Page 1

PNEG-1758

Competitor/Dri-Tek Control Panel

Operation Manual

PNEG-1758

Date: 07-21-10

Page 2

2 PNEG-1758 Competitor/Dri-Tek Control Panel

Page 3

Table of Contents

Contents

Chapter 1 Competitor/Dri-Tek Control Panel ......................................................................................................4

Dryer Control Panel Featuring the Series 2000 Control System ........................................................... 5

Special Features ....................................... ... .... ... ... ... .......................................................................... 10

Safety Circuit Shutdown Messages .................................................................................................... 10

Chapter 2 Warranty ..............................................................................................................................................15

PNEG-1758 Competitor/Dri-Tek Control Panel 3

Page 4

1. Competitor/Dri-Tek Control Panel

Instructions de Programmation

Programming Instructions

MOISTURE CONTROL

CONTRÔLE D’HUMIDITÉ

LUMIÈRE EN MARCHE (“ON”)

LIGHT “ON”

ON

MARCHE

OFF

ARRÊT

WHEN DISCHARGE MOISTURE ABOVE SETPOINT

Quand l’évacuation d’humidité est au - dessus

du point de consigne

Réglage des minuteries, délais en temps et températures.

Setting timers, time delays and temperatures

Utiliser le mode choisi (select)

Using the mode select

Checking the hour meter

Vérification du Compteur d’Heure

1. Appuyez le bouton du programme que vous désirez changer soit

pour changer l’heure ou soit pour changer la température.

1. Press the button for the program that you wish to

change the time or temperature in.

2. Utilisez les boutons “augmenter” et “diminuer” pour changer

la température ou l’heure présente.

2. Use the increase and decrease buttons to change

the present time or temperature.

3. Après avoir changé l’heure ou la température, l’ordinateur

acceptera automatiquement la nouvelle valeur.

3. After the time or temperature has been changed,

the computer automatically accepts the new value.

1. Pressing the mode select button will toggle the

display between timer values, grain temperature

and plenum temperature.

1. Appuyez le bouton de mode choisi (select) reversera

l’affichage entre les valeurs de temps, la température du

grain et la température du plénum.

Pressing the increase button changes the display

to the total hours on the dryer. It will automatically

return to the main screen after the button is released.

Appuyer sur le bouton “augmenter” changera l’affichage

aux heures totales sur le séchoir. Il retournera automatiquement

à l’écran principal après avoir relâché le bouton.

Turn off and lockout power

before inspection or service.

Hazardous voltage may

cause serious injury

or death.

S’assurer que le courant

électrique soit arrêté et fermé

avant d’inspecter ou de

travailler sur cet équipement.

La tension dangeureuse peut

résulter de blessures graves

ou la mort.

CONTROL POWER

COMMANDE DE PUISSANCE

DRYING MODE

MODE DE SECHAGE

LOAD AUGER

FOREUSE DE CHARGE

STAGED BATCH

GROUPE ETAGÉ

STAGED

BATCH

CONT. FLOW

FLOT CONTINU

GROUPE

ETAGÉ

FLOT

CONTINU

CONT.

FLOW

OFF

ARRÊT

OUTSIDE LIGHT

LUMIÈRE EXTÉRIEURE

ON

MARCHE

ARRÊT

MARCHE

ARRÊT

MARCHE

ARRÊT

ARRÊT

MARCHE

ARRÊT

MARCHE

OFF

VENTILATEUR

FAN

HEATER

RADIATEUR

UNLOAD AUGER

DÉCHARGER LA FOREUSE

DRYER POWER

PUISSANCE DU

SÉCHOIR

START

DÉMARRER

STOP

ARRÊTER

OFF

1 SPEED

VITESSE 1

VITESSE 2

METERING ROLL SPEED

VITESSE DU COMPTEUR

DE ROULEMENT

125

250

2 SPEED

AUTO

OFF

ON

OFF

ON

AUTO

AUTO

AUTO

TIMED

SHUTDOWN

ARRÊT

SYNCHRONISÉ

FAN RUNS EXCEPT

DURING BATCH UNLOAD

LE VENTILATEUR FONCTIONNE

EXCEPTÉ DURANT LE

DÉCHARGEMENT DE LOT

FAN RUNS

CONTINUOUSLY

HEARER “ON”

