Page 1

PNEG-1 71 7

CE Approved GSI/FFI Portable

Dryer Manual

Operation Manual

PNEG-1717

Date: 12-08-10

Page 2

Models:

1100 Se rie s (Models 1108, 1112, 1114, 1116, 1118, 1120, 1122, 1126, CFAB190, CFAB270, CFAB320,

CFAB370, CFAB400, CFAB460, CFAB510, CFAB511, CFAB601)

1200 Series (Models 1214, 1216, 1218, 1220, 1222, 1226, C2120A, C2122A, C2125A, C2130A,

C2132A, C2140A)

1200S Series (Models 1214S, 1218S, 1220S, 1222S, 1226S, CF2141, CF2181, CF500H,

CF2221, CF650M)

2300 Series (Models 2314, 2318, 2320, 2322, 2326, CF3142, CF3182, CF3202, CF3222, CF3262)

2400 Series (Models 2420, 2426, CF1000H, CF1300M)

3400 Series (Models 3414, 3418, 3420, 3422, 3426, CF4143, CF4183, CF4203, CF4223, CF4263)

3600 Series (Models 3620, 3626, CF1500H, CF2000M)

X-Stream Configuration - Uses same model numbers (and components) as listed above. The only

difference is that the fans are pointed in different directions.

2 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................5

Dryer Operation ..................................................................................................................................... 5

Precautions ........................................................................................................................................... 5

Chapter 2 Safety .....................................................................................................................................................6

Safety Guidelines .................................................................................................................................. 6

Emergency Stop Switch ................................... ... ... ... .... ... ... ... .... ... ... ..................................................... 7

Chapter 3 Installation ............................................................................................................................................8

Transporting/Single Fan ................................... ... ... ... .......................................... .... ... ... ... ... .................. 8

Location of the Dryer ............................................................................................................................. 9

Foundation ............................................................................................................................................ 9

Supporting the Dryer ............................................................................................................................. 9

Anchor Points ........................................................................................................................................ 9

Wet/Dry Grain ....................................................................................................................................... 9

Electrical Power Supply ...................................................................................................................... 10

Fuel ..................................................................................................................................................... 11

Chapter 4 Specifications .....................................................................................................................................13

FFI Dimensions ................................................................................................................................... 13

FFI Specifications ................................................................................................................................ 15

GSI Dimensions .................................................................................................................................. 17

GSI Specifications ............................................................................................................................... 19

All Stack Dimensions .......................................................................................................................... 21

All Stack Specifications ....................................................................................................................... 24

Stack Dryer Foundation Specifications ............................................................................................... 28

Chapter 5 Vision Control Panel ..........................................................................................................................29

Vision Control Panel Layout ................................................................................................................ 29

Control Power Switch .......................................................................................................................... 29

Fan Switch .......................................................................................................................................... 29

Heater Switch ...................................................................................................................................... 30

Load Auger Switch .................................... ... .... ... ... ... .... ...................................... .... ... ... ... ................... 30

Unload Switch ..................................................................................................................................... 30

Outside Light Switch ........................................................................................................................... 30

Start Switch ......................................................................................................................................... 30

Stop Switch ......................................................................................................................................... 30

Chapter 6 Vision Touch Screen Display ........................ ... ... ... .... ... ....................................... ... ... .......................31

Boot Screen ........................................................................................................................................ 31

Chapter 7 Vision Test Firing .... ... ... .... .......................................... .......................................................................32

Dryer Pre-Season Checks .................................................................................................................. 32

Burner Test Fire .................................................................................................................................. 33

Dryer Shut Down ................................................................................................................................. 35

Emergency .......................................................................................................................................... 35

Chapter 8 Vision/Dri-Tek Dryer Operation .........................................................................................................36

Full Heat Drying ..................................................... ... .... ... ... ... ....................................... ...................... 36

Final Moisture ...................................................................................................................................... 36

Drying Temperatures .................................................... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ......................... 36

Initial Setup Parameters ............................ ............................................. ............................................. 36

Timer and Delay Settings .................................................................................................................... 36

Setting the Temperatures ......................................................................................................

Start-Up .................................. ............................................. ................................................................ 36

Continuous Flow Drying Mode Using Regulation of Grain Temperature ............................................ 37

Continuous Flow Drying Mode Using Regulation of Moisture: 5 MR SP ............................................ 41

.............. 36

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 3

Page 4

Table of Contents

Chapter 9 Vision Illustrations .............................................................................................................................44

Supply Line (LP Shown) ...................................................................................................................... 44

28" and 36" LP 1" NPT CE Pipe Train Assembly ................................................................................ 45

40" and 42" LP 1-1/2" NPT CE Pipe Train Assembly .......................................................................... 45

LP Vaporizer Coil Adjustment ............................................................................................................. 46

28" and 36" LP/NG 1" NPT CE Pipe Train Assembly ......................................................................... 47

Vision Fan/Heater Control Box ............................................................................................................ 49

Top Auger Drive .................................................................................................................................. 49

Discharge Safety Switch ..................................................................................................................... 50

Meter Roll Speed Sensor .................................................................................................................... 50

Vision Upper Control Box ........................ ... ......................................................................................... 51

Vision Control Panel (Rear) ................................................................................................................ 52

Vision Lower Control Box (Back Panel) .............................................................................................. 53

Chapter 10 Service ...............................................................................................................................................54

Seasonal Inspection/Service ............................................................................................................. 54

Lubrication Procedure ....................................................................................................................... 56

Fan Blade Removal and Installation .................................................................................................. 57

Fan Motor Removal and Installation ...................................... ............................................................ 57

Heater Parts Removal and Installation ............................ ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ........ 58

Metering Roll Servicing .......... ... ... .... ... ... ... ......................................................................................... 58

Main Controls ............................................................................ ... ... ... ... .... ... ..................................... 58

How to Clear a Jammed Meter Roll (All Power “OFF”) ...................................................................... 58

Chapter 11 Vision Schematics and Wiring Diagrams .................................... ... ... .... ... ... ...................................59

Fan/Heater Standard ......................................................................................................................... 59

Front Panel ........................................................................................................................................ 60

Upper Control Box ............................................................................................................................. 82

380-400 VAC 3 Phase ..................... ... ... ... ... .... ... ... ... .... ... ... .......................................... ..................... 83

Ladder Diagram ................................................................................................................................. 84

Chapter 12 Warranty ............................................................................................................................................87

4 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 5

1. Introduction

Keep the dryer clean.

Dryer Operation

Thank you for choosing a CE Approved GSI/FFI Vision Series Grain Dryers.

Please read this manual before installing or operating the equipment.

Make sure you and your employees understand all requirements, hazards and precautions associated

with this equipment. Failure to do so could result in SERIOUS INJURY or DEATH.

Ensure you have the correct power and fuel supply for the dryer.

Do not alter or modify this equipment.

Follow all local directives, codes and regulations when installing this equipment.

Authorities having jurisdiction should be consulted before installations are made.

Precautions

1. Keep ALL guards, safety decals and safety devices in place. NEVER operate with guards removed.

2. Restrict access to trained persons only.

3. NEVER bypass safety devices.

4. Switch OFF and LOCK all power and fuel before entering, servicing or accessing the equipment.

5. Follow all servicing instructions.

6. Keep the dryer CLEAN.

7. DO NOT exceed maximum temperatures or pressures.

8. Drying unclean grain will reduce the performance of the dryer and can cause fires.

9. CAUTION Equipment on the dryer can START AUTOMATICALLY.

10. Feed and discharge equipment must match dryer throughput.

11. DO NOT allow foreign material to be drawn into the fan.

12. When drying products not included in this manual refer to GSI for further precautions and instructions.

13. Check for leaks at least every day. Repair before operation.

Use Caution in the Operation of this Equipment

This dryer is designed and manufactured with operator sa fety in mind. However, residual hazards remain

due to the nature of grain drying. Use extreme caution at all times.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 5

Page 6

2. Safety

PROHIBITION

Example: No smoking or naked flames

MANDATORY ACTION

Example: Wear ear defenders

Instructions for your safety

HAZARD

Example: Rotating auger

Safety Guidelines

Please observe all safety decals on the equipment.

Safety decals on this equipment use the following system:

6 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 7

Emergency Stop Switch

2. Safety

In event of emergency press the Emergency Stop to stop all dryer equipment (power remains connected).

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 7

Page 8

3. Installation

Washers

Locking nut

19 mm Minimum diameter

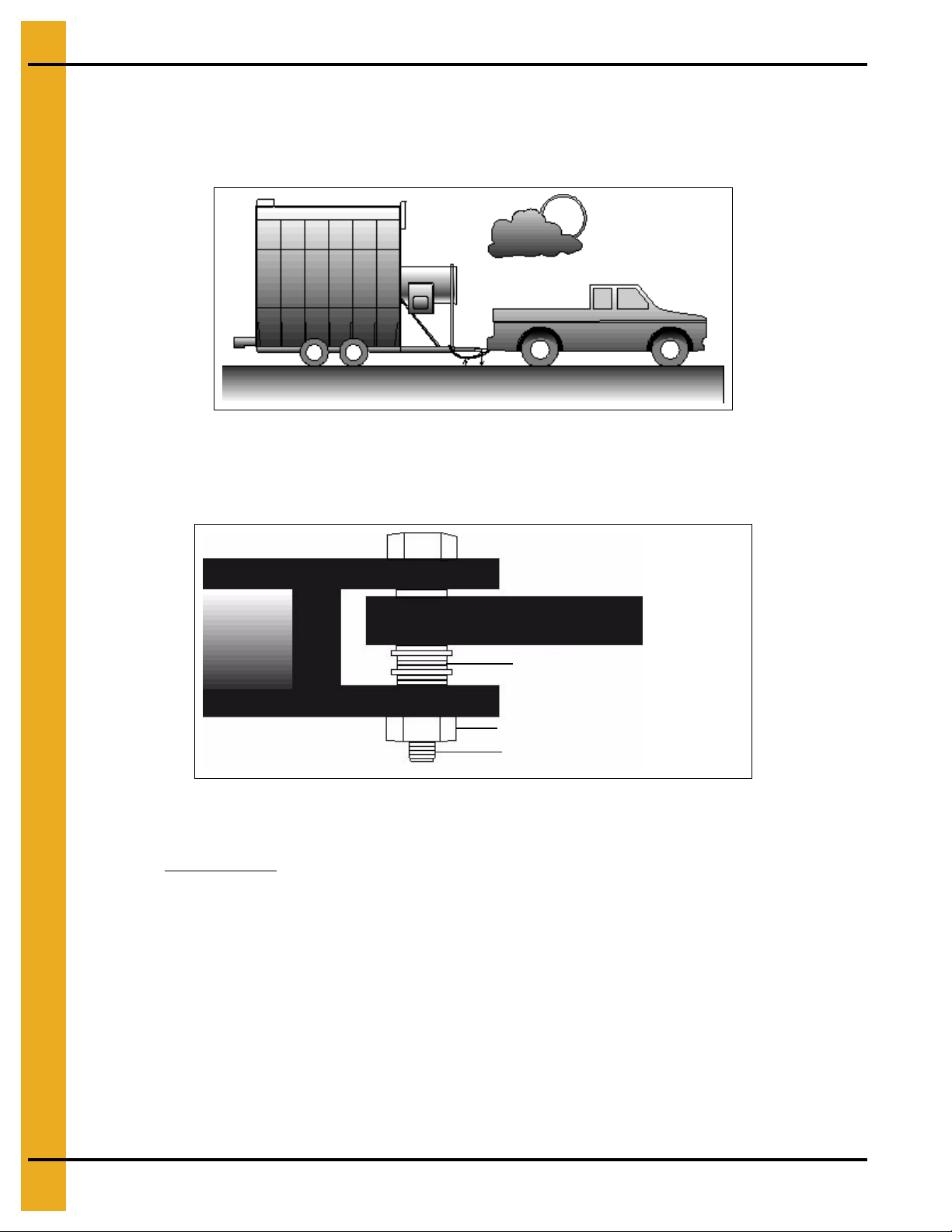

Transporting/Single Fan

When transporting the unit by truck or tractor observe these precautions:

1. Hitch height is 350 mm-430 mm. (See Figure 3A.)

Figure 3A

2. Hitch pin diameter is 19 mm minimum. Must be securely fastened. (See Figure 3B.)

3. Minimize hitch movement. (See Figure 3B.)

Figure 3B

4. Use a safety chain. (See Figure 3A.)

5. Dryer must be empty

and towed in accordance with all applicable laws and regulations.

6. Tyre pressure should be 3.8 bar.

7. Maximum towing speed is lowest of 70 km/h or statutory speed limit.

8. After first 80 km and every 300 km check:

a. Wheel bearing temperature <= 65°C.

b. Wheel nuts torque = 160 Nm.

8 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 9

Location of the Dryer

Consider:

1. Wet and dry storage.

2. Access to power and fuel.

3. Proximity to other structures (maintain minimum 1m clearance).

4. Noise.

5. Over head power.

Always install out of doors.

Foundation

1. Dryers should be installed on a suitable concrete base/foundation.

2. Foundation design to be carried out by qualified engineer.

3. Take into account ground and weather conditions.

3. Installation

4. Refer to dryer dimensions and loaded weights in table on Pages 11-25.

Supporting the Dryer

1. Wheels are for transport only.

2. Support under the hitch (drawbar removed).

3. Support every 2m on both sides.

4. Ensure the dryer is level in all directions.

5. Ensure supports can carry the full weight of the dryer.

6. Allow 400 mm clearance under the dryer for cleaning.

Anchor Points

Anchor to the concrete slab to ensure stability against high winds.

Wet/Dry Grain

Wet Grain Supply

1. Wet grain supply to the dryer intake may be gravity or powered auger/conveyor.

2. Powered fill equipment can be connected via the contactor provided in the dryer control box.

3. After the initial fill the system will run to maintain the dryer level.

4. Dryer fill is monitored by the out of grain timer. (Refer to PNEG-1710 for setting this timer.)

5. Dryer shuts down when out of grain.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 9

Page 10

3. Installation

Dry Grain Removal

1. Dry grain discharges at the rear of the dryer (front discharge optional).

2. Dry grain removal may be electrically connected to contactor provided in the main control box.

Electrical Power Supply

Ensure there is adequate electrical power to run the dryer. All supplies are 3 phase with neutral and

include a protective earth.

NOTE: Excessive voltage drops can cause equipment malfunction. Size supply and conductors to ensure

maximum 5% voltage drop under all start and run conditions.

