Page 1

PNEG-1743

Vision for Tower Dryers

Operation Manual

PNEG-1743

Date: 05-12-10

Page 2

2 PNEG-1743 Vision for Tower Dryers

Page 3

Table of Contents

Contents

Chapter 1 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

Dryer Operation ..................................................................................................................................... 6

Emergency Stop Switch ................................... ... ... ... .... ... ... ... .... ... ... ..................................................... 6

Operating Precautions ..................................... ... ... ... .... ... ... ... .... ... ........................................................ 7

Chapter 2 Decals ....................................................................................................................................................9

Chapter 3 Vision Control Panel ..........................................................................................................................11

Control Power Switch .......................................................................................................................... 11

Stop Button ......................................................................................................................................... 11

Outside Light Switch ........................................................................................................................... 12

Start Button ......................................................................................................................................... 12

Unload Switch ..................................................................................................................................... 12

Meter Roll Adjustment ......................................................................................................................... 12

Load Switch ..................... .... ... ............................................................................. .... ... ......................... 13

Fan Switch .......................................................................................................................................... 13

Heater Switch ...................................................................................................................................... 13

Chapter 4 Boot Screen ........................................................................................................................................14

Boot Screen Description and Button Explanations ............................................................................. 14

Software Update Procedure ............................. ................................................ ................................... 15

Chapter 5 Operations ..........................................................................................................................................19

Default Operation Screen .................................................................................................................... 19

Timers Button ...................................................................................................................................... 20

Load Delay .................................................................................. ... ... .... ... ... ... .... ... ......................... 20

Out Of Grain (OOG) Timer ............................................................................................................. 20

Fan Delay................ .......................................... ... .......................................... .... ............................ 20

Unload Delay..... ... ... ... .... ... ... .............................................................................. ... ... ... ................... 20

Cool Down.. ... .... ... ... ... .... ... ............................................................................. .... ... ... ... ................... 20

Temp Button ........................................................................................................................................ 21

Plenum Temperature Setpoint.................................. ... ... ... .... ... ... ... ... .... ... ... ... ................................ 22

Grain Temperature Setpoint........................................................................................................... 22

Setup Button ..................................... ... ... ... ... .... .......................................... ... ..................................... 23

Drying Mode...................................................................................... .... ... ... ... .... ... ... ... ................... 23

Moisture Control Setup................................ ... ... ... .... ... ... ... .......................................... ... ................ 24

Unload Parameters............................ ... ... .......................................... .... ......................................... 24

Plenum Temp Manager........ ... .......................................... .... ... ... ... ................................................ 25

Calibrate Moisture Sensor.............................................................................................................. 25

Extended Setup Screen.................................................................. ... .... ... ... ... ................................ 26

Diagnostics............................................................................................................................... 26

Differential ................................................................................................................................ 27

BPH Calibration........................................................................................................................ 27

Set Time/Date .......................................................................................................................... 28

Temp Scale.............................................................................................................................. 28

Dryer Model.............................................................................................................................. 28

Data Logger Setup....................................................................................................................29

User Saved Defaults ................................................................................................................ 30

View Button......................................................................................................................................... 30

Table View................................... ... ... ... ... .... ... ... ....................................... ... ... .... ... ... ... ................... 30

Select Data Log Sample Time...................................................................................................

Graph View. ... .... ... ... ... .... ... ... ... .... ... ... .......................................... ... ... .... ... ... ................................... 31

Owner’s Manual ................................ ... ... .... ... .......................................... ... ....................................32

Error History ............................................ .......................................... .... ..........................................32

System Information......................... ... .......................................... ... ................................................ 32

Software Version Info..................................................................................................................... 33

31

PNEG-1743 Vision for Tower Dryers 3

Page 4

Table of Contents

M/C Button .......................................................................................................................................... 33

Modifying Temperature Setpoint ..................................................................................................... 33

Modifying Moisture Setpoint............................................................................................................ 34

Resetting Factory Defaults............. .... ... ... ... .......................................... ... .... ... ... ................................. 34

Chapter 6 Moisture Control Options ..................................................................................................................35

Continuous Flow Drying................. ....................................... ... .... ... ... ... ... .... ... .................................... 35

Temperature Controlled Schemes.................................................................................................. 35

Moisture Controlled Schemes ........................................................................................................ 39

Chapter 7 Initial Settings Check .........................................................................................................................42

Dealer Suggested Initial Settings Check ........... ... ... ... .... ... ... ... .......................................... ... .... ... .. ...... 42

Owner Suggested Initial Settings Check ....... .... .......................................... ... ... ... .... ........................... 42

Chapter 8 Safety Circuit Shutdown Messages ......................................................................... ... ......................43

Fan/Heater Shutdown Messages ........................................................................................................ 43

Main I/O Shutdown Messages .......................................................... ... ... .... ... ... ... .... ... ... ..................... 46

Moisture Control Shutdown Messages ............................................................................................... 48

Chapter 9 Warranty ..............................................................................................................................................49

4 PNEG-1743 Vision for Tower Dryers

Page 5

1. Safety

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1743 Vision for Tower Dryers 5

Page 6

1. Safety

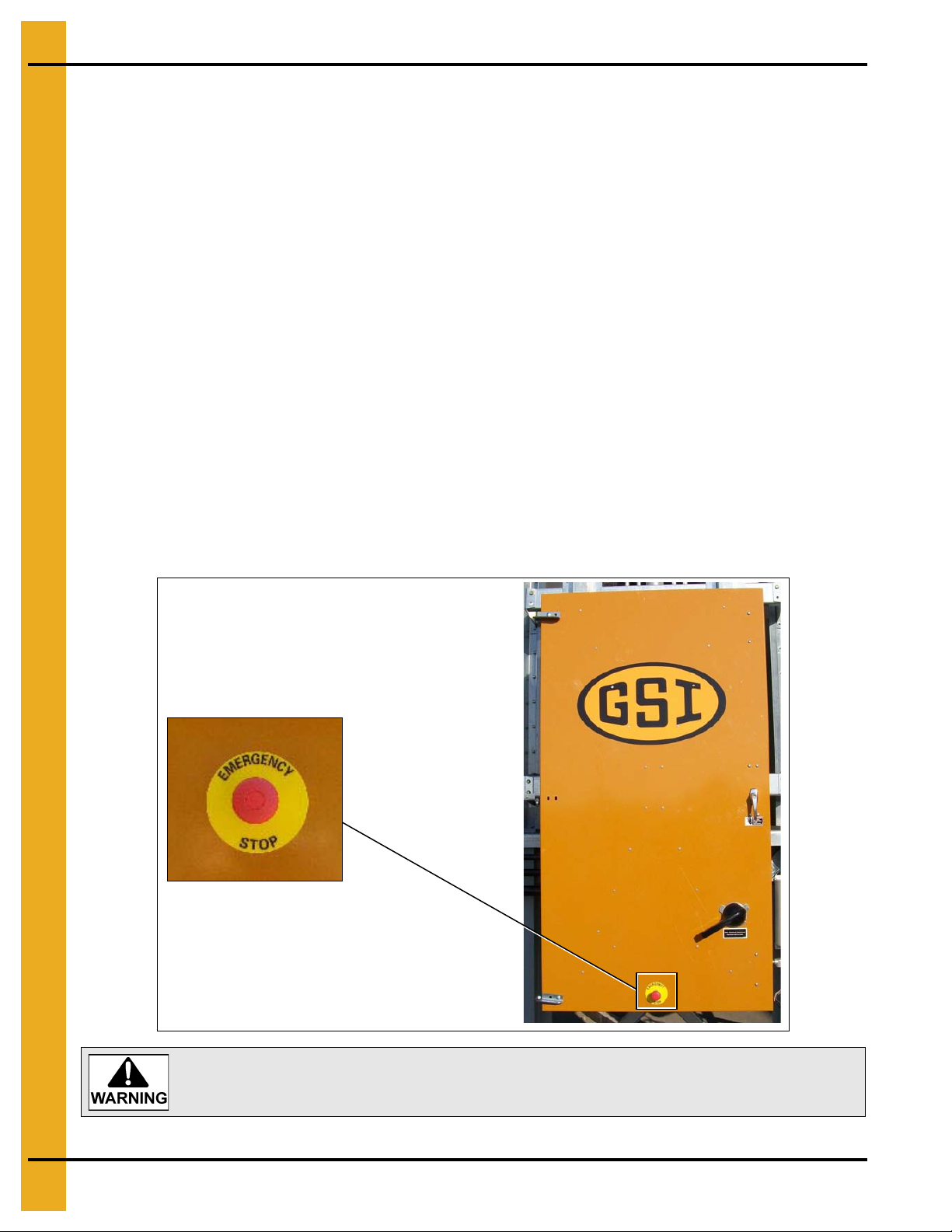

Emergency Stop

Pushing the Emergency Stop switch does not interrupt the main power to the

upper control box panel.

Dryer Operation

Thank you for choosing a GSI product. It is designed to give excellent performance and service for

many years.

This manual describes the operation for all standard production model dryers. These dryers are available

with liquid propane or natural gas fuel supply and 3 phase 230, 380, 460 or 575 volts (50 Hz or 60 Hz)

electrical power.

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

Emergency Stop Switch

The Emergency Stop switch is located on the upper control box door. Pushing the Emergency Stop switch

will interrupt the control power and stop all dryer functions.

6 PNEG-1743 Vision for Tower Dryers

Page 7

1. Safety

Keep the dryer clean. Do not allow fine material to accumulate in the plenum

chamber or surrounding the outside of the dryer.

Operating Precautions

READ THESE INSTRUCTIONS BEFORE INSTALLATION AND OPERATION

SAVE FOR FUTURE REFERENCE

1. Read and understand the operations manual before attempting to operate the unit.

2. Keep ALL guards, safety decals and safety devices in place. NEVER operate dryer while guards

are removed.