DURING BATCH DRY

CYCLE ONLY

(LE RADIATEUR EST EN

MARCHE (ON) PENDANT LE

CYCLE DE SÉCHAGE DE

LOT SEULEMENT)

HEATER “ON” WHEN

FAN RUNNING

LOW SPEED

VITESSE LENTE

HIGH SPEED

VITESSE RAPIDE

STAGED BATCH

GROUPE ETAGÉ

CONTINUOUS

CONTINU

ON

OFF

ON

LES VENTILATEURS

FONCTIONNENT

CONTINUELLEMENT

(RADIATEUR EN

MARCHE QUAND LE

VENTILATEUR

FONCTIONNE)

DC-1980

MOISTURE CONTROL SET POINT

POINT DE CONSIGNE DU CONTRÔLE D’HUMIDITÉ

PLENUM TEMPERATURE SET POINT

POINT DE CONSIGNE DE TEMP DE PLÉNUM

HI LO SPEED

VITESSE HAUTE LENTE

DISCHARGE

DÉCHARGE

LO-FLAME

FLAMME BASSE

HI-FLAME

FLAMME HAUTE

PURGE

PURGE

MOTOR

MOTEUR

OVERLOAD

SURCGARGE

ERROR

ERREUR

NO AIRFIOW

PAS D’ÉCOULEMENT D’AIR

% GRAIN

% GRAIN

°F PLENUM

PLÉNUM F

°C HOUSING

BOITÎER C

VAPOR

VAPEUR

TEMP HI-LIMIT

TEMP LIM-ÉLEVÉE

FLAME OUT

FLAMME ÉTEINTE

PROGRAM

(TIMERS)

PROGRAMME

(MINUTERIES)

PROGRAM

(TEMPERATURES)

PROGRAMME

(TEMPÉRATURES)

PROGRAM

(DELAYS)

PROGRAMME

(DÉLAIS)

MODE SELECT

TIMERS/PLENUM TEMP/

GRAIN TEMP

MODE CHOISI (SELECT)