Power Supply Disconnect

Supply connections are made at the main power disconnect on the upper control box.

Machine to Earth Grounding

1. The dryer must be connected to an adequate earth connection.

2. This must be carried out and tested in accordance with EU Directives, local regulations, codes and

EN60204 “Electrical Equipment of Machines”.

3. Failure to do so will result in equipment malfunction and can result in a dangerous fault condition.

4. Electrical supplies from generators must also include adequate, tested earth connection supplied by

the generator installer.

5. A 2.4m copper ground rod, supplied with the dryer must be installed in accordance with

local regulations.

Connecting Auxiliary Conveyors

Load and discharge conveyors connected into the dryer must not exceed electrical load information in

Specifications Chapter on Pages 15-25.

Motors exceeding these must be powered separate from the dryer with separate conta ctor a nd overloa d

device for each motor. Control may still be performed by the dryer.

10 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 11

3. Installation

Fuel

Liquid Propane (LP)

Liquid Draw

1. LPG is vaporized internally within the dryer.

2. LPG pipework and controls from the tank to the dryer must be installed by the gas supplier in

accordance with local directives, laws, codes and regulations.

3. LPG tank should be sized to supply the full heat input of all burners. See heater rating plates

for details.

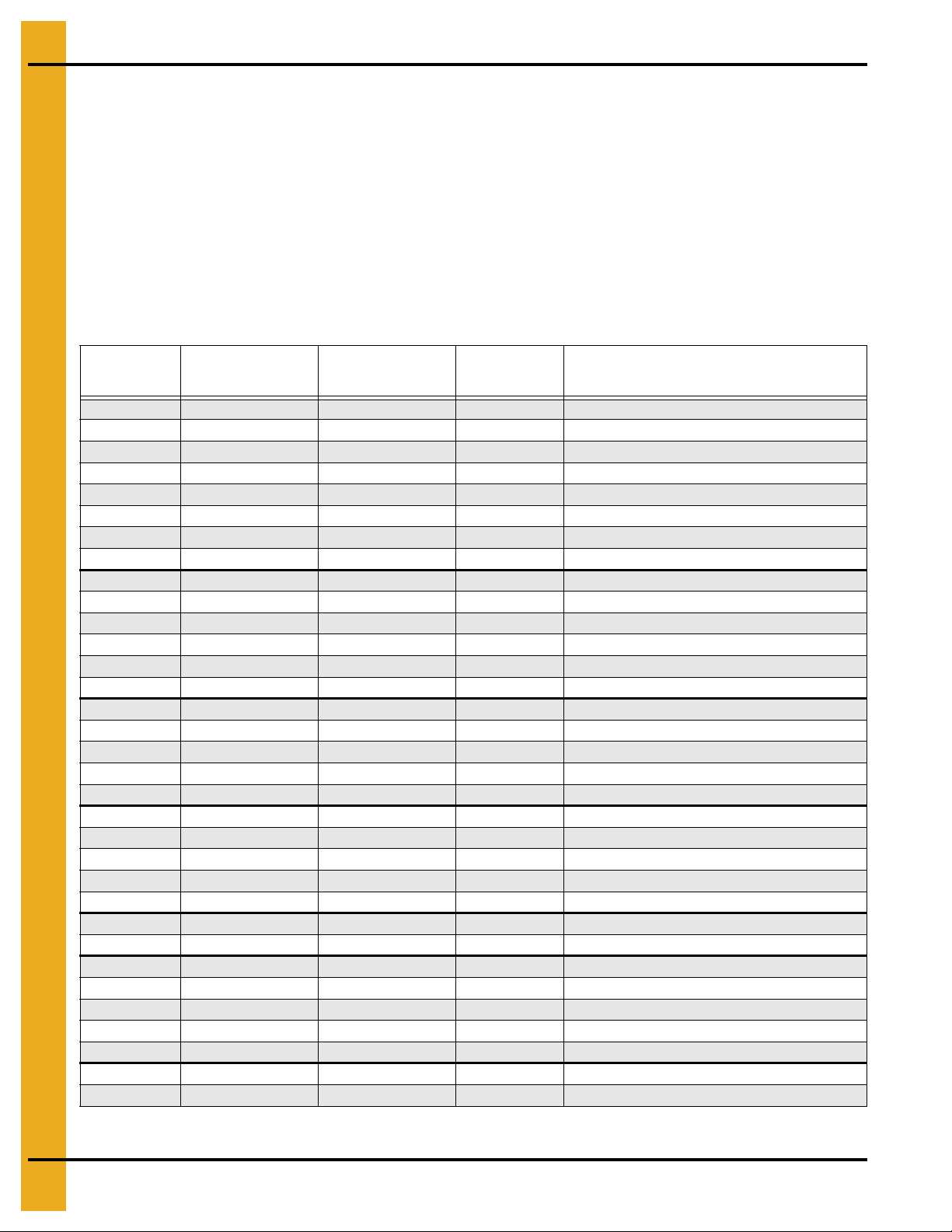

Fuel System Specifications and Recommendations (LP) Liquid Propane

Dryer

Model #

1108/190 880 131 15 7.8

1112/270 1320 195 15 9.6

1114/320 1685 250 15 10.9

1116/370 1685 250 15 10.9

1118/400 2052 302 15 12.0

1120/460 2200 326 15 12.4

1122/511 2491 370 22 13.2

1126/601 2785 414 22 13.9

1214/2120 1700 250 22 (U)8.8 (L)6.8

1216 1993 294 22 (U)10.2 (L)6.8

1218/2125 1993 292 22 (U)10.2 (L)6.8

1220/2130 2565 382 22 (U)10.7 (L)7.8

1222 2931 434 22 (U)11.7 (L)7.8

1226/2140 3078 458 22 (U)12.2 (L)7.8

1214S/2141 2052 302 22 (U+L) 8.8

1218S/2181 2638 390 22 (U+L) 10.3

1220S/500H 3371 501 22 (U+L) 10.7

1222S/2221 4104 609 22 (U+L) 11.7

1226S/650M 4397 653 22 (U+L) 12.2

2314/3142 3445 510 22 T 10.7 B (U+L) 7.8

2318/3182 4104 609 22 T 11.7 B (U+L) 8.8

2320/3202 4837 717 22 T 12.2 B (U+L) 10.2

2322/3222 5130 760 22 T 13.7 B (U+L) 10.2

2326/3262 7183 1063 22 T 14.2 B (U+L) 11.2

2420/1000H 5277 784 22 (T+B, U+L) 10.2

2426/1300M 7622 1130 22 (T+B, U+L) 11.2

3414/4143 5130 760 22 T 10.8 M 10.8 B (U+L) 7.8

3418/4183 6156 911 22 T 11.7 M 11.7 B (U+L) 8.8

3420/4203 7036 1043 22 T 12.2 M 12.2 B (U+L) 10.2

3422/4223 7622 1130 22 T 13.7 M 13.7 B (U+L) 8.3

3426/4263 9381 1389 22 T 14.2 M 14.2 B (U+L) 11.2

3620/1500H 7915 1174 22 (T+M+B, U+L) 10.2

3626/2000M 11433 1646 22 (T+M+B, U+L) 11.2

* Maximum line size for 30m length. ** Maximum burner pressure 450 mBar.

Maximum Heat

Capacity kW

Maximum Fuel

Flow l/h

Fuel Line

Size mm *

Heater Orifice Diameter mm **

(U = Upper, L = Lower, Heater Position)

(T = Top, M = Middle, B = Base Dryer Module)

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 11

Page 12

3. Installation

Natural Gas (N)

Gas Volume and Pressure

Natural gas supply should offer:

1. 49 MJ/m3 calorific value.

2. 650 mBar supply pressure. (Lower pressure may inhibit dryer performance.)

3. Gas pipework and controls from the supply to the dryer must be installed by the gas supplier in

accordance with local directives, laws, codes and regulations.

Check the supply capacity against dryer requirements. (See heater rating plates for details.)

Fuel System Specifications and Recommendations (NG) Natural Gas

Dryer

Model #

1108/190 880 82 32 9.7

1112/270 1320 123 38 11.9

1114/320 1685 157 38 13.3

1116/370 1685 157 38 13.2

1118/400 2052 188 50 14.1

1120/460 2200 206 50 14.9

1122/511 2491 233 50 15.3

1126/601 2785 261 50 16.5

1214/2120 1700 158 38 (U)10.5 (L)8.1

1216 1993 186 50 (U)12.9 (L)8.1

1218/2125 1993 186 50 (U)12.9 (L)8.1

1220/2130 2565 239 50 (U)13.3 (L)8.1

1222 2931 273 50 (U)13.3 (L)8.1

1226/2140 3078 287 50 (U)14.1 (L)8.1

1214S/2141 2052 191 38 (U+L) 10.5

1218S/2181 2638 246 38 (U+L) 12.9

1220S/500H 3371 314 50 (U+L) 13.3

1222S/2221 4104 316 50 (U+L) 14.1

1226S/650M 4397 410 50 (U+L) 14.9

2314/3142 3445 321 50 T 13.3 B (U+L) 9.7

2318/3182 4104 316 50 T 14.1 B (U+L) 10.5

2320/3202 4837 451 80 T 14.9 B (U+L) 12.9

2322/3222 5130 478 80 T 15.3 B (U+L) 12.9

2326/3262 7183 669 80 T 16.6 B (U+L) 13.7

2420/1000H 5277 492 80 (T+B, U+L) 12.9

2426/1300M 7622 710 80 (T+B, U+L) -13.7

3414/4143 5130 478 80 T 13.3 M 13.3 B (U+L) 9.7

3418/4183 6156 574 80 T 14.1 M 14.1 B (U+L) 10.5

3420/4203 7036 656 80 T 14.9 M 14.9 B (U+L) 12.9

3422/4223 7622 710 80 T 15.3 M 15.3 B (U+L) 12.9

3426/4263 9381 874 80 T 16.6 M 16.6 B (U+L) 13.7

3620/1500H 7915 738 80 (T+M+B, U+L) 12.9

3626/2000M 11433 1065 80 (T+<M+B, U+L) 13.7

* Maximum line size for a 100' distance. ** Maximum burner pressure 450 mBar.

Maximum Heat

Capacity kW

Maximum Fuel Flow

m3/h

Fuel Line Size

mm *

Heater Orifice Diameter mm **

(U = Upper, L = Lower, Heater Position)

(T = Top, M = Middle, B = Base Dryer Module)

