Page 1

PNEG-1708

GSI Modular Tower Dryer

TM-1008, TM-1010, TM-1012 and TM-1015

Construction Manual

PNEG-1708

Date: 08-01-11

Page 2

2 PNEG-1708 GSI Modular Tower Dryer

Page 3

Table of Contents

Contents

Chapter 1 Introduction .......................................................................................................................................... 4

Chapter 2 Safety ..................................................................................................................................................... 5

Safety Guidelines .................................................................................................................................. 5

General Safety Statement ..................................................................................................................... 6

Electrical Power Supply ........................................................................................................................ 6

Chapter 3 Safety Decals ........................................................................................................................................ 7

Safety Decal # DC-GBC-1A ................................ ... ... .... ... ... ... .... ... ... ... .................................................. 8

Safety Decal # DC-1943 ....................................................................................................................... 9

Safety Decals # DC-985, DC-990 and DC-991 ................................................ ... ................................ 10

Safety Decals # DC-987, DC-988 and DC-989 ................................................ ... ................................ 11

Safety Decals # DC-1061 and 420-1473-8 ......................................................................................... 12

Safety Decals # DC-1063 and DC-1064 ............................................................................................. 13

Information Decals .... ... ....................................................................................................................... 14

Chapter 4 Dryer Overview and Specifications .................................................................................................. 15

Dimensions and Capacities for all Models .......................................................................................... 18

Dimensions - TM-1008 ........................................................................................................................ 19

Dimensions - TM-1010 ........................................................................................................................ 20

Dimensions - TM-1012 ........................................................................................................................ 21

Dimensions - TM-1015 ........................................................................................................................ 22

Chapter 5 Required Tools and Critical Tool Characteristics ........................................................................... 23

Critical Tool Characteristics ................................................................................................................ 23

Comprehensive Tool List .................................................... ... .... ... ... ... ... ............................................. 28

Chapter 6 Unloading and Staging the Modules ................................................................................................ 29

Chapter 7 Placing and Installing the Base/Unload Module .............................................................................. 30

Base/Unload Module Placement Considerations ................... ....................................... ... ... .... ... ......... 30

Securing the Unload Module ............................................................................................................... 32

Chapter 8 Assembling Ladders, Platforms and Catwalks ............................................................................... 34

Crate as Work Bench ................................... .... ... ... ............................................................................. 34

Installing Outside Ladder with Safety Cage ........................................................................................ 35

Overview Catwalk and Platform Assembly ......................................................................................... 39

Attaching Catwalks and Platforms to Dryer Modules .................... ... ... ... ....................................... ... ... 40

Chapter 9 Burner/Blower Module - Special Considerations ............................................................................ 48

Chapter 10 Lifting and Stacking the Modules ................................................................................................... 51

Overview for Safety ........................................................................................................................... 51

Recommended Stacking Order: Model 800 Series Dryer ................................................................. 52

Recommended Stacking Order: Model 1010 Series Dryer ............................................................... 53

Recommended Stacking Order: Model 1200 Series Dryer ............................................................... 54

Recommended Stacking Order: Model 1500 Series Dryer ............................................................... 55

Lifting ................................................................................................................................................. 56

Chapter 11 Electrical Connections ................................. ...................... ....................... ....................................... 64

Electrical Overview Minimal Connections .......................................................................................... 64

Air Switch ....................................................................................................................

Flame Sensor and Ignitor Wires (Spark Plug) ................................................................................... 67

Bindicator, Outside Overheat and Moisture Sensor .......................................................................... 69

Plenum Temperature ............................... ... .......................................... .... ... ...................................... 70

....................... 65

Chapter 12 Gas Pipe Train Overview ................................................................................................................. 71

Gas Pipe Train (Natural or LP) Overview Minimal Connections ..... ....................... ...................... ...... 71

Chapter 13 Finishing Touches: Removing Wrinkles and Dents from Screens .............................................. 73

Chapter 14 Warranty ............................................................................................................................................ 75

PNEG-1708 GSI Modular Tower Dryer 3

Page 4

1. Introduction

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of lading

to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

This warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provides field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will become void

and field improvements may be denied.

4 PNEG-1708 GSI Modular Tower Dryer

Page 5

2. Safety

DANGER

WARNING

CAUTION

NOTICE

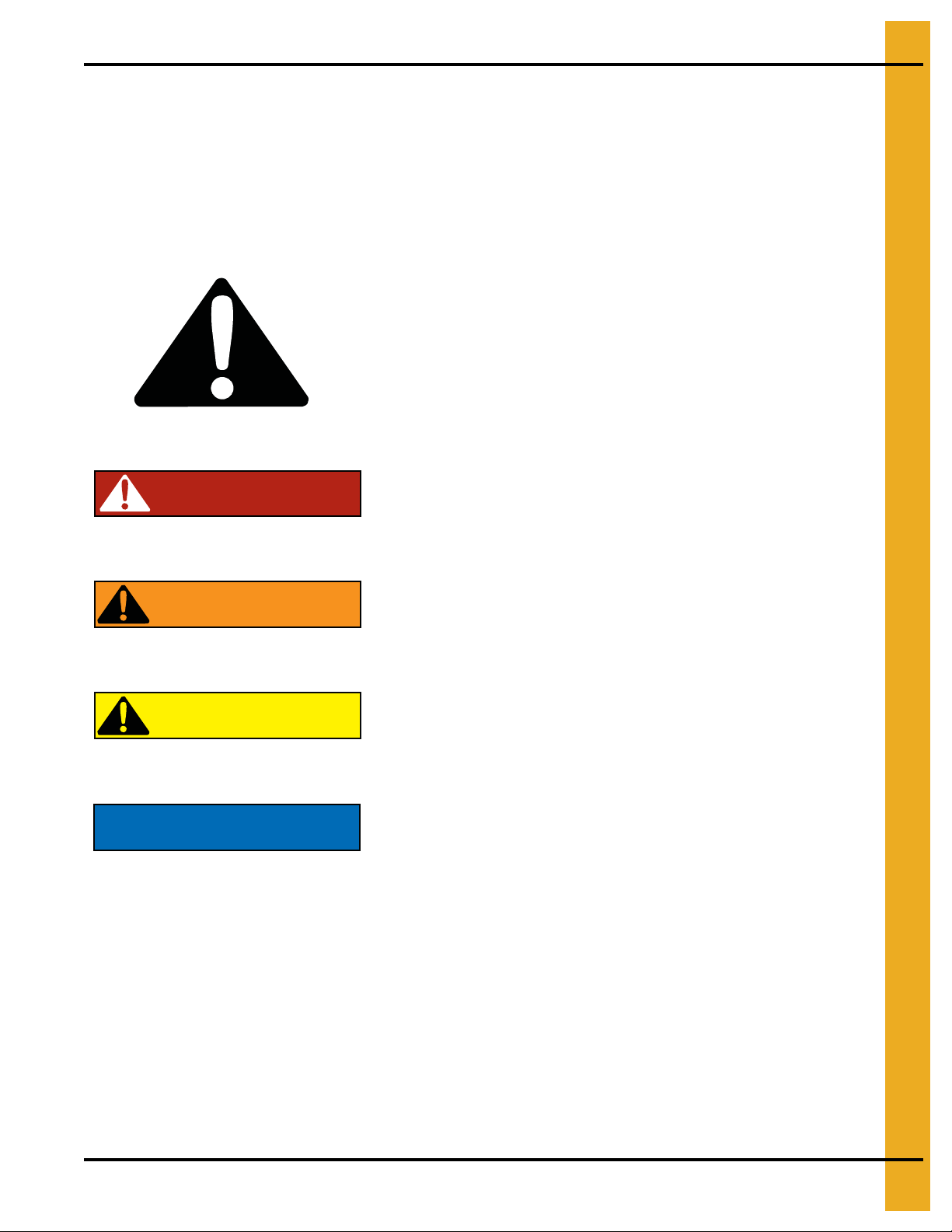

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1708 GSI Modular Tower Dryer 5

Page 6

2. Safety

This product has sharp edges, which may cause serious injury. To avoid injury, handle

sharp edges with caution and always use proper protective clothing and equipment.

General Safety Statement

Our foremost concern is your safety and the safety of others associated with tower drye r. This manu al is

to help you understand safe operating procedures and some problems that may be encountered by the

operator and other personnel.

As owner and/or operator, you are responsible to know what requirements, hazards and precautions exist

and inform all personnel associated with the equipment or in the area. Safety precautions may be required

from the personnel. Avoid any alterations to the equipment, which may produce a very dangerous

situation, where SERIOUS INJURY or DEATH may occur.

You should consider the location of the tower dryer site relative to power line locations or electrical

transmission equipment. Contact your local power company to review your installation plan or for

information concerning required equipment clearance. Clearance of portable equipment that may be taken

to the tower dryer site should also be reviewed and considered. Any electrical control equipment in contact

with the tower dryer should be properly grounded and installed in accordance with National Electric Code

provisions and other local or national codes.

This product is intended for the use of grain drying. Any other use is a misuse of the product.

Sidewall bundles or sheets must be stored in a safe manner. The safest method of storing sidewall

bundles is laying horizontally with the arch of the sheet upward, like a dome. Sidewall sheets stored on

edge must be secured so that they cannot fall over and cause injury. Use care when handling and moving

sidewall bundles.

Personnel operating or working around equipment should read this manual. This manual must be

delivered with equipment to its owner. Failure to read this manual and its safety instructions is a misuse

of the equipment.

NOTE: A careful operator reduces risk of personal injury and equipment damage.

Electrical Power Supply

GSI recommends you contact your local power company and request that a representative inspect the

dryer installation. Be sure the wiring is compatible with the power company’s system and that adequate

power is supplied to the dryer.

6 PNEG-1708 GSI Modular Tower Dryer

Page 7

3. Safety Decals

Some of the required safety decals are placed on the dryer before shipping. The remainder are placed on

the dryer during electrical installations. The purpose of the safety decals is to immediately alert all

personnel to the hazards of an operating dryer. The safety decal does not replace the need for all

personnel to know and understand safe dryer operations and requirements. Read the “Dryer Operations

and Service Manual”.

NOTE: Safety decals should be read and understood by all people in or around the dryer area.

Safety decals on Pages 8-13 identify and give the location of all safety decals that should be on each tower

dryer. Safety decals are listed in numerical order.

If the safety decals on the following pages are not on the dryer, or if they are damaged, immediately

contact GSI for replacement safety decals.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

PNEG-1708 GSI Modular Tower Dryer 7

Page 8

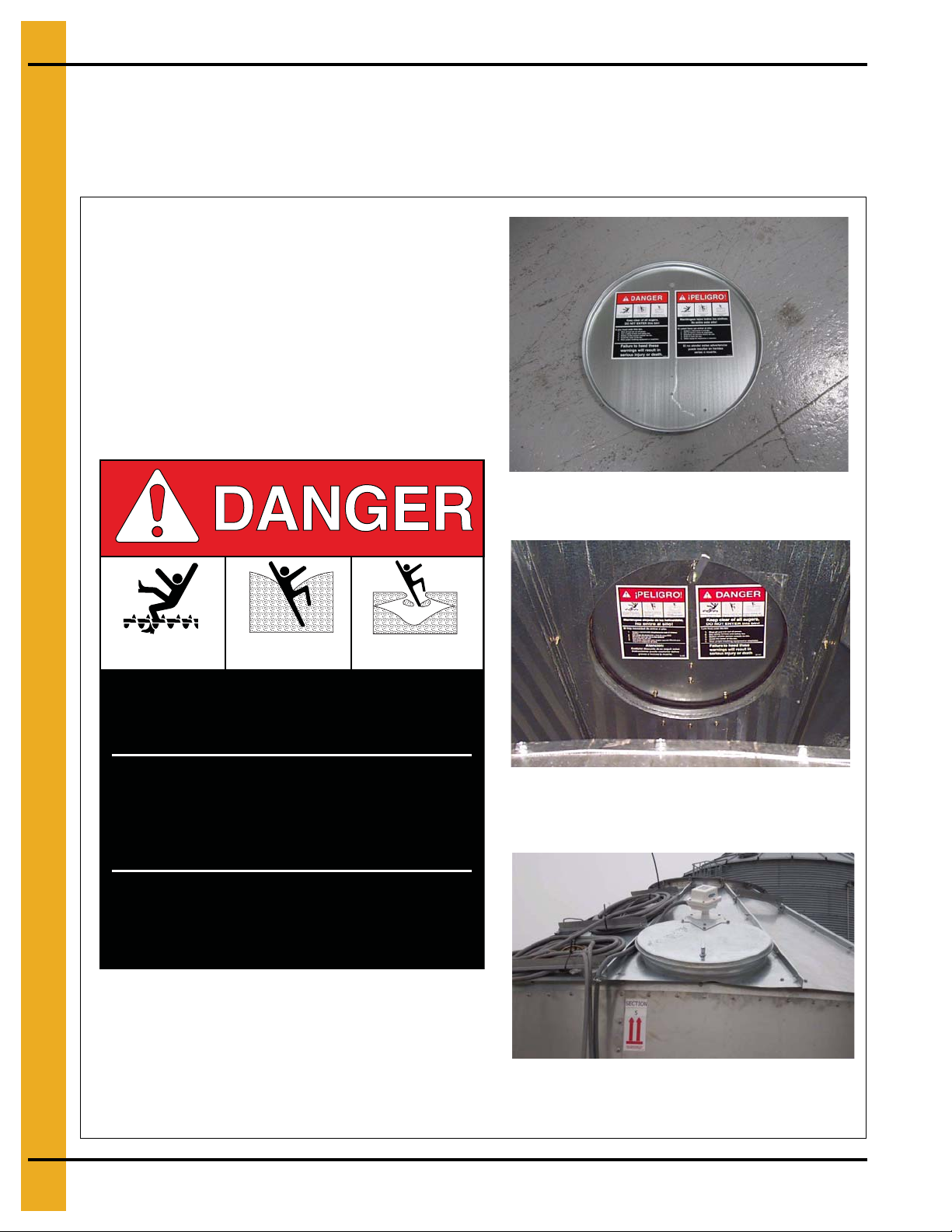

3. Safety Decals

Rotating flighting will

kill or dismember.