MINUTERIES/TEMP PLÉNUM/

TEMP GRAIN

HOURS

X 1000

HEURES

X 1000

HOURS

HEURES

DC-2004

LOAD DELAY

DÉLAI DE CHARGE

DRY TIME

TEMPS DE SÉCHAGE

OUT OF GRAIN TIME

TEMPS HORS GRAIN

COOL TIME

TEMPS DE REFROIDISSEMENT

UNLOAD TIME

TEMPS DE DÉCHARGE

UNLOAD DELAY

DÉLAI DE DÉCHARGE

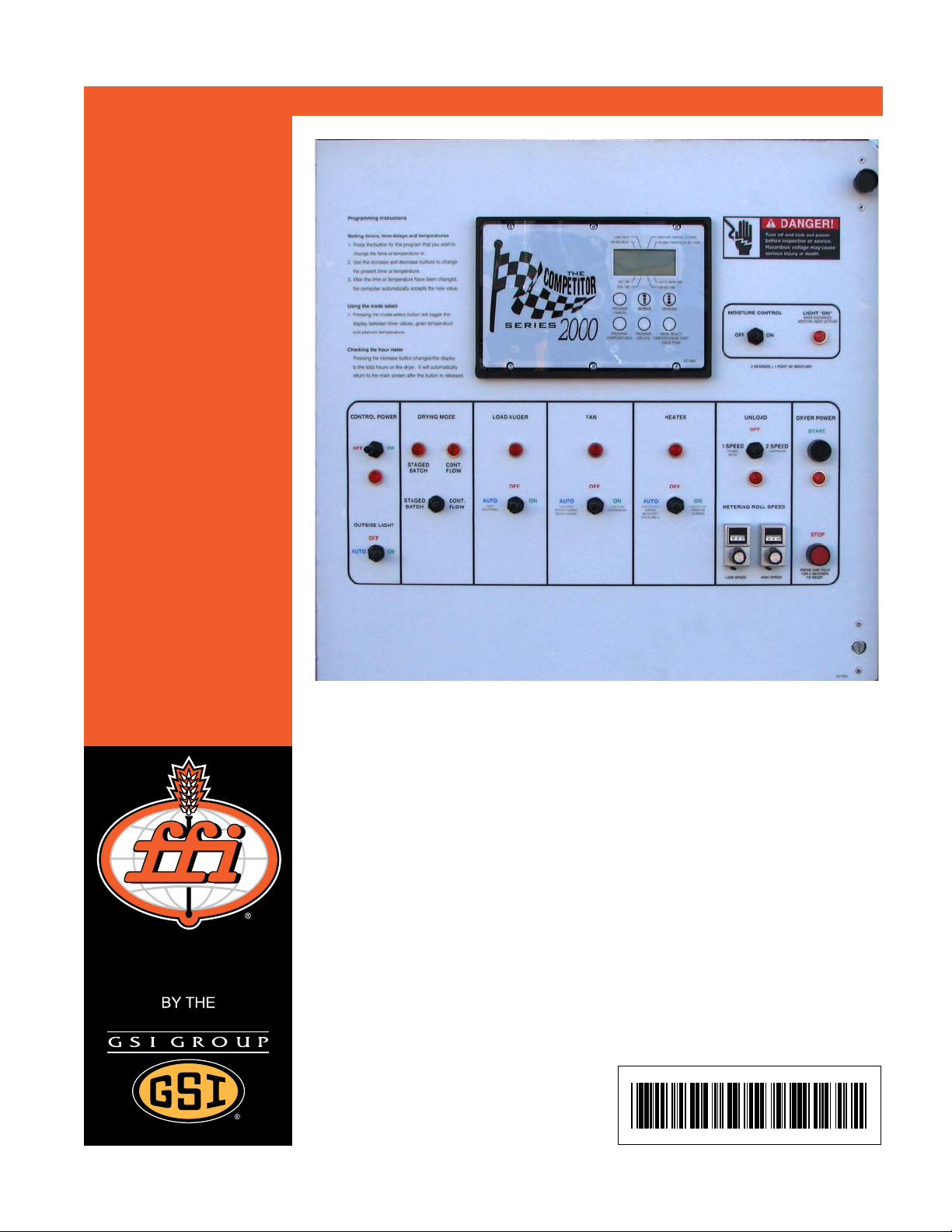

Figure 1A Grain Dryer Control Panel

4 PNEG-1758 Competitor/Dri-Tek Control Panel

Page 5

1. Competitor/Dri-Tek Control Panel

Dryer Control Panel Featuring the Series 2000 Control System

The control panel provides easy access to gauges and controls. The Competitor Series 2000 Control

System is a computerized control system that gives instant information regarding dryer operation.

Moisture Control (Temperature Based)

The Series 2000 dryer has a built in moisture control. It controls the moisture level of discharged grain by

sensing grain column temperature.

Moisture Control Switch

This switch turns the power ON or OFF to the moisture control. The light beside the switch is illuminated

when the grain column temperature is below the moisture control setpoint.

Control Power Switch

The power to the Series 2000 Control System is turned ON or OFF with this switch.

Outside Light

The dryer outside light is turned ON or OFF here.

Drying Mode Switch

This is used to select staged batch or continuous flow drying.

Load Auger Switch

This is used to select the operation of the fill auger. In both the AUTO and MANUAL positions, the load

auger will operate if the dryer is low on grain and will automatically shut off when the dryer is full. In the

AUTO position only, the dryer will shutdown after a preset period of time set on the out of grain timer.

NOTE: If the load auxiliary motor overload relay is being utilized in the dryer control pane l, this switch will

also control the operation of the auxiliary equipment.

Fan Switch

The fan is turned ON or OFF with this switch. The ON position operates the fan continu ously during staged

batch and continuous flow modes. The AUTO position is used in batch mode only and allows the fan to

shutdown during the unloading operation if desired. The light comes ON only when air pressure is sensed.

Heater Switch

This switch is used to turn the burner ON or OFF. The ON position will operate the burner continuously,

but only when the fan is running. The AUTO position is used in batch mode only and allows the heater to

be turned OFF to cool the grain and during the unloading operation. The burner light comes ON only when

flame is detected.

PNEG-1758 Competitor/Dri-Tek Control Panel 5

Page 6

1. Competitor/Dri-Tek Control Panel

Unload Switch

The Unload switch turns the metering rolls and discharge auger ON or OFF and selects the operation of

the metering rolls.