3. Keep visitors, children and untrained personnel away from dryer at all times.

4. Never attempt to operate the dryer by jumping or otherwise bypassing any safety devices on

the unit.

5. Always set the main power supply disconnect switch to OFF and lock it in the OFF position using

a padlock before performing any service or maintenance work on the dryer or the auxiliary

conveyor equipment.

6. Keep the dryer and wet holding equipment CLEAN. DO NOT allow fine material to accumulate.

7. On LP fired units, set pressure regulator to avoid excessive gas pressure applied to a burner

during ignition and when the burner is in operation. Do not exceed maximum recommended

drying temperatures.

8. DO NOT operate the dryer if any gas leak is detected. Shut d own and repair before further operation.

9. Clean grain is safer and easier to dry. Fine materials can be highly combustible, and it also requires

removal of extra moisture.

10. Use CAUTION in working around high-speed fans, gas burner, augers and auxiliary conveyors which

can START AUTOMATICALLY.

11. Be certain that capacities of auxiliary conveyors are matched to dryer metering capacities.

12. DO NOT operate in an area where combustible material will be drawn into the dryer.

13. The operating and safety recommendations in this manual pertain to the common cereal

grains as indicated. When drying any other grain or products, consult the factory for

additional recommendations.

14. Routinely check for any developing gas plumbing leaks.

15. Before attempting to remove and reinstall the fan blade, contact GSI for the recom mended procedu re.

Use Caution in the Operation of this Equipment

This dryer is designed and manufactured with operator safety in mind. However, the very nature of a grain

dryer having a gas burner, high voltage electrical equipment and high speed rotating parts, presents

hazards to personnel which cannot be completely safeguarded against without interfering with the efficient

operation of the dryer and reasonable access to its components.

Use extreme caution in working around high speed fans, gas-fired heaters, augers and auxiliary

conveyors, which may start without warning when the dryer is operating on automatic control.

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable drying system, follow the recommendations within the Owner’s Manual

and make it a practice to regularly inspect the unit for any developing problems or unsafe conditions.

Take special note of the Operating Precautions before attempting to operate the dryer.

PNEG-1743 Vision for Tower Dryers 7

Page 8

1. Safety

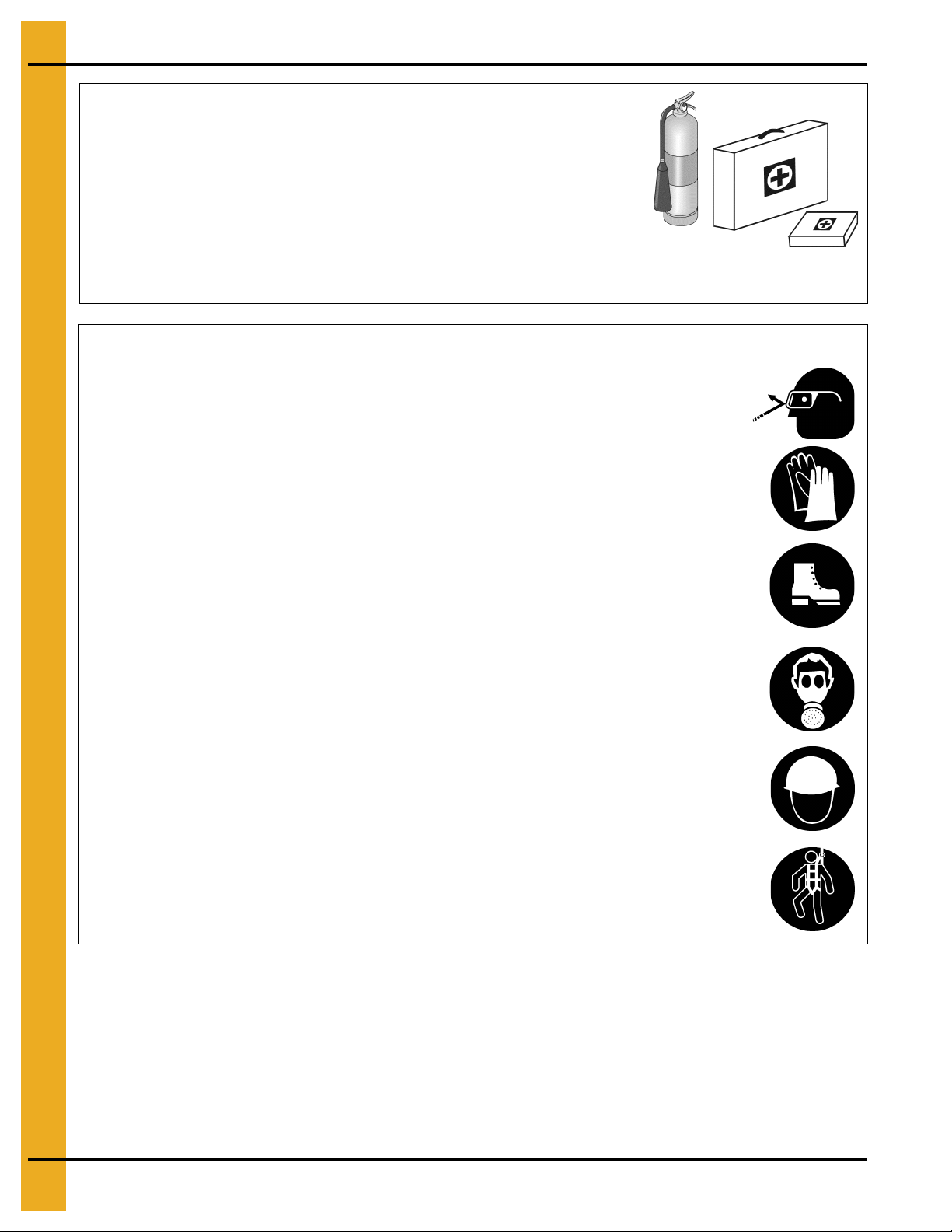

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Wear Protective Clothing

Wear close fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Long hair should be tied up and back.

Safety glasses should be worn at all times to protect eyes

from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel toe boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoe strings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel Toe Boots

Respirator

Hard Hat

Fall Protection

8 PNEG-1743 Vision for Tower Dryers

Page 9

2. Decals

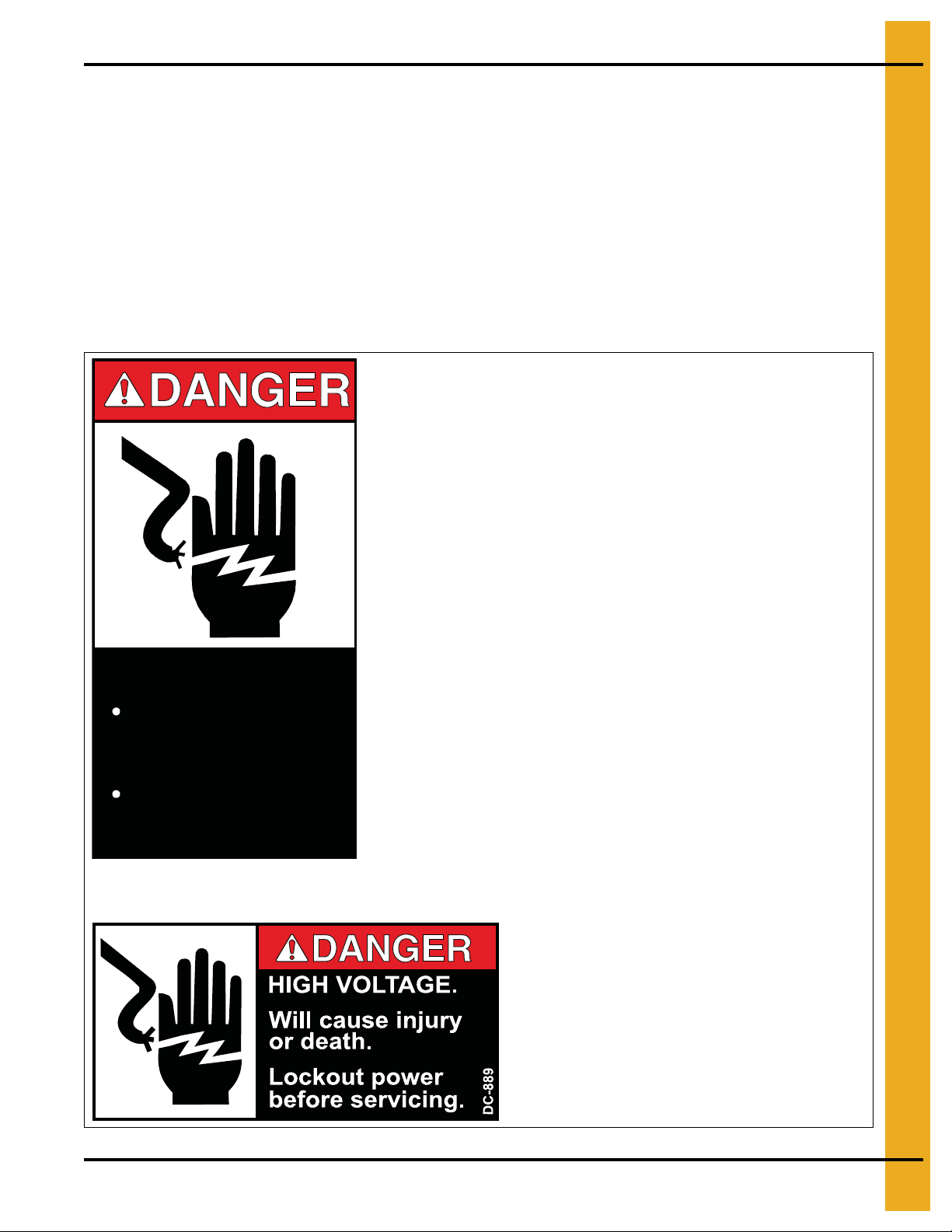

HIGH VOLTAGE.

