Page 1

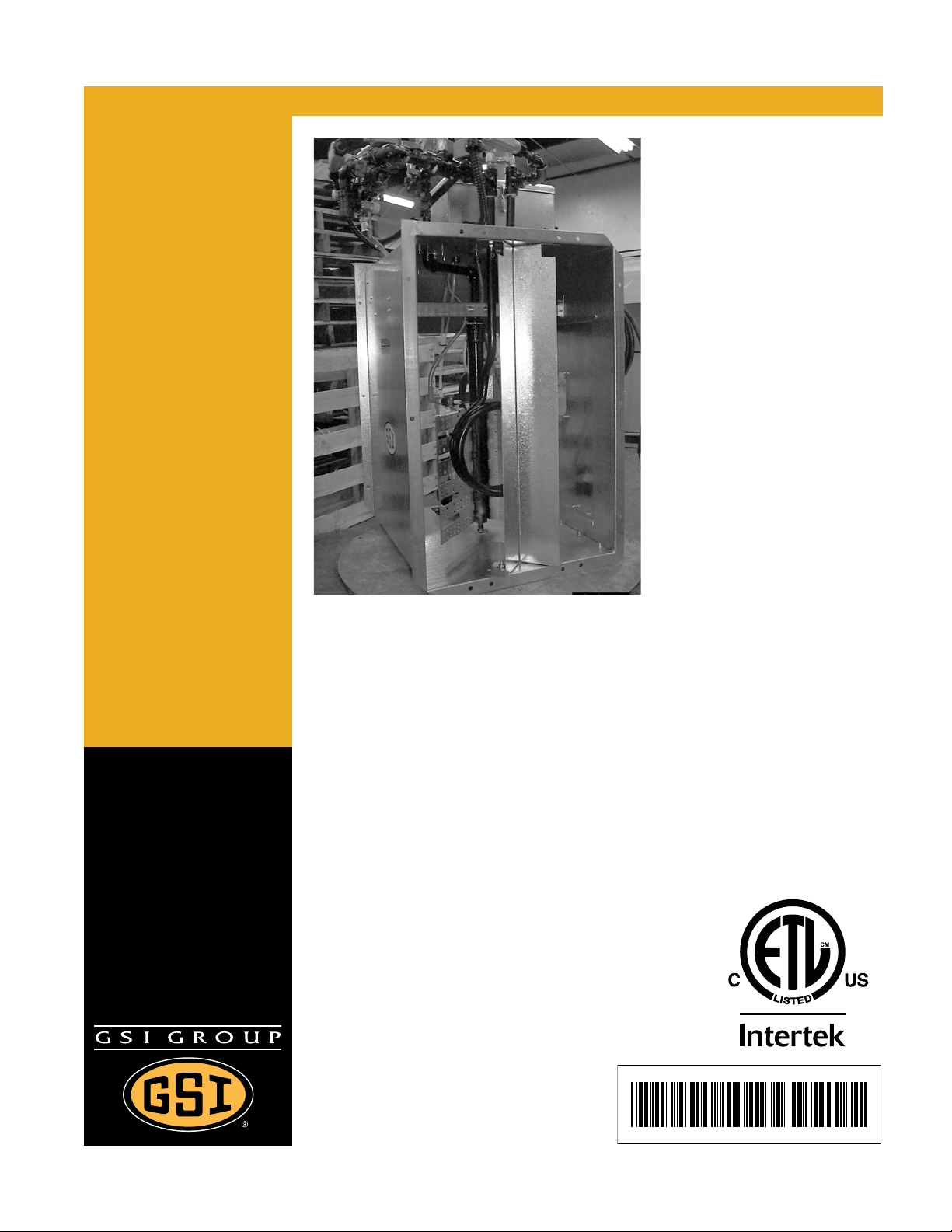

PNEG-1776

Deluxe Downwind Centrifugal

Heater Inst allation and Operating

Instructions - Canadian

Model # CH_-_ _-_ _-D (HIGH)

Model # CL_-_ _-_ _-D (LOW)

Owner ’s Manual

PNEG-1776

Date: 09-25-12

Page 2

Check List

This equipment shall be installed in accordance with the current inst allation codes for gas burning

appliances and equipment, CAN1-B149.1 and B149.2, or applicable provincial regulations which

should be carefully followed in all cases. Authorities having jurisdiction should be consulted before

installations are made.

1. All wire connections

2. Spark plug gap 0.125

3. Pipe train tightness and gas leaks

4. Flame sensor tight

5. Fuse in place, extra fuse provided

6. Indicator light

7. Pressure gauge

8. Regulator adjusted

9. Shut off valve operates correctly

10. Vapor High-Limit

11. Unit cycles ON to OFF

12. Heat rise even across transition

13. Unit cycles High-Low (High-Low only)

14. All decals and serial number tag

15. Aesthetic appearance

16. Manual

Tester Signature:

Date:______________________________

______________________________

2 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

Fuel Warning ......................................................................................................................................... 6

Power Warning ...................................................................................................................................... 6

Proper Use of Product .................. ................ ................. ................ ................ ................ ........................ 6

Heater Operation ................................................................................................................................... 6

Safety Instructions ..................... ... .... ...................................... .... ... ... ... ... .... ... ... ... .................................. 7

Chapter 3 Decals ....................................................................................................................................................9

Roof Damage Warning and Disclaimer ................................................................................................. 9

Heater Access Door Decals ................................................................................................................ 10

Control Box Decals ............................................................................................................................. 11

Chapter 4 Specifications .....................................................................................................................................12

Heater Specifications .......................................................................................................................... 12

Chapter 5 Installation ..........................................................................................................................................13

Machine to Earth Ground .................................................................................................................... 13

Previously Installed Units ................................. ... ... ... .... ... ... ................................................................ 13

Fuel Connection .................................................................................................................................. 13

Liquid Propane Models .................................................... ... ... .... ... ... ... ... .... ... ... ... .... ............................ 13

Propane Vapor Models ....................................................................................................................... 14

Natural Gas Models ............................................................................................................................ 14

Standard Heater - Second Heater Installation ........................................................ ... ... ... ... .... ... ... ... ... 15

Electrical Installation (460V Fans) .......................... .................... ................... ................... ................... 16

Bin Configuration ................................................................................................................................. 17

Plenum Thermostat Mounting ............................................................................................................. 17

Transition High-Limit Installation ......................................................................................................... 19

Chapter 6 Operation ............................................................................................................................................20

Operating Temperature Table .......................... ... ... .......................................... ................................... 20

Cycling Heater Operation .................................................................................................................... 20

High-Low Heater Operation ................................................... .......................................... ................... 21

Adjusting the Vaporizer ....................................................................................................................... 22

BTUs for Gauge Pressure (PSI) Reading Propane Models (Approximate) ........................................ 23

BTUs for Gauge Pressure (PSI) Reading Natural Gas Models (Approximate) ................................... 24

Chapter 7 Service .................................................................................................................................................25

Seasonal Inspection and Service ........................................................................................................ 25

Chapter 8 Troubleshooting - Heater ...................................................................................................................27

Chapter 9 Wiring Diagrams .................................................................................................................................28

CSA Centrifugal Heater Schematic ........................ ... .... ... ... ... .... ... ... ... ... .... ... ... ................................... 28

CSA Centrifugal Diagram .................................................................................................................... 29

Chapter 10 Parts List ...........................................................................................................................................31

CSA Heater Control Box Assembly (HF-8184) .................................................................................. 32

Downwind Centrifugal Heater Control Parts ...................................................................................... 34

Downwind Centrifugal LP Pipe Train Components ........................................................................... 36

Downwind Centrifugal LP High-Low Pipe Train Components ........................................................... 38

Downwind Centrifugal NG Pipe Train Components .......................................................................... 40

Downwind Centrifugal NG High-Low Pipe Train Components .......................................................... 41

Downwind Centrifugal Propane Vapor Pipe Train Components ........................ .......................... ...... 42

Downwind Centrifugal Propane Vapor High-Low Pipe Train Components ....................................... 44

15 HP and 30 HP Centrifugal Housing .............................................................................................. 46

LP Supply Pipe Train Assembly ........ ... ... .......................................... ... .... ... ...................................... 47

Chapter 11 Warranty ............................................................................................................................................49

PNEG-1776 Deluxe Downwind Heater - Canadian 3

Page 4

1. Introduction

Thank you for choosing a GSI product. It is designed to give excellent performance and service for

many years.

This manual describes the operation of the CSA Deluxe Downwind Heater. It is designed for low to

medium temperature grain conditioning and is ideal for the aeration of rice, popcorn or other select grains.

It is available in both propane vapor and natural gas models.

