Page 1

PNEG-1797

CE Approved T-Series

Tower Dryer

Operation Manual

PNEG-1797

Date: 06-11-12

Page 2

2 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 3

PNEG-1797CE CE Approved T-Series Tower Dryer 3

Page 4

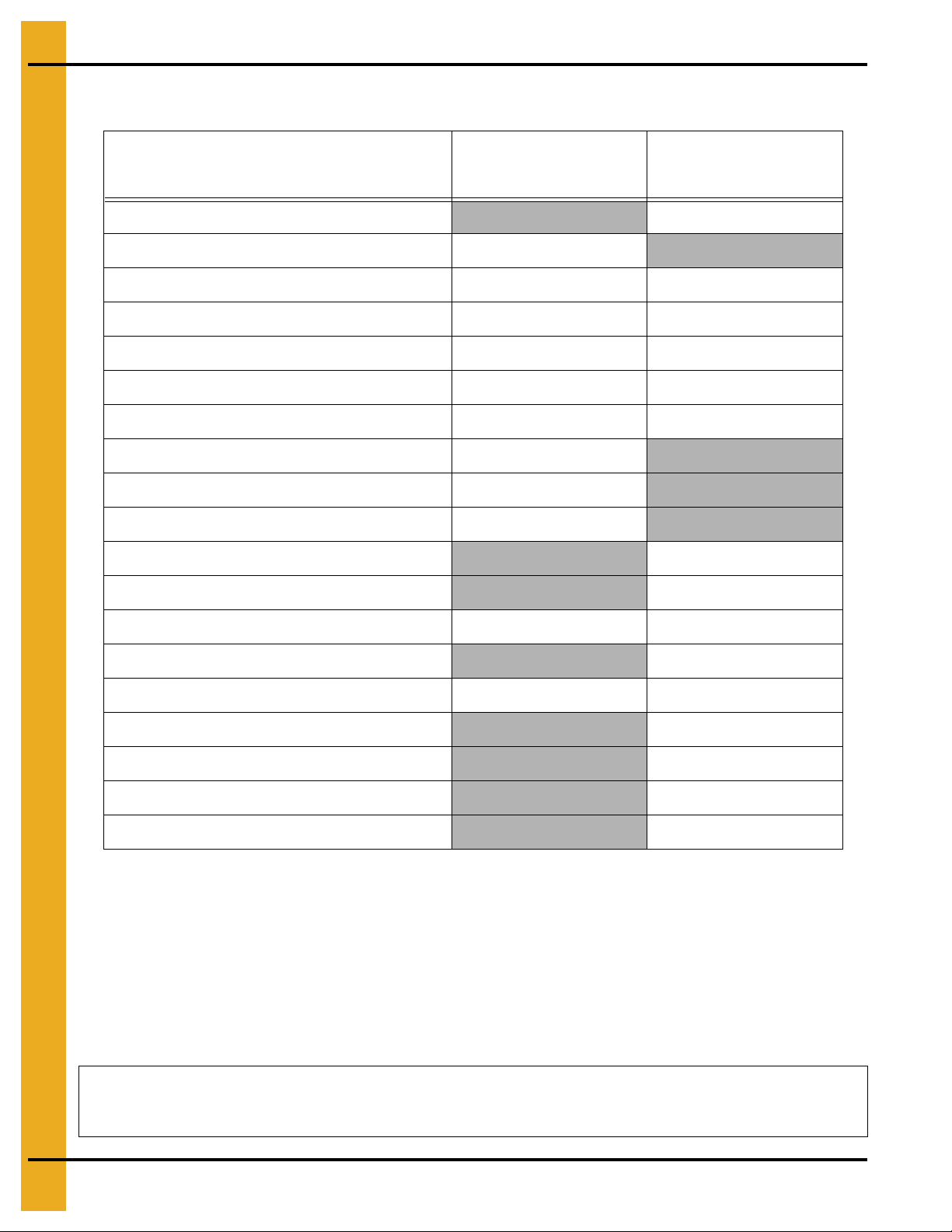

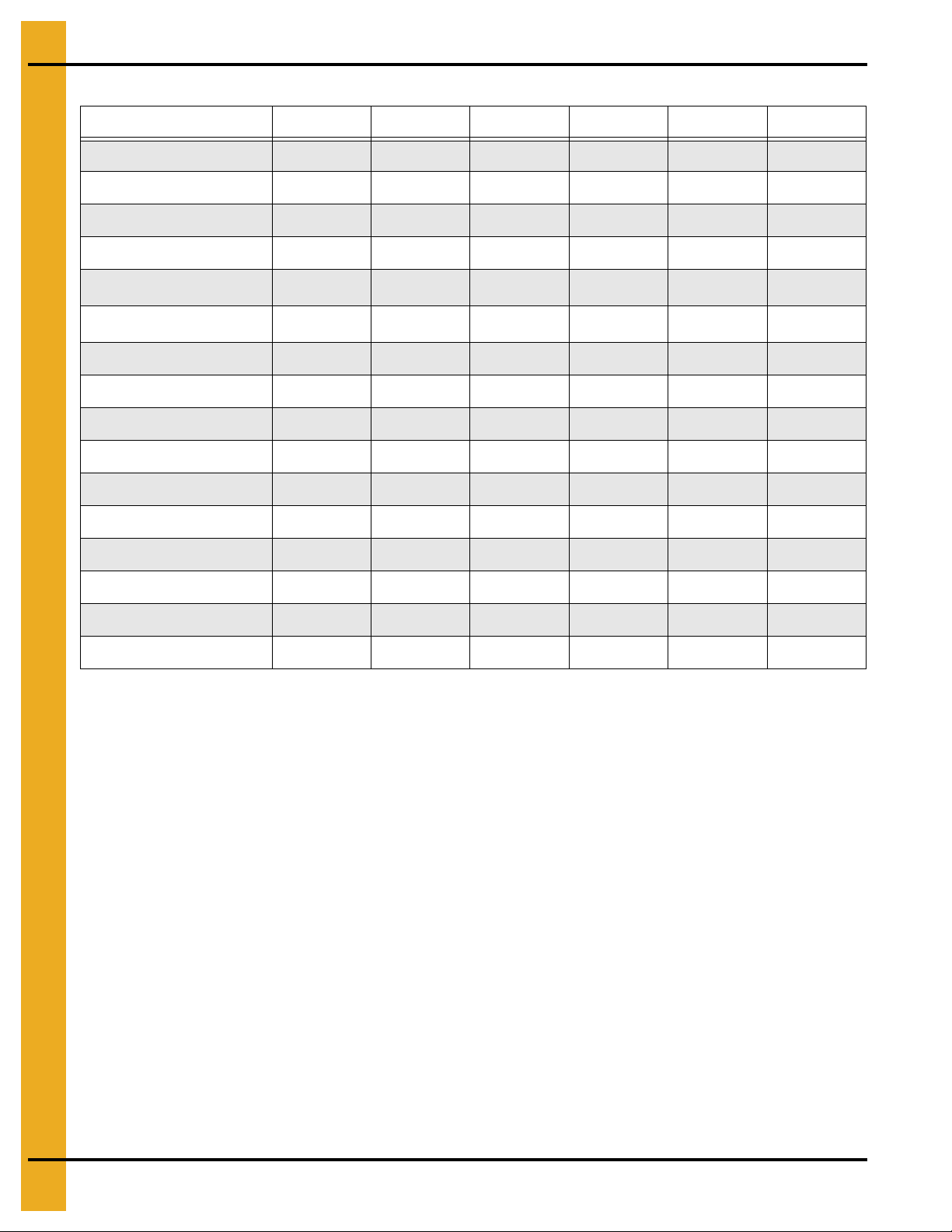

Tower Dryer Gas Train Commissioning Check List and Sign-Off

Name: _______________________Signed: _______________________ Date: ____________

All information, illustrations, photos and specifications in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any

time without notice.

Function

Component Set Point

Pass/Fail/NA

Check Fuel Supply Shut Off Valve

Check Main Fuel Supply Pressure

Set/Test Main Gas Regulator Pressure

Set/Test Over Pressure Shut Off (OPSO) Pressure

Set/Test Pressure Relief V a lve

Set/Test Maximum Gas Pressure Switch

Set/Test Minimum Gas Pressure Switch

Set Pilot Burner Pressure

Set Burner High Flame Pressure

Set Burner Low Flame Pressure

Test Pilot Line Manual Shut Off Valve

Test Main Gas Manual Shut Off Valve

Set/Test Plenum High-Limit

Carry Out Leak Test

Check Purge Time

Check Pilot Ignition

Check Main Flame Ignition

Check Modulating Valve Operation

Check Burner Shut Down

4 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 5

Table of Contents

Contents

Chapter 1 Safety .....................................................................................................................................................7

Safety Guidelines .................................................................................................................................. 7

Tower Dryer Operations and Service .................................................................................................... 8

Safety Precautions .............................................. ... ... .... ... ... ... .... ... ........................................................ 8

Working at Heights ................................................................................................................................ 9

Entering Grain Dryers ............................ ... ... ....................................................................................... 10

Precautions to Reduce Risk of Fire ..................................................................................................... 12

Chapter 2 Decals ..................................................................................................................................................13

Chapter 3 Specifications .....................................................................................................................................20

Electrical .................................... ................ ................ ................. ................ ......................................... 20

Fuel ..................................................................................................................................................... 21

Dimensions ......................................................................................................................................... 23

Chapter 4 Dryer Installation ................................................................................................................................26

Dryer Layout ........................................................................................................................................ 26

Foundation .......................................................................................................................................... 26

Standard Base for Models 1050, 1260, 1575, 1875 and 20100 .......................................................... 27

Standard Base for Model 24100 ......................................................................................................... 28

Fuel Connections ................................................................................................................................ 29

Electrical Connection .......................................................................................................................... 29

Connecting Auxiliary Conveyors ......................................................................................................... 29

Chapter 5 Operating Controls .............................................................................................................................30

Vision Control Panel Layout ................................................................................................................ 30

Chapter 6 Vision Touch Screen Display ........................................................................... .... .............................32

Select Data Log Sample Time ............................................................................................................ 33

Optional Operation Screen ............... ... ... ... ... .... ... ... ... .... ... .......................................... ... ...................... 34

Setting the Timers ............................................................................................................................... 35

Setting the Temperatures .................................................................................................................... 36

The Setup Screen ............................................................................................................................... 37

Viewing the Owner’s Manuals on the Display Screen ......................................................................... 40

Viewing the Dryer Shut Down History ................................................................................................. 41

Chapter 7 Dryer Start-Up .....................................................................................................................................42

Dryer Commissioning .......................................................................................................................... 42

Pre-Season Checks ............................................................................................................................ 46

Chapter 8 Dryer Start-Up and Operation ...........................................................................................................53

Drying Temperatures .......................... ... ... ... .......................................... .... ... ... ... .... ............................ 53

Initial Setup Parameters ............................ ............................................. ............................................. 53

Start-Up .................................. ............................................. ................................................................ 53

Continuous Flow Drying Mode Using Advanced Moisture Control ..................................... .... ... ... ... ... 54

How the Advanced Moisture Control Works ....................................................................................... 58

Chapter 9 Drying Time Tables ............................................................................................................................59

Chapter 10 Service ...............................................................................................................................................65

Pre-Seasonal Inspection and Service ..................... .... ... ... ... .......................................... ... .... ... ... ...... 65

Seasonal Inspection and Service ...................................................................................................... 65

In Case of Fire ................................................................................................................................... 66

End of Season Service ...................................................................................................................... 66

Pre-Season Service Check List ......................................................................................................... 67

End of Season Shut Down Procedure ............................... ... .... ... ... ... ... .... ... ... ................................... 67

Chapter 11 Lubrication ........................................................................................................................................68

PNEG-1797CE CE Approved T-Series Tower Dryer 5

Page 6

Table of Contents

Chapter 12 Error Messages ................................................................................................................................69

Safety Circuit Shut Down Messages ................................................................................................. 69

Input/Output Generated Errors .......................................................................................................... 70

Master Display Generated Errors ...................................................................................................... 71

Chapter 13 Wiring Diagrams for Pactrol Burner Control .................................................................................72

Upper Terminal Strip Wiring .............................................................................................................. 72

Burner/Fan Control Wiring ................................................................................................................. 73

Lower Terminal Strip Wiring .............................................................................................................. 74

Safety Relay Wiring ........................................................................................................................... 75

Upper Terminal Strip Field Connections ............................................................................................ 76

Lower Terminal Strip Field Connections ............................................................................................ 77

Chapter 14 Wiring Diagrams for Honeywell Burner Control ............................................................................78

Upper Terminal Strip Wiring .............................................................................................................. 78

Burner/Fan Control Wiring ................................................................................................................. 79

Lower Terminal Strip Wiring .............................................................................................................. 80

Safety Relay Wiring ........................................................................................................................... 81

Upper Terminal Strip Field Connections ............................................................................................ 82

Lower Terminal Strip Field Connections ............................................................................................ 83

Chapter 15 Warranty ............................................................................................................................................85

