Page 1

PNEG-1745

WatchDog

Installation and Operation Manual

PNEG-1745

Date: 06-07-10

Page 2

2 PNEG-1745 WatchDog

Page 3

Table of Contents

Contents

Chapter 1 Safety ..................................................................................................................................................... 4

Safety Guidelines ...... ... ......................................................................................................................... 4

Dryer Operation ..................................................................................................................................... 5

Emergency Stop Switch .. .... ... ... ... .... ... ... ... ... .... ................................................ ... .... ... ........................... 5

Safety Precautions .... ... ... .... ... ............................................................................................................... 6

Chapter 2 Introduction .......................................................................................................................................... 8

Description ............................................................................................................................................ 8

Features ................................................................................................................................................ 8

Chapter 3 Installation ............................................................................................................................................ 9

Internet Connection ............................................................................................................................... 9

Package Contents ........................................................................................................................... 9

Install Procedure ............................................................................................................................ 11

Network Setup ............................................................................................................................... 15

Default Configuration .......................... ... ... ... .... ... ... ... .............................................................. 15

Configuring the WatchDog Network Settings ......................................................................... 15

Configuring a Modem/Router .......................................... ................................................ ... .... 18

Static IP ........................................................................................................................... 18

DHCP Reservations ........................................................................................................ 18

DHCP Pool ......................................................................................................................18

Accessing the WatchDog .............................................................................................................. 19

Direct Connection ................................................................................................................................ 20

Package Contents ......................................................................................................................... 20

Install Procedure ............................................................................................................................ 22

Installation at the Dryer .......................................................................................................... 22

Installation at the PC .............................................................................................................. 24

Accessing the WatchDog .............................................................................................................. 27

Chapter 4 WatchDog Operation .......................................................................................................................... 28

Login Screen .......... ... ... ... .... ... ... ... ....................................................................................................... 28

Default Operation Screen .................................................................................................................... 29

Table Sample Time Button ............................................................................................................... ... 29

Timer Button ............................................................................................................................ ... ... ... ... 30

Temperature Button ............................................................................................................................ 31

Setup Button ................................................ .... ............................................. ... ... .... ... ... .......... ... ... ... ... 33

Select Time Interval ....................................................................................................................... 33

Metering Roll Speed Setpoint ........................................................................................................ 34

Shutdown Dryer ............................................................................................................................. 34

Manage Accounts .......................................................................................................................... 34

Change Password ......................................................................................................................... 34

Change Site Name ........................................................................................................................ 35

View Button ......................................................................................................................................... 35

M/C (Moisture Setpoint) Button ........................................................................................................... 36

Shutdown Screen ............................................................................................................................. ... 36

Text Version ........................................................................................................................................ 37

Chapter 5 WatchDog Software Update .............................................................................................................. 38

Chapter 6 Troubleshooting ................................................................................................................................. 43

Chapter 7 Technical Support .............................................................................................................................. 44

Chapter 8 Appendix A ......................................................................................................................................... 45

Acquiring and Installing a BlueTree Cellular Modem .......................................................................... 45

Chapter 9 Warranty .............................................................................................................................................. 47

PNEG-1745 WatchDog 3

Page 4

1. Safety

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

Personnel operating or working around electric fans should read this manual. This manual

must be delivered with the equipment to its owner. Failure to read this manual and its

safety instructions is a misuse of the equipment.

WARNING! BE ALERT!

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment of

these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

4 PNEG-1745 WatchDog

Page 5

1. Safety

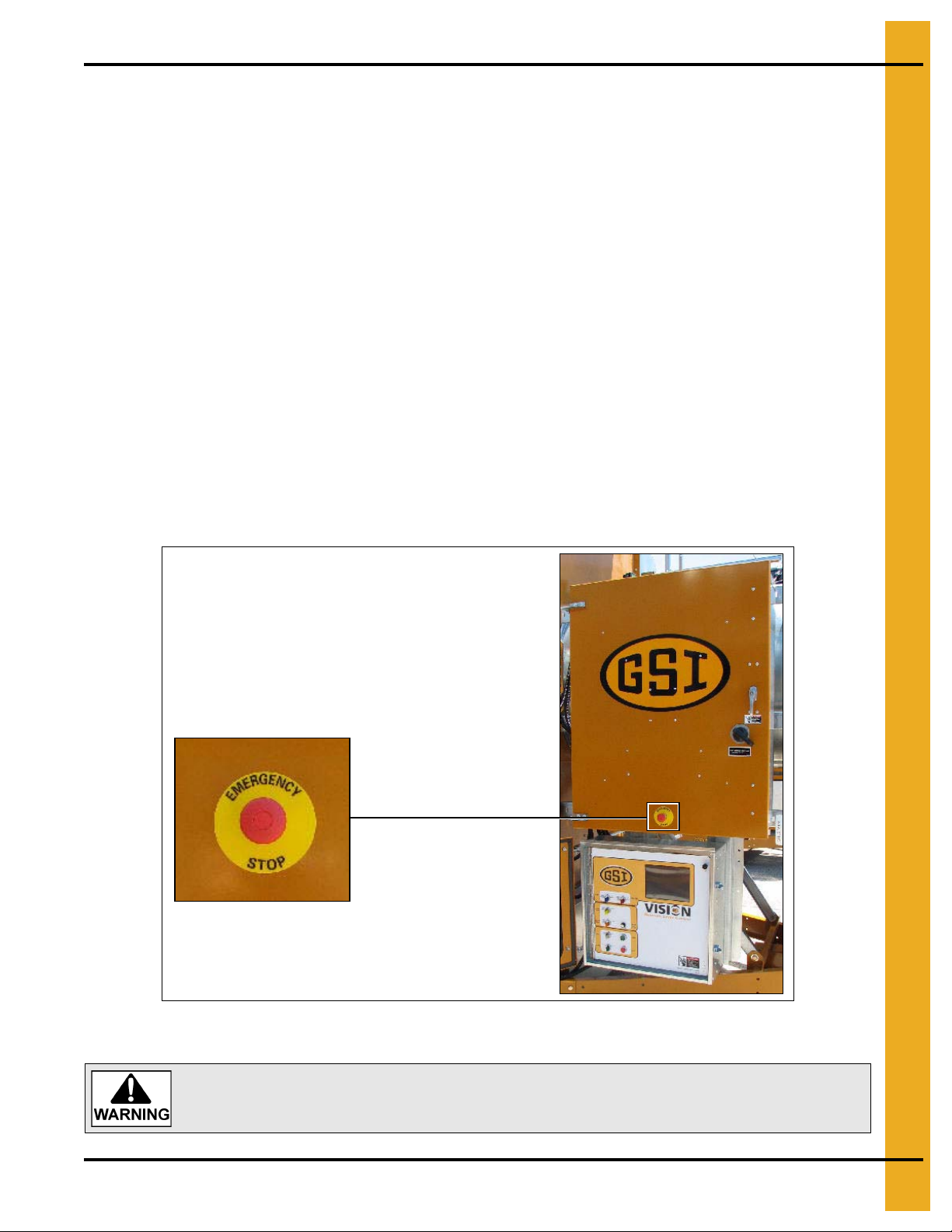

Pushing the Emergency Stop switch does not interrupt the main power to the

upper control box panel.

Dryer Operation

Thank you for choosing a GSI product. It is designed to give excellent performance and service for

many years.

This manual describes the operation and service for all standard production model dryers. T hese models

are available for liquid propane or natural gas fuel supply, with either 1 phase 230 volt, or 3 phase

230 or 440 volt electrical power.

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may produce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

Emergency Stop Switch

The Emergency Stop switch is located on the upper control box door. Pushing the Emergency

Stop switch will interrupt the control power and stop all dryer functions.

PNEG-1745 WatchDog 5

Page 6

1. Safety

Safety Precautions

READ THESE INSTRUCTIONS BEFORE INSTALLATION AND OPERATION

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before attempting to operate the dryer.

2. NEVER operate the dryer while the guards are removed.

3. Power supply should be OFF for service of electrical components. Use CAUTION in checking voltage

or other procedures requiring the power to be ON.

4. Check for gas leaks at all gas pipe connections. If any leaks are detected,

Shutdown and repair before further operation.

5. NEVER attempt to operate the dryer by jumping or otherwise bypassing any safety devices on

the unit.

