Page 1

PNEG-1820

CE Compliant Top Dry

Series 2000 Autoflow

Operators Manual

PNEG-1820

Date: 04-10-12

Page 2

2 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 3

Table of Contents

Contents

Chapter 1 Safety .....................................................................................................................................................4

Safety Guidelines .................................................................................................................................. 4

Fan/Heater Installation and Operating Instructions ............................................................................... 5

Safety Sign-Off Sheet ........................................................................................................................... 7

Chapter 2 Decals ....................................................................................................................................................8

Chapter 3 Fuel and Electrical Specifications ....................................................................................................11

Top Dry CE Heater Specifications ...................................................................................................... 11

Chapter 4 Electrical Installation .........................................................................................................................12

Machine to Earth Connection .............................................................................................................. 12

Emergency Stop ........................ ... .... ... .......................................... ... ................................................... 12

Chapter 5 Fuel Installation ..................................................................................................................................13

Fuel Supply ......................................................................................................................................... 13

Liquid LPG ................................... .... ... ... ... ... ....................................... ... .... ... ... ... .... ... ......................... 13

Vapor LPG ................................... .... ... ... ... ... ....................................... ... .... ... ... ... .... ... ... ...................... 13

Natural Gas ......................................................................................................................................... 13

Chapter 6 Control Panel ......................................................................................................................................14

Dryer Control Panel ............................................................................................................................. 14

Chapter 7 Control System ...................................................................................................................................16

Electronic Monitoring Control System ................................................................................................. 16

Chapter 8 Fill System Control Box .....................................................................................................................19

Chapter 9 Error Messages and Valve Proving System .......................................................................... ..........22

Error Messages ................................................................................................................................... 22

Valve Proving System ......................................................................................................................... 24

High Gas Pressure Switch .................................................................................................................. 24

Chapter 10 Initial Start-Up ...................................................................................................................................25

Dryer Commissioning ........................................................................................................................ 25

Chapter 11 Pre-Season Checks ..........................................................................................................................27

Set Control Switches ......................................................................................................................... 27

Control Power Switch ........................................... ... .... ... ... .......................................... ... ... ................ 27

Drying Chamber ................................................................................................................................ 28

Rotary Switches ................................................................................................................................. 28

Linear Actuator ..... ... ... ... .......................................... .... .......................................... ... ......................... 28

Power Start Button ............................................................................................................................ 28

Fuel Check ........................................................................................................................................ 28

Fan .................................................................................................................................................... 28

Aeration Fan ...................................................................................................................................... 28

Fill System .................................. .... ................................................................................................... 29

Air Switch ........................................................................................................................................... 29

Burner Test Fire ....................... ... .... ... .......................................... ... ................................................... 29

Dryer Shut Down ............................................................................................................................... 29

Emergency ........................................................................................................................................ 29

Chapter 12 Autoflow Theory ...............................................................................................................................30

Top Dry Autoflow Theory of Operation .............................................................................................. 30

Chapter 13 Start-Up Procedure ................................................................................................

Initial Dryer Start-Up .......................... ... ... ... .... ... .......................................... ... ................................... 32

Normal Start-Up ....................... ... .... ... .......................................... ... ................................................... 34

Last Fill .............................................................................................................................................. 34

Chapter 14 Warranty ............................................................................................................................................35

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 3

..........................32

Page 4

1. Safety

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

DANGER

WARNING

CAUTION

NOTICE

4 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 5

1. Safety

Fan/Heater Installation and Operating Instructions

Thank you for choosing a Top Dry Series 2000 Autoflow.

This manual describes the operation of CE Compliant Top Dry Series 2000 single fan, multi-fan heater

control units.

Our principal concern is your safety. This manual is written to help you understand safe operating

procedures for you and your co-workers.

As owner and/or operator, it is your responsibility to know that requirements, hazards and precautions

exist and to inform all personnel associated with the equipment or who are in the area.

Do not alter the equipment. Alterations may produce a very dangerous situation, where serious injury or

death may occur.

CE Compliance

This dryer has been designed to comply with EU Directives. Compliance depends upon the dryer being

constructed, installed and operated in accordance with GSI instructions.

General Safety

Before operating your Top Dry, please read and understand this manual.

Keep the manual available for operators and maintenance technicians.

Make sure all operators are aware of potential hazards, risks and safe operating procedures.

Never enter the dryer when it is operating.

The Top Dry is designed for drying agricultural corn, seeds and grain only.

To reduce the risk of fire, keep the dryer clean, paying special attention to the area around the fan

and heater.

Use only genuine GSI parts.

Never bypass any safety device or interlock.

Electrical Safety

Electrical connections and maintenance must be carried out in accordance with Local Codes and

Directives by qualified engineers only.

The dryer must be fitted with a suitable, lockable electrical shut off device (isolator).

Flammable Fuels

Fuel supply and connections must be made in accordance with Local Codes and Directives by qualified

gas fitters.

The fuel supply must include over pressure protection and a lockable manual isolator valve.

Check the fuel type is correct or the dryer and supply pressures meet the dryer requirements

Safety Guards

Safety guards must be fitted securely at all times when operating the dryer.

If a guard becomes damaged lease fit a genuine replacement before using the dryer.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 5

Page 6

1. Safety

WARNING

Drying flammable grains and seeds.

Safety in Maintenance

Shut off and lock power and fuel supply to the dryer before entering or carrying out service or maintenance.

Before entering the drying bin allow run the fan only for 20 minutes to purge products of combustion and

cool and heater components.

Ensure the grain chutes are empty by performing a manual dump before entering.

Before opening the fuel train safely de-pressurise the system.

Access to items at high level will require suitable safe access equipment, such as scaffold.

Dust

Dust may be created in the movement of corn, grain or seeds to and from the Top Dry. Use a

suitable respirator.

Noise

Sound levels around the fan and heater may exceed 80 dBa. Avoid working in this area and wear

hearing defenders.

FOR GUIDANCE OR ASSISTANCE ON ANY ISSUES RELATING TO THE SAFE USE OF THE TOP

DRY CONTACT:

GSI Group

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

Exercise caution when drying highly flammable grains and seeds.

For example rapeseed, canola, linseed, sunflower and milo.

All grain and seed must be whole (minimal cracked or crushed), clean and dust free.

Dry at low temperatures (< 50°C).

Avoid dust and chaff being drawn into the fan and heater.

Keep the fan, heater, drying plenum and ducts clean at all times.

In the event of a fire (or suspected fire).