Will cause serious

injury or death.

Lockout power

before servicing.

DC-1224

Decal: DC-889

Decal DC-889 has two locations. One inside the

fan/heater control box and another on the dryer upper

control box door next to the main power disconnect.

Decal: DC-1224

Decal DC-1224 is located in two places on the fan/heater control box. One on the

lid and one on the front of the fan heater control box. Another location for this

decal is inside the upper control box for the dryer.

Contact the local power company to have a representative survey the installation to assure the wiring is

compatible with their system and adequate power is supplied to the unit. Safety deca ls should be read and

understood by all people in the grain handling area. Inspect all decals and replace any that are

illegible, worn or missing. Contact your dealer or the factory to order replacement decals.

If a decal is damaged or is missing, contact:

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

A free replacement will be sent to you.

NOTE: Decals are not shown actual size.

PNEG-1743 Vision for Tower Dryers 9

Page 10

2. Decals

Flame and pressure

beyond door. May

cause serious injury.

Do not enter when

dryer is running.

DC-1061

WARNING!

Decal: DC-1062

Decal DC-1062 is located inside the cooling section of the dryer on the two

access doors to the metering section.

Decal: DC-1063

Decal DC-1063 is located on the louvered

access door to the cooling section of the dryer.

Decal: DC-1064

Decal DC-1064 is located on the louvered access

door to the cooling section of the dryer.

Decal: DC-1061

Decal DC-1061 is located on the outside

of the heat section door.

DO NOT STAND ON DRUM!

Rotating drum will cause

serious injury or death.

Disconnect power before

servicing.

DC-1062

Airborne particles during

operation. May impair

vision and breathing.

Do not enter when

dryer is running.

DC-1063

WARNING!

High speed belt drive

operating overhead.

Can cause serious injury.

Keep head and hands

clear. Do not enter when

dryer is running.

DC-1064

10 PNEG-1743 Vision for Tower Dryers

Page 11

3. Vision Control Panel

Fan switches

Load switch

Unload switch

Outside

Light switch

Control

Power switch

Stop button

Start switch

Meter Roll

Adjustment

Touch screen

Heater switches

Control Power Switch

The Vision control system is turned ON or OFF with this switch.

NOTE:

Stop Button

This button stops all dryer functions except the blower (fan). If the blower switch, noted on the panel as

the Fan switch, is in the ON position, the blower will continue to run for 15 minutes. If you desire the

blower to be OFF, turn the blower switch to the OFF position. If an automatic dryer shutdown occurs,

first determine and correct the cause of the shutdown. Then, press the Stop button to reset the dryer

before restarting.

PNEG-1743 Vision for Tower Dryers 11

Figure 3A

This switch does not disconnect the power that is present at the breakers, contactors, transformer(s),

fuses or other electrical components found in the control or power box. Turn the main disconnect

handle to the OFF position prior to servicing any of the installed components.

Page 12

3. Vision Control Panel

Outside Light Switch

The dryers outside service light is turned ON or OFF here. It also can be set on AUTO, which turns the

light ON while the dryer is running and OFF if a shutdown occurs.

Start Button

Push the Start button and all of the selector switches on the control panel will be activated.

Unload Switch

The Unload switch turns the metering rolls and discharge auger ON or OFF and selects the operation of

the metering rolls. In the MANUAL position, the meter rolls will operate in one Speed only. In the AUTO

position, the meter rolls switch to a multi-speed mode for moisture control operation. The switch will

illuminate whenever the load auger is operating.

NOTE: If the unload auxiliary controls are being used, this switch will also control the operation of the

auxiliary equipment.

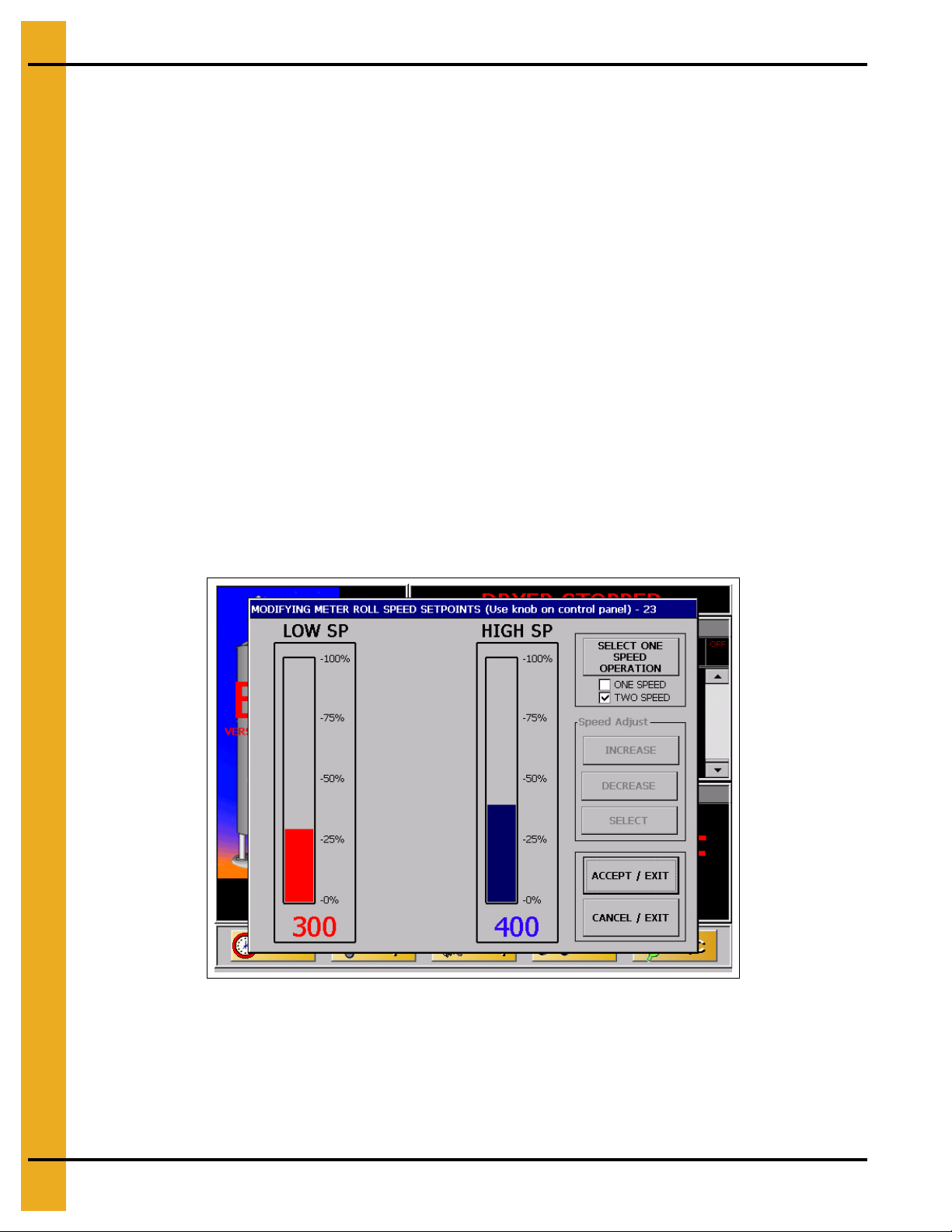

Meter Roll Adjustment

This knob allows the user to adjust the meter roll setpoint(s). Pressing the knob will bring up the “Modifying

Meter Roll Speed Setpoints” screen. (See Figure 3B.)

Figure 3B

NOTE: Screen may vary depending on the moisture control scheme selected.

Turning the knob clockwise will adjust the selected (red color) setpoint in a positive direction and vice

versa. Pressing the knob will switch between setpoints.

12 PNEG-1743 Vision for Tower Dryers

Page 13

3. Vision Control Panel

Load Switch

This is used to select the operation of the fill auger. In both the AUTO and MANUAL positions, the load

auger will operate if the dryer is low on grain and will automatically shut OFF when the dryer is full. In the

AUTO position, the dryer will shutdown if the out of grain timer expires. The load delay is disabled

when the Load switch is in the MANUAL position. The switch will illuminate whenever the load auger

is operating.

Fan Switch

The fan is turned ON or OFF with this switch. Turning the switch to the ON position will turn the fan

ON. Turning the switch to the OFF position turns the fan OFF. The light inside the switch will illuminate

whenever the air pressure sensor detects air movement through the fan.

NOTE: The fan AUTO position is not used for continuous flow operation.

Heater Switch

The burner (heater) is turned ON or OFF with this switch. Turning the switch to the ON position will

start the burner ignition sequence if the fan is also running. Turning the switch to the OFF position turns

the burner OFF. The light inside of the switch will illuminate only when the flame sensor detects the

burner flame.

NOTE: The heater AUTO position is not used for continuous flow operation.