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

4 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 5

2. Safety

DANGER

WARNING

CAUTION

NOTICE

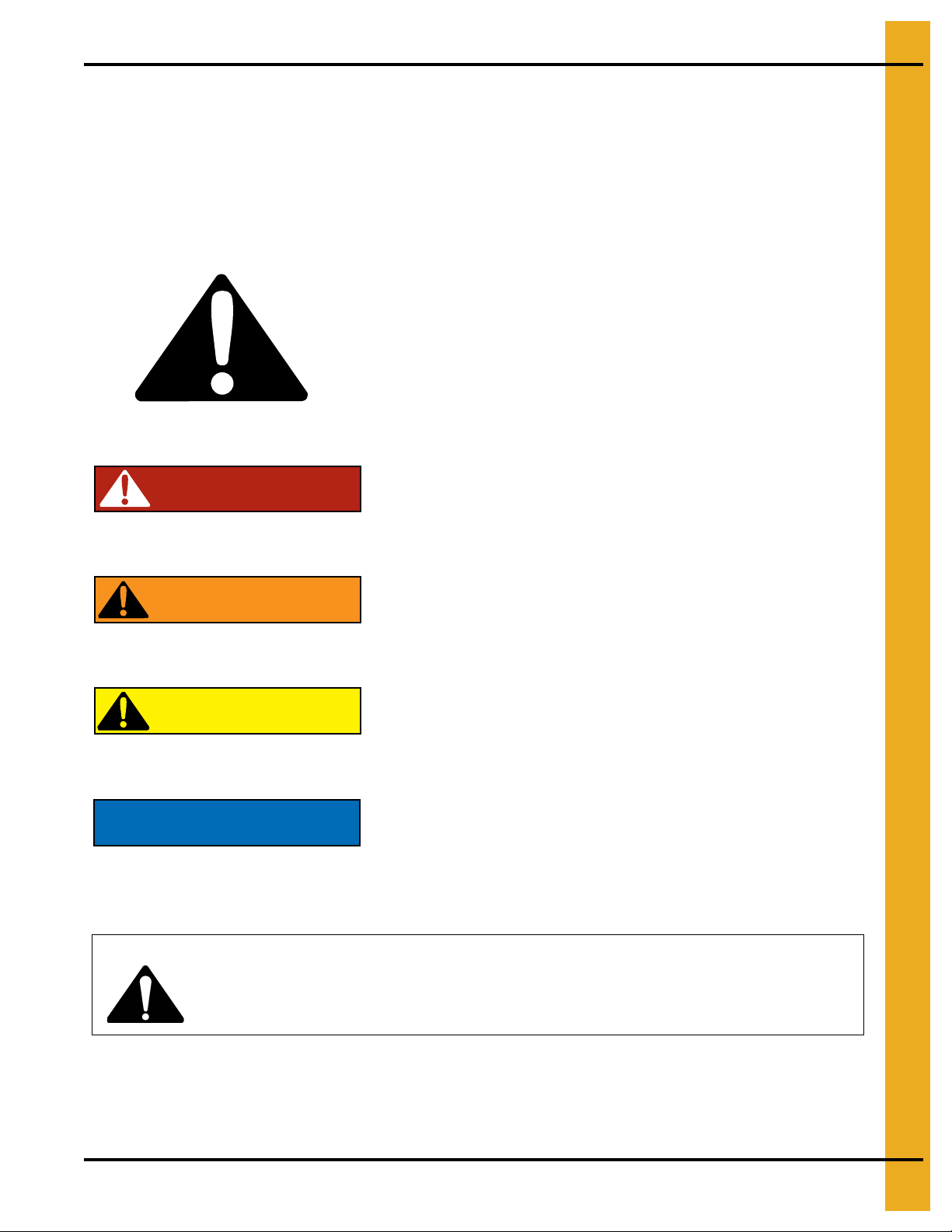

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Personnel operating or working around electric fans should read this manual. This

manual must be delivered with the equipment to its owner. Failure to read this manual

and its safety instructions is a misuse of the equipment.

WARNING! BE ALERT!

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1776 Deluxe Downwind Heater - Canadian 5

Page 6

2. Safety

CAUTION

Do not use propane tanks which have previously been used for ammonia unless

they have been purged according to procedures of the National LP Association.

Be sure fuel supply system complies with all local codes for LP gas installations.

DO NOT USE FLAME FOR LEAK TESTING.

Fuel Warning

WARNING

Power Warning

Be sure power is disconnected and locked out before installation. Failure to do so may cause serious injury

or death.

IMPORTANT: Heater must be interlocked with fan for safe operation.

IMPORTANT: Thermostat must be installed for safe operation.

Proper Use of Product

This product is intended for the use of grain drying only. Any other use is a misuse of this product. This

product has sharp edges. These sharp edges may cause serious injury. To avoid injury handle sharp

edges with caution and use proper protective clothing and equipment at all times. Guards are removed for

illustration only. All guards must be in place before and during operation.

Heater Operation

Thank you for choosing a GSI product. It is designed to give excellent performance and service for

many years.

This manual describes the operation of the GSI CSA Deluxe Downwind Centrifugal Heater. Many models

are available to accommodate low, medium or high temperature grain conditioning.

6 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 7

2. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Install and Operate Electrical Equipment Properly

Electrical controls should be installed by a qualified electrician

and must meet the standards set by the National Electrical Code

and all local and state codes.

Disconnect and lock out all power sources before installing

wires/cables or servicing equipment.

Electric Shock Hazard

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may produce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

PNEG-1776 Deluxe Downwind Heater - Canadian 7

Page 8

2. Safety

Install and Operate Gas-Fired Equipment Properly

Fuel supply should be installed by a qualified gas

technician and must meet local and state codes for

gaseous fuel supplies.

Disconnect and lock out all fuel sources before

servicing equipment.

Explosive Gases

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

8 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 9

3. Decals

The GSI Group recommends contacting your local power company, and having a representative survey

the installation so the wiring is compatible with their system, and adequate power is supplied to the unit.

If a decal is damaged or missing, contact:

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

A free replacement will be sent to you.

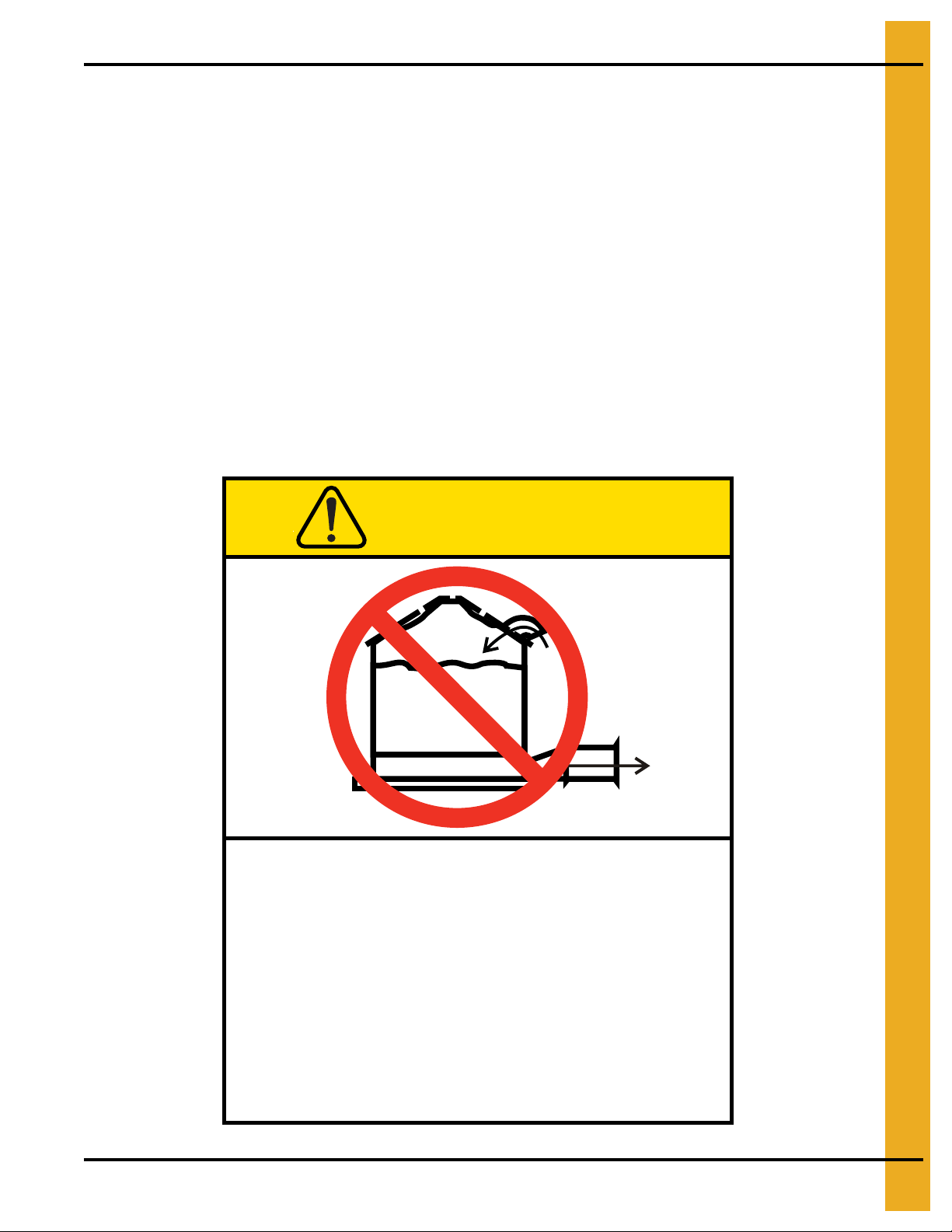

Roof Damage Warning and Disclaimer

The manufacturer does not warrant any roof damage caused by excessive vacuum or internal

pressure from fans or other air moving systems. Adequate ventilation and/or “makeup air” devices

should be provided for all powered air handling systems. The manufacturer does n ot recommend

the use of downward flow systems (suction). Severe roof damage can result fro m any blockage of

air passages. Running fans during high humidity/cold weather conditions can cause air exhaust

or intake ports to freeze.

CAUTION

Excessive vacuum (or pressure) may

damage roof. Use positive aeration

system. Make sure all roof vents are

open and unobstructed. Start roof

fans when supply fans are started.