1. Shut down the entire dryer.

2. Turn OFF fuel at the tank or supply valve.

3. Shut off and lock electrical power.

4. Evacuate the area.

5. Call the fire department.

6 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 7

1. Safety

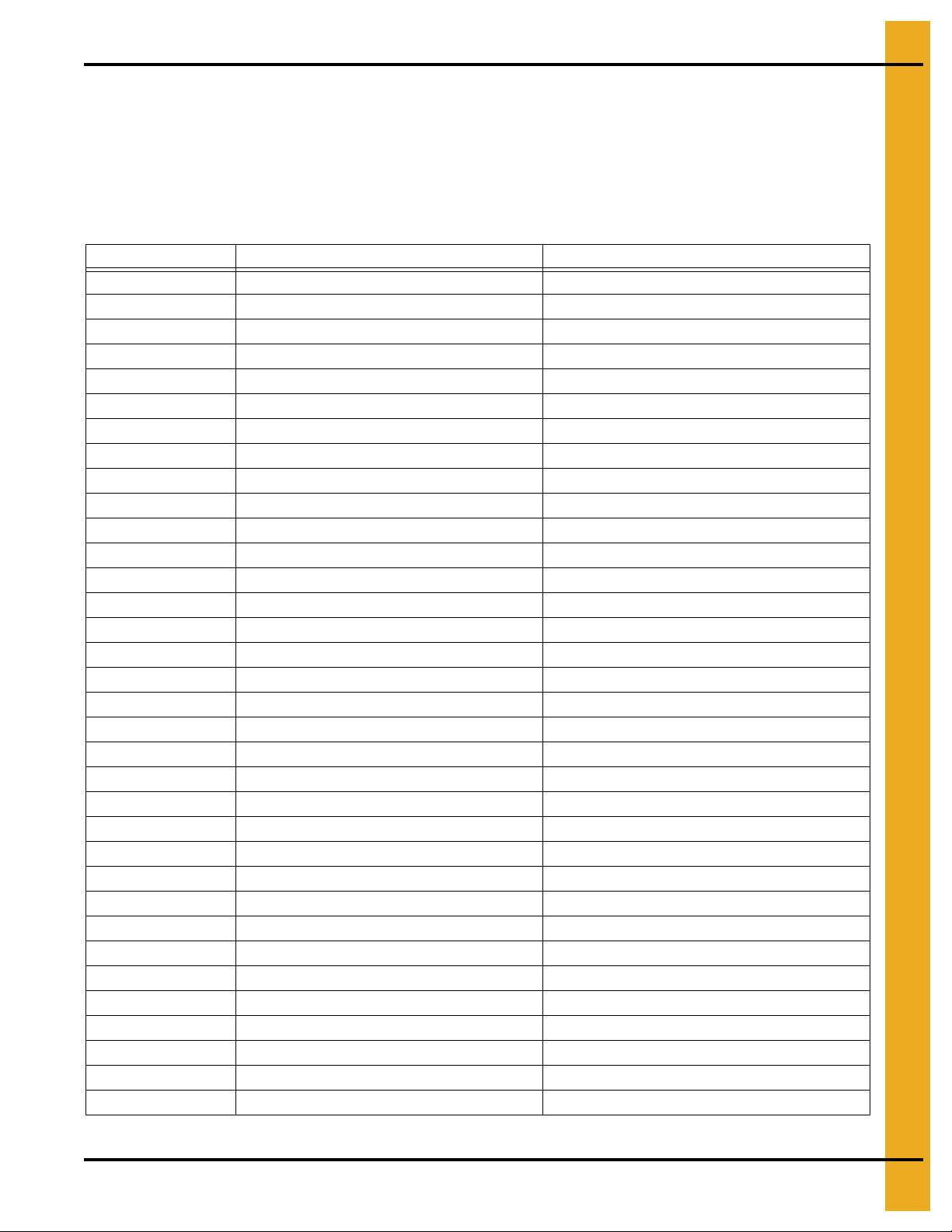

Safety Sign-Off Sheet

As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe operating

and safety procedures for this auger. This sign-off sheet is provided for your convenience and personal

record keeping. All unqualified persons are to stay out of the work area at all times. It is strongly

recommended that another qualified person who knows the shut down procedure be in the area in the

event of an emergency.

Date Employee Name Supervisor Name

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 7

Page 8

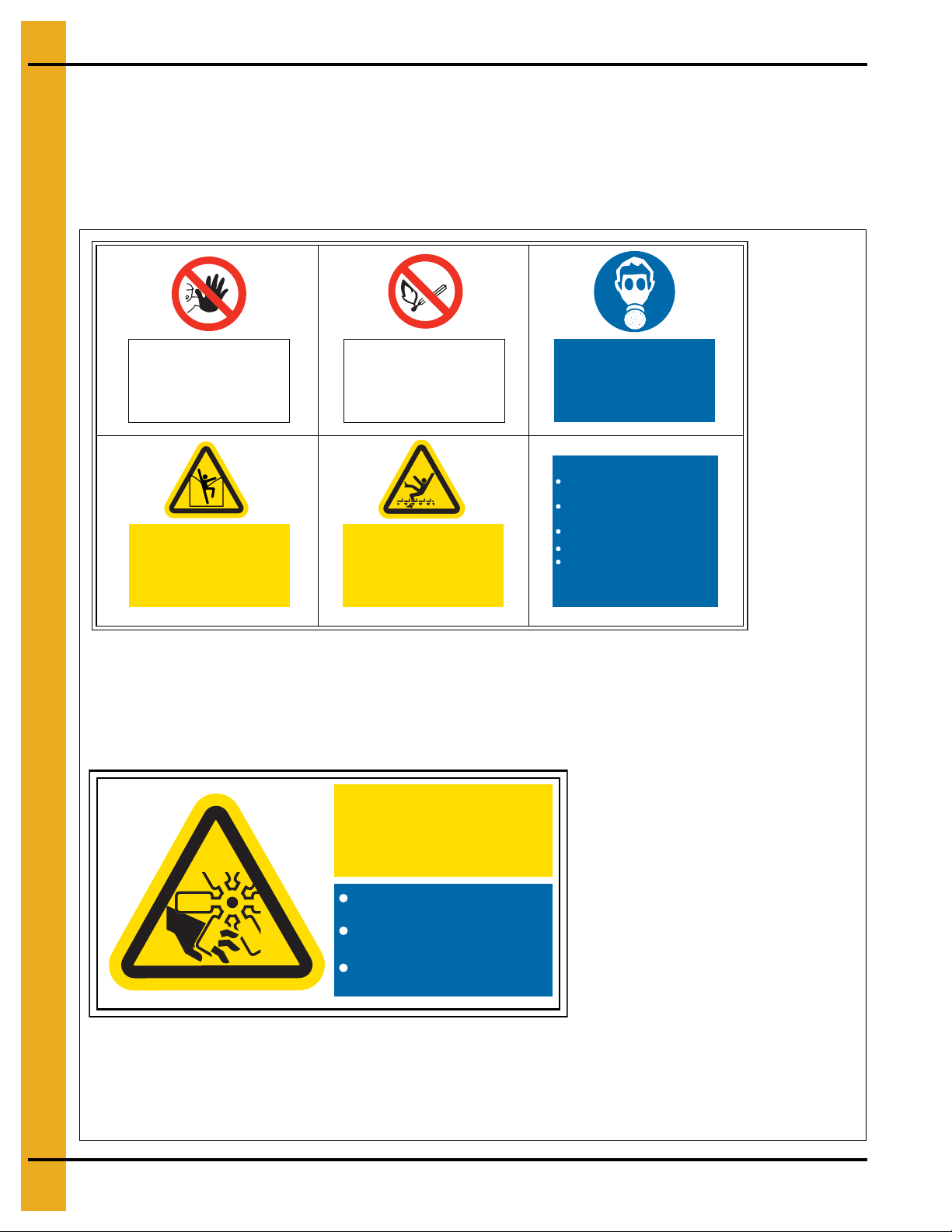

2. Decals

Respirators

must be worn

in this area

No entry to

unauthorised

personnel

DC-2161

Isolate and lock all power

before entering this bin

Do not walk directly

on stored material

Before entering:

Disconnect and lock all electrical

power

Use safety harness and safety line

Ensure someone else is outside

the bin

Disconnect and lock fuel supply

Permit required for entry into

confined space

Suffocation and

Entrapment Hazard

Automatic Machinery

No smoking or

naked flames

DC-2161

Background: White

Colors: Black, ANSI Yellow, ANSI Blue and ANSI Red

Size: 8.860" x 5.910"

Do not operate with guards

removed

Isolate and lock from power

before removing guards

Replace all guards before

reconnection to power

Automatic

Rotating

Fan Blades

DC-2162

DC-2162

Background: White

Colors: Black, ANSI Yellow and ANSI Blue

Size: 3.940" x 1.970"

Safety decals must be read and understood by all people in and around the top dry area. If any safety

decals are not displayed on the top dry or if they are damaged, contact the GSI Group, Inc. for replace ment:

Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

8 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 9

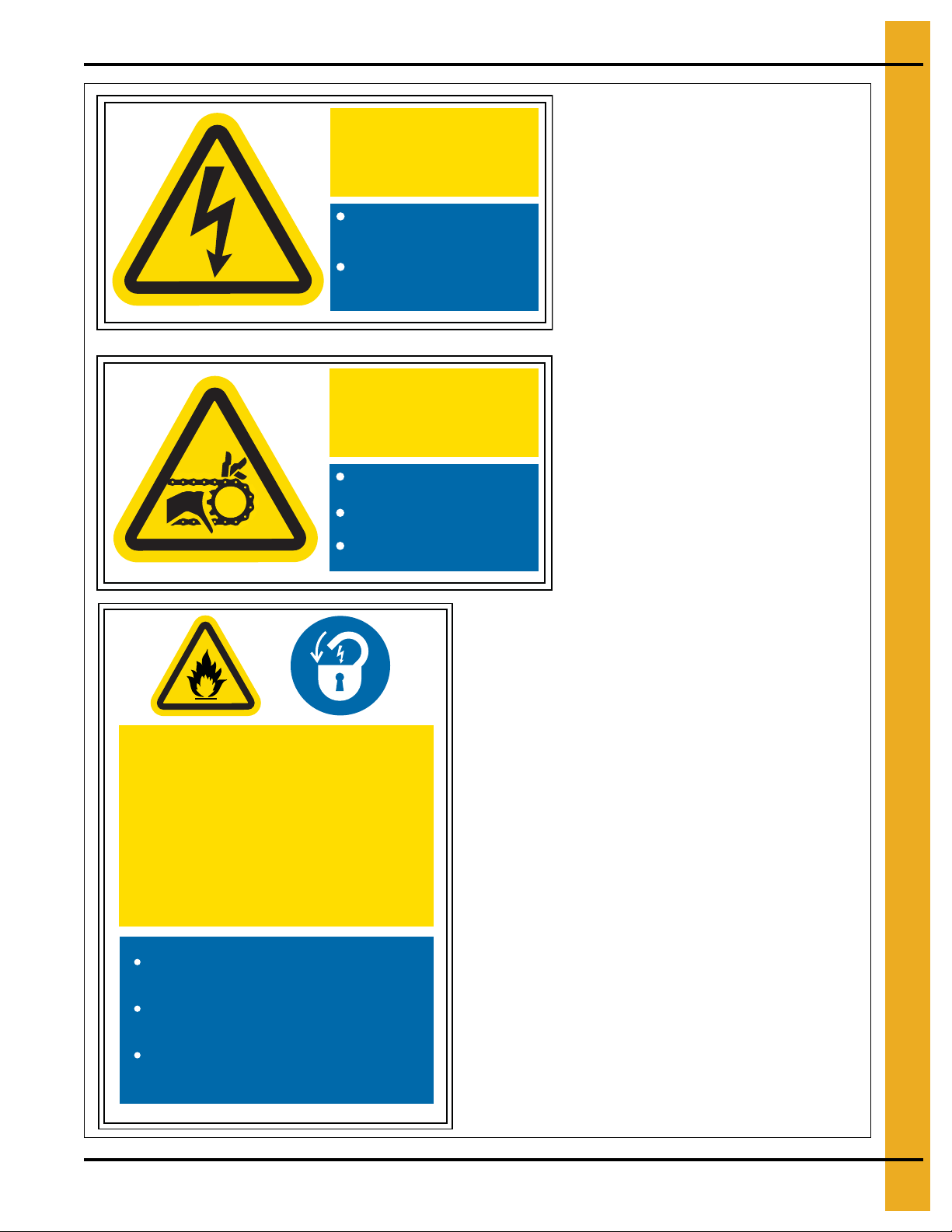

Isolate and lock from power

before removing guards or

opening enclosure

Replace all guards and lock

enclosure before reconnecting

to power

High

Voltage

DC-2163

DC-2163

Background: White

Colors: Black, ANSI Yellow and ANSI Blue

Size: 3.940" x 1.970"

Automatic

DC-2164

Background: White

Colors: Black, ANSI Yellow and ANSI Blue

Size: 3.940" x 1.970"

DC-2165

Do not open door while drier is

running

Disconnect and lock electric and

gas supply before opening

Close and lock door before

reconnecting

High Temperature

and Pressure

Equipment Can Start

Unexpectedly

DC-2165

Background: White

Colors: Black, ANSI Yellow and ANSI Blue

Size: 5.910" x 3.940"