6. Set pressure regulator to avoid excessive gas pressure being applied to the burner during ignition

and when the burner is in operation. DO NOT exceed maximum recommended drying temperature.

7. Keep the dryer clean. DO NOT allow fine material to accumulate in the plenum chamber.

Clean grain is easier to dry. Fine material increases resistance to airflow and requires removal

of extra moisture.

8. Keep auger drive belts tight enough to prevent slippage.

9. Use CAUTION in working around high speed fans, gas burners, augers and auxiliary conveyors

which can START AUTOMATICALLY.

10. Keep area around air inlet to the fan clear of any obstacles and combustible materials.

11. BEFORE attempting to remove and reinstall any propeller, make sure to read the

recommended procedure.

12. Make sure that capacities of auxiliary conveyors are matched to dryer auger capacities.

13. DO NOT operate in an area where combustible material will be drawn into the fan.

DO NOT

operate dryer.

14. The operating and safety recommendations in this manual pertain to the common cereal

grains as indicated. When drying any other grain or products, consult the factory for

additional recommendations.

15. Routinely check for any developing gas plumbing leaks. Check LP vaporizer for contact with

burner vanes.

6 PNEG-1745 WatchDog

Page 7

1. Safety

Use Caution in the Operation of this Equipment

This dryer is designed and manufactured with operator safety in mind. However, the very nature of a

grain dryer having a gas burner, high voltage electrical equipment and high speed rotating parts, presents

hazards to personnel which cannot be completely safeguarded against without interfering with the efficient

operation of the dryer and reasonable access to its components.

Use extreme caution in working around high speed fans, gas-fired heaters, augers and auxiliary conveyors,

which may start without warning when the dryer is operating on automatic control.

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable drying system, follow the recommendations within the Owner’s Manual

and make it a practice to regularly inspect the unit for any developing problems or unsafe conditions.

Take special note of the Safety Precautions on Page 6 before attempting to operate the dryer.

PNEG-1745 WatchDog 7

Page 8

2. Introduction

Description

The WatchDog System allows for remote monitoring of a Vision dryer. There are two (2) configurations

available: Internet Connection and Direct Connection.

Internet Connection allows the user to view the dryer from any device that has a web browser. Internet

Explorer and Mozilla Firefox were the only two (2) browsers tested, but other browsers should be able to

view it without problem. Some phones are available that view the graphics correctly; other phones will

have to view the text version.

Direct Connection allows one computer to view the dryer status. A hardwire from the dryer is connected

to the WatchDog enclosure residing at the computer. The cable should run no longer than a distance of

1000' and CAT5 is recommended.

Features

1. Remote monitoring of dryer.

2. Remote shutdown of dryer.

3. Remote drying parameter adjustment. (Plenum and grain temperature setpoints, timer setpoints, etc.)

4. Web browser is the only software needed by the customer.

5. Text message and/or e-mail can be sent to alert customers of shutdowns. (Not available on Direct

Connection type.)

6. Can be updated via SD card.

8 PNEG-1745 WatchDog

Page 9

3. Installation

4

5

6

1

2

Internet Connection (Part #: VIS-WATCH-IC)

This option requires an active internet connection be present at the dryer via Ethernet (RJ-45 connection).

It is recommended that either an Internet Service Provider (ISP) technician or someone versed in

networking be present during installation.

GSI is not responsible for the required connection.

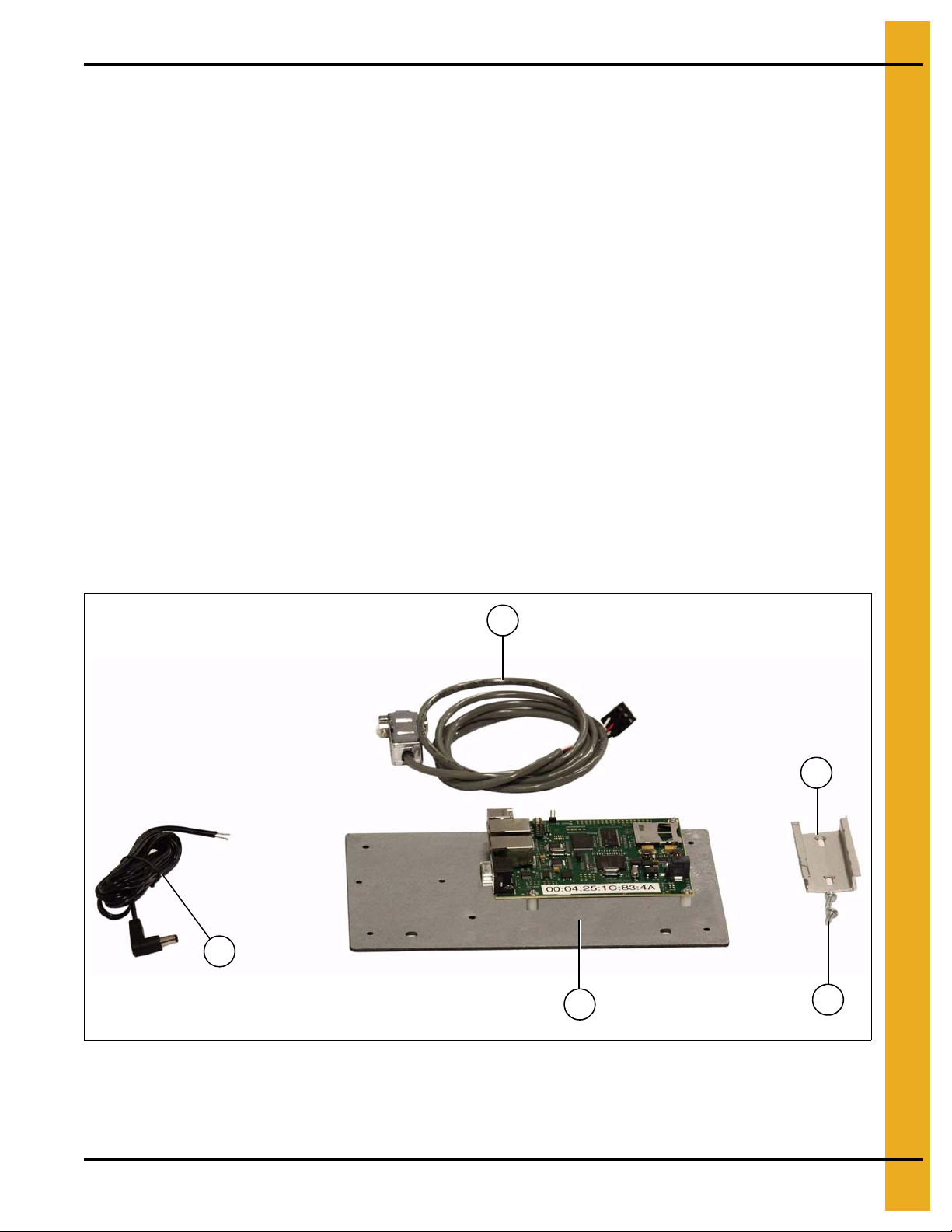

Package Contents

The contents of this package are pictured in Figure 3A. Please refer to Figure 3A during installation.

Package contains:

1. Mounting plate with WatchDog circuit board attached.

2. WatchDog power cable.

3. Two (2) 1/4" mounting nuts. (Not Shown)

4. DB9 to 3 position quick connect cable (Serial Cable #1).

5. 3" DIN rail.