Flowing material will

trap and suffocate.

Crusted material will

collapse and suffocate.

Keep clear of all augers.

DO NOT ENTER this bin!

Failure to heed these

warnings will result in

serious injury or death.

If you must enter the bin:

1. Shut off and lock out all power.

2. Use a safety harness and safety line.

3. Station another person outside the bin.

4. Avoid the center of the bin.

5. Wear proper breathing equipment or respirator.

DC-GBC-1A

Tower roof access port with decals in place.

Inside view - Access port installed with

decals in place.

Outside view - Access port installed with

decals in place.

Safety Decal # DC-GBC-1A

Location of Decals

English and spanish decals are placed on inside of tower roof access port before shipping.

8 PNEG-1708 GSI Modular Tower Dryer

Page 9

Safety Decal # DC-1943

Example - Electrical control system

Location of Decal

On outside of main power box and inside main power box door.

3. Safety Decals

PNEG-1708 GSI Modular Tower Dryer 9

HIGH VOLTAGE.

Will cause injury

or death.

Lockout power

before servicing.

HAUTE TENSION.

Causera des

blessures ou la

mort.

Bloquez le courant

avant de faire

l’entretien.

DC-1943

Page 10

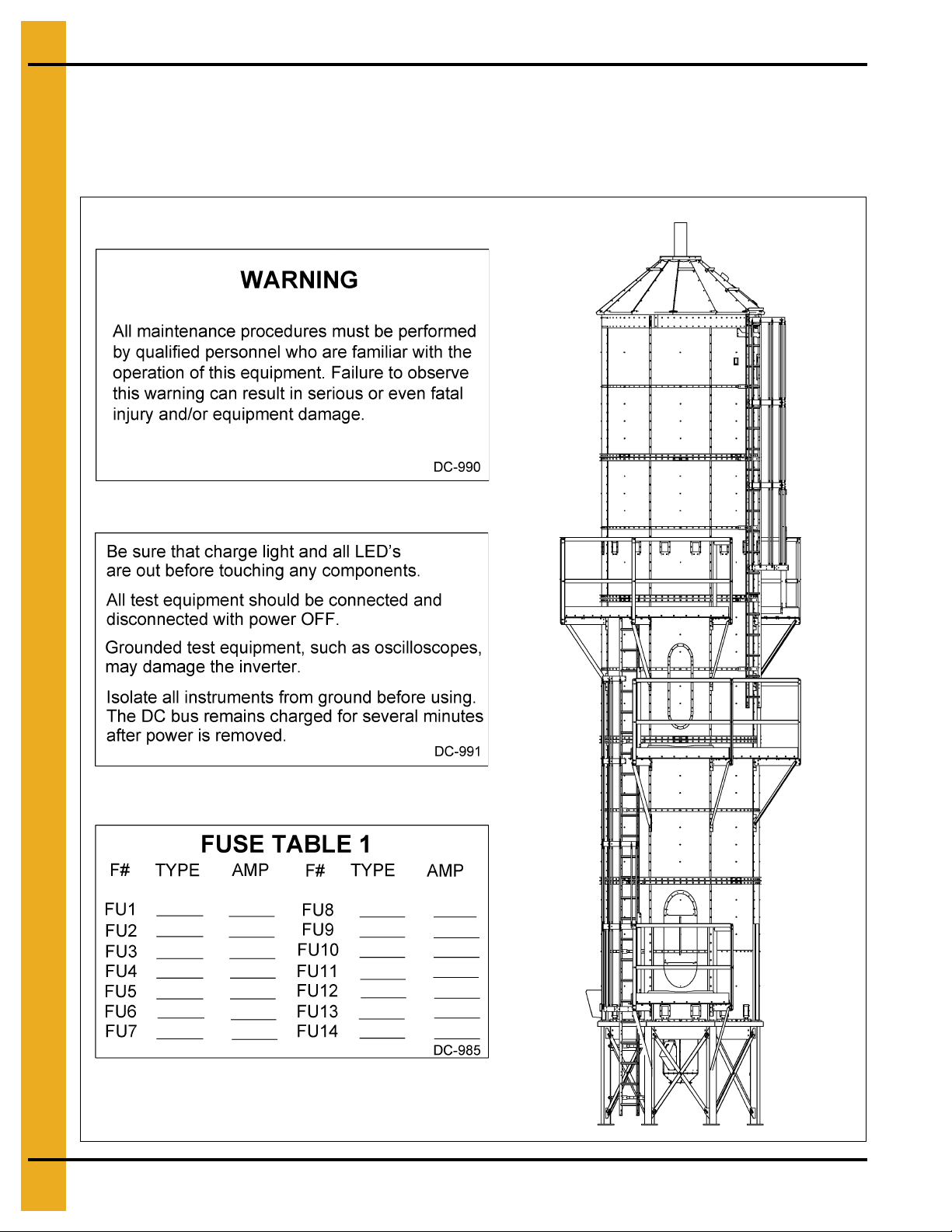

3. Safety Decals

Safety Decals # DC-985, DC-990 and DC-991

Location of Decal

Inside main power box door, on same side as main electrical disconnect.

10 PNEG-1708 GSI Modular Tower Dryer

Page 11

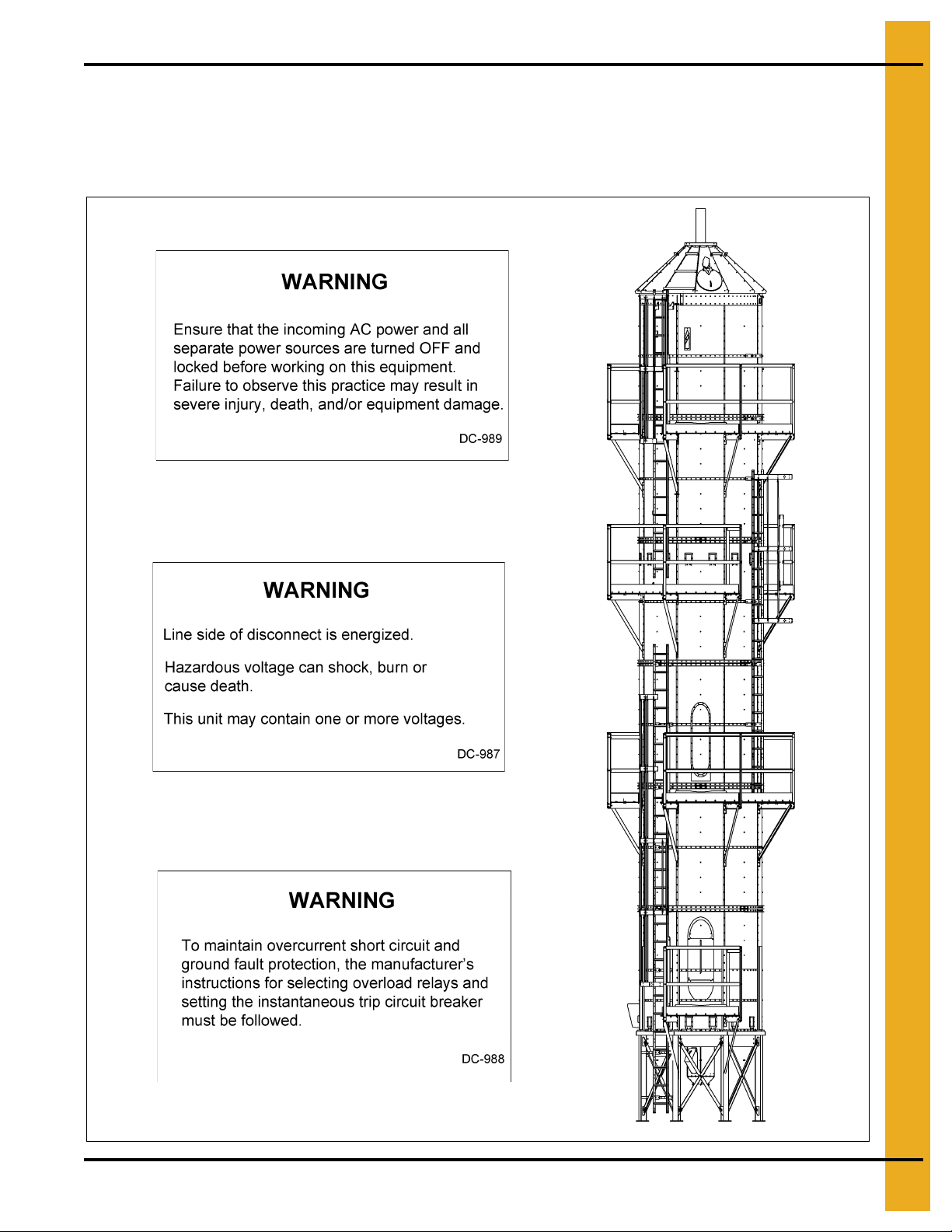

Safety Decals # DC-987, DC-988 and DC-989

Location of Decal

Inside main power box door, on same side as main electrical disconnect.

3. Safety Decals

PNEG-1708 GSI Modular Tower Dryer 11

Page 12

3. Safety Decals

Flame and pressure

beyond door. May

cause serious injury.

Do not enter when

dryer is running.

WARNING!

DC-1061

Safety Decals # DC-1061 and 420-1473-8

Location of Decal

On outside of heat module door.

12 PNEG-1708 GSI Modular Tower Dryer

420-1473-8

Page 13

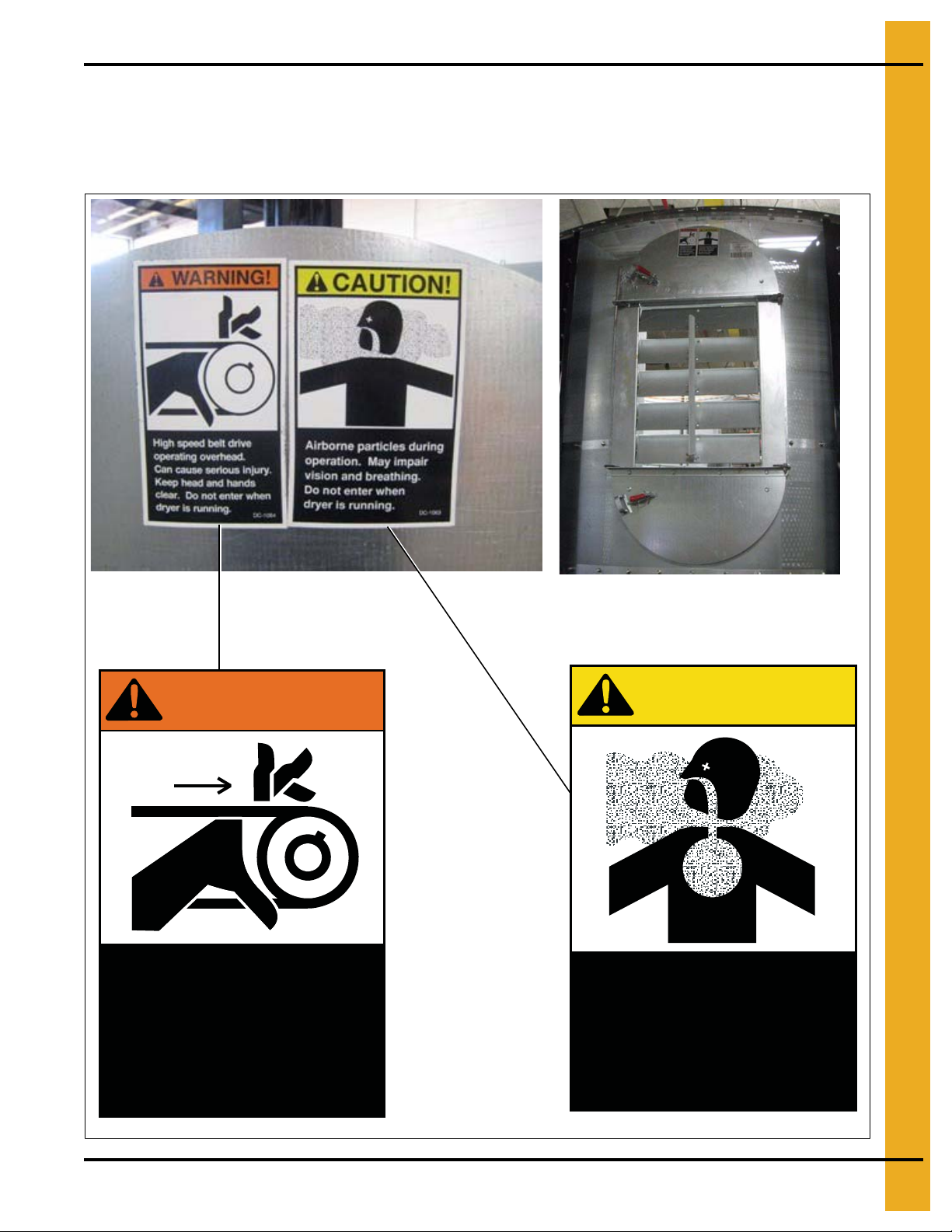

Safety Decals # DC-1063 and DC-1064

High speed belt drive

operating overhead.

Can cause serious injury.

Keep head and hands

clear. Do not enter when

dryer is running.

WARNING!

DC-1064

Location of Decal

On outside of cool module door.

3. Safety Decals

PNEG-1708 GSI Modular Tower Dryer 13

CAUTION!