• In the 2 Speed position, if the Moisture Control switch is ON and the Drying Mode switch is turned

to continuous flow, the metering roll speed will alternate between the high speed metering roll

potentiometer setting and the low speed me tering roll potentiometer setting, depending on the

control signal from the moisture control th ermostat. The discharge auger will operate continuously.

• In the 1 Speed position, if the Moisture Control switch is ON and the Drying Mode switch is

turned to continuous flow, the metering roll speed will operate at the high speed metering roll

potentiometer setting or turn OFF depending on the control signal from the moisture control

thermostat. The discharge auger will operate whenever the metering rolls are operating.

• In both the 1 Speed and the 2 Speed positions, if the Moisture Control switch is OFF and the

Drying Mode switch is turned to continuous flow, the metering roll speed can be manually

controlled by adjusting the high speed metering roll potentiometer. The discharge auger will

operate continuously.

• If the Drying Mode switch is turned to staged batch, the Unload switch should be set to the

1 Speed position. The discharge auger and metering rolls will only operate during the unload

cycle of the staged batch operation and the speed of the metering rolls is adjusted using the high

speed metering roll potentiometer.

NOTE: If the unload auxiliary motor overload relay is being utilized in the dryer control panel, the same

switch will also control the operation of the auxiliary equipment.

Low Speed Metering Roll Potentiometer

Use this to adjust the low speed of the metering roll when the 2 Speed automatic moisture control feature

of the dryer is in use.

High Speed Metering Roll Potentiometer

Use this to:

• Set the high speed of the metering roll when the 2 Speed automatic moisture control feature of

the dryer is utilized.

• Set the speed of the metering rolls when the 1 Speed automatic moisture control feature of the

dryer is utilized.

• Set the speed of the metering rolls during continuous flow operation when the moisture control

is not used.

• Set the rate of grain discharge from the dryer during the unload cycle of staged batch

dryer operation.

Dryer Power Start Switch

This switch starts and operates the dryer based on switch settings. If other switch settings are in the OFF

position, individual dryer components can be operated by turning the Drying Mode switch to continuous

flow, pressing the Dryer Power Start button and then turning ON the desired dryer component.

6 PNEG-1758 Competitor/Dri-Tek Control Panel

Page 7

1. Competitor/Dri-Tek Control Panel

Dryer Power Stop Switch

This switch stops all dryer functions. If an automatic dryer shutdown occurs, first determine and correct

the cause of the shutdown. Press the Dryer Power Stop button to reset the dryer before restarting.

Series 2000 Control System

The Series 2000 System controls all timing functions and safety circuit checks. It is designed to simplify

dryer operation by providing messages and warnings on its Liquid Crystal Display (LCD).

Turning ON Series 2000 Control System

Turn the Control Power switch to ON. The monitor will display “GSI” and the current software

version number.