While GSI’s Technical Support group can offer suggestions,

6. Two (2) self-tapping 1/4" screws.

7. Ten (10) cable ties for routing wires. (Not Shown)

8. Four (4) cable tie anchors for routing wires. (Not Shown)

Figure 3A

PNEG-1745 WatchDog 9

Page 10

3. Installation

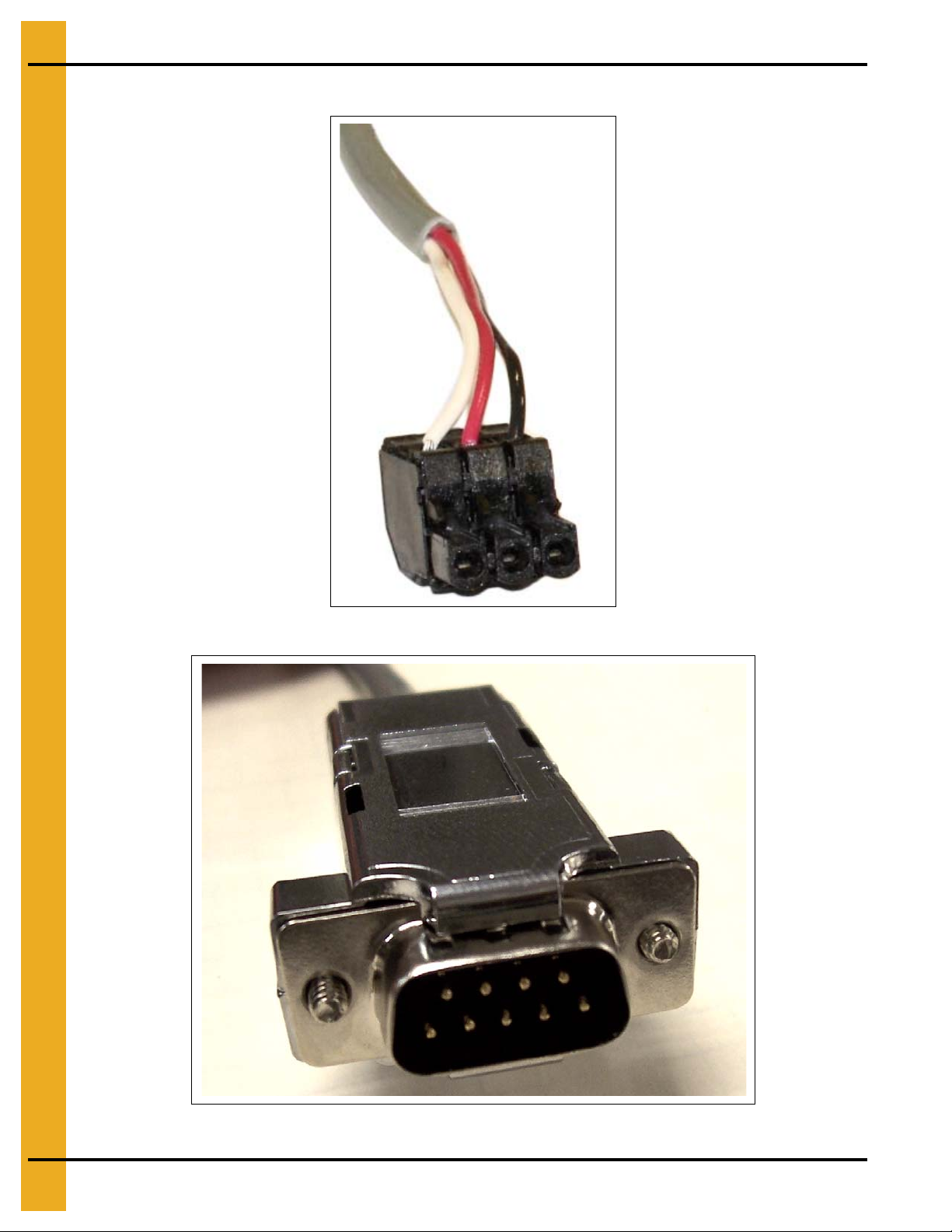

Serial cable connector figures: (See Figure 3B and Figure 3C.)

Figure 3B 3 Position Quick Connect

Figure 3C DB9 Connector

10 PNEG-1745 WatchDog

Page 11

3. Installation

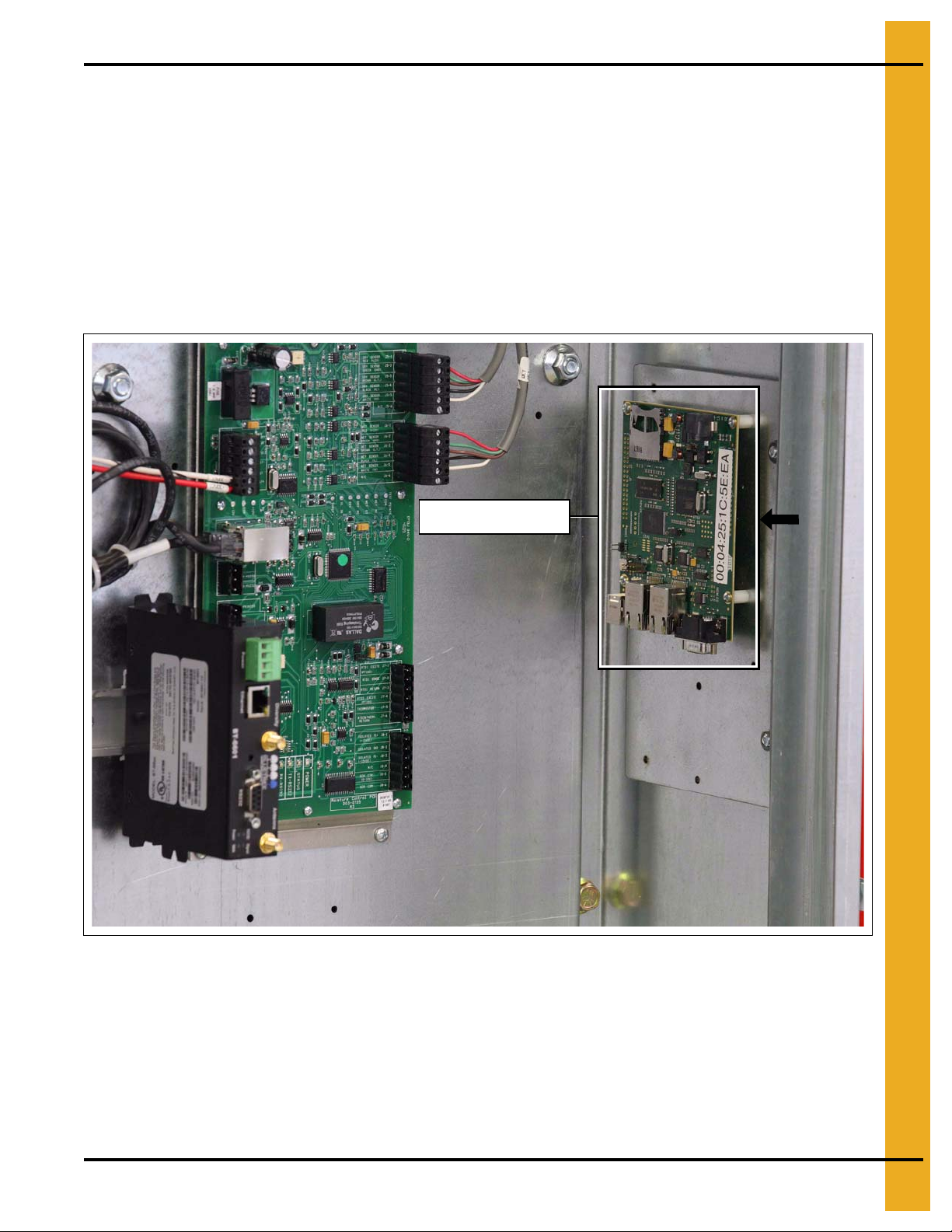

Mounting plate with

WatchDog circuit board

Install Procedure

This installation takes place in the lower control panel of the Vision system. Follow the steps listed below

to install the components:

1. Turn OFF power to dryer and control panel.

2. If a cellular modem is being installed, first refer to Appendix A on Page 45 for a few extra instructions

and then return here.

3. Place mounting plate with WatchDog circuit board attached over two (2) existing bolts on the right

side of the lower control panel. Secure it using the two (2) 1/4" nu ts supplied. Position the mount ing

plate so the white sticker is in clear view. (See Figure 3D.)