PNEG-1743 Vision for Tower Dryers 13

Page 14

4. Boot Screen

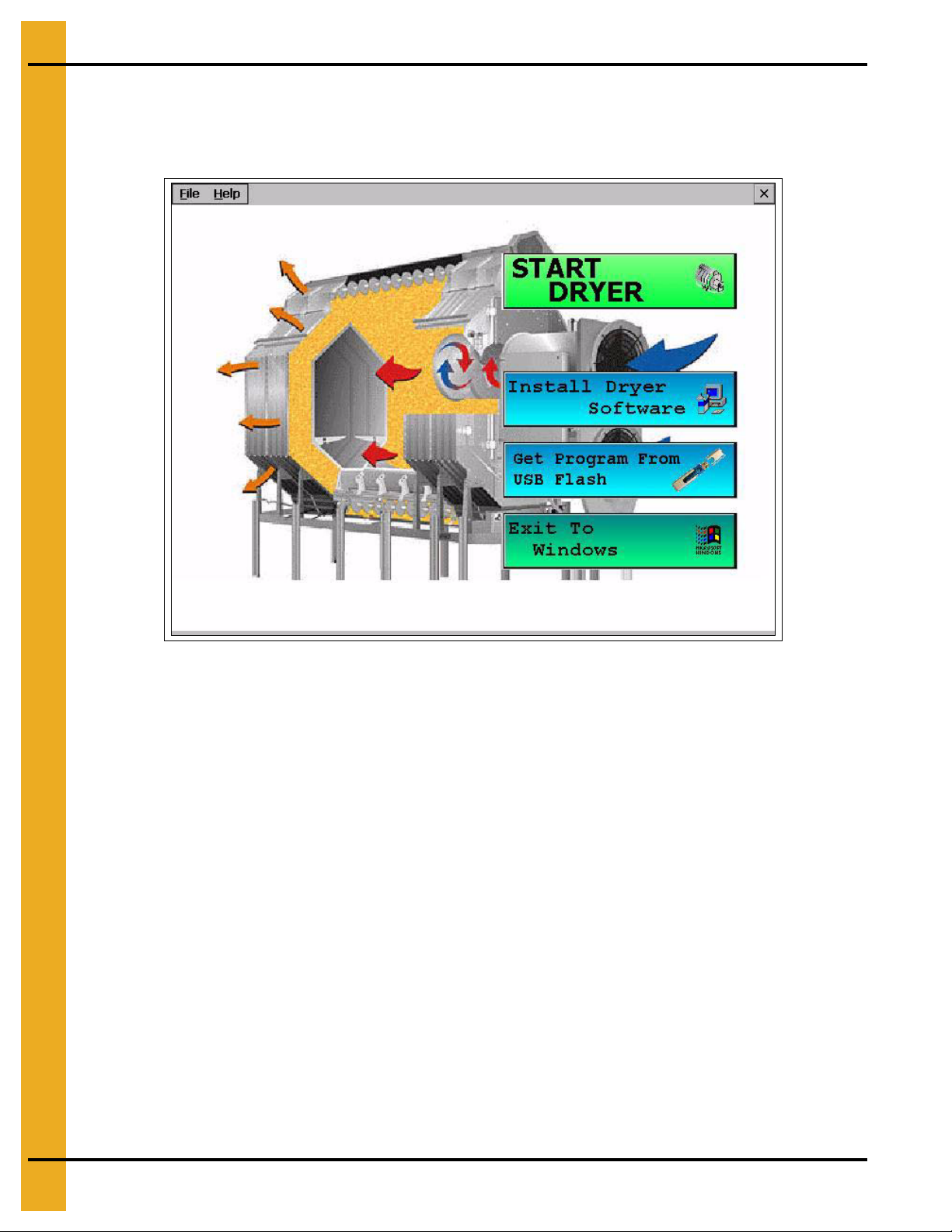

Boot Screen Description and Button Explanations

Turning the Control Power switch to the ON position, will start the Vision computer. The first screen to

appear will be the Boot Screen. Notice that there are four (4) buttons on the Boot Screen. (See Figure 4A.)

Figure 4A

1. Start Dryer: This button accesses the dryer program.

2. Install Dryer Software: This button is used in updating the Vision software, which is described

further in this chapter.

3. Get Program From USB Flash: This button is used in updating the Vision software, which is

described further in this chapter.

4. Exit To Windows: This button should NOT be used in normal operation. Only the GSI Group

employees should press this button. Turn the Control Power switch OFF, then ON if this button is

inadvertently pushed to return to the regular Boot Screen.

14 PNEG-1743 Vision for Tower Dryers

Page 15

Software Update Procedure

Control

Power switch

Get Program From

USB Flash button

1. Cycle the Control Power switch. The Vision computer will start. (See Figure 4B.)

4. Boot Screen

Figure 4B

2. When the “Boot Screen” appears, touch the “Get Program From USB Flash” button. (See Figure 4C.)

PNEG-1743 Vision for Tower Dryers 15

Figure 4C

Page 16

4. Boot Screen

3. Insert USB flash drive into USB port.

4. The display will now confirm that program files were found.

Figure 4D

Press “Yes” to copy.

5. After the program files are transferred, the “Boot Loader” screen will appear. (See Figure 4E.)

Figure 4E

16 PNEG-1743 Vision for Tower Dryers

Page 17

4. Boot Screen

NOTE: A Display I/O, Main I/O,

Moisture Control and one entry for

each Fan/Heater on the dryer

should appear.

Select the “Scan Network” button. This scan will check the dryer to make sure all parts of the control

system are communicating directly.

6. After the scan is complete, the Display I/O, Main I/O, Moisture Control and the Fan/Heater(s) sho uld

be shown as “Nothing to Report”. (See Figure 4F.)

Touch the “Exit” button.

7. Choose the “Select Program” button from the “Boot Loader” screen. (See Figure 4G.)

Figure 4F

Figure 4G

PNEG-1743 Vision for Tower Dryers 17

Page 18

4. Boot Screen

8. Select the program file you wish to upload by touching the “Move Up” and “Mo ve Down” buttons until

the desired program file is highlighted. Then, choose the “Accept/Exit” button.

9. Touch the “Start Upload” button.

10. When the “Upload Progress” screen appears, select the “Start Upload” button. (See Figure 4H.)

Figure 4H

11. The Vision computer will now begin programming each of the network circuit boards on the dryer.

The box on the right of the screen lists the network circuit boards detected in the scan. Each circuit

board listed will have to be reprogrammed, so this may take a few minutes. File upload progress for

the circuit board that is highlighted is displayed in the box on the left. (See Figure 4H.)

12. Once the upload is complete, choose the “Exit to Dryer” button to leave the “Boot Loader” screen and

start the dryer.

13. The dryer will begin running the program that was just installed.

14. The dryer control is now ready to operate the dryer.

15. In the event it is determined that reversion to the previous software version is necessary, go back to

the Boot Screen and select “Install Dryer Software” and follow the instructions above to re-install the

previous software.

18 PNEG-1743 Vision for Tower Dryers

Page 19

Operations

Dryer Operation

Animation

Dryer St atus

Dryer Status

Charts

Plenum(s)

Configuration

Buttons

Default Operation Screen

5. Operations

Figure 5A

The “Default Operation Screen” is divided into five (5) sections. (See Figure 5A.)

1. Dryer Operation Animation: Located on the left side of the “Default Operation Screen”, the dryer

operation animation shows the status of the fans/heaters, load and unload augers and meter rolls.

It will also display the grain temperature, moisture content, moisture control setpoint and the

bushel counter.

2. Dryer Status: Located at the very top of the right side of the “Default Operation Screen”, the dryer

status will tell the user if the dryer is stopped, started, loading or unloading.

3. Dryer Status Chart: This chart, located directly under dryer status, will sh ow the grain temperature,

moisture in/out, temperature out and meter roll output (M.R.O) over a period of time.

4. Plenum(s): Located directly below dryer status chart, the plenum section will show temperature

setpoint, actual plenum temperature and burner status.

5. Configuration Buttons: Select from “Timers”, “Temp”, “Setup”, “View” and “M/C” buttons.

PNEG-1743 Vision for Tower Dryers 19

Page 20

5. Operations

Timers Button

Select the button. A new screen will appear called the “Select Timer to Modify” screen.

(See Figure 5B.) There are five (5) timers that can be modified.

Figure 5B

1. Load Delay: (Default setting - 2 minutes) This delay is used to prevent the load auger from

over-cycling. The load delay is active only when the Load switch is in the AUTO position. The timer

starts when the dryer calls for grain.

2. Out Of Grain (OOG) Timer: (Default setting - 8 minutes) The “OOG” timer should be set to the

maximum time it takes for the dryer to refill during continuous or batch drying modes. The computer

will display the time required to fill the dryer on the previous load, aiding you in setting an accurate

time. If the dryer runs out of grain while the Load switch is in the AUTO position, the “OOG” timer

automatically shuts off the dryer after the period of time preset on the timer.

3. Fan Delay: (Default setting - 3 seconds) The “Fan Delay” timer controls the amount of time between

each fan startup to reduce the dryer inrush amperage.

4. Unload Delay: (Default setting - 1 minute) The “Unload Delay” timer is used to regulate the amount

of time the unload auger runs after the metering rolls stop.

5. Cool Down: (Default setting - zero minutes) The dryer fans will operate for a “Cool Down” period in

the event that the dryer experiences a shutdown, other than that of a plenum, grain high temperature

or fan motor overload situation. The dryer can also be restarted by pressing the “Start” button on

the front of the Vision control panel. This prevents the fans from shutting down because of

nuisance warnings.

To change a timer setpoint, touch the button of the timer you wish to modify. The “Modifying Timer

Setpoint” screen will then be displayed, which is shown in Figure 5C on Page 21. T he left nu mber pad is

used to modify the minutes and the right number pad will modify the seconds. Touching the “Default”

button will automatically set the timer to the default setpoint for that timer. The “Accept” button will save

the displayed time as the setpoint. Choosing “Cancel” will exit the “Modifying Timer Setpoint” screen

without saving any changes and the timer will stay at the currently saved setpoint.

20 PNEG-1743 Vision for Tower Dryers

Page 21

5. Operations

Figure 5C

Temp Button

To adjust the temperature setpoints, touch the button at the bottom of the “Default Operation

Screen”. A new screen will appear called the “Select Temperature Setpoint to Modify” screen.

(See Figure 5D.)

Figure 5D

PNEG-1743 Vision for Tower Dryers 21

Page 22

5. Operations

Modify the setpoint for each of the temperatures by selecting the corresponding button.