Do not operate when conditions exist

that may cause roof vent icing.

GSI Group, Inc. 217-226-4421

PNEG-1776 Deluxe Downwind Heater - Canadian 9

DC-969

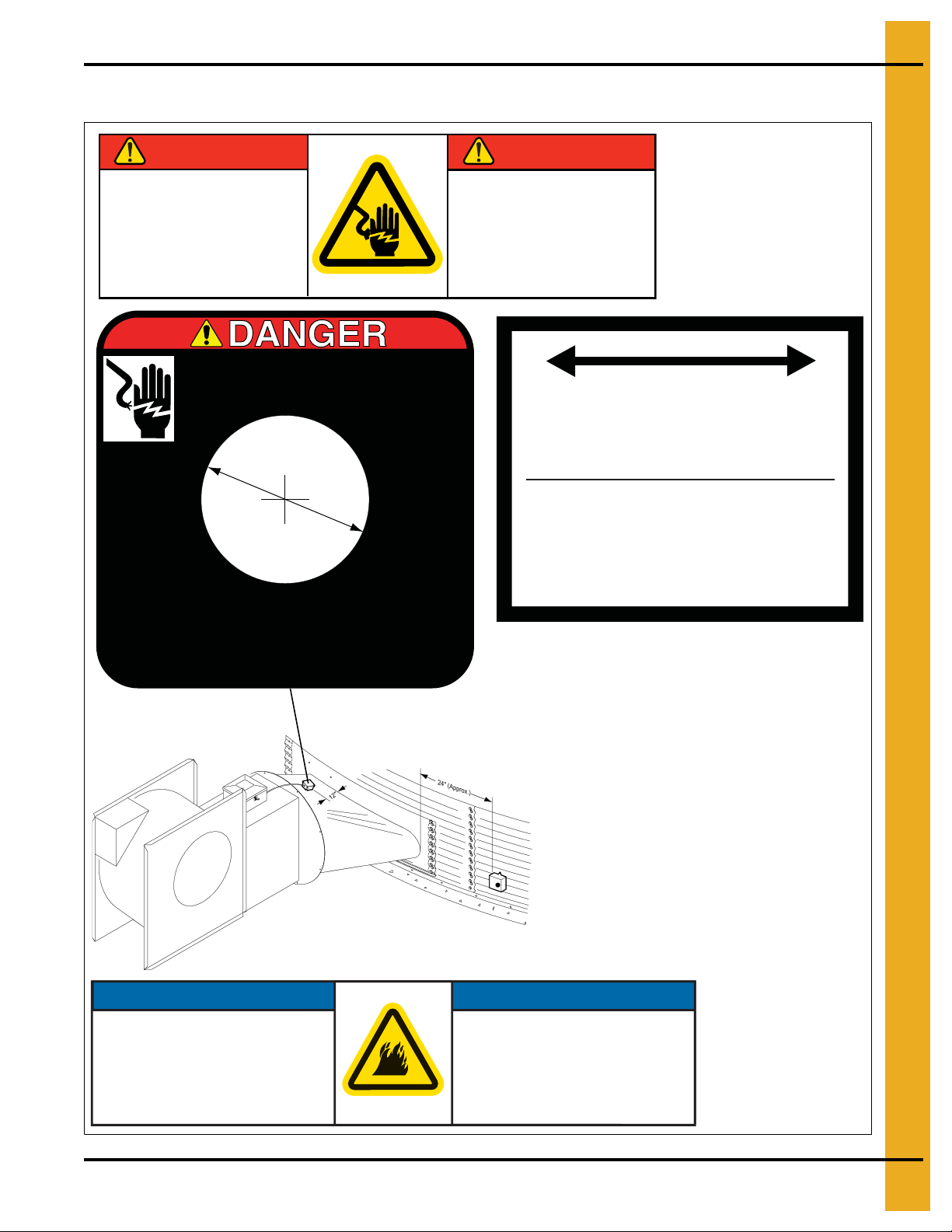

Page 10

3. Decals

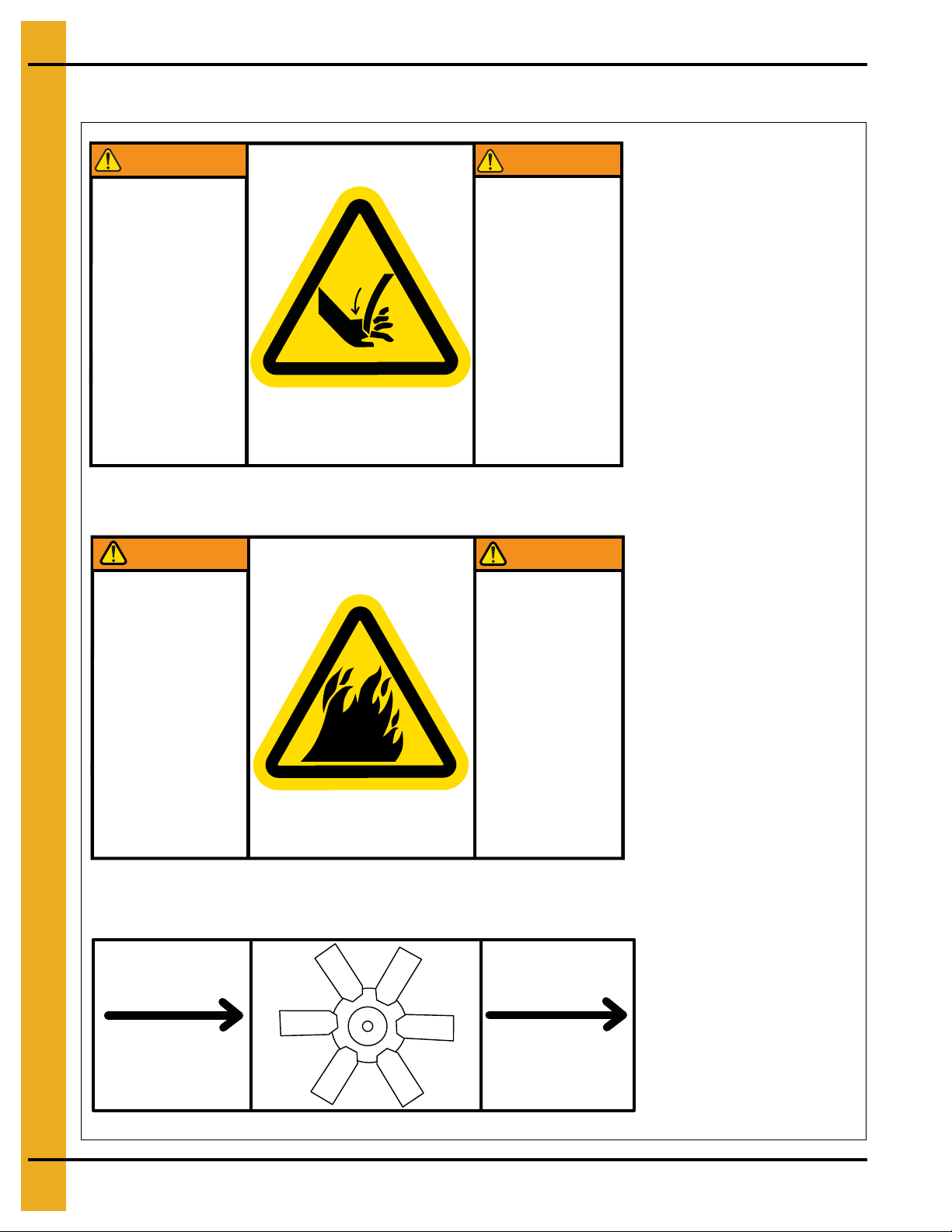

DC-1959

Flame and pressure

beyond door can

cause serious injury.

Do not operate with

service door removed.

Keep head and

hands clear.

La flamme et la

pression au-delà de la

porte peuvent causer

des dommages

sérieux. Ne pas faire

fonctionner si la porte

de service est

enlevée. Gardez les

mains et la tête

éloignés.

WARNING

GSI Group 217-226-4421

AVTERISSEMENT

AIRFLOW

AIRFLOW

CIRCULATION D’AIR

CIRCULATION D’AIR

DC-1971

Size: 4-7/8" x 3"

Located above access

door on heater housing.

DC-1949

DC-1959

Size: 4-7/8" x 3"

Located above access door

on heater housing.

DC-1971

Size: 4-3/4" x 1-5/8"

Located above access

door on heater housing.

Heater Access Door Decals

WARNING

Stay clear of rotating

blade. Blade could

start automatically.

Can cause serious

injury. Disconnect

power before

servicing.

AVERTISSEMENT

Restez éloigné de la

lame tournante. La

lame peut se mettre

en marche

automatiquement.

Peut causer de

sérieuses blessures.

Vérouillez le courant

avant l’entretien.

DC-1949GSI Group Inc. 217-226-4421

10 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 11

Control Box Decals

DANGER

DANGER

WARMER

PLUS CHAUD

PLUS FROID

COLDER

VAPORIZER ADJUSTMENT

AJUSTEMENT DU VAPORISATEUR

Vaporizer coil should be adjusted so that vapor

pipe train is warm (100-125 degrees F) to

the touch.

La bobine du vaporisateur devrait être ajustée

pour que la vapeur du conduit de transmission

soit chaude au toucher (100-125 degrés F˚).

DC-535

NOTICE

NOTICE

Size: 4-3/8" x 1-3/8"

Located in control box on

side opposite switches.

DC-1948

HIGH VOLTAGE.

Will cause injury or death.

