Page 1

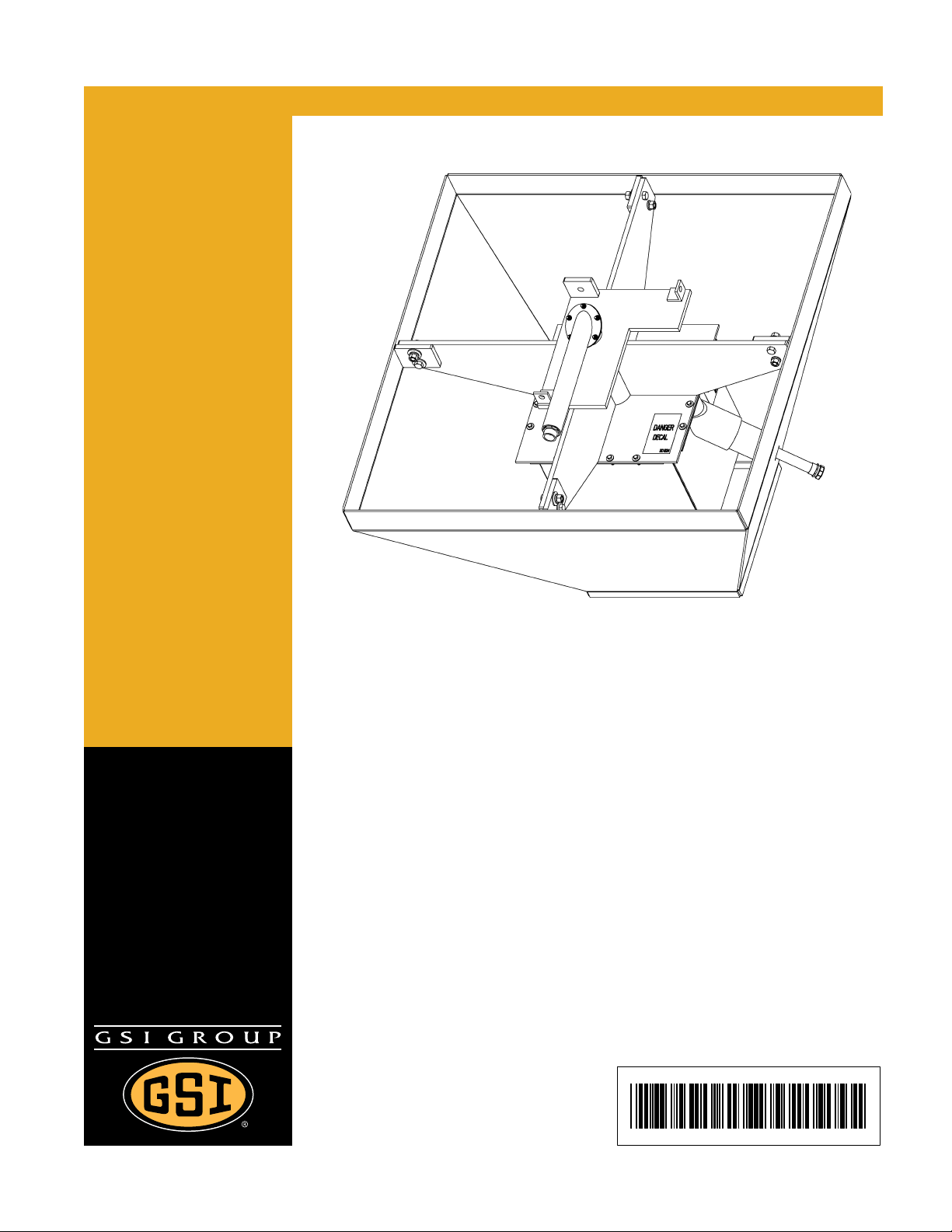

Series II Sweep Protected Cord

Slip Ring Sump

Installation Manual

PNEG-1722

Date: 12-07-09

PNEG-1 72 2

Page 2

2 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 3

Table of Contents

Contents

Chapter 1 Introduction ....................................................................................................................................... 4

Product Information ............................................................................................................................ 4

General Information ........................................................................................................................... 4

Capacities and Specifications ............................................................................................................ 4

Slip Ring Introduction ......................................................................................................................... 5

Chapter 2 Safety .................................................................................................................................................. 6

Safety Guidelines ... ... ... ... ................................................................................................................... 6

Safety Instructions ..................... ... .... .......................................... ... ... ... ... ............................................ 7

Operator Qualifications ....................................................................................... .... ... ... ... ................ 11