Plenum Temperature Setpoint - Press the “Plenum X Temp” button to change the individual

plenum setpoints. The “X” refers to a number between 1 and 6. Plenum #1 refers to the heater closest

to the ground.

Grain Temperature Setpoint - This setpoint is used for all temperature based moisture control

schemes. For more information, see the Moisture Control Options Chapter on Page 35.

The plenum temperature setpoint range is 50 F-250 F. The current temperature setpoint is displayed next

to the corresponding “Plenum” button.

The grain temperature setpoint range is 50 F-160 F. The current temperature setpoint is displayed next to

the “Grain Temperature” button.

Touch the desired plenum button of the setpoint you wish to change. The “Modifying Temperature

Setpoint” screen will appear. (See Figure 5E.)

Figure 5E

Enter the desired temperature using the displayed number pad, t hen touch the “Accept” button. Touch ing

the “Cancel” button will return you to the “Select Temperature Setpoint to Modify” screen without

saving changes.

22 PNEG-1743 Vision for Tower Dryers

Page 23

5. Operations

Setup Button

The Setup screen will allow you to configure other parameters of the dryer. To access the “Select

Hardware Setup Parameter to Modify” screen, also known as the “Setup Screen”, touch the

button. (See Figure 5F.)

Figure 5F

The following list can be modified:

1. Drying Mode: The button will display the “Drying Mode Selection” window.

Select continuous flow. A check mark is displayed next to the currently selected drying mode.

(See Figure 5G.)

Figure 5G

PNEG-1743 Vision for Tower Dryers 23

Page 24

5. Operations

2. Moisture Control Setup: The moisture control setup operations are described in

greater detail in the Moisture Control Options Chapter on Page 35.

Figure 5H

3. Unload Parameters:

a. Set Maximum Unload Rate: The meter roll speed set point cannot be set higher than this value.

This prevents choking downstream augers.

b. Set Minimum Unload Rate: The meter roll speed setpoint cannot be set lower than this value.

(See Figure 5I.)

Figure 5I

24 PNEG-1743 Vision for Tower Dryers

Page 25

5. Operations

4. Plenum Temp Manager: This will reduce the plenum temperature setpoint(s) if the

unload rate reaches its maximum allowable value for the time specified by the “Time Between Steps”

menu. Once the time has been exceeded, the dryer will reduce the temperature setpoint(s) by the

value given in the “Size of Temperature Step”. If the unload rate falls below the maximum allowable

value for the “Time Between Steps” period, the temperature setpoint(s) will be increased by the “Size

of Temperature Steps” until the original setpoints are met. (See Figure 5J.)

NOTE: Default setting is “OFF”.

Figure 5J

5.

Calibrate Moisture Sensor:

There are two (2) moisture/temperature sensors per

dryer - one for incoming grain (wet) and another for outgoing (dry). Each device has one moisture

and one temperature sensor included. (See Figure 5K.)

Figure 5K

PNEG-1743 Vision for Tower Dryers 25

Page 26

5. Operations

Calibrating moisture: Take several moisture samples of the grain over an extended period of

time, average these values and calibrate the sensors accordingly.

Example: If the dryer’s exiting moisture (dry) is reported at 15.5% on the Vision screen and the

averaged samples yielded a value of 15%, then the calibration screen would be used to enter

-0.5% as the “Dry Moist Offset”.

Calibrating temperature: Take several temperature samples of the grain over an extended

period of time, average these values and calibrate the sensor accordingly.

Example: If the dryer’s incoming temperature (wet) is reported to be 105°F on the Vision scree n

and the average samples yield a value of 100°F, adjust the “Dry Temp” to -5.

6.

Extended Setup Screen

The following list can be modified here:

1. Diagnostics:

Figure 5L

Check Light Outputs: Allow the user to verify the controller is attempting to illuminate each

individual switch. If there is a check mark present on the Vision screen, the corresponding

switch should be lit. If not, there is a wiring issue.

Check Switch Wiring: Allows user to verify the controller is recognizing switch positions

correctly. If the “Fan 1” switch is in the “AUTO” position, the “FAN 1 AUTO” box should be

checked. If not, there is a wiring issue.

Setup Metering Rolls: This option can be used to calibrate the SCR board.

Set MR Speed Via Screen: Normally, the meter roll adjustment knob on the control panel

is used to set the metering roll setpoint. In the event of a knob malfunction, the metering roll

setpoint can be adjusted by this screen.

Calibrate Moisture Sensors: Previously mentioned in the preceding “Setup Screen”

section on Page 23. This is just another way to access those settings.

26 PNEG-1743 Vision for Tower Dryers

Page 27

5. Operations

2. Differential: The button will display the “Modifying Burner Differential Settings”

screen. (See Figure 5M.) Adjusting the burner differential settings allo ws the operator to keep

the plenum temperature within a certain range.

NOTE: 1° is the default and preferred setting.

Figure 5M

Example: If you have the temperature setpoint at 180°F and you select +/- 3° as the burner

differential, then the burner will switch to low heat at 183°F and back to high heat at 177°F.

To modify a burner differential setting, touch the plenum button you wish to modify, then

select one of the five (5) differential setting buttons on the right side of the screen. The

“Accept/Exit” button will save the settings and return to the “Setup Screen”.

3. BPH Calibration: The button will display the “Unload Bushels Setup” screen.

(See Figure 5N.) The bushel counter can be cleared by touching the “Clear” button. The bushel

counter can be calibrated by touching the “Increase” and “Decrease” buttons.

Figure 5N

PNEG-1743 Vision for Tower Dryers 27

Page 28

5. Operations

4. Set Time/Date: The button will display the “Set Time/Date” window.

(See Figure 5O.)

Use the “Up” and “Down” buttons to change each of the parameters. “Accept/Exit” will save

settings and return to the “Setup Screen”.

Figure 5O

5. Temp Scale: The button allows the user to select either English units or SI units.

Depending on what temperature scale you are now operating, this button will display a

pop-up window asking if you want to switch to SI (Celsius, metric tons, etc.) or English units

(Fahrenheit, bushels, etc.).

6. Dryer Model: This button will display the “Dryer Hardware Setup” window.

The following items must be entered correctly:

a. Number of Fans

b. Fuel

c. Model Number

Figure 5P

To edit these parameters, touch the “Select” button until a check mark appears next to the

corresponding detail specific to the dryer model.

28 PNEG-1743 Vision for Tower Dryers

Page 29

5. Operations

7. Data Logger Setup: By turning the data logger on, it records the following

parameters of the dryer every 5 minutes.

a. Dryer grain temperature

b. Incoming grain temperature

c. Incoming grain moisture

d. Outgoing grain temperature

e. Outgoing grain moisture

f. Meter roll speed

g. Bin number

h. Hour

i. Minute

Figure 5Q

Looking Up Data Logger Records

1. Go to our website (www.grainsystems.com) and click on the “GRAIN DRYER VISION

CONTROL” link at the right side of the page.

2. Download the “LOGVIEWER INSTALLER” at the top right of the page to the desktop.

3. Execute the “LOGVIEWER SETUP” file and install the program.

4. Open the “Dryer Data Logviewer” program.

5. Navigate the menu to “File” -> “Open”. Select the log file that was downloaded

from Vision.

6. Data can be exported to an Excel spreadsheet by “File” -> “Export to spreadsheet file”.

PNEG-1743 Vision for Tower Dryers 29

Page 30

5. Operations

8. User Saved Defaults: Here, you have the following options:

Save Settings: Allows user to store the current setup of the dryer for retrieval later.

Restore Settings: Restores the system to the settings last saved by pressing the “Save

Settings” button.

View Button

Choose the button to open the “View Selection Window”. (See Figure 5R.) The following six (6)

options are displayed:

Figure 5R

1. Table View: This is the “Default Operation Screen”. (See Figure 5S.)

Figure 5S

30 PNEG-1743 Vision for Tower Dryers

Page 31

5. Operations

Select Data Log Sample Time

Notice the “Sample Time” button in the upper left hand side of the dryer status chart. By touching this

button, the sample time can be changed from the default (1 minute) to 5, 10 or 15 minutes. Select the

desired sample time and touch “Accept/Exit” to exit. Also, notice that the chart can be cleared by selecting

the “Clear Table” button at the bottom. (See Figure 5T.)

Figure 5T

2. Graph View: This is the “Optional Operation Screen”. (See Figure 5U.)

Figure 5U

To initiate this option, press the “Graph View” button, then touch the “Exit” button. Notice that the

Dryer Status Chart and Plenum(s) sections have been replaced by the graph view. You can choose

what the graph will display by touching any of the colored buttons under the graph (i.e. moisture in,

moisture out, dryer temperature, grain temperature in, grain temperature out and meter rolls).

Touching these buttons once will display them on the graph and touching them again will remove

them. The “Setup” button will bring up the “Graph Setup” window and allow you to choose the length

of time (1, 2, 4 or 8 hours) for the horizontal scale.

PNEG-1743 Vision for Tower Dryers 31

Page 32

5. Operations

3. Owner’s Manual:

This manual can be viewed on the Vision display screen. To view a manual, touch the “View” button.

When the “View Selection Window” appears, choose the “Owner’s Manual” button. A new display will

appear called an “Explorer Window”. The “Explorer Window” will show the manuals that are stored

in the computer memory. To select a desired manual, “Double Tap” the corresponding manual icon,

much like double clicking a mouse on the computer. Once selected, it may take a few seconds for

the manual to be displayed. Once the manual is displayed, use the scroll bars on the right to scroll

through the pages. To exit the manual and return to the Default Operation Screen, touch the

“X” button in the upper right hand corner of the screen.

