Page 1

PNEG-1744

H-Series Catwalk Installation

Supplement for GSI Bins Built with Stiffeners

Instruction Manual

PNEG-1744

Date: 05-21-10

Page 2

2 PNEG-1744 H-Series Catwalk Installation

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................4

Chapter 2 Dryer Dimensions, Stiffener and Catwalk Locations ........................................................................6

Catwalk Support Assembly at Stiffener ................................................................................................. 6

Dryer Catwalk Layouts .......................................................................................................................... 7

14' Long Dryer Catwalk Layout .........................................................................................................7

18' Long Dryer Catwalk Layout .........................................................................................................8

20' Long Dryer Catwalk Layout .........................................................................................................9

22' Long Dryer Catwalk Layout .......................................................................................................10

26' Long Dryer Catwalk Layout .......................................................................................................11

Dryer Size vs Support Attachments Needed .................................................. .... ... ... ... ... .... .............12

Truss Bracket Attachments for Channel Supports .............................................................................. 13

Truss Bracket, Catwalk Section Edge Locations .............................................................................13

Truss Bracket, Catwalk 8' Section Center Locations ................................ ... ... .... ... ... ... ... .... ... ... ... ....13

Catwalk Support Installation for Locations with No Stiffeners .........................................................14

Catwalk Locations ......................................................... ... ... ... .... ......................................................... 16

Middle Module Location ...................................................................................................................16

Top Module Location ................................................ ... ... .......................................... ... ... .................17

Chapter 3 Installation Instructions ....................................... ..............................................................................18

Chapter 4 Warranty ..............................................................................................................................................19

PNEG-1744 H-Series Catwalk Installation 3

Page 4

1. Introduction

Please note that the original catwalk installation instructions (included in CATM-01-5 and CATH-01-5)

were written for Farm Fans (FFI) dryers supported with buttresses. This supplement contains catwalk

installation instructions for dryers built with “stiffeners”. Please follow this supplement when installing

a catwalk on a dryer with stiffeners. You will be referred back to the original manual when necessary.

Please study the table included for specifications that are specific to your particular size of equipment.

Install the catwalk on each module prior to lifting modules into place.