PNEG-1745 WatchDog 11

Figure 3D

Page 12

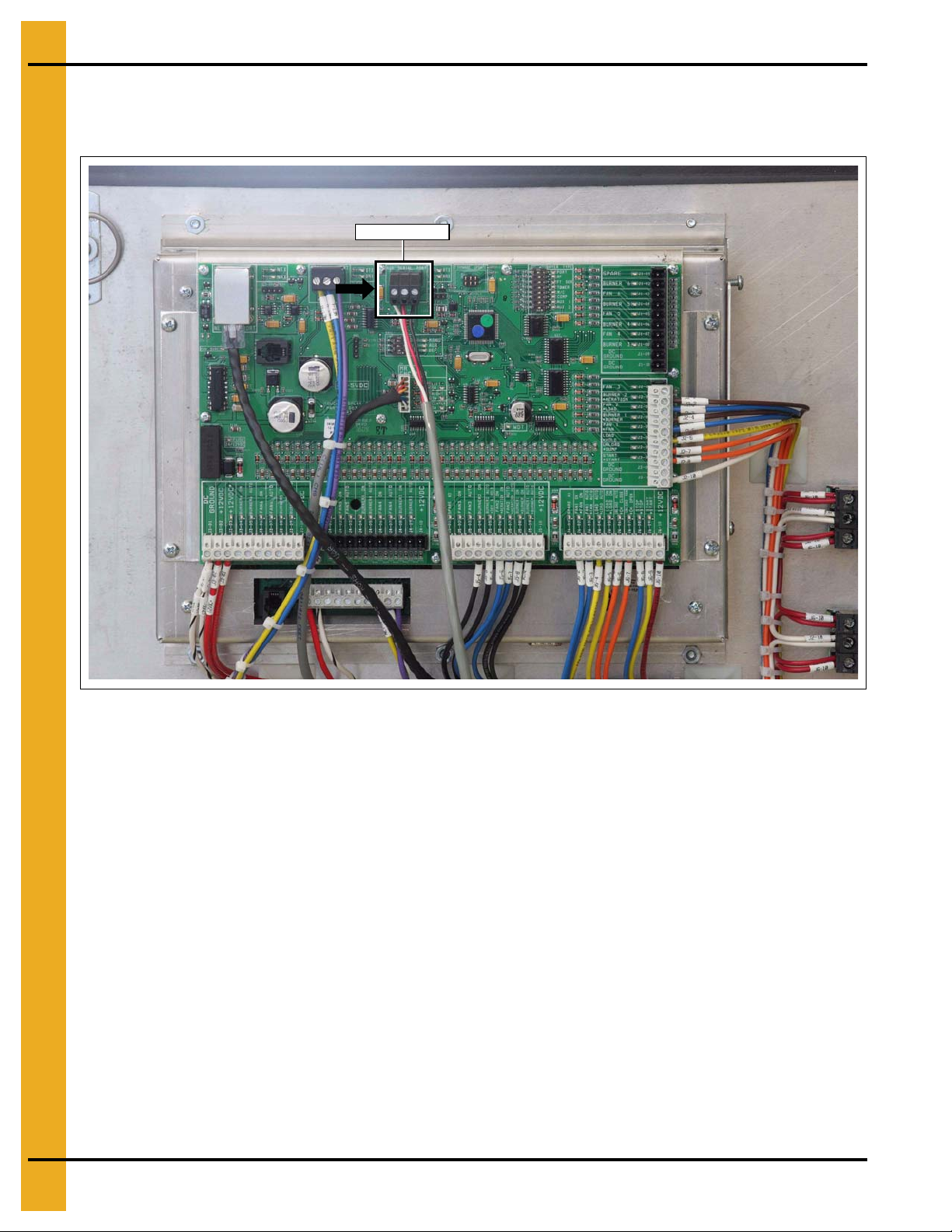

3. Installation

Aux serial port

4. Connect the 3 position quick connector of Serial Cable #1 to the “AUX SERIAL PORT” on the

Display I/O board located on the back of the touch screen. The connector is polarized so care should

be taken to plug it in correctly. (See Figure 3E.)

Figure 3E

12 PNEG-1745 WatchDog

Page 13

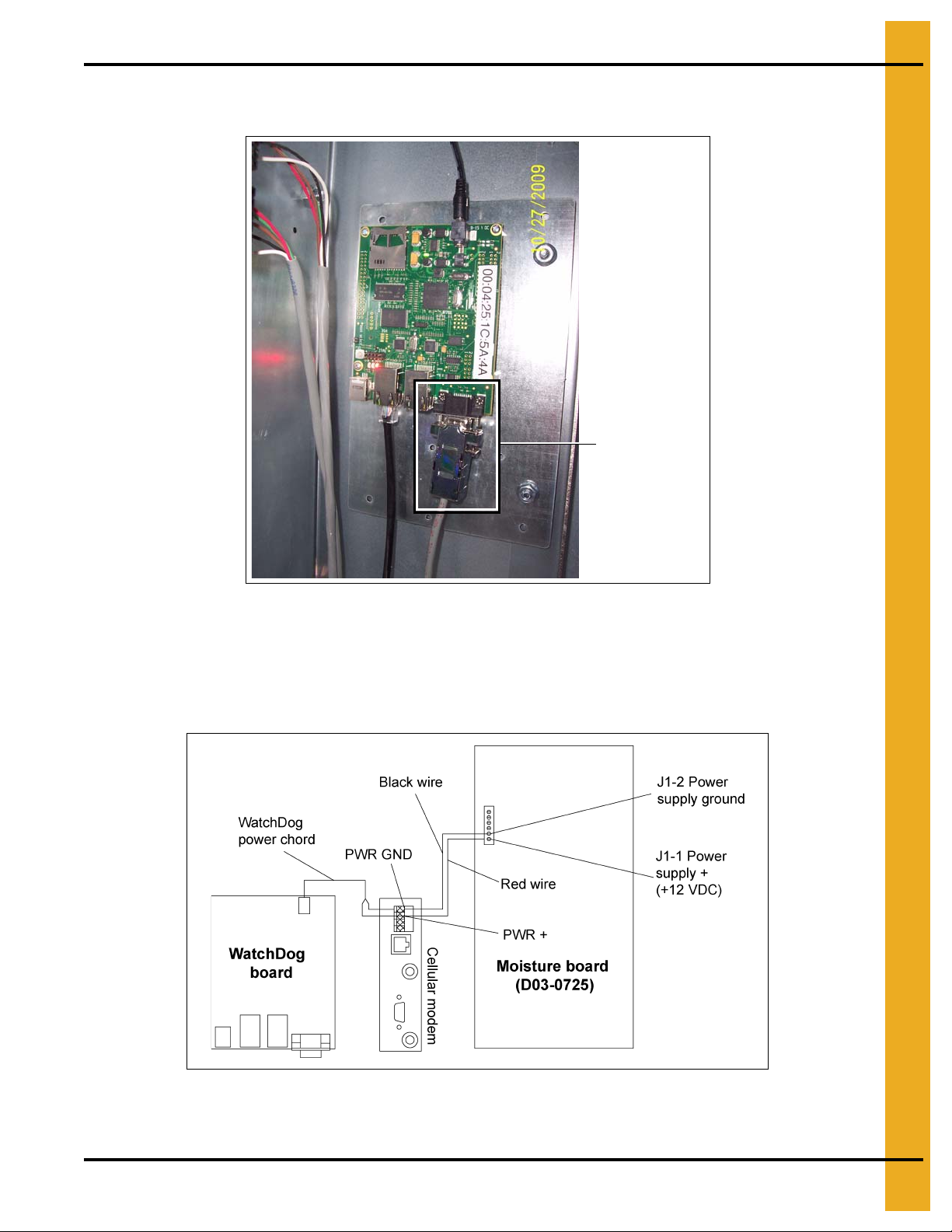

3. Installation

DB9 Connector

5. Plug the DB9 connector of Serial Cable #1 into the DB9 connector on the WatchDog circuit board.

Tighten the two (2) screws to secure the connection. (See Figure 3F.)

Figure 3F

6. If a cellular modem is being used, the bare leads of the WatchDog power cable should be connected

to the cellular modem power terminals as follows:

Black with faint white line lead - PWR +

Black lead with faint white writing lead - PWR GND

Figure 3G

NOTE: These are the same slots holding the wires coming from the moisture control panel.