Airborne particles during

operation. May impair

vision and breathing.

Do not enter when

dryer is running.

DC-1063

Page 14

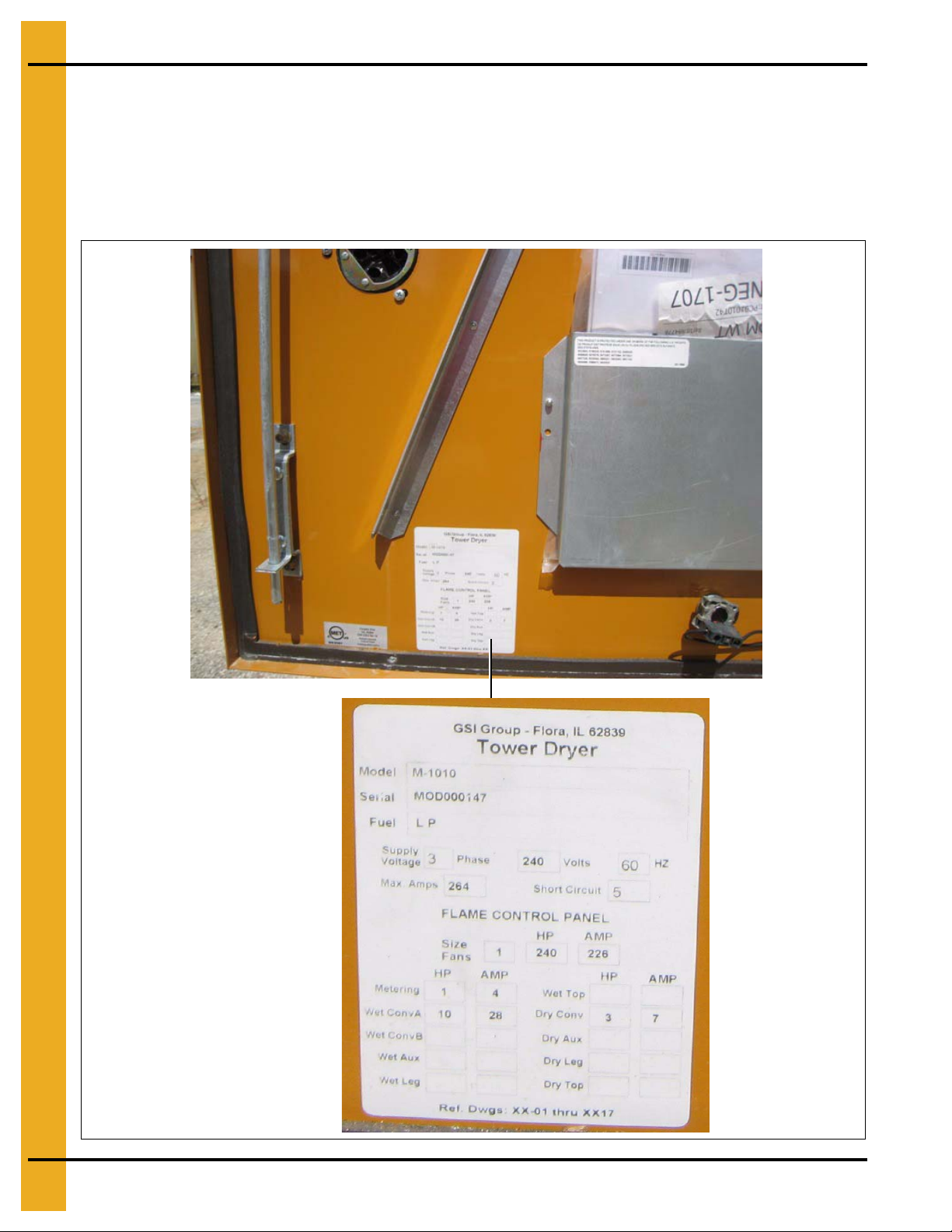

3. Safety Decals

Example - Information decal

Information Decals

Nameplate for Main Power Box

Location of Decal

Inside main power box door, on same side as main electrical disconnect.

14 PNEG-1708 GSI Modular Tower Dryer

Page 15

4. Dryer Overview and Specifications

All models of the GSI Modular Tower Dryer include a base/unload module, a burner/blower module,

a roof module and one or more heat modules. Heat modules can be “empty” or with turners based on

owner preference.

Module 1 on ALL models.

NOTE: New dryers ship with corrugated sheets.

Figure 4A Base/Unload Module

Figure 4B Burner/Blower Module

PNEG-1708 GSI Modular Tower Dryer 15

Page 16

4. Dryer Overview and Specifications

Figure 4C Heat Module - w/ Turners

Figure 4D Empty Heat Module

16 PNEG-1708 GSI Modular Tower Dryer

Page 17

4. Dryer Overview and Specifications

Figure 4E Heat Module - w/ Door Kit

Figure 4F Roof Module

PNEG-1708 GSI Modular Tower Dryer 17

Page 18

4. Dryer Overview and Specifications

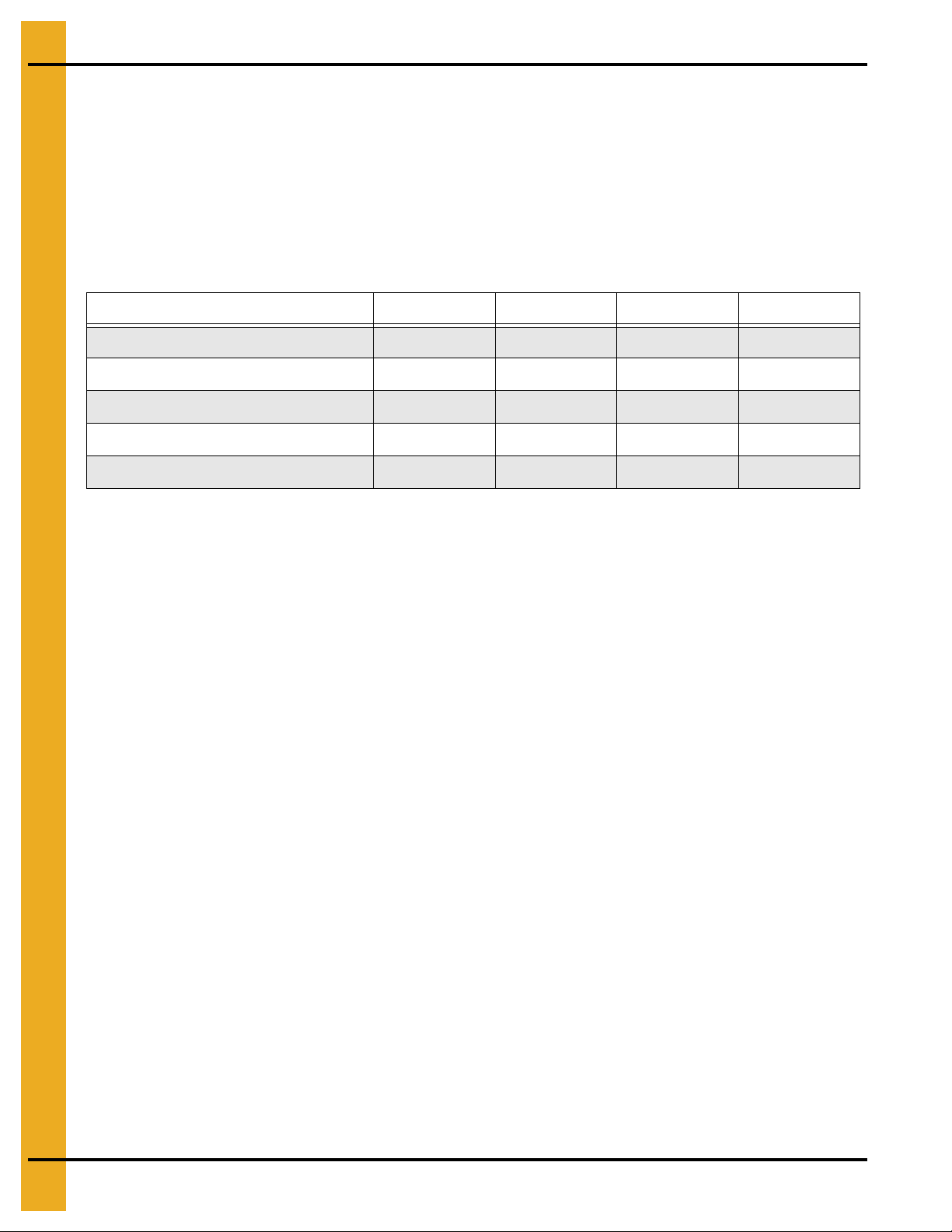

Dimensions and Capacities for all Models

There are four (4) models of the GSI Modular Tower Dryer. Each model is 10' 10" in diameter.