Machinery

Do not operate with guards

removed

Isolate and lock from power

before removing guards

Replace all guards before

reconnection to power

DC-2164

2. Decals

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 9

Page 10

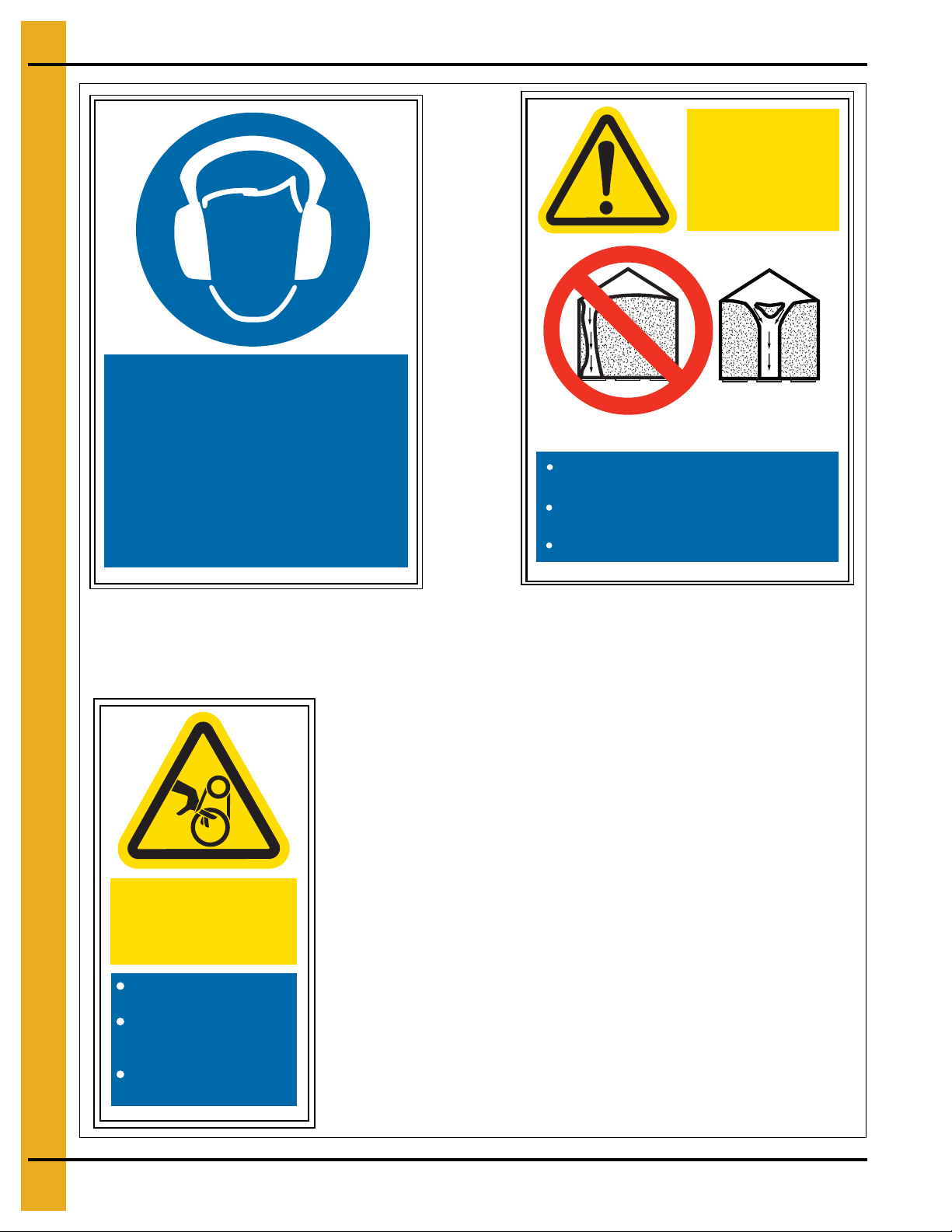

2. Decals

DC-2166

Ear protection

must be worn

in this area

DC-2166

Background: White

Colors: Black and ANSI Blue

Size: 5.910" x 3.940"

NO YES

Use CENTRE OUTLET ONLY until NO

grain remains above the outlet

Failure to follow

these instructions

will result in

structural damage

or collapse

Side outlets to be used ONLY when this

condition is satisfied

Lock all side outlets to prevent incorrect use

DC-2210

DC-2210

Background: White

Colors: Black, ANSI Yellow, ANSI Blue and ANSI Red

Size: 5.910" x 3.940"

Automatic Machinery

May Start

Unexpectedly

Replace all guards before

reconnection to power

Isolate and lock from

power before removing

guards

Do not operate with

guards removed

DC-2211

DC-2211

Background: White

Colors: Black, ANSI Yellow and ANSI Blue

Size: 3.940" x 1.970"

10 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 11

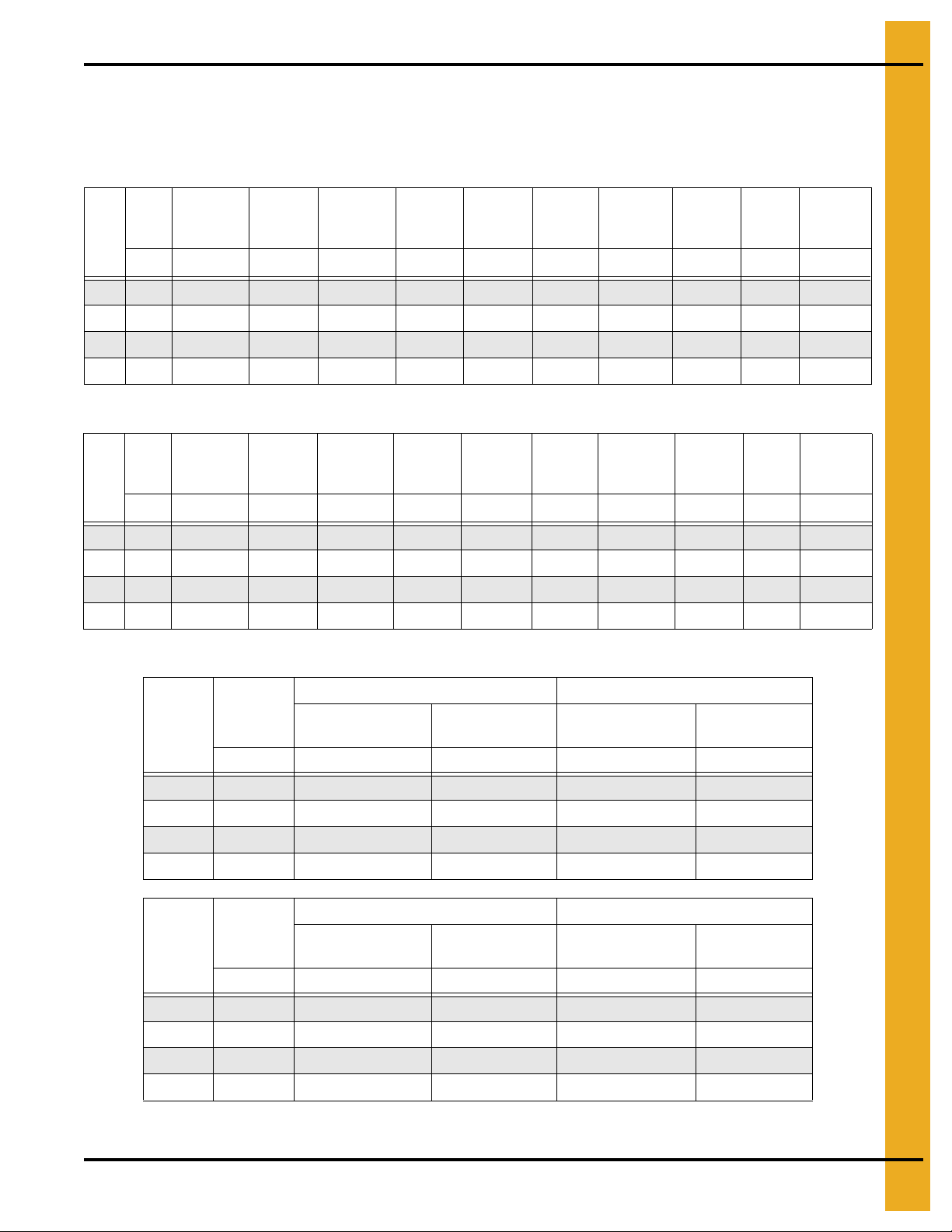

Top Dry CE Heater Specifications

Fuel Specifications

3. Fuel and Electrical Specifications

LPG Gross CV = 98.37 MJ/m

kW

kW

Maximum

Air

3

/s m3/s

m

Maximum

Air

3

/s m3/s

m

Motor

Fan

36" 11.19 8.74 2.83 747.30 373.65 1311.91 495.30 420.00 16.00 9.74 50.31

40" 11.19 12.75 5.20 747.30 373.65 1786.16 674.19 420.00 16.00 11.37 68.50

42" 22.00 16.06 7.79 871.85 373.65 2635.04 994.10 420.00 28.00 13.80 101.06

42" 30.00 17.95 8.50 871.85 373.65 3119.11 1 177.21 420.00 28.00 15.02 119.62

Natural Gross CV = 38.6 MJ/m

Motor

Fan

36" 11.19 10.39 3.31 747.30 373.65 1311.91 495.30 420.00 16.00 12.04 122.26

40" 1 1.19 12.75 5.20 747.30 373.65 1786.16 674.19 420.00 21.00 14.05 166.46

42" 22.00 16.06 7.79 871.85 373.65 2635.04 994.10 420.00 28.00 17.06 245.56

42" 30.00 17.95 8.50 871.85 373.65 31 19.11 1177.21 420.00 27.00 18.56 290.68

3

Minimum

Air

3

Minimum

Air

Maximum

Static

Pa Pa kW kW mBar mBar mm

Maximum

Static

Pa Pa kW kW mBar mBar mm

Minimum

Static

Minimum

Static

Maximum

Heat

Maximum

Heat

Minimum

Heat

Minimum

Heat

Maximum

Burner

Pressure

Maximum

Burner

Pressure

Minimum

Burner

Pressure

Minimum

Burner

Pressure

Orifice

I.D.