PNEG-1745 WatchDog 13

Page 14

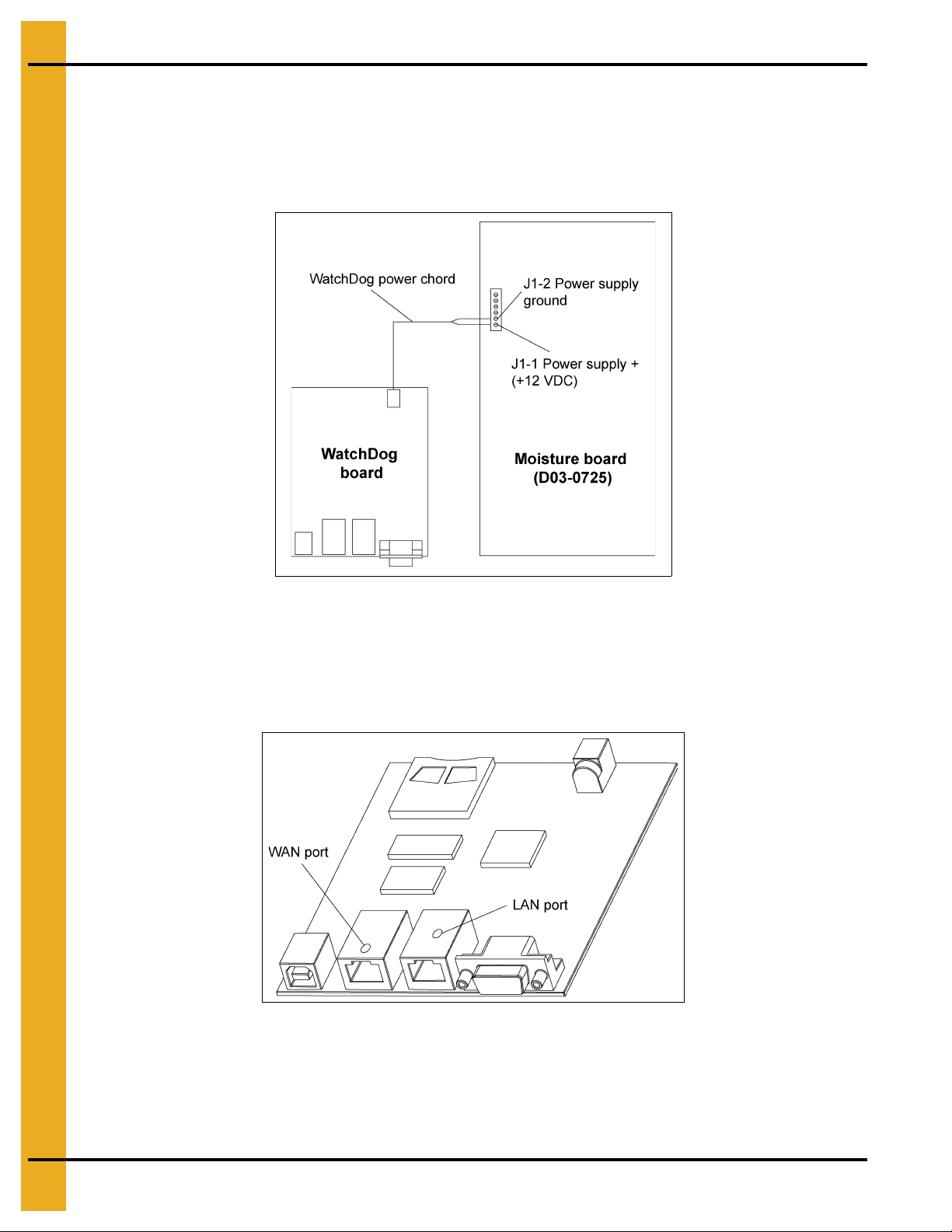

3. Installation

If a cellular modem is NOT being used, the bare leads of the WatchDog power cable should be

connected to the moisture control board as follows:

Black with faint white line lead - J1-1 “POWER SUPPLY+ (+12 VDC)”

Black lead with faint white writing lead - J1-2 “POWER SUPPLY GROUND”

Please refer to Figure 3H.

Figure 3H

7. The barrel connector of the WatchDog power cable should be plugged into the power connector on

the WatchDog circuit board. (See Figure 3H.)

8. Plug the Ethernet cable with a live internet connection into the WAN port on the WatchDog circuit

board. The WAN port is to the left, farthest from the cabinet door. (See Figure 3I.)

Figure 3I

NOTE: Use cable ties and anchors to secure wires.

9. Turn ON power to the dryer and control panel. A green LED should illuminate on the WatchDog

circuit board indicating power. A red LED will illuminate when the WatchDog has finished booting

and is ready to monitor.

14 PNEG-1745 WatchDog

Page 15

3. Installation

Network Setup

This section is intended to help ISP or network technicians install th e WatchDog. If this section does not

make sense to you, it is strongly advised to request the service of a network technician.

Default Configuration

The WatchDog’s Wide Area Network (WAN) port default is setup as a Dynamic Host Configuration

Protocol (DHCP) client. The script to configure the port is only executed on start-up. To pull down an

Internet Protocol (IP) address, it needs to be attached to a DHCP server when it is booted.

The Media Access Control (MAC) address is printed on a label that is attached to the front of the

WatchDog board.

Configuring the WatchDog Network Settings

To access the WatchDog setup, connect a computer to the LAN (Local Area Network) port of the board,

using a CAT5 network cable. Refer to Figure 3I on Page 14 for LAN port location. Make sure the red “SYS”

LED is illuminated on the board, as this ensures the Operating System (OS) has booted completely.

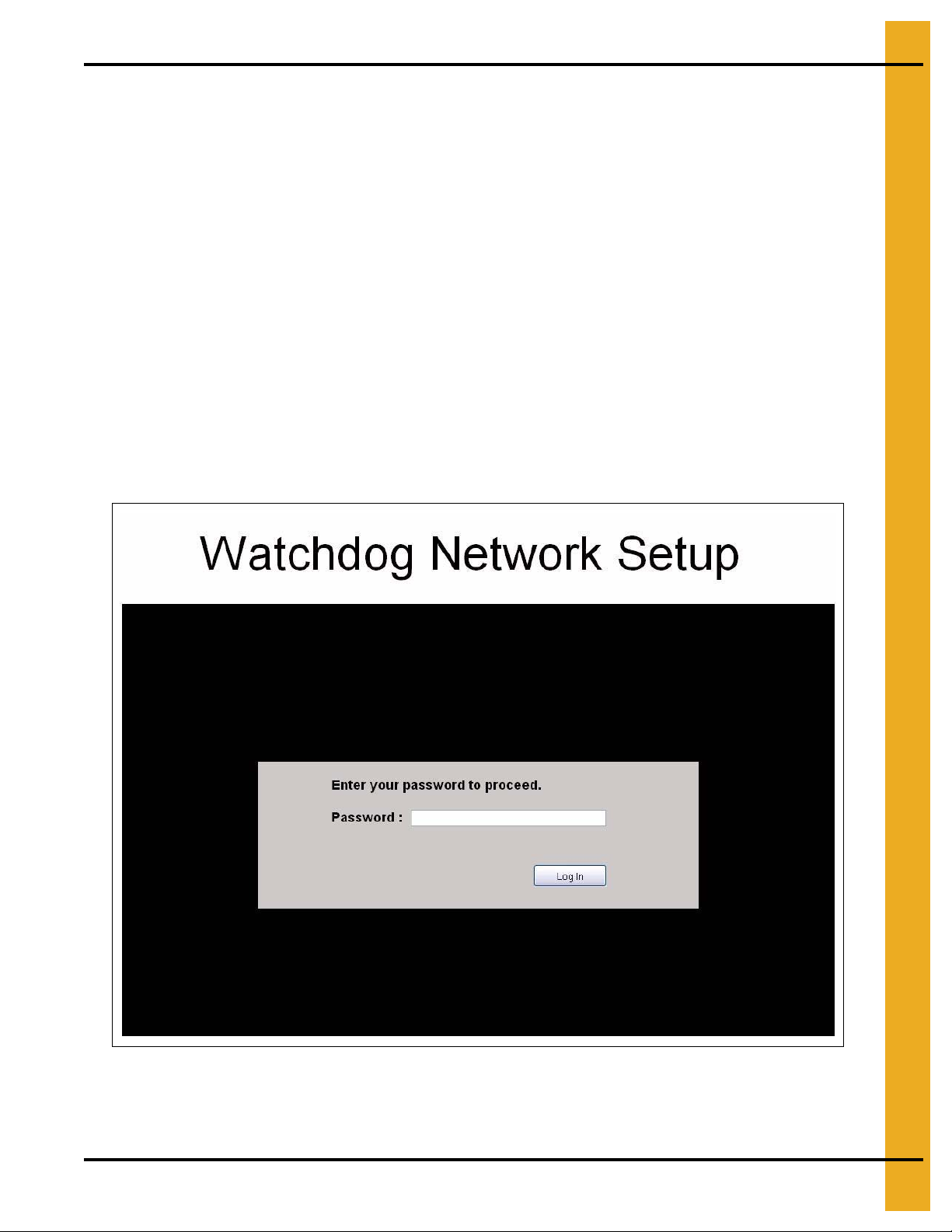

Open a web browser (i.e. Internet Explorer, Mozilla Firefox …) and type “http://10.0.0.1/setup” into the

URL bar. (Where you would normally type www.google.com for example.) This will bring up a Login screen

as shown in Figure 3J.