Lockout power before servicing.

HAUTE TENSION.

Causera des blessures ou la mort.

Fermez le courant avant l’entretien.

Remove plug to

reset high limit.

Enlevez le contact pour

reinitialiser la limite élévée.

DC-1165

DC-535

DC-1165

DC-1702

Size: 5.825" x 1-1/2"

3. Decals

DANGER

HIGH VOLTAGE

Will cause serious

injury or death.

Lockout power

before servicing.

DANGER

HAUTE TENSION

Causera de sérieuses

blessures ou la mort.

Couper/verrouiller le

courant avant l’entretien.

DC-1948GSI Group 217-226-4421

DC-1948

Thermostat must be installed for

operation.

Failure to do so may damage

equipment and cause fire.

PNEG-1776 Deluxe Downwind Heater - Canadian 11

NOTICE

NOTICE

Le thermostat doit être installé

pour fonctionner.

Omettre cette installation peut

endommager l’équipement et

provoquer un feu.

DC-1702

Page 12

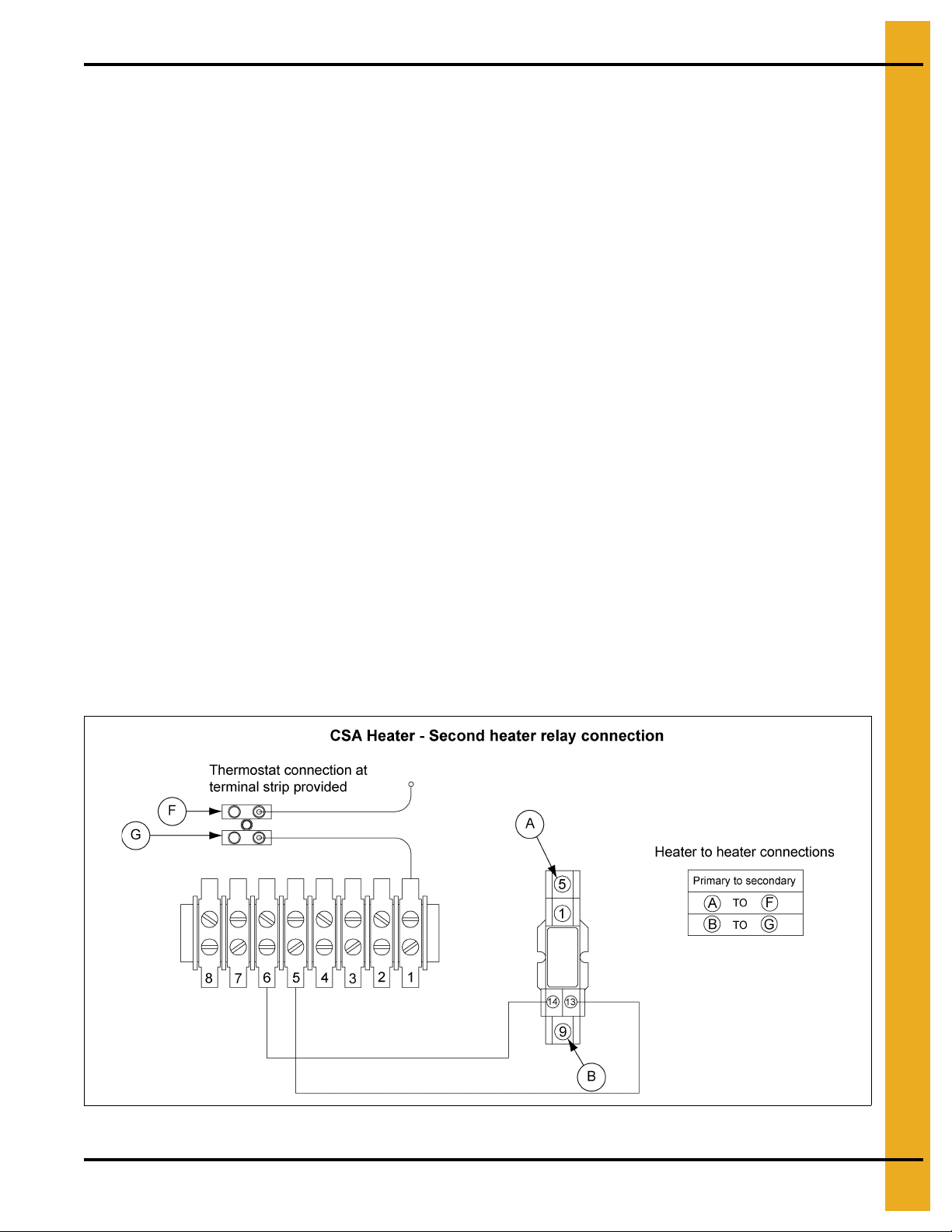

4. Specifications

Heater Specifications

All Models

15 HP 30 HP

Inside Height 30-1/4" 33-1/4"

Inside Width 19-1/2" 21-3/4"

Length 33" 33"

High Temp BTU Rating 2,300,000 4,000,000

Maximum Fuel Flow (GPH) 26 44

Orifice 17/64 21/64

Liquid Propane

Natural Gas

Operating Pressure Range 1-15 1-15

Minimum Line Size 1/2" 1/2"

Maximum Fuel Flow (CFH) 2212 3173

Orifice 21/64 7/16

Operating Pressure Range 1-7 1-7

Minimum Line Size 1" 1"

12 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 13

5. Installation

Always disconnect and lock out power before working on or around heater.

Machine to Earth Ground

It is very important that a machine to earth ground rod be installed at the fan. This is true even if there is

a ground at the pole 15' away. This ground needs to be as close to the fan as possible, but no more than

8' away. The ground rod should be connected to the fan contro l panel with at least a # 6 solid bare copper

ground wire, or in accordance with local requirements. The machine to earth ground provides additional

safety if there is a short. It also provides the grounding necessary for long life and operation of the solid

state circuit boards used on control circuits and the electronic ignition systems.

Previously Installed Units

It is recommended that previously installed units be checked to see that a machine to earth ground

has been installed by an electrician.

Standard electrical safety practices and codes should be used when working with a heater. Refer to the

National Electric Code Standard Handbook by the National Fire Protection Association. A qualified

electrician should make all wiring installations.

WARNING

Fuel Connection

IMPORTANT: Do not use propane tanks that have previously been used for ammonia unless they have

been purged according to procedures of the National LP association.

Fuel supply system must comply with local codes for LP gas installation.

Liquid Propane Models

1. LP models are designed to run on liquid propane with liquid draw from the propane tank. Avoid using

propane supply tanks that have been used for vapor draw for long periods of time. When using liquid

draw systems any moisture that may be present in tank or lines may freeze when system is used in

cold weather. To avoid this situation, purge the system with methanol.

2. Run proper size line (See Specifications on Page 12) to liquid pipe train on heater. Have a qualified

gas service person inspect installation to be sure that everything is installed according to local codes

and ordinances.

3. After installation is complete check all connections for leaks with liquid detergent or comparable.

Wear rubber gloves and eye protection. Avoid contact with liquid propane. DO NOT USE FLAME

FOR LEAK TESTING.

PNEG-1776 Deluxe Downwind Heater - Canadian 13

Page 14

5. Installation

Propane Vapor Models

1. Propane vapor models are designed to run directly off of a supply tank or from a separate

external vaporizer.

2. Run proper size line (See Specifications on Page 12) to pipe train on heater. Have a qualified gas

service person inspect installation to be sure that everything is installed according to local codes

and ordinances.

3. After installation is complete check all connections for leaks. DO NOT USE FLAME FOR

LEAK TESTING.

Natural Gas Models

1. Natural gas models are designed to run directly off of a supply tank or from a separate

external vaporizer.

2. Run proper size line (See Specifications on Page 12) to pipe train on heater. Have a qualified gas

service person inspect installation to be sure everything is installed according to local codes

and ordinances.

3. After installation is complete check all connections for leaks. DO NOT USE FLAME FOR

LEAK TESTING.