Orifice

I.D.

Maximum

Gas

Flow

m3/h

Maximum

Gas

Flow

m3/h

Electrical Specifications

380 VAC 400 VAC

Fan

Motor

kW A A A A

36" 11.19 22.67 68.01 21.54 64.61

40" 11.19 22.67 68.01 21.54 64.61

42" 22.00 44.57 133.70 42.34 127.02

42" 30.00 60.77 182.32 57.74 173.21

Motor

Fan

kW A A A A

36" 11.19 22.67 68.01 21.54 64.61

40" 11.19 22.67 68.01 21.54 64.61

42" 22.00 44.57 133.70 42.34 127.02

42" 30.00 60.77 182.32 57.74 173.21

Maximum Current

Draw FLA

415 VAC 440 VAC

Maximum Current

Draw FLA

Maximum Start

Current

Maximum Start

Current

Maximum Current

Draw FLA

Maximum Current

Draw FLA

Maximum Start

Current

Maximum Start

Current

NOTE: When commissioning, check motor ratings on individual motors and set overloads accordingly.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 11

Page 12

4. Electrical Installation

The electrical supply must be capable of the full demand from the dryer, including aeration fan, fill and

empty equipment and start currents.

All CE Top Dry fans are star delta starting.

Refer to electrical specifications Table on Page 11 for minimum current demand per fan heater.

For twin fan units, double the minimum demand.

Allow for fill and empty equipment loads.

Power supply to the dryer must include a suitable, lockable supply disconnect switch (isolator).

Machine to Earth Connection

The dryer must be connected to earth.

In most cases this will be via the earth supply provided with the power supply.

Where no earth is supplied or for generator supplies, a ground rod must be used. This must be selected

and installed by a qualified engineer, in accordance with EU Directives and/or Local Regulations

and Codes.

Emergency Stop

The dryer is fitted with an emergency stop.

It is recommended that auxiliary fill and empty equipment be installed so that in the event of an emergency

stop, all equipment is stopped.

This is the responsibility of the installer.

The dryer is supplied with a door safety switch. This must be connected to the required terminals so that

the dryer is stopped if the door is opened.

12 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 13

5. Fuel Installation

Fuel Supply

The dryer requires a suitable fuel supply. Refer to fuel specifications Table on Page 11 for fuel

flow requirements.

Liquid LPG

Dryers with internal vaporizers require LPG in liquid form.

Vapor LPG

Dryers without internal vaporizers require LPG in vapor form.

LPG tanks must have adequate vaporizing capacity to supply the maximum fuel flow given in

fuel specifications Table on Page 11. Alternatively and external vaporizer may be used.

For twin fan units, double the fuel flow.

Primary pressure regulation is required at the tank, including over pressure protection.

Supply pressure at the dryer should be 1.5 bar-2.0 bar (150 kPa-200 kPa).

Natural Gas

Natural gas dryers require a supply capable of the maximum flow given in fuel specifications

Table on Page 11.

For twin fan units, double the flow.

Minimum supply pressure at the dryer must be 750 mBar (75 kPa).

Primary pressure regulation should include over pressure protection.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 13

Page 14

6. Control Panel

Dryer Control Panel

Figure 6A

Moisture Control Switch

Determines if the grain temperature set point is used in the operation of the dryer.

When “ON” position, the grain will be dumped when it reaches the temperature set point and the dry timer

has reached zero.

When “ON” the switch is lit when the grain is below set point.

Control Power Switch

Turns ON/OFF power to the electronic monitoring control system.

Aeration Fan Switch

Controls the operation of the aeration fan located at the bottom of the bin.

AUTO = Fan runs only with the main drying fans.

ON = Fan comes on when the dryer is running.

14 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 15

6. Control Panel

Load Auger Switch

Controls the operation of the drying chamber fill system(s).

Switch is lit when the fill system(s) are running.

AUTO = Fill system(s) start and stop automatically depending level of grain in drying chamber. When

operating in the Autobatch mode the fill system(s) will shut off 2/3 of the way through the dry

cycle regardless of drying chamber level.

ON = Fill system(s) are ON when the dryer is running.

Fan Switch

Controls the operation of the main drying fan(s).

Switch is lit when airflow is sensed.

AUTO = Main drying fan(s) start when drying chamber is full.

ON = Main drying fan(s) come ON and stay ON when the dryer is running.

Heater Switch

Controls the operation of the burner(s).

Switch is lit when the burner is ON.

Small lights above and below the heater switch indicate if the burner(s) are in high-fire or low-fire.

AUTO = Burner(s) light when drying chamber is full remain on until the dryer shuts down or is stopped.

ON = Burner(s) light anytime the main drying fan(s) are running.

Dump Switch

Controls the operation of the drying chamber dump chutes.

Switch illuminate when the chutes are moving.

MANUAL CLOSE = Chutes close.

AUTO = Chutes automatically dump at the end of the drying cycle.

MANUAL OPEN = Chutes open (dump).

NOTE: Manual open and close only operate when the dryer Stop button has been pressed.

Dry and Hold Switch

When ON the normal dump cycle will be inhibited at the end of the dry cycle.

Dryer Power Start Switch

Starts the dryer.

Lit up when dryer is running.

Dryer Power Stop Switch

Stop the dryer.

Also used to reset after an error or fault.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 15

Page 16

7. Control System

Electronic Monitoring Control System

Figure 7A

Electronic Monitoring Control System

This controls all timing functions and safety circuits. It provides printed messages and warnings.

Turn control power to “ON” to start the control. The control will enter the main drying screen.

Setting the Dry, Cool and Unload Timers

These set the dry, cool and dump cycle times. The timer settings are displayed above the Timer button.

To alter the setting:

1. Press the Dry, Cool or Unload Timer button.

2. Press “modify”.

3. Press “increase” or “decrease” to adjust the settings.

4. Press “enter”.

5. To enter the new value into memory, press “reset”.

During drying the remaining time for each timer is displayed. The control retains these values in the even t

of a power failure. Pressing “reset” returns the timers to their initial setting. The cool timer is not used in

an Autoflow system.

16 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 17

7. Control System

Setting the Delays

The following timers are set using the same procedure, but the Rese t button does not need to be pressed

to enter the new values into memory immediately.

AUX. 1 DELAY - Not used.

REFILL DELAY - Used only on batch units. This delays the start of drying to allow the drying chamber to

fill. If the unit does not refill within this time the unit will give a “dry chamber empty” error.