4 PNEG-1744 H-Series Catwalk Installation

Page 5

NOTES

PNEG-1744 H-Series Catwalk Installation 5

Page 6

2. Dryer Dimensions, Stiffener and Catwalk Locations

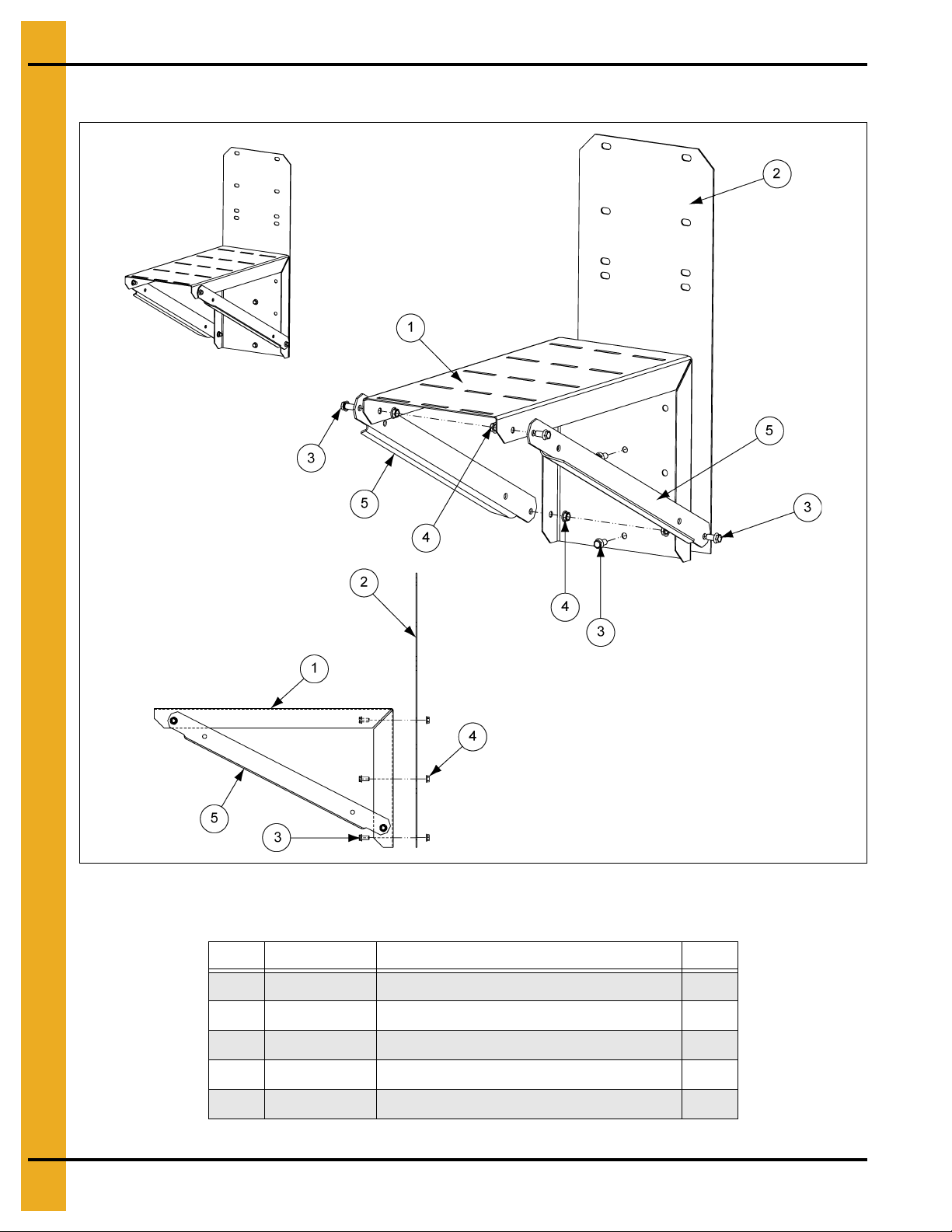

Hardware to attach to stiffener can be at a

different location than shown.

Catwalk Support Assembly at Stiffener

Figure 2A

Catwalk Support Assembly at Stiffener Parts List (D04-0499)

Ref # Part # Description Qty

1 D01-2468 Support at Stiffener 1

2 D01-2469 Stiffener Adapter Plate 1

3 S-9067 Flange Bolt 3/8"-16 x 3/4" ZN Grade 5 7

4 S-968 Flange Nut 3/8"-16 ZN Grade 5 7

5 401-4718-3 Brace at Stiffener 2

6 PNEG-1744 H-Series Catwalk Installation

Page 7

2. Dryer Dimensions, Stiffener and Catwalk Locations

Figure 2G on Page 13

Figure 2H on Page 13

Figure 2G

on Page 13

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2G

on Page 13

Dryer Catwalk Layouts

14' Long Dryer Catwalk Layout

Figure 2B

PNEG-1744 H-Series Catwalk Installation 7

Page 8

2. Dryer Dimensions, Stiffener and Catwalk Locations

Figure 2G on Page 13

Figure 2I on Page 14

Figure 2G on Page 13

Figure 2G

on Page 13

Figure 2I

on Page 14

Figure 2G

on Page 13

18' Long Dryer Catwalk Layout

Figure 2C

8 PNEG-1744 H-Series Catwalk Installation

Page 9

2. Dryer Dimensions, Stiffener and Catwalk Locations

Figure 2G on Page 13

Figure 2H on Page 13

Figure 2G

on Page 13

Figure 2G

on Page 13

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2G

on Page 13

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2H

on Page 13

20' Long Dryer Catwalk Layout

Figure 2D

PNEG-1744 H-Series Catwalk Installation 9

Page 10

2. Dryer Dimensions, Stiffener and Catwalk Locations

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2G

on Page 13

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2G

on Page 13

22' Long Dryer Catwalk Layout

Figure 2E

10 PNEG-1744 H-Series Catwalk Installation

Page 11

2. Dryer Dimensions, Stiffener and Catwalk Locations

Figure 2I

on Page 14

Figure 2G

on Page 13

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2H

on Page 13

Figure 2G

on Page 13

Figure 2I

on Page 14

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2G

on Page 13

26' Long Dryer Catwalk Layout

Figure 2F

PNEG-1744 H-Series Catwalk Installation 11

Page 12

2. Dryer Dimensions, Stiffener and Catwalk Locations

Dryer Size vs Support Attachments Needed

Dryer

Length

14'

18'

20'

22'

26'

# of Modules

2 4' 0 2 4 2 0

34'0 4840

2 4' 4 0 4 0 2

34'8 0804

2 2' 0 4 6 4 0

32'0 81280

2 4' 0 4 6 4 0

34'0 81280

2 2' 2 4 6 4 2

32'4 81284

Corner

Length

6' Catwalk

Sections

8' Catwalk

Sections

Figure 2G

on Page 13

Figure 2H

on Page 13

Figure 2I

on Page 14

Figure 2G on Page 13 = D01-2425. Used at the edges of both 6' and 8' catwalk sections.

Figure 2H on Page 13 = D01-2437. Used at center of 8' catwalk sections. Note that 6' catwalk sections do

not require center supports.

Figure 2I on Page 14 = Support for catwalk edge locations without a stiffener. (As seen on Page 14 of

layout for new stiffener supports.)