Figure 3J

PNEG-1745 WatchDog 15

Page 16

3. Installation

The default password is default. The password is the same as is used to access the WatchDog.

Therefore, if the user has changed the password, the setup password will be whatever they have ch anged

it to. If the user forgets his/her password, see the user manual for resetting the password.

Once logged in, Figure 3K should be displayed on the screen.

Figure 3K

The current setup is displayed to the left of this screen. The address will differ from Figure 3K. If the device

is setup as a DHCP Client and the IP address that is displayed is “10.11.12.1”, this means the DHCP

Server did not serve the board an IP address. If you were expecting the board to pull down a n IP address,

reset the power on the modem/router and then the WatchDog board. If these addresses need to be

modified, click the “Configure” button to the right. This will take you to Figure 3L.

Figure 3L

16 PNEG-1745 WatchDog

Page 17

3. Installation

At first, neither DHCP or Static is selected. Choose one or the other depending on how you would like to

setup the WatchDog’s network parameters. If “Static IP” is selected, the following fields are displayed for

entry: IP Address, Subnet Mask, Default Gateway, DNS 1 and DNS 2. Figure 3M depicts these entries.

Figure 3M

Note that all fields are required when using the Static IP option. If you are missing any of the addresses,

contact your service provider and they will be able to give you the missing information.

Once you have chosen the setup that you would like, click “Apply Settings”. After clicking the button you

will be redirected to a page that counts down from 90 seconds. This is changing the board’s configuration

and resetting it so the changes will take effect. The network scripts only execute on boot, so the WAN port

on the board needs to be connected to the modem/router on boot.

After the timer expires, you will be redirected back to the Network Status page. (See Figure 3K on

Page 16.) If the page does not display the addresses correctly, make sure the red LED on the WatchDog

board is ON and then refresh the web page.

PNEG-1745 WatchDog 17

Page 18

3. Installation

Configuring a Modem/Router

If the WatchDog board is connected to a modem/router that is configurable, listed below are a few

recommendations to assist with setup. The methods below do not cover every configuration that is

available. If the modem is not configurable, refer to Page 17 for setting the WatchDog network to the static

IP allocated by the service provider.

Static IP

This is the preferred method for installation. Acquire the LAN’s default gateway address of the

modem/router. Replace the last number of the default gateway with a number that is not within the DHCP

pool range. For example, if the default gateway is 192.168.2.1 and the modem/router’s DHCP pool range

is 100 to 200, replace the last number of the default gateway address with, say, 50. This would result in

an address of 192.168.2.50. Using the WatchDog network Setup screens, set the static IP address of the

board to the chosen IP address, refer to Page 17.

In the router/modem configuration, forward incoming request on ports 22, 23 and 80 to the static IP.

DHCP Reservations

A reservation can be an option in the configuration of a modem/router. It can be set to serve a given

MAC address with a certain IP address when it is introduced to the network. As mentioned above, the

MAC address of the WatchDog board can be found on a label on the front of it.

Once the IP address has been setup for the MAC address, forward incoming request on ports 22, 23 and

80 to the board.

DHCP Pool

If the modem/router does not have DHCP reservations, the board can be allowed to pull an IP address

from the DHCP server’s IP range. This method is only recommended when the WatchDog is the only node

on the network.

Reduce the IP range of the DHCP server down to one IP address. This will be the only IP address that the

DHCP server is allowed to serve to the network. Once the range has been narrowed to one, forward

incoming request on ports 22, 23 and 80 to the single IP address.

18 PNEG-1745 WatchDog

Page 19

3. Installation

Accessing the WatchDog

The WatchDog is accessed from any PC that has an internet connection and web browser. Some phones

are available that view the graphics correctly; other phones will have to view the text version.

1. Make sure that the dryer is powered up and the Vision application is running.

2. On the PC or phone, open up a web browser, i.e. Internet Explorer, Mozilla Firefox, etc.

3. In the URL bar, enter the static IP address given by the ISP. There is no need to put “www”, simply

enter the number sequence. The IP address shown in the Figure 3K on Page 16 is just for illustration

purposes. The IP address you enter will be different.

4. The “Login Screen” should now appear. If it does not, run back through the install procedure to verify

everything is connected properly.

Figure 3N

5. Once the “Login Screen” appears, move on to Chapter 4 “WatchDog Operation” on Page 28.

PNEG-1745 WatchDog 19

Page 20

3. Installation

4

2

2

3

1

Direct Connection (Part #: VIS-WATCH-IC)

This option allows the user to connect their dryer directly to one Personal Computer (PC) using two (2)

short-haul modems and four (4) wires, CAT5 is recommended. Text messaging and e-mail is not

available with this option.

Package Contents

The contents of this package are pictured in Figure 3O. Please refer to Figure 3O during installation.

Package contains:

1. WatchDog enclosure (white case).

2. Two (2) short-haul modems w/ power supplies.

3. DB25 to 3 position quick connect cable (Serial Cable #2).

4. DB25 to DB9 serial cable (Serial Cable #3).

5. Ten (10) cable ties for routing wires. (Not Shown)

6. Four (4) cable tie anchors for routing wires. (Not Shown)

Figure 3O

20 PNEG-1745 WatchDog

Page 21

Serial cable connector figures: (See Figures 3P, 3Q and 3R.)

3. Installation

Figure 3P 3 Position Quick Connect

Figure 3Q DB9 Connector

PNEG-1745 WatchDog 21

Figure 3R DB25 Connector

Page 22

3. Installation

Aux serial port

Install Procedure

This installation is split into two (2) steps. Some installation is done in the lower control panel of the Vision

system at the dryer and the rest at the PC location. This manual does not cover running the wires between

the two (2) locations, as this is the customer’s responsibility. CAT5 cable is recommended by GSI.

Installation at the Dryer

The following items will be installed at the dryer location:

1. One short-haul modem w/ power supply.

2. DB25 to 3 position quick connect cable (Serial Cable #2).

3. Use cable ties and anchors when necessary.

Follow the steps listed below to install all components required at the dryer:

1. Turn OFF power to dryer and control panel.

2. Connect the 3 position quick connector of Serial Cable #2 to the “AUX SERIAL PORT” on the

Display I/O board located on the back of the touch screen. The connector is polarized so care should

be taken to plug it in correctly. (See Figure 3S.)

Figure 3S

22 PNEG-1745 WatchDog

Page 23

3. Installation

3. Plug the DB25 connector of Serial Cable #2 to one of the short-haul modems. Care should be taken

to make sure the switches on the short-haul modem match those in Figure 3U.

DCE

Figure 3T

Dryer side

switch positions

SIM

T-ON/R-ON

4321

Figure 3U

PNEG-1745 WatchDog 23

Page 24

3. Installation

4. Now, the four (4) wires that run from the dryer to the PC location need to be connected to the

short-haul modem. Use the following table to document what color is attached to which terminal.

This will help in connecting the other end of the cable at the PC location.

Table 1: Wire Colors at Dryer

Terminal # at Dryer Wire Color

1

2

3

4

NOTE: The order of the colors in the picture are for illustrative purposes only.

5. The short-haul modem power supply should be plugged into a 120 VAC receptacle (not provided)

and the barrel connector into the short-haul modem. The red power light should come ON.

6. Turn ON power to dryer and control panel.

NOTE: Clean-up and arrange the wires using the provided cable ties and anchors.

Installation at the PC

The following items will be installed at the PC location:

1. WatchDog enclosure (white case).

2. One short-haul modem w/ power supply.

3. DB25 to DB9 serial cable (Serial Cable #3).

4. 3' Ethernet Cable.