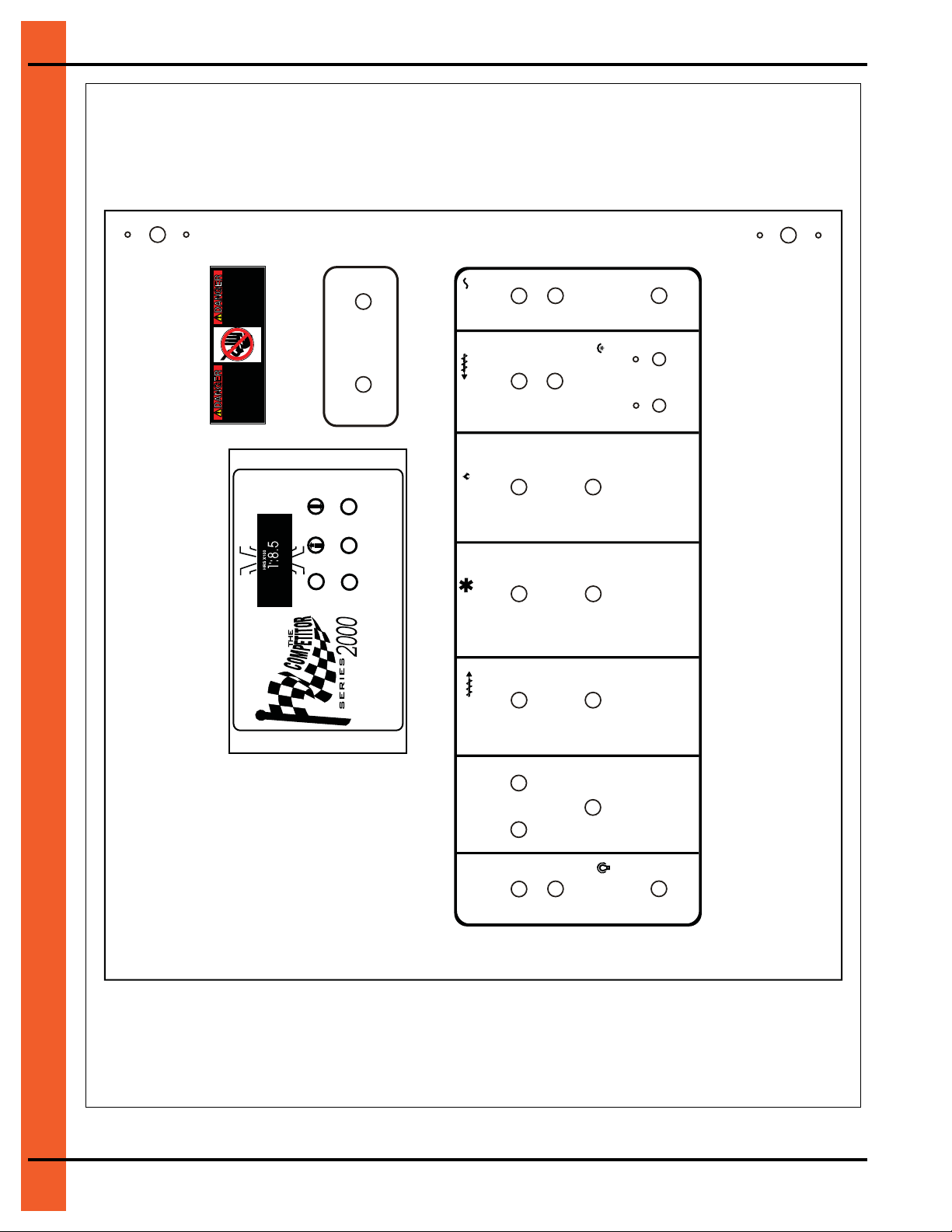

Figure 1B Series 2000 Dryer Control Panel

PNEG-1758 Competitor/Dri-Tek Control Panel 7

Page 8

1. Competitor/Dri-Tek Control Panel

“CARROT”

Setting the Dry, Cool, Unload and Out of Grain Timers

These switches are used to set the drying cycle times in the staged batch drying mode only. The Drying

Mode switch must be in the staged batch position. Out of grain sets the length of time the dryer will run

before shutting down when the Load switch is in the AUTO position. To change the setting of these timers,

follow these instructions:

1. Press the Program (Timers) button until the “carrot” (See Figure 1C) is above the timer you want

to modify.

2. Use the UP and DOWN arrow keys to change from the present time to the desired setting. The new

time is automatically accepted.

3. Keep pressing the Program (Timers) button until the carrot disappears or press the Mode Select

button once to exit.

During the operation, the remaining time on each timer is displayed on the screen. If the power goes out

or if the dryer is stopped, these times are saved by the controller. When the dryer is restarted the timers

will continue timing down. The timers will return to their initial settings by pressing and holding the “Stop”

button for 5 seconds.

Figure 1C Dryer LCD Display

Setting the Load and Unload Delays

The load delay is used to delay the starting of the load auger when the dryer is unloading to prevent the

load auger from starting and stopping too often. The unload delay is used to control the amount of time

the unload auger runs after the metering rolls stop to allow for auger clean out.

1. Press the Program (Delays) button until the carrot is under the time delay to be changed.

2. Use the UP and DOWN arrow keys to change from the present time to the new one. The new time

is automatically entered.

3. Keep pressing the Program (Delays) button until the carrot disappears or press the Mode Select

button once to exit.

8 PNEG-1758 Competitor/Dri-Tek Control Panel

Page 9

1. Competitor/Dri-Tek Control Panel

Setting the Moisture Control and Plenum Setpoint

1. Press the Program (Temperatures) button until the carrot is under the temperature setting to

be changed.