12 PNEG-1744 H-Series Catwalk Installation

Page 13

2. Dryer Dimensions, Stiffener and Catwalk Locations

Truss Bracket Attachments for Channel Supports

Truss Bracket, Catwalk Section Edge Locations

Figure 2G

Truss Bracket, Catwalk 8' Section Center Locations

Figure 2H

PNEG-1744 H-Series Catwalk Installation 13

Page 14

2. Dryer Dimensions, Stiffener and Catwalk Locations

Catwalk Support Installation for Locations with No Stiffeners

Figure 2I Typical Catwalk Support Installation where no Stiffener is Installed

14 PNEG-1744 H-Series Catwalk Installation

Page 15

2. Dryer Dimensions, Stiffener and Catwalk Locations

Catwalk Support Installation for Locations with No Stiffeners Parts List

Ref # Part # Description Qty

1 D31-0055 Column Bulkhead 1

2 401-4713-4 Catwalk Section 1

3 401-4753-0 Adapter Channel Support 4

4 401-4717-5 Support Angle 2

5 401-4719-1 Brace at Dryer 2

6 S-9067 Flange Bolt 3/8"-16 x 3/4" ZN Grade 5 8

7 S-968 Flange Nut 3/8"-16 ZN Grade 5 8

8 401-4720-9 Filler Plate 1

9 325-2091-8 Channel - Support 1

10 S-7645 Carriage Bolt 5/16"-18 x 3/4" ZN Grade 5 20

11 S-3611 Flange Nut 5/16"-18 ZN YDP 22

12 S-6606 Flange Bolt 5/16"-18 x 3/4" ZN Grade 5 2

PNEG-1744 H-Series Catwalk Installation 15

Page 16

2. Dryer Dimensions, Stiffener and Catwalk Locations

Catwalk Locations

Middle Module Location

Figure 2J Location of Catwalk for Middle Module

Middle Module Location Parts List

Ref # Part # Description Qty

1 SS-692308 9-5 Gauge 2 Ring 1

2 SS-7053 N.S. 8 Gauge Splice 2

3 D01-0872 Stiffener Attach Angle 1

4 D01-2468 Support at Stiffener 1

5 D01-2469 Stiffener Adapter Plate 1

6 S-9067 Flange Bolt 3/8"-16 x 3/4" ZN Grade 5 13

7 S-968 Flange Nut 3/8"-16 ZN Grade 5 13

8 401-4718-3 Brace at Stiffener 2

16 PNEG-1744 H-Series Catwalk Installation

Page 17

Top Module Location

2. Dryer Dimensions, Stiffener and Catwalk Locations

Figure 2K Location of Catwalk for Top Module

Top Module Location Parts List

Ref # Part # Description Qty

1 SS-692308 9-5 Gauge 2 Ring 1

2 SS-7053 N.S. 8 Gauge Splice 1

3 D01-2468 Support at Stiffener 1

4 401-4718-3 Brace at Stiffener 2

5 S-9067 Flange Bolt 3/8"-16 x 3/4" ZN Grade 5 13

6 S-968 Flange Nut 3/8"-16 ZN Grade 5 13

7 D01-2469 Stiffener Adapter Plate 1

PNEG-1744 H-Series Catwalk Installation 17

Page 18

3. Installation Instructions

For Step 1, please refer to the instructions included in the original manual. Follow Step 2 in this

supplement. Then, return to the original manual for Steps 4-8. (Step 3 in the original manual is

obsolete for dryers without buttresses.)

Step 2: Build catwalk support assemblies (part numbers: D04-0499, D01-2425 and D01-2437). Refer to

Table on Page 12 to determine the number of support assemblies and catwalk platforms needed for the

dryer, based upon its length and the number of modules.

Step 3: To install the assemblies on the dryer: A two-stack dryer will have one catwalk on the top module.

A three-stack dryer will have one catwalk on the middle module, as well as one on the top module.

NOTE: There are pla ces where you must install supports where there is no stiffener. (See Figure 2I

on Page 14.) To determine if this situation is applicable to the particular dryer, please refer to

Table on Page 12, as well as dryer layouts and locate the dryer size.

Now, return to the original manual for Steps 4-8.

To install the catwalk support assembly on the middle module, measure 17. 54" from the top of the stiffener

to the top of the assembly (D04-0499). Use the hardware referenced in Figure 2J on Page 16.

To install the catwalk support assembly on the top module, measure 16.57" from the top of the stiffener to

the top of the assembly (D04-0499). Use the hardware referenced in Figure 2K on Page 17.

Once all supports are in place, install catwalk sections as indicated in Table on Page 12 and dryer catwalk

layouts, using the appropriate layout length.

Step 9: On the truss bracket, install the plate with the hole

See Figure 2G on Page 13 for these connections and Table on Page 12 for the quantities required.

On the truss bracket, install the plate without the hole

of the catwalk. See Figure 2H on Page 13 for these connections and Table on Page 12 for the

quantities required.

Go to Step 13 of the existing manual to finish the hand rail installation.

when there is a gap between catwalk sections.

where the support needs to go in the center

18 PNEG-1744 H-Series Catwalk Installation

Page 19

4. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1744 H-Series Catwalk Installation 19

Page 20

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2010 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Loading...

Loading...