14 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 15

5. Installation

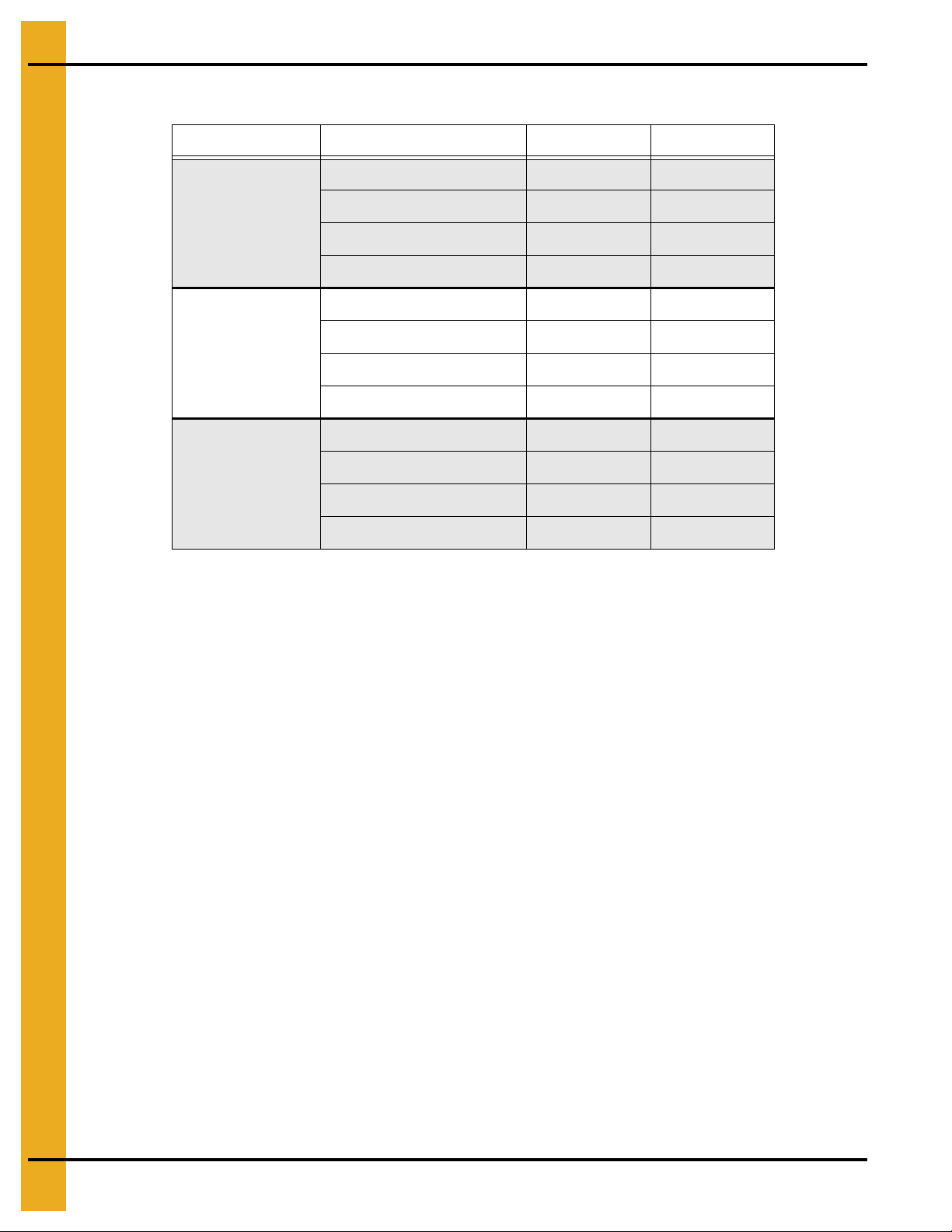

Standard Heater - Second Heater Installation

Two (2) standard heaters may be connected to one grain drying system and wired so they cycle tog ether.

One of the heaters should have a thermostat connected to it as per the installation instructions. That

heater will be referred to as the primary. The other heater (without the thermostat) will be referred to as

the secondary.

1. Install relay base (TD-100283) in primary heater control box.

2. Connect wire between terminal 13 on relay base to terminal 5 on terminal strip in primary heater.

3. Connect wire between terminal 14 on relay base to terminal 6 on terminal strip in primary heater.

4. Run two (2) wires (18 gauge) between primary and secondary heater.

5. Connect wires to terminals 5 and 9 (points A and B) on relay base in primary heater.

6. Connect wire from terminal 9 in primary to (point F) in secondary unit.

7. Connect wire from terminal 5 in primary to (point G) in secondary unit.

8. Install relay (TD-100282) in relay base.

Follow these additional steps for HIGH-LOW units.

1. Install relay base (TD-100283) in master heater control box.

2. Connect wire between terminal 13 on relay base to green wire from HIGH-LOW thermostat in master

unit. Do not disconnect other wires from green wire 3. Connect wire between terminal 14 on relay

base to terminal 14 on other relay base in master heater.

3. Run two (2) wires (18 gauge) between master and slave heater.

4. Connect wires to terminals 5 and 9 (points A and B) on relay base in master heater.

5. Connect wire from terminal 9 in master to terminal 6 (point G) in slave unit.

6. Connect wire from terminal 5 in master to cycle solenoid and red light in slave unit. Do not connect

wire to side of cycle solenoid and light that are connected to terminal.

Figure 5A CSA Heater - Second Heater Relay Connection

PNEG-1776 Deluxe Downwind Heater - Canadian 15

Page 16

5. Installation

Electrical Installation (460V Fans)

1. Connect power cord to fan control box.

2. Make field connections of wires in fan box as shown in Figure 5B. 110V power supply or

0.5 KVA 460V to 110V transformer must be used to supply power for heater.

3. Connect deluxe thermostat control (optional) in heater box as shown in Figure 5A on Page 15.

IMPORTANT: Heater must be interlocked with fan for safe operation.

IMPORTANT: Thermostat must be installed for safe operation.

Figure 5B 460 Volt Fan Control Box

16 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 17

Bin Configuration

Thermostat must be installed to operate as plenum high-limit safety.

5. Installation

Figure 5C

IMPORTANT: When mounting two (2) heaters on a bin it is imperative that they be situated as shown in

Figure 5C. Plenum thermostat must be to the right of master heater and master heater must

be to the right of slave heater.

Plenum Thermostat Mounting

The plenum thermostat must be ordered separately from the heater unit.

1. Follow installation instructions provided with the thermostat assembly.

2. Position the housing so that the bolt flanges are vertical and the cord exits the housing from the

bottom. Mark position.

3. Use 6 (4.00") or 8 (2.66") self-drilling screws to mount the housing to the bin sidewall. DO NOT

TIGHTEN COMPLETELY. Insert corrugation seal into gap between housing and sidewall.

Tighten screws.

4. Caulk between the housing and the sidewall to seal.

CAUTION

Heater control device (thermostat or humidistat) is required for heater warranty on all heaters.

PNEG-1776 Deluxe Downwind Heater - Canadian 17

Page 18

5. Installation

Figure 5D Plenum Thermostat Mounting on Bin Wall

Figure 5E Side view of thermostat showing corrugation seal.

18 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 19

Transition High-Limit Installation

1. Mark location on transition one foot up from the bottom (entrance collar) and centered in

the transition.

2. Drill or knock out 7/8" diameter hole on marked location.

3. Install transition high-limit using supplied self-drilling screws.

5. Installation

Figure 5F The transition connecting the heater to the bin with the plenum thermost at in place.

PNEG-1776 Deluxe Downwind Heater - Canadian 19

Page 20

6. Operation

Operating Temperature Table

IMPORTANT: Do not exceed plenum temperatures listed in table.

Low Temperature Batch

Corn 5°-20° Above Ambient Temperature 120° 140° 160°

Rice 5°-10° Above Ambient Temperature 100° 100° Not Recommended

Beans and

Wheat

5°-20° Above Ambient Temperature 110° 120° Not Recommended

High Temperature

Batch Dry No Stirring

High Temperature

with Stirring

Continuous Flow

(Recirculating)

This table is not intended as a drying guide. It should be used as a reference for setting m aximum

plenum temperature for safe operation.

Cycling Heater Operation

1. Thermostat must be wired into heater control box for heater to operate.

2. Open all manual shut off valves to heater unit.

3. Start fan. This will supply power to heater.

4. Turn thermostat dial to its highest setting.

5. Turn toggle switch ON.

6. Heater should now be lit. If not check to see that all gas is ON.

7. Set thermostat to desired setting. (See deluxe thermostat manual for adjusting deluxe

thermostat control.)

8. Gas pressure should be adjusted so burner is on 75% of the time.

9. Watch as burner goes through a few cycles, to be sure that it is operating properly.

20 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 21

6. Operation

High-Low Heater Operation

1. High-limit and cycling thermostat must be wired into heater control box for heater to operate.

2. Open all manual shut off valves to heater unit.

3. Start fan. This will supply power to heater.

4. Turn thermostat dial to its highest setting.

5. Turn toggle switch ON. Both indicator lights should illuminate indicating power to the control circuit.

6. Heater should now be lit. If not check to see that all gas is ON.

7. Loosen the retaining nut holding bypass valve screw in place. Open the bypass valve all the way.

8. Turn thermostat dial back slowly until heater cycles to low flame.

9. Adjust bypass valve so that low flame pressure is at desired setting. (As low as possible.)

10. Turn thermostat dial to desired setting and wait for bin plenum to come up to temperature. Heater

should cycle to low flame after a few minutes.

11. If heater does not cycle to low flame increase high flame gas pressure by adjusting the regulator.

High flame should be adjusted so the heater cycles at least once a minute. Low flame should be

12.

adjusted so there is enough flame for unit to keep operating.

13. Watch as burner goes through a few cycles, to be sure that it is operating properly back to high flame.

Figure 6A

PNEG-1776 Deluxe Downwind Heater - Canadian 21

Page 22

6. Operation

Adjusting the Vaporizer

1. Vaporizer should be adjusted so the vapor pipe train runs warm to the touch (100°-120°F).

2. Loosen 5/16" pivot bolts on adjustment bracket.

3. Tilt vaporizer away from burner to cool. Tilt toward burner to heat. Vaporizer may be raised or lowered

for vertical adjustments.

4. Tighten 5/16" pivot bolts to fix vaporizer position.

IMPORTANT: Only move vaporizer 1" at a time. Allow heater to run a few minutes for temperature

to equalize.

Figure 6B Figure 6C

Vaporizer adjustment: Away from burner to cool. Toward burner to heat.