6 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 7

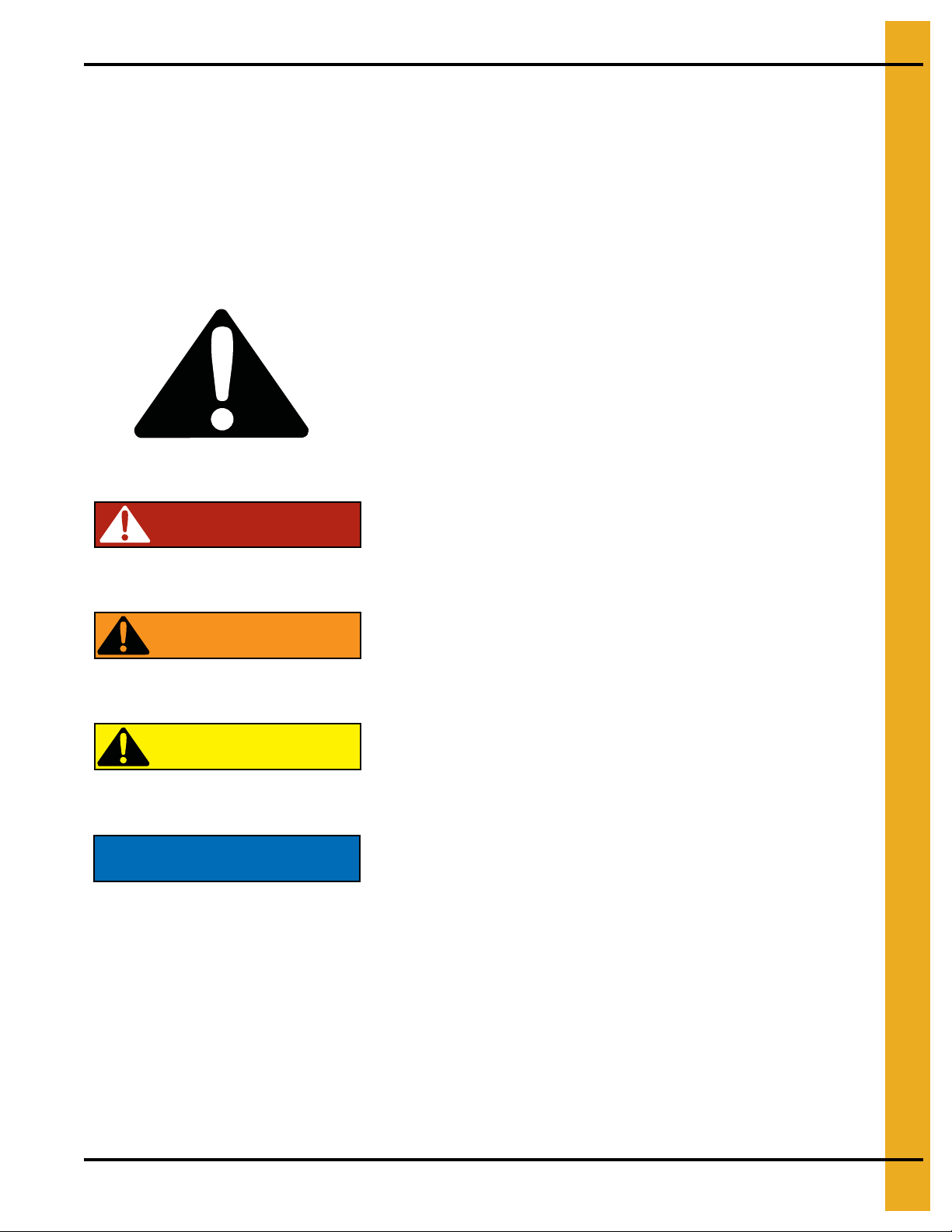

1. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1797CE CE Approved T-Series Tower Dryer 7

Page 8

1. Safety

Tower Dryer Operations and Service

This manual contains important information that all owners/operators must understand, relating to:

1. Personal safety.

2. Preventing equipment problems.

The owner/operator must inform anyone operating or working around this equipment of these

safety guidelines.

Failure to read this manual and it’s safety instructions is a misuse of the equipment and may lead to

serious injury or death.

Safety Precautions

1. Read the operating manual.

2. Electrical installation must be in accordance with relevant IEC standards, EU Directives and

Local Codes/Regulations.

3. The entire dryer must be electrically earthed.

4. Gas/liquid fuel supply must be in accordance with European Standards, EU Directives and

Local Codes/Regulations.

5. NEVER operate the dryer without guards in place.

6. DISCONNECT and LOCK OUT all power and fuel before adjusting, servicing, accessing or e ntering

the dryer or associated equipment. The ONLY safe place to do this is at the main power panel.

TURN OFF the incoming power at the main disconnect, LOCK the handle and TAG it to prevent

inadvertent re-start. Be sure to lock out any other equipment attached to the dryer such as elevators

and conveyors.

NEVER rely on the ON/OFF controls at the PLC interface. These are not safety shut offs.

In addition, ensure the gas supply has been locked out at the main gas valve feeding the dryer.

7. NEVER bypass any safety device.

8. Whilst the dryer is running no-one should be inside or on the dryer.

9. Observe recommended drying temperatures.

10. Keep the dryer clean throughout.

11. Use CAUTION. The dryer and associated equipment may START AUTOMATICALLY.

12. Keep fan inlets clear of any foreign objects.

13. Auxiliary equipment capacity must be matched to the dryer.

14. Keep drive belts correctly tensioned.

15. Dry clean grain only for optimum performance.

16. Dryer operators must be trained and competent.

17. Follow required maintenance procedures and intervals.

8 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 9

1. Safety

Working at Heights

Whilst the equipment has been designed to operate primarily at ground level, at some stages during the

life cycle it will be necessary to operate at heights. For this reason the equipment has been provided with

access ladders, platforms and walkways. These have been designed to recognized safety standards to

minimize the risk to health and safety to operators and technicians working on them. In addition attention

should be paid to the following safety requirements.

1. The ladders, platforms and walkways are for use by competent and trained personnel only. NEVER

allow children or members of the general public to gain access to the equipment, its ladders or

access platforms.

2. Where the equipment is sited in an unsecured location, access must be restricted by use of security

fencing and lockable gates.

3. Lower sections of ladders on the equipment should be fitted with a lockable safety gate, to prevent

unauthorized access.

4. Ensure any hot surfaces have had adequate time to cool before working on or in the equipment.

This may require running the equipment fans only to cool off external screens and internal

burner components.

5. The equipment should be OFF and all power LOCKED OFF before work on or in the equipment.

Ensure the power isolator is OFF and LOCKED and TAGGED to prevent inadvertent re-start.

This must include all equipment attached to the dryer/bin on which you are working. (See Figure 1A.)

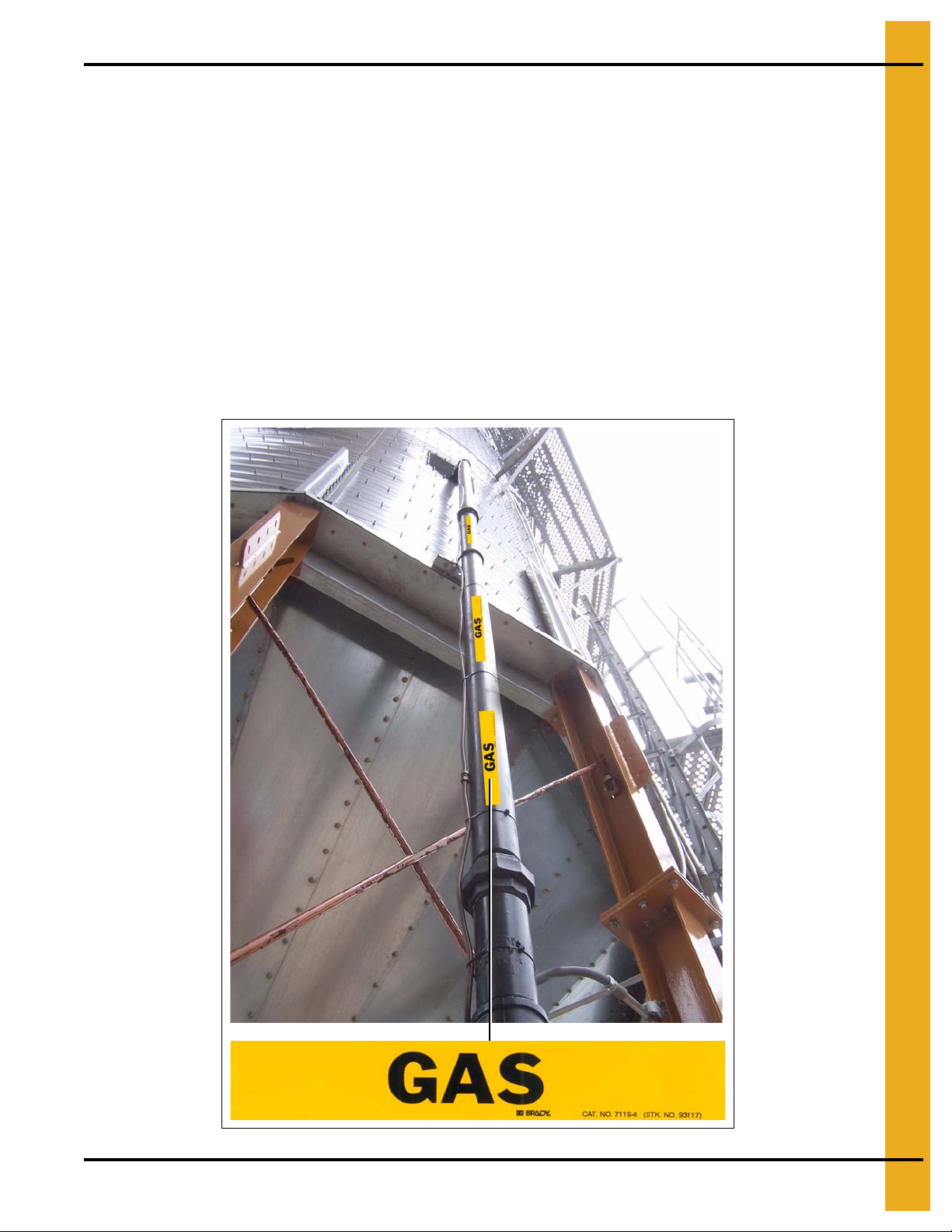

Figure 1A

6. Ensure the fuel supply is OFF and LOCKED. (See Figure 1B.)

Figure 1B

PNEG-1797CE CE Approved T-Series Tower Dryer 9

Page 10

1. Safety

7. NEVER attach lifting equipment to ladders or platforms.

8. When working on the equipment, NEVER go outside the safety rails provided.

9. NEVER walk on the roof of the equipment.

10. Do not work at heights during high winds, heavy rain, snow, ice or storm.

The majority of routine cleaning and service can be carried out from the service platforms provided.

However in exceptional circumstances it may be necessary to access other parts of the equipment. In

particular, in the rare event that access is required to repair or r eplace the g rain level switches. On th ese

occasions additional access and safety equipment may be required. Wherever possible we recommend

the use of powered access lift platforms or ‘cherry pickers’. In exceptional circumstances access may

require the use of safety harness. Such work must only be carried out b y specialist technicians trained and

qualified in working at heights and only after a complete risk assessment has been carried out and safe

working methods established.

Entering Grain Dryers

Wherever possible it is recommended not to enter grain dryers. However, if you have to enter the, observe

the following minimum

precautions:

1. NEVER

2. Make sure you are aware of all the possible hazards

3. Complete a risk assessment

4. You may need to complete a permit to work

approved by the dryer owner or supervisor.

5. Ensure the dryer has been purged of any products of combustion. Shut off the burner but leave the

fans running for at least 30 minutes before entry.

6. Do not smoke or use naked flames in or around the dryer.

7. Where there is a risk of harmful gases or vapors, check the atmosphere with a suitable analyzer. If

necessary, run the fans for longer to provide a safe breathable atmosphere. If in doubt do not enter

8. Switch OFF, lock and tag

equipment feeding and emptying the dryer. This will require turning the main power isolator to OFF,

LOCKING it and apply a TAG to prevent inadvertent re-start. (See Figure 1C on Page 11.)

allow a child or untrained, inexperienced person to enter a grain dryer at any time.

present within the dryer.

and identify any control measures that may be required, including:

• Personal protective equipment, such as hand, eye, foot, hearing, head and

respiratory protection.

• Safe access equipment.

• Safety equipment, such as safety line and harness.

• Supplementary lighting.

and prepare a safe system of work and have it

power supplies to ALL equipment associated with the dryer. Include

.

10 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 11

Figure 1C

9. You may also need to lock out any associated equipment attached to the dryer.

1. Safety

10. Shut OFF, lock and tag

the fuel supply at the main incoming valve. (See Figure 1D,)

Figure 1D

11. Never work alone, it is recommended to work in teams of at least three (3) so help is immediately

available in the event of emergency.

12. On completion of the work, check all team members are out of the dryer and all work tools have

been recovered.

13. Close and lock all dryer accesses.

14. Do not re-connect power or fuel supplies until approved by the dryer owner or supervisor.

PNEG-1797CE CE Approved T-Series Tower Dryer 11

Page 12

1. Safety

WARNING

Keep the dryer clean. Do not allow fine material to accumulate in the plenum

chamber or surrounding the outside of the dryer.

Precautions to Reduce Risk of Fire

Whilst the dryer has been designed to minimize the risk of ignition of combustible dust and dirt, this can

only be ensured by regular inspection and cleaning. At least every five (5) days.

1. Refer to Page 10 for required precautions before entering the dryer. The dryer must be locked out

and tagged at the main power and fuel supply before entering.

2. Open the dryer access hatches and check for any significant build-up of dust or particles of grain.

3. Using an industrial vacuum cleaner, clean the plenum. Do not use compressed air.

4. Check inside other dryer accesses and clean as required.

5. Check all personnel are out of the dryer, close and lock all accesses before re-starting drying.

6. This procedure may be carried out more regularly in conditions of extreme dust and dirt.

Exercise greater caution when drying highly flammable grains and seeds. For example rapeseed, can ola,

linseed, sunflower and milo.

All grain and seed must be whole (minimal cracked or crushed), clean and dust free.

Dry at low temperatures (< 40°C).

Avoid dust and chaff being drawn into the fan and heater.

Keep the fan, heater, drying plenum and ducts clean at all times.

In the event of a fire (or suspected fire).

• Shut down the entire dryer.

• Turn OFF fuel at the tank or supply valve.

• Shut off and lock electrical power.

• Evacuate the area.

• Call the fire department.

Use Caution in the Operation of this Equipment

This dryer is designed and manufactured with operator safety in mind. However, the very nature of a grain

dryer having a gas burner, high voltage electrical equipment and high speed rotating parts, presents

hazards to personnel which cannot be completely safeguarded against withou t interfering with the efficient

operation of the dryer and reasonable access to its components.

Use extreme caution at all times when working on or around the dryer.

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. Follow the recommendations within the Owner’s Manual and make it a practice to regularly inspect

the unit for any developing problems or unsafe conditions.

Take special note of the safety precautions on Page 8 before attempting to operate the dryer.

12 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 13

2. Decals

Safety decals must be read and understood by all people in and around the dryer area. If a ny safety decals

are not displayed on the dryer or if they are damaged, contact The GSI Group, Inc. for replacement:

International Decals

International, translated versions of the decals fitted to the equipment are available as part of the

Language Pack that was supplied with the product. If you need further copies or a different language,

please contact GSI or you dealer.

The international decals have been designed to be placed directly over the USA standard versions.

Normally these will be factory fitted, but if you need to change them, please refer to the decal cross

reference sheet, provided with the Language Pack and the decal locations given in the user’s manual.

Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

PNEG-1797CE CE Approved T-Series Tower Dryer 13

Page 14

2. Decals

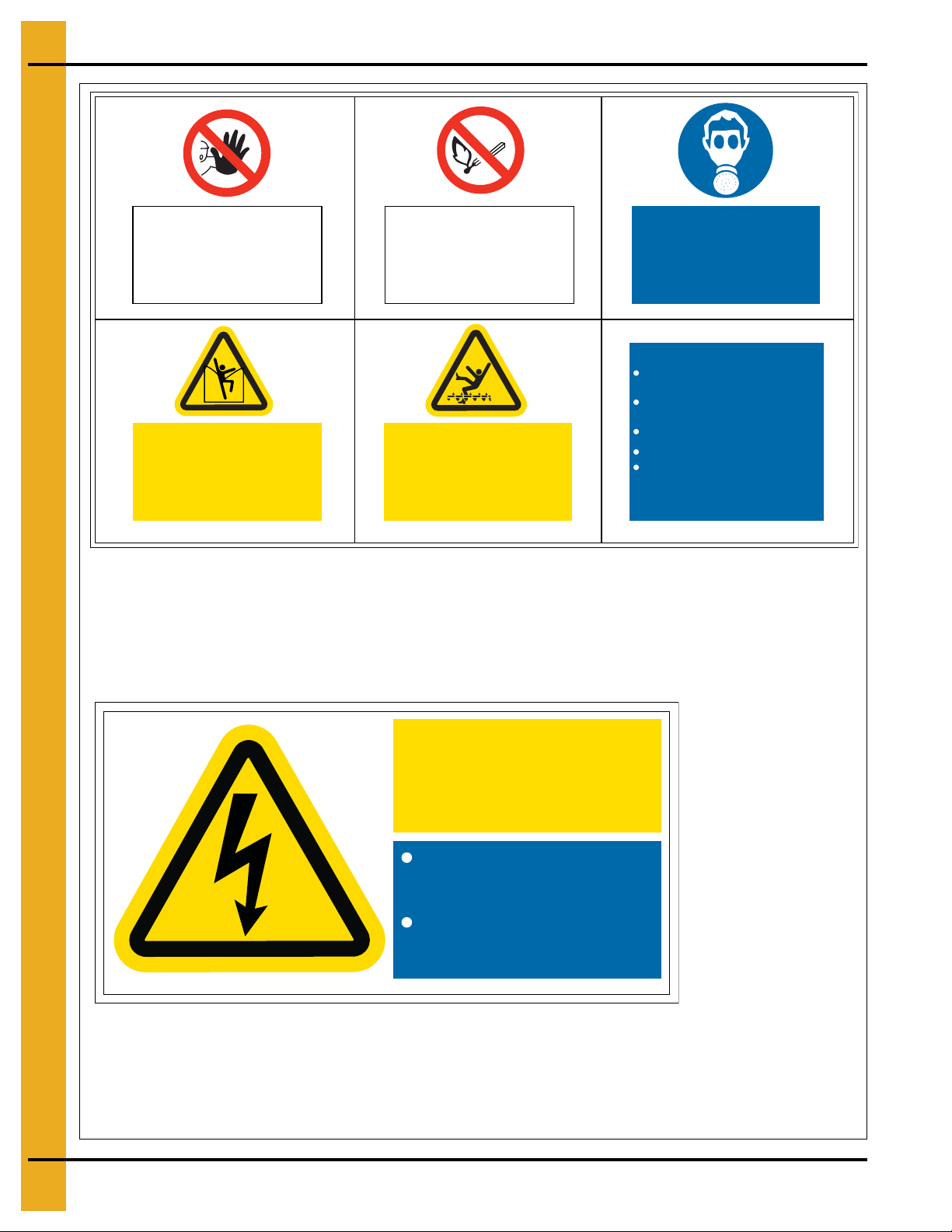

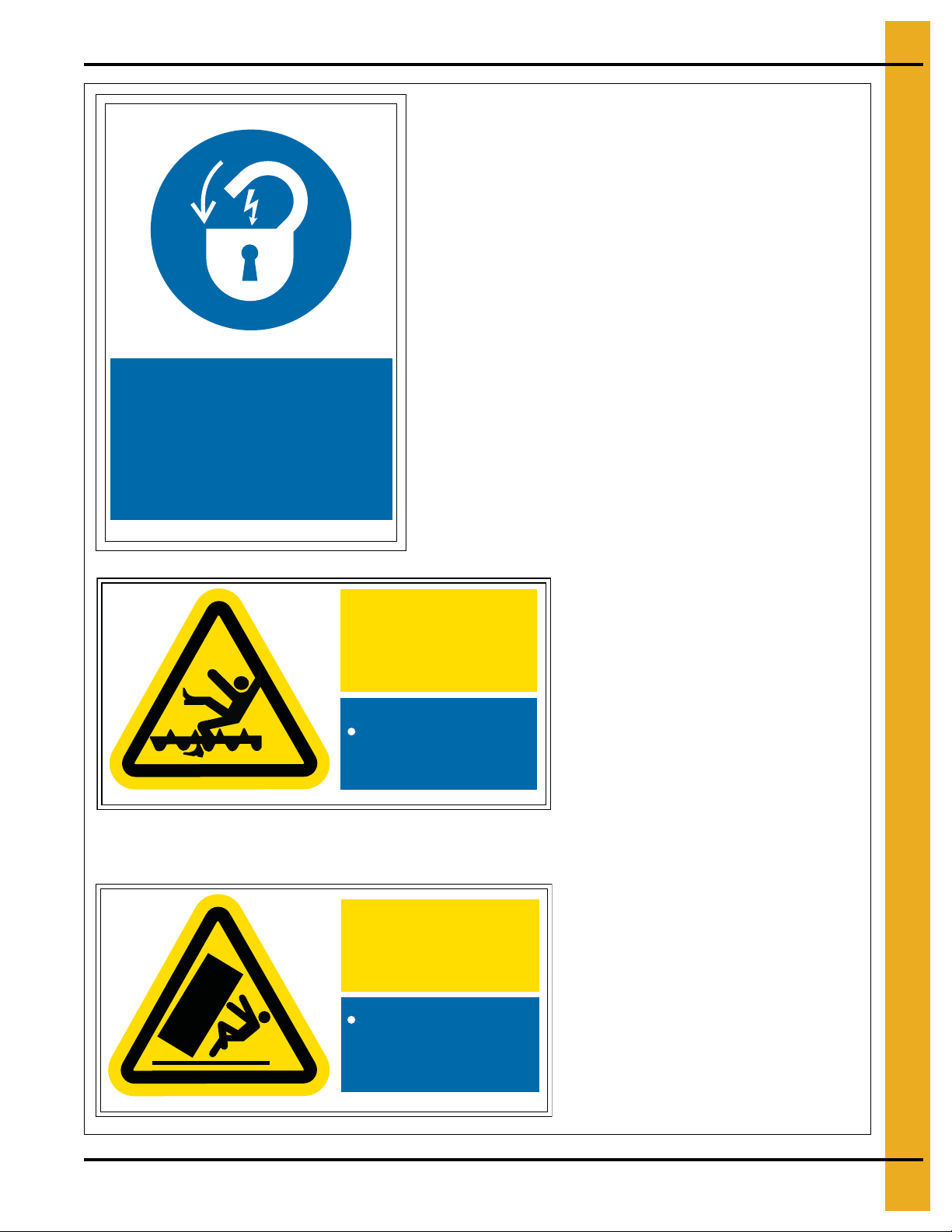

DC-2163

DC-2163 is located on outside and inside of the main power panel doors.

Quantity: 3

DC-2161

DC-2161 is located on inside and outside of the roof access hatches.

Quantity: 2

No entry to

unauthorised

personnel

Suffocation and

Entrapment Hazard

Do not walk directly

on stored material

No smoking or

naked flames

Automatic Machinery

Isolate and lock all power

before entering this bin

Respirators

must be worn

in this area

Before entering:

Permit required for entry into

confined space

Disconnect and lock all electrical

power

Disconnect and lock fuel supply

Use safety harness and safety line

Ensure someone else is outside

the bin

DC-2161

High

Voltage

Isolate and lock from power

before removing guards or

opening enclosure

Replace all guards and lock

enclosure before reconnecting

to power

DC-2163

14 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 15

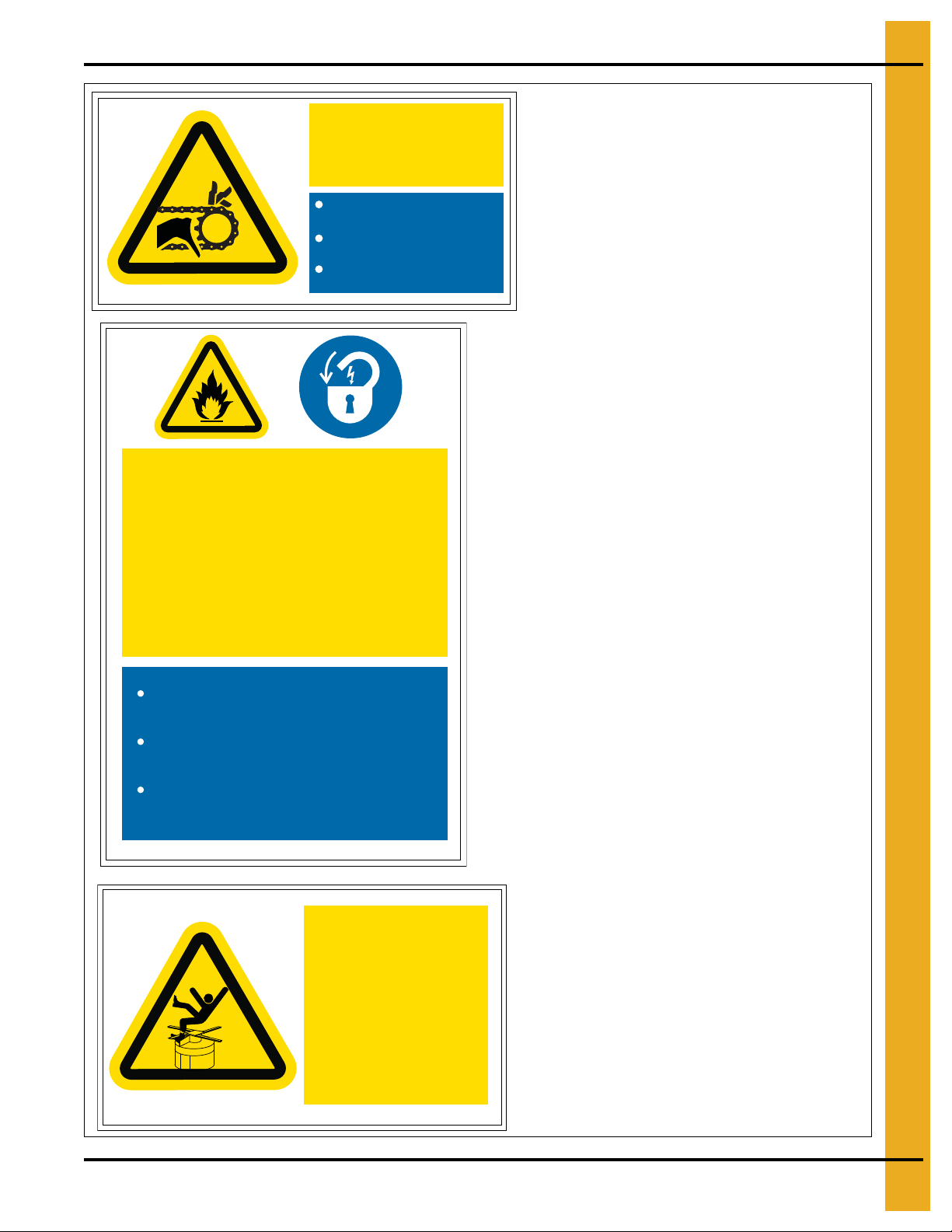

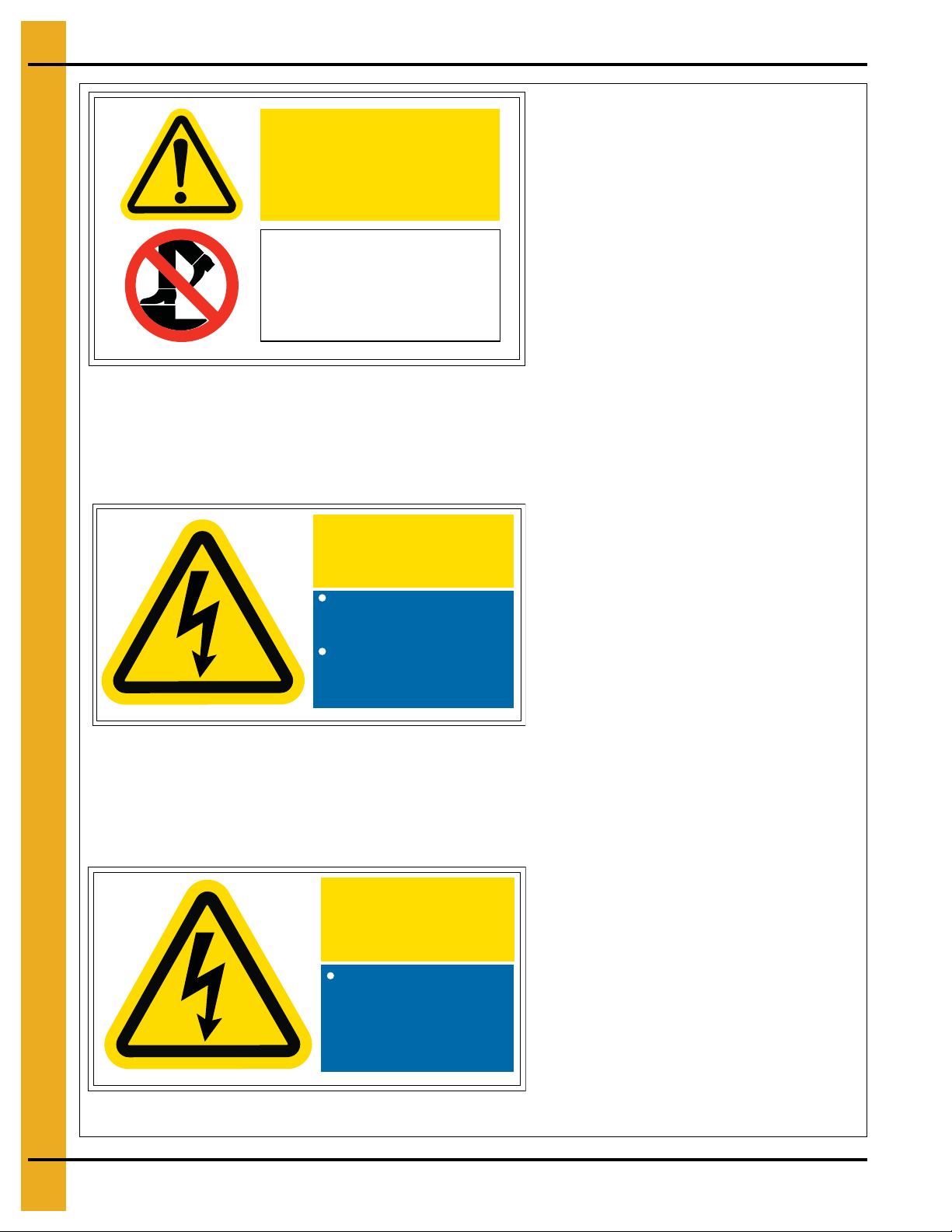

2. Decals

Do not stand on

rotating drum

Serious injury

may result

DC-2212

Rotating drum

below

DC-2212

DC-2212 is located on the outside of the hopper

service access hatch.