Chapter 3 Decals ............................................................................................................................................... 12

Chapter 4 Assembly ......................................................................................................................................... 14

Chapter 5 Start-up ............................................................................................................................................. 21

Preform Pre-start Checks .................................................... ... .... ... ... ................................................ 21

Chapter 6 Maintenance ..................................................................................................................................... 22

Maintain the Hopper ............................ ............................................. ................................................ 22

Slip Ring Maintenance ..................................................................................................................... 22

Chapter 7 Troubleshooting .............................................................................................................................. 26

Chapter 8 Parts List .......................................................................................................................................... 28

Components ..................................... ............................................. ................................................... 28

Slip Ring Replacement Parts ........................................................................................................... 30

Chapter 9 Warranty ........................................................................................................................................... 31

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 3

Page 4

1. Introduction

Product Information

1. The Series II Sweep hopper with collector ring includes the following components:

• Hopper

• Collector ring

• Center brace support

• Collector ring shield

NEVER enter a grain bin unless ALL power driven equipment has been shut

down. Disconnect and lock out power before entering the bin or servicing

the equipment.

General Information

1. GSI reserves the right to improve its product whenever possible and practical to do so. We reserve

the right to change, improve and modify products at any time without ob ligation to make changes,

improvements and modifications on equipment sold previously.

2. This new hopper with collector ring has been engineered and manufactured to give years of

dependable service. The care and maintenance of this equipment will affect the satisfaction and

service obtained. By following the instructions and suggestions recommended, the owner should

receive quality service for many years. If additional information or assistance should be required,

please contact GSI.

3. It is important to check both the quantity of parts and their descriptions with the packing list enclosed

within each package. All claims for freight damage or shortage must be made by the consignee

within ten (10) days from the date of the occurrence of freight damage. The consignee should

accept the shipment after noting the damage or loss.

Capacities and Specifications

Electrical controls and wiring should be installed by a qualified electrician. The motor disconnect

switches and conductor cables should comply with the National Electrical Code and any local codes

which apply. Reset and motor starting stations should be located so that the operator can see that all

personnel are clear of the equipment.

1. Disconnect and lock out the power before entering the bin.

2. Disconnect and lock out the power before servicing the equipment.

There should ALWAYS be two (2) people in the work area.

A main power disconnect switch capable of being locked only in the OFF position

should be used. It should be locked whenever work is being done on the hopper.

4 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 5

1. Introduction

Slip Ring Introduction

Slip rings must be enclosed and protected from any contact by personnel.

Specifications and Listings

1. R-Series slip ring products are built to UL specifications but are not generally certified or listed by

any independent certifying or regulatory body.

2. The following specifications apply to all R-Series slip rings:

a. R-Series slip rings are intended for industrial use and require a permanent mounting means.

b. Maximum RPM for units w/o ball bearings is 125. Maximum for units with ball bearings is

500 RPM.

Temperature and Ampere/Voltage Ratings

1. R-Series slip rings withstand a maximum ambient temperature of 220°F.

2. The model number of the slip ring assembly indicates the ampacity and voltage rating of each type

of ring and brush included on the assembly. (See Page 30.) NOTE: The actual ampacity may be

affected by the type and size of the core lead wire (refer to NEC Table 310-16, 17, 18, 19 and

applicable notes).

Markings

1. Every slip ring is marked with a label on the outboard bearing (or enclosure) which includes the

Insul-8/IER name and logo, the product catalog number and the individual product serial number.