12 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 13

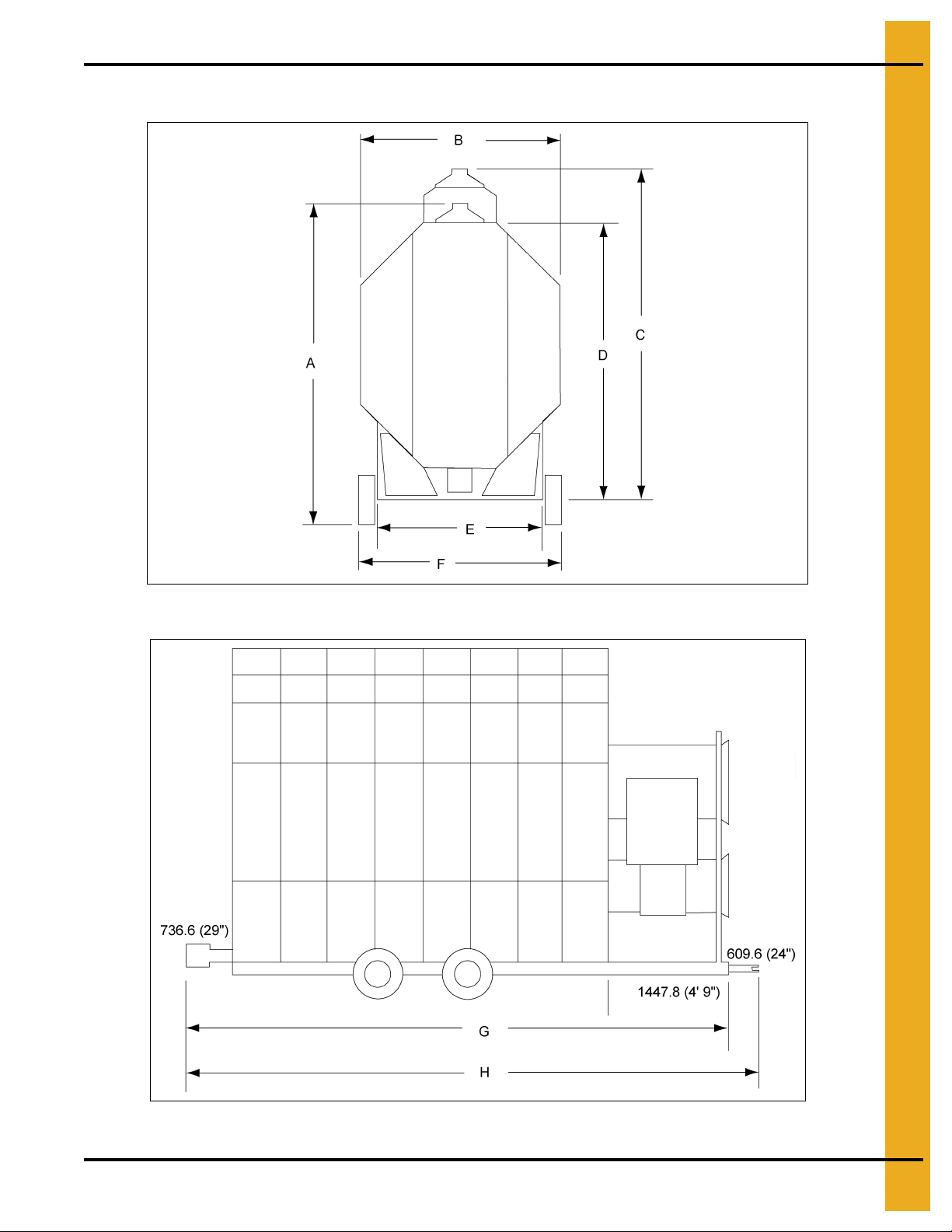

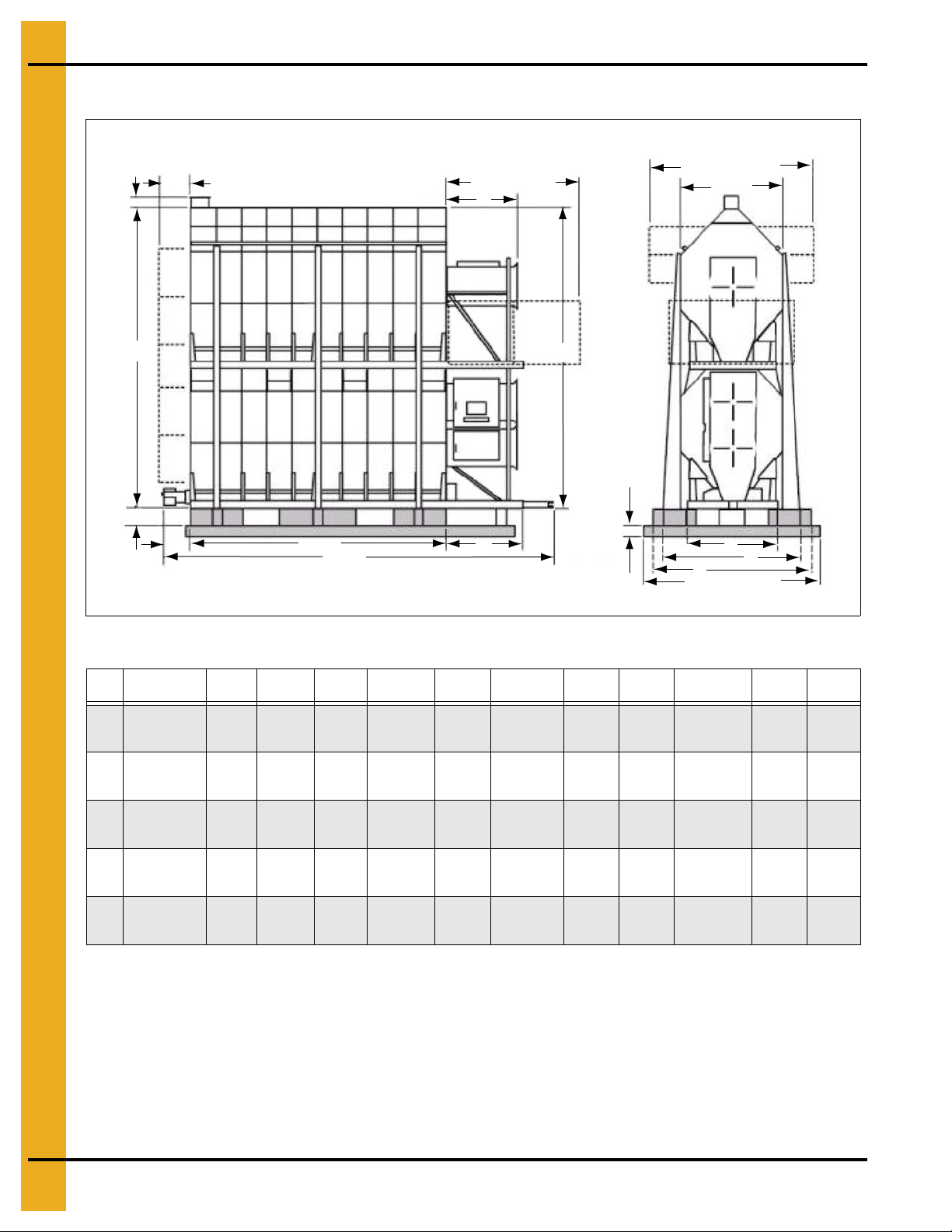

FFI Dimensions

4. Specifications

Figure 4A

Figure 4B

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 13

Page 14

4. Specifications

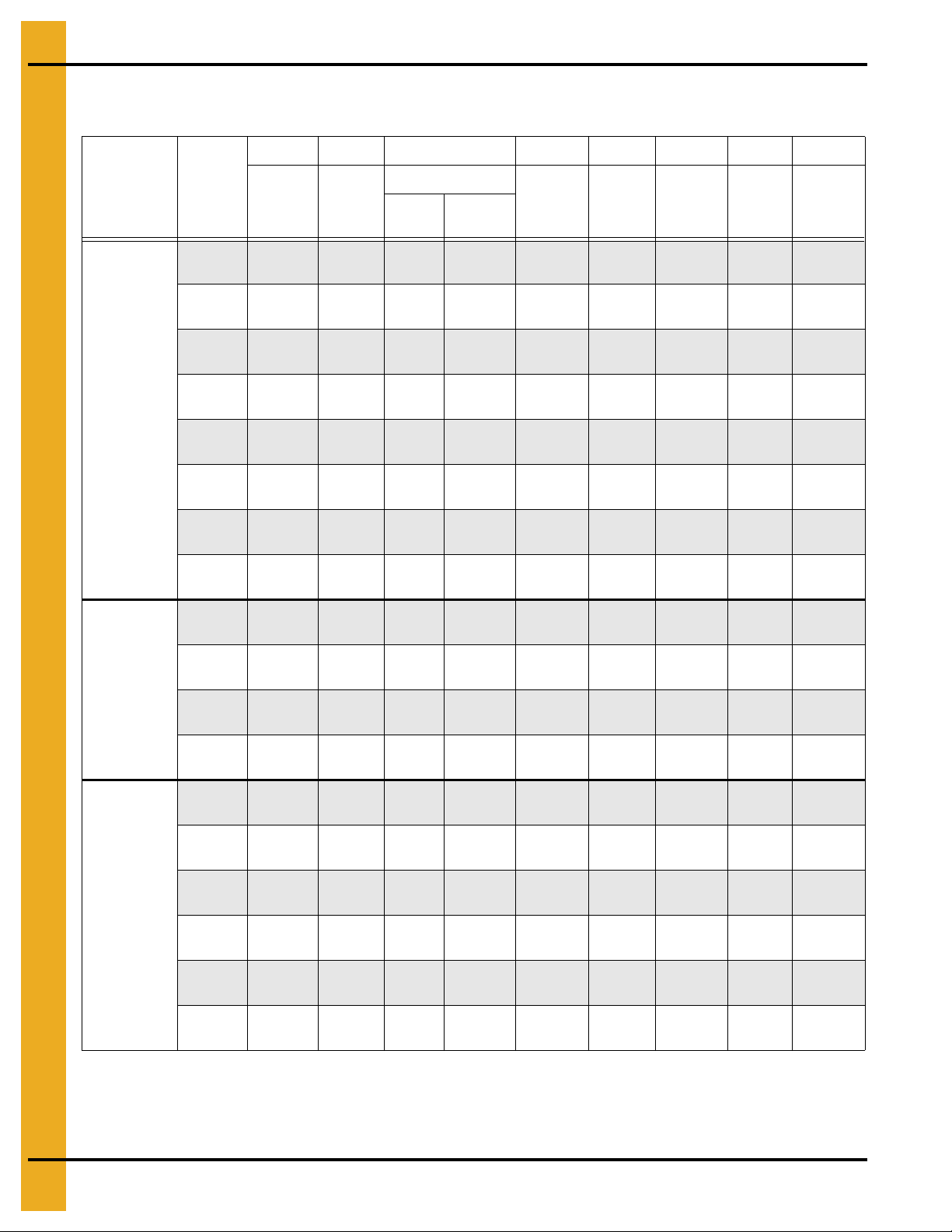

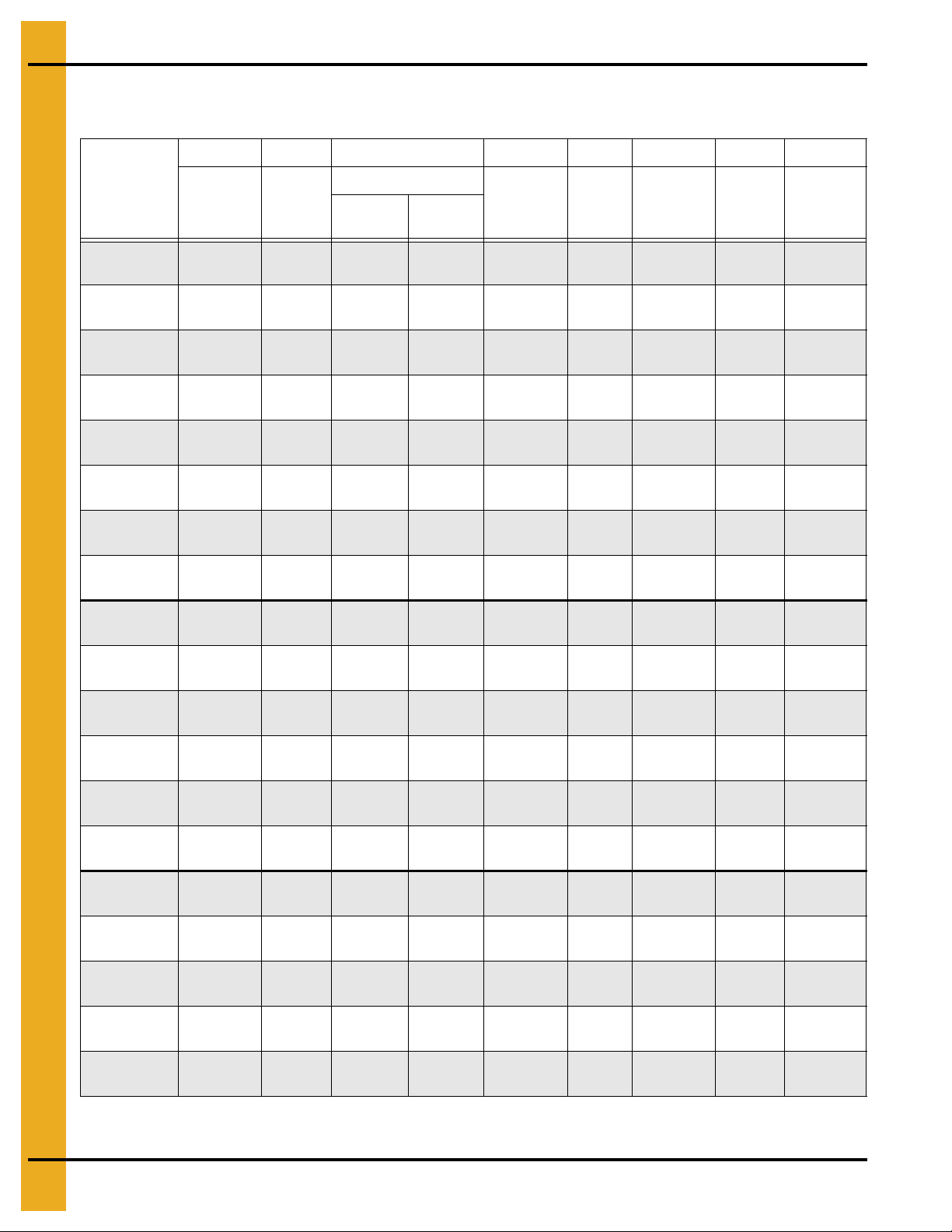

Single Module FFI Transport and Installation Dimensions

Values are Valid for Transportation of Stack Modules

AB C DE FGH

1 Fan CFAB

Series Dryers

Dryer

Basket

190T (10')

270 (12')

320 (14')

370 (16')

400 (18')

460 (20')

511 (22')

601 (26')

320 (14')

Transport

Height

3632.2

(11' 11")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

Installed

Width

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2641.6

(8' 8")

Installed Height

Wet

Bin

3962.4

(13')

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

Standard

Top

3505.2

(11' 6")

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

Height w/o

Wet Bin

3124.2

(10' 3")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

Frame

Width

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

Transport

Width

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

Installed

Length

5232.4

(17' 2")

5842.0

(19' 2")

6451.6

(21' 2")

7061.2

(23' 2")

7670.8

(25' 2")

8280.4

(27' 2")

8890.0

(29' 2")

10109.2

(33' 2")

6451.6

(21' 2")

Transport

Length

5842.0

(19' 2")

6451.6

(21' 2")

7061.2

(23' 2")

7670.8

(25' 2")

8280.4

(27' 2")

8890.0

(29' 2")

9499.6

(31' 2")

10718.8

(35' 2")

7061.2

(23' 2")

2 Fan CFAB

410 (18')

Series Dryers

510 (22')

600 (26')

2120 (14')

2122 (16')

2125 (18')

C2100A

Series Dryers

2130 (20')

2132 (22')

2140 (26')

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

4089.4

(13' 5")

NOTE: All dimensions are in mm.