FILL #1 DELAY - This timer keeps the fill system running for a period of time after the Drying Chamber

switch has detected grain. The purpose is to eliminate rapid start/stop in the fill system. Set the timer so

that grain covers the Upper Level switch, but does not reach the Chamber Overflow switch.

If the Autoflow controls two (2) fill systems, this timer keeps fill system #1 running after fill system #2 has

stopped. (Fill system #1 is the system the delivers direct to the drying chamber.) Set the time to completely

empty fill system #1, but should not allow grain to reach the Chamber Overflow switch.

FILL #2 DELAY - This timer is used where two (2) fill systems are controlled. It ke eps fill system #2 running

for a period of timer after the Drying Chamber Upper Level switch has detected grain. Set the timer so that

grain covers the Upper Level switch, but does not reach the Chamber Overflow switch.

OUT OF GRAIN DELAY - This allows the dryer to continue running for a period of time after the Drying

Chamber Low Level switch has detected no grain. This stops nuisance shut downs. Once the out of grain

timer has elapsed the dryer will shut down and report “no grain”. If you are getting “no grain” shut down s,

increase the timer.

FAN DELAY - Used only on twin fan units to delay the start of the second (slave) fan. Recommended

setting is 3 seconds.

FANS OFF DELAY - Allows the fans to be stopped during the dump cycle. Options are 1.00 (ON) and

0.00 (OFF). When ON the fans will stop during the dump cycle and restart following.

Standard Setup

The setup mode is used to program the computer with different variables that influence how the dryer

will operate.

CLEAR TOTAL BATCHES - Press the Reset button to clear the total batches. Press the Enter button

to continue.

CLEAR WARNING HISTORY - Press the Reset button to clear the warning history. Press the Enter button

to continue.

TIME UNTIL LOAD OFF - In Autobatch mode is the percentage of time through the dry cycle that the fill

systems will be shut off regardless if the dryer is full or not. Press the Enter button to return to the main

drying screen.

Extended Setup

SET DATE SET MONTH SET YEAR SET HOUR SET MINUTE -

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 17

Page 18

7. Control System

Use the Increase and Decrease buttons to select the correct time or date. Press the Enter b utton to accept.

LOW LEVEL TEST MODE - Use the Increase and Decrease buttons to enable or disable Drying Chamber

Low Level switch monitoring.

WET TANK TEST MODE - Use the Increase and Decrease buttons to enabled or disabled wet supply

level switch monitoring.

START FANS WITH HIGH - Use the Increase and Decrease buttons to enable or disable fan starting

based on the Upper Drying Chamber Level switch. Recommended practice is fans starting with the Drying

Chamber Low Level switch.

AERATION FAN BYPASS - Use the Increase and Decrease buttons to enabled or disabled. When

enabled the fan runs after the dryer stops.

# OF FILL SYSTEMS - Use the Increase and Decrease buttons to select one or two (2) fill systems under

dryer control. Note setting of fill #1 and fill #2 system timers on Page 19.

SELECT DRYER TYPE - Use the increase and decrease select dryer model:

AF3 - Three (3) drying fan Autoflow.

AF2 - Two (2) drying fan Autoflow.

AF1 - Single drying fan Autoflow.

AB3 - Three (3) drying fan Autobatch.

AB2 - Two (2) drying fan Autobatch.

AB1 - Single drying fan Autobatch.

SELECT TEMP SCALE - Use the increase and decrease to select Fahrenheit or Celsius.

MODEM INIT STRING - Not used. Press the Enter button to return to the main drying screen.

BURNER DIFFENTIAL - Use the Increase and Decrease buttons to change temperature difference

between high-fire and low-fire. Recommended setting 3°C.

Help

Currently not used.

Plenum

Set target plenum temperature.

Grain

Set target grain temperature with Increase/Decrease buttons.

Screens

By pressing the Screens button, you can toggle between two (2) screens. Screen #1 displays the current

plenum and grain temperatures and their set points in parenthesis. Screen #2 displays the status of the

Drying Chamber Rotary switches and the total number of batches. In all screens the dry time and dump

time are displayed at the bottom of the screen.

18 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 19

8. Fill System Control Box

Figure 8A

The fill system control box houses the motor starters for fill system #1, fill system #2 and the aeration fan.

Switches are located on the front of the fill system control box and an Emergency Stop switch is located

on the side of the control box.

Fill system #1 and fill system #2:

0 = OFF

1 = Manual ON

AUTO = Operates under dryer control

Aeration fan:

0 = OFF

1 = Manual ON

AUTO = Operates under dryer control

Emergency Stop switch:

This switch will stop the dryer when pushed and should be used in case of emergency.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 19

Page 20

8. Fill System Control Box

Flame probe

Ignitor

9

10

3

1

2

4

6

7

8

5

Flame probe

Ignitor

Vaporizer

Figure 8B Ignitor and Flame Probe Assemblies

20 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 21

8. Fill System Control Box

Loosen this bolt to

adjust the vaporizer coil.

Loosen this bolt to

adjust the vaporizer coil.

Flame Probe, Ignitor and Burner Assemblies Parts List

Ref # Description

1-3 Flame Probe Assembly Network

1 Boot 8 mm Silicone 90°

2 Flame Sensor 6" Long Rod

3 Flame Sensor Bracket

4-8 Ignitor Assembly

4 Dual Probe Ignitor Bracket

5 Ignitor Air Deflector Angle

6 Ignitor Half Clamp

7 Ignitor Flame

8 Ignition Wire Assembly (Includes Both Wires)

9 Cone

10 Vaporizer Coil

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 21

Figure 8C LP Vaporizer Coil Adjustment

Page 22

9. Error Messages and Valve Proving System

Error Messages

Burner * Loss Flame

The flame sensor in burner number * has failed to detect flame. Possible causes:

Burner failed to light.

1. Check fuel supply and pressure.

2. Check spark.

3. Check all solenoid valves are opening.

Flame sensor needs adjusting.

1. It must be in the flame.

2. It can be bent gently if required.

Fan * Vapor High-Limit

The LP gas vapor temperature has exceeded 109°C causing the high-limit to open. This will reset when

cool. The vaporizer must be adjusted to move it further from the flame to prevent this re-occurring.

Fan * Housing High-Limit

The temperature in the fan/heater housing has exceeded 109°C. Housing high-limit must be

manually reset.

Plenum High-Limit

The dryer plenum has gone over temperature. The plenum high-limit resets automatically when cooled.

The low-fire gas pressure needs to be lowered or the cycle set poin t on the high-low thermostat needs to

be increased if the error is displayed frequently.

NOTE: Vapor, plenum and housing high-limit errors will cause the burner control to lock out. This can only

be reset by pressing the illuminated Reset button on the burner control.

Fan * Motor Overload

The thermal overload in the control box on fan number one has tripped, indicating an over current

condition. The overload must be reset manually.

Fan * Loss of Airflow

The burner control air switch is not sensing adequate airflow to allow the burner to light.

1. Check fan is operating at correct speed.

2. Check for damaged fan blades.

3. Check air inlet is not impeded.

4. Check pressure switch.

5. Adjust pressure switch.

22 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 23

9. Error Messages and Valve Proving System

Drying Chamber Overflow

The grain level in the drying chamber has reached the Drying Chamber Overflow Rotary switch. Grain will

have to be dumped from the drying chamber to the storage chamber before the unit can be re-started. This

error indicates that either the drying chamber High Level Rotary switch is faulty or the time on the load

delay or Aux. 1 delay needs to be lowered.