2. The marking on slip rings includes the maximum amperage and voltage.

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 5

Page 6

2. Safety

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

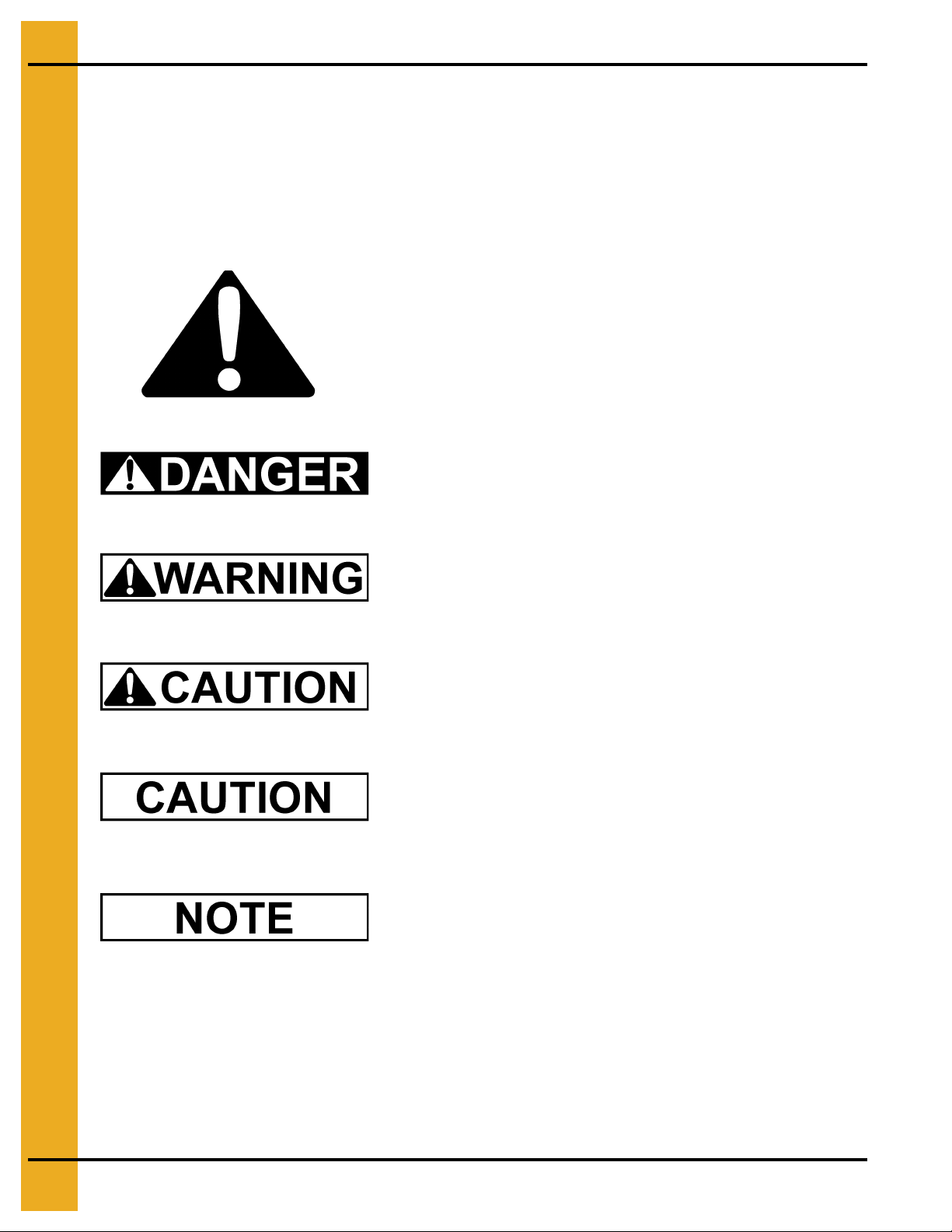

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

6 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 7

2. Safety

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want

to keep you as a customer. This manual is to help you understand safe operating p rocedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may

be required from the personnel. Avoid any alterations to the equipment. Such alterations may produce

a very dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Rotating Flight

Grain augers can kill or dismember.

Keep clear of all augers and never enter the bin unless all

power is disconnected and locked out. Failure to do so will

result in serious injury or death.

Read and Understand Manual

Rotating Flight

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 7

Page 8

2. Safety

Install and Operate Electrical Equipment Properly

Electrical controls should be installed by a qualified electrician

and must meet the standards set by the National Electrical Code

and all local and state codes.

Disconnect and lock out all power sources before installing

wires/cables or servicing equipment.

Electric Shock Hazard

ELECTRICAL WARNINGS

A. Install and ground the slip ring and the entire unit in accordance with the National Elect ric Code

and local codes and/or ordinances.

B. DANGER: Hazard of electrical shock or burn. Always disconnect the power from the collector ring

before attempting to perform any service function. Follow lock out/tag out procedures as outline d

in O.S.H.A., section 1910.147 where appropriate.

C. Do not use this slip ring with electrical loads greater than the rated current and voltage.

D. Information regarding the current and voltage rating of each slip ring is recorded on a tag

permanently fastened to the ring assembly.

E. 1 R-Series Slip Rings withstand a maximum ambient temperature of 220°F.

F. The model number of the slip ring assembly indicates the ampacity and voltage rating of each

type of ring and brush included on the assembly. NOTE: The actual ampacity may be affected

by the type and size of the core lead wire (refer to NEC Table 310-16, 17, 18, 19 and

applicable notes).