2641.6

(8' 8")

2641.6

(8' 8")

2641.6

(8' 8")

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

4419.6

(14' 6")

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

3581.4

(11' 9")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

1955.8

(6' 5")

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

7670.8

(25' 2")

8890.0

(29' 2")

10109.2

(33' 2")

6451.6

(21' 2")

7061.2

(23' 2")

7670.8

(25' 2")

8280.4

(27' 2")

8890.0

(29' 2")

10109.2

(33' 2")

8280.4

(27' 2")

9499.6

(31' 2")

10718.8

(35' 2")

7061.2

(23' 2")

7670.8

(25' 2")

8280.4

(27' 2")

8890.0

(29' 2")

9499.6

(31' 2")

10718.8

(35' 2")

14 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 15

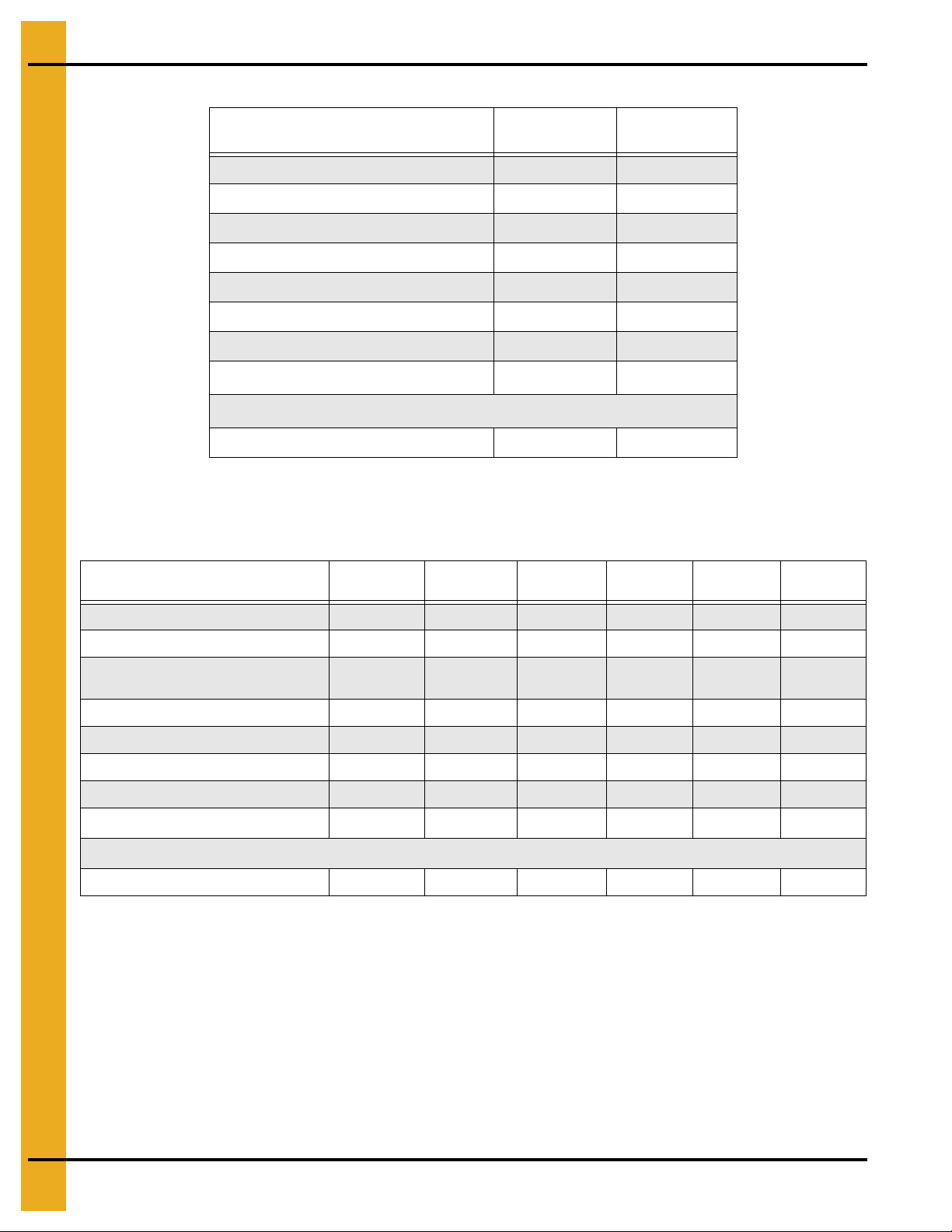

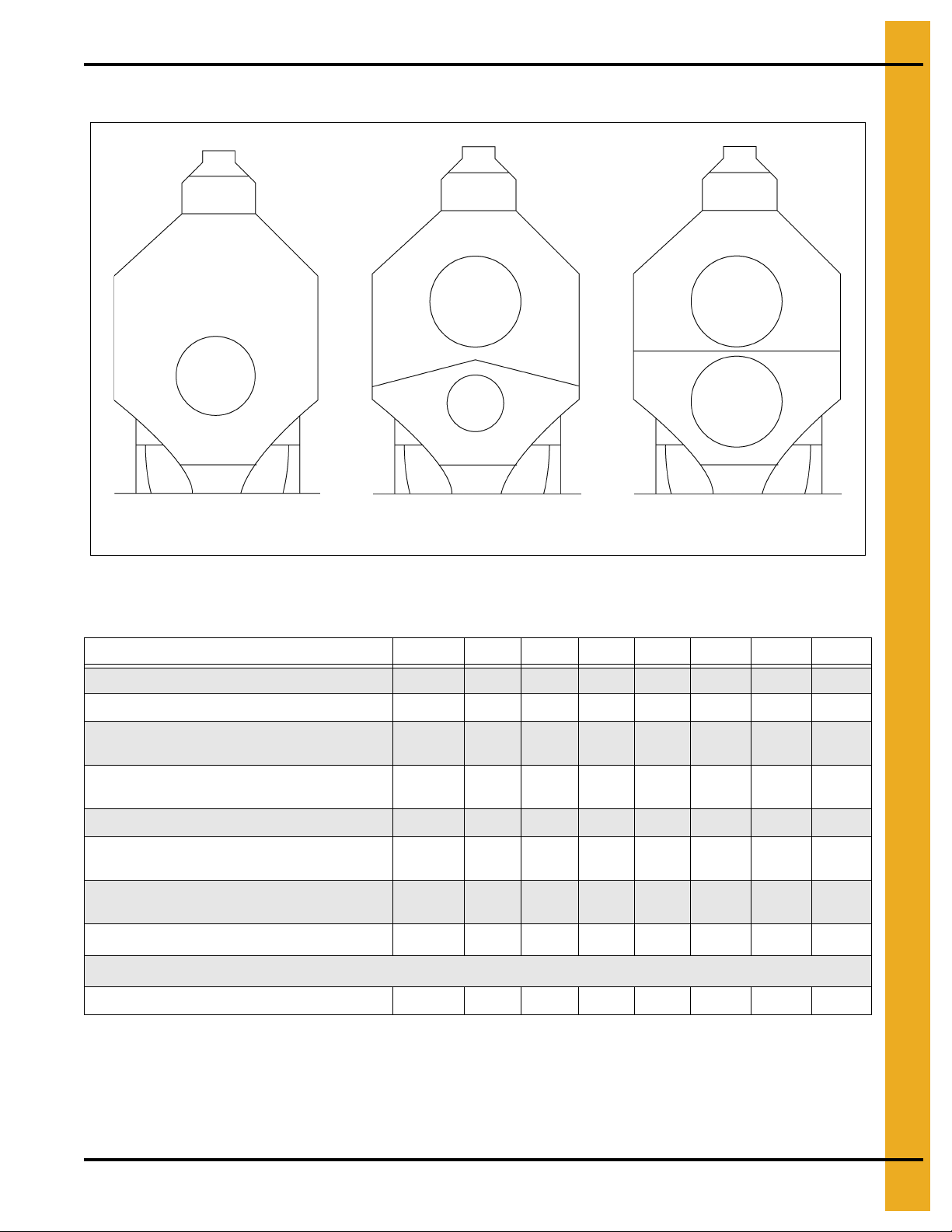

FFI Specifications

2 Fan CFAB profile

C2100A Profile

1 Fan CFAB profile

4. Specifications

Figure 4C

1 Fan CFAB Specifications

CFAB 150 8'CFAB 190

Total Holding Capacity (Bushels) 173 216 294 357 436 509 565 622 735

Grain Column Holding Capacity (Bushels) 149 186 257 300 376 414 460 506 598

Fans

Top Auger

Capacity (BPH) 680 925 1150 1800 2800 2800 2800 2800 2800

Bottom Auger

Meter Roll Drive

Capacity - Maximum Rate

Electrical Load (Fans, Top and Bottom Augers2)

380 Volt, 50 Hz, 3 Phase 23 30 30 32 40 46 61 69 91

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unlo ad conveyor equipment.

1

(BPH)

28"

10-13 HP

8" Dia.

1.5 HP

8" Dia.

1 HP

SCR,

3/4 HP

1120 1400 1680 1960 2240 2520 2800 3080 3640

10-13 HP

8" Dia.

2 HP

8" Dia.

1.5 HP

SCR,

3/4 HP

10'

28"

CFAB 270

12'

36 "

15 HP

8" Dia.

2 HP

8" Dia.

2 HP

SCR,

3/4 HP

CFAB 320

14'

40 "

15 HP

8" Dia.

5 HP

8" Dia.

3 HP

SCR,

3/4 HP

CFAB 370

16'

40 "

15 HP

8" Dia.

5 HP

8" Dia.

3 HP

SCR,

3/4 HP

CFAB 400

18'

42 "

20 HP

8" Dia.

5 HP

8" Dia.

3 HP

SCR,

3/4 HP

CFAB 460

20'

42 "

25 HP

8" Dia.

7.5 HP

8" Dia.

5 HP

SCR,

3/4 HP

CFAB 51 1

22'

42 "

30 HP

8" Dia.

7.5 HP

8" Dia.

5 HP

SCR,

3/4 HP

CFAB 601

40 HP

8" Dia.

10 HP

8" Dia.

7.5 HP

SCR,

3/4 HP

26'

42 "

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 15

Page 16

4. Specifications

2 Fan CFAB Specifications

CFAB 510

22'

Total Holding Capacity (Bushels) 622 735

Grain Column Holding Capacity (Bushels) 506 598

Fans 36" 15 HP (2) 40" 20 HP (2)

Top Auger 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BPH) 2800 2800

Bottom Auger 8" Dia. 5 HP 8" Dia. 7.5 HP

Meter Roll Drive SCR, 3/4 HP SCR, 3/4 HP

Capacity - Maximum Rate

1

(BPH)

3080 3640

Electrical Load (Fans, Top and Bo ttom Augers2)

380 Volt, 50 Hz, 3 Phase 69 109

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% t o 100% of maximum rate.

2

Excludes auxiliary load and unl o ad conveyor equipment.

C2100A Specifications

CFAB 600

26'

C2120A

14'

Total Holding Capacity (Bushels) 375 436 490 544 599 708

Grain Column Holding Capacity (Bushels) 322 376 415 460 517 600

Fans

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BPH) 1800 2800 2800 2800 2800 2800

Bottom Auger 8" Dia. 3 HP 8" Dia. 3 HP 8" Dia. 3 HP 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP

Meter Roll Drive SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP

Capacity - Maximum Rate1 (BPH)

Electrical Load (Fans, Top and Bottom Augers2)

380 Volt, 50 Hz, 3 Phase 50 56 56 63 69 87

1

Actual discharge rate is controlled by meter ro ll sp ee d ad ju stment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unl oad conveyor equipment.

28" 10-13 HP/

28" 10-13 HP

1960 2240 2520 2800 3080 3640

C2122A

16'

28" 10-13 HP/

36" 15 HP

C2125A

18'

28" 10-13 HP/

36" 15 HP

C2130A

20'

28" 10-13 HP/

40" 20 HP

C2132A

22'

28" 10-13 HP/

42" 20 HP

C2140A

26'

28" 10-13 HP/

42" 25 HP

16 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 17

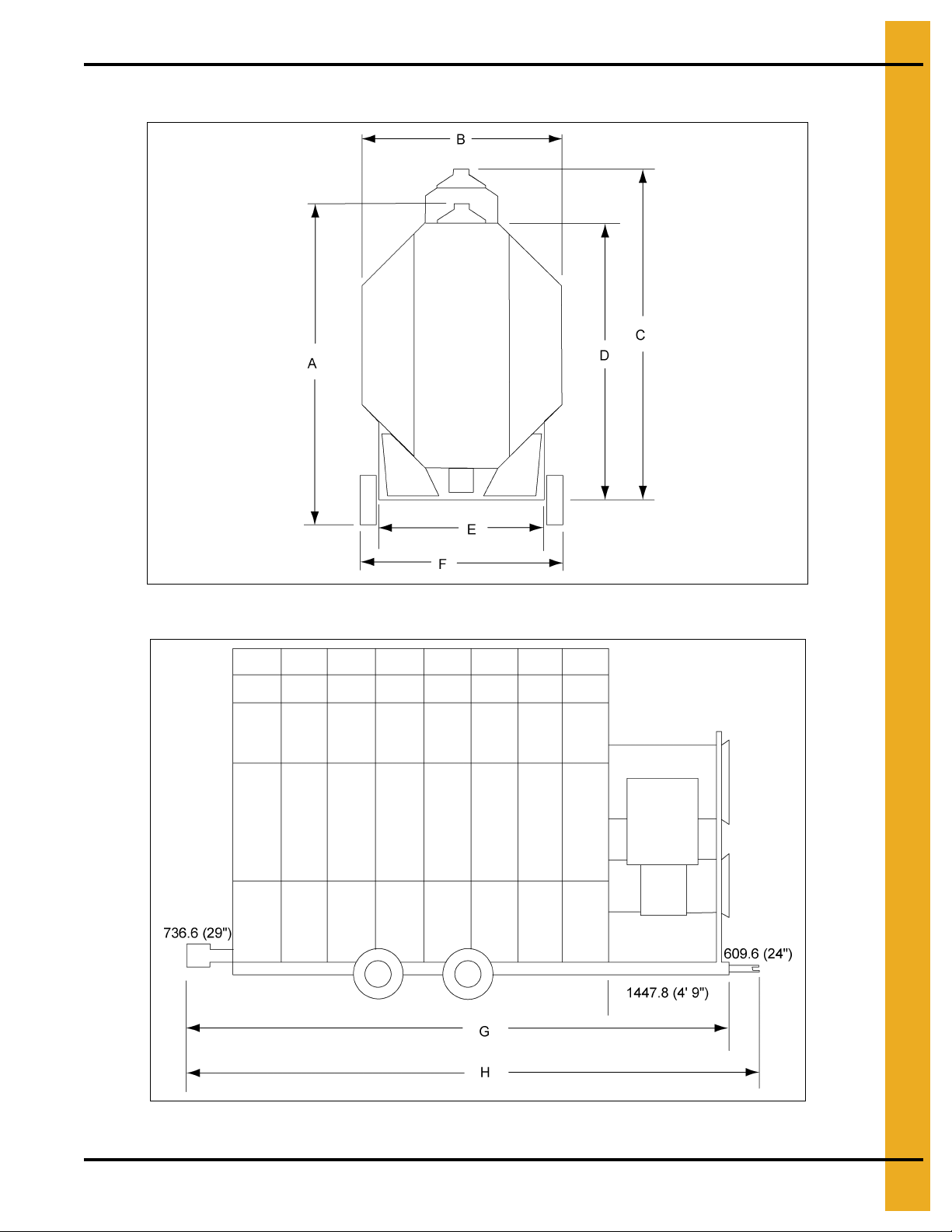

GSI Dimensions

4. Specifications

Figure 4D

Figure 4E

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 17

Page 18

4. Specifications

AB C DEFGH

Single Module GSI Transport and Installation Dimensions

Values are Valid for Transportation of Stack Modules

Dryer

Basket

1108T

1112

1114

1116

1118

1120

1122

1126

1214

Transport

Height

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

Installed

Width

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

Installed Height

Wet

Bin

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

Standard

3962.4

3962.4

3962.4

3962.4

3962.4

3962.4

3962.4

3962.4

3962.4

Top

(13')

(13')

(13')

(13')

(13')

(13')

(13')

(13')

(13')

Height w/o

Wet Bin

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

Frame

Width

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

Transport

Width

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

Installed

Length

4622.8

(15' 2'')

5842.0

(19' 2'')

6451.6

(21' 2'')

7061.2

(23' 2'')

7670.8

(25' 2'')

8280.4

(27' 2'')

8890.0

(29' 2'')

10109.2

(33' 2'')

6451.6

(21' 2'')

Transport

Length

5232.4

(17' 2'')

6451.6

(21' 2'')

7061.2

(23' 2'')

7670.8

(25' 2'')

8280.4

(27' 2'')

8890.0

(29' 2'')

9499.6

(31' 2'')

10718.8

(35' 2'')

7061.2

(23' 2'')

1216

1218

1220

1222

1226

1214S

1218S

1220S

1222S

1226S

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

4089.4

(13' 5'')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2641.6

(8' 8'')

2641.6

(8' 8'')

2641.6

(8' 8'')

2641.6

(8' 8'')

2641.6

(8' 8'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

4419.6

(14' 6'')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3962.4

(13')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

3581.4

(11' 9'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

1955.8

(6' 5'')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

2438.4

(8')

7061.2

(23' 2'')

7670.8

(25' 2'')

8280.4

(27' 2'')

8890.0

(29' 2'')

10109.2

(33' 2'')

6451.6

(21' 2'')

7670.8

(25' 2'')

8280.4

(27' 2'')

8890.0

(29' 2'')

10109.2

(33' 2'')

7670.8

(25' 2'')

8280.4

(27' 2'')

8890.0

(29' 2'')

9499.6

(31' 2'')

10718.8

(35' 2'')

7061.2

(23' 2'')

8280.4

(27' 2'')

8890.0

(29' 2'')

9499.6

(31' 2'')

10718.8

(35' 2'')

NOTE: All dimensions are in mm.