1. TM-1008

2. TM-1010

3. TM-1012

4. TM-1015

Model TM-1008 TM-1010 TM-1012 TM-1015

900 1125 1350 1690

BPH Capacity (20%-15%) 542 670 720 1010

BPH Capacity (25%-15%) 800 1000 1200 1500

BPH (Set in Maximum Cool) (20%-15%) 480 600 720 900

BPH (Set in Maximum Cool) (25%-15%) 900 1125 1350 1690

18 PNEG-1708 GSI Modular Tower Dryer

Page 19

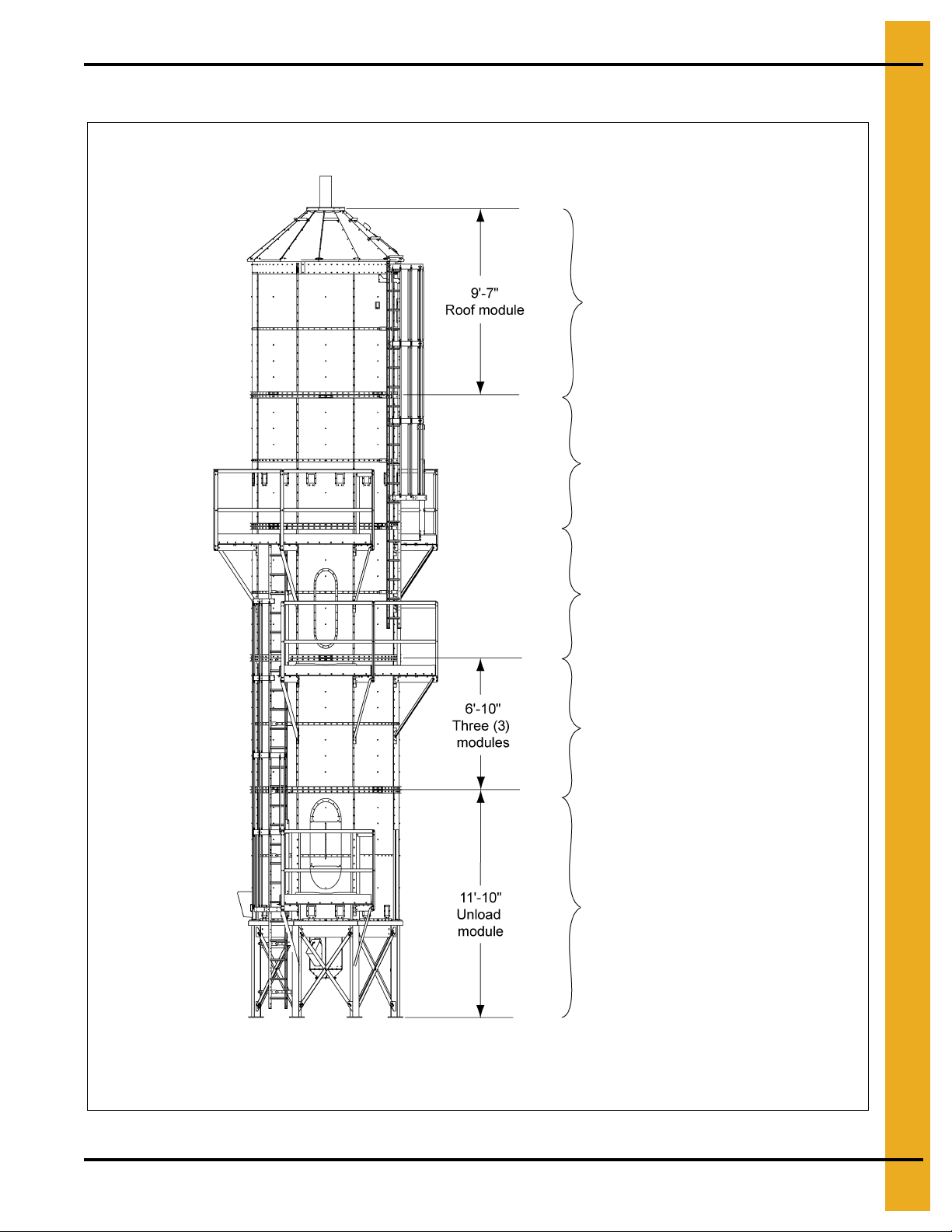

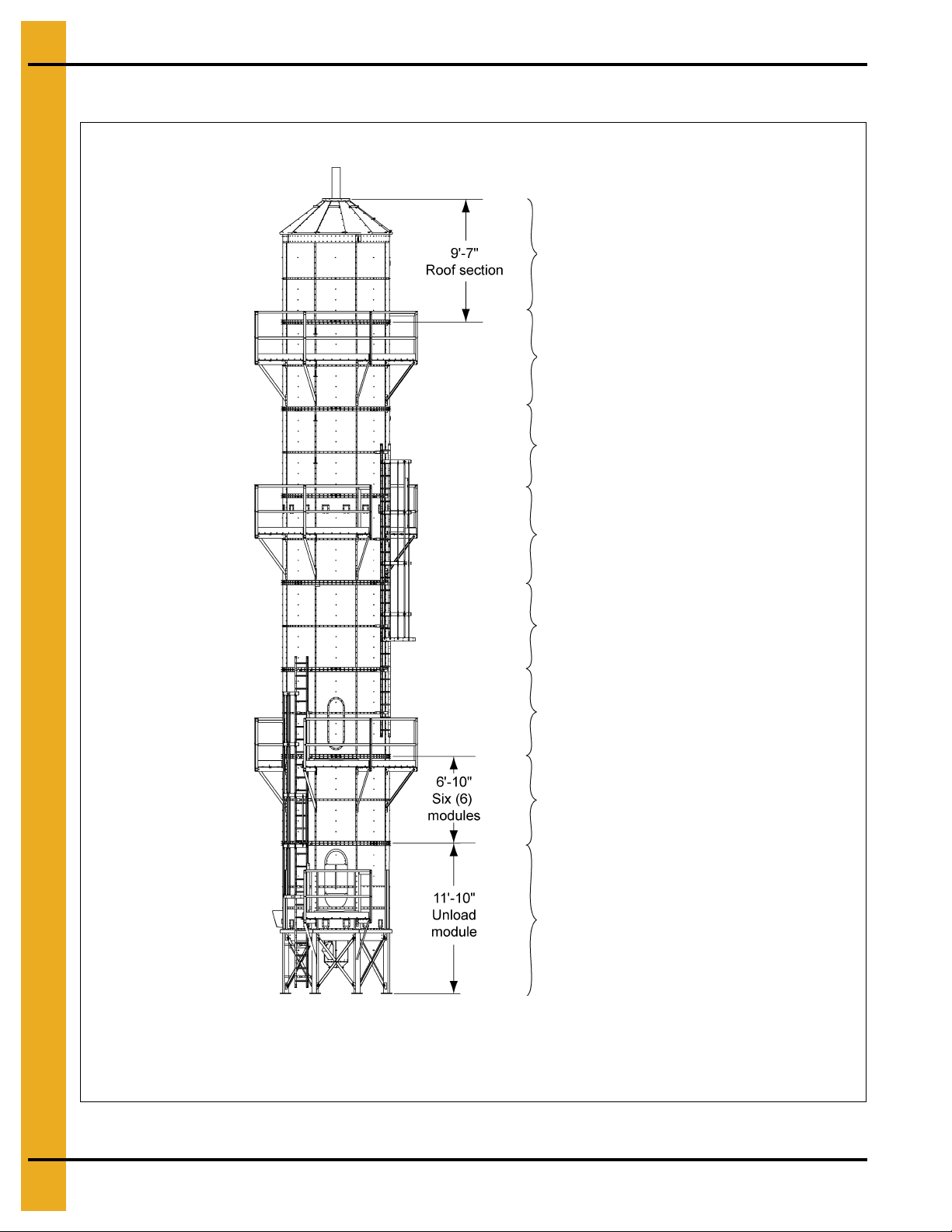

Dimensions - TM-1008

M-1008T - Five (5) modules total, usually

ships on two (2) trucks. All five (5)

modules are 10'-10" in diameter.

The 1008 model includes a platform at the base/unload,

ladders and safety cages to a stepover platform,

ladders and safety cages to a full catwalk and ladders

and safety cages to the roof access.

Module - 1 Base/unload

(See Figure 4A on Page 15.)

Module - 2 Heat module - burner/blower

(See Figure 4B on Page 15.)

Module - 3 Heat module - w/ door kit

(See Figure 4E on Page 17.)

Module - 4 Heat module - w/ turners

(See Figure 4C on Page 16.)

Module - 5 Roof module

(See Figure 4F on Page 17.)

Total weight = 18000 lbs.

NOTE: Please refer to Page 51 for individual section weights.

4. Dryer Overview and Specifications

Figure 4G TM-1008

PNEG-1708 GSI Modular Tower Dryer 19

Page 20

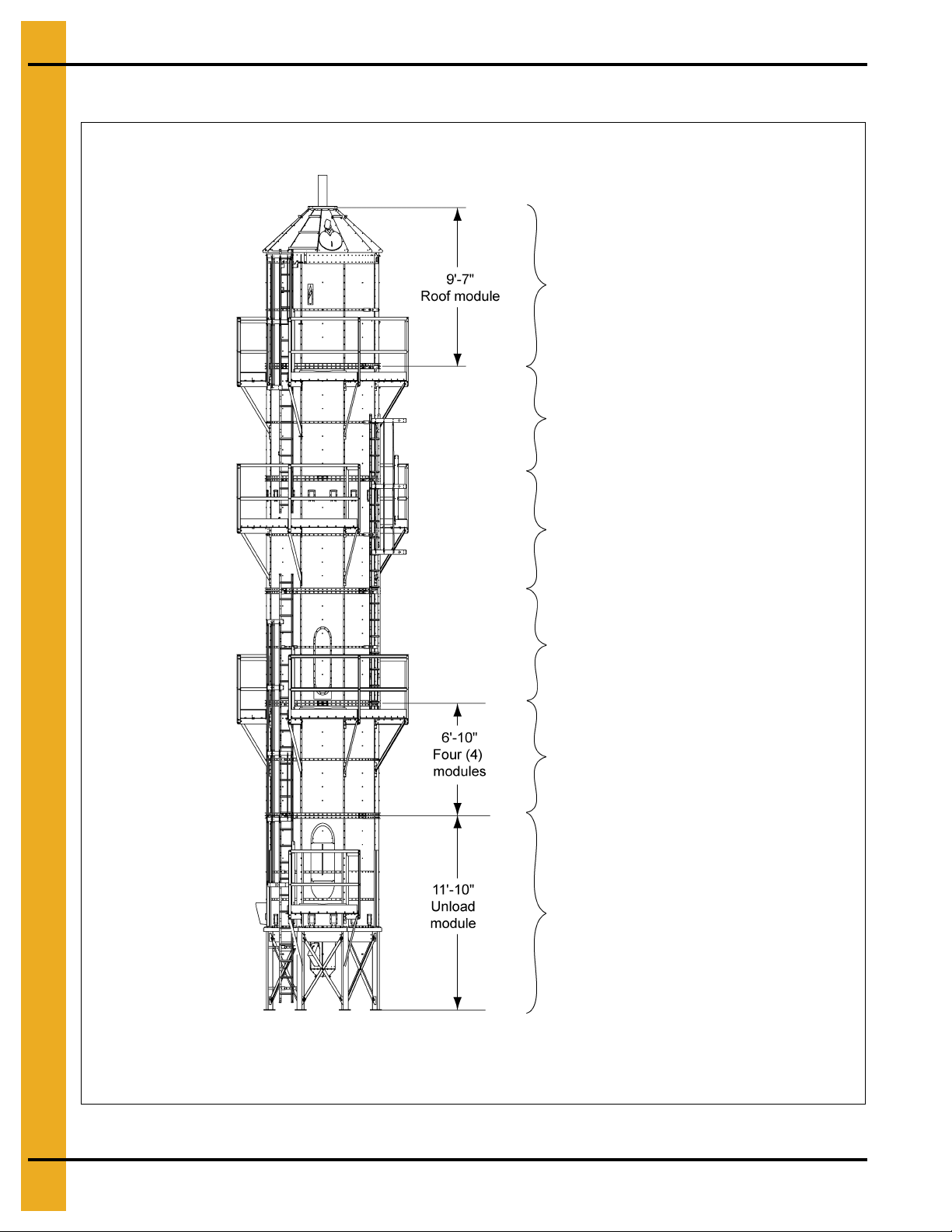

4. Dryer Overview and Specifications

M-1010T - Six (6) modules total, usually

ships on two (2) trucks. All six (6)

modules are 10'-10" in diameter.

The 1010 model includes a platform at the

base/unload, ladders and safety cages to three (3)

full catwalks and ladders and safety cages to the

roof access.

Module - 2 Heat module - burner/blower

(See Figure 4B on Page 15.)

Module - 1 Base/unload

(See Figure 4A on Page 15.)

Module - 3 Heat module - w/ door kit

(See Figure 4E on Page 17.)

Module - 6 Roof module

(See Figure 4F on Page 17.)

Module - 5 Heat module - empty

(See Figure 4D on Page 16.)

Module - 4 Heat module - w/ turners

(See Figure 4C on Page 16.)

Total weight = 21645 lbs.

NOTE: Please refer to Page 51 for individual section weights.

Dimensions - TM-1010

Figure 4H TM-1010

20 PNEG-1708 GSI Modular Tower Dryer

Page 21

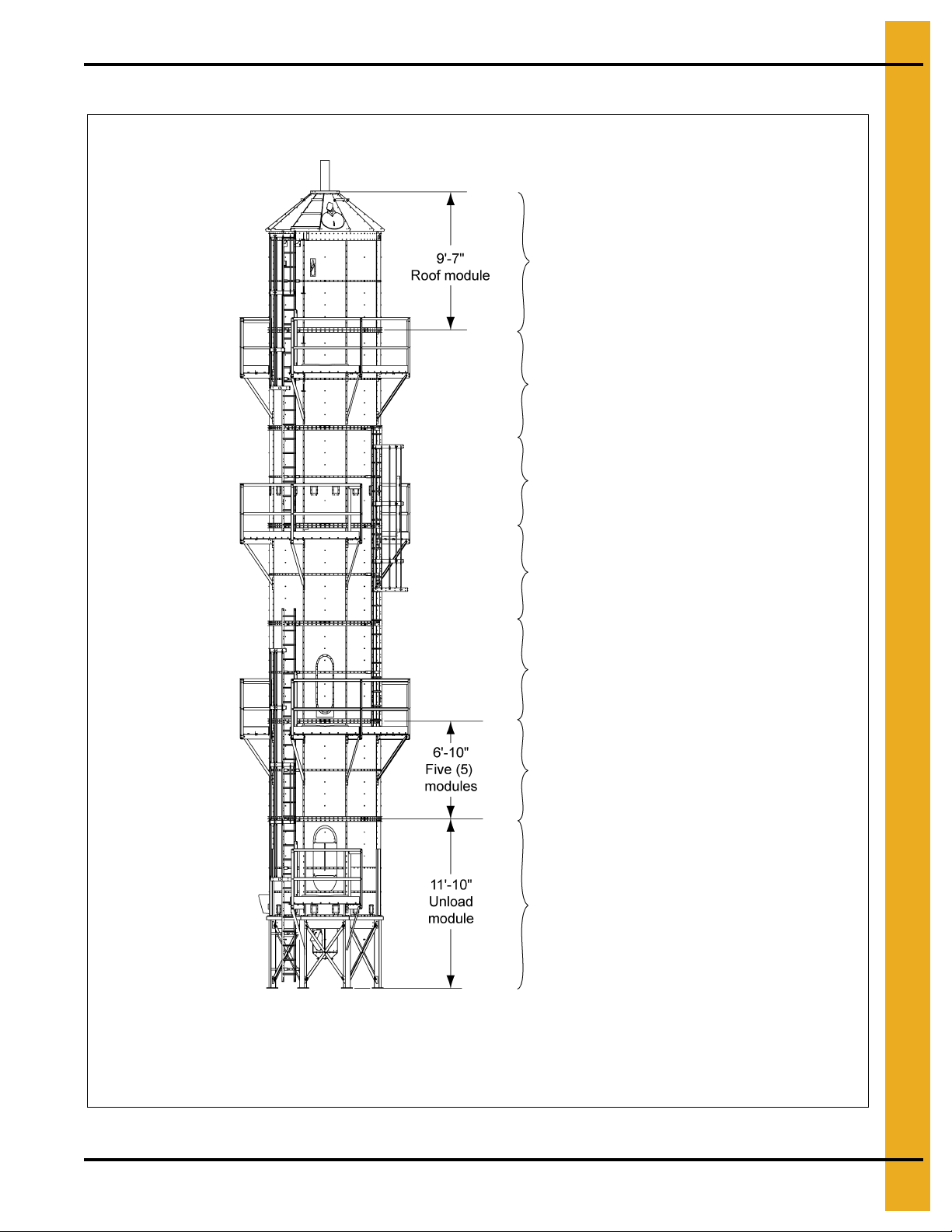

Dimensions - TM-1012

M-1012T - Seven (7) modules total, usually

ships on three (3) trucks. All seven (7)

modules are 10'-10" in diameter.

The 1012 model includes a platform for the

base/unload module, ladders and cages to a full

catwalk stepover platform, ladders and cages to

three (3) catwalks and ladders and cages to the

roof access.

Module - 1 Base/unload

(See Figure 4A on Page 15.)

Module - 2 Heat module - burner/blower

(See Figure 4B on Page 15.)

Module - 3 Heat module - w/ door kit

(See Figure 4E on Page 17.)

Module - 4 Heat module - empty

(See Figure 4D on Page 16.)

Module - 6 Heat module - empty

(See Figure 4D on Page 16.)

Module - 7 Roof module

(See Figure 4F on Page 17.)

Total weight = 23095 lbs.

Module - 5 Heat module - w/ turners

(See Figure 4C on Page 16.)

NOTE: Please refer to Page 51 for individual section weights.

4. Dryer Overview and Specifications

PNEG-1708 GSI Modular Tower Dryer 21

Figure 4I TM-1012

Page 22

4. Dryer Overview and Specifications

Module - 5 Heat module - w/ turners

(See Figure 4C on Page 16.)

M-1015T - Eight (8) modules total, usually

ships on three (3) trucks. All eight (8)

modules are 10'-10" in diameter.

The 1015 model includes a platform for the

base/unload module, ladders and cages to a

full catwalk stepover platform, ladders and

cages to three (3) catwalks and ladders and

cages to the roof access.

Module - 1 Base/unload

(See Figure 4A on Page 15.)

Module - 2 Heat module - burner/blower

(See Figure 4B on Page 15.)