22 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 23

6. Operation

BTUs for Gauge Pressure (PSI) Reading Propane Models

(Approximate)

High Temperature

Operating Pressure (PSI)

Diameter

2 4 6 8 10 12 14 16 18 20

15 HP 1,315,765 1,797,071 2,206,654 2,557,392 2,861,118 3,128,624 3,369,657 3,592,923 3,806,082 4,015,753

30 HP 2,007,794 2,742,244 3,367,248 3,902,456 4,365,927 4,774,128 5,141,934 5,482,626 5,807,897 6,127,845

Gauge Pressure (PSI) Reading to Maintain Temp (Approximate)

Heat Rise (F)

Diameter Static Pressure

60 80 100 120 140 160 180

2" 2 3 4 6 8 10 13

15 HP

30 HP

4" 1 2 3 5 6 8 10

6" 1 1 2 3 5 6 7

2" 2 3 5 6 9 11 14

4" 1 3 4 6 7 912

6" 1 2 3 5 6 810

8" 1 2 3 4 578

PNEG-1776 Deluxe Downwind Heater - Canadian 23

Page 24

6. Operation

BTUs for Gauge Pressure (PSI) Reading Natural Gas Models

(Approximate)

High Temperature

Operating Pressure (PSI)

Diameter12345678910

15 HP 1006116 1268133 1509530 1732015 1937235 2126771 2302144 2464811 2616167 2757542

30 HP 1788650 2254458 2683609 3079138 3443973 3780926 4092700 4381886 4650963 4902297

Gauge Pressure (PSI) Reading to Maintain Temp (Approximate)

Heat Rise (F)

Diameter Static Pressure

60 80 100 120 140 160 180

2" 2 3 5 7 9 11 14

15 HP

30 HP

4" 1 2 4 5 7 9 11

6" 1 2 3 4 5 6 8

2" 1 2 4 5 7 9 11

4" 1 2 3 5 6 8 10

6" 1 2 3 4 5 6 8

8" 1 1 2 3 4 6 7

24 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 25

7. Service

Seasonal Inspection and Service

All parts are made of weather-proof construction and are designed to require a minimum of service;

however, we recommend the following items be checked and serviced, as described, before the unit is

used each season. Replace any damaged or questionable parts.

THESE CHECKS WILL HELP ELIMINATE POSSIBLE MINOR FAULTS AND ASSURE DEPENDABLE

OPERATION OF THE EQUIPMENT WHEN IT IS NEEDED.

1. Check fan and service it as described within the fan installation and operation manual.

2. Shut off electrical power. Remove heater control box cover and inspect for moisture, rodent damage

or accumulated foreign material remove any foreign material present. INSPECT AND TIGHTEN ALL

LOOSE TERMINAL CONNECTIONS. Replace any damaged or deteriorated wiring.

3. Shut off fuel and remove and clean gas line strainer.

4. Remove the orifice from the burner venturi and inspect for obstructions. Also, inspect and clean out

the burner venturi and the ports within the burner cup. Blow out with compressed air or disassemble

and thoroughly clean these parts. Foreign material in the venturi or burner cup will impair heater

operation and cannot be expected to burn out when the heater is started.

5. Inspect and clean the electrodes on the ignitor plug. Use an ignition point file to remove carbon and

rust between the electrode surfaces.

6. Inspect flame rod and ignitor plug wires for possible damage or poor connections.

7. After completing all checks and performing any necessary service, check the control device, as

described under the following appropriate heading.

Heaters Equipped with a Humidistat Control

Temporarily remove humidistat control from air plenum chamber of bin. Rotate the knob through the 20%

to 80% humidity range. The switch within the humidistat should produce a small “click” when the lever

passes the point of prevailing humidity.

NOTE: For additional information, refer to instructions that accompanied the humidistat.

Heaters Equipped with a Thermostat Control

Slowly rotate the thermostat dial through its temperature range. The switch within the thermostat should

produce a small “click” when the dial passes the point of prevailing temperature. Set the dial to a setting

at least 10°F above the prevailing temperature and proceed to the next step.

8. Test operate the fan and heater. Make sure to follow operating instructions, INCLUDING. After fan

starts operating and the heater purge interval has elapsed (approximately 20 seconds delay), the

heater should come ON and start operating.

9. Slowly change the humidistat or thermostat setting and cycle the heater OFF and ON to make sure

the device is controlling the heater and is operating properly.

PNEG-1776 Deluxe Downwind Heater - Canadian 25

Page 26

7. Service

10. LP MODELS ONLY - After heater has been operating for some time and temperatures have

stabilized, check temperature of the gas line between outlet side of vaporizer and the gas regulator.

If gas line becomes “frosted” with an accumulation o f ice build-u p, adjust vaporize r slightly closer to

the flame. If line reaches a high temperature where it is hot to the touch, adjust vaporizer further away

from the flame.

NOTE: If gas temperature exceeds approximately 220°F, the vapor high-limit thermostat will open

the electrical circuit to the liquid gas solenoid valve and shut off fuel flow to stop the heater.

This condition can be verified by temporarily connecting a jumper wire across the connections

of the high-limit and observing that the burner re-lights. If high-limit vapor thermost at causes

the burner to stop operating, it may also cause the burner to go into a safety lock out

condition. Refer to heater operating instructions for restarting procedure.

11. Vaporizers should be inspected and serviced prior to each season of operation, including

the following:

a. Carefully inspect the surfaces of the vaporizer coil and the inlet and vapor outlet pipes for

evidence of severe corrosion or abrasion of metal which could cause subsequent leakage of

liquid propane, gross overheating and fire hazard.

b. Insecure mounting of either the vaporizer or burner, due to loosened bolts, can cause interference

between burner vanes and vaporizer pipes, with the natural vibration of the unit causing erosion

of the pipe metal at the point of maintained contact.

c. If there has been significant abrasion of the steel vaporizer pipe, it must be replaced.

12. When satisfied that heater is operating properly, make sure to reset the control d evice to the p roper

setting and restore the fan and heater for normal type operation.

IMPORTANT: Use care when troubleshooting this product. Limit exposure to potential hazards by

following all recommended safety practices.

26 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 27

8. Troubleshooting - Heater

Trouble Probable Cause Check-Out Procedure

Burner will not fire. No gas

pressure on gauge.

No ignition spark.

Burner will not fire. No gas

pressure on gauge. Constant

ignition spark.

Burner will not fire. Gas pressure

on gauge. No ignition spark.

1. Heater not wired.

2. Fan not running. 2. Fan contactor must be energized for heater to run.

3. Blown fuse. 3. Visually check fuse.

4. Bad ON/OFF switch.

5. Housing high-limit switch. 5. Reset switch. Check for power on terminals 1 and 8.

6. Thermostat open.

7. Flame probe open.

1. Gas supply.

1. Loose wire.

2. Ignitor/spark plug.

3. Ignition transformer/wire.

1. Visually check fan control box to see if wires

are connected.

4. Check ON/OFF switch contact block for proper installation

and continuity. Check for power on terminals 1 and 8.

6. Plenum temperature above set point temperature or

open circuit.

7. Remove wires from flame probe and check with

ohm meter. Probe should be closed when cold.

1. Make sure all valves are open to heater and gas tank is

not empty.

1. Check for power on terminals 4 and 7. Look for loose wires

or incorrect wiring.

2. Turn gas OFF to heater. Check gap on ignitor. Check

porcelain for any sign of cracks. Remove plug wire from

spark plug/ignitor. Carefully holding wire by insulation.

Try to get an arc between end of wire and heater housing

(or other wire using two (2) pole transformer).

3. Turn gas OFF to heater. If no spark present after

checking ignitor, remove wire from ignition transformer.

Check for spark at ignition transformer with an insulated

screwdriver. Spark should jump a minimum 1/4" gap.

Replace transformer if no spark is established, replace the

ignition wires.

1. Check for gas at burner. If no gas, remove pipe train and

check orifice and burner ring for blockage.

2. Check to be sure flame probe is in good condition and is

located in flame. Flame probe contacts should open when

probe gets hot.

4. See that flame burns continuous and is not intermittent.

On ring burners be sure flame burns completely

around ring.

5. Have tank and lines checked by a qualified gas

service man.

Burner will not fire or fires for

30 second and locks out. Gas

pressure on gauge. Spark is ON.

1. Plugged orifice.

2. Flame probe.

3. Incorrect supply voltage. 3. Voltage to heater must be 110V AC.

4. Regulator set too low.

5. Moisture in fuel.

PNEG-1776 Deluxe Downwind Heater - Canadian 27

Page 28

9. Wiring Diagrams

CSA Centrifugal Heater Schematic

28 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 29

CSA Centrifugal Diagram

9. Wiring Diagrams

PNEG-1776 Deluxe Downwind Heater - Canadian 29

Page 30

NOTES

30 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 31

10. Parts List

1. CSA Heater Control Box Assembly (HF-8184) - (See Pages 32-33.)

2. Downwind Centrifugal Heater Control Parts - (See Pages 34-35.)

3. Downwind Centrifugal LP Pipe Train Components - (See Pages 36-37.)

4. Downwind Centrifugal LP High-Low Pipe Train Components - (See Pages 38-39.)

5. Downwind Centrifugal NG Pipe Train Components - (See Page 40.)

6. Downwind Centrifugal NG High-Low Pipe Train Components - (See Page 41.)

7. Downwind Centrifugal Propane Vapor Pipe Train Components - (See Pages 42-43.)

8. Downwind Centrifugal Propane Vapor High-Low Pipe Train Components - (See Pages 44-45.)

9. 15 HP and 30 HP Centrifugal Housing - (See Page 46.)