18 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 19

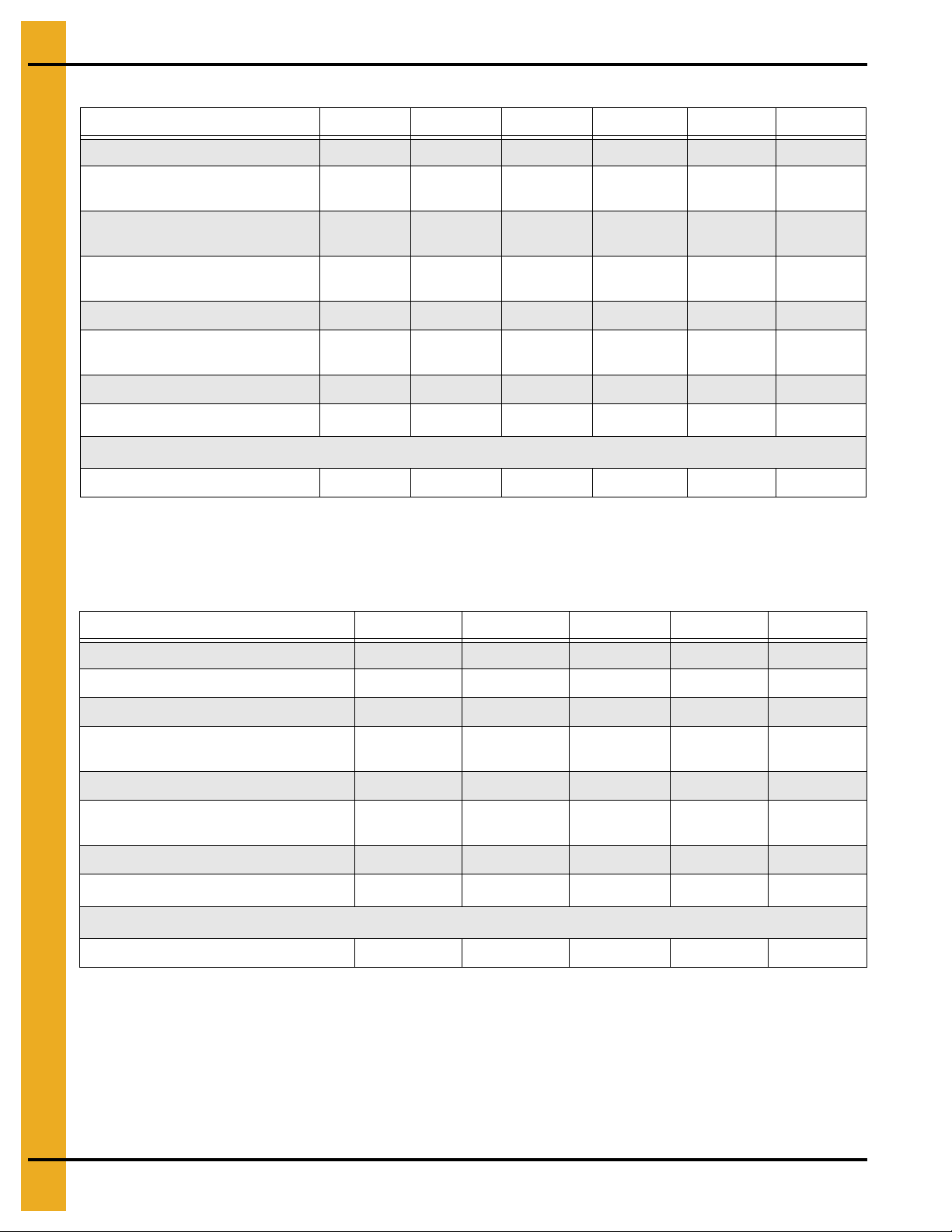

GSI Specifications

1200 Series profile

1200S Series profile

1100 Series profile

4. Specifications

Figure 4F

1100 Series Dryer Specifications

1108T 1112 1114 1116 1118 1120 1122 1126

Total Holding Capacity (Bushels) 190 327 381 436 490 544 599 708

Grain Column Holding Capacity (Bushels) 160 282 329 376 423 470 517 611

Fans

Top Auger

Capacity (BPH) 2900 2900 3800 3800 3800 3800 3800 3800

Bottom Auger

Meter Roll Drive

Capacity - Maximum Rate

Electrical Load (Fans, Top and Bottom Augers2)

3 Phase, 380 Volt 22 33 36 44 49 68 75 88

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

1

(BPH)

28''

10-13 HP

8'' Dia.

1-1/2 HP

8'' Dia.

1 HP

SCR,

3/4 HP

1120 1680 1960 2240 2520 2800 3080 3640

36''

15 HP

8'' Dia.

3 HP

8'' Dia.

1-1/2 HP

SCR,

3/4 HP

40''

15 HP

8'' Dia.

5 HP

8'' Dia.

3 HP

SCR,

3/4 HP

40''

15 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

SCR,

3/4 HP

42''

20 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

SCR,

3/4 HP

42''

25 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

SCR,

3/4 HP

42''

30 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

SCR,

3/4 HP

42''

40 HP

8'' Dia.

10 HP

8'' Dia.

10 HP

SCR,

3/4 HP

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 19

Page 20

4. Specifications

1200 Series Dryer Specifications

1214 1216 1218 1220 1222 1226

Total Holding Capacity (Bushels) 381 436 490 544 599 708

Grain Column Holding

Capacity (Bushels)

Fans

Top Auger

Capacity (BPH) 3800 3800 3800 3800 3800 3800

Bottom Auger

Meter Roll Drive SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP

Capacity - Maximum Rate

Electrical Load (Fans, Top and Bottom Augers2)

3 Phase, 380 Volt 50 61 61 70 75 90

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

1

(BPH)

329 376 423 470 517 611

26'' 10-13 HP

36'' 10-13 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

1960 2240 2520 2800 3080 3640

26'' 10-13 HP

36'' 15 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

26'' 10-13 HP

36'' 15 HP

8'' Dia.

5 HP

8'' Dia.

5 HP

28'' 10-13 HP

40" 15 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

28'' 10-13 HP

42'' 20 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

28'' 10-13 HP

42'' 25 HP

8'' Dia.

10 HP

8'' Dia.

10 HP

1200S Series Dryer Specifications

1214S 1218S 1220S 1222S 1226S

Total Holding Capacity (Bushels) 381 490 544 599 708

Grain Column Holding Capacity (Bushels) 329 423 470 517 611

Fans 28'' 10-13 HP (2) 36'' 10-13 HP (2) 36'' 15 HP (2) 36'' 15 HP (2) 40'' 25 HP (2)

Top Auger

Capacity (BPH) 3800 3800 3800 3800 3800

Bottom Auger

Meter Roll Drive SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP SCR, 3/4 HP

Capacity - Maximum Rate

Electrical Load (Fans, Top and Bottom Augers2)

3 Phase, 380 Volt 50 50 80 80 115

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

1

(BPH)

8'' Dia.

5 HP

8'' Dia.

5 HP

1960 2520 2800 3080 3640

8'' Dia.

5 HP

8'' Dia.

5 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

8'' Dia.

7-1/2 HP

8'' Dia.

10 HP

8'' Dia.

10 HP

20 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 21

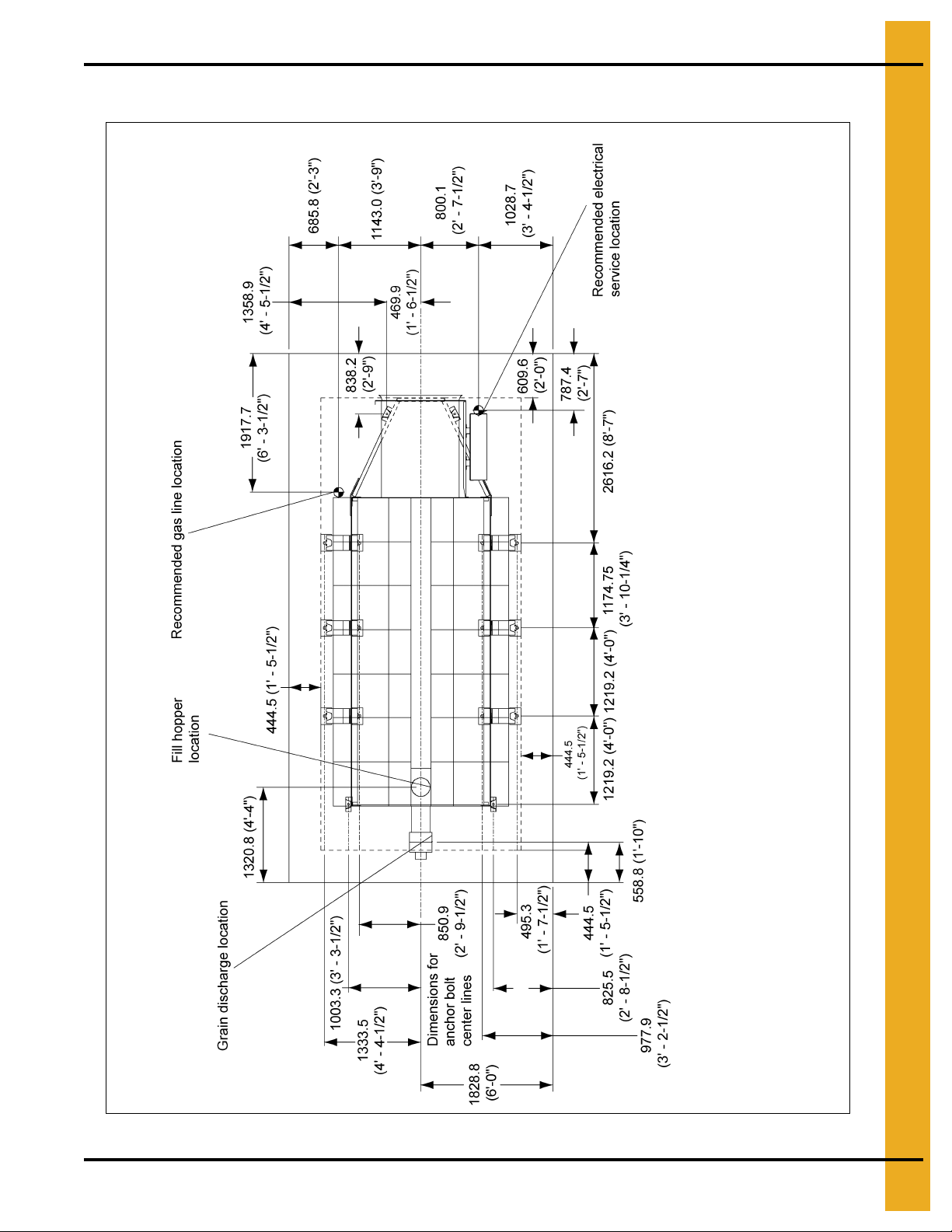

All Stack Dimensions

NOTE: All dimensions are in mm.

4. Specifications

Figure 4G Example of Stack Dryer Footprint

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 21

Page 22

4. Specifications

“X” - Varies with dryer length (See Chart on Page 23.)

“X” - Varies with dryer length

(See Chart on Page 23.)