2. Use the UP and DOWN arrow keys to change from the present temperature to the new one. The new

time is automatically entered.

3. Keep pressing the Program (Temperatures) button until the carrot disappears or press the Mode

Select button once to exit.

Dryer Safety Circuit

The Series 2000 Control System continuously checks all safety circuits on the dryer and will automatically

shut the dryer down should a problem occur. The cause of the dryer shutdown will be shown on the LCD

display. To restart the dryer after a safety shutdown, first correct the reason for the shutdown and then

press the Dryer Power Stop button to reset the circuit. Press the Start button.

LOAD DELAY

DÉLAI DE CHARGE

UNLOAD DELAY

DÉLAI DE DÉCHARGE

HI LO SPEED

VITESSE HAUTE LENTE

DISCHARGE

DÉCHARGE

LO-FLAME

FLAMME BASSE

HI-FLAME

FLAMME HAUTE

PURGE

PURGE

MOTOR

MOTEUR

OVERLOAD

SURCGARGE

DRY TIME

TEMPS DE SÉCHAGE

COOL TIME

TEMPS DE REFROIDISSEMENT

PROGRAM

(TIMERS)

PROGRAMME

(MINUTERIES)

PROGRAM

(TEMPERATURES)

PROGRAMME

(TEMPÉRATURES)

ERROR

ERREUR

HOURS

X 1000

HEURES

X 1000

PROGRAM

(DELAYS)

PROGRAMME

(DÉLAIS)

Figure 1D Series 2000 Control System

MOISTURE CONTROL SET POINT

POINT DE CONSIGNE DU CONTRÔLE D’HUMIDITÉ

PLENUM TEMPERATURE SET POINT

POINT DE CONSIGNE DE TEMP DE PLÉNUM

NO AIRFIOW

PAS D’ÉCOULEMENT D’AIR

% GRAIN

% GRAIN

°F PLENUM

PLÉNUM F

°C HOUSING

BOITÎER C

VAPOR

VAPEU R

TEMP HI-LIMIT

TEMP LIM-ÉLEVÉE

FLAME OUT

FLAMME ÉTEINTE

OUT OF GRAIN TIME

TEMPS HORS GRAIN

UNLOAD TIME

TEMPS DE DÉCHARGE

HOURS

HEURES

MODE SELECT

TIMERS/PLENUM TEMP/

GRAIN TEMP

MODE CHOISI (SELECT)

MINUTERIES/TEMP PLÉNUM/

TEMP GRAIN

DC-2004

Monitoring Grain Temperatures, Plenum Temperature or Timers

Use the mode select to decide which of the modes you want to view.

Checking the Hour Meter

Press the UP arrow key and the total hours on the machine are displayed along with the batch count and

minutes since the last shutdown in five (5) successive screens. The screens appear in the following order:

Hours X 100, balance of hours, balance of minutes, batch count and minutes since last shutdown.

For example, five (5) screens displaying 5 | 23 | 12 | 144 | 188 would be: 523 Hours, 12 minutes on the

Hour Meter, Batch Count at 144 and 188 minutes since the last shutdown.

PNEG-1758 Competitor/Dri-Tek Control Panel 9

Page 10

1. Competitor/Dri-Tek Control Panel

Special Features

Dual Batch Drying Temperature Mode

To greatly improve quality in batch mode, reduce the plenum temperature at the end of the

drying cycle. This will reduce peak temperature that the grain on the inside of the column

attains and thereby reduce over-drying.

Enter dual batch drying temperature mode by switching ON dipswitch number four (#4), the

fourth switch from the bottom, on the dipswitches located inside the control box on

the back of the computer control board. This enables two (2) plenum and two (2) grain

temperature settings, high and low. Set these parameters the same way the single p lenum

and grain temperature settings are made. The first of each temperatures being set will be

the low setting and will be indicated by the word “Low” on the screen. The second setting

will be identified by “High” on the display screen.

Typically, the plenum settings would be 170 for low and 230 for high and the low grain

temperature setting would be 10° to 20° below the normal moisture control temperature

setting which becomes the new high setting.