10. LP Supply Pipe Train Assembly - (See Page 47.)

PNEG-1776 Deluxe Downwind Heater - Canadian 31

Page 32

10. Parts List

CSA Heater Control Box Assembly (HF-8184)

32 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 33

10. Parts List

CSA Heater Control Box Assembly (HF-8184) Parts List

Ref # Part # Description Qty

1 DSA-VIS-POWR Dryer Switch Assembly Vis Power ON/OFF 1

2 C-8707 Control Box Backing Plate - C-8705 1

3 HF-7697 Bracket, Standard Term Strip 1

4 HF-4624-CSA Fenwal, Flame Detection Board - CSA Version 15 Sec Purge 1

5 AIRSWITCH Switch, Air (Antunes) 1

6 TFH-2013 Terminal, Strip 8 Conductor ELD-8-009 1

7 E160-1137 Lug Ground, #TA-2 (CSA) 2

8 C-8718 Single Pole Midget Fuse Block 1

9 E240-1107 Connector, T.B., 12 Pole, 10A, 12 Gauge 1

10 C-8715 1-1/2" x 13/32" Fuse Puller 1

11 C-8719 Slow Blow 2A Midget Fuse 500 VAC, 10 KA I.R. 1

12 90-0009 Lamp, Oil Tight 1/4" Tab 120V Amber 4

13 HF-7454 High-Limit Box Body 1

14 HF-7455 High-Limit Box Lid 1

15 HF-7439 Switch, High-Limit 250° 1

16 FH-1310 Cord Connector, Heyco 2

17 FH-1309 Lock Nut 1/2" with Pipe Threads 2

18 048-1018-0 Hole Plug - BP - 7/8" 1

19 WR-163SOOWA Wire, 16/3 Type Soow-A Yellow 1

20 FH-7401 C-8705 Adapter Plate - 24" VA 1

20 FH-7402 C-8705 Adapter Plate - 28" VA 1

20 FH-7403 C-8705 Adapter Plate - 18" VA 1

PNEG-1776 Deluxe Downwind Heater - Canadian 33

Page 34

10. Parts List

Downwind Centrifugal Heater Control Parts

34 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 35

10. Parts List

Downwind Centrifugal Heater Control Parts List

Ref # Part # Description Unit

1 C-8708 Control Box Backing Plate - C-8706 All

2 HF-4624-CSA Fenwal, Flame Detection Board-CSA Version 15 Sec Purge All

3 HH-1487 Transformer, Single Pole 120V 60CY 6000V All

4 HF-7697 Bracket, Standard Term Strip All

5 TFH-2013 Terminal, Strip 8 Conductor ELD-8-009 All

6 C-8718 Single Pole Midget Fuse Block All

7 HH-7063 Switch, Air (Antunes) All

8 C-8715 1-1/2" x 13/32" Fuse Puller All

9 C-8719 Slow Blow 2A Midget Fuse 500 VAC, 10KA I.R All

10 E240-1107 Connector, T.B., 12 Pole, 10A, 12 Gauge All

11 HF-8209 Centrifugal Downwi nd Control Box LP Cycling All

12 DSA-VIS-POWR Dryer Switch Assembly Vis Power ON/OFF All

13 90-0009 Lamp, Oil Tight 1/4" TAB 120V Amber All

14 E160-1137 Lug, Ground, #TA-2 (CSA) All

PNEG-1776 Deluxe Downwind Heater - Canadian 35

Page 36

10. Parts List

Downwind Centrifugal LP Pipe Train Components

36 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 37

10. Parts List

Downwind Centrifugal LP Pipe Train Components Parts List

Ref # Part # Description Qty HP

1 707-1175-9 Union, 3/4" SCH 40 Black 1 All

2 THH-4121 Nipple, 3/4" Close SCH 40 Black 7 All

3 HF-7794 Orifice Holder - Quad Heater - 3/4" 1 All

4 D08-0017 Tee, 1" x 1" x 3/4" SCH 40 Black 1 All

5 D08-0014 Plug, 1" Square Black 1 All

6 D03-0837 V a lve, 3/4" NP T Full Port, Lever, CSA, Brass 1 All

7 THH-4154 Tee, 3/4" x 3/4" x 1/4" SCH 40 Black 1 All

8 THH-4120 Elbow, 3/4"-90° SCH 40 Black 1 All

9 056-2223-8 Valve, Solenoid 3/4" NPT 115V Din 50 PSI 1 All

10 THH-4124 Tee, 3/4" x 3/4" x 3/4" SCH 40 Black 1 All

11 HH-7102 Nipple, 3/4" x 2-3/4" SCH 40 Black 1 All

12 D03-0880 Regulator, LP 5-20 PSI Spring, 0.5 Orifice, 3/4" NPT 1 All

13 THH-4158 Tee, 3/4" x 1/4" x 3/4" SCH 40 Black 1 All

14 THH-4125 Nipple, 3/4" x 2" SCH 40 Black 1 All

15 007-1338-8 Bushing, Flush 1" to 3/4" 1 All

16 D03-0881 Valve, Relief - 15-50 PSI Spring LP, 1" NPT, 300F Rating 1 All

17 D67-0021 Nipple, 3/4" Close SCH 80 Black 1 All

18 THH-4149 Elbow, 3/4" x 1/2" Reducing SCH 40 1 All

19 FLX-3788 Plug, 1/4" NPT Pipe 1 All

20 HF-8205 Orifice Plug, (3/4) Drill: 9/32" 1 15" High

20 HF-8204 Orifice Plug, (3/4) Drill: 23/64" 1 30" High

PNEG-1776 Deluxe Downwind Heater - Canadian 37

Page 38

10. Parts List

Downwind Centrifugal LP High-Low Pipe Train Components

38 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 39

10. Parts List

Downwind Centrifugal LP High-Low Pipe Train Components Parts List

Ref # Part # Description Qty HP

1 707-1175-9 Union, 3/4" SCH 40 Black 1 All

2 THH-4121 Nipple, 3/4" Close SCH 40 Black 7 All

3 HF-7794 Orifice Holder - Quad Heater - 3/4" 1 All

4 D08-0017 Tee, 1" x 1" x 3/4" SCH 40 Black 1 All

5 D08-0014 Plug, 1" Square Black 1 All

6 D03-0837 V a lve, 3/4" NP T Full Port, Lever, CSA, Brass 1 All

7 THH-4154 Tee, 3/4" x 3/4" x 1/4" SCH 40 Black 1 All

8 THH-4120 Elbow, 3/4"-90° SCH 40 Black 1 All

9 056-2228-7 Valve, Solenoid 3/4" NPT 115V Din with Bypass 1 All

10 056-2223-8 Valve, Solenoid 3/4" NPT 115V Din 50 PSI 1 All

11 THH-4124 Tee, 3/4" x 3/4" x 3/4" SCH 40 Black 1 All

12 THH-4158 Tee, 3/4" x 1/4" x 3/4" SCH 40 Black 1 All

13 HH-7102 Nipple, 3/4" x 2-3/4" SCH 40 Black 1 All

14 D03-0880 Regulator, LP 5-20 PSI Spring, 0.5 Orifice, 3/4" NPT 1 All

15 THH-4125 Nipple, 3/4" x 2" SCH 40 Black 1 All

16 007-1338-8 B ushing, Flush 1" to 3/4" 1 All

17 D03-0881 Valve, Relief - 15-50 PSI Spring LP, 1" NPT, 300F Rating 1 All

18 D67-0021 Nipple, 3/4" Close SCH 80 Black 1 All

19 THH-4149 Elbow, 3/4" x 1/2" Reducing SCH 40 1 All

20 FLX-3788 Plug, 1/4" NPT Pipe 1 All

21 HF-8205 Orifice Plug, (3/4) Drill: 9/32" 1 15" High

21 HF-8204 Orifice Plug, (3/4) Drill: 23/64" 1 30" High

PNEG-1776 Deluxe Downwind Heater - Canadian 39

Page 40

10. Parts List

Downwind Centrifugal NG Pipe Train Components

Downwind Centrifugal NG Pipe Train Components Parts List

Ref # Part # Description Qty HP

1 707-1 175-9 Union, 3/4" SCH 40 Black 1 All

2 THH-4121 Nipple, 3/4" Close SCH 40 Black 1 All

3 HF-7794 Orifice Holder - Quad Heater - 3/4" 1 All

4 THH-4137 Tee, 1" x 1" x 1" SCH 40 Black 2 All

5 D08-0014 Plug, 1" Square Black 1 All

6 THH-4117 Nipple, 1" Close SCH 40 Black 8 All

7 D03-0838 Valve, 1" NPT Full Port, Lever, CSA, Brass 2 All

8 THH-4152 Tee, 1" x 1" x 1/4" SCH 40 Black 1 All

9 THH-4115 Elbow, 1"-90° SCHED 40 Black 1 All

10 056-2224-6 Valve, Solenoid 1" NPT 115V Din 2 All

11 THH-4163 Tee, 1" x 1/4" x 1" SCH 40 Black 1 All

12 D03-0881 Valve, Relief - 15-50 PSI Spring LP, 1" NPT, 300F Rating 1 All

13 THH-4037 Nipple, 1" x 2-1/2" SCH 40 Black 2 All

14 D08-0007 Reducer, 1-1/2" x 1" Hex Bushing 2 All

15 D03-0819 Regulator, NG 4-10 PSI Spring, 1.19 Orifice, 1-1/2" NPT 1 All

16 FLX-3788 Plug, 1/4" NPT Pipe 1 All

17 HF-8204 Orifice Plug, (3/4) Drill: 23/64" 1 15" High

17 406-2442-1 Orifice Plug, (3/4) Drill: 15/32" 1 30" High

40 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 41

10. Parts List

Downwind Centrifugal NG High-Low Pipe Train Components

Downwind Centrifugal NG High-Low Pipe Train Components Parts List

Ref # Part # Description Qty HP