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

8 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 9

Wear Protective Clothing

Wear close fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

2. Safety

Eye Protection

Long hair should be tied up and back.

Safety glasses should be worn at all times to protect eyes

from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel toe boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoe strings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Gloves

Steel Toe Boots

Respirator

Hard Hat

Fall Protection

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 9

Page 10

2. Safety

Operate Unload Equipment Properly

• Untrained operators subject themselves and others to SERIOUS INJURY

or DEATH. NEVER allow untrained personnel to operate this equipment.

• NEVER work alone.

Operate Unload

Equipment Safely

• Keep children and other unqualified personnel out of the working

area at ALL times. Refer to the Start-Up section of this manual for

diagrams of the work area.

• Make sure ALL equipment is locked in position before operating.

• NEVER start equipment until ALL persons are clear of the work area.

• Keep hands and feet away from the auger intake and other moving parts.

• NEVER attempt to assist machinery operation or to remove trash from equipment while

in operation.

• Be sure all operators are adequately rested and prepared to perform all functions of operating

this equipment.

• NEVER allow any person intoxicated or under the influence of alcohol or drugs to operate

the equipment.

• Make sure someone is nearby who is aware of the proper shut down sequence in the event of an

accident or emergency.

• ALWAYS think before acting. NEVER act impulsively around the equipment.

• NEVER allow anyone inside a bin, truck or wagon which is being unloaded by an auger or

conveyor. Flowing grain can trap and suffocate in seconds.

• Use ample overhead lighting after sunset to light the work area.

• Keep area around intake free of obstacles such as electrical cords, blocks, etc., that might

trip workers.

• NEVER drive, stand or walk under the equipment.

• Use caution not to hit the auger when positioning the load.

• ALWAYS lock out ALL power to the equipment when finished unloading a bin.

• Be aware of pinch point s. A pinch point is a narrow area between two surfaces that is likely to trap

or catch objects and so is a potential safety hazard.

10 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 11

2. Safety

Operator Qualifications

A. The User/Operator must be competent and experienced to operate auger equipment. Anyone who

works with or around augers must have good common sense in order to be qualified. These

persons must also know and meet all other qualifications, such as:

i. Any person who has not read and/or does not understand all operation and safety procedures

is not qualified to operate any auger systems.

ii. Certain regulations apply to personnel operating power machinery. Personnel under the age

of 18 years may not operate power machinery, including augers. It is your responsibility, as

owner and/or supervisor, to know what these regulations are in your area or situation.

iii. Unqualified or incompetent persons are to remain out of the work area.

iv. O.S.H.A. (Occupational Safety and Health Administration) regulations state: “At the time of

initial assignment and at least annually thereafter, the employer shall instruct every employee

in the safe operation and servicing of all equipment with which the employee is, or will be

involved”. (Federal Occupational Safety and Health Standards for Agriculture. Subpart D,

Section 1928.57 (a) (6)).

B. As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe

operating and safety procedures for this auger. The sign-off sheet is provided for your convenience

and personal record keeping. All unqualified persons are to stay out of the work area at all times.

It is strongly recommended that another qualified person who knows the shut down procedure is

in the area in the event of an emergency.

Date Employee Name Supervisor Name

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 11

Page 12

3. Decals

The below Figure show the location of the decals and safety signs which should appear on the Series II

Sweep hopper with collector ring.

HIGH VOLTAGE.

Will cause serious

injury or death.

DC-1224

On top of slip ring

shield plate

Lockout power

before servicing.

DC-1224

Location: Top of shield plate

and side of shield.

Size: 2-7/8" x 5"

Part #: DC-1224

NOTE: Please remember safety signs provide important safety information for people working near

bin unloading equipment that is in operation. Any safety signs that are worn, missing, painted

over or otherwise illegible should be replaced immediately. Obtain FREE replacements by

contacting GSI.

12 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 13

3. Decals

A. DANGER Sign No. DC-1395 was supplied with your bin unloading equipment. This safety sign

should be applied to the side of the bin near the bin opening, so it will be viewed by people

entering into the bin storage building. Do not cover any safety signs or any other signs that are

already there.

B. If the safety sign location suggested is not in full view because of equipment modifications, other

equipment in the area or any reason, then locate the safety sign in a more suitable location.

C. Be certain the surface is clean, dry and free of dirt and oil. Peel paper backing from decals and stick

into place. The adhesive backing will bond on contact.

NOTE: Please remember, safety signs provide important safety information for people working near bin

unloading equipment that is in operation.