Both capacity and quality will improve using this feature while operating in batch dry and

cool or all heat modes.

Emergency Cooling Mode

To enter an emergency cooling mode, switch ON switch number seven (#7), which is the

second switch from the top on the dipswitch inside of the control box on the back of the

computer control board. This initiates a mode in which only the dryer fan runs, in case there

is a plenum temperature or grain high-limit warning. When either of these safeties shuts

down the dryer, run the fan to help cool the grain and/or plenum high-limit back down to a

safe level. After flipping the switch, press the Start button and only the fan will run for

approximately five minutes.

Burner ON/OFF Operation

Due to changing fuel conditions and to aid in drying wheat and other low temperature grains in hot

weather, an ON/OFF burner has been developed in recent years.

By moving the third switch, number six (#6), on the dipswitch located inside the control box on the back of

the computer control board to ON, the burner can be changed from a high-low burner to an ON/OFF

burner. The burner will operate exactly the same as the high-low burner, however, when the setpoint is

reached, the burner cycles OFF instead of switching to a lower pressure. The vaporizer cools much more

quickly and allows a closer tolerance on the setpoint and to operate at lower temperature rises.

Safety Circuit Shutdown Messages

Vapor High Temperature

This shutdown message indicates that the LP gas vapor temperature sensor, located in the gas pipe train

downstream from the vaporizer has opened. This indicates that the vaporizer is running too hot and must

be readjusted. This sensor is set at 200°F and automatically resets itself when cool.

10 PNEG-1758 Competitor/Dri-Tek Control Panel

Page 11

1. Competitor/Dri-Tek Control Panel

Loss of Flame

The flame sensor failed to detect a burner flame, indicating that the burner has failed to light. There is a

problem with the flame sensing circuitry or the dryer is not getting burner fu el. The burner switch light will

be lit any time flame has been sensed by the burner controls.

Housing High Temperature

The temperature high-limit, located on the fan /heater housing has opened, indicating an over temperature

condition has occurred toward the rear of the fan/heater housing in a n oblong covered electrical box. This

control is set at 200°F and MUST BE MANUALLY RESET.

Rear Discharge Warning

The lid on the grain discharge box has opened, indicating that grain is not being taken away fast enough

at the discharge box.

Motor Overload

One of the thermal overloads on either the fan, load, unload or auxiliary motors has opened, indicating an

over current condition. The overloads MUST BE MANUALLY RESET.

Grain High Temperature

An over temperature condition has occurred in one of the grain columns, causing the control to shutdown

the dryer. This control is set at 210°F and automatically resets itself when cool.

Out of Grain

The dryer has run low on grain and the out of grain timer has timed out, shutting the dryer down. The

unload auger will clean out the dryer if in continuous flow operation.

Plenum High Temperature

An over temperature condition has occurred inside the dryer plenum. This control is a 300°F limit and

automatically resets itself when cool. See Emergency Cooling Mode on Page 10.

No Airflow

The contacts in the Air switch have opened due to insufficient airflow for the burner to operate. The

contacts in the Air switch have opened due to the fan not turning or the Air switch may need adjusting.

Air

The Air switch contacts have closed prior to the fan starting, indicating a free wheeling blade or improper

setting of the Air switch.

Grain and Plenum High Temperature (Both at Same Time)

If both of these warnings appear on the screen at the same time, one of the two (2) mechanical high-limits,

located in each of the two (2) grain columns, has been tripped due to heat exceeding their 200° setpoint

or one or both have failed. They will automatically reset when the temperature returns below 200°.

NOTE: The emergency cooling feature will not function if either or both of these mechanical sensors

are tripped.

PNEG-1758 Competitor/Dri-Tek Control Panel 11

Page 12

1. Competitor/Dri-Tek Control Panel

Error Conditions

Figure 1E

12 PNEG-1758 Competitor/Dri-Tek Control Panel

Page 13

1. Competitor/Dri-Tek Control Panel

Figure 1F

PNEG-1758 Competitor/Dri-Tek Control Panel 13

Page 14

NOTES

14 PNEG-1758 Competitor/Dri-Tek Control Panel

Page 15

2. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions of

use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1758 Competitor/Dri-Tek Control Panel 15

Page 16

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2010 by GSI Group

Printed in the USA

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Loading...

Loading...