Bin Grain High-Limit Full

The grain level in the storage chamber has reached the storage chamber High Level Rotary switch located

1 m below the fan and heater(s). Grain will have to be removed from the storage chamber before the unit

can be re-started.

Bin High-Limit Switch Bad

The Storage Chamber High Level switch has failed. Switch must be repaired or replaced.

Out of Grain

The grain in the wet supply tank has fallen below the Wet Supply Rotary switch. If there is grain against

the Drying Chamber Low Level Rotary switch the dryer can be re-started by pressing the Stop switch to

clear the error and then the Start switch.

Wet Supply Empty Press <Enter> to Dry Remaining Grain

The Start button is pushed and grain is below the Wet Supply Level switch whilst grain remains in the

Drying Chamber Low Level Rotary switch. If the Enter button is pushed the dryer will re-start, but the fill

system(s) will not re-start.

Cannot Start Dryer Wet Supply Empty

The Start button is pushed and grain below the Wet Supply Level switch and there is no grain in the

drying chamber.

Dry Chamber Empty

The grain is below the drying chamber low level switch and the Aux. 1 timer has reached zero. If the

error is being caused due to the settling of grain after the fans start the time on the Aux. 1 timer can

be lengthened.

Fill * Motor Overload

The thermal overload for fill system number * has tripped, indicating an over current condition. The

overload must be reset manually.

Aeration Overload

The thermal overload for the aeration fan has tripped, indicating an over current condition. The overload

must be reset manually.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 23

Page 24

9. Error Messages and Valve Proving System

High gas pressure switch

Valve proving system

Low-fire adjustment screw

High-low valve

Grain High-Limit

The grain temperature in the drying chamber is too high.

Valve Proving System

The main safety shut-off valve is fitted with a proving system which will prevent burner start-up if the valve

is leaky.

Figure 9A

Check the light status on the VPS. Red light indicates leaky valve. VPS is reset by pressing the

Reset button.

High Gas Pressure Switch

In addition to the high pressure relief, the main solenoid valve is fitted with a High Pressure switch. This

will cause the burner to shut down if the pressure exceeds the pre-set level.

24 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 25

10. Initial Start-Up

Dryer Commissioning

Electrical

1. Carry out earth bonding test per EN60204 and/or local electrical laws and regulations.

2. Check adequate power supply. (Refer to electrical specifications Table on Page 11.)

3. Voltage at phases must be within 5% of rated voltage.

4. Voltage drop must not exceed 5% when under full load.

5. Check overload settings for each motor circuit.

6. Complete full electrical tests in accordance with EU Directives and local laws, regulations and codes.

Gas Train

1. Pressure test.

• Close inlet valve.

• Close firing valve.

• Fit pressure test nipple into main solenoid inlet flange.

• Attach hand bellows and pressure gauge.

• Pressurise gas train with air to 35 kPa (350 mBar).

• Check for pressure loss at gauge.

• Use leak detection to test for leaks.

2. Set inlet pressure per fuel specifications Table on Page 11.

3. Set relief valve to open at 550 mBar (55 kPa).

• Apply air pressure via main solenoid inlet flange.

• Increase/decrease spring pressure in relief valve.

• Valve should open at 55 kPa maximum.

4. Set over High Pressure switch to 500 mBar.

5. Set burner high fire pressure.

• Note required high fire pressure from fuel specifications Table on Page 11.

• Set plenum temperature to approx. 100°C above ambient.

• Light burners.

• Check high-low valve is fully open.

• Read pressure at burner gauge.

• Adjust pressure a regulator to give required pressure.

• Lock regulator.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 25

Page 26

10. Initial Start-Up

Gas Train (Continued)

6. Set burner low-fire pressure.

• Set plenum temperature to approx. 10°C above ambient.

• Light burners.

• On low fire, adjust high-low valve minimum setting to give pressure as per fuel specifications

Table on Page 11.

7. Read pressure at burner gauge. (See Figure 9A on Page 24.)

8. Run burners and check burner modulates correctly.

9. Check gas pressure remains stable fill out gas train commissioning check sheet.

26 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 27

11. Pre-Season Checks

Before the dryer is filled, inspect the unit and check the operation of the dryer as follows. Never enter a

bin where grain is present.

Set Control Switches

• Moisture Control switch - “ON”

• Aeration Fan switch - “OFF”

• Load Auger switch - “OFF”

• Fan switch - “OFF”

• Heater switch - “OFF”

• Dump switch - “AUTO”

• Dry and Hold switch - “OFF”

• Autoflow Emergency Stop switch - “OUT”

• Actuator switch - “ON”

• Fill System Control Box Emergency Stop switch - “OUT”

Control Power Switch

Turn the control power switch ON. The switch will illuminate. If a fault is found an error message will be

displayed on the screen. If all are found safe, the main drying screen will be displayed.

Figure 11A Top Dry Component Placement

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 27

Page 28

11. Pre-Season Checks

Drying Chamber

Inspect each dump hopper for obstructions.

Make sure that the gap between the discharge flow plates and the floor sheets is a minimum of 38 mm.

Rotary Switches

Check all rotary switches are spinning freely.

Linear Actuator

Turn the Dump switch “manual open”.

Check the stroke on the actuator is 300 mm to 350 mm. Adjust if necessary.

Make sure that all pulleys and cables move freely.

With the actuator extended, view each dump chute to make sure they are completely open.

The dump chutes should hinge smoothly.

Turn Dump switch to “AUTO” position and press the Stop switch. The chutes should raise.

Power Start Button

Ensure there is grain in the wet supply tank.

Push the dryer Start button. The screen should no longer flash “STOPPED”.

Fuel Check

Check for leaks as described previously.

Fan

Check fan rotates freely and in the correct direction. (See fan direction decal on Page 8.) If required

reverse the fan by swapping over phases L1 and L3.

Make sure the fan runs smoothly with no vibration.

Aeration Fan

Check fan rotates freely and in the correct direction. (See fan direction decal on Page 8.) If required

reverse the fan by swapping over phases L1 and L3.

Make sure the fan runs smoothly with no vibration.

28 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 29

11. Pre-Season Checks

Fill System

Prepare the wet storage tank to deliver grain to the dryer.

Make sure all personnel clear.

Switch load auger to “AUTO”.

Grain should be delivered from the wet supply tank to the dryer.

When the display shows “GRAIN LOW LEVEL YES” close the valve that supplies the fill system(s) with

wet grain from the wet supply tank.

When the load auger empties turn it “OFF”.

Air Switch

With the drying fan running, adjust the air switch so that it just stops sensing airflow, then increase the

air switch sensitivity by 1 full turn.

Figure 11B Air Switch Adjustment

Repeat on the slave unit for 2 fan dryers.

Burner Test Fire

Check burner operation and high-low firing rates as per on Page 25.

Note, the burner control runs a fixed purge period of 35 seconds before the burner lights.

Dryer Shut Down

For long term shut down, allow the burner to burn out by shutting off the fuel whilst burning.

Press Stop.