Module - 3 Heat module - w/ door kit

(See Figure 4E on Page 17.)

Module - 4 Heat module - empty

(See Figure 4D on Page 16.)

Module - 7 Heat module - empty

(See Figure 4D on Page 16.)

Module - 6 Heat module - empty

(See Figure 4D on Page 16.)

Module - 8 Roof module

(See Figure 4F on Page 17.)

Total weight = 24545 lbs.

NOTE: Please refer to Page 51 for individual section weights.

Dimensions - TM-1015

22 PNEG-1708 GSI Modular Tower Dryer

Figure 4J TM-1015

Page 23

5. Required Tools and Critical Tool Characteristics

Equipping the field crew with the right tools is essential for a smooth installation. The GSI Modular

Tower Dryer requires a number of standard tools. Please pay particular attention to the following item

descriptions as the characteristics of the following tools are extremely important information for proper

installation. A comprehensive list of tools required to assemble and install the GSI Modular Tower Dryer

is included later in this chapter.

Critical Tool Characteristics

1. 1-1/8" Hammer drill star bit at least 12" long is REQUIRED. While the anchor bolts are 1" in

diameter, the holes for the anchor bolts MUST be 1-1/8" in diameter to allow room for the required

epoxy. Additionally, anchor bolts must be sunk deep enough so that no more than 2"-3" is above

the plate.

An air compressor hose is needed to blow out the dust from the holes prior to dropping in the anchor

bolts and epoxy. (See Figure 5A.)

2. Air compressor with hose: After drilled the holes for the anchor bolts, an air compressor with hose

is REQUIRED in order to blow all dust and debris out of the holes.

Figure 5A Anchor Bolts Sunk - No More than 3" Remains above Plate

3. Punches: 1/4" Line up punches - at least 8

5/8" line up punches - at least 8

Ideally, during the installation process, crews will work in two (2) person teams with one team working

inside the dryer and one team working outside the dryer. Each crew member should have at least

two (2) punches available to them.

Punches should be long enough to provide significant leverage to the user and should have narrow

and pointed tips to facilitate the initial punch placement. (See Figure 5B and Figure 5C on Page 24.)

PNEG-1708 GSI Modular Tower Dryer 23

Page 24

5. Required Tools and Critical Tool Characteristics

Figure 5B Line Up Punch and Hammer

Figure 5C Line Up Punch Inserted Through Connecting Channels of Dryer

24 PNEG-1708 GSI Modular Tower Dryer

Page 25

5. Required Tools and Critical Tool Characteristics

4. Socket sets and impact wrenches:

• 3/8" Drive 1/2" socket set

• 3/8" Drive 9/16" socket set

• 1/2" Drive socket set

• 15/16" Deep well 1/2" drive sockets

• 1/2" Deep well 1/2" drive sockets

• Short 1/2" 1/2" drive sockets

• 9/16" Deep well 1/2" drive sockets

• 1/2" Impact wrenches

• 3/8" Drive extensions (6" to 10") for 9/16" shallow socket

Accessing the bolts that connect sections of the dryer together requires passing through the hole in

the channel as shown in Figure 5D.

When installing, in all possible situations, place the impact on the bolt. Do NOT tighten the nut

as it will not lock down on the ring. Always tighten the bolt. (See Figure 5D.)

Figure 5D Connecting channels often requires the use

of socket extensions. Please plan accordingly.

PNEG-1708 GSI Modular Tower Dryer 25

Page 26

5. Required Tools and Critical Tool Characteristics

5. Laser transit level tool: After placing the unload/base module on the concrete foundation and

establishing its proper orientation to other equipment it must be leveled. GSI strongly recommends

using a Laser transit leveling tool to level the unit. (See Figure 5E.) If a Laser transit is not

available, a carpenter’s level may be used.

It is critical to establish the base/unload module as level. Even a minor deviation at this level

will be a significantly greater deviation at the top section. Therefore, pay particular attention to

confirming the levelness of the base/unload module. Shims are available to assist with leveling the

base/unload module. (See Figure 5F.)

Figure 5E Laser Transit Level

Figure 5F

26 PNEG-1708 GSI Modular Tower Dryer

Page 27

5. Required Tools and Critical Tool Characteristics

Compression channel ledge

a. Compression channel: Regardless of what leveling tool is used, the prope r reference point f or

leveling the unload module of the dryer is the Compression Channel and NOT the base/leg

plates on the concrete. See Figure 5G for reference.

The Compression Channel is the “ledge” around the unload module of the dryer. Use this as the

reference point for leveling the unit. Do NOT use base plates/feet to determine whether or not unit

is level.

PNEG-1708 GSI Modular Tower Dryer 27

Figure 5G Unload Module with Compression Channel Marked

Page 28

5. Required Tools and Critical Tool Characteristics

Comprehensive Tool List

• C6 Epoxy gun

• 1/4" Line up punches

• 1/2" x 9/16" Box end combination wrenches

• 1/2" Open end wrenches

• 9/16" Open end wrenches

• 32 OZ Ball peen hammers

• 5/8" Line up punches

• Small pry bars

• 3/8" Drive socket and extension

• 3/8" Drive 1/2" socket set

• 3/8" Drive 9/16" socket set

• 1/2" Drive socket set

• 4' Level

• Vice grips

• 25' Tape measures

• 15/16" Wrenches

• 15/16" Deep well 1/2" drive sockets

• 1/2" Deep well 1/2" drive sockets

• Short 1/2" 1/2" drive sockets

• 9/16" Deep well 1/2" drive sockets

• Caulk gun and 2 tubes of clear silicone

• 36" Pipe wrenches (rigid aluminum)

• 48" Pipe wrench (rigid aluminum)

• 18" Pipe wrenches

• Torque wrench (all 3/8" grade 8 bolts will need 45 ft./lbs.)

• 20' Ladders

• 6' Ladders

• 3/8" High speed drill bits

• 5/16" High speed drill bits

• 1/2" Impact wrenches

• 1/2" Drills

•1-1/2" Sockets

• Cordless sawzall

• 1-1/2" Hammer drill

• 1-1/8" Bits (hammer drill star bits)

• 3/8" and 5/16" Bit for impact driver

• 100' with a four (4) way box

• Air compressor with hose

28 PNEG-1708 GSI Modular Tower Dryer

Page 29

6. Unloading and Staging the Modules

NOTE: Concrete and gravel make the best staging ground.

NOTE: Leave adequate space between modules to attach platforms and catwalks.

1. Place modules on ground that is as solid and level as possible. Soft ground/grass will make

preparation for installation more difficult. Concrete or gravel ground is preferable for pre-installation

work. If no gravel or concrete area is available for staging the modules, consider placing the modules

on 2 x 4’s or other blocking material to prevent the modules from sinking into the ground.

2. Place modules next to sequential modules (i.e. place Module 2 near Module 3 and Module 3 near

Module 4, etc.) to make the stacking and connection of multiple modules easier.

3. Leave at least 4' to 5' of space between each module. Catwalks and/or platforms are attached

to appropriate modules before modules are stacked upon each other and lifted into place.

(See Figure 6A.)

Figure 6A Unload and Staging Considerations

PNEG-1708 GSI Modular Tower Dryer 29

Page 30

7. Placing and Installing the Base/Unload Module

Base/Unload Module Placement Considerations

If the concrete foundation is ready and adequately cured, place the base/unload module on it and take

careful and complete consideration of the surrounding equipment. Be sure to consider any planned

options such as augers and any potential equipment to be added later.

1. Consider the location of the electrical box and control panel. Orient base/unload module so that

personnel will have adequate and safe access to the electrical box and control panel. Remember,

the Vision control box can be remote mounted. (See Figure 7A.)

2. Consider any auxiliary equipment that will be used with the GSI Modular Dryer. One set of X-braces

on the unload may be removed without compromising structural integrity to allow for easier access.

3. Ensure that there is adequate overhead clearance for the entire tower dryer height and that the

clearance between the dryer walls and other equipment is sufficient to allow for catwalks

and/or platforms. (See Figure 7B on Page 31.)

Figure 7A

30 PNEG-1708 GSI Modular Tower Dryer

Page 31

7. Placing and Installing the Base/Unload Module

Figure 7B Consider overhead clearance for the entire height of the dryer.

4. Ladder brackets are not pre-installed on modules. Consider installation location of ladders and

brackets. Note that ladder brackets will be offset at each catwalk and will not line up in a straight line.

(See Figure 7C.)

IMPORTANT: When planning dryer location, ladders brackets will serve as good reference point for

where catwalks and/or platforms will be placed higher up on the dryer. Be sure to

allow for adequate spacing and clearance between the module dryer wall AND the

platforms and/or catwalks that will be attached higher up and any other equipment

in the area.

Figure 7C Ladder Brackets - Indentify location on each

module and surrounding equipment considerations.

PNEG-1708 GSI Modular Tower Dryer 31

Page 32

7. Placing and Installing the Base/Unload Module

CAUTION

While it is normal to encounter rebar on occasion when drilling the holes for anchor

bolts, should this happen more than 3 or 4 times, it is necessary to contact GSI for

splice plates to complete the drilling of the anchor bolt holes. (See Figure 7D.)

Securing the Unload Module

1. After determining the orientation of the unload module, use a 1-1/8" drill bit at least 12" long to drill

holes for the anchor bolts.

NOTE: Anchor bolts are 1" in diameter but the hole for them must be 1-1/8" in diameter to allow for

the required epoxy.

NOTE: It may be necessary to loosen or remove the bolts on the X-braces to gain easier access to

the holes for the anchor bolts. If X-braces are removed or loosened to drill the anchor bolt

holes, be sure to tighten the X-braces again when done.

Figure 7D

2. Use a laser transit to level the unload module.

IMPORTANT: ALWAYS use the compression channel as the point of reference for estab lishing

the levelness of the unit.

(See Figure 7E.)

Never use the feet/anchor plates to determine levelness.

Figure 7E

32 PNEG-1708 GSI Modular Tower Dryer

Page 33

7. Placing and Installing the Base/Unload Module

Do NOT remove more than one set of X-braces on the base/unload module as doing

so may compromise the structural integrity of the dryer . One set may be remove d to

accommodate auxiliary equipment.

NOTE: Shims are provided to assist with leveling if necessary. (See Figure 7F.)

Figure 7F

3. After drilling the holes, all debris and fine material must be removed from the holes.

4. Use a compressed air hose to blow the dust and debris out. Then, drop anchor bolt in holes to confirm

depth is adequate.

5. Once the unit is level, fill anchor bolt holes approximately 1/2" full with the provided epoxy. Press

anchor bolts in holes. (See Figure 7G.)

NOTE: Epoxy should ooze up and out of the hole at the base of the plate. If it does not, add epoxy

and repeat. No more than 2" to 3" of the bolt should remain above the plate. (See Figure 7G.)

6. After all anchor bolt holes have been filled with epoxy and all anchor bolts have been inserted into

the holes to the proper depth, allow epoxy to set for 4 to 6 hours before installing and tig htening nuts

or stacking another module of the dryer on top of it.

CAUTION

Figure 7G

PNEG-1708 GSI Modular Tower Dryer 33

Page 34

8. Assembling Ladders, Platforms and Catwalks

Crate as Work Bench

Because the base/unload module requires the epoxy to set for a MINIMUM of 4 hours before other

modules can be set on top of it, this is an excellent time to begin assembly of the ladders, platforms and

catwalks. Once the crate is empty, use a hammer to pound the exposed nails and/or staples back into the

frame so that the surface is smooth.

The crate makes an excellent work bench for assembling items throughout the installation process.

(See Figure 8A and Figure 8B.)

Figure 8A Crate as Work Bench

Once the modules have been staged, open the crate that shipped with the dryer modules.

The crate contains catwalk and/or platform materials, ladders and safety cages, as well as the hoses for

pipe train.

Optional items such as an auger kit will also ship in crates. Installation instructions for optional accessories

are in separate installation manuals.

Unload the materials from the crate and place them nearby in like-item groups (i.e. gas train pipes

together, catwalk and platform flooring together, etc). (See Figure 8B.)

Figure 8B Shipping Crate

34 PNEG-1708 GSI Modular Tower Dryer

Page 35

8. Assembling Ladders, Platforms and Catwalks

Installing Outside Ladder with Safety Cage

Outside Ladder Bracket

Outside ladder brackets are not pre-installed prior to shipping. Pre-assemble safety cages on the ground

prior to attaching to the dryer.

Top Safety Cage

Pre-assemble the top safety cage as follows. (See Figure 8C, Figure 8D below and Figure 8F to

Figure 8H on Page 36.)

1. Snug bolt one formed ladder section to two (2) outside ladder stiffeners. Snug bolt four (4) safety

cage brackets to outside ladder stiffeners. (See Figure 8C.)

Figure 8C

2. Bolt pairs of safety cage hoop halves together. (See Figure 8D.)

Figure 8D

PNEG-1708 GSI Modular Tower Dryer 35

Page 36

8. Assembling Ladders, Platforms and Catwalks

LADDER BOL TS - insert bolts toward outside of ladder, so climbers do not snag

on bolt shafts.

Install all formed ladder sections so rungs with rough, textured side for

gripping are on top, so climbers do not slip.

3. Snug bolt safety cage hoops to safety cage brackets. (See Figure 8E and Figure 8F.)

Figure 8E

Figure 8F

4. Snug bolt seven (7) vertical supports to safety cage hop halves. (See Figure 8G.)

5. Snug bolt top safety cage assembly to outside ladder brackets. (See Figure 8G.)

6. Tighten all bolts.

7. Use splice plate between ladders sections to connect. (See Figure 8H.)

Figure 8G

WARNING

WARNING

36 PNEG-1708 GSI Modular Tower Dryer

Figure 8H

Page 37

8. Assembling Ladders, Platforms and Catwalks

Safety Cage Extensions

Install safety cage extensions from top safety cage to bell safety cage just above foundation as follows.