NOTE: If the Safety Sign cannot be easily read for any reason or has been painted over, replace it

immediately. Additional Safety Signs may be obtained free of charge from your dealer, distributor

or ordered from the factory.

Order SAFETY SIGN NO. DC-1395

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 13

Page 14

4. Assembly

1. Assemble the slip ring shield onto the cross brace assembly using four (4) 1/4" x 1" hex bolts and

nuts. Assemble one nut and bolt to each side of the collector ring shield. Do not tighten these at

this point. (See Figure 4A.)

Figure 4A

2. As the sump should be installed into the floor, place the cross brace and slip ring shield into the

sump so that the lower conduit shroud exits on the side that is intended to accept the slip ring wiring.

As the assembly is placed into the sump, slide the lower shroud assembly onto the conduit shroud

tube of the slip ring shield. (See Figure 4B.)

Figure 4B

14 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 15

4. Assembly

3. Once the assembly is aligned properly, attach the cross brace to the sump with four (4) 1/2" x 1-3/4"

hex bolts and nuts. Do not tighten these at this point.

4. Using the lower shroud assembly, mark the center lines of the plate onto the sump wall. These

marks will be used to create the conduit exit hole through the sump wall.

5. Once the marks have been double checked on the wall, unbolt the cross assembly from the sump

and remove the slip ring shield from the cross brace assembly.

6. Drill up to a 2" hole at the marked location on the sump wall. Remove any burrs created in the drilling

process from the conduit exit hole in the sump wall.

7. Assemble the 1" x 9-3/8" conduit to the 1" chase nipple using one 1" conduit coupling.

8. Feed the nine (9) stranded wires from the slip ring through the conduit assembly and fasten it to the

slip ring. (See Figure 4C.)

Figure 4C

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 15

Page 16

4. Assembly

9. Feed the nine (9) stranded wires from the slip ring through the vertical pivot tube rubber grommet

and bolt the slip ring to the cross brace assembly using four (4) 1/4" x 1" hex bolts, lock washers

and hex nuts. It is important that the rubber grommet remains stationary and intact. Failure to do

so can result in severed wires during operation.

Electrical controls and wiring should be installed by a qualified electrician. The motor disconnect

switches and conductor cables should comply with the National Electrical Code and any local

codes which apply. Reset and motor starting stations should be located so that the operator can

see that all personnel are clear of the equipment.

NOTE: The liquid-tight flex conduit may need to be trimmed to length.

10. Attach the 1" liquid-tight flex conduit coupling to one end of the 1" x 16" liquid-tight flex conduit.

11. Attach the 1" x 45° liquid-tight flex conduit coupling to the other end of the 1" x 16" liquid-tight

flex conduit.

12. Remove the protective housing from the slip ring.

13. Feed the multi-conductor cord through the conduit assembly and the 1" conduit hub on the slip ring.

14. Attach the 1" x 45° liquid-tight flex conduit coupling to the 1" conduit hub on the slip ring. Be sure

to turn the conduit assembly down. (See Figure 4D.)

Figure 4D

16 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 17

4. Assembly

15. Wire the multi-conductor cord to the slip ring using the fork terminals provided in the

following manner.

1. Thermal protection leads

a. Wire the “P1” lead from the control panel to ring “1”.

b. Wire the “P2” lead from the control panel to ring “2”.

2. Drive motor leads

a. Wire the three (3) power leads to rings “3”, “4” and “5”.

b. Wire the ground lead to ring “9”.

3. Auger motor leads

a. Wire the three (3) power leads to rings “6”, “7” and “8”.

b. Wire the ground lead to ring “9”.

16. Replace the protective housing onto the slip ring.

17. Feed the multi-conductor cord through the slip ring shield and attach the slip ring shield to the cross

brace assembly using sixteen (16) 1/4" x 1" hex bolts, flat washers, lock washers and nuts.

18. Feed the multi-conductor cord through the lower shroud assembly and through the drilled conduit

exit hole in the sump wall.

19. Slide the lower shroud assembly into the slip ring shield. (See Figure 4E.)

Figure 4E

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 17

Page 18

4. Assembly

20. Make sure that the lower shroud assembly and the drilled conduit exit hole in the sump wall hole

are aligned. Bolt the cross brace assembly to the sump using eight (8) 1/2" x 1-3/4" hex bolts,

flat washers, lock washers and hex nuts.

21. Slide the lower shroud assembly into position against the sump wall. Tack weld the lower shroud

assembly to the sump wall.

22. Without damaging the slip ring stranded wires, connect the L-shaped pivot plate to the head section

back shield using two (2) 1/2" x 1-3/4" hex bolts, flat washers, lock washers and hex nuts.

