Chapter 4: Basic Operations

• Make sure to set the interval and sampling rate settings through either the Dryer Data: Table View or

Dryer Data: Graph View windows (see Monitoring Grain and Dryer Data in Real Time, page 38).

• Make sure that the dryer is powered on.

• Make sure that the USB (Universal Serial Bus) flash drive is formatted to FAT32 (32-bit File Allocation

Table).

To download dryer data to a USB flash drive:

1. Open the control panel door and locate the single-board computer (SBC) board.

Use extreme caution when opening the control panel door with the dryer

CAUTION

into a USB port.

2. Insert the USB flash drive in an available USB port on the SBC board then return to face the control

panel.

A message notifying you that the downloading process is set to begin is displayed onscreen. The

data that is downloaded is that which is present in the database at the time of download.

powered on. To avoid electrical shock and potential damage to the board, do not

touch the board with tools or with your hands when inserting the USB flash drive

IMPORTANT: Do not remove the USB flash drive until the transfer is complete.

3. Once a message notifying you that the download was successful is displayed onscreen, remove the

USB flash drive.

A compressed data file (ZIP) that contains a file in the comma separated value (CSV) format is saved

to your USB flash drive.

4. Close the control panel door and make sure that it is secure.

After You Finish

Transfer the data to your personal computer or local network, so that you can compile and track grain and

dryer information.

PNEG-1851 Vision N2 39

Page 40

NOTES

40 PNEG-1851 Vision N2

Page 41

5 The Drying Modes

Topics Covered in this Chapter

▪ Continuous Flow Mode

▪ Staged Batch Mode

▪ Selecting a Drying Mode

Continuous Flow Mode