4. Error History: shows the Dryer Shutdown History.

Viewing the Dryer Shutdown History

The dryer will keep track of all safety shutdown warnings. To view the “Shutdown History”, select

the “View” button. When the “View Selection Window” appears, touch the “History” button. A new

window called “Shutdown History” will appear. (See Figure 5V.) A list of all shutdown warnings

are listed. This list can be sorted by:

a. Warning

b. Date/Time

c. Node

Figure 5V

The whole list can be copied to a USB flash drive and transferred to a personal computer as a

text file by pressing the “Copy To USB Flash Card” button.

The list can also be cleared to start a new list by selecting the “Clear History” button.

To return to the “Default Operations Screen”, touch the “Exit” button.

5. System Information: Touching button will display the current software version the

dryer is running and the time and date.

32 PNEG-1743 Vision for Tower Dryers

Page 33

5. Operations

6. Software Version Info: This option will list the major software changes and

additions in relation to the last software release.

Figure 5W

M/C Button

The button is used to change setpoints for the moisture controls. Pressing the button will

access one of the following two (2) screens, depending on the drying scheme selected.

Modifying Temperature Setpoint

Figure 5X

PNEG-1743 Vision for Tower Dryers 33

Page 34

5. Operations

Modifying Moisture Setpoint

Figure 5Y

Resetting Factory Defaults

If the Vision system starts malfunctioning, sometimes restoring the factory defaults will alleviate

the problem.

NOTE: This will completely change the system setup, so this procedure is encouraged to be performed

by a service technician.

1. Turn control power “OFF”.

2. Locate the “DEF” dipswitch on the Display I/O board.

3. Push the switch to the left.

4. Turn control power “ON” and make sure the red light next to the “DEF” switch is lit.

5. At the “Boot Screen”, press “Start Dryer”.

6. Once a message appears instructing you to push the switch back to the left, the setting has

been reset.

7. Turn control power “OFF”.

8. Push the “DEF” dipswitch to the right.

9. The Vision system is now ready to operate normally.

34 PNEG-1743 Vision for Tower Dryers

Page 35

6. Moisture Control Options

Control Scheme

Control Parameter

Drying Mode

Continuous

Flow

Temperature Moisture

Variable 5 Speed5 Speed2 Speed

Moisture Control Options

Moisture Control is used to regulate the moisture of the outgoing grain. For example, if a user is drying

corn, the desired moisture content of the dried corn is usually around fifteen percent (15%). The moisture

control schemes are designed to achieve that value with minimal effort from the user.

Continuous Flow Drying

There are two (2) parameters the dryer can monitor to adjust Continuous Flow operation in an attempt to

have consistent outgoing moisture: Temperature and Moisture. When we say “Adjust Continuous Flow

Operation”, this means changing the unload rate of the dryer. By varying the unload rate, this changes the

amount of time the grain stays in the drying chamber. This results in heating the grain more or less,

depending on whether the unload rate is increased or decreased.

The following is a depiction of how the Continuous Flow modes break down.

Temperature Controlled Schemes

The temperature controlled schemes use the grain temperature sensors as a reference parameter. As the

grain temperature varies, the controls adjust the unload rate accordingly.

For example, we will assume a grain temperature setpoint of 105°. If the grain temperature sensor on

the dryer is reporting 110°, the grain is 5° hotter than we would like it to be. To adjust the operation,

the control scheme would realize the grain is getting too hot and increase the speed of the unload to

lessen the amount of time the grain is exposed to the heating chamber. The opposite is true if the grain

temperature sensor on the dryer reports lower than the setpoint. The unload rate would decrease. This

means the grain temperature is directly proportional to the unload rate. If the grain temperature rises, the

unload rate should increase.

The temperature controlled schemes have an exclusive option available for drying rice. This option is

available in the two (2) temperature modes by switching the “COMP” dipswitch on the Display I/O board.

The only change in the 2 Speed and 5 Speed temperatur e modes when drying rice is instead of monitoring

the four (4) temperature sensors located at the 60% point of the column, it monitors the temperature

sensor at the discharge. This allows the kernel temperature to stay at or below a set temperature with

a kernel temp shutdown alarm during multiple pass drying common in rice. This is an exclusive

GSI Group feature.

PNEG-1743 Vision for Tower Dryers 35

Page 36

6. Moisture Control Options

2 Speed Temperature

When to Use:

For use when good management is available and a quick reacting time is desired in all heat or dry and

cool operation.

How it Works:

The user should stabilize the dryer with the Unload switch in the “MANUAL” position. It is imperative

that the dryer is outputting the desired moisture content grain before switching the unload to the

“AUTO” position.

The user specifies two (2) desired meter roll speeds (Low and High) and a grain temperature setpoint for

this scheme. If the grain temperature sensors on the dryer report a temperature 1° above the setpoint, the

dryer will select the fastest unload rate (High). If the sensor reads 1° below the setpoint, the controller will

run at the slower speed (Low).

There is also an “ON/OFF” option associated with the 2 Speed. The user only specifies one unload rate

(ON) and the controller knows the other speed is zero (OFF). If the temperature sensor reads 1° above

the setpoint, the metering rolls will run at the “ON” speed. The metering rolls are turned OFF if the

temperature falls below the setpoint.

NOTE: A “Max Grain Temp” is ava ilable for this scheme. By enabling this feature, the dryer will shutdown

and issue a warning if the grain temperature exceeds the “Max Grain Temp” value.

Setup Procedure

1. Press the “Stop” button on the control panel if the dryer is running.

2. From the “Setup” screen, select “Drying Mode”, then “Continuous Flow”.

3. From the “Drying Mode Selection” screen, select “M/C Setup” to access “Continuous Flow Setup”.

4. Select “Temperature” from the “Continuous Flow Control Schemes” group.

5. If desired, enable the “Max Grain Temp” safety.

6. Select “2 Speed” from the “Temp Based Options” group.

7. Press the “Accept” button and return to the “Default Operation Screen”.

8. Press the “Meter Roll Speed” adjustment knob to access the “Modifying Meter Roll Speed

Setpoints” screen.

9. If the “ON/OFF” option is desired, verify the “ON/OFF” check box at the top right of the window is

selected. If “ON/OFF” is not desired, make sure the “2 Speed” check box is selected.

10. Press the “Meter Roll Speed” adjustment knob until the “HIGH SP” bar is colored red. Adjust the

“HIGH SP” by turning the knob until the desired setpoint is reached.

11. If “ON/OFF” is selected, skip to the next step. Depress the knob until the “LOW SP” bar is colored

red. Turn the knob until the setpoint is attained.

12. Press “Accept/Exit”.

13. From the “Default Operation Screen”, press the “M/C” button and enter a grain temperature setpoint.

14. Turn the “Unload” switch to the “AUTO” position.

15. Press the “Start” button on the control panel.

36 PNEG-1743 Vision for Tower Dryers

Page 37

6. Moisture Control Options

5 Speed Temperature

When to Use:

For use with a wider moisture variation spread and for when a close and quick reacting moisture control

is desired in all heat or dry and cool operation.

How it Works:

The user should stabilize the dryer with the Unload switch in the “MANUAL” position. It is imperative

that the dryer is outputting the desired moisture content grain before switching the unload to the

“AUTO” position.

There are five Speeds associated with this drying scheme, but the user only selects one unload rate.

The meter roll setpoint is used as the middle or medium speed. The other four Speeds are offsets of the

medium speed, two higher and two lower. These offsets are labeled as follows: Low (LO), Medium-Low

(M-LO), Medium (MED), Medium-High (M-HI) and High (HI). The unload rate is determined by the

difference between the grain temperature setpoint and the actual temperature sensor reading. If the

reading is exactly that of our temperature setpoint (a zero offset), MED would be selected, because

we are at the correct speed.

When setting up the 5 Speed Temperature scheme, there are two (2) sets of parameters: “Inner” and

“Outer”. Both have a temperature and a meter roll speed associated with them. “Inner” refers to the M-LO

and M-HI speeds, while “Outer” refers to LO and HI.

Let’s pretend we have the parameters set as they are presented in the following table.

Inner (M-LO and M-HI) Outer (LO and HI)

Temperature 1° 3°

Meter Speed Offset 3% 12%

We will set the meter roll setpoint to 50% and grain temperature setpoint to 100° for convenience. If the

grain temperature actually is 100°, the MED unload would be selected (50% in our example). Should the

grain temperature climb to 101°, the controller will change to M-HI , which increases the unload rate by 3%.

Now the dryer’s unload is running at 53% (50% + 3% = 53%). If the grain temperature continu es to climb,

reaching 103°, HI will be selected which increases the unload rate by 12%. This 12% increase is in relation

to the MED speed, NOT the M-HI, so the unload rate is now at 62% (50% + 12% = 62%). If the grain

temperature falls back below 105°, the controller changes back to M-HI.

The same is true for grain temperatures below the setpoint, only the values are subtracted rather than

added. If the grain temperature falls to 99°, the controller will select M-LO, changing the unload rate to

47% (50% - 3% = 47%).

The following table depicts how the controller would act when setup as the example above.

LO (Outer) M-LO (Inner) MED M-HI (Inner) HI (Outer)

Grain

Temperature

Less than or

equal to 97°

Between 98°

and 99°

At 100°

Between 101°

and 102°

Greater than or

equal to 103°

Unload Rate 38% 47% 50% 53% 62%

NOTE: These are not necessarily the values that should be used with this scheme; these numbers were

chosen strictly for explanation purposes.

PNEG-1743 Vision for Tower Dryers 37

Page 38

6. Moisture Control Options

This scheme also has a feature called “Auto-Centering”. If the controller is staying in HI the majority of the

time, it probably means the metering roll setpoint (MED) is set too low. To alleviate this problem, the unload

rate is continually averaged. Once an hour, the controller changes the metering roll setpoint (MED) to the

averaged value. In the example above, if the controller stayed in HI for an entire hour, it would change the

metering roll setpoint to 62% and would now act according to the table below.