Quantity depends upon dryer model.

1. Splice outside ladder stiffeners with ladder stiffener splices. Snug bolt outside ladder stiffeners

behind formed ladder sections. (See Figure 8I.)

Figure 8I Close Up - Pointing to ladder stiffener splice.

Install ladder stiffener splice with four (4) bolts.

2. Install safety cage brackets and safety cage hoops like top safety cage.

3. Before lifting each section, tighten bolts in outside ladder with safety cage for that section.

As dryer is constructed, continue installing safety cage extensions to each section of dryer before

lifting it. (See Figure 8J.)

Figure 8J Close Up - Outside Ladder Brackets

PNEG-1708 GSI Modular Tower Dryer 37

Page 38

8. Assembling Ladders, Platforms and Catwalks

Figure 8K Ladder Bracket for Rings

Figure 8L Ladder Bracket for Sheets

38 PNEG-1708 GSI Modular Tower Dryer

Page 39

8. Assembling Ladders, Platforms and Catwalks

Catwalk plankCatwalk plank

Kick plate

Catwalk plankCatwalk plank

Catwalk plankCatwalk plank

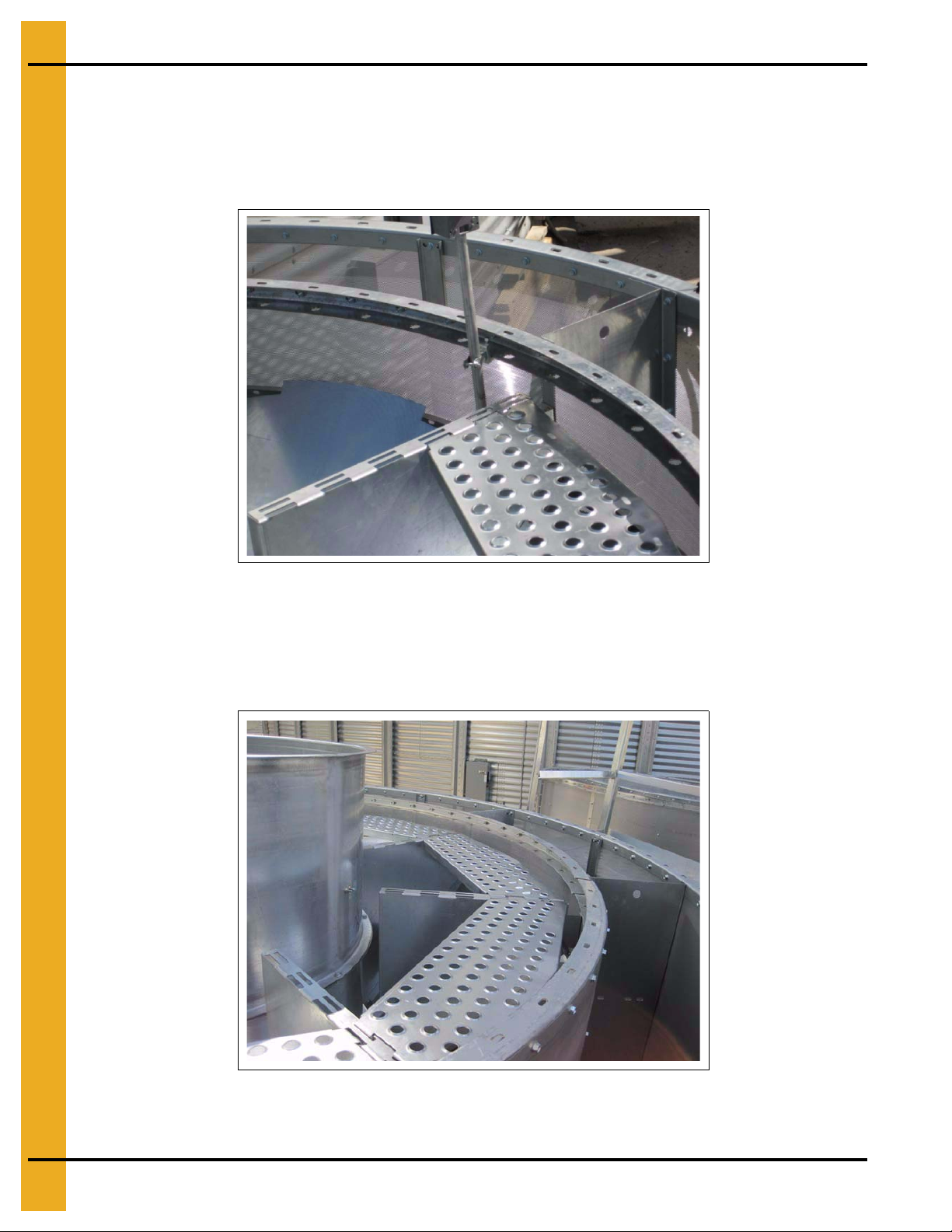

Overview Catwalk and Platform Assembly

NOTE: This is a basic overview of the process as it relates to the Modular Tower Dryers and is intended

to be a general guide for catwalks and platforms as they are assembled on the GSI Modular

Tower Dryer.

Catwalk and platform parts are shipped in the shipping crate that accompanies the modules. Assemble all

floor planks and kick plates before assembling the dryer or stacking and connecting the modules. Use the

shipping crate as a work bench to assist in the assembly of kick plates, catwalks and platforms.

1. Match longer kick plates to longer catwalk platforms and match shorter kick plates to shorter

catwalk platforms.

2. Attach kick plates to planks with nuts and bolts. For safety purposes, all nuts should be to the inside.

3. Tighten fully with power impact. (See Figure 8M and Figure 8N.)

Figure 8M Catwalk Planks

Figure 8N Kick plate attached to catwalk plank.

Assembled on shipping crate as work bench.

NOTE: The assembly is shown lying upside down.

4. Attach the curved kick plates to the catwalk planks that will be used at the stepover sections

immediately off of ladders. Curved kick plates are provided for safety purpo ses and help prevent feet

or boots from slipping and getting wedged between the platform and the dryer wall. (See Figure 8O.)

Figure 8O Catwalk plank with curved kick plate for use at stepover locations.

PNEG-1708 GSI Modular Tower Dryer 39

Page 40

8. Assembling Ladders, Platforms and Catwalks

Attaching Catwalks and Platforms to Dryer Modules

Catwalks and platforms are attached to the appropriate modules while they are on the ground, before

modules are stacked on other modules or lifted into place on the unload module.

5. Remove four (4) bolts per seam on sections to attach catwalk support braces. Be careful not to push

bolts back into channel between the screens. If bolts are accidentally pushed back into the channel

when installing the catwalk support brackets, the easiest way to remove them is by creating an

extra-long handled wrench. An example of this is shown in Figure 8P. Attach a regular wrench to a

long pole, in this case one of the long safety cage bars was used. A crew member can then access

the bolt from the channel by reaching in with the extra-long wrench. Carpenter’s putty can be placed

on the end to help pick up the bolt if needed. The wrench can then be used to hold the bolt in place

back in the proper hole as it is re-tightened.

Figure 8P

Figure 8Q

40 PNEG-1708 GSI Modular Tower Dryer

Page 41

8. Assembling Ladders, Platforms and Catwalks

Catwalk bracket

Support braces

Catwalk brace

Cut-off angle

Support braces

Nut to inside

6. Attach catwalk brackets as shown in Figure 8R.

NOTE: All brackets must attach facing/angling the same direction. In the example on the right, all

brackets will face to match the bracket being installed.

Figure 8R Attaching catwalk bracket to dryer module.

7. Assemble catwalk brace/support braces by connecting as shown in Figure 8S and Figure 8T using

one nut and one bolt.

IMPORTANT: Finger-tighten only at this time so that the pieces act like a hinge. Place nut to the

inside as shown in Figure 8S and Figure 8T. This helps prevent snagging.

Figure 8S

Figure 8T

PNEG-1708 GSI Modular Tower Dryer 41

Page 42

8. Assembling Ladders, Platforms and Catwalks

NOTE: All catwalk brackets and all catwalk brace should face the same direction.

Catwalk bracket

Catwalk brace

Gap to leave open for

ladder access.

Ladder brackets

8. Attach catwalk brace to dryer wall using the previously installed catwalk brackets. Catwalk brace

attach to outside of bracket. (See Figure 8U.) Tighten fully with impact.

Lower arm of catwalk brace connects to top hole of bracket and upper catwalk brace arm connects

to top hole of bracket. (See Figure 8U.)

In Figure 8U, the catwalk brackets all face . The catwalk brace attach to the outside of the

bracket and the catwalk brace all face .

9. Make sure, all catwalk brace should face the same direction.

Figure 8U

10. Make sure brackets and/or catwalk brace are NOT installed over the ladder braces as this would

block ladder installation. (See Figure 8V.)

Figure 8V

42 PNEG-1708 GSI Modular Tower Dryer

Page 43

8. Assembling Ladders, Platforms and Catwalks

Dryer

Align this SLOT away from dryer

and to HOLE in catwalk transition

Catwalk transition

No bolt used here

Catwalk transition

Dryer

No bolt used here

11. After attaching the catwalk brace to the catwalk brackets on the dryer wall, attach a catwalk transition

to the top of each catwalk brace. (See Figure 8X.)

IMPORTANT: Note the hole alignment on the catwalk transition. The “five (5) hole” pattern near the

center of the transition MUST be oriented so that the center hole is AWAY from the

dryer wall. (See Figure 8W and Figure 8X.)

Figure 8W

NOTE: Transition must line up on catwalk brace slot to slot. The SLOT indicated in the Figure 8W

must be oriented away from the dryer wall. Do NOT fill the middle hole of the transition.

PNEG-1708 GSI Modular Tower Dryer 43

Figure 8X

Page 44

8. Assembling Ladders, Platforms and Catwalks

Catwalk transition

Nuts and bolts

Catwalk plank

Kick plate

Dryer

12. Attach catwalk planks (with kick plates attached) to catwalk transitions.

13. There are two (2) planks between catwalk brace. The longer plank with the kick plate goes farther

away from the dryer wall with the kick plate on the outside and the shorter plank goes closest to the

dryer wall with the kick plate to the inside (to prevent stepping or slipping between the plank and the

dryer). (See Figure 8Y.)

Use nuts and bolts to connect catwalk planks to catwalk transitions.

Note in Figure 8Y only the inside plank has been places. It is located closer to the dyer wall. The

longer plank further from the dryer wall has not yet been placed and connected.

NOTE: Left nut is the middle hole mentioned in previous steps that had to be oriented away from

dryer wall. This is required so that the catwalk floor planks fit correctly. (See Figure 8Y.)

NOTE: Left nut shown in Figure 8Y is NOT in the correct slot.

Figure 8Y

44 PNEG-1708 GSI Modular Tower Dryer

Page 45

8. Assembling Ladders, Platforms and Catwalks

Stepover section

Handrail supports are

attached at this point.

Kick plates

14. Install the catwalk plank with the curved kick plate at the stepover point immediate beside ladders.

This is an added safety feature to help prevent feet from being wedged between the catwalk and

the dryer wall when stepping over or off a ladder. (See Figure 8Z.) This is the stepover section

immediately beside a ladder. Use ladder brackets for placement guidance.

Figure 8Z

15. Stepover kick plates are installed at stepover locations. These kick plates are lower to step-in

and higher where the handrail supports attach. (See Figure 8AA below, Figure 8AB and Figure 8AC

on Page 46.)

PNEG-1708 GSI Modular Tower Dryer 45

Figure 8AA

Page 46

8. Assembling Ladders, Platforms and Catwalks

Closed end of platform

Step-in end of platform

Handrail

Handrail

Figure 8AB

Figure 8AC

16. Attach handrail supports to catwalk brace as shown in Figure 8AD and Figure 8AE.

17. Attach handrails to handrail supports as shown in Figure 8AD and Figure 8AE. Make sure curved

side of handrails is to the inside for use. The sharper flat sides should be to the outside.

Figure 8AD

46 PNEG-1708 GSI Modular Tower Dryer

Figure 8AE

Page 47

8. Assembling Ladders, Platforms and Catwalks

Handrails

18. Connect handrails to the inside of supports as shown in Figure 8AF. Nuts should be to the outside

and the curved side of the handrail should be to the inside of the platform or catwalk for use.

(See Figure 8AF.) Note handrail orientation. Flat side goes to the outside away from the dryer.

Rounded side goes to the inside for hand safety. Outside away from the dryer. (See Figure 8AF.)

Also note the placement of connecting handrails to handrail support.

Figure 8AF

19. When assembling catwalks and platforms be sure to leave open the area between seams where

ladder brackets are located. Ladders will be installed at these points to connect the platforms

and catwalks.

20. Attach ladder to roof module at this time, BEFORE lifting roof to be connected to other modules.

21. Do not attach other ladders at this time. Ladders for all other modules below the roof module will be

attached AFTER the roof module and/or other modules are lifted and placed.

PNEG-1708 GSI Modular Tower Dryer 47

Page 48

9. Burner/Blower Module - Special Considerations

1. Before lifting and stacking modules, be sure the floor planks are installed for the burner/blower

module. These should be factory installed. The burner/blower module contains flooring to support

the user when entering the dryer to perform cleaning or maintenance duties.

The flooring planks for the burner/blower module are similar to catwalk planks but have “TABS” on

the ends to drop into slots in the burner/blower module. (See Figure 9A.)

Figure 9A

In Figure 9A, one plank has been placed. Note the longer planks will be placed to the outside (closer to

the dryer wall) and the shorter planks to the inside (closer to the burner/blower).

In Figure 9B, multip le flooring planks have been installed along the outer portion (closer to the dryer wall).