All Stack Dimensions (Continued)

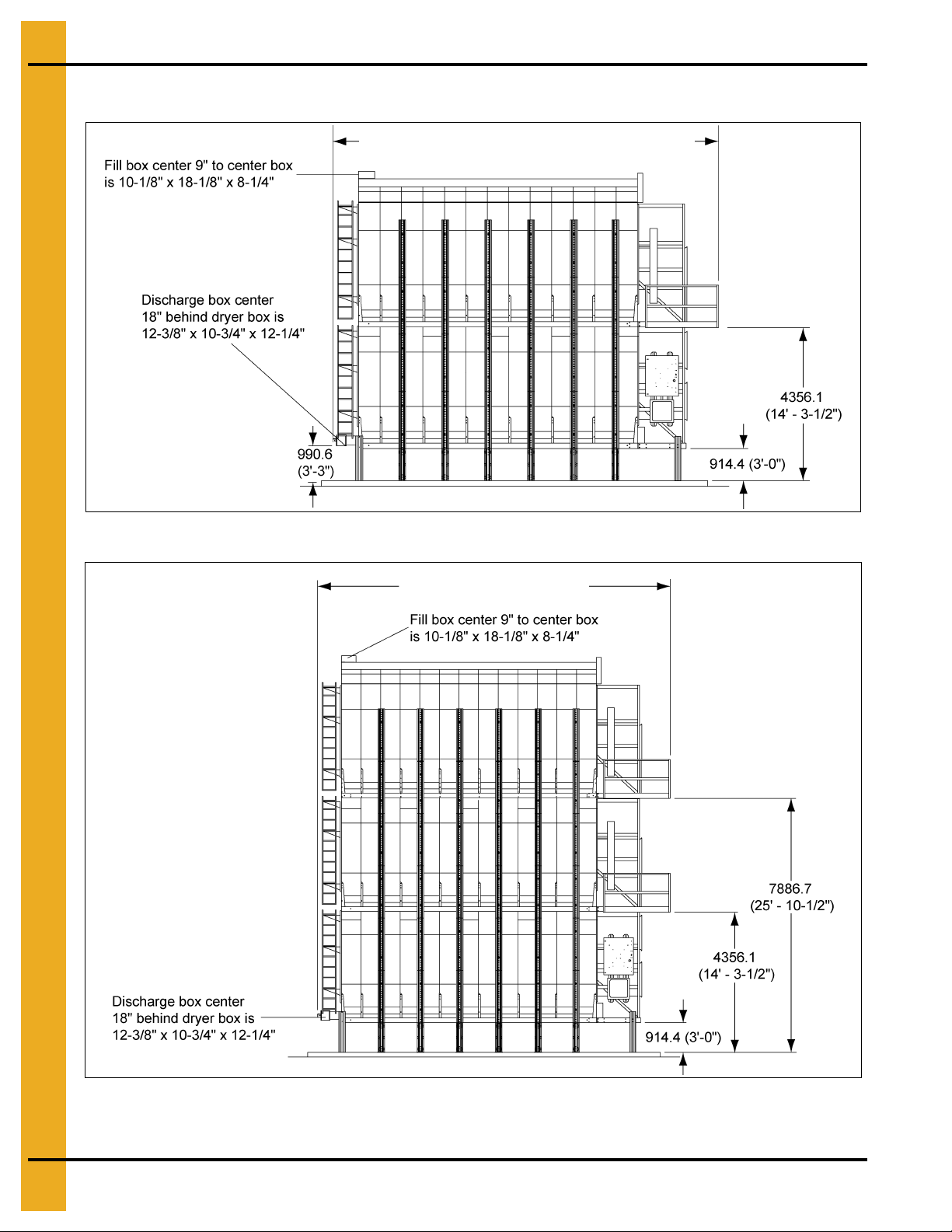

Figure 4H Side View - 2 Module Stack Dryer

Figure 4I Stack Dryer Dimension (Side View - 3 Module Stack Dryer)

NOTE: All dimensions are in mm.

22 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 23

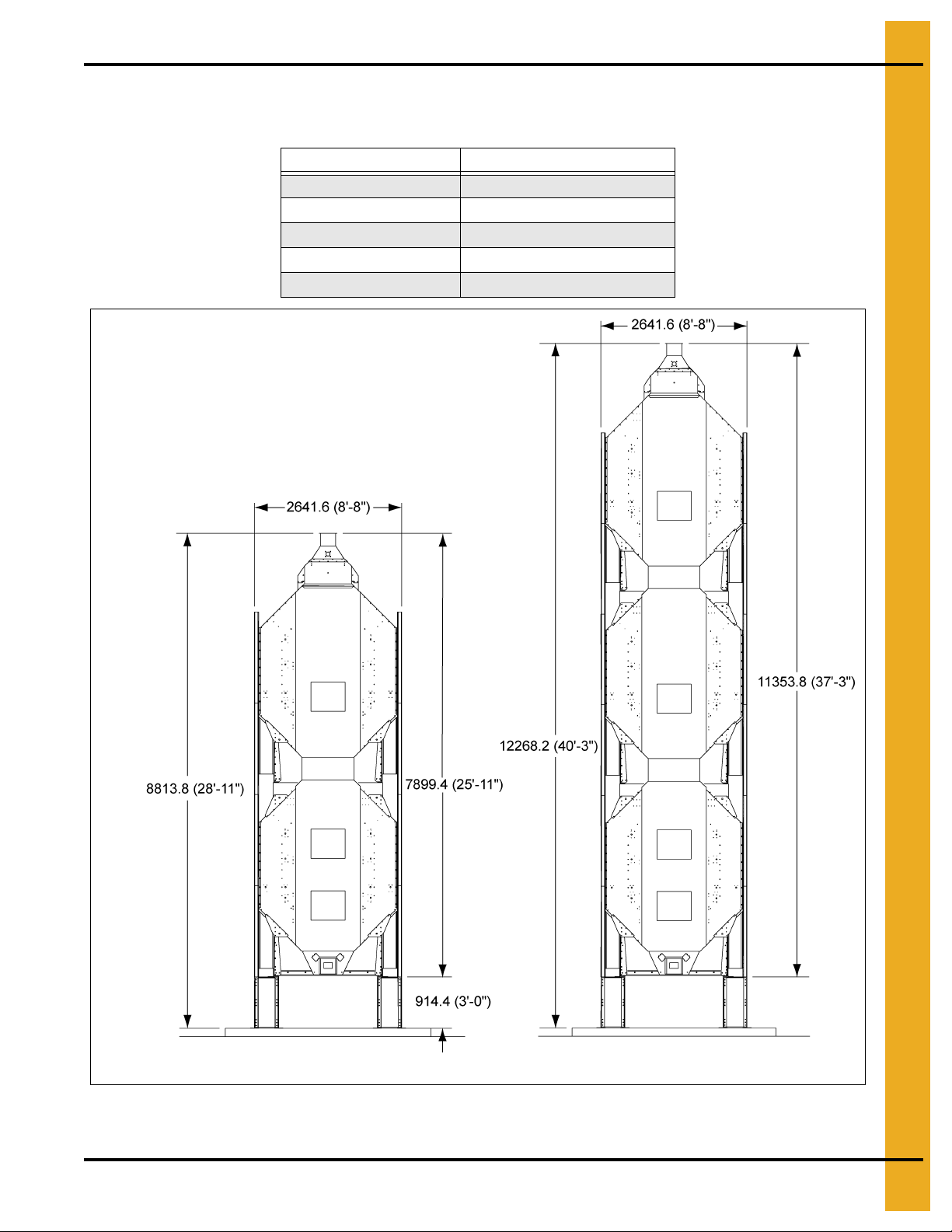

All Stack Dimensions (Continued)

End View - 2 Module Stack Dryer

End View - 3 Module Stack Dryer

Dryer Installed Length (1, 2 and 3 Module Stacks)

Basket Length Installed Length

14 7264.4 (23' 10")

18 8483.6 (27' 10")

20 9093.2 (29' 10")

22 9702.8 (31' 10")

26 10922.0 (35' 10")

4. Specifications

Figure 4J

NOTE: All dimensions are in mm.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 23

Page 24

4. Specifications

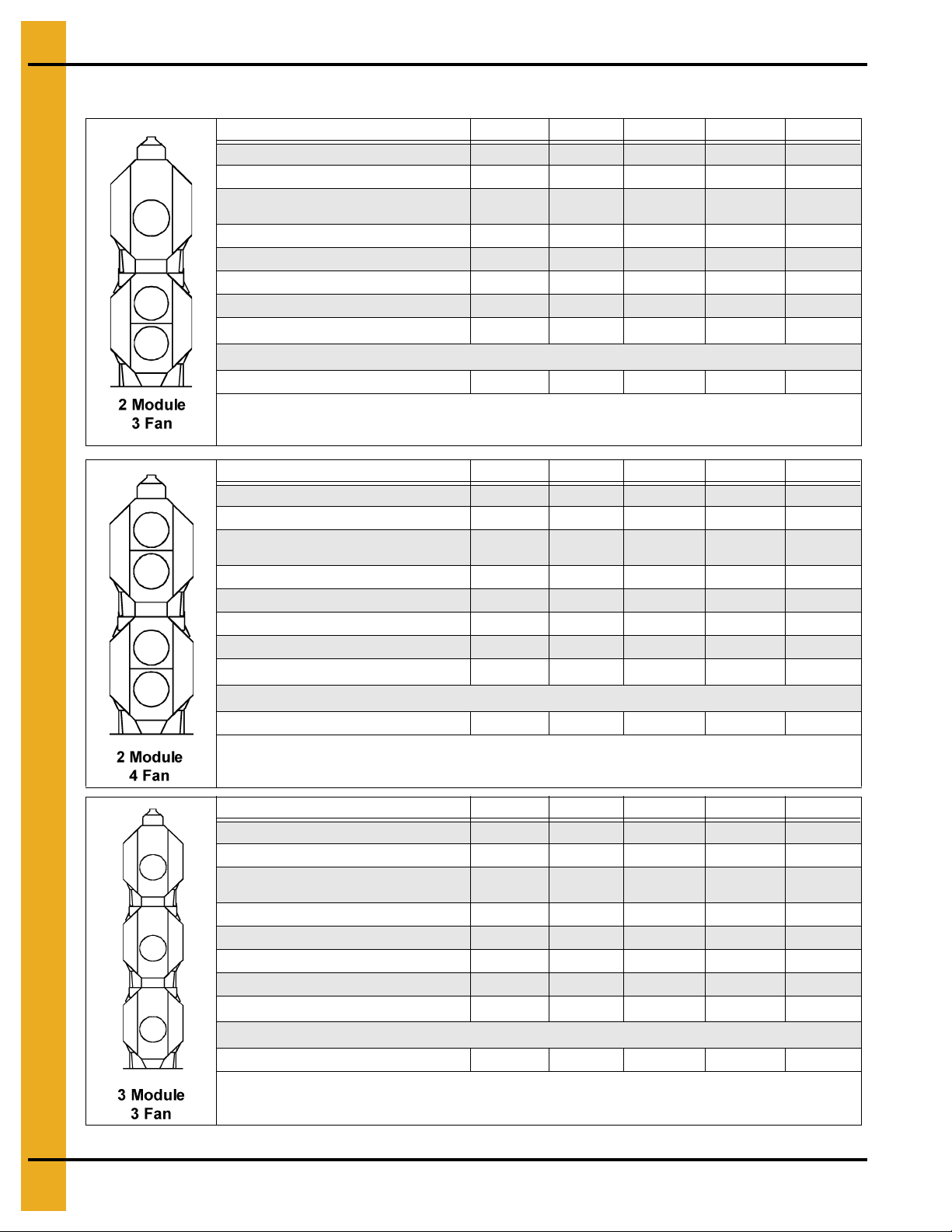

All Stack Specifications

Total Holding Capacity (Bushels) 731 940 1044 1149 1304

Grain Column Holding Capacity (Bushels) 679 873 970 1067 1261

Fans

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BPH) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

Capacity - Maximum Rate

Electrical Load (Fans, Top and Bottom Augers2)

3 Phase, 380-400 Volt 61 66 91 96 141

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

Total Holding Capacity (Bushels) 731 940 1044 1149 1304

Grain Column Holding Capacity (Bushels) 679 873 970 1067 1261

Fans

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BPH) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

Capacity - Maximum Rate

Electrical Load (Fans, Top and Bottom Augers2)

3 Phase, 380-400 Volt 69 69 98 98 154

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

1

1

(BPH)

(BPH)

14' 18' 20' 22' 26'

28" 10-13 HP

40" 15 HP

1960 2520 2800 3080 3640

14' 18' 20' 22' 26'

28" 10-13 HP

28" 10-13 HP

1960 2520 2800 3080 3640

36" 10-12 HP

42" 20 HP

36" 10-13 HP

36" 10-13 HP

36" 15 HP

42" 25 HP

36" 15 HP

36" 15 HP

36" 15 HP

42" 30 HP

36" 15 HP

36" 15 HP

40" 25 HP

42" 40 HP

40" 25 HP

40" 25 HP

14' 18' 20' 22' 26'

Total Holding Capacity (Bushels) 1074 1381 1534 1688 1995

Grain Column Holding Capacity (Bushels) 1022 1314 1460 1606 1898

Fans

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BPH) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

1

Capacity - Maximum Rate

Electrical Load (Fans, Top and Bottom Augers2)

3 Phase, 380-400 Volt 72 88 116 131 179

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

(BPH)

40" 15 HP

40" 15 HP

1960 2520 2800 3080 3640

42" 20 HP

42" 20 HP

42" 25 HP

42" 25 HP

42" 30 HP

42" 30 HP

42" 40 HP

42" 40 HP

24 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 25

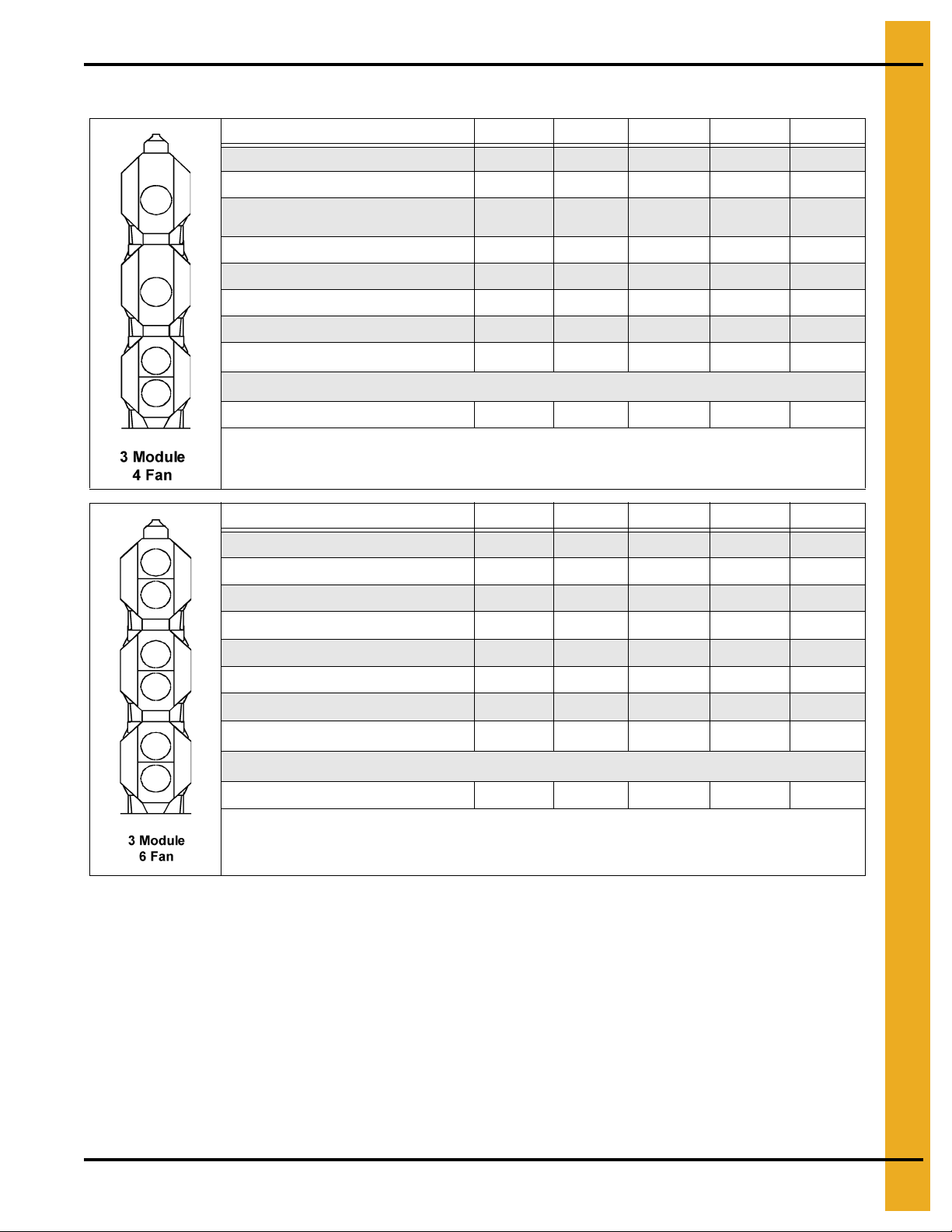

All Stack Specifications (Continued)