LO (Outer) M-LO (Inner) MED M-HI (Inner) HI (Outer)

Grain

Temperature

Unload Rate 50% 59% 62% 65% 74%

Less than or

equal to 97°

Between 98°

and 99°

At 100°

Between 101°

and 102°

Greater than or

equal to 103°

NOTE: A “Max Grain Temp” safety is available for this scheme. By enabling this feature, the dryer will

shutdown and issue a warning if the grain temperature exceeds the “Max Grain Temp” value.

Setup procedure

1. Press the “Stop” button on the control panel if the dryer is running.

2. From the “Setup” screen, select “Drying Mode”, then “Continuous Flow”.

3. From the “Drying Mode Selection” screen, select “M/C Setup” to access “Continuous Flow Setup”.

4. Select “Temperature” from the “Continuous Flow Control Schemes” group.

5. If desired, enable the “Max Grain Temp” safety.

6. Select “5 Speed” from the “Temp Based Options” group.

7. If Auto-Centering is desired, select “Auto-Centering” from the “5 Speed Setup” group until the

“Enabled” box is checked.

8. Select “5 Speed Setup” from the “5 Speed Setup” group.

9. Press the “Select” button until “Positive Inner Limit” is circled in red.

10. Use the “Inc” and “Dec” buttons on the left to adjust the “Temperature” offset for the “Inner” set.

11. Use the

“Inc” and “Dec”

buttons on the right to adjust the “Metering Speed” offset of the “Inner” set.

12. Press the “Select” button until the “Positive Outer Limit” is circled in red.

13. Use the “Inc” and “Dec” buttons on the left to adjust the “Temperature” offset for the “Outer” set.

14. Use the

“Inc” and “Dec”

buttons on the right to adjust the “Metering Speed” offset of the “Outer” set.

15. Return to the “Default Operation Screen”.

16. Press the “Meter Roll Speed” adjustment knob to access the “Modifying Meter Roll Speed

Setpoints” screen.

17. Adjust the meter roll speed to the desired setpoint and press “Accept/Exit”.

18. Return to the “Default Operation Screen”.

19. Press the “M/C” button and enter a grain temperature setpoint.

20. Turn the “Unload” switch to the “AUTO” position.

21. Press the “Start” button on the control panel.

38 PNEG-1743 Vision for Tower Dryers

Page 39

6. Moisture Control Options

Moisture Controlled Schemes

The moisture controlled schemes use the exiting moisture sensor as a reference parameter. As the grain

moisture content varies, the controls adjust the unload rate accordingly.

For example, our outgoing (dry) moisture setpoint will be set at 15%. If the outgoing moisture sensor

reports a reading of 16%, the grain is 1% wetter than we desire. To account for this, we decrease the

unload rate, therefore increasing the amount of time the grain is in the heating chamb er. The relationship

between moisture and unload rate is inversely proportional. As the exiting moisture increa ses, the unload

rate should decrease.

5 Speed Moisture

When to Use:

For use with a wider moisture variation spread and for when a moderate reacting moisture control is

desired in all heat operation. Not recommended for dry and cool operation.

How it Works:

The user should stabilize the dryer with the Unload switch in the “M ANUAL” position. It is imperative that the

dryer is outputting the desired moisture content grain before switching the unload to the “AUTO” position.

There are five Speeds associated with this drying scheme, but the user only selects one un load rate. The

meter roll setpoint is used as the middle or medium speed. The other four Speeds are offsets of the medium

speed, two higher and two lower. These offsets are labeled as follows:

Medium (MED), Medium-High (M-HI) and High (HI)

. The unload rate is determined by the difference

between the moisture setpoint and the actual moisture sensor reading. If the reading is exactly that of our

moisture setpoint (a zero offset), MED would be selected, because we must be at the correct speed.

Low (LO), Medium-Low (M-LO),

When setting up the 5 Speed Moisture scheme, there are two (2) sets of parameters: “Inner” and “Outer”.

Both have a moisture and meter roll speed associated with them. “Inner” refers to the M-LO and M-HI

speeds, while “Outer” refers to LO and HI.

Let’s pretend we have the parameters set as they are presented in the following table.

Inner (M-LO and M-HI) Outer (LO and HI)

Moisture 0.2% 0.5%

Meter Speed Offset 3% 12%

We will set the meter roll setpoint to 50% and the dry grain moisture setpoint to 15% for convenience.

If the dry grain moisture is actually 15%, the MED unload would be selected (50% in our example). Should

the dry grain moisture climb to 15.2%, the controller would change to

M-HI

, which increases the unload rate

by 3%. Now the dryer’s unload is running at 53% (50% + 3% = 53%). If the dry grain moisture continues

to climb, reaching 15.5%, HI will be selected which increases the unloa d ra te by 12%. This 12% increase

is in relation to the MED speed, NOT the

the dry grain moisture falls back below 15.5%, the controller changes back to

M-HI

, so the unload rate is now at 62% (50% + 12% = 62%). If

M-LO

.

The same is true for dry grain moistures below the setpoint, only the values are subtracted rather than

added. If the dry grain moisture falls to 14.8%, the controller will select M-LO, changing the unload rate

to 47% (50% - 3% = 47%).

The following table depicts how the controller would act when setup as the example above.

LO (Outer) M-LO (Inner) MED M-HI (Inner) HI (Outer)

Grain

Temperature

Unload Rate 38% 47% 50% 53% 62%

Less than or

equal to 14.5%

Between 14.6%

and 14.8%

Between 14.9%

and 15.1%

Between 15.2%

and 15.4%

Greater than or

equal to 15.5%

NOTE: These are not necessarily the values that should be used with this scheme; these numbers were

chosen strictly for explanation purposes.

PNEG-1743 Vision for Tower Dryers 39

Page 40

6. Moisture Control Options

This scheme also has a feature called “Auto-Centering”. If the controller is staying in HI the majority of

the time, it probably means the metering roll setpoint (MED) is set too low. To alleviate this problem,

the unload rate is continually averaged. Once an hour, the controller changes the metering roll setpoint

(MED) to the whatever the averaged value. So in the example above, if the controller stayed in HI for an

entire hour, it would change the metering roll setpoint to 70% and would now act according to the

table below.

LO (Outer) M-LO (Inner) MED M-HI (Inner) HI (Outer)

Grain

Temperature

Unload Rate 50% 59% 62% 65% 74%

Less than or

equal to 14.5%

Between 14.6%

and 14.8%

Between 14.9%

and 15.1%

Between 15.2%

and 15.4%

Greater than or

equal to 15.5%

NOTE: A “Max Grain Temp” safety is available for this scheme. By enabling this feature, the dryer will

shutdown and issue a warning if the grain temperature exceeds the “Max Grain Temp” value.

Setup Procedure

1. Press the “Stop” button on the control panel if the dryer is running.

2. From the “Setup” screen, select “Drying Mode”, then “Continuous Flow”.

3. From the “Drying Mode Selection” screen, select “M/C Setup” to access “Continuous Flow Setup”.

4. Select “Moisture” from the “Continuous Flow Control Schemes” group.

5. If desired, enable the “Max Grain Temp” safety.

6. Select “5 Speed” from the “Moisture Based Options” group.

7. If Auto-Centering is desired, select “Auto-Centering” from the “5 Speed Setup” group until the

“Enabled” box is checked.

8. Select “5 Speed Setup” from the “5 Speed Setup” group.

9. Press the “Select” button until “Positive Inner Limit” is circled in red.

10. Use the “Inc” and “Dec” buttons on the left to adjust the “Moisture” offset for the “Inner” set.

11. Use the

“Inc” and “Dec”

buttons on the right to adjust the “Metering Speed” offset of the “Inner” set.

12. Press the “Select” button until the “Positive Outer Limit” is circled in red.

13. Use the “Inc” and “Dec” buttons on the left to adjust the “Moisture” offset for the “Outer” set.

14. Use the “Inc” and “Dec” buttons on the right to adjust the “Metering Speed” offset of the “Outer” set.

15. Return to the “Default Operation Screen”.

16. Press the “Meter Roll Speed” adjustment knob to access the “Modifying Meter Roll Speed

Setpoints” screen.

17. Adjust the meter roll speed to the desired setpoint and press “Accept/Exit”.

18. Return to the “Default Operation Screen”.

19. Press the “M/C” button and enter a dry grain moisture setpoint.

20. Turn the “Unload” switch to the “AUTO” position.

21. Press the “Start” button on the control panel.

40 PNEG-1743 Vision for Tower Dryers

Page 41

6. Moisture Control Options

Variable Moisture

When to Use:

For use when minimum moisture management is available and when large, quick changes in moisture are

not expected. Can be used during all heat and dry and cool operation.

How it Works:

The user should stabilize the dryer with the Unload switch in the “MANUAL” position. It is imp erative that

the dryer is outputting the desired moisture content grain before switching the unload to the “AUTO”

position. Within one minute of switching the unload to “AUTO”, the dryer uses the current state of the

sensors as a reference for future adjustments. The dryer will then run through a 30 minutes learning period

and controller adjustments will begin after.

The controller continuously monitors the moisture coming in and out of the dryer and the column grain

temperature 2/3 of the way down the dryer. The control action is mainly based on the dry moisture sensor

at the outlet of the dryer. If the moisture coming out of the dryer is not right at the target, the controller will

speed up or slow down the unload rate accordingly. The wet moisture sensor and the grain temperature

sensor are intended to detect moisture spikes coming into the dryer so that the moisture controller can

react ahead of time. For example, if the wet sensor detects a jump of moisture coming into the dryer, the

controller will start slowing down the unload speed immediately. However, the controller does not act to

the full scale right away. Instead, it slows down the dryer gradually so that the grain currently in the dryer

will not be over-dried.