The inner planks have yet to be placed.

Figure 9B

48 PNEG-1708 GSI Modular Tower Dryer

Page 49

9. Burner/Blower Module - Special Considerations

Tabs and slots

Thermistor conduit

NOTE: The plank nearest the thermistor housing will need to be cut to allow it to drop into place.

This should be factory installed.

In Figure 9C, the installer is marking the plank so that it can be field cut for proper fit.

Figure 9D shows the marks where the plank needs to be cut for proper fit.

Note the tabs and slots on burner/blower floor planks. This helps differentiate them from catwalk planks.

(See Figure 9C.)

Figure 9C

Figure 9D

PNEG-1708 GSI Modular Tower Dryer 49

Page 50

9. Burner/Blower Module - Special Considerations

Cut plank

Figure 9E shows the field-cut plank installed in the burner/blower module. Note how the cut out now fits

around the thermistor.

Figure 9E

Figure 9F shows burner/blower planks installed.

Figure 9F

50 PNEG-1708 GSI Modular Tower Dryer

Page 51

10. Lifting and Stacking the Modules

Overview for Safety

Before lifting any modules make sure the lifting capacity of the crane is adequate for the total combined

weight of the module or modules, as well as any attached accessories such as catwalks, platforms

and ladders.

• Roof = 2200 lbs.

• Turner = 2550 lbs.

• Heat = 1450 lbs.

• TM-1008 Blower section = 4000 lbs.

• TM-1010 Blower section = 4100 lbs.

• TM-1012 Blower section = 4200 lbs.

• TM-1015 Blower section = 4500 lbs.

• Unload = 6250 lbs.

rd

• Heat section with 15 channels = 1675 lbs. (3

• Catwalks = 1140 lbs.

Module on every dryer.)

NOTE: Section weights do NOT include the additional weight of the catwalk that will be attached to the

appropriate section(s). Catwalk weight is approximately 1140 lbs.

The GSI Modular Tower Dryer is designed for quick and safe on-site installation. In order to maximize

safety, always perform as much work as possible as close to the ground as possible. Use the illustration

guides included later in this section for reference.

All sections of the GSI Modular Tower Dryer come labeled by the factory. Separate labels identify the dryer

sections by name and by their sequential placement in the overall stacking of the Modular Tower Dryer.

To determine the weight of multiple sections when lifting them together, simply add the section weights

together and if applicable, add the weight of the catwalk as well.

NOTE: It is recommen ded to attach ladder to roof module BEFORE lifting roof off of ground. Attach ladder

to section below roof module AFTER roof module is placed upon it.

NOTE: 8' Ladder section will only be able to be attached after the section is stacked on another section.

PNEG-1708 GSI Modular Tower Dryer 51

Page 52

10. Lifting and Stacking the Modules

Step 1:

Stack and connect

Roof to Module 4

Step 2:

Stack and connect Roof/4

to Module 3

Step 4:

Stack and connect

Roof/4/3/2 to Base

Base/Unload

This suggested sequencing plan maximizes safety and convenience, by performing most

work close to the ground.

IMPORTANT: Make sure crane is of adequate lifting capacity. The recommended strap length is 6' long.

NOTE: Catwalks, ladders and other accessories not shown for clarity. Be sure to include weight of accessories when

combining modules.

Step 3:

Stack and connect Roof/4/3

to Module 2

NOTE: If the crane is not sufficient to lift the combined weight of Roof/4/3/2 as shown,

replace step 4 with connecting Modules 3 and 2, stacking 3/2 on the base and then placing

Roof/4/3 on top of Base/2.

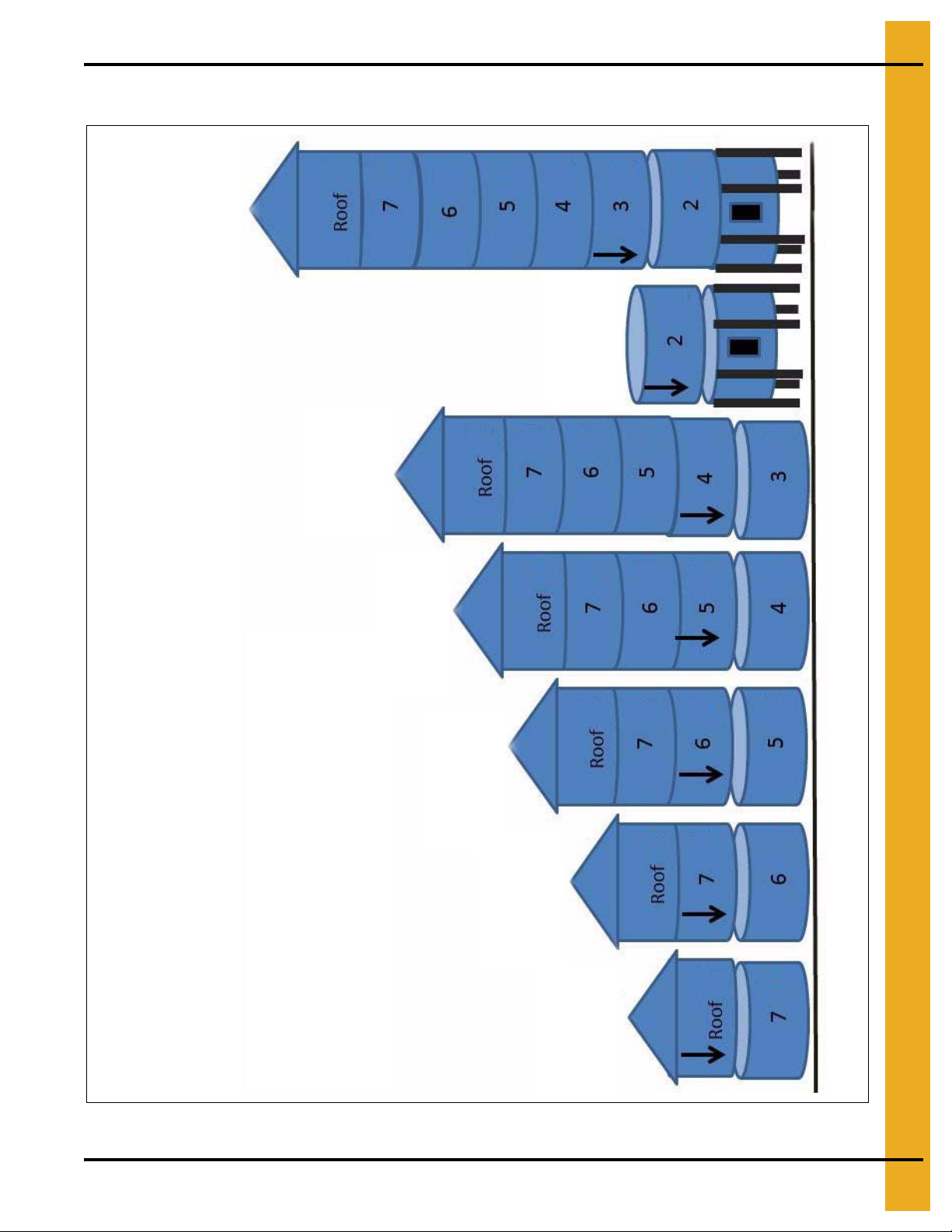

The GSI Modular Tower Dryer is designed to maximize safety and minimize assembly time. All models

will be assembled in similar fashion by: Lifting the roof module, stacking it on to the dryer module to be

directly underneath it and connecting those modules together. Then, the conjoin ed modules are lifted and

stacked on the next highest dryer module and connecting the modules. In this way, the vast majority

of work will be completed no more than ten feet (10') off of the ground. See the following figures on

Pages 52-55 for the specific recommendations for each model of the GSI Modular Tower Dryer.

NOTE: In all instances, six feet (6') lifting straps are recommended.

Recommended Stacking Order: Model 800 Series Dryer

Figure 10A Model 800

52 PNEG-1708 GSI Modular Tower Dryer

Page 53

10. Lifting and Stacking the Modules

Step 1:

Stack and connect

Roof to Module 5

Step 2:

Stack and connect

Roof/5 to Module 4

Step 4:

Stack and connect

Roof/5/4/3 to Module 2

Base/UnloadBase/Unload

Step 5:

Stack and connect

Roof/5/4/3/2 to Base

This suggested sequencing plan maximizes safety and convenience, by performing

most work close to the ground.

IMPORTANT: Make sure crane is of adequate lifting capacity. The recommended strap length is 6' long.

NOTE: Catwalks, ladders and other accessories not shown for clarity. Be sure to include weight of accessories

when combining modules.

NOTE: If the crane is not sufficient to lift the combined weight of

Roof/5/4/3/2 as shown, replace step 4 with connecting Modules

3 and 2, stacking 3/2 on the base and then placing Roof/5/4 on

top of Base/2/3.

Step 3:

Stack and connect

Roof/5/4 to Module 3

Recommended Stacking Order: Model 1010 Series Dryer

Figure 10B Model 1010

PNEG-1708 GSI Modular Tower Dryer 53

Page 54

10. Lifting and Stacking the Modules

Step 1:

Stack and connect

Roof to Module 6

Step 2:

Stack and connect

Roof/6 to Module 5

Step 5:

Stack and connect

Module 2 to Base

Step 6:

Stack and connect

Roof/6/5/4/3 to Base/2

Base/UnloadBase/Unload

Step 4:

Stack and connect

Roof/6/5/4 to Module 3

This suggested sequencing plan maximizes safety and convenience, by performing

most work close to the ground.

IMPORTANT: Make sure crane is of adequate lifting capacity. The recommended strap length is 6' long.

NOTE: Catwalks, ladders and other accessories not shown for clarity. Be sure to include weight of accessories

when combining modules.

NOTE: If the crane is not sufficient to lift the combined weight of

Roof/6/5/4/3 as shown, replace step 4 with connecting Modules 3 and 2,

stacking 3/2 on the base and then placing Roof/6/5/4 on top of base/2/3.

Step 3:

Stack and connect

Roof/6/5 to Module 4

Recommended Stacking Order: Model 1200 Series Dryer

Figure 10C Model 1200

54 PNEG-1708 GSI Modular Tower Dryer

Page 55

10. Lifting and Stacking the Modules

Step 1:

Stack and connect

Roof to Module 7

Step 2:

Stack and connect

Roof/7 to Module 6

Step 3:

Stack and connect

Roof/7/6 to Module 5

Step 6:

Stack and connect

Module 2 to Base

Step 7:

Stack and connect

Roof/7/6/5/4/3 to

Base/2

Base/UnloadBase/Unload

Step 5:

Stack and connect

Roof/7/6/5/4 to

Module 3

This suggested sequencing plan maximizes safety and convenience, by performing

most work close to the ground.

IMPORTANT: Make sure crane is of adequate lifting capacity. The recommended strap length is 6' long.

NOTE: Catwalks, ladders and other accessories not shown for clarity. Be sure to include weight of accessories

when combining modules.

NOTE: If the crane is not sufficient to lift the combined weight of

Roof/7/6/5/4/3 as shown, replace step 4 with connecting Modules 3

and 2, stacking 3/2 on the base and then placing Roof/7/6/5/4 on

top of Base/2/3.

Step 4:

Stack and connect

Roof/7/6/5 to Module 4

Recommended Stacking Order: Model 1500 Series Dryer

Figure 10D Model 1500

PNEG-1708 GSI Modular Tower Dryer 55

Page 56

10. Lifting and Stacking the Modules

Lifting

1. Use four (4) clevis hooks to connect the crane’s lifting straps to the module.

2. Remember, all modules except the roof, lift from four (4) lift points around the outside of the unit.

NOTE: The recommended strap length for lifting is 6' long.

Figure 10E

Figure 10F

56 PNEG-1708 GSI Modular Tower Dryer

Page 57

10. Lifting and Stacking the Modules

3. When maneuvering lifted modules across open ground, have personnel beside it to guide it and

minimize sway. When lifting the module on top of another module, be sure personnel have hard hats.

4. Carefully lower the module so that the connecting channels of each module are touching and can be

connected with nuts and bolts, however, do NOT lower fully at this time.

DO NOT REST THE UPPER MODULE(S) ON THE LOWER MODULE(S) AT THIS TIME. KEEP

SOME DEGREE OF TENSION ON THE MODULE FROM THE CRANE. ONLY FULLY LOWER

THE UPPER MODULE(S) ONCE ALL CONNECTIONS ARE MADE AT THE CONNECTING

CHANNELS WITH NUTS AND BOLTS.

Connecting Modules

5. Use the punches to line up connecting holes so that nuts and bolts can be loosely inserted at this time.

NOTE: Significant hammering and prying to accomplish hole alignment is to be expected.

Figure 10G

Figure 10H

NOTE: Ideally, crews will work in two (2) person teams with one team working inside the dryer and one

team working outside the dryer. Each person should have at least two (2) punches with narrow

pointed tips and long enough to provide significant leverage. Place step ladders and tools INSIDE

modules before stacking for ease of access.

PNEG-1708 GSI Modular Tower Dryer 57

Page 58

10. Lifting and Stacking the Modules

Ladder brackets

6. When stacking one module on top of another, be sure to line up ladder brackets.

In Figure 10I, ladder brackets are circled.

Figure 10I

7. Installation should proceed with a team of two (2) working to connect the modules from inside of the

dryer and two (2) working to connect the modules on the outside of the module.

For ease of assembly, place all tools, hardware and step ladders inside the module before stacking

another module on top of it.

Figure 10J shows a team of two (2) working to connect the modules on the inside.

Figure 10J

NOTE: For best results, use a two (2) person team on the inside and a two (2) person team on the outside

of the module dryer when connecting modules.