23. Without damaging the slip ring stranded wires, fasten the vertical brace rod to the head section

back shield and L-shaped pivot plate using two (2) 1/2" x 2" hex bolts, lock washers and hex nuts.

(See Figure 4F.)

Figure 4F

24. Feed the nine (9) stranded wires from the slip ring through the horizontal tube assembly. Take care

to ensure that none of the wires becomes stripped or damaged in this process.

25. Feed the horizontal tube assembly and nine (9) stranded wires from the slip ring through the hole

in the head section back shield.

26. Attach the horizontal pivot tube and vertical pivot tube together using five (5) 1/4" x 1" hex bolts and

serrated flange nuts. It is critical that the two (2) flanges are seated and create a proper seal so that

contaminants do not enter the space around the stranded wires. (See Figure 4G on Page 19.)

18 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 19

4. Assembly

Figure 4G

27. Attach one 1" liquid-tight flex conduit coupling to each end of the 1" x 48" liquid-tight flex conduit.

28. Feed the nine (9) stranded wires from the slip ring through the 1" conduit coupling and 1" x 48"

liquid-tight flex conduit assembly.

29. Attach the 1" x 48" liquid-tight flex conduit assembly to th e pivot tube using the 1" conduit coupling.

(See Figure 4H.)

Figure 4H

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 19

Page 20

4. Assembly

30. Feed the nine (9) stranded wires from the slip ring through one of the holes in the rig ht junction box.

31. Connect the 1" x 48" liquid-tight flex conduit assembly to the junction box using the 1" liquid-tight

flex conduit coupling.

32. Wire the nine (9) stranded wires to the junction boxes in the following manner.

1. Thermal protection leads

a. Wire the “P1” lead from the both motors to “1”.

b. Wire the “P2” lead from the both motors to “2”.

2. Drive motor leads

a. Wire the three (3) power leads to “3”, “4” and “5”.

b. Wire the ground lead to “9”.

3. Auger motor leads

a. Wire the three (3) power leads to “6”, “7” and “8”.

b. Wire the ground lead to “9”.

20 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 21

Preform Pre-start Checks

To ensure that the drive is not unexpectedly started, turn OFF and lock out or tag

out the power source before proceeding. Failure to observe these precautions

could result in bodily injury.

Failure to perform any or all of these pre-start checks may cause damage to the

equipment and/or cause SERIOUS INJURY or DEATH to those in the work area.

Failure to perform any or all of these pre-start checks may also be a misuse

of the equipment. Any misuse of the equipment may void the warranty.

1. Make sure ALL shields are in place.

ALWAYS keep ALL guards and shields in place, until all the power is

disconnected and locked out.

2. Inspect the collector ring for any problems or potential problems.

5. Start-up

3. Be aware of any emergency shut down procedures. Two (2) people must always be in a position

where the operation of the equipment can be monitored.

4. Before starting the auger for the first time, make sure that all parts are assembled correctly

according to the instructions in this manual.

Make certain ONLY trained operators are in the work area before operating or

moving the machine. Two (2) people must always be in a position where the

operation of the equipment can be monitored.

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 21

Page 22

6. Maintenance

Maintain the Hopper

ALWAYS shut down and disconnect the power supply before adjusting, servicing

or cleaning the equipment.

1. Use caution when repairing or replacing equipment parts.

2. Make sure ALL decals are legible and tightly attached to the hopper. If necessary, replace them

FREE OF CHARGE by contacting GSI at:

GSI

P.O. Box 20

1004 E. Illinois St.

Assumption, IL 62510

Phone: 1-217-226-4421

3. Make sure ALL electrical wiring is not damaged and that it meets proper wiring codes.

4. Make sure ALL components are in good working condition before use.

5. Grease the center pivot tube at least two (2) times each season.

Slip Ring Maintenance

Lubrication

All bearings are lubricated for life at the factory. Additional lubrication should not be required.

Do not apply any lubricants or solvent cleaning agents to any part of the

slip ring.

Brush Holders

Make the first inspection shortly after installation and before operation. Make continuing inspections on

a regular basis after every 200-400 hours of operation under normal conditions.

Brush Holders

1. Inspect brush holders for proper alignment. Locate brush holders so that the entire brush contact

surface rides squarely on the ring with the brush moving freely in the brush holder. Position brush

holders so that the brush makes contact with the middle of the conductor and is not offset.