5. Use cable ties and anchors when necessary.

Follow the steps listed below to install all components required at the PC location:

1. Fill in Table 2 below with the wire colors in the same order as Table 1 above from 1-4.

Table 2: Wire Colors at Dryer and PC

Terminal # at Dryer Wire Color Terminal # at PC

1 3

24

3 1

42

24 PNEG-1745 WatchDog

Page 25

SIM

3. Installation

DCE

T-ON/R-ON

4321

PC Side

DTE

4321

T-ON/R-ON

SIM

Dryer side

Figure 3V

Connect the wires to the short-haul modem according the terminal numbers listed at the right of

Table 2 on Page 24.

2. Plug the DB25 connector of Serial Cable #3 to the short-haul modem. Care should be taken to make

sure the switches on the short-haul modem match those in Figure 3X on Page 26.

Figure 3W

PNEG-1745 WatchDog 25

Page 26

3. Installation

PC side

switch positions

SIM

DTE

T-ON/R-ON

4321

DB9 Connector

RJ-45 Connector

Figure 3X

3. Attach the DB9 connector of Serial Cable #3 to the DB9 connector on the WatchDog enclosure.

Figure 3Y

4. Plug an Ethernet cable into the RJ-45 connector on the WatchDog enclosure. Please refer

to Figure 3Y.

5. Attach the other end of the Ethernet cable to the Ethernet port on the PC.

26 PNEG-1745 WatchDog

Page 27

3. Installation

6. The short-haul modem power supply should be plugged into a 120 VAC receptacle and the barrel

connector into the short-haul modem. The red power light should come ON.

7. Plug the power cable from the WatchDog enclosure into a 120 VAC receptacle.

Accessing the WatchDog

The WatchDog is accessed from the PC that the WatchDog enclosure is atta ched to. This PC will be used

in the section to connect to the dryer.

1. Make sure that the dryer is powered up and the Vision application is running. Also, verify the

WatchDog enclosure and both short-haul modems are plugged in.

2. On the PC, open up a web browser, i.e. Internet Explorer, Mozilla Firefox.

3. In the URL bar, enter “10.0.0.1” without the double quotes. There is no need put “www”, simply enter

the number sequence.

4. The “Login Screen” should now appear. If it does not, run back through the install procedure to verify

everything is connected properly.

Figure 3Z

5. Once the “Login Screen” appears, move on to Chapter 4 “WatchDog Operation” on Page 28.

PNEG-1745 WatchDog 27

Page 28

4. WatchDog Operation

Login Screen

When the web browser initially makes contact with the WatchDog System, you will be presented with a

screen requesting a password. (See Figure 4A.) Once the password has been entered, you must press

the LOG IN button to accept the password. Default password is default.

Figure 4A

If you have forgotten the password, press the “Forgot Password” button shown in Figure 4A. This will bring

up the screen shown in Figure 4B. This screen will ask for the WatchDog board’s “MAC Address”. This

sequence of numbers and letters (all capitals) can be found on a sticker located on the top of the

WatchDog board.

Figure 4B

Once the password has been reset, you may log in with the default password, which is simply default

(all lower case), but immediately go to the setup menu an d change the de fault pa ssword to someth ing of

your choice. Please record and place the new password information in a safe place.

28 PNEG-1745 WatchDog

Page 29

4. WatchDog Operation

Default Operation Screen

The screen in Figure 4C will be displayed, unless the dryer is shutdown, upon connection to the dryer if it

is a tower dryer. This very closely resembles how the screen would appear at the dryer. All the buttons

function exactly as they would if pressed on the dryer screen, except for the Setup and View buttons.

These buttons on this screen allow changes to be made to the setup of the WatchDog System and to view

information related to the WatchDog System. The menus/information below each button will be described

more fully in the following sections.

Figure 4C

All information displayed around the dryer picture, is exactly as it would appear on the d ryer scr een. The

lower right 1/4 of the screen shows the state of each burner, once again, as it would be displayed at the

dryer. The log of temperatures and moistures on the right hand side of the screen functions exactly as it

does at the dryer, but the data displayed may be different. (It is not downloaded from the dryer.) Finally,

the status bar displayed in the upper right hand corner gives the current status of the dryer and shows the

same information that is presented at the dryer.

Table Sample Time Button

Pressing the button in the upper left hand of the table view will bring up the screen shown in

Figure 4C. This sets the number of minutes for each sample that is entered into the data log table.

NOTE: If the sample time (See Figure 4D on Page 30) for the WatchDog System is set longer than the

history time interval, the table will miss samples.

PNEG-1745 WatchDog 29

Page 30

4. WatchDog Operation

Figure 4D

Timer Button

Pressing the button will display a screen similar to that in Figure 4E. The actual layout will vary

depending on the type of dryer and its particular setup. Pressing any of these timer buttons will allow

modification of that timer’s setpoint value.

Figure 4E

30 PNEG-1745 WatchDog

Page 31

4. WatchDog Operation

For example, pressing the button will bring up the timer minutes modification dialog box

shown in Figure 4F. Enter the number of minutes and press OK.

Figure 4F

Another dialog box will then appear prompting the second’s setpoint to be entered as shown in Figure 4G.

Figure 4G

Depending on the security settings of the particular browser you may have to temporally allow

scripted windows. Using Internet Explorer, simply right click and select OK and press Timer button again .

All other timer setpoints are set similarly.

Temperature Button

Pressing the button will bring up a screen very similar to that shown in Figure 4H on Page 32.

It may vary slightly depending on the dryer’s setup. The current setpoint of each plenum an d grain column

temperature is shown to the right of each setpoint button.

PNEG-1745 WatchDog 31

Page 32

4. WatchDog Operation

Figure 4H

Pressing the button will bring up a dialog requesting a new setpoint value to be entered.

(See Figure 4H.) Once the new value has been entered, press the OK button to accept or CANCEL to

keep the old value. All other temperature setpoints are set similarly. (See Figure 4I.)

Figure 4I

32 PNEG-1745 WatchDog

Page 33

4. WatchDog Operation

Setup Button

Pressing the button will bring up the screen shown in Figure 4J. The Setup screen is not used

to setup the dryer as it would at the dryer control, but it is used to further setup the WatchDog System.

The Setup screen has been broken into six (6) distinct functions and these will be addressed in the

following sections.

Figure 4J

Select Time Interval

This set of radio buttons allows the user to select how often the WatchDog System contacts the dryer for

information. For example, if 20 Seconds is chosen, as shown in Figure 4K, the WatchDog screen will be

updated once every 20 seconds. If you have limited Internet bandwidth, it is best to choose the longest

interval that is acceptable.

Figure 4K

PNEG-1745 WatchDog 33

Page 34

4. WatchDog Operation

Metering Roll Speed Setpoint

This portion of the Setup screen allows the user to adjust the metering roll speed setpoints. Only the

setpoints required by the current setup are shown, so the screen may vary from the one shown in

Figure 4L. Do not enter a percent (%) symbol, e.g. to enter 50% simply enter 50 and press OK.

Figure 4L

Shutdown Dryer

Pressing the stop sign displayed on the Setup screen will shutdown the dryer. Yo u will be asked if th is is

correct via a small dialog box before the dryer will be shutdown. (See Figure 4M.)

Figure 4M

Manage Accounts

This section of the Setup screen is used to add or delete e-mail and text messaging accounts to be notified

when the dryer experiences a shutdown. Clicking “Edit Accounts” will open a new window, allowing entry

of e-mail account or text message information. Please use the help (shown after pressing the Edit

Accounts button) button for more information. (See Figure 4N.)

Figure 4N

Change Password

Click the “Change Password”, under the setup menu (See Figure 4O), to change the current password.

If you have used the method described on Page 28 to reset the password to the default value,

please change the password, for security reasons, immediately. Follow the instructions for changing

the password.

Figure 4O

34 PNEG-1745 WatchDog

Page 35

4. WatchDog Operation

Change Site Name

The site name is displayed at the top of the webpage. This is a way to personalize the WatchDog remote

monitoring system. It is especially useful when viewing more than one WatchDog on a single PC. This will

identify which site the user is currently looking at. The site name is also included in the text messages and

e-mails that are sent due to dryer shutdowns. (See Figure 4P.)

Figure 4P

View Button

Pressing the will bring up a screen giving information about the WatchDog System. The

version number is currently displayed with other information being added as needed. (See Figure 4Q.)