NOTE: The wet moisture sensor can be disabled in this scheme. The wet moisture reading reported will

be ignored by the calculations.

NOTE: A “Max Grain Temp” safety is available for this scheme. By enabling this feature, the dryer will

shutdown and issue a warning if the grain temperature exceeds the “Max Grain Temp” value.

Setup Procedure

1. Press the “Stop” button on the control panel if the dryer is running.

2. From the “Setup” screen, select “Drying Mode”, then “Continuous Flow”.

3. From the “Drying Mode Selection” screen, select “M/C Setup” to access “Continuous Flow Setup”.

4. Select “Moisture” from the “Continuous Flow Control Schemes” group.

5. If desired, enable the “Max Grain Temp” safety.

6. Select “Variable” from the “Moisture Based Options” group.

7. If desired, enable/disable the “Upper Moisture Sensor”.

8. Return to the “Default Operation Screen”.

9. Turn the “Unload” switch to the “MANUAL” position.

10. Press the “Start” button on the control panel.

11. Press the “Meter Roll Speed” adjustment knob to access the “Modifying Meter Roll Speed

Setpoints” screen.

12. Adjust to desired speed and press “Accept/Exit”.

13. Wait at least 30 minutes, depending on the size of the dryer and check for consistent dry moisture.

If moisture is not consistent, repeat Steps 11 and 12.

14. If you have made it here, the grain must be exiting consistently. If not, return to Step 11.

15. Turn the “Unload” switch to the “AUTO” position.

PNEG-1743 Vision for Tower Dryers 41

Page 42

7. Initial Settings Check

Dealer Suggested Initial Settings Check

1. Power on using the Control Power switch. Wait approximately 30 seconds.

2. Now viewing the “Boot Screen”, select “Start Dryer”.

3. Setup timers.

4. Using the “Extended Setup Screen”, select the following options to configure the dryer. Please use

Operations Chapter on Page 19 as a reference guide.

a. “Dryer Model” and check and verify the following parameters:

• Number of Fans

• Fuel

• Model Number

b. Set date and time settings.

c. Set temp scale settings.

d. Set data logger settings.

5. Using the “Setup Screen”, select the following options to configure the dryer. Please use Operations

Chapter on Page 19 as a reference guide.

a. Set unload parameters settings.

b. Check burner mode settings.

c. Moisture control setup. (Refer to Moisture Control Options Chapter on Page 35 for detailed

operation descriptions.)

Owner Suggested Initial Settings Check

1. Power on using the Control Power switch. Wait approximately 30 seconds.

2. Now viewing the “Boot Screen”, select “Start Dryer”.

3. Using the “Setup Screen”, select the following options to configure the dryer. Please use

Operations Chapter on Page 19 as a reference guide.

a. Set drying mode settings.

b. Select moisture control setup. (Refer to Moisture Control Options Chapter on Page 35 for detailed

operation descriptions.)

4. Set switches appropriately on the control panel.

5. Select the “Start” button on the control panel.

42 PNEG-1743 Vision for Tower Dryers

Page 43

8. Safety Circuit Shutdown Messages

In the event of a dryer malfunction, the following error screen will appear:

Figure 8A

After you press the “Help” button, the “Shutdown Help File”, shown in Figure 8A, is displayed. It will display

a picture of the part that may have caused the shutdown, along with a reason for the error.

Fan/Heater Shutdown Messages

“X” represents a number between 1 and 6 in the following message names. Fan/Heater #1 is closest to

the ground and the numbers increase as you move upwards.

0201 - Fan #X Motor Overload

This message indicates that the thermal overloads on either the fan, load, unload or auxiliary motors have

opened, indicating an over current condition. The overloads must be manually reset. The message will

identify which fan overload caused the shutdown.

0202 - Burner #X Housing Temp High-Limit

This error indicates that the temperature high-limit locate on the fan/burner housing opened, indicating an

over temperature condition occurred towards the rear of the fan/heater housing. This control is set at

210°F (99°C) and automatically resets itself when cooled. This can be caused by a grain column plugged

with trash or the meter rolls may be adjusted to run too slowly. Feel the grain columns to determine which

one may be causing the problems. If all the columns are hot to the touch, check the meter roll set tings. If

all columns are not hot, examine the column that feels the hottest. Make sure you can see the grain moving

down the column screens.

PNEG-1743 Vision for Tower Dryers 43

Page 44

8. Safety Circuit Shutdown Messages

0203 - Burner #X Vapor Temp High-Limit

This message indicates that the LP gas vapor temperature sensor located in the gas pipe train

downstream from the vaporizer has opened, indicating that the vaporizer is running too hot and must be

readjusted. This sensor is set at 200°F (93°C) and automatically resets itself when cooled. The message

will identify which burner caused the shutdown. Try adjusting the vaporizer coils farther away from the

burner’s flame. You may also want to try switching the burner mode from High/Low to ON/OFF, especially

on warmer days.

0204 - Burner #X Plenum Overheat

This message indicates that an over-temperature condition occurred inside the dryer plenum. This control

is a 300°F (149°C) limit and automatically resets itself when cooled. The message will identify which

plenum caused the shutdown.

0205 - Burner #X Grain Overheat

A grain high-limit sensor runs through the center of the columns of each module. The safety is tied to the

lowest fan/heater on that module. If the sensor reaches 210°F, it will open, shutting down the dryer. There

could possibly be a plugged column.

0206 - Burner #X Gas Pressure High-Limit

A gas over-pressure switch is placed on the high side of the gas re gulator. If the gas pressure exceeds a

certain value, the dryer will shutdown. This is not standard on all dryers.

0207 - Burner #X Lost Airflow

This error message is displayed when airflow (air pressure) has been established but was subsequently

lost. This could happen if, during the dryer’s operation, the grain settled or if grain shrinkage occurred in

the grain columns, thereby causing a loss of air pressure in the plenum chamber.

0208 - Burner #X No Airflow

Contacts in the air switch failed to open due to the fan not turning or the air switch may nee d adjustment.

The message will identify which fan caused the shutdown.

0209 - Burner #X Ignition Failure

This condition occurs during the initial ignition of the burner. If the burner fails to light, check to make sure

that the gas has been turned ON and/or the Maxon valve has been turned ON.

020A - Burner #X Lost Flame Detection

The flame sensor failed to detect a burner flame which had been established but was lost subsequently

and there is a problem with the flame sensing circuitry or the dryer is not getting burner fuel. The message

will identify which burner caused the shutdown.

020B - Burner #X Plenum Overheat (Thermistor)

This message indicates that an over-temperature condition occurred inside the dryer plenum. This control

is a 300°F (149°C) limit and automatically resets itself when cooled. The message will identify which

plenum caused the shutdown.

44 PNEG-1743 Vision for Tower Dryers

Page 45

8. Safety Circuit Shutdown Messages

020C - Burner #X Grain Overheat (Thermistor)

This error indicates that an over-temperature condition has occurred in one of the grain columns causing

the control to shutdown the dryer. This control is set at 210°F (99°C) and automatically resets itself when

cooled. This can be caused by a grain column plugged with trash or the meter rolls may be adjusted to run

too slowly. Feel the grain columns to determine which one may be causing the malfunction. If all the

columns are hot to the touch, check the meter roll settings. If all columns are not hot, examine the column

that feels the hottest. Make sure you can see the grain moving down the column screens.

020D - Plenum #X Temperature Sensor Shorted

This error indicates there is a shorted condition with one of the grain temperature sensors located inside

the left or right grain columns. This could be a shorted sensor or the sensor wires could be shorted.

020E - Plenum #X Temperature Sensor Open

This error indicates there is an open condition with the plenum temperature sensor located inside the

plenum chamber. This could be an open sensor or the sensor wires could have an open connection.

020F - Grain #X Temperature Sensor Shorted

This error indicates there is a shorted condition with one of the grain temperature sensors located inside

the left or right grain columns. This could be a shorted sensor or the sensor wires could be shorted.

0210 - Grain #X Temperature Sensor Open

This error indicates there is an open condition with the grain temperature sensor located inside the plenum

chamber. This could be an open sensor or the sensor wires could have an open connection.

0211 - Fan #X Contactor did not Close

The auxiliary contactor on the fan contactor did not close when the fans were supposed to be started.

Could possibly be a bad contactor or some wiring is loose.

0212 - Fan #X had Airflow Before Fan Power

The air switch contacts have closed prior to the fan starting, indicating a freewheeling blade or improper

setting of the air switch. The message will identify which fan caused the shutdown. This indicates that

12 VDC has been lost to terminal J4-04 on the fan/heater board.

0213 - Fan #X Network Connection Failed

This error is generated whenever the fan/heater board has lost its communications link with the

Input/Output board (upper control panel) and the master display board (lower control panel). Check the

Ethernet cable jacks to make sure they are plugged in tightly.

0214 - Gas Pressure Low-Limit

Between the regulator and solenoids on the pipe train, there is a low limit pressure switch. This safety is

connected to the J4-02 terminal on Fan/Heater board. Loss of gas supply or improper limit adjustment

could cause this warning.

PNEG-1743 Vision for Tower Dryers 45

Page 46

8. Safety Circuit Shutdown Messages

Main I/O Shutdown Messages

0E01 - Main I/O - Primary Unload Motor Overload

This message indicates that the unload motor overload has been tripped in the upper control box. This

indicates that 12 VDC has been lost to terminal J1-02 on the Input/Ou tput board. Push the red button on

the overload to reset this error. This is caused by the motor operating under too much load, which uses

more current (amperage). If the problem continues, then check the motor to make sure it is not being

overworked. You may need to call an electrician to measure the motor’s full load amps (FLA).

0E02 - Main I/O - Primary Load Motor Overload

This message indicates that the motor overload has tripped on the load motor overload located in the