58 PNEG-1708 GSI Modular Tower Dryer

Page 59

10. Lifting and Stacking the Modules

Outside channels - Bolted every other hole

Inside channels - Bolted every hole

8. On all models of the GSI Modular Tower Dryer, the first two (2) connecting seams - between the

base/unload module and Module 2 and between Module 2 and Module 3 - require a nut and bolt in

EVERY hole of the connecting channel, both INSIDE and OUTSIDE of the dryer.

a. For all other connecting seam after/above the first two (2), every other hole may be bolted.

OUTSIDE of dryer: Two (2) connecting channels between two (2) modules. (See Figure 10K.)

NOTE: Every connecting hole must have a nut and bolt in place.

INSIDE of dryer: Two (2) connecting channels between two (2) modules. (See Figure 10K.)

PNEG-1708 GSI Modular Tower Dryer 59

Figure 10K

Page 60

10. Lifting and Stacking the Modules

14.4 Volt cordless impacts are NOT recommended for installation as they will

not sufficiently torque the bolts. Use electric impact and torque to 45 ft./lbs. If

bolts are not torqued properly, channels will co mpress when filled and bolts will

become loose.

Nut

9. Once all holes (or every other hole based upon which seam of the dryer you are working on at

the time) have a nut and bolt installed and are finger tightened, tighte n with an electric impact: torque

to 45 ft./lbs.

NOTE: When installing, in all possible situations, place the impact on the bolt. Do NOT tighten the

nut as it will not lock down on the ring. Always tighten the bolt. (See Figure 10M.)

NOTE: Accessing the bolts that connect sections of the dryer together requires passing through

the hole in the channel as shown. Narrow 3/8" drive sockets and/or extensions are required.

(See Figure 10L.)

CAUTION

Figure 10L Connecting Dryer Sections on Outside

Figure 10M Always tighten the bolt, not the nut to achieve torque specifications.

60 PNEG-1708 GSI Modular Tower Dryer

Page 61

10. Lifting and Stacking the Modules

Caulk seam

Channels

10. To stack additional sections, repeat the process as described above - always remember to line up

the ladder brackets on the modules -- and follow the suggested sequence illustrated earlier in

this chapter.

• Consider the orientation of each module as it pertains to ladders and catwalks before placing it

on the module for connection.

• Secure the module with clevis hooks and lifting straps. Lift with crane and place on top of

next module.

• Place section together but do not fully rest upper section on lower section.

• Use hammers and punches to line up connecting holes in channels both inside and outside

of dryer.

• Insert nut and bolt and finger tighten in every hole or every other hole as appropriate.

• Tighten with power impact.

• Caulk gaps with clear food-grade silicone as needed.

Figure 10N Gap Un-Caulked

Figure 10O Gap Caulked

NOTE:

ALWAYS stack and connect so that as much work as possible is done as close to the ground

as possible. Use the illustrations at the beginning of this chapter as a gu ide to accomplish this.

PNEG-1708 GSI Modular Tower Dryer 61

Page 62

10. Lifting and Stacking the Modules

Figure 10P

NOTE: It is normal for “dents” or “wrinkles” to appear in the screen during this process of stacking and

connecting. Most “dents” and/or “wrinkles” will be eliminated or greatly reduced in the final step of

the installation process.

62 PNEG-1708 GSI Modular Tower Dryer

Page 63

Venturi

3/8" Grill to venturi

5/16" Grill guard

3/8" Bolt

Burner/blower

5/16" Bolt

3/8" Bolt

Stiffener splice plate

(GT4-5074)

10. Lifting and Stacking the Modules

Figure 10Q

Stiffener Splice

Place stiffener splice plate over stiffener at joint of section 1 (base/unload section) and section 2

(burner/blower section).

NOTE: Seal the upper bolts 5/16" with electrical tape. To avoid drop into the dryer while placing

PNEG-1708 GSI Modular Tower Dryer 63

Figure 10R

stiffener splice.

Page 64

11. Electrical Connections

Vision control panel

Electrical Overview Minimal Connections

One of the most beneficial features of GSI Module Tower Dryers is the fact that much of the electrical

wiring is done at the plant prior to shipping. This is an advantage for the customer as fewer electrical

connections need to be made in field, thereby making is a quicker and safer installation. The connections

to be made in the field by the customer are:

• Air switch

• Flame sensor and ignitor wires (spark plug)

• Bindicator, outside overheat and moisture sensor

• Plenum temperature

• Gas pipe train (natural or LP) overview minimal connections

Adjustable overheat honeywell thermostat capillary is ran up to burner section.

These connections are reviewed in greater detail this section.

Another advantage of the GSI Modular Tower Dryer is the ability of the vision control box to be remote

mounted. The control box can remain on the unload module as shown and shipped or if the customer

prefers, it can be remote mounted in a more convenient location for user access or to allow auxiliary

equipment access to the tower dryer.

If the vision control panel remains mounted on the unload module of the GSI Modular Tower Dryer,

the protective rain shield should be installed as shown in Figure 11A to help protect it from the elements.

Figure 11A

64 PNEG-1708 GSI Modular Tower Dryer

Page 65

11. Electrical Connections

Air flow sensor

Wire clip

Rubber grommet

Air Switch

1. The air flow sensor connects to the grill guard on the fan with a rubber grommet and feeds through

to a connecting point on the outside of the electrical control box, which connects to the sensor on the

inside of the control box. (See Figure 11B, Figure 11C below and Figure 11D on Page 66.)

Figure 11B

2. Connect the air flow sensor (copper tubing) from the grill guard inside of dryer burner/blower to the

rubber grommet on the side of the outside control box. (See Figure 11C.)

PNEG-1708 GSI Modular Tower Dryer 65

Figure 11C

Page 66

11. Electrical Connections

Electrical control box

Rubber grommet

3. The rubber grommet connects to the air flow sensor inside of the control box. (See Figure 11D.)

Figure 11D

66 PNEG-1708 GSI Modular Tower Dryer

Page 67

11. Electrical Connections

Electrical control box

Holes through which flame sensor and

ignitor wires will be passed. See close

up in Figure 11F on Page 68.

Flame Sensor and Ignitor Wires (Spark Plug)

1. From inside the burner/blower module, the flame rod wire and the spark plug wire will be passed

through these holes as shown in Figure 11F.

2. The flame sensor and ignitor wires connect to the electrical control box.

PNEG-1708 GSI Modular Tower Dryer 67

Figure 11E

Page 68

11. Electrical Connections

Figure 11F

68 PNEG-1708 GSI Modular Tower Dryer

Page 69

11. Electrical Connections

Bindicator

Conduit

Bindicator

Conduit

Junction box

Copper tubing

Bindicator, Outside Overheat and Moisture Sensor

The bindicator is mounted on the roof with its wiring running the height of the dryer in conduit and is

connected by the customer is the field. (See Figure 11G.)

Figure 11G

The outside overheat (copper tubing) runs the circumference of the dryer on the roof module. It connects

to a junction box with conduit running the height of the dryer and is connected to the control panel by the

customer in the field. (See Figure 11H.)

Figure 11H

PNEG-1708 GSI Modular Tower Dryer 69

Page 70

11. Electrical Connections

Conduit clamps

Plenum Temperature

Plenum temperature is monitored through the wiring in the conduit that runs up through the burner/blower

floor. This was referenced in burner/blower module on Page 48, when installing the floor planks in the

burner/blower module as it was necessary to cut a floor plank to fit around the conduit.

Connecting this is also done in the field by the customer. (See Figure 11I.)

Figure 11I

After installing the conduit clamps, simply route the conduit through the clamps and close them.

(See Figure 11J.)

Figure 11J

70 PNEG-1708 GSI Modular Tower Dryer

Page 71

12. Gas Pipe Train Overview

Gas Pipe Train (Natural or LP) Overview Minimal Connections

Another beneficial feature of the GSI Modular Tower Dryer is the fact that the gas pipe train comes

pre-fitted and pre-assembled from the factory. This minimizes the connections that need to be made in the

field. The result, is a quicker and simpler installation process.

Only three (3) connections need to be made in the field to complete the gas train. (See Figure 12B.)

Figure 12A

The three (3) connecting hoses for the gas train are for:

• Liquid in

• Vapor out

• Return to burner

All three (3) are shown in the Figure 12A and ship in the crate along with catwalks, platforms and

other hardware.

Each hose has unique fittings and can only be installed in the proper location.

Figure 12B

PNEG-1708 GSI Modular Tower Dryer 71

Page 72

12. Gas Pipe Train Overview

3/4"

1"

1. The largest connecting hose connects inside the dryer for the return to blower. (See Figure 12C.)

Figure 12C

2. The remaining two (2) connecting hoses are installed inside the dryer as shown.

NOTE: All three (3) connecting hoses are pre-sized for correct connections and cannot be connected in

the wrong location as a result.

72 PNEG-1708 GSI Modular Tower Dryer

Page 73

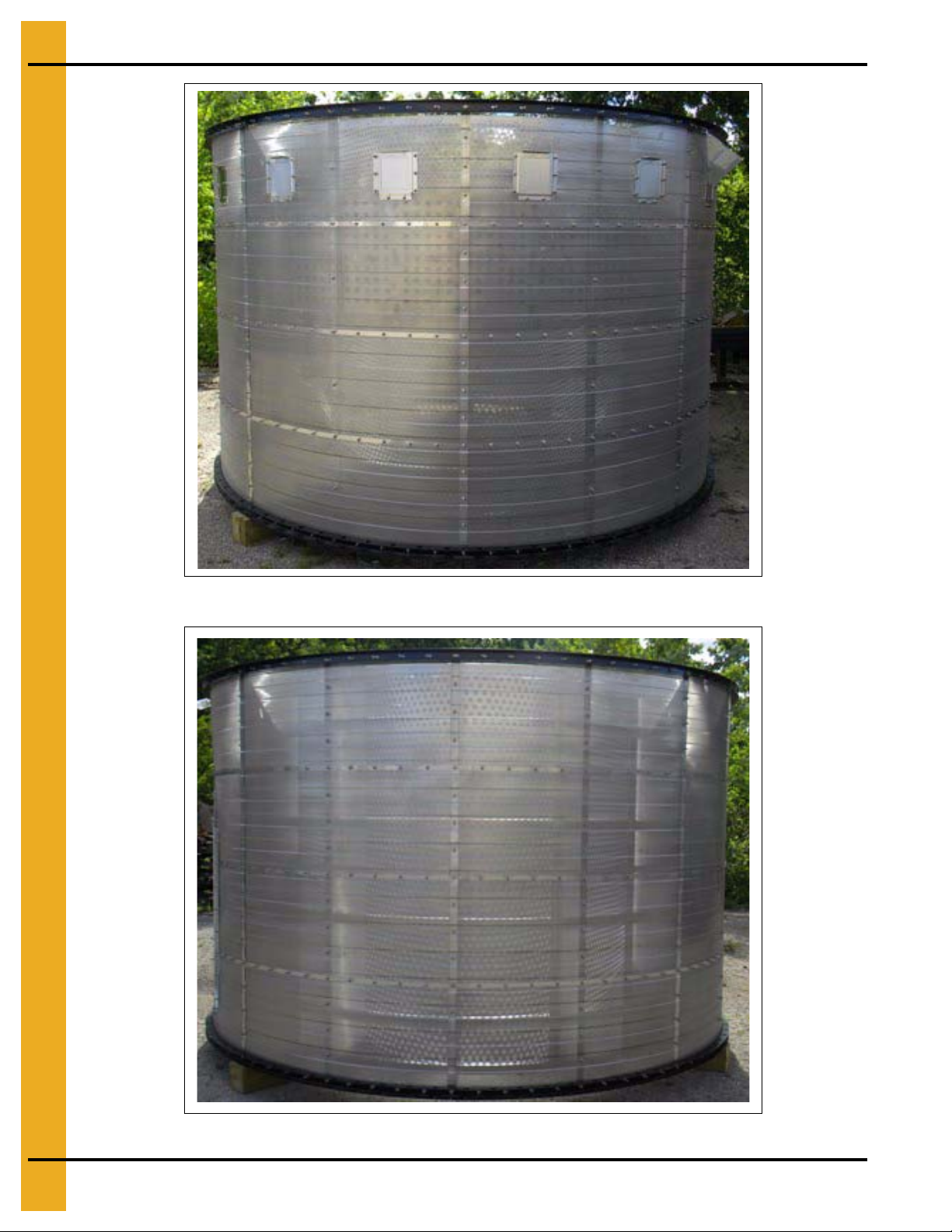

13. Finishing Touches: Removing Wrinkles and Dents from Screens

During the installation process it is common for screen to “dent” or “wrinkle” from the pressures and

stresses of assembling. Examples of “denting” and “wrinkling” in the screens are circled in the Figure 13A.

They are often most visible in bright, reflective sunlight. Removing (or grea tly minimizing) these dents and

wrinkles is one of the final steps in the installation process. When removing wrinkles, work from the

top down.

1. Using all proper safety equipment and precautions, crew members should loosen the nuts on the

nearest columns one at a time until the “dent/wrinkle” literally “pops” out. Then, the nut(s) can

be re-tightened.

In Figure 13A, the columns in which the nuts should be loosened are between the arrow marks.

2. On occasion, it may be necessary to loosen the nuts connecting modules together. If this is the case,

ALWAYS re-tighten with impact when “wrinkle/dent” has “popped” out.

NOTE: In Figure 13A, the circles area highlights the wrinkle or dent in the dryer screen. The arrows

indicate the seams on which the nuts/bolts should be loosened to “pop” it out.

NOTE: New dryers ship with corrugated sheets.

Figure 13A

PNEG-1708 GSI Modular Tower Dryer 73

Page 74

NOTES

74 PNEG-1708 GSI Modular Tower Dryer

Page 75

14. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1708 GSI Modular Tower Dryer 75

Page 76

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2011 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Loading...

Loading...