2. Check brush holder clamps for tightness. Set clamp bolts at 10 in-lbs. maximum.

3. Inspect brush terminations at the holder to assure that no external force is imp osed on the holder.

We recommend flexible or soft wire leads for these terminations. Use external clamps to support

the entire weight of the leads.

22 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 23

6. Maintenance

Brushes

1. Inspect for wear. If the distance from the top of the insulator to the lower part of the brush spring is

0.093" or less, replace the brush.

Figure 6A

2. Inspect brush contact surface by removing the brush. Remove surface dirt, oxidation, pitting or

other contaminants (with a wire brush).

3. To remove and replace the brush:

a. Remove the clamp screw from the brush holder.

b. Remove the screw from the brush lead.

c. Remove the brush holder.

d. Replace the brush.

e. Re-assemble.

Brush Fit Inspection

1. Brushes must run at 90° ± 3° square on the rings. If brush is not square, adjust position of brush

holder on brush post.

2. Brushes need not run on the center of the rings, but there should be no forceful friction against

the insulators.

3. The brush spring cross-bar must be seated in the brush slot.

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 23

Page 24

6. Maintenance

Figure 6B

Brush Springs

1. Inspect and test brush springs to assure uniform brush pressure. If brush springs fall below

recommended pressure, replace entire brush holder.

Brush Spring Tension

Brush Amperage Spring Pressure

15 1.0 lb. min

35 1.5 lbs. min

75 3.0 lbs. min

Figure 6C

24 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 25

6. Maintenance

Rings

1. Inspect the ring surface for dirt, oxidation or other contaminants. A properly operating ring will have

a film that appears burnished in color with a darker surrounding color where the brushes track.

If the ring requires cleaning, order slip ring polishing kit #41286.

Electrical Connections

1. Inspect all electrical connections for corrosion and tightness. Clean corroded parts with a wire

brush and/or muriatic acid. Loose and/or corroded terminations will cause a concentration of

excessive heat.

Brush Rigging

1. Brush posts are supported between two (2) outboard bearings. The brush posts extend to the

outboard bearings and are secured by a notch in the outboard.

2. Spacing between the outboard bearings is critical to assure the free rotation of the brush rigging.

The brush posts are cut to an exact length in order to provide the proper spacing. Locate the

outboard bearings against the insulator and have a 0.20" clearance without deformation of

the material.

Do not over-tighten the outboard brush post jam nuts. Make a final check to

assure there is no binding of the outboard brush rigging or binding of brushes

with insulator barriers.

Enclosure Inspection

1. Moisture is a major cause of slip ring deterioration. Water will corrode parts and breakdown

insulation. Dust and dirt present within the enclosure will effect the proper operation of the

assembly. Most dusts cause excessive brush and slip ring wear and conductive dust, if allowed

to accumulate, will form a path for short circuiting.

2. A properly designed NEMA 4 enclosure will be dust tight and watertight. However, NEMA 4

enclosures do not eliminate internal condensation. Condensation can be eliminated with the

addition of a breather, drain and a thermostatically controlled heater.

3. Periodically perform an inspection by removing the enclosure and checking for condensation, water

and dust collection. If contaminants are found, wipe the enclosure and the assembly with a lint free

cloth. If the problem persists, take steps to remedy the leakage or condensation problem.

Slip Ring Storage

1. When storing the slip ring, keep it at room temperature in a clean, dry, protective place. Place

self-contained or bagged absorbent material in the collector ring enclosure during extended periods

of storage. Remove absorbent material before putting collector ring into operation.

Serial Number

1. Make the following information available when ordering replacement parts or discussing the slip

ring with the factory by recording the information in the spaces provided here. This information is

located on the packing slip, factory invoice and serial number tag.

Catalog No. Slip Ring:_________________________

Serial No.:________________________________

Date of Purchase:____________________________

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 25

Page 26

7. T roubleshooting

Problem Possible Cause Solution

1. Power cords may be unplugged. 1. Plug in the power cords.

2. Foot switch may not be actuated. 2. Make sure the foot switch is depressed

and the switch is operating properly.

Sweep will not run.

Intermittent signal

or loss of signal.

3. Overloads may be tripped. 3. Reset the overloads.

4. The collector ring may not be making

good connections.

1. Brush wear. 1. Verify brush wear per section.

2. Spring pressure. 2. Check spring pressure per section.

3. Dirty contact surface. 3. Check contact surfaces for cleanness.

4. Bad springs. 4. Visually check for spring fit and function.

5. Short in wire. 5. Check core wiring for short circuit.

4a. Check the collector ring terminals for

proper contact.