Emergency

In case of an emergency, push the Emergency Stop switch located on the side of the Auto flow control box

and the fill system control box.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 29

Page 30

12. Autoflow Theory

Top Dry Autoflow Theory of Operation

Control Panel Switch Status

• Control power: “ON”

• Moisture control thermostat: “ON”

• Aeration fan: “AUTO”

• Load auger: “AUTO”

• Fan: “AUTO”

• Heater: “AUTO”

•Dump: “AUTO”

• Dry and hold: “OFF”

Emergency Stop Switch Status

• Autoflow control box emergency stop: “pulled out”

• Fill system control box emergency stop: “pulled out”

• Actuator co ntrol box 24V switch: “ON”

• Aeration fan bypass: “enabled”

With no grain in the drying chamber and wet grain in the wet storage tank, fill system #1 and fill system #2

(if fitted) will start.

When grain reaches the Drying Chamber Low Level switch, the aeration fan and the master drying fan

will start.

After the fan delay time the slave drying fan (if fitted) will start, the air switch will close and the dry timer

will start to count down.

After a 20 seconds purge delay, the fan/heater unit(s) will ignite.

When the plenum temperature reaches the cycle set point, the fan/heater unit(s) will cycle to low-fire.

The fan/heater units will continue to cycle throughout the drying process.

When grain reaches the Chamber High Level switch, the fill #2 delay will begin to count down.

When the fill #2 delay reaches zero, fill system #2 will shut off and the fill #1 delay will begin to count down.

When the fill #1 delay reaches zero fill system #1 will shut off.

If the grain drops below the High Level switch, the fill system(s) will start and refill the drying chamber.

When the dry timer reaches zero, if the grain temperature is below set point, the dryer will go into

temperature hold.

When the grain temperature reaches set point, the unit will continue to the dump cycle.

In the dump cycle, the grain is dumped into the storage chamber.

When the dump timer reaches zero, the dump chutes raise.

30 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 31

12. Autoflow Theory

During the dump cycle 1/3 of the grain is dumped into the storage chamber.

After the dump cycle, the unit returns to the beginning of the dry cycle, the fill system(s) refill the drying

chamber and the process begins again.

The unit continues with the same operation until either no grain is present agai nst the Wet Supply Rot ary

switch or the storage chamber becomes full.

If the wet storage tank becomes empty, the fill #1 and fill #2 delays starts to count down.

When the delays reach zero, the fill system(s) and dryer shut off.

Wet supply hopper empty “out of grain” error is displayed. If there is grain above the Drying Chamber Low

Level switch, the unit can be re-started by pressing the Start switch.

When the Start switch is pressed, the screen on the dryer control panel will read “press enter to dry

remaining grain”. If the Enter button is pushed the dryer will re-start without running the fill system(s). The

dryer will remain running until the completion of the next dump cycle, af ter which an “out of g rain” error is

displayed on the dryer control panel and the dryer stops.

If the storage chamber reaches full during the dump cycle, the dryer will continue through the dump cycle

and will continue to the next dry cycle.

When the dry cycle is complete, the unit will not continue to the dump cycle. A “bin grain high-limit” error

will be displayed on the screen and the dryer will stop.

If the dryer stops for any reason, the aeration fan will remain running if the aeration fan bypass is enabled.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 31

Page 32

13. Start-Up Procedure

Initial Dryer Start-Up

1. With Control Power switch OFF, turn ON the main power supply.

2. Pull out all Emergency Stop switches.

3. Set the switches as follows:

• Moisture Control switch - “ON”

• Aeration Fan switch - “AUTO”

• Load Auger switch - “OFF”

• Fan switch - “AUTO”

• Heater switch - “AUTO”

• Dump switch - “AUTO”

• Dry and Hold switch - “OFF”

4. Make sure there is wet grain in the wet supply tank.

5. Turn control power “ON” position.

6. The screen will display a copyright message and software version number.

7. The screen should read “STOPPED”. The chamber high level and the chamber low level should both

read “NO”.

8. Set the dry timer using the drying charts for the specific bin size, fan and heater size, drying

temperature and grain input moisture content.

9. Set the dump timer as follows:

• 18' Diameter bin = 30 Seconds

• 21' Diameter bin = 33 Seconds

• 24' Diameter bin = 36 Seconds

• 27' Diameter bin = 39 Seconds

• 30' Diameter bin = 42 Seconds

• 36' Diameter bin = 36 Seconds

10. Set all other delays and timers as prescribed in the electronic monitoring control section on Page 16

of this manual.

11. Press the Reset button for timer changes to take effect immediately.

32 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 33

13. Start-Up Procedure

CAUTION

Be sure all personnel are clear of fill systems. Place the Load Auger switch on the

dryer control panel to the “AUTO” position.

12. Set the grain temperature set point as follows:

• 82°C Drying temperature = 38°C Grain temperature set point

• 77°C Drying temperature = 39°C Grain temperature set point

• 71°C Drying temperature = 41°C Grain temperature set point

• 66°C Drying temperature = 42°C Grain temperature set point

• * 60°C Drying temperature = 43°C Grain temperature set point

• * 54°C Drying temperature = 45°C Grain temperature set point

• * 49°C Drying temperature = 46°C Grain temperature set point

* When drying at a temperature lower than 66°C the grain temperature set point on the moisture

control thermostat may require a lower setting at right.

13. Press the Start switch on the dryer control panel.

14. The fill system(s) should start immediately.

15. When the grain reaches the Drying Chamber Low Level switch, the fan and heater(s) should start.

16. When the grain reaches the drying chamber, Low Level Rotary switch reaches the Drying Chamber

High Level Rotary switch the fill system(s) should stop.

17. When the dry timer reaches zero, the display should read “TEMP HOLD”.

18. When the grain temperature reaches the grain temperature set point, the dryer should continue to

the dump cycle.

19. The dump chutes should lower, grain should dump from the drying chamber into the storage chamber

and the fill system(s) should start.

20. After the dump cycle, the dryer should continue to the beginning of the next dry cycle.

21. After the fourth dump, stop the dryer.

22. Test the moisture of the dried grain.

23. If the moisture of the grain is too high, increase the grain temperature set point 2.5°C for each

additional point of moisture to be removed.

24. If the moisture of the grain is too low, decrease the grain temperature set point 2.5°C for each

additional point of moisture to be added.

25. After the moisture control thermostat is adjusted, decrease the time on the dry timer by one-half.

The dry timer should not be set lower than the amount of time it takes the dryer to refill after the

dump cycle.

26. Re-start the dryer. The time on the dry timer should expire before the grain reaches the

temperature set point.

27. Any time a change is made to the grain temperature set point, the dryer must dump four (4) times

before the full effect of the change will be made on the moisture of the grain.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 33

Page 34

13. Start-Up Procedure

Normal Start-Up

When the dryer is started with grain in the drying chamber that has already been partially dried, the drye r

can be started without making any adjustments to time or temperature; however, the moisture of the grain

should be checked after the fourth dump.

Last Fill

1. Stop the dryer when all the wet grain has been loaded into the drying chamber and turn OFF the

Moisture Control switch.

2. Set the time on the dry timer for twice the recommended amount using the charts for the specific bin

size, fan and heater size, drying temperature and grain input moisture content.

3. Push the Reset button.

4. Turn the Dry and Hold switch to the “ON” position.

5. Turn the Load Auger switch to the “OFF” position.

6. Press the Start switch.

7. When the dryer shuts down install the fan inlet cover(s).

8. Let the aeration fan cool in the top and store or manually dump into the storage chamber.

34 PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow

Page 35

14. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1820 CE Compliant Top Dry Series 2000 Autoflow 35

Page 36

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2012 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-203943

Loading...

Loading...