To tal Holding Capacity (Bushels) 1074 1381 1534 1688 1995

Grain Column Holding Capacity (Bushels) 1022 1314 1460 1606 1898

Fans

Top Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BPH) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

1

Capacity - Maximum Rate

Electrical Load (Fans, Top and Bottom Augers2)

3 Phase, 380-400 Volt 80 91 123 133 192

1

Actual discharge rate is controlled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

(BPH)

28" 10-13 HP

40" 15 HP

4. Specifications

14' 18' 20' 22' 26'

36" 10-13 HP

42" 20 HP

1960 2520 2800 3080 3640

36" 15 HP

42" 25 HP

36" 15 HP

42" 30 HP

40" 25 HP

42" 40 HP

14' 18' 20' 22' 26'

Total Holding Capacity (Bushels) 1074 1381 1534 1688 1995

Grain Column Holding Capacity (Bushels) 1022 1314 1460 1606 1898

Fans 28" 10-13 HP 36" 10-13 HP 36" 15 HP 36" 15 HP 40" 25 HP

To p Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Capacity (BPH) 3800 3800 3800 3800 3800

Bottom Auger 8" Dia. 5 HP 8" Dia. 5 HP 8" Dia. 7.5 HP 8" Dia. 7.5 HP 8" Dia. 10 HP

Meter Roll Drive SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP SCR, 1/3 HP

Capacity - Maximum Rate1 (BPH)

1960 2520 2800 3080 3640

Electrical Load (Fans, Top and Bottom Augers2)

3 Phase, 380-400 Volt 97 97 137 137 218

1

Actual discharge rate is cont rolled by meter roll speed adjustment, at 5% to 100% of maximum rate.

2

Excludes auxiliary load and unload conveyor equipment.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 25

Page 26

4. Specifications

H

L

E

B

C

A

D

L

J

N

M

F

G

2362.2 (7'-9")-SAFETY

PLATFORM

3962.4 (13'-0")-OPTIONAL

CATWALK

4267.2 (14'-0")

812.8 (2'-8")-REAR SAFETY CAGE

SEE NOTE 3

SEE

NOTE 2

SEE

NOTE 1

All Stack Specifications (Continued)

Figure 4K

ABCD

14'

18'

20'

22'

26'

7048.5

(23'-1-1/2")

8267.7

(27'-1-1/2")

8877.3

(29'-1-1/2")

9486.9

(31'-1-1/2")

10706.1

(35'-1-1/2")

660.4

(2'-2")

660.4

(2'-2")

660.4

(2'-2")

660.4

(2'-2")

660.4

(2'-2")

4267.2

(14'-0")

5486.4

(18'-0")

6096.0

(20'-0")

6705.6

(22'-0")

7924.8

(26'-0")

1422.4

(4'-8")

1422.4

(4'-8")

1422.4

(4'-8")

1422.4

(4'-8")

1422.4

(4'-8")

NOTE: All dimensions are in mm.

1

E

406.4

(16" Min.)

406.4

(16" Min.)

406.4

(16" Min.)

406.4

(16" Min.)

406.4

(16" Min.)

FGHJ LMN

3403.6

(11'-2")

3403.6

(11'-2")

3403.6

(11'-2")

3403.6

(11'-2")

3403.6

(11'-2")

1466.85

(4'-9-3/4")

1466.85

(4'-9-3/4")

1466.85

(4'-9-3/4")

1466.85

(4'-9-3/4")

1466.85

(4'-9-3/4")

203.2

(0'-8")

203.2

(0'-8")

203.2

(0'-8")

203.2

(0'-8")

203.2

(0'-8")

2438.4

2438.4

2438.4

2438.4

2438.4

(8'-0")

(8'-0")

(8'-0")

(8'-0")

(8'-0")

(23'-9-1/2")

(23'-9-1/2")

(23'-9-1/2")

(23'-9-1/2")

(23'-9-1/2")

7251.7

7251.7

7251.7

7251.7

7251.7

3048.0

(10'-0")

3048.0

(10'-0")

3048.0

(10'-0")

3048.0

(10'-0")

3048.0

(10'-0")

1930.4

(6'-4")

1930.4

(6'-4")

1930.4

(6'-4")

1930.4

(6'-4")

1930.4

(6'-4")

1. A 12" thick reinforced concrete foundation and 16" pedestal (min.) are required. See bulletin

FL-02-2 for details. 32" Thick pedestal required for heat reclaimer option. (See bulletin FL-03-2

for details.)

2. Approximate location of standard service platform shown. See bulletin SP-02-2 for details.

For information on optional catwalk, see bulletin CATH-01-5.

3. For safety cage information, refer to bulletin SC-01-2.

26 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 27

All Stack Specifications (Continued)

H

L

E

B

C

A

D

L

J

K

N

F

G

4267.2 (14'-0")

812.8 (2'-8")-REAR SAFETY CAGE

SEE NOTE 3

2362.2 (7'-9")-SAFETY

PLATFORM

3962.4 (13'-0")-OPTIONAL

CATWALK

SEE

NOTE 2

SEE

NOTE 1

4. Specifications

Figure 4L

A BCD

14'

18'

20'

22'

26'

7048.5

(23'-1-1/2")

8267.7

(27'-1-1/2")

8877.3

(29'-1-1/2")

9486.9

(31'-1-1/2")

10706.1

(35'-1-1/2")

660.4

(2'-2")

660.4

(2'-2")

660.4

(2'-2")

660.4

(2'-2")

660.4

(2'-2")

4267.2

(14'-0")

5486.4

(18'-0")

6096.0

(20'-0")

6705.6

(22'-0")

7924.8

(26'-0")

1422.4

(4'-8")

1422.4

(4'-8")

1422.4

(4'-8")

1422.4

(4'-8")

1422.4

(4'-8")

1

E

406.4

(16" Min.)

406.4

(16" Min.)

406.4

(16" Min.)

406.4

(16" Min.)

406.4

(16" Min.)

FGHJKL N

3403.6

(11'-2")

3403.6

(11'-2")

3403.6

(11'-2")

3403.6

(11'-2")

3403.6

(11'-2")

1466.85

(4'-9-3/4")

1466.85

(4'-9-3/4")

1466.85

(4'-9-3/4")

1466.85

(4'-9-3/4")

1466.85

(4'-9-3/4")

203.2

(0'-8")

203.2

(0'-8")

203.2

(0'-8")

203.2

(0'-8")

203.2

(0'-8")

2438.4

(8'-0")

2438.4

(8'-0")

2438.4

(8'-0")

2438.4

(8'-0")

2438.4

(8'-0")

914.4

(3'-0")

914.4

(3'-0")

914.4

(3'-0")

914.4

(3'-0")

914.4

(3'-0")

7251.7

(23'-9-1/2")

7251.7

(23'-9-1/2")

7251.7

(23'-9-1/2")

7251.7

(23'-9-1/2")

7251.7

(23'-9-1/2")

1930.4

(6'-4")

1930.4

(6'-4")

1930.4

(6'-4")

1930.4

(6'-4")

1930.4

(6'-4")

NOTE: All dimensions are in mm.

1. A 12" thick reinforced concrete foundation and 16" pedestal (min.) are required. See bulletin

FL-02-2 for details. 32" Thick pedestal required for heat reclaimer option. (See bulletin FL-03-2

for details.)

2. Approximate location of standard service platform shown. See bulletin SP-02-2 for details.

For information on optional catwalk, see bulletin CATH-01-5.

3. For safety cage information, refer to bulletin SC-01-2.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 27

Page 28

4. Specifications

Stack Dryer Foundation Specifications

Stack Dryer Foundation

Basket Length 14 18 20 22 26

Concrete Pad Size (12' x “X”)

Concrete (Cubic Yards) (Cubic Meters)

#4 Rebar (Feet)

Anchors

1

2

3

3

10" (254 mm) Depth with 36" (914.4 mm) wide x 36" (914.4 mm) deep footings along each side.

#4 Reinforcing rods on 1' (304.8 mm)-0" centers. Both directions in slab and bottom of footing.

Use 3/4" (19.05 mm) x 9-5/8" (244.475 mm) minimum anchors with epoxy. GSI part #: Anchor (GTC-0003)

epoxy (GTC-0004).

2

(mm)

1

12' (3657.6) x

24' (7315.2)

20-3/4

(15.86451)

900'

(274320)

16 20 22 24 28

12' (3657.6) x

28' (8534.4)

24-1/4

(18.54046)

1060'

(323088)

12' (3657.6) x

30' (9144.0)

26

(19.87843)

1140'

(347472)

12' (3657.6) x

32' (9753.6)

27-1/2

(21.02526)

1220'

(371856)

Minimum soil bearing capacity = 2000 PSF.

Concrete specifications:

• Compressive strength at 28 days - 4000 PSI.

• Minimum cement content - 6 sacks/yard.

• Maximum slump - 4"±1".

12' (3657.6) x

36' (10972.8)

31

(23.7012)

1400'

(426720)

28 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 29

Vision Control Panel Layout

AUTO

AUTO

AUTO

AUTO

AUTO

(FANS RUN

EXCEPT DURING

BATCH UNLOAD)

(LES VENTILATEURS

FONCTIONNENT EXCEPTÉ

PENDANT UN

DÉCHARGEMENT DE LOT)

(FANS RUN

CONTINUOUSLY)

MARCHE

ON

MARCHE

ON

MARCHE

ON

MARCHE

ON

AUTO

MARCHE

ON

MARCHE

ON

(LES VENTILATEURS

FONCTIONNENT

CONTINUELLEMENT)

OFF

ARRÊT

OFF

ARRÊT

OFF

ARRÊT

OFF

ARRÊT

OFF

ARRÊT

OFF

ARRÊT

(HEATER “ON”

DURING BATCH DRY

CYCLE ONLY)

(RADIATEUR EN MARCHE

PENDANT LE CYCLE DE

SÉCHAGE SEULEMENT)

(HEATER “ON” WHEN

FAN RUNNING)

(RADIATEUR EN MARCHE

QUAND LE VENTILATEUR

FONCTIONNE)

(FANS RUN EXCEPT

DURING BATCH UNLOAD)

(LES VENTILATEURS

FONCTIONNENT EXCEPTÉ

PENDANT UN

DÉCHARGEMENT DE LOT)

(FANS RUN

CONTINUOUSLY)

(LES VENTILATEURS

FONCTIONNENT

CONTINUELLEMENT)

(HEATER “ON”

DURING BATCH DRY

CYCLE ONLY)

(HEATER “ON” WHEN FAN

RUNNING)

(RADIATEUR EN MARCHE

PENDANT LE CYCLE DE

SÉCHAGE SEULEMENT)

(RADIATEUR EN MARCHE

QUAND LE VENTILATEUR

FONCTIONNE)

TIMED SHUTDOWN

ARRÊT SYNCHRONISÉ

MANUAL

MANUEL

MANUAL

MANUEL

COMPUTER SELECTED

MODE

MODE SÉLECTIONNÉ

PAR L’ORDINATEUR

PRESS KNOB TO

ADJUST SPEED

APPUYEZ SUR LE BOUTON

POUR AJUSTER LA VITESSE

AUTO

OFF

ARRÊT

OFF

ARRÊT

START

DÉBUTER

STOP

ARRÊTER

2

1

FAN

VENTILATEUR

Fan switches

Heater switches

To uc h

screen

Load auger

switch

Unload auger

switch

Operator light

switch

Control power

switch

Stop switch

Start switch

Meter roll speed

FAN

VENTILATEUR

2

HEATER

BRÛLEUR

1

HEATER

BRÛLEUR

LOAD AUGER

CHARGER

LA FOREUSE

UNLOAD

AUGER

DÉCHARGER

LA FOREUSE

METER ROLL

SPEED

VITESSE DE

COMPTEUR

DE ROULEMENT

LIGHT

LUMIÈRE

POWER

COURANT

START

STOP

DÉBUTER

ARRÊTER

Lockout power

before servicing.

Will cause injury

or death.

HIGH VOLTAGE.

Fermez le courant

avant l’entretien.

Causera blessure

ou la mort.

HAUTE TENSION.

DC-1981

5. Vision Control Panel

Figure 5A

NOTE: Switches on this panel operate via software and MUST NOT be used as a service lock outs.

ISOLATE and LOCK OFF at the main disconnect when servicing.

Switches illuminate to indicate specific element is running.

Control Power Switch

Controls power to the Vision control system only.

NOTE: Does not disconnect the power to co mponents in the upper and lower control boxes. Use the main

Fan Switch

disconnect for this.

1. Selects/deselects each fan.

2. Bottom fan is always # 1.

3. ON (1) = Continuous fan.

4. AUTO (0/1) = Fan operates except during unload.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 29

Page 30

5. Vision Control Panel

Heater Switch

1. Selects/deselects each heater.

2. ON (1) = Burner operates with fan.

3. AUTO (0/1) = Burner operates in staged batch dry cycle only.

Load Auger Switch

1. Controls the fill system and auxiliary equipment where used.

2. In all modes the load auger operates when grain level is low.

3. AUTO (0/1) = Dryer shuts down after a preset period (out of grain timer) when incoming grain flow

ceases to the dryer. Timer disabled in MANUAL.