Figure 4Q

PNEG-1745 WatchDog 35

Page 36

4. WatchDog Operation

M/C (Moisture Setpoint) Button

Pressing the button will bring up a dialog box requesting to modify the current grain temperature

setpoint or the moisture setpoint depending upon the setup of the dryer. For example, Figure 4R shows

the dialog box that is presented when using temperature to control the moisture output of the dryer.

Figure 4R

Shutdown Screen

If the drying equipment experiences a shutdown, the screen in

System and an audio file will be played (dogs ba rk ing). It in dicates that the drye r h as sh utdown and gives

the reason why.

The shutdown can only be cleared by pressing the STOP button at the dryer.

Figure 4S

will be displayed by the WatchDog

Figure 4S

36 PNEG-1745 WatchDog

Page 37

4. WatchDog Operation

Text Version

The text version of WatchDog leaves all of the fancy graphics behind and simply displays a few key

parameters denoting the status of the dryer. This version was put in place to allow phones that cannot

handle the graphics the ability to monitor the dryer. Shutdowns will still be displayed when using the

text version. (See Figure 4T.)

To access, scroll to the bottom of the webpage and click on the “Click Here for the Text Version” link. There

is not a password associated with this version, but no parameters can be changed from the text version.

It is strictly a monitoring system.

Figure 4T

PNEG-1745 WatchDog 37

Page 38

5. WatchDog Software Update

Process

This process assumes the user is using Windows XP.

1. Make an SD card readable by your computer. This may require a special piece of equipment from a

consumer electronics store. Below is an example of an SD card. (See Figure 5A.)

Figure 5A

2. Download the “WatchDog Update Version 1.03 installation program” file from http://www.gsiag.com/

gsi/progs/watchdog/to a directory on your computer.

3. Execute the “WatchDog Update v103.exe” from whatever directory you downloaded it to.

4. Read the License Agreement. If you agree to the terms, select the “I agree to the terms of this license

agreement” and click the “Next” button. (See Figure 5B.)

Figure 5B

38 PNEG-1745 WatchDog

Page 39

5. Click the “Next” button to proceed. (See Figure 5C.)

5. WatchDog Software Update

Figure 5C

6. This will bring you to a list of changes made from the previous version. Click “Next” to proceed.

(See Figure 5D.)

Figure 5D

PNEG-1745 WatchDog 39

Page 40

5. WatchDog Software Update

7. Select the drive that your SD card is using and click “Next”. (See Figure 5E.)

Figure 5E

8. Verify the correct drive has been selected and click “Next”. (See Figure 5F.)

Figure 5F

40 PNEG-1745 WatchDog

Page 41

5. WatchDog Software Update

9. The installer is now ready to install the update to the SD card. Click “Next” to install. (See Figure 5G.)

Figure 5G

10. Once the files have been transferred, the SD card installation is complete. Click “Finish” to exit

the installer. (See Figure 5H.)

Figure 5H

PNEG-1745 WatchDog 41

Page 42

5. WatchDog Software Update

11. After turning the WatchDog power OFF, insert the SD Card into the WatchDog board as

shown in Figure 5I.

Figure 5I

12. Once the SD Card is securely placed in the reader, return power to the WatchDog board and allow

3 minutes to pass.

13. After 3 minutes have passed, turn the WatchDog power OFF and then remove the SD Card from

the board.

14. Return power to the WatchDog board and wait for the red “SYS” light to come ON. The WatchDog is

now updated.

42 PNEG-1745 WatchDog

Page 43

Internet Connection Problems

Problem Potential Fix

“Check connection between WatchDog and Dryer.

Also check Vision Version. Should be 1.00 or newer.”

is being displayed.

6. Troubleshooting

1. Check the current version of Vision. It should be 1.00 or newer.

2. Make sure the Vision is powered ON and the dryer application

is running.

3. Check the connection points of the Serial Cable #1 between

the WatchDog circuit board and Display I/O circuit board.

4. If this happens on initial install, check that the cable is wired to

the 3 position connector correctly. Below is the correct wiring.

Use on ohm meter to check continuity.

1. Check the Ethernet connection to the WatchDog circuit board.

“Internet connection to the dryer has been lost” is

being displayed.

Login Password does not work. Refer to “Forgot Password Screen” Figure 4A on Page 28.

2. Verify the internet connection is working by removing the

Ethernet cable from the WatchDog circuit board and plugging

it into a PC. On the PC, open a web browser and try to access

a website of the choice. If this fails, contact the ISP.

Direct Connection Problems

Problem Potential Fix

1. Check the current version of Vision. It should be 1.00 or newer.

2. Make sure the Vision is powered ON and the dryer application

is running.

3. Check the connection points of the Serial Cable #2 between

the WatchDog circuit board and Display I/O circuit board.

4. If this happens on initial install, check that the cable is wired to

“Check connection between WatchDog and Dryer.

Also check Vision Version. Should be 1.00 or newer.”

is being displayed.

the 3 position connector correctly. Below is the correct wiring.

Use on ohm meter to check continuity.

5. Check that the red lights ON both short-haul modems are lit.

Also, open the WatchDog enclosure and verify the circuit

board has a green LED lit.

1. Make sure the power chord is plugged into 120 VAC

The green power light ON, the WatchDog circuit board

inside enclosure is not lit.

Login Password does not work. Refer to “Forgot Password Screen” Figure 4A on Page 28.

receptacle. If it is plugged in, plug in another appliance to verify

the receptacle is active i.e. lamp, tv, etc.

2. Check the fuse on the WatchDog enclosure. If it is blown there

is a spare taped to the inside of the enclosure.

PNEG-1745 WatchDog 43

Page 44

7. Technical Support

This section lists the pertinent contact information to be used in the event of WatchDog System failure.

There are three (3) possible options for help.

Internet Provider

If the WatchDog System is not accessible via the Internet please make sure the Internet Co nnection being

used is viable. This can be done in a number of ways, but contacting the Internet Provider for assistance

would probably be the best way to address this problem.

Dealer

If you have an Internet based WatchDog and, cannot connect to the WatchDog System over the Internet

and you have already checked the connection with the Internet Provider 1., please contact your dealer for

the next steps.

If you have a Direct Connected WatchDog System and you cannot access the system, once again contact

your dealer for advice.

The following items need to be checked by the dealer, in addition to anything they might have

already tested:

1. Make sure all connections from the Vision System, through the WatchDog System and even the

connections made at your PC, if you have a Direct Connect System, are good.

2. If you have a Direct connect system, make sure the TX and RX lights are blinking on the short -haul

MODEMs. If not check the connections and possibly replace the MODEMs.

3. Make sure the software version of the Vision System matches that of the WatchDog System.

The version numbers of both systems can be found by pressing the VIEW button and then the

SYSTEM INFORMATION.

GSI Contact Information

If the Internet Provider and dealer have been unsuccessful in resolving the problem, then contact GSI at

the following number:

217-226-5500

44 PNEG-1745 WatchDog

Page 45

8. Appendix A

Acquiring and Installing a BlueTree Cellular Modem

To acquire a GSI recommended cellular modem, contact the following company:

USAT Corporation

www.usatcorp.com

sales@usatcorp.com

919-942-4214

Ask for a GSI Group account manager.

If you are installing a BlueTree modem acquired from USAT Corporation, there are a few extra installat ion

steps for mounting. Perform the following list of instructions before returning to the “Install Procedure”:

1. Secure the 3" piece of DIN rail to the lower control panel back plate using the two (2) self-tapping

1/4" screws that are provided with the package. Attach the cellular modem to the DIN rail.

(See Figure 8A.)

Figure 8A

2. Connect the cellular modem power terminal (PWR +) to J1-1 on the moisture control circuit board.

Connect the cellular modem ground terminal (GND) to J1-2 on the moisture control circuit board.

The moisture control circuit board is located on the back plate of the lower control panel.

(See Figure 8B.)

Figure 8B

PNEG-1745 WatchDog 45

Page 46

8. Appendix A

Ethernet connector

Antenna connector

3. Connect one end of an Ethernet cable to the Ethernet connector on the cellular modem.

Please refer to Figure 8C.

4. Run the antenna wire for the cellular modem through a knockout in the bottom of the control panel

and connect the BNC connector to the modem. The antenna is magnetized and should be placed

with the least obstructions to the nearest tower.

Figure 8C

5. Return to the “Install Procedure” on Page 11.

46 PNEG-1745 WatchDog

Page 47

9. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1745 WatchDog 47

Page 48

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2010 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Loading...

Loading...