Quantity: 2

Do not operate with guards

removed

Isolate and lock from power

before removing guards

Replace all guards before

reconnection to power

Automatic

Machinery

DC-2164

DC-2165

DC-2165 is located on the heat section inner and

outer access hatches.

Quantity: 2

DC-2164

Background: White

Colors: Black, ANSI Yellow and ANSI Blue

Size: 3.940" x 1.970"

DC-2165

Do not open door while drier is

running

Disconnect and lock electric and

gas supply before opening

Close and lock door before

reconnecting

High Temperature

and Pressure

Equipment Can Start

Unexpectedly

PNEG-1797CE CE Approved T-Series Tower Dryer 15

Page 16

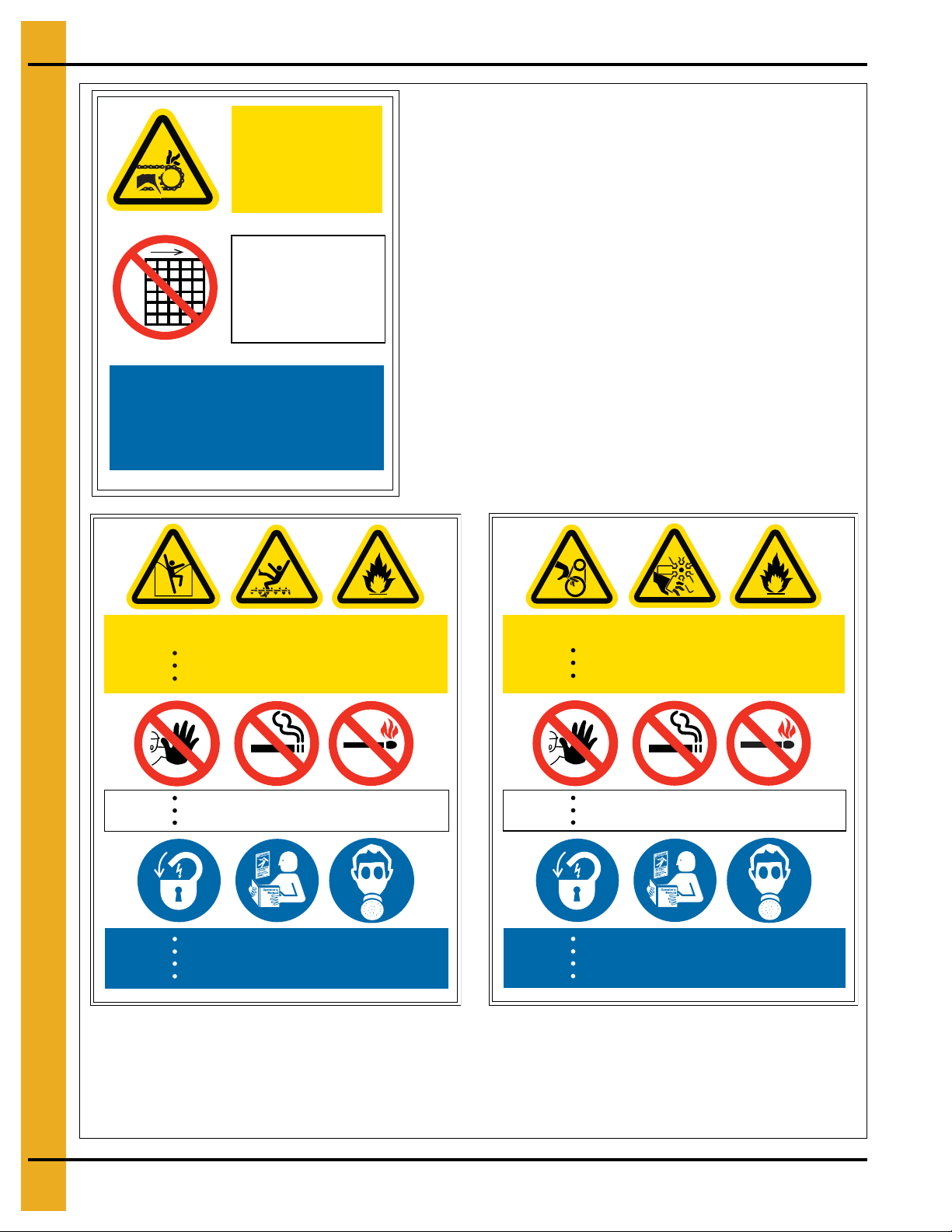

2. Decals

Confined Space

High Temperature

Exposed fan and belt drive

Automatic machinery

No unauthorized access

No smoking

No exposed flames

Lock out all electrical power before entering

Lock out fuel supply before entering

Refer to owners manual before entering

Wear respiratory protection

DC-2216

DC-2216

DC-2216 is located on the cool section (intake plenum)

access hatch.

Quantity: 1

Confined Space

High Temperature

Powered machinery can kill or dismember

Flowing material will bury and suffocate

No unauthorized access

No smoking

No exposed flames

Lock out all electrical power before entering

Lock out fuel supply before entering

Refer to owners manual before entering

Wear respiratory protection

DC-2215

DC-2215

DC-2215 is located on upper and middle level

access hatches.

Quantity varies with size of dryer.

DC-2214

DC-2214 is located on the grain sampling access hatch.

Quantity: 1

Automatic

conveying

equipment

Do not remove

guarding

Grain Sampling Point

below

DC-2214

16 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 17

2. Decals

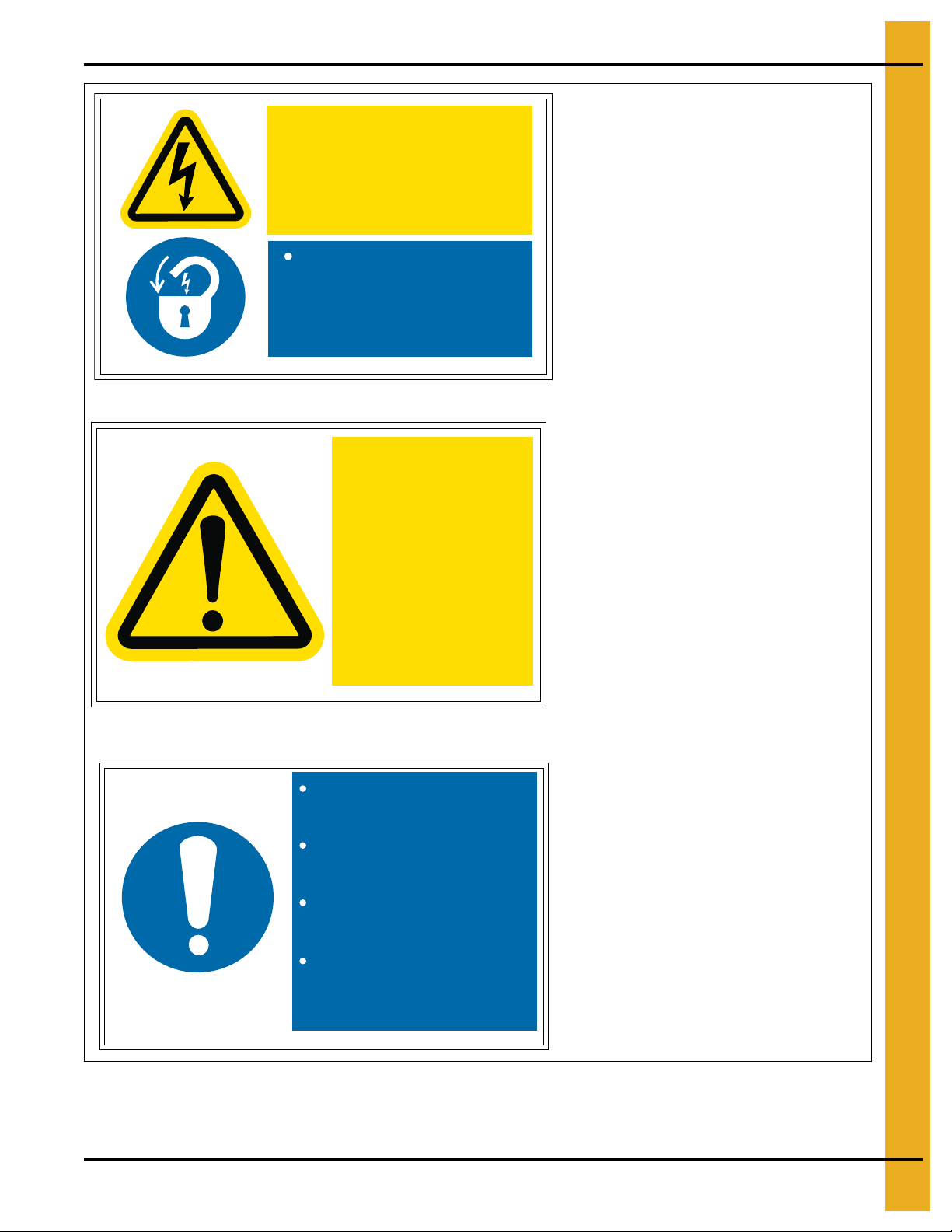

Electrical Lockout

DC-2217

BEFORE working on or in the dryer

SWITCH OFF, LOCK and TAG

to prevent accidental start-up

DC-2217

DC-2217 is located adjacent to the electrical lock out handle on

the main power panel.

Quantity: 1

DC-2230

Background: White

Colors: Black, ANSI Y ellow and ANSI Blue

Size: 6.000" x 3.000"

DC-2231

DC-2231 is located on the outside of the

main power panel doors.

Quantity: 2

DC-2230

Lock out all electrical

power before entering

Auto equipment can

start at any time

Rotating auger will

crush and cut

DC-2231

Secure legs to

foundation prior to

opening doors

Crush

Hazard

PNEG-1797CE CE Approved T-Series Tower Dryer 17

Page 18

2. Decals

DC-2233

If an overload or a fault current

interruption occurs, circuits must

be checked to determine the cause

of the interruption

If a fault condition exists, the

current-carrying components should

be examined and replaced if

damaged, and the integral current

sensors must be replaced

Electric shock and

fire hazard

DC-2234

To maintain overcurrent short

circuit and ground fault

protection, the manufacturer’s

instructions for selecting

overload relays and setting

the instantaneous trip circuit

breaker must be followed

Electric shock and

fire hazard

DC-2234

DC-2234 is located on inside main power

panel door.

Quantity: 1

DC-2233

DC-2233 is located on inside main power

panel door.

Quantity: 1

DC-2232

DC-2232 is located on roof panels adjacent

to roof steps.

Quantity: 4

Slip and fall hazard

Can cause severe

injuries

Do NOT step or stand

in this area

DC-2232

18 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 19

DC-2235

High Voltage

Insure that the incoming AC

power and all separate power

sources are turned off and

locked before working on this

equipment

Failure to observe practice

below may result in severe

injury, death, and/or

equipment damage

All maintenance

DC-2235

DC-2235 is located on inside and outside

main power panel door.

Quantity: 2

DC-2236

DC-2236 is located on inside main power

panel door.

Quantity: 1

DC-2237

DC-2237 is located on inside main power

panel door.

Quantity: 1

procedures must be

performed by qualified

personnel who are

familiar with the

operation of this

equipment.

2. Decals

For precise location of all safety decals, please refer to manual provided with the language pack for

the dryer.

PNEG-1797CE CE Approved T-Series Tower Dryer 19

Failure to observe this

warning can result in

serious or even fatal

injury and/or equipment

damage.

DC-2236

Be sure that charge light and all

LED’s are out before touching any

components.

All test equipment should be

connected and disconnected with

power off.

Ground test equipment, such as

Insure that the incoming AC

oscilloscopes, may damage the

power and all separate power

inverter.

sources are turned off and

locked before working on this

Isolate all instruments from

equipment

ground before using. The DC bus

remains charged for several

minutes after power is removed.

DC-2237

Page 20

3. Specifications

Dryer Specifications

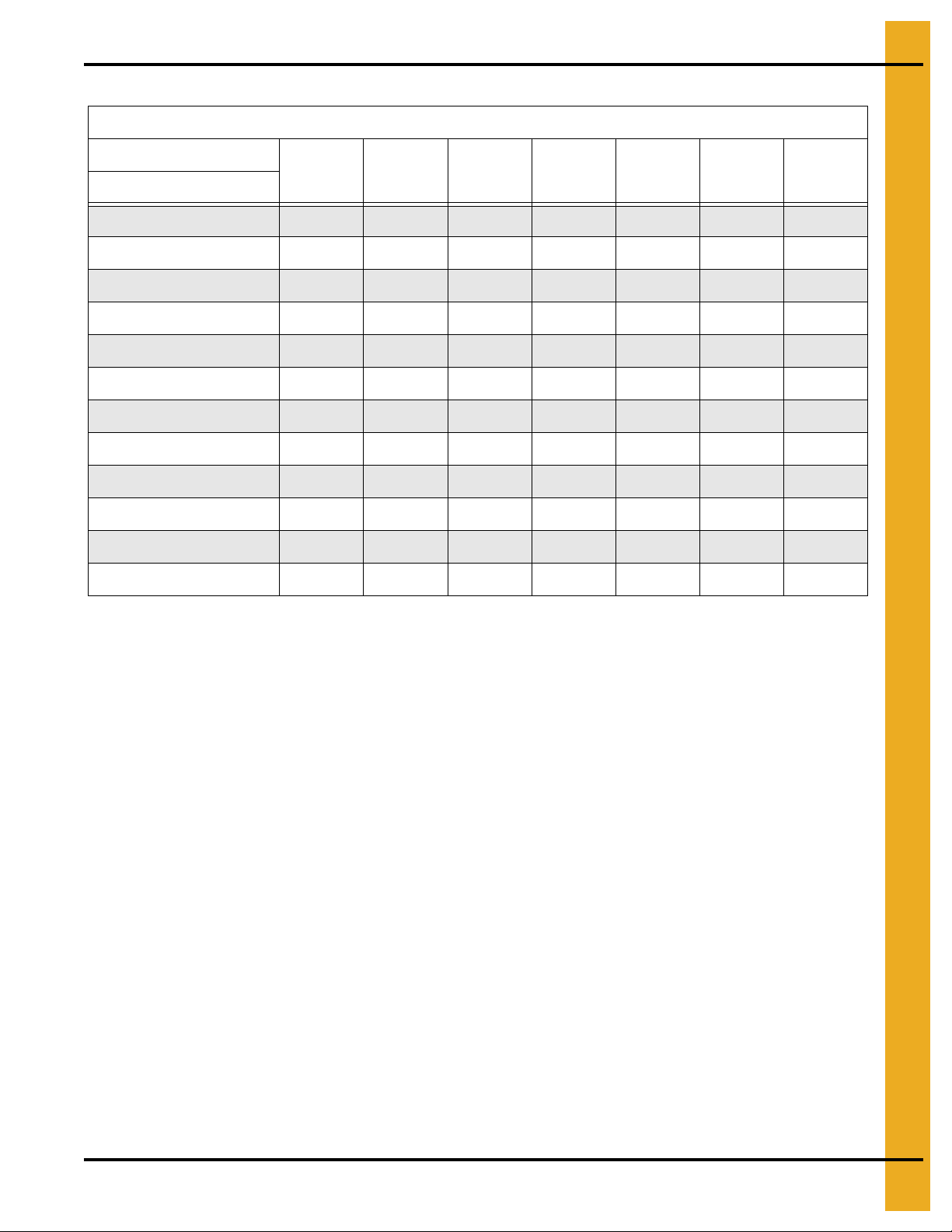

Models 1050 1260 1575 1875 20100 24100

Blower Size 43" Axial 43" Axial 8490 8542 8542 8600

Blower RPM 1750 1750 1035 856 981 818

Blower kW 37.50 45.00 56.25 56.25 75.00 75.00

Metering kW 0.75 0.75 0.75 0.75 0.75 0.75

Drying m3/s

3

Cooling m

Grain Column 324 mm 324 mm 324 mm 324 mm 324 mm 324 mm

Tower Diameter 3.65 m 3.65 m 3.65 m 3.65 m 3.65 m 3 .65 m

Overall Height 13.9 m 15.9 m 18.0 m 21.0 m 23.1 m 26.1 m

Wet Holding (T) 7.677.677.677.677.677.67

Heat Holding (T) 15.49 19.20 23.22 29.41 31.90 38.07

Cool Holding (T) 5.56 6.81 7.75 8.99 11.46 12.70

Dryer Holding (T) 31.29 36.25 41.20 48.64 53.59 60.99

Outside Catwalks 001223

T/H (20%-15%) 25 30 38 46 51 61

T/H (25%-15%) 151823273037

/s

19.98 22.86 36.42 38.63 46.57 51.15

6.85 8.27 18.21 19.32 23.28 25.58

Electrical

Standard voltages are:

1. 240V, 480V or 575V, 60 Hz

2. 380V, 400V or 415V, 50 Hz

The power panel includes:

1. Main power disconnect.

2. Motor starters and overloads (standard direct on line, star/delta and soft start are options).

3. Control circuit breakers for the individual blower motors.

4. Auxiliary 7.5 kW motor starters for dry and wet grain handling equipment.

5. A correctly designed power supply is required, including safety earth connection.

Please note that the figures given on Page 72 are minimum figures and do not take into account starting

currents. Please allow for these when designing the required power supply for the dryer.

20 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 21

3. Specifications

Minimum Electrical Power Requirements

3 Phase Power Requirements (A)

Supply Voltage

230 380 400 415 440 460 575

Model #

T-1050 204 123 117 113 106 102 81

T-1260 226 136 130 125 118 113 90

T-1575 258 156 148 143 135 129 103

T-1875 258 156 148 143 135 129 103

T-20100 316 191 181 175 165 158 126

T-24100 316 191 181 175 165 158 126

F-1050 204 123 117 113 106 102 81

F-1260 226 136 130 125 118 113 90

F-1575 258 156 148 143 135 129 103

F-1875 258 156 148 143 135 129 103

F-20100 316 191 181 175 165 158 126

F-24100 316 191 181 175 165 158 126

Fuel

1. Fuel types are LPG or natural gas vapor.

2. Minimum supply pressure is,

a. 350 mBar natural gas at full burner flow rate.

b. 350 mBar LPG vapor at full burner flow rate. Higher pressures may be required to obtain

maximum burner output.

3. Burner flow rates are as table on Page 22.

PNEG-1797CE CE Approved T-Series Tower Dryer 21

Page 22

3. Specifications

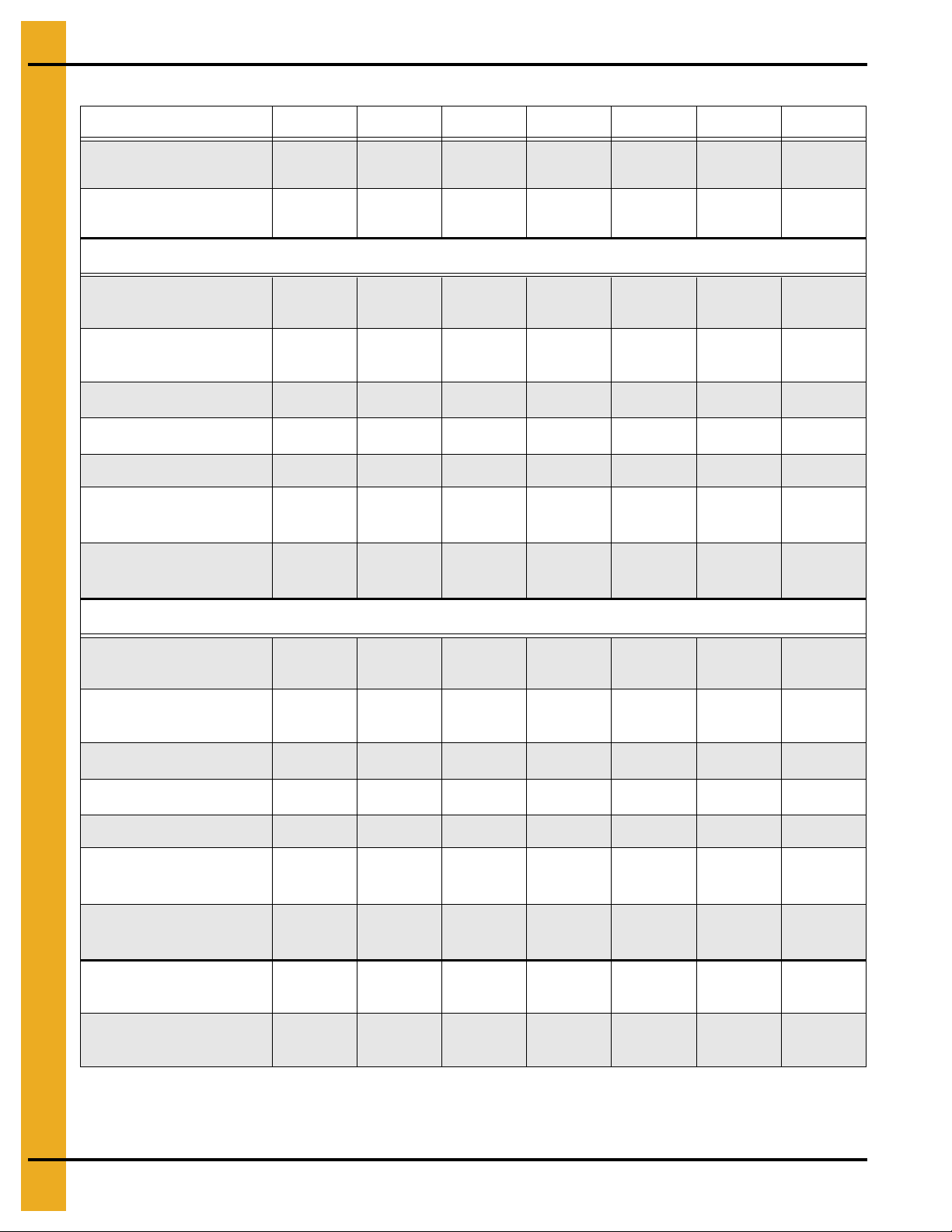

T-Series and F-Series Fuel Specifications

T-Series and F-Series T/F-1050 T/F-1260 T/F-1575 T/F-1875 T/F-1054 T/F-20100 T/F-24100

Maximum Burner

Output (kW)

Average Burner

Output (kW)

LPG Fuel LPG Gross CV

Maximum Gas Flow

LPG (m

3

/h)

Average Gas Flow

3

LPG (m

/h)

Supply Pressure (mBar1)

Regulator Setting (mBar2)

3254 3831 4882 5180 6244 6858 7722

1871 2203 2807 2979 3590 3943 4440

93.8 MJ/m

3

125 147 187 199 240 263 296

72 85 108 114 138 151 170

350-700 350-700 350-700 350-700 350-700 350-700 350-700

206 206 206 206 206 206

Regulator Spring Black Cadmium Cadmium Cadmium Cadmium Cadmium Cadmium

Burner Pressure High-Fire

2

O6)

mm (H

Burner Pressure Low-Fire

2

O7)

mm (H

418 1375 807 1189 1447 972

16.7 55.0 32.3 47.5 57.9 38.9

Natural Gas Fuel NG Gross CV

Maximum Gas Flow

3

NG (m

/h)

Average Gas Flow

3

NG (m

/h)

Supply Pressure (mBar1)

Regulator Setting (mBar2)

303 357 455 483 582 640 720

174 205 262 278 335 368 414

350-700 350-700 350-700 350-700 350-700 350-700 350-700

21 206 206 206 206 206 206

39 MJ/m

3

Regulator Spring Black Cadmium Cadmium Cadmium Cadmium Cadmium Cadmium

Burner Pressure High-Fire

mm (H

2

O6)

Burner Pressure Low-Fire

mm (H

2

O7)

Pressure Relief

Set Point (mBar

4

)

Over Pressure Valve

5

Set Point (mBar

)

500 500 500 500 500 500 500

450 450 450 450 450 450 450

719 1189 697 1009 1241 855

28.8 47.6 27.9 40.3 49.7 34.2

22 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 23

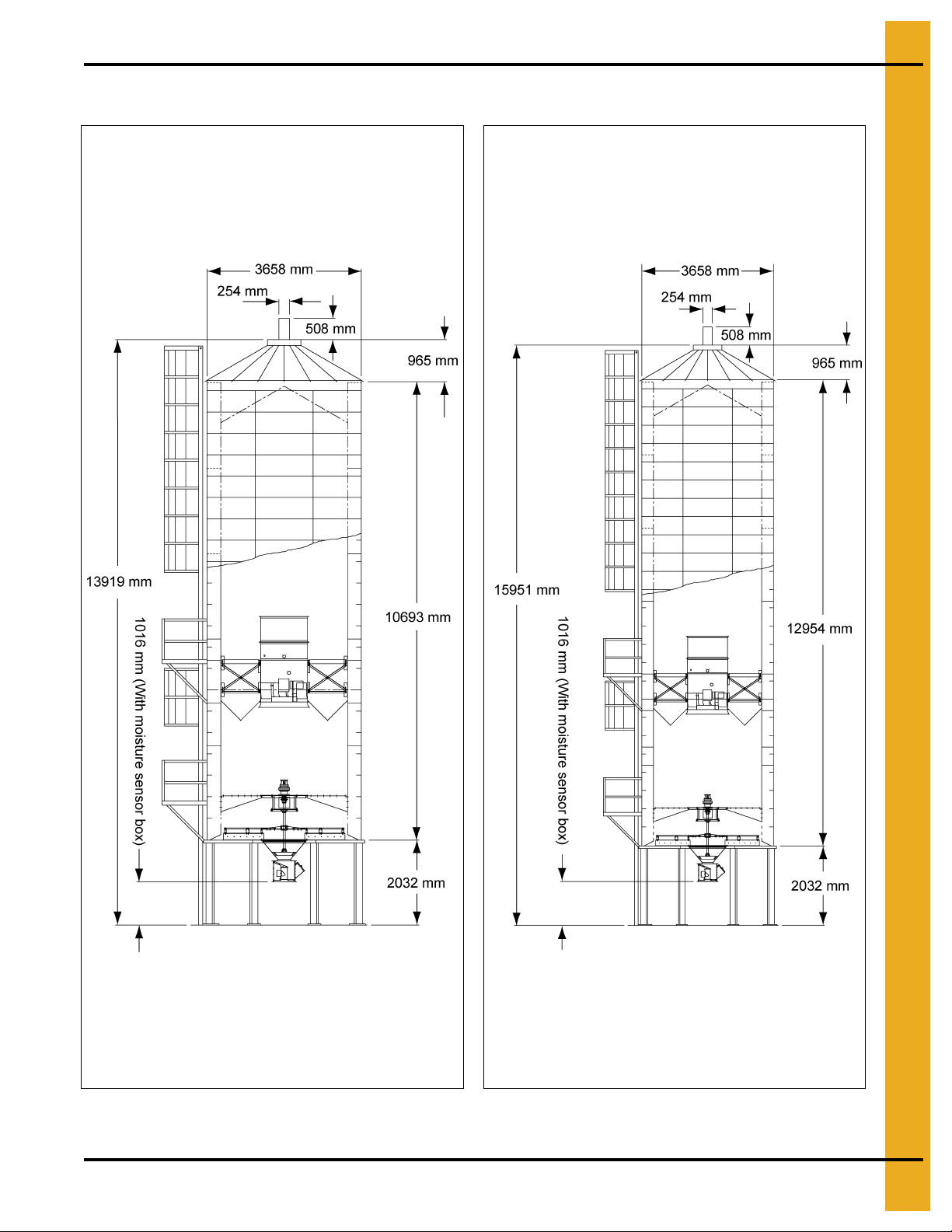

Dimensions

3. Specifications

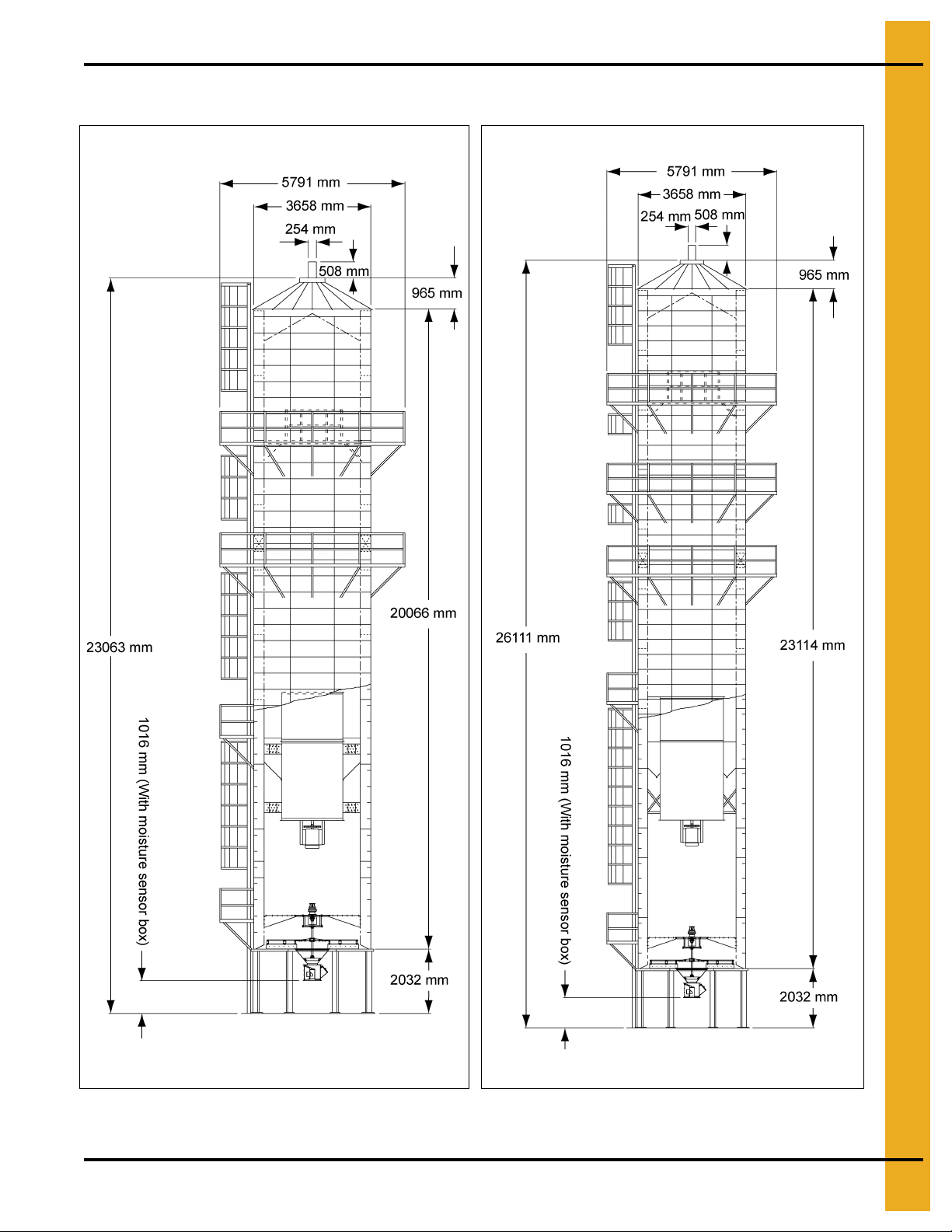

Figure 3A 1050 Figure 3B 1260

PNEG-1797CE CE Approved T-Series Tower Dryer 23

Page 24

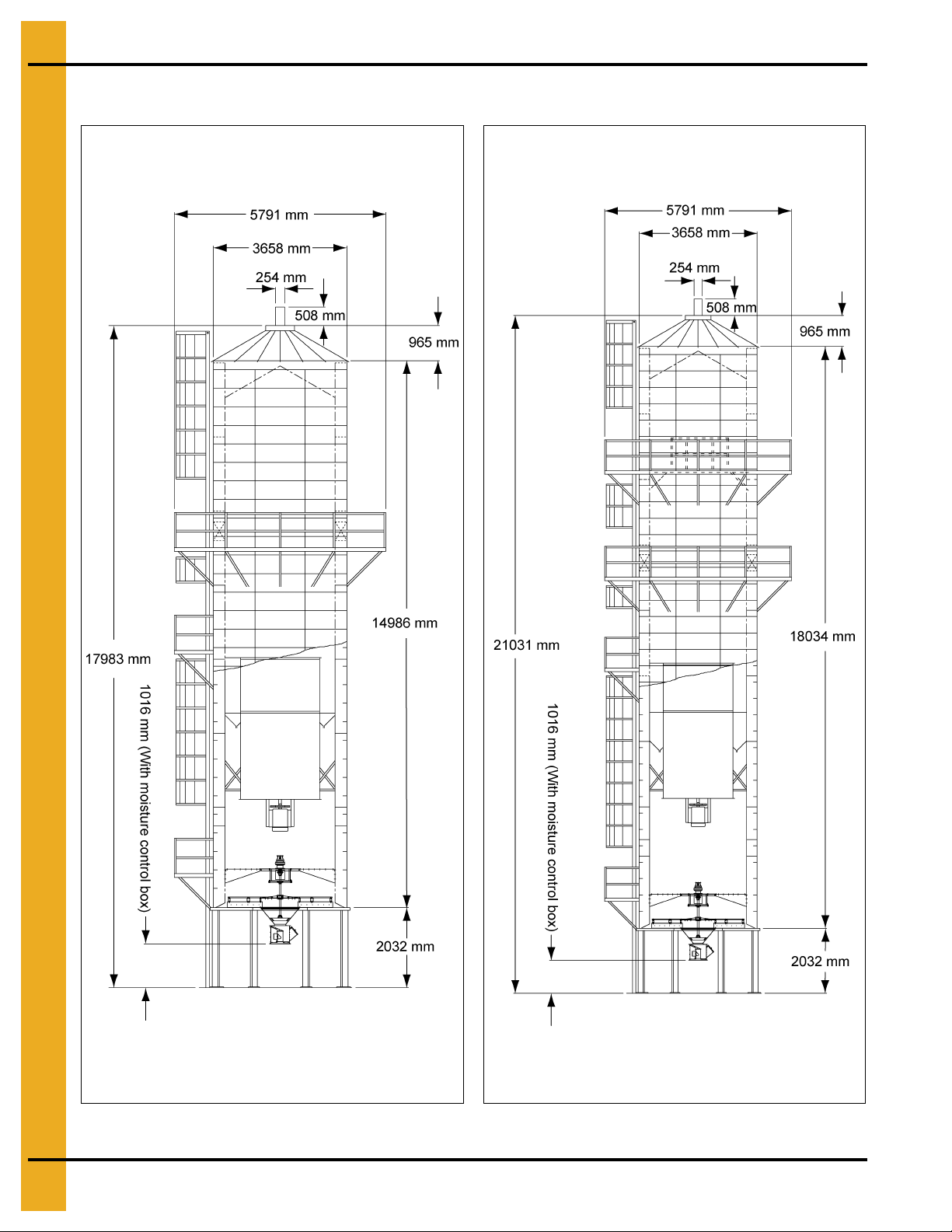

3. Specifications

Dimensions (Continued)

Figure 3C 1575 Figure 3D 1875

24 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 25

Dimensions (Continued)

3. Specifications

Figure 3E 20100

PNEG-1797CE CE Approved T-Series Tower Dryer 25

Figure 3F 24100

Page 26

4. Dryer Installation

Dryer Layout

System Layout

When considering dryer location make allowance for:

1. Grain handling systems.

2. Location of storage bins.

3. Wet grain supply.

4. Prevailing wind direction.

5. Fuel and power supply.

6. Noise.

7. Control panel location.

Site Location

Do not locate the dryer:

1. Inside a building.

2. Adjacent to combustible material which may be sucked in.

3. Within 2.0 m of other structures. Refer to specifications on Pages 20-22 and dimensions

on Pages 23-25.

You may need to obtain local permission for the dryer construction and should also consider:

1. Electrical code.

2. Fuel installation regulations.

3. Insurance requirements.

Foundation

Standard foundation details are given in Figure 4A on Page 27 and Figure 4B on Page 28. For ground

conditions outside of these standards a local engineer will be required to carry out site specific

foundation design.

26 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 27

4. Dryer Installation

Standard Base for Models 1050, 1260, 1575, 1875 and 20100

Figure 4A

PNEG-1797CE CE Approved T-Series Tower Dryer 27

Page 28

4. Dryer Installation

Standard Base for Model 24100

Figure 4B

28 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 29

4. Dryer Installation

Fuel Connections

LPG Dryers with Internal Vaporizers

The dryer is designed to operate on liquid LPG with gross calorific value of 93.8 MJ/m3. The fuel supplier

should provide liquid fuel from the tank to intake point at the strainer on the dryer pipe train.

Natural Gas (NG) Dryers

The dryer is designed to operate on natural gas with gross calorific value of 39.0 MJ/m3. The dryer is

equipped with a natural gas supply pipe system connected to the heater solenoid valves. A regulated

pressure of 700 mBar must be provided at the connection to the dryer, with gas available in sufficient

volume to maintain operating pressure.

Commissioning Checks

Before starting the dryer check:

1. Pressure tightness.

2. Over pressure valve operation.

3. Pressure relief operation.

4. Maximum pressure switch operation.

Electrical Connection

1. Power supply must be adequate for the full current draw, plus starting loads for the electrical

equipment on the dryer.

2. Power is connected into the main disconnect in the dryer power panel.

3. The dryer must be properly earthed (grounded), which may require the installation of a suitable

ground rod. This must be designed and carried out by a suitably qualified electrician in accordance

with local regulations and codes and taking into account site ground conditions.

4. Earth connection should be made into the PE terminal in the power panel and to a suitable location

on the dryer structure.

5. The electrical installer should carry out full electrical safety checks including earth continuity during

commissioning of the dryer.

Connecting Auxiliary Conveyors

Auxiliary load and unload equipment can be wired directly to the dryer.

1. Maximum power not to exceed 7.5 kW.

2. Larger than 7.5 kW must be powered from an alternative source and contactor, though control may

be run through the dryer control panel.

PNEG-1797CE CE Approved T-Series Tower Dryer 29

Page 30

5. Operating Controls

Heater switch

Fan switch

Load auger switch

Unload auger switch

Operator light switch

Control power switch

Stop switch

Start switch

Meter roll speed

Touch screen

WARNING

Switches on the vision panel are for control purposes only. For servicing and

maintenance switch OFF and lock at the main disconnect.

Vision Control Panel Layout

Figure 5A

Vision controls are used on several GSI drying products. It can operate any dryer in either a batch or a

continuous flow mode. All operating instructions for the T-Series dryer describes continuous flow

operation only.

30 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 31

5. Operating Controls

1. CONTROL POWER switch turns ON/OFF power to the control.

2. FAN switch starts/stops the fan. AUTO position is not used on T-Series and F-Series dryers.

3. HEATER switch turns the heater ON/OFF. AUTO position is not used on T-Series and

F-Series dryers.

4. LOAD AUGER switch selects operating mode wet fill conveyor. In AUTO and MANUAL, the wet fill

conveyor operates to keep the dryer full. In AUTO only the dryer shuts down if it is low on grain for a

pre-set period.

5. UNLOAD switch controls ‘Accutrol’ metering system and unload conveyor. In MANUAL, the

metering system operates at the speed set by the METERING ROLL SPEED switch. In AUTO, it runs

in multi-speed mode, controlled by the automatic moisture control.

6. OUTSIDE LIGHT switch controls the service light. In AUTO, the light is ON while the dryer is running

and OFF when shut down.

7. START switch starts and operates the dryer.

8.

STOP switch

the stop has been pressed. To stop the blower before this time, turn the BLOWER switch to OFF.

stops all dryer functions except the blower which will continue to run for 15 minutes after

The STOP switch is also used to re-set after a shut down.

PNEG-1797CE CE Approved T-Series Tower Dryer 31

Page 32

6. Vision Touch Screen Display

These two (2) buttons are

used to update software.

(See PNEG-1506 vision

programming manual.)

2

3

4

5

1

Boot screen appears when the control power is switch ON. (See Figure 6A.)

Figure 6A

Default operation screen opens when START DRYER is pressed.

Figure 6B

32 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 33

6. Vision Touch Screen Display

Modify button

1. Dryer operation animation shows the status of the fan/heaters, load and unload augers and meter

rolls. Also grain temperature, moisture content, M/C set point and tones counter.

2. Dryer status indicates if the dryer is stopped, started, loading or unloading.

3. Dryer status chart shows the grain temperature, moisture in/out, temperature out and metering roll

speed. Over a period of time.

4. Plenum shows the plenum temperature set point (SP), actual plenum temperature and

burner status.

5. Setup buttons provides access to timers, temperature set points, dryer model and moisture

control setup.

Figure 6C

Select Data Log Sample Time

To change the sample time:

1. Press modify.

2. Select required time.

3. Press Accept/Exit.

To clear the table, press Clear Table button. (See Figure 6C.)

PNEG-1797CE CE Approved T-Series Tower Dryer 33

Page 34

6. Vision Touch Screen Display

Optional Operation Screen

Press View button give four (4) options. (See Figure 6D.)

Figure 6D

1. Table view: Default operation screen view. (See Figure 6B on Page 32.)

2. Graph view:

a. Press then .

b. Press any of to select which data is graphed.

c. Press to select time period.

3. Owner’s manual: See Page 40.

4. History: See Page 41.

34 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 35

Setting the Timers

Operation screen for setting timers

Modifying timer set point

Press to open the timers screen. (See Figure 6E.)

6. Vision Touch Screen Display

1. Press to set the load system delay during unload. Reduces load motor cycling.

2. Press to set the dryer shut down delay after the OUT OF GRAIN switch opens.

Set to the maximum time for the dryer to refill during drying (this is displayed during loading on

the screen).

3. Press to set the time between sequential fan starts (multiple fan dryers only).

4. Press to set the unload system overrun following metering system shut down

(allows unload system to clear itself).

PNEG-1797CE CE Approved T-Series Tower Dryer 35

Figure 6E

Page 36

6. Vision Touch Screen Display

5. Use when setting timers. Note default values may be entered.

6. Press then to return to the operation screen. (See Figure 6B on Page 32.)

Setting the Temperatures

1. Press to display temperature setup screen. (See Figure 6F.)

Figure 6F

2. Press then use key pad to alter plenum temperature.

3. Press then use key pad to alter grain temperature.

Note default units are °F. This can be changed to °C in SETUP.

4. Press then to return to the operation screen.

36 PNEG-1797CE CE Approved T-Series Tower Dryer

(See Figure 6B on Page 32.)

Page 37

The Setup Screen

Press adjust other dryer settings.

6. Vision Touch Screen Display

Figure 6G

1. select continuous flow or staged batch drying modes.

2. adjust time and date settings.

3. select correct dryer model an details, as follow:

a. Number fan/heaters = 1

b. Load system = end

c. Dryer length (ft.) = 22 (Models 1875, 20100 and 24100)

18 (Models 1050, 1260 and 1575)

d. Number modules = 1

e. Fuel = LP

4. See Page 57 for detailed setup.

PNEG-1797CE CE Approved T-Series Tower Dryer 37

Page 38

6. Vision Touch Screen Display

5. changes between SI and American units.

6. see service section on Page 65.

7. burner mode should be ALL HIGH/LOW. (See Figure 6H.)

Figure 6H

8. to adjust the switching range of the burner. (See Figure 6I on Page 39.) Default is

3°F (1°C). Tower dryers have just 1 plenum.

38 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 39

6. Vision Touch Screen Display

Figure 6I

9. allows the dryer throughput meter to be calibrated on Figure 6J.

Setting = (Actual tons per hour/Recorded tons per hour)*100

Figure 6J

PNEG-1797CE CE Approved T-Series Tower Dryer 39

Page 40

6. Vision Touch Screen Display

Viewing the Owner’s Manuals on the Display Screen

Press then the Owner’s Manual button. (See Figure 6K.)

At the explorer screen, double press the manual and wait for it to open on screen.

Figure 6K

Use the scroll bar to navigate the manual. (See Figure 6L.)

Figure 6L

40 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 41

Viewing the Dryer Shut Down History

Press and then history. (See Figure 6M.)

6. Vision Touch Screen Display

Figure 6M

The shut down history is displayed and can be copied to a flash disc for viewing on another computer.

PNEG-1797CE CE Approved T-Series Tower Dryer 41

Page 42

7. Dryer Start-Up

WARNING

BEFORE STARTING THE DRYER. All safety guards must be in place. All personnel

must away from the dryer. All access doors must be closed.

Dryer Commissioning

Electrical

1. Carry out earth bonding test per EN60204 and/or local electrical laws and regulations.

2. Check adequate power supply. (Refer to table on Page 22.)

3. Voltage at phases must be within 5% of rated voltage.

4. Voltage drop must not exceed 5% when under full load.

5. Check overload settings for each motor circuit.

6. Complete full electrical tests in accordance with EU directives and local laws, regulations and codes.

Gas Train

1. Pressure test

a. Close inlet valve. (See Figure 7E on Page 50.)

b. Close firing valve. (See Figure 7I on Page 52.)

c. Close pilot line valve. (See Figure 7G on Page 51.)

d. Fit pressure test nipple into main solenoid inlet flange.

e. Attach hand bellows and pressure gauge.

f. Pressurize gas train with air to 35 kPa (350 mBar).

g. Check for pressure loss at gauge.

h. Use leak detection to test for leaks.

i. Repeat on outlet flange.

j. Repeat on pilot line.

2. Set inlet pressure per table on Page 22.

3. Set relief valve per table on Page 22.

a. Apply air pressure via main solenoid inlet flange.

b. Increase/decrease spring pressure in relief valve.

c. Valve should open at 50 kPa maximum.

42 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 43

4. Set over pressure shut off (OPSO) per table on Page 20.

a. Apply air pressure via main solenoid inlet flange.

b. Increase/decrease spring pressure in OPSO.

c. Valve should shut at 45 kPa maximum.

5. Set operational pressure per table on Page 22.

a. Open main gas valve.

b. Adjust pressure at regulator.

6. Set pilot flow rate.

a. Close pilot line manual shut off valve. (See Figure 7G on Page 51.)

b. Close ‘firing valve’ on main gas line. (See Figure 7I on Page 52.)

c. Start blowers.

d. Start burners.

e. When pilot solenoid valve opens, adjust flow rate to give pilot pressure of 4 kPa.

7. Dryer Start-Up

f. Adjustment is on pilot solenoid valve. (See Figure 7A.)

g. Open pilot line manual shut off valve. (See Figure 7G on Page 51.)

h. Re-set burner control. (It will have gone to lock out after previous attempt to light.) Reset can be

done by cycling the burner switch on the PLC panel.

i. Start burner.

j. Pilot should now light and stay alight. After 10 seconds, main valve should open and a fter further

4 seconds burner control revert to lock out and pilot extinguish (main flame is shut off). If pilot

does not stay alight, then the pressure and/or flame rod will need to be adjusted to ensure the

burner control is getting a strong flame current. See Step 7 on Page 44.

Figure 7A Pilot Valve Flow Adjustment

PNEG-1797CE CE Approved T-Series Tower Dryer 43

Page 44

7. Dryer Start-Up

7. Checking pilot flame current.

a. The minimum flame signal, measured at the burner control, should be 1.25 VDC.

b. Flame signal can be checked at the Honeywell burner control, located in the main power panel,

as shown in Figure 7C on Page 45.

c. Flame rod may be re-positioned or gently bent to get better contact with the flame. Ensure rod is

well clear of burner to prevent grounding when hot. Be careful not to damage ceramic insulator

surrounding flame rod. (See Figure 7B.)

d. Check burner is properly grounded.

e. Check neutral supply to burner control is 0 VAC.

Figure 7B Burner End Plate, Spark, Pilot and Flame Rod Locations

Ref # Description

2 Main Gas

3 UV Sensor Connection (Optional)

4 Spark Ignitor

5 Flame Rod Locations

5* Flame Rod Alternate Locations

6Pilot Gas

NOTE: Minimum acceptable flame signal is 1.25 VDC.

44 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 45

7. Dryer Start-Up

Flame simulator

test jack

Negative (-)

meter lead

Positive (+)

meter lead

One mega

ohm/volt meter

Figure 7C Honeywell Test Flame

8. Set burner high-fire pressure.

a. Re-open main gas ‘firing valve’. (See Figure 7I on Page 52.)

b. Note required high-fire pressure from table on Page 22.

c. Set plenum temperature to approximately 100°C above ambient.

d. Light burners.

e. Check modulating valve has driven fully open.

f. Read pressure at burner gauge. (See Figure 7I on Page 52.)

g. Adjust pressure a regulator to give required pressure.

h. Lock regulator.

9. Set burner low-fire pressure.

a. Set plenum temperature to approximately 5°C above ambient.

b. Light burners.

c. On low-fire, adjust modulating valve minimum setting to give pressure as per table on Page 20.

10. Read pressure at burner gauge. (See Figure 7I on Page 52.)

PNEG-1797CE CE Approved T-Series Tower Dryer 45

11. Run burners and check burner modulates correctly.

12. Check gas pressure remains stable.

13. Fill out gas train commissioning check sheet. (See Page 4.)

Page 46

7. Dryer Start-Up

Pre-Season Checks

1. Inspect the accutrol metering system.

a. Open the two (2) access doors and inspect the sweep metering system to ensure that the system

is able to move freely.

2. Gas train

a. Check for any leaks by pressurizing the line with air and using gas leak disclosing so lution or by

doing pressure loss tests.

b. Leaks must be rectified by opening and resealing the joint.

3. Wiring

a. Check wiring on the dryer and inside the control panels for signs of damage or loose connections.

Rectify any faults.

4. Electrical power

a. Check all circuit breakers in the panel are closed.

b. Turn ON the electrical power supply to the dryer.

c. Check for correct voltage on all phases.

5. CONTROL POWER switch

a. Turn the CONTROL POWER switch to ON.

b. At boot screen appears (See Figure 6A on Page 32), press .

c. Any faults will be displayed on the Main screen.

d. If no faults are found safe, the START switch will illuminate.

46 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 47

6. START switch

a. Check all selector switches are OFF.

b. Push the DRYER START switch.

c. Selector switches be activated.

7. Fuel check

a. Open the gas supply to the dryer.

b. Check correct supply pressure. (See Table on Page 22.)

8. Load auger. With grain supply OFF.

a. Start and stop load auger to check correct operation and rotation.

b. Turn the load auger to AUTO and allow to run for 8 minutes.

c. Dryer should stop and display OUT OF GRAIN error message.

d. Press STOP to clear message.

9. Unload operation

7. Dryer Start-Up

a. Turn unload auger to AUTO. Check correct operation and rotation.

b. Turn unload auger to MANUAL position. Check correct operation and rotation.

10. Accutrol sweep metering system operation

a. With unload in AUTO, check metering speed increases and decreases as control is adjusted.

b. Turn unload OFF. Unload will continue for 60 seconds and shut down.

11. FAN switch

a. Turn FAN switch to ON the OFF and check correct operation and rotation.

12. Burner safety

a. Turn fuel OFF.

b. Start the fan.

c. Turn HEATER switch to ON.

d. Burner should attempt to light and then lockout.

e. Display should read “Ignition Failure Fan 1”.

PNEG-1797CE CE Approved T-Series Tower Dryer 47

Page 48

7. Dryer Start-Up

13. Burner test fire

a. Turn fuel ON.

b. Set plenum temperature to 60°C.

c. Start the fan.

d. Turn HEATER switch to ON.

e. After purge the burner should light.

f. Adjust the pressure regulator to required burner pressure. (See Table on Page 22.)

g. Lock the regulator.

h. When the plenum reaches set point, adjust the MINIMUM setting on the modulating valve

(See Figure 7I on Page 52) to the required setting. (See Table on Page 22.)

i. Allow the burner to cycle between high and low and stabilize at the set point.

j. Fine adjustment may be needed to obtain good temperature modulation.

14. Dryer shut down

a. Short term shut down.

• Turn burner OFF.

• Turn fan OFF.

• Turn load OFF.

• Turn unload OFF.

• Close main fuel valve.

b. Long term shut down.

• Close the fuel supply and allow the burner to burn out.

• Turn all selector switches to OFF.

• Turn control power OFF.

• Disconnect main power.

15. Emergency PRESS EMERGENCY STOP.

48 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 49

7. Dryer Start-Up

Safety shut off section

(See Page 51.)

Modular section

(See Page 52.)

Pilot section

(See Page 51.)

Regulator section

(See Page 50.)

Inlet section

(See Page 50.)

PNEG-1797CE CE Approved T-Series Tower Dryer 49

Figure 7D Tower Dryer CE Pipe Train (2" Shown)

Page 50

7. Dryer Start-Up

Figure 7E Inlet Section

Figure 7F Regulator Section

50 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 51

7. Dryer Start-Up

Figure 7G Pilot Section

Figure 7H Safety Shut Off Section

PNEG-1797CE CE Approved T-Series Tower Dryer 51

Page 52

7. Dryer Start-Up

Figure 7I Modulator Section (Modulating Motor Not Shown)

52 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 53

8. Dryer Start-Up and Operation

WARNING

BEFORE STARTING THE DRYER. All safety guards must be in place. All personnel

must away from the dryer. All access doors must be closed.

Drying Temperatures

Drying temperatures differ from crop to crop. Please check the drying temperature does not risk damage

to the crop before proceeding.

1. Shelled corn moisture content of 20%-30% (93°C-104°C).

2. Small grain (wheat, oats, barley, milo), 65°C-90°C.

3. Soybeans 50°C-60°C.

Initial Setup Parameters

With the control power ON and the dryer control screen visible.

1. Timer and delay settings: Follow procedures in Setting the Timers on Page 35 to set.

a. Load timer.

b. Out of grain (OOG) timer.

c. Fan delay timer.

d. Unload delay timer.

Use default settings as a starting point and adjust subsequently if required.

2. Setting the temperatures. Follow procedure in Setting the Temperatures on Page 36 to set.

a. Plenum temperature.

b. Grain temperature.

Start-Up

1. Make sure pre-season checks have been carried out.

2. Start the control system, with all selector switches OFF.

3. At boot screen (See Figure 6A on Page 32), press .

4. Turn load auger to MANUAL.

5. Press Start button.

6. Allow dryer to fill.

The dryer is now ready to begin drying.

PNEG-1797CE CE Approved T-Series Tower Dryer 53

Page 54

8. Dryer Start-Up and Operation

1. Select this

option

2. Press to open

setup window

4. Select ON

5. Accept

3. Set unload

maximum/

minimum

Continuous Flow Drying Mode Using Advanced Moisture Control

7. Press and set dryer to CONTINUOUS FLOW. Press .

8. Press .

Figure 8A

54 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 55

8. Dryer Start-Up and Operation

7. Accept

6. Set grain type.

Bin # is for

reference only.

9. Set minimum unload rate to 10% and maximum to suit the unload equipment.

10. Set plenum temperature management ON to reduce risk of over-drying when unload rates are limited

by a low maximum unloading rate.

11. Return to Moisture Control window and set grain type. Optional printer may also be setup.

Figure 8B

12. Turn UNLOAD switch OFF.

13. Open fuel supply.

14. Turn LOAD AUGER switch to AUTO.

15. Refer to drying tables on Pages 59-64. Select the initial unload rate for the dryer model, drying

temperature and moisture content. Example: Model 1575 drying wheat from 18% to 13% at 80°C

initial unload rate = 60.

16. Turn FAN to ON.

17. Turn HEATER to ON.

18. If the dryer is filled with wet grain, let the fan and heater run for 6 minutes per 1% of moisture to

be removed.

Example: 18% - 13% = 5% removal. Time = 5 (%) x 6 (min.) = 30 minutes.

This step is only required at initial start-up. Re-starting with dry grain, omit this step.

19. Then, turn UNLOAD AUGER to MANUAL and set the METER ROLL SPEED, (MANUAL SPEED).

To do this push on the meter roll adjustment knob and turn to set initial unload rate. Grain should

start to run.

PNEG-1797CE CE Approved T-Series Tower Dryer 55

Page 56

8. Dryer Start-Up and Operation

Figure 8C

20. Take three (3) samples with an accurate moisture meter and calculate the average moisture.

Calibrate the wet and dry grain sensors until the on screen reading agrees with the average.

To do this:

a. Press .

b. Press .

c. Calculate difference between actual moisture reading an that on screen.

d. Increase or decrease the on screen reading by the calculated difference.

Example:

Actual = 17%;

On screen = 18.3%.

Difference = Actual - On screen = -1.3%

Enter -1.3% in the calibration screen.

56 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 57

8. Dryer Start-Up and Operation

Calibrate sensors

by touching the

arrows buttons.

Press and set target

moisture content

Figure 8D

21. Turn UNLOAD to AUTO. Advanced moisture control is now active.

22. Set the target moisture and let the dryer run. Make no more changes to allow the system to stabilize.

23. The dryer runs in MANUAL for 30 minutes being switched to AUTO to ensure grain is flowing evenly.

PNEG-1797CE CE Approved T-Series Tower Dryer 57

Figure 8E

The screen displays a timer to show remaining time to full AUTO control.

Page 58

8. Dryer Start-Up and Operation

How the Advanced Moisture Control Works

1. Wet and dry moisture and grain temperature are continually monitored.

2. Control action is mainly based on the dry sensor.

3. Grain flow is increased or decreased to maintain the required dry moisture.

4. The wet sensor and the column grain temperature sensor are intended to detect moisture spikes

coming into the dryer so that the moisture controller can react ahead of time. If the wet sensor detects

a jump of moisture coming into the dryer, the controller will slow down the unload speed immediately.

This process is gradual, to prevent over-drying.

5. MANUAL control is use at the start of drying to allow the controller to gather sufficient information to

adequately control.

IMPORTANT: Once drying has commenced DO NOT make frequent adjustments to drying parameters.

This will cause control instabilities and result in over or under drying. Allow the controller to

manage the dryer.

58 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 59

9. Drying Time Tables

Model 1050

Corn

Moisture

In Out

17% 15% 71 83 95

18%15%546372

19% 15% 44 51 58

20%15%374350

21% 15% 32 38 43

22%15%293338

23% 15% 25 30 34

24%15%232630

25% 15% 20 24 27

26%15%182124

27% 15% 16 19 22

28%15%151720

29% 15% 13 15 18

30%15%121416

32% 15% 10 12 13

35% 15% 8 9 11

75°C

% Unload Rate

88°C

% Unload Rate

100°C

% Unload Rate

Wheat, Barley, Milo

Moisture

In Out

15% 13% 50 59 70

16%13%384453

17% 13% 31 36 43

18%13%263137

19% 13% 23 27 32

20%13%202428

21% 13% 18 21 25

23%13%141720

25% 13% 11 13 16

60°C

% Unload Rate

70°C

% Unload Rate

80°C

% Unload Rate

Soybeans

Moisture

In Out

15% 13% 57 66 74

16%13%434955

17% 13% 35 40 45

18%13%303438

19% 13% 26 29 33

50°C

% Unload Rate

55°C

% Unload Rate

60°C

% Unload Rate

20%13%232629

21% 13% 20 23 26

PNEG-1797CE CE Approved T-Series Tower Dryer 59

Page 60

9. Drying Time Tables

Moisture

In Out

17% 15% 85 99 -18% 15% 65 75 86

19% 15% 53 61 69

20% 15% 44 51 60

21% 15% 38 45 51

22% 15% 35 39 45

23% 15% 30 36 40

24% 15% 27 31 36

25% 15% 24 29 32

26% 15% 22 25 29

27% 15% 19 23 26

28% 15% 18 20 24

29% 15% 16 18 21

30% 15% 14 17 19

32% 15% 12 14 15

35% 15% 10 1 1 13

Model 1260

Corn

75°C

% Unload Rate

88°C

% Unload Rate

100°C

% Unload Rate

Wheat, Barley, Milo

Moisture

In Out

15% 13% 60 70 83

16% 13% 45 53 63

17% 13% 37 43 51

18% 13% 31 37 44

19% 13% 27 32 38

20% 13% 24 28 33

21% 13% 21 25 30

23% 13% 17 20 24

25% 13% 14 16 19

60°C

% Unload Rate

70°C

% Unload Rate

80°C

% Unload Rate

Soybeans

Moisture

In Out

15% 13% 68 78 88

16% 13% 51 58 65

17% 13% 41 47 53

18% 13% 35 40 45

19% 13% 31 35 39

20% 13% 27 31 35

21% 13% 24 28 31

23% 13% 19 22 25

25% 13% 15 18 20

50°C

% Unload Rate

55°C

% Unload Rate

60°C

% Unload Rate

60 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 61

9. Drying Time Tables

Model 1575

Corn

Moisture

In Out

17% 15% -- -- -18% 15% 89 -- -19% 15% 72 85 97

20%15%627282

21% 15% 53 62 71

22%15%475563

23% 15% 42 49 56

24%15%374450

25% 15% 33 40 45

26%15%303540

27% 15% 27 31 36

28%15%242832

29% 15% 22 26 29

30%15%202326

32% 15% 17 19 22

35%15%131517

75°C

% Unload Rate

88°C

% Unload Rate

100°C

% Unload Rate

Wheat, Barley, Milo

Moisture

In Out

15% 13% 83 97 -16%13%637387

17% 13% 51 60 71

18%13%445160

19% 13% 38 44 53

20%13%333946

21% 13% 30 35 41

23%13%242833

25% 13% 19 22 26

60°C

% Unload Rate

70°C

% Unload Rate

80°C

% Unload Rate

Soybeans

Moisture

In Out

15% 13% 95 -- -16%13%718191

17% 13% 57 66 74

18%13%495663

50°C

% Unload Rate

55°C

% Unload Rate

60°C

% Unload Rate

19% 13% 43 49 55

20%13%384348

21% 13% 33 38 43

PNEG-1797CE CE Approved T-Series Tower Dryer 61

Page 62

9. Drying Time Tables

Moisture

In Out

17% 15% 92 -- -18% 15% 69 81 92

19% 15% 56 66 75

20% 15% 48 56 64

21% 15% 42 48 56

22% 15% 37 43 49

23% 15% 33 38 43

24% 15% 29 34 39

25% 15% 26 30 35

26% 15% 23 27 31

27% 15% 21 24 28

28% 15% 19 22 25

29% 15% 17 20 23

30% 15% 15 18 21

32% 15% 13 15 17

35% 15% 10 12 14

Model 1875

Corn

75°C

% Unload Rate

88°C

% Unload Rate

100°C

% Unload Rate

Wheat, Barley, Milo

Moisture

In Out

15% 13% 65 76 90

16% 13% 49 57 68

17% 13% 40 47 55

18% 13% 34 40 47

19% 13% 29 34 41

20% 13% 26 30 36

21% 13% 23 27 32

23% 13% 18 21 26

25% 13% 15 17 21

60°C

% Unload Rate

70°C

% Unload Rate

80°C

% Unload Rate

Soybeans

Moisture

In Out

15% 13% 74 84 95

16% 13% 55 63 71

17% 13% 45 51 57

18% 13% 38 43 49

50°C

% Unload Rate

55°C

% Unload Rate

60°C

% Unload Rate

19% 13% 33 38 43

20% 13% 29 34 38

21% 13% 26 30 34

23% 13% 21 24 27

25% 13% 17 19 21

62 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 63

9. Drying Time Tables

Model 20100

Corn

Moisture

In Out

17% 15% -- -- -18% 15% 79 92 -19% 15% 65 75 86

20%15%556473

21% 15% 48 56 64

22%15%424956

23% 15% 37 44 50

24%15%333944

25% 15% 30 35 40

26%15%273136

27% 15% 24 28 32

28%15%222529

29% 15% 19 23 26

30%15%182124

32% 15% 15 17 20

35%15%121416

75°C

% Unload Rate

88°C

% Unload Rate

100°C

% Unload Rate

Wheat, Barley, Milo

Moisture

In Out

15% 13% 74 87 -16%13%566578

17% 13% 46 53 63

18%13%394554

19% 13% 34 39 47

20%13%303541

21% 13% 27 31 37

23%13%212529

25% 13% 17 20 24

60°C

% Unload Rate

70°C

% Unload Rate

80°C

% Unload Rate

Soybeans

Moisture

In Out

15% 13% 85 97 -16%13%637281

17% 13% 51 58 66

18%13%445056

50°C

% Unload Rate

55°C

% Unload Rate

60°C

% Unload Rate

19% 13% 38 43 49

20%13%343843

21% 13% 30 34 38

23%13%242731

25% 13% 19 22 25

PNEG-1797CE CE Approved T-Series Tower Dryer 63

Page 64

9. Drying Time Tables

Moisture

In Out

17% 15% -- -- -18% 15% 91 -- -19% 15% 74 86 99

20% 15% 63 73 84

21% 15% 55 64 73

22% 15% 48 56 64

23% 15% 43 50 57

24% 15% 38 44 51

25% 15% 34 40 45

26% 15% 31 36 41

27% 15% 27 32 37

28% 15% 25 29 33

29% 15% 22 26 30

30% 15% 20 24 27

32% 15% 17 20 22

35% 15% 13 16 18

Model 24100

Corn

75°C

% Unload Rate

88°C

% Unload Rate

100°C

% Unload Rate

Wheat, Barley, Milo

Moisture

In Out

15% 13% 85 99 -16% 13% 64 75 89

17% 13% 52 61 73

18% 13% 44 52 62

19% 13% 39 45 54

20% 13% 34 40 47

21% 13% 30 36 42

23% 13% 27 28 37

25% 13% 19 23 27

60°C

% Unload Rate

70°C

% Unload Rate

80°C

% Unload Rate

Soybeans

Moisture

In Out

15% 13% 97 -- -16% 13% 72 82 92

17% 13% 58 67 75

18% 13% 50 57 64

50°C

% Unload Rate

55°C

% Unload Rate

60°C

% Unload Rate

19% 13% 43 50 56

20% 13% 38 44 49

21% 13% 34 39 44

23% 13% 27 31 35

25% 13% 22 25 28

64 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 65

10. Service

WARNING

BEFORE SERVICING THE DRYER. Turn OFF and LOCK electrical power at the

MAIN DISCONNECT. Turn off fuel supply.

Pre-Seasonal Inspection and Service

1. Inspect control panels for loose wires, rodent damage and accumulated foreign material. Clean and

repair as required.

2. Lubricate the blowers, motors and metering system as per lubrication table on Page 68.

3. Check blower belts tension.

4. Inspect and clean the burner. Check that holes in the stainless steel air mixing plates are clear.

Clean if required.

5. Check connections to flame rod and spark plug. Clean or replace if necessary.

6. Check gas train drain valve and drain any accumulated water. Close before dryer operation.

7. Check the discharge area is cleaned of stalks and old grain. Inspect the sweeps for excessive wear.

8. Remove covers from burner.

IMPORTANT: The covers to the discharge sections on the tower dryers must be in place and clamped

down at all times when the dryer is in operation. If the cover is off during operation, the

vacuum created by the blowers will suck foreign matter from the discharge area and deposit

it in the heat section of the dryer plugging the inside screens of the dryer also creating a

fire hazard.

See pre-season check list on Page 67.

Seasonal Inspection and Service

1. Follow lubrication guides in the lubrication table on Page 68.

2. Keep the cooling chamber floor clear of dust and dirt. Check each day before starting drying. Failure

to do so could result in a fire. Dirt can be swept into the unload systems.

3. Keep the heat section clear of dust or dirt. Check the hopper divider that separates the heat section

from the cooling section to ensure that it remains clean and open.

4. Check the grain discharge area on the dryer. On ‘Accutrol’ sweep dryers check the sweeps for trash

or stalk build ups that could be obstructing grain flow.

5. If undried grain is left in the dryer for more than a week during the drying season, inspect the plenum

roof to make sure that there is no wet grain sticking to the roof that could restrict grain flow. When

the dryer is re-started make sure that all grain columns are evenly unloading.

6. If the perforated outer sheets on the dryer have become excessively dirty, they may need to be

washed off to prevent inhibited airflow.

PNEG-1797CE CE Approved T-Series Tower Dryer 65

Page 66

10. Service

In Case of Fire

1. Hit emergency stop.

2. Shut off power.

3. Shut off fuel.

4. Do not try to cool a fire by running fan(s).

5. Never run grain from the dryer into the elevator or storage if a fire is known or suspected.

6. Locate the area of the fire.

7. If safe to do so, tackle the fire with a suitable extinguisher. Check for secondary fires.

8. Emergency discharge slide gates at the bottom of each column as well as easy access gates located

near the hopper discharge area permit fast dumping of each individual grain column.

9. If in doubt call the fire department.

End of Season Service

1. Always empty the dryer at the end of the drying season.

2. Shut off electrical power and lock.

3. Shut off gas/fuel supply and lock.

4. Clean out the plenum roof grain cushion and remove any grain that may be hanging up on the

plenum roof.

5. Make sure the grain exchangers are clean.

6. Clean out the hopper that divides the heat section from the cooling section.

7. Clean the cooling chamber floor.

8. Remove all grain and trash from the metering drum floor. This grain can be raked out by hand by

opening the slide gates located in the hopper bottom of the dryer.

9. Make sure gas supply is shut off to the dryer.

10. Open the gas train drain valve located on the bottom of the gas train.

11. Cover the burner with a tarpaulin or plastic.

66 PNEG-1797CE CE Approved T-Series Tower Dryer

Page 67

Pre-Season Service Check List

___ Lubricate blower bearings.

___ Lubricate blower motor bearings, if needed.

___ Check blower belts and adjust if necessary.

___ Clean burner ports.

___ Inspect flame rod and spark ignitor.

___ Check oil levels in gearboxes.

___ Inspect divider hopper between heat and cooling section. Clean if necessary.

___ Inspect bindicator grain level switches.

___ Inspect metering system access door cover seals.

___ Lubricate metering system access door cover hold-down latches.

___ Lubricate modulator motor linkage.

___ Check butterfly operation in modulating valve.

10. Service

___ Check gas pressure gauges.

___ Check interior of maxon shut off valves for corrosion. Clean if necessary.

___ Clean control and power panels, tighten loose connections and check for leaks.

___ Inspect metering systems. Clean accumulated stalks and old grain.

___ Start-up dryer and check operating controls.

___ Other: Itemize ___________________________________________________________

End of Season Shut Down Procedure

___ Start unload and empty all grain from dryers.

___ Clean out grain cushion (on plenum roof under fill spout). Clean plenum roof.

___ Clean off grain exchangers.

___ Clean out divider hopper, between heating and cooling section.

___ Clean inside cooling sheets and cooling floor.

___ Remove all grain and trash from unload section of dryer.

___ Open emergency grain discharge doors (and drain doors in Zimmerman dryers).

___ Open drain valve in gas train.

___ Cover burner with a tarp or plastic sheeting.

PNEG-1797CE CE Approved T-Series Tower Dryer 67

Page 68

11. Lubrication

Location Instructions

Accutrol (sweep unload)

top and bottom

drive bearings.

Accutrol (sweep unload)

coupling hub.

Blower shaft bearings.

Blower motor bearings.

Metering variable speed

drive motor.

Accutrol gearbox.

Lubricate slowly until lube

shows through seal.

Wipe clean.

Remove the two (2) lube

plugs from the cover. Lubricate

slowly until grease begins

seeping through relief plug.

Lubricate bottom bearing

plug slowly counting the grease

gun pump until lube shows

through the seal. Wipe clean.

Use same # of grease gun

pumps for top bearing.

See motor lubrication

procedure below.

See motor lubrication

procedure below.

Grease filled gearbox.

Replenish grease to the first

stage (upper) reduction

mechanism through grease

fitting provided (typically

quantity = 0.3 oz. of grease).

Type of

Lubrication

High quality, grade #2

lithium based grease.

High quality, grade #2

lithium based grease.

High quality, grade #2

lithium based grease.

High quality, grade #2

lithium based grease.

High quality, grade #2

lithium based grease.

High quality, grade #2

lithium based grease.

Lubrication Interval

Beginning of season (annually).

Beginning of season (annually).

Every 4 weeks of

dryer operation.

Every 2 years. (Normal

operation, ever 8-10 months

continuous operation.)

Every 2 years. (Normal

operation, ever 8-10 months

continuous operation.)

Beginning of season (annually).

¹Lubrication of motors - Operate motor for 20 minutes. Clean grease fitting. Remove grease relief plug and using a