Unload Switch

1. Operates the unload system and auxiliary equipment where used.

2. MANUAL (1) = Metering rolls run in single speed only.

3. AUTO (0/1) = Metering rolls in variable speed mode (moisture control).

Outside Light Switch

1. AUTO (0/1) = Light OFF when dryer shuts down.

Start Switch

1. Starts the dryer subject to other switch settings.

Stop Switch

1. Stops all dryer functions.

2. Resets control following fault related shut down.

30 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 31

6. Vision Touch Screen Display

Buttons used to

update software. (See

PNEG-1506 Vision

programming manual.)

Boot Screen

1. With the Power switch ON, pushing the START initiates the Vision computer.

2. The boot screen has four (4) “buttons”. (See Figure 6A.)

3. The Start Dryer button enters the Default Operation screen.

Figure 6A

NOTE: See PNEG-1456 for vision touch screen display details.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 31

Page 32

7. Vision Test Firing

Ensure all safety shields are fitted, all doors are closed, and all personnel are

clear of the dryer before starting dryer.

Fix gas leaks immediately.

Dryer Pre-Season Checks

1. Perform these checks at the start of each season.

2. If any checks fail, consult your dealer.

3. Do not use the dryer unless checks are successful.

1. Inspect metering roll compartments for foreign objects which may cause damage.

2. Ensure that all switches on the dryer control panel are OFF.

3. Turn ON the electrical power supply to the dryer.

4. Switch Control Power to ON.

5. At the Boot screen press Start Dryer. The dryer check safety circuits. Any fault will be displayed and

must be rectified. If circuit checks are successful Start switch will illuminate.

6. Push the Dryer Start switch. Selector switches will be activated.

7. Open the main fuel supply on NG, adjust main regulator to minimum. Open main valve and set

pressure on supply line to 50 KPa and the shut off valves on the dryer.

8. Check for gas leaks.

9. With grain supply shut off, check correct rotation of the load auger. (Clockwise from drive end;

counterclockwise for front load dryers.)

10. Set Load Auger to AUTO position. After 8 minute the dryer should shut down and indicate an out of

grain error. Press Stop to reset. Press Start to re-start.

11. Set Unload switch to AUTO. Set (push then turn) metering rolls to 500 and press ACCEPT/EXIT.

Check bottom auger for counterclockwise rotation (at drive end). The meter roll motor should

rotate clockwise as viewed from the drive end of the gearbox. Auxiliary unload equipment should

also operate.

12. Set Unload switch to MANUAL. Set metering roll to 500 and press ACCEPT/EXIT. The botto m auger,

metering rolls and unload equipment should operate correctly.

13. CE Dryers have 7" metering rolls. Check metering roll speed of 4.3 RPM when roll speed is

1000 (maximum).

14. Ensure drive chain tension correct and all sections of the meter rolls rotate.

15. Turn the Unload switch OFF. The bottom auger will run for 60 seconds to allow for clean out.

32 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 33

7. Vision Test Firing

Dryer Pre-Season Checks (Continued)

16. Confirm that the meter roll control increases and decreases speed.

NOTE: Brushes inside the DC meter roll motor to become corrod ed after a period of no use, causing

a roll malfunction. This may be fixed by tapping the motor with a rubber mallet. Subsequent

operation should be normal.

17. Check fan rotation (counterclockwise) and reverse if required. (Swap any 2 phases on the fan

power supply.)

18. Check the burner safety function. Turn OFF the main gas valve. With the fans ON, turn the Heater

ON. The dryer should shut down after 20 seconds and “Ignition Failure Fan #” will appear. Reset the

dryer and repeat for each fan/heater.

Burner Test Fire

Repeat the following for each fan/heater:

1. The dryer must be full of grain, or the Air switch disabled. (SETUP > DIAGNOSTICS > DISABLE

TESTING > Yes > EXIT) After 5 minute, air switches will return to normal and cannot be disabled

again until the dryer has been re-started.

2. Test fire each burner. Turn the Burner switch to ON. The burner should ignite after a 10 seconds

purge delay.

3. Gas pressure should be shown on the gauge.

4. Adjust the plenum set point to 90°C (Temp > Plenum 1 Temp > 90 > Accept). Burner should be

in High-Fire.

5. Set gas pressure at regulator (use ball valve on NG).

6. Drop plenum set point until burner goes to Low-Fire.

7. Set Low-Fire pressure using needle valve screw on cycle valve. Burner should cycle between high

and low 1-3 times per minute.

8. If the burner does not cycle to Low-Fire, increase the regulator setting.

9. If the burner does not cycle to High-Fire, decrease gas pressure cycle valve.

10. If the flame pops or flutters, the pressure is too low. This can damage the burner. Increase pressure

to eliminate.

Approximate setting should be:

LP Gas Natural Gas

High-Fire 450 mBar High-Fire 450 mBar

Low-Fire 70-220 mBar Low-Fire 70-220 mBar

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 33

Page 34

7. Vision Test Firing

Watch gauge for pressure

Throughput adjuster

Low-Fire needle valve

Pressure regulator

(High-Fire)

High pressure switch

Watch gauge for pressure

Supply line ball valve

Regulator

Figure 7A NG Pipe Train

Figure 7B NG Supply Pipe Train

34 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 35

Dryer Shut Down

To shut down the dryer,

1. Close the fuel supply valve.

2. Let the dryer run out of fuel.

3. Press the Dryer Stop button.

4. Turn OFF the control power.

5. Turn OFF the dryer safety disconnect and turn OFF the main power to the dryer.

Emergency

In case of emergency, push the Emergency Stop button.

7. Vision Test Firing

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 35

Page 36

8. Vision/Dri-Tek Dryer Operation

Full Heat Drying

Full heat drying discharges hot grain. This yields higher drying capacity, but requires cooling elsewhere.

Final Moisture

Cooling will remove up to 3% additional moisture. The target moisture should be increased to allow for this

to prevent over drying.

Drying Temperatures

Recommended temperatures are as follow:

Product Top Fan Bottom Fan

Shelled Corn 110°C 84°C

Soybeans 54°C 54°C

Wheat, Barley, Milo, Oats 66°C 66°C

Drying efficiency is maximized by using highest possible temperatures, subject to avoiding product

damage/quality losses.

Dryer shut down, if still full, should be preceded by cooling for 10-15 minute to prevent water vapor

condensation and freezing in low temperatures.

Initial Setup Parameters

Power-up the dryer and press Start Dryer on the touch screen.

Timer and Delay Settings

To set the timers, touch the button at the bottom of Operation screen. The Select Timers to Modify

screen will appear. Refer to PNEG-1710 for instructions to set the timer and delays.

Setting the Temperatures

Press button on the Operation screen. Follow screen instructions to set plenum temperatures.

Start-Up

Follow pre-season checks in Service Chapter on Page 54.

Drying mode options are:

1. Regulation of Grain Temperature on Page 37.

2. Regulation of Moisture: 5 MR SP on Page 41.

3. Regulation of Moisture: Variable MR SP (not recommended for single module dryers).

36 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 37

8. Vision/Dri-Tek Dryer Operation

Continuous Flow Drying Mode Using Regulation of

Grain Temperature

Full Heat Continuous Flow Operation

In this example incoming grain 25% and target is 15% moisture.

1. Set continuous flow drying. SETUP > DRYING MODE > CONTINUOUS FLOW > ACCEPT/EXIT.

2. Set drying mode. M/C SETUP > REGULATION OF GRAIN TEMPERATURE > ACCEPT/EXIT > EXIT.

Figure 8A

3. Ensure the Unload switch is OFF (0).

4. Ensure fuel supply is on at all shut off valves.

5. Fill the dryer with grain. Load auger = AUTO (0/1).

6. Switch all fans switch ON (1).

7. Start each burner. Heater = ON (1).

8. Set plenum temperatures to 80°C.

9. Refer to PNEG-1650/PNEG-1651 for the full heat settings for the dryer. Note the drying time and

speed settings for the drying requirements.

10. Run the fans and burners for the drying time +10%. Example: 10% Removal = 54 Minute so run

fans/heaters for 54+5.4 = 59-60.

11. After the required time set unload auger to MANUAL (1).

12. Set the meter roll speed, (manual speed) to the “1 Speed setting” noted from the drying chart. Press

Accept/Exit button to set this value into the computer. Grain should begin to run.

13. Run again for 10% longer than the drying time noted from the chart. This will even out, but over dry

the grain in the dryer.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 37

Page 38

8. Vision/Dri-Tek Dryer Operation

Figure 8B

14. Set the plenums 15°C to 30°C apart. Warmest at the top.

15. DO NOT ADJUST THE DRYER FOR MOISTURE DURING THIS PROCESS. THIS WILL CAUSE

CONTROL INSTABILITY.

16. After the run time in Step 13 on Page 37, set the moisture control. Unload switch = AUTO.

17. Push the meter roll adjustment knob. Ensure 2 Speed is selected.

18. Set the high and low speeds according to the drying chart. Toggle between speed settings by

pressing the adjustment knob. Press ACCEPT.

Figure 8C

19. Moisture control is now active.

20. Set the temperature set point. M/C > Set Temperature Set Point 40°C > ACCEPT. Run on these

settings as a starting point before adjusting moisture or meter roll settings. Moisture control will not

be precise at this stage.

38 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 39

8. Vision/Dri-Tek Dryer Operation

Figure 8D

21. After the required run time check the outgoing moisture and adjust the moisture control/meter roll

settings if required. A change in the settings will take the same drying time to show in the outgoing

moisture readings. 3°C Increase in temperature = 1% Moisture reduction.

Dry and Cool Continuous Flow Operation

1. Follow Steps 1-9 on Page 37 for full heat continuous flow setup.

Figure 8E

2. Refer to PNEG-1650/PNEG-1651 for the dry and cool settings for the dryer. Note the drying time and

speed settings for the drying requirements.

3. Run the bottom fan/heater only for 20 minute. This will start the bottom drying grain.

4. Start the top fans and burners and run for drying time +10%. See Step 10 on Page 37 example in full

heat drying start-up.

5. 20 Minute before drying time elapses, turn the bottom heater OFF but let the fan run and cool this

section. Set the upper plenum thermostats to the recommended temperature.

6. Follow Step 11 on Page 37 to Step 21 in full heat continuous flow operation.

NOTE: 2 Speed meter roll option works well if the grain entering the dryer has consistent moisture content.

For widely varying moisture contents, the 5 Speed option is recommended.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 39

Page 40

8. Vision/Dri-Tek Dryer Operation

5 Speed

setup button

5 Speed box is

checked.

Continuous Flow 5 Speed Temperature Control

1. Enable the 5 Speed option: SETUP > M/C Setup > ENABLE 5 SPD TEMPERATURE.

2. Enter 5 Speed setup: 5 SPD SETUP. (See Figure 8G.)

3. Initially use default settings.

Figure 8F

(See Figure 8F.)

Figure 8G

4. Inner and outer limits dictate the points at which the speed increases either side of the set point.

These are set as shown in Figure 8G using the INC (increase) and DEC (decrease).

40 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 41

8. Vision/Dri-Tek Dryer Operation

Continuous Flow Drying Mode Using Regulation of Moisture:

5 MR SP

Full Heat Continuous Flow Operation

1. Follow Steps 1-8 on Page 37 for full heat continuous flow setup.

2. Set continuous flow: SETUP > DRYING MODE > CONTINUOUS FLOW > ACCEPT > EXIT.

3. Enter 5 Speed moisture regulation mode: SETUP > M/C Setup > ENABLE 5 SPD.

Figure 8H

4. Set required moisture set point M/C > Enter set point > ACCEPT.

5. Setup 5 Speed control parameters: 5 SPD SETUP. (See Figure 8I on Page 42.)

6. Use defaults to start.

7. Adjust offset as required to fine tune moisture control. This will increase (INC) or decrease (DEC)

the stage at which the dryer adjusts the metering roll speeds to maintain the required drying

set point.

8. At this stage, drying must be started manually, following the same procedure given in Step 9

on Page 42 to Step 12 on Page 43 for full heat continuous flow temperature control.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 41

Page 42

8. Vision/Dri-Tek Dryer Operation

Figure 8I

Figure 8J

9. Calibrate the moisture sensors, taking the average of at least three (3) samples both incoming (moist)

and outgoing (dry). Step 17 on Page 38, SETUP > M/C Setup > CALIBRATE SENSORS > enter

offset > ACCEPT. (See Figure 8K on Page 43.) Example: Reading = 18.3%, Sample = 17%,

Offset = -1.3%. The moisture tester gives an average moisture of 17%, but the moisture sensor on

the dryer reads 18.3%.

42 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 43

8. Vision/Dri-Tek Dryer Operation

Calibrate sensors by touching the arrow buttons.

Figure 8K

10. Once the discharged grain has reached the desired moisture content, turn the Unload switch

to AUTO.

11. Moisture control (5 Speed) is now active.

12. If you press the meter roll knob, you will now notice that there is one meter roll speed to adjust.

How the Moisture Control Works

The controller continuously monitors the moisture coming in and out of the dryer, as well as the column

grain temperature at the end of the drying section. Howeve r, the co ntrol act ion is based on the sensor at

the outlet of the dryer. If the moisture coming out o f the d ryer is no t at the target, the controlle r will spe ed

up or slow down the unload accordingly. How the meter rolls react depends on the set point and the actual

moisture coming out of the dryer. As long as the outgoing moisture is three-tenths above or below the set

point, the meter rolls run on the middle speed. Once the moisture begins to drift from the set point by

over three-tenths either above or below the set point, the speed will automatically switch between middle

and low, or middle and high speed. This is a very fast response and will bring grain back towards the

set point quickly.

The manual speed setting is responsible for the first pass of drying because the controller does not yet

have enough information about the grain in the dryer. Set the manual unloading speed as close as it

should be for the grain currently in the dryer before switching to moisture control mode. The manual

speed setting does not need to be adjusted after the moisture control is activated.

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual 43

Page 44

9. Vision Illustrations

Supply line

(liquid) solenoid

Plenum air

pressure switch

Supply line

(liquid) solenoid

Manual shut

off valve

Fan/heater control box

Left grain high-limit

thermostat

Plenum air

pressure switch

Supply Line (LP Shown)

Figure 9A

44 PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Page 45

28" and 36" LP 1" NPT CE Pipe Train Assembly

9. Vision Illustrations

Figure 9B