4b. Make sure the springs have correct

tension according to the owner’s manual.

(Ring polishing kit available.)

Adjust or replace as necessary.

26 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 27

NOTES

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 27

Page 28

8. Parts List

Components

28 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 29

Components Parts List

System Ref # Part # Description

ALL 1 GC04615 Standard 15K Sump

12" 2 GK80042 Protector Cord Slip Ring Cross Brace, 12" System

16" 2 GK80041 Protector Cord Slip Ring Cross Brace, 16" System

ALL 3 GC11833 Slip Ring Shield

ALL 4 GC04624 Lower Conduit Shroud

ALL 5 GC04547 Slip Ring, XPFC, 9 Ring, CA12707

ALL 6 GC04653 1" IMC Conduit, 9-3/8", 1" NPT Both Ends

ALL 7 S-8519 1" Conduit Coupling, Galvanized

ALL 8 S-2122 1" Conduit Fitting, Steel Chase Nipple

ALL 9 S-6998 1/4"-20 x 1" HHCS Bolt Zinc Grade 5

ALL 10 S-2041 1/4" Lock Washer Zinc

ALL 11 S-1102 1/4" Hex Nut Zinc Grade 2

8. Parts List

ALL 12 GC04654 1" Conduit Fitting, 45°, Rigid Flex

ALL 13 GC07881 1" Flexible Conduit, 16"

ALL N/S GC07602 10 Gauge Power Cord, 9 Strand, 12'

ALL 14 S-8518 1" Conduit Fitting, Straight, Rigid Flex

ALL 15 S-1430 1/4" Flat Washer Zinc Grade 2

ALL 16 S-2121 1/2" Flat Washer Zinc

ALL 17 S-3883 1/2"-13 x 1-3/4" HHCS Bolt YDP Grade 8

ALL 18 S-236 1/2" Lock Washer Zinc

ALL 19 S-3729 1/2"-13 Hex Nut YDP Grade 5

ALL 20 GK80038 Horizontal Protector Cord Slip Ring Tube Assembly

ALL 21 S-8244 1/4"-20 x 3/4" HHCS Bolt Zinc Grade 5

ALL 22 S-7215 1/4"-20 Serrated Flange Nut Zinc

12" 23 GC06716 Vertical Brace Rod Weldment, 12" System

16" 23 GC06717 Vertical Brace Rod Weldment, 16" System

ALL 24 GC07575 1" Flexible Conduit, 48"

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 29

Page 30

8. Parts List

Slip Ring Replacement Parts

Slip Ring Bore Size

Z A B, C, D E, F, G, H J, K

*

Special

Bore

2

Brushes

1.50

30067A 30067B 30067C 30067D A = 10 Amp/250V 02800 02807

30066A 30066B 30066C 30066D B = 15 Amp/250V 28000 02807

30068A 30068B 30068C 30068D C = 35 Amp/250V 02801 02808

30068A 30068B 30068C 30068D D = 35 Amp/600V 02801 02808

30069A 30069B 30069C 30069D E = 75 Amp/600V 02802 02809

02840 02845 02850 02855 F = 110 Amp/600V 02803 02810

02841 02846 02851 02856 G = 150 Amp/600V 02804 02811

02842 02847 02852 02857 H = 225 Amp/600V 02805 02805 (x2)

02843 02848 02853 02858 J = 300 Amp/600V 02806 02806 (x2)

N/A DRA3-20A-2500 DRA3-20A-4000 DRA3-20A-8000 K = 200 Amp/600V

N/A 03309 03247 03247 L = 400 Amp/600V

N/A 03248 03248 03248 M = 600 Amp/600V

2.5, 3.0, 3.5 4.0, 4.5, 5.0, 6.0 8.0, 10.0

* Consult the factory for custom application configurations.

1

Brush Holders

Single

Brushes and holders

sold as a unit in this

Amp/Volt range

Double

30 PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump

Page 31

9. Warranty

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive

components, shall be free from defects in materials for a period of time beginning on the twelfth (12

the date of purchase and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period).

th

) month from

During the extended warranty period, GSI will replace the frame or basket components that prove to be defective

under normal conditions of use without charge, excluding the labor, transportation, and/or shipping costs incurred in

the performance of this extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE

OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT,

SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user.

GSI shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer,

agent or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment

at initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse,

alteration, accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to

products manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

9101239_1_CR_rev7.DOC (revised July 2009)

PNEG-1722 Series II Sweep Protected Cord Slip Ring Sump 31

Page 32

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2009 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Loading...

Loading...