1 707-1175-9 Union, 3/4" SCH 40 Black 1 All

2 THH-4121 Nipple, 3/4" Close SCH 40 Black 1 All

3 HF-7794 Orifice Holder - Quad Heater - 3/4" 1 All

4 THH-4137 Tee, 1" x 1" x 1" SCH 40 Black 2 All

5 D08-0014 Plug, 1" Square Black 1 All

6 THH-4117 Nipple, 1" Close SCH 40 Black 9 All

7 D03-0838 Valve, 1" NPT Full Port, Lever, CSA, Brass 2 All

8 THH-4152 Tee, 1" x 1" x 1/4" SCH 40 Black 1 All

9 THH-4115 Elbow, 1"-90° SCHED 40 Black 1 All

10 056-2230-3 Valve, Solenoid 1" NPT 115V Din with Bypass 1 All

11 056-2224-6 Valve, Solenoid 1" NPT 115V Din 2 All

12 THH-4163 Tee, 1" x 1/4" x 1" SCH 40 Black 1 All

13 FLX-3788 Plug, 1/4" NPT Pipe 1 All

14 THH-4037 Nipple, 1" x 2-1/2" SCH 40 Black 2 All

15 D08-0007 Reducer, 1-1/2" x 1" Hex Bushing 2 All

16 D03-0819 Regulator, NG 4-10 PSI Spring, 1.19 Orifice, 1-1/2" NPT 1 All

17 D03-0881 Valve, Relief - 15-50 PSI Spring LP, 1" NPT, 300F Rating 1 All

18 HF-8204 Orifice Plug, (3/4) Drill: 23/64" 1 15" High

18 406-2442-1 Orifice Plug, (3/4) Drill: 15/32" 1 30" High

PNEG-1776 Deluxe Downwind Heater - Canadian 41

Page 42

10. Parts List

Downwind Centrifugal Propane Vapor Pipe Train Components

42 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 43

10. Parts List

Downwind Centrifugal Propane Vapor Pipe Train Components Parts List

Ref # Part # Description Qty Unit

1 707-1175-9 Union, 3/4" SCH 40 Black 1 All

2 THH-4121 Nipple , 3/4" Clo se SCH 40 Black 8 All

3 HF-7794 Orifice Holder - Quad Heater - 3/4" 1 All

4 D08-0017 Tee, 1" x 1" x 3/4" SCH 40 Black 1 All

5 D08-0014 Plug, 1" Square Black 1 All

6 D03-0837 Valve, 3/4" NPT Full Port, Lever, CSA, Brass 1 All

7 THH-4154 Tee, 3/4" x 3/4" x 1/4" SCH 40 Black 1 All

8 THH-4120 Elbow, 3/4"-90° SCH 40 Black 1 All

9 056-2223-8 Valve, Solenoid 3/4" NPT 115V Din 50 PSI 2 All

10 THH-4124 Tee, 3/4" x 3/4" x 3/4" SCH 40 Black 1 All

11 HH-7102 Ni pple, 3/4" x 2-3/4" SCH 40 Black 1 All

12 D03-0880 Regulator, LP 5-20 PSI Spring, 0.5 Orifice, 3/4" NPT 1 All

13 THH-4158 Tee, 3/4" x 1/4" x 3/4" SCH 40 Black 1 All

14 THH-4125 Nipple, 3/4" x 2" SCH 40 Black 1 All

15 007-1338-8 Bushing, Flush 1" to 3/4" 1 All

16 D03-0881 Valve, Relief - 15-50 PSI Spring LP, 1" NPT, 300F Rating 1 All

17 D67-0021 Nipple, 3/4" Close SCH 80 Black 1 All

18 D03-0841 Valve, 3/4" NPT LP Quick Shut Off CSA 1 All

19 FLX-3788 Plug, 1/4" NPT Pipe 1 All

20 HF-8205 Orifice Plug, (3/4) Drill: 9/32" 1 15"

20 HF-8204 Orifice Plug, (3/4) Drill: 23/64" 1 30"

PNEG-1776 Deluxe Downwind Heater - Canadian 43

Page 44

10. Parts List

Downwind Centrifugal Propane Vapor High-Low Pipe Train

Components

44 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 45

10. Parts List

Downwind Centrifugal Propane Vapor High-Low Pipe Train Components Parts List

Ref # Part # Description Qty Unit

1 707-1175-9 Union, 3/4" SCH 40 Black 1 All

2 THH-4121 Nipple , 3/4" Clo se SCH 40 Black 9 All

3 HF-7794 Orifice Holder - Quad Heater - 3/4" 1 All

4 D08-0017 Tee, 1" x 1" x 3/4" SCH 40 Black 1 All

5 D08-0014 Plug, 1" Square Black 1 All

6 D03-0837 Valve, 3/4" NPT Full Port, Lever, CSA, Brass 1 All

7 THH-4154 Tee, 3/4" x 3/4" x 1/4" SCH 40 Black 2 All

8 THH-4120 Elbow, 3/4"-90° SCH 40 Black 1 All

9 056-2228-7 Valve, Solenoid 3/4" NPT 115V Din with Bypass 1 All

10 056-2223-8 Valve, Solenoid 3/4" NPT 115V Din 50 PSI 2 All

11 THH-4124 Tee, 3/4" x 3/4" x 3/4" SCH 40 Black 1 All

12 THH-4158 Tee, 3/4" x 1/4" x 3/4" SCH 40 Black 1 All

13 HH-7102 Nipple, 3/4" x 2-3/4" SCH 40 Black 1 All

14 D03-0880 Regulator, LP 5-20 PSI Spring, 0.5 Orifice, 3/4" NPT 1 All

15 THH-4125 Nipple, 3/4" x 2" SCH 40 Black 1 All

16 007-1338-8 Bushing, Flush 1" to 3/4" 1 All

17 D03-0881 Valve, Relief - 15-50 PSI Spring LP, 1" NPT, 300F Rating 1 All

18 D67-0021 Nipple, 3/4" Close SCH 80 Black 1 All

19 D03-0841 Valve, 3/4" NPT LP Quick Shut Off CSA 1 All

20 FLX-3788 Plug, 1/4" NPT Pipe 1 All

21 HF-8205 Orifice Plug, (3/4) Drill: 9/32" 1 15"

21 HF-8204 Orifice Plug, (3/4) Drill: 23/64" 1 30"

PNEG-1776 Deluxe Downwind Heater - Canadian 45

Page 46

10. Parts List

15 HP and 30 HP Centrifugal Housing

15 HP and 30 HP Centrifugal Housing Parts List

Ref # Part # Description Unit

1 HF-8214 Heater Top Panel: 15 HP Canadian 15

1 HF-8215 Heater Top Panel: 30 HP Canadian 30

2 HF-7655 Downwind Housing Side: L.H. 10-15 15

2 HF-7784 Downwind Housing Side: L.H. 20-30/40 30

3 HF-7654 Downwind Housing Side: R.H. 10-15 15

3 HF-7783 Downwind Housing Sid e: R.H. 20-30/40 30

4 HF-8368 Heater Bottom Panel: 10-15 Canadian 15

4 HF-8369 Heater Bottom Panel: 20-30 Canadian 30

5 HF-7661 Downwind Housing Profile Top: 10-15 15

5 HF-7785 Downwind Housing Profile Top: 20-30 30

6 HF-7662 Downwind Housing Profile Bottom: 10-15 15

6 HF-7786 Downwind Housing Profile Bottom: 20-30 30

7 HF-8076 Down Profile Angle - Side CHD-15 15

7 HF-8071 Down Profile Angle - Side CHD-30 30

8 HF-7665 Burner Mounting Grip: Downwind Heater All

9 HF-7856 Grip - Access Door Window All

10 HF-7855 Access Panel Assembly Downwind Heater - Blank All

1 1 HF-8361 Heater Air Diverter 10-15 HP 15

11 HF-8362 Heater Air Diverter 30-40 HP 30

12 HF-7711 Burner Assembly: Downwind 10-15 Deluxe 04 15

12 HF-7793 Burner Assembly: Downwind 20-40 Deluxe 04 30

46 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 47

LP Supply Pipe Train Assembly

10. Parts List

LP Supply Pipe Train Assembly Parts List

Ref # Part # Description Qty

1 HH-4846 Tee, 1/2" x 1/2" x 1/4" SCH 80 Black 3

2 TFC-0027 Valve, 1/4" NPT 250# Relief 3

3 THH-4113 Nipple, 1/2" x Close SCH 80 Black 3

4 HH-1251 Strainer, 1/2" Y 250# WOG SCH 80 1

5 D03-0840 Valve, 1/2" NPT LP Quick Shut Off CSA 1

6 HF-7586 Nipple, 1/2" x 2" SCH 80 Black 2

7 TFC-0100 Valve, 1/2" NPT Solenoid LP with Din 1

PNEG-1776 Deluxe Downwind Heater - Canadian 47

Page 48

NOTES

48 PNEG-1776 Deluxe Downwind Heater - Canadian

Page 49

11. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive

components, shall be free from defects in materials for a period of time beginning on the twelfth (12

the date of purchase and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period).

th

) month from

During the extended warranty period, GSI will replace the frame or basket components that prove to be defective

under normal conditions of use without charge, excluding the labor, transportation, and/or shipping costs incurred in

the performance of this extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1776 Deluxe Downwind Heater - Canadian 49

Page 50

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2012 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-302071